Hi! And welcome to this month’s edition of THE CRUST. Recent reciprocal tariff announcements from the U.S. have redrawn the shrimp trade map, raising import duties sharply for key export nations. Indonesia now faces a 19% tariff, and Vietnam 20%, while other countries await final rates. These changes will surely reshape sourcing preferences in the U.S. market.

But the clear winner remains Ecuador, with its shrimp imports still subject to by far the lowest tariff among major exporters. As a result, Ecuador is poised to strengthen its foothold in the U.S. However, one saving grace for others is that Ecuador has not yet advanced significantly into the value-added segment, leaving some room for countries like Indonesia and Vietnam to compete in this highermargin niche. This could be a window of opportunity as demand shifts away from bulk products toward convenience and differentiation.

Meanwhile, rising geopolitical tensions are adding to the complexity. The ongoing border conflict between Cambodia and Thailand is causing concerns across Southeast Asia. Thailand, once the largest shrimp exporter in the world, has seen its production shrink in past years due to EMS and structural changes in the industry. A prolonged conflict could further disrupt its recovery efforts and limit investment and farm operations, potentially reshuffling the regional production landscape yet again.

While Ecuador consolidates its lead, the impact of tariffs is being felt most by farmers in exporting countries. Higher import duties reduce U.S. demand, which in turn pushes farmgate prices down in home markets. Indonesia, which exports over 80% of its shrimp to the U.S., is especially vulnerable. Combined with disease outbreaks and rising input costs, shrimp farmers are operating under increasing financial pressure.

Shrimp farming today leaves almost no room for error—a failed cycle can undo years of hard work. The key now is to drive down production costs, adopt safer practices, and maintain consistent quality to survive in this volatile environment.

This will be an interesting development to watch— how countries adapt to this new market shift, redefine their strategies, and strengthen their positions. For all our readers out there, as always, stay resilient, stay safe, and we hope you enjoy this issue.

Rizky Darmawan Chief Editor

When it comes to the unseen infrastructure that powers our cities, towns, and farmlands, few consider the revolution happening just beneath our feet. But for Novean Husni Dini Reca, an industry veteran and technical author at PT. Rusli Vinilon Sakti, the future of polymermade piping is both visible and vital.

At a recent seminar during the Shrimp Aquaculture Conference 2025 in Bali, Husni, who brings over two decades of experience in the polymer pipe industry, shared his expertise and trademark inclusive spirit. He began by encouraging participants to explore not only the technical advantages but also the broader impact of making informed material choices.

Polymer Pros and Cons

According to Husni, polymer pipes offer a range of advantages over their metal and concrete counterparts.

They are lightweight due to their density being lower than water, making them easier to transport and install, especially in challenging terrains. Their flexibility also makes them resistant to impacts and even seismic movements, a crucial trait in earthquakeprone regions. “SDPE pipes can even be rolled up,” he pointed out, underscoring the adaptability of modern polyethylene solutions. Beyond flexibility, polymer pipes are also noncorrosive, immune to rust, and resistant to a wide range of chemicals, making them a lowmaintenance choice for longterm infrastructure. In contrast, traditional materials often require extensive anticorrosion measures. Most compelling to decisionmakers, perhaps, is their costeffectiveness: “Polymer pipes are relatively more economical compared to metal or concrete pipes. They do not require special treatment,” he added.

Despite their many advantages, he acknowledged that polymer pipes do have some limitations. For one, they are not particularly resistant to sharp objects or fire. Therefore, shrimp farmers looking to use this type of pipe should take care to keep them away from those potential risks. In addition, the pressure rating of polymer pipes is not as high as that of metal or concrete pipes.

Material Choices

He noted that Indonesia’s polymer pipe landscape is quite diverse, with key materials including polyethylene (PE), chlorine-modified ethylene (PVC), and various types of polypropylene. He briefly explained the process: ethylene is used to produce PE, which can then be developed into PPR and other derivatives. When ethylene is modified with chlorine, it produces PVC, which also has several variants such as oPVC and uPVC.

structures like walls, making them highly versatile,” he added.

Choosing the right type of pipe is one thing; determining the correct size is another. Husni emphasized that getting the pipe size right is crucial. Not just for safety, but also for cost efficiency. For instance, if the pipe is too thin, the maximum operating pressure cannot be achieved, which can lead to leaks or damage. On the other hand, using pipes with excessively large diameters increases costs and requires more space for installation. Accurate sizing also affects how easy the system is to maintain.

According to him, the most suitable types of pipes for shrimp farming, agriculture, and livestock are PVC and HDPE. PVC pipes, he explained, require special fittings for bends and often need additional structural support. In contrast, HDPE pipes are more flexible and can follow the contours of the land—sometimes even allowing installation without fittings. “HDPE pipes are ideal for straight buildings or linear

He then shared a few tips with shrimp farmers on how to perform proper calculations, introducing formulas such as the HazenWilliams equation to estimate head loss. “The HazenWilliams formula is widely used to calculate head loss in piping systems because it’s simple and practical,” he explained. For pressure loss in pipe fittings, more specific formulas are applied to ensure each part of the system is properly op timized.

