THE SAFETY NET

How to Drive (Safely) on Black Ice

Driving in freezing temperatures can be fraught with all sorts of challenges, including limited visibility, frosty windshields or even rapidly draining EV batteries

Icy conditions could also cause problems for motorists during flash freezing events, when melting snow re-freezes after a sudden drop in temperature. This phenomenon can often result in the formation of black ice, which poses a real danger for even veteran winter drivers.

Austin employees have worked 8,300,922 hours without a Lost Time Accident through 01/2025.

Learn how to keep calm and get your vehicle to safety Winter driving isn’t only about dealing with snow; ice on the road is a real threat. Black ice is dangerous because it’s invisible (the term “black ice” being somewhat of a misnomer, as the ice is invisible). However, you can better protect yourself by understanding and knowing how to deal with this winter issue.

SAFEST WAY TO DRIVE ON BLACK ICE

If you hit black ice on the road, keep the steering wheel straight and avoid using the brakes. If the car turns left or right, gently turn the wheel in the same direction to correct course. Lift your foot off the gas to slow the vehicle down, then head for a surface with more traction like snow or sand.

STEP 1

Understand that black ice is like regular ice. It is a glaze that forms on surfaces (especially roads, sidewalks , and driveways) because of a light freezing rain or because of melting and re-freezing of snow, water, or ice on surfaces. It’s called “black ice” because it tends to look like the rest of the pavement on the road, although in

reality, it’s actually clear. Black ice forms without creating bubbles, which allows it to blend in with any surface it forms over.[1] Black ice is dangerous precisely because it’s hard to detect in advance.

STEP 2

Know where to expect black ice. Black ice usually forms just about the freezing point. Sometimes in frigid weather conditions on highways, black ice will form due to the heat of tires on the road coupled with the freezing temperature. Keep an eye on the weather and highway reports.

• Black ice forms most commonly at night or in the early morning when the temperatures are at their lowest, or when the sun isn’t around to warm the roads.

• Black ice tends to form on parts of the road without much sunshine, such as along a tree-lined route or a tunnel. It will also form more frequently on roads that are less traveled on.

• Black ice forms readily on bridges, overpasses and the road beneath overpasses. This is because the cold air is able to cool both the top and under the bridge or overpass, bringing about faster freezing.

STEP 3

Know when to expect black ice. Black ice tends to form in the early morning and evening. During the daylight hours, the road is usually warmer and less likely to create black ice. But remember: less likely does not mean “never”. Always be prepared for the possibility of encountering black ice.

• See the signs of black ice. If you are driving and see cars suddenly swerve for no apparent reason, black ice is a likely cause.

STEP 4

Know how to see black ice - sometimes. While black ice is transparent, it can sometimes be seen in the right lighting conditions - if you are looking for it. Black ice almost always forms in very smooth, very glossy sheets. This glossy surface is your indication of potential black ice. If the majority of the road you’re driving on appears a dull black color, but the patch just ahead of you appears shiny, you may be about to drive onto black ice - don’t panic, follow the instructions below.

• This technique for helping to detect black ice won’t work at night, but dawn, daylight and dusk all offer enough light to see.

• If you are unfamiliar with this glossy appearance, think of a nice new car’s black spray paint compared to an older, un-kept car’s black paint job.

• You won’t always be able to see black ice, but looking for it can’t hurt. It may also help you to stay focused in less than ideal driving conditions. Just be sure to keep your eyes on the rest of your environment as well.

STEP 5

Practice driving on slippery surfaces. If possible, (and with a seasoned winter driver) practice driving on ice in a safe surrounding. Find a nice, large, empty parking lot with ice on it. Drive on ice. Practice braking on ice. Understand how your car feels and handles in these conditions. Know what ABS braking feels like if you have it. Practicing this under controlled conditions can actually be a lot of fun!

STEP 6

Deal with a black ice encounter. If you do hit black ice, your first reaction must be to remain calm and avoid overreacting. The general rule is to do as little as possible and allow the car to pass over the ice. Do not hit the brakes, and try to keep the steering wheel straight. If you feel the back end of your car sliding left or right, make a very gentle turn of the steering wheel in the same direction. If you try to struggle against it by steering in the opposite direction, you risk skidding or spinning out (see below for what to do if this happens).

