Hello and welcome to the June 2025 edition of THE CRUST. As the dust settles from SAC2025, many of us are still reflecting on the energy, conversations, and connections made during the event. What stood out the most wasn’t just the scale or diversity of participants—it was the shared determination to push this industry forward, despite the growing challenges we all face.

Last month’s event in Bali brought together over 300 stakeholders from across the globe, and in that gathering, we witnessed what happens when ideas meet action. From technical sessions to deepdive discussions, and from expert panels to groundbreaking product showcases, the message was clear: we’re not just surviving—we’re adapting, evolving, and building.

But as we turn the page to June, we’re reminded that the real work begins after the conference. The knowledge we gained, the solutions we discussed, and the collaborations we sparked must now be brought back to our farms, businesses, and communities. Whether it’s improved disease control, smarter data application, or finding strategic responses to trade uncertainty—this is the time to act.

Rizky Darmawan Chief Editor

And there is no shortage of new developments to keep our eyes on. This month, global attention turned toward ongoing negotiations around Trump’s reciprocal tariffs, as affected countries scramble to secure exemptions and protect their export sectors. The uncertainty around U.S. trade policies continues to unsettle global supply chains, with seafood—particularly shrimp—sitting at the center of these tensions. At the same time, China’s economic rebound remains tepid, casting doubt over demand recovery in one of shrimp’s most important markets.

Back home, shrimp prices remain volatile, and disease threats like EHP and white feces syndrome continue to challenge farmers across Indonesia and the region. It’s a tough season for many, but if SAC2025 reminded us of anything, it’s that this industry is full of fighters, innovators, and problem-solvers. The spirit we saw in Bali should now fuel the actions we take in the months ahead.

For those who missed SAC2025, don’t worry—the conversation continues. We’ll keep sharing insights and outcomes in the pages of THE CRUST. Let this be your monthly reminder that you’re not alone in this journey.

Shrimp farming is a major industry in Southeast Asia, but it continues to face a range of challenges—from environmental fluctuations and economic pressures to recurring disease outbreaks. Despite these issues, recent advancements in modern shrimp feeds are offering promising solutions to improve shrimp health, boost productivity, and promote sustainable growth across the sector.

At the Shrimp Aquaculture Conference (SAC) 2025 in Bali, fish nutritionist and aquafeed expert Dr. David Sutter, speaking on behalf of CJ Feed and Care, shared his insights on the role of modern shrimp feeds.

Sutter noted that countries in Southeast Asia—such as Vietnam, Thailand, and Indonesia—primarily rely on intensive or superintensive shrimp farming systems. These are typically characterized by small pond sizes and limited water exchange. In Indonesia, shrimp production largely follows this model, with intensive systems and relatively compact ponds. According to him, much of the recent growth in Indonesia’s shrimp sector has been driven by the cultivation of Vannamei shrimp.

“Despite a huge potential for further growth, Indonesia’s shrimp farmers face significant hurdles. These challenges are multifaceted, stemming from seasonal changes, water quality issues, prevalent disease outbreaks, and a global economic slowdown impacting the shrimp

market,” he explained.

Indonesia experiences distinct rainy and dry seasons, each bringing its own set of challenges. During heavy rains, a sudden influx of freshwater can cause pond temperatures to drop—sometimes by as much as 6°C. According to Sutter, this leads to hypo-osmotic stress, forcing shrimp to rebalance their internal systems, while lower temperatures reduce feed intake and weaken their overall resilience.

As a result, disease outbreaks become more common. White Spot Syndrome (WSS) and Enterocytozoon hepatopenaei (EHP) are currently widespread in Indonesia. Sutter warned that from January to April 2025, the country is likely to see a rise in WSS and EHP infections.

