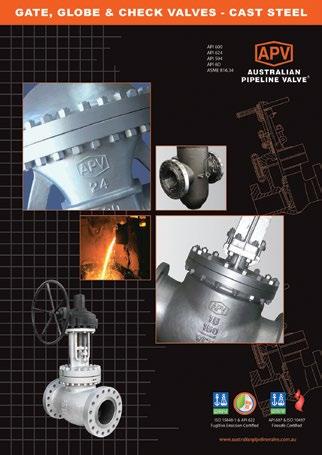

QUALITY COMMITMENT

Quality is Our First Priority.

Consistent product quality and a proven track

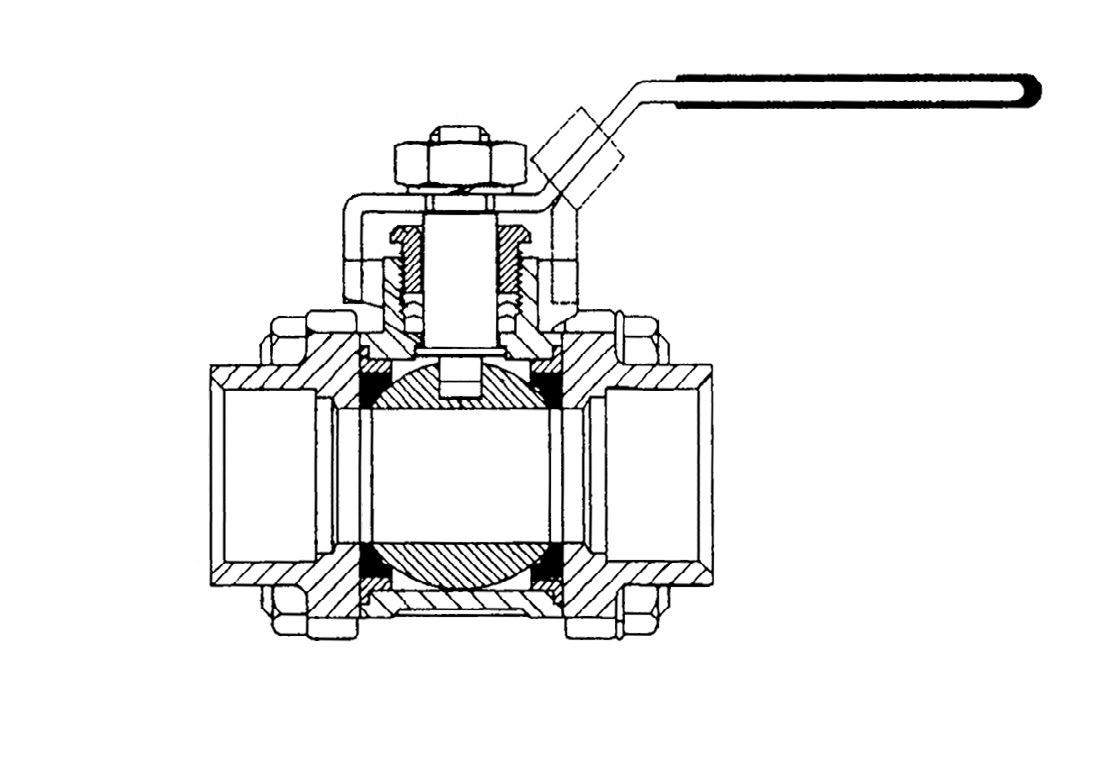

FEATURES

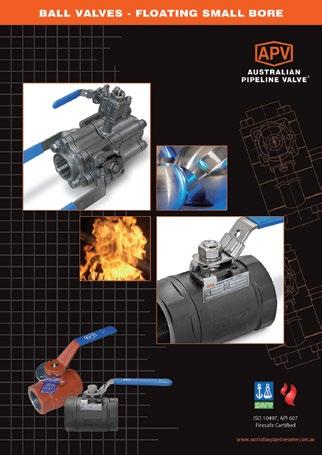

• L190 1000PSI, L197 2000PSI up to 50NB.

• Reinforced TFE seats increase durability.

