CASE STUDY: Kwik Kopy Moonee Ponds enhances output with new Ricoh Pro C7500

Starleaton has re-commenced trading as Starleaton Pty Ltd, using the same website and branding of the business that was recently placed into liquidation.

The ability to effectively ‘re-start’ the business comes from the ownership of the Starleaton brand, company name and intellectual property that was always owned by the person who started the business – Peter Eaton – father of Ben Eaton, Melissa Spooner (nee Eaton), and Josh Eaton – through his vehicle Starleaton Pty Ltd.

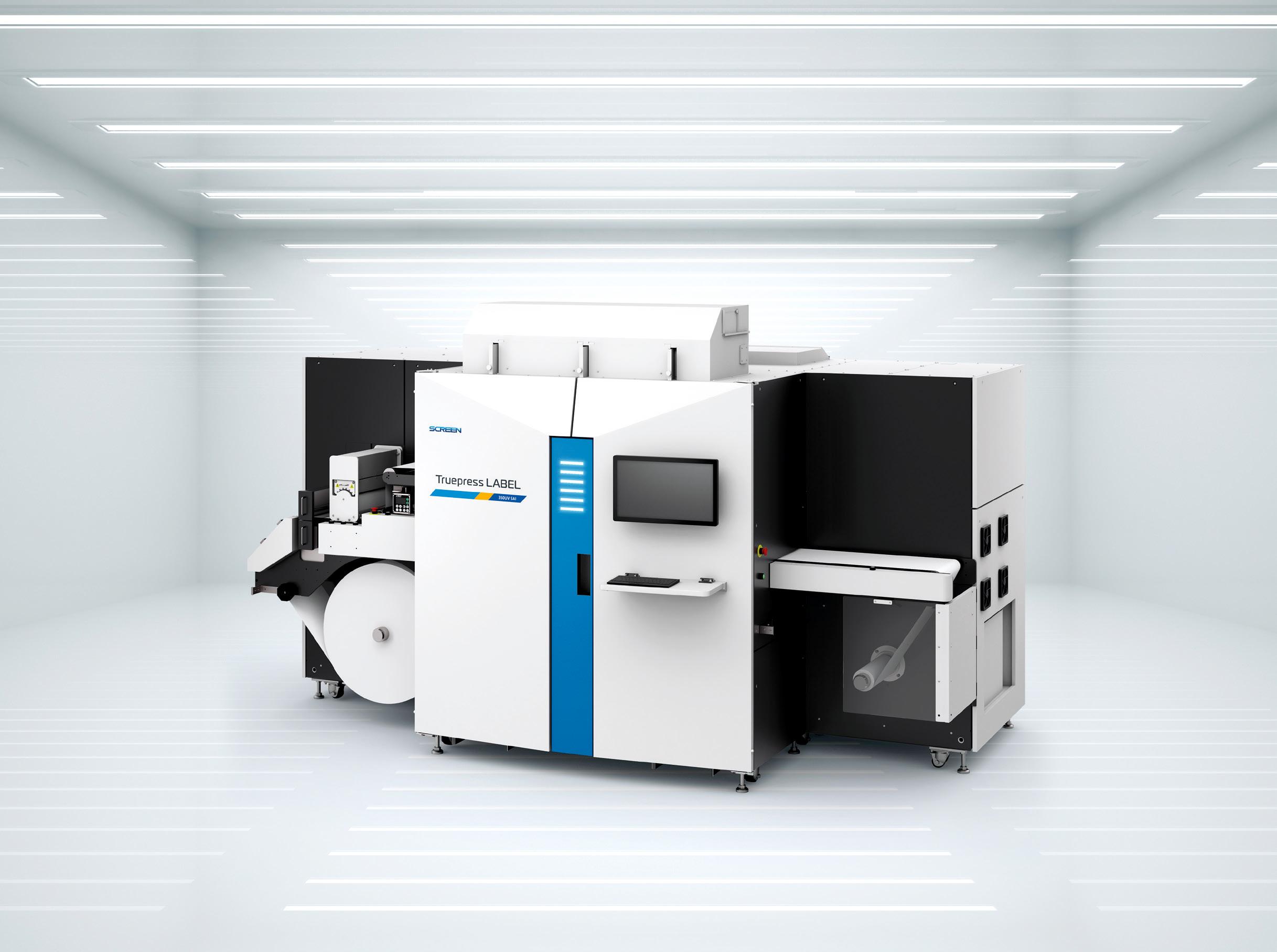

■Truepressロゴ(型式・シリーズ名)【ポジ版】

Event season is upon us yet again – the next two to three months are going to see some of the biggest printing and packaging tradeshows and conferences happen, including Printing United 2025, Labelexpo Europe 2025, and PMG’s very own Australia and New Zealand Printing and Packaging Week (ANZPPW), which covers several Trans-Tasman printing and packaging events. This issue of AP provides a sneak peek into some of the latest innovations from industry-leading manufacturers that will be shown at Printing United 2025 (from page 16). The event promises new technologies and discussions around key trends impacting the printing space.

We also explore Label Image’s purchase of a new Durst Tau 340 RSC LED label machine and celebrate alongside one of the industry’s most well-known familyrun businesses, Bailey Print Group’s 40th anniversary.

We hope you enjoy reading this issue.

Managing Director

James Wells / 0414 995 104 james@intermedia.com.au

Subscriptions / (02) 9660 2113 subscriptions@intermedia.com.au

Subscription rate (5 issues) Australia $79

The business that went into administration, was saved with a last-minute Deed of Company Arrangement (DOCA) and then placed into liquidation, was Starleaton Holdings Pty Ltd and SDS Bidco that was owned by the three siblings with the brand effectively ‘licensed’ to the business by Peter Eaton.

In an email recently sent to previous customers by Melissa (melissa.eaton@starleaton.com.au), she explained that the business is operating again under “new ownership”.

“I wanted to personally reach out and let you know that while Starleaton is continuing under new ownership, I’m still here to assist you with any of your orders or printing inquiries (sic),” Melissa said in her email.

“Our product range has been streamlined – you can view the full selection online at www.starleaton.com.au. If there’s a specific item you’ve been purchasing from us and you want to confirm it’s being continued, please reach out, I’ll be happy to check for you. And if you’re

unable to find what you’re looking for online, don’t hesitate to contact me directly or email our team at customerexperience@starleaton.com.au – we’ll be more than happy to help.

“I look forward to continuing to work with you and your business. Thank you for your ongoing trust and support, it means a lot to both the business and to me personally.”

In her email, Melissa does not share a phone number; however, the company’s new premises are located at 7 Cleg Street in Artarmon – nearby the previous premises where Ben Eaton ran his business at Unit 6, 12 Frederick St, St Leonards.

In the initial administrator’s report dated 15 February 2024, Andrew Blundell and Simon Cathro identified a complex corporate and related party ownership and funding structure of the Starleaton Group.

Editor Hafizah Osman / 0431 466 140 hosman@intermedia.com.au

Printed by Hero Print Alexandria, NSW, 2015

National Sales Manager

Carmen Ciappara / 0410 582 450 carmen@proprint.com.au

Mailed by D&D Mailing Services Wetherill Park, NSW, 2164

Design and Production Manager

Sarah Vella / 0406 967 559 svella@intermedia.com.au

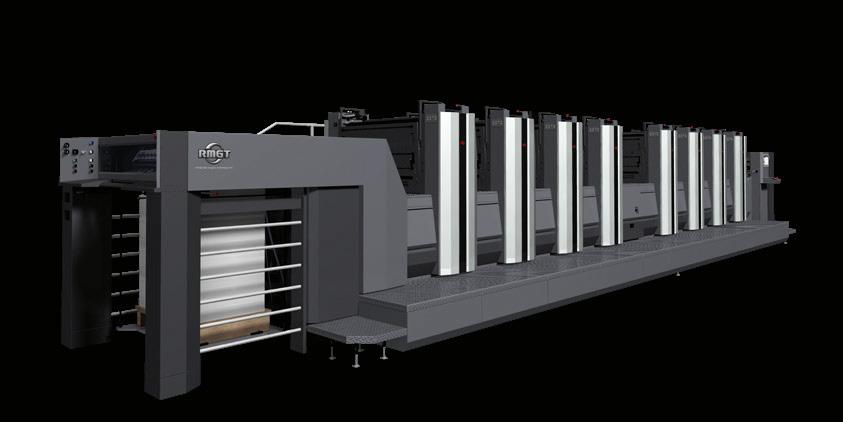

RELIABILITY

•Dependable performance

•Trusted platform

•Easy maintenance

PRODUCTIVITY

•High machine uptime

•High volume label printing

•Consistently high print speed

AUTOMATION

•Seamless integration

• Streamline production

• Maximum efficiency

CMYKhub has revealed plans to move towards 24-hour production at its new purpose-built headquarters in Melbourne, a move that will also create new job opportunities.

The new premises will represent twice the space of its current premises, which is currently spread over six locations in Heidelberg, Melbourne. The new headquarters on Wright Road will also feature 500sqm of office space across two levels.

CMYKhub CEO Dayne Nankervis said the new facility’s scale and design are key to the company’s ambitions for 24-hour operations.

“We have a total goal of this factory being a 24-hour operation, which will mean new staff – so we will be actively recruiting,” Nankervis said.

“This setup, with its purpose-built layout, new equipment, and proximity to the city and major freight hubs, positions us for strong, sustainable growth.”

The new CMYKhub headquarters also aims to set a new benchmark for sustainability. The new building is highly insulated, and the company is currently installing a 300-kilowatt solar system.

Omnigraphics and MMT Print group director and former CEO David Walton has taken a step back from the day to day running of the business to allow other staff to be promoted within the business.

Walton made the changes to the business late last year, and has been excited to promote staff from within the company to new positions.

Walton has stepped back from the role of CEO, that has been taken over by former general manager – sales, Jarrod Whyte.

Based in Brisbane, Whyte now manages the MMT Print operations on the Gold Coast as well as Omnigraphics in Melbourne.

Many of the lights are motion-censored and the factory’s HVAC system provides better heating, cooling, and humidity control.

“The layout supports a seamless production flow – always moving forward, never backward,” Nankervis said.

According to Nankervis, constructing the new facility has been a multigenerational goal for the company.

“While this building has been in planning for two to three years, the broader goal has been a decade in the making,” he said.

“We supply around 4000 businesses and small printers each month – a number

“Jarrod has added to his responsibilities as the former general manager – sales by taking on the administrative side and managing the overall business rather than just the sales team.

that’s growing. Our success directly supports our clients’ success, so it’s vital that we mitigate risks and provide them with confidence in our operations.

