THE SAFETY NET

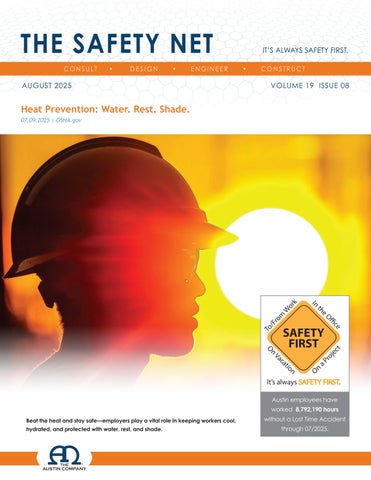

Heat Prevention: Water. Rest. Shade. 07.09.2025 | OSHA.gov

Beat the heat and stay safe—employers play a vital role in keeping workers cool, hydrated, and protected with water, rest, and shade.

There are many factors that have a role in creating an occupational heat stress risk to workers.

WATER

Employers should provide cool water for workers to drink. Proper hydration is essential to prevent heat-related illness. For those working two hours or more, also provide access to additional fluids that contain electrolytes.

For short jobs, cool potable water is sufficient. Workers should be encouraged to drink at least one cup (8 ounces) of water every 20 minutes while working in the heat not just if they are thirsty.

For longer jobs that last more than two hours, employers should provide electrolyte-containing beverages such as sports drinks. Workers lose salt and other electrolytes when they sweat. Substantial loss of electrolytes can cause muscle cramps and other dangerous health problems. Water cannot replace electrolytes; other types of beverages are needed. Water or other fluids provided by the employer should not only be cool, but should also be provided in a location that is familiar to the workers, near the work, easy to access, and in sufficient quantity for the duration of the work.

Workers should be aware that use of certain personal protective equipment (e.g., certain types of respirators and impermeable clothing) can increase the risk of heat-related illness.

Workers should not rely on feeling thirsty to prompt them to drink. They should be reminded to drink on a regular basis to maintain hydration throughout their shift and beyond.

REST

When heat stress is high, employers should require workers to take breaks. The length and frequency of rest breaks should increase as heat stress rises. In general,

workers should be taking hourly breaks whenever heat stress exceeds the limits shown in Table 2 under Determination of Whether the Work is Too Hot section on the Heat Hazard Recognition page.

Breaks should last long enough for workers to recover from the heat. How long is long enough? That depends on several factors including environmental heat (WBGT) and the worker’s physical activity level, as well as the individual worker’s personal risk factors. The location of the breaks also matters. If workers rest in a cooler location, they will be ready to resume work more quickly. Breaks should last longer if there is no cool location for workers to rest.

Some workers might be tempted to skip breaks. In hot conditions, skipping breaks is not safe! Employers should make sure that workers rest during all recommended break periods.

Both NIOSH and ACGIH have recommendations on appropriate lengths of work and rest cycles as a function of the workload and the WBGT (ACGIH 2017, NIOSH 2016)

SHADE

Workers should be given a cool location where they can take their breaks and recover from the heat.

Outdoors, this might mean a shady area, an airconditioned vehicle, a nearby building or tent, or an area with fans and misting devices.

Indoors, workers should be allowed to rest in a cool or air-conditioned area away from heat sources such as ovens and furnaces.

Loud noise on the job can quietly steal your hearing

OSHA Standards For Hearing Protection: Avoid Hearing Loss

07.08.2025 | Health + Safety

Workers in any industry who are exposed to high levels of noise can suffer permanent hearing loss. Understand the employer’s responsibility and the employees’ rights when it comes to hearing protection.

Exposure to high levels of noise can cause permanent hearing loss. Damage to your hearing can be prevented, but once permanent noise-induced hearing loss occurs, it cannot be cured or reversed. Hearing loss usually occurs gradually, so you may not realize it is even happening until it is too late.

You may have hearing loss if:

• It’s difficult to hear what people are saying in groups or meetings if there is background noise.

• People typically sound as if they are mumbling when they are speaking.

• You often have to ask people to repeat what they say.

• It’s not easy to understand what others are saying when having a phone conversation.

• You are experiencing a ringing or noises in one or both ears.

• You sometimes don’t hear back-up alarms or a cell phone ring tone.

It seems understandable that a one-time exposure to a sudden, powerful noise, like an explosion, can damage your hearing instantly. But it’s also important to consider that prolonged exposures (day after day) to loud noise can also lead to a gradual, but permanent, loss of hearing.

Occupational noise is sometimes referred to as a stealth long-term hazard because it is a painless, gradual process.

According to OSHA, twenty-two million workers are exposed to potentially damaging noise at work each year. U.S. businesses pay more than $1.5 million in penalties annually for not protecting workers from noise, and hearing loss directly impacts the quality of life not only for those workers but also their families.

Workers who are exposed to high levels of noise can suffer permanent hearing loss and then sometimes not even surgery or a hearing aid can help. In addition, even repeated exposures to loud noise for just short periods of time can add up to permanent damage to hearing.