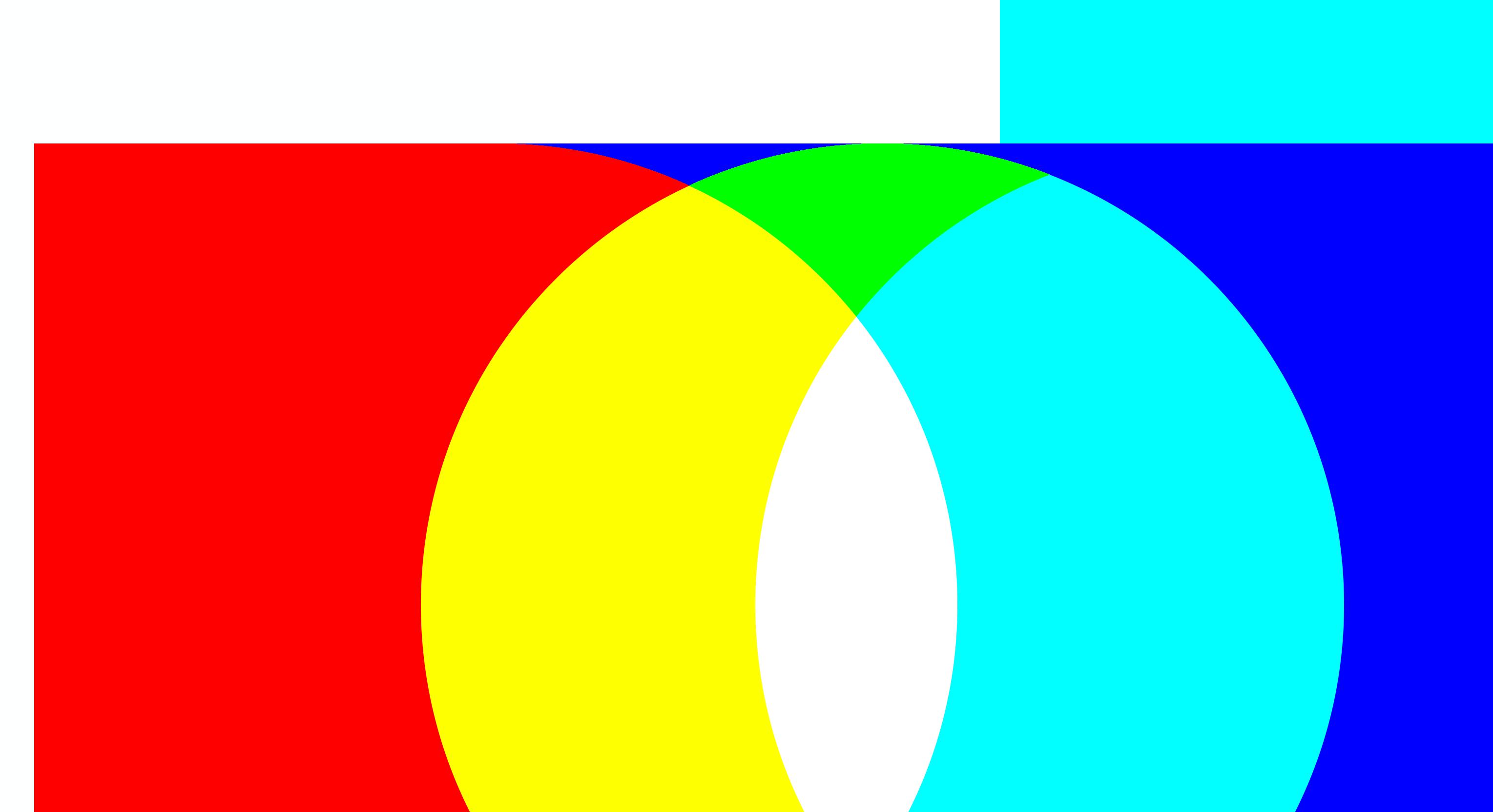

Sutter believes that one of the most effective ways to address these challenges is by improving feed quality and nutrient delivery. Feed stability plays a critical role—when feeds are unstable, they tend to lose essential nutrients like phosphorus, nitrogen compounds, and carbohydrates into the water. Instead of benefiting the shrimp, these nutrients end up enriching the pond environment, which can lead to water quality issues.

“This not only wastes nutrients but can also negatively impact the pond environment and the broader ecosystem. Therefore, good feed stability is essential to reduce nutrient losses and ensure more nutrients reach the animal”, he said.

In addition to stability, Sut-

ter emphasized the importance of nutrient digestibility. Shrimp naturally release nitrogen compounds, especially ammonia, as part of their metabolism. When feeds contain nutrients that are difficult to digest, more phosphorus, nitrogen, and carbohydrates are excreted as waste, which can accumulate and disrupt the pond environment. For that reason, both feed stability and nutrient digestibility are absolutely essential.

One of the main focuses of his research has been optimizing phosphorus delivery. Feeds typically draw phosphorus from three sources: animalbased ingredients like fishmeal, plant proteins— where much of the phosphorus is bound in indigestible phytate—and mineral additives. His research shows that finetuning phosphorus levels can significantly boost feed efficiency, lowering the feed conversion ratio (FCR) and greatly enhancing shrimp growth.

Protein and amino acid supply are both crucial— and closely connected—for shrimp growth and health.

Sutter explained that essential amino acids, which are the building blocks of protein, must be provided through the feed for opti-

mal shrimp growth. Each essential amino acid has an optimal level needed to support the best performance.

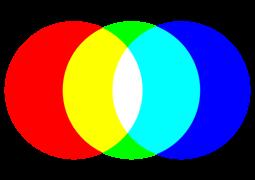

Protein and amino acid supply are also critical and interdependent. Sutter explained that essential amino acids, which are the building blocks of protein, must be provided through the feed to support shrimp growth. Each essential amino acid has an optimal level for shrimp performance: if the supply falls short, growth is limited; if it’s too high, performance can also decline. For example, an excess of certain amino acids like methionine can actually reduce growth. That’s why finding the right balance is so important. “High protein alone doesn’t guarantee the best growth,” Sutter explained. “It’s really about the balance

THE CRUST - RZ, AB

Dr. David Sutter

At the Aquaculture Shrimp Conference 2025, Dr. Benedict Standen, Head of Aquaculture Marketing Global at dsmfirmenich, delivered a compelling presentation on the concept of smart pathogens, with Vibrio as the prime example. Unlike many pathogens that can be managed through simple elimination or reduction strategies, Vibrio presents a far more complex challenge.

“They’re everywhere,” Standen explained, emphasizing that Vibrio species are a natural part of aquatic ecosystems, including those where wild shrimp live. In fact, up to 20% of the microbial community in wild shrimp may consist of Vibrio. Rather than trying to eliminate them, farmers should focus on building the shrimp’s resilience so they can thrive despite the presence of Vibrio.

of the most striking observations shared was that Vibrio load in healthy shrimp is often similar to that in diseased shrimp. The difference lies in what those bacteria are doing. It’s about virulence, not volume. Some Vibrio strains can remain benign until environmental conditions trigger their shift into a harmful, toxin-producing state.

effect.

