THE SAFETY NET

Workplace Stress and Mental Health Matters

Stress can be harmful to our health and increase mental health challenges. Mental health challenges can include clinical mental illness and substance use disorders as well as other emotions like stress, grief, feeling sad and anxious, where these feelings are temporary and not part of a diagnosable condition.

SAFE T Y FIRST. Austin employees have worked 5,827,269 hours without a Lost Time Accident through 08/2023.

LOCATION CONSULTING DESIGN & ENGINEERING DESIGN-BUILD CONSTRUCTION & CONTRACTING OCTOBER 2023 VOLUME 17 ISSUE 10

IT’S ALWAYS SAFETY FIRST. CONSULT • DESIGN • ENGINEER • CONSTRUCT

08.13.2023 | EHS Today

While there are many things in life that induce stress, work can be one of those factors. However, workplaces can also be a key place for resources, solutions, and activities designed to improve our mental health and well-being.

STATISTICS

• Nearly one in five US adults live with a mental illness2.

• Workplace stress has been reported to cause 120,000 deaths in the US each year3.

• Approximately 65% of U.S. workers surveyed have characterized work as being a very significant or somewhat significant source of stress in each year from 2019-20214

• 83% of US workers suffer from work-related stress.

• 54% of workers report that work stress affects their home life 5 .

• For every $1 spent on ordinary mental health concerns, employers see a $4 return in productivity gains.

UNDERSTANDING THE PROBLEM

Workplace stress and poor mental health can negatively affect workers through1:

• Job performance

• Productivity

• Work engagement and communication

• Physical capability and daily functioning

Loneliness. Isolation. Uncertainty. Grief. Fear. Stress can increase these and other mental health challenges and can be harmful to our health . Read more about understanding the problem here

GUIDEANCE AND TIPS FOR EMPLOYERS

Workplaces can have many stressors. Issues in the workplace can exacerbate the risk of experiencing mental health challenges. Combined, these stressors can

make it more difficult for workers to get their tasks done; threaten their productivity, happiness, and well-being; and lead to burnout. Read more about guidance and tips for employees here

TRAINING RESOURCES

The idea of talking about stress and mental health at work might feel scary or too personal. These can be sensitive topics that require a foundation of trust and goodwill to broach, or alternatively, the support for a worker to seek external resources and assistance outside of the workplace Find more training resources here

REAL-WORLD SOLUTIONS

There’s no one-size-fits-all strategy when it comes to alleviating workplace stress

OUTREACH MATERIALS

It is imperative to talk about mental health; shine light on the stressors; strategize about ways to alleviate stress them; and be on the lookout for signs and symptoms of stress and mental health emergencies so that people can either direct themselves, their friends, co-workers or family members to helpful coping and resiliency resources or other supportive networks and services if needed. The key is to build awareness, and the outreach products identified below will help with that goal. Find more outreach materials here.

1 Centers for Disease Control and Prevention. (July 2018). Mental Health in the Workplace.

2 National Institute of Mental Health. (January 2022). Mental Illness.

3 Goh, J., Pfeffer, J., & Zenios, S. A. (2015). The relationship between workplace stressors and mortality and health costs in the United States. Management Science, 62(2), 608-628.

4 American Psychological Organization. (October 2021). Stress in America: Stress and decision-making during the pandemic.

5 The World Health Organization (2022). Mental health in the workplace.

America’s Safest Companies 2023: S&B Engineers and Constructors

08.10.2023 | EHS Today

S&B’s safety motto is: See it. Own it. Solve it.

S&B Engineers and Constructors: Engineering and construction | Houston, TX

4,800 employees | 22 sites | 123 EHS professionals

Compromise is unacceptable at S&B Engineers and Constructors with respect to safety.

To ensure that everyone lives up to their potential when it comes to safety, the company embraces the concept of personal ownership. Their motto is: “See It, Own It, Solve It (SOS).” If an employee sees something that they consider unsafe, they need to take personal accountability in that situation and act, either by personal intervention or by getting someone else involved to address the issue. And to further emphasize the importance of this concept, the company has a program called Life Saving Commitment. “This is a tool that reinforces personal ownership and accountability when S&B team members are performing work that has a known risk of serious injury or fatality if hazards are not properly controlled,” says Brad Gibson, vice president of HSE. “They have been developed with the understanding that human error is normal and that even the best people make mistakes. When errors do occur, these Life Saving Commitments and their critical

elements will prevent an unrecoverable and potentially fatal outcome. As such, a Life Saving Commitment is something that an individual makes for themselves, their coworkers and their family.” The goal, Gibson says, is for all employees to actively care for each other and to treat each other like a family member.

In tandem with the SOS, S&B has a program called People Observing People (POP), which is a behavior-based safety program. For this program, the company focuses on the following areas:

• Fall protection

• Tools and equipment

• Mobile equipment

• Body positioning

If unsafe behavior is observed and corrected, employees are asked to document this progress through a POP database. Comments and suggestions are also encouraged, and the company is currently averaging 2,000 observations per week.

