THE SAFETY NET

Starting in April, spring means brighter days, flowers blooming, and warmer temperatures! While the spring months get us closer to the hot summer, they also bring with them a wide array of specific hazards to look out for.

LOCATION CONSULTING DESIGN & ENGINEERING DESIGN-BUILD CONSTRUCTION & CONTRACTING MARCH 2023 VOLUME 17 ISSUE 3 SAFE T Y FIRST. Austin employees have worked 5,455,563 hours

Time Accident

without a Lost

through 02/2023.

IT’S ALWAYS SAFETY FIRST. CONSULT • DESIGN • ENGINEER • CONSTRUCT

and Home 03.15.23 | SafetyStage & Centers for Disease Control and Prevention

Spring Safety Topics For The Workplace

BIOLOGICAL HAZARDS

Biological hazards include vector-borne diseases, venomous wildlife and insects, and poisonous plants. Venomous snakes, spiders, scorpions, and stinging insects can be found throughout various geographic regions, and are especially dangerous to workers who have allergies to the animal. Poisonous plants can cause allergic reactions if their oils come in contact with skin. These plants can also be dangerous if burned and their toxins are inhaled.

POISONOUS PLANTS

Many plants are poisonous to humans when ingested or through skin contact with plant chemicals. The most common problems with poisonous plants arise from contact with the sap oil. Several plants native to the United States can cause an allergic skin reaction. These include poison ivy, poison oak, and poison sumac.

Any workers who spend time outside are at risk of exposure to poisonous plants. Some jobs include farmers, foresters, landscapers, gardeners, painters, roofers, pavers, construction workers, laborers, and mechanics. Forestry workers and firefighters who battle forest fires are at additional risk. They can develop rashes and lung irritation from contact with damaged or burning poisonous plants.

VENOMOUS SPIDERS

Venomous spiders found in the United States include the black widow and the brown recluse. These spiders can be dangerous to outdoor workers. These spiders occasionally find their way inside structures or buildings and can also present a risk to indoor workers including machine operators, janitors, and cashiers (Bureau of Labor Statistics

Monthly Review – Insects bites, stings cause thousands of workplace ). Spiders are usually not aggressive and most

bites occur because a spider is trapped or unintentionally contacted. It is important for employers to educate their workers about their risk of exposure to venomous spiders, how they can prevent and protect themselves from spider bites, and what they should do if they are bitten.

VENOMOUS SNAKES

Venomous snakes found in the United States include rattlesnakes, copperheads, cottonmouths/water moccasins, and coral snakes. A venomous bite is called an “envenomation.” Although death from venomous snake bites is rare, a worker with a severe envenomation or allergy to snake venom can die from a venomous bite. Each year, an estimated 7,000–8,000 people are bitten by venomous snakes in the United States, and about 5 of those people die. The number of deaths would be much higher if people did not seek medical care.

Workers are far more likely to suffer long-term injuries from snake bites than to die from them. For those bitten by rattlesnakes, 10–44 percent will have lasting injuries. An example of a disability or permanent injury is the ability to use a finger or losing part or all of it.

Employers should train their workers about their risk of exposure to venomous snakes, how workers can prevent and protect themselves from snake bites, and what they should do if they are bitten.

Some venomous snakes can be difficult to see in the environment.

INSECTS

Stinging or biting insects can be hazardous to outdoor workers. Stinging or biting insects include bees, wasps, hornets, and fire ants.

The health effects of stinging or biting insects range from mild discomfort or pain to a lethal reaction for those workers allergic to the insect’s venom. Anaphylactic shock is the body’s severe allergic reaction to a bite or sting and requires immediate emergency care. Thousands of people are stung by insects each year, and as many as 90–100 people in the United States die as a result of allergic reactions. This number may be underreported as deaths may be mistakenly diagnosed as heart attacks or sunstrokes or may be attributed to other causes.

It is important for employers to train their workers about their risk of exposure to insects and scorpions, how they can prevent and protect themselves from stings and bites, and what they should do if they are stung or bitten.

3

Microplastics, Fast Fashion and Saving the Bees: EHS Today’s Sustainability News

04.01.2022 | EHT Today - Nicole Stempak

This week, we’ve found a few stories looking at the human impact on the environment and are inspired by some initiatives to be more sustainable.

It’s difficult to believe it’s already April! We’re having a moment where we simultaneously feel that time is whizzing by and also barely moving—the way we felt in high school when we eagerly awaited the final bell.

We’re looking at the month ahead and excited at all the celebrations. In recognition of some upcoming religious holidays, Happy Passover, Easter and Eid Mubarak for those who observe them. Here in the Great Lakes, we also look forward to the tradition of Dyngus Day . Bring on the paczki and pierogi!

We’re also looking forward to celebrating Earth Day. This year, we’re taking a hard look at our habits and daily routine and asking ourselves what we can do differently for the betterment of our planet.

For some, that could mean walking or biking instead of driving. For others, it could mean cooking a vegetarian dish at home. For all of us, it can mean pausing to

appreciate the wonder and bounty Mother Earth provides us and considering what small and not-so-small changes we can make to ensure future generations can have the same experience.

With that in mind, we’ve found a few stories looking at the human impact on the environment and are inspired by some initiatives to be more sustainable.

MICROPLASTICS DETECTED IN HUMAN BLOOD

Plastic doesn’t dissolve. Instead it gets broken into smaller and smaller particles, called microplastics. They’ve been found in water supplies, animals and now—for the first time—human blood.

