Fall Prevention or Fall Protection? 5 Things

to Consider

03.2024 | American Society of Safety Professionals

Working at height is a known safety hazard. When determining the best way to protect a worker from the hazards of working at height, it’s important to consider fall prevention before fall protection.

Fall prevention is especially critical in situations where fall arrest systems or other forms of PPE are ineffective or not typically used, such as potential falls of less than 15 feet, says Rob Brauch, president of Occupational Health and Safety Solutions Inc., a longtime safety professional and member of ASSP. A fall from 15 feet can achieve a speed of impact of 21 miles per hour and hit the body with 9,000 joules of energy — the equivalent of two exploding grams of TNT.

“Many of those falls occur when a person is climbing on machines they shouldn’t have been climbing, working from a ladder that wasn’t secure or being in an area that wasn’t protected,” he says.

These types of falls are also alarmingly common — they represent nearly half of falls that result in injuries or death, according to U.S. Bureau of Labor Statistics — yet are not often the focus of fall prevention or fall protection efforts.

“These fatalities do not need to occur,” Brauch says. “Many are preventable without going through all the various steps needed to get into harness, have tie-offs and do all the different things we’d have as traditional fall protection.”

Brauch recommends tackling these situations with fall prevention.

5 THINGS TO CONSIDER IN FALL PREVENTION VERSUS FALL PROTECTION

When comparing fall prevention and protection controls, you should consider several factors, including some methods that address temporary work under 15 feet.

1. AIM FOR BEST PRACTICES, NOT JUST COMPLIANCE

Fall-related issues make up four of the Top 10 OSHA citations:

• No. 1: Fall protection programs.

• No. 3: Ladders.

• No. 4: Scaffolding.

• No. 8: Fall prevention training.

To address these common hazards, many organizations use PPE, believing it is a fast, effective and affordable way to achieve compliance.

“When compliance with OSHA regulations is the sole concern, it’s common to ‘PPE it away,’” Brauch says.

But fall protection does not always tick all those boxes.

Combined with the cost of purchase, inspection, training and replacement, “PPE also has hidden costs in terms of diminished worker mobility, decreased efficiency and less job satisfaction,” Brauch says.

By focusing on best practices instead of compliance, you can often solve the issue in a way that optimizes efficiency and quality of outcomes, he adds. ...continued on next page