This level of participation reflects the level of emphasis placed on safety. As Gibson explains, “The safety of personnel shall have priority over the protection of property and operational considerations.”

3

America’s Safest Companies 2023: Cajun Industries

08.01.2023 | EHS Today

Construction company Cajun Industries adheres to the belief that all accidents are preventable and injury is not an acceptable by-product of their work.

Cajun Industries LLC: Construction | Baton Rouge, LA

1,842 employees | 3 sites | 49 EHS professionals

At construction company Cajun Industries, every employee must embrace the value that “all accidents are preventable and injury is not an acceptable byproduct of our work,” explains Colton Possoit, professional development specialist at Cajun. “As managers, we recognize that profits are enhanced by our Zero Accident Goal.” That number “zero” is significant for Cajun Industries, as the company has maintained a zero-fatality rate since its founding in 1973, 50 years ago. The company is also pursuing a goal of Cajun’s goal is zero OSHA recordable injuries and zero motor vehicle accidents.

Cajun Industries devotes a lot of time, effort and attention to safety and health training, which includes an accredited training facility and a corporate training department. The company provides nationally recognized training in areas such as rigging, signaling, carpentry, heavy equipment, cranes and welding. “Our training efforts are ongoing, with weekly Hazard Awareness Trainings (HATbox) and regular periodic reviews of training records,” Possoit says. “We also use Credential Verification Services to track and verify employee training. At Cajun, we believe in a familyoriented safety culture and take pride in our dedication to providing comprehensive safety and health training for all employees, new and experienced.”

One of the hallmarks of an America’s Safest Companies winner is they go above and beyond what a typical company would do. As Possoit explains, in the years 2020-21, there were numerous recalls of fall protection equipment. At that time, Cajun’s management team undertook an extensive survey to learn and understand what brands of all fall protection were being utilized by Cajun and job sites across the Gulf South. That led to an evaluation of three U.S.-based fall protection equipment manufacturers with no safety recalls, with the goal of only using the best and safest fall protection gear.

Achieving that goal, Possoit points out, meant collecting and destroying $260,000 worth of fall protection equipment that hadn’t been produced by one of the three preferred manufacturing brands.

The company also has a very structured mentor program. “All Cajun employees are assigned a Cajun mentor during their first 90 days of employment,” he explains. The mentor stays in close proximity to the mentee and communicates Cajun-specific information such as policies, standard operating procedures and best practices. “At the end of the 90 days the employee’s supervisor makes the determination on whether or not the newly hired individual needs to be mentored any longer.”

Also, employees with less than one year of working in industrial construction are paired with a mentor for one year. “The experienced Cajun employee serves as an additional set of eyes to assist that employee with industrial construction hazards.”

What Is a Safety Culture and Why Do You Need One?

06.20.2023 | EHS Today

The existence of an active safety culture is a mitigating factor likely to result in lesser penalties or no penalties at all.

The term “safety culture” gets bandied about a lot, but it’s also a term that nobody quite understands. What exactly is safety culture? And what, if any, impact does it have on a company’s liability risks?

WHAT SAFETY CULTURE IS

Safety culture is one of those fuzzy concepts like “obscenity” that nobody can precisely define but everybody knows it when they see it. Safety culture is first and foremost a mindset, a set of shared values and thinking among all the members of an organization.

When we say a company has a “good safety culture,” we basically mean that people who work their care about and accord high priority to safety—that safety is a part of the company’s DNA that gets transmitted to all progeny. Probably the best way to identify safety culture is by looking for the characteristics it’s associated with. Thus, according to a study from the University of Illinois, in a workplace with a safety culture, everyone at every level of the company places enduring value and a priority on safety and:

• Is committed to personal responsibility for safety.

• Acts to preserve, enhance and communicate safety concerns.

• Strives to actively learn, adapt and modify their behavior based on lessons learned from safety errors and incidents.

• Is rewarded in a manner consistent with these values. Safety culture generally yields safe performance. Although accidents and injuries can still happen at companies with

strong safety cultures, such mishaps tend to be more the product of bad luck than carelessness, neglect, or lack of adequate safety resources.

HOW SAFETY CULTURE AFFECTS LIABILITY

Safety culture also has an important—albeit indirect—impact on a company’s liability risks. OSHA regulations don’t say employers need a good “safety culture.” In fact, they don’t mention the term at all.

Nevertheless, safety culture is a concept that OSHA officials embrace and refer to in enforcing regulatory requirements. An organization’s safety culture, or lack thereof, is a factor considered by:

• OSHA inspectors in determining whether to issue citations and how to classify them, e.g., as “serious” or “willful.”

• OSHA inspectors and administrators in deciding how much to fine an organization for a particular violation.