Building on its strong track record in designing COVID19 tests during the pandemic, Nusantics through its aquaculturefocused business line, CeKolam, has adopted the principles of precision medicine used in human healthcare and applied them to aquaculture species like shrimp. The focus is especially on preventive approaches, which remain a more effective strategy in aquaculture compared to curative ones.

“And one of the lessons that we learned from the pandemic is that when we do the early detection, we can manage what we need to do next. That’s what we call precision medicine on the human side,” said Dr. Sidrotun Naim during her presentation at the 2025 Shrimp Aquaculture Conference.

Early detection, especially using reliable tools like PCR, is a crucial piece of the puzzle in achieving comprehensive shrimp health management. According to Naim, a common mistake among farmers is applying treatments in the pond without properly identifying the underlying issue, which often leads to less effective results.

Revata Utama, Founder and CEO of Nusantics, explained that shrimp possess a unique innate immune system that differs significantly from humans or even terrestrial livestock. This distinction makes selecting the right treatment products for shrimp health far more complex. Therefore, it is crucial for farmers to map and assess their input products to ensure they align with the dynamic needs of the shrimp.

“They put more probiotics in the pond, they put more minerals in the pond, vitamins and other additives, which sometimes might not deliver the right results because we don’t have all the data. So we listen to your concerns and we want to find out why sometimes when you put in certain probiotics, it doesn’t really work well when managing the infections,” Revata said.

This issue is further complicated by the fact that many probiotic products don’t contain what’s actually stated on the label. Data collected by CeKolam from its thirteen partner farmers revealed a number of inconsistencies, ranging from mismatched bacterial strains to the presence of harmful opportunistic bacteria, and in some cases, contamination with dangerous pathogens. Such bacterial contamination in probiotic products not only causes financial losses but also poses serious risks to the farm environment.

To make matters worse, the effectiveness of probiotics can be further compromised by contamination that occurs during onfarm handling—particularly when probiotics are fermented or recultured before use. This is a common practice among farmers, but without strict biosecurity measures, it significantly increases the risk of introducing unwanted bacteria.

“So if you don’t really know the probiotic composition that you purchase and just believe in the packaging claim, you might input the wrong nutrients that allow all these opportunistic pathogens to go up and that the result is going to be bad,” Revata added.

Understanding the type and composition of probiotics used is essential for managing the shrimp microbiome effectively. Just as human microbiome research has shown that gut composition is dynamic and everchanging, the same applies to shrimp. Applying probiotics without first understanding the current state of the shrimp’s microbiome could result in ineffective treatment, as the products may no longer match the actual needs of the animal.

whether the shrimp’s digestive system and microbiome are healthy and ready to fight off pathogens. That’s why CeKolam offers a holistic health monitoring program that goes beyond early pathogen detection. It also checks gut health and microbiome composition, water quality, and even the bacterial contents of probiotic products.

“Like what Dr. Naim mentioned, in humans, we learn the concept of precision medicine where we give the right medication and treatment plan based on your genetics, your microbiome, your clinical profile and your metabolite profile in hopes that we can give you better treatment and you can recover faster from your disease. So why don’t we apply that to aquaculture as well?” Revata said.

They concluded that maintaining the abundance and diversity of beneficial bacteria helps shrimp suppress pathogen levels while stabilizing their immune system. Therefore, providing the right inputs that support the right microbes is key to helping shrimp defend themselves during pathogen attacks.

According to Revata, identifying diseases through PCR is just one part of the picture. Equally important is understanding

At the Shrimp Aquaculture Conference 2025 recently, Alban Caratis, Global Aquaculture Manager at Phileo by Lesaffre, delivered a compelling presentation on shrimp gut health.

Caratis opened his talk by challenging the idea that modern shrimp farming is more art than science. For him, it remains firmly rooted in science, especially given the technological advancements that continue to transform the industry. These include the integration of IoT, artificial intelligence, innovative diagnostic tools, and cutting-edge omics technologies like genomics, proteomics, and metabolomics.

Despite these breakthroughs, Caratis emphasized that shrimp farmers still face serious challenges, from disease outbreaks to unstable profit margins. Citing a study conducted in Vietnam, he pointed out that 70% of farms reported frequently experiencing gut health issues. Yet, most farmers are only able to identify these problems once they become severe and highly visible, such as in the case of white feces syndrome.

Caratis likened the situation to the Titanic, saying, “When you see the iceberg, it’s already too late.” He emphasized the need to pay attention to gut disorders that may not be immediately visible but are just as harmful. Managing gut health in shrimp is complex, he explained, due to the multifaceted nature of gut function, limited diagnostic tools, a still poorly understood microbiome, the influence of diet, and varying farming conditions.

