THE SAFETY NET

Ladders are one of the most common home improvement tools, but they can also be one of the most hazardous. Don’t let a simple task put you out of commission with a serious injury. Take safety into your own hands by taking ladder safety seriously.

Austin employees have worked 5,400,762 hours without a Lost Time Accident through 01/2023.

LOCATION CONSULTING DESIGN & ENGINEERING DESIGN-BUILD CONSTRUCTION & CONTRACTING MARCH 2023 VOLUME 17 ISSUE 3

SAFE T Y FIRST.

IT’S ALWAYS SAFETY FIRST. CONSULT • DESIGN • ENGINEER • CONSTRUCT Ladder Safety Month

Weeklysafety.com

Make sure to choose the right ladder for the job.

Ladders are typically made from one of three basic materials: wood, fiberglass or metal (aluminum).

• When working near electricity, do not use a metal ladder.

• Look for the duty rating that can be found on a label on the ladder. The duty rating is the total amount of weight your ladder will support.

• Make sure that the work you are doing with the ladder does not exceed the ladder’s maximum load rating.

Step Stool – recommended for projects under 8 feet

Step Ladder – great for tasks like changing a light bulb or a smoke detector battery

Platform Ladder – handy if both hands are needed for a project like painting, or if the task takes longer

Extension Ladder – to get even higher for tasks like cleaning gutters or hanging holiday decorations

Articulating Ladder – versatile multi-purpose ladder can be used as a step ladder, extension ladder, a staircase ladder or even a 90-degree leaning ladder

Inspect the ladder before every use to be sure everything is in working order.

• If any part of the ladder is damaged, broken or missing, do not use it!

• Never use one side of a disassembled step ladder as an extension ladder.

• Read the instructions that come with the ladder as well as the safety information label(s) on the ladder before using it.

• Always use the ladder as intended and follow all manufacturer’s warnings for the specific type of ladder you are using.

If a ladder has been in contact with oil, grease or any other material that may cause it to become slippery when used, carefully clean the ladder to ensure it resumes its original, safe condition.

Use a ladder with non-slip feet set up on a firm, level, non-slippery surface. If you are using a step ladder, make sure that all four feet are supported so that the ladder doesn’t rock.

If a ladder must be set up in front of a door, make sure the door is locked, blocked open or properly guarded.

The two most common ladder accidents include:

1. Missing the last step when climbing down

2. Overreaching

• Wear clean, slip-resistant shoes to maximize traction and avoid slipping.

• To keep your balance, always maintain three points of contact—two hands and a foot or two feet and a hand—while climbing up or down a ladder.

• Always face the ladder when climbing. Don’t skip steps when climbing up or down.

• Don’t carry tools in your hand when climbing a ladder. Instead, you can use a tool pouch, a tool belt, or ask someone to be your assistant.

• Be attentive to foot placement on each step and pay close attention to what you are doing. Exercise caution and look for every step.

• Don’t overreach. Keep your center of gravity, and your body, between the side rails. If you can’t easily reach what you need, climb down and move the ladder for easier and safe access to the project area.

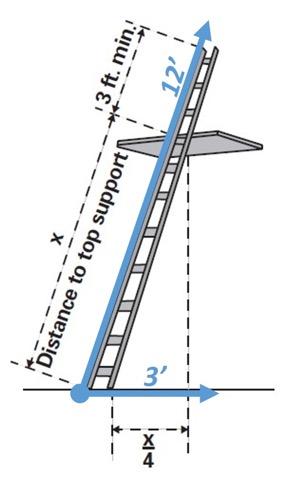

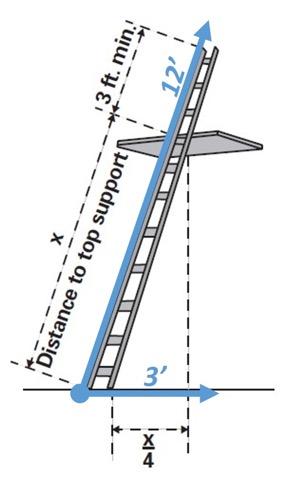

Ensure extension ladders are placed at a proper angle before climbing up and when in use.

• For every four feet high, the base of the extension ladder should be one foot out away from the wall or other surface it is leaning against.

For example: If the ladder is 12 feet high the base should be moved away from the wall or other sturdy structure by 3 feet.

ALWAYS lean the extension ladder on a stable structure that can withstand the intended load when in use. Do Not lean extension ladders against unstable surfaces such as stacked boxes or materials.

allow at least 3 feet (36 inches) of the extension ladder to extend above the edge or point of support when used to reach another surface.

stand on the three top rungs of an extension ladder. An extension ladder is too long if it extends more than 3 feet beyond the upper support point, as it can act like a lever and cause the base of the ladder to move or slide out.

Unlike step ladders, step stools are designed in a way that allows a person to stand on the top step, also known as the

Do not use a step stool in a closed position, like a small extension ladder, or in a partially open position. Every time a step stool is used, the base must be spread fully open with the spreaders locked. Always ensure the locking mechanism is engaged before climbing.

• Always climb onto a step stool from the front. Do not climb onto a step stool at an angle or from the side or back. Never climb or stand on the braces at the rear of the step stool.

• Never attempt to move the step stool while standing on it, or by standing on something else (like a shelf) and pushing the step stool with your foot. Always get down from the step stool and move it to the next secure and stable location you need to use it before climbing on again. ...continued on next page

3

• Because step stools are not fixed ladders, do not step onto a step stool from another platform. For example, do not climb from one step stool to another step stool in order to save time.

• Step stools should never be used on any slippery surface or on snow or ice.

COPYRIGHT AND DISCLAIMER

• When using, do not place a step stool on top of another object like boxes, a desk, or a table. If additional height is required, use a ladder more suitable to the task that can be used safely.

