Too Much Jargon Could Hinder Worker

Morale, Study Shows

09.17.2025 | Safety & Health Magazine

Gainesville, FL — If employees are having to “circle back,” “ladder up” or look for “low-hanging fruit,” it might be hurting their morale, researchers say.

A team from the University of Florida and George Washington University surveyed more than 1,800 participants who were given the scenario of starting a new job. Half the participants received jargon-filled emails regarding “intranets” and “EFT” payments. The other participants were sent emails with plain language.

The participants who received the jargon-filled messages found it more difficult to process information and reported feeling insecure and less likely to ask for help.

“It doesn’t just make them feel bad about the information they’ve been given,” study co-author Olivia Bullock, assistant professor of advertising at UF, said in a press release, “it makes them feel bad about themselves.”

Results also show that older participants reported more difficulty processing the jargon-filled emails but were more likely to ask for clarification. Younger participants were less likely to ask for or seek help.

“You need people to be willing to collaborate, share ideas and look for more information if they don’t understand something at work,” Bullock said. “And jargon might actually be impeding that information flow across teams.

“Always reduce jargon. The benefit of using jargon doesn’t outweigh the cost.”

The study was published in the International Journal of Business Communication.

AAA Survey Finds Nearly All Drivers Get Aggressive Behind The Wheel

08.15.2025 | AAA Magazine

12% know someone who was injured or killed in a road rage incident

A recent survey of U.S. drivers found that 96% admitted they’ve been aggressive behind the wheel within the past year.

The AAA Foundation for Traffic Safety conducted the survey of more than 3,000 drivers aged 16 or older as part of a three-part study.

Let’s change our driving culture so we can achieve the safe mobility vision for all road users.

A little more than 10% of the drivers who said they had engaged in aggressive behaviors also admitted to lashing out with violent behaviors, including:

• Following other vehicles with the intent to confront the driver

• Stepping out of their vehicle

• Throwing objects at other vehicles

• Attempting to run other vehicles off the road

• Physically threatening other drivers

• Respondents listed several reasons for their aggressive behaviors:

• Wanting to get to a destination more quickly

• Perceived threats to safety

• Seeking control over “sometimes chaotic” driving environments

• Attempting to educate other drivers on the correct way to behave

• Retaliating against perceived slights

• Punishing other drivers for bad behavior

AAA says the results also show that the most significant predictor of whether people will drive aggressively is “the extent to which other drivers in your area engage in aggressive driving behaviors.”

Around 20% of the respondents said they know someone who was threatened by another driver with a weapon during a road rage incident, and 12% know someone who was injured or killed in a road rage incident.

“This work also concludes that road etiquette and manners can be a protective factor against aggressive driving,” David Yang, president and executive director of the AAA Foundation for Traffic Safety, said in a press release. “Let’s change our driving culture so we can achieve the safe mobility vision for all road users.”

AAA OFFERS TIPS TO HELP CONTROL ROAD RAGE:

• Stay calm and don’t engage aggressive drivers: no eye contact, no gestures, no response.

• Give space and let aggressive drivers pass. Keep your distance.

• Call 911 if threatened and go to a public place. Don’t drive home.

• When starting to feel angry behind the wheel, take a deep breath before reacting.

• “Choose time over tension”: Leave early, give space and arrive safely.

OSHA’s 2025 Top 10 Cited Standards Highlight Persistent Safety Challenges

10.14.2025 | Occupational Health & Safety

OSHA unveiled its preliminary list of this year’s most cited workplace safety violations. Fall protection remains a top concern, but the entire list offer insight into where safety professionals should focus their efforts.

Each year, OSHA’s list of most frequently cited standards offers a revealing snapshot of where workplaces are struggling to meet safety requirements. At the National Safety Council’s 2025 Safety Congress & Expo, held this week at the Colorado Convention Center, OSHA Regional Administrator Eric Harbin unveiled the agency’s preliminary Top 10 for fiscal year 2025, based on data as of Aug. 12. The list once again underscores the persistence of long-standing hazards. “They have the ability, they have the desire, they just need the knowledge,” Harbin said, noting that small businesses often want to comply but lack resources. OSHA hopes to close that gap by promoting consultation programs and training support.

1. FALL PROTECTION – GENERAL REQUIREMENTS (1926.501)

For the fifteenth consecutive year, fall protection tops the list, with 5,914 violations. Roofing, framing and siding contractors accounted for most of the citations. OSHA’s fall protection rules are clear: employers must provide guardrails, safety nets or personal fall arrest systems when workers face fall hazards. Hazards often stem from unprotected edges, unsafe scaffolds or improperly used ladders.