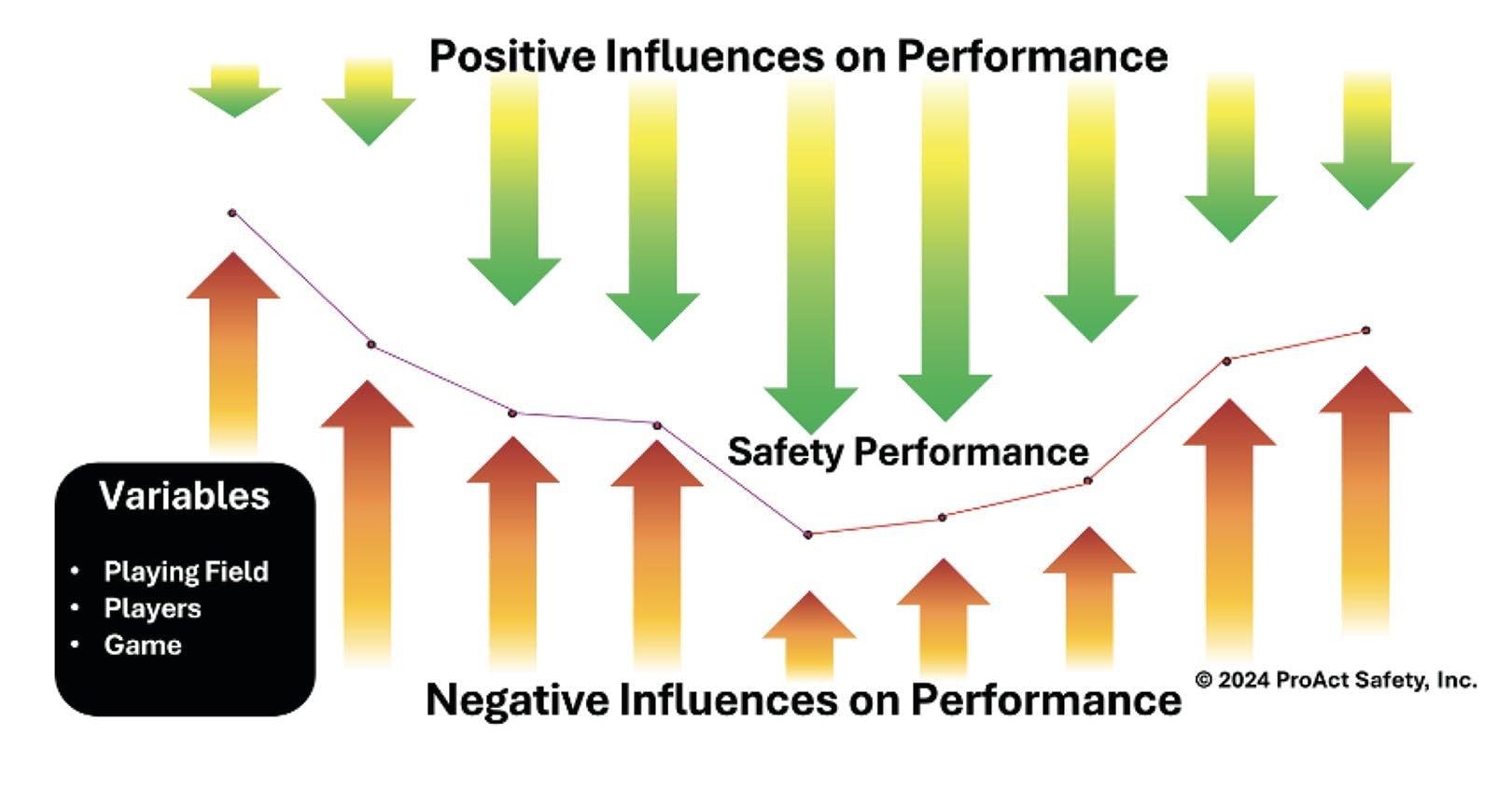

2. FOCUS ON THE “SWEET SPOT” IN THE HIERARCHY OF CONTROLS

The hierarchy of controls presents the ideal prioritization of hazard controls to address a safety issue, starting at elimination, then flowing down to substitution, engineering controls and administrative controls, with PPE as the solution of last resort.

But since working from height is often an integral part completing the job, it may not be possible to eliminate the hazard, and substitution is rarely practical. So, while PPE can be effective, it presents associated trade-offs, costs and movement restrictions.

That’s why Brauch recommends engineering and administrative controls, which he calls the “sweet spot” of the hierarchy.

3. DETERMINE WHETHER FIXED OR TEMPORARY FALL PREVENTION CONTROLS WILL WORK

“Alternative and technical solutions exist in the form of fixed or temporary engineering controls for fall prevention . . . where other accepted fall protection methods may be too complex, restrictive or impossible,” Brauch says.

Fixed engineering controls that remove the worker from the hazard include permanent elevated walkways, platforms and other structures, Brauch explains. However, since much of the work performed at height is nonroutine, often involving maintenance or repair, a fixed solution may be impractical.

4. ASSESS WHETHER THE SITUATION WARRANTS TEMPORARY CONTROLS

Any constraint on permanent fall prevention solutions may require temporary controls. For example, temporary controls may be preferable in these situations:

• Non-routine task.

• Short-duration task where bringing in scaffolding contractors may cause project delays and increase costs.

• Task that requires workers to have mobility while staying safe.

• Task involving older machinery installed without safe access at height.

• Work from a permanent walkway or elevated platform that restricts normal operator access needed for production.

• Work involving a machine around which you can’t install guardrails.

5. EXPLORE ENGINEERING CONTROLS

FOR FALL PREVENTION

1. Scaffolds or Scissor Lifts: These devices are proven and widely accepted for intended applications, but are subject to detailed, comprehensive OSHA regulations. Training is critical, Brauch says, because incidents do still occur.

2. Mobile Ladder Stands: While these devices have limitations — for example, they can’t cantilever out, they require a large footprint — mobile ladder stands are an effective solution to safer work at height when used in accordance with American Ladder Institute standards

3. User-Configurable Elevated Platforms And Walkways: These look similar to scaffolds, but they are preengineered by a trained and certified assembler so they don’t require intensive scaffold certification training. They can also be assembled without special tools, offer reconfigurability options and fit into tight spaces. When using these devices, it’s important to understand working load limits and ensure that handrails and guardrails are installed at the proper height, Brauch says.

4. Specialized Mobile Device With A Cantilever Deck: Using counterweights or other means, these devices allow for greater reach through specialized ascent platforms without sacrificing rated load. With locking wheels, their footprint can be minimized and the device can be cantilevered in various directions and set to heights from 9 to 12 feet.

WHAT’S NEXT? A FOCUS ON FALL PREVENTION

Brauch recommends all safety professionals familiarize themselves with the ANSI/ASSP Z359.1-2020 Fall Protection Code and consider a range of solutions.

“Using temporary deployment of engineering controls can be both safe and more cost-effective,” Brauch says, but warns: “Training and correct use of any fall prevention devices are just as important as they are for PPE.”

OSHA Issues Final Rule on Hazard Communication Standard

05.23.2024 | EHS Today

On May 20, OHSA announced a final rule from its Occupational Safety and Health Administration that will update the current Hazard Communication Standard to better protect workers by improving the amount and quality of information on labels and safety data sheets and allow workers and first responders to react more quickly in an emergency.

The updates take effect on July 19, 2024.

Aligned primarily with the seventh revision of the United Nations’ Globally Harmonized System of Classification and Labelling of Chemicals, the updated standard will require labels on small packaging to be more comprehensive and readable and makes changes to help ensure trade secrets no longer prevent workers and first responders from receiving critical hazard information on safety data sheets.