This material is the copyrighted property of Weeklysafety.com, LLC. Purchase of this material from Weeklysafety.com, LLC grants the owner the right to use this material for workplace safety and education purposes only. Use of this material for any other purpose, particularly commercial use, is prohibited. This material, including the photos, may not be resold. Weeklysafety.com, LLC does not warrant or assume any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed in these materials. Photos shown in this presentation may depict situations that are not in compliance with applicable Occupational Safety and Health Administration (OSHA) safety requirements. These materials are meant for informational purposes only and it is not the intent of Weeklysafety.com, LLC to provide compliance-based training. The intent is more to address hazard awareness in the construction and related industries, and to recognize the potential hazards present in many workplaces. These materials are intended to discuss Federal Regulations only, as individual State requirements may be more stringent. Many states operate their own state OSHA and may have standards that are different from information presented in this training. It is the responsibility of the employer and its employees to comply with all pertinent OSHA safety rules and regulations in the jurisdiction in which they work.

PHOTO ACKNOWLEDGMENTS

Unless specified below, all photos are the copyrighted property of Weeklysafety.com, LLC and may not be used in any other training materials or resold for any purpose.

The Austin Company New Member of Construction Safety Research Alliance

CSRA does scientific research to improve construction safety throughout the industry. We are excited to announce that Charlie Engel, Director of Safety has been appointed to represent Austin in one of CSRA studies of “Eliminate Serious/Fatality on Project”. The committee consist of 32 members from 28 companies specializing in construction, general industry, utilities, and agriculture.

Each company was given an assignment after the conference to select five different tasks that they perform or oversee from their company and analyze each step or phase of work to determine if a Significant Injury or Fatality exist. Each company will present results in May 2023.

The Austin Company is now a member of Construction Safety Research Alliance (CSRA) through the University of Colorado Bolder.

The Austin Company is now a member of Construction Safety Research Alliance (CSRA) through the University of Colorado Bolder.

FACE Report: Site Superintendent Run Over By Backing Dump Truck

01.24.2023 | Health + Safety

Case report: #71-231-2022

Issued by: Washington State Fatality Assessment and Control Evaluation Program

Date of report: Dec. 5, 2022

A 60-year-old site superintendent working for a housing construction contractor was in charge of directing subcontractors and scheduling dump trucks to haul away debris. Two dump truck drivers employed by a recycling company were emptying dumpsters. While one dumpster was being emptied, a 5-gallon bucket of paint spilled onto the street. The superintendent assigned a subcontractor to get sawdust to absorb the paint and told the drivers he was going to direct vehicles away from it. The drivers entered their trucks to pick up the next dumpster located close to the spilled paint. The driver of the first truck drove out of the alley, turned right and parked on the side of the street near the superintendent. The driver of the second truck then turned left onto the street, checked his mirrors and got a hand signal from the superintendent to begin backing up. As he was backing up, he lost sight of the superintendent and ran over him. It is unknown why the superintendent

was in the backing zone, or why the driver could not see him. Although the truck’s backup alarm was working, the truck did not have a backup camera, nor was an observer signaling that it was safe to back up. The truck drivers were not trained on backing up at construction sites.

To help prevent similar occurrences, general contractors at multi-employer jobsites should:

• Continuously assess the hazards of vehicles to workers on foot and ensure hazards are corrected.

• Require workers to wear ANSI Class 2 high-visibility garments when exposed to vehicular traffic.

• Employers who use dump trucks should:

• Consider installing pedestrian proximity detection systems on trucks.

• Train drivers that they must use a signaler or backup camera when backing near workers on foot.

• Create and enforce policies that drivers maintain visual contact with workers on foot at all times, and that workers on foot stay out of backing zones unless trained and acting as an observer signaling the driver.

5

5 Ways Technology Can Improve Manufacturing Safety

01.26.2023 | EHS Today by

Eric Whitley

A new year offers new possibilities. Here’s why now is the perfect time to introduce some new ideas into the manufacturing industry—and how they can improve workplace safety.

Even through uncertainties—and there has been no shortage of them in recent times—innovation in technology is maintaining its relentless pace.

Setbacks in past years have called for unprecedented ways to adapt and improve more conventional practices. As we begin to settle into the new normal, there has never been a better time to push through and explore new ideas within the manufacturing industry.

The old proverb reminds us that necessity is the mother of invention. The saying has never been more relevant than in the shift of global production and safety demands.

2022 saw a lot of promising trends that could define (or redefine) the future of the manufacturing industry. We hope these trends continue to gain traction in the new year. Now is the perfect opportunity to take a step back and assess these ideas, which might not yet be fully embraced and implemented at your organization.

5G AND EDGE COMPUTING

Edge computing revolutionizes how we think about data, process information and make connections in a globalized world. As its name implies, edge computing takes the analytical power of a computer to the boundary where the physical meets the virtual.

In other words, edge computing brings the power of analytics to the handheld devices we use daily. With the wireless connectivity capabilities of 5G, edge computing enables seamless data transfer and remote control like never before.

The applications are limitless, especially with the capability to gather and analyze comprehensive real-time data. Optimizing production and streamlining supply chain operations—all while promoting a robust safety culture— ensure a boost in an organization’s overall performance.

A facility that reaps the benefits of interconnected devices has the capacity for remote monitoring, control and advanced analysis. Some of the many possible applications for edge computing include: heating and ventilation

systems that recommend optimal conditions, safety sensors that pick up on potential concerns, and data backup systems that gather historical information.

Real-time safety reporting allows companies to capture leading indicators while also maintaining the capability to track traditional lagging indicators. Additionally, processes relying on pen-and-paper or spreadsheet monitoring are now able to take a step forward.

