south west and west midlands

south west and west midlands

10 COOL ENTREPRENEURS GREEN TECHNOLOGY, WHAT’S WORKING FOR THE WORLD?

AMBITIOUS LEADERS

Skills

Career Ahead

Cyber & IT

Science & Technology

Deals Manufacturing

stability, and they’re relying on the new government for it

The new Labour government hit the ground running after winning July’s General Election.

Fast and furious came the announcements – the promise of a new skills body, Skills England, to “bring together the fractured skills landscape”.

Then there are the proposed planning reforms to boost UK housebuilding and the setting up of Great British Energy to invest in clean, home-grown energy. There’s a new trade strategy too.

Of note for businesses is a promise to support the country’s impressive science and technology sector. Just one announcement by Business and Trade Secretary Jonathan Reynolds was for more than £100 million in funding for aerospace research and development projects, an important sector for this region.

The UK’s Science Secretary, Peter Kyle, also announced an action plan to identify how AI can drive economic growth – but in the next breath the government quietly revealed plans to scrap £1.3 billion of funding for AI and technology projects which had been promised by the previous Conservative administration.

And the axe didn’t stop there. Chancellor Rachel Reeves said that some major infrastructure projects which had previously got the green light are once again stalled at red. That includes the major £1.7 billion A303 Stonehenge tunnel – although another major project in our region, the £460 million A417 Birdlip bypass project in Gloucestershire which is already almost a year into construction, is continuing. Other construction projects, including hospitals and railway lines have also been stopped.

Nicky Godding Editor

These cuts, says the Chancellor, will help plug the multi-billion-pound funding gap left by the previous administration.

Whatever your politics, most people agree that fresh eyes on the British economy are no bad thing. Business organisations such as the CBI and the British Chambers of Commerce are supportive.

As Ian Bell, Executive Director of Bath Chamber of Commerce and Business West, said: “Chambers of Commerce and initiatives are never aligned to any particular political party. We simply work as best we can with whichever government comes out on top at the ballot box.

“However, one thing that business does prefer is a clear cut result, which provides greater certainty about how things are likely to go.”

Olivia Parrish, Chair of the Coventry and Warwickshire Chamber of Commerce’s Mid-Warwickshire Local Business Forum, agreed. “Sometimes, just a change from the status quo is required to create a positive reaction and it does feel like the new government is speaking the right language when it comes to business.”

Robert Elliot, Herefordshire and Worcestershire Chamber of Commerce Director, added: “As a Chamber we represent 1,200 businesses across both counties. These businesses have their challenges, but are incredibly resilient and now look forward to the new government providing stability, the opportunity to plan ahead and most importantly grow.”

In this issue of The Business Magazine we are once again flying the flag for the region’s businesses.

Wildfires pose a significant and growing threat worldwide. The combination of climate change, dry conditions and human actions has led to more frequent and intense fire seasons, with 2024 so far seeing wildfires spread across southern Europe, the USA and South America.

They also contribute up to 20 per cent of global carbon emissions.

The total cost of wildfires in the USA is between $394 billion and $893 billion a year.

So it’s timely that Bath fire detection company Optect has teamed up with USA-based Sonic Fire Tech to develop what it says is a groundbreaking solution combining advanced robot systems with entirely new detection and suppression technologies.

Optect has been aided by tech start-up and scale-up support organisation SETsquared in Bristol.

Now the Optect team is in the final 30 in the Autonomous Wildfire Response category of the global $11 million XPRIZE Wildfire competition. This is a

The technology is powerful and scalable, which are essential features for taking on massive megafires

four-year programme incentivising the innovation of firefighting technologies to end destructive and costly wildfires.

The competition challenges teams to autonomously detect high-risk fires in a 1,000 sq km environmentally challenging area and suppress them within 10 minutes, leaving decoy fires untouched.

Team Optect deploys drones to spot fires from high in the sky, and flying robot taxis that deploy fireextinguishing robo-dogs to zap flames with sound waves.

Infrasound wildfire suppression sounds futuristic but could soon be a reality.

Sonic Fire Tech recently showed its device extinguishing high-temperature wood fires in seconds from several feet away. The technology is powerful and scalable – essential features for taking on massive megafires.

Optect has also recently launched a new flame detection product boasting up to 10 times the range of current devices. With the help of SETsquared, the company has grown its customer base and is now poised to reduce fire risk significantly across various wildfire and industrial applications.

Matthias Jaeger, Chief Technical O cer at Optect, said: “The challenge, as with many XPRIZE competitions, is set close to the limit of possible, and in response, we’re pushing technology to the limits too.

“To pull o a live demo within the project's timeline will be an extraordinary achievement, but technology milestones are being conquered on a regular basis. We look forward to demonstrating our solution in a real-world environment in 2025.”

It’s never too late to follow your dream. A Warwickshire mum has taken the reins of her dream job after learning how to care for horses.

Isabelle Padilla, 32, from Quinton is now working at the stables of top British racehorse trainers Richard Newland and Jamie Insole in Droitwich after completing a level 1 diploma as part of the RMF Equine Management Programme, funded by the West Midlands Combined Authority (WMCA).

Isabelle said: “I love horses and started riding at aged four. As a teenager I worked as a hairdresser and doing nails and beauty, but my heart wasn’t in it. When I was presented with this training course, I just couldn’t believe it.

“Every day you meet new people and learn new things, and the training helped me to get a job at a stables working for Richard Newland.

“They are helping me train further to become a head travelling girl where I get to travel the country and abroad with horses.

“Thanks to RMF and the WMCA I have a career in something for which I have a real passion.”

Science park sold for £6.5m for possible nuclear SMR development

South Gloucestershire and Stroud College (SGS) has sold its 40-acre Gloucestershire Science and Technology Park at Berkeley for £6.5 million to Chiltern Vital Berkeley (CVB).

CVB is a subsidiary of Chiltern Vital Group which develops large scale projects across the education, energy, entertainment and regeneration sectors. The group is chaired by Lord Michael Grade CBE, former Chairman of the BBC and Chief Executive of Channel 4.

The Group is currently developing projects across the UK, including a 200-acre energy and technology business park in Yorkshire and Collegelands in Glasgow, one of the UK’s largest regeneration projects –

now 90 per cent complete.

Chilton Vital is also supporting RollsRoyce SMR in the roll out of its Small Modular Reactors. It is expected that Berkeley/Oldbury will be at the centre of new nuclear if Rolls Royce SMR secures the go-ahead for its plans from the O ce for Nuclear Regulation.

Berkeley was one of the first civil nuclear power stations in the world. Its nuclear research laboratory helped develop the UK’s nuclear fuel programme. SGS saved the laboratory site from demolition in 2016 and built a science and technology park, but it acknowledged that only with private investment can the full potential of the site be realised.

Arkell’s raises a glass to the “oldest commercial relationship in the English Football League”

A Swindon brewery believes it has one of the longest commercial relationships on record in the English Football League after it renewed its longstanding association with Swindon Town Football Club.

Arkell’s Brewery, which began brewing beer in Swindon in 1843, has just signed a record agreement with the club for the next three years.

The deal includes continued sponsorship of the prominent Arkell’s Stand – the first thing visitors see when arriving at the stadium.

The Arkell’s Stand holds great historical significance for the town. In 1896, Thomas

Arkell donated £300 for its construction (around £50,000 today).

Brewery Sales Director, Nick Arkell, said: “Our commitment to the club remains unwavering, and as Swindon's longestrunning company, it feels natural to cement our relationship with the town's football team.

“As the club’s first sponsor, this partnership epitomises our shared history and dedication to the town.”

The club’s Chief Commercial O cer, James Watts, said: “We are delighted that Arkell’s support remains as strong as ever as it shows a commitment to all local businesses and supporters.”

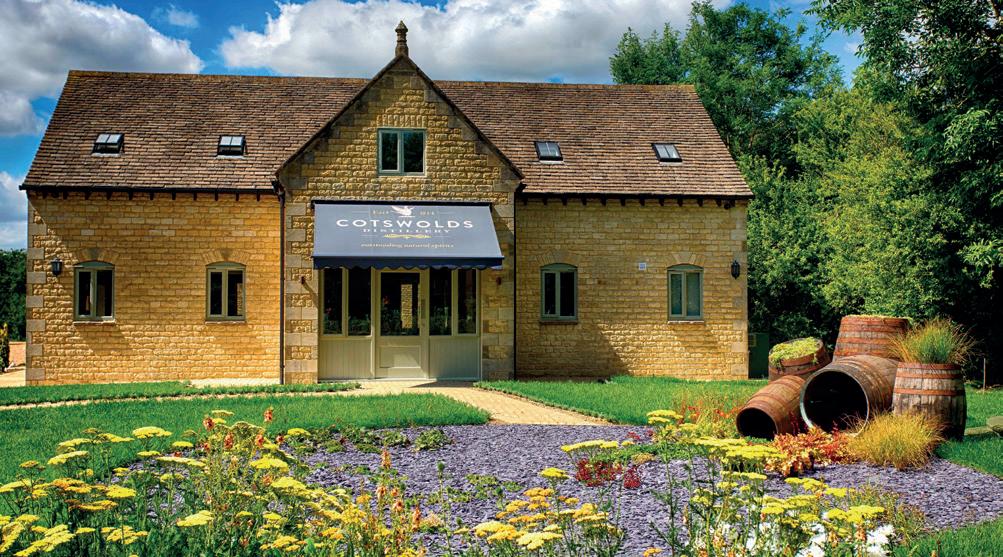

Cotswolds Distillery has unveiled a new bio-diverse wetlands ecological treatment system at its distillery in Shipston-on-Stour, Warwickshire.

