Witness with your own eyes a fully integrated system from design and development to parts

inspection.

RMGT’s Head Office Factory in Fuchu City, Hiroshima Prefecture, manufactures large and mid-size offset presses and is the company’s main facility. As printing presses require exacting precision, the Head Office Factory utilizes a fully integrated system from design and development to parts machining, assembly, and pre-shipping inspection. We invite you to visit the Head Office Factory, where you can see the technological expertise and creativity behind the manufacturing that builds in reliability to produce offset presses with proven functions and exceptional printing quality We are constantly refining and improving our production lines, so even customers who have previously visited our factory are sure to discover something new.

Everyone at the Head Office Factory is ready to extend a warm welcome. An online video offers more detailed information about RMGT and our operations. The video can be accessed via the QR code at right. If you are unable to use the QR code, the video can also be accessed at the URL below. https://youtu.be/3FQfsABk-tk

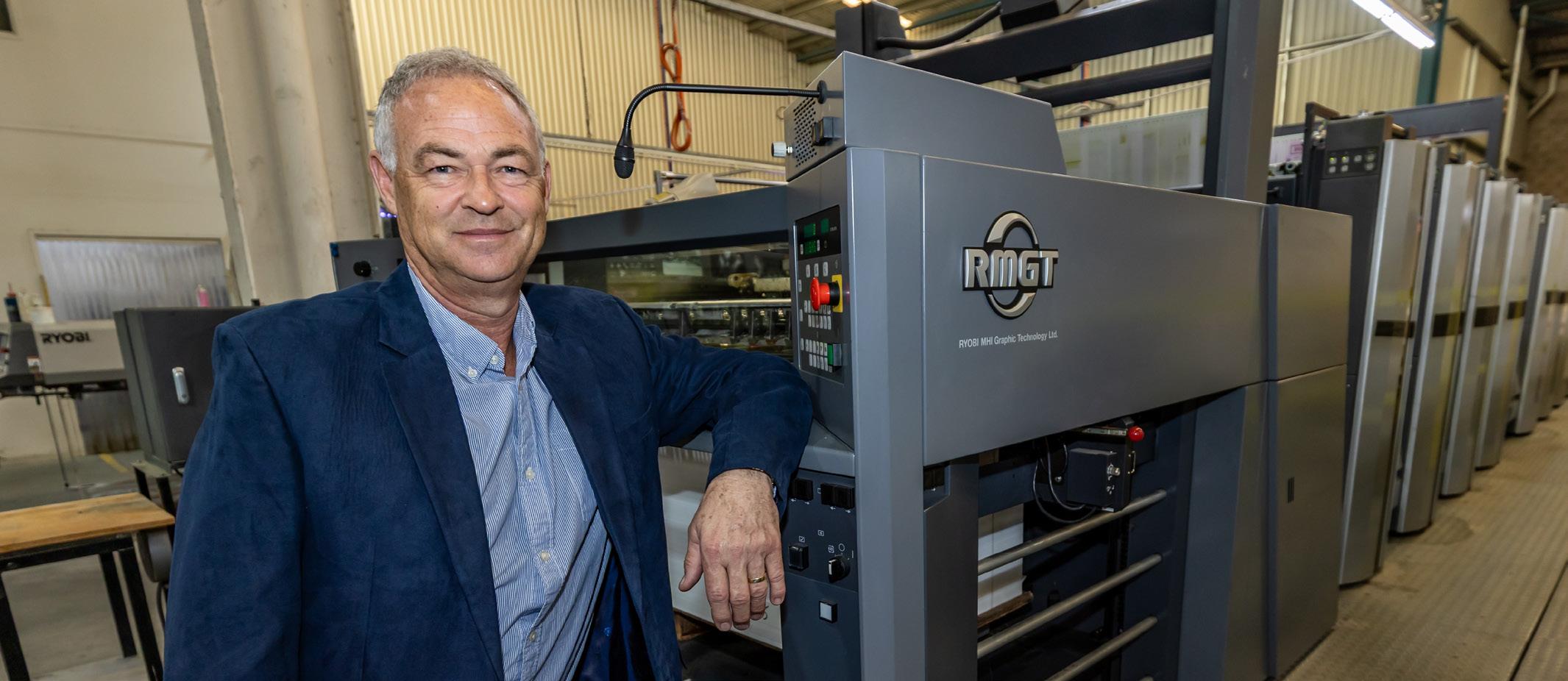

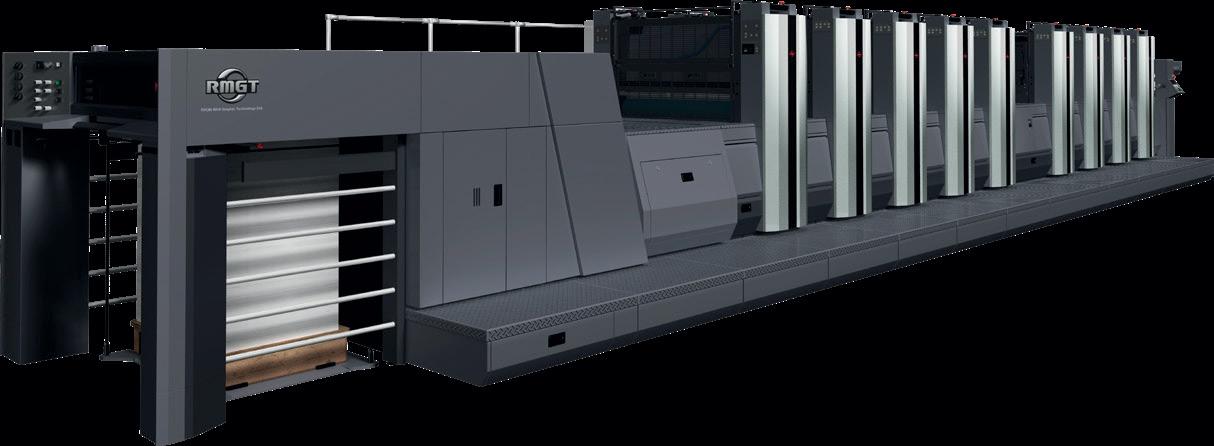

LEP Colour Printers has invested in three new RMGT 9 Series presses from Cyber Australia to improve processes at its facilities in Queensland and Victoria

Acompany that prides itself on being a fast, reliable, and dependable dedicated trade printing partner, LEP Colour Printers knew it needed some of the best machines in the market to remain competitive, whilst providing fast turnarounds and without compromising on quality.

To deliver on these needs, LEP Colour Printers recently turned to its long-time technology partner Cyber Australia to purchase and install not just one but three RMGT 9 Series machines for its premises in Queensland and Victoria, boosting its output, improving its speed to market in multi-folds, and fully transforming its production capabilities.

This strategic investment has marked a significant milestone in LEP’s journey to deliver faster, higher-quality, and more sustainable print solutions to its clients nationwide, highlighting its innovation and commitment to serving the evolving needs of the Australian print market.

Established in 2001, LEP Colour Printers is headquartered in Forest Glen in Southeast Queensland and expanded

its operations in 2013 with the addition of a facility in Port Melbourne, Victoria. Its range of products includes business cards, brochures and flyers, DL flyers and cards, stationery, presentation folders, posters, postcards, magazines, calendars, and more.

LEP Colour Printers CEO John Bromfield said, “Our production facility in Port Melbourne was something we invested heavily in. The way our business model works is that with both our production facilities, we’re able to produce jobs in either place, then deliver across the eastern seaboard of Australia either on the same day, the next day, or within a couple of days.

“We specialise in wholesale printing, focusing solely on delivering highquality results without altering customer artwork. Our lean manufacturing approach ensures timely delivery and cost-effective solutions that help our clients save both time and money. That model has supported our growth and business model, and all through that journey, Cyber Australia has been a business partner.”

Cyber Australia and LEP’s relationship began in 2005 when the former owner of LEP Mike Brooks bought an exhibited Ryobi 755 from Cyber Australia at PacPrint. Through the years, the companies built on this partnership, acquiring the very first RMGT 9 Series press – sight unseen – in Australia when it was first launched and followed it with two more presses shortly after – until now.