STEP 7

Slow down by de-accelerating. Lift your feet off the accelerator completely and keep your steering wheel fixed in the position it’s in. Slowing down will give you more control and prevent needless damage.[8]

• Do not touch the brakes. Doing so will likely cause you to skid. The idea is to slide over the ice in the direction the steering wheel is facing; usually black ice patches aren’t longer than 20 feet (6 metres).

...continued on next page

STEP 8

If you can, shift into a low gear . Low gears will give you more control.

STEP 9

Head for areas of traction. Black ice is virtually invisible, but you may be able to head towards areas of pavement that offer more traction. Such areas of traction may include textured ice, snow-covered areas, spots with sand, etc.

STEP 10

If you skid or lose traction, stay calm. Hopefully, you are now going slow and this will make it easier. Black ice is often (although not always) patchy, so hopefully your tires will soon find traction. Use the minimum amount of braking possible, although some braking will be necessary if skidding a lot, as follows:

• If you have anti-lock braking system (ABS), just put your foot on the brake, apply firm pressure and the car will pump the brakes for you as you skid.

• If you don’t have ABS, pump the brakes gently as you skid.

• Always steer the car in the direction you want the car to go.

STEP 11

If you end up going off the road, try to steer into things that will cause the minimum amount of damage. Ideally, steer into an empty field, a yard, or a fluffy snowbank. Of course, you may not have much choice in the matter, but you can at least try.

STEP 12

After the black ice encounter, stay calm . You’re likely to be a bit rattled, but panicking isn’t going to help at any stage. If you must keep driving, do so very, very slowly. Alert other drivers that you’re going slowly by flashing your lights at all times.

STEP 13

Get off the road as soon as possible. It’s better to wait a while at a rest stop, diner, or even on the side of the road until the road crews can salt and/or sand the roads than to deal with an accident. This will also provide you with a chance to recover your senses and feel less panicked. Have a hot drink and relax a while.

• If there is a pile up: Very rarely ice and/or black ice can make extremely hazardous conditions that can cause multi-car accidents on a highway. You will have to evaluate quickly whether staying in your car (where you have some safety protection) or getting out (where you can flee further collisions but will have to walk on icy surfaces, in freezing temperatures, with other cars spinning out of control around you) is safer. Consider your location, the speed of travel, geographic location, your warmth, and your physical abilities.

STEP 14

Prevent or minimize future encounters with black ice. There are several things that you can do to reduce the chances of being surprised by black ice. While knowing how to drive on it remains a number one priority, here are some other things to do:

• Travel slowly. Don’t try to speed during icy weather as this will take away any control you might have had on the black ice.

• Don’t tailgate.

• Keep your windshield clear of ice, snow, dirt, and anything else that can prevent you from seeing out of it properly. To get snow and ice off the windshield of your car, you might be tempted to turn on your windshield wipers. It might seem like the wipers and the washer fluid will work, but they don’t. In fact, if you use your windshield wipers to get ice off the windshield, you could ruin them. Use an ice scraper to scrape the ice from the windshield of your car before starting the vehicle.

• Turn your headlights on early in the afternoon to help you see any possible sheen from black ice.

• Check your tire tread . Worn tread causes accidents in any conditions, and will ensure you lack traction when needed on black ice. In addition, consider having snow tires fitted.

• An important thing to remember is to NEVER drive in potentially icy conditions with your cruise control active.

7 Tips for a Safer Office

01.18.2023 | EHS Today

The need for safe practices extends to all areas of a workplace – including offices. Here, from the Texas Department of Insurance, are seven simple steps employers can take to help office workers stay injury-free.

. Clear walkways of boxes, files and other items that can be tripping hazards. Prevent clutter by encouraging workers to put items back in their proper location.

. Don’t stretch electrical cords across walkways or hide them under rugs. Instead, anchor and cover the cords, and do your best to keep them out of high-traffic areas.

. Don’t allow workers to stand on chairs to reach for something up high. Place stepladders around the office for workers to use.