Funded by wine and spirits company Berry Bros & Rudd, which invested in the distillery last year, the wetlands will naturally process three-quarters of the wastewater from the distillery’s whisky making, creating a bio-diverse habitat for local wildlife and reducing the amount of tanker trucks and local tra c.

The distillery worked with Living Water

Ecosystems and RHS Chelsea Flower

Show gold-medal winner, Rachael White Designs to build the facility, a system of cells covering nearly two acres of former marshland.

The cells can process both the spent lees, the residual liquid left in the still after the second distillation, and wash water waste – water used in the plant for rinsing tanks, floors and cleaning maintenance.

It is believed the new system will reduce distillery waste by tens of thousands of litres per week.

The system uses a variety of plants and their natural biological processes to break down the chemical compounds deemed as contaminants in the waste streams. Plants were bedded in August last year and have begun processing waste liquid from the whisky making. The clean water from this new treatment system will be used to grow a coppice of willows to provide shelter and habitat for wildlife.

The new wetlands site also includes untouched grassland and a wildflower area for pollinators and visitors to enjoy, as well as new beehives to help the pollinator population. In time, new additions will be made to the site including bird boxes and pathways for visitors.

Dan Szor, Cotswolds Distillery founder, said: “We have been looking for ways to improve our waste management and a wetlands treatment system seemed like the perfect solution.”

The Cotswold town of Tetbury, once home to King Charles before his succession to the throne (he still owns Highgrove House there), is perhaps a surprising place for the emergence of cutting-edge science and technology.

But a team of scientists from Naicker Scientific in the town have secured £30,000 to further develop technology to purify ice frozen in the moon's soil to try and make human habitation on the lunar surface viable.

Naicker Scientific has developed the SonoChem system. This employs a groundbreaking core technology to

purify water derived from lunar ice.

Harnessing powerful sound waves, it spontaneously forms millions of tiny bubbles in contaminated water.

The extreme temperature and pressure created within each micro bubble generates free radicals (unstable atoms which are highly chemically reactive), e ectively removing contaminants.

It is part of the Aqualunar Challenge – a £1.2 million international prize funded by the UK Space Agency’s International Bilateral Fund.

The challenge is a collaboration with the Canadian Space Agency and Impact Canada. The UK track of the challenge is awarding 10 UKled finalist teams £30,000 each to develop their technologies, before a winner and runners-up are announced next spring.

Around the lunar south pole, it’s estimated that 5.6 per cent of the soil is water frozen as ice. For a permanent crewed base on the moon to be possible, astronauts will need a reliable supply of water for drinking and growing food, as well as oxygen for air and hydrogen for fuel.