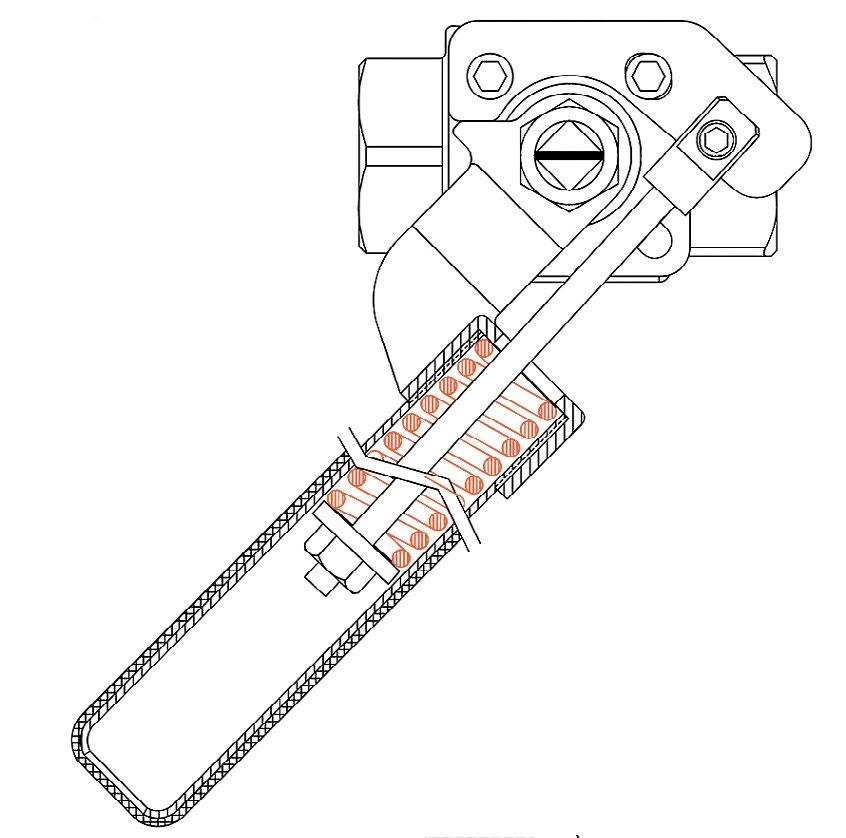

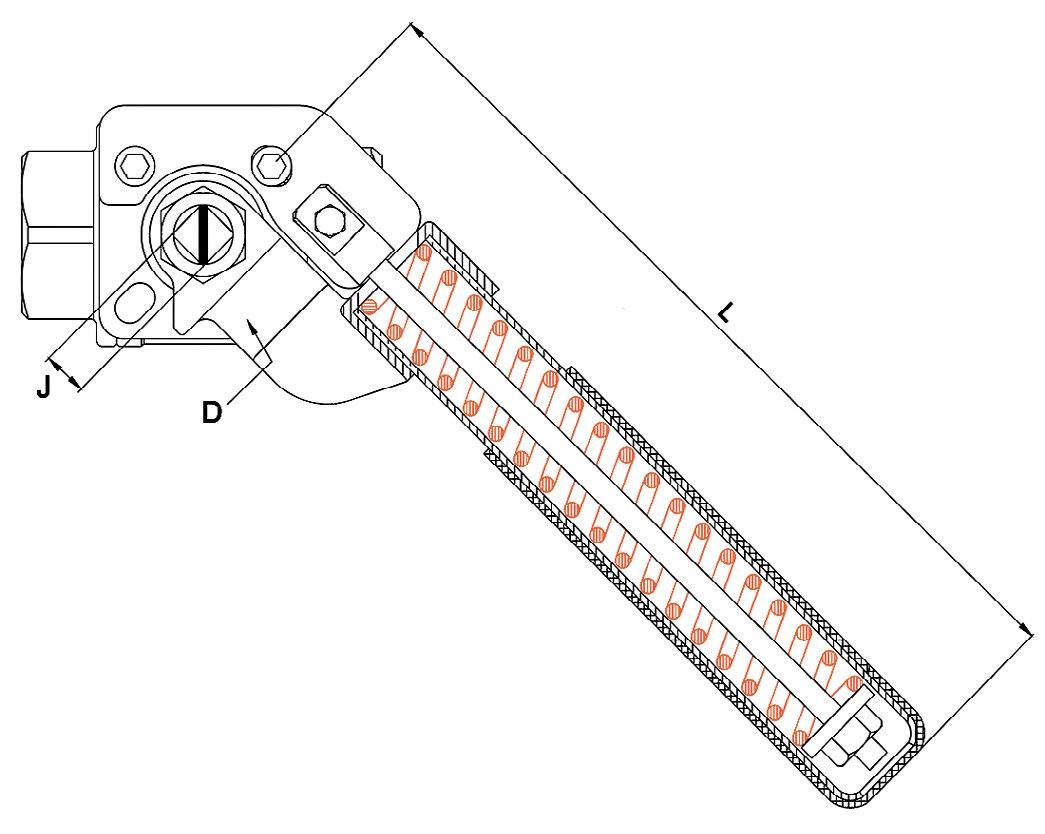

• Self adjusting Belleville packing spring.

• Bottom-loaded blow-out proof stem.

• NPT threaded ends complies with ANSI B1.20.1.

• BSP threaded ends complies with BS 21, ISO 7/1.

• Tested according to MSS SP-110/API 598.

• Optional Mount Pad.