. Install domed mirrors at intersections so employees can see if someone is approaching from a different direction, making collisions less likely to happen. Consider installing windows in stairwell doors as well.

Use skid-resistant materials such as carpet on floors to help reduce slips, trips and falls.

. Adjust employees’ workstations to fit them specifically. This includes monitor stands, keyboard trays and chairs.

Encourage employees to work ergonomically, including placing desk items close enough to eliminate the need to stretch to reach for them. Cilck to Learn More.

First Aid: More Than Just a Bandage

01.20.2025 | Safety Management Suit

Minutes count when someone is injured or becomes ill on the job. Employers can keep the situation from getting worse by providing the correct type of first aid treatment right away.

Anyone who’s been designated by the employer to provide first aid must have thorough training on how to respond to the injuries and illnesses anticipated in the workplace. Employees who aren’t designated first aiders should know how to promptly report injuries and illnesses.

Where an accident can result in suffocation, severe bleeding, or other life-threatening or permanently disabling injury or illness, OSHA expects a three- to four-minute response time from the time of injury to the time of administering first aid. If such a life-threatening or serious injury is unlikely, OSHA allows a longer response time, such as 15 minutes. The employer should obtain estimates of Emergency Medical Services (EMS) response times for all locations and for all times of the day and night that workers will be present.

TRAINING DESIGNATED FIRST AID PROVIDERS

To ensure treatment is available within these timeframes, OSHA requires employers to train persons to render first aid when there’s no nearby hospital, clinic, or infirmary that’s used to treat all injured or ill employees. First aid providers perform the initial assessment of injuries and illnesses and provide immediate care and life support before EMS professionals arrive.

OSHA recognizes any nationally accepted and medically sound first-aid training program that covers the fundamentals of first aid as meeting the requirements stated in 1910.151 . Employers using first aid and/or cardiopulmonary resuscitation (CPR) courses must ensure that the course adequately covers the types of injuries and illnesses likely to be encountered in the workplace.

Employees who are expected to render first aid as part of their job duties also must be trained under the Bloodborne Pathogens standard at 1910.1030 . This standard applies to occupational exposure in general industry. Occupational exposure is defined as “reasonably anticipated skin, eye, mucous membrane, or parenteral contact with blood or other potentially infectious materials (OPIM) that may result from the performance of an employee’s duties.”

This training must be offered upon initial assignment, at least annually thereafter, and when new or modified tasks or procedures affect an employee’s occupational exposure. Training must cover all elements of the standard including, but not limited to: information on bloodborne pathogens and diseases, methods used to control occupational exposure, hepatitis B vaccine, and medical evaluation and post-exposure follow-up procedures. HIV and HBV laboratory and production facility workers must receive specialized initial training, in addition to the training provided to all workers with occupational exposure.

Ladder Incidents Have Decreased

From 2020 to 2024, there was a 21% decrease in ladderrelated accidents that resulted in serious injury or loss of life.

A new survey, 2024 Ladder Safety Training and Citations Survey , from the American Ladder Institute , found that from 2020 to 2024 there was 21% decrease in ladder related accidents that resulted in loss of life or serious injury.

The survey showed that less than a quarter of the surveyed organizations experience ladder-related accidents/ incidents. Data was unchanged from 2016 to 2018 and 2020 to 2024.

Over the last two years the most common ladder-related accidents or incidents were the ladder being set up incorrectly, followed by using the wrong ladder for the job (too long, too short, wrong material, wrong application).

Additionally, 4 out of 10 survey respondents indicated that the quantity of ladder-related accidents/ incidents at their organizations has stayed approximately the same over the last five years. Nearly one third of respondents saw a decrease in the number of ladder-related accidents.

With regard to OSHA, 7 out of 10 respondents have not received any ladder-related citations/violations from OSHA in the past 12 months. Companies with zero citations have increased by 2% since 2020.

And from 2020 to 2024, the percentage of organizations who believe human error is a cause to the continued OSHA citations increased from 61% to 63%.

More than half of the respondents feel that the accident/incidents could have been avoided with the proper training.