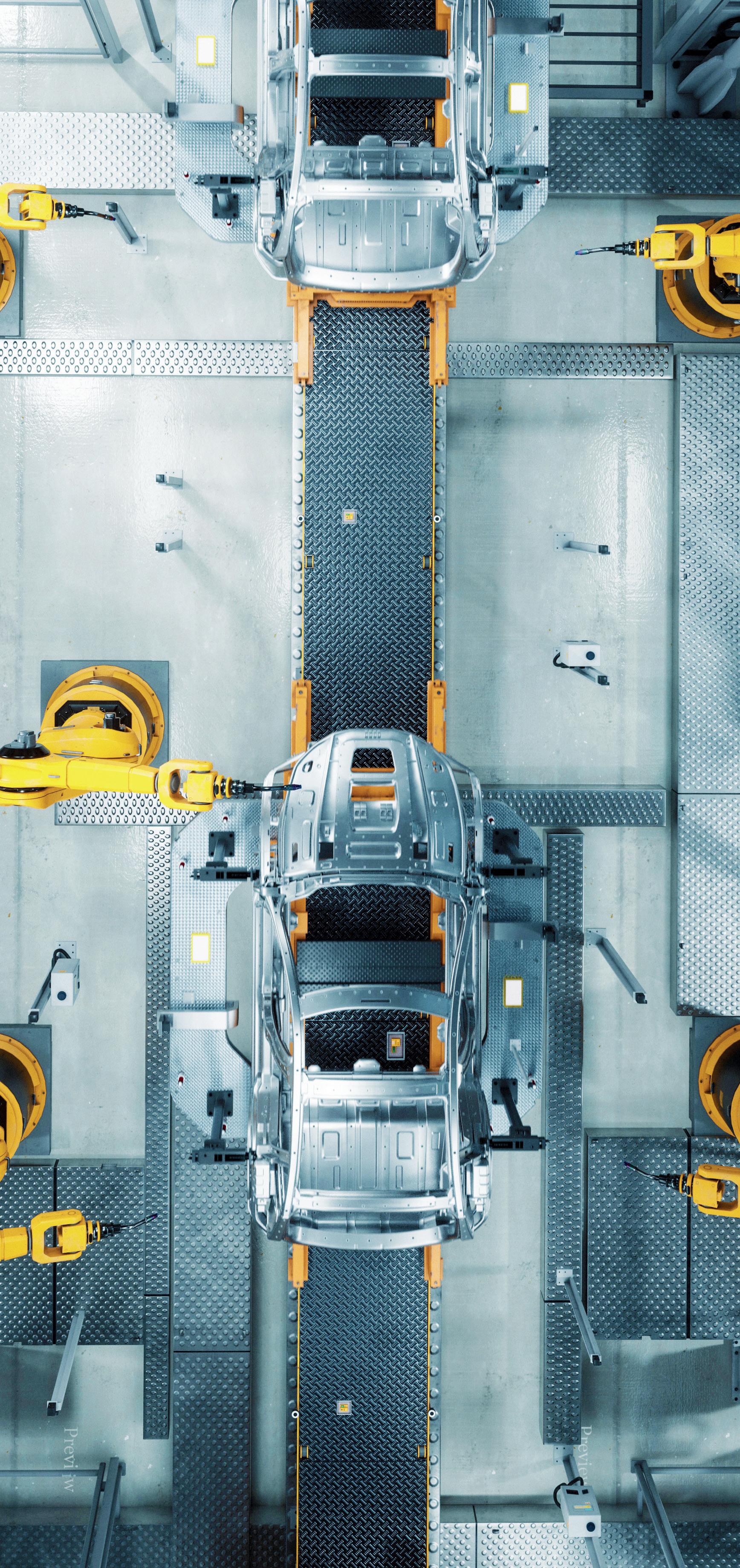

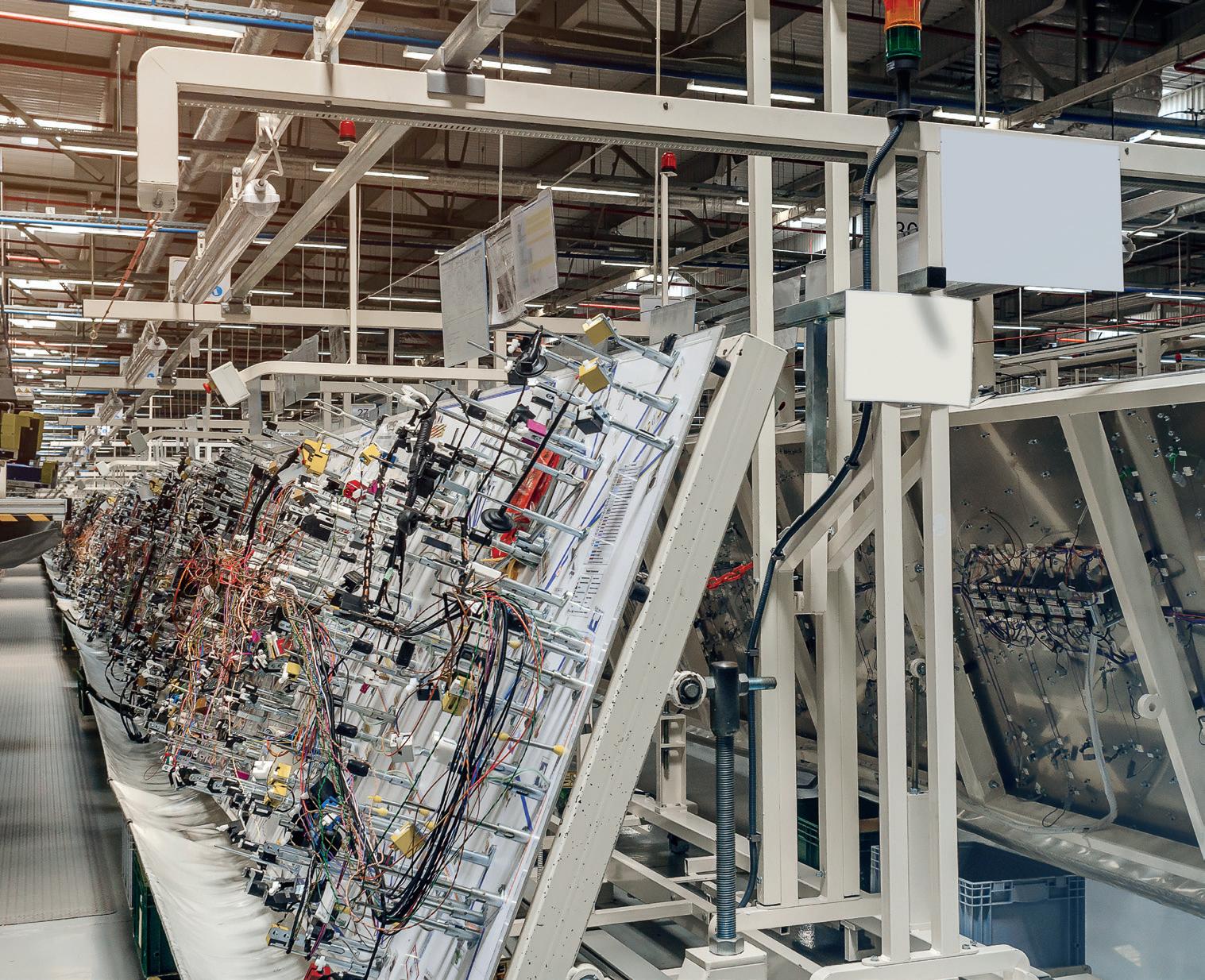

The UK’s automotive industry is fundamental to this country’s future, but it can’t do it alone

The UK automotive sector could fuel £50 billion of green growth over the next decade, according to the UK’s influential trade association for the automotive industry, the Society of Motor Manufacturers and Traders (SMMT).

That’s a serious claim – but the organisation warns: “Provided the right conditions are in place.”

Those include government policies and consumer incentives to help 17 million drivers switch to zero emission motoring by 2035, halving the number of fossil fuel cars in use.

The analysis forms the basis of the SMMT’s Vision 2035 which also includes a series of five pledges for the industry: Net zero mobility for all, Britain as a global power in vehicle production, an upskilled workforce for the new automotive technologies, clean, cost-e ective energy and a proper industrial transformation strategy (something the whole of the manufacturing sector has long been calling for).

The UK automotive industry has had a torrid few years, and it’s not back on the open road yet. While the country had been investing in developing electric vehicles for a decade before Brexit, the UK’s departure from the European Union put the brakes on.

If the country’s focus is economic growth and net zero, you can't deliver that without decarbonising road transport, so the automotive industry will be central to the UK strategy

The country’s exit forced radical changes in supply chains. One of these was the Rules of Origin requirements within the UK and EU’s Trade and Co-operation Agreement. These are scheduled to come into force in 2027 and require that an increasing percentage of parts in an electric vehicle must be made in the UK or EU. If car manufacturers don’t meet these thresholds, exported cars in either direction will face a 10 per cent tari .

With more than 70 per cent of all UK-made vehicles exported, and more than half of those going to the EU, these rules will be disproportionately felt in the UK.

Then there was Covid, which stalled car production. While the sector has somewhat recovered from the dark days of 2020,

things aren’t yet back to what they were. In the first six months of this year, UK car production fell 7.6 per cent. Despite manufacturing 416,074 vehicles, this was 34,000 fewer than in the same period last year.

This overall fall was driven by a significant decline in exports. While vehicles produced for the UK market increased by more than 17 per cent year-on-year to 106,157 in the first six months, those manufactured for export fell by just under 14 per cent to 309,917.

However, the decline in total vehicle exports had to a certain extent been expected, said the SMMT. This could be due to manufacturers retooling lines to make electrified models, following £23.7 billion of UK investment announced last year.

Mike Hawes is the Chief Executive of the SMMT. He says: “If the country’s focus is economic growth and net zero, you can't deliver that without decarbonising road transport, so the automotive industry will be central to the UK strategy.”

The new Labour government has said it remains committed to the decarbonisation of road transport. But there could be an issue here. Last year the previous government said it would delay the UK ban on the sale of new petrol and diesel cars until 2035. It was previously set at 2030. The new Labour government has said it wants to move the date back to 2030.

“That will divide the industry”, said Mike. “And it’s not clear what it means. If we revert to the previous target, the last government’s definition was that would mean the end of conventional petrol and diesel engines.

“They never clearly defined what you could sell after 2030 until 2035. A vehicle has to have significant zero emission capability, but they didn’t define what that was. So it’s still an open issue.”

Last year Labour launched its automotive sector strategy. This addressed some of the issues around demand, infrastructure and competitiveness.

“Labour’s approach will result in a new industrial strategy for the country –something we've been calling for ever since

the one from the last government withered away on the vine,” said Mike.

“The new government understands that you must bring together not just policies but government departments, because the issue involves the Departments for Business, Transport, Energy Security and Net Zero. It also involves Trade and the Treasury – and when you look at the international perspectives, it will increasing involve the Foreign, Commonwealth and Development O ce.”

The Labour government wants to encourage the market, especially for those less able to a ord an electric vehicle, and drive the roll-out of infrastructure – a critical enabler to achieve the strategy. It wants to encourage investment in automated manufacturing and gigafactories.

“They rightly want to focus on growing the UK automotive industry, but this will have to be done in an increasingly competitive global environment,” Mike said. “We want a good relationship with Europe – a better one than we've had before (which shouldn’t be di cult), but everyone has to take into account the protectionism that’s happening around the world.

“What can we do to make sure we have good and progressive relations with all markets when in some cases they are turning their back on international trade?”

There is concern across the UK that this country is being flooded by overseas automotive imports, with China often cited. Mike acknowledges that the market share of Chinese brands is growing.

“Currently their share of the UK market is between four and five per cent, and a significant portion of that is MG.”

This British brand was acquired in 2007 by SAIC Motor Corp, the Chinese stateowned automotive company. There are also newcomers such as BYD, but the di culty in establishing a new brand overseas shouldn’t be underestimated.

Mike says: “A new entrant must convince consumers to invest considerable money in an unfamiliar brand. It will also need to

build a dealer network and aftermarket. That’s all expensive and takes time.

“Sometimes it’s a bit easier with a new technology like EV, and that's why the Chinese in particular are doing better in the EV market than they are in the general market. Their EVs are perhaps priced more competitively, but they’re still not cheap, and there remains a good degree of brand loyalty among UK consumers who want to know the companies they’re buying from.”

But this country is in a good position. Last year more than £22 billion of automotive investment was announced, more than the preceding seven years put together.

“The industry must now realise those investments – such as the gigafactories which have been announced,” said Mike. “I know the market is really tough for EVs at the moment, but the UK, EU and other markets are committed to the decarbonisation of road transport. That means that those who are making vehicles to fit that requirement, using batteries made locally, are in a good place.”

And now that the UK is a free trading nation, it can look at new markets. We have signed trade agreements with Japan, an important one, and with Australia and New Zealand which are useful – but relatively small markets.

Where the UK government direction di ers from the European Union is in tari s. First the USA put 100 per cent tari s on Chinese electric vehicles (more a symbolic gesture to reassure US automotive manufacturers, according to Mike, as China doesn’t sell many into the USA market). More recently the EU has also announced increased tari s on the import of Chinese EVs – which hasn’t been met with mass celebration in certain parts of the European automotive industry because of how their manufacturers have constructed supply chains.

“The UK government is taking a more nuanced view,” said Mike. “China is a critical trading partner and owns a number of UK automotive brands. This country wants free and fair trade with the world, but we will have to watch the market closely.”

Discussions are ongoing with other countries such as Mexico, Canada and potentially India to improve access to those markets.

A big issue facing the UK is equipping the country’s automotive workforce with the new skills they’ll need to produce electric vehicles.

“While our workforce is highly skilled in making cars with internal combustion engines, they will have to understand new electric vehicle technology,” said SMMT’s Mike Hawes. “These are high voltage systems so additional training will be needed for something like 80 per cent of the workforce.

“Then there’s the service repair aftermarket. And that's where there is a massive skills gap, because a mechanic will know the ins and the outs of an internal combustion engine, but an electric vehicle is very di erent. However, this is an ongoing transition so there is time for companies to invest in skills development – as long as they've got the wherewithal to do so.”

The next few years are going to be tough for the UK’s automotive sector. Not just for big companies but also for the supply chain. Many are small or medium-sized businesses which don’t have deep pockets but which will, in many cases, have to change what they make because it’s not needed for the new electric vehicles. They will need to reskill their workforce.