The agency said that workers will also benefit from other changes in the updated standard, including a clearer

hazard classification process to provide more complete and accurate hazard information on labels and safety data sheets; updated physical hazard classes to better inform users on safe handling of explosives, aerosols and chemicals under pressure; and updated precautionary statements on how to safely handle, store and dispose of hazardous chemicals.

The final rule also addresses issues that arose since the implementation of the 2012 standard and improves alignment with other federal agencies and Canada.

Established in 1983, the Hazard Communication Standard provides a standardized approach to workplace hazard communications associated with exposure to hazardous chemicals. OSHA updated the standard in 2012 to align with the third revision of the GHS to provide a common and coherent approach to classifying chemicals and communicating hazard information.

Any heat illness prevention program should include the following points:

• Workers should be provided with adequate water, rest, and shade during the course of the work day.

• New or returning workers should be allowed to gradually increase workloads and take more frequent breaks as they build up their tolerance to working in the heat.

• Emergency plans for first aid and medical transport should any employee show signs of heat illness.

• Safety meetings to train workers on heat illness prevention.

• Safety meetings to train workers to recognize symptoms of heat-related illnesses in themselves and their co-workers.

• Training program for supervisors on preventing and recognizing heat-related illness.

• Monitoring program set up during every shift to ensure water, rest and shade are being adequately provided and heat-related illnesses are being prevented and caught early as symptoms are noticed.

Every year, dozens of workers die and thousands more become ill while working in extreme heat or humid conditions. More than 40 percent of heat-related worker deaths occur in the construction industry, but workers in every field are susceptible. There are a range of heat illnesses and they can affect anyone, regardless of age or physical condition.

Some companies are getting creative with their heat illness prevention programs. Here are some awesome examples of how companies across the country and making sure their workers stay safe, but still get the job done, when temperatures soar in the summertime.

• Implement a buddy system within shifts so workers can keep an eye on each other and report heat illness symptoms quickly to the supervisor.

• Set up portable canopies outside with misting hoses woven throughout the frames to cover workers with a fine mist of water to help keep everyone cool.

• Cooling caps and bandanas are provided to all outdoor workers.

• Monitor the OSHA-NIOSH heat safety app and follow the provided recommendations.

• When temperatures are expected to be especially high, provide earlier shift options and additional breaks.

• Keep reinforcing the heat illness prevention message throughout the entire summer by sending text messages and emails to all workers, posting signs and posters around the job site and giving frequent toolbox talks on the hazards of heat exposure.

• When working inside shops, hangars, and warehouses that get exceedingly hot, provide plenty of large fans, ice machines and water dispensers and rotate jobs to cooler locations inside and out.

• Train all workers in First Aid/CPR with emphasis on recognition of heat stress.

• Share the message about heat illness prevention as often as possible on social media by sharing pictures of your crews to inspire others and make sure to use the hashtag #WaterRestShade.

Workers need to be aware of their specific limitations and remember that sometimes their body may not cool off fast enough. Factors that can increase the chance of heat stress include:

• High Temperature and Humidity.

• Not Drinking Enough Water.

• Direct Exposure (With No Shade) or Extreme Heat.

• No Breeze or Wind.

• Physical Activity Without Breaks.

• Use of Bulky Protective Clothing and Equipment.

To learn more about heat-related illnesses like heat cramps, heat exhaustion, and heat stroke you can visit our popular article on Recognizing Heat Stress and visit the OSHA page on Occupational Heat Exposure.

All companies that have outdoor workers, or any employees that work in a warm or hot environment for any part of the work day, should be having safety meetings and giving toolbox talks on heat stress. Ideally the message should be reinforced throughout the summer, at least once a month, but more often if possible.