This adaptability comes down to several key traits. According to Standen, Vibrio species are Rstrategists—they multiply quickly and take advantage of nutrientrich or sterile environments with little microbial competition. Ironically, common aquaculture practices like excessive disinfection or overfeeding can create ideal conditions for Vibrio to thrive. Probiotics, often introduced too late, struggle to establish themselves. The message is clear that prevention must begin early, giving beneficial microbes a head start before Vibrio gains a foothold.

Even more concerning is Vibrio’s ability to form biofilms— protective communities that adhere to pond liners, feeders, or aerators. Within these hidden zones, bacteria communicate via quorum sensing, protect themselves from treatments, and wait for a moment, such as a temperature change or weakened shrimp immunity, to attack.

“Like anything biological, they’re also changing and evolving. And very often these evolutions make them stronger,” he said.

Another crucial strategy in the fight against Vibrio is disrupting its communication system, also known as quorum sensing. In simple terms, quorum sensing is how bacteria “talk” to each other using chemical signals. This communication allows them to coordinate behaviors such as forming biofilms or increasing virulence. It’s essentially how bacteria move from being harmless individuals to a dangerous threat.

What makes Vibrio a “smart” pathogen is not merely its presence or abundance, but its behavior. One

According to Standen, outsmarting Vibrio requires farmers to be just as strategic as the pathogen itself. The focus must shift from reacting to disease outbreaks to building a layered, preventative defense system, from water and feed management to advanced microbial interventions. “When I talk about a war, it really is a war,” said Standen.

One of the most promising innovations discussed is the development of targeted pathogen inhibition tools. Working with dsmfirmenich, Standen’s team has focused on defeating Vibrio at the structural level. Since Vibrio are gramnegative bacteria, they have an outer membrane, like a protective shell. To kill them effectively, this shell must first be breached. That’s where the socalled “permeabilizing complex” comes in.

By breaking down the membrane, this complex allows other antimicrobial agents to act more effectively. Backed by lab tests in Austria, dsmfirmenich’s researchers have demonstrated this approach using dyes that signal membrane damage, clearly showing how the tech-

Dr. Benedict Standen

For example, Vibrio harveyi can even use quorum sensing to trigger bioluminescence—a visible sign of bacterial coordination. The way to interfere with this process is through quorum quenching by using natural agents such as probiotics, phytogenics, or plantderived compounds to “cut the phone lines” between bacteria. For example, Bacillus probiotics have demonstrated strong quorum-quenching effects, significantly reducing bioluminescence and biofilm formation. This lowers virulence, even when the bacteria themselves are still present.

In addition, functional ingredients like cinnamaldehyde, a compound derived from cinnamon, offer further tools to reduce Vibrio’s ability to cause harm. In lab tests with Vibrio harveyi, adding cinnamaldehyde didn’t immediately reduce bacterial abundance, but it did significantly suppress their quorum sensing ability, as indicated by reduced bioluminescence. At higher concentrations, cinnamaldehyde even began to kill the pathogen directly.

As Indonesia continues to climb the ranks of global shrimp exporters, one company is setting its sights on transforming the nation’s aquaculture landscape. Haida Group, a leading Chinese agribusiness giant, is making major strides in Indonesia through its local subsidiary, Haida Indonesia. In a recent presentation at the 2025 Shrimp Aquaculture Conference, the company outlined its ambitious plans to modernize shrimp farming, enhance feed quality, and build a more resilient and productive industry.

Wu Xiao Guo, R&D Manager of Haida Agriculture Indonesia, explained that Haida is no newcomer to the sector. With over 600 global subsidiaries and operations in more than 10 countries across Asia, Africa, and the Americas, the group has firmly positioned itself as a pioneer in aquaculture innovation. In 2024, Haida recorded a staggering 26.52 million tons in total feed sales, with aquafeed accounting for 5.6 million tons, making it the global leader in the segment.

“Central to Haida’s success is its strong commitment to research and development. The company boasts over a thousand postgraduates and seven specialized research institutes. This robust intellectual backbone allows Haida to continually push the boundaries of productivity and sustainability, especially in shrimp farming,” Wu said.

He mentioned that in Indonesia, shrimp export performance is promising, currently ranking fourth globally, but there is room for growth. One key market yet to be fully tapped is China, the world’s

largest shrimp importer. To penetrate this competitive market, Haida emphasizes the importance of meeting specific buyer demands, particularly in terms of quality and production practices.

Haida has evaluated three dominant shrimp farming models in Indonesia, including traditional cement ponds, large flat plastic film ponds, and smaller inclined plastic film ponds. Each comes with its advantages and limitations in terms of space, yield, and technological requirements. To address these challenges, Haida introduced a new concept, the Automatic Drainage High Production System (ADHP) model.

Launched in 2018, this model integrates advanced technology, efficient water management, and smart production strategies. Haida has already established an ADHP demonstration farm on Bangka Island, which has welcomed over a thousand visitors, including farmers, technicians, and potential partners. According to Wu, this model can significantly increase yield per square meter while minimizing disease risks, common bottlenecks in traditional farming methods.

However, the ADHP model demands a balance of three core elements: technology, management, and products. “If anyone is missing, the model won’t be sustainable,” Wu emphasized.

In shrimp aquaculture, feed costs represent a significant share of production expenses, 50-55%. Recognizing this, Haida has invested heavily in high-quality feed development and processing

technologies. The company employs a range of advanced machinery, including ultrafine grinders and high-temperature sterilization processes, to enhance feed texture, digestibility, and water stability.