With the new purchases, a 920PF-8 LED Smart-FPC and 920ST-4 LED presses have been installed at LEP’s Queensland site, while another 920PF-8 LED SmartFPC press is making its way into its Port Melbourne facility.

Having had the two machines for about 12 months now, Bromfield said buying the same 920PF-8 LED Smart-FPC press for both of LEP’s sites will allow for colour and quality consistency between factories.

“Because we’re running the same platform on two different sites, from a customer assurance perspective, the result of a job, from a print quality point of view, is going to be the same whether it’s produced in Victoria or in Queensland,” he said.

“Also, back in the day, 75 per cent of our print runs were less than 1,500 sheets and our premises were taking 24 minutes to do a setup or make ready. So, we worked on our Theory of Constraints – which is removing bottlenecks in our business – adopted lean manufacturing and installed these machines to deliver on a ‘Formula 1’ mentality of make ready around five minutes.”

According to Bromfield, having been predominantly a short-run, four-colour gang printer, these new presses add to the strengths of the company’s business model of gaining efficiencies on fullcolour work.

“Looking at what our business is, what we’re good at, who our customers are, and what we’re trying to achieve, the 8-colour 920PF-8 LED Smart-FPCs and 4-colour 920ST-4 LED presses are the perfect fit for our business needs,” he said.

“Our business is dedicated to supporting small and mid-sized clients rather than large-scale print corporations. We have a clear understanding of our core strengths and remain focused on delivering excellence within those areas. Expanding into fields outside our established expertise is not part of our strategic direction or business philosophy. So, these new investments lend themselves well to the kind of work we do and what our customers require from us – which is speed to market, quick turnaround times, and quality jobs created at an affordable price point.

“With the 8-colour recipe, and with the efficiencies that come from the added features that it offers, we have hit productivity levels that are two and a half to three times more than what’s possible on a conventional press.”

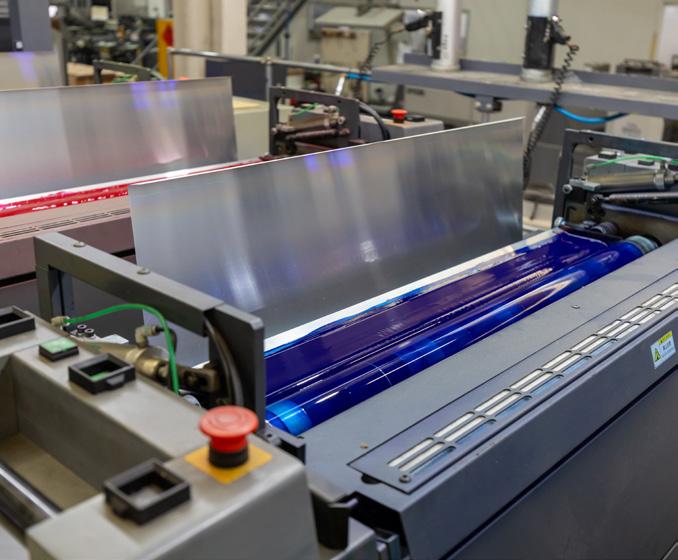

All three sheet-fed offset machines are SRA1 size, which is what LEP has built a business on, with the added benefits of LED UV and convertible perfecting, so that all the jobs get done in one-pass rather than two.

“The perfecting capabilities of these presses is not just about having state-ofthe-art technology, but also about speed – printing in one pass with instant curing. For example, we’ve printed magazines on these presses that have been done from start to finish in a couple of hours. The customer was over the moon. In the past, this process would have required several days to complete, as it involved waiting for the ink to dry and managing issues such as markings, scuffing, and bruising. With the latest machines, these challenges have been eliminated, enabling significantly faster turnaround times and an exceptional ability to meet market demand,” Bromfield said.

“The impact on our business has been tremendous, delivering significant gains in both quality and capacity. The presses have effectively given us more time, allowing us to increase production and efficiency. Overall, they have enhanced our operations and established a new benchmark for what it means to remain competitive and relevant in today’s market.”

Handling sheet widths of up to 920mm (900mm printing area), the 920PF-8 LED Smart-FPC and 920ST-4 LED presses enable printing of international A1-size posters as well as 8-up printing in both international A4-size and letter-size. They can also print on paper from 0.04mm in thickness up to 0.6mm, enabling flexible handling of a wide range of jobs, and can print up to 13,000 sheets per hour.

The machines are also highly automated, improving the work efficiency of each printing process. With their SmartFPC (Smart-Fully automatic Plate Changer) functionality, plate changing is simultaneous. Automatic blanket cleaning and ink roller cleaning also mean fewer manual touchpoints is required.

In addition, with a press information display that enables operations to be monitored at the delivery section and the PDS-E system for managing printing quality, work efficiency is improved by the centralisation of operations at the delivery end.

According to Cyber Australia managing director Bernard Cheong, the LED UV machines also have the added benefit of a 28.5 per cent cost saving on plates and a 43 per cent cost saving on electrical consumption per month when compared against B1-size presses – a plus on the sustainability front.

This is also supported by a newly developed predictive ink density control system that quickly achieves and maintains the target density with minimum wasted sheets.

“In business, there are so many variables. So, if we can remove some of these variables, it is a big plus. In this case, there’s no variable as to how long we need to wait before we can convert the sheet – when it’s out of the press, we can convert straight away, eliminating one of the big variables in printing,” Cheong said.

“These versatile RMGT 9 Series presses offer the latest automation and laboursaving systems, including a large-screen press information display for confirming printing status at a glance, together with the same maintenance functions, sheetfed air presets, and smart make-ready functions as our flagship RMGT 10 Series.

“Faster job changeovers boost printshop productivity, and the new Smart Assist Printing automatic printing function reduces operator workload significantly, creating new potential for business.”

With the speed and advantages of LED UV technology now part of LEP’s capabilities, Bromfield noted that the new machines integrate seamlessly with the company’s existing equipment. This alignment is expected to create new opportunities across several of LEP’s key target markets.

“We run a very well organised and lean production operation at both our sites. The new presses sit alongside – physically and systematically – our other machines and this system fits very well with our business in terms of integration,” Bromfield said.

“We’ve already seen additional work coming through various channels since we installed the presses. Some existing customers that used to send their slightly more higher end quality work elsewhere have been sending them to us as soon as they heard about us moving into the LED UV space. The fact that they are already well received by the market is reassuring and encouraging for us. That gives us a lot of confidence in some of the other things we’re looking to do going forward.

“We’ve got a few things in the pipeline, which we want to keep a little closer to our chest until it comes to fruition, but we’re very confident that the machines will be an enabler of these new business opportunities.

“To stand head and shoulders ahead in today’s environment, you’ve got to be contemporary; you’ve got to keep up – not just ahead of the curve in terms of what the market wants.”

He added that the press also suits an environment where it’s very difficult to get skilled trades people – a common challenge faced by many in the printing industry in Australia.

“It’s evident that hiring skilled staff is a challenge for many businesses. The RMGT 9 Series is a future press in the sense that you’re not relying on having a huge workforce. So, you’re automatically reducing your labour costs and your dependency on skilled personnel,” Bromfield said.

“Everybody is working towards what is called ‘dark room manufacturing’, so this series supports the move in that direction. You still need staff, but they don’t need to be as hands-on with the machines as before.”

Bromfield and Cheong expect LEP and Cyber Australia’s relationship to only strengthen over time.

“We have a personal interest in the LEP business, so we always look at the best of what we can do and offer. We like to think that we are in this together and the relationship goes well beyond just the sale of a press. We like to work together with our clients to get the best outcome that’s mutually beneficial,” Cheong said.

Bromfield said Cyber Australia has always exceeded LEP’s expectations in delivery, installation, and service, unwavering on its market offerings.

“Cyber Australia has worked with LEP for so many years, and they’ve done installations for us many times,” he said.

“Cyber knows our business very well and we work very closely with their engineers. So, from an implementation perspective, the installs were very smooth, just as always, as Cyber knew what our requirements were from the start.

“Cyber has also been very supportive, working with our business to minimise disruption downtime. As businesses, I believe we work very well together. It’s not just about selling a piece of machinery; there’s an added level of care in ensuring things go as smooth as possible with minimal business disruption. That’s how you strengthen a business relationship.

