Omni Packaging acquisition P05

Acquires Tape Printers of Australia

Ball & Doggett hire P06

David Reece joins the company

Heidelberg/Manroland deal P06

The companies partner in the sheetfed space

Hybrid launches PACKS 11 P08

The new version boasts RIP integration

Suntory Oceania launches P08

The move highlights growth in Australia

BulletProof can launch P10

East Coast Canning + Printing unveils new tech

Pakko in midst of move P10

Company is relocating to a new headquarters

Detmold gets new HQ P11

Consolidates staff from eight sites into one Planet Ark in the green P11

The organisation steps out of voluntary admin

Durst strengthens hybrid labels production P14-16

Durst redefines the hybrid printing concept through its strategic partnership with OMET

Rethinking packaging for a sustainable world: Google P18-19

The business recently discussed its forwardthinking approach to sustainable packaging

Graffica ends financial year on a high with multiple orders P20

Its new and returning customers make significant machinery purchases

“We don’t just make a pretty picture”: Paul Rumens P22-23

Tweak’s Paul Rumens addresses his desire to make packaging work in the real world

The biggest Labelexpo yet P24-27

More than 600 industry suppliers have already booked their spots for Labelexpo Europe 2025

Currie Group partners to display future-ready products P28

The latest advancements and cutting-edge solutions will be shown at Labelexpo Europe

Packaging reimagined at AIP Conference P30-31

The 2025 Australasian Packaging Conference set the tone with forward-thinking dialogue

BOBST innovation enhances customer experience P32

The company explores its sustainable VISION CI flexo printing technology

Trends shaping the packaging industry in 2025: Opal P33

Outlines its view on the emerging trends transforming the packaging industry

It takes a village to sell a business: Mattingly P34

Why selling a business is a full-contact sport in stakeholder management

Rethinking the CRS: Building a circular economy that works P36

Are we solving the right problem?

Smithers

Significant growth projected for printed packaging labels and release liners

A guide to the upcoming local and international events around the world

Labelexpo Europe 2025 is expected to make history as its largest show to date. Spanning over four massive halls, more than 600 industry suppliers have already booked into the tradeshow, which will take place from 16-19 September at Fira Gran Via in Barcelona. With organisers promising an expansion 12 per cent larger than the 2023 edition, new innovations will most likely be discovered down every aisle and around every corner.

This issue contains a preview of the tradeshow, providing a snapshot of some of the latest and greatest that will be displayed and talked about.

ProPack will also be in Barcelona to hear the noise of the new machinery in operation, feel the textures of substrates, and see print qualities for ourselves. We hope to catch you at the show too.

Omni Packaging, a sustainable packaging solutions provider and one of Australia’s largest local custom tape printers, has acquired Tape Printers of Australia – one of the country’s longest-standing custom tape printing companies.

Tim Salisbury, founder of Omni Group, said the acquisition marks an exciting step forward for the company’s continued growth and innovation.

“As Australia’s largest local custom tape printer, this acquisition is a significant step toward our future growth. We’ll continue to lead the way in custom packaging solutions, while providing even greater value, speed, and flexibility for our customers,” Salisbury said.

With this acquisition, Omni Packaging strengthens its ability to offer an even broader range of custom-printed tapes, including custom printed paper tapes, water activated gummed tapes, heavy-duty PVC tapes, printed masking and specialty tapes, and perforated tapes.

According to Omni Packaging, customers of Tape Printers of Australia will now benefit from Omni Packaging’s broader product range, advanced printing technologies, and national distribution network.

The company said the acquisition also reflects Omni Packaging’s continued investment in local manufacturing and its commitment to leading the way in sustainable, innovative packaging solutions.

In January, Omni Group announced the appointment of Jonathan Salisbury as managing director, taking the reins from his father and founder, Tim Salisbury.

Jonathan, who has spent more than a decade working in the business, was previously head of supply chain and machinery.

Ball & Doggett has appointed David Reece to the role of labels & packaging national sales manager, reinforcing its long-term commitment to growth, innovation, and customer success within the sector.

Based at Ball & Doggett’s Pemulwuy office in NSW, Reece will lead the company’s national sales effort within the narrow web market, with a strong focus on helping customers unlock value through expert advice, trusted products, and dedicated service.

Reece is a well-respected figure in the industry, bringing over 30 years of experience with recognised names such as Jet Technologies and Avery Dennison.

Ball & Doggett said his deep technical knowledge and commercial insight will be invaluable in supporting customers as they navigate new technologies, market opportunities, and evolving industry trends.

“I’m thrilled to be joining Ball & Doggett at such an exciting time for the business. The narrow web and label sectors are evolving rapidly, and I look forward to working closely with our customers to help them navigate these changes, unlock new opportunities, and grow their businesses with the support of a truly committed and customer-focused team,” Reece said.

In response to the market need for long-run folding carton printing for food, beverage, and consumer packaging using large format (VLF)/format class 6 sheetfed offset presses, and coinciding with its 175th anniversary, Heidelberg has partnered with Manroland Sheetfed to add the Cartonmaster CX 145 in format class 6 to its portfolio for packaging customers.

The Cartonmaster CX 145 is based on Manroland Sheetfed’s Roland Evolution 900, which Heidelberg is incorporating into its digital ecosystem.

The press can be integrated into both the Prinect workflow and the workflow solutions of third-party suppliers. Customers can access performance data for their press in the Heidelberg Customer Portal.

“Our new Cartonmaster CX 145 makes Heidelberg a full-range provider for folding carton printing. As part of our growth strategy, we are expanding our range of solutions for the packaging sector and, at the same time, plugging a gap in our portfolio,” the company’s chief technology and sales officer Dr. David Schmedding said.

In addition to Reece’s appointment, Ball & Doggett has also expanded its team with several highly regarded specialists in recent years, including:

• Phil Rennell , who has had expertise in developing the digital printing landscape in Australia and New Zealand with experience in commercial printing, labels and packaging, and textile and apparel printing technologies and markets.

• Tatjana Ferguson, an experienced sign and display professional with years of expertise in the industry and OEM space, adding a fresh perspective and depth to one of Ball & Doggett’s most dynamic and creative categories.

• Tammy Arhontissas, a packaging specialist with deep industry experience, supporting

the growing demand for fibre-based and sustainable packaging solutions.

• Sean Strange, a well-known leader in the sign and display industry, with a strong track record in business growth, product innovation, and technical expertise across digital cutting technologies.

• Matt Murphy, a respected industry professional recognised for his customerfirst mindset, market knowledge, and ability to build long-standing partnerships.

• Sean Edel, a packaging specialist with more than 20 years of experience across FMCG and packaging markets. Edel brings strong commercial, category, and product expertise and leads growth and innovation within Ball & Doggett’s essential packaging category.

Heidelberg supplies a full range of products for folding carton printing.

The company offers packaging customers Speedmaster presses in a wide variety of configurations in both the 50cm x 70cm and 70cm x 100cm formats, all the way through to the new Peak Performance generation of the Speedmaster XL 106.

Together with its partner MK, it also provides solutions for postpress applications, including robotics. The Boardmaster flexographic web printing system in the Heidelberg portfolio covers the top end of the productivity range in folding carton production.

By launching the Cartonmaster CX 145, Heidelberg is bridging the gap between its

Speedmaster portfolio and the Boardmaster. The company has integrated all these presses into its digital ecosystem comprising equipment, Prinect software, consumables, and service as well as training and consulting.

The Roland Evolution 900 is a 6B3 large format press that includes new TripleFlow inking technology, providing three separate inker running modes, while the AC Drive promises users an annual saving of up to 10,000 kWh – or eight years over the lifetime of the press.

It prints at up to 16,500 sheets/hour, takes up to 0.04mm to 1.2mm in stock thickness, as well as a sheet format minimum of 600mm by 850mm and a sheet format maximum of 1060mm by 1450mm.

At Labelexpo Europe 2025, we proudly present our commitment to reliabilty, simplicity and perfomance, the pillars that define our production excellence. With smart, efficient, and future-ready solutions, we empower our customers to elevate their labels printing business.

Experience the next chapter of labels and flexible packaging printing evolution. Discover the future, crafted by our digital printing systems.

Hybrid Software has unveiled its latest innovation in its flagship PACKZ software. The new PACKZ 11 launch introduces PACKZ Max, featuring integrated Harlequin RIP technology for screening control from within the PACKZ PDF editor.