Shrimp are naturally prone to gut disorders because of both their environment and gut anatomy. “The shrimp’s gut is the main entry point for many pathogens today,” he said. Since shrimp live and feed along the pond bottom, they are constantly exposed to potentially harmful microorganisms. Moreover, the hepatopancreas and midgut, key regions of the digestive system, are not protected by a chitin layer, making them especially vulnerable to infection.

Caratis underscored the widespread nature of gut-related diseases in shrimp farming, stating, “Three out

Alban Caratis

of four diseases primarily affect the gut,” referring to issues like Vibrio infections, EHP, and white feces syndrome. He also pointed out that compared to fish, shrimp have more limited defense mechanisms as they lack adaptive immunity and do not have an acidic barrier in the gut.

To address these challenges, Caratis shared that Phileo has launched a project to sample shrimp from commercial farms in China, Vietnam, and India. The goal is to evaluate gut health directly on the farm and gather data on factors associated with gut disorders. “We have the ambition to create the first world map of gut disorders in shrimp farming,” Caratis announced, aiming to raise awareness and develop tailored strategies for better management.

The methodology used in this project, known as Digescan, involves assessing the shrimp’s hepatopancreas and assigning scores based on four key parameters: hepatopancreas color, tubule deformation, lipid droplets in the tubules, and the presence of ATM (aggregated transformed microvilli). Caratis presented data from a well-managed shrimp farm in China, highlighting variations in gut health scores and underscoring the need for improved diagnostic tools.

In addition to mapping out gut health in shrimp, Caratis also discussed its management challenges. Given the many factors that influence shrimp gut health, from environmental and biological to physiological, he emphasized the importance of maintaining a balanced microbiota, commonly through the use of probiotics.

However, instead of relying solely on bacteria-based probiotics, he encouraged exploring other microorganisms like yeast. This type of probiotic has been somewhat overlooked in the search for probiotic-based solutions in shrimp farming.

“Yeast are well-characterized probiotics in most farm species and even in humans. But in shrimp, we are really just scratching the surface. However, they have several advantages for managing gut disorders compared to traditional probiotics that are mostly bacteria-based. They have a fast activation time. They have a high and more diverse beta-glucan composition in their cell wall,” Caratis said.

He then shared results from a trial in Vietnam that tested the effectiveness of the yeast probiotic Actisaf SC47 in managing gut disorders. The trial involved co-infecting shrimp with EHP and Vibrio alginolyticus to replicate white feces syndrome, applying the probiotic through both water and feed. The results showed that the yeast probiotic helped reduce gut disorders and improved gut health scores, even in the presence of pathogens.

Caratis reaffirmed that gut health remains a critical issue in shrimp farming and stressed the need for ongoing research and development of effective solutions. He invited those interested in the topic to connect and support efforts to develop a new generation of probiotics tailored specifically for shrimp.

The shrimp aquaculture industry continues to face significant biological and economic challenges, particularly from the persistent threat of Enterocytozoon hepatopenaei (EHP). This microscopic parasite, which infects the hepatopancreas of shrimp, has been linked to severe growth retardation, poor feed conversion ratios (FCR), and considerable economic losses—estimated to exceed USD 1 billion annually. While EHP doesn’t typically cause direct mortality, its damage to the hepatopancreas makes shrimp more vulnerable to secondary infections, especially from Vibrio bacteria, leading to indirect but devastating impacts.

Harikumar Sampath, Associate Scientist at Kemin Aquascience™, explained this during his presentation at the Shrimp Aquaculture Conference 2025. According to him, EHP has been a major concern since it was first reported in 2004. The parasite’s life cycle is complex: it spreads through both horizontal and vertical transmission and begins its infection by releasing spores that use a polar tube to inject infectious material directly into shrimp cells. Once inside, the parasite hijacks the host’s energy reserves to multiply and, upon maturation, ruptures the cells, releasing more spores into the environment and perpetuating the cycle.

“So now we hypothesize that the functionally active molecule from plant extracts would act by preventing the adhesive mechanism. It should also work to prevent internal multiplication by blocking essential metabolic enzymes of EHP. And it should also work against secondary infections,” he said.

Using Kemin’s proprietary phytogenic database, which has been built over years of research, and supporting literature, the team identified compounds with antiparasitic activity and molecular similarity to known inhibitors of related microsporidia. They then conducted high-throughput in silico screening, including molecular docking and dynamics simulations, to test more than 40,000 bioactive compounds for their ability to bind and inactivate essential EHP enzymes. These computational models, which now reach over 90% accuracy, significantly accelerated the research process.

Key target enzymes were selected from EHP’s genome, and promising compounds were benchmarked against known anti-microsporidian drugs used in humans. The results revealed three lead phytobiotic compounds with strong binding affinities and thermodynamically stable interactions with target enzymes, indicating high potential for disrupting the parasite’s internal proliferation.

To validate these findings further, the team performed in vitro assays to test whether these compounds could inhibit the parasite’s polar tube extrusion, an essential step in EHP’s infection mechanism. One standout compound showed a significant reduction in polar tube activity, confirming its ability to block spore adhesion and entry into host cells.

