LOCATION CONSULTING DESIGN & ENGINEERING DESIGN-BUILD CONSTRUCTION & CONTRACTING JANUARY 2023 VOLUME 17 ISSUE 1

T Y FIRST. Austin employees have worked

hours without a Lost Time Accident through 11/2022.

we need to make safety personal to make our message more effective. THE SAFETY NET IT’S ALWAYS SAFETY FIRST. CONSULT • DESIGN • ENGINEER • CONSTRUCT When Safety Hits Close to Home 12.12.22 | EHS Today by Nicole Stempak

SAFE

5,281,434

Sometimes,

In my previous column, I shared some advice for making the most of safety conferences. Based on the positive feedback I received, it seems many of you can appreciate the need to make safety personal. That got me thinking about some of my own experiences with safety.

Back in 2019, I was working in a drafty building. It was so cold that the office manager ordered personal heaters for any employee who wanted one. I got a personal heater but had to move some things around so that I could plug the space heater directly into a wall outlet.

Once I did, I started walking around cubicles and instructing my colleagues to do the same. I was surprised that no one else had seen the videos of fires caused by space heaters plugged into power strips, extension cords or outlet extenders. I mentioned it to my friends, and one taught me that electric blankets and electric mattress toppers need to be plugged into the wall as well. It can seem like a minor detail. It can even seem like an inconvenience to rearrange furniture and dedicate precious electrical wall outlet space to these devices. But now, I recognize what’s at stake, and I realize I have a responsibility to do better and help others, too.

I am embarrassed to think about how I didn’t always practice electrical safety when I was a college student living in the dorms. My alma mater, as I imagine happens at other universities, had strict requirements about what you could and couldn’t bring into the dorms. Some of those restrictions were common courtesies or for hygienic purposes, such as no amps to play loud music or house pets, but the majority were focused on electrical safety. Our dorms came with mini fridges and microwaves. We could bring blenders, coffee makers and toasters but not George Foreman grills or hot plates. My roommates and I brought them anyway—and hid them when not in use to avoid confiscation during a random inspection.

From our student perspective, we wanted a way to prepare food quickly and easily in our rooms. We didn’t always want to go to the cafeteria or even the dormitory kitchen, which required both time and equipment that we either didn’t have or didn’t want to bother with. Never mind the fact that those kitchens often had strange stains and lingering smells despite housekeeping’s best efforts.

I calculated the risks and determined the benefit of illicitly using a George Foreman to make a panini was worth it.

I did, at least, unplug it immediately after use. Now that

I’m older (and perhaps a little wiser), I understand that the university imposed those rules keep us safe.

I also remember how the residence hall fire alarms were so sensitive that microwave popcorn often prompted evacuations and a visit from the local fire department. It was an annoying disruption at the time, but fortunately there was never a fire in my dorm.

Once, there was an actual fire in another dormitory hall. Several students lost their belongings, either because of the blaze or the water used to douse it.

The fire was the result of a floor lamp. According to reports, the lamp was knocked onto a beanbag and covered by clothing while turned on and caught flame. It was an accident, but it also opened my eyes to electrical hazards.

I probably shouldn’t admit my past safety transgressions to a bunch of experienced professionals, though I suspect you see them on a daily basis. You might even feel like you

could turn blue in the face for all the educating you do to prevent or avoid accidents. It may seem an impossible task, but please don’t give up. We desperately need you, even if we don’t realize it or express our gratitude (at least, not in the moment).

I hope you’re able to help protect colleagues, friends and family from the many hazards out there. One way to help your message resonate is to bravely share your own bad examples, as I have done above.

Sometimes, the rules are sufficient. Sometimes, the rewards and incentives are enough to change behaviors. Other times, we need to hear others’ mistakes.

We owe it to others, and ourselves, to never stop trying to make safety personal—even if that means admitting our own faults—to make the workplace better for all.

Project Candlelight

3

Left to right - John Helton, Tony Goodeaux, Tom Morris, Kyle Perciak, Sherdric Grant, Ervin McCarroll, Craig Herndon and Charlie Engel taught an OSHA 30 Hour class at our Kankakee Illinois – Project Candlelight.

Every Austin employee assigned to a project full time (Eastern, Western and West Michigan offices) has their OSHA 30 Hour or equivalent.