“For our clients, it sends a strong message: we’re here for the long term. It shows our ongoing commitment to reinvest and provide them the security to focus on their businesses, knowing we’re here to support them.”

CMYKhub recently unveiled its Komori Lithrone GX40RP at its new headquarters – the first of two new machines making their debut. The company has also installed a Canon varioPRINT iX3200 B3 press, which was purchased last year at drupa.

“Following this restructure, our Queensland state manager, Calli McCool has been promoted to national sales manager and is now working much closer with our Melbourne team.

“Calli is working with staff such as Ella Boromeo who is new to the industry and enjoying her first career progression since leaving university. It has been great to see Calli passing on learnings from her 23 years of experience to the young guns coming through our business.

“This frees me up to do a bit more on the sustainability side of the business and work ‘on’ the business, rather than ‘in’ the business on a day-to-day basis.”

Omnigraphics & MMT Print also recently created an internal customised software solution across its business to improve operational efficiency, while MMT Print has made a substantial investment in custom-made finishing equipment with automation to improve its signage manufacturing operations.

Fujifilm Australia has appointed a new CEO, welcoming Michio ‘Mich’ Kondo to the role as of 4 August.

Kondo, who is based at Fujifilm Australia’s headquarters in Macquarie Park, will oversee operations across both Australia and New Zealand. He takes the reins from Richie Matoba, who has led the business for the past three years and will now transition to a new leadership role at Fujifilm North America.

During Matoba’s tenure, Fujifilm Australia celebrated several major milestones. The company opened the House of Photography retail store in Sydney, delivered the first Aperto Lucent Open MRI machine outside of Japan to Altus Medical Imaging in Gladesville, and launched the world’s first ‘printed memories’ campaign. Fujifilm Australia also marked its 20th anniversary, celebrating two decades of innovation and community contributions.

“Richie’s leadership has helped Fujifilm Australia consistently grow and make meaningful contributions to the local community,” the company said in a statement.

As for Kondo, he brings a wealth of international experience to the Australian market. Over the past 12 years, he has served as managing director of Fujifilm operations in Canada, Turkey, and the Middle East Africa regions. In these roles, he oversaw local subsidiaries and played a key role in growing the medical, photo imaging, and graphic divisions in a wide range of markets.

Kondo has also focused on portfolio expansion following the integration of Hitachi’s medical division and led the launch of the office printer division, unlocking new commercial opportunities.

“Mich is eager to leverage his experience to contribute to the further growth of Fujifilm Australia,” the company said.

Alex King, division manager, human resources and corporate communications at Fujifilm thanked Matoba for his time as CEO and welcomed Kondo.

“We’re incredibly grateful to Richie for his leadership and innovative thinking over the last three years. With Mich in the team, we hope to continue innovating with customers and partners in the region, while supporting our community with new technology,” King said.

Kondo said he is looking forward to building on the strong local legacy that Fujifilm Australia has built over the years.

“I’m excited to get to know the local team and customers in Australia. Fujifilm Australia has a strong history of innovation, and I’m looking forward to continuing this trend,” he said.

Durst has revealed its long-awaited new third-generation label printer will be known as G3 ahead of the official launch at Labelexpo Europe in Barcelona.

But apart from the name, there is no image of the product or any specifications. It is safe to assume that this will be a new label printer to complement the existing Tau and Tau RSC products, but it is not known whether it be a mid-market or premium product compared to the existing range.

Durst has been teasing the industry with a product that is ‘Out of the Box’ and now the box has been opened.

Durst Oceania managing director Matt Ashman shared some details about the product to be unveiled in a few days.

“I am extremely excited to see the Durst label business enter its third generation of machinery and for it to debut at Labelexpo in Barcelona,” Ashman said.

“This label printer will continue to follow

Melbourne-based wide-format trade printer Mediapoint has strengthened its production capabilities with the installation of a new Zünd G3 3XL-3200 cutter, adding to its already extensive machinery fleet.

“We’ve focused our investments over the past year on making what we already do even better,” Mediapoint managing director Jamie Xuereb said.

This marks Mediapoint’s second Zünd cutter, reinforcing a 12-year relationship with the Swiss manufacturer. The company’s first Zünd G3 2XL-3200, installed in 2013, significantly boosted productivity with features such as a largeformat table and a tandem vacuum system, which enables continuous cutting by allowing materials to be loaded while the machine is operating.

Recognising the long-term benefits of Zünd’s technology, Mediapoint recently upgraded

released.

“Experience ease of use through intelligent design, where every detail is crafted for

its original machine and invested in a new G3 3XL-3200, taking full advantage of Zünd’s modular system for flexibility.

“We’d been running efficiently with just one – and surprisingly, it was keeping up with our Durst D4,” Xuereb explained.

“But we started seeing an increase in the type of work that demanded faster turnaround from our finishing team. So, we added another Zünd to boost our speed and precision, particularly for larger volume jobs.

“Working directly with the brand is always the best experience. For us, partnering with companies like Zünd and Durst –where you have local support and direct contact with the manufacturer – is a huge

delivering exceptional results at full speed. “RELIABILITY. SIMPLICITY. PERFORMANCE. G3.”

advantage. When we’re investing in equipment, it’s really important to know we can speak directly with the brand.”

Xuereb added that many of Mediapoint’s investments are driven by a philosophy of refining their core offering rather than expanding too broadly.

“Sometimes the risk is going too wide –trying to do too many things and losing focus. In this industry, everyone has their niche. If you stretch too far, there’s a real danger of neglecting what you do best.”

The newly installed cutter has also brought operational improvements,” Xuereb said.

“It’s helped us speed up turnaround and added more flexibility to our board offering.”

Dale Hawkins, managing director of Zünd Australia, said Mediapoint’s longstanding partnership highlights the lasting value of Zünd’s cutting systems, offering exceptional performance and flexibility for future upgrades.

“Working with Jamie and Jason has been a pleasure. Their dedication and professionalism have made them an outstanding partner. We’re excited to support their continued growth,” Hawkins said.

IVE print sales manager Nicole Jandik describes her journey into the print world and how she manages to promote change within the business

It all started with a newspaper advertisement – that’s how IVE print sales manager Nicole Jandik ended up in this industry.

At the tender age of just 19, Jandik applied for a customer service representative role at Lilyfield Printing in Sydney’s west, with no real idea what printing even was.

“I still remember walking down the back stairs at the Regents Park plant for the first time. The smell of ink and chemicals hit me like a wall; and I was in! The hustle of the presses, the energy of the bindery –it was my first introduction to the world of manufacturing and print,” she recounted.

Over the next few years, Jandik transitioned from print production to positions in account management and sales roles.

“I’m forever grateful to the people who took the time to train me. I learnt on the ground, gaining hands-on experience while also studying Print Technology and Administration at TAFE – a course that was phased out only just a few years later,” she said.

Jandik moved from Lilyfield Printing to Concord Printing in Alexandria, NSW, continuing in account management and sales, then transitioned from manufacturing to print brokering with PMA Global. Following that, she joined Labelcraft, which Jandik found to be one of her best jobs.

“In this role, I was selling wine labels, having meetings in cellar doors across regional

More recently, she was a finalist in the Women in Industry Awards and joined the Women in Print (WIP) NSW Committee. She’s also a certified Mental Health First Aider – something she truly values.

As a leader in print and member of the WIP committee, Jandik is promoting change within the industry by leading by example, adding that she believes in “walking the talk” and following through on promises.

“One of the most valuable things we can give back to our industry is our experience – both the highlights and overcoming challenges. Over time, I find even greater purpose in adding value, in whatever way I can,” she added.

NSW, and always heading home with a bottle of something fantastic,” she said.

Eventually, Jandik landed a job at McMillans, back on the manufacturing side. McMillans became Bluestar, which evolved into IVE – where she remains in a sales role today.

“Over the years, my experience in the print industry has grown and evolved alongside the industry itself. I began in commercial sheet-fed printing but as the market shifted with the emergence of digital printing and rapid technological advancement, our skillsets needed to evolve too,” she said.

“Despite these changes, one constant remains – sales is still fundamentally about relationships. People buy from people.

“As IVE diversified, I had the opportunity to broaden my capabilities beyond print. This included areas such as business strategy, team leadership, warehousing, kitting and logistics, technology platforms, creative and content production, wide format, retail, data, and packaging.

“With diversification also came acquisition and business transition – experiences that brought change and a high level of responsibility. From a sales perspective, this evolution has allowed me to present a much stronger and broader value proposition.”

Some of Jandik’s career highlights include being awarded the State Medal for Printing Technology and Administration while studying at Ultimo, and Employee of the Year at Lilyfield.

“For me, it’s about time – time spent with those who are new to the industry and time spent with those who’ve been in it a while and are evolving. I’ve learnt to borrow and adapt great habits and ideas from others and now it’s my turn to do the same.

“We have some incredible women in our industry who are leading the way and there are so many inspiring stories across our industry shared through trade publications, the Women in Print website, and platforms like the Visual Media Association.

“The stories, experiences, and little anecdotes stick with me, and I aim to impart that to the next generation.”

Moving forward, some of Jandik’s aims are to simply be better, improve, and stay relevant –both personally and professionally.

“I’m always looking to educate myself, embrace change, and aim to actively participate in our industry,” she said.

“I genuinely enjoy working with the team, sharing my experiences (hopefully sparing them from learning everything the hard way), and encouraging more strategic thinking. Supporting others to grow and succeed – individually and as a team – gives me a real sense of purpose as a key goal.

“Adding value is extremely important to me. Whether it’s within the workplace or across the wider industry, I’m always seeking ways to contribute meaningfully. Being part of the Women in Print Committee NSW for example, allows me to give back at an industry level, and to be part of something bigger.”