Haida’s feed manufacturing process involves heating at temperatures above 100°C for more than 30 minutes, which not only improves durability in water but also plays a critical role in eliminating harmful pathogens. Scientific studies by Haida show that high heat treatments can inactivate dangerous viruses like White Spot Syndrome Virus (WSSV) and pathogens such as Enterocytozoon hepatopenaei (EHP), both major threats to shrimp farming.

To ensure product consistency, Haida applies rigorous quality control measures aligned with ISO 9001, HACCP, and BAP certifications. All feed data is digitally tracked and analyzed through a centralized server system, allowing real-time monitoring of raw materials and production output. This level of oversight, combined with strict SOP adherence, reduces dependency on manual labor and strengthens production reliability.

Another exciting direction is Haida’s move into animal health products, complementing its nutritional offerings with solutions for disease prevention and farm hygiene. This holistic approach will form the backbone of an integrated service model that merges product excellence, technical training, and real-time farm support.

Beyond product development, Haida aims to strengthen its local technical support team, which currently includes over 100 aquaculture professionals. By upskilling university graduates and local technicians, while also engaging Chinese experts, Haida hopes to build a vibrant, well-trained community of aquaculture specialists who can support shrimp farmers nationwide.

In its final message, Wu expressed a clear vision to create a comprehensive, systematic aquaculture service in Indonesia. This will begin with top-tier products, followed by technological development, and culminate in the establishment of a sustainable farming model tailored to local conditions. “Backed by the strength of Haida Group’s global R&D and supply network, Haida Indonesia is well-positioned to become a catalyst for growth in the country’s shrimp farming sector,” he concluded.

THE CRUST - DEE, AB

Wu Xiao Guo

Dr. Albert G. J. Tacon, founder and owner of AquaHana LLC, brought over 50 years of expertise in aquatic feeds and nutrition to the Shrimp Aquaculture Conference (SAC) 2025 in Bali. In a presentation titled “Nutritional Approaches to Improving Larval Shrimp Quality and Performance”, delivered in collaboration with Erwin Suwendi of STP, he explored key challenges in shrimp farming. The talk highlighted the importance of innovative nutritional strategies and the shift toward more controlled, sustainable hatchery production systems.

Tacon highlighted a key challenge in hatchery operations: feed selection is often made by technicians rather than nutritionists. He emphasized that everything found in live feeds— enzymes, hormones, and other nutrients—can be replicated in formulated dry feeds. In his view, the future of hatchery management lies in simplifying the process. He stressed that larval quality is directly linked to the quality of broodstock, genetics, and, most importantly, the larval feed. “Quality larvae can only be produced with quality feed,” he stated, underscoring the fundamental importance of this often-overlooked principle.

When it comes to feed formulation, Tacon explained that over 40 to 50 essential nutrients must be included in biologically available forms. He proudly referenced STP’s success in producing feeds that have shown strong results among farmers. The guiding philosophy, he noted, is to support farmers— because when farmers fail, feed sales stop. “While all essential nutrients are vital, some may be more critical for broodstock. Ultimately, animal metabolism relies on glucose, and a complete spectrum of essential minerals, vitamins, and fatty acids is necessary”, he added.

Looking to the future, Tacon highlighted algae, yeast, bacteria, and hydrolysates as promising sources of DHA and EPA. He noted that wild shrimp feed on natural ingredients, such as seaweed and crabs—not soybean meal, which is commonly used in formulated feeds—underscoring the importance of replicating natural diets for improved performance.

Despite the growing variety of available ingredients, he pointed out a major gap in nutritional research: most studies focus on the grow-out phase, while the specific dietary needs of nauplii, mysis, post-larvae, nursery stages, and broodstock remain largely under-researched.

Tacon emphasized that five key factors ultimately determine whether a feed succeeds or fails—whether it’s for larvae, broodstock, or grow-out production. He began by highlighting the importance of the culture system and, critically, water quality. Oxygen, he stressed, is even more important than feed, with a minimum of 5 ppm required for the animal to properly digest food. Achieving adequate oxygen levels necessitates efficient aeration systems, moving beyond conventional perforated tubes to more advanced solutions like aero tubes.

He made it clear that even the best-quality feed will fall short if these fundamental conditions aren’t properly managed. He illustrated this with the concept of “specific dynamic action,” noting that shrimp’s oxygen consumption drops significantly when they are fed only once or twice a day, compared to more frequent, smaller feedings.

The second factor is live food selection and nutrient levels, which also applies to feed selection. While artemia is popular, Tacon noted its lack of DHA and other essential nutrients, making enrichment necessary. He emphasized that feed selection and nutrient content are critical—whether using live food or encapsulated feed— and that feeding methods may vary depending on financial resources.

The third critical factor is leaching and water stability. Tacon explained that every second a feed remains in the water uneaten, nutrients are lost through leaching. Higher water temperatures and lower salinity further exacerbate this issue. He stressed that shrimp feed continuously— not just a few times a day— lation. Leaching, he reiterated, refers to the loss of water-soluble nutrients, which leaves the pellet physically intact but nutritionally empty. Therefore, feeding frequency is making leaching a serious concern. The physical characteristics of the feed, including particle size and water stability, are vital to optimal formu-

extremely important to mimic the natural, continuous feeding behavior of wild shrimp.

The fourth factor is feed transportation and storage. Tacon argued that a feed company’s responsibility doesn’t end at production—it also includes ensuring proper transportation and on-farm storage. He cited his experience with a 6,000-hectare farm in Mexico to highlight the complexities of managing feed on such a large scale. Similarly, the quality of algae or enriched artemia also depends heavily on how they are transported and stored.