5 Ways Automated Maintenance Can Improve Workplace Safety

12.02.22 | EHS Today by Bryan Christiansen

12.02.22 | EHS Today by Bryan Christiansen

Computerized maintenance management systems can enhance safety in the maintenance field, offering EHS professionals another tool to help create a safer workplace. Establishing a robust maintenance strategy is critical for optimizing facility safety.

Companies invest in advanced technologies to simplify, standardize and improve the quality of maintenance work using digital solutions, such as Computerized Maintenance Management Systems (CMMS). The technology provides multiple features for managing maintenance workflows, personnel, facility layouts, inventory and critical maintenance data — all resulting in improving safety features for employees.

CMMS solutions collaboratively work with other enterprise solutions and are applicable across industries and facilities. The market for this technology is expected to reach $1.72 billion by 2028 , indicating the technology’s significance in enhancing asset productivity and safety standards in facilities.

Modern maintenance operations are anchored in data. Technicians require equipment operating metrics to create maintenance schedules, allocate budgets and quantify asset effectiveness.

Safety professionals should learn how these automated maintenance solutions work and ways to utilize different sets of maintenance data, collected and analyzed by the systems, to improve workplace safety and automate risk analysis. These systems keep detailed logs of all maintenance activities, including the mean time between repairs; parts used; and the requester, approver and implementer of preventive or corrective maintenance. They also keep records of deferred or incomplete tasks. These solutions can significantly enhance safety in the maintenance field, thus reducing workplace accidents and illnesses . Here are five ways maintenance professionals can leverage CMMS technology to improve workplace safety.

1. TRACKING COMPLIANCE WITH SAFETY REGULATIONS

Companies must comply with multiple statutory regulations that dictate safety and mandatory operation standards targeting production assets, personnel and operating procedures. Supervisory authorities conduct frequent audits and inspections to verify compliance. Proper maintenance is vital for enhancing facility and asset compliance with multiple regulations, such as emission levels, energy consumption and security.

CMMS systems assist maintenance teams in tracking all the maintenance tasks required to achieve the required and/or recommended safety and compliance standards. Technicians incorporate mandatory inspection tasks into routine maintenance schedules. The systems generate alerts when these inspections are due as well as allocate the tasks to the available technicians.

The system tracks and standardizes the implementation of these tasks. It contains standard templates that allow maintenance teams to document inspections following industry standards. The maintenance team sends all safety reporting and inspection data to a centralized data management system for approval and storage. Field technicians can report incomplete maintenance activities, emerging safety risks and inadequate inspection tools and spare parts.

Companies can share regular inspection data with relevant regulatory authorities for evaluation and verification. Centralizing data allows remote access to it, meaning senior management can establish measures to rectify impending compliance issues before external auditors visit facilities. Safety professionals can use computerized maintenance data to track and enhance facility compliance with environmental, health and safety regulations.

2. STANDARDIZING MAINTENANCE SAFETY PROCEDURES AND POLICIES

The scale and complexity of maintenance activities vary from one facility to another. On a daily basis, maintenance technicians are exposed to a number of hazards, such as unguarded machinery, fires, falls from heights, trips, hazardous emissions and electrical hazards. These hazards impede the quality and rate of maintenance work completion. Some equipment parts are hard to reach, increasing maintenance workloads and injury risks.

CMMS solutions can reduce maintenance workloads and exposure to these hazards. Companies can develop standard operating procedures (SOP) and host them on the CMMS platform. The SOP contains checklists, lock-out/ tag-out (LOTO) measures and sequential procedures that technicians must complete before performing physical work. The system also holds comprehensive maintenance manuals that technicians can refer to when maintaining assets as well as standard technical documents to record maintenance.

Safety professionals working with maintenance staff can periodically evaluate the relevance of existing safety policies and procedures. They can compare how the standard procedures impact maintenance work

completion, accuracy and safety. This allows safety professionals to develop more effective policies that guarantee maximum employee and equipment safety. These solutions assist safety personnel to remotely update and share additional safety information. This means that policy changes can be made faster and cheaper, ensuring everyone reads from the same page regarding the company’s latest safety standards.