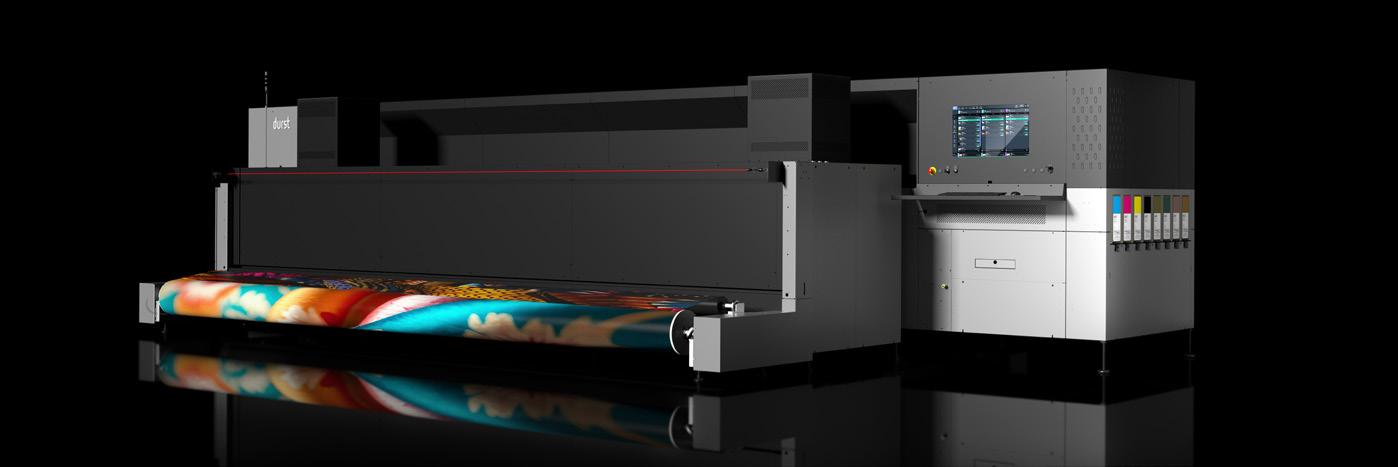

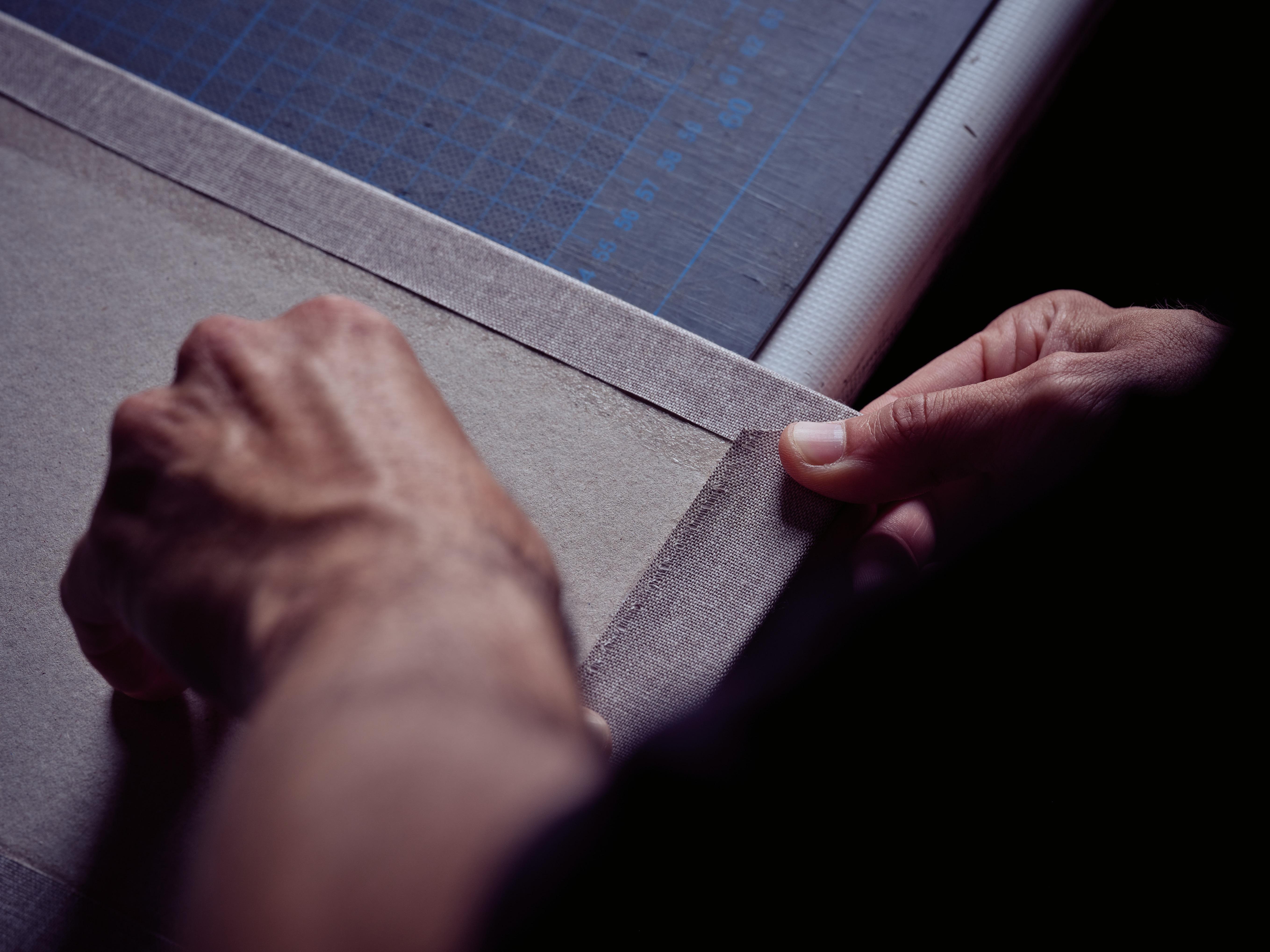

Perth-based Label Image first made its move from flexo to digital with a Durst machine, and has now installed a Durst Tau 340 RSC LED label press

Anew financial year, new premises, and a new Durst Tau 340 RSC LED label printer – it has been a busy few months for familyrun Label Image in Perth.

Today, Label Image is an innovative label printing service company dedicated to providing high quality label printing. Australian owned and founded, the company has a rich history spanning more than 35 years, consistently serving businesses across both local and interstate markets.

The current management, led by Nick and Emma Godwin, arrived in Perth almost 10 years ago looking for a business to acquire within engineering and manufacturing.

“We used to run a small heating maintenance company in the UK and when we moved to Perth, we wanted to purchase an established business,” Label Image co-owner Nick said.

The couple ultimately chose to purchase the then 30-year-old company, Label Image, based in Osborne Park.

“The business was created in 1986, and we bought it from the original owners in 2016, as we felt this was the right move and the ideal industry for us,” Nick said.

Label Image continued to trade at the same location in Guthrie Street, Osborne Park, for almost four decades, until just a few weeks ago.

“We inherited the previous rented premises at Guthrie Street and have recently moved to our new premises at Carbon Court just over a month ago. Both premises are similarly-sized – but the big difference is we now own our new building, and we have a higher ceiling that allows us for more racking and higher capacity for storage, as well as a mezzanine that we added,” Nick said.

“Through the years, our network has grown to provide to all kinds of industries nationwide, giving us extensive experience in providing labels to any industry we encounter.

“Manufacturing on our own premises allows our graphic designers to consult directly with one of our highly skilled print technicians.”

Durst Oceania managing director Matt Ashman said Durst is very excited that Label Image has installed the Tau 340 RSC LED label printer, complete with LED curing and the new Durst HawkAI system delivering outstanding quality at 1200 dpi.

“Durst, as a business, is immensely proud to have Nick and Emma continue being a part of the Durst family. We are pleased to support the family business and have the confidence that the Tau 340 RSC LED will back their growth moving forward

and across multiple vertical markets,” Ashman said.

“Durst Oceania labels and flexible packaging sales manager Graham Blackall has worked hard with Nick and Emma to develop a closer relationship and understand their business needs.

“We look forward to working with Nick and Emma, and the wider Label Image team as they introduce to their customers the tremendous output of this machine utilising the latest innovations unique to Durst.”

When Nick and Emma began working within the then recently acquired Label Image in 2016, the business was unproductive and lacking efficiency, according to the pair.

“When we purchased the business, we had three flexo machines and we soon realised that we needed to invest in a digital label printer,” Nick said.

“It was hard-going for us at the time – there were a lot more people to manage and there was a significant amount of work required to get output from those old flexo machines.

“It was 2019 when we decided to make the investment in digital technology. At the time, we researched several different models in the market, and we decided to go with Durst.”

The first Durst Emma and Nick purchased was a Tau 330 label printer, which Nick said transformed how Label Image operated as a business. At that time, the install was the first of its kind in Australia and the second Tau model in the country.

“Going digital with Durst was definitely the right decision for us,” he said.

“Digital printing not only suits the type of work we do, but it also suits the run lengths for our clients. We work with a lot of small to medium business and they are looking at various run lengths, and this is certainly more suited to digital over flexo.”

Label Image timed the installation of the Durst Tau 330 perfectly in 2019, as this allowed the company to capitalise on the COVID boom in trade for label printers.

“At the time, it was a relatively significant risk for us financially, as it was only a couple of years after we purchased the business; but we were very fortunate to be in the right place at the right time,” Label Image co-owner and client services manager Emma Godwin said.

“COVID saw tremendous growth for our business. We found a lot of companies coming to us, needing work, as they were previously getting their labels overseas and with the lockdowns in place, needed to source their labels locally.

“After installing the Durst Tau 330 in 2019, we were quickly up and running and in a perfect position to win lots of new clients. The good news is, we have been able to retain most of these clients since then.”

As Label Image’s experience with Durst never faltered, Nick and Emma found themselves choosing Durst again when they were presented with an opportunity to elevate their business and purchase a new machine.

The Tau 340 RSC LED is a benchmark in productivity and flexibility with print speeds of 80m/min, a native resolution of 1,200 dpi by 1,200 dpi, and up to eight colour stations. Customers achieve flexolike productivity in a 24/7 environment, where even challenging label designs with small negative text or skin tones are being produced with competitive TCO.

The Tau 340 RSC LED features an LED lamp system with instant on/off functionality, extending the life of the

machine and amping power saving abilities by at least 32 per cent. It also comes with head reliability due to Advanced Autocleaning functionality.

In addition, the Tau RSC UV LED’s ink demonstrates high performance in resistance and durability. It is available in standard colour configuration of CMYK, orange, violet, and green, with an optional white, extending the colour gamut up to 95 per cent pantone coverage.

This also enables low ink consumption, high opaque white, and a broader application diversity – including a wider latitude in post finishing as it can work with laminates and overcoats.

“With the purchase of the new premises, we decided to upgrade from the Tau 330 to a new Tau 340 RSC LED label printer,” Emma said.

“The reason we upgraded from the Tau 330 to the Tau 340 RSC LED is, we needed more speed as the old machine was restricted to 40 linear metres a minute. The new machine features a different print configuration and, as a result, delivers 80 linear metres a minute.

“This helps with our larger run lengths for our major clients. It also allows us to print on CMYK + white which is also a huge advantage. While we feel as though we can cover most colours with CMYK, we are increasingly receiving silver ink jobs –so we need to put the white down for that.