• Courts and administrative tribunals like the Occupational Safety and Health Review Commission (OSHRC) in deciding whether to uphold OSHA fines and penalties on appeal.

THE BOTTOM LINE

The existence of an active safety culture is a mitigating factor likely to result in lesser penalties or no penalties at all. Lack of a safety culture is an aggravating factor likely to lead to more severe penalties, as well as targeted followup enforcement under programs like the Severe Violator Enforcement Program (SVEP).

5

Fire Protection

09.12.2023 | Weeklysafety.com

Join the National Fire Protection Association (NFPA) and organizations across the nation this year in observing National Fire Prevention Week October 8 – 14, 2023.

The 2023 Fire Prevention Week campaign works to educate everyone about simple but important actions they can take to keep themselves and those around them safe from home fires.

Today’s homes burn faster than ever. You may have as little as two minutes (or even less time) to safely escape a home fire from the time the smoke alarm sounds. Your ability to get out of a home during a fire depends on early warning from smoke alarms and advance planning.

The National Fire Protection Association (NFPA) is a global nonprofit organization, established in 1896, devoted to eliminating death, injury, property, and economic loss due to fire, electrical, and related hazards.

Since 1922, the NFPA has sponsored the public observance of Fire Prevention Week. In 1925, President Calvin Coolidge proclaimed Fire Prevention Week a

national observance, making it the longest-running public health observance in our country. During Fire Prevention Week, children, adults, and teachers learn how to stay safe in case of a fire. Firefighters provide lifesaving public education in an effort to drastically decrease casualties caused by fires.

Fire Prevention Week is observed each year during the week of October 9th in commemoration of the Great Chicago Fire , which began on October 8, 1871, and caused devastating damage. This horrific conflagration killed more than 250 people, left 100,000 homeless, destroyed more than 17,400 structures, and burned more than 2,000 acres of land.

This year’s Fire Prevention Week campaign provides an ideal opportunity to educate workers about the importance of fire safety. NFPA has everything you need from ready-to-use press releases and safety tip sheets to printable activities, logos, and more. (The press release and event flyer are also available in Spanish.)

The NFPA provides plenty of Safety Tip Sheets that can be great resources to hand out to workers, post on bulletin boards, email out to staff, or even use to host a quick safety meeting.

• Host a family fire safety event or send home kid-friendly activities with employees. Stock up on educational brochures , stickers, fire hats, coloring books and sheet pads, posters, Sparky the Fire Dog value packs, and other materials that make great giveaways during your Fire Prevention Week.

• Host a short safety meeting on fire safety at home and at work.

• Include information about Fire Prevention Week in your organization’s newsletter.

• Post Fire Prevention posters or safety tip sheets around the workplace.

• Provide fire extinguisher use training to workers.

In a fire, mere seconds can mean the difference between a safe escape and a tragedy. Fire safety education isn’t just for school children. Teenagers, adults, and the elderly are also at risk in fires, making it important for every member of the community to take some time every October during Fire Prevention Week to make sure they understand how to stay safe in case of a fire.

On the NFPA website , you’ll find loads of safety resources to make sure that every person knows what to do in case of a fire. You can find everything from apps to videos to printables and much more, to make sure your workers have the resources they need to keep their family and community safe.

• Ensure all workplace fire extinguishers are fully charged, operating properly, and ready, if needed. Confirm that all fire extinguishers are readily accessible in the event of an emergency and annual inspections are scheduled. If your company participates in Fire Prevention Week this year make sure to share the message on social media using the hashtag #FirePreventionWeek

For more information about Fire Prevention Week, including access to tons of free resources, visit firepreventionweek.org

Here are some great ideas of ways your organization can participate in Fire Safety Week this year:

Awareness campaigns, like Fire Prevention Week , offer a great opportunity to safety management, business owners and management to highlight the importance and commitment the organization has to safety, for workers, their families, and the community. It doesn’t take a lot of time, money, or resources to participate. At minimum, consider staff email, a brief safety meeting, or a poster on the central bulletin board.