The fifth and final factor is the feeding system, including feeding rate and frequency. Tacon noted that, ironically, the most critical personnel in a hatchery or farm—those responsible for feeding—often receive the lowest wages. “Effective feeding management is paramount to replacing live foods like polychaetes,” he ex-

At Mida Trade Ventures, we’ve always believed in the transformative power of aquaculture and in the role technology can play in driving efficiency, traceability, and value throughout the seafood supply chain. That belief is what brought us to SAC 2025 in Bali, where one of the most urgent and widely discussed topics was the collapse of eFishery — a defining moment for aquaculture not just in Indonesia, but across Southeast Asia.

The session gathered leading voices from government, investment, sustainability, and industry. While many themes emerged, one in particular struck a chord with us and others involved in shrimp: the concept of scale, and how quickly it can become an illusion when not grounded in reality.

For several years, eFishery was widely regarded as a trailblazer in Indonesia’s aquaculture tech space. Starting with smart-feeding devices, the company rapidly expanded into digital platforms, farmer financing, and shrimp trading. On paper, the growth was remarkable, thousands of connected ponds, simplified access to credit for farmers, and a seemingly seamless,

vertically integrated ecosystem.

Yet beneath the surface, questions lingered about how sustainable and grounded that scale truly was. While the company’s vision captured attention, those closer to day-to-day aquaculture operations recognized the immense complexity involved in managing such a widespread and multi-layered system.

As noted during the panel, managing a network of farmers, logistics, and financial services at that scale isn’t impossible— but it demands significant capital, robust infrastructure, and operational discipline. In hindsight, some of the growth targets and reported metrics may have outpaced what the organization could realistically support on the ground.

Growth is essential to progress in any industry, especially one as dynamic as aquaculture. However, when it exceeds a company’s internal capacity, lacks financial discipline, and stretches governance frameworks beyond their limits, it becomes difficult to sustain.

In eFishery’s case, the company expanded beyond its original focus on smart-feeding technology into areas like shrimp trading and farmer financing. These moves required not only different business models, but also deeper operational control and risk management—areas where the organization may not have been fully prepared.

Panelists noted that while the company’s evolution appeared innovative from the outside, the pace of change may have outstripped its internal systems and talent. In fast-moving sectors like aquatech, early warning signs are often masked by impressive growth figures. But growth alone, if not anchored by strategy and structure, can quickly become unstable.

So what should the rest of us take away from this?

At Mida Trade Ventures, we operate between global buyers and Southeast Asian producers. We recognize the value of technology in improving traceability, market access, and operational efficiency. But this moment reminds us to ask tougher questions:

Is growth driven by real market demand, or by vanity metrics?

Are we creating solutions that truly fit into the day-to-day of shrimp farming, or simply layering tech on top of unresolved

THE CRUST - MIDA

structural issues?

Are we building long-term systems that support farmers not just with data, but with infrastructure, fair pricing, and resilience?

eFishery’s fall isn’t just a cautionary tale — it marks a turning point for the industry. As we look ahead, stake holders across the aquaculture ecosystem must shift their focus from rapid expansion to building resilience and long-term value. Technology providers need to develop solutions grounded in the reali ties of farm operations, while investors must go beyond surface-level growth metrics and examine the strength of governance and business fundamentals. Regulators have a key role in ensuring that innovation in strategic sectors like aquaculture is matched with appropriate oversight. At the same time, farmers and operators should be discerning in choosing partners that truly support their productivity and sustainability.

At Mida Trade Ventures, we believe the path forward lies in transparency, collaboration, and trust. Scale will always matter—but only if it’s built to last.

In shrimp aquaculture, the stakes are high when it comes to disease prevention. Pathogens such as white spot virus (WSV), Enterocytozoon hepatopenaei (EHP), Vibrio species that cause Acute Hepatopancreatic Necrosis Disease (AHPND), and Infectious Myonecrosis Virus (IMNV) continue to challenge Indonesian farmers. While white spot, EHP, and Vibrio are global threats, IMNV remains a unique concern in Indonesia.

As highlighted by Melony Sellars, CEO of Genics, at the 2025 Shrimp Aquaculture Conference, each of these pathogens can cause major economic losses—whether through mass mortality or by reducing growth rates and feed efficiency over time. That’s why biosecurity isn’t just a best practice—it’s a critical necessity.

To be truly effective, farmers need to apply robust biosecurity measures at three key stages of the production cycle: pond preparation, water treatment, and feed management.

The first crucial stage is pond preparation. In Indonesia, many farmers use HDPE-lined ponds, which offer benefits in terms of cleanliness and easier maintenance. However, these liners also come with certain vulnerabilities. According to Melony, it’s essential to inspect the pond liners thoroughly for any tears or damage after the harvest. Even small rips can create hiding spots for pathogens—especially hardy, spore-forming ones like EHP—that survive in the moist sediment beneath. If not properly addressed, these pathogens can easily infect the next crop.

Effective pond preparation includes thoroughly drying and liming any exposed sediment, followed by proper repair and sealing of the pond liners. One area that often requires special attention is around the outlet, which is a common hotspot for lingering pathogens. Cutting out and rewelding this section can significantly reduce the risk of recontamination. Additionally, pathogen testing—whether on harvested shrimp or pond sludge—provides valuable insights into which pathogens are present, enabling farmers to tailor their pond treatment accordingly.