The ability to take computing power closer to the front lines eliminates inefficiencies associated with latency. For applications that require immediate actions, such as surveillance and safety detection in hazardous environments, detection urgency is the utmost priority. 5G technologies enable teams to receive data in a heartbeat, while edge computing lowers the dependency on transmission lags to get truly real-time responses.

DIGITIZATION AND AUTOMATION

Emerging technology relies on the premise that data and information come in a form that enables analysis. What is even more appealing is the ability to effortlessly gather data with incredible precision.

In some cases, modern tools have the capacity to accurately monitor conditions without any human intervention whatsoever. For example, imagine having the ability to improve safety procedures while also eliminating the exposure of workers to avoidable hazards.

A smart factory is a concept that describes the operational level a facility can reach through digitization and automation. With the proper infrastructure, physically distant objects can virtually interact through instantaneous data transfer.

Sensing devices, linked through a cloud-based system, enable advanced analytical processes, such as machine learning and artificial intelligence (AI), that allow for further integration into other autonomous systems.

By having a firm grasp on a facility’s operations, companies can get a better idea of the various opportunities for automation. After all, efficiency and safety gains are the result of eliminating hazardous actions, manual work or redundant tasks.

Insights from advanced analytics can help improve maintenance schedules by automating tasks and servicing requirements. High-risk consequences that rely on urgent actions, such as safety shut-off procedures, also stand to benefit from automated responses.

Real-world examples can include varying degrees of digitization and automation , including:

• manual activities that rely on human intervention,

• semi-automated tasks that use tools and equipment to reduce manual intervention, and

• fully-automated processes with more autonomy and self-sufficiency.

The level of automation depends on the requirements and capabilities of a facility as well as its budget. The prioritization of automation is based on evaluating the impacts on production and workplace safety.

Ultimately, automation allows workers to focus their time and effort on more complex, value-adding tasks. Automation also allows workers to tackle situations they might not have been able to address previously.

ROBOTICS AND AI

Robotics and AI have been trending for several years and continue to dominate technological research and advancement.

Modern robotic systems are now more precise than ever and do not merely rely on hard-set instructions. Instead, more intelligent platforms incorporate continuous learning and improvement abilities, which optimize their actions and increase overall performance.

A practical use case for industrial robots is to introduce them into hazardous procedures and harsh environments. There are plenty of manufacturing processes that involve extreme temperatures, rough environments, toxic byproducts, or even a combination of intense situations.

If a job includes physically getting into a high-risk condition, robotics and AI systems are a safer, more practical alternative. If a human were involved in such a scenario, additional precautions for PPE and specialized training would be required—a potential problem amid labor shortages and limited resources.

AI algorithms can also identify patterns that are too subtle or too complex for the naked eye by gathering enormous amounts of historical and real-time information. Moreover, AI capabilities can alert workers about any detection of workplace or environmental hazards. For example, installed cameras can monitor an area for passing equipment, falling debris, gas leaks and other potentially preventable hazards. Robotic systems can use the same information when assessing the need to cease operations or run an adaptive program that resolves a specific concern.

...continued on next page

7

GREEN ENERGY

EHS departments are usually at the top of our minds when talking about occupational safety. Typical projects and discussions can easily leave out environmental aspects— unless a major incident is in question. Recently, however, there’s been a stronger focus on environmental, social and governance (ESG) initiatives and corporate social responsibility (CSR).

And the concern for environmental sustainability is, in fact, a shared responsibility between customers and providers. According to the Future Consumer Index, 38% of global consumers agree that businesses should make their production more responsible. With a more pronounced awareness of green practices, consumer support has been a driver for green energy initiatives in the manufacturing industry.

Green energy is a loose term that describes the conscious effort to incorporate renewable practices into business operations. Non-renewable energy sources still dominate the majority of conventional factories; however, optimistic projections forecast that 27% of total energy resources can come from renewable alternatives by 2030. Greater computing power, unsurprisingly, comes with massive energy requirements. To put things in perspective, approximately 2% of the total U.S. electricity usage goes into the operation of data centers.

Taking advantage of renewable energy sources allows companies to instead scale operations sustainably.

Popular options for cleaner energy continue to include solar and wind power, with technology giants like Google and Microsoft setting an example of deriving energy consumption from such sources.

Sustainable practices in sourcing supplies and production techniques are another focus point for manufacturers. Reducing waste by-products and resource conservation are among the top priorities in the industry.

Buyback programs provide another incentive for consumers to take part in recycling and the reuse of products. On the other hand, advanced technology promotes practices for utility conservation, particularly for water supply systems and heating and ventilation systems.

DIGITAL TWINS

Arguably one of the most aptly named concepts today, digital twins refer to a virtual replica of an existing system. A computer program reads and copies data from existing physical systems to create a digital model, which can provide valuable insights for running simulations and test scenarios.

The ability to run virtual tests provides information on production processes and helps identify ways to improve safety practices in manufacturing . Organizations can learn a few things from automotive manufacturers, who have thus far been able to squeeze the most value out of digital twins.

Ford, for instance, develops seven digital twins to narrow down improvement opportunities from several aspects of design and production. Each digital twin represents a set of variables for a specific area, including design, supply, construction and operations. Digital models then assess the manufacturing process and customer experience. Collectively, these data sets allow Ford to understand the evolution of a product from conceptualization to usage.

By performing tests on a virtual replica, companies can evaluate the effectiveness of their programs better without the risk of any real-life incidents. While comprehensive planning can theoretically eliminate safety threats, simulations can uncover any unanticipated interactions of complex systems.

We’ve only scratched the surface when it comes to use cases and applications for digital twins. Such simulated platforms could even help improve safety procedures and protocols in the event of emergencies, including hazardous chemical spills, natural disasters and disease outbreaks.