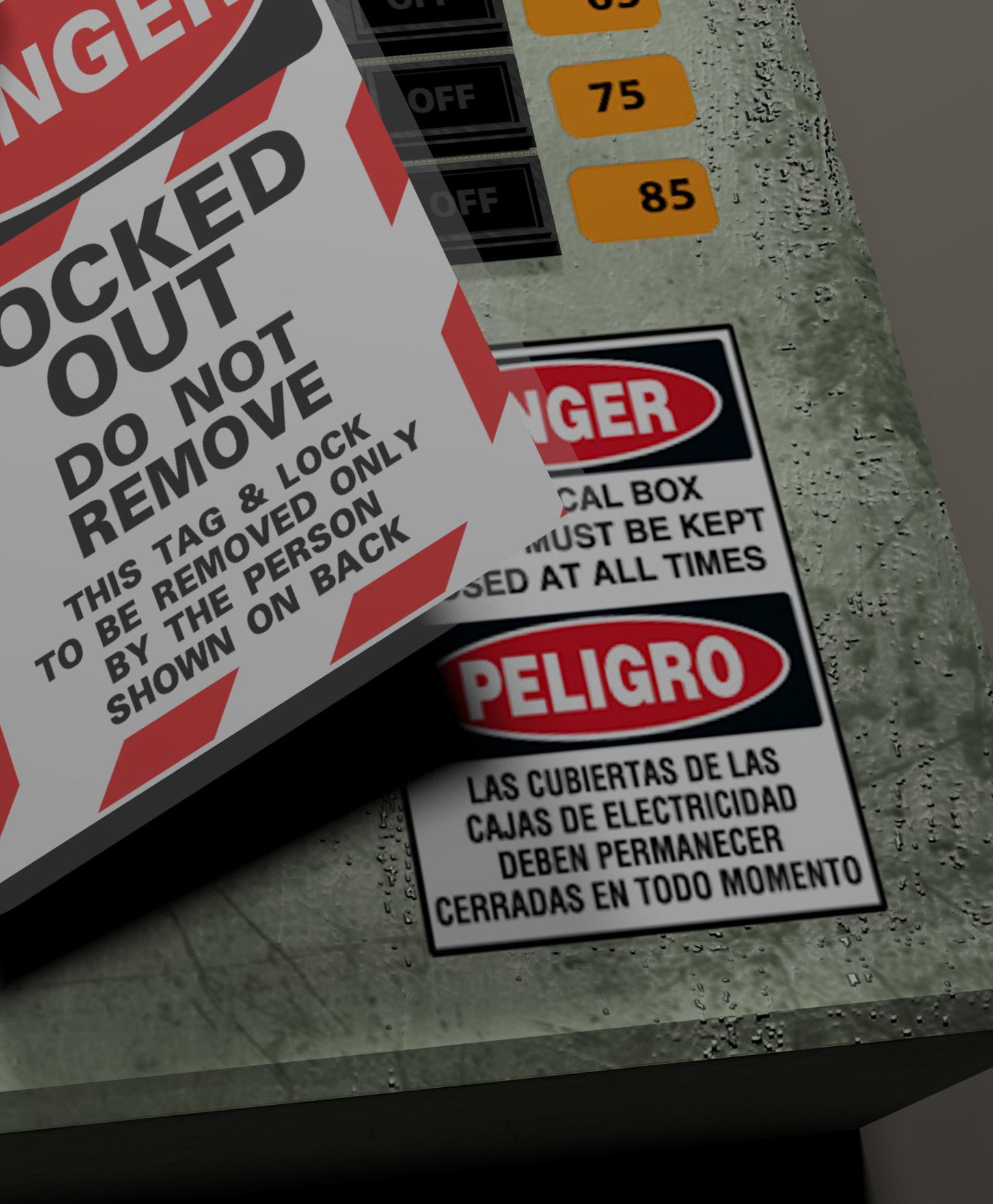

Top 5 LOTO Violations and How to Avoid Them

07.15.2024

| JJ Keller

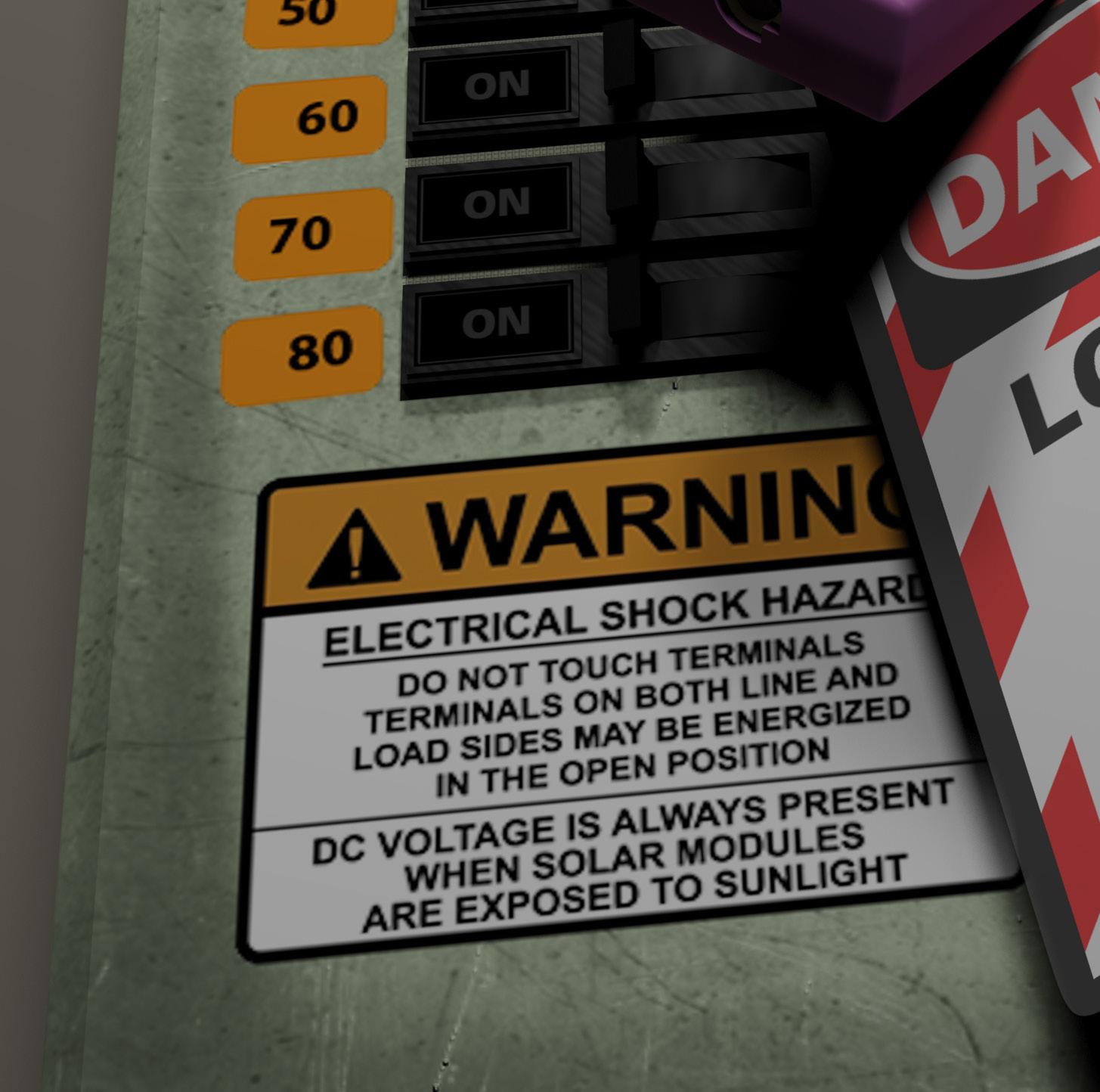

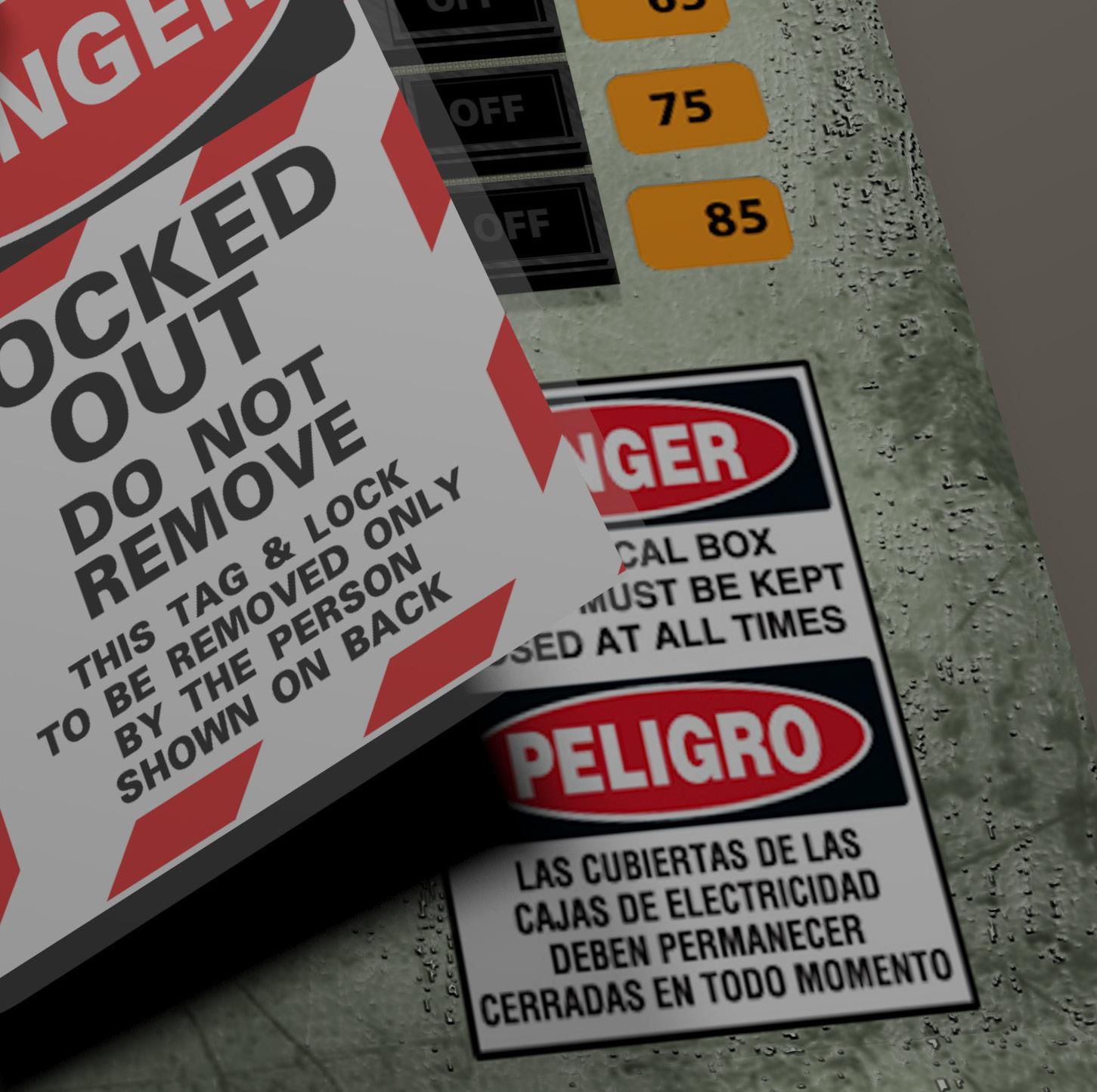

The numbers are in for fiscal year 2023, and once again the Control of Hazardous Energy, more commonly known as lockout/tagout (LOTO) , is a top-violated general industry standard. The standard requires employers to establish a program for affixing lockout or tagout devices to energy-isolating devices on machines and equipment to prevent their unexpected energization, startup, or release of stored energy. This applies in all general industry workplaces where employees perform servicing or maintenance on machines or equipment that could expose them to the unexpected release of hazardous energy.

the steps employees must take to isolate machines and equipment from their energy sources and to render them safe for employees to perform servicing and maintenance.