Despite years of emphasis, falls remain the leading cause of death in construction. Harbin said roofing was the top industry cited, a reminder that high-risk trades must redouble efforts in training, supervision and jobsite hazard assessments.

2. HAZARD COMMUNICATION (1910.1200)

Hazard Communication once again claims the second spot, with 2,546 violations. Interestingly, Harbin noted roofers — not traditionally thought of as chemical-intensive — were the top violators.

The HazCom standard requires employers to develop a written program, maintain Safety Data Sheets, properly label containers and train workers on chemical hazards. Compliance lapses often involve missing SDSs, outdated labeling or insufficient worker training. With chemical exposures present in nearly every industry, even small employers must ensure hazard communication programs are current and accessible.

3. LADDERS (1926.1053)

With 2,405 violations, ladder safety continues to be a problem across construction trades. Roofing again led the way, followed by framers and siding contractors.

OSHA requires ladders to be strong enough to support intended loads, free from slipping hazards and positioned properly. Common citations include using ladders at unsafe angles, overloading, or failing to remove damaged ladders

from service. The fact that ladders remain a top-three violation highlights how everyday tools can still present serious risks when not used correctly.

4. CONTROL OF HAZARDOUS ENERGY (LOCKOUT/TAGOUT) (1910.147)

Lockout/Tagout recorded 2,177 violations, with plastic products manufacturers and machine shops topping the list.

The standard requires employers to establish energy control procedures that prevent machines from starting unexpectedly during servicing. Violations often involve missing lockout devices, inadequate training or failure to develop written procedures. OSHA emphasizes that controlling hazardous energy is critical: without it, workers face crushing, amputation or fatal injuries. Even industries less traditionally associated with heavy machinery are seeing citations, underscoring the importance of consistent LOTO programs.

5. RESPIRATORY PROTECTION (1910.134)

Respiratory protection slipped to fifth with 1,953 violations. The most common problem, Harbin said, was failing to provide medical evaluations for workers required to wear respirators. The standard covers respirator selection, fit testing, medical clearance and training. Violations occur when employers fail to evaluate airborne hazards, use the wrong type of respirator, or neglect program administration. With hazards ranging from silica dust to chemical vapors, respiratory protection remains a cornerstone of OSHA compliance.

6. FALL PROTECTION – TRAINING REQUIREMENTS (1926.503)

Training remains a weak spot, with 1,907 violations. Roofing again led the citations, and Harbin pointed out that the top issue was failing to provide any training at all. The rule requires employers to ensure workers can recognize fall hazards and use fall protection systems properly.

...continued on next page

Employers must also certify training in writing and retrain workers as needed. Without this foundation, even the best fall protection equipment cannot be used effectively.

7. SCAFFOLDING (1926.451)

Scaffolding ranked seventh with 1,905 violations, just two fewer than fall protection training. Industries most often cited included masonry, roofing, framing and siding. OSHA’s requirements include that scaffolds support at least four times the intended load and provide proper guardrails or fall arrest systems. Violations often involve incomplete guardrails, unsafe planking or lack of access ladders. Scaffolding remains one of construction’s most hazardous activities, and the close margin with fall training means it could shift rankings when OSHA finalizes the fiscal year data.

8. POWERED INDUSTRIAL TRUCKS (1910.178)

Powered industrial trucks — including forklifts and lift trucks — accounted for 1,826 violations. The most frequent issue, Harbin noted, was employers not ensuring that operators were properly trained.

The standard covers vehicle design, maintenance and safe operation. Daily inspections, load limits and operator certification are required. Forklift-related incidents often cause serious injuries, making training and supervision critical to safe operation.

9. PERSONAL PROTECTIVE AND LIFESAVING EQUIPMENT – EYE AND FACE PROTECTION (1926.102)

Eye and face protection violations totaled 1,665, with roofing again leading the way. “The number one reason was not providing protection at all,” Harbin said.

The standard requires employers to provide appropriate PPE for hazards such as flying particles, liquid chemicals and radiation. OSHA mandates compliance with ANSI standards, and employers must ensure PPE fits comfortably, accommodates prescription lenses if needed, and is maintained in good condition. Despite relatively low cost and availability, noncompliance remains widespread.

10. MACHINE GUARDING (1910.212)

Rounding out the list, machine guarding violations totaled 1,239. Harbin cited missing or inadequate guards at the point of operation as the most common problem.

The standard requires machines to have barriers that prevent access to moving parts, sparks or flying debris. Guards can be fixed, interlocked or adjustable. Too often, guards are removed for convenience or left unrepaired, exposing workers to serious hazards.