WHY YOU SHOULD ADOPT THESE IDEAS

Technology has empowered us to uplift and streamline our practices. However, reaping its benefits does not stop at acquiring new tools. There needs to be proper care and attention in the execution of such significant changes. Innovations in recent years continue to revolve around the availability of data and the capacity to perform agile actions. The use cases that can maximize these technologies include critical responses to potential hazards as well as a heightened precision in manufacturing processes. Employing the appropriate tools and strategies also can significantly impact safety and production efficiency.

A good start for companies is to take a step back, find the business critical priorities that will drive value and study the available technologies that can help them succeed in their goals.

The good news is that there is no shortage of tools to explore. If you have the budget for implementing them, you can achieve a massive return on investment (ROI) through:

• Enhanced operational efficiency attained through databased strategies;

• Real-time visibility into processes across the production cycle;

• Quick decision-making with readily available data;

• A strong focus on workplace safety through minimizing risks and hazards;

• A significant improvement in crisis response time for shop floor engineers and plant managers; and

• Infusing agility and sustainability across functions.

CONCLUSION

Stepping into uncharted territory can be daunting, even intimidating. The past few years, and all the challenges they have brought, have taught us that inventive work methods can help a facility gain a competitive advantage — and that can trigger a ripple effect across the entire business. New ideas arise frequently, and a solution that fits your business might be just around the corner. Lean into, or at the very least don’t be afraid, of new technologies and their untapped possibilities.

Authorized Trainer Class by University of Texas Arlington

I was given the opportunity to attend Authorized Trainer class offered by University of Texas Arlington. This class teaches techniques that can be used to be a more effective instructor. In addition to being organized and knowledgeable of the subject matter you teach, there are things that an instructor can do to keep your audience engaged. We learned how to develop a proper “Course Objective” and “Course Outline” to meet every “Class Goal”. Great class!

9

From Left to Right – Randy Jones, Martin Morales, Charlie Engel, Eric Mendes, Ernest Sierra, Jaime Galindo and UT Instructor Simon Chavez

Addressing Burnout In The Workplace

02.02.2023 | EHS Today

These are challenging times. It’s time to show workers you care about their mental and physical well-being. Individuals are burning out at alarming rates.

People feel a constant demand to deliver, so they’re burning out or they’re leaving their jobs. COVID-19, the Great Resignation and economic uncertainty have amplified the burnout rate given the number of changes in the workplace and at home, especially among working parents.

For EHS professionals, there typically isn’t an option to work remotely , as the pandemic increased demand for on-site health and safety products and protocols. EHS all-stars were part of the front line, risking their lives every day to keep manufacturing plants and warehouses open—and keeping the country going. These demands have led to increased stress and burnout among EHS personnel.

WHY BURNOUT IS A THREAT TO WORKPLACE SAFETY

Burnout is a state of physical, mental and emotional exhaustion. It is characterized by feelings of energy

depletion, detachment from work and decreased effectiveness in one’s professional life. According to the World Health Organization (WHO), burnout is an occupational phenomenon that occurs when someone experiences long-term stress or tension related to their job.

The WHO defines burnout as an “occupational syndrome resulting from chronic workplace stress that has not been successfully managed.” The organization’s definition further states that it can manifest with symptoms such as exhaustion, cynicism and a sense of reduced accomplishment. In addition to these mental symptoms, physical signs such as headaches and insomnia may also occur due to prolonged periods of workplace stress. Furthermore, those suffering from burnout may find themselves struggling with decreased performance at work or in other areas of their lives.

Employee burnout is a serious problem that can have disastrous effects on employees, their families and the businesses they work for. As such, it’s essential for EHS managers to understand the signs of burnout. They also need to know how to prevent and manage burnout in order to ensure employee well-being.

As an EHS manager, there are several steps you can take to help your employees avoid burnout:

• First, ensure that your staff has access to resources needed for job performance. This includes adequate training and support from colleagues or management.

• Additionally, regularly evaluate working conditions within the company—both physical environment and workloads—as these are often major factors associated with burnout.

• It’s also important to provide opportunities for feedback so you can identify any areas where employees may be struggling or not feeling supported by the company culture.

THE LINK BETWEEN BURNOUT AND STRESS

The COVID-19 pandemic has had a significant effect on the mental health and well-being of workers around the globe. The past three years have created an atmosphere that has caused stress and anxiety for many employees. Given the disruption so many of us have felt — some with no end in sight — it’s important to understand how these events are impacting our mental health . We also need to learn what we can do to protect ourselves from harm.

Experts have previously observed that workers experience higher levels of stress during times of economic insecurity. This could be due to financial worries, job loss or simply because people feel an overall sense of instability in their lives. For those already struggling with existing mental health issues, this insecurity can make them even more vulnerable to anxiety and depression.

Whether it’s compassion fatigue or burnout, stress is a common element in both. life, and you need to figure out ways to address it. There are different strategies experts recommend, including a focus on:

• Sleep,

• Nutrition,

• Time management,

• Cleanliness and

• Keeping organized/reducing clutter.

You may view stress as a personal issue, but it’s also a workplace concern. Team morale impacts communication.

If your organization has a constant turnover of staff, you’re always onboarding new talent, which hinders productivity and poses challenges to safety.

Creating strong communication protocols within your organization, no matter how big or small, will help you retain top talent and grow your organization. Continual review with your team on how to become more efficient and improve internal communication will go a long way in reducing burnout in your clinic.

EHS personnel who are burning out often feel a lack of trust from their organization. As Lea Brovedani wrote in an article for EHS Today , there are five tenets of trust that are critical to the health of an organization:

“Caring - Demonstrate genuine care of others.

Employees can tell if compliance is about CYA (Cover Your Assets) rather than caring for them as individuals.

“Commitment - Keeping your word or not stopping until your work or task is completed. When you are committed to a safe workplace, it becomes a value that is nonnegotiable, and everyone lives and breathes it.

“Consistency - Words and actions are aligned. The rules apply to everyone.