2. PERIODIC INSPECTIONS, 1910.147(C)(6)(I)

Energy control procedures must be inspected at least annually to ensure that the procedures and the requirements of 1910.147 are being followed. Periodic inspections must be:

• Performed by an authorized employee other than the one(s) utilizing the energy control procedure being inspected, and

1. ENERGY CONTROL PROCEDURES, 1910.147(C)(4)(I)

Employers covered by the standard must establish an energy control program tailored to the machinery and equipment in each workplace to protect employees from the unexpected release of hazardous energy during servicing and maintenance activities. One of the main pieces of this program includes energy control procedures. These procedures specify

• Conducted to correct any deviations or inadequacies identified.

Where lockout is used for energy control, the periodic inspection must include a review, between the inspector and each authorized employee, of that employee’s responsibilities under the energy control procedure being inspected.

Employers must document certification of these inspections. The certification must identify the machine or equipment on which the energy control procedure was being utilized, the date of the inspection, the employees included in the inspection, and the person performing the inspection.

3. ENERGY CONTROL PROGRAM, 1910.147(C)(1)

1. Preparation for Shutdown,

2. Machine or Equipment Shutdown,

3. Lockout or Tagout Device Application,

4. Stored Energy, and

5. Verification of Isolation.

5. AUTHORIZED EMPLOYEE TRAINING, 1910.147(C)(7)(I)(A)

Authorized employees must be trained in the recognition of applicable hazardous energy sources, the type and magnitude of the energy available in the workplace, and the methods and means necessary for energy isolation and control.

Employers must establish a program consisting of energy control procedures, employee training, and periodic inspections to ensure that before any employee performs servicing or maintenance on a machine or equipment where the unexpected energizing, start up, or release of stored energy could occur and cause injury, the machine or equipment must be isolated from the energy source, and rendered inoperative. Employee training is outlined in paragraph (c)(7).

4. PROCEDURE ELEMENTS, 1910.147(D)

Employers’ energy control procedures must address specific elements and actions, and these procedures must be done in the following sequence:

An authorized employee is one who locks out or tags out machines or equipment to perform servicing or maintenance on those machines or that equipment. Any employee who performs one or more procedural elements of an employer’s energy-control program for the purpose of servicing or maintenance is considered an authorized employee.

10 Facts About the State of Workplace Safety in the U.S.

06.17.2024 | Smerican Society of Safety Professionals

While U.S. workplace safety has improved since the passage of the landmark Occupational Safety and Health (OSH) Act in 1970, progress has recently stalled — even as enduring problems like safety inequity continue and new hazards emerge.

The comprehensive annual report, “Death on the Job: The Toll of Neglect, 2024” published by the American Federation of Labor and Congress of Industrial Organizations (AFL-CIO) covers the state of workplace safety in the U.S., highlighting several key issues:

• Black and Latino workers are at greater risk for injury, illness or death on the job.

• New and worsening hazards such as workplace violence, heat and infectious disease must be addressed to reduce their growing threat to workplace safety and well-being.

• Job safety agencies have been flat-funded for years, not even keeping up with inflation. Employees and resources have shrunk as responsibilities have grown.

• The OSH Act is more than 50 years old now and needs updates, particularly to its whistleblower programs and protections, and to strengthen criminal prosecution and penalties.

• Workplace injuries and illnesses remain underreported and costly, and the way data reporting has changed, obscuring the true scope of these problems.

The 256-page report presents extensive data to support the findings, but these 10 facts reveal what they uncovered about the state of workplace safety in the U.S.

1. BLACK AND LATINO WORKERS ARE PUT AT GREATER RISK

Latino workers face the greatest risk of dying at work — their job fatality rates are 24% higher than the overall average, while Black workers have fatality rates 14% higher. In 2022, 734 Black workers died on the job, the highest number in at least 20 years.

“Death on the Job” cites a recent North Carolina study in explaining these mortality rate disparities: Segregation by race into more hazardous industries and occupations plays a substantial role.

To combat these rising rates, the report calls for targeted OSHA enforcement and training programs in workplaces and industries with greater density of these of demographics to help reduce job fatalities and improve working conditions,.

2. ROADWAY COLLISIONS ARE THE LEADING CAUSE OF DEATH AT WORK

Roadway collisions remain the leading cause of workplace deaths, responsible for 2,066 or 38% of all fatalities in 2022. The next leading cause of death — falls, slips and trips — claimed 865 workers’ lives, or 16% of total deaths. Violence and exposure to harmful substances/ environments are close behind, with each accounting for 15% of overall deaths.

