Quality is Our First Priority.

Consistent product quality and a proven track record makes Australian Pipeline Valve a dependable choice where total reliability is the number one concern.

Since its founding, APV’s philosophy has been focused on quality. Our valves are manufactured in full compliance to worldwide standards (such as ASME/ANSI, API, EN, ISO, BS, AS).

CORROSION RESISTANT

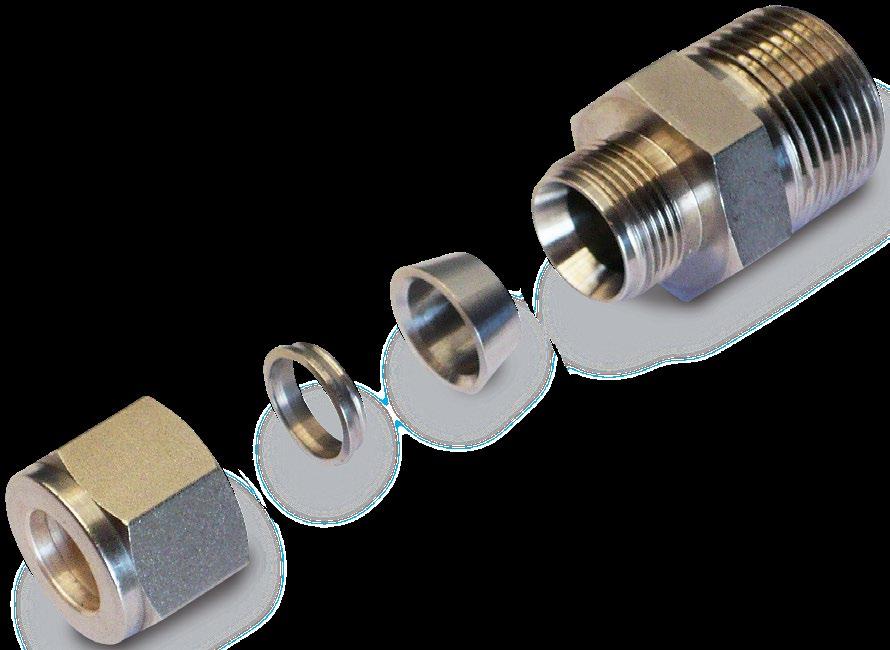

Ferrules have a very strong corrosion resistance because of the special hardening process used in manufacturing.

INTERCHANGEABLE

Tube Fittings are interchangable with market leaders with full Ferrule and nut interchangeability.

GAUGEABLE

Tube Fittings are manufactured in accordance with exacting tolerances which ensure a quality Tube Fitting.

CERTIFICATION

Twin-lok Tube Fittings are all batch tested and have been design tested for leakage. Full material certification can be supplied.