OPTIONS

L Locking Device

V Vented Ball

P Equipped with Pneumatic Actuator

M Mounting Pad

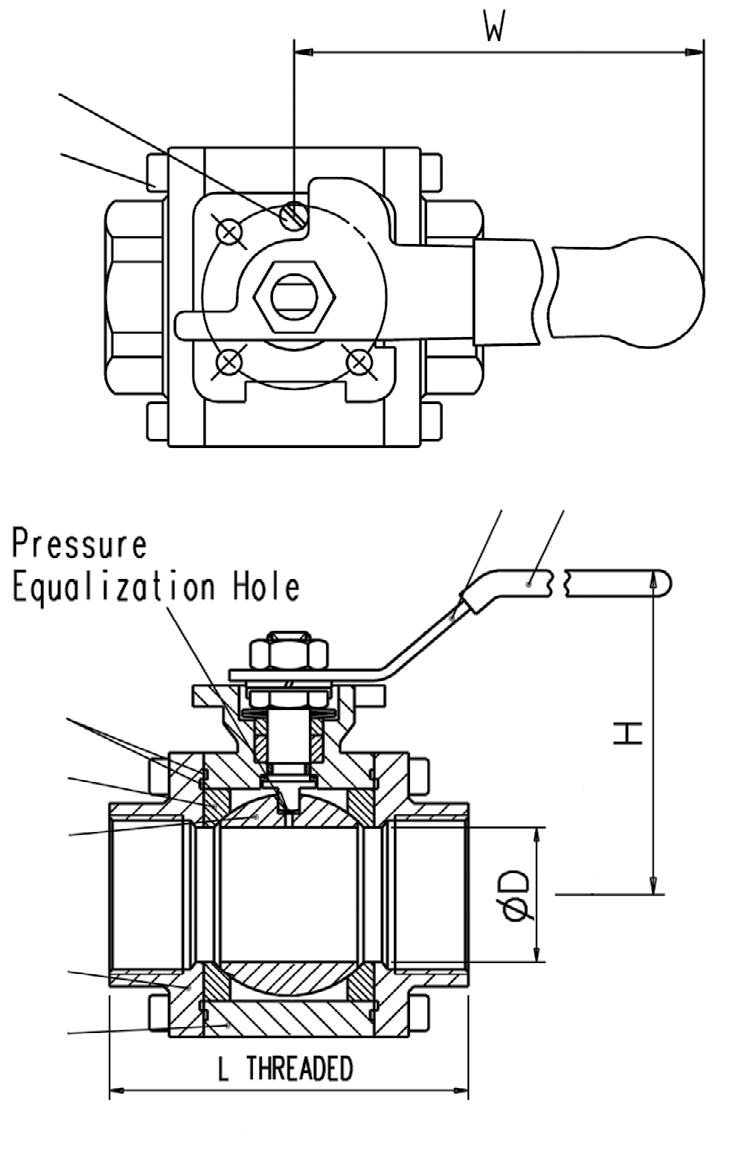

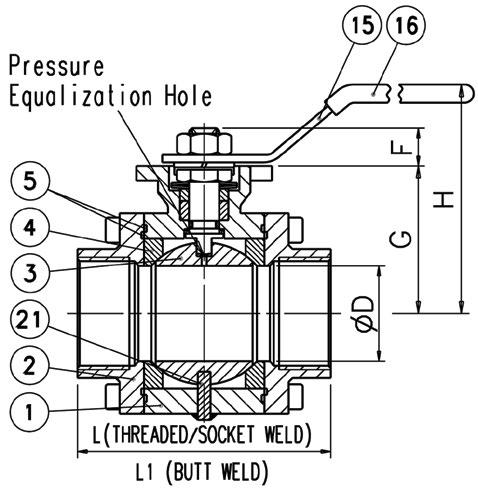

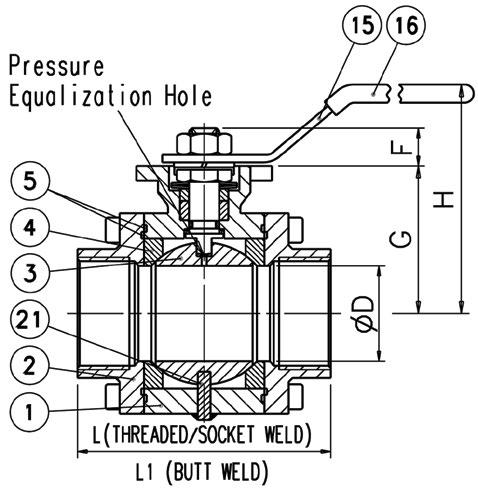