“The graphical user interface of the new Durst Tau 340 RSC LED machine is also very easy to use and operator friendly. As a result, we are expecting to have every staff member trained on the machine –even our daughter Eliza, who is in Year 11 at school, has been able to operate the machine and print jobs. It is also very easy to maintain the machine as well.”

Automation is also a key functionality of the Tau 340 RSC LED as it comes with Durst Label Software tools that help users organise their production workflow to be more efficient and cost effective. This includes Lift ERP, Smart Shop, Smart Editor, Workflow, Analytics, and HawkAI.

Durst Oceania labels and flexible packaging sales manager Graham Blackall said, “Unique to Durst, HawkAI focuses on three primary themes: more applications, more automation, and less waste. It uses camera vision systems and artificial intelligence to automate print quality, significantly reducing waste and improving print quality.

“HawkAI goes one large step further than similar inspection systems available on the market. It corrects print mistakes, such as missing nozzles, inline and in real-time, without any setup needed or operator intervention.

“Additionally, it aims to significantly reduce setup time and waste, enhancing efficiency and an even more competitive total cost of ownership for the Tau RSC platform printers.

“The Tau 340 RSC LED also comes with analytics, that allow remote servicing as if the engineer was on site – an important feature for a business like Label Image due to remoteness of Perth from the Eastern Seaboard.”

The Tau 340 RSC LED installation

To maintain work across its broad client base, Label Image ran both the Tau 340 RSC LED and Tau 330 across both premises for a short period to limit the amount of down time.

“Before we traded-in the Tau 330, we kept it running while we were installing the Tau 340 RSC LED. As a result, we only had half a day of down time while we were waiting

on our semi rotary finishing equipment to come across from the other premises,” Nick said.

“Overall, the installation of the new machine was very smooth, and Durst Oceania was very helpful with trading in our previous machine. During installation, the remote support we received from Durst Oceania was excellent and any issues were resolved very quickly.

“Graham and the team at Durst have been great to work with. Since Graham has come on board, we have received excellent customer service, and he has been on point with everything and helped us through the entire process.

“He is very knowledgeable about digital label printing and the Durst machines. He has always been very responsive, and the entire changeover has gone a lot better than we actually expected.”

Like a lot of label converters, Label Image has a very broad customer base, with its spectrum spanning from the home entrepreneur to global recognisable brands.

“We do a bit of work across a lot of different industries – fresh produce and primary producers through to chemical companies, mining companies, and corporates,” Emma said.

“One of the beautiful things is, we get to meet a lot of different types of people – from grow your own farmers or beekeepers that make their own honey, right through to much larger companies.

“Some of our clients travel up to four hours to work on their labels with us, and we like our customers to know that our doors are open and that we are happy to sit down with them to go over their designs and provide assistance.

“Depending on the time of year, we may have a fresh produce client in the winter and a pool chemical company in the summer, and because we have such a broad client base –if one business segment is not doing as well, we have found another industry will be busy –which helps us to have a steady flow of work.

“A majority of our business revolves around Perth and WA, but we also do work interstate and do trade work for other printers.

“Year-on-year we have grown the amount of work that we are producing through the business, and this has allowed us to purchase the new building and the new Durst machine.

“I don’t believe our business would be in this position if we were still relying on those flexo machines. We have noticed that the resolution of the new machine is better as well, and we hope that producing better quality labels for our clients can help us win new business.”

The Label Image business currently employs nine staff members including co-owners Nick and Emma, as well as seven additional workers – with Nick and Emma’s daughter Eliza being the 10th employee in the company.

Eliza is still in Year 11 at school, but in her available time works as a production assistant and customer service manager – handling quotes and invoicing as well as operating the new Durst 340 RSC LED label printer.

“I really enjoy the creative and textural aspects involved with printing labels as well as handing over the finished product to happy customers,” Eliza said.

Eliza is also a qualified lifeguard and junior AFL player and aspires to work in the family business after she leaves school and obtains business qualifications at university.

Discover G3, our latest innovation, at Labelexpo Europe 2025. Experience ease of use through intelligent design, where every detail is crafted for operator comfort, intuitive handling, and effortless maintenance. Embrace automation for seamless production, with integrated systems working in harmony to deliver real-time correction, consistent performance, and minimal operator involvement. Achieve highest performance and outstanding quality through innovative technology and precision engineering, delivering exceptional results at full speed. RELIABILITY. SIMPLICITY. PERFORMANCE. G3.

Visit us at Labelexpo Europe 2025 Barcelona, 16 –19 September Hall 3, Booth E79

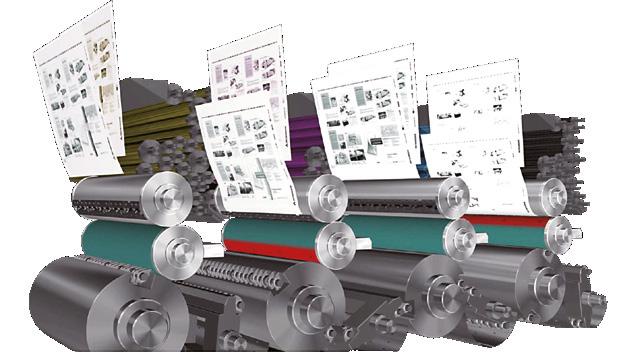

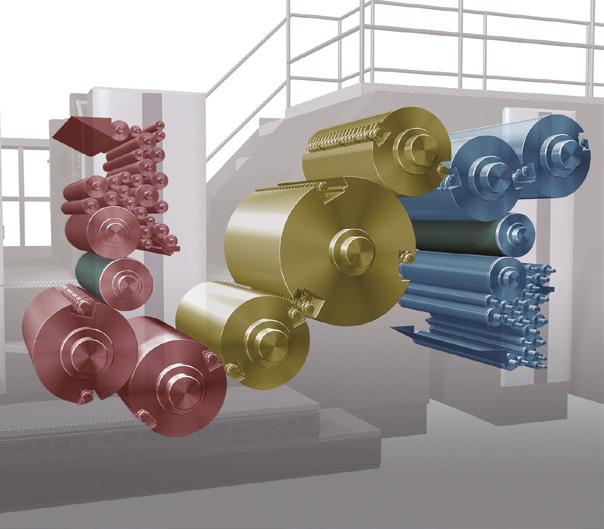

Leading manufacturers will put their equipment and technology on display, and discuss the latest trends at one of the printing industry’s largest tradeshows in the US

Printing United 2025 will soon be upon us with four days of dynamic and comprehensive printing innovations. Taking place in Orlando, Florida from 22-25 October, the event promises more than a million square feet of equipment, solutions, and the latest trends.

Communities within the industry, including commercial and publishing, wide format, apparel decoration, industrial print, and labels and packaging will be represented on the show floor through dynamic exhibits, educational sessions, and live demonstrations.

Here’s what some leading exhibitors will be showcasing:

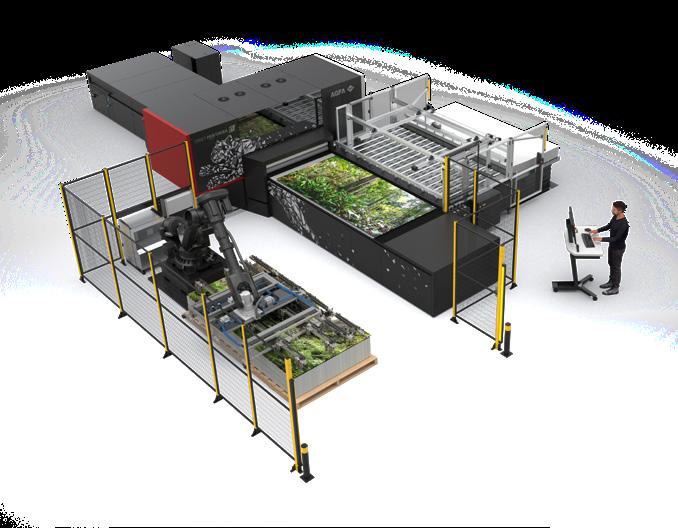

Automation, speed, and versatility will take centre stage with Agfa at Printing United 2025, where the inkjet printing company is set to make a powerful impression with a line-up of high-performance printers it introduced earlier this year.

Under the banner ‘Powerful by Nature’, Agfa will demonstrate how its latest

innovations combine productivity, versatility, and smart automation to empower print service providers.

The Onset Panthera FB3216, a true flatbed powerhouse equipped with an autoloader that maximises throughput while maintaining precision and energy efficiency. Built for speed and reliability, it is ideal for high-volume POS, retail graphics, and packaging applications.

The Jeti Tauro H3300 XUHS will showcase its fierce speed and automation, featuring the Flex RTR system for seamless roll-to-

roll printing and the MAX Bot stacker for advanced media handling. As the boldest member of the Tauro family, it is designed for 24/7 hybrid productivity.

Completing the line-up, the Anapurna Ciervo H2500 brings agility and versatility in a compact format. This model will appear in a limited-edition wrap by street artist DZIA, marking 20 years of Anapurna innovation.

All printers on the booth will be powered by Asanti v7, and visitors can join dedicated demos to explore the software’s workflow, automation, and sustainability features in action.

Smartech Business Systems is the distributor for Agfa in the A/NZ region.

Canon will showcase its Colorado M5W, a fully modular UVgel roll-to-roll printer for large-format graphics, and its Arizona 2380 GTF, part of Canon’s Arizona 2300 FLXflow range.

With print speeds of up to 159m²/h, the Colorado M5W, part of the Colorado

M-series, is a 1.6m printer that offers productivity at exceptional quality and a spectacular application range.

Now including hassle-free white, this machine is also designed for the lowest total cost of ownership: with low ink and energy use, and low media waste. Additionally, it can be easily upgradable to scale with a business. The machine can be configured as M3, M3W, M5, or M5W – with W indicating white option.

As for the Arizona 2300 FLXflow range, it is ideal for mid-to-high volume operations, offering a patented, uniquely intelligent way to not only ‘Hold and Float’ media, but also perform an Instant Switch between the two modes.

Whether it’s for retail graphics, interior décor, packaging, or an industrial market segment, the Arizona 2300 series of flatbed printers with Arizona FLXflow technology can easily handle an extensive array of media – from rigid and heavy to delicate or flexible, enabling versatile, accurate and highly productive multiboard and double-sided printing.

Additional quality modes and improved workflow integration, combined with other technologies such as UV-LED curing and

DigiTech will feature its TruFire LT3/X2 and TruFire LT3/X3 flatbed printers with conveyors and cutters.