New research published in the journal Environment International found that plastic was in the blood of 17 of 22 study participants. More research is needed, but these findings should still sound alarm bells. Especially because the health impact and implications of such a finding are not yet known.

Half of the blood samples showed traces of polyethylene terephthalate (PET) plastic, widely used to make drink

bottles. More than a third had polystyrene (PS), used for disposable food containers and many other products. A quarter of the blood samples contained polyethylene, which are used to make plastic shopping bags.

“This is proof that we have plastics in our body -- and we shouldn’t,” said study author Dick Vethaak, an ecotoxicologist at Vrije Universiteit Amsterdam in the Netherlands, to the Agence France-Presse

“Where is it going in your body? Can it be eliminated? Excreted? Or is it retained in certain organs, accumulating maybe, or is it even able to pass the blood-brain barrier?”

The study authors said that participants could have been exposed to microplastics through air, water and food as well as through products, such as toothpastes, lip glosses and tattoo ink. They do not know if plastic particles in the bloodstream can be transported to organs.

Read more summaries of the findings from The Guardian and Smithsonian Magazine .

EUROPE TAKES A SWIPE AT FAST FASHION

The European Commission has proposed some new fashion rules. Specifically, it’s targeting the fast fashion industry. As we’ve previously reported , the fashion industry is a major polluter; the fast fashion industry is even worse because sells clothes that are affordable, trendy and aren’t made to last—but their plastics-derived materials are. The effort is part of a bigger initiative to ensure that more physical goods that are either made or imported into the European Union (EU) are more sustainable.

“It’s time to end the model of ‘take, make, break, and throw away’ that is so harmful to our planet, our health and our economy,” said EU executive vice-president Frans Timmermans in a press conference, according to the German broadcaster Deutsche Welle.

The proposal would set new standards for how durable and reusable clothes need to be and would introduce bans on the destruction of unsold textiles, according to NPR. Companies would also be required to include how sustainable and recyclable a clothing item is on its label. If the EU does enact new standards, it could mean big changes for what people wear or how they buy clothes, at least in Europe. But considering some well-known fast fashion brands are based in Europe (cough, cough, Zara, cough, cough H&M), we might see a trickle down effect in the U.S.

Maybe it’ll add more fuel to the global push towards sustainability and higher standards. Earlier this week,

the U.S. Securities and Exchange Commission proposed rules requiring companies to disclose greenhouse gas emissions , notably in its value chain (Scope 3) since that’s where the metaphorical sausage is made.

Read more about the proposed changes here .

A NEW CAMPAIGN TO SAVE THE BEES

In the recent past, we’ve heard of honeybees dying in droves because of a fungus-virus combination. (You can read more about it here .) They’re also facing habitat loss, pesticide use, climate change and urbanization. Those that survive are strained and challenged to find food and help pollinate our food supply. ( This story about how the almond milk trend harms bees prompted us to switch milk alternatives.)

We know how important bees are, so we were buzzing with excitement when we stumbled upon some news from the town of Appleton, Wis. In 20202, the small city instituted a No Mow May, where residents kept their lawn mowers in the shed for the whole month.

The reason: “Lawns typically provide poor habitat for bees. But if allowed to flower, lawn weeds — perhaps better characterized as plants other than grass — can provide rare spring food for bees emerging from hibernation.”

A study from a nearby university found that No Mow May lawns concluded that No Mow May lawns had five times the number of bees and three times the bee species than mown parks. The movement is spreading to other communities in Wisconsin and in other states. Not everyone is a fan of lawns with high grass and other weeds, but it does seem like an easy way to help pollinators have a fighting chance. There’s still plenty more we need to do, but we’re more than happy to ignore our chores for a good cause.

Read more here

5

Construction Workforce Shortage Tops Half a Million in 2023

02.19.2023 | EHS Today

In 2022, there were more than 390,000 job openings per month, the highest level on record.

Like every other industry, worker shortages are an issue in the construction industry.

A recent model developed by Associated Builders and Contractors found that the industry will need to attract an estimated 546,000 additional workers on top of the normal pace of hiring in 2023 to meet the demand for labor.

“The construction industry must recruit hundreds of thousands of qualified, skilled construction professionals each year to build the places where we live, work, play, worship, learn and heal,” said Michael Bellaman, ABC president and CEO, in a statement. “As the demand for construction services remains high, filling these roles with skilled craft professionals is vital to America’s economy and infrastructure rebuilding initiatives.”

ABC’s model uses the historical relationship between inflation-adjusted construction spending growth, sourced from the U.S. Census Bureau’s Construction Put in Place survey, as well as payroll construction employment, sourced from the U.S. Bureau of Labor Statistics, to convert

anticipated increases in construction outlays into demand for construction labor at a rate of approximately 3,620 new jobs per billion dollars of additional construction spending.

This increased demand is added to the current level of above-average job openings. Projected industry retirements, shifts to other industries and other forms of anticipated separation are also embodied within computations.

RETIREMENT CONTINUES

Job openings continue to raise as the industry averaged more than 390,000 job openings per month in 2022, the highest level on record.

Added to that is the industry unemployment rate of 4.6% in 2022, which was the second lowest on record, higher than only the 4.5% unemployment rate observed in 2019. National payroll construction employment was 231,000 higher in December 2022 than in December 2021.