Following these lab results, Kemin designed in vivo trials

using a cohabitation model that simulated real-world farming conditions. Infected shrimp were kept in cages within tanks housing healthy shrimp, which were fed with diets supplemented with the phytobiotic prototype. Over a 40-day period, the healthy shrimp exposed to EHP showed significantly lower parasite loads and maintained normal growth rates when fed the supplemented diet. These results mirrored those seen in uninfected control groups, indicating the prototype’s effectiveness in both limiting infection and mitigating growth suppression.

The prototype, now named Pathorol, was also tested in commercial field conditions across EHP-affected farms in India, China, and Thailand. The trials demonstrated consistent reductions in EHP copy numbers, improved growth performance, and strong return on investment for farmers.

Sampath claimed that un-

like many phytogenic products on the market, Pathorol’s key differentiator lies in its vertical integration: Kemin cultivates certified plant material across its own farms in the U.S., India, and China, and uses patented extraction and biotransformation processes to maximize active compound yield and consistency.

He added, Pathorol now in the final stages of patent approval in the U.S., represents a promising and eco-friendly breakthrough in EHP management. Its multifunctional action and proven efficacy in both lab and farm settings could offer shrimp producers a much-needed tool to combat one of the industry’s most persistent challenges.

As the industry continues to grapple with disease threats and antibiotic alternatives, this phytobiotic approach highlights the importance of science-driven innovation grounded in practical, field-based realities.

At SAC 2025 in Bali, Indonesia’s shrimp sector gathered to reflect on its future. From disease control to investment, one topic repeatedly rose to the surface: traceability.

Once a marketing buzzword, traceability is now a serious business differentiator—shaping trade access, buyer trust, and long-term partnerships. Global markets no longer accept QR codes or blockchain demos as proof. They want systems grounded in real practices and independently verified. Trust is being rebuilt through transparency, and traceability is becoming a baseline expectation, not a value-add.

At Mida Trade Ventures, we work between Southeast Asian producers and international buyers who are raising the bar. In the past, basic sourcing details were enough. Today, buyers, especially in the EU and North America expect full visibility into farming practices, inputs, and labor conditions, often backed by third-party verification. The shift is not just about more data, but better data: credible, consistent, and audit-ready.

Yet most current systems still fall short. Field data is often delayed or incomplete, and poor connectivity in farming areas limits real-time reporting. Even where digital tools exist, they rarely connect to the full chain—from pond to export. Buyers now request

input logs, environmental metrics, even labor documentation, while fragmented regulations and tightening import rules create further complexity.

As one panelist said at SAC 2025, “Traceability systems are only as strong as the weakest link—and too often, that’s where they start.”

eFishery’s recent challenges offer a cautionary tale for the industry. As an early tech leader, the company brought digital tools like feed automation and farm apps into Indonesia’s aquaculture scene, sparking optimism around innovation.

But as the company expanded into financing and trading, the operational complexity increased faster than the systems could evolve. Much of the farm-level data, while valuable, was not initially structured for external verification, with gaps in standardization, timestamps, and integration across the supply chain.

This became a problem as global buyers began demanding traceability that’s not just digital, but verifiable and linked across the entire supply chain. eFishery’s case shows that technology alone isn’t enough—it must be grounded in shared standards, practical adoption, and real-world accountability.

In this sense, eFishery’s journey offers a cautionary lesson. While their tech platforms promised better visibility and efficiency, they struggled with core challenges: inconsistent data inputs, lack of integration across the supply chain, pressure to show quick success for investors. These gaps weakened the credibility of the data collected, making it difficult to deliver traceability that global buyers can trust. Their eventual collapse, tied to allegations of financial misconduct at the managerial level, underscores a deeper truth: traceability requires more than apps and automation. It depends on accurate, verifiable data, independent oversight, and a system designed to reflect on-the-ground realities, not just boardroom expectations.

The pressure is mounting. In July 2025, the U.S. confirmed a 19% tariff on Indonesian shrimp, lower than the earlier 32%, but still a sign that price alone won’t cut it.

Vietnam now faces a 20% tariff, India 34%, while Ecuador, thanks to strong trade deals and integrated systems, sits at just 14%. Elsewhere, standards are tightening. The EU is enforcing its Deforestation Regulation and labor checks, while markets like South Korea and the Middle East are starting to require better supply chain documentation.

ry entry point. At the same time, buyers are willing to pay more for products as an encouragement to the suppliers so they can comply to prove their transparency and sustainability efforts. All of these are being done to fulfill the responsibility to the end customers. To stay in the game and move up the value chain, we must meet both the minimum requirements and the premium expectations.

To stay competitive, Indonesia’s shrimp industry must treat traceability as a collective effort, not just a task for farmers. Systems must function in low-connectivity areas and involve active input from processors and exporters. But private sector effort alone won’t be enough.