While our workforce is highly skilled in making cars with internal combustion engines, they will have to understand new electric vehicle technology

“Cars of the future will still have four wheels, a chassis, seats and so forth, but many of the parts will be di erent,” said Mike. “The need now is for power control technology. We need to make sure we've got a resilient, capable and innovative supply chain and a workforce fit for the future.”

There is a misconception that competitiveness is all about the cost. It's not, says Mike. “It's about making the right product well and at the price you make it.”

What about other technologies? The government has invested a lot of money in

researching the use of hydrogen in transport. Is it worthwhile?

“At the moment it's hard to see hydrogen being commercially viable to compete with batteries at the same cost by 2030, or even 2035,” said Mike.

“Looking longer term and at di erent use cases, including for o -road heavy duty construction work, some manufacturers believe it could have a key role to play. Others are not so sure. There are certainly some cases where batteries won’t really be suitable – such as long-distance coaches where passengers won’t want to stop for two hours to recharge. The question will be –what’s the alternative? Could it be hydrogen fuel cells?”

The jury is still out on that.

What isn’t in dispute is that the UK’s automotive industry is fundamental to this country’s future. And the government is taking that seriously.

The country has a total budget of £4 billion being invested in automotive research and development. This is being undertaken in 22 centres across the country, many working with our universities, particularly the University of Warwick and Warwick Manufacturing Group, the MTC in Coventry, the Institute for Advanced Automotive Propulsion Systems in Bath and MIRA Technology Park near Nuneaton, Warwickshire.

Warwick-based Astheimer Design has joined forces with Prodrive in Banbury to develop what they say will be the most e cient last-mile electric vehicle.

The companies have formed a new joint venture, ELM Mobility Ltd, to launch the “Tuk-Tuk of the Western World”.

Astheimer Design is a world-class design studio which has worked on major automotive projects including an all-electric long range concept car which it developed with a consortium of British companies. The project was funded by the O ce for Zero Emission Vehicles. It also worked with a Swedish start-up on designing the world’s first, purpose-built, fully electric truck.

Prodrive has been designing, building and racing world championship winning cars for 40 years, across both rally and track.

With a long history of successful collaborations, these companies have developed a vehicle platform which they say will revolutionise last-mile logistics, o ering an e cient commercial vehicle that will significantly impact our urban environment.

ELM Mobility unveiled its new electric vehicle at Cenex this month and will also present it at the Leaders in Logistics Summit in Twickenham in October.

Another Oxfordshire company is also on a mission to revolutionise green transport in urban environments.

Evri has electric cargo bikes operating in London, Bristol, Oxford and Cambridge ...

Electric Assisted Vehicles (EAV), which has just moved into larger accommodation at Wates Way in Banbury, has developed an award-winning e-cargo bike for this rapidly growing market segment. The company, which now has 25 employees, won its biggest order to date this summer.

More logistics businesses are deploying e-cargo bikes across the UK. In June, delivery company Evri said it was investing a further £19 million in new plans to fast-

track the roll-out of electric cargo bikes. The move is expected to give Evri the UK’s biggest fleet of e-cargo bikes for parcel delivery.

The business plans to grow its fleet of e-cargo bikes to 3,000 over the next decade.

Evri has e-cargo bikes operating in London, Bristol, Oxford and Cambridge and currently delivers 1.5 million parcels a year by bike or EV. It aims to triple that number to around four million over the next year.

Amazon is also using electric cargo bikes. It says millions of packages have been delivered in this way across some of the UK’s biggest cities using its micromobility hubs. These are physical centres within urban areas where packages are sorted before the final leg of their journey.

Packages arrive from Amazon fulfilment centres and then loaded on to delivery vehicles, taking traditional vans o city centre roads. Amazon says it’s planning to invest around £300 million in the electrification and decarbonisation of its transportation network in the UK.

There are seven big premium and sports car manufacturers in the UK, four mainstream car manufacturers, four commercial vehicle manufacturers and more than 60 specialist car manufacturers. Many proud British car marques are now owned by foreign investors.

You could say it’s selling o the family silver, but it’s also a blessing, according to Mike Hawes, CEO of the Society of Motor Manufacturers and Traders.

“The challenge of transitioning an 100-year-old technology to a new one needs someone with deep pockets to fund it,” he said. “In the case of Mini and Rolls-Royce, BMW now owns them both which means they have access to their technology and supply chain.”

Such iconic marques might be foreignowned, but they retain their British identity – and their British manufacturing bases.

The UK is also good at attracting research and development investment from all over the world, and many international brands have a British design centre. That’s why seven out of the 10 Formula 1 teams are

We want to keep our intellectual capability here and our links to UK universities, which is very important

based in the UK, even though they race under another flag, according to Mike.

“We want to keep our intellectual capability here along with our links to UK universities, which is very important.”

But international links are important, added Mike. “If you’re going to understand global markets, you need to understand the consumer in China and the USA as well as in Europe, and you can only do that by having some exposure to them.”

Founded by Lionel Martin and Robert Bamford in 1913 in a small London workshop, Aston Martin is now an internationally admired (and desired) luxury brand. Wilbur Gunn, the Anglo-American engineer, founded Lagonda at his home in Staines, West London in 1904.

While the car marque has had its ups and downs financially over the decades, in 2014, industry veteran Andy Palmer was

appointed CEO of Aston Martin Lagonda. He oversaw the development and launch of the DBX, the company’s first foray into the growing luxury SUV market.

He departed after Lawrence Stroll became Executive Chairman of Aston Martin Lagonda in 2020 following leading new investment into the company. The company employs more than 2,800 people, many at its Warwickshire factory and head o ce.

Jaguar Land Rover was bought by India’s Tata Motors in 2008. It is now Britain’s largest automotive manufacturer. The Range Rover, Defender, Discovery and Jaguar – all iconic brands, sit under the Jaguar Land Rover banner today.

But the marques go back many decades. The first Jaguar car was produced in 1935. In 1961 the iconic E-type sports car was built.

The Land Rover was first introduced at the Amsterdam Motor Show in 1948. Since then they have become emergency workhorses around the world.

Jaguar Land Rover has two design and engineering sites, three vehicle manufacturing facilities, an engine manufacturing centre and a battery assembly centre in the UK. It also has vehicle plants in China, Brazil, India, Austria and Slovakia, as well as seven technology hubs across the globe. It employs around 11,000 people, mainly at its manufacturing site in Solihull and its product engineering centre and head o ce at Gaydon.

The Morgan Motor Company was established in Malvern in 1909. At its core the company is a true coachbuilder.

Using ash, aluminium and leather –every Morgan is built at Pickersleigh Road, the historic home of Morgan since 1914 and the only place in the world where Morgan sports cars are built.

McMurtry Automotive was set up by Sir David McMurtry, one of the UK’s most successful engineers, who established global engineering company Renishaw more than 50 years ago.

In 2019 the Morgan family sold a majority shareholding to Italian company Investindustrial, which has since invested in the business. The Morgan Motor Company now employs around 250 people.

Renishaw employs more than 5,000 people and is now a world-leading additive manufacturing, industry process and measurement control company.

Sir David established McMurtry Automotive in Gloucestershire in 2016 with cofounder Thomas Yates, who previously worked at Mercedes’ high-performance powertrain division.

The collaboration has resulted in the Spéirling, a pure electric single-seater hypercar.

This June, the Spéirling PURE smashed the closed- wheel track record at Hockenheim.

LEVC (The London Electric Vehicle Company) in Coventry was the UK’s first manufacturing plant dedicated entirely to the production of EVs. Its heritage goes back to 1908 when its founders began importing vehicles for sale to

the London cab trade. By 1948 the company was designing and building its own, in collaboration with the Austin Motor Company. In 2006 it was bought by Chinese automotive manufacturer Geely Auto. By 2017 the company was

One of its latest builds is the Midsummer, celebrating more than two centuries of combined coachbuilding experience between Morgan and Italian car design company Pinifarina. The number of hand-formed elements of Midsummer is higher than other Morgan models and features greater complexity. The hand-beaten aluminium body panels take more than 250 hours to produce.

designing and building electric vehicles. The world’s first zero-emissions capable electric cab went on sale the following year. By 2022, it had sold 5,000 TX taxis in London. The business is now global and expanding (see next page).

From The London Taxi Company to LEVC, a new style of EV cabs has taken over London, and the business is expanding and diversifying globally

LEVC (The London Electric Vehicle Company) in Coventry is the UK’s first manufacturing plant dedicated entirely to the production of EVs. As a taxi cab supplier its heritage goes back to 1908 but over the years it has changed ownership (and name). In 2006 it was bought by Chinese automotive manufacturer Geely Auto. By 2017 the company was designing and building EVs.

Geely owns a number of other global car brands, including Norfolk-based sports car manufacturer Lotus.