7

NSC Awards Innovators Aiming to Solve Most Common Workplace Injury

07.19.2023 | EHS Today

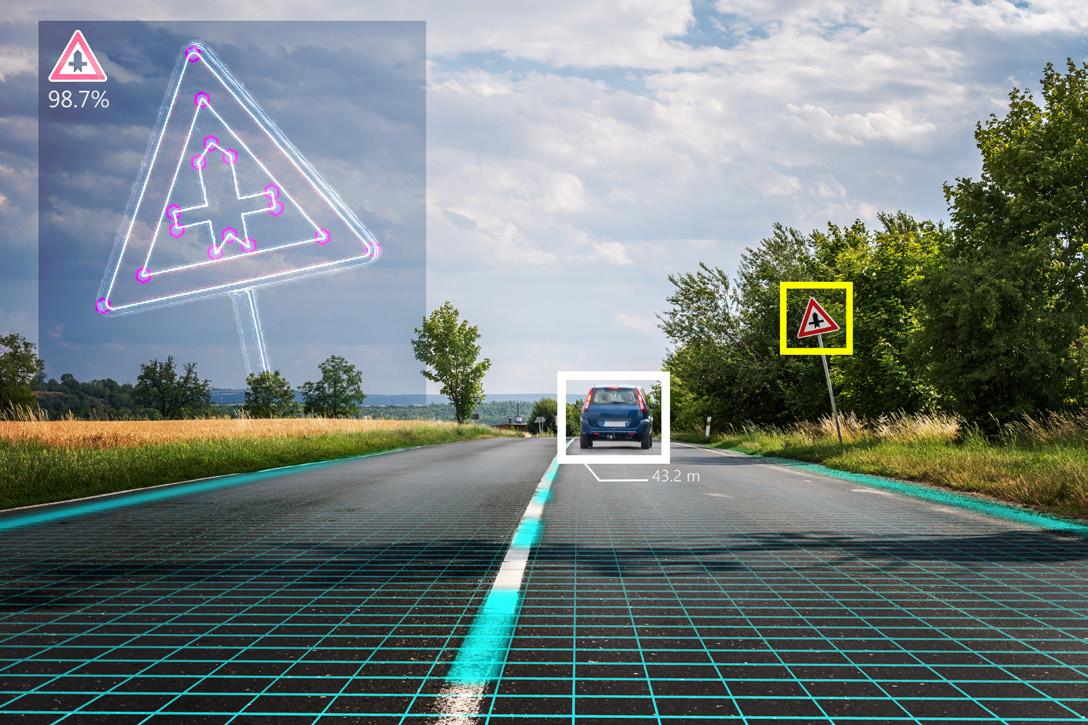

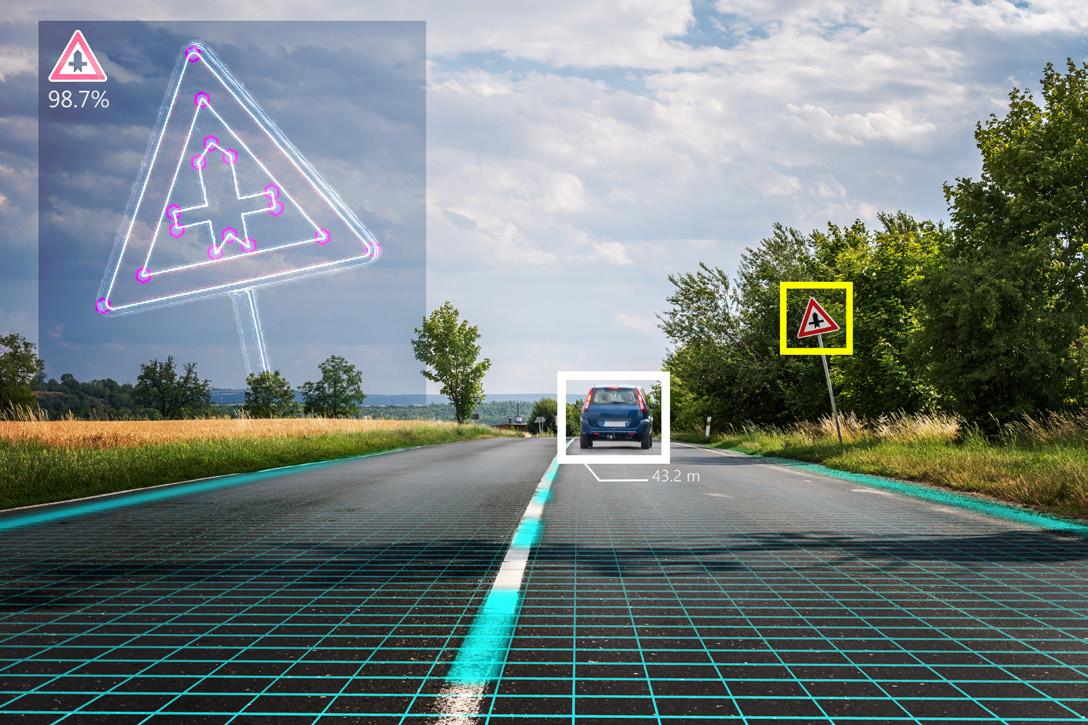

While MSDs are complex, technology advancements are helping in the search for solutions.

In an effort to reduce instances of work-related musculoskeletal disorders, or MSDs, the National Safety Council , awarded nearly $275,000 through its recentlylaunched Research to Solutions (R2S) grant and MSD Solutions Pilot Grant 1.0 programs to help nine leading organizations advance promising new safety technologies.