OSHA General Industry Standard 1910.95(c)(1) The employer shall administer a continuing, effective hearing conservation program… whenever employee noise exposures equal or exceed an 8-hour time-weighted average sound level (TWA) of 85 decibels… without regard to… the use of personal protective equipment.

OSHA Construction Standard 1926.52(b) When employees are subjected to sound levels exceeding those in Table D-2 of this section, feasible administrative or engineering controls shall be utilized. If such controls fail to reduce sound levels within the levels of the table, personal protective equipment as required in Subpart E, shall be provided and used to reduce sound levels within the levels of the table.

SOUND LEVEL METER

Sound intensity is measured in decibels (dB). When decibels are adjusted (weighted) for how the human ear senses sound, the sound level intensity is measured as dBA. OSHA recommends that workplace noise levels be kept below 85 dBA as an 8-hour time-weighted average. As the noise level increases, it can damage your hearing more quickly.

Repeated exposures to noise above 85 decibels or one exposure above 140 decibels can lead to irreversible hearing loss. Fortunately, with today’s hearing loss prevention strategies and technologies, work-related hearing loss can be nearly always prevented.

WHAT CAN EMPLOYERS AND WORKERS DO TO PREVENT WORK-RELATED HEARING LOSS?

First, find out if the noise in the workspace is hazardous. There are different ways you can measure or estimate the noise level of any working environment.

1. A sound level meter is a handheld device with a microphone that measures noise moment to moment.

2. A dosimeter documents the average noise exposure over time, like throughout the entire working day, or just during a particular task.

3. A personal noise indicator is a warning device that indicates if the surrounding sound level is above or below 85 dBA.

4. The 2-3 foot rule can be used to quickly evaluate a work environment. Stand about an arm’s length away from a co-worker and if you have to raise your voice to be heard then you should assume that the sound level is at or above 85 dBA.

5. There are also cell phone apps that have been developed that provide sound level data. The NIOSH Sound Level Meter App is free and provides features of sound level meters and noise dosimeters.

The NIOSH Recommended Exposure Limit (REL) for occupational noise exposure is 85 decibels, A-weighted, as an 8-hour time-weighted average (85 dBA as an 8-hr TWA) using a 3-dB exchange rate. Exposures at or above this level are considered hazardous.

There are several steps to take to reduce noise in the work environment before reaching for personal hearing protection.

1. REDUCE - Choose equipment that is quieter.

2. MOVE - Move the equipment farther away (safely, following OSHA standards) with the use of extension cords, additional welding leads, and air hoses.

3. BLOCK - Create barriers to help block the noise.

4. MAINTAIN - Proper maintenance of tools and equipment can result in lower noise levels.

...continued on next page

Workers must be protected from hazardous levels of noise If you are not required to be in a high noise area, move to a quieter area to work. Operate noisy machines during shifts when fewer people are exposed. Changing seals, lubricating parts, using sharp blades and bits, installing mufflers, and replacing faulty or worn equipment or parts can reduce occupational noise levels significantly.

OSHA Construction Standard 1926.101(a) Wherever it is not feasible to reduce the noise levels or duration of exposures to those specified in Table D-2, Permissible Noise Exposures, in 1926.52, ear protective devices shall be provided and used.

Workplace noise is measured using special noise monitoring equipment and the levels are displayed in decibels. Normal speaking voice is usually around 70 decibels (dB) and operating a loud construction excavator is usually around 110 dB. OSHA recommends that hearing protective devices be worn any time noise exposures meet or exceed 85 dBA.

When choosing hearing protection, consider the employee’s hearing needs on the job, their current hearing

ability, convenience, ease of use, the work environment and the compatibility with any other PPE the worker may need to wear. The best hearing protection is a solution that is worn properly by the worker every single time they are exposed to loud noise on the job.

OSHA General Industry Standard 1910.95(i)(1) Employers shall make hearing protectors available to all employees exposed to an 8-hour time-weighted average of 85 decibels or greater at no cost to the employees. Hearing protectors shall be replaced as necessary.

Hearing protection must be provided for the level and/or range of noise that workers will be exposed to during their work hours.

• Different types of devices may be used depending on the work environment as well as the hazardous noise.

• Where noise levels are extremely dangerous or potential impact noise levels are present workers may have to wear two layers of hearing protection such as a combination of ear plugs and ear muffs.

OSHA General Industry Standard 1910.95(i)(3) Employees shall be given the opportunity to select their hearing protectors from a variety of suitable hearing protectors provided by the employer.

• Never improvise hearing protection by stuffing cotton, tissue, wax or other items into your ears.

• Items can get stuck in the ear canal and in severe cases puncture the ear drum.

OSHA Construction Standard 1926.101(c) Plain cotton is not an acceptable protective device.

OSHA General Industry Standard 1910.95(i)(4) The employer shall provide training in the use and care of all hearing protectors provided to employees.

OSHA General Industry Standard 1910.95(i)(5) The employer shall ensure proper initial fitting and supervise the correct use of all hearing protectors.