This release also debuts support for extensions to the industry-standard CF2 file format for folding carton and corrugated packaging, along with an automatic upgrade from 1D to 2D barcodes supporting the GS1 Sunrise 2027 initiative, paving the way or the future of barcodes on packaging.

“PACKZ Max is a true game-changer, built entirely on Hybrid’s proprietary tech stack with the industry-leading Harlequin RIP inside,” Hybrid Software product manager Pascal Wybo said.

“For the first time ever, flexo prepress service providers and printing houses can handle all prepress operations within a single unified application. This delivers unprecedented process efficiency, superior screening quality, smooth gradients, and consistent colour while eliminating the need for costly additional RIP servers.”

PACKZ Max converts artwork into precise dot patterns, generating real-time rasterised previews and expertly managing final output to platesetters. By seamlessly combining

advanced PDF editing with live RIP previews, precise screening, and optimised 1-bit TIFF output, PACKZ Max aims to maximise print quality and operational efficiency for both flexo and offset printing workflows.

Hybrid Software said with the launch of PACKZ 11, it introduces support for new extensions to the CF2 format co-developed with other industry leaders to meet the unique demands of folding carton and corrugated printing.

The technology incorporates critical features such as bend angles and sequencing of creasing lines, providing essential data for 3D visualisation and automated formatting.

The extended CF2 format can be seamlessly interpreted by 3D modeling software, including Hybrid Software’s iC3D ray-tracing software as well as by structural design management systems and digital cutting and folding machines. The advancement

strengthens Hybrid Software’s commitment to improved system interoperability and open, standardised formats.

PACKZ 11 also aims to empower label and packaging professionals to meet the demands of GS1 Sunrise 2027, the initiative set out by the global non-profit organisation that sets supply chain standards, including requirements for barcode support.

The new version automatically identifies traditional barcodes and converts them into data-rich GS1 QR Codes and GS1 Data Matrix symbols, enhancing visibility of information about a product for traceability, and deeper consumer engagement.

PACKZ 11 is also packed with other enhancements that elevate prepress and packaging print workflow to empower users with efficient tools, cutting-edge innovation, and the ability to stay ahead of industry standards.

Suntory has officially launched Suntory Oceania, its $3 billion multi-beverage business in Australia, the fourth-largest multi-beverage group in the region.

The new venture, announced in August 2023, brings together a portfolio of more than 40 brands across spirits, RTD (ready-todrink) alcoholic beverages, soft drinks, coffee, energy and sports drinks, juice, and water.

Dai Minato, CEO of Suntory Beverage & Food Oceania, said the move signalled the company’s strong belief in the region’s potential.

“Our mission is to bring the best of Suntory to Oceania and demonstrate the immense confidence we have in Australia’s growth potential,” he said.

The company’s Queensland facility – a $400 million carbon-neutral site – has been transformed from a greenfield location in just over two years. It will produce 20 million cases annually at launch, with capacity to

expand to 50 million. The site was officially opened by senator Anthony Chisholm and Queensland minister for finance and trade, Ros Bates.

“At Suntory, our culture is shaped by our unique ‘Yatte Minahare’ spirit, which has encouraged us to dream big and make those dreams a reality for over a century. I’m excited by the ambition of our people, the strength of our brands, and the opportunity to shape new beverage experiences. This is just the beginning,” Minato said.

Suntory Global Spirits – Oceania managing director Mark Hill said the local market’s

momentum was a key driver, adding, “The Australian beverages market is one of the most energetic and innovative in the world. Suntory Oceania gives us the platform to truly ignite the industry”.

“Our Queensland facility complements our global production footprint – which includes distilleries and bottling sites across North America, Europe, and Japan – and will produce more of the drinks Australians love, like those from the rapidly growing RTD category.”

Suntory will extend the Oceania business to New Zealand in January 2026.

After three years of development and testing, New South Wales-based East Coast Canning + Printing is set to unveil the world’s most durable digitally printed can.

East Coast says the BulletProof can sets a new standard for brewers, offering durability, a broader scope for design options and brand integrity, while meeting the manufacturer’s own high standards in sustainability for the beverage industry.

East Coast founder and general manager Chris Kelly said the impact of the new can on the brewing industry is simply professionalism.

“When your packaging holds up after being tossed around in transit or sitting in ice for hours, it reflects on your whole brand. This helps brewers release more styles, ship more confidently, and grow their brand without worrying about how the can’s going to hold up in the real world,” he said.

The new product can handle the demanding conditions of supply chains – from enduring the heat of tunnel pasteurisation to withstanding scratches from transport or storage in ice.

Kelly said the biggest improvement has been the adhesion or how well ink bonds to the can.

“Digital printing has always had a few durability challenges, but we’ve worked hard over several years to solve them. Through a mix of tighter controls and process tweaks (and yes, some serious science), we’ve been able to lock the ink in place in a way that’s genuinely approaching the level of offset printed cans,” he said.

“The result is a can that behaves like a can should – able to take a hit, sit in ice, and still look the part when it matters the most to brands.”

As a result, he described the innovation as transformative not only for the industry but East Coast too.

“From being Australia’s first mobile canning company to introducing our multimillion-dollar digital direct-to-vessel printing technology, BulletProof is a new step forward in offering beverage producers a canning and printing solution that gives consumers a top-quality brand experience when they are holding the can.”

The BulletProof cans are also fully recyclable and offer matte and spot gloss finishes directly printed onto the aluminium, ensuring aesthetic appeal and environmental responsibility. Additional design attributes like CMYK colour palette, tactile feel, and metallic finishes have historically relied on wrap-around or shrink-sleeve labels, complicating recycling processes.

“We don’t chase ‘green’ as a trend, we build better packaging solutions because we believe the best version of this industry is one that’s also good for the planet,” Kelly said.

“But sustainable options only work if they’re great products too. Improving performance like we have here by making the cans more durable, more versatile, more useful for more brewers is exactly how we help those sustainable solutions succeed in the long run.”

According to East Coast, by eliminating adhesive labels, the company has prevented over 33 tonnes of single-use plastic from entering the Australian beverage market in just two years.

The initial rollout of the BulletProof can includes the 375ml classics and select varieties of the sleek can sizes (330ml and 355ml). East Coast anticipates the 330ml, 355ml, 440ml, and 500ml classics to be available next year.

Pakko’s quiet move signals a bigger shift in Australian manufacturing

Brisbane-based packaging manufacturer

Pakko is in the midst of a quiet but significant transition, preparing to relocate to a new purpose-built headquarters in Virginia, QLD.

While the company has confirmed operations remain steady at its current site, with no interruptions to production, the move marks an intentional step forward for the business.

With increasing demand, deeper national reach, and ongoing investment in local manufacturing, Pakko CEO and founder Nina Nguyen said it is positioning itself for what’s next.

“We’ve designed this move to be seamless for our clients. It’s business as usual, but

behind the scenes, we’re building for the future,” Nguyen said.

Pakko has built its reputation on speed,

reliability, and sustainable custom packaging solutions for Australian businesses.

Nguyen said this next chapter gives the team room to grow, streamline, and explore new possibilities, while staying true to the values that shaped the company from the start.

“Many businesses right now, across industries and at every scale, are feeling the weight of rising costs and shifting conditions. It’s a tough environment, but not without possibility,” she said.

“Pakko’s steady momentum is a small reminder that progress can still happen, even in uncertain times. While our focus remains on strengthening what we do internally, we’re open to conversations that spark new ideas, fresh energy or unexpected partnerships. Sometimes, the best shifts happen when things feel the most uncertain.”

The full details of the new headquarters will be announced once the transition is complete. For now, Pakko’s move hints at more than just a change of address –it signals momentum, resilience, and the beginning of something bigger.

Detmold Group is constructing its new Adelaide headquarters to foster collaboration and innovation, and support continued local and international growth.

The group’s new global headquarters will accommodate up to 240 employees, with staff from eight sites across Adelaide metropolitan suburbs Brompton, Hindmarsh, and Regency Park consolidating under one roof by the end of 2026.

Staff from the Detmold Group corporate functions and sales companies Detpak, PaperPak, Detmold Medical, and Cup & Carry will relocate to the new head office, which sits alongside existing manufacturing and warehousing facilities.

Detmold Group CEO Sascha Detmold Cox said the company’s new headquarters represents a “strategic investment in the future of the Detmold Group”.