Unveiled in March of this year through the Council’s MSD Solutions Lab , these new grant programs aim to foster innovative, transferable solutions to mitigate MSDs – the most common workplace injury – across a range of sectors and workplaces.

For the inaugural 2023-2024 grant cycle, NSC called upon R2S applicants to support one or more key research areas, including emerging technologies, solutions to jobs or tasks known to have high MSD risk, MSD management systems, future of work, and total worker wellbeing. This year’s R2S grant winners include the following organizations:

• Rutgers University (Piscataway, New Jersey), awarded $75,000 to implement an automated image captioning system, designed to help employers better identify ergonomic risk factors and real-time solutions.

• Iowa State University (Ames, Iowa), awarded $61,000 to develop a predictive model and AI-based ergonomics app for risk assessment and mitigation that enables

employers in high-risk industries to understand shoulder MSD risk in different scenarios impacting their workers – with and without an exoskeleton – to make more informed decisions about injury mitigation.

• Virginia Tech (Blacksburg, Virginia), awarded $51,000 to implement inexpensive, camera-based marker-less sensors along with machine-learning models to assess worker physical exposures and MSD risks more efficiently, accurately and comprehensively.

• University of Waterloo (Waterloo, Canada), awarded $37,000 to generate evidence-based guidance on computer vision-based MSD risk assessment technology in the workplace, so employers can better determine the optimal approach and timing for integrating computer vision-based MSD risk assessment tools into their ergonomics programs.

“Hoping that the work we do each day translates to safer outcomes for millions of workers on the frontline is what inspires our team to continually push the boundaries of safety innovation,” said R2S grant winner Dr. Maury A. Nussbaum, CPE, professor of Industrial and Systems Engineering at Virginia Tech, in a statement. “MSDs are notoriously complex, as is their prevention, but technology advancements have made it possible for research teams like ours to collaborate with others, assess root causes, and propose scalable solutions more effectively than ever. We are honored to build on this progress through our work with the MSD Solutions Lab and R2S grant.”

The MSD Solutions Pilot Grant 1.0, designed to help organizations prevent MSDs specifically caused by manual materials handling, provides MSD Pledge members with the opportunity to team with technology providers to trial emerging solutions in real-life applications. Pledge members selected for the inaugural MSD Solutions Pilot Grant 1.0 include:

• Amerisure Insurance,awarded $10,000, will work with both computer-vision provider TuMeke Ergonomics and HeroWear, which specializes in passive back-assist exosuits, to prevent MSDs enterprise-wide.

• Burlington Hydro,awarded $10,000, will use TuMeke Ergonomics’ computer vision technology to assist with conducting ergonomic assessments of the company’s powerline technicians.

• General Electric Aerospace Erlanger Kentucky, awarded $10,000, will partner with HeroWear to better understand the operational benefits and worker impact of using exosuits to unload cargo trailers.

• Guarantee Electrical Company, awarded $10,000, will work with TuMeke Ergonomics to detect unsafe postures and glean data-driven insights to optimize their workplace safety programs.

• Lafarge North America, awarded $10,000, will team with TuMeke Ergonomics to use computer vision technology to scan construction workers’ movements during manual material handling activities to better identify MSD risks and assess targeted solutions.

“Overexertion involving handling objects is the No. 1 cause of disabling workplace injuries, and uncovering safer ways to help employees lift, lower and transport items is fundamental to achieving a drastic reduction in MSD injuries worldwide,” said Paul Vincent, executive vice president of workplace practice at NSC, in a statement. “Both grant programs call upon the industry’s brightest minds to help advance and find new ways to solve this pressing safety challenge.”

The inaugural grant recipients will have an opportunity to present their safety findings at the 2024 NSC Safety Congress & Expo or another event next year.

9

Protecting Construction Workers Against Extreme Temperatures

04.17.2023 | EHS Today

The right PPE can help workers maintain healthy and safe body temperatures while minimizing the risk of heat-related illness or injury.

Between 2011 and 2019, there were 344 worker-related deaths caused by environmental heat exposure, according to the Bureau of Labor Statistics. It’s widely thought, however, that this number is an underrepresentation, not inclusive of worker deaths due to conditions like heart attack, which can be brought on or exacerbated by unsafe heat conditions.

In the three years since this data was recorded, we’ve seen record-shattering temperatures around the globe. Over the past year, for instance, 67 all-time high-temperature records have been broken across the U.S.; globally, 230 such records have been broken over that same time period. As temperatures continue to rise, it’s reasonable to expect the number of heat-related worker deaths, injuries and illnesses to rise as well.

While these extreme temperatures continue to impact the health and safety of workers across geographies and industries, the global construction industry is particularly vulnerable to the effects of unprecedented heat.

Construction workers are required to engage in hard, physical labor outdoors and often work longer hours during the year’s hottest months due to the increased hours

of daylight. The combination of record-breaking heat, physical labor and long hours puts construction workers in significant danger.