“Competence - A skill or knowledge that aligns with the task. Everyone should be trained so they have the skills and abilities to do their job safely.

11

...continued on next page

HOW BURNOUT CONTRIBUTES TO LABOR CHALLENGES

Since early 2021, millions of people have voluntarily quit their jobs, known as the Great Resignation. Causes for the mass exodus include low wage increases, micromanagement, concern about going back to the workplace after COVID-19 pandemic and lack of flexibility by management.

Labor shortages, combine with mass layoffs, have only exacerbated the labor challenges companies and workers face. Employment issues will likely continue for the foreseeable future, especially as the Federal Reserve and other economic forces manipulate the landscape. Here are three ways to prevent your team from burning out because of the changing labor dynamics:

LISTEN TO YOUR EMPLOYEES.

Even the most brilliant of minds are not mind readers, so you cannot expect that you will fully know what’s on the minds of your employees or what they want out of their work role. You can find out, though, by simply asking.

To do so, create a safe environment where employees can speak freely and without retribution. Ask employees how they are doing and what they need from the company at

the present moment. Is there anything that the company can do to help them navigate through these changing times? How can management better support them?

Then, take action or make decisions based on what they tell you. Prove to employees that what they say matters—and you’re listening . This is an ongoing exercise, not a one-anddone practice. Repeat the process on a regular basis and see how those conversations shift or progress. You may be surprised with what you find—and the impact small changes can have on the safety culture at your organization.

ASK ABOUT WHAT FLEXIBLE WORK MEANS TO YOUR TEAM.

Flexibility is different for everyone, so if your team would like to work remotely (if possible) for a certain amount of time, then get creative on how to make that happen. Some people thrive in an office environment, while others thrive working remotely.

The most important thing is to be flexible with the policies and frequently communicate with your team to see how it’s working (or not) for them. Then, continue to readjust or reassess based on changing conditions and employees’ needs; just because something works today doesn’t mean it will work six months from now.

FOCUS ON YOUR TEAM’S PROFESSIONAL AND PERSONAL PHYSICAL AND MENTAL HEALTH NEEDS.

The COVID-19 pandemic has been traumatic for everyone. As a result, having a psychologically safe workplace is more important than ever.

Psychological safety is the belief that one can take risks without fear of negative consequences or humiliation. When employees have this sense of security, they are able to bring their best self to work and be more creative, innovative and collaborative. Psychological safety is essential to creating a productive workplace environment.

A psychologically safe workplace encourages open communication and allows teams to engage in constructive dialogue without fear of judgment, criticism or reprisal. Employees should feel comfortable expressing opinions, sharing ideas and asking questions.

Creating a psychologically safe workplace requires commitment from leadership at all levels within the organization. Leaders must create an environment where team members feel accepted for who they are and respected for their contributions.

Burnout has been increasing in every sector. Maintaining open communication with your team, creating a safe space where they feel comfortable asking questions, and getting them the help they need goes a long way toward retaining workers and keeping them healthy.

HOW TO ADDRESS BURNOUT

One way to help combat burnout is for leadership to take downtime seriously. Executives need to use their vacation time and encourage their teams to do the same.

We have seen vacation habits change since the onset of the pandemic. People may be concerned about or wondering how to spend that vacation time, but simply taking it is the most important part. Do what you feel comfortable doing, even if it’s just for an afternoon. Staycations can be relaxing if you can resist the urge to work or check email.

Another way to address burnout is to establish boundaries around working hours. Encouraging employees and yourself to spend some time each day relaxing is crucial to maintaining well-being for yourself and your team. Some tips to create the work-life balance:

HAVE A STANDARD START AND END TO YOUR WORKDAY.

The pandemic might have changed the way people work, but not necessarily for the better. With so many companies

opting to switch their in-person working hours to remote ones, flexibility has been introduced that some might see as a benefit. However, this newfound flexibility can easily lead to employees working more hours than they would if they were in an office setting.

Employees may think that having flexible working hours means that they can take extended breaks throughout the day or even fewer days off per week, but this isn’t always the case. For many people, these flexible schedules can lead to longer workdays and less of a distinction between work life and home life.

MANAGE DISTRACTIONS/INTERRUPTIONS.

Every time you are interrupted, it can take up to 30 minutes to get back your focus. If there’s any way for you to isolate yourself in time blocks, you’ll accomplish more work in less time. Turn off whatever sounds, apps and notifications you feel comfortable with on your personal and work devices.

SCHEDULE BREAKS FREQUENTLY.

If you can work in 50-minute increments without interruptions, then give yourself a 10-minute stretch break. Go for a walk around the office, shop floor or outside for some fresh air if you can.

GET PROPER NUTRITION AND EXERCISE.

Vitamin D deficiency is a huge issue for many of us, and if we are indoors all the time, we’re not getting enough sunshine, a natural source of vitamin D.

Work with a nutritionist to find out the proper food and vitamin supplements you need for proper health. Also, be sure to develop an exercise routine. Work with your healthcare provider to create an exercise plan that’s safe and effective.

CONCLUSION

The workplace can be a stressful environment, and the consequences of burnout in the workplace can be significant. Providing mental health resources, offering flexible working arrangements and paid time off, establishing clear expectations around workloads, and providing support systems will go a long way toward keeping your organization healthy. By implementing effective strategies for reducing stress and addressing symptoms of burnout they occur, employers can create a more positive atmosphere for their employees.

13

Incident investigations

02.07.2023 | WeeklySafety.com

Incident investigations, including a thorough root cause analysis, should be happening after any injury, property damage event, or near miss happens on the job. Following the investigation, appropriate corrective actions can be implemented to prevent future incidents

The term accident often used when referring to an unplanned, unwanted event. However, accident suggests an event that was random, and could not have been prevented. Since nearly all worksite fatalities, injuries, and illnesses are preventable, the term incident is more applicable in most of these unfortunate situations.