3. AUTOMATING AND OPTIMIZING MAINTENANCE SCHEDULES

A faulty asset is prone to breakdowns and failures that can injure operators, release toxic materials and energy into the environment, or initiate fires and other workplace accidents. Some companies experience frequent asset breakdowns accompanied by heavy maintenance workloads due to a lack of a proper maintenance schedule. Implementing appropriate maintenance measures reduces the severity and frequency of these failures. Proper maintenance also extends an asset’s life, increases efficiency and improves safety.

Companies can enhance operational safety by investing in an automated maintenance solution. The technology stores information about each asset, its maintenance requirements and maintenance frequency. Manual maintenance management in a facility with multiple physical assets can be challenging, as planning can take longer than expected and can lead to inadequate or deferred maintenance.

In contrast, computerized technology automates maintenance scheduling and work allocation. Managers can easily automate the creation and distribution of maintenance schedules; prioritize and approve work orders; and store, retrieve and analyze work tickets.

By optimizing maintenance schedules, companies ensure all assets receive the appropriate preventative and corrective measures as well as avail enough personnel to perform these tasks. Safety personnel receive timely alerts regarding scheduled and emergency maintenance, helping them to prepare the necessary safety signages, assign safety supervisors to various maintenance teams, distribute personal protective equipment (PPE) and prepare the appropriate safety checklists.

4. TRACKING MAINTENANCE RISKS AND AUTOMATING SAFETY AUDITS

Maintenance technicians are regularly exposed to a range of risks in their line of duty. Some safety risks are recurring; ...continued on next page

5

others happen once and can result from poor work practices, faulty tools or deliberate violations of safety rules.

Technicians must report all safety-related incidents irrespective of their severity or consequences. Some safety risks may arise due to outdated maintenance procedures and technologies, incorrect tools and PPE usage, or failure to conduct a comprehensive root cause analysis.

Automated maintenance technologies can help record and track safety risks and incidents across the facility. Companies distribute the technology through handheld devices, and technicians can remotely log these issues without leaving their workstations.

A CMMS solution accommodates audio, video and text content, so maintenance teams can provide additional evidence to explain risk levels and inform other team members. The company can maintain a comprehensive database of all maintenance risks across the facility. The data is vital for automated safety audits and for developing relevant safety training programs.

Safety audits take time to complete since they are the result of combining information from different sources. Safety personnel with access to CMMS data can gain insights into common safety issues faced by maintenance personnel in the field, which can help them quickly evaluate the effectiveness of incident-reporting systems. These solutions use standard safety reporting templates, making it easier for safety auditors to determine the cause, propagation and impact of several maintenance-related risks.

5. ENHANCING SHOP FLOOR LAYOUTS FOR BETTER MAINTAINABILITY

Maintenance safety risks do not emanate solely from work practices and machinery. Facility layouts and designs can impact maintainability and workplace ergonomics, as it is more difficult for technicians to work in a poorly-organized workspace.

All machinery and safety signs should be visible from a distance, walking paths should be marked, confined spaces well-lit and ventilated, and emergency exits and facilities should be visible and easily accessible.

When uploading facility data to a CMMS solution, companies can also upload facility layouts. Such measures ensure everyone in the maintenance team knows where a particular asset or piece of safety equipment is located. Ergonomics and design experts can also evaluate these layouts and highlight safety risks based on the organization of the shop floor. They can compare the effectiveness of different floor layouts and their impact on the maintainability of assets.

Companies reorganize floor layouts with the acquisition of new production assets and process modifications. Safety personnel work collaboratively with process engineers and technicians to evaluate hazards and risks that impede asset productivity and equipment maintainability in order to develop friendlier layouts and eliminate safety risks.

ANOTHER TOOL IN THE SAFETY TOOLKIT

While CMMS solutions are designed to automate maintenance workflows, they can be beneficial for enhancing facility safety, too. Safety professionals should have some working knowledge of CMMS solutions so they can access and analyze vast amounts of maintenance data to develop more effective safety policies; promote positive safety culture among maintenance technicians; automate and simplify safety audits; and improve cross-departmental communication. These solutions can become a key tool for EHS professionals to improve workplace safety. They should work closely with maintenance personnel when conducting safety audits and to customize CMMS solutions that can help reduce and eliminate maintenance-related safety issues.