With the EU set to ban imports of untraceable seafood from Indonesia by September 2026, government leadership is critical. Clear standards, infrastructure support, and credible enforcement mechanisms must follow. Without coordinated action, Indonesia risks losing access to markets that are no longer willing to trade on trust alone.

At Mida Trade Ventures, we recognize the importance of practical, end-to-end traceability and are exploring ways to support systems that are grounded in the realities of the field; reliable, usable, and built to last.

Indonesia remains competitively placed, but that window is narrowing. In many key markets, especially the EU and U.S., traceability is no longer optional; it’s becoming a regulato- THE CRUST - MIDA

Shrimp farming continues to face a range of complex challenges. External factors such as disease outbreaks, declining water and environmental quality, and rising electricity costs all play a significant role in determining the success of a farming operation.

In terms of water management, maintaining good water quality is becoming increasingly difficult, especially with the impacts of climate change and growing pollution –particularly from microplastics. These tiny plastic particles can be ingested by shrimp, directly affecting their health. In addition, microplastics provide a surface for viruses like WSSV (White Spot Syndrome Virus) to replicate. The situation is further exacerbated by poor biosecurity practices and lack of proper waste management on many farms.

Faced with both environmental pressures and rising production costs, Kamaru Budianto, Marketing and Sales Director at Yuki Water, proposed the use of a set of green water systems during the 2025 Shrimp Aquaculture Conference as a way to address these growing challenges.

Recirculating Aquaculture System

Although the Recirculating Aquaculture System (RAS) isn’t a new technology, Kamaru sees it as a promising solution. It’s still rarely used in shrimp farming, largely due to a common misconception that RAS must always be operated indoors, which he said isn’t true.

According to Kamaru, RAS actually offers a lot of flexibility. One major benefit is water efficiency. Since the system reuses the same water throughout the cultivation cycle, it can drastically reduce overall water use. Another advantage is biosecurity. As a closed system, RAS helps protect against external disease outbreaks and reduces dependence on external water sources like industrial wells. With proper water treatment in place, the system stays clean with less effort, because the water is constantly being filtered and reused.

Kamaru Budianto

Since dissolved oxygen (DO) has a direct impact on shrimp health and growth, its concentration needs to be maintained above 4 ppm and distributed evenly throughout the entire pond. Farmers typically rely on paddlewheels to increase DO, but according to Kamaru, these mainly improve oxygen levels at the surface. As a result, DO levels near the pond bottom are often much lower.

“It will be pretty low. And shrimp are bottom dwellers— they’re not fish. That’s why they need high DO at the bottom of the pond, not in the middle, not at the top. Once you do this test, you’ll understand why your shrimp are vulnerable to disease: they’re not getting enough dissolved oxygen, and you’re wasting a lot of electricity on a technology that isn’t working as effectively or efficiently,” he said.

Kamaru added that DO levels are influenced by four main factors: bubble size, water movement, contact time with water, and water temperature. With these factors in mind, he introduced a product called Mazzei, designed to increase DO by thoroughly mixing air with every drop of water. As a result, the water flowing into the pond is consistently rich in oxygen, thanks to more effective mixing, extended contact time along the pipeline, and the use of microbubbles.

The next solution Kamaru proposed is the use of UVC technology along with its filtration system. While the initial investment may be relatively high, it becomes more cost-effective in the long run—especially when compared to the rising cost of chlorine over a 10-year period, which is the typical lifespan of a UVC system. This is because chlorine dosing tends to increase over time as disease pressure rises.

To maximize the effectiveness of UVC treatment, having a proper pre-filter system is essential. Why are pre-filters so important? Because they help clarify the water, allowing the UVC disinfection system to perform at its best. Kamaru said that one of the main limitations of UVC systems is their reduced effectiveness in turbid water. When water contains many suspended particles, especially fine ones around 30 microns, the UV light can’t penetrate properly, giving pathogens places to hide.

This is why underperforming UVC systems are often the result of either inadequate pre-filtration or poor-quality equipment. A proper pre-filtration setup typically includes two key components: mechanical filters and biofilters.

Mechanical filters are designed to remove larger particles such as sand, clay, and other suspended solids. However, with the right design and sizing, these filters can also capture smaller pollutants like microplastics, heavy metals, and disinfection byproducts, which can pose serious risks to shrimp health and water quality.

Biofilters, on the other hand, work by cultivating beneficial bacteria that help break down toxic compounds in the water. These bacteria convert harmful ammonia into nitrite, and then into less harmful nitrate, significantly improving water quality and helping maintain a more stable and healthy pond environment.

It’s perfectly understandable that shrimp farmers want to grow their crops as quickly as possible. Logically, if every day in the cultivation cycle carries risk, then shortening the growout period, by accelerating shrimp growth, means reducing that risk. The most common way to boost growth is by feeding, especially with high-protein diets.