The TruFire LT3/X2 is ideal for large capacity jobs. The auto unloader operator can change sheets of media in under 10 seconds. This printer is designed for those large print shops that need real output capable of running all day at more than 60 sheets per hour printed and cut (including unloading and reloading time).

The machine also uses advanced UV technology to deliver bold, vibrant prints that are built to last. With instant UV curing, colours stay bright and resistant to scratches, fading, and harsh weather.

As for the TruFire LT3/X3, it builds on the impressive features of its predecessor, the TruFire LT3/X2, with more added capabilities. It was launched in 2024 with three rows of printheads and a speed increase of up to 150 boards per hour printed and cut. Like the LT3/X2, it is ideal for large capacity jobs.

It is also a true flatbed and is available in various configurations to suit any size print shop. Plus, it uses high-speed Kyocera

engineering in mind, this machine is an industrial printing workhorse.

Wayne McIntyre from Celmac, DigiTech’s local distributor, said the machine is a precision printing system that is “redefining digital printing”.

“The DigiTech TruFire LT3/X3 has three rows of print heads, is 30 per cent faster, and the quality on it is extraordinary. This machine is all about productivity and it is what DigiTech specialises in,” McIntyre said.

Durst North America looks forward to bringing the latest innovations and pioneering technologies to the 2025 Printing United Expo.

For the first time in North America, the P5 500 TEX iSUB superwide dye sublimation printer will be shown proudly in the Durst booth. Alongside it, the P5 X true flatbed and roll-to-roll printer, will be making its Printing United Expo debut.

Rounding out the wide format lineup is the tried-and-true Durst P5 530 HS D4, showcasing the strength and evolution of the P5 platform. Durst will also bring a Tau 340 RSC E label printer, demonstrating the strength of the Durst portfolio.

Durst will also be presenting its new Open Software Initiative for the first time at Printing United 2025. The Open Software Initiative is a neutral, modular platform for software solutions designed to go beyond Durst systems.

Under the slogan ‘One Software Ecosystem. Any Brand. Any Printer.’, this modular, cloud-enabled software platform can be flexibly used and integrated by print service providers, integrators, resellers, and OEMs, giving them access to powerful and flexible modules built on proven Durst software technologies.

It also allows seamless integration of third-party solutions regardless of printer type or manufacturer. These modules are bundled under the umbrella of Smart Factory.

The platform focuses on interoperability, open APIs, and integration readiness – clearly separated from Durst’s existing proprietary solutions for Durst hardware customers.

“Our vision is to create an open, futureproof software ecosystem for the entire printing industry – developed by us, but available to everyone,” Durst CEO and co-owner Christoph Gamper said.

“This sets new standards for productivity, automation, and vendor independence.”

Durst Oceania managing director Matt Ashman said the Open Software Initiative, which Durst Oceania is a partner of, “enables Durst’s incredible software legs to grow”.

“Making it available to a wider network means more businesses will be able to benefit from the high advantages the solutions can offer,” Ashman said.

“With the Open Software Initiative and the Smart Factory portfolio, we’re not just offering products – we’re creating an open framework that allows partners to contribute their own solutions, services, or integrations,” Durst software and solutions business unit director Michael Deflorian said.

“We are proud to have callas software as a strong OEM partner, and through them, we can now offer complete PDF workflow solutions – not just core technologies – to our OEM network. This is a true blueprint of how we envision future OEM partnerships within the Open Software Initiative.”

Durst will be on Booth #3156 focusing on proprietary software Durst Workflow and Durst Analytics for full integration with Durst printing systems and on Booth #2266 presenting its Open Software Initiative.

Fujifilm will be showcasing three Revoria presses and wide format inkjet equipment at Printing United 2025. The complete suite of Fujifilm products on display will include:

• The Revoria Press PC1120: A highperformance 6-colour print machine that maximises print engine productivity by printing 120 pages per minute, high-output resolution at 2,400 dpi by 2,400 dpi, supports a broad range of stocks, and comes with various feeding and finishing options to streamline workflow from print to post-press.

• The Revoria Press EC2100S: A new mid-range production press that is equipped with a specialty CMYK+ toner station in addition to the fourcolour toners, enabling five-colour printing in one pass. It prints at a high speed of 100 pages per minute and is primarily utilised for an extensive

range of commercial printing and quick printing.

• The Revoria Press SC285S: Also a newly launched mid-range production press, the machine also enables five-colour printing in one pass thanks to a specialty toner station in addition to the four-colour toners. It is capable of printing speeds of 85 pages per minute and is utilised for quick printing and in-house printing.

• The Acuity Ultra R2: Announced in mid-2021, the award-winning Acuity Ultra R2 is available in 5m or 3.2m versions. Targeted for superwide printing, the machine is a modular system that can be upgraded to add light colours, white, or high-speed modes, depending on the requirements of the print business.

• The Acuity Prime: A true flatbed with a unique, exceptional design and high value, the Acuity Prime offers high quality printing on a range of rigid and flexible media, supported by its five dedicated vacuum zones and jettable primer.

• The Acuity Triton: Powered by AQUAFUZE ink technology, this machine is a new roll-fed printer platform. It meets a multitude of market requirements by combining the benefits of LED UV and water-based inkjet technologies.

Heidelberg

Heidelberg will present a dynamic digital showcase to Printing United this year, highlighting its full Prinect Suite workflow – including Prinect Touch Free, Jetfire 50, Versafire LP, Stahfolder TH 66 Fireline, and Heidelberg Customer Portal.

Within Heidelberg’s Prinect Workflow Solutions, Prinect Production Manager

digitises a print shop and automates production, colour, and quality management, as well as provides important data for analysis and reporting.

Prinect Business Manager integrates into a business’ process, production, analyses, and customers into the smart print shop workflow.

Prinect Touch Free is an AI-driven central control system that enables PSPs to harmonise digital and offset print jobs into one workflow. It automatically optimises production processes, adapting to changes in real-time across three stages to ensure the most efficient method form PDF to finished product.

The Jetfire 50 is a future-proof production machine for commercial printing. Boasting high productivity with a print speed of up to 4,560 SRA3 sheets per hour duplex and an enormous application media flexibility and reliability, this machine enables fast, profitable production.

As for the Versafire LP, it is a high-performance four-colour digital printing system tailored for the commercial sector. With a productivity of up to 2.6 million A4 pages per month, it excels in handling high volumes.

The recently launched Stahfolder TH 66 Fireline is tailored to the needs of digital finishing by directly going from the digitally printed sheet to the finished cut and/or folded product in a single operation. This solution enables the automated production of short and very short runs with variable cut and folded products.

Finally, the Heidelberg Customer Portal is an all-in-one digital portal that provides easy access to production and workflow apps, analytics, service and maintenance, shopping, and administration tools. It simplifies operations with a single interface to streamline print shop responsibilities.

“At Printing United 2025, Heidelberg will be showcasing our cutting-edge equipment as well as streamlined workflows and digital finishing, all designed to drive performance and unlock new opportunities,” the company said.

HP

HP’s large format division will spotlight its newest print innovations at Printing United

on Booth #4249, including the new HP Latex 730 and 830 Printer Series along with its compact all-in-one rigid and flexible printer – the HP Latex R530 Printer.

This latest portfolio aims to helps users tap into new markets and expand to highvalue print applications while optimising operational costs. Attendees can also expect some major announcements from the HP Large Format team during the event.

Located on Booth #2200 at this year’s Printing United Expo, Kongsberg Precision Cutting Systems (PCS) will present three of its advanced cutting solutions for the print and signage industry, including:

• The new Entro 24 cutting and milling solution which will be making its global exhibition debut, live producing signage, graphics and packaging applications on foam and dibond

• The award-winning Ultimate 64 digital cutting table, showcasing how it achieves continuous high volume multi-batch production on materials including vinyl and oppboga

• MultiCam’s Apex3R Evo CNC router, which delivers advanced routing capabilities across an array of materials, including acrylic, PVC and aluminium.

Visitors can also discover the C24 table, paired with Digitech’s X3 Printer with IMC Stacker on the Digitech Booth (#3016).

The solutions are underpinned by the company’s ‘Shaping Your Future Together’ campaign and will demonstrate through real-life application examples how its industry-leading products, customer support and materials expertise combine to empower businesses to push creative boundaries while improving overall efficiency and productivity.

Konica Minolta

Konica Minolta will be exhibiting at Printing United (Booth #5200), where it will showcase a range of its advanced presses including the AccurioWide 250,

AccurioPress C14010S, AccurioLabel 400, AccurioShine 3600 with iFoil One option, and AccurioJet 30000.

The AccurioWide 250 is a versatile UV LED printer with superior image quality and high productivity for both outdoor and indoor job applications. The four-colour plus white ink configuration creates opportunities to print on transparent material for backlit applications or printing white as a spot colour. The six-colour ink configuration offers a larger colour gamut, enabling the capability to print hard-to-hit colours.

The recently enhanced AccurioPress C14010S is a high-volume, toner-based production press. The updated press features a fifth station for white toner. Other upgrades include new hardware, firmware and accessories, including the new IQ-601 for the latest in one-touch color management.

The AccurioLabel 400 is the company’s latest label press, offering CMYK and a new fifth station white dry-toner for true white applications that expands creative label design, production speeds of up to 40m/min, and resolution equivalent to 3600 dpi by 2400 dpi.

As for the AccurioShine 3600 with iFoil One option, it is the company’s newest inkjet spot UV printer that enables in-house spot UV varnishing without the need for screens, plates, or dies, and utilises innovative technology for adding 2D and 3D multiple coating and dimensional texture effects in a single pass.

Konica Minolta’s AccurioJet 30000 is a 29.5-inch sheet-fed LED UV inkjet press offering faster throughput, reduced waste and higher margins. It delivers crisp, consistent colour with instant UV curing. No make-ready or drying time is needed,

making it a high-performance solution that outpaces offset and aqueous inkjet technologies. The AccurioJet 30000 machine will not be at the booth, but Konica Minolta will be showcasing output via video.

Every Konica Minolta device comes with the White Glove Service program, offering worry-free implementation and service to process optimisation. Information will also be available on Konica Minolta’s workflow solutions ecosystem – a comprehensive suite of tools including AccurioPro Color Manager, AccurioPro Dashboard, AccurioPro Flux, and Asanti streamline colour management – which automates print production, optimises shop floor operations, and enhances collaboration.