3. WORKPLACE VIOLENCE, HEAT ILLNESS AND INFECTIOUS DISEASE ARE GROWING THREATS

The report advocates for new OSHA standards to address workplace violence, heat illness and infectious diseases.

While the COVID-19 pandemic magnified the need for an infectious disease standard, workplace violence and heat illness have been growing insidiously.

Over the past 30 years, heat stress has killed approximately 1,000 workers and caused nearly 33,000 serious lost-time injuries and illnesses, according to BLS, and those numbers are rising. In 2022, BLS reported 43 work-related fatalities from heat exposure , a 19%

increase from 2021. Hot working conditions contribute to other injuries due to sweat, fogging personal protective equipment, dizziness and hot tools and equipment.

Workplace violence is also on the rise, after decreasing for decades until 2011, when the rate increased 41% in one year. Since then, the injury rate associated with workplace violence has remained at 3.8 or higher and is now 4.3 per 10,000 workers, the majority of whom work in healthcare, social assistance and educational services. Women workers experienced 66% of these serious injuries.

4. FATALITY DATA REPORTING RULES OBSCURE INFORMATION

In 2020 (starting with 2019 data), the Bureau of Labor Statistics (BLS) updated its disclosure methodology policy on fatalities, resulting in less descriptive data than it had published under the Census of Fatal Occupational Injuries

According to the report, this makes it impossible to “stratify deaths in one occupation by certain demographics like country of origin or gender, workplace homicides by type of weapon used or by perpetrator, unintentional overdose deaths by different industries.” It’s now harder to glean important insight on trends in workplace safety, even as data collection and analysis grow.

...continued on next page

5. OSHA’S JURISDICTION DOUBLED AS ITS RESOURCES DECLINED

In March 2024, Congress passed legislation that appropriated OSHA a budget of $632 million, level funding from the previous year, but lower than the rate of inflation. Under OSHA’s current budget, the agency has enough to spend $3.93 to protect each worker it is required to protect under the OSH Act.

Federal OSHA also lacks enough inspectors to carry out its duties. In 2023, the agency had enough compliance officers to inspect workplaces in its jurisdiction once every 186 years. If that isn’t sobering enough, when AFL-CIO first issued its “Death on the Job” report, federal OSHA had enough inspectors to inspect workplaces every 84 years. This leaves investigations lacking as well. Federal OSHA inspected the workplace in 40% of formal complaints and 20% of informal complaints.

While state plan agencies have fared better with growing ranks, they still have limited personnel. Between federal and state agencies, there are currently 1,875 inspectors responsible for enforcing the safety and health regulations at more than 11.5 million workplaces, which translates to one inspector responsible for every 80,014 workers.

While the Biden administration has shored up the number of federal OSHA inspectors from an all-time low in 2019, fully staffed the agency’s head office for the first time since the Obama administration and requested a 3.5% increase in OSHA funding for FY 2025, the agency still has much ground to cover to close the gap between its responsibilities and its ability to perform them, the report concludes.

6. MONETARY PENALTIES FOR OSHA VIOLATIONS REMAIN WEAK

Penalties for OSHA violations have always been relatively low, “due to statutory limitations and enforcement policies that prioritize the settlement of cases to achieve more expedient abatement of hazards, rather than imposing the maximum fines,” the report says.

In 2023, the average penalty for a serious violation under federal OSHA was $4,597, compared with an average penalty of $4,354 for serious violations in 2022. In FY 2023, the average penalty for a serious violation for state OSHA plans combined remained lower, at $2,406; in 2022, it was $2,221.

This increase is due in part to a 2015 law that allowed OSHA to raise maximum penalties by approximately 80% (the amount of inflation since the last time OSHA penalties were increased in 1990) and to regularly update penalties to account for future inflation.

This raised the maximum penalty for serious violations to $16,131, and for willful and repeat violations to $161,323.

According to OSHA inspection data, the average total penalty in a fatality case in 2023 was $20,996 for federal and state OSHA plans combined.

7. FEW OSHA VIOLATION CASES ARE PROSECUTED

According to information provided by the Department of Labor, since the passage of the OSH Act in 1970, only 137 cases have been referred for prosecution.

By comparison, the Environmental Protection Agency opened 199 criminal cases related to federal environmental laws in 2023 alone. In 74% of the criminal

cases charged, an individual defendant was prosecuted, and those prosecutions generated a 100% conviction rate.

“The aggressive use of criminal penalties for enforcement of environmental laws, and the real potential for jail time for corporate officials, serve as a powerful deterrent,” the report says.

Criminal penalty provisions in the OSH Act are limited to willful violations that result in a worker’s death — endangerment or serious injury aren’t covered — or where false statements are made in required reported. These are limited to misdemeanors.

Contrast that with federal environmental laws, where criminal penalties apply in cases where there is simply “knowing endangerment,” and the law makes such violations felonies.

8. THE OSH ACT’S WHISTLEBLOWER PROVISIONS NEED REVISION

One of OSHA’s key responsibilities is to enforce the antiretaliation provisions of the OSH Act, but those efforts are often constrained by limited resources — for example, the number of workers alleging retaliation for raising safety concerns during the pandemic rose and the agency was assigned more statutes to enforce — without additional funding. The total number of cases, under all statutes, received by OSHA’s whistleblower program in 2023 was 3,243, up from the 2,755 received in 2022.