“We’re very grateful to Cyber and RMGT for their continued investment in this industry and what they enable businesses like us to do. There has been a lot of consolidation in this industry and ongoing challenges for small commercial printers, including significantly rising input costs; the decline in demand for printed materials as electronic mediums continue to penetrate our lives; and the ever increasing shortage of skilled print trades people.

“This partnership between RMGT, Cyber Australia, and LEP shows these printers how our investment in new machinery and producing quality work can give them the confidence to transition from a high cost, high risk printing operation to a low cost, sales focussed business where margins and profitability are higher by outsourcing work to LEP.”

Bromfield added Cyber Australia has also always gone out of its way to support LEP in its endeavours.

“With Cyber, we’ve always had the faith that they’ve got our back. There has always been a depth of specialist mechanical and electrical engineers available to support us in unlikely times. It’s hard to put a value on that loyalty,” he said.

The adoption of LED UV technology will allow LEP to:

• Provide sharper print quality and consistency across all jobs

• Deliver faster turnaround times with “dry-to-dry” efficiency

• Offer more competitive pricing and enhanced value to clients

• Expand into new markets with the ability to print on a wider variety of substrates

• Reduce environmental impact through lower energy usage and eco-friendly processes.

Cover Story p3-6

3-6 Cyber: Australian print company LEP Colour Printers recently turned to its longtime technology partner Cyber Australia to purchase and install three RMGT 9 Series machines for its premises in Queensland and Victoria.

12-14 Helping Hand: Allflex Packaging strives to keep production local; Iain MacIntyre reports.

16 Comment: Ruth Cobb introduces the inaugural New Zealand Printing & Packaging Forum.

17 Keynote: Gau Kurman showed how to implement Ai into your business.

18-19 Pride In Print Awards: The expert panel made a deep dive into the awards and the pride they bring to the industry.

20-22 Forum Pics: Photographer Deane Cohen captured the moments at the Printing & Packaging Form.

10 Currie Group: Flexo options have expanded thanks to Currie Group’s partnership with Uteco and Bimec.

23 Printerverse: Deb Corn explains how to turn downtime into a print sales opportunity.

24 Konica Minolta: Sustainability remains a key focus for Konica Minolta now and in the future.

26 Heidelberg: Shift 2026 combined expert presentations with interactive workshops at Heidelberg’s Home of Print.

27 Sustainability: New Zealand needs a container return scheme that is fit for purpose, says Deanne Holdsworth

28 Print Expertise: Strategic print marketing offers lessons on the permanence of print, says Daniel Edwards.

30 Aarque Group: Darrin Weir and the Aarque Group team say thank you to their customers and supply partners.

32 Durst: The Durst P5 X meets the demands of an ever evolving print and signage sector.

34 HP: The HP Latex FS70 W printer is the company’s latest and most productive HP Latex solution.

36 Currie Group: Working with global print leaders sees Currie Group help businesses maximise the value of wide format innovation.

38 NZSDA Update: Mikayla Hopkins is planning for next year’s Sign & Print Expo.

39 NZSDA President: You can learn from your mistakes, says Logan Sutton.

40 NZSDA Profile: Clarkson Signs is the latest NZSDA member to achieve Master Sign Maker accreditation.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS:

Ruth Cobb, Deb Corn, Daniel Edwards, Deanne Holdsworth, Mikayla Hopkins, Iain MacIntyre, Logan Sutton

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz +61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2025: Contents of this magazine are subject to copyright and cannot be

From your team at Wholesale Print we wish you, your family and your work family a safe and happy holiday season. The Wholesale Print team will be taking a break, and will be closed from 22nd December till 5th January 2026. If you’re not already one of our thousands of trade partners, call us 0800 289 774 or register online at www.wholesaleprint.co.nz

COLOR-LOGIC , has expanded its training and support programmes to better serve printers whose employees are not fluent in English. Mark Geeves, Color-Logic director of sales and marketing says, “Color-Logic recognizes this gap and is committed to providing resources that meet the needs of a diverse, worldwide audience. Print embellishments are a universal language of beauty and sophistication. By offering multilingual training and support, Color-Logic empowers the industry to thrive globally, regardless of language barriers.”

XSYS has launched Thermoflex Edge, the third generation of its laser imagers. Scheduled for commercial release in March 2026, its open architecture allows integration into existing workflows. XSYS says customers can easily implement surface screenings in a much shorter time. It adds that, with support for Woodpecker Nano 2400dpi and Woodpecker Nano 2540dpi surface screening, running at speeds of up to 8.5 square metres per hour, the system gives platemakers and printers freedom to adapt flexo plates to any challenge.

BOBST has launched its FlexJet module, calling it an industry first, all digital label solution that allows converters to produce pure digital multilayer labels and offers the ability to print digitally on the glue side and the liner. Bobst says FlexJet enables shorter runs, faster turnaround, infinite SKU variation, and versioning, while simplifying traditional multistep workflows. It adds the inline, all digital approach reduces setup time, waste, and process steps, minimising operational complexity and accelerating time to market for brand owners.

Epson has completed construction on its inkjet printhead factory at Tohuku Epson, Japan. Built with a total investment of US$33.7m ($59.55m), the completion of the new factory quadruples Tohoku Epson’s future printhead production capacity.

The company sees increasing demand for commercial and industrial inkjet printers along with an analogue to digital technology shift in sectors where the printing media is not paper, such as in digital textile printing. It adds that many commercial and industrial inkjet printers now use PrecisionCore MicroTFP printheads. They can adapt

Siegwerk has improved its EcoVadis sustainability rating, earning a new ranking in the 94th percentile of all companies assessed. It received an EcoVadis Silver Medal, achieving an overall score of 75 out of 100 points, reflecting particularly advanced practices across all criteria.

The company provides printing inks and coatings for

these printheads for different applications by assembling MicroTFP print chips in various combinations.

Epson is strengthening its printhead sales business to accelerate inkjet innovation and expand the applications for digital printing, which has a far lower environmental impact than conventional printing. It says the range of printing applications continues to expand along with emerging needs in areas such as electronics and bioprinting. It will collaborate with partners for innovative ideas and technologies as well as expanding the possibilities of PrecisionCore technology through open innovation.

Tohoku Epson began manufacturing CHIPS

packaging applications and labels. It says the new rating reflects continuous progress in implementing its sustainability goals and the effectiveness of its holistic sustainability agenda HorizonNow.

With over 150,000 rated companies in its network, independent business sustainability ratings provider EcoVadis offers a comprehensive analysis of a company’s performance in areas such as environmental impact, labour and human rights, ethics, and sustainable procurement. It bases its methodology on international sustainability standards, including the Global Reporting

printheads in 1995. It launched volume production of PrecisionCore printheads in June 2013 on an automated assembly line that makes extensive use of Epson robots. It has accumulated expertise in printhead production and built a solid base of production technology, increasing its competitive advantage as a domestic production site.

The company has designed the new building to enable more efficient operations, from component processing to assembly. In addition, the new process design aims to reduce labour and save space, minimising in-process inventory and introducing automated transport robots and efficient layouts to reduce the workload on operators.

Initiative, the United Nations Global Compact and ISO 26000, covering 250 industries and more than 185 countries.

The percentile rank compares a company’s score against all companies rated by EcoVadis worldwide. Here, the silver rating starts at the 85th percentile and the gold rating at the 95th percentile.

Alina Marm, head of global sustainability and circular economy at Siegwerk, says, “We have made great progress in the various areas of our sustainability agenda HorizonNow, confirming that we are on the right track on our journey of creating a truly sustainable business.”

Fujifilm Business Innovation has added new specialty colours, White and Silver, to the existing palette of Clear, Pink, and Custom Red for its Revoria Press EC2100S and Revoria Press SC285S models.

The expanded colour palette enables printing on dark, transparent, textured, and specialty media with metallic effects, especially for branding and promotional materials.

The company says White and Silver toners significantly broaden the creative potential and commercial appeal of digital print applications. White toner helps to create bright, vivid images on dark or transparent substrates, making it ideal for premium innovative marketing collateral. Silver toner introduces a luxurious metallic shimmer that enhances visual impact and perceived value, perfect for high-end business cards, brochures, and promotional items.