LEVC’s new global headquarters opened in Ansty, Coventry in 2017. As the UK’s only dedicated EV manufacturing plant, it represented an initial investment of more than £500 million, which also included the development of the TX taxi cab.

At the time, this was the largest greenfield investment in the UK by a Chinese company. Since then, LEVC has produced and developed sustainable mobility solutions for the commercial vehicle space – most famously the TX range-extended electric taxi.

Geely’s investment now exceeds £1 billion, supporting hundreds of jobs in research, development and production, both at Ansty and throughout its local supply chain.

Last year LEVC launched its EV platform, Space Orientated Architecture (SOA), codeveloped with Geely. The company says it is the world’s first EV platform focused on maximising interior space, o ering multiple seating and load-carrying configurations. It can support a wide range of new products – from passenger carrying models to commercial vehicles.

Using this new platform, LEVC has just launched a new luxury MPV (multi purpose vehicle), the L380, in China. This is the first of a range of full electric models. Following the start of sales in China, it plans to launch the L380 into other world markets, including the UK, within the next two years.

Chris Allen, LEVC’s Managing Director in Coventry, said: “The Coventry team is well integrated into wider operations and benefits from the expertise within the Geely group. In this fast-changing environment it is Geely’s ambition that the group represents product quality, sustainable performance and the latest in technological solutions.”

... it is Geely’s ambition that the group represents product quality, sustainable performance and the latest in technological solutions

LEVC employs around 400 sta at its UK head o ce and retail sites. Most are based at its Ansty manufacturing hub, with an additional warehousing facility in Ryton as well as two main London based retailers. It also has a network of independent retailers across the UK and recently appointed Murray Group in Plymouth, its latest retailer location, to o er full sales and service facilities for TX.

The company says that its TX taxi is making a significant contribution to the UK’s transport decarbonisation ambitions. Last year it reached the milestone of more than 50 per cent of London taxis being zero emission capable, saving 200,000 tonnes of CO2 from entering the world’s atmosphere globally.

Now the company can see a demand for sustainable, safe, accessible and clean purpose-built transport outside of just the taxi trade.

LEVC has actively looked at where its TX can help address other transport needs in society. This includes selling to the NHS for patient transfers and partnering with councils to help ensure children with mobility and carer needs have greater ease of access to education, where transport can be a barrier. The TX also supports care home residents and other sectors where wheelchair access is required.

The company’s long term ambition is to be a leading provider of zero-emission mobility solutions in markets around the world.

Chris said: “Our newly announced luxury MPV, the L380, is the first of a new range of innovative, spacious, fully electric models, which will see the brand accelerate its transition from a high-end taxi manufacturer to a leading provider of e-mobility solutions. We expect L380 to launch in the UK within the next two years, and as such, the team are currently working through pricing, specification and exact positioning for the new model.”

The

world needs hundreds of thousands of new pilots. Where will they come from? We meet one man who can see the way ahead

By Nicky Godding, Editor

According to Airbus, the world’s top commercial aeroplane manufacturer, over the next 20 years the aviation industry will need more than 585,000 pilots (and more than 640,000 technicians and engineers) to meet an ever-growing demand for flight.

Where will all these pilots come from? This country’s government doesn’t support any pilot training initiatives and UK banks don’t o er student loans to those wanting to learn to fly. Until very recently it has been a career mostly for those with deep pockets, or fortunate enough to find a sponsor willing to bankroll them to the tune of around £100,000 each.

One man who feels the deep iniquity of this is Lee Woodward, Co-founder and CEO of Skyborne Airline Academy, which has its headquarters and a training academy at Gloucestershire Airport. It has a second at Vero Beach in Florida. Jointly, the academies train hundreds of pilots every year. And such is the demand that Skyborne is expanding.

Lee set up Skyborne Airline Academy in 2016, with entrepreneur Tom Misner, who is now the academy’s chairman. In the 1970s, Tom established the world’s largest chain of audio engineering schools, selling it in 2010 for more than $300 million Australian dollars.

Lee says: “Tom’s school had more than 45,000 students around the world training in audio engineering, media and music production. These were his passions – but so was education.”

Lee knows all about passion. Did he always want to be a pilot? “Always, always, always – from as young as I can remember. And I only ever wanted to be a commercial pilot, as much as I loved military aircraft.”

He remembers the moment his career path became clear. “As a young child, I’d go to Manchester Airport to watch the aeroplanes. One day I saw a crew walking out to a Dan Air 727 and climb up the steps. I just knew then that’s what I wanted to do.”

Coming from a working-class background, Lee thought it was a pipe dream. But an inspirational maths teacher at his

comprehensive school in Widnes suggested it could be a reality.

“He said, if you really want to do this, you can. He took me under his wing, and I never looked back. In 1989, BA announced it would o er 600 pilot training scholarships over a five-year period. There were around 120,000 applications and I was accepted the second year.”

After completing training with BA, he flew Boeing 757/767 and 747 aircraft before becoming a trainer and examiner. He left BA in 2003 after losing his Class 1 medical and joined the then fledgling pilot training company, CTC Aviation, in Southampton. He later regained his medical.

“I owe everything to that BA scholarship,” He says. “When you remove the funding barrier, you see the quality of candidates go up almost exponentially. Applicant numbers increase between 15 and 20 times so that means the talent pool is so much bigger and we can find the very, very best individuals. If airlines are serious about recruiting the best talent, then they should find a way to fully fund or at least part sponsor the training.”

Some are. Last year Skyborne was selected by British Airways to train pilots in its Speedbird Pilot Academy, which provides fully funded flight training for up to 100 candidates a year. BA says that it wants to make a flying career more accessible to a wider selection of people.

“The applicant numbers for the Speedbird Pilot Academy are enormous,” admits Lee. “We share the contract with Flight Training Europe in Spain, but we are the preferred, and only, UK supplier and will train around 80 or so out of the 100.

“BA make it a tough selection process, with only around five per cent of applicants successful.”

In total, including the BA Speedbird contract, Skyborne annually enrols around 170 students to train as pilots at Gloucestershire Airport, and around 300 in Florida. Next year student numbers will rise at both locations – 300 in the UK and 400 in the USA.

Skyborne employs around 60 people in the UK and more than 200 in the USA, of which 93 are flight instructors.

... if students need more training there's no further cost, we cover it all, so it's one fee –that's it

It aims to stand out from other training schools in a number of ways. “All our training is delivered in an airline-focused way,” says Lee.

“We train in an incremental fashion, similar to how Tom did it in his audio engineering business. He called it progressive continuous learning. We have adapted it to suit our training environment.

“Pilots in ground school are exposed to aircraft and simulator experiences to better contextualise the theoretical phase and cement their learning.

“We also take principles that the UK CAA (Civil Aviation Authority) regard as best practice – such as loss of control, runway incursion/excursion, controlled flight into terrain and so on, and bring this into the flight school of training.”

It also puts all trainee pilots through two days of formal customer service training, which Lee says is unique to Skyborne.

airline.

“Pilots should know the full value they bring to their airline. The influence they can have on the passenger experience is still, even behind the locked door, significant.

“We help our trainees understand that the second they put on their uniform they will be viewed as being on duty, even if

second they put on their uniform they will as they’re not.”

This isn’t the first time that Lee has built up a pilot training academy. At CTC Aviation, he helped develop the cadet pilot training programme, which became known as “CTC Wings”.

By 2015 CTC had become the biggest independent pilot training company in the world, and Lee was Director of Business Development and Chief Operating O cer of the largest division in the company.

Success brought CTC to the attention of a larger business and that year it was bought by L-3 Communications in a transaction that valued CTC Aviation at around £140 million.

Lee could have stayed under the new ownership or returned to flying, but a chance encounter with global entrepreneur Tom Misner o ered him the opportunity to establish his own academy.

How does Skyborne select its trainee pilots?

“We look at aptitude and attitude. Pilots complete both psychometric and aptitude assessments, followed by an airline-style, competency-based interview.

“We want the very best people to come to our training school, but we also have a duty of care to individuals. They, or their sponsors, will spend more than £100,000 on their training.

“Around 80 per cent of our students have parents who will take out a second mortgage and make significant financial commitments to get them through. I am

happy to say that 98 per cent of our trainees succeed and all successful trainees get placed in their first job.”

Lee says Skyborne is unique in the industry to o er performance protection. This means that after completing selection, if a student fails in training, the academy will refund everything minus around £10,000, which is a non-refundable deposit.

“And if students need more training, there's no further cost, we cover it all, so it's one fee – that's it.

“We back our selection process. I think there's nothing worse than students in training being worried about the consequence of failure. So unless the student has committed a gross error, or fails to apply themselves, they will get the refund.”

Skyborne has also invested in its facilities. The academy at Gloucestershire Airport is purpose-built, with training rooms and a large hangar facing onto the airfield. Its site in Vero Beach, Florida is bigger and accommodates all students on site. At the Gloucestershire site, trainees live in Skyborne accommodation in the centre of Cheltenham. “Here they prefer being in a town,” said Lee.