UNDERSTANDING THE TRENDS

As in past years, fall-related violations dominated, with roofing, framing and siding contractors recurring across multiple categories. But the list also shows risks in manufacturing, plastics and machine shops. Harbin emphasized that small businesses often make up a large share of citations because they lack in-house safety resources.

Importantly, the 2025 list is preliminary. An update on these Aug. 12 statistics is expected before the end of OSHA’s Oct. 1-to-Sept. 30 fiscal year, according to Harbin. Harbin noted that rankings could shift slightly once final data are compiled, especially when it comes to the scaffolding and fall protection-training requirements, which are currently only separated by two violations.

A PATH FORWARD

Also, the prevalence of the roofing industry unscored another important trend: that small businesses often want to comply but lack the resources. OSHA hopes to close that gap by promoting support programs.

To help smaller businesses address these hazards, OSHA works with state agencies offer consulting programs to help employers improve compliance. Harbin closed his presentation with a reminder that free consultation programs are available, particularly for small businesses that want to do better but need guidance.

“These employers want to protect their workers,” he said. “They have the ability, they have the desire, they just need the knowledge.”

Nicotine Pouches a Serious Poisoning Risk For Young Kids, Study Finds

09.24.2025 | National Safety Council

Cases of young kids ingesting nicotine from pouches have surged in recent years, researchers are warning.

A team from Nationwide Children’s Hospital and Central Ohio Poison Control looked at nearly 135,000 cases of nicotine ingestions – all involving kids younger than 6 – that were reported to U.S. poison centers from 2010 through 2023.

They found that ingestion rates for nicotine pouches, which contain nicotine powder and are placed in the mouth, have soared 763% since 2020 (when data on the pouches first became available) – to around 4 per 100,000 cases from 1 per 100,000.

The pouches were also more likely to be associated with serious medical outcomes or hospital admissions than other nicotine products such as gum/ lozenges, e-liquids, powder/granules, and tablets/capsules/caplets.

“The nicotine level in pouches can pose a serious risk of nicotine exposure, especially for younger children,” the Food and Drug Administration says. “The harmful effects of nicotine poisoning vary depending on the situation. The effects may include confusion, vomiting and loss of consciousness.

“Containers for nicotine pouches – with bright, colorful designs – may seem tempting to children. They can even resemble candy containers.”

THE RESEARCHERS AND THE FDA OFFER THE FOLLOWING TIPS:

• Store nicotine products up and out of sight and away from food — preferably in a locked cabinet, drawer or box.

• Buy only FDA-authorized nicotine pouches with child-resistant packaging and ensure those child-resistant features are engaged when not using the product.

• Keep nicotine products in their original containers, which likely have childresistant features.

• Avoid using nicotine pouches or other nicotine products around kids. Tell your children that products should only be handled by adults.

• Save the national Poison Help Line – (800) 222-1222 – in your phone and post it on paper in a visible place in your home.