“Despite sharp increases in interest rates over the past year, the shortage of construction workers will not disappear in the near future,” said ABC Chief Economist Anirban Basu, in a statement. “First, while single-family

home building activity has moderated, many contractors continue to experience substantial demand from a growing number of mega-projects associated with chip manufacturing plants, clean energy facilities and infrastructure. Second, too few younger workers are entering the skilled trades, meaning this is not only a construction labor shortage but also a skills shortage.

“With nearly 1 in 4 construction workers older than 55, retirements will continue to whittle away at the construction workforce,” said Basu. “Many of these older construction workers are also the most productive, refining their skills over time. The number of construction laborers, the most entry-level occupational title, has accounted for nearly 4 out of every 10 new construction workers since 2012. Meanwhile, the number of skilled workers has grown at a much slower pace or, in the case of certain occupations like carpenter, declined.

FILLING THE GAP

“To fill these important roles, ABC is working hard to recruit, educate and upskill the construction workforce through our national network of more than 800 apprenticeships, craft, safety and management education programs—including more than 300 government-registered apprenticeship programs across 20 different construction occupations—to build the people who build America,” said Bellaman. “ABC

members invested $1.6 billion in 2021 to educate 1.3 million course attendees to build a construction workforce that is safe, skilled and productive.”

In 2024, the industry will need to bring in more than 342,000 new workers on top of normal hiring to meet industry demand, and that’s presuming that construction spending growth slows significantly next year.

7

Construction Industry Needs To Improve Efforts to Recruit Women

03.27.2023 | EHS Today

“If we want construction careers to be a viable option for all people, we have to change the culture and perception of our industry, starting with our own projects.”

As March 8 is International Women’s Day , here is a look at how women are faring in construction.

A new white paper from The National Center for Construction Education & Research (NCCER) released on March 6, In Her Own Words: Improving Project Outcomes was compiled from interviews with 176 tradeswomen.

“The U.S. economy is at a critical juncture,” said Boyd Worsham, CEO of NCCER, in a statement. “We need to re-shore manufacturing, decarbonize energy, and upgrade our infrastructure. As we continue to struggle in building a workforce to fulfill these needs, we must recognize that we are not effectively appealing to the largest percentage of the population— women—in our recruiting and retention efforts.”

The white paper highlights the unique benefits women bring to the construction workforce, the obstacles they encounter getting in and staying in the industry, and their advice on what contractors can do to recruit and retain more women.

“Regarding women simply as a way to make up for the quantity gap in the construction workforce ignores the unique qualities they bring to the job site,” said Dr. Tim Taylor, Director of Research for NCCER, in a statement.

NCCER note that women shared their recommendations on ways to improve both recruitment and retention of women both on project sites and in the industry overall. Suggestions were made on how to “tackle obstacles that the industry has worked on for years and brought up other hurdles that may be surprising for some.”

“With an expected shortage of 1.9 million craft professionals through 2025, there is a tremendous opportunity for women to get involved in an industry that offers competitive wages, benefits, and career growth,” said Jennifer Wilkerson, NCCER Vice President of Innovation and Advancement, in a statement. “If we want construction careers to be a viable option for all people, we have to change the culture and perception of our industry, starting with our own projects.”

Do You Know How to Use an AED?

01.24.2023 | Safety + Health

An AED is used to assess a person’s heart rhythm during a medical emergency. After reading the rhythm, it will administer an electric shock, if needed, to help restore a normal heart rhythm during sudden cardiac arrest. If a co-worker has lost consciousness, the Mayo Clinic says to follow these steps:

1. Check to see if the person is breathing and feel for a pulse.

2. If you don’t feel a pulse and the person isn’t breathing, call 911 if you’re alone with the victim and then begin CPR. If someone is nearby, ask them to call for help and, if possible, ask another co-worker to bring the AED to you.

3. Turn on the AED when it gets to you. The device will provide you with step-by-step instructions, including how to put the electrode pads on the victim’s chest.

4. Once the pads are placed, the AED will automatically measure the victim’s heart rhythm and determine if a shock is needed. If a shock is necessary, the AED will direct you to stand back and push a button to deliver the shock.

5. After the shock is delivered, the AED will guide you to continue CPR if needed.

9

Fall Protection Leading Practices

02.23.2023 | Liberty Mutual Insurance

The U.S. construction industry loses more than $11.3 billion a year to serious, nonfatal workplace injuries, and falls from elevation remains the highest individual contributor with $2.73 billion (24.1% of the total cost) Projects in the construction industry involve rigorous planning, coordinating, and adjusting to deliver a satisfactory product to clients. Similarly, preplanning is critical to identify fall risks, select the appropriate equipment for the hazards identified, and educate workers on safe work practices.

REDUCE THE RISK OF INJURIES FROM FALLS WHEN WORKING AT HEIGHTS

1. Elimination. The first question employers should ask is – can we feasibly eliminate the fall risk without introducing new and more serious risks? Elimination could entail working with owners, architects, and engineers on Prevention through Design (PtD) e.g., relocating equipment to ground level or designing a

higher parapet around the roof perimeter. Another option may include altering the means and methods, or sequencing the work activities on a project to help reduce the risk of falls.

2. Prevention. When a fall risk cannot be eliminated, we should turn our attention to trying to prevent the fall through passive fall protection, which includes physical barriers, guardrails, covers, etc. Passive fall protection is generally considered to provide a higher level of safety since there is less opportunity for error.

3. Protection. As a last option, a personal fall arrest system (PFAS) is needed to help protect a worker if a fall risk cannot be eliminated or prevented.