Bryan Christiansen is the founder and CEO of Limble CMMS, a modern and mobile software solution that helps managers organize, automate and streamline their maintenance operations.

CPWR: Construction Industry Accounts For About Half Of Job-Related Electrical Deaths

11.21.2022 | Safety + Health

Silver Spring, MD — Roughly half of the fatal workplace injuries related to electricity exposure in a recent 10-year period occurred in construction, according to a new report from CPWR – The Center for Construction Research and Training.

Using 2011-2020 data from the Census of Fatal Occupational Injuries , researchers identified 1,501 fatal occupational electrical injuries in all industries. Of those, 49.1% involved construction workers. Additionally, 24.4% of nonfatal electrical injuries occurred in construction. CPWR says the industry employs 7% of the U.S. workforce.

Overall, fatal injuries were more often a result of direct exposure (58.8%) than indirect (38.9%). Direct exposure is associated with contacting a live wire, while indirect exposure may include operating a crane that touches a power line.

The researchers also analyzed OSHA enforcement data. Among their findings:

• In 2020, establishments with fewer than 10 employees accounted for 71.5% of OSHA citations for violations of federal electrical standards, while comprising 81.4% of all establishments.

• By North American Industry Classification System code, 70.5% of citations for electrical standards involved specialty trade contractors; the NAICS code for construction of buildings (26.1%) and heavy and civil engineering construction (3.4%) followed. Specialty trade contractors accounted for 71.1% of fatal electrical injuries.

• OSHA citations for violations of federal electrical standards decreased 73.5% from 2011 to 2021. Electrical standard citations comprised 2.7% of citations in construction in 2021 – down from 6.5% in 2011.

7

How to Protect Temporary Workers

11.30.2022 | EHS Today

OSHA has developed a resource “Protecting Temporary Workers: Best Practices for Host Employers,” that’s tailored to the needs of host employers.

Keeping temporary workers safe is always an issue. To address this an article on NIOSH’s Science blog offers some research ideas and resources on how to address this issue.

In accordance with regulations from OSHA, “host employers and staffing companies are jointly responsible for protecting the safety and health of temporary workers.” However, the authors note, there is “often confusion regarding the respective safety and health responsibilities of each employer and a general lack of clarity regarding the best ways to protect and promote the safety and health of temporary workers. “

To make the point of how important this issue is, the article includes an example of how a tragic accident could have been avoided.

A 28-year-old temporary worker was employed by a staffing company to work as an equipment cleaner at a food manufacturing plant. He died when rotating machine parts pulled him into the machine causing fatal injuries.

How was it preventable? The host employer’s procedures for cleaning the equipment were unsafe, including steps in which cleaners worked near the machine while it was energized and parts were moving. The host employer should conduct regular job hazard analyses to identify potential hazards and develop, implement, and enforce a hazardous energy control (lockout/tagout) program during the cleaning process.

Furthermore, while the host employer’s permanent employees were trained on procedures to ensure workers were not exposed to energized equipment during maintenance or cleaning, the host employer did not provide this training to cleaners employed through the staffing company. According to OSHA, in most cases, the staffing company should provide general safety and health awareness training, and the host employer should provide site- and task-specific safety and

health training that is equivalent to the training provided to the host employer’s permanent workers performing the same or similar work.

(Source: Massachusetts Fatality Assessment and Control Evaluation (FACE) Program, 11MA050)

RESEARCH

Research demonstrates that temporary workers experience higher injury rates compared to permanent (non-temporary) workers and offers several reasons for this.

Temporary workers are often new to the job, which is a known risk factor for occupational injuries and illnesses.

Temporary workers also tend to be younger than permanent workers, and younger workers experience higher rates of injuries on the job compared to older workers.

• In one study, over 40% of temporary workers reported never receiving safety training from either their staffing company or host employer, compared to 25% of permanent workers.

RESOURCES

OSHA has developed a resource Protecting Temporary Workers: Best Practices for Host Employers , that offers best practices tailored specifically to the needs of host employers. The document provides information on:

• Evaluating and addressing workplace safety and health in a written contract

• Training for temporary workers and their worksite supervisors

• Reporting, responding to, and recordkeeping of temporary worker injuries and illnesses

The document also includes checklists that can be printed or completed electronically and scenarios illustrating how the best practices might be implemented.