“Purpose-built with sustainability, collaboration and employee wellbeing in mind, our new corporate home integrates

Following a recent meeting of creditors, Planet Ark Environmental Foundation has been returned to its directors and is no longer under voluntary administration.

At the second meeting of creditors, the Deed of Company Arrangement (DOCA) submitted by the organisation was unanimously approved, reflecting the strong support from Planet Ark’s employees and stakeholders.

“[This] marks the beginning of a new chapter for the organisation. With renewed focus and vigour, we remain committed to our mission of empowering Australians to take positive environmental actions,” Planet Ark said, in a statement.

“We are immensely grateful for the backing and goodwill shown by our supporters during this time, and for the leadership of voluntary administrators Michael Jones and Bruce Gleeson of Jones Partners Insolvency & Restructuring, who have guided Planet Ark through this process with a great deal of professionalism and care. As we move forward, Planet Ark will continue delivering our wellknown and well-loved programs with the same passion and dedication that have made them cornerstones of environmental action in Australia for decades.

contemporary design with environmentallyresponsible solutions and an open-plan layout that supports collaboration and innovation,” Detmold Cox said.

“Bringing our Detmold family under one roof will help foster stronger connections, knowledge sharing, and a unified culture aligned with our core values.”

Family-run Adelaide construction business Centina and design studio, Studio Nine Architects, have been appointed to build and design the new 5,100sqm headquarters at 260 Regency Road, Regency Park.

The new three-level building will include formal and informal meeting spaces with an open-plan design, breakout areas, on-site

parking, end-of-trip facilities, an onsite café, and a green outdoor terrace.

The building will adopt green design features to maximise natural lighting and ventilation and shade for energy efficiency, well-being and comfort, along with rainfall harvesting and recirculation.

Site-works for the development-approved build will commence in June with project completion scheduled for October 2026.

There will be about 75 people on site each day, with up to 200 employed for the entire project. Manufacturing at Brompton will continue, with planning underway to also relocate those operations to Regency Park within the next five years.

“This milestone reaffirms our belief in the strength of Planet Ark’s mission and the value it brings to communities, schools, businesses, and governments across the country. We thank all those who have stood by us and look forward to working together toward a more sustainable future.”

Planet Ark entered voluntary administration in April following a review of the organisation’s financial position and future viability.

“Established in 1992, Planet Ark has proudly worked for decades to inspire Australians to live more sustainably through a range of well-known environmental campaigns and programs including National Tree Day and National Recycling Week,” it said, in April.

“Despite the dedication to this work by the Planet Ark team, the impact of COVID-19 on stakeholder support, current economic climate and ongoing funding challenges have significantly impacted our operations.

“Voluntary administration provides an opportunity for an independent assessment of the organisation’s affairs and to explore potential options for restructuring that will allow the organisation to continue our important work.

“Planet Ark recognises the importance of the environmental mission we continue to pursue every day and we sincerely believe that the organisation’s contribution to that mission will continue with renewed strength beyond this process.”

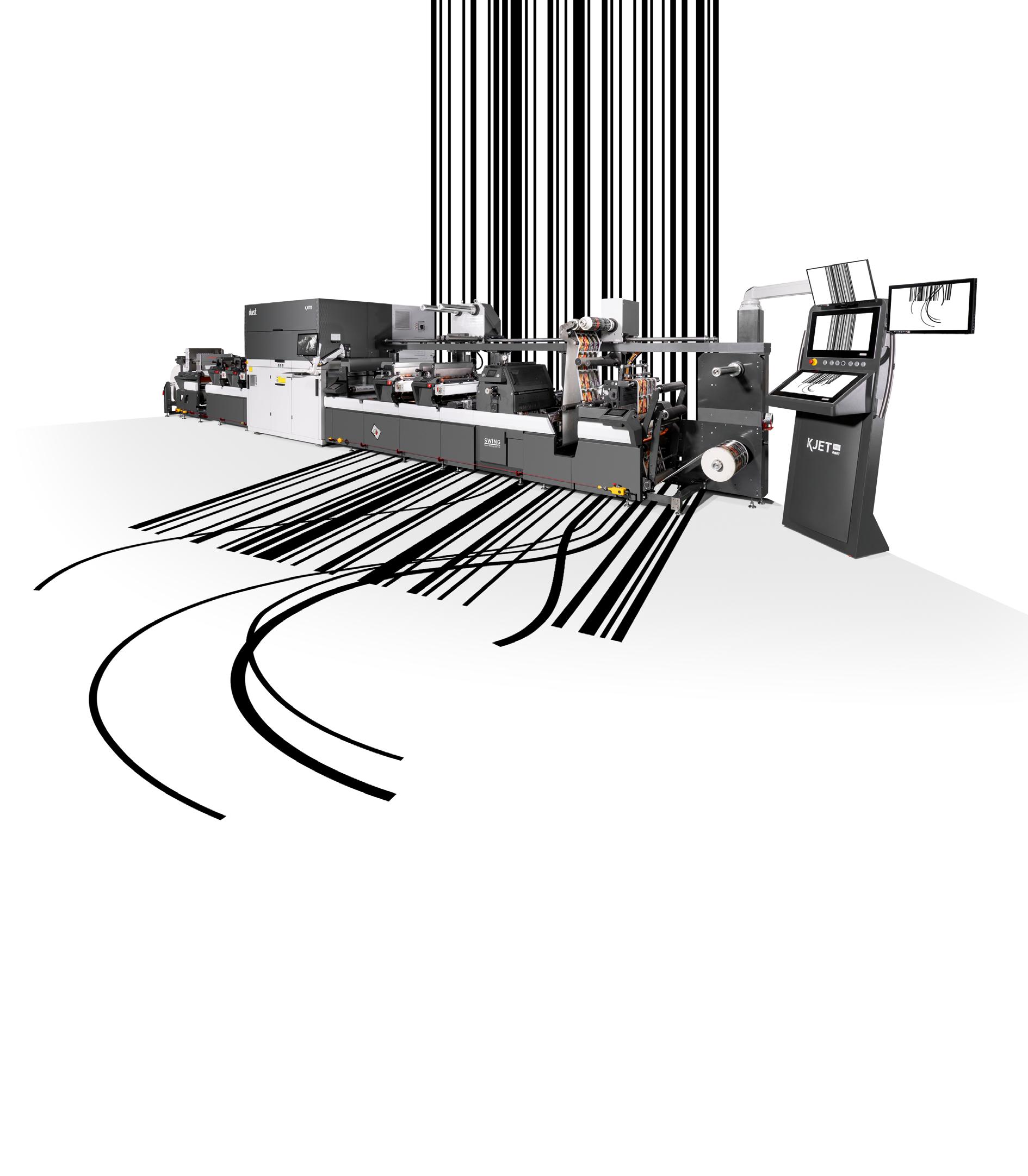

Durst Labels Factory aims to power print and elevate workflows with hybrid labels printing solutions. Next-level productivity can be achieved with the Durst-OMET KJet, a cylinderbased printing system, and XJet, a premium sleeve-based printing system, designed to optimise labels printing efficiency and reduce unnecessary costs.

The launch of the KJet follows an announcement at Labelexpo Europe in 2023, extending the hybrid development partnership between the two organisations beyond the XJet platform.

“The current XJet platform, which has been the leading hybrid solution in the market with multiple installations worldwide, will be further improved and expanded,” both companies said at the time.

Durst Oceania managing director Matt Ashman emphasised the importance of providing customers with a single, reliable point of contact in the market.

As a result, Durst has assumed exclusive responsibility for the global sales of the KJet and XJet.

“The launch of the KJet and the introduction of the XJet strengthens our incredible relationship with OMET,” Ashman said.

“These two Italian industry powerhouses – one from the mountains and one from the lakes – have joined forces to help transition analogue businesses to a digital future delivering a truly collaborative and complimentary partnership. Durst Oceania is proud to bring these solutions to the regions of Australia, New Zealand and beyond.

“This partnership and collaboration delivers the Durst digital engine cradled within the traditional engineering supplied by OMET that is historically loved and highly regarded by the label converting community.

“The KJet and XJet product range has been designed to fit both small and large label converting, delivering medium volume to high volume work for those businesses looking to augment and complement their traditional analogue label products with a cutting-edge inkjet solution that only an OMET and Durst partnership can deliver.