While this is a valid cultivation strategy, excessive feeding— particularly with high-protein feed—comes with its own set of consequences. One of the main issues is the increase in organic waste, which can lead to a higher frequency of water exchange. Insufficient water exchange can lead to increased ammonium levels, higher plankton density, and elevated organic matter. These conditions can trigger harmful microbial blooms such as Vibrio.

Rubiyanto Haliman, AVP and Deputy Head of the Technology Division at CP Prima, shared at the 2025 Shrimp Aquaculture Conference that to reduce the buildup of organic matter in shrimp ponds, farmers often rely on frequent water exchange.

For example, if a farmer uses feed with 28% crude protein (CP), it’s recommended to exchange at least 2.5 metric tons of water for every kilogram of feed given. If the protein content increases to 32%, the water exchange should also be increased to around 3.5 metric tons per kilogram. And if the protein level rises to 36%, ideally, the water exchange should go up to 4 metric tons per kilogram of feed.

“So, as the protein level in the feed increases, proper water management becomes even more critical to maintain water quality and support healthy shrimp growth,” Rubi explained.

He also pointed out that feed is the largest cost component

in shrimp farming, and higher protein means higher production costs. While high-protein diets can help accelerate growth, they also bring greater financial challenges.

On the regulatory side, the government, through the Indonesian National Standard (SNI), has set minimum protein requirements for shrimp feed: 30% for the grow-out phase and 28% for the finishing stage before harvest.

Rubiyanto Haliman

“But starting two or three years ago, some farmers and feed producers started to introduce a high level of protein contents up to 35-36 percent, which, if you compare with the terrestrial animals, is much higher,” kata Rubi

The use of high-protein feed for shrimp may need to be reconsidered. Research shows that using feed with lower protein content, but given more frequently, yields results that are not significantly different. From an environmental perspective, low-protein feed also tends to be more eco-friendly. “This finding opens up opportunities for optimizing feeding strategies without compromising shrimp health or yield,” Rubi said.

Instead of focusing solely on crude protein content, farmers and feed producers should start paying closer attention to something more fundamental namely the amino acid profile, particularly essential amino acids like methionine and lysine. In a balanced diet, methionine and lysine should make up approximately 1.7% and 4.5% of the feed, respectively.

In fact, aquatic animals like shrimp and fish require digestible protein more than crude protein. Digestible protein is made up of essential amino acids, often referred to as true protein. The amino acid profile in a feed formulation is critical for maintaining feed quality and ensuring optimal growth.

The digestibility of protein, specifically the amino acid composition, plays a crucial role in feed efficiency. Methionine and lysine are key limiting amino acids, and if not present in sufficient quantities, the shrimp cannot synthesize protein effectively. This means that even a feed with high crude protein can be ineffective if its amino acid profile is unbalanced.

Eco-friendly shrimp feed, by using the concept of true protein, offers a balanced approach by providing sufficient nutrients while minimizing pollution and cost. Defined as feed with adequate protein that does not excessively pollute pond water, eco-friendly options help reduce total organic matter, ammonia concentration, and plankton instability. They are also more economically viable, as feed accounts for at least 50% of total production cost.

In summary, the adoption of eco-friendly feed represents a promising strategy for Indonesian shrimp farmers to navigate current economic and environmental challenges. Rubi concluded that by focusing on digestibility, amino acid balance, and water quality management, the industry can move toward more sustainable and cost-effective production systems.

If you’ve ever noticed that shrimp in one restaurant look pale and pink, while in another they’re a bold, glowing red. You’re not imagining things. Around the world, people have very different ideas about what “good shrimp” should look like, and color plays a surprisingly big role.

This isn’t just about presentation. It’s about tradition, culture, and expectation, and the choices made by farmers and processors to satisfy them. Let’s take a quick trip around the globe to understand how shrimp color is seen differently in three of the biggest shrimp market: China, the United States, and Europe, and what it means for the shrimp on your plate.

In China, red isn’t just a color, it’s a symbol of luck, celebration, and prosperity. So, it’s no surprise that shrimp that turn bright red when cooked are especially prized. Chinese buyers often prefer shrimp with a color grade known as A4, a rich, deep red that stands out in dishes like hot pot, seafood platters, and banquet spreads.

Shrimp that are less red, even if they taste the same, may be considered lower quality by local consumers. That’s why exporters work hard to select or process shrimp that hit that perfect red tone. The right appearance can be just as important as freshness or size.

U.S.A.

American consumers, on the other hand, tend to focus more on flavor, convenience, and value. A nice pink or orange tint in cooked shrimp is familiar, but color isn’t a deal-breaker. Whether it’s grilled, sautéed, or chilled for a shrimp cocktail, people care more about whether the shrimp is juicy, well-cooked, and satisfying.

Because of this, producers don’t have

to tailor the color of shrimp as precisely for the U.S. market. As long as it’s safe, tasty, and reasonably priced: it sells.

In Europe, especially in countries like Germany, France, and the Netherlands, consumers tend to avoid shrimp that look too red or shiny. Bright colors can seem unnatural, even if no coloring agents were used. Here, the ideal shrimp cooks to a gentle, natural pink, without looking overly processed or artificial.