9

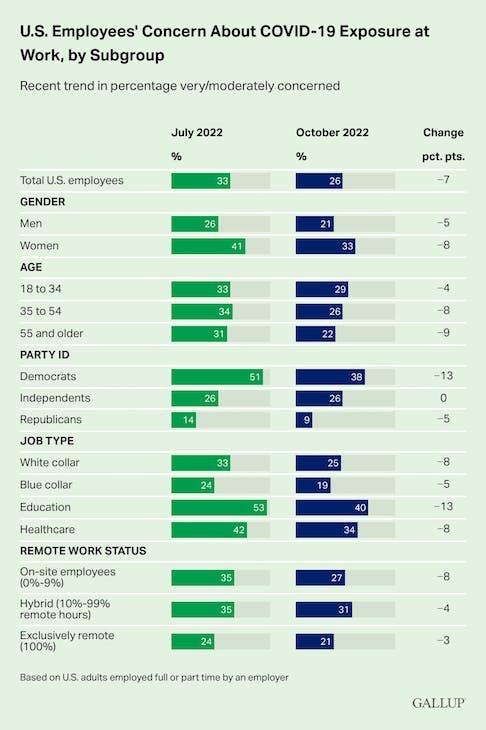

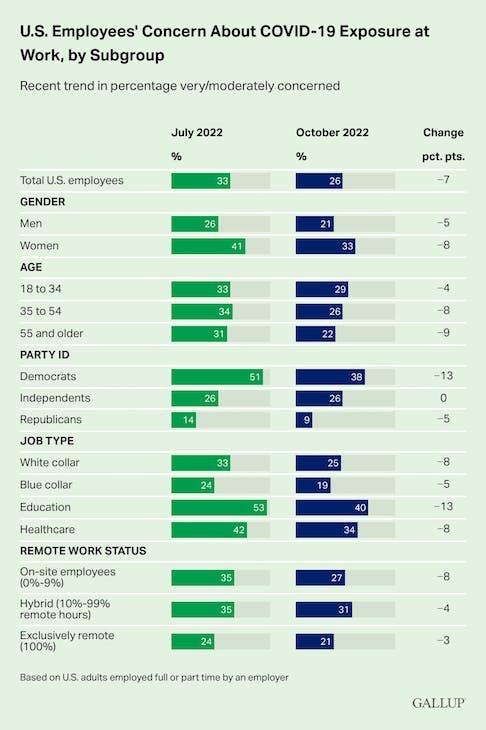

People Still Worried About Catching COVID at Work

12.07.2022 | EHS Today

A recent Gallup poll found that one in four still say they are “very” (6%) or “moderately” (20%) concerned about being exposed to the coronavirus at work.

COVID-19 has not disappeared.

In fact, cases are on the rise again. According to a New York Times, tracking tool the average test positivity rate is up 40% as reported by Barron’s on Dec. 5.

Hospitalizations are up as well. For the week ending on Nov. 29, the CDC’s latest data shows that there was a 17.6% increase in new hospital admissions compared to the week prior, as reported by COVID hospitalizations have reached in the last three months, according to Yahoo.

“If we are going to see a big [COVID] surge, it’s going to start to ramp up now,” Jeffrey Shaman, Ph.D., an epidemiologist at Columbia University, told the newspaper. “And it’s going to extend and probably peak in late December and early January.”

This uptick has sparked discussions in California about bringing back mask mandates. During a press conference

on Dec. 1, LA County Public Health Director Barbara Ferrer said that the largest county in the US had reached “medium” COVID-19 transmission levels and will require face coverings if it reaches the “high category”, as reported by ABC News .

Workers have been keeping an eye on this and back in November, a Gallup poll found that nearly two-thirds of employees (64%) said they expect COVID-19 infections in the U.S. to increase in the upcoming fall and winter months. The research showed that 14% of workers expect infections to increase “a great deal” and 50% “a moderate amount,” while just 8% think infections will decrease and 29% think they will stay the same.

With that in mind employees still fear that they are concerned about being exposed to the virus at work. While the numbers have decreased, about one in four still say they are “very” (6%) or “moderately” (20%) concerned about being exposed to the coronavirus at work, while a third are “not too concerned” and 41% are “not concerned at all.”