The second critical stage is water treatment. Pathogens can enter through both saltwater and freshwater sources, and if not properly treated, they can jeopardize the entire production cycle. Common disinfection methods include chlorine, ultraviolet (UV), and ozone-based systems. However, these tools must be used and maintained correctly to be effective.

Take chlorine, for example. Chlorine granules degrade over time, especially when stored in hot or sunny conditions. As a result, the expected concentration may not match the actual potency. Farmers need to test whether the target disinfection level—typically 10 ppm after 24 hours—has been achieved. To support this, a guidebook has been developed to help farmers calculate the correct chlorine dosage based on factors like organic load and pond volume, which are often overlooked.

For example, chlorine granules degrade over time, especially when stored in heat or sunlight. This means the assumed concentration may not reflect the actual potency, and farmers must test whether they are achieving the necessary disinfection

levels—usually 10 ppm after 24 hours. Genics has developed a “guidebook” to help farmers calculate the correct chlorine dosage based on organic load and pond volume, which are often overlooked variables.

UV systems, though effective, also require careful monitoring. Bulbs lose efficacy over time, and water flow rates must be calibrated to ensure sufficient exposure. Regular testing of water before and after UV treatment— using tools such as eDNA analysis—can help verify whether the system is functioning properly.

The third critical stage is feed input—particularly the use of polychaetes in broodstock maturation. Indonesia has the advantage of access to high-quality, pathogen-free broodstock. However, this benefit can be undermined if wild-caught polychaetes are used as feed, as they are often carriers of pathogens like WSSV or EHP. Melony said that once the feed is infected, broodstock can transmit these pathogens to their offspring, meaning farmers may unknowingly stock infected post-larvae (PL) into their ponds—setting up the crop for failure before it even starts.

This biosecurity gap can be avoided by ensuring that any

polychaetes used in hatcheries are also free of pathogens. Leading hatcheries provide multipathogen test reports for both broodstock and PLs, offering transparency and accountability. Choosing PLs that come with these test results is a simple yet effective way to reduce disease risks right from the start of the production cycle.

Embracing a holistic view of biosecurity means not only addressing individual weak points, but also linking them into a cohesive, resilient system. Farmers who regularly monitor, test, and refine their practices are far more likely to avoid costly disease outbreaks. The message is clear: by strengthening biosecurity at these three critical points, shrimp farmers can boost survival rates, improve productivity, and safeguard their long-term profitability.

THE CRUST - AB

Dr. Melony Sellars

Is sustainability a cost or an opportunity? For the global shrimp industry, this isn’t just a theoretical question— it’s becoming a key consideration in long-term business planning. Caleb Wurth, Regional Director of the US Grains Council, emphasized that sustainability is no longer a distant issue. “It’s going to be a part of your lives going forward,” he said at the 2025 Shrimp Aquaculture Conference, urging producers to think five to ten years ahead.

A global survey revealed that in 2015, only about 45% of consumers believed they could make a personal impact on climate change, even though 55% expressed concern about the issue. By 2022, that mindset had shifted significantly: over 65% of consumers reported being worried about the climate, and nearly 60% believed they could help make a difference.

This growing climate awareness, particularly among Gen Z, carries major implications for the market.

Today’s younger consumers are no longer satisfied with just low prices; they expect traceability, ethical sourcing, and environmentally responsible practices. While sustainability might once have been seen as an added cost or a marketing label, Wurth described it as a powerful differentiator in an increasingly competitive and values-driven global marketplace.

influenced by trust, transparency, and meaningful action. For producers, countries, and industries alike, knowing where you stand—and where your customers stand—on the sustainability spectrum is key to shaping relevant, future-proof strategies.

Wurth said that avoiding the sustainability conversation is no longer an option. Global regulations are evolving fast, from greenhouse gas (GHG) disclosures and ESG reporting to deforestation checks and eco-labeling schemes. Whether producers are exporting to the EU, navigating California’s unique standards, or keeping up with China’s new environmental standards, one thing is clear that the world is moving toward more accountability.

“It’s here to stay. And no matter what the ideology is, you know, sustainability and some sense of the word or definition, will be in our future,” Caleb said.

He emphasized the importance of evaluating sustainability through three main pillars: economic, environmental, and social. Each of these pillars offers a wide range of entry points for companies to improve both their environmental footprint and their bottom line.

Understanding the customer segments has never been more important. As Wurth explained, about 16% of consumers identify as environmental activists—they’re vocal, committed, and deliberately choose products that reflect their values. On the other end of the spectrum, around 23% are either skeptical or indifferent to climate issues.

Aquaculture, in particular, has a distinct position in this sustainability conversation. Unlike overfished wild-capture industries, aquaculture offers a scalable and more controlled solution to meet growing global seafood demand. “We have too many people and too few fish,” Wurth said bluntly, highlighting the consumption-pressure dynamics that drive this shift. But with opportunity comes responsibility.

However, the real challenge and opportunity lay in the middle: the majority of consumers who are moderately concerned or undecided. Wurth said this is where most shrimp buyers fall, and they can be

To illustrate how sustainability can evolve from buzzword to brand asset, Wurth shared the story of how the U.S. Grains Council turned dry distillers’ grains (DDGS)—a byproduct of the ethanol industry—into a sought-after, sustainable feed input. Initially overlooked, DDGS found new value when repurposed for aquafeeds and poultry diets. By aligning their feed solution with sustainability metrics—such as reducing the need for forage fish or improving phosphorus availability—the Council was able to reposition a waste product into a climate-friendly innovation.