FEATURES

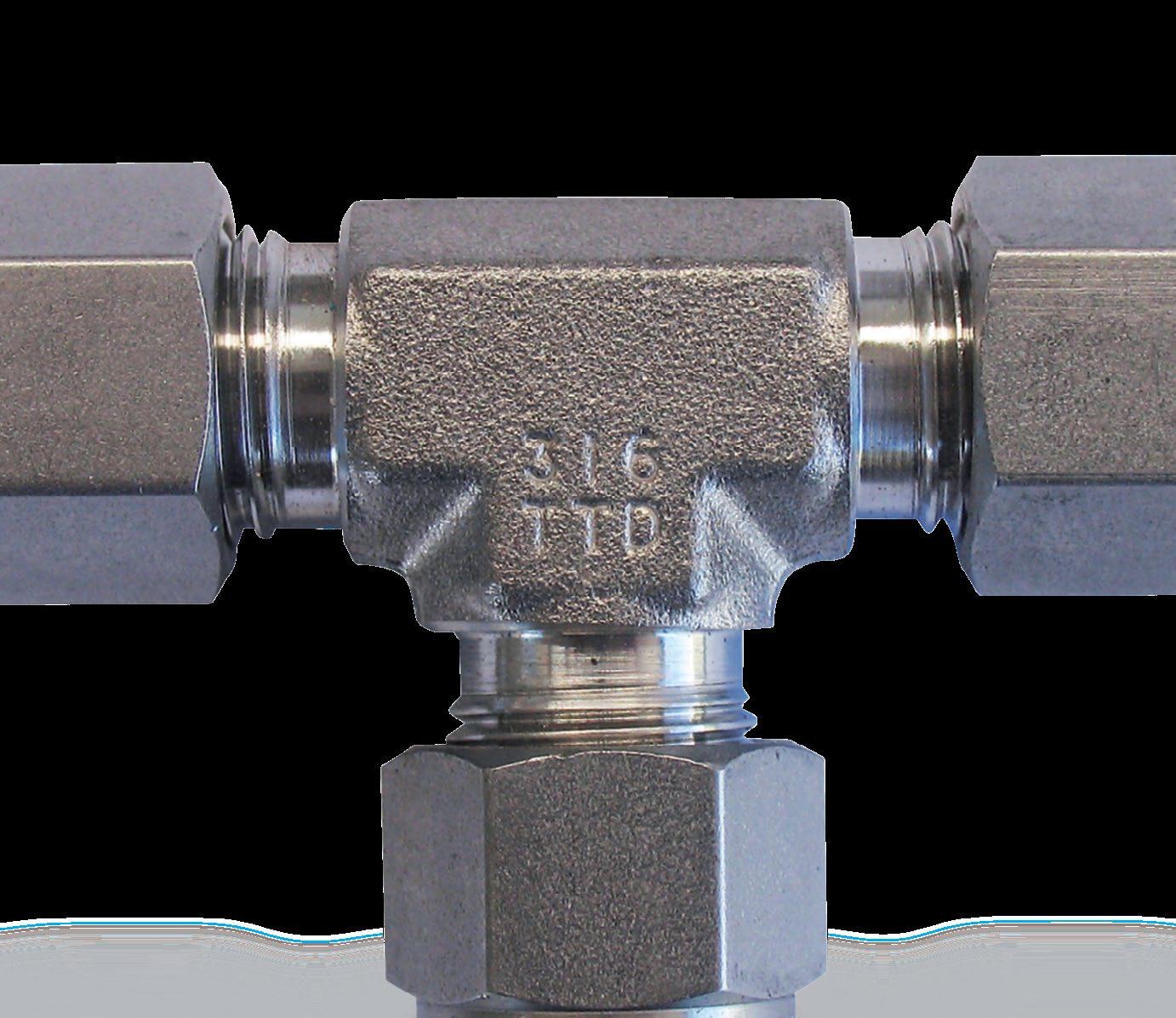

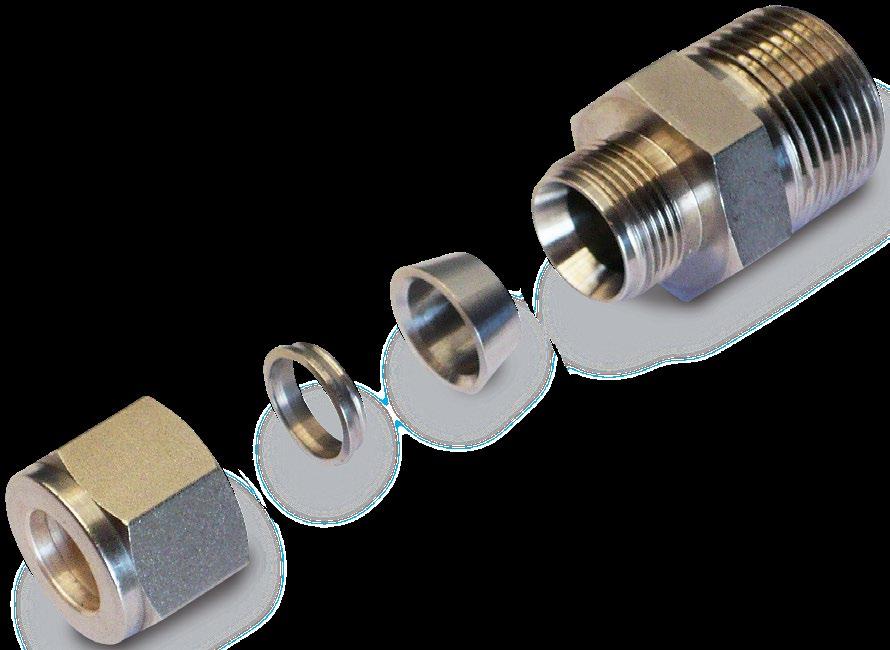

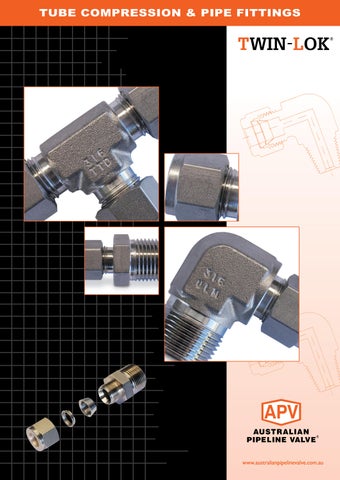

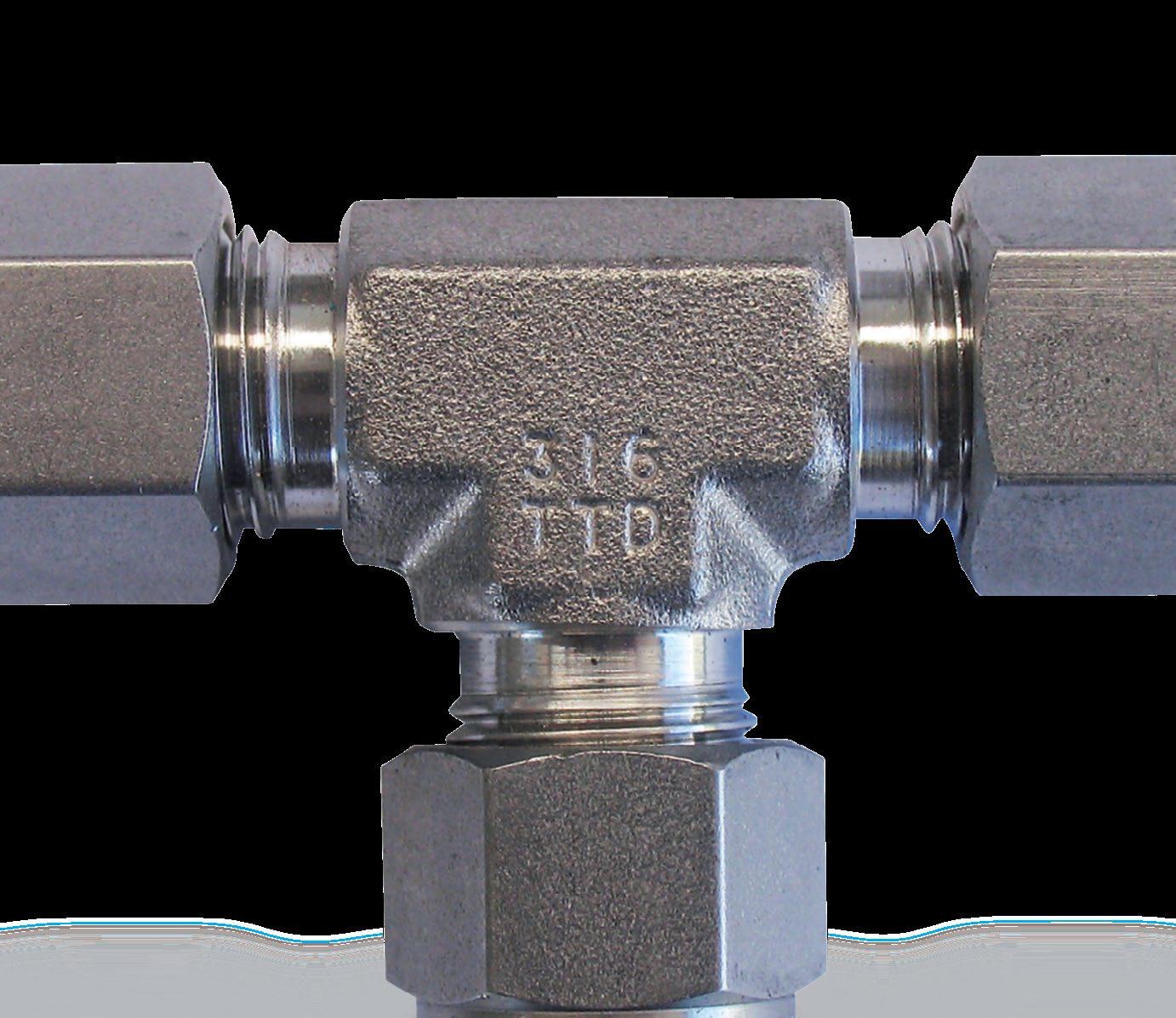

Twin-Lok compression Tube Fittings are manufactured to meet the specifications required for a wide range of applications in hydraulic, chemical, process control, petrochemical and instrumentation. The tube fittings are composed of four parts: body, front ferrule, back ferrule and nut. The twin-ferrule design compensates for any tolerances in tube O.D., wall thickness, material hardness and assures leak-proof connections.

MATERIAL

Tube fittings are available as standard in 316 Stainless Steel. Straight fittings are machined from bar stock & shaped bodies from forgings.

DIMENSIONS

Tube fittings are supplied in metric and fractional sizes from 6mm to 25mm or 1/8” to 1” available with NPT, BSPT and BSPP threads.

Twin ferrule tube fittings (also available in single ferrule style) Fully interchangeable with both Market Leaders

Size [where different] (I-Imperial M-Metric)

Screwed/Special End Modifier Suffix Twinlok* Identifier

Indicates Fully Interchangeable Clone