SAFETY TRAINING FINDINGS

The survey found that nearly all organizations (98%) use a form of ladder safety training. The year-overyear comparison shows an increase in the number of organizations paying for safety training (35%, up from 28% in 2020). However, year-over-year comparison shows an increase in the number of organizations paying for safety training. In 2020, 28% of organizations were paying for ladder safety training.

In 2024, 64% of respondents said a training refresh was required annually, compared to 62% in 2020 and 58% in 2018.

In 2024, 4% of respondents said only new employees were required to take ladder safety training, compared to 8% in 2020 and 13.5% in 2018.

In-person (classroom or on the job site) and video/online ladder safety training are the top two formats of ladder safety training. Participants could select more than one option.

OSHA Updates: COVID Rulemaking Terminated, Fines Increase

01.15.2025 | EHS Today

Best way to protect healthcare workers from COVID-19 and other infectious diseases is to complete Infectious Diseases rulemaking.

COVID RULEMAKING

On January 15, OSHA announced that it has terminated its COVID-19 healthcare rulemaking .

On June 21, 2021, OSHA issued an Emergency Temporary Standard to protect workers from COVID-19 in healthcare settings, which also served as a proposed rule on which OSHA requested comments. The agency received public input on this proposal during multiple comment periods and public hearings from June 2021 through May 2022. OSHA submitted a draft final COVID-19 rule to the White House Office of Management and Budget on Dec. 7, 2022.

On April 10, 2023, President Biden signed into law House Joint Resolution 7, which terminated the national emergency related to the COVID-19 pandemic.

With today’s announcement, OSHA is now terminating the rulemaking because the most effective and efficient use of agency resources to protect healthcare workers from occupational exposure to COVID-19, as well as a

host of other infectious diseases, is to focus its resources on the completion of an Infectious Diseases rulemaking for healthcare.

PENALTY ADJUSTMENT

Adjusted OSHA civil penalty amounts for 2025.

Based on inflation for 2055, OSHA has made changes to civil penalties.

In 2015, Congress passed the Federal Civil Penalties Inflation Adjustment Act Improvements Act to advance the effectiveness of civil monetary penalties and to maintain their deterrent effect. Under the Act, agencies are required to publish “catch-up ” rules that adjust the level of civil monetary penalties and make subsequent annual adjustments for inflation no later than January 15 of each year.

On Jan. 15, 2025, the maximum OSHA penalties for serious and other-than-serious violations will increase from $16,131 to $16,550 per violation. The maximum penalty for willful or repeated violations will increase from $161,323 to $165,514 per violation.

OSHA Promotes Scott Ketcham to Deputy Assistant Secretary

01.17.2025 | Safety + Health

“OSHA TAKES FALLS VERY SERIOUSLY. TOO MANY LIVES ARE LOST EACH YEAR FROM WORKERS WHO FALL TO THEIR DEATH.”

Washington — Scott Ketcham has been promoted to deputy assistant secretary at OSHA.

According to the agency’s organizational chart, Ketcham will oversee OSHA’s 10 regions and its directorates of Enforcement Programs and Construction . He joins Jim Frederick as a deputy assistant secretary.

Ketcham has worked for OSHA for two decades in various regional and area offices, most recently as director of the Directorate of Enforcement Programs. He has also served as director of the Directorate of Construction. In 2024, he presented the agency’s annual Top 10 list of most frequently cited standards at the annual NSC Safety Congress and Expo in Orlando, FL.

Erin Gilmore succeeds Ketcham as director of the Directorate of Enforcement Programs, taking on the role in an acting capacity. Most recently, she had served as the directorate’s deputy director.

OSHA Joins with NSC to Eliminate Roadway Fatalities

01.21.2025 | EHS Today

In 2023, roadway deaths accounted for 37% of all workrelated fatalities.

On January 16, OSHA announced it has joined the National Safety Council Road to Zero Coalition, the nation’s largest traffic safety alliance dedicated to eliminating roadway fatalities.

“Unlike other workplaces, the roadway is not a closed environment,” said Assistant Secretary for Occupational Safety and Health Doug Parker, in a statement. “Preventing work-related roadway incidents requires a combination of traffic safety principles and sound safety management practices. By collaborating with the National Safety Council and the Road to Zero Coalition, we can promote safe driving policies to prevent needless tragedies.”