11

Warning: The Workplace Could Be Hazardous to Your Mental Health

| EHS Today by Dave Blanchard

The Surgeon General is urging companies to be proactive in protecting their workers’ well-being.

When I was a kid, I used to think that the U.S. Surgeon General was a doctor who treated all the senior officers in the U.S. Armed Forces. As I got a little older, and I figured out there was no connection to the military in the role, I got a clearer idea of who the Surgeon General was—namely, the person who put all those warning labels on cigarette packages. Those warnings, in fact, were quite effective in keeping me from smoking; not so much, unfortunately, in my dad’s case.

According to the Department of Health and Human Services, the US Surgeon General is “the nation’s doctor, providing Americans with the best scientific information available on how to improve their health and reduce the risk of illness and injury.” That job description is even more impressive than the imaginary one I concocted in my youth.

The current Surgeon General, Dr. Vivek Murthy, has largely been focused on the pandemic for the past few years, and lately he’s been particularly concerned about its lingering effects—not just the physical nature of the virus, but also its impact on mental and emotional health as well. In October 2022, Dr. Murthy’s office released a Framework for

Mental Health & Well-Being in the Workplace, which is said to be the first time a Surgeon General has issued a report specifically addressing workplace mental health.

“A healthy workforce is the foundation for thriving organizations and healthier communities,” said Murthy in announcing the framework. “As we recover from the worst of the pandemic, we have an opportunity and the power to make workplaces engines for mental health and well-being, and this framework shows us how we can start. It will require organizations to rethink how they protect workers from harm, foster a sense of connection among workers, show workers that they matter, make space for their lives outside work, and support their growth. It will be worth it, because the benefits will accrue for workers and organizations alike.”

In explaining the need for workplaces to increase their vigilance on promoting mental health, Murthy cited several disturbing workplace statistics:

• 76% of U.S. workers last year reported at least one symptom of a mental health condition (such as anxiety or depression). Prior to the pandemic, the percentage was 59%.

12.06.2022

• 81% of workers anticipate seeking work at organizations that support mental health

• 84% of workers have experienced at least one workplace incident that has had a negative impact on their mental health.

The framework maps out five essential areas that employers should focus on to contribute to a culture of workplace safety (see sidebar below, “How to Support the Mental Health of Your Workers”). In fact, as we noted in EHS Today’s Mental Health in the Workplace Report, companies must do a better job of allocating resources to prioritize mental health awareness, support and treatment. Substance abuse, workplace violence and major depressive episodes have markedly increased since the onset of COVID, and yet nearly 30% of the 1,100 people surveyed for the report say that their companies still devote much more attention to protecting employees’ physical health than their mental health.

As an advocate for the nation’s youth, Murthy has helped raise the general public’s awareness of the mental health crisis in school-aged children, and it’s hoped that the workplace framework will contribute to a heightened sense of alarm among all employers. Safety leaders have long known about the importance of protecting their workers from dangers both external and internal, and having the Surgeon General’s imprimatur on the framework can go a long way in reinforcing the message that an organization’s

financial health is ultimately dependent on its employees’ mental and physical health.

HOW TO SUPPORT THE MENTAL HEALTH OF YOUR WORKERS

1. PROTECTION FROM HARM

• Prioritize workplace physical and psychological safety

• Operationalize diversity, equity & inclusion policies

2. CONNECTION AND COMMUNITY

• Foster collaboration and teamwork

• Cultivate trusted relationships

3. WORK-LIFE

HARMONY

• Make schedules as flexible and predictable as possible

• Respect boundaries between work and non-work time

4. MATTERING AT WORK

• Build a culture of gratitude and recognition

• Connect individual work with organizational mission

5. OPPORTUNITY FOR GROWTH

• Offer quality training, education, and mentoring

• Ensure relevant, reciprocal feedback

Source: US Surgeon General’s Framework for Mental Health & Well-Being in the Workplace

13

Survey Finds Reasons Employees Don’t Wear PPE

12.05.2021

| J.J. Keller

A survey of safety professionals found that the most common excuse given by employees for not wearing required personal protective equipment (PPE) was that they simply didn’t feel like wearing it.

The survey, conducted by J. J. Keller & Associates, Inc., also identified challenges with sizing, supply chain issues, and getting employees to wear PPE during hot days. But overall, the most common challenge was getting employees to wear PPE in the first place.