Australian industry supply association

Visual Connections has appointed Craig Heckenberg, managing director of Epson Australia and New Zealand, to its Board. He replaces long serving director John Wall, who retired earlier this year.

Mitch Mulligan, president of Visual Connection, says, “Craig has an outstanding reputation in our industry, not only for his deep knowledge of the sector but his broad commercial experience, financial and marketing expertise, and strong leadership qualities.

Fujifilm Business Innovation says these colours enable designers and printers to craft more dynamic, eyecatching designs, opening new avenues for differentiation in competitive markets.

The Revoria Press EC2100S and Revoria Press SC285S models feature advanced technology including a specialty toner station that supports five-colour

printing in a single pass, expanding the creative palette for high value, short run, and customised jobs. They offer compact design, high speed performance, printing up to 100 and 85 pages per minute respectively, and high-resolution output at 2400dpi. They are ideally suit commercial printing, quick turnarounds, and in-house production environments.

“We are fortunate to have a very strong Board, and it will only be enhanced by Craig’s presence. We are delighted to welcome him to the team.”

Karren Challoner-Miles, executive general manager of Visual Connections, adds, “From the discussions we have had with Craig over the past weeks and months, it has become clear that his views are very aligned with those of the Visual Connections Board and operational team.

“His strategic approach and innovative style which will be a huge asset to us as we continue to evolve Visual Connections events, programmes and other initiatives to deliver even better value to our members and to the industry as a whole”

Craig says, “I am genuinely excited by the direction the association is taking. There is a strong vision for the future, and I am eager to play a part in helping bring that to life. I look forward to working with Karren, Mitch, and the Visual Connections Board and operational team.”

The ANZ converting industry is set to benefit from a new strategic collaboration with packaging leaders Uteco and Bimec, and the European Flex-Converting Alliance (FlexCA), which will provide greater access to a wide range of world-class products, backed by the industry’s largest service and support operation.

Through two separate distribution agreements, signed earlier this year, Currie Group has become the exclusive distributor in Australia, New Zealand and the Pacific Islands for Uteco’s wide range of high-end flexographic, rotogravure and digital printing equipment, coaters, laminators and specialty customised equipment, and for Bimec’s world class slitter-rewinders for converting plastic films, paper and laminates.

As well as being recognised as industry leaders in their own right, Uteco and

Bimec are also central players in FlexCA, a European alliance of printing and converting manufacturers which also includes CMG, ENCA, Smartjet and Vision, and these agreements will also allow Currie Group customers to access the full range of solutions offered by this market-leading alliance of companies.

Both Uteco and Bimec have been represented in the ANZ region for many years, by Flexo Australia and Web Dynamics respectively, and Currie Group has worked closely with these agents for many months to ensure a seamless transition which will support, and add value, for customers across the region.

Reno Lauriola from Flexo Australia will join the Currie Group team, bringing his extensive knowledge and expertise to the partnership, while Jade Gillard from Web Dynamics will hand over the Bimec agency to pursue other business interests.

Currie Group already has a strong footprint in the label and flexible packaging area, particularly through their partnerships with other world-leading original equipment manufacturers. Mark Daws, Currie Group director – Labels & Packaging ANZ, says this experience has positioned the Group well to expand into the high-end, high-volume end of the market with these new partnerships.

He says, “Flexible packaging is certainly an area where we are seeing massive growth, and these new agreements represent a significant step in expanding our offering to the higher volume converting sector by adding the unique value proposition offered by Uteco, Bimec and the wider FlexCA alliance.

“These new partnerships allow for a collaborative approach where we can pull in products and resources from any, or all, of the alliance members, to create solutions which are driven by each particular customer’s needs and objectives.”

Currie Group’s extensive network of technical specialists and service professionals was a key factor in these new agreements, providing customers across the region with unparalleled technical and service support. They will be backed by the full resources of Uteco, Bimec and FlexCA, who will act as strategic consultants and ‘end-to-end’ partners for all customers in the region.

Daws says these latest agreements align with the company’s commitment to provide complete, end to end solutions by partnering with leading brands who provide high quality, premium products.

He says, “Uteco, Bimec and their alliance partners, are internationally well-regarded manufacturers of quality equipment and solutions for the flexible packaging sector, and we are very pleased to be able to represent them in the South Pacific region.

“In the coming months we look forward to welcoming our new partners to the region, and to introducing them to our new and existing customers.”

New Zealand Printer magazine and PrintNZ thank attendees, speakers and sponsors of our inaugural New Zealand Printing & Packaging Forum incorporating the People In Print and Rising Stars Of Print Awards on October 14

Innovative Kiwi company supports Print In New Zealand and keeps production local.

Staying at the forefront of technological advancement in the flexible packaging industry and further developing both its people and business systems are among key focuses for East Tamaki, Auckland-based Allflex Packaging.

Established more than 30 years ago, the business was purchased by Peter and Kay Logan in May 2016 when trading as Allflex Print and Packaging/B&G Distributors. At that time the couple had recently returned to New Zealand after almost 20 years offshore in various countries and finally Switzerland.

Kay explains, “Peter had served in various corporate roles with the Tetra Laval Group, but it was time to head home, and he had a desire to ‘make’ something in New Zealand.”

“The profile of the previous company, aligned with Peter’s engineering, technical, sales and marketing and corporate governance experience, has contributed to the business experiencing considerable growth since. We are now well positioned in the flexible packaging industry.”

The company’s main service offering is to supply flexible packaging materials and print, laminate and/or convert them for the food industry, predominantly for vegetables, confectionery, bakery and snack food. Kay says, “This is the bulk of our business, however, additionally we do produce for the industrial and pet food industries.

“We have two flexographic presses and can print up to eight colours on one and

six colours on the other. We laminate films using a solventless, high-speed laminator.

“We utilise different technologies for perforating: hot needle perforation mainly for pie bags, and laser technology to perforate film for produce bags. This is a relatively new addition to our capabilities which has opened up new opportunities for us.

“In conversion we can make most types of bags available on the supermarket shelves today. This includes stand-up pouches with or without a zip, three-side seal bags with or without a zip, side-weld bags such as courier bags/mailers with reseal or permanent tape, and back-seal bags with or without a gusset for sweets etc.

“Our work in the produce category is something we are really proud of, having

developed in house laser technology to meet the needs of this segment. This is an industry where the ‘vegetables wait for no one’ and it is vital we help secure a timely, consistent and quality delivery for our customers.”

About 10 per cent of the company’s business comes from exports. She continues: “We export custom manufactured product to Samoa, New Caledonia and Australia, and are definitely looking for additional growth in these markets.”

The purchase and development of equipment for the company’s own laboratory enables it to precisely check various aspects on the production line. Kay comments, “We are able to monitor our success, or failure, by checking for example the hole size of our perforations, friction of our films, tensile strength of film and lamination structure strengths etc.”

The business has implemented a bespoke management information system. She says, “We do have a lot of different product lines and variability across our range, and so to manage this we have a very detailed Bills of Materials system which allows us to individually store product specifications. This allows us to produce consistent, quality product on every run.

“We work constantly to not only improve the quality of product but to develop our

systems and processes. For example, we recycle as much as we can, from reusing office supplies as much as possible, to cardboard and core waste.

“Additionally, we maintain an active social media presence with LinkedIn for example to highlight our achievements –such as the recent addition of wrapping our completed rolls of film with Allflexbranded wrap.”

The business also keeps a “keen eye out” for new market opportunities. Kay explains, “For example, the increasing

demand for stand-up pouches. If we believe in a market opportunity, we will invest in relevant machinery to fill the gap in our expertise and then go out and find work in the appropriate categories. We do take pride in the fact that we will take calculated risks to keep developing and growing the business.”

Allflex Packaging’s staff members undergo regular training relevant to its operations as well as any certification that is either a legal requirement or advantageous to individual staff or the business as a whole.

Kay says, “In the areas of dangerous goods, forklift, first aid, site safety and health and safety, we have aimed to create a business that focuses on staff safety, health and workplace happiness alongside, and no less important, top quality product, service and delivery to our customers.

“We pride ourselves on a core philosophy of creating a family atmosphere, which embraces the wide variety of cultures of our staff. We hold regular lunches or morning teas and provide staff with a uniform to create an environment of pride in ourselves and what we do as a group together.