Investigating a worksite incident, which may be a fatality, an injury, an illness, property damage, or a close call, provides employers and workers the opportunity to identify hazards in their operations and shortcomings in their safety and health programs. Most importantly, it enables employers and workers to identify and implement the corrective and preventative actions necessary to prevent future incidents.

Incident investigations that focus on identifying and correcting root causes, not on finding fault or blame, also improve workplace morale and increase productivity, by demonstrating an employer’s commitment to a safe and healthful workplace.

Incident investigations are often conducted by a supervisor, but to be most effective, these investigations should include managers and employees working together, since each bring different knowledge, understanding, and perspectives to the investigation. In conducting an incident investigation, the team must look beyond the immediate causes of an incident. It is far too easy, and often misleading, to conclude that carelessness or failure to follow a procedure was the main cause of an incident. When the incident investigation fails to uncover the root cause(s) of the incident then the organization will fail to identify the systemic changes and measures that are needed to prevent future incidents.

Remember – before an incident investigation begins, all emergency response actions need to be completed and the incident site must be safe and secure for entry and investigation.

OSHA RECOMMENDS A FOUR-STEP SYSTEMS APPROACH TO INCIDENT INVESTIGATIONS.

STEP 1 – PRESERVE AND DOCUMENT THE SCENE

Preserve the integrity of incident location and prevent material evidence from being removed or altered. Use cones, tape, or other means of guarding to prevent unauthorized entry.

STEP

2 – COLLECT INFORMATION

Information about what happened before and during the incident can be collected through visual observation of the location, interviews, and document review efforts.

STEP 3 – DETERMINE ROOT CAUSES

There is often more than one root cause that can be uncovered during any incident investigation, and finding these root causes requires a deep evaluation of the incident.

STEP 4 – IMPLEMENT CORRECTIVE AND PREVENTATIVE ACTIONS

Steps taken after an incident to prevent future similar incidents, should be implemented in such a way that specifically addresses the root cause(s) found during the investigation.

When a program weakness is identified during an incident investigation, it is important to ask why it existed and why it was not previously addressed.

For example:

• If a step in the standard operating procedure was skipped, why was the procedure not followed exactly?

• Did production pressures play a role, and, if so, why were production pressures permitted to jeopardize safety?

• Was the procedure out-of-date or safety training inadequate? If so, why had the problem not been previously identified, or, if it had been identified, why had it not been addressed?

These examples illustrate that it is essential to discover and correct all the factors contributing to an incident, which nearly always involve equipment, procedural, training, and some other safety program deficiency. Simply placing blame on the employee, indicating that they made a mistake, or failed to follow the procedure, is not acceptable during an incident investigation.

A successful root cause analysis identifies all root causes—there are often more than one.

For simpler incidents, brainstorming and checklists may be sufficient to identify the root cause(s). For more complicated incidents, logic/event trees should also be considered. Timelines, sequence diagrams, and causal factor identification can also be useful tools.

Regardless of the tools used, the investigation should be seeking to answer these four important questions:

1. What happened?

2. How did it happen?

3. Why did it happen?

4. What needs to be corrected so it doesn’t happen again?

Addressing underlying or root causes is necessary to truly understand why an incident occurred, to develop truly effective corrective and preventative actions, and to minimize or eliminate serious consequences from similar future incidents.

To assist employers and workers in conducting effective incident investigations, and to develop corrective action plans, the following resources can help:

OSHA Fact Sheet: The Importance of Root Cause Analysis

During Incident Investigation

OSHA Incident Investigations: A Guide for Employers

NSC How to Conduct an Incident Investigation

Washington State Department of Labor & Industries

Accident Investigation Basics PowerPoint Presentation

15

How Management Leadership Can Improve Health & Safety

01.31.2023 | WeeklySafety.com

Management provides the leadership, vision, and resources that are critically needed to implement an effective safety and health program.

In any organization, management typically refers to the business owners, managers, and supervisors. Effective management leadership, when it comes to workplace safety, means that the leaders of the organization behave in a positive way that promotes health and safety throughout the company.

Management leadership has a responsibility to create a culture of safety by making worker safety and health a core organizational value. To do this, management staff must be fully committed to eliminating hazards, protecting workers, and continuously improving workplace safety and health, even when things get tough, finances get tight, growth happens quickly, or production is maximized.

Management personnel should be setting an example for all workers through their own actions and by visibly demonstrating and communicating their safety and health commitment throughout the organization. A great

way management can set the precedent that safety is important is by providing sufficient resources to implement and maintain the safety and health program.

A clear, written safety policy helps management leadership communicate that safety and health is a primary organizational value—as important as productivity, profitability, product or service quality, and customer satisfaction.

Organizations should establish a written safety policy signed by top management describing the organization’s commitment to safety and health and pledging to establish and maintain a safety and health program for all workers.

Once the policy is drafted and signed, management can communicate the policy to all workers and relevant parties including employees, contractors, staffing agencies, new and temporary workers, suppliers, and vendors, as well as visitors and customers.

When management has set safety standards for the organization, leadership staff should set a good example

and follow the same safety procedures required of the workers. Safety and health should also be a considering factor in all business decisions, including contractor and vendor selection, purchasing, and facility modification.

By establishing specific goals and objectives, management sets expectations for managers, supervisors, and workers, and for the program overall. The goals and objectives should focus on specific actions that will improve workplace safety and health.

There should be realistic, measurable goals set for improving safety and health within the organization. Instead of focusing on injury and illness rates, goals emphasizing injury and illness prevention are preferred.

Management can develop plans to achieve the safety goals by assigning tasks and responsibilities to particular people, setting timeframes, and determining resource needs.