DIMENSIONS

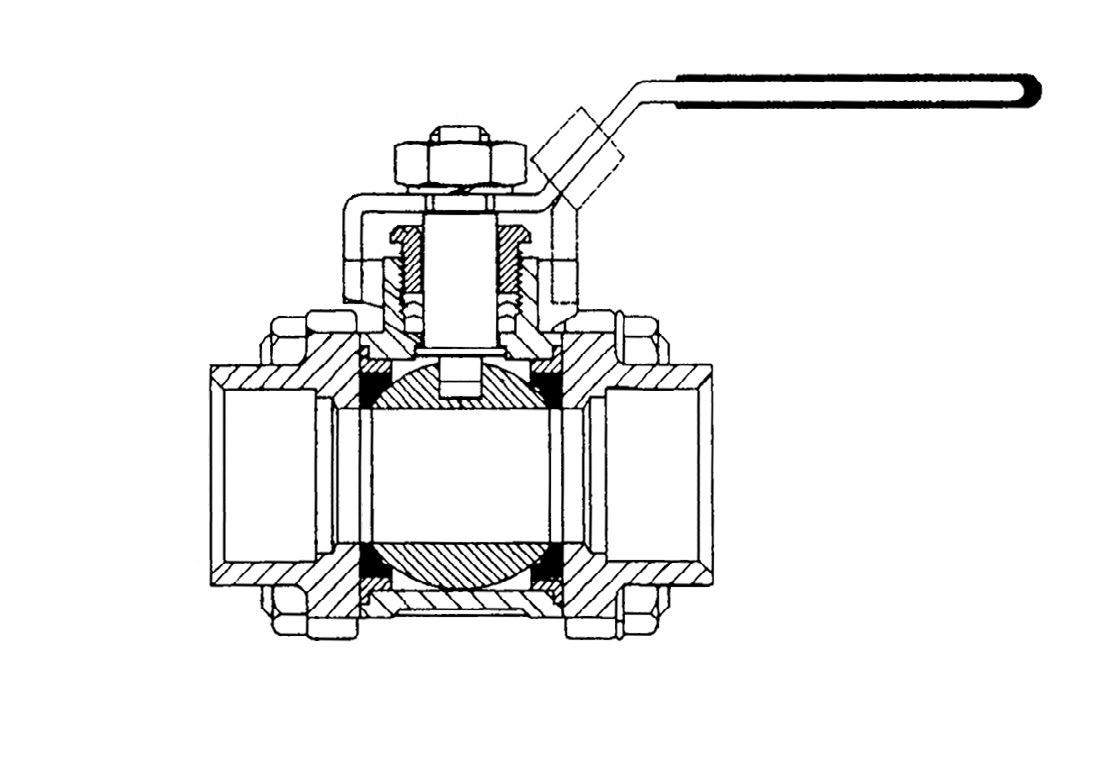

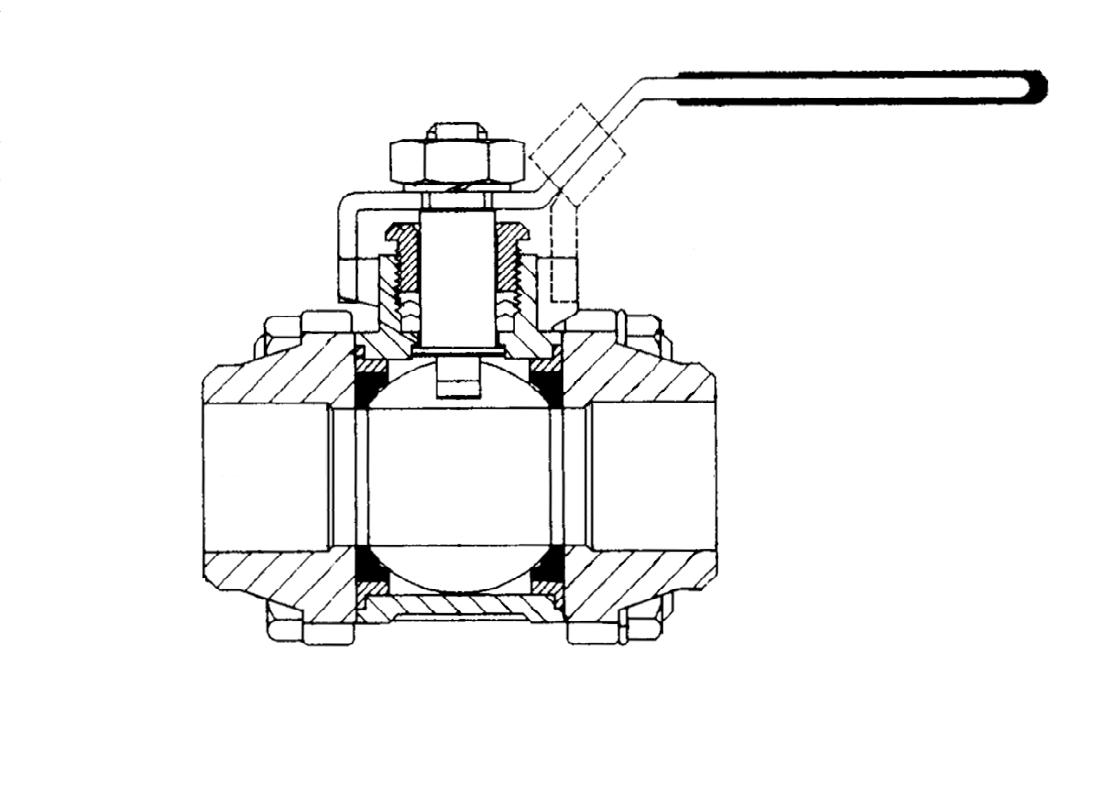

FEATURES

• Adjustable packing gland.

• Bottom-loaded blow-out proof stem.

• Low operating torque.