“We are Hazard Analysis and Critical Control Point (HACCP) certified and ensure that the factory is kept to the highest standards of cleanliness, tidiness and order.”

Peter points out that the business constantly monitors global trends in films and barriers. He says, “We have had success introducing ALOX (aluminium oxide)-based film to one of our larger customers, with initial trials to ensure suitability for their product having gone smoothly. The moisture and oxygen barrier of this film is very impressive and globally recognised.

“We try and work with only a few partners in film purchasing, most of which is normally imported as most of these films

are not currently made in New Zealand. Keeping our sourcing tight means we get consistent quality and can get a timely and helpful response if something does go awry. All our suppliers also require certification to ensure the quality of the raw materials that we use.”

One major concern for the business is the “continual leakage” of production offshore, mainly to various Asian countries.

Peter says, “We try our utmost to be competitive, however, which can be difficult as sometimes the finished products are being imported at a lower price than the cost of raw materials, even before we start manufacturing. Considering prices for those raw materials tend to be based on common global supply chains and a United States Dollar denomination it is hard to believe how this happens.

“There are risks to purchasing offshore and we find customers approaching us due to supply chain disruptions and large minimum order quantity requirements with imported packaging. Also, many customers appreciate the face-to-face support, knowledge and back up buying locally gives. Being local also means that we can help our customers if they have an urgent job requiring a shorter than normal lead time without having to deal with shipping issues.

“We bought the business to make things in New Zealand for New Zealand; to pay tax here and contribute to employment in the sector. However, this is getting increasingly difficult with many consumers buying directly offshore and we see some of our competitors looking for an exit strategy.

“We strongly believe in the Printed in New Zealand logo and hope this might convince some people to stay local and to understand the importance to the New Zealand economy of producing goods here, providing employment and stimulating the New Zealand economy, rather than watch that money disappear offshore.

“Anybody entering the manufacturing industry in New Zealand, instead of importing finished goods, needs to understand that it is a capital-intensive business and therefore you need a lot of cash up front and then ongoing cashflow to continue to fulfil NZ’s compliance regulations and to develop further.”

Despite such challenges, Kay and Peter have a positive attitude for Allflex’s future. He says, “We can read every day about how the overall manufacturing sector is faltering but we do believe there are brighter times on the horizon.

“We believe our business will continue to grow because we are continuously innovating, we are prepared to take calculated risks, and we carry very little debt. We also strive to provide unwavering support to our customers and pull out all stops to provide quality, locally manufactured product.”

Iain Macintyre

PrintNZ and New Zealand Printer bring back print forums.

It was a pleasure to co-host the 2025 Print & Packaging Forum with New Zealand Printer last month. It has been a few years since we last held a Forum, and being able to switch up the format and tie it into the People In Print Awards was just the ticket. Having both our organisations aligned helped cement the right balance of sponsors, speakers and attendees, each of which are vital to the success of the event.

Being able to put a broad array of speakers in front of the industry provided the opportunity to test the appetite of the audience to do this again, and it was a 100 per cent success with all attendee feedback forms indicating they would be keen to do it again in 2026.

The range of topics saw there was something for everyone and interspersing the keynote speakers with panel sessions helped to break up the format and meant the audience had a chance to hear from some of our own.

Keynote speakers included, of course, AI which is the hot topic of every conference you attend at the moment, regardless of the industry. Supahuman showed examples of

how AI can be used to relieve busy people from doing tedious tasks, particularly in areas such as data reporting, data analysis and preventative maintenance. We are all somewhere along our AI journey and it is good to keep looking at what the next step might be.

The second keynote from Nikki Withington of Square One talked about the opportunities for designing great packaging and how to apply a sustainability lens over it so that it serves the key purpose of presenting and protecting the product enclosed in it, while reducing the environmental impact of the lifecycle of the packaging.

And keeping to the sustainability theme, Zephyr Brown shared Soar/SCG’s sustainability journey, the lessons they have learned along the way, and provided some easy starters for businesses looking to not only reduce their carbon footprint, but to save money while doing it.

Industry insights and opportunities from our panel of printers was very well received and we appreciate the people that were prepared to be part of this and share their thoughts on what they are

seeing in their own businesses, alongside their bigger picture view of the challenges and opportunities that print presents. These are grass-roots conversations that attendees really value.

Supporting this with panels talking about training and the Pride In Print Awards gave the audience a chance to ask questions and understand the importance of both to the future of our industry. And it was all wrapped around conversations with and by suppliers letting us know what the latest and greatest is, and where they see the industry moving from a products and supply point of view.

Closing off the forum with an industry update and then moving through to the People In Print/Rising Star awards, provided attendees the opportunity to stay and network further, while celebrating those that were being recognised for their work in the industry over the last 12 months. We were joined by another tranche of people who came for the Awards part of the evening, bringing the total attendees across the day close to 100.

The Awards presented the perfect platform to present Tony Sayle with a Lifetime Membership of PrintNZ, joining a small elite club of those that have made an extraordinary contribution to the organisation. It was a real thrill to acknowledge Tony’s contribution and present him with his Award.

The day wrapped up with the presentation of 49 People In Print Awards and 11 Rising Stars, all of whom were nominated by their peers and each one of them deserving the recognition of the industry.

There is a lot of work that goes into organising a day like this, but the reward comes from seeing everybody get something out of it. Not every speaker suits every attendee, but I am sure there was at least one nugget in there for everyone, whether that was something new to put in place at work, a new contact, or fresh insights into the industry. Whatever it was, thanks to those of you that demonstrated your commitment to your own growth and the growth of the industry by coming along, and we look forward to seeing even more of you at next year’s event.

Ruth Cobb

Quit doomscrolling, you can achieve real AI wins that you won’t see on your LinkedIn feed.

At the recent inaugural New Zealand Printing & Packaging Forum, keynote speaker Gau Kurman, chief marketing officer at Supahuman, shared how the company helps businesses implement AI into their processes with some impressive outcomes.

She said, “We are here because AI is here. We can’t ignore the fact that it is coming to our doorstep. AI isn’t about replacing people; it’s about freeing them. As chief marketing officer, my job is to connect all the dots for our customers and our partners, creating the bridges so they can make the connections that will help them understand what we do.

“In 2025, the speed of technology really matters. Ten years ago, the speed would probably not be the first thing you would think of in your organisation but now we can see how the speed at which technology is implemented can help unlock opportunities for business. And while AI is everywhere in conversation, only a few companies have turned it into something that actually saves time, reduces risk, or improves quality.

“When the Internet arrived it changed the world, but AI will dwarf that, and we are seeing this on a daily basis. When customers approach us, they say, ‘Our team is just drowning in admin work’. The stats don’t lie. About 30 to 40 per cent of the work they do is taken up with admin.

They want to know how they can remove the admin and automate that work.

SupaHuman has delivered over 200 AI solution projects across Australia and Aotearoa New Zealand. Gau continued, “We have never seen a business that doesn’t want to grow and what we’ve learned is that successful teams don’t start with AI tools; they start with a problem worth solving. They need to ask themselves: ‘What is the one repetitive task that’s draining our time and energy?’”

Gau shared case studies where Supahuman had implemented AI solutions into companies that needed to free up their time.

Soil & Rock, a New Zealand engineering consultancy, found that its engineers were spending hours, even days, manually compiling technical reports for clients. They wanted to automate their reporting times.

With AI-driven workflows, the reports are now auto-generated from their existing lab and field data. The result is the same quality and same compliance but completed in under two hours instead of two days.”

Their report times have reduced by 90 per cent with fewer human errors. This gives the team members more time for actual analysis and client collaboration.

Commercial cleaning company Jani King has recently implemented AI in its sales department. The company prides itself on its sustainability and on its people. As it goes through a period of accelerated growth, Jani King looks for ways that technology can help.

The question Jani King asked was, “How can our salespeople get to talk to the right people at the right time?”

Its sales team members were taking 15 to 20 minutes to complete a task, researching prospective clients. Supahuman built an agent that does that can now be done in 90 seconds with accuracy and no human error.

The outcome for Jani King is that people can now spend more time talking to the customers. When they start work, the AI has done all the hard work for them, and they are presented with all the information they need.