Management provides the resources needed to implement the safety and health program, pursue program goals, and address program shortcomings when they are identified. Resources needs will of course vary depending on the organization’s size, complexity, and hazard types. Resources for safety and health program development may include capital, equipment, supplies, staff time, training, access to information and tools, and access to safety and health experts.

After estimating and allocating the resources needed to establish and implement a safety program, management must allow time in workers’ schedules for them to fully participate in the program. Safety and health should not be an afterthought, but rather should be integrated into planning and budgeting processes of the company.

Management leadership is responsible for providing and directing resources to operate and maintain the safety and health program, meet the commitments that have been set, and then further pursue the program goals.

Once the safety and health program is established, management leadership has the right to expect performance. Management will lead the program effort by establishing roles and responsibilities and providing an open, positive environment that encourages communication about safety and health.

There is typically a safety department manager or safety team that leads the safety program effort, makes plans, coordinates activities, and tracks progress. This person or group becomes the bridge between management leadership and employees.

Management can provide positive recognition for meeting or exceeding safety and health goals aimed at preventing injury and illness, which may include actions like reporting near misses, attending training, and conducting inspections. Successful programs reward, rather than discipline, workers who identify problems or concerns. Maintaining a positive and encouraging tone is important. A successful safety and health program establishes ways for anyone in the organization to communicate freely about safety and health issues, without fear of retaliation.

17

OSHA Directors Have Increased Authority to Cite Certain Types of Violations

01.29.2023 | EHS Today

The changes are aimed to stop “employers from repeatedly exposing workers to life-threatening hazards or failing to comply with certain workplace safety and health requirements.”

On January 26, OSHA announced new enforcement guidance changes which can “save lives and hold employers to greater account for safety and health failures.”

The announcement said these changes will “target employers who put profit over safety.” It will do this by making the penalties “ more effective in stopping employers from repeatedly exposing workers to lifethreatening hazards or failing to comply with certain workplace safety and health requirements.”

OSHA Regional Administrators and Area Office Directors now have the authority to cite certain types of violations as “instance-by-instance citations” for cases where the agency identifies “high-gravity” serious violations of OSHA standards specific to certain conditions where the language of the rule supports a citation for each instance of non-compliance.

Existing guidance on instance-by-instance citations are outlined in the OSHA Field Operations Manual, and CPL 02-00-080, “Handling of Cases to be Proposed for Violationby-Violation Penalties.”

These conditions include lockout/tagout, machine guarding, permit-required confined space, respiratory protection, falls, trenching and for cases with other-thanserious violations specific to recordkeeping.

The change is intended to ensure OSHA personnel are applying the full authority of the Occupational Safety and Health Act where increased citations are needed to discourage non-compliance. The new guidance covers enforcement activity in general industry, agriculture, maritime and construction industries, and becomes effective 60 days from Jan. 26, 2023. The current policy has been in place since 1990 and applies only to egregious willful citations.

In a second action, OSHA is reminding its Regional Administrators and Area Directors of their authority not to group violations, and instead cite them separately to more effectively encourage employers to comply with the intent of the OSH Act.

“Smart, impactful enforcement means using all the tools available to us when an employer ‘doesn’t get it’ and will respond to only additional deterrence in the form of increased citations and penalties,” explained Assistant Secretary for Occupational Safety and Health Doug Parker, in a statement.

“This is intended to be a targeted strategy for those employers who repeatedly choose to put profits before their employees’ safety, health and wellbeing,” Parker added. “ Employers who callously view injured or sickened workers simply as a cost of doing business will face more serious consequences.”

OSHA

Release 01.26.2023 | US Department of Labor

Facing manslaughter charges in worker’s 2021 trench collapse death, Colorado contractor who willfully ignored federal law surrenders to police.

A4S LLC did not use legally required trench protection systems.

BRECKENRIDGE, CO – The owner of a Vail construction company facing felony manslaughter charges has surrendered to local law enforcement after the Summit County Sheriff’s Office in Breckenridge, Colorado, issued an arrest warrant on Jan. 24, 2023, related to the findings of a federal safety investigation into a deadly trench collapse in November 2021.

In May 2022, the U.S. Department of Labor’s Occupational Safety and Health Administration cited Peter Dillon, owner of the now-defunct A4S LLC, after a worker installing residential sewer pipes suffered fatal injuries when the trench around him caved in. The collapse resulted from deteriorating conditions at the project, which A4S LLC could have prevented by using legally required trench protection systems.

OSHA issued three willful citations to A4S LLC for not ensuring the excavation was inspected by a competent person, failing to instruct employees on the recognition and avoidance of unsafe conditions and not having a trench protective system in place. Investigators also issued an additional serious citation for not having a safe means of egress within 25 lateral feet of employees working in a trench.

The agency proposed penalties of $449,583 and placed the company in OSHA’s Severe Violator Enforcement Program.

The department referred the case to the 5th Judicial District Attorney’s office recommending criminal charges for A4S LLC’s refusal to require safety protection, despite worsening trench conditions that included at least one trench collapse.

A4S LLC has since shuttered and Dillon agreed to forfeit any future ownership, leadership or management position that involves trenching or excavation, or the oversight of workplace safety and health.

“There is no excuse for Peter Dillon’s failures to protect workers when federal requirements clearly outline and require safety measures proven to save lives,” explained Regional Solicitor of Labor John Rainwater in Dallas.

“Today’s arrest by the Summit County Sheriff’s Office cannot recover a life lost in this senseless tragedy but it is a step toward seeking justice for the family.”

Collapses and cave-ins pose the greatest threat to trenching and excavation workers. In 2022, OSHA reported that at least 39 industry workers died, 22 of them in the first six months of the year. The Bureau of Labor Statistics reports that 166 workers died in trench collapses from 2011 to 2018.