OSHA Construction Standard 1926.95(b) Where employees provide their own protective equipment, the employer shall be responsible to assure its adequacy, including proper maintenance, and sanitation of such equipment.

Remember these important tips to avoid hearing loss while on the job:

• Workers who are exposed to high levels of noise can suffer permanent hearing loss.

• Workers must be protected from hazardous levels of noise.

• Workers must pay attention to all signs and warnings of potentially dangerous noise levels.

• OSHA regulations state that 85 decibels (dB) is the action level where workers may need to use hearing protection.

• Hearing protection must be provided for the level and/ or range of noise that workers will be exposed to during their work hours.

• Never improvise hearing protection by stuffing cotton, tissue, wax or other items into your ears.

• Proper personal protective equipment such as ear plugs or ear muffs must be maintained and worn correctly at all times.

The Leading Causes of Serious Injuries and Fatalities in Construction, Manufacturing, and Utilities

07.08.2025 | EHS Today

Discover the common causes of workplace fatalities across industries so you can learn how to prevent them.

James had been working in construction for over 20 years. He thought he’d seen everything. He’d spent plenty of time navigating busy sites, working on scaffolding, and operating heavy machinery. He always took safety seriously. One afternoon, he lost his balance on some scaffolding and fell four floors. Despite immediate medical attention, James didn’t survive.

Stories like James’ are far too common in high-risk industries like Construction, Manufacturing, and Utilities. In 2023 the construction sector recorded 1,057 fatalities – the highest of any industry in the US.

As a safety manager, being aware of the common causes of workplace fatalities is essential. It’s the only way you can mitigate risks and create a safer workplace. In the following blog post, we’ll cover some of the common causes of workplace fatalities across construction, manufacturing, and utilities.

FALLS

In the construction industry, falls, slips and trips were the cause of 421 fatalities, or 39.2% of industry fatalities in 2023. The nature of construction work makes the industry prone to these types of incidents. Construction sites are busy places. Workers may fall due to unsafe ladders, scaffolding failures, or human error.

In manufacturing, slips, trips, and falls from platforms occur frequently. Uneven or slippery surfaces coupled with poor housekeeping make manufacturing sites prime locations for falls. In 2016, Volvo was fined £900k (or over $1.16 million) after a

worker fell from a worn step ladder and had to be placed in a medically induced coma for two weeks. The worker still suffers from complications.

Utilities workers can experience falls during their routine maintenance work. Activities near power lines, poles, and substations leave utilities professionals vulnerable to these types of injuries.

CONTACT OR STRUCK-BY INCIDENTS

Struck-by or contact incidents occur when a worker comes into forcible contact with an object or piece of equipment. In 2023, contact incidents accounted for 15% (779) of all workplace deaths. In the same year, being struck by a propelled, falling, or suspended object was the leading cause (51% or 394) of contact injury deaths. Being struck, caught or compressed by running powered equipment accounted for 29% of contact injury deaths, or 226 fatalities. Why could this be? Risks are especially rife in fast-paced production environments. With plenty of moving equipment on the job, there’s potential for disaster around every corner. Robotic arms, forklifts, and other heavy machinery create constant hazards. Falling objects, moving conveyor belts, or improperly secured loads leave plenty of room for danger.

Busy construction sites also create the perfect storm for struck-by incidents. Heavy moving machinery and falling debris places workers at risk. Contact incidents were the fourth most common cause of fatalities within the construction industry in 2023, accounting for 148 deaths. Workers in the utilities sector are also threatened by the nature of their job. Falling tools, equipment, or debris are common causes of workplace fatalities here.

MACHINERY AND EQUIPMENT ACCIDENTS

Machinery and equipment accidents are a leading cause of injury in the manufacturing and utilities sectors. These incidents stem from improper use, malfunction, or lack of safeguarding on machines. In the UK in 2024, 16% of fatal injuries and 12% of non-fatal injuries in the manufacturing sector were due to contact with moving machinery. In the utilities industry, machinery-related incidents are commonplace. Workers face risks from high-powered equipment that can be treacherous to operate or even get near to.

CONFINED SPACE HAZARDS

There are risks of confined space hazards across the construction, manufacturing, and utilities sectors. Confined

spaces pose significant risks due to limited oxygen flow and inadequate ventilation. A restricted space also makes it harder for workers to escape in an emergency. In the USA, exposure to harmful substances led to 566 deaths in 2023 and oxygen deficiency caused 55 deaths.

A lack of fresh air can lead to dangerous conditions. Poor air quality can damage the lungs and increase the risk of heart disease, stroke, and certain cancers. The nature of the work within the construction, manufacturing, and utilities industries also means workers may be coming into contact with dangerous dusts, gases, vapours, smoke, and fumes. UK studies have found that 50% of demolition workers, 40% of insulation installers, 30% of pipefitters, and 20% of electricians are exposed to dangerous asbestos while completing their duties.

Employees in the utilities and construction sectors are at risk due to their work, which may take them into sewers, tunnels, underground, in electrical vaults, or other confined spaces. Trenching and excavation tasks are also hazardous.