In 2023, roadway deaths accounted for 37% of all workrelated fatalities. And the NSC estimates more than 44,000 people died in traffic crashes in 2023.

“The most dangerous thing a person can do on the job is get in a vehicle,” said Lorraine Martin, NSC president and CEO, and chair of the Road to Zero Coalition, in a statement. “That’s what makes this partnership so critical. By joining Road to Zero, OSHA strengthens our ability to protect workers both on and off the job. Together, we can create safer roads for everyone – whether they are driving for work or sharing the roads with those who do.”

The Road to Zero Coalition, established by NSC in 2016, features a collaboration with the U.S. Department of Transportation and over 2,000 transportation safety stakeholders to combat the public health crisis of fatal and nonfatal traffic injuries on our roads.

The Road to Zero Coalition was incorporated into the current National Roadway Safety Strategy. The Coalition was founded on the belief that roadway crashes are preventable, and through collective efforts, roadway fatalities can be eliminated by 2050.

Joining the Coalition allows OSHA to work collaboratively with road safety leaders to make sure road users practice safe driving behaviors and roadside workers have access to the latest technologies to keep them from harm.

Previous Road to Zero successes include the dissemination of the 2024 Community Traffic Safety Grants to help local organizations implement safety programs, the release of the Massive Hazards report on light truck proliferation, and Secretary Pete Buttigieg joining the Coalition for a fireside chat during its Annual Meeting in 2024.

Safe Use of Circular Saws

01.21.2025 | Safety + Health

Circular saws can cause serious injuries if not operated safely.

Used for straight sawing, they’re designed to either cut across or along the grain of wood, depending on the blade on the tool, according to OSHA. “The operator adjusts the height of the blade,” the agency adds. “Then, holding the stock, the operator pushes the blade across it to perform the cut.”

If you’re working with a circular saw, OSHA says you can protect yourself by:

• Making sure to keep your hand out of the cut line.

• Checking that you’re using the correct blade for the material being cut.

• Operating the saw at the speed specified in the owner’s manual.

• Maintaining the blade and keeping it sharpened.

• Replacing cracked blades immediately.

• Using the saw’s machine guards and anti-kickback fingers to secure the material you’re cutting.

And remember to wear safety glasses to make sure your eyes are protected from flying particles.

New year, new you? You can do it! Use these tips from UC Davis Health when planning your New Year’s resolutions: Set yourself up for success. Choosing one or two goals is a good route to go. If you have more than a couple, they could overwhelm you and result in you losing your focus. Another bit of advice: “Avoid picking a goal that you’ve tried in the past but failed,” UC Davis Health says. “You may set yourself up to fall into the same pitfalls that stopped you previously. Instead, pick something different where you can set up a better path to success. Or maybe you can modify a previous goal if that’s something you still want to accomplish.”

Think through your goal. How will you accomplish your goal? What steps will you take to make changes? By what date do you want to achieve your goal? Do some research and put your plan in writing. And remember: Be specific. If your resolution is to learn a new language, for example, use statements like, “I will practice three times a week.”

Be realistic. You should start small. If you want to lose weight, don’t tell yourself you’re going to lose 30 pounds in 90 days. Instead, commit to losing 1-2 pounds a week. This makes the goal more achievable.

Team up. Accountability is key, so it’s a good idea to partner with a friend or family member to help you stay on track. A spouse can cook healthier meals with you. A neighbor can be your walking partner. Or ask someone to do a weekly check-in with you to measure your progress.

Give yourself time. Change won’t happen overnight, so be patient with yourself. Don’t let one bad day steer you off course. Keep doing what you set out to do and eventually it will become part of your lifestyle!

What We Can Learn From OSHA’s 2024 Top 10 Safety Violations

01.21.2025 | EHS Today

Learn what OSHA’s 2024 top 10 incident list reveals about the limitations of compliance and the need for proactive, continual safety improvement.

KEY TAKEAWAYS:

• OSHA’s 2024 top 10 violations list remains largely unchanged from previous years, with issues like fall protection, hazard communication, and machine guarding consistently showing up.