• Optional mounting pad complies with ISO 5211 for ease and interchangeability of actuation.

• Basic design complies with MSS SP-110.

• NPT threaded ends complies with ANSI B 1.20.1.

• BSP threaded ends complies with BS 21, ISO 7/1.

• Tested according to MSS SP-110/API 598.

OPTIONS

L Locking Device

V Vented Ball

P Equipped with Pneumatic Actuator

M Mounting Pad

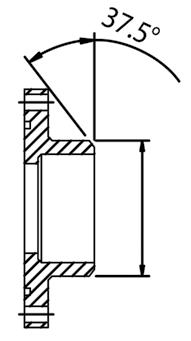

DIMENSIONS

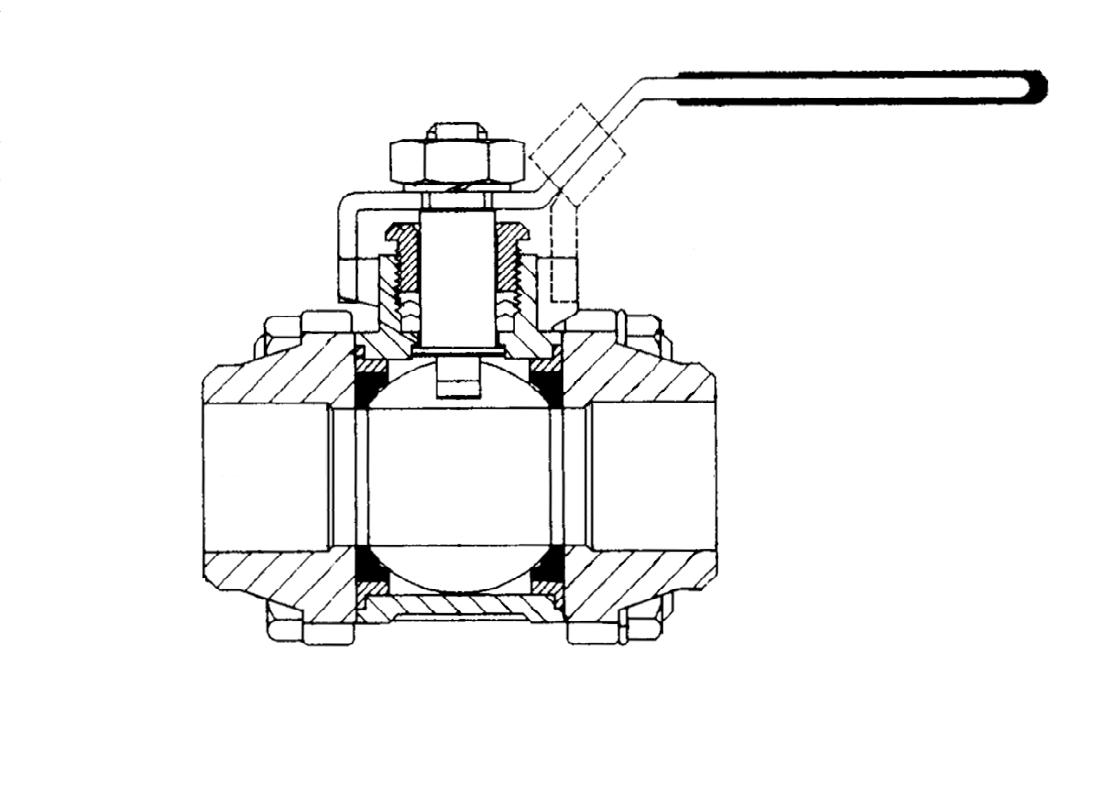

FEATURES

• Reinforced TFE seats increase durability.

• Adjustable packing gland.

• Bottom-loaded blow-out proof stem.

• Low operating torque to reduce automation costs.

• Mounting pad complies with ISO 5211 for ease and interchangeability of actuation.

• Basic design complies with MSS SP-110.

• NPT threaded ends complies with ANSI B 1.20.1.

• BSP threaded ends complies with BS 21, Buttweld also available.

• Tested according to MSS SP-110/API 598.