316 Stainless Steel

316L Stainless Steel

Aluminium M4 Alloy 400

INC6 Alloy 600

A625 Alloy 625

A825 Alloy 825

A2507 Alloy 2507

Alloy C-276

6-Moly

Titanium (Grade 4)

Brass

Carbon Steel

PTFE

for NPT

for BSP Taper/ISO

for BSP Parallel/ISO

for SAE Straight

for SAE Straight with O-seal

for AN Flare Fitting

for Tube Socket Weld

Male Pipe Weld Imperial

Male Pipe Weld Metric

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

Dimensions

Dimensions for reference only, subject to change.

Dimensions

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

DESIGN

TWINLOK® precision Instrument pipe fittings and adapters are designed and manufactured to very stringent tolerances under rigid quality control procedures approved to ISO 9001:2000 to provide leak free connections for chemical, petrochemical, processing plants, oil, gas and power generation industries, etc..

MATERIAL

TWINLOK® precision pipe fittings and Adapters are available as standard stainless steel 316. The raw materials used confirm to chemical requirements listed in specification below.

a) Bar Stock

ASME-SA-479 Type 316-SS

BS970 316-S31

DIN 4401

ASTM A276 Type 316

b) Forgings

ASME-SA-182 316

BS970 316-S31

DIN 4401

TWINLOK® Stainless steel 316 precision pipe fittings are heat code traceable back to the original mill heat from which it was made.

• Sizes ranges from 1/8” through 1”.

• Pipe threads

NPT (National Pipe Taper) and exceed the requirement of ANSI B1.20.1. (thread sealant is required)

All exposed threads protected with plastic caps to prevent damage and packed in sealed, clear plastic bag for cleanliness.

• Working pressures calculated in accordance with power piping code ANSI B31.1 and refiner piping code ANSI B31.3.

• Straight fittings machined from Bar Stock.

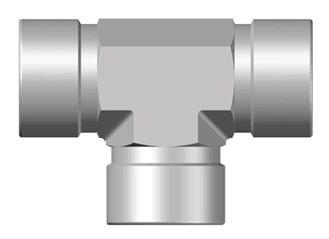

• Elbows, Tees and Crosses machined from close grain forgings.

Fitting Type Model Code 3

Adaptor Straight

Adaptor Reducing HCG Coupling Straight HCRG Coupling Reducing E Elbow Female ME Elbow Male SE Elbow Street

HP Plug Pipe Hollow

P Plug Hex HN Nipple Straight HLN Nipple Long HRN Nipple Reducing

RB Reducing Bush

T Tee Female Equal

ST Tee Street

Threaded Seal

Viton O-ring

Buna O-ring

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

Dimensions for reference only, subject to change.