“The beauty of this hybrid solution is that it is a true hybrid of the Durst RSCi and the KFlex or XFlex combined with all the advantages that those robust and reliable machines deliver.

“The sky is the limit with various configurations available – yes, you can have your flexo unit with this configuration; yes, you can have your slitting unit with this configuration.

“This is truly the best of all worlds for the astute converter that can access every solution and every module available with the KFlex and the XFlex machines combined with the fastest and highest quality LED UV inkjet printing engine available on the market today.

“We have seen the labels category growing exponentially; however every business is looking for versatility in the investment that they make in today’s competitive world and every dollar needs to deliver.

“Hence, it was essential for Durst to grow its partnership with OMET, as this is what traditional label converters have been telling us is needed in the marketplace – and we have delivered.”

Durst has been at the forefront of the digital printing revolution and evolution for the last 20 years – assisting strong traditional analogue businesses embrace, expand, and depend on digital solutions that complement their rich analogue products.

“Some have thought that digital technology was designed and created to usurp analogue technology. However, Durst has known for many years that this is not the case,” Ashman said.

“Businesses that have invested in rich analogue knowledge and capability are looking to add a digital solution. What’s more, a hybrid digital solution can elevate the final product and future-proof their businesses. The Durst digital label technology is represented by the RSCi platform, which has been very successful globally in its own right, offering direct-tomedia high quality inkjet up to 100 linear metres per minute and high opacity white.

“The question I always get asked is who will support the sale, installation, and service for a hybrid product like the KJet and the XJet. The answer is simple – Durst will. Durst Oceania will install, service and support all KJet and XJet sales in the Oceania region.

“Our message to existing and future OMET customers is straightforward – visit our stand at Labelexpo Europe in September or attend our Durst Beyond event at the Durst head office at Brixen from 13-15 September. You will see the KJet installed at the Durst Customer Experience Center and see the benefits of this hybrid product as it is demonstrated to the world.

“Customers are always invited to visit the Durst headquarters and experience the KJet printing system firsthand. In addition, our exhibit at Labelexpo Europe in Barcelona offers another opportunity to explore Durst’s latest innovations and meet and network with like-minded businesses across the globe. We will also organise educational sessions and seminars as well as visits to key label converters in the region, so visitors can see

firsthand how the Durst digital technology can make a real difference to the profitability and success of your business.

“We welcome all print providers from any speciality to come and experience the KJet and XJet collaboration as we have seen the growth of start-up business units within non-related traditional print providers that have embraced the value that label converting can offer.”

Durst sales director for labels and packaging Thomas Macina shared his excitement regarding the KJet and the importance of the OMET partnership.

“The combination of digital with flexo offers an innovative hybrid solution that maximises productivity and flexibility, enabling printers to select between flexo or digital printing. This optimises efficiency and reduces costs while meeting evolving market demands such as personalisation and just-in-time deliveries in a single-pass. We have been leading the inkjet label printing market for many years and we provide solutions for all label converters

around the world – starting with entry level solutions up to industrial needs with 100m/ min and 510 millimetres wide,” Macina said.

“We have been observing a clear market trend towards end-to-end production and this is why we have reinforced our partnership with OMET. At drupa, we launched the KJet – which is the perfect combination of a dual-servo cylinder based flexo unit combined with the robustness, efficiency, and productivity of the Durst RSCi digital print engine. This provides operators with a new experience in terms of simplicity, minimal set-up time, and low waste.”

Durst CEO and co-owner, Christoph Gamper described the K-Jet as a product that is “beyond your standard label press”.

“It is customised to the needs of the converter and it is a perfect synergy. We see the alliance with OMET as the best of both worlds. There is no need to invent everything by ourselves. We are the digital experts – this is where we are coming from and this is where we are going,” he said.

Representing an unprecedented partnership between two of the industry’s most respected manufacturers, Durst and OMET, the KJet represents the pinnacle of hybrid technology, offering operators a seamless experience with its user-friendly interface and ultra-short web path. This design not only minimises waste but also reduces setup times, showcasing the advantages of digital printing.

Combining the great ‘cylinder-base dual-servo’ flexo technology from OMET with the robustness and reliability of Durst RSCi digital printing engine, the KJet line is born to be the benchmark in hybrid printing machines.

The power of its automation and register control redefine the concept of versatility and extend the boundaries of printing and converting solutions. Endless possibilities of applications, from labels to packaging without compromising on performance or print quality.

“The combination of digital with flexo enables printers to select between flexo or digital printing, thereby optimising efficiency and reducing costs while meeting evolving market demands such as personalisation and just-in-time deliveries in a singlepass,” Durst Oceania managing director Matt Ashman said.

Power your print and elevate your workflow with the hybrid labels printing solutions Durst-Omet KJet and XJet – combining inkjet, flexo and in-line finishing for unmatched efficiency.

For more information, please visit

durst-group.com/labels-factory

Google packaging sustainability lead Miguel Arevalo recently discussed the company’s forward-thinking approach to sustainable packaging at the Empack 2025 forum

As the world grapples with the urgency of sustainability, the packaging industry finds itself at a crossroads. The quest for solutions that balance environmental responsibility with functionality, consumer satisfaction, and economic viability has never been more complex. Amid this landscape, Google’s approach to packaging is redefining the future of design and materials.

With Miguel Arevalo as Google packaging sustainability lead, Google’s packaging team is a driving force behind the company’s efforts to rethink packaging – not just as a logistical necessity but as a catalyst for global change.

Their work is at the forefront of Google’s mission to revolutionise packaging, making it more sustainable, transparent, and adaptable to the evolving needs of a rapidly changing world.

For the Google packaging team, sustainable packaging is not a “one-size-fits-all”

solution but an ongoing experimentation, learning, and iteration journey.

As Arevalo explained at the recent Packaging Innovations & Empack 2025 event, “Packaging is not just about protecting the product. It’s about ensuring that it has minimal environmental impact, that it can be reused and recycled, and that it serves the future needs of our planet”.

Google’s packaging approach prioritises using fibre-based materials to drive circularity. Recognising the challenges of mixed-material packaging, Google focuses on a single material stream – fibre – to leverage the existing paper waste stream and improve recyclability rates.

“We acknowledge plastic’s versatility across various applications; however, its ubiquity in packaging poses direct challenges to its effective recyclability. Recognising this, our team focuses on maximising the potential of fibre,” Arevalo said.

“This strategy requires the elimination of plastics from our packaging to ensure compatibility with existing recycling systems.”

Google’s packaging evolution centres on the concept of circularity. With millions of products shipping globally, its team recognises the need for packaging that works across diverse regions and product categories.

Google’s commitment to eliminating plastic from its packaging reflects a focus on material circularity, ensuring that packaging components can be readily recycled within existing infrastructure.

Arevalo said Google is committed to developing plastic-free packaging solutions that prioritise recyclability.

“We need to ask ourselves: how can we create packaging that is truly circular, ensuring materials are effectively recycled?” Arevalo added.

In the race to develop sustainable packaging, transparency and knowledge sharing have become cornerstones of Google’s strategy.

According to Arevalo, one of the biggest challenges in the packaging sector today is managing consumer expectations. With sustainability claims often clouded by greenwashing, they believe honest communication is crucial to building consumer trust.

“One of the key lessons we’ve learnt is that consumers want transparency. They don’t just want to hear about what we’re doing – they want to understand why and how we’re doing it,” Arevalo said.

“It’s not about making bold claims; it’s about telling a story that aligns with our long-term sustainability goals. We’ve adopted an open-source approach to support this, developing resources like our Plastic-Free Packaging Design Guide. By sharing our journey, including successes and challenges, we aim to empower other companies to accelerate their sustainability efforts.”

At Google, Arevalo said pursuing sustainability is not about achieving perfection overnight but about making incremental improvements.

“Sustainability is a journey. It’s about progress, not perfection. We must acknowledge that we’re constantly learning and improving as we go along. No solution is perfect, but we’re committed to reducing our impact every step of the way,” Arevalo noted.

He also believes in collaboration within the packaging industry and across sectors.

“No single company can tackle these challenges alone. We need to work together to drive real change,” Arevalo said.

“Google’s approach to packaging is rooted in partnerships – with suppliers, competitors, and industry leaders – to develop holistic solutions that benefit the environment and society. At Google, we believe innovation in sustainability should be a collaborative effort, not a competitive one.