Manufacturing often produces oxygen-deficient environments. Warehouses that aren’t fitted with the proper filtration systems expose workers to toxins. Warehouse equipment may also entrap workers in a location where it’s difficult to get out.

ELECTRICAL HAZARDS

Electricity is all around us, so electrical incidents can happen across all sectors. However, some of the activities performed within the construction and utilities sectors can make these accidents more prevalent. Electrical injuries include electric shock, electrical burns, loss of muscle control, and thermal burns. A voltage as low as 50 volts can have an impact on the body.

In construction and utilities, workers run the risk of electrical hazards from working with things like exposed wiring, power lines, improper grounding and faulty equipment. Contact with electricity caused 142 deaths in the US in 2023.

Caught-In or Between Accidents

Construction and utilities workers must face risks associated with operating heavy machinery, working on unstable structures, or even being trapped by trench collapses.

In manufacturing, workers may get entangled with machines, or suffer from conveyor belt accidents. Even if an injury isn’t fatal, the risk of losing limbs or dealing with crushed body parts is high.

The Impact of AI on Mitigating Risk in Construction

07.07.2025 |

Construction Project Zone Weekly

Risk management within construction has always been a moving target. Costs fluctuate, materials arrive late, and safety incidents disrupt progress. Contracts contain loopholes that only become evident when problems arise. Traditional risk management relies on experience, intuition, and reactive problem-solving. That approach worked in the past, but today’s projects operate under tighter margins, compressed timelines, and more stringent regulations. This guide explores how AI is transforming risk mitigation in construction, covering cost prediction, safety enhancements, supply chain stability, and quality control. The construction firms that master these tools will not just reduce risk. They will redefine how projects are planned, executed, and completed.

Predictive Analytics: Reducing Cost and Schedule Risks Cost overruns and schedule delays remain persistent challenges in construction. Traditional forecasting relies on historical trends, manual calculations, and subjective assessments. This approach often lacks precision, leading to budget miscalculations and unforeseen disruptions. AI-driven predictive analytics offers a more accurate and data-driven alternative. Machine learning models process historical project data, supplier reliability scores, labor productivity rates, and environmental conditions. These algorithms identify risk patterns that signal potential delays. Supply chain bottlenecks, labor shortages, or sudden weather changes become more predictable, allowing project managers to adjust before setbacks occur. AI continuously refines its predictions as new data flows in, creating an adaptive risk management system. Resource planning benefits from AI’s ability to analyze real-time data. Construction sites generate vast amounts of information from equipment sensors, workforce tracking, and material logs. AI processes this data to optimize resource allocation, preventing shortages and reducing downtime. Scheduling tools dynamically adjust project timelines, ensuring one delay does not disrupt the entire construction sequence.

AI-driven cost oversight improves financial accuracy. Algorithms scan procurement records, subcontractor bids, and invoices for inconsistencies. By flagging discrepancies early, AI prevents budget overruns before they escalate. When combined with real-time financial tracking, construction firms gain better visibility into spending trends, helping them course-correct before costs spiral out of control. Please note: The ability to forecast risks with greater accuracy strengthens decision-making. AI does not replace experienced professionals but enhances their ability to maintain project budgets and schedules with data-driven insights. AI-Driven Safety Enhancements: Preventing Accidents Before They Happen Safety risks remain a major concern in construction. Traditional safety measures rely on training programs, manual inspections, and compliance checks. While these strategies help mitigate hazards, they do not always prevent incidents before they occur. AI introduces a proactive approach by detecting risks in real time and predicting safety threats before they escalate. Computer vision plays a key role in AI-driven safety monitoring. AI-powered cameras analyze live video feeds from job sites, identifying unsafe behaviors such as workers operating without protective gear or moving through restricted areas. When a risk is detected, automated alerts notify safety managers, allowing them to intervene immediately. AI-enhanced image recognition also detects structural weaknesses and equipment malfunctions, preventing failures that could lead to injuries. Wearable technology further strengthens AI’s impact on jobsite safety. Smart helmets and vests equipped with biometric sensors track worker fatigue, heart rate, and environmental conditions. AI analyzes these signals to detect signs of exhaustion or exposure to hazardous materials. When a risk threshold is met, supervisors receive real-time alerts, reducing the likelihood of accidents caused by human error.

Predictive safety analytics adds another layer of protection. AI models analyze past incident reports, weather patterns, and project schedules to identify when and where safety

risks are most likely to emerge. Site managers can use this data to adjust work schedules, reinforce training, or implement additional protective measures in high-risk areas. Compliance automation also benefits from AI. Natural language processing tools review safety documentation and incident reports, ensuring regulatory standards are met. This reduces the burden of manual paperwork while improving accuracy in compliance reporting.

AI-Powered Quality Control: Reducing Rework and Structural Failures Defects in construction lead to costly rework, project delays, and in severe cases, structural failures. Traditional quality control depends on manual inspections, material testing, and compliance checks. These methods work but are limited by human oversight and time constraints. AI strengthens quality assurance by automating inspections and identifying inconsistencies before they cause larger problems. Computer vision and deep learning algorithms analyze images and videos from job sites. AI-powered drones and robotics scan buildings for defects that are not always visible to the human eye.