Respondents were asked to select the reasons for employee failure to wear PPE. They could choose multiple responses, so the results total more than 100%. Top reasons included:

• Just didn’t want to wear it: 72%

• Didn’t think it was necessary: 50%

• Made the job more difficult: 50%

ENCOURAGE THE RIGHT CHOICE

The top two responses suggest that employees make a conscious decision not to wear PPE. Getting them to think about their reasons for that choice and the potential consequences could help encourage the correct choice.

If employees refuse to wear PPE, they’re essentially choosing to accept the risk of injury. However, employees don’t have the authority to make that choice. Employers require PPE not only because it prevents injuries, but because federal regulations require employers to provide PPE and enforce its use.

At home, individuals may choose to accept the risks of certain behaviors, like mowing the lawn without hearing protection. At work, employees might think they’re smart enough to avoid injury, or think the odds of getting hurt are low and the risk is worth the benefit of not wearing PPE.

To encourage the right choice, employers might try one of the following approaches:

Impacts on others: Point out that an injury has consequences for the employee, the employee’s family, the company, and even the employee’s coworkers. By choosing to accept the risk of personal injury, they’re imposing the consequences on others. This is one reason employees don’t have the authority to make that choice. Remind them that every worker who suffered a lifechanging injury also decided to accept the risk.

Risk and reward: Acknowledge that the injury risk may be low, and that working carefully further reduces risk. Then, describe the potential injuries that could occur (like loss of an eye) and ask them to consider the impacts of those life-changing injuries. Finally, ask if the risk is worth whatever benefit they get from not wearing PPE. They may realize that they’re taking a big risk for a minimal reward.

What’s the benefit: Ask what benefit they get by not wearing PPE. Reasons might include comfort, fit, heat, loss of dexterity, or limited vision. Employers can usually offer something to mitigate or reduce those problems.

Although employees probably won’t admit it, some might refuse to wear PPE out of a desire for control. They may have thought, “I’m a responsible adult and can work without injury, so I don’t need to wear PPE.” Remind them that they don’t have authority to choose to accept the risk of injury and the consequences, and further, their families (as well as their employer) don’t want them to take that risk or pay that price.

15

Seasonal Flu

WORKPLACE SAFETY AND THE FLU

This page includes information for workers and employers about reducing the spread of seasonal flu in workplaces. It provides information on the basic precautions for all workplaces, including additional precautions for healthcare settings. Getting a flu vaccine is more important than ever during the COVID-19 pandemic to:

• Protect yourself, family, coworkers and other members of the community,

• Make the flu less severe if you get it, and

• Reduce the burden on our healthcare systems responding to the COVID-19 pandemic.

Health and Human Services’ Centers for Disease Control and Prevention (CDC) has updated guidance for protecting individuals from seasonal flu. Refer to this page for updates on the most recent seasonal flu vaccine. Each year the vaccine is revised to protect against the influenza viruses that research indicates will be most common this season.

VACCINATION RECOMMENDATIONS FOR

2022-2023

FLU SEASON

• CDC Recommendations

• Advisory Committee on Immunization Practices (ACIP)

• World Health Organization

QUICK FACTS ABOUT SEASONAL FLU

• Seasonal influenza (flu) can be transmitted year-round but is more common in the fall and winter seasons. Infections usually peak between December and February.

• Exposure to flu is more likely among certain occupations such as healthcare workers . General precautions are also recommended during flu season for non-healthcare workers

• Getting a seasonal flu vaccination is one of the most effective ways to prevent infection, and it can also reduce the severity and duration of illness.

• Good hand hygiene, cough and sneeze etiquette , and staying home when sick are also critical components of prevention.

• Improving ventilation can also minimize the inhalation of influenza, COVID-19, and other respiratory viruses that may be circulating. For additional information regarding protecting workers from COVID-19, please see OSHA’s COVID-19 Safety and Health Topics page.

• Because influenza viruses change frequently, worldwide monitoring by public health agencies is necessary to determine the predominant circulating strains. The CDC provides up-to-date information on U.S. flu activity

12.02.22 | EHS Today by Bryan Christiansen

12.02.22 | EHS Today by Bryan Christiansen