“Packaging is a multidisciplinary challenge. It involves design, materials science, logistics, and consumer behaviour. Working in silos doesn’t work.

“We openly share our learnings and insights, empowering companies to develop solutions. It’s not enough to claim something can be done; we believe in demonstrating how solutions are achieved. We collaborate with material manufacturers, logistics partners, and

competitors to push the boundaries of what’s possible in packaging. We aim to accelerate innovation and share knowledge so the entire industry can evolve.”

According to Arevalo, Google is actively looking into other distribution solutions that can challenge current produce-usedispose paradigms to other closed loops.

Google has been working on internal closed-loop systems to develop solutions to move product components among its suppliers to their assembly centres and has created reusable closed-loop systems to eliminate single-use packaging and drive circularity across their supply chain.

At the heart of Google’s packaging strategy is a focus on design. Arevalo stresses that a product’s packaging design is integral to its sustainability. From reducing unnecessary materials to creating designs that encourage reuse, the aesthetic and functionality of packaging play a crucial role in driving sustainable behaviours.

“The packaging must work not just for today but for the long-term,” Arevalo said.

“We need designs that work for consumers, are scalable, and are within existing infrastructure. That means considering everything from the material’s life cycle to its end-of-life impact.”

As the packaging industry faces increasing pressure to become more sustainable, Google’s packaging team�s work serves as a beacon for others in the industry.

Through innovation, transparency, and collaboration, Google is showing that sustainable packaging is not just about reducing waste but about rethinking the entire lifecycle of a product’s packaging.

Arevalo finds the future of packaging balances environmental stewardship with cutting-edge innovation.

“It’s about rethinking packaging from the ground up, from the materials we use,” Arevalo concluded.

“At Google, we’re committed to pushing boundaries and leading the charge, and we also know that the more we collaborate, the faster we’ll get there. It’s not about being perfect; it’s about making meaningful progress together.”

Arevalo added that as we look to the future, it’s clear that the packaging industry is undergoing a transformative shift.

With leaders like Arevalo at the helm, the future is one where packaging becomes a key player in the fight against climate change, driving innovation, and collaboration at every stage of the supply chain.

Graffica has closed the financial year with both new and returning customers making significant machinery purchases, and onboarding new products

Graffica has reported a very successful financial year, bringing in business from new and returning customers and expanding its range of solutions.

Neil Southerington, owner of the printing packaging and converting machinery company, said several customers have purchased new kit from his business.

Graffica is celebrating the recent sale of a high speed Fengchi laminating machine to a Melbourne-based business.

“We’re very excited about this opportunity as it’s the first Fengchi laminating machine to come to the Australian and New Zealand market,” Southerington said.

“The customer viewed the machine on several occasions at drupa last year.

“It isn’t unusual for major capital expenditure to have a long gestation period, and they have since made the investment as they were in awe of it.

“We’ll provide more details to the market once the machine has been installed at the customer’s premises.”

The Fengchi laminating machine delivers up to 15,000 sheets per hour. In addition to its high speed, the fully servo machine delivers on fast set-up times, accuracy, partial lamination, two-sided lamination, and lightweight top sheets to single face.

Graffica also sold a high-end WonderJet water-based digital printer, CorrFold folder gluer, and high-speed slotter/ creasing machine to a customer in the Australia and New Zealand region.

“The customer bought the WonderJet water-based multi-pass digital printer, which was also a first for Australia and New Zealand,” Southerington said.

“This client is a return customer of ours. Previously, they purchased two Autobox carton making machines (one with two colour flexo print), and more recently, a CorrFold folding box gluer with a pre-creasing unit, as well as the Matrix 1700 high-speed quick-set fully automated slotting/creasing machine.

“The WonderJet brings impressive new technology to the custom box market. We’re seeing more demand for shortto medium-run personalised packaging, and this machine is a great fit for that.”

WonderJet’s product portfolio encompasses an extensive array of printing presses, ranging from the WDMS250 model that seamlessly blends multi-pass, high-precision scanning with high-speed single-pass printing, to a diverse selection of multi-pass and single-pass digital printers, and a comprehensive range of supporting equipment and consumables.

The new single-pass machine comes with white ink and prints at speeds of up to 105m/min.

“White ink is the holy grail of the brown box business,” Southerington added.

Another successful installation for the financial year Graffica is proud to highlight is at Victoria-based Affinity Print. The company invested in an 850 CartonFold folding box gluer and a 1060 fully optioned Century die cutter, offering clients high-end packaging solutions.

“At drupa last year, we were able to view the new die cutters from Century. There were only two manufacturers of die cutters with full blanking (in-line waste removal) previously, but there are now three with the addition of the 1060mm by 760mm sheet size MEB 1060mm die cutter with stripping and blanking station,” Southerington said.

“The die cutting machines displayed resulted in sales, with a Century die cutter installed

at Affinity Print earlier this year, as part of its expansion into a brand-new facility, along with a fully optioned folder gluer.

“The 1060 fully optioned automatic flatbed Century die cutter is known for its die cutting, stripping, and creasing of high-end coloured cardboard boxes. The 850 CartonFold folding box gluer’s capabilities covers the whole gamut of box folding. The machines add significant value to Affinity Print’s packaging needs.”

According to Southerington, the new financial year is looking equally positive for A/NZ, with its recently added Matrix glue plotter range for box makers and display customers, and its Ameida cutting tables enhanced with the addition of ‘auto feed and deliver’ capabilities.

Following drupa, Graffica also secured the agency for Huatai die cutting and embellishing machines. Graffica will be promoting high-end machinery from the China-based company, including small and medium format die cutters that are able to process up to 9,000 sheets per hour at an accuracy of 0.075mm, in addition to stripping and dedicated foiling machines.

As for JIT cartons and custom boxmakers, Graffica is now offering AOPACK machines, a highly advanced custom box maker with up to 150 box styles. Line glue application and cutting table technology heads incorporated, and basic print can also be achieved on the machines.

Guowei’s latest range of guillotines, distributed in partnership with Robert Allan from Melbourne-based Allan’s Graphic Engineers, will also be a focus for Graffica moving forward.

“The Guowei guillotines, which are available from 52cm to 300cm, were a highlight at the recent PacPrint tradeshow and will be a key focus of ours moving forward as well,” Southerington added.

“Graffica has enjoyed many years of great success, and we look forward to our involvement in the buoyant corrugated and carton-board box market. All the best to everyone for this financial year.”

See our range of folding box gluers, board slitters, creasing machines, auto loaders, unloading cutting tables and more. Discover

“We

In this feature, Tweak managing director Paul Rumens addresses his desire to make packaging work in the market, on the shelf, and in the real world

There’s a calm precision about Paul Rumens that feels earned –the kind of presence that comes from decades spent not just working in design but mastering its intricacies. Now managing director at Sydney-based creative studio Tweak, Rumens is an interesting hybrid: a creative thinker with a technical backbone and a craftsman’s eye for detail.

With an extensive background in packaging, Rumens has worked for many agencies over the years, across many categories, but the intricacy and challenge of what it takes to get effective packaging to work has always drawn him back into the space.

He’s not just a design purist – he’s also a generalist in the best sense of the word. A former Apple-certified engineer, a retoucher, a 3D designer, an occasional illustrator – Rumens’ lateral skill set is rare. But it’s his strategic lens that drives the process.

Rumens started his professional journey early – leaving school at just 16 years of age in London, he entered a youth training scheme that placed him with a company focused on packaging and production. He quickly proved a natural fit within a team that valued craft and detail, immersing himself in the predigital world of bromide cameras, paste -up tables, and scalpels.

As the design industry evolved, Rumens adapted seamlessly, transitioning from analogue to digital while upholding the craftsmanship of his early years. He understood that digital tools were only as powerful as the decisions behind them.

“The best thing about the scheme was that for the vast majority, I was placed in a real company doing real work. This was also while the industry was shifting to digital workflows, so being in a real workplace allowed me to experience this firsthand,” he said.

“Instead of using a rotary, I was using PostScript. But it was still about discernment. You still had to see what needed adjusting.”

That attention to detail became his calling card. While working in corporate identity, Rumens became known as the person who would catch what others missed.

“I remember a design director once said, ‘I want Paul to check it. He’ll fix the kerning’. That was my reputation – the guy who actually cared about the spacing between letters,” Rumens recalled.