But the larger problem is the OSH Act itself, which has not kept up with protections included in other whistleblower statutes.

• The OSH Act provides only 30 days to file a discrimination complaint, compared with the 180 days provided by several other laws.

• The act provides no opportunity for interim reinstatement for workers while the case is being resolved, nor a separate right of action for the complainant to pursue the case on their own. During this time, workers are in limbo, with no recourse or redress for discriminatory actions. Other whistleblower statutes provide these rights.

9. WORKPLACE INJURIES AND ILLNESSES ARE UNDERREPORTED AND COSTLY

In 2022, more than 3.5 million workers across all industries, including 2.8 million in the private sector, experienced work-related injuries and illnesses that were voluntarily reported by employers, a rate of 2.7 per workers. It is 81% higher in the state and local public sector, which reported a combined injury rate of 4.9 per 100 workers.

But the true toll is estimated to be between two and three times greater, or 5.6 million to 8.4 million injuries or illnesses a year. Research shows that one-third to two-thirds of work-related injuries and illnesses are not captured in the BLS Survey of Occupational Injuries and Illnesses. This is driven by several factors, including:

• Some employees are reluctant to report injuries due to fear of retaliation, incentive programs that penalize workers who report injuries and drug testing programs for workplace injuries.

• Not all injuries or illnesses are appropriately attributed to the workplace.

• Some states don’t report any data.

• Certain injuries are excluded from the survey’s scope, such as those among self-employed individuals.

To better understand the impact of these injuries and illnesses — reported or not — Liberty Mutual Insurance launched a household survey to collect information through interviews, resulting in the 2023 Workplace Safety Index.

It estimated the employer cost of the most disabling workplace injuries at more than $58 billion a year — more than $1 billion per week. The top five injury causes that account for 62.7% of the total cost burden:

• Overexertion Involving Outside Sources (Handling Objects).

• Falls on The Same Level.

• Falls to a Lower Level.

• Struck by Object or Equipment (Being Hit by Objects).

• Other Exertions or Bodily Reactions (Awkward Postures).

10. WORKERS COVER THE COST OF THEIR INJURIES — AND THOSE COSTS VARY

A comprehensive 2011 study of government data found that workers’ compensation covered only 21% of the direct and indirect costs of injury and illness, with 13%

...continued on next page

borne by private health insurance, 11% by the federal government and 5% by state and local governments.

But workers and their families bore the most significant cost burden at 50%. Workers’ incomes are also impacted long-term; a 2011 study found that injured workers’ incomes are, on average, nearly $31,000 lower over 10 years than had they not suffered an injury.

One major contributor to the severe loss of income is the gross deficiencies and inequities in the workers’ compensation system, according to a 2015 ProPublica and National Public Radio investigative report cited by the researchers. Since 2003, legislators in 33 states have passed laws reducing benefits or limiting eligibility, leading to wide variance in benefits. For example, in 2015, the maximum compensation for loss of an eye was $261,525 in Pennsylvania, but only $27,280 in Alabama. Fifteen workers die each day in the U.S. from job injuries, but investing in occupational safety agencies like OSHA, keeping up with evolving hazards and making a commitment to workplace safety can reduce that number in time.

ADDITIONAL DATA POINTS

• More than 300 workers died each day from hazardous working conditions in 2022 (this includes those who die from illness and injury).

• Fifteen workers die each day from job injuries.

• The number of workers killed on the job at ages 2024 increased 12% to 323 fatalities in 2022 from 289 fatalities in 2020.

• More than 5,000 workers were killed on the job in the United States in 2022.

• An estimated 120,000 workers died from occupational diseases.

• The job fatality rate increased again to 3.7 per 100,000 workers in 2022.

• Black workers’ job fatality rate was the highest it has been in nearly 15 years — 4.2 per 100,000 workers.

• Latino workers’ job fatality rate increased again to 4.6 per 100,000 workers — meaning they continued to face the greatest risk of dying on the job out of all workers at 24% higher than the national average; the rate marked a 24% increase over the past decade.

• The rate of serious workplace violence injuries has increased to 4.3 per 10,000 workers.

• The cost of job injuries is estimated at $174 billion to $348 billion a year.

• The most dangerous industries are agriculture (including forestry, fishing and hunting), mining (including quarrying and oil and gas extraction), transportation and warehousing, construction, and wholesale trade.

• Among the industries with the greatest reported injury and illness rates in 2022 were nursing and residential care facilities and hospitals.

• Musculoskeletal disorders from repetitive motion injuries continue to be a major problem, accounting for 28% of all serious work-related injuries and illnesses in private industry.

• States with the highest fatality rates in 2022 were:

• Wyoming (12.7 per 100,000 workers).

• North Dakota (9.8 per 100,000 workers).

• Mississippi (6.9 per 100,000 workers).

• New Mexico (6.8 per 100,000 workers).

• West Virginia (6.8 per 100,000 workers).

• Louisiana (6.4 per 100,000 workers).