The biggest challenge for the still young business to date has, not surprisingly, been Covid, when planes across the world were grounded.

“At that time our students couldn’t see a career pathway, but I kept saying – this will come to an end soon, there will suddenly be a global shortage of pilots. We are in that situation now. And many airlines are still playing catch up.”

Skyborne bought its Vero Beach site in 2021 from Flight Safety International and was able to continue training there as pandemic restrictions were somewhat more relaxed than in the UK.

“While we still trained at Gloucestershire Airport, it was a lot tougher and the stress on our sta and students was high.”

Does Lee miss flying? “I really do, but I’ve been so busy setting up Skyborne in Gloucestershire and Florida.

“I keep my licence going and get tested ever year. I’m still a trainer and examiner and I’ve definitely not flown my last flight.”

Home for Lee is the New Forest, but with two major sites in Gloucestershire and Florida, he doesn’t get as much time with his family there as he would like. “I play tennis and golf, and when I’m at home I get out on the water sailing as much as I can.”

As we close the interview Lee returns to a main concern, the cost of training.

“I’d love to find a funding solution to enable more people from all backgrounds to train as pilots, as I was able to do, and we will find one eventually. We’ve got all the statistics to show banks why their risk profile is almost negligible. I won’t give up.”

A new report from a team led by the Royal Agricultural University (RAU) in Cirencester, has shown how using by-products from farming could scale up cultured meat production and bring down costs.

This type of agriculture sees meat produced by culturing animal cells in a lab.

Simple forms of such meat like mince and nuggets are already possible.

According to research, cultivated product could cut the climate impact of meat by up to 92 per cent, and reduce air pollution by up to 94 per cent, but it isn’t currently authorised to be sold in the UK.

And research from Green Alliance, an independent environmental think tank and charity, found the UK’s sustainable protein industry (which actually replaces animal proteins in the food system entirely) could be worth up to £6.8 billion annually and create 25,000 jobs by 2035.

The RAU report, Culture Clash? What cultured meat could mean for UK farming, looked at the issues and the university team partnered with nine farms to explore what cultured meat mean might mean for them. It also investigated the threats and opportunities as seen by UK farmers.

Professor Tom MacMillan, Elizabeth Creak Chair in Rural Policy and Strategy at the RAU, who led the study, said: "The environmental cost of meat production globally means we need to throttle back, and widening the range of safe, tasty and a ordable alternatives to traditional meat can help.

"While the jury is out on whether cultured meat will fit the bill, we’ve found that it needn’t spell disaster for farmers.

"Those who spoke to us for this study had concerns about the technology but, for the most part, had many bigger challenges on their plates. Some were also interested

in its opportunities, from supplying raw materials to even producing it on their farms," he added.

Farming by-products which could be used in cultured meat production include leftovers from making rapeseed oil and blood from traditional meat production, which is sometimes used as fertiliser – or wasted. Both are rich in amino acids, the costliest and least sustainable ingredients used to grow cultured meat.

Linking cultured meat production and farming could also benefit some farmers and address concerns over the threat that such new technology poses to traditional farming, which has led Italy and some US states to ban cultured meat.

The farmers' main concerns were around wider social issues, such as big companies controlling the food system or the knock-on e ects for rural communities, more than about the direct impact on their businesses.

ProCook unveils plans for 10 extra stores next year – and 100 more after that

Total annual revenues have ticked up slightly at ProCook, to £62.6 million at the end of March.

The Gloucester-based direct-toconsumer kitchenware brand also plans to open 10 more stores and a further 100 in the medium term.

ProCook was founded as a family business in the 1990s. It launched on

the London Stock Exchange in 2021.

Chief Executive, Lee Tappenden, said: “We have improved our trading performance, returning to profitability and reducing net debt.

“We have a clear plan to accelerate profitable growth and are focused on building a stronger business that will support our ambitions.”

An urban regeneration scheme first announced way back in 2020 has finally been completed. Cheltenham Borough Council and Plexal’s Hub8, a workspace to support growth in the local tech community, opened the doors to the 20,000 sq ft MX Innovation Centre –the heart of their shared urban Minster Exchange (MX) scheme.

Located next to the Wilson Art Gallery and Museum and Cheltenham Public Library near the high street, the MX will o er startups town centre space to develop.

Cllr Rowena Hay, Leader at Cheltenham Borough Council, said: “This innovative new space will be a place for start-ups, academia, industry and government, particularly through its links into Golden Valley. It will also be a hub for the community, with a café and events space.

The Golden Valley is the ongoing multimillion pound development which will support the growth ambitions of the region’s cyber sector.

Bruce Gregory, Managing Director at Hub8 by Plexal, said: “We’re over the moon to have o cially cut the ribbon on the MX

We’ve already welcomed 60 businesses, with a total capacity for 400 members

Innovation Centre. It’s been a long time coming. We’ve already welcomed 60 businesses, with a total capacity for 400 members. These companies are working on everything from cyber security and marketing through to recruitment and food tech, demonstrating a diverse pipeline of talent.”

The project’s initial budget of just over £5 million ballooned to more than £9 million. The council said the project had been part-funded through government grants and the county’s Growth Hub. In 2022, Cheltenham Borough Council pledged a further £2.5 million. The following summer the council voted to extend the funding up to £9.27 million.

As the new Labour government set out its ambitious strategy to boost housebuilding, SNG (Sovereign Network Group) and Vistry Group, a leading mixed-tenure developer, have formed a new joint venture partnership to build 595 new homes in Thornbury, South Gloucestershire.

Outline planning consent for the site was secured in February last year, and it will provide up to 50 per cent a ordable homes including social rent, a ordable rent and shared ownership. Kent-headquartered Vistry will sell the open market homes via one of its three retail brands, Linden Homes, Countryside Homes or Bovis Homes.

The planning permission also includes the provision of a primary school, retail and community space, public gardens, open space and allotments. The partnership will contribute more than £6.5 million to improve local infrastructure and transport, as well as providing the council with support to operate the school and nursery that will be built on site.

Tom Titherington, Chief Investment and Development O cer at SNG, said: “This site is a positive step towards delivering our ambitious plans for tens of thousands of good, a ordable homes that are desperately needed. I’m delighted that our joint venture with Vistry will form a vital part of the delivery of this vision in South Gloucestershire.”

Cllr Mark Hawthorne, Leader of Gloucestershire County Council, is standing down and leaving politics.

Mark, 49, who has been active in Gloucestershire politics over the last 20 years, said: “This is not a political move – it simply means I am moving out of politics. I have been thinking about this for a while.

“The great thing about being a politician is that every four years the public get to say if they want you to continue, and as a politician you get to make that choice too.”

Mark was first elected as a county councillor in 2009. He was elected as Leader of the Council in 2010. Prior to that he served as Leader of Gloucester City Council between 2004 and 2007.

As a founding member of pan-regional growth partnership The Western Gateway, Mark worked to position Gloucestershire as a key player across the region and through his role on the

“The great thing about being a politician is that every four years the public get to say if they want you to continue ...”

Local Enterprise Partnership Board, (wound up earlier this year), helped secure a billion-pound pipeline of national investment to deliver some significant infrastructure schemes and projects across the county.

He added: “I have had lots of conversations about the future, but I haven’t anything lined up.

“I do need to go out there and earn a crust. I will look at some of the skills I have gained in local government and helping business across the region.”

Peer to peer (P2P) lender FOLK2FOLK has passed the £700 million lending milestone, which it says cements its position as the largest P2P lending platform to small businesses in the UK.

Since its launch in 2013, FOLK2FOLK has connected hundreds of local businesses with investors, providing loans from £100,000 to help them start, grow and diversify.

Investors enjoy the security of property-backed investment opportunities delivering returns –currently from 8.75 per cent per annum – and a track record of zero capital losses to date.

FOLK2FOLK, based in Gloucester and Cornwall, said hitting the £700 million lending milestone shows its commitment to regional growth by bringing small businesses and investors together, with resulting positive knock-on impacts for local economies across the UK.

Benefits range from job creation and housebuilding to enhancing local supply chains and improving leisure and tourism facilities, the company said.

In the past 12 months, FOLK2FOLK has funded a range of projects including a start-up creating custom handmade cricket bats, the purchase and operation of local village stores with post o ces and a multi-million pound renewable energy project.

Investors can self-select their investments, earning a fixed monthly income while knowing their funds are making a di erence in regional communities. Over the past year, FOLK2FOLK paid out £15.78 million in interest to investors.

The UK’s first inland surfing lake opened in Bristol in 2019. The Wave is now attracting close to 80,000 surfers every year. We meet its CEO, Hazel Geary

By Nicky Godding, Editor

If you don’t know what you want to do in life, learn skills to help you tackle anything a job might throw your way.

Hazel Geary, Chief Executive at The Wave in Bristol, picked mechanical engineering at university – a degree which gave her lots of transferable skills, not least being able to problem solve.