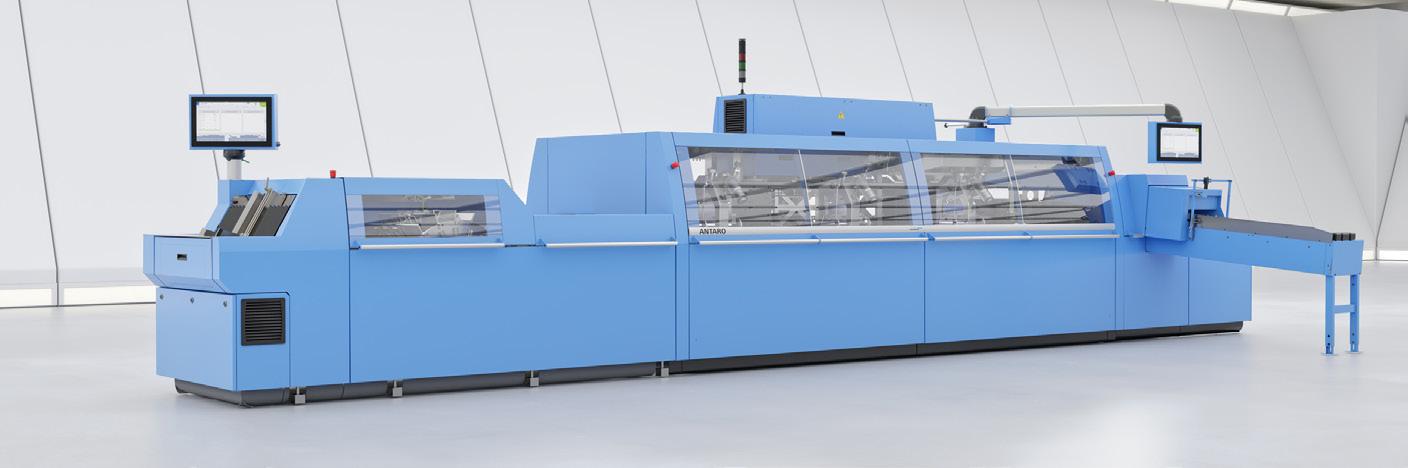

Müller Martini will present the North American debut of its Antaro Digital perfect binder and the Hunkeler GEN8 EVO roll-to-stack solution at Printing United. The cutting edge solutions will serve as the centrepiece technologies of the company’s booth.

As part of Müller Martini’s commitment to innovation, these technologies highlight its focus on delivering advanced, future-ready solutions tailored to evolving market needs.

The Antaro Digital exemplifies state-ofthe-art automation, offering seamless production workflows and precision for today’s modern print businesses. Its newly integrated endsheet tipper provides for both softcover and hardcover book production capabilities within the same machine.

Coupled with the InfiniTrim ‘Robotic’ three knife trimming system and the Solema Mini-Sol stacker with Omega693 cobot palletiser, this solution suits short-run digital

book manufacturing with minimal labour and zero make-ready capabilities.

Meanwhile, the Hunkeler GEN8 EVO roll-to-stack solution aims to set a new benchmark in production efficiency. Its robust design, increased speeds, and reduced waste deliver high-quality output while minimising operating costs.

Its intuitive operation and future-proof platform ensure adaptability for evolving customer needs, solidifying its role in print finishing.

“We can’t wait to meet you and help you unlock new possibilities for your business,” Müller Martini said.

printIQ

printIQ recently announced the launch of V49, a software update that introduces powerful new capabilities designed to transform print business operations through enhanced inventory management, streamlined product cataloguing, and advanced mass distribution functionality. The company will be focusing on this launch at Printing United.

The release’s standout feature is the highly anticipated Inventory Planning Board, addressing one of the most requested features from printIQ’s global client base.

This centralised dashboard provides unprecedented visibility into purchasing requirements across all upcoming orders, enabling smart consolidation of multiple jobs using identical materials and supplierspecific filtering for efficient purchase order management.

V49 also introduces significant enhancements to the Product Catalogue Board, creating a central hub for managing Store Items, Product Range Items, Single Product Creation Items, and Kits.

This customer-facing interface allows direct ordering whilst serving as a complete repository for viewing and reordering available items – particularly valuable for label printers managing extensive SKU ranges.

Building on V48.2 foundations, the Mass Shipping capabilities now handle jobs requiring deliveries to hundreds of addresses through CSV integration for distribution list uploads. Users can filter and manage deliveries in batches.

Additional improvements include inventory status intelligence providing real-time visibility into stock levels and purchase requirements, plus enhanced Outsource Purchase Orders supporting split deliveries to multiple customer addresses with integrated supplier portal management.

International

Rollem International will host live demonstrations at Printing United, featuring the award-winning Insignia Series die cutters.

The Insignia7H die cutter features a 30-inch capacity which is ideal for B2 cutsheet presses. Visitors will view automated carton production while witnessing speed, ease of operation, and die changeovers.

This is a great opportunity for PSPs to see first-hand this production geared system while learning about its many functions. Watch as the IS7H turns press sheets into high value finished products, all in one step, with just one operator.

Functions include die-cutting, creasing, perforating, and kiss-cutting with automatic matrix removal – all in one process.

Attendees will learn how the Insignia7H easily generates profits in folded cartons, packaging, photo products, retail tags, decals, shaped postcards and more.

Rollem will also feature live demos on the Insignia6 PLUS die cutter showcasing its versatility with a pressure sensitive decal kiss-cutting demonstration. This model offers a touch-screen controller for ease of operation. It’s ideal for digital users who change jobs frequently.

“Adoption of our Insignia line has been extremely successful. Our new customers are growing their market share with packaging, in-store retail items, commercial photo products and more,” Rollem International sales manager Doug Sherwood said.

The Printing United booth will also feature Rollem’s line of Card Converting Slitters with options for all types of print shops, including the Jetstream XY Slit, Score & Perf system.

Vanguard Digital Printing Systems, a Durst Group company, will be showcasing its award-winning solutions at this year’s Printing United Expo.

Leading the lineup will be the Vanguard Radnor hybrid printer, making its Printing United Expo debut, and will be showing off its unmatched speed and quality.

Also on display will be the VK3220T-HS ultra-productive flatbed printer with a new, automated offloading option, showcasing its productivity and versatility.

Rounding out the exhibit, Vanguard will be debuting the next evolution of a trusted Vanguard solution, which is a testament to Vanguard’s commitment to offering the best equipment available to all print service providers.

Stop by the Vanguard Digital booth #3162 to experience the company’s innovation and see how productivity can be redefined.

Canon Production Printing and Grafico showcase how speed, creativity, and customisation, with the Colorado, bring ideas to life on The Block

Canon Production Printing, in partnership with renowned design and printing company, and longtime collaborator of The Block , Grafico, has played a key role in one of the most creatively ambitious episodes of this season – the DIY Wallpaper Challenge.

Filmed at the scenic town of Daylesford, Victoria, the episode showcased the contestants’ artistic flair while also marking the debut of the Canon Colorado M-series on Channel 9‘s hit Australian renovation TV show.

The episode demonstrated what’s possible when creativity meets innovation. More than just a printer, the Canon Colorado M-series is a tool for transformation – empowering designers and print professionals to deliver bold, personalised outcomes at speed.

A challenge unlike any other

The concept for the DIY Wallpaper Challenge was simple but ambitious – five teams, five houses, one day.

Each pair of contestants worked with an artist to create a unique painted design. The design was then captured digitally using Canon photography equipment and transformed onsite into bespoke wallpaper using the Canon Colorado M-Series.

Behind the scenes, success depended on close collaboration between Canon’s experts, Grafico’s design and production teams, and The Block contestants. From concept to install, five custom wallpapers were created, printed, and applied — all in one fast-paced filming day.

“To see the journey from a physical artwork to a digitally printed wallpaper within hours was absolutely amazing,” Canon Production Printing head of sales and professional services Steven Badger said.

“This kind of turnaround is only possible with technology like the Colorado.”

From high-speed production to impeccable colour fidelity, the Canon Colorado delivered exactly what the challenge demanded – custom wallpaper prints produced accurately and quickly under time pressure.

Grafico founder Damian Corney said, “The Block is all about speed and we need equipment that delivers under pressure. The Canon Colorado has been a fantastic asset for us”.

Now in its 11th year working on The Block , Grafico knows what it takes to impress

on national television and push creative boundaries. The company has witnessed firsthand how wallpaper has surged in popularity and complexity in recent years, with clients increasingly seeking custom designs, unique finishes, and lightning-fast turnaround times.

According to Corney, wallpaper isn’t what it used to be. The team at Grafico sees strong trends emerging for 2025 such as hand-drawn Australiana motifs, textured linens, timeless stripes and ginghams – all with a twist. But most importantly, customers are now demanding personalisation.

“None of our clients want to just pick something from a catalogue anymore. They want something unique, tailored to their room – whether it’s colour, scale, or complete custom artwork. That’s exactly what the Canon technology allows us to deliver in-house and with total confidence,” Corney said.

When the episode (Episode 23) aired on 2 September, Canon Production Printing and Grafico were ready for the spotlight, showing how powerful technology can bring creative ideas to life – beautifully and efficiently.