• While traditional contractor prequalification and compliance programs have reduced minor injuries, they have done little to address serious injuries and fatalities, as they focus on meeting minimum safety requirements rather than ensuring effective safety systems.

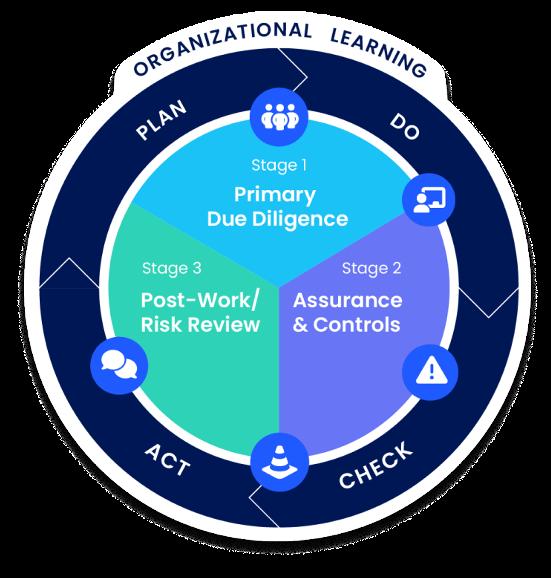

• Avetta’s Safety Maturity Index (SMI) offers a more comprehensive approach, assessing contractors’ safety management systems and encouraging continual improvement through a Plan-Do-Check-Act framework.

• Trials of the SMI revealed that many contractors considered “compliant” under traditional metrics had poor safety practices, while some “non-compliant” contractors demonstrated strong safety systems, proving that compliance alone is not a reliable indicator of future safety performance.

INTRODUCTION

Every year, the Occupational Safety and Health Administration (OSHA) releases its top 10 list of the most frequently cited workplace safety violations. These citations offer critical insights into where safety measures fall short in workplaces across the United States. Despite advances in technology and safety programs, OSHA’s top 10 citation list has remained virtually unchanged for years, reflecting deeper systemic challenges related to workplace safety.

In this post, we’ll examine these workplace safety challenges related to contract workers and introduce a new strategy for proactive safety improvement.

2024 OSHA TOP 10 VIOLATIONS LIST

Below is the list of OSHA’s top 10 safety violations between Oct. 1, 2023, and Sept. 5, 2024. Looking back on past lists, it’s clear that the same issues have been consistently problematic for decades.

1. Fall Protection (General Requirements) –6,307 violations

2. Hazard Communication – 2,888 violations

3. Ladder Safety – 2,573 violations

4. Respiratory Protection – 2,859 violations

5. Lockout/Tagout – 2,443 violations

6. Powered Industrial Trucks – 2,248 violations

7. Fall Protection (Training Requirements) – 2,050 violations

8. Scaffolding – 1,873 violations

9. PPE (Eye and Face Protection) – 1,814 violations

10. Machine Guarding - 1,541 violations

STUCK IN THE ERA OF COMPLIANCE

The enduring presence of these violations suggests that many organizations remain stuck in a compliance-driven safety model, particularly when it comes to contract workers. Rather than focusing on preventing incidents before they occur, organizations are primarily concerned with meeting minimum regulatory standards. While the importance of due-diligence and traditional methods of evaluating contractor compliance remains, a better future includes no-longer screening contractors based merely on past violations or metrics like total recordable incident rate (TRIR) without assessing the actual quality of their safety management systems.

Supplier prequalification continues to be the predominant model for supplier safety, where companies screen potential suppliers based on past safety performance and safety policies. Though this is a helpful step to identify safe suppliers, it only tells part of the story.

While compliance-focused programs can reduce minor injuries, they have done little to address serious injuries and fatalities. The absence of past injuries or the maintenance of an average TRIR is not a strong indicator as to the presence of a contractor’s safety capacity. In fact, industries relying solely on these lagging safety indicators may be overlooking deeper safety issues, as many “compliant” organizations may lack the systemic safeguards necessary to prevent more significant incidents.