But she knew after a short stint as an engineer at the car manufacturer Nissan that a career in a boiler suit and steelies wasn’t her cup of tea (in fact only 20 per cent of UK engineering graduates go on to build a long-term career in the sector) so Hazel, now 42, began replanning her career.

Those 20 intervening years of problem solving, first as a management consultant and latterly in project management in the gym and leisure sector (of which more later) have brought her to her current role.

inland and build a world-first, health and wellbeing-focused surfing destination in Bristol.

Last year she accepted the job of CEO at The Wave in Bristol, the UK’s first inland surfing destination, taking over from Craig Stoddart. He’d worked with founder, Nick Hounsfield, to raise the funding, build and open this ambitious project.

The Wave, which opened rather inauspiciously in November 2019 just before the global pandemic, had long been a passion project for Nick. He wanted to bring a ‘slice of the ocean’

Having worked in healthcare for 18 years (he graduated as an osteopath in 1997) he saw that many of the physical and mental health issues people battled with were due to inactivity, a disconnection from nature and a lack of community.

He built a team around him, secured £30 million of investment and spent the next few years throwing his all into planning and overseeing the building of what is now a stunning destination at Easter Compton, just a few minutes o the M5 at Junction 17.

Up to 1,000 perfect waves are produced an hour generated by renewable energy. You can’t guarantee waves in the ocean, so for time-poor surfers who want to learn, improve or just enjoy the sport, it’s the perfect destination, any time of year.

The role at The Wave could have been written for Hazel. It had opened to much fanfare in November, then had to close the following March when the first lockdown was imposed.

“The project at Pune, near Mumbai, was a joint venture between David Lloyd and Talwalkers Better Value Fitness. We planned and built a nine-storey, 90,000 sq ft facility from scratch. It had swimming pools, tennis and badminton courts, gyms and restaurants.”

At the end of 2019, and with the project successfully completed, Hazel returned to the UK with her husband and first child. Their plan was to spend six months figuring out what to do next.

Cashflow is an issue for any young business and The Wave had invested heavily in excavating the lake itself, installing new technology to generate the waves, building a new shop, restaurant and changing facilities, and landscaping to preserve and improve the natural biodiversity of the land (which was green belt).

The venue also built its own solar farm in 2023. “We now generate 125 per cent of our electricity consumption every year and push surplus energy back into the grid,” says Hazel.

While Covid shut all leisure destinations for months, The Wave was able to reopen sooner than many in 2020 –albeit with reduced capacity – because its activities were outdoors.

But with a second baby on the way amid a global pandemic, she found her expertise in demand.

The Wave at Bristol is now a true destination and having taken on the CEO mantle from Craig, Hazel is building on everything that he and Nick, now a nonexecutive director, planned.

Over the next two years the business recovered well and has grown significantly. Last year it turned over around £10 million and now employs almost 300 people.

“I returned to consultancy, working with lots of consumer-facing businesses, including helping start-ups fundraise and get their ideas o the ground. For others, I was called in to help fix particular issues, often associated with Covid disruption.”

“Lots of them are on fixed-term contracts because we’re a seasonal business,” explains Hazel. “But many disappear to warmer climates over the winter and return to us the next year.

For The Wave, as with pretty much every sporting venue, Covid was a big challenge.

“Our whole purpose is about creating a happier, healthier world one wave at a time,” she says.

Which is a great slogan. But is it succeeding?

Most definitely. When I arrive for this interview (on a windy, overcast summer morning), scores of people are milling around.

“We welcome back around 44 per cent of our seasonal sta – incredible when you compare us to other seasonal businesses.”

Prior to taking over at The Wave, Hazel spent almost 10 years with David Lloyd Leisure. “When I joined, there were about 90 sites across the UK and a further 10 or so across Europe.

wetsuits of our seasonal sta – incredible when

Some are in wetsuits preparing for a session, others comfortably settled with laptops and frothy co ees at long rustic tables in the woodframed café (which serves local food), overlooking the lake.

“I was recruited to help solve the strategy problems that fell between the cracks of everybody else's day jobs.”

She quickly became product director, managing everything from food and beverage to children and adult products, even gym design. Her experience culminated with three years in India taking the David Lloyd concept to the sub-continent.

Our whole purpose is about creating a happier, healthier world one wave at a time

Young mums with pre-school children are tucked into another part of the café. On the other side of the space there’s a large, airy shop and outside, a purpose-built children’s play area. The site even a skate ramp.

“We no longer charge an entrance fee for people who just want to come and sit in our café and enjoy this incredible space,” says Hazel.

Alongside its aim to be sustainable, The Wave wants to be accessible to more people.

“Surfing is seen as expensive,” admits Hazel. “It has been considered a middle-class sport and we want to change that.

“We want to welcome people of all ages, backgrounds and abilities, so our impact programme is all about how we try to unlock those barriers.”

One of its programmes is supporting the adaptive surfing community. In July, The Wave hosted the English Para Surfing Open, attracting athletes from all over the country.

“We have a 20-strong team trained in supporting people with all sorts of physical challenges,” Hazel adds.

The Wave also works with other groups, often laying on transport from Bristol, supported by its corporate partners, including Good Energy.

“This year through our Big Blue project, we aim to give out 750 surfs to local schools and charities to get young people down here who otherwise wouldn’t have been able to come.

“Our most a ordable sessions are our Play in the Bay sessions, for young children who just want to come and play as families in the water. Children from as young as six months can enjoy. They can bring their own body boards or use ours, and our wetsuits. Or they can just jump in and out of the waves, without needing any equipment at all.”

A growing area of business is catering for corporate events.

“Many businesses want somewhere di erent, and we’re a cool place to be. They don’t have to go near the water, but if they do, we o er team events. And the great thing is that because so few people surf, it’s rare that anyone in the group will be an expert so everyone has a good time together – it’s a great leveller. What you don’t see around here is unhappy people. All we see are smiles.”

And that’s important to Hazel, who understands (particularly from her three years in India) the importance of good customer service.

“Customers are at the heart of everything we do. An important piece of the jigsaw for me is making sure our Wavemakers – as all of our team are known – are well trained, love what they do, and can create an incredible experience for absolutely every single person that walks through that door.”

It’s working. Last year, The Wave welcomed around 80,000 surfers, many returning multiple times. And that doesn’t count those visiting the site shop, café or other facilities.

“We estimate that we welcomed up to around 250,000 people.”

Having got the Bristol site up and running, what about expansion? It could be on the cards.

“Discussions have been ongoing for a while on a site in Enfield, in north London and we are talking to others. Covid slowed things down, but we continue to explore potential new locations. However, our focus for the last two years has been to make sure that this business is profitable so that we have a successful blueprint for a second one.”

The Wave was the first inland surfing destination, but others have seen the opportunities. “There are sites under development in Birmingham and Edinburgh. And it’s important we support each other. The industry is growing, and we want it to grow safely.”

Does Hazel surf? “I wasn’t a surfer when I joined, now I’ve gone from being a complete novice to moving towards advanced. My children are still very young but my oldest is learning to surf and my youngest wants to learn when she’s old enough. Our coaches are always in the water for the lessons, and we have separate lifeguards in red who are positioned around the water. Safety is paramount.”

Her husband, though, is a golfer. She sighs. “The Wave isn’t for everyone, though he says he’s happy to surf when the sun is shining.”

Office workers spend 75 per cent of their time sitting. It’s bad for your health, says the NHS. What can help is a chair designed for you

By Ian Mean, Business West Gloucestershire Director and The Business Magazine contributing writer

I looked up ergonomics in the Oxford dictionary. It told me it was “the study of people’s e ciency in their working environment”.

It was the explanation I needed to understand the rationale of an interesting company making very special o ce chairs, and appropriately called Ergochair.

Based at Yate near Bristol, Ergochair has achieved double-digit growth every year for almost a decade and now has a multimillion-pound turnover making these chairs, many of them customised to the individual’s working needs.

Managing Director Ben Caton, 35, who used to run health clubs, tells me: “The powerful statistic that got me about Ergochair was that in the last 15 years we have helped more than 115,000 people sit better, and lead more comfortable lives.

”For me, as someone who was the end user of the product before I ran the company, it’s the science behind a human being’s wellbeing in whatever posture they use throughout their day.”

Ben asks a pertinent question about how we look after our employees in their work environment: are we really aware enough of the wellbeing of our sta ?

So how can a company justify spending what might seem quite a lot of money on one of Ben’s customised chairs, which range from £600-£1,200?

“You wouldn’t think twice about buying a really good mattress,” he says. ”And then thinking that’s going to make a real di erence to my sleep.

“However, there are people who would question the provision of a good o ce

“Not all homeowners have a good office set-up in their garage”

chair. Just look at the time spent – they are pretty similar.

“How much time do you sit down at work? Four or five years ago, it might have been the majority of the working day – that all changed with Covid.

“Working at home, people are probably sitting on a dining room chair, a sofa or a bean bag. Not all homeowners have a good o ce set-up in their garage.”

Ben believes that providing a good o ce chair is quite an easy way of keeping sta happy.