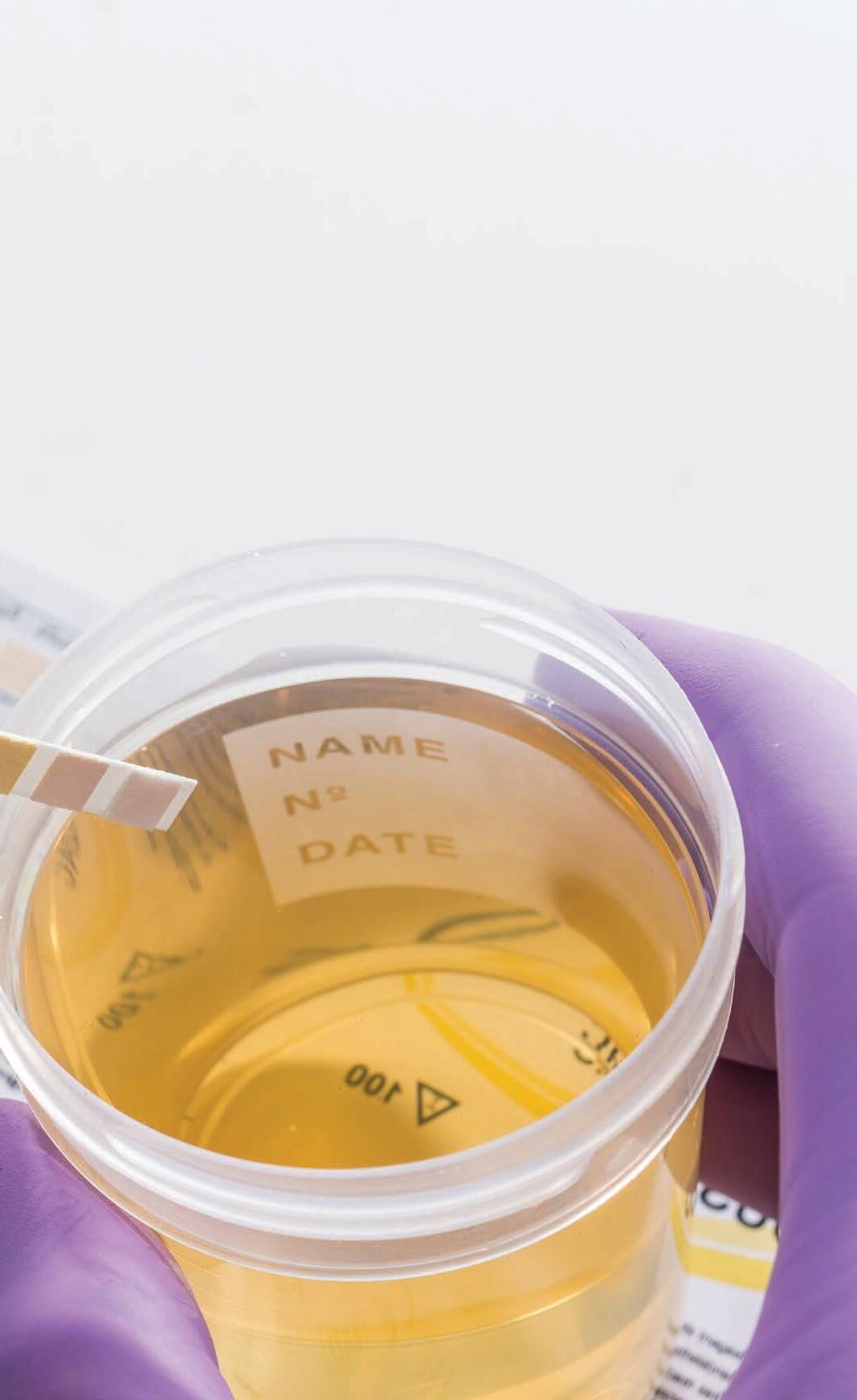

Fentanyl Positivity Is More Than Seven Times Higher in Random Tests vs. Pre-Employment Drug Screening, Finds 2025 Quest Diagnostics Drug Testing Index

09.02.2025 | PRNewswire

Majority of fentanyl positives also contain other drugs, with co-positivity with marijuana doubling since 2020. The percentage of employees in the general U.S. workforce testing positive for fentanyl in random drug tests far exceeded those in pre-employment testing, according to the 2025 Quest Diagnostics Drug Testing Index™ from Quest Diagnostics (NYSE: DGX), a leading provider of diagnostic information services.

The new report reveals changing patterns of drug use by the nation’s workforce. While the analysis of more than 8 million drug tests shows that overall workplace urine drug positivity declined slightly last year, to 4.4% from 4.6%, the sharp increase in fentanyl in random drug checks suggests more workers are using the highly addictive opioid after they have passed pre-employment screens. Random drug testing involves unscheduled and unannounced drug tests of employed individuals after they have presumably passed pre-employment drug screens.

In 2024, the general U.S. workforce positivity for fentanyl was 707% higher in random tests (1.13%) compared to pre-employment tests (0.14%). This is a stark contrast to

other categories of drugs, such as marijuana or other opiates, where less variation is seen in random and preemployment positivity rates. For example, in the general U.S. workforce, marijuana’s positivity rate in random testing was 42% lower than its positivity rate in pre-employment testing over the past five years. In contrast, the fentanyl positivity rate in random testing has been 400% higher than in pre-employment testing over the past five years.

In addition, 60% of specimens positive for fentanyl in the U.S. general workforce in 2024 were also found to be positive for other drugs. About 22% of fentanyl-positive workforce drug tests were also positive for marijuana, a rate that has doubled since 2020, when only 10% of fentanyl positives were also positive for marijuana. A large percentage of fentanyl positives were also found to be positive for amphetamines – 16% in 2024 compared to 11% in 2020.

“The new Quest data indicates a worrying increase in fentanyl positivity in random drug tests as well as fentanyl drug-combing among the nation’s workforce in day-today work environments,” said Suhash Harwani, PhD, Senior Director of Science for Workforce Health Solutions at Quest Diagnostics. “It is disturbing to see increased use of fentanyl on-the-job and in combination with other drugs, given fentanyl’s extreme potency, which can increase risk of impairment, accidents, and potential overdose. It also raises concern that employees are turning to a dangerous drug like fentanyl after they’ve passed a pre-employment drug screen, putting the overall wellness of the workforce at risk.”