ADDRESSING AREAS OF CONCERN ON JOB SITES

Misuse of equipment. Consider a worker using PFAS along the edge of the building with a fixed anchor point

overhead and a 25-foot self-retracting lanyard (SRL) to increase their work area. It’s a common scenario, but what are the concerns?

• Swing falls can occur when an anchor point is not directly overhead. If a swing fall occurs, this could result in the worker striking the structure or nearby equipment, and could increase the likelihood of suspension trauma due to added pressure from the fall.

• A non-leading edge (LE) SRL may fail if it contacts the sharp/abrasive edge of the structure. Leading edge lanyards or SRLs are designed specifically to meet ANSI Z359.14 requirements regarding sharp and abrasive edges.

It’s imperative to follow the manufacturer’s guidance and specifications to help reduce the risk of failure. Consider speaking with them ahead of time to select the appropriate equipment for your application.

Anchor points. Ensure that an anchor point is available near the work area and that it is capable of supporting at least 5,000 pounds per person attached as required by OSHA’s CFR 1926.502(d)(15) .

Equipment manufacturers have

developed a variety of options for permanent, portable, and temporary anchorage solutions, such as:

• Wire cable chokers and cross arm straps. These are often used as temporary anchor points on approved structural components.

• For roofing, common options include single point anchors (temper anchors, standing seam, etc.), horizontal lifelines, davit systems, and fall carts.

• For concrete structures, options include cast-in-place anchor points, concrete straps, removable anchors (wedge anchors), and concrete clamping devices (parapet clamps).

Fall distance. Workers may have a false sense of security because they are “tied-off.” Without adequate training, crews may not understand how far they will fall before they are brought to a stop. The Risk Control resources available on Liberty Mutual SafetyNet™ can assist you with fall distance calculations and selecting appropriate equipment. There are also several excellent infographics available as part of the National Campaign to Prevent Construction Falls.

11

7 Tips For Safe Use of Ladders

02.23.2023 | Safety + Health by Kevin Druley

Ladders are common at workplaces across the country. So common, according to Ryan Moss, president of the American Ladder Institute, that safety can get overlooked.

“I think it’s important for us to realize that ladders are safety equipment, not just a throwaway tool,” Moss said.