In addition to having a negative impact on worker health and safety, rising temperatures can harm construction businesses in the form of lost or less efficient labor. Construction employees must work slower and take more breaks in high-heat environments, and they must take time away from the jobsite to recover in the wake of a heat-related illness or injury. Though heat-related death, illness and injury are the most severe outcomes of working in a too-hot environment, the negative effect of lost labor is a notable consideration for businesses in the construction industry.

Thankfully, there is much that can be done to help construction workers stay safe and healthy through the hottest days of the year—and to ensure the continuation of effective, efficient and safe labor on the jobsite.

One such measure is to equip workers with the right protective gear for the environment in which they’ll be working. Many forms of PPE can actually increase a worker’s temperature by minimizing airflow, reducing the body’s natural ability to cool itself by sweating, and through the added weight of the equipment that the wearer must carry while working. However, there are specific PPE

features and types that can help do the opposite, allowing workers to maintain healthy and safe body temperatures while minimizing the risk of heat-related illness or injury.

CHOOSE THE RIGHT HARD HAT FOR THE JOB

One of the easiest places for construction site managers and employers to begin when looking for ways to protect their workers against high temperatures is with the hard hat, a mainstay of the construction site. It’s essential that construction workers are equipped with the best hard hat for the conditions under which they’ll be working— and some hard hats are simply better suited for high temperatures than others.

Certain hard hat features can help minimize heat retention and keep workers safe from heat-related illness or injury. For example, all hard hats will retain some of the heat put off by the sun’s rays, but studies have shown that lighter colored hats retain less heat than darker hats, making lighter hats a better option for outdoor construction work.

Additionally, a wide brim can offer necessary shade when working under the direct sunlight, and integrated vents—suitable for jobsites without electrical hazards—help improve air flow around the head.

ACCESSORIES OFFER INCREASED PROTECTION

Choosing a hard hat with heat-minimizing features is important for heat safety, but the benefits of these integrated features can be enhanced even further by the addition of heat-reducing hard hat accessories.

Sweat-wicking helmet liners and brow pads can be affixed to the inside of a hard hat to help prevent added moisture, and the associated humidity, from building up inside a worker’s hat. Anti-glare decals can minimize the impact of the sun’s glare, and sunshades and sunshields can be used to increase the shade offered around the hard hat wearer’s head, neck and face.

OTHER HEAT-PROTECTIVE GEAR

In addition to choosing the best hard hat and accessories for high temperatures, workers can utilize other protective gear that has been specifically designed to minimize heat and maintain the wearer’s body temperature at a safe and healthy level.

A number of PPE manufacturers offer a range of protective gear designed uniquely for high-heat work environments. Items like cooling vests utilize phase change material technology to maintain a set temperature for an extended

period of time, thereby offering continuous cooling benefits to workers.

Separately, workers should, when possible, opt to wear clothes made of breathable fabrics underneath their PPE, and consider accessories like UV-protective goggles or sunglasses for added protection from the sun.

What other steps can those in the construction industry take to protect workers in high-heat scenarios?

The right protective gear can make a significant difference in the health and safety of workers laboring in high-heat environments, but those in the construction industry can— and should—take other precautionary steps to ensure worker well-being.

The Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH) offer a Heat Safety Tool , which gives users access to the heat index for their specific worksite. Based on that heat index, the OSHA-NIOSH Heat Safety Tool provides a risk level to outdoor workers. Workers and employers can use this information—and other, similar tools—to plan and prepare appropriately for their work conditions.

Construction employers must also provide workers with an adequate number of breaks to rest in the shade and drink water. Plan the most physically taxing labor for the coolest times of day—early in the morning or towards the evening hours. Educate workers on the causes and symptoms of heat-related illness, and have an emergency plan in place to help those on the jobsite handle a dangerous situation properly.

As temperatures continue to rise, the construction industry— and the companies that produce protective gear for construction workers—will have to keep innovating and identifying new and improved ways to make sure all workers get home safely at the end of the day.

11

Ready For a Safety Walkaround?

05.28.2023 | Safety + Health

We’ve got tips.

THE PREVENTION SIDE OF INCIDENTS.

That’s how Tarah Kile, director of the Consultation, Education and Training Division at Michigan OSHA, describes safety walkarounds.

“Those opportunities to walk your shop, walk your floor or walk your jobsite are invaluable,” Kile said. “Any organization that doesn’t want to have an incident, wants to lower their incident rates or keep their employees safe really should participate.”

Safety professionals, management and workers from any area of an organization can take part in walkarounds, which are aimed at identifying and resolving hazards. Even in industries that have specific requirements for the timing and scope of certain inspections (construction and mining are two), conducting regular safety walkarounds can bring big benefits.

“To me, it’s one way of confirming and verifying all the training that we do, all the awareness that we do, all the communication that we do throughout the organization is

actually being applied,” said David Consider, senior safety consultant at the National Safety Council.