These tools detect cracks, misalignments, and improper installations early, reducing the need for expensive corrections later in the project. Machine learning models assess material performance by analyzing supplier records, environmental conditions, and past project outcomes. If a batch of materials shows a higher likelihood of failure, AI flags it before installation. This ensures only materials meeting specifications are used, reducing the risk of premature wear or failure.

...continued on next page

AI enhances quality control through Building Information Modeling (BIM). AI-enabled BIM platforms compare design blueprints with actual construction progress. Any deviations trigger automated alerts, allowing teams to correct mistakes before they escalate. AI simulations also test structural resilience under different stress scenarios, ensuring compliance with engineering standards before materials are placed on-site. Please note: AI does not replace inspectors or engineers. Rather, it provides them with powerful tools to catch issues that might otherwise go unnoticed. Strengthening Supply Chain and Labor Risk Management with AI Supply chain disruptions and labor shortages create significant risks for construction projects. Delayed materials, price fluctuations, and workforce gaps slow progress and increase costs. Traditional planning methods rely on historical data and reactive decisionmaking, which often fails to anticipate emerging challenges. AI provides a more proactive and adaptive approach to mitigating these risks. AI-driven procurement systems analyze market trends, supplier performance, and geopolitical factors to predict material shortages and price volatility. These systems recommend alternative suppliers, optimize order timing, and adjust procurement strategies before disruptions occur. Predictive analytics helps construction firms secure materials in advance, reducing project slowdowns caused by supply chain instability

AI-powered logistics platforms improve material tracking and distribution. RFID sensors and IoT-enabled devices provide real-time shipment visibility, alerting project managers to potential delays. Automated scheduling tools

adjust deliveries based on project timelines, preventing material shortages or excessive inventory buildup. Labor shortages add another layer of complexity. AI-enhanced workforce analytics platforms assess skill availability, predict future labor gaps, and recommend hiring or training strategies. These systems also optimize workforce distribution by matching job assignments with workers based on skill level and availability. Automation further mitigates labor risks. AI-powered robotics and autonomous equipment handle repetitive tasks such as excavation and bricklaying, allowing human workers to focus on higher-value responsibilities. AI-assisted workforce planning also helps contractors identify projects at risk due to labor shortages, enabling early interventions. Transforming Traditional Risk Management Through AI-Driven Insights AI is shifting construction risk management from reactive problemsolving to proactive decision-making. Traditional methods rely on historical data, manual oversight, and generalized contingency planning. AI enhances these approaches by processing real-time project data, identifying emerging risks, and providing actionable insights before they become costly setbacks. Despite AI’s advantages, human expertise remains essential. The most effective risk management frameworks integrate AI with institutional knowledge, ensuring that digital insights align with on-theground realities. Successful firms combine algorithmic risk assessments with superintendent evaluations, continuously validate AI models with field data, and maintain transparent accountability structures across all stakeholders.

HAVE YOU COMPLETED THE SAFETY QUIZ?

In case you missed it, scan the QR code or click the link below to take the quiz today!

As part of our ongoing commitment to workplace safety, it’s always been a requirement to kick off meetings with a safety topic when three or more people are present.

These quizzes will be featured in each edition of the Safety Net, as well as on MyAustin. This is a fun and effective way to reinforce safety knowledge.

Get ready to test your knowledge and become a safety expert!

Proactive Safety Planning is Vital to Construction Safety

07.08.2025 | EHS Today

A strong safety record is a result of preparation and accountability, not luck.

Fall hazards are one of the most serious and persistent risks in the construction industry, especially in roofing and other construction work at elevation. Whether workers are installing shingles, repairing decking, or maintaining rooftop air conditioning units, the risk of falling is constant—and often has fatal results.

A ROOFER FALLS TO HIS DEATH IN OHIO

In October 2024, a roofing contractor in Ohio was cited by the Occupational Safety and Health Administration (OSHA) following a fatal fall at a residential re-roofing project. According to OSHA, one worker fell approximately 15 feet from the roof onto an asphalt driveway and died from acute blunt force trauma to his head and torso.

The agency launched an investigation and ultimately cited the employer for six alleged safety violations, proposing a combined penalty of $236,447. It’s a steep penalty, but hardly the cost of human life. One of the violations was classified as willful, the most serious category under OSHA’s enforcement framework.

The centerpiece of OSHA’s citation was the allegation that the company failed to provide fall protection for employees working more than 6 feet above lower levels, as required by federal regulation. This willful citation alone accounted for $165,515 of the total proposed fine.

Here is a breakdown of the other citations:

• OSHA cited the company for allegedly failing to provide proper anchorage for personal fall arrest systems. According to the agency, “anchor points were installed by nailing ropes directly into the roof decking” instead of using reinforced anchors.

• OSHA also cited safety training violations, claiming multiple employees were not trained on fall hazards, procedures for inspecting fall protection systems or use of personal fall arrest systems.