One of his most technically demanding projects – and a personal favourite – was redrawing the London Underground Tube Map.

“It taught me which rules you could break, and which you couldn’t. It was one of

those jobs where the reward is in the finesse. You finish it and feel a true sense of accomplishment,” he said.

Another test of patience and precision came with the digital remastering of the Glenfiddich range – originally built in bromide. It was a laborious process, but one that made Rumens appreciate how nimble the tools of today really are.

“It was such simpler times back then! I was provided with the master bromides; I had to scan them in (we had a dedicated Mac for that) then run it through Adobe Streamline, to convert it to outlines, but it would lose a lot in translation. It was

a meticulous process to redraw over the top,” he recalled.

“The other issue is that the master bromide was not the original – it was a bromide of a bromide, of a bromide – this causes the issue of rounding and some areas ‘filling in’ a bit. The goal was not to make a perfect facsimile, but to interpret what the original intent was.”

In 2001, craving a new challenge, Rumens packed up his life in London and moved to Sydney. He worked on everything from annual reports for Westpac to advertising for P&O Cruises. But packaging, according to Rumens, offers something other design disciplines don’t: tangibility.

“You can hold it; you can turn it over. It has to work from all angles – physically and emotionally,” he said.

In January 2008, he joined Tweak and moved up the ranks over almost 18 years.

There’s something old school in Rumens’ approach – not in his methods, but in his principles. He values integrity over speed, clarity over flash, and collaboration over hierarchy. He is a design leader who builds trust, champions integrity, and continues to shape packaging with the same care he learned in a London studio more than 30 years ago – one detail at a time.

“At Tweak, design is not just about aesthetics – it’s about strategy, problemsolving, and trust. We don’t just make a pretty picture. We make something that works in the market, on the shelf, in the real world,” Rumens said.

Rumens currently manages the Colgate -Palmolive account across Australia and Asia, guiding this year’s design and artwork projects for Total, Optic White, Ajax, and Palmolive.

“One of the biggest, most impressive artwork projects for Colgate-Palmolive was probably the roll out of Total for the Asia Pacific market, but my personal favourite is the Palmolive Dish Australian Extracts. We worked with Aboriginal Art by Lani, who created some beautiful art, but then we had to manoeuvre the challenge of getting the art to work on pack, which we did successfully,” he said.

A unique leadership style

One thing that defines Rumens’ leadership style is his refusal to rush.

“Clients say, ‘We need it now’. But if you don’t get it right at the start, it takes longer in the end. Good briefing saves time, even if it doesn’t feel like it,” he said.

Problem-solving is what drives him – not just in creative execution, but in the way Tweak operates. He recounts a project for a natural skincare range that included a leaf texture no one could trace the origin of.

“I asked, ‘Where did this come from? Who owns it?’ No one knew. So, we recreated it –photographed, illustrated, tiled it properly. Now they can use it at any scale, even wrap a bus with it. That’s the kind of thinking that saves you later,” Rumens mentioned.

This proactive mindset has paid off. Clients who have left Tweak often come back, citing the studio’s foresight and clarity in communication and in process. At Tweak, he has helped foster a culture where ideas are interrogated, artwork is built with intent, and freelancers and clients alike are treated with respect and professionalism.

“Tweak has always been very focused on doing the best work, not the most work. We don’t want to be a big company that loses its core value. Our plan is simple –keep the standard high and produce the best work we can, and create long-term relationships that build in-depth brand knowledge,” he said.

“We’re not just designing; we’re advising. We’re saying, this won’t work, or this will, but only if you do X, Y, Z. That’s what sets Tweak apart.”

In an era of AI-generated visuals and fastturnaround artwork, Rumens remains focused on what matters: design that works, storytelling that holds up to scrutiny, and packaging that reflects the values of the brand behind it.

His view is that the best design is not only beautiful, but fit for purpose, adaptable, and underpinned by sound thinking.

And while he sees AI as a powerful new tool, he believes its use in packaging must be carefully managed – not just creatively, but legally and ethically.

“Just recently, news broke that Disney is suing AI firm MidJourney, and the evidence is very compelling. Until we have all the answers about the legalities around AI, we must tread carefully to not put our clients at risk. That’s not to say we don’t use AI, but it is just another tool on the belt,” he said.

He’s also deeply invested in getting sustainability messaging right.

“There have been many trends over the years, but the biggest now is sustainability – how do you keep packaging looking great but recyclable? The industry has used special materials such as foil board as a crutch for many years,” Rumens said.

“We have been walking the sustainability path for a while, but every region is different, and the biggest challenge is on a global design that does not have the same restrictions that we do.

“It’s not as easy as slapping on a green icon. We have to make sure it’s APCOcompliant, accurate, and country-specific. The details matter – if you’re going to charge more for a sustainable product, the pack has to justify it.”

What still keeps Rumens in this industry and excites him about design is problem solving and “making things real”.

“That moment when a concept turns into packaging you can hold in your hand and it works? That’s magic,” he said.

More than 600 industry suppliers have already booked their spots for Labelexpo Europe 2025, with organisers expecting it to be the biggest Labelexpo event to date

Informa Markets is set to deliver its biggest Labelexpo event to date with Labelexpo Europe 2025, taking place from 16-19 September at Fira Gran Via in Barcelona.

More than 600 industry suppliers have already booked into the event, with 15 per cent exhibiting for the first time at the show and the show’s expansion already 12 per cent larger than the 2023 edition.

Evolving with the industry, Labelexpo Europe 2025 is also incorporating folding cartons for the first time, a strategic move responding to the convergence of inline and digital technologies, with the show once again cementing its position as a global platform for innovation and industry trends.

Here are some of the products that will be on show:

Bobst (Booth: 5E43)

Bobst will demonstrate the reality of its vision for outstanding packaging production at Labelexpo Europe. High-performance solutions with new processes, technologies, and features will be on show.

Among the innovations set to debut at the show, Bobst will unveil a “breakthrough digital printing solution for labels” developed to boost production agility, unlock new applications, and changing complex label production – all in a single pass.

Made possible by the high modularity and versatility of the Bobst Digital Master series platform, this industry-first, all-digital label solution is targeted at converters looking to diversify and add higher value for their customers.

Adding a unique dimension to the event, Bobst will also offer exclusive visits to customer sites, as nearby printing companies open their doors to showcase end-to-end label production with highly versatile solutions in action.

“Our commitment to the four pillars of the Bobst vision – digitalisation, automation, connectivity, and sustainability –continues to fuel our product innovation and dedicated service program, always with our focus on application versatility at the core,” Bobst PL labels marketing director Patrick Graber said.

Print & Pack Australia is the authorised agent for Bobst in Australia and New Zealand.

Canon (Booth: 4E07)

Canon has confirmed it will demonstrate a selection of its technologies for labels and packaging production at Labelexpo Europe, including LabelSteam LS2000 and Edale CartonLine.

The company will showcase the LabelStream LS2000, a water-based, five-colour (CMYK plus white) inkjet digital label press. Designed for industrial-scale label printing, the LS2000 prints with speeds of up to 40m/min with a maximum printing width of 340mm.

Canon will also display a newly developed UVgel Factory Solution for Labels, featuring the Colorado M-series, Fotoba Jumbo Roll JRL 17 and Colex flatbed cutting table. This configuration will show automated roll printing and digital finishing of applications, including shaped posters, kiss-cut self-adhesives and labels.

Also on display will be Edale CartonLine, a single-pass flexographic carton production line that offers multiple in-line embellishments and traditional flatbed finishing.

“We look forward to displaying our range of innovative technologies and demonstrating how we can support converters to achieve long-term business success,” Canon EMEA senior manager of marketing and innovation for labels and packaging Edoardo Cotichini said.

Dantex (Booth: 5E73)

Dantex will showcase its latest innovations in digital printing and flexographic plate processing. Its stand will feature live demonstrations of the high-performance PicoJet digital UV inkjet press, which will operate in real-time to highlight its impressive speed, precision, and reliability.

Also to be featured is the newly developed PicoColour press, designed for increased flexibility and affordability, providing highquality output in a compact footprint.

Dantex’s flagship press, the PicoJet 1200, is capable of printing at speeds of up to 75m/min. To ensure its printhead technology is running at 100 per cent output at any speed, Dantex’s engineers have developed a climate-controlled electronics system to ensure there is no over-heating or requirement for extraction fans – this keeps the print environment as clean and energy efficient as possible.