OPTIONS

L Locking Device

V Vented Ball

P Equipped with Pneumatic Actuator M Mounting Pad W Seal Welded

* For 4” refer to separate drawing

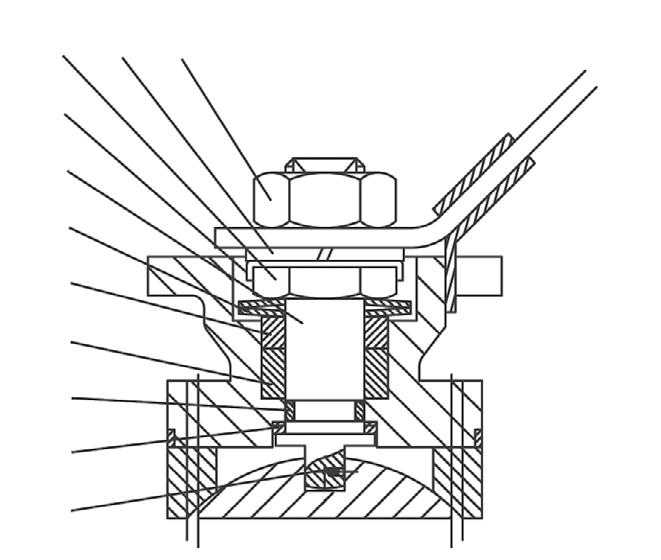

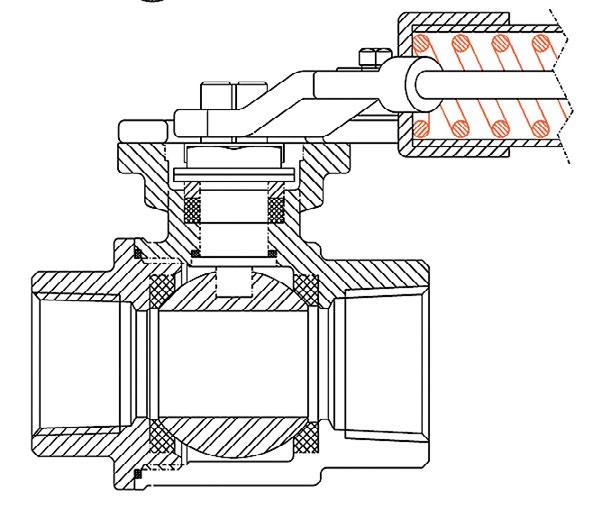

• High Cycle Triple Barrier Stem Seal System

• V-Type Packing for Maximum Stem Sealing

• Full Port DN 8NB~80NB (1/4”- 3”)

• 2000PSI (13790 kPa) for 25NB 1500PSI (10342 kPa) for 32~80NB

• Long life for Actuated Valve Applications

• Belleville Washer Set for Automatic Compression of Stem Sealing

• Direct Mount Pad (ISO 5211)

• TA Luft Fugitive Emission Compliant

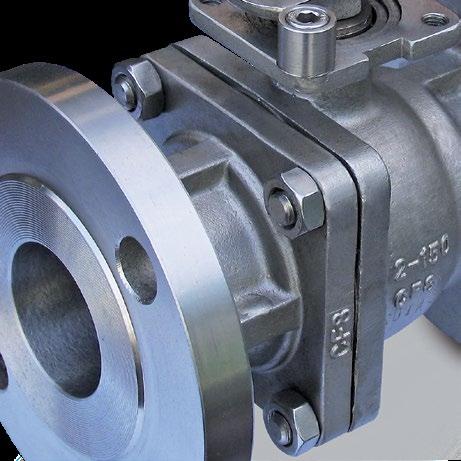

• Precision Investment Heavy 2 Piece Cast Body

• Blow-Out Proof Stem

• Available in Carbon Steel or Stainless Steel

• Various End Connections Available (NPT, ISO 7/1, ISO 228/1, BSP, DIN 2999, DIN 259, etc.)

10. PTFE V-Ring Stem Packing Set

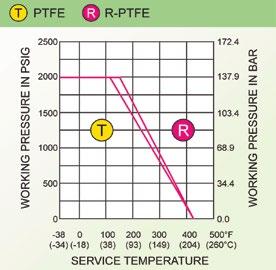

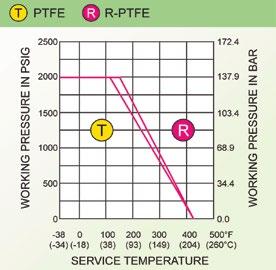

PRESSURE/TEMPERATURE RATING

Full Bore - 2000 PSI (8~25NB) 1500 PSI (32~80NB)