This preference comes from a broader cultural emphasis on clean labels, transparency, and minimal processing. If a shrimp looks “too perfect,” some European shoppers might suspect additives or chemical treatment, even when none are involved.

Here’s the surprising part: Most of the shrimp sold around the world are actually the same species, vannamei, or whiteleg shrimp. The difference in color comes from how the shrimp are handled, cooked, and sometimes even what they eat before harvest.

Exporters and farmers work behind the scenes to match these different preferences. They adjust feed, cooking times, and processing techniques, all so the same shrimp can meet the expectations of different countries.

Next time you see shrimp in the grocery store or on your dinner plate, take a moment to notice the color. Whether it’s light pink or deep red, that shrimp likely went through a carefully controlled journey to match what someone, somewhere, believes shrimp should look like.

Because in the global shrimp business, color isn’t just a visual detail, it’s a message. And getting it right takes a surprising amount of effort.

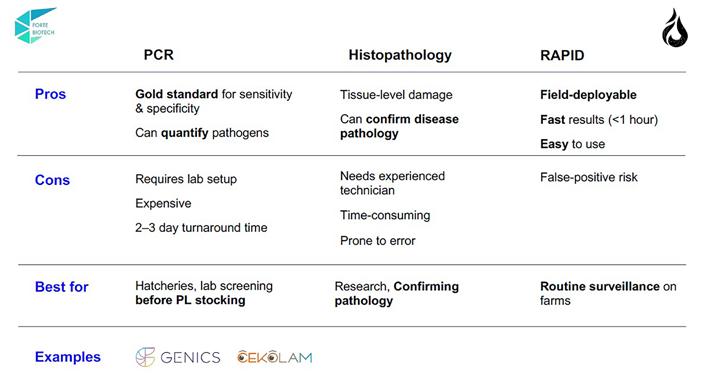

hrimp farming is big business, but also a risky one. Every year, shrimp producers face billions of dollars in losses due to disease outbreaks. Despite modern techniques and better infrastructure, farmers often rely on gut feeling, delayed diagnostics, or outdated lab reports. In such a high-stakes environment, access to fast and reliable disease detection could mean the difference between profit and total crop loss.

Kit Yong, Founder of Forte Biotech, knows this all too well. His interest in shrimp farming began not in a lab, but at home. His uncle, a shrimp farmer in Malaysia, often asked him to translate English-language research articles. This hands-on exposure to real farming issues sparked a passion for bridging the gap between science and practice. “I had to tell him, ‘Don’t put chlorine in the ponds,’” Kit recalled. “That’s when I realized how little access farmers had to the right information,” he said at the 2025 Shrimp Aquaculture Conference.

Over time, Kit saw how shrimp farming sometimes resembled gambling. “You might get lucky the first few times. But if you don’t know what you are doing or what is happening in your pond, you will eventually lose,” he said.

Diseases like Enterocytozoon hepatopenaei (EHP), white spot, and Infectious Myonecrosis Virus (IMNV) are notorious in the industry. EHP can cause stunted growth, leading to poor feed conversion and reduced harvest weight. White spot kills shrimp rapidly. IMNV adds another layer of unpredictability. Altogether, Kit estimated that these and other pathogens cost the industry up to USD 2 billion annually.

The root causes, he explained, often boil down to two simple factors: greed and laziness. Overstocking to maximize profit can overstress shrimp. Poor pond preparation or unverified postlarvae (PL) sources invite pathogens. In one case, he cited, a farmer in Vietnam purchased PLs from 31 different hatcheries, each one accompanied by a clean PCR certificate. Independent testing, however, revealed that 90% of those samples

carried EHP.

Kit emphasized that without reliable diagnostics, farmers are left guessing. “If you cannot tell whether your shrimp are sick, you cannot make informed decisions. By the time symptoms appear, it’s often too late,” he said.

To solve this challenge, Kit and his team developed RAPID, which is Really Accurate Prone Infection Detector. It is a portable, fieldfriendly device designed to bring laboratorygrade diagnostics directly to shrimp farms. Unlike traditional Polymerase Chain Reaction (PCR) testing, which can take days and requires expensive equipment, RAPID delivers results in under one hour.

“The idea was to make it so simple, even a drunk farmer could use it,” Kit joked. But behind the humor lies serious innovation. RAPID can detect multiple diseases from a single sample and match the sensitivity of quantitative Polymerase Chain Reaction (qPCR), down to 10 copies per reaction. It does not require cold storage, centrifuges, or advanced lab skills. Farmers simply collect the sample, follow basic disinfection protocols, and run the test.

Forte Biotech also offers RAPID Plus (for higherprecision diagnostics), Rapid Max (for highvolume farms), and PCRcompatible reagents for those with existing lab infrastructure. Each solution is designed to meet different operational needs while preserving ease of use.