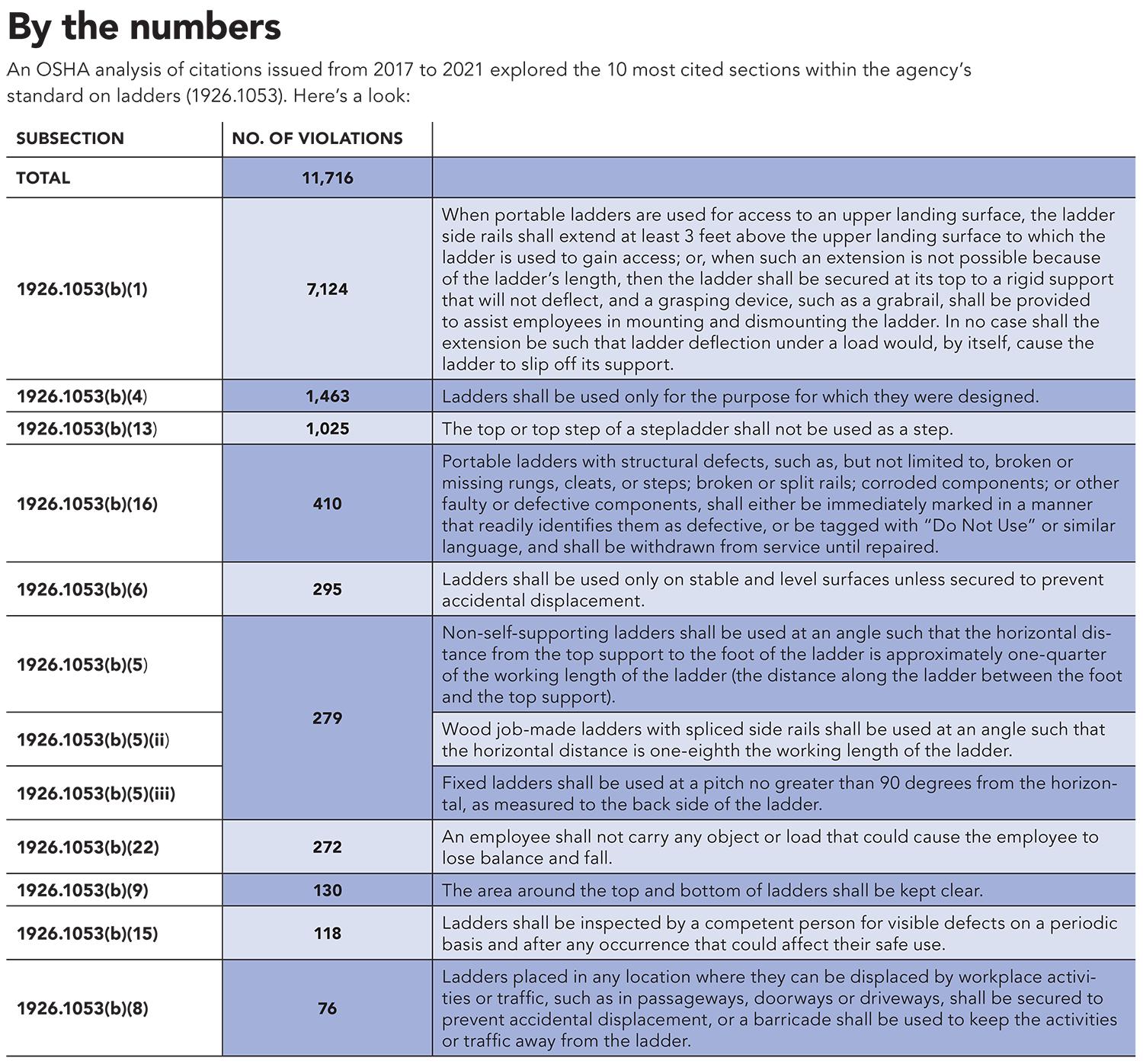

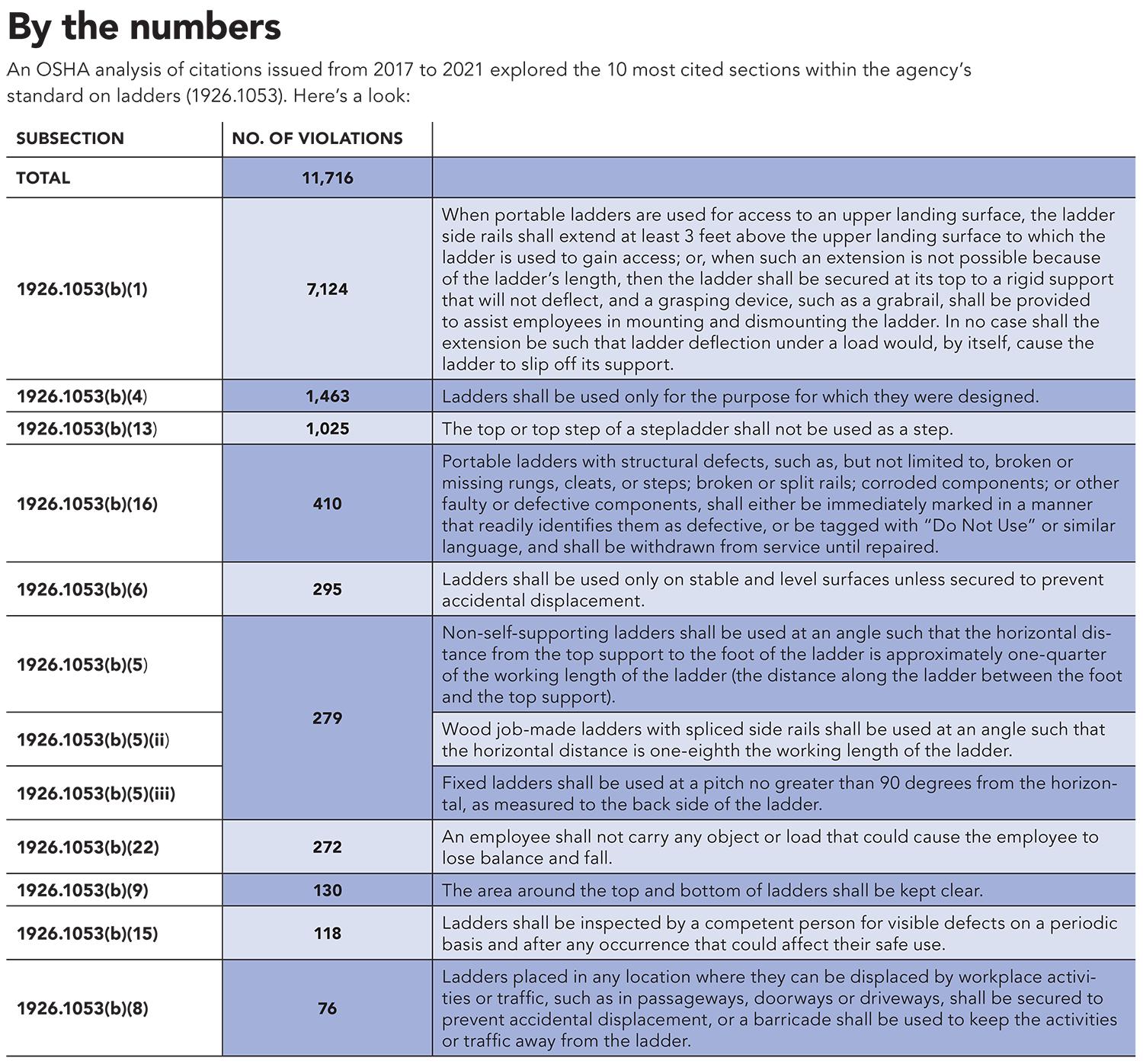

The numbers back him up. From 2017 to 2021, ladderrelated incidents accounted for more than 800 deaths and 27,000-plus nonfatal injuries resulting in days away from work, according to a recent OSHA analysis of Bureau of Labor Statistics data.

“When you look at those numbers, they are significant,” said Erin Gilmore, director of OSHA’s Office of Construction Services, “and it’s an example of why ladder safety is so important. It contributes to falls when ladders are used unsafely, and those falls will have impacts on workers’ lives when they are injured or killed.”

Here are seven tips for reducing the risk of ladder-related incidents and injuries.

1. PICK THE RIGHT LADDER

According to ALI Vice President Mike Van Bree, “One of the big issues is users not selecting the right ladder for the task”

– whether out of convenience or availability. Choose the right ladder for the job and make sure you receive training on its proper use. Failure to do so often leads to ladder users overreaching, climbing too high or getting into an awkward position.