Here are five tips for making your safety walkarounds effective.

1 BRING A GROUP

Safety doesn’t fall only on safety pros, so get others involved in the walkaround process. That could be a small group of three to four people or a larger group of eight to 10.

“At a minimum, I’m taking representatives from management and I’m taking representatives from the worker side of the house,” OSHA Region 3 Assistant Administrator Nicholas DeJesse said. “Management, obviously, because they oversee the process. Workers because they are intimately involved in every aspect of the work when it comes to the process.

“A worker will know if a process or machine is running properly. They will know when it’s running improperly, as well.”

Participation by representatives from different parts of the organization can add knowledge and varying perspectives to the walkaround process.

“Grab a janitor. Grab an accountant,” Kile said. “Somebody with a fresh set of eyes that can ask questions you don’t think to ask is really important.”

However, she cautions against making safety walkaround teams too big. “You don’t want to overwhelm the workers.”

2 REWARD THE GOOD

Consider has an unwritten “2-to-1” rule, which involves pointing out to workers two good things for every safety hazard he discovers. Some safety pros extend it to 5-to-1, he noted.

“It’s so easy to find the things we’re doing wrong,” he said. “But what we struggle with sometimes is finding the good and recognizing the good.”

If he spots a worker not wearing safety glasses, for example, Consider’s approach would be as follows: “I’ll tell them, ‘Hey, great work area. It’s nice and clean. It’s organized. You’ve got a cord in the back that’s been identified. You’ve got some cones back there. Nice job. But, I need you to put those safety glasses on.’”

Rewarding correct behaviors, Consider added, takes away uneasiness that workers may have when the next safety walkaround takes place.

3 DOCUMENT YOUR FINDINGS

This can be as simple as taking handwritten notes and documenting hazards with photos, or even using an inspection app.

“If we can be more efficient and tap into technology, absolutely,” Consider said.

Kile pointed out that workers in an organization that’s new to safety walkarounds could be taken aback by a camera or a clipboard. “If you’re new to this and your culture isn’t used to it, I would say walk out with a smile and your PPE and take your notes afterward.”

The safety pro should then collect group members’ notes and photos after the walkaround and compile them in a report that begins with an executive summary. Consider suggesting starting the follow-up report with positive observations before noting identified hazards/takeaways that need attention. Once the report is complete, distribute it to key members of the organization and use it as a template for future reports.

Documentation also applies to safety pros. DeJesse said that should include updates on what actions were taken. For an unguarded part on a machine, for example, that

could involve communicating with employees to stay clear of the part, posting warning signs or stanchions to keep workers away until a new piece of Plexiglas is delivered, and then installing the guard.

“You don’t want to work in a factory full of nothing but workarounds,” DeJesse said. “And you never want to find 10 things, then a month later find the same 10 still not corrected.”

4 PRIORITIZE FIXES

Now that you’ve identified safety issues, which should be corrected first?

Experts say start with the hazards that cause immediate concern.

“If it’s immediately dangerous, we get people out of that situation,” Kile said. “There’s no question about that.”

Resources from OSHA’s Safe + Sound program include a safety walkaround fact sheet that features a hazard prioritization matrix.

It uses five levels of “likelihood of occurrence or exposure” (frequent, probable, occasional, remote and improbable), along with four categories of “severity of injury or illness consequence” (negligible, marginal, critical and catastrophic).

By using the matrix, safety pros can determine which hazards should be prioritized. (Find the matrix and more at osha.gov.)

“Anything that you find that can be fixed right away, should be,” Kile said.

5 FOLLOW UP, THEN DO IT AGAIN

So, let’s say your safety walkaround group has identified 10 hazards that need attention. Now what?

“I like ensuring we have a robust, quality follow-up system in place,” Consider said.

A week after the walkaround, Consider suggests going out and checking to see if a hazard has been resolved and if the solution is working. Check back again in a month, and again in three months. “Now we’re letting folks know we care about them, that we’re interested, and it’s not a oneand-done,” he said.

Fixing a guard on one machine and following up can create a template should another machine need attention. “It brings about best practices,” Consider said.

13

Understanding Anchor Points For Fall Protection

07.24.2023 | JJ Keller Management Suite

Must an anchor point be able to support 5,000 pounds? Not necessarily. But how do you identify alternatives?

Anchor points must either be able to support 5,000 pounds for each worker, or must meet a safety factor of two. That safety factor depends on things like the weight of the employee, the potential falling distance, and the use of deceleration devices that reduce the arresting force.

If the anticipated force is 1,000 pounds, for example, then the safety factor requires an anchor capable of supporting 2,000 pounds. Working with a fall protection provider should help determine the arresting force.

The other challenge is getting an assessment by a qualified person. The regulation allows an anchor “designed, installed, and used under the supervision of qualified person” as part of a complete personal fall protection system. This raises questions of how to evaluate the strength of a potential anchor. Anchor points may be:

• Engineered or certified.