Mount Pad

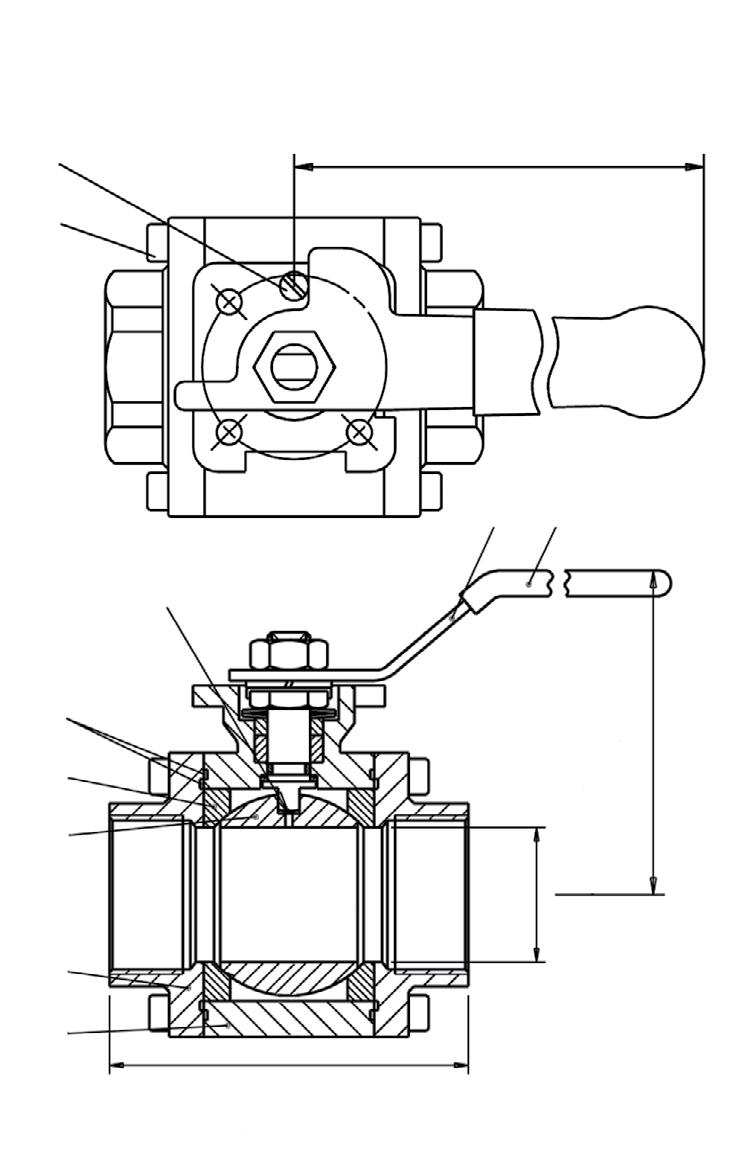

FEATURES

• High Cycle Triple Barrier Stem Seal System

• V-Type Packing for Maximum Stem Sealing

• Full Port DN 8NB~100NB (1/4”- 4”)

• 1000PSI (6895 kPa)

• Long life for Actuated Valve Applications

• Belleville Washer Set for Automatic Compression of Stem Sealing

• Direct Mount Pad (ISO 5211)