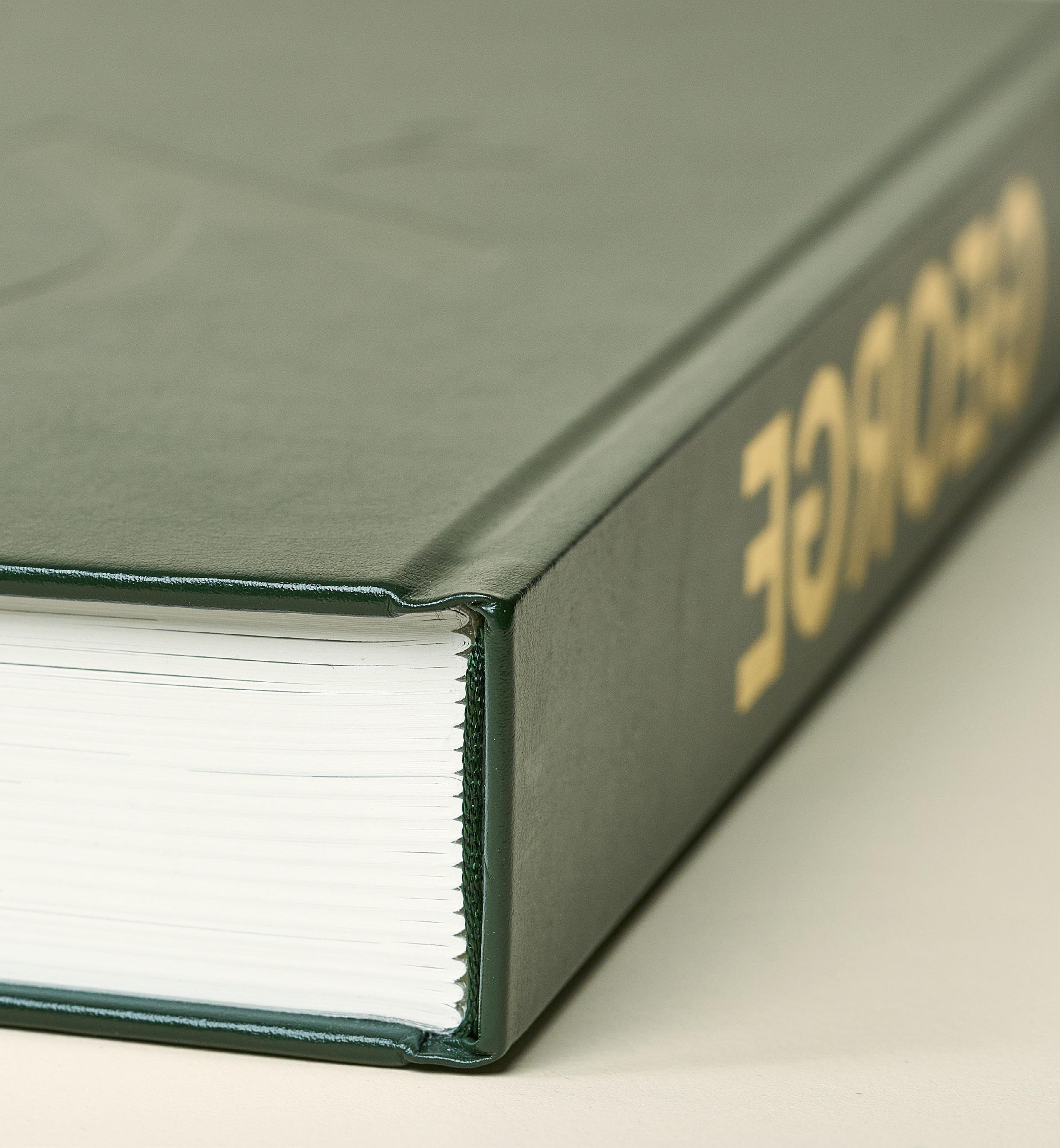

The installation of a Ricoh Pro C7500 digital colour press with 5th colour option has provided Kwik Kopy Moonee Ponds with enhanced output opportunities, in addition to improved productivity and reduced downtime

Established in 1991, Kwik Kopy Moonee Ponds in Melbourne is a trusted local expert in printing, signage, and design solutions. Owned by Vivek Patel and Ripal Patel, the centre has more than 32 years of industry experience, helping businesses create high-quality branding and marketing materials.

The centre proudly serves businesses in Ascot Vale, Highpoint City, Maribyrnong, Essendon, Strathmore, Brunswick West, and surrounding areas.

It provides a diverse range of printing services for customers across Melbourne’s northern suburbs. The firm’s in-house design team creates tailored printing and design solutions – everything from signs, business cards, brochures, and large-scale signage and banners, to flyers, media walls, window decals, and other promotional materials.

With a strong commitment to precision, speed, and creativity, Kwik Kopy Moonee Ponds aims to deliver exceptional results under tight deadlines.

In early 2024, to support business growth, a decision was made to boost production

capacity and extend output offerings to include five colour printing.

Kwik Kopy Moonee Ponds needed a way to reduce production times and differentiate itself in the market.

As the business expanded, the team found it challenging to meet the tight turnaround times required by customers. In addition, there was a growing desire to find a new point of differentiation in the market.

“Many of our customers need their print jobs completed very quickly,” owner Vivek Patel said.

“We needed to find a way to complete runs faster but also wanted to offer an additional level of service. It reached the stage where we were having to outsource some jobs because we simply didn’t have the production capacity in-house.”

After carefully examining a range of options, a decision was taken in mid-2024 to deploy a Ricoh Pro C7500 digital colour

press with 5th colour option. Once it was in place, staff received a day of on-site professional training conducted by Ricoh.

With the machine installed, Kwik Kopy Moonee Ponds can now deliver print jobs that make use of clear, silver, and gold toners and complete larger print jobs up to 20 per cent faster than was previously possible.

“We could tell immediately that we had made the right decision,” Patel said.

“Ricoh also installed a smaller IM C4500 multi-function printer to help us with smaller print jobs and our internal administration functions such as invoicing.”

machine

The Ricoh Pro C7500 digital colour press with 5th colour option delivers true production-level performance.

Powerfully robust and creatively engineered, the Ricoh Pro C7500 with 5th colour option enables enhanced performance, upgraded media handling, and built-in automation –for users to take on more work and meet the growing desire for creative communication that engages audiences and drives actions.

It prints at speeds of up to 95 pages per minute, with a maximum paper capacity of 16,200 sheets. It supports media from 40gsm to 470gsm, prints at 2400 dpi by 4800 dpi resolution, takes on oversized options up to 49.6-inches long, and includes professional inline finishing.

An intuitive 21-inch Smart Operation Panel provides a wider field of vision and the ability to remotely monitor the system from a smartphone or tablet. Specialty toners can be swapped in under 15 minutes, minimising downtime.

Built-in automation, such as colour calibration, front-to-back registration and auto duplexing up to 13-inches by 38-inches keeps work flowing smoothly for operators of all skill levels.

As for its 5th colour toners, it includes gold, silver, neon pink, neon yellow, clear, white, and invisible red, enabling users to achieve vivid colours comparable to offset, from brighter oranges to deeper purples and luscious greens.

Applications can be elevated with premium gold and silver, while neon pink or neon yellow can be used for high-impact messaging.

The machine opens the door to a new set of customers with invisible red for affordable security on certificates and tickets. Apply white as a base layer to deliver incredible graphics on coloured and transparent media. Clear can also be added to photos and logos for a slick look and to explore unique patterns for luxury effects.

With the new Ricoh Pro C7500 digital colour press and 5th colour option operational, Kwik Kopy Moonee Ponds was quickly experiencing some significant benefits including faster production runs and more diversified print outputs.

Print jobs that used to take around eight hours now only take about six and a half hours, reducing the previous turnaround time by 20 per cent.

Patel said the machine’s ability to print using five colours meant the firm could now offer a diverse range of new outputs. This was achieved by printing with clear, gold, and silver toners and using a much wider range of substrates, between 40gsm and 470gsm.

“Our new Ricoh printer is really exceeding our expectations. It is reliable, delivers rapid output, and allows us to meet the requirements of our customers for top quality, fast-turnaround print jobs,” Patel said.

Patel stated that while there are no immediate plans to increase the firm’s

print capacity, he would certainly consider Ricoh when the time comes.

“Our new Ricoh printer is easily coping with an output of between 70,000 and 90,000 pages per month,” he said.

“I’m confident it can deliver even more than that and so it is likely to meet our requirement for growth for quite some time.”

• Established: 1991

• Headquarters: Melbourne

• Employee size: 4 staff

• Website: kwikkopy.com.au/ location/vic/moonee-ponds

From its print workshop in Melbourne’s northern suburbs, Kwik Kopy Moonee Ponds caters to the printing needs of both individual and business clients. The team can utilise existing designs and materials or develop everything from logos to page layouts from scratch.

Key highlights after the install of the Ricoh Pro C7500 digital colour press with 5th colour option include:

• Enhanced output opportunities: The Ricoh Pro C7500 digital colour press with 5th colour option can deliver outputs on a wider variety of substrates

• Improved productivity: Print jobs that previously took eight hours to complete can now be finished in around 6.5 hours

• Reduced downtime: Maintenance tasks, that traditionally would have required a technician, can now be completed in-house, saving time and resources.

Bailey Print Group is a success story of family, resilience, and vision

Australian Printer isn’t the only one celebrating a monumental milestone this year; It has been 40 years since Brisbane-based Bailey Print Group first made its foray into the Australian print and visual communications space.

Bailey Print Group is not just a business. It’s a success story of family, resilience, and vision. The award-winning, secondgeneration company, proudly based in Brisbane, has transformed over the years to now offer an extensive range of signage and vehicle wraps, all crafted in its stateof-the-art facility in Salisbury.

A finalist in 2020 in the Brisbane Lord Mayor’s Business Awards for Outstanding Small Business and being a multiple ProPrint Award Printer 50 winner are just some of the company’s accolades.

Backed by four decades of industry expertise, the company’s skilled team delivers end-to-end solutions in design, manufacturing, printing, and installation, consistently achieving high-quality results on time and on budget. With a strong commitment to sustainability, Bailey Print Group leverages advanced print

technologies to provide solutions that marry exceptional craftsmanship with environmental responsibility.

Bailey Print Group director Samantha Bailey-Jensen, who has been with the company for 26 years, co-manages the business with her brother Peter Bailey, who joined the business right after school and has been at the helm for more than 30 years.

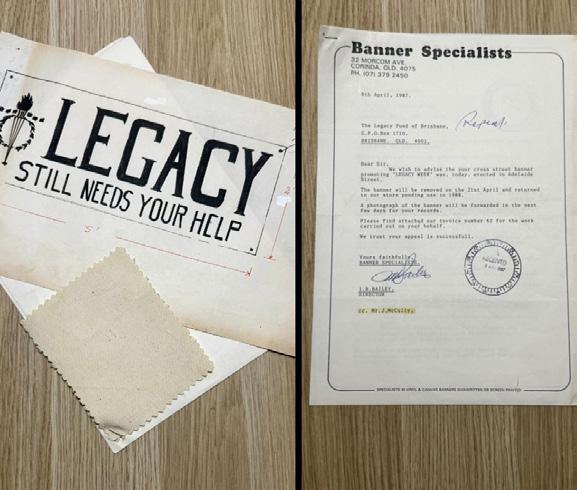

Bailey Print Group was started by their parents in 1985 as Banner Specialists –operating from the dining table of their family home.

“My father Ron had worked for many years in the outdoor advertising industry – in billboards production and printing –and decided it was time to step out on his own in 1985. He took a punt and started doing cross street banners for the Brisbane City Council, which my mother Halina used to sew under our house,” BaileyJensen said.

“That same sewing machine that we used when the business was started is still in use today. In the early days, all we had was that sewing machine and two sign writers who did everything by hand.

“Banners that now take us one or two hours to print used to take a week for someone to hand sign write – painting the canvas background first, waiting for that to dry, then using an overhead transparency to trace the lettering out before painting it on.

“It was the same with artwork. We used stencil lettering, colouring pencils, or felt pen to mock it up then drove it to the client.