• Non-engineered or non-certified.

ENGINEERED OR NOT?

An engineered point is designed as an anchor, like a ring that bolts in place or a portable system with weights. Although employers probably don’t test them after installation, they should meet OSHA’s requirements when properly installed. Engineers design these systems to meet the strength requirements.

More often, employers use non-engineered or fieldexpedient anchors. Determining whether a proposed anchor point is strong enough requires an evaluation. For example, many employers use steel I-beams or H-beams as part of an anchor system. This can be acceptable using an appropriate clamp or attachment, but not when simply wrapping a strap around the beam (since sharp edges could cut the strap). Other building structural supports, however, many not be strong enough.

HOW STRONG IS IT?

Determining the strength of the potential anchor requires an evaluation because you probably won’t test it by

dropping a weight. The regulation requires that the system be designed and installed by a qualified person. But what does that mean? Employers can use structural beams, even if they weren’t “installed” as anchors. However, the qualified person would evaluate the beam and other components (including the means of attachment) to determine whether the complete system is satisfactory. For non-certified points, the qualified person might look at the anchor attachment, and even look at engineering drawings for the facility to see the grade of steel used. In addition, the person might evaluate any recommendations from the fall protection manufacturer regarding compatibility.

Note that employees should never use things like ladders, scaffolds, or guardrails as fall protection anchors. For working on flat roofs, some employers want to use existing structures like a flagpole or air conditioner as an anchor. Those options might be conveniently located, but they’re unlikely to qualify as acceptable as anchor points.

Employers lacking in-house expertise should work with a fall protection supplier who can suggest options and systems that should meet OSHA’s requirements. A good supplier may also have someone on staff who is qualified to oversee the system installation.

Finally, remember that if an employee falls, the anchor will undergo considerable stress, and the employer must

inspect all system components to verify that they’re still safe to use. When using expedient structures, consider the potential effects on those structures if they arrest a falling worker. Building structures might be strong enough to arrest a falling worker, but that force could compromise structural integrity.

15

When Does an Employee Complaint Result in an OSHA Inspection?

07.31.2023 | JJ Keller Management Suite

Employees who don’t feel comfortable reporting concerns to their employer might call OSHA to complain. Worse, if an employee did report to the employer but got no response, the employee might then call OSHA. But will those complaints result in an OSHA inspection?

A complaint made anonymously or claiming vague allegations that don’t suggest violations might cause OSHA to follow up with a phone call but won’t necessarily bring OSHA knocking on your door. However, certain elements of employee complaints increase the likelihood of OSHA showing up. These include:

1. The employee provides a written and signed complaint that an injury occurred and the hazard still exists, or the complaint indicates imminent danger.

2. The concern relates to a current emphasis program, like heat stress or amputation hazards.

3. The employer received an egregious, willful, or failureto-abate citation in the last three years.

4. The facility is currently undergoing an OSHA inspection, or OSHA was already planning to inspect the facility for some reason.

5. OSHA followed up via phone with the employer regarding the complaint, but the employer’s response was deemed inadequate.

Not all of the above elements need to be in place, and just one might result in an inspection. However, if the complaint happens to check several boxes, OSHA is more likely to visit your facility in response to the complaint.

EVALUATING COMPLAINTS

Before starting an inspection, OSHA will determine if the complaint offered reasonable grounds to believe that a violation exists. If OSHA finds that the employer is aware of the hazard and is correcting it (based on documentation the employer provided), the agency might not conduct an inspection.

When complaint inspections do occur, the inspection is generally limited to the hazards listed in the complaint. Of course, other violations in plain sight could get cited as well. Also, inspectors may expand the inspection based on their professional judgment or based on conversations with workers.

OSHA doesn’t necessarily follow up on complaints in the order they get reported. OSHA ranks complaints based on the severity of the alleged hazard and the number of employees exposed. Complaints deemed low priority might get handled via phone or fax rather than on-site inspections.

PRIORITIZING COMPLAINTS

OSHA’s top priority is imminent danger situations where workers face an immediate risk of death or serious physical harm.

Second priority goes to any fatality or catastrophe, such as an accident that requires hospitalization of three or more workers.

Third priority is employee complaints and referrals from other agencies.

Lower inspection priorities include inspections targeted toward high hazard industries, planned inspections in other industries, and follow-up inspections to determine whether previously cited violations have been abated.

AVOIDING COMPLAINTS

Not every employee complaint will result in an OSHA inspection. It might only result in a phone call from OSHA. Still, the best way to avoid a complaint-related inspection is to ensure that employees don’t have cause to contact OSHA. A combination of maintaining compliance, emphasizing safety, and encouraging employees to report concerns (along with promptly and effectively addressing those reports) helps create a work environment where employees won’t feel the need to call OSHA.

17