• OSHA claimed the company failed to report a workrelated fatality within eight hours, as required by regulation.

If OSHA’s allegations are accurate, this case—and many others like it—underscores the importance of having a thorough, well-executed safety program for fall protection. Proactive safety planning helps prevent injuries and

limits the legal consequences that often follow serious workplace accidents.

FAILING TO PLAN IS PLANNING TO FAIL

For contractors, implementing a comprehensive safety program is essential to preventing injuries and complying with OSHA’s standards. Roofing work, for example, regularly exposes crews to serious hazards, including falls, ladder accidents, tool-related injuries, extreme heat and adverse weather. To that end, a strong safety program starts with a written safety manual—a foundational document that outlines company-wide safety policies and procedures. This manual should cover essential topics, such as fall protection, personal protective equipment (PPE), ladder safety, emergency response, and who within the company is responsible for managing and enforcing safety. To secure employees’ compliance, the manual should be distributed to all employees, referenced often and updated regularly based on lessons learned in the field.

Building on the safety manual, contractors should develop a job hazard analysis (JHA) for each construction project. A JHA helps identify specific risks tied to individual tasks

and work environments. For example, replacing a roof on a steep slope in high summer temperatures may require additional controls beyond what’s covered in the general manual, such as increased hydration breaks and modified work hours.

The JHA examines how each task interacts with the jobsite, the tools and the crew, giving employers a clear way to anticipate safety hazards before they occur. Together, the safety manual and JHA form a two-pronged approach: one sets the baseline and the other adapts company policy to the unique risks of each jobsite.

However, the most critical step of any safety program is implementation. Safety plans must move beyond paper and into daily practice. That means training workers before they ever step onto a jobsite, reinforcing safety expectations through supervision, and taking action when policies are ignored. Supervisors or designated safety personnel should inspect sites frequently and document any corrections made. Violations should be addressed with progressive discipline, starting with retraining and escalating to suspension or termination of employment when necessary.

...continued on next page

A strong safety record reflects preparation and accountability, not luck.

Each of these actions should be documented in a centralized database in the event of future incidents. A well-implemented safety program not only reduces the risk of serious injury but also helps protect the business from costly enforcement actions, mitigating the risk of willful citation items.

TRAIN EARLY AND OFTEN

A strong safety program begins with early and thorough training and keeps reinforcing it over time. New hires should receive hands-on instruction from a competent trainer before stepping onto their first jobsite. Companies with effective safety programs use this initial period to set expectations, establish safe work habits and explain the common risks (e.g., falls, ladder use and heat exposure). Training should always be provided in a language which the worker is fluent in (typically, English or Spanish) to ensure comprehension. Additionally, before starting work and before starting any new or unfamiliar tasks, employees should be given a written test to confirm they understand core safety principles.

But wise employers don’t stop there. Construction safety programs also include consistent and ongoing training. For example, weekly toolbox talks are a practical tool for reinforcing key topics and identifying knowledge deficiencies. These short meetings double as informal check-ins where supervisors can ask questions and spot misunderstandings early. Many companies also hold periodic safety stand-downs or company-wide seminars to

focus on high-risk areas. OSHA’s website is a useful resource, and its summaries of real-world safety incidents, such as the one referenced above, can be turned into case studies to drive home the importance of prevention.

Investing in outside training can strengthen both safety and regulatory compliance. Third-party providers offer specialized sessions on fall protection, and OSHA 10- and 30-hour courses are widely available. Many construction employers send frontline workers to OSHA 10 or fall-specific training, while supervisors complete the same courses, along with OSHA 30-hour certification. Employers can also bring in outside consultants to lead safety seminars or audit procedures. OSHA’s investigators tend to view these efforts favorably, especially where training can be independently verified.

IT’S NOT A MATTER OF LUCK

Roofing and other elevated construction work comes with serious risks, but those risks can be managed through planning, training and consistent enforcement. Companies with effective safety programs identify hazards, build clear written policies and implement job-specific plans that are actually followed in the field. They train workers early and often, supervise actively, and address violations before they lead to harm. This approach not only protects workers, but can also mitigate legal exposure should accidents occur. Like every other aspect of construction, a strong safety record reflects preparation and accountability, not luck.

Chemical Safety Board to Facilities: Be Prepared for Hurricane Season

07.08.2025 | Health + Safety

Washington — Chemical facilities should prepare now for hurricane season to “help prevent catastrophic chemical releases” and “ensure the safety of workers, emergency responders and surrounding communities,” the Chemical Safety Board says.

The National Oceanic and Atmospheric Administration recently issued a forecast that calls for a 60% chance of “above normal” activity in the Atlantic during this hurricane season, which lasts through Nov. 30. That includes an estimated six to 10 hurricanes (74 mph winds or higher) and three to five major hurricanes (111 mph winds or higher).

“Extreme weather events continue to become more frequent and severe each year,” CSB Chair Steve Owens said in a press release. “Facilities that produce, use, store or otherwise handle hazardous chemicals must take steps now to prepare for hurricanes and other extreme weather.”