INTRODUCING THE SAFETY MATURITY INDEX

The Safety Maturity Index, developed by Avetta in partnership with the National Safety Council (NSC) and companies like Entergy and Cargill, represents a systembased approach to safety management. It assesses the effectiveness of a contractor’s safety management system (SMS), including systems, processes, and methods across multiple categories:

1. Safety leadership and structure

2. Hazard identification and controls

3. Worker training and competency

4. Incident management and response

5. Improvements and communications

Contractors are scored on a 0-100 grading scale, where an A grade represents a score between 90 and 100, and a D grade represents a score below 70.

Organizations must transition from a narrow focus on supplier prequalification and compliance to broader safety assurance and continuous improvement models. Avetta’s Safety Maturity Index (SMI) offers a framework for assessing and enhancing safety performance beyond simple compliance. It is a tool that organizations can use to evaluate suppliers’ safety management systems, helping them identify not just whether a supplier is compliant but also how mature and effective their safety practices truly are.

The Safety Maturity Index is rooted in 15 years of NSC research and incorporates data from Avetta’s network of 130,000 global suppliers and 1.5 million contract workers. Safety and risk professionals from companies like Entergy and Cargill contributed to the design and testing of this index, ensuring it reflects real-world supply chain safety challenges.

THE PLAN-DO-CHECK-ACT FRAMEWORK IN SMI IMPLEMENTATION

The SMI is based on the Plan-Do-Check-Act (PDCA) cycle , which fosters continuous improvement in safety practices. This system is designed not only to assess contractors but

...continued on next page

also to enable organizations to deploy better systems and safeguards, reducing serious injuries and fatalities (SIFs) over time. Notably, the SMI is not just a static measurement tool but is intended to drive continuous improvement through actionable steps.

1. Plan: Clients collaborate with Avetta to define safety goals, outcomes, and identify suppliers for assessment.

2. Do: Avetta enables the SMI, incorporating additional supplier requirements for prequalification and worker training programs.

3. Check: Avetta provides clients with dashboards, reports, and analytics to assess the safety maturity of suppliers based on their SMI scores.

4. Act: Clients use SMI data to prioritize supplier enablement programs, inform compliance decisions, and deploy NSC safety resources to enhance supplier safety maturity.

By leveraging the SMI, organizations can move beyond the traditional “red or green” compliance mindset and begin building critical system elements for better safety performance, as well as continual improvement. Compliance should be seen as the baseline, and SMI can help organizations progress from compliance to safety assurance and proactive risk management.

SMI IN ACTION: UNCOVERING CRITICAL INSIGHTS

SMI provides a new lens through which organizations can view their safety programs, offering deeper insights than traditional compliance measures. Early deployments of the SMI have shown that many suppliers, while technically compliant, did not have effective systems in place to prevent serious safety incidents. The SMI helps organizations identify these gaps and take proactive steps to close them.

In trials involving 20,000 contractors across 25 countries, Avetta compared SMI scores (A-D) to traditional compliance indicators (green for compliant, red for noncompliant). Key findings revealed that 60% of suppliers with a “green” compliance status had a C or D grade in the SMI, indicating that many “compliant” suppliers were at higher risk than expected. Conversely, some noncompliant (red) suppliers had strong safety systems, with A or B grades in the SMI.

These results underscore that standard compliance checks are insufficient to understand supplier safety risks or the likelihood of a serious accident. By integrating SMI into their supplier safety programs, organizations can prioritize relationships with suppliers that have robust safety systems and avoid those who may pose higher risks despite meeting minimum regulatory standards.

CONCLUSION

The persistence of OSHA’s Top 10 citation list reveals that we are still stuck in an outdated, compliance-driven era. Basic prequalification and compliance programs, while important, are not enough to drive significant reductions in serious incidents and fatalities. To truly improve workplace safety, organizations must move beyond compliance and embrace assurance and continual improvement models like Avetta’s Safety Maturity Index . By doing so, they can build safer workplaces, reduce risk, and create a proactive culture of safety maturity.

For organizations ready to move beyond compliance, Avetta’s SMI offers the tools and insights needed to transform supplier safety programs. Now is the time to make the shift, improve safety performance, and protect workers from the hazards that continue to appear on OSHA’s annual list.