A January 2025 CDC report suggests a slight increase in fatal overdoses in January 2025 compared to January 2024 following consecutive years of decline. Fentanyl has since proliferated in the U.S. and most overdose deaths – 7 out of 10 – are estimated to involve illegally manufactured fentanyls (IMFs), according to the CDC. Starting July 7, 2025, the Department of Health and Human Services’ Federal Drug-Free Workplace Program added fentanyl to the authorized drug testing panel. The majority of opioid-related overdose deaths involve multiple substances.

OTHER KEY FINDINGS FROM THE QUEST DIAGNOSTICS REPORT INCLUDE:

MARIJUANA LEADS WORKPLACE DRUG DETECTIONS AS POST-ACCIDENT POSITIVITY REMAINS HIGH

Marijuana remains the most frequently detected substance, with positivity holding steady at 4.5% in the

...continued on next page

general U.S. workforce year over year. Marijuana positivity following workplace accidents also remains high – postaccident positivity was 7.3% in 2024, just slightly below the record high of 7.5% in 2023. Among federally mandated, safety-sensitive workers, marijuana positivity declined slightly to 0.87% from 0.95% in 2023.

OVERALL POSITIVITY TRENDS REMAIN ELEVATED DESPITE MODEST DECLINES

In 2024, the combined U.S. workforce urine drug positivity rate declined slightly to 4.4%, down from 4.6% in 2023. While the dip marks the first reduction following three years of elevated positivity, the rate remains stubbornly high, with a 4% or higher overall drug positivity rate persisting over the past 10 years.

“The overall drug positivity rate continues to reflect persistent trends,” said Sam Sphar, Vice President and General Manager of Workforce Health Solutions at Quest Diagnostics. “When we talk to employers, they tell us the same thing the Quest data tells us – that drug abuse is an ongoing issue among the American workforce. Many also realize that permissive attitudes around drug use can put their non-substance using employees, not to mention the general public, at risk.”

AMPHETAMINES POSITIVITY RATES INCREASE;

OTHER POSITIVITY REMAINS CONSISTENT

In the general U.S. workforce, amphetamines continued their upward climb, with positivity increasing to 1.7%, up from 1.5% in 2023. Cocaine positivity remained unchanged at 0.24%.

In contrast, several opioids and related substances showed ongoing declines. 6-AM, the metabolite of heroin, decreased to 0.004%. Opiates declined to 0.13% (from 0.14% in 2023), and oxycodones positivity remained unchanged at 0.27%.

TESTING POSITIVITY FOR SUSPICION OF DRUG USE DECLINES

The 2025 Quest Diagnostics Drug Testing Index reveals that drug test positivity continues to vary significantly depending on the testing circumstance. In the general U.S. workforce, for-cause testing, used when employers have reasonable suspicion of substance use, showed a 33.1% positivity rate in 2024, a decline from 39.4% in 2023. Post-accident testing positivity fell slightly from 10.4% to 10.2%, while return-to-duty testing, administered to employees coming back after a violation of a company drug policy, declined from 8.4% to 7.9%.

“While it’s encouraging to see slight declines in for-cause, post-incident and return-to-duty drug test positivity rates, the rates continue to be elevated. For instance, the Quest data showing that about one in three employees tested for cause were positive for drug use demonstrates opportunities for employers to bolster psychologically safe practices and recovery-supportive programs, enhancing both employee reporting and safety initiatives,” said Claire Bryant, Senior Program Manager of Workplace Wellbeing at the National Safety Council.

Among federally mandated, safety-sensitive workers, who are typically subject to stricter testing protocols, for-cause positivity was 12.6% compared to 14.5% in 2023, post-accident positivity stood at 4.5% compared to 4.6% in 2023, and return-to-duty testing had a 4.8% positivity rate compared to 5.2% in 2023. These figures suggest that within highly regulated industries compliance programs and proactive safety strategies appear to result in lower workforce drug testing positivity versus the general U.S. workforce.

HAVE YOU COMPLETED THE SAFETY QUIZ?

In case you missed it, scan the QR code or click the link below to take the quiz today!

As part of our ongoing commitment to workplace safety, it’s always been a requirement to kick off meetings with a safety topic when three or more people are present.

These quizzes will be featured in each edition of the Safety Net, as well as on myAustin. This is a fun and effective way to reinforce safety knowledge.

Get ready to test your knowledge and become a safety expert!