As for the PicoJet 1200 DRS, it is built on a modular platform, making it available as a reel-to-reel press or as a bespoke hybrid system. This flexibility allows the incorporation of features such as die cutting and flexo station options. It can also be custom configured in a variety of base and additional colour stations.

The PicoColour is built on the PicoJet platform and benefits from this advanced technology. Offering a print width of 254mm and speeds up to 50m/min, the PicoColour is available as CMYK or CMYK+White with compact inline finishing.

Offering outstanding printed results and suitable for short- to long-run jobs, this press provides all the benefits of digital printing for today’s demanding production environment.

Experts from Dantex’s UK headquarters and subsidiaries in Germany, France, Poland, and Switzerland, together with local agent Nekkorb Solutions’ Sam Kay (Mob: +64277283723) will be on hand to offer advice and support.

Durst (Booth: 3E79)

At Labelexpo Europe 2025, Durst Group will showcase two highly innovative printing machines.

Delivering a full hybrid line, the Durst KJET, in a 420mm wide configuration with nine colours (LED), will boast numerous conventional features. The new press includes the latest developments to facilitate processes for operators, especially in prepress.

Next to the KJET, a compact, scalable digital printing unit with the new Tau RSC LED ink will be on display at the Durst booth. The press will be equipped

with features that demonstrate why Durst is leading the digital labels UV inkjet market.

“At Labelexpo Europe 2025, we proudly present our commitment to reliability, simplicity, and performance – the pillars that define our production excellence,” Durst Group said.

“With smart, efficient, and future-ready solutions, we empower our customers to elevate their label printing business. Experience the next chapter of labels and flexible packaging printing evolution at Labelexpo Europe, where you’ll also discover the future, crafted by our digital printing systems.”

Epson (Booths: 3E35 and E42)

At Labelexpo Europe, Epson will present its latest innovations in commercial and industrial label production, including the debut of its SurePress L-5034. The press is a new water-based ink digital label printing platform, engineered for higher productivity without compromising print quality, making it a suitable choice for label converters looking to increase productivity and operational efficiency on a broad range of substrates, from non-coated textured papers to metallised stocks.

Its optimiser liquid technology, jetted alongside colour inks, optimises dot formation and ensures precise control of drop placement, resulting in stunning image quality. Its advanced six-colour ink set (CMYK plus orange and green) offers an impressive colour gamut and extensive Pantone coverage.

Equipped with Epson’s PrecisionCore technology, the L-5034 delivers a native resolution of 1200dpi, ensuring outstanding image quality for fine details, small text, and smooth gradations.

Capable of handling a web width of 340mm and accommodating high-capacity rolls up to 120kg, the L-5034 is also built for versatility and reliability.

The new L-5034 will be accompanied by Epson’s other SurePress models, the L-6534VW and L4733AW, and an extensive range of ColorWorks on-demand colour label printers, including the C8000e series, the

new ColorWorks D6000 series on-demand industrial label, and a demonstration of Epson’s first collaborative robot (AX6) in action with the ColorWorks C6000Pe, automating a test tube labelling process.

Fujifilm (Booth: 5D73)

Fujifilm’s stand will feature analogue and digital zones, offering an immersive experience that reflects its commitment to supporting traditional print processes while accelerating its shift to digital.

In the analogue area, live flexo plate production will be taking place using Fujifilm’s Flenex FW water-wash plates. This setup will showcase how fast and efficient high-quality platemaking can be, with complete platemaking cycles taking less than 40 minutes.

Alongside this, there will be demonstrations of Fujifilm’s LuXtreme LED UV system and CuremaX inks and varnishes, underlining Fujifilm’s expertise in providing sustainable, energy-efficient production solutions.

A dedicated presentation stage will host regular sessions on the benefits of Fujifilm’s analogue and digital solutions. These will include real-world customer success stories brought to life as partners and users take the stage to share how Fujifilm technologies have helped them grow and adapt.

The Jet Press FP790, Fujifilm’s innovative water-based digital inkjet press designed for flexible packaging, will be on show, offering a true alternative to flexo without compromising on quality or regulatory compliance.

Fujifilm’s leading flagship B2 digital inkjet press, the Jet Press 750S, increasingly relevant for folding carton applications, will also be featured. Also on display will be one of Fujifilm’s new ‘5UPER COLOUR’ 5-colour presses. Launched recently in Europe, the highly anticipated mid-range Revoria Press SC285S features an additional speciality toner station to allow five-colour printing in one pass.

Fujifilm’s Imprinting Solutions will also be featured on the stand, highlighting their versatility across a range of packaging applications.

At Labelexpo Europe, Heidelberg and Gallus will unveil a new chapter in their vision for smart, connected printing with the debut of two new machines.

As the label industry faces increasing demand for shorter runs and faster turnaround times, and converters are challenged to maintain productivity and profitability while navigating complex market dynamics and tightening margins, the launches at the show aim to tackle these pressing industry needs.

The companies said the new solutions will enable label converters to scale efficiently, respond rapidly to shifting market demands, and remain competitive in a fast-evolving landscape.

In addition, Heidelberg and Gallus’ joint appearance aims to reflect their commitment to leveraging this momentum as part of their growth strategy for the packaging and label segment – showcasing new technologies and end-to-end solutions that drive efficiency, productivity, and quality, to meet the evolving demands of brand owners and converters.

Gallus’ modular solutions are designed to work seamlessly not just within its own ecosystem, but also alongside complementary partner technologies from across the production line. These collaborations further demonstrate the company’s commitment to whole-industry advancement through shared purpose, vision, and a connected, end-to-end print ecosystem.

The booth will also feature a robust, unified lineup of technologies and samples, including sheetfed offset innovations for the efficient production of wet glue and in-mold labels, Heidelberg Prinect, Gallus Screeny, Gallus Services, and Gallus Classics.

“Together with the continued strength of our partnership with Heidelberg and a growing network of partners and collaborators, we’re looking forward to a successful event in Barcelona,” Gallus Group CEO Dario Urbinati said.

Hybrid Software (Booths: 5E55,E45, and E46)

Hybrid Software will unveil major upgrades to its PACKZ, CLOUDFLOW, and iC3D product lines at Labelexpo Europe. The latest innovations aim to focus on accelerating prepress workflows, automating complex label tasks, and enhancing design-to-print accuracy for label and packaging production.

Highlights include:

• PACKZ Max: The PDF editor now integrates Harlequin RIP directly for precise flexo screening, 1-bit TIFF output, and high-quality flexo and offset printing

• Packzimizer: Automated ganging and lane planning tool for digital label printing that optimises layout, minimises waste, and improves press efficiency. Packzimizer can also be automated as a module of the CLOUDFLOW workflow automation suite

• Multi-layer label automation: Prepress for peel-off labels now supports adhesive-free zones, CLP/CHS compliance, and 3D visualisation, powered by PACKZ and CLOUDFLOW

• CLOUDFLOW Colorspace: The 2025 EDP and Pinnacle Award winning software ensures consistent, precise colour reproduction across diverse substrates and printing technologies

• iC3D 11: Introduces smart embellishment application with spot colour detection and visual previews of foil, embossing, and varnish early in the prepress workflow

• SmartDFE: Hybrid Software’s OEM Software division (Global Graphics Software) will demonstrate the nextgeneration SmartDFE, the AI-driven digital front end recently recognised with the King’s Award for Enterprise.

Hybrid Software CEO Mike Rottenborn said, “We are excited to unveil the next generation of innovation from Hybrid Software at Labelexpo Europe 2025. Through intelligent automation, AI-driven workflows, and unparalleled innovation, our newest products allow our industry to work smarter – and not harder – for unmatched label quality”.

Konica Minolta (Booths: 5E61 and 5G60)

Together with MGI Digital Technology, Konica Minolta will be showcasing its latest advancements in digital label printing technology, offering attendees the opportunity to experience high-quality, sustainable, and cost-effective solutions.

Solutions on display will include:

• The AccurioLabel 400: Konica Minolta’s latest digital label press is setting new standards in label printing technology with a resolution of 2400 dpi by 1200 dpi. Including its innovative Intelligent Quality Care technology, impeccable colour consistency is ensured throughout the entire print run. The machine also features a new white toner, boasting more than 70 per cent opacity, while maintaining the same unparalleled reliability as the company’s trusted CYMK toners.