Gau said, “You might not be building boats or writing reports, but the story is the same. Every print and manufacturing business is full of processes that could run smarter. That could include generating quotes, estimates, or proof sheets; preparing compliance and audit documentation; updating SOPs, training packs, or onboarding materials; as well as writing customer reports or monthly summaries.

“The difference between doing this manually and intelligently can be the difference between staying competitive or getting left behind.”

Gau stresses the importance of keeping humans in the loop. She said, “AI is great at speed and accuracy, but it’s your people who give meaning to the work. That has been the biggest lesson from every organisation we’ve worked with. In every story I’ve shared, the real success wasn’t in automation, it was in what people could now focus on.”

She concluded “The future of work isn’t AI versus humans; it’s AI alongside humans.”

Expert panel explains why Pride In Print means exactly what it says.

At the New Zealand Printing & Packaging Forum, PrintNZ chief executive Ruth Cobb convened a panel on the Pride In Print Awards. The panel of experts comprised four-time Supreme Award winner Dave Gick of Logick Print; Pride In Print judges Tim Upton from Blue Star Wellington and Natasha Poznanovic from Fujifilm Business Innovation; as well as Awards manager Tania McDougall from PrintNZ.

Ruth, and the audience, asked the panel a series of questions.

Question: What are the judges looking for to make a gold medal entry?

Natasha: We are looking for everything from clean print and good design to finishing. Entries may have amazing design and print where everything looks fine but then it is a blunt knife on the end. For example, they might have used the wrong grain on the paper. Sometimes these things are overlooked because the people are excited about how good the job looks, so they miss the details in the finished product.

What do we not want to see? Well, please only send one piece of print. If you send five pieces, then something will be wrong with one of them. We just want the one piece. Also, we don’t want to know who

you are. Please don’t place your name or anything that identifies you on the entry.

Tim: We are looking for perfection. Start off with the basics such as clean print and the register. The other thing that is important is to include a little story with the print. You might have a great job that is printed on a two-colour press with a 50,000 run. That makes a big difference. Take care when you are doing the entry to make sure it doesn’t have any small imperfections.

For packaging, it’s the same scenario. We are looking at things like the machine it was printed on; if you have used the correct stock for what the job is; are the joins lining up correctly.

We want to see the ‘Wow Factor’. There are always a few jobs when you walk in on the first day of judging and you go, “Wow, this is amazing”. All the judges are passionate about print, and we just want to see beautiful pieces.

Question: How valuable is the information on the entry form?

Tim: For most jobs we will know how they are printed, but when there is a little bit of a story to be told about it, that story can really help us. That might be something like laminating and foiling where the judges say how did they

actually do that? It is really important to get that message across.

Natasha: Please tell us about the process. Entrants take different approaches for telling us their stories. Sometimes we get two sentences and sometimes we get War and Peace. We need to know why the entry contains what it contains and why is that piece there? It might be something has never been done before but they have done their research and that can be amazing and offer a point of difference.

Question (to Dave): When you are choosing samples for entries, how do you ensure that you are putting your best foot forward?

Dave: For us, Pride In Print is significant to how our business operates. All our team members are invested in all the critical areas that judges look for in entries. So, when a client initiates a job, we are aware it could be an entry. Typically, it is not about Pride In Print but along that process someone might say this is going to be a pretty cool job, it would be nice to put it in Pride In Print.

Of course, at that point, we need the approval of the customer. Some of our clients don’t want the jobs promoted, whether that is social media or Pride In Print. Others would like to see the work

go in. From getting the brief; pulling the job apart; finding best practice from the production right through to the execution at the end, we are aware of the job. We will earmark samples, sometimes during production and sometimes at the end and we will put those samples away throughout the year.

We aren’t perfect. Sometimes we don’t do it quite right. We do test the judges.

Question: As a small business of only four or five people, have you ever felt that you haven’t had the opportunity to win the award?

Dave: I was lucky enough to be at the first Pride In Print Awards at the Auckland Town Hall. The business I was working for saw the value of believing in and understanding the awards system. That was critical.

I don’t think the size of the business has any influence. It is important to remember, when you enter, that there are two parts to the entry form. One part goes to the judges with no reference about where that entry has come from or who produced it. It is impartial. The other part tells the story of the work’s production.

Question: How has winning gold medals impacted your business?

Dave: Certainly, for the team, it has been huge. We are human, we are all different, but the majority of our people buy into it and they have pride in what they do. We have had team members that have been in tears because they had been in the industry for 30 years and they had never achieved that. People are really important

to us. Working collectively, shoulder to shoulder as a team and with the supply chain, it’s driving the excellence from within for the customer. It’s producing the job above the level of expectation

Question (for Tania): How are the judges selected?

Tania: We receive recommendations and suggestions from throughout the industry. That gives us a variety of people. We need judges who can walk the walk. We also give our sponsors the opportunity to recommend someone. And we try to rotate the judges because it is good to have new blood in there, but we also appreciate the importance of retaining the history and the knowledge of people who have been judging for a long time.

It is good to keep that depth there. We have teams of judges based on their field of expertise across the 14 categories that we have. We are also lucky enough to have some judges who can judge across a couple of categories. It is a full on two days and everything needs to be looked at with full attention to detail.

Question: How is a job “taken off the table”?

Tim: Basically, we have a negative and positive form with a degree of difficulty. Generally, if there are more negative marks, it will be discarded. If it is marginal, then it might come up for discussion. We don’t all agree and we have some heated discussions. We are all passionate and we go in to battle for jobs that we believe are produced beautifully.

Question: How do you get to the

Supreme Award after judging the categories?

Tim: When there is 8-10 on the Supreme table and there will be 8-10 judges in those areas. Ruth will assign some specialist judges to talk about the job. And we will have time to look at the jobs again after hearing what they have said.

Ruth: Then they will vote until we have narrowed it down. It is all blind voting. When they leave that room, the judges will not know which job has won. Only the chief judge will know that.

Question: Do you think the economy and the cost that people are willing to put into print leads to less beautiful work being entered than 10 years ago?

Natasha: No, I don’t think so. Now is the time we should be prouder about what we are doing because the industry changes daily. It is called Pride In Print for a reason. Be proud of what you achieve. It is not just about competing against someone else. It is about what you do during the year. Dave mentioned that while you are working, put something aside to enter in Pride In Print. We need to encourage the future generations.

Tim: We take every entry seriously. We know that every company is proud of their work.

Ruth: The awards were set up to raise the quality of print in New Zealand. In the first year, it awarded 16 gold medals from 1000 entries. This year, there were over 100 gold medals from 500 entries. That shows the incredible improvement in the quality of the work being produced.

We do get into the debate as to why we don’t have first second and third as they do in Australia for their National Print Awards. That’s when it does become a competition and you are basically saying that one job is not as good as another job. The message goes out that job is not worthy and that is simply not true.

Natasha: That is exactly it. We have a Supreme Award, but the programme is about taking pride in every entry.

Tim: I agree, it doesn’t really become a competition until we have category and process winners. We judge each job on its merits. If 10 entries in one category are worthy of a gold, then they all get a gold. If there are none worthy, then no one gets a gold.

Dave: I am a firm believer in gold or bust. That’s the way it has been for 32 years, and we still believe in what the awards system can do for us. The culture is about uplifting the excellence of print.

Photographer Deane Cohen captured the moments… Forum provided a platform for discussions and connections.

The recent New Zealand Printing & Packaging Forum gave industry professionals the chance to talk about the latest trends; catch up with old friends; and make new connections.

Print service providers should deliver on meaningful, personal engagements that matter to their customers and drive their bottom lines

There are many opportunities to bring modern, data driven print offerings to businesses if you look around, evaluate the offering, and develop strategies on how to improve it for everyone.

Recently, I went to a doctor’s appointment at a medical centre and was aghast at the “reading materials” offered to waiting patients – magazines from 2022 and 2023, and a newsletter about the medical group. Needless to say, everyone, including me, was scrolling on our phones. But did we have to be? That was the question I pondered as I waited to be called.

The lowest-hanging fruit would be to convince the medical group to subscribe or re-subscribe to publications so that the waiting area materials are current. But what’s the point of that when you can read the same content, or enough of it, online? That isn’t a unique or relevant print experience.