The agency offers reports and safety videos related to extreme weather hazards and their potential impact on chemical facilities.

“The CSB’s materials provide important practical tools and recommendations that can help facilities mitigate their risk of severe damage and protect lives,” Owens said.

The board also recommends facilities consult the Center for Chemical Process Safety’s guidance document on planning for natural hazards.

USA Lone Worker Safety Legislation and Policy

07.22.2024 | EcoOnline

Find out more about the law on lone working, the main hazards and risks of working alone and offer advice on solutions for your business in the US.

For many organizations, lone working increases productivity, flexibility and allows businesses to operate on a wider scale. However, despite this, there are a number of risks that pose a threat to lone working staff. Lone workers do not have access to immediate help should an accident occur which often makes their roles more dangerous than office-based jobs. If a lone worker suffers a fall, is attacked by an assailant or has a medical accident and is unable to call for help, they could be seriously harmed.

So how can you ensure that your lone working staff are protected whilst at work? In this article, we’ll discuss the main risks and hazards associated with lone working, and take a look at different scenarios where lone working may be considered unsafe.

WHAT IS CLASSED AS LONE WORKING?

Lone working is when work activities are carried out without the direct and immediate support of supervisors or colleagues. To put it simply, if an employee cannot be seen or heard by a colleague, they are lone working, whether that is for all or part of their working day.

IS IT LEGAL TO WORK ALONE?

Working alone is completely legal and in most cases it is safe to do so. However, a risk assessment should be carried out on lone working activities so employers can assess and mitigate any potential dangers to their staff.

WHAT IS OSHA?

The Occupational Safety and Health Administration is an agency of the United States Department of Labor and was created to ensure safe and healthy working conditions for individuals living in the United States. OSHA standards are

rules that describe the methods that employers must use to protect their employees from hazards. There are OSHA standards for construction work, maritime operations, and general industry, which is the set of rules that applies to most worksites.

WHAT IS THE LAW ON LONE WORKING?

Health and safety legislation differs across states and many do not have specific policies for lone working.

Under OSHA’s guidelines companies who employ lone workers must account for each employee:

• Throughout each work shift at regular intervals appropriate to the job assignment to ensure the employee’s safety and health; and

• At the end of the job assignment or at the end of the workshift, whichever occurs first

Alongside this, employers should also implement their own regulations to help ensure the safety of their lone workers.

These could include:

• Conducting thorough lone worker risk assessments

• Producing a written health and safety policy and ensuring all employees understand it

• Taking steps to reduce or eliminate risk in order to create a safe working environment

• Providing information, instructions, lone worker training and supervision where appropriate

• Regularly reviewing and improving upon lone worker risk assessments and policies

The Washington State Department of Labor and Industries have also introduced a guide “Working Alone Safely: Controlling the Risks of Solitary Work.” The guide contains recommendations, such as, supervisors periodically visiting or observing lone workers and regular communication throughout a shift or period when someone is working alone. The guide also recommends the use of automatic warning devices and supervisors checking in with staff once the period of lone work is over.

LONE WORKING FAQ

• Can employers legally ask someone to work a night shift alone?Employers can legally require one person to work overnight alone. Security guards regularly monitor buildings alone throughout the night, whilst other roles such as a hotel receptionists or a petrol station attendants may work alone out of hours. Employees

...continued on next page

who work in these roles may be seen as easy targets for threats, such as theft or violence, and extra precautions should be put in place.

• Is it legal for an apprentice to work alone?It is legal for an apprentice to work alone if it is safe to do so. Employers have the same responsibilities to apprentices as they do any other employee. Therefore, they hold a primary responsibility for the health and safety of the apprentice and are required to carry out risk assessments and manage any potential threats.

• Are you allowed to work alone in a factory?Working alone in a factory is also allowed. However, the job role being carried out alone in the factory should be taken into consideration. For example, if operating machinery, you must ensure it is suitable for one person to do this alone. You should also take into consideration how an alarm can be raised in an emergency and what the response time is likely to be.

• Can a 16 year old work alone?A 16-year-old can work alone if the organization employing them has conducted a risk assessment and found it safe to do so. Young people under 18 have different employment rights from adult workers, including where and when they can work. You can find out more about young worker legislation here.

• Are you allowed to work alone in a shop?Working alone in a shop is completely legal and common practice. Extra safety measures should be taken however, as lone shop workers can become easy targets for robberies and other crimes. A risk assessment must also be carried out and consider the local crime rates, employee training levels and what emergency procedures are in place.

WHAT ARE THE MAIN RISKS AND HAZARDS THAT LONE WORKERS FACE?

Certain environments increase the risk to employees, particularly those in which customers may become upset, aggressive or take advantage of a lone worker.

Environments where alcohol, gambling and/or money are involved, as well as sensitive social work, can cause sudden mood changes and hostile behaviour. Utility workers often operate in rural areas, underground or with dangerous machinery and face environmental risks. If an accident were to happen, they may not be able to call for help. Similarly, staff who travel to different locations as part of their role may not be able to notify managers should an accident happen whilst on the road.