“If any changes were needed, we would drive back, photocopy the artwork, cutout the stencil, recolour it, before driving it back again.

“Thankfully things improved with the fax machine, but for Peter and me, this was our holiday job. We grew up living and breathing this business and it certainly became part of our DNA early on in our lives.”

As business grew, the company progressed from the Bailey dining table to the space underneath their Queenslander house. In the early ‘90s, the business started laying foundations for its future – undertaking a major renovation of a disused printery in South Brisbane, purchasing its first digital printer, and hiring its first production team.

Another big move happened in the 2000s – this time to East Brisbane, when the company also rebranded and shifted away from solvent printing, and they have never looked back since.

2001 also marked the year the company produced one of its biggest projects –for the Goodwill Games in Brisbane.

“These games were one of the standout highlights in our journey. We secured the contract to deliver all city dressing and precinct banners, along with venue activation signage,” Bailey-Jensen said.

“As part of this project, we also manufactured and installed a landmark banner on the southern face of Brisbane’s iconic Story Bridge.

“This milestone not only showcased our large-scale production capabilities but also elevated our profile as a trusted supplier for major event signage.”

In 2014, founders Ron and Halina Bailey retired, marking the start of a new era. That was when Samantha Bailey-Jensen returned to the business as co-director alongside her brother Peter, after more than a decade building her career in advertising overseas. At the same time, Banner Specialists rebranded as Bailey Print Group to better represent its diverse and expanding capabilities.

“I never set out to join the family business when I graduated from University. When Ron first offered me a role, I initially refused, but he convinced me to give it a go as he wanted the Bailey legacy to continue. What kept me here was the strong foundation built on customer service and quality. Those old-school values remain at the heart of everything we do – but today, we combine them with innovation, new technology, and fresh thinking to lead the business into the future,” Bailey-Jensen said.

Bailey Print Group was also successful in winning work for the Australian team at the 2018 Commonwealth Games –a milestone that cemented the company’s

reputation in major event signage. This later led to the business securing a contract for the Tokyo 2020 Summer Paralympics.

“Everything was signed off and we were ready to fly to Tokyo to deliver and install the signage. But then, COVID hit and unfortunately, the project didn’t go ahead,” Bailey-Jensen recalled.

“Although the cancellation was a major setback, it underscored the team’s resilience. Rather than letting it define them, the team used the experience to sharpen their focus and adapt quickly. When our backs were against the wall after losing all our event signage contracts overnight, one of our proudest moments came from pivoting the business to produce face shields. We knew nothing about medical-grade PPE, but we leaned on our networks, problem-solved, and gave it a red-hot crack.

“A moment I’ll never forget was when a Brisbane hospital confirmed our first order. When we delivered the face shields, the staff were crying in relief –they had nothing to protect them from the virus before that.”

That single order catapulted Bailey Print Group into producing 20,000 face shields for the Queensland Government. It kept every staff member employed through one of the toughest times for business.

“Moments like these highlight what have defined Bailey Print Group across four decades – resilience, adaptability, and a determination to step up when it matters most,” Bailey-Jensen said.

The Bailey Print Group of today

The company’s most significant transformation came in 2021 with the creation of a state-of-the-art print and wrap facility at Salisbury, equipped with cutting-edge technology. Bailey Print Group’s diverse portfolio now includes interior wallpapers, printed panelled soffits, event and display signage, and vehicle wraps.

“Peter always had this vision of wanting to build a wrapping garage, and that’s

what we have done at Salisbury with the creation of Bailey Print Garage. Fleet wrapping and car wrapping is a newer component of our business, but has since become one of our core services,” Bailey-Jensen mentioned.

In just a short time, Bailey Print Garage has emerged as one of Brisbane’s premier vehicle wrapping and fleet branding specialists – a reputation reinforced by its global win at the 2024 Avery Dennison Wrap Like Royalty Award for Colour Change. The accolade has propelled the business onto the world stage, showcasing its craftsmanship and creativity to an international audience.

The company’s passion for efficiency and commitment to eco-friendly signage was also a factor that drove the design of the Salisbury premises, which was nine months in the planning.

Bailey Print Group is up to its 14th digital printer now. The location houses an HP 1500 and 3200 roll-to-roll large format printer, an HP Latex R2000 flatbed printer, which was installed in 2021, an Océ cutting machine, various finishing machines, as well as a few other supporting equipment.

More recently, projects for the FIFA Women’s World Cup and the Brisbane 2032 Olympics organising committee have elevated Bailey Print Group’s profile.

“In three weeks, we built six Olympic Rings and Paralympic Agitos for Brisbane 2032 while producing signage for the FIFA Women’s World Cup – a surreal moment for a small Brisbane signage company working with two of the world’s biggest sporting brands. We knew our father would be very proud of what we’ve done,” Bailey-Jensen said.

Sustainability as a principal

Bailey Print Group has fused sustainability into the nucleus of the company, becoming a provider of advanced print solutions that reflect its commitment to excellence and environmental responsibility.

“We try and minimise our impact where we can. Moving toward sustainability is

an important part of minimising the impact associated with printing,” Bailey-Jensen said.

The business constantly looks for innovative ways to reduce not only its own carbon footprint but that of its clients as well and ensure that its mode of printing is the cleanest available.

Bailey Print Group suggests ways for clients to reuse collateral and provide eco-conscious material alternatives including PVC free substrates, wallcoverings produced from inners of single use water bottles, and timbers and fibrous renewable boards, all which help sharpen its customers’ sustainability edge.

Through its R3VOLUTION initiative, the company also creates custom bags from its clients’ own banners, giving the product a chance to be recycled, reused, and repurposed.

“For the FIFA Women’s World Cup, we diverted around 300kg of vinyl and mesh from landfill by converting banners to duffel bags, backpacks, and ball bags, which were then distributed to grassroot women’s football clubs around Brisbane as a memento,” Bailey-Jensen said.

Working with HP has also enabled the business to put its cartridges through Close the Loop, which are then shredded and mixed with toner powder to produce TonerPlas, a product added to asphalt for road paving. It also sends back offcuts of corflute which is then made into brick strapping.

In addition, it has fitted out its facility and is driving down emissions with a 264-panel rooftop 81.6 kW solar energy system which powers its entire operation including its HP Energy Star eco printers.

“Our solar system generates significant environmental benefits which primarily come from avoided power plant emissions and equates to saving over 45,965kg of coal being incinerated per year,” she said.

A vision for the future

Bailey-Jensen and Peter Bailey’s dedication has built an incredible business, and the journey continues.

To mark its 40th anniversary, Bailey Print Group partnered with White Label Brewing to launch its own four-pack Printers Pale beer. The beer and can labels were produced by the brewer, while the case boxes were designed and printed by Bailey Print Group.

“To mark the occasion, we launched a weekly client campaign offering the chance to win our limited-edition Printers Pale. The initiative has been a resounding success, strengthening client engagement while spotlighting our premium print packaging capabilities,” Bailey-Jensen said.

November marks Bailey Print Group’s official birthday, which it plans to celebrate with a special event involving its clients, suppliers, and staff in recognition of the partnerships and people that have shaped the business’ journey.

“It’s inspiring to reflect on how long we’ve been doing this and that we’re still delivering the very best signage for Brisbane,” Bailey-Jensen said.

“We’ve made a conscious decision not to grow too big – we like where we are, staying in our lane, and focusing on what we do best. We’re confident in our craft and in what we deliver. We hope our recent project wins segway into other campaigns.

“We’re quite focused on delivering for Brisbane on the runway to green and gold, and we’ve most recently completed a high-profile signage project with the Queensland Academy of Sport.

“Beyond that, our focus remains on continually reinvesting in the business, pivoting strategically, generating fresh ideas, nurturing long-term client relationships, and fostering a passionate, skilled team.

“We embrace innovation and technology that streamlines processes, enhances outcomes, and enables smarter decisionmaking. This approach has laid a solid foundation for sustainable growth and ongoing success.”

“As we reflect on four decades of Bailey Print Group, one thing stands out above all – our people,” the company stated.

“We’ve been fortunate to have an incredible team throughout the years – talented, dedicated individuals who have shaped our journey. Many have been with us for years, some for decades. Their loyalty, passion, and craftsmanship form the foundation of our quality, consistency, and success.

“At Bailey Print Group, we’ve always treated our team like family, because when you genuinely care for your people, great things follow. Here’s to the legends – past and present – who’ve helped make us what we are today.”

Bailey Print Group recently received a call from donor liaison manager Sally Gardner at Legacy Brisbane, who uncovered quotes, hand-drawn artwork, and fabric samples from 1987 in the company’s archives. 38 years later, Bailey Print Group is still proud to be working with Legacy Brisbane today – a true testament to the company’s ethos of honouring long-standing relationships with clients, building trust, and bridging shared values.

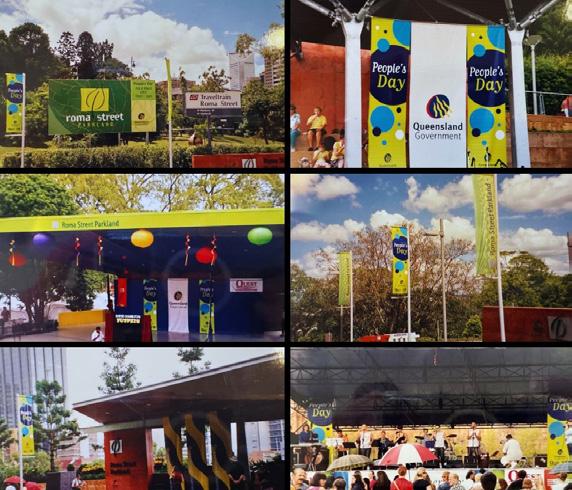

3 March 2002 was when the late Queen Elizabeth II and the late Duke of Edinburgh visited Roma Street Parkland during their Golden Jubilee Commonwealth tour. As part of the duo’s visit, they attended a “People’s Reception” and a “Meet the People” walk at that time, and Her Majesty planted a commemorative tree to mark the 50th anniversary of her accession to the throne. Bailey Print Group created the signage for the event.

Print Group created the signage for part of the Golden Jubilee Commonwealth tour

Bailey Print Group works while the city sleeps, transforming spaces and delivering high-quality signage solutions for major infrastructure and event projects across Brisbane. An example is the 2015 opening of Brisbane’s Legacy Way – the 4.6km twin tunnel connecting the Western Freeway to the Inner City Bypass. Bailey Print Group produced and installed three large format banners to cover the freeway gantry signage – which was all completed overnight.

The large format banners for the 2015 opening of Brisbane’s Legacy Way