I looked at the printed newsletter. In classic form, it was all about the medical group. The information wasn’t connected to patients beyond establishing credibility for the practice and validating their choice of medical providers. It was not a relevant print experience.

The medical centre is a mall of doctors’ offices and treatment centres, from eye exams to chemotherapy. There was an opportunity to educate all waiting patients at every office about everything

offered in the complex, highlight feelgood patient stories, welcome new practices, and more.

Instead, it was filled with brief “press release” information clearly targeted at the people who worked there. It was a true printed newsletter. It had a purpose; just not one I can correlate with sitting in a waiting area – unless the format was updated or a second version was created for patients.

What relevant print experience would keep me off my phone? That was the question. And I knew the answer. I would have turned to print if there was relevant, topical, and timely information about the area I live in – like upcoming street fairs, festivals, concerts, and events. Or about the area I shop in, such as new stores or special offers for readers. Or about new restaurants, and established ones, I may not have heard of.

A community magazine isn’t a new concept, but it could be a fantastic print experience and opportunity for marketers and printers to reinvent what it is and monetise it as a product. Office by office, business by business, neighbourhood by neighbourhood.

After my appointment, I was waiting by the elevator and saw a flyer hanging on the wall. It promoted a series of podcasts featuring doctors from the medical group, covering topics from the common cold to cardiology. There was a QR code to scan that brought you to the site where

the podcasts live. Finally, a relevant print experience for patients, created with nothing more than a colour copier.

What if the flyer were transformed into a mini magazine? It could be an extension of the newsletter or a standalone piece with more information about the podcast offerings. And yes, it could be done, because I had done it.

David Drucker, founder of high resolution printing and packaging, and Noel Tocci, founder of Tocci Made, are my co-hosts for the Making It With Print series on the Podcasts from The Printerverse channel.

We presented at the Digital Book World Conference in NYC in 2023 and created a print experience through a podcast brochure to share with the digital publishers. I wanted to show them that it was possible to educate, promote, market, and sell digital media through a digital bridge from print. They loved it.

The biggest takeaway from that event was that the digital publishers weren’t averse to using print at all, or creating a print experience. They just didn’t know how. They don’t work in print, even though many of their companies are among the largest print publishers in the US and beyond. Different divisions, different businesses. We helped them connect the print possibilities to their world.

You can too. Venture out and experience the print experience offered by businesses. Make a note of the places where it’s missing or could be vastly improved. Then do something about it. These businesses don’t know all their options – or that they can collaborate with a printer, marketer, and designer to create meaningful, personal engagements that matter to their customers and their bottom lines.

Deborah Corn is the Intergalactic Ambassador to The Printerverse at Print Media Centr.

Sustainability has been central to Konica Minolta’s innovation for more than 20 years – and continues to remain a key focus for the future.

Sustainability is vitally essential for all print businesses today.

Embracing a clear environmental vision is the only way forward.

The world today is still firmly focused on mass production, mass consumption, and mass disposal. Unsurprisingly, this is causing significant problems, not least of which is the depletion of natural resources.

For obvious reasons, there has been an increased focus on environmentally responsible sourcing, supply chain management, and manufacturing within the print industry. This is something that customers are increasingly demanding too, actively seeking to reduce their carbon footprint with manufacturers that embrace long-term environmental responsibility.

With Mintel’s latest Global Outlook on Sustainability: A Consumer Study 2024-25 reporting sustainability as the most critical issue concerning brands, it’s clear this is a key concern facing the wider print industry.

The challenges

Here’s a quick overview of the main environmental challenges in production print:

Energy consumption

Production print processes consume large amounts of energy, especially with older, traditional equipment. From powering large presses to the drying and curing processes, the energy demand is substantial and often relies on nonrenewable sources.

Waste generation

A substantial amount of waste is produced, including excess paper and setup sheets used for calibrating and adjusting presses.

Misprints, overproduction, and leftover materials all play a big part too.

Recyclability

Coatings, lamination or complex substrates, like composites or metallic inks, mean that some printed materials are challenging to recycle. While these features may improve the durability or aesthetic value, they can make recycling much harder.

Why sustainability is key for print providers

In short: addressing environmental issues is no longer optional for print providers.

Here’s why it really matters:

Reputation and responsibility

Environmental challenges affect all of us today. As businesses and consumers become more conscious, it’s vital to be transparent with our own commitments and actions towards sustainability. This demonstrates print providers understand their customers’ needs and are actively helping them reduce their impact.

Cost and time savings

Efficient use of printing devices, materials and reducing waste can lower production costs. As well as minimising errors, using automated systems also helps reduce paper waste and optimise resource usage.

Compliance

Many regions are introducing stricter regulations regarding waste and emissions. By adopting sustainable practices early, printers can avoid potential compliance issues too.

As a result, printing companies should establish robust investment criteria, prioritising technologies and processes

that drive sustainability. This includes setting standards to evaluate both the environmental impact and return on investment of new equipment and materials.

Here to help

Sustainability is at the heart of Konica Minolta’s business. It has been an essential factor in the past 20 years of its innovation and is a focus for the future too. Here’s how Konica Minolta can help print businesses solve environmental challenges:

• Konica Minolta’s Simitri HD polymerised toners are significant innovations designed to reduce environmental impact. The toners require lower fusing temperatures, reducing energy use and carbon emissions.

• Konica Minolta is certified by INGEDE for optimal recyclability. This foundation informs the design of products and promotes the use of recycled materials (its toner bottles are made with up to 60 per cent recycled plastics), to reduce the amount of primary raw materials required.

• All Konica Minolta production printing devices are made in factories with certified quality (ISO 9001), environmental management (ISO 14001) and an occupational health and safety management system (ISO 45001).

• Konica Minolta is also transforming waste into valuable resources through its Clean Planet Programme – with more than 87 per cent of recycled materials being converted into secondary raw materials.

At a local level, Konica Minolta is committed to reducing its environmental footprint through local initiatives such as a free Cartridge Recycling Program and an equipment recycling agreement with the Australia New Zealand Recycling Platform (ANZRP) via TechCollect. As part of its broader environmental leadership, the company takes full lifecycle responsibility and promotes green practices through energy efficient technologies and waste reduction.

Visit www.konicaminolta.co.nz for more information.

The new Konica Minolta AccurioLabel 400 press helps you profit from the latest trends in the Digital print customised label market. With the addition of our Vivid white colour option, you can capitalise on special finishes on a wide range of clear and metallic label media to produce striking Labels in one pass efficienc y

Whether you’re a label print specialist looking to upgrade your digital capacity, or adding labels to your offering for the first time, you’ll profit from the flexibility and speed the new AccurioLabel 400 Press brings to your business.

SCAN TO REQUEST A FREE SAMPLE PACK

Two-day event combined expert keynote presentations with interactive, hands on workshops.

Recently, Heidelberg welcomed more than 200 international guests from the printing industry, at its Home of Print, to Shift 2025, its new two-day event combining expert keynote presentations with interactive, hands-on workshops.

The event focused on the pressing challenges facing the industry, including rising costs, growing competitive pressures, and increasing difficulty in recruiting skilled personnel.

Another key issue discussed was the structural shift in order volumes. Where printing companies once relied on large-volume jobs, they must now fulfil a growing number of smaller orders, a model that is difficult to manage profitably with traditional workflows.

To address this, industry leaders at Shift 2025 explored the transformative potential of end to end digitisation, process automation, and robotics. Heidelberg sees these technologies as critical to reducing manual intervention and ensuring operational efficiency in a rapidly evolving market.

Practical examples

The first day focused on practical applications from various companies. Rob Cross, co-managing director of UK-based Micropress Printers, described how the company has accelerated its processes and alleviated the shortage of personnel

thanks to automation, robotics, and AI. Micropress produces on a Speedmaster XL 106 with Plate to Unit and on several digital printing systems.

It controls all processes via Prinect. At the folding machines, robots, including a StackStar P from Heidelberg, place the packages on pallets. Autonomous Mobile Robots (AMR) move the pallets between the individual machines.

Bauer Packaging, Germany, specialises in label printing and packaging production. The company has largely digitised its production. Using a combination of Prinect Production from Heidelberg and Symphony from Ctrl-s, the numerous label orders are bundled, the impositions are automatically laid out, and the output is sent to several digital printing systems.