“Let this tragedy serve as a reminder to other employers who willingly fail in their responsibilities to keep workers safe that the U.S. Department of Labor will exhaust every resource to hold employers accountable for protecting workers, including recommending criminal prosecution. OSHA has pledged to work with state prosecutors to raise the stakes in appropriate trenching death cases, and this is an example,” added OSHA Regional Administrator Jennifer S. Rous in Denver.

OSHA has a National Emphasis Program on trenching and excavations. Trenching standards require protective systems on trenches deeper than 5 feet. Additionally, trenches must be inspected by a knowledgeable person and have a safe means of entering and exiting prior to allowing a worker to enter.

19

National News

Pandemic Took Heavy Toll on Productivity

01.17.2023 | EHS Today

IBI’s analysis estimates that the cost associated with the loss of work hours is $213.1 billion for 2020 and 2021. While debate still continues about the productivity level of employees during the pandemic, when looking strictly at the lost number of hours during this time, the picture becomes more clear.

The Integrated Benefits Institute (IBI) , a nonOK, wprofit research and educational organization focused on workforce health and productivity, analyzed data from the US Current Population Survey to estimate the number of lost hours attributed to the pandemic, and the cost associated with the loss of work hours.

The cost associated with the loss of work hours is $213.1 billion ($167.4 billion in the first year and $45.7 billion in the second year).

And the number of lost hours attributed to the pandemic was 6.6 billion hours (5.2 billion in the first year and 1.4 billion in the second year).

Looking at specific industries, the industries that had the greatest losses were:

• Educational services, health care, and social assistance ($30.8 billion)

• Public administration ($27.1 billion)

• Construction ($23.9 billion)

• Waste management services ($22.4 billion)

• Manufacturing ($21.5 billion).

While the effects of the pandemic can’t be reversed, the workplace has changed permanently in a number of ways so IBI spoke to 1,800 employers about how to see how they are adapting and they offered these insights:

COMMUNICATION IS A KEY ELEMENT

Leadership must think differently about how they show up, communicate, and interact with employees. Honesty and transparency are the most important part of promoting trust. Communicate broadly and often through multiple channels.

TRUST, SAFETY, AND INCLUSION HAVE HEIGHTENED IMPORTANCE

Employees’ sense of security can be strengthened by comprehensive programs that include financial education and well-being and leave of absence benefit offerings to meet employee needs.

EMPLOYEE WELL-BEING AND PRODUCTIVITY MAY NEED STABILIZATION

Benefits and HR professionals can provide a reliable and sustainable business case for investments in workforce health and productivity. Employers have long considered the health of the workforce primarily from the perspective of managing health costs. By treating the health and well-being of the workforce as a strategic asset in a company’s valueadded process, employers can create a high-performance workforce.

THE BASICS, SUCH AS PREVENTATIVE SCREENING AND WELL VISITS, ARE STILL VALUABLE

To avoid expensive events, engage employees before their conditions deteriorate. There are now options such as home screenings and on-site services available to offer employees. Develop communication plans to raise employees’ awareness of the benefits of regular preventive checks and highlight options and costs available.

21

The Challenge Of Getting Everyone More Involved In Safety

02.13.2023 | JJ Keller Management Suite

A common challenge for safety professionals is getting employees and supervisors more involved in safety and more supportive of safety. Reasons that employees and supervisors don’t support safety could include that they don’t understand the value, or they simply choose not to engage and instead focus on production or other priorities. Perhaps the question should not be “how do we get everyone to participate?” but rather “how can we get them to CHOOSE to participate?” One possible answer could involve showing them the value of safety.

INCENTIVES WITH PURPOSE

Employers commonly offer incentives for participation in safety activities, such as hosting a pizza party, offering prizes, or using similar methods to get employees more involved. These efforts do encourage participation, at least for the duration of the event, and may help demonstrate that the company values safety. Unfortunately, some employees participate for the payout, then return to the

job without increasing their long-term investment in safety. Events and activities can be worthwhile by increasing participation and awareness, and even making safety “fun.” However, workers should not participate only for the free food or prizes. While you have their attention, consider how to show them the value of safety and how it impacts them personally.

WE DO THIS FOR YOU

Obviously, employers must comply with OSHA regulations, and injuries take away from profits. An unsafe work environment creates other consequences such as increased turnover, decreased job satisfaction, and decreased productivity. These all cost the employer time and money. But beyond that, you just don’t want anyone getting hurt!

Some employees might express opinions like “the company only cares about money.” While every employer needs to

worry about the bottom line, remind workers that safety rules keep them safe. The company might pay the cost of injuries, but workers pay the price — and you don’t want them getting hurt.

Numerous studies show that most employees would choose appreciation over money or prizes. Everyone wants to feel valued. To make people want to support safety, they need to understand how safety benefits them, and recognize that the company values them.

Your company invests time and resources on safety training, audits, and enforcement. Let your employees know, “We do this for you!” Show workers how safety benefits them, not just the company’s bottom line.

WE NEED YOUR HELP

Ideally, employees will actively promote safety. Safety professionals know that a successful program requires active participation. As one step, give workers “to do” items rather than “do not” items. Minor changes in how you express the rules and expectations can increase their “to do” items. For example:

Instead of saying, “Do not block the exit door,” try saying, “Make sure the exit route is always clear.” Get as specific as possible, so instead of saying, “Keep the workplace clean,” try saying, “Immediately clean up any trash or spills that you notice.”

By giving them action items and describing how these rules benefit them, you can hopefully encourage them to take a more active role in their own safety. The ultimate goal is getting everyone to continually watch for hazards, support one another’s efforts, and immediately address or report any problems. Safety doesn’t just go along with the job; it is part of the job!

23

The Austin Company is now a member of Construction Safety Research Alliance (CSRA) through the University of Colorado Bolder.

The Austin Company is now a member of Construction Safety Research Alliance (CSRA) through the University of Colorado Bolder.