In some environments, no matter how stringent the risk assessment or safety measures put in place, the risk is too great to allow for lone working. So how can you assess the risk to your lone workers and make the judgement call?

LONE WORKER RISK ASSESSMENTS AND POLICY

The first and most important step in determining whether your employees are safe to work alone is carrying out a thorough risk assessment for each employee/environment as appropriate.

View our full guide on lone worker risk assessments

If the risks identified through the process are too high or uncontrollable, you must not let your employees work alone under any circumstance.

If, however, steps can be taken to reduce risk to a controllable level, in line with legislation, it may be safe to allow your employees to work alone, following the implementation of a lone worker policy.

WHAT IS A LONE WORKER POLICY? HOW DO YOU KNOW IF YOUR WORKERS ARE SAFE?

A lone worker policy is a guide that sets out your companies’ rules on working alone and helps your employees to understand the risks of their role. It also provides your staff with practical advice and instruction on how to safely carry out their roles and what procedures to follow should an incident occur.

A regular review of both your risk assessments and lone worker policy will help you identify whether your lone workers are safe. You may also wish to carry out inspections to ensure safe work practices are being followed.

USING APPS TO MONITOR LONE WORKING

Being able to monitor your employee’s whereabouts is extremely important in keeping them safe, as accidents can occur at any time. Regular communications should be maintained with lone working staff and procedures put in place so that employees can quickly communicate with their employer and raise the alarm if needed.

Manual methods of monitoring can be time-consuming, unreliable and often include a large amount of paperwork. Significant advances in mobile technology have led many companies to switch to app-based lone worker solutions to help them monitor and protect their remote staff.

EcoOnlines lone worker solution is an easy-to-use app and online monitoring hub that offers a way for lone

workers to raise an alarm in a dangerous situation. It monitors the location of lone workers in real-time via the hub so that assistance can be sent directly to an employee in an emergency.

Before a period of lone work or travel, employees start a timed session on the app which can be viewed by a monitor on the cloud-based hub. If an employee fails to

end their lone working session safely, a session expiry alert will be sent to their employer or chosen monitor.

The app features check-in reminders which prompt users to check-in routinely to confirm that they are safe. If a worker finds themselves in a dangerous situation, they can trigger a panic alert and help can be quickly dispatched to their location.

Many employees still go unrecognized in their day-to-day contributions, says O.C. Tanner report.

Employee recognition has always been part of a successful talent management strategy, but in the time of AI, it’s becoming essential.

A report from O.C. Tanner, released on July 8, finds that employees believe in-person recognition will be important to them in the future. Three in four say delivering personalized messages of appreciation (74%) makes recognition more valuable. AI plays a supporting role – 55% of employees say it can improve the recognition experience, and nearly 60% believe it helps craft better recognition messages.

“Today’s business leaders are rightly focused on improving efficiency and performance in the workplace, but our research reveals that when this emphasis becomes overly transactional, it can undermine authentic human connection and results,” said Mindi Cox, chief people and marketing officer, in a statement. “This report outlines how organizations can enhance recognition practices that encourage great work and support their unique culture while also bolstering the connections that make our workplaces distinctly human.”

THE RESEARCH HIGHLIGHTS SEVERAL KEY TRENDS:

Recognition is most impactful when it’s personal and purposeful: Awards linked to company purpose are 10x more meaningful; those that highlight an employee’s impact are 11x more meaningful; and when an award symbolizes that someone is truly valued, meaningfulness increases 12x. Custom awards also drive results –recipients are 5x more likely to do great work and 4x more likely to be engaged.

Recognition may be a workplace norm, but it’s far from universal. Most organizations recognize service anniversaries (75%) or top performers (63%), yet many employees still go unrecognized in their day-to-day contributions.

Recognition must be inclusive and fully integrated to succeed: While nearly 61% of employees use digital platforms for recognition, success requires more than just technology – especially for offline and frontline workers. Employees with limited tech access are 57% less likely to believe their program is equally accessible to all, and 46% more likely to feel recognition is an empty gesture. Yet just 65% feel it’s embedded in their culture. To experience positive workplace outcomes like increased engagement and belonging, companies must ensure recognition programs are available for all employees and amplified across the organization.

Multi-generational workforces value different kinds of recognition, and symbolism plays a powerful role for younger employees. Millennial and Gen Z leaders are 3x more likely than their Baby Boomer counterparts to say that receiving a meaningful symbolic award is a career highlight. Younger talent prioritizes recognition that reflects identity, purpose, and impact.

Meaningful recognition fuels culture when it’s authentic and personal. While 61% of employees describe recognition experiences as very meaningful – feeling genuinely seen and connected to a shared purpose – there’s a critical caveat. Even in workplaces with formal recognition programs, 54% of employees say the recognition they receive can still feel like an empty gesture. To make it meaningful, organizations must go beyond the award itself. Custom awards that are exclusive to an organization are 8x more impactful than generic ones – and when personalized, that impact jumps to 24x.