“If I said to any business owner, I can give you a way to hold on to that incredibly talented member of sta for an extra five years, the return on that chair investment would not be questioned.”

Ergochair has six new products coming on stream this year and their growth aspiration according to Ben is to become the preeminent player in Europe.

“We are making progress in the UK,” Ben said. “But the Europeans have found a way to blend architectural beauty and designled thought with a passion for ergonomics and the wellbeing of their sta ”.

Nine pioneering startups have secured £50,000 to develop prototypes using artificial intelligence (AI) to enhance creative production and help grow the UK’s creative economy.

The programme is run through Digital Catapult, the UK's innovation agency for advanced digital technology.

The BBC will work with Bristol-based Fictioneers, which has developed a collaborative canvas for storytellers and software engineers who are making personalised, game-like experiences in real and virtual locations, and Bath-based The Gentleman Octopus to improve its audio output and audience engagement.

The Gentleman Octopus applies robotic technology and engineering approaches, alongside software development and extended reality technologies to provide design services and bespoke installations, builds and visualisations for events, festivals, theatre, marketing and event management companies.

The aim of this collaboration is to enable the BBC to deliver more immersive content.

Cloud service provider AWS will work with Bristol-based companies Nulight Studio, Noods Radio, Force of Habit and London-based SuperScout to pioneer new AI-based production methods.

Two other Bristol-based businesses are also involved. Gritty Talent aims to improve engagement, retention and progression of talent in the creative sector. Weaving Change wants to democratise fashion by developing AI to suggest personalised outfits from users' existing wardrobes.

Matthew Hawn, CEO of Fictioneers, said: “Generative AI has the potential to be far more than a tool for generating gigabytes of anodyne content. Our prototype demonstrates how AI can become a bicycle for creative minds. We’re not replacing storytellers, we’re giving them superpowers.”

Brazilian Jiu Jitsu association Roger Gracie Bristol (RGB) has received investment of £390,000 from BBRC (Bristol & Bath Regional Capital) to improve the lives of local people.

RGB generates social impact with initiatives that bring people in personal crisis “onto the mats” through interventions, programmes and concessionary rates for struggling and vulnerable people.

Since 2017, RGB has helped more than 30 vulnerable women, 38 ex-military and 35 Avon and Somerset policemen with selfdefence skills.

It has also provided 18 child scholarships for families struggling with costs, and a crisis management rehabilitation programme for children with ongoing issues of parental drug addiction, neglect and abuse, while employing seven members of the local community.

Tech firm

It is led by two brothers who grew up in the Southmead area. And its clubs in Southmead and East Bristol now provide regular training sessions to more than 800 members.

The brothers hope to double this thanks to the investment from BBRC’s nvestment fund City Funds. There are plans for three more clubs across Bristol in the next few months.

Luke Chamberlain, Head Coach and Cofounder at RGB, said: “Our mission is to empower more than 2,000 members of the Bristol community with Jiu-Jitsu as a way to find focus and support.”

Jari Moate, investment director at BBRC, added: “RGB is delivering significant impact for local people and will be able to double its e orts as a result of this investment. It’s great to hear the stories of the people that have benefited from its training sessions.”

A Portishead company specialising in electrical monitoring and asset integrity for industries such as subsea, rail and industrial has undergone a management buyout.

Edward Davies, Hugo Mansfield, James Carnegie and Rebekah Howard have bought a majority stake in Viper Innovations from co-founders Neil Douglas and Max Nodder who retain a minority stake, as does long-standing investor and customer, Oceaneering International Services. The company is aiming to diversify its portfolio and go for international growth in subsea markets.

Edward Davies, Managing Director, said: “From a sustainably growing and profitable base in subsea energy and rail, our objective is to grow existing electrical monitoring and asset integrity solutions in our current sectors and extend them into new sectors and geographies.”

As we travel more, we increasingly cook exotic dishes, and Bart Ingredients is with us every step of the way

By Nicky Godding, Editor

Every kitchen has at least one herb or spice in the cupboard, even if it’s just a little pot of pepper (the best-selling spice in the world).

But if you’re the boss of one of the UK’s most well-known spice companies, you could have 500. Adam Sims, 38, who took over as Chief Executive of Bristol-based

Bart Ingredients earlier this year, must have a very large spice rack to accommodate Bart’s full range (and he does admit his wife groans a bit when he comes home with yet another spice mix).

Adam’s top seat at Bart’s table comes after nine years at the company, most recently as Chief Commercial O cer, but he’s undertaken many roles there, including business development, finance and category insights.

The business was founded in Bristol by Jo and Reg Bartlam in 1963, when the most exotic spices in our kitchen cupboards were probably nutmeg and cinnamon.

But as we all began traveling further afield, our tastebuds got increasingly demanding and by 1983, Jo and Reg had built a factory in the city’s Bedminster area. They sold the business in 2010 and today it’s owned by Germany’s largest spice producer, Fuchs Gruppe.

“I enjoy the food sector and perhaps because I like solving puzzles, I also enjoy navigating the often complex supply chains that are part of it ...”

Fuchs has invested in Bart, including funding a move to a purpose-built 167,000 sq ft site at Severn Beach in 2021 after rising demand saw the business outgrow its Bedminster site. The smart new facility now houses Bart’s entire dry goods business. It has another facility in Newbury which handles wet goods such as sauces, pastes, marinades and relishes.

The move to Severn Beach happened during Covid and with a lot of the production and packaging lines coming from Italy, it was a challenging project to complete, according to Adam.

“Getting engineers over was impossible,

so we had to do a lot via WhatsApp calls. But with sales going through the roof because everyone was cooking from home, we had to get it done to meet a big uptick in demand,” he said.

Adam, who grew up in Portishead, has always worked in the food sector. After completing a degree in accounting and finance at Bournemouth University, his first job was in the accounts department at Dairy Crest in Surrey. With time out to go travelling for six months (including in Jordan and Southeast Asia), he returned to Dairy Crest – this time to the food manufacturer’s site in Frome, Somerset.

In all, he spent seven years at the dairy company, rising to Site Accountant before looking for wider management opportunities elsewhere.

“I enjoy the food sector and perhaps because I like solving puzzles, I also enjoy navigating the often complex supply chains that are part of it. So when the job of Head of Commercial Finance came up at Bart in 2014, I went for it.”

With hundreds of product lines to account for from suppliers across the world he was certainly challenged, but what Bart also o ered was career development.

He explains: “I began learning about all

parts of the business, from products to commercial development, and realised that I enjoyed a wider remit.”

By January last year he had become Chief Commercial O cer and took over as Chief Executive this April.

He says that the backing of Fuchs Gruppe, the second largest herbs and spices manufacturer in the world, is driving growth.

“Fuchs bought Bart in 2017, and the first couple of years were spent integrating the businesses and planning for growth. Then the pandemic hit, during which we moved to our new site, so it’s only in the last year that we’ve really begun to tap into the huge opportunities available to us as part of the bigger group.”

Bart is Fuchs Gruppe’s only UK brand, and where previously it was supplying the UK from Germany, production for some items has now been switched to Bristol, boosting the company further.

In his new role, Adam’s first priority earlier this year was to commission new packaging which pays homage to each spice’s continent of origin and the specific plants which produce the ingredients. The new packaging also has useful tasting notes.

Adam said: “The UK herbs and spices sector has grown by more than £150 million since 2019 and shows no signs of slowing. Within this Bart is currently the fastest-growing brand, with sales increasing more than 60 per cent year-on-year.”

He also wants people in Bristol and across the South West to learn more about and be proud of the business born here 60 years ago.

“We employ around 200 people across both our sites, and we are really proud of where we come from.”

Bart sources its herbs and spices from around 70 countries globally. Most of them are processed in their country of origin to keep them as fresh as possible, and sent to Bart’s Severn Beach facility where they are sorted, bottled and packed for sale.

It also encourages its growers to be as carbon-friendly as possible. “We buy pepper from Vietnam and Brazil, its’ two main growing regions. The pepper vine grows like a totem and many growers have in the past used concrete poles. But as part of the Fuchs Gruppe, we have researched and invested in alternative, better ways to grow pepper and are now encouraging our suppliers to save carbon by growing them against the Mexican lilac – known as the Gliricidia tree.”

Sustainability is a growing focus for Bart. “We have always worked with our suppliers on food safety. Now we also make sure that our sourcing is ethical.”

For Adam it’s all about quality. “We will work with suppliers who achieve the quality we expect. If they haven’t got accreditations such as Fair Trade, Fair for Life or Rainforest Alliance, then we can have a bigger impact by educating and supporting them to become accredited, rather than working with a company which might have a certificate but which we believe isn't supplying the quality we need.

Bart can’t source any of its herbs from the UK at the moment because the country doesn’t grow them in volume, but this is something Adam wants to investigate. “It would be fantastic to collaborate

“We employ around 200 people across both our sites and we are really proud of where we come from”

with growers in the UK and I’m open to discussion.”