“It’s just a matter of looking and seeing what is the job, and then asking, ‘What size ladder do I need to do the job?’” said Richard Fairfax, former deputy assistant director at OSHA and currently a principal consultant for NSC Networks – part of the Workplace Area at the National Safety Council. “And most people, they go grab a ladder from a stack of ladders and they set it up. And if it’s the wrong size, they’re going to try to make do rather than fix it.”

2. INSPECT BEFORE USE

Section (b)(15) of OSHA’s standard on ladders – 1926.1053 – states, “Ladders shall be inspected by a competent person for visible defects on a periodic basis and after any occurrence that could affect their safe use.”

During an inspection, look for loose steps, rungs, nails, screws and bolts; broken or damaged parts; and compromised warning labels. Also, make sure climbing and

gripping surfaces are free of debris and slippery substances.

“Workers will typically just use ladders” without inspecting them, said Damon Bonneau, safety and occupational health specialist in OSHA’s Office of Construction Services. “But a competent person needs to inspect the ladder and make sure that the ladder is being used in a safe manner.”

Fairfax added that workers who spot a defective ladder should clearly tag the equipment and make sure it’s taken out of service.

3. GO (3 FEET) ABOVE AND BEYOND

An agency analysis of OSHA Information System data from 2017 to 2021 found that the most cited subsection of the

standard on ladders was (b)(1), which requires that side rails of portable ladders extend 3 feet above the surface being accessed.

Not doing so can create preventable hazards during access and egress. For instance, standing on the three top rungs of a straight, single or extension ladder – a practice OSHA prohibits.

“A lot of that is due to the height not necessarily being taken into account appropriately beforehand and the ladder just simply isn’t long enough” to access the work surface with the 3-foot clearance required, Gilmore said. “But that’s what they have, so that’s what is used.”

13

...continued on next page

4. MAINTAIN THREE POINTS OF CONTACT

Casually climbing ladders can lead to injuries – and even death.

Always maintain three points of contact when climbing, OSHA says. This means using two hands and one foot or two feet and one hand. And your body should be positioned near the middle of the step. Face the ladder when climbing.

“A lot of people are too fast going down a ladder,” Fairfax said. “They skip steps or they want to go down facing away from the ladder so they can kind of slide down the ladder if they’re wearing gloves. So it’s just important to take the same approach going down a ladder as it is climbing up the ladder.”

Whatever the case, avoid carrying tools or other items when climbing up or down a ladder, as well.

“Ladders aren’t made for carrying materials up and down on,” Fairfax said. “You have other equipment for that.”

Regarding the debate over whether workers should use rungs or rails to maintain three points of contact: OSHA regulations don’t specify. “As long as they can safely access and egress that ladder, that’s what we want them to do,” said Damon Bonneau, safety and occupational health specialist in OSHA’s Office of Construction Services.

5. MONITOR THE WEATHER

Mulligan said foremen on jobsites can set workers up for success by understanding if and when harsh winter weather is expected. “I think about work as if we’re a soccer team or a football team or a hockey team,” Mulligan said. “Can the team be successful” in cold conditions?

Start the day by checking a mobile weather app, and continue to monitor it. Many weather apps are available at no cost.

6. MAKE A SPACE

Have you seen a telephone technician or cable crew place cones to designate a working space?

Fairfax recommends doing the same for ladder users.

“When you’ve got a ladder up against the side of a building or are somewhere using it, it’s real important to stick up a couple of cones 3 or 4 feet away from it so people see the cones and stop.

“Because I can’t tell you the number of accidents I’ve looked at where someone’s got a ladder and it’s right near the corner of a building and someone on a forklift, or

someone walking really fast or someone pushing a pallet jack or something like that, turns around the corner and they smack right into the side of the bottom of the ladder.”

7. SECURE DURING TRANSPORT AND WHEN STORING

Oregon OSHA advises laying ladders parallel to truck beds during transport, padding points of contact with soft materials and securing the equipment to prevent movement. If transporting a ladder on a vehicle rack, make sure the rack has abrasion-resistant contact points or place and secure soft items between the ladder and rack.

Van Bree said vibration and road shock during ladder transport can cause damage quickly if the equipment isn’t secured.

“If you don’t catch that, it can lead to a problem and structurally compromise the ladder,” he said.

When storing ladders, Oregon OSHA recommends keeping them in well-ventilated areas away from threats of impact/ physical damage and free from heat sources. Make sure wood and fiberglass ladders aren’t subjected to excessive humidity, moisture and sunlight.

“Where possible, storing the product inside obviously is going to be better for it,” Moss said. “Winter or summer.”

How to Create a Happy Company

03.01.2023 | EHS Today by Adrienne Selko

A study from Robert Half offers six practices that will make employees happy, and productive.

As a proud owner of an oversized pair of rose-covered glasses, I feel the need to point out that many workplaces are great places full of happy employees. What makes these employees happy?

A study from Robert Half International highlights, and explains, six factors that influence employee happiness. (The report is quite robust and I would recommend reading it, as this is just an excerpt.)

RIGHT FIT FOR THE JOB AND COMPANY

A good fit entails both skills and temperament. Painting an accurate picture of the role and the organizational culture when hiring is a safeguard that can help you avoid skill alignment issues. When you set expectations by clearly communicating to prospective candidates what an open position entails, you greatly reduce the risk that they end up feeling surprised, unchallenged or disappointed once on the job.