Compucut Auto-Control calculates the cutting programs fully automatically on Polar cutting technology. Around 700 orders are processed every day. Orders received by 7pm are delivered on the same day from 9pm.

For the more than 600 million folding cartons produced annually, Bauer Packaging works with a new highperformance Mastermatrix 106 CSB die cutter, among other equipment.

On the second day of the event, Heidelberg and its partners presented

itself as a solution provider and system integrator for end to end production in commercial and packaging printing, from the PDF file to the delivered product.

AI-supported workflow software Prinect Touch Free targets efficient, automated production in a hybrid production environment. Presenters paid special attention to hybrid print production with Speedmaster technology on the one hand and digital printing with Jetfire 50 and Versafire systems on the other. They focused on fully automated workflow control via the new Prinect Touch Free workflow.

The AI-supported software guides an order independently and without human intervention through the entire manufacturing process, always taking into account the most cost-effective production route, available capacity, the current order backlog, and delivery dates. Heidelberg has scheduled Prinect Touch Free availability from the end of 2025.

Dr. David Schmedding, chief technology and sales officer at Heidelberg, said, “With Shift, Heidelberg has created a platform where participants can network, discuss the topic of digital transformation and gain inspiration for solutions.

“We want to support our customers as partners with all our process expertise and experience in process digitalisation.

“Heidelberg will therefore continue the format due to the extremely positive feedback. The industry can already look forward to Shift 2026.”

As New Zealand considers a national Container Return Scheme (CRS), it’s time

to ask if we are we solving the right problem?

As the New Zealand Government considers plans to implement a national Container Return Scheme (CRS), it’s time to pause and ask some fundamental questions: What problem are we trying to solve? Is this about reducing litter, or are we truly committed to building a local circular economy that works for Aotearoa?

At Pact, we support the intent behind the CRS. We’ve seen firsthand how such schemes can have a positive impact in Australia. We operate two of the largest PET recycling plants in Australia, which can collectively recycle around 2 billion PET beverage bottles a year.

That’s most of the plastic beverage bottles collected through the state-run scheme. The success of a CRS depends not just on its intent and the amount of material collected, but on its design, execution, and integration into the broader waste and recycling ecosystem.

Beyond litter: The bigger picture

If the CRS is intended as a litter-reduction initiative encouraging people to take their empty cans and bottles back to collect a refund, we risk missing the forest for the trees. Litter is a symptom, not the root cause, and needs a strategic response.

The real opportunity lies in creating a system that retains valuable materials within New Zealand, reprocesses them locally, and feeds them back into our manufacturing supply chains.

Unfortunately, the current proposals raise more questions than answers. Are we collecting containers only to ship them offshore for processing? Or are we investing in the infrastructure needed to recycle these materials here, to the highest possible standard? Without clarity on this, we risk undermining the very sustainability goals the CRS is meant to support.

Having the right infrastructure, investment, and integration

A CRS cannot exist in isolation. It must be aligned with other stewardship

schemes, kerbside collection systems, and the broader product stewardship for all packaging. Fragmentation will only lead to inefficiencies, increased costs, and confusion for consumers and industry alike.

The International Extended Producer Responsibility Alliance (EXPR) draws on its members’ 30 years of experience to recommend harmonisation of Extended Producer Responsibility (EPR) and CRS systems to prevent duplication of collection networks. This is particularly relevant for New Zealand, with its population of 5 million across a geography the size of the UK.

And why limit our thinking to any one stream of containers as is the case in the proposed CRS scheme? We should draw from other learnings when making an approach to collection and recycling and investigate the use of technologies from non-waste industries to improve our circular economy.

For example, using 3D QR codes to help consumers understand which products can be recycled, or broadening the scheme to incentivise the collection of more than just drink containers.

To manage material flows, international best practice shows that the Producer Responsibility Organisation (PRO) responsible for the scheme should own the materials collected. This way, the PRO can channel the material in the best way to ensure development of local infrastructure and improve the retention and reuse of local material over time.

There needs to be an understanding of the commercial reality of assets needed

to collect, process, and then utilise the local materials.

There is a challenge to investing in local recycling infrastructure where there is uncertainty of the waste roadmap for New Zealand and a high-cost barrier to invest. For those in the recycling industry, commercial realities can be stark. Introducing eco-modulated fees would encourage the use of locally recycled content and help to build New Zealand’s circular economy.

The private sector also needs access to co-investment through centralised funding to ensure there is enough investment in infrastructure to create a viable local circular economy.

If we’re serious about circularity, we need to co-invest in scalable, local solutions that close the loop onshore. Recovery of materials is one step in the solution to minimising litter; we need to ensure that we do not create unintended consequences by making a solve for one issue without ensuring that the end solution is in place.

A closed loop local circular economy should be the shining aim, which includes collection, recycling, and remanufacturing onshore. This has the benefits of reducing litter, emissions, improving local sustainability and creating jobs.

A poorly designed CRS could have unintended consequences: duplication of logistics, underutilised local infrastructure, and disruption to existing kerbside systems that are already optimised for certain material streams. Worse, it could erode public trust in recycling altogether.

We urge the government to take a holistic, systems-based approach. Engage with industry. Leverage the expertise of those who’ve operated in this space for years. And above all, ensure that any scheme introduced is fit-for-purpose for New Zealand – not just a copy-paste of overseas models.

By Deanne Holdsworth, executive general manager, Pact Packaging New Zealand

Posterboy Printing recently designed a strategic print marketing range for a plumbing business, which founder Daniel Edwards says has lessons to be learnt from.

Irecently designed a full suite of print materials for a local plumbing business. My goal was to create a toolbox of print marketing tools that the plumbers could distribute during their workday.

We used designs and offers that are evergreen and targeted at driving shortterm customer activity or building longterm brand recall. The idea was they could leverage every site visit into a marketing effort – with little effort. Promoting their business becomes an easy part of their everyday tasks.

Vehicle graphics: Plumbers’ vans are mobile billboards, wrapped in durable vinyl to maximise visibility. Parked at job sites or driven through neighbourhoods, they generate thousands of daily impressions.

This medium leverages the plumbers’ constant mobility, ensuring the brand reaches homeowners who may need services later and making it a costeffective choice for broad exposure. I encouraged a simple design with cut vinyl over printed vinyl for its longevity in the Australian sun.

Short-term activation: The goal of this piece was to generate enquiries and drive short-term activity. A DL-sized flyer on cardstock was distributed by the plumbers to 10 houses on either side and 20 across the street from their job site, capitalising on the mobility of the work, and trying to win more work in a small area.

It featured an evergreen offer with a clear call to action – “Fix Your Leaking Tap at a Fixed Price”. This was supported by a prominently displayed phone number and QR code linking to the booking page. I chose this focused, fixed price offer for its cut-through, over a generic message such as “call for a free quote”.

It prompts action but won’t attract too many tyre kickers. The reverse side of the flyer adds value with a plumbing maintenance checklist. If they don’t have a leaky tap, perhaps they will keep a checklist around for reference.

Magnetic flyer: A second DL-sized flyer was intentionally designed as a ‘keeper’

for homeowners – something they would hold onto for future reference. It is a heavyweight flyer with a magnet on the back and is an ‘important phone numbers’ resource. The magnet lists prefilled local contacts (police, hospital, council) and personal numbers (school, mum, dad, doctor, dentist) that homeowners can fill in, alongside the prefilled plumber’s details in a bold ‘plumber’ field.

I selected this format for the opportunity that it may become a valuable resource of local and personal contact details that can be kept on a fridge for years.

Stickers: When plumbing issues arise, the place people go first is the misbehaving appliance, making the side of the troublesome machine the perfect place for contact details. Vinyl stickers, waterproof and UV-stable are applied to hot water systems, under sinks, and on the side of toilet tanks by the plumbers during jobs.

With clear contact details, they are designed to be discreet and respectful to avoid early removal and be noticed when homeowners troubleshoot a broken appliance. This subtle medium capitalises on tradespeople often working on systems for longer than the tenant/worker has been there.

By putting a plumber’s contact details on the system during a call, it puts those

details in the perfect place at the perfect time, and will stay there for years at zero cost, generating return customers.