This success, Wurth explained, was made possible by investing in technologies that improved yield while using fewer resources. It’s a model that he believes the shrimp industry in Indonesia and beyond can learn from. The challenge ahead isn’t just producing more—it’s producing smarter. Whether it’s refining inputs like feed, restoring natural ecosystems like mangroves, or developing better data to track GHG emissions, the goal is to improve margins while reducing environmental strain.

Tired of the usual dinner routine? In parts of Asia— and even a few places beyond—there’s a quirky and interactive dining experience waiting for you: shrimp fishing restaurants.

It’s exactly what it sounds like. Instead of ordering shrimp off the menu, you grab a rod, sit beside an indoor pond, and fish them out yourself. It’s part game, part tradition, and all about the fun of earning your meal, one prawn at a time.

This trend is especially popular in Taiwan, where it’s known as diaoxiaqiu (釣蝦場), a social late-night activity that’s been around since the 1990s. But the idea has also caught on in Thailand, where Bangkok and beach towns like Cha-am feature lively shrimp ponds. You’ll also find versions of it in Singapore, Hong Kong, mainland China, and even Houston, where a Taiwanese-style shrimp fishing venue opened recently.

So how does it work?

The Shrimps

The stars of the show are usually Macrobrachium rosen-

bergii, commonly known as the giant river prawn. These freshwater prawns are ideal for indoor ponds: they’re hardy, grow fast, and have those long, blue-tinted claws that make them fun to catch—and delicious to eat.

Some venues, especially in larger spaces or outdoor-style setups, may also stock:

• Penaeus monodon (black tiger prawn)

• Metapenaeus ensis (greasyback shrimp)

• Other local or seasonal species depending on availability

But giant river prawns are by far the most common due to their size, activity level (making them more challenging to catch), and wide culinary appeal.

Don’t expect high-tech gear—this is meant to be simple and social. Most restaurants provide a basic fishing setup:

• A lightweight bamboo or fiberglass rod

• A small float

• A short line with a pair of tiny J-hooks

• The most commonly used bait is dried tiny shrimp, often called “xia mi” in Mandarin.

The trick is patience: when the float bobs, you wait a few seconds and then gently lift. Too fast, and you miss. Too slow, and the shrimp escapes with dinner.

After fishing, most restaurants offer to cook your catch on the spot. The most common method is grilling the shrimp over hot charcoal, typically with a bit of salt and nothing more—letting the natural sweetness and texture of the fresh prawn shine through. Some venues allow you to grill it yourself at your table, adding to the hands-on fun. Others will clean and cook the shrimp for you, sometimes offering options like garlic butter, spicy seasoning, or dipping sauces on the side. It’s simple, fresh, and unbelievably satisfying—especially knowing you caught it yourself.

Stéphane Ralite’s presentation at the 2025 Shrimp Aquaculture Conference was not merely a technical discussion, but rather an indepth exploration of the invisible forces that shape the success of modern shrimp farming. Representing Lallemand Animal Nutrition, a company with over a century of expertise in microbiology, Ralite, who is the Product Manager at the company, highlighted the crucial role of microorganisms, particularly bacteria, in managing aquatic ecosystems.

Lallemand’s legacy began in the 19th century, crafting yeast for bread and alcohol production. But its microbial reach now spans from human probiotics to aquaculture, the latter a sector where microbial management has become a

cornerstone of sustainability and profitability.

Shrimp farmers, Ralite emphasized, face the monumental task of controlling pond environments while minimizing external water exchange to avoid pathogens. Every feed input introduces organic matter, which transforms the pond into a dynamic microbial battlefield, one where bacteria are both allies and adversaries.

At the heart of this microbial dance is the nitrogen cycle. Proteins in shrimp feed release ammonia, a compound that, if mismanaged, can disrupt pond health and stunt shrimp growth. Heterotrophic bacteria and nitrifying microbes, those that convert ammonia to less harmful nitrates, are essential in maintaining equilibrium. But these beneficial populations are sensitive, influenced by factors like oxygen levels, alkalinity, and salinity. One small shift can send the system spiraling into imbalance.

fectively. However, not all Bacillus subtilis are created equal. Selecting the right strain is crucial. Otherwise, instead of controlling nitrogen, one might inadvertently fuel pathogen growth.

While managing water quality is vital, the story doesn’t end there. The gut microbiota of shrimp is equally significant. As Ralite explained, gut bacteria influence immunity, feed conversion, and resilience against disease. “In fact, our microbiomes weigh more than our largest internal organs, so it’s no surprise that microbial stability in shrimp matters just as much,” he said.

One of the greatest microbial threats in shrimp farming is Vibrio, a genus that includes both harmless and highly pathogenic species. Ralite emphasized how fast Vibrio can proliferate, often outcompeting beneficial bacteria, especially in saline environments. Disinfecting hatchery water removes all microbes good and bad, creating a blank slate. But once introduced, Vibrio outpaces slowergrowing Bacillus, leading to potentially catastrophic consequences. The solution? Seed the system with beneficial bacteria first, giving them a head start to colonize and protect.

Ralite’s experiments demonstrated that adding specific heterotrophic bacteria carefully selected from Lallemand’s microbial library of over 12,500 strains can help manage ammonia levels ef

Experiments showed that using specific probiotic strains, like Pediococcus acidilactici, can help form protective biofilms in the shrimp gut, biological fortresses that limit Vibrio colonization. Other strategies include using yeast cell wall products that trap Vibrio, similar to special traps for flies. But again, timing is key. Adding molasses, for example, provides food for both heterotrophic bacteria and Vibrio. If misapplied, this wellintentioned step can backfire.