“Practicing diligence in each step of the hiring process — from crafting detailed job postings to conducting in-depth interviews, skills testing candidates, thoroughly checking references, and giving them an opportunity to meet different people within the company. This process sets the stage for both employee and employer happiness,” says David Jones, Senior Managing Director at Robert Half Asia Pacific.

A SENSE OF EMPOWERMENT

Empowering your staff to make decisions on their own, or with minimal direction from you, improves employee happiness in multiple ways:

• Empowerment helps staff develop critical skills they can use to advance their careers and make greater, more meaningful contributions to the company.

• Empowerment makes workers feel more invested in the jobs they do because they are the ones making decisions. ...continued on next page

15

• Letting go of the reins also helps team members build confidence as they realize they are able to make the right decisions.

• Empowered employees feel more comfortable questioning the status quo and suggesting new ideas. Large organizational changes or disruptions, like a staff restructuring, are less likely to knock these workers down.

FEELING APPRECIATED

It doesn’t have to break the bank to instill loyalty. Establishing a positive working environment can generally make your employees happier. Simply show your staff that you appreciate their hard work and dedication. Offering a sincere thank you for a job well done has a much greater motivational impact than many people realize.

“Fostering positive emotions through gratitude is easy and powerful,” explains Dr. Christine Carter, author of The sweet spot: how to find your groove at home and work.

“The science on this is blazingly clear. There are loads of research studies that show how much higher functioning people are when they feel appreciated by their teams and their manager.”

INTERESTING AND MEANINGFUL WORK

“Happy workers understand why their tasks matter and how they connect to the overall objective,” says author Todd Henry, who speaks about productivity, creativity and pass for work and leadership. “When there is a gap in that connection, people tend to drift and have difficulty investing emotionally. Employees who have a strong, through-line, that ties their work together tend to be happy, fulfilled and engaged even when times get tough.”

Gaining a sense of meaningful progress and achievement is particularly important to millennials. According to the survey, Robert Half conducted with Nic Marks, a sense of pride and a sense of accomplishment are among the strongest drivers of happiness for employees under 35.

A SENSE OF FAIRNESS

Fairness matters deeply to employees. So deeply, in fact, that a single instance of unfair treatment — whether actual or perceived — is often enough to turn a happy, satisfied employee into one who is cynical and skeptical of the company.

What can managers do to improve fairness in the workplace?

• First, strive to be transparent in your decision-making. Be sure policies around pay, promotions, and projects are clear. Every member of your team should know what they must do to earn a new title or a higher salary.

• Give employees a chance to alert you when they feel a sense of inequality. Often, employees just want to be heard and know that their concerns are being taken into account.

POSITIVE WORKPLACE RELATIONSHIPS

A sense of camaraderie at work improves employee communication, cooperation, and collaboration. Staff cohesion also leads to greater innovation. Employees across the board say they have good team relationships at work. None of the recipients reported significant dissatisfaction in this area. This is good news for employers: those who say they have good relationships with others on their team are 2.7 times more likely to be happy on the job than those who do not get along well with colleagues.

Regulatory Update: New Safety Alert on Hazards of Emergency Discharges from Pressure Release Valves

03.09.2023 | EHS Today

The alert is a result of an investigation into the deaths and injuries from hazards identified with emergency pressurerelief systems.

On March 6, the U.S. Chemical Safety and Hazard Investigation Board (CSB) issued a new Safety Alert titled “Hazards Posed by Discharges from Emergency Pressure-Relief Systems.” The alert highlights hazards identified with emergency pressure-relief systems from four CSB investigations.

The alert advises facilities that while a discharge from emergency pressure-relief systems can help protect equipment from unexpected and undesired high-pressure events, it can also seriously harm or fatally injure workers and cause extensive damage to a facility if the discharge is not made to a safe location.

“All four of the incidents highlighted in the CSB’s safety alert underscore the importance of thoroughly evaluating emergency pressure-relief systems to ensure they discharge to a safe location where they will not harm people,” said CSB Chairperson Steve Owens, in a statement.

The four incidents highlighted in the CSB’s safety alert resulted in 19 deaths and 207 injuries. They include:

On May 19, 2018, an ethylene release ignited, injuring 23 workers at the Kuraray America, Inc. ethylene and vinyl alcohol copolymer plant in Pasadena, Texas. The CSB’s animation of this event shows how this incident occurred during the startup of a chemical reactor system following a turnaround. High-pressure conditions developed inside the reactor and activated the reactor’s emergency pressure relief system, discharging flammable ethylene vapor horizontally into the ambient air in an area where a number of contractors were working.

On November 15, 2014, approximately 24,000 pounds of highly toxic methyl mercaptan were released from an insecticide production unit at the E.I. du Pont de Nemours and Company (DuPont) chemical manufacturing facility in La Porte, Texas. The release fatally injured three operators and a shift supervisor inside a manufacturing building. During the early phases of the investigation, CSB investigators identified a number of worker safety issues—separate from the release scenario— including that

...continued on next page

17

several emergency pressure-relief systems at the facility were designed to discharge hazardous materials in a way that posed a risk to workers and the public.

• On May 4, 2009, highly flammable vapor released from a waste recycling process, ignited, and violently exploded at Veolia ES Technical Solutions, LLC, in West Carrollton, Ohio. The incident injured four employees, two seriously. Following the initial explosion, multiple other explosions occurred that t significantly damaged every structure on the site. Residences and businesses in the surrounding community also sustained considerable damage. The CSB concluded that uncontrolled venting from emergency pressure-relief valves to the atmosphere allowed tetrahydrofuran (THF) vapors to accumulate to explosive concentrations outside process equipment, and the vapors subsequently found an ignition source.