Kit likened the value of early detection to driving a car with a working fuel gauge. “You would not drive blind, not knowing when to refuel. That is how a lot of farmers operate today,” he said.

A striking example of RAPID’s impact comes from a growout farm in Sarangani, Philippines. After noticing that two sideby-side ponds were behaving differently, one showing sudden mortality, the other healthy, the farm used RAPID to test both. It detected AHPND in the “healthy” pond, even before symptoms appeared. The farm responded by isolating the area and applying probiotics and stricter biosecurity measures. Two months later, the shrimp were still growing normally with good feed conversion and minimal mortality.

Kit urged farmers not to rely solely on visual symptoms or wait for outbreaks before taking action. “Routine surveillance, testing weekly or biweekly, lets you act fast. You can apply treatment early, quarantine infected ponds, and avoid wasting medication on healthy stock,” he said.

He closed with a call to action. “We cannot control tariffs, market prices, or weather. But we can control how smart and efficient we are in farming. That is where the power lies.”

At the Shrimp Aquaculture Conference (SAC) 2025, the second day talk show titled “Live After eFishery Scandal” convened some of the region’s sharpest voices in aquaculture, investment, and policy to address the industry’s most pressing crisis, the collapse of eFishery. Once hailed as Indonesia’s flagship aquaculture tech unicorn, eFishery’s downfall due to alleged fraud sent shockwaves far beyond the shrimp sector.

Moderated by Cynthia Darmawan, COO of Delta Marine Group, the session opened with a sober reminder of how eFishery symbolized the promise of agri-tech transformation in Southeast Asia. “It wasn’t just a startup. “It was a symbol of what was possible,” Cynthia said.

Fred Puckle Hobbs, co-founder of Tathva, a Singapore-based blue economy advisory firm, was among the first panelists to speak. “This wasn’t a case of unfortunate market conditions, it was a textbook fraud,” he said. “And worse, many investors never asked the right questions. There was too much pressure to grow and too little oversight.”

Fred emphasized that while the collapse was damaging, it did not reflect the health of the shrimp industry as a whole. “Farming hasn’t stopped. Shrimp are still being produced and sold. What failed was not aquaculture, but the expectations placed upon it by venture

capital looking for unicorns.”

Faizil Ikram, Principal at MDI Ventures, Telkom Indonesia’s venture capital arm explained how investor excitement played a role in enabling eFishery’s growth beyond its core. “The original pitch was strong: solving productivity through IoT feeders and connecting farmers to the supply chain,” he said. “But then it shifted toward trading, informal lending, and unsustainable burn rates, all in pursuit of scale.”

Faizil also noted how eFishery’s downfall impacted the broader investment climate. “Foreign investors now question Indonesia’s startup governance. They wonder if due diligence is enough, if the legal system protects their capital. The ripple effect is real, and we’re seeing funding dry up, not just in aquaculture but across agritech.”

Doni Ismanto Darwin, Special Staff from the Indonesian Ministry of Marine Affairs and Fisheries expressed the government’s disappointment noting that they had supported eFishery. He stressed that while the government doesn’t regulate startup business models directly, the need for a stronger ecosystem and better governance is now clear. “We need to protect the farmers and the ecosystem they rely on. This includes ensuring that startups don’t monopolize or distort the sector with unchecked influence,” he added.

George Samuel, a shrimp farmer and aquaculture entrepreneur, provided a reality check. “I run operations in Bangka, and I never saw eFishery offer their services there. So, when I saw the numbers they claimed, I knew something didn’t add up,” he said.

George also criticized the bandwagon behavior of many investors. “People kept asking, ‘Who else is investing?’ rather than ‘What is the actual business performance?’. Too many bets were placed on pitch decks rather than ponds.”

The panel discussion returned frequently to the importance

of governance and fundamentals. Fred pointed out that 90% of blue economy funding today comes in the form of grants and equity, and only 10% in sustainable debt. “This is backwards. Agriculture needs credit, not hype. It’s time we stop treating agri-tech like fintech with mud on its boots,” he insisted.

Despite the critical tone, the conversation ended on a hopeful note. The collapse of eFishery, panelists agreed, could serve as a reset rather than a ruin. “This doesn’t have to be remembered as a collapse, it can be a correction,” said Fred. “We still have the farmers, the markets, and the product. What we need is the right capital, the right questions, and honest storytelling.”

Doni encouraged more young Indonesians to enter aquaculture with integrity and innovation. “We have the market, and we have the momentum,” he said. “What we need now is collaboration, between startups, government, farmers, and financiers.”

The session concluded with a call to action, urging the industry to pause relying on unicorns to carry its future and instead build resilient, responsible systems from the ground up. As Cynthia noted in her closing, “This was never about one company. It’s about how we move forward as a sector, how we rebuild trust,

Rizky

Darmawan

Veni Vidi Fishy

Gemilang

Lim

My secret to joy in life is in finding balance Balance in family, sweating, and making decisions

Cover : Aladam