The CAV-3 check valve is a one piece body machined from bar stock and is designed for minimum pressure drop. The valve has a light weight compact design that provides maintenance-free dependable service. 10,000 PSI Model also available to 2”

Flowturn 40 Series 3 way L-port Ball Valves, are a rugged compact design, offer positive shut off or directional control of fluids in process, power and instrumentation applications. The unique design ensures excellent sealing characteristics while accomodating a superior temperature range and cycle life.

A high integrity metal to metal bonnet anti ingress seal ensures leak tightness at high pressures up to 413 Bar (6000 PSI). These valves are available in two-way and multi-way 3/4/5 configurations in brass, 316 stainless steel, Monel and Inconel construction, with a wide variety of port connections. A trunnion mounted version with Kel-F or Polyaman or metal seats is available for higher pressures up to 689 Bar (10,000 PSI).

• 6~25 NB (1/4”~1”)

• Uni-Body, multi gland seal design*.

• L-port.

• Broad temperature range.

• Blow out proof stem.

• Available in one piece stem/ball*, floating ball.

• Panel mountable option.

• Bi-Directional flow.

• Handle indicates preferred direction of flow.

• Positive handle stops.

• 100% factory Nitrogen tested.

• Low operating torque.

• Vent option.

• Manual, electric or pneumatic actuation.

• Screwed tube fitting ends.

• Option - also available with 316SS handle and locking device

* Refer to drawing, several design options available.

MATERIAL OF CONSTRUCTION

• Ingress seals fitted as standard

• Flexible packing for replacement can extend field life further.

• Full material traceability of main components.

• Materials of construction can be supplied to meet the requirements of NACE MR-01-75 latest revision.

8

9

10

11 Packing

Also refer to pressure temperature ratings of elastomers (such as Viton and Buna) and the overall pressure rating of the valve design itself, can reduce the pressure temperature rating of the valve.

3-way,

(1/4”~1”)

compression - Twin Ferrule

(Male / Female)

MODEL FCV3 (ONE WAY)

3000 SERIES

Available Size 1/8” to 1/2” pipe thread.

Pressure Rating Up to 16 bar [232psi]

Temperature Rating Up to 120OC

End Connection

BSP/BSPT/NPT/SAE Straight Thread

• Bifold style

• Side fixing panel or mount option.

MATERIAL OF CONSTRUCTION

4000 SERIES

Available Size 1/8” to 1/2” pipe thread.

Pressure Rating Up to 40 bar [580psi]

Temperature Rating Up to 120OC

End Connection

BSP/BSPT/NPT/SAE Straight Thread

8 Valve Body

(1) Adjustable Nut set to maximum travel. (3) Variable controllable open position.

Allows direct exhaust of compressed air due to increase of cylinder rod displacement speed, this result in reductions of cycle time.

Available Size 1/8” to 1/2” pipe thread.

Pressure Rating Up to 10 bar [145psi]

Temperature Rating Up to 120OC

Sealing Material Viton

End Connection BSP/BSPT/NPT PIPE Threads

MATERIAL OF

DIMENSIONS MM & KG

Twinlok Vent Screens protect from dust, dirt, and insects. Twinlok Vent Screens and Bug or ‘Mud Dauber” Screens are manufactured from 316 Stainless Steel. Threaded into an exhaust or inlet port they offer effective protection against the ingress of dirt, dust, and insects with minimal effect on flow. The function of the Twinlok Vent Screen is based on a specially designed stainless steel wire mesh.

DESIGN

Low profile

High mechanical resistance

Exceptional corrosion resistance

Construction 316 stainless steel body

Service Pneumatic to 6000 psi (413.7 bar)

Function Dust and bug screen

Port Sizes 1/8” to 1” NPT

Style Side-ported

“Australian Pipeline Valve produces isolation, control and flow reversal protection products for severe and critical service media in utility, steam, pipelines, oil & gas and process industries. APV valves and pipeline products form the most competitive portfolio in the market.”