• On March 23, 2005, during the startup of an isomerization unit following a maintenance turnaround, a series of explosions occurred at the BP refinery in Texas City, Texas. The incident fatally injured 15 workers and injured an additional 180 workers. During the startup, a distillation tower flooded with flammable hydrocarbons and was over-pressurized. This activated the tower’s emergency pressure-relief system, which created a geyser-like release from the vent stack and formed a flammable vapor cloud that soon ignited and exploded.

“OSHA requires employers to provide a safe workplace. Effective and safe pressure relief systems help ensure safe

operations of plants across the country,” said CSB Board Member Catherine Sandoval, in a statement. Using findings from these four incidents the CSB’s safety alert issues three key lessons for facilities.

1. Follow existing good practice guidance.

2. Evaluate whether the atmosphere is the appropriate discharge location or if there are safer alternatives.

3. Ensure hazardous chemicals vented into the atmosphere discharge to a safe location.

The alert also calls on companies to evaluate and, when appropriate, update their emergency pressure relief systems to prevent future incidents and protect workers and surrounding communities from harm.

“Our safety alert calls on companies to evaluate and, when appropriate, update their emergency pressure relief systems to prevent future incidents and protect workers and surrounding communities from harm,” said Board Member Sylvia Johnson, in a statement.

The CSB’s core mission activities include conducting incident investigations; formulating preventive or mitigative recommendations based on investigation findings and advocating for their implementation; issuing reports containing the findings, conclusions, and recommendations arising from incident investigations; and conducting studies on chemical hazards. The agency’s board members are appointed by the president and subject to Senate confirmation. The Board does not issue citations or fines but makes safety recommendations to companies, industry organizations, labor groups, and regulatory agencies such as OSHA and EPA.

New

OSHA

03.06.2023

Memos On Instance-By-Instance And Grouping Citations

| JJ Keller

In January 2023, OSHA published two memos on citations that could result in higher fines for employers. One memo covers “instance-by-instance” citations where, for example, OSHA may issue one citation for each employee not using fall protection. The other memo covers “grouping” citations where doing so would increase the gravity and penalty.

INSTANCE-BY-INSTANCE

Where an inspection finds a high-gravity serious violation involving certain conditions, OSHA may issue separate citations for each instance. This would not be used with all regulations, however. Covered conditions include lockout/ tagout, machine guarding, permit-required confined space, respiratory protection, falls, trenching, and cases of other-than-serious violations specific to recordkeeping. Instance-by-instance citations might be applied per machine, entry, or employee, and when each instance cannot be abated by a single method. The memo notes that compliance officers using instance-byinstance citations should consider one or more of the following factors:

• The employer received a willful, repeat, or failure to abate violation within the past five years.

• The employer failed to report a fatality, inpatient hospitalization, amputation, or loss of an eye per 29 CFR 1904.39.

• The proposed citations are related to a fatality/catastrophe.

• The proposed recordkeeping citations are related to an injury or illness caused by a serious hazard.

• This guidance becomes effective March 27, 2023. The former policy adopted in 1990 applied only to egregious willful citations.

GROUPING CITATIONS

In another memo, OSHA reminded Regional Administrators that they need not group violations, and could cite separately. Specifically, the memo states, “In cases where grouping does not elevate the gravity or classification and resulting penalty, then violations should not be grouped if the evidence allows for separate citations.”

The memo noted that grouping would be appropriate when the same abatement measures correct multiple violations. The memo further states that grouping should be considered when:

• Two or more serious or other-than-serious violations constitute a single hazardous condition that is overall classified by the most serious item,

• Two or more other-than-serious violations considered together create a substantial probability of death or serious physical harm, or

• Two or more other-than-serious violations results in a high gravity other-than serious violation.

OSHA would not, however, group citations from multiple inspections of the same establishment, nor group violations from inspections of several different establishments.

19

OSHA updates data used for its Site-Specific Targeting Program

02.16.2023 | Safety + Health

Washington — OSHA is revising its Site-Specific Targeting inspection program to update the Form 300A data it requires.

Form 300A is an annual summary of work-related injuries and illnesses. Under current OSHA regulations, establishments with 250 or more employees and those with 20-plus employees in certain high-hazard industries must submit Form 300A data to the agency each year.

According to an OSHA directive issued Feb. 7, the SST inspection program is for non-construction workplaces with 20 or more employees and directs agency enforcement resources toward establishments with the highest rates of injuries and illnesses.

Among the significant changes listed in the directive, OSHA will use calendar year 2021 data, instead of CY 2019 data, to select which “high-rate” establishments the agency

will inspect. “High rate” is considered above the average DART (days away, restricted or transferred) rate for either manufacturing or non-manufacturing establishments.

The two DART rates will allow the agency to “equally target” manufacturing and nonmanufacturing establishments.

For “upward trending” establishments – those with DART rates that were at least twice the national average of the private sector’s rate in 2019 and have continued to trend upward through 2021 – OSHA will use 2019-2021 data instead of 2017-2019 data.

In addition, 2021 data will be used for a random sample of establishments that didn’t send in Form 300A data during the year. The agency will test the reliability of Form 300A data with a random sample of low-rate establishments.