• An AccurioLabel prototype (technology preview): Konica Minolta will present a prototype of the AccurioLabel as a technology preview: With a newly added IQ unit for inline quality control, this new system will bring even more automation and productivity, and it will be the next generation version of its wellestablished AccurioLabel 230. While the new model will not be available immediately, Konica Minolta shares an early look at what is on the horizon.

• The MGI JETvarnish 3D Web 400: The MGI JETvarnish 3D Web 400 is the ideal solution for label printers as well as flexible packaging producers, who are looking for a digital way for embellishment to differentiate their services. The web-solution turns printed jobs into remarkable products that will immediately catch the attention of customers.

• The MGI Octopus Web: The MGI Octopus Web offers a brand-new technology for digital cutting and finishing of self-adhesive labels, using 4-axis cutting heads equipped with cutting blades.

• The GM DC350Nano: The DC350Nano is the most compact unit in GM’s series of label-finishing machines. With semirotary die cutting, lamination, and a genuine pneumatic knife box with crush knives, it is perfect for short-run label production.

Screen�s Truepress LABEL L350UV SAI-S flagship digital inkjet narrow web press will be showcased in several configurations

Screen will demonstrate how productivity and cost-effectiveness drives growth and profitability with the Truepress LABEL 350UV SAI-S, which the company calls the industry�s workhorse digital label press.

Known for its reliable precision-Japanese print engine design, wide colour gamut with extended orange and blue, new Digital Primer option for embellishing, alongside advanced workflow management, the Truepress LABEL 350UV SAI-S will be operating constantly to showcase the real-world productivity benefits of Screen inkjet innovations.

Visitors will see firsthand how Screen’s digital inkjet solutions deliver next-level productivity and profitability for shortrun printing jobs with unparalleled press uptimes and workflow versatility.

While the 350UV SAI-S will be shown as a roll-to-roll device, Screen has also experienced recent gains in the hybrid digital-flexo market with installs featuring Lombardi and Rotocon flexo converting stations, and a solution feeding into Grafiske Machinfabrik (GM) finishing.

“Screen GP Australia is delighted to attend Labelexpo Europe 2025 – for the first time in Barcelona, Spain,” Screen GP Australia managing director Peter Scott said.

“The extra space has enabled Labelexpo organisers to go beyond traditional label production and more effectively embrace flexible packaging and folding cartons –two areas of great interest for Screen, with the new Screen Truepress PAC 520P and PAC 830F digital presses shown at drupa, targeting paper-based flexibles and plastic flexibles respectively.

“Naturally, our highly successful Truepress Label L350UV SAI series will be prominently featured, as it is the most popular production inkjet digital press globally, with downtime as little as just 2 per cent using our TRUST service network.

“Screen Europe is holding full details of its Labelexpo display until right before the show but, suffice to say, there will be surprises. It’s all about flexibility, quality and reliability. Screen can supply stand-

alone digital label solutions for near-line finishing, or our partners can provide complete in-line hybrid solutions.”

Jet Technologies distributes Screen technology in Australia and New Zealand.

Xeikon/Flint Group (Booths: 3E55 and 3G55)

Xeikon’s technologies that support both environmental targets and operational efficiency will be on show under the Flint Group banner.

The Xeikon solutions that will be featured at Labelexpo Europe include:

• The Xeikon LX3000: Powered by Xeikon’s Cheetah 3.0 dry toner technology, the LX3000 is designed for converters seeking sustainable, high-performance label production. Featuring the new ECO toners and advanced energy-saving features, this press is the smart choice for short-run and food-safe applications with minimal environmental impact.

• The Xeikon PX3300HD: Setting new standards for UV inkjet with breakthrough resolution, smoother gradients and sharper text. Designed for markets where bold colours and durability matter – think industrial, health, and beauty or beverage – this press combines speed, quality and robustness in one powerful platform.

• The Xeikon TX500 with inline metallisation from Kurz: An industryfirst hybrid solution combining dry toner with metallised effects in a single pass. Perfect for premium wine and spirits labels and other high-end applications, this setup delivers eye-catching embellishments with digital flexibility and zero compromise on food safety.

Marking its first year in Barcelona after four decades in Brussels, Labelexpo Europe 2025 also coincides with Flint Group’s largest-ever presence at the event.

Flint Group CEO Pepyn Dinandt, who will be present at the event, said, “Those visiting our stand can expect so much more than product showcases and machine demonstrations. As a partner to printers, we are prepared to meet, guide, and advise printers on their journey into a more sustainable and profitable future”.

Labelexpo Europe offers Currie Group’s technology partners with an opportunity to present their latest advancements and cutting-edge solutions

Several of Currie Group’s manufacturing partners will be at Labelexpo Europe, showcasing their latest and greatest innovations. Industry leaders including AB Graphic, HP Indigo, and Omet promise to deliver on speed, productivity, and efficiency.

Here’s what will be on display:

AB Graphic

AB Graphic will unveil its latest innovation in digital finishing at Labelexpo Europe, with the launch of its newest DigiLase –a laser finishing system featuring two laser beams instead of one, thereby doubling the cutting speed and significantly increasing overall production efficiency.

Already sold to a customer in Germany, the DigiLase with dual lasers will be showcased live at the event, offering a glimpse into the future of high-speed, automated digital finishing.

Visitors to AB Graphic’s 484m² stand will see a total of 10 machines in action, including two Digicon Series 3 lines – a 430mm version set up for premium embellishment and a 350 model producing multi-layer labels.

Other highlights will include a 540mm wide converting line with AB Graphic’s ASU, Converter and Vectra AutoSet turret rewinder, the Ti200 RFID inserter and an SRI unit demonstrating slitting, rewinding and inspection with advanced automation.

Also on display will be a Shrink Sleeve Seaming Rewinder, a Booklet Machine with braille inkjet module, and a new DigiLase with integrated automated workflow.

In addition, AB Graphic technology will be featured on the HP stands, including the DigiLite and Digicon Series 3, along with Fast Track and Vectra AutoSet.

HP recently launched the HP Indigo 6K+ Digital Press and will be running live demos of the press at Labelexpo Europe.

The Indigo 6K+ Digital Press is built on the industry-leading HP Indigo 6K Digital Press.

The new HP Indigo 6K+ introduces innovative advancements in AI-powered tools, automation, scalability, and press robustness. Operated by the new SmartControlSystem, which has been designed to improve diagnostics, uptime and press reliability for enhanced robustness, it efficiently manages shortto medium-volume label production with intelligent automation and precision. With the new integrated system, converters can produce more jobs per shift while minimising waste and reducing unplanned maintenance interruptions.

The HP Indigo 6K+ is driven by a suite of automation and AI powered tools, designed to maximise production efficiency. Key solutions include the HP PrintOS Suite, Automatic Alert Agent 2.0 (AAA 2.0), HP Spot Master, and HP Nio. These advancements empower operators with real-time insights, shorter setup, intuitive troubleshooting, and automated colour management.

With a wide substrate range and support for complex applications such as smart labels with brand protection features and data-driven design tools, the HP Indigo 6K+ also empowers converters to diversify into new markets.

Featuring seven ink stations and spot colours, the HP Indigo 6K+ covers up to 97 per cent of the colour gamut and the industry’s broadest range of specialty inks – including Silver ElectroInk, Invisible and Fade-Resistant inks, and a comprehensive White ink portfolio.

Enabling a shorter job setup and execution also means the HP indigo 6K+ reduces media-related CO₂ emissions per job by up to 20 per cent and cuts media waste.

OMET has confirmed it will feature two printing presses operating on its stand at Labelexpo Europe, including the world premiere of a brand-new machine making its debut at the show.

At the heart of OMET’s presence will be the exclusive preview of a brand-new printing and converting platform, designed to redefine industry standards.

Its unique features will be unveiled for the first time at the show through live demonstrations that highlight its technical innovations, performance, and application potential.

According to OMET, this solution has been developed to meet the evolving needs of the market and provide printers worldwide with new competitive advantages.

Alongside the new launch, a second OMET machine will also be in operation –already well-established for its reliability, versatility, and high-quality performance in shrink sleeve and flexible packaging production.

This press will also be featured in a packed schedule of live demos throughout the exhibition.

AB Graphic, HP Indigo, and OMET are distributed by Currie Group in A/NZ.