Ralite also discussed how environmental stressors, like sudden rainfall, can disrupt microbial stability, triggering disease outbreaks even in shrimp already hosting pathogens like Acute Hepatopancreatic Necrosis Disease (AHPND). Gut microbiome shifts often precede visible disease symptoms, making them an earlywarning system for farmers. Shrimp infected with Enterocytozoon hepatopenaei (EHP), a parasite that drains energy and weakens immune systems, are particularly vulnerable to secondary infections like Vibrio, further reinforcing the importance of gut microbial management.

To combat these challenges, some farms like one in Brazil that Ralite highlighted, have adopted innovative multitrophic systems. These include anaerobic tanks for denitrification, aerobic biofilters, tilapia for organic matter reduction, and full water recirculation systems. The result? Enhanced microbial control, lower discharge, and improved water quality. Probiotics are applied in feed and even coated onfarm to maintain microbial consistency across the production cycle.

Ralite closed with a message that management is key. Various additives, bacteria, or whatever else we can use are not magic. They are just bricks in the larger structure of farm management. Success lies not in any single product but in how well these tools are used together, adapted to each farm’s unique ecosystem, including biosecurity, oxygen level control, water quality, soil, and feed management. And just like microbes, the best farmers are those who respond, evolve, and adapt.

The global shrimp trade landscape has shifted dramatically in just a year. Once dominated by concerns over antidumping and countervailing duties, the conversation has now turned to newly imposed tariffs under the Trump administration, measures that are reshaping market dynamics and placing fresh pressure on exporters like Indonesia.

At the Shrimp Aquaculture Conference (SAC) 2025, Ronnie Tan, the Regional Aquaculture Consultant – Southeast Asia for the US Grains Council, guided a focused discussion on the implications for Indonesia’s shrimp industry. Featuring expert insights from Caleb Wurth, Regional Director US Grain Council Southeast Asia and Oceania; Jacob George, Director of Seafood Exporter Bumi Menara Internusa (BMI); and Nicholas Leonard, Founder of Haven Foods, the session offered comprehensive perspectives from situation analysis, strategic responses, and longterm solutions.

Caleb acknowledged Indonesia’s disadvantaged position but highlighted it as a strategic opening. He urged

Indonesia to bring shrimp into the fold of larger trade talks, pairing it with stronger sectors like petroleum and textiles in negotiations. He also emphasized the need for direct engagement with US policymakers to push for fairer treatment of Indonesian shrimp in the American market.

From the processors’ side, Jacob said that in the short term, the industry has seen a spike in US bound shipments ahead of a looming July 9 tariff deadline. However, this increase, he cautioned, does not reflect growing demand but rather a preponement of existing orders due to market

uncertainty. Jacob warned of a potential glut in US inventory, especially if demand continues to soften amid declining foot traffic in foodservice and retail sectors. He stressed the need for Indonesia to adapt by focusing on niche products and areas where it has natural advantages.

Meanwhile, Nicholas contextualized the tariffs as part of the Trump administration’s typical negotiation strategy, starting high and aggressive to bring trade partners to the table. Nicholas noted that a 10% tariff would result in only a slight decline in demand (around 5%), but if Indonesia remains at 30% while competitors enjoy lower rates, demand for Indonesian shrimp could drop significantly, especially in the foodservice segment. He explained that Indonesia is strong in retail, whereas Ecuador dominates the foodservice channel. As inflation and operational costs rise, Nicholas anticipates a shift in US consumer behavior from dining out to home cooking, which could favor Indonesian exporters if positioned correctly.

All three speakers acknowledged that Indonesia is overreliant on the US market, with 67% of its shrimp exports going there. While Caleb urged Indonesia to maintain its US ties due to consumer preferences and simpler product specs, Jacob warned that concentrating too heavily on one market is risky. He encouraged the industry to expand into Europe and China, despite tougher quality and traceability standards. Jacob stressed that without meeting these stricter specifications, discussions with new markets are futile.

Nicholas underscored the need for industrywide collabo

ration and investment in efficiency. He urged Indonesian farmers, processors, and government bodies to work as one. Using Ecuador as a benchmark, he acknowledged that their success came from tight supply chain integration, something Indonesia currently lacks. Yet Nicholas warned against fully copying the Ecuadorian model, fearing it might lead to job losses.

Instead, he advocated for Indonesia to learn and adapt selectively, enhancing farm efficiency without sacrificing employment.

In the discussion on supply chain integration, all three agreed that stronger collaboration between farmers and processors is essential. Caleb challenged farmers to take the lead in organizing and shortening the supply chain to strengthen branding and traceability. Jacob admitted that while some collaboration exists, it is inconsistent and insufficient. He called for more transparency, honesty, and shared data among stakeholders. Nicholas emphasized maintaining the diversity of Indonesian farms rather than moving toward consolidation, suggesting SOP development, experimentation with farm models, and collective problemsolving as better alternatives.

When it came to reputational issues, such as the soaking of shrimp due to delays from harvest to processing, all agreed that these are fixable problems. Jacob explained that such practices were accepted in the US market but are unsuitable for Europe and China. He stressed that aligning product specs with target market expectations is critical. Nicholas added that other countries sometimes project these issues onto Indonesia for competitive reasons, and that it’s essential to challenge such narratives with facts, proper specs, and consistent quality.

Darmawan

Shrimp is love

Shrimp is life

Veni Vidi Fishy

Gemilang Lim

My secret to joy in life is in finding balance

Balance in family, sweating, and making decisions