• TA Luft Fugitive Emission Compliant

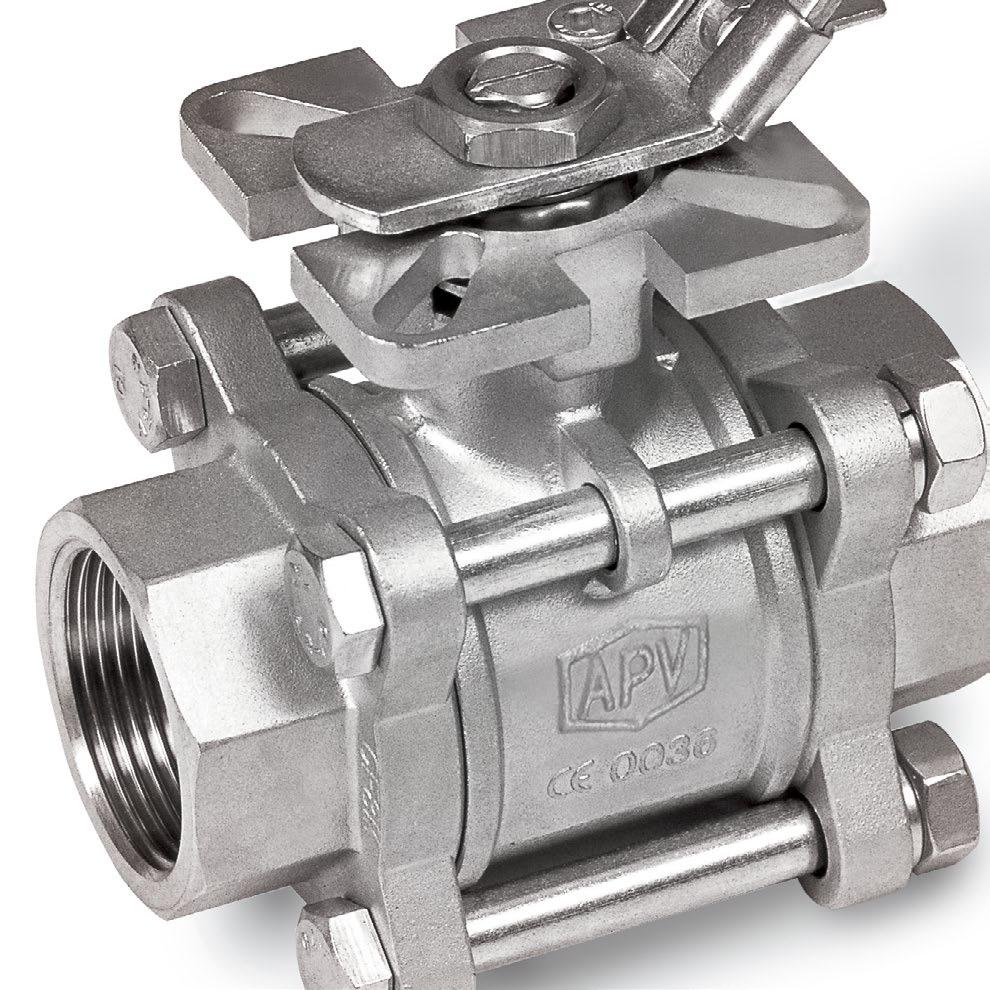

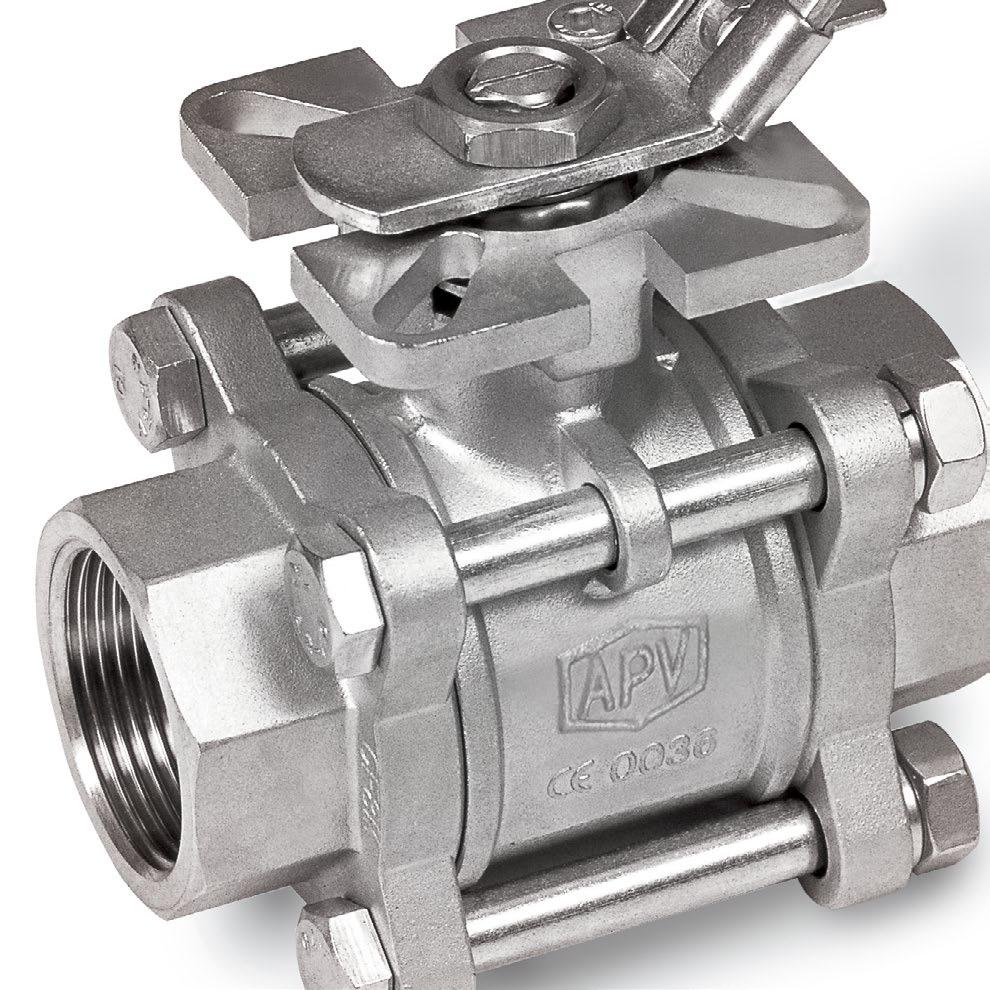

• Precision Investment Heavy 3 Piece Cast Body

• Blow-Out Proof Stem

• Available in Carbon Steel or Stainless Steel

• Various End Connections Available (NPT, BSP, SW, BW etc.)

PTFE V-Ring Stem Packing Set

• High Cycle Triple Barrier Stem Seal System

• V-Type Packing for Maximum Stem Sealing

• Full Port DN 8NB~80NB (1/4”- 3”)

• 1000PSI (6895 kPa) for 8~80NB

• Long life for Actuated Valve Applications

• Belleville Washer Set for Automatic Compression of Stem Sealing

• Mount Pad (ISO 5211)

• TA Luft Fugitive Emission Compliant

• Precision Investment Heavy 3 Piece Cast Body

• Blow-Out Proof Stem

• Available in Carbon Steel or Stainless Steel

• Various End Connections Available (NPT, BSP, SW, BW etc.)

FEATURES

• Full Port

• Pipe thread in accordance with ANSI B2.1, B2.21 1973, DIN 259/2999, BSP BS 21

• Blow-out proof stem

• -50°C to 220°C (CF8M/CF8)

• -29°C to 220°C (WCB)

• Carbon Steel, Stainless Steel

• Size - DN 8NB~80NB (1/4”- 3”)

• Threaded End

Mounting Pad ISO 5211 as option

OPTIONS

L Locking Device

V Vented Ball

P Equipped with Pneumatic Actuator

M Mounting Pad

(Optional Mount Pad)

VT-3W SIZE - DN 8NB~80NB (1/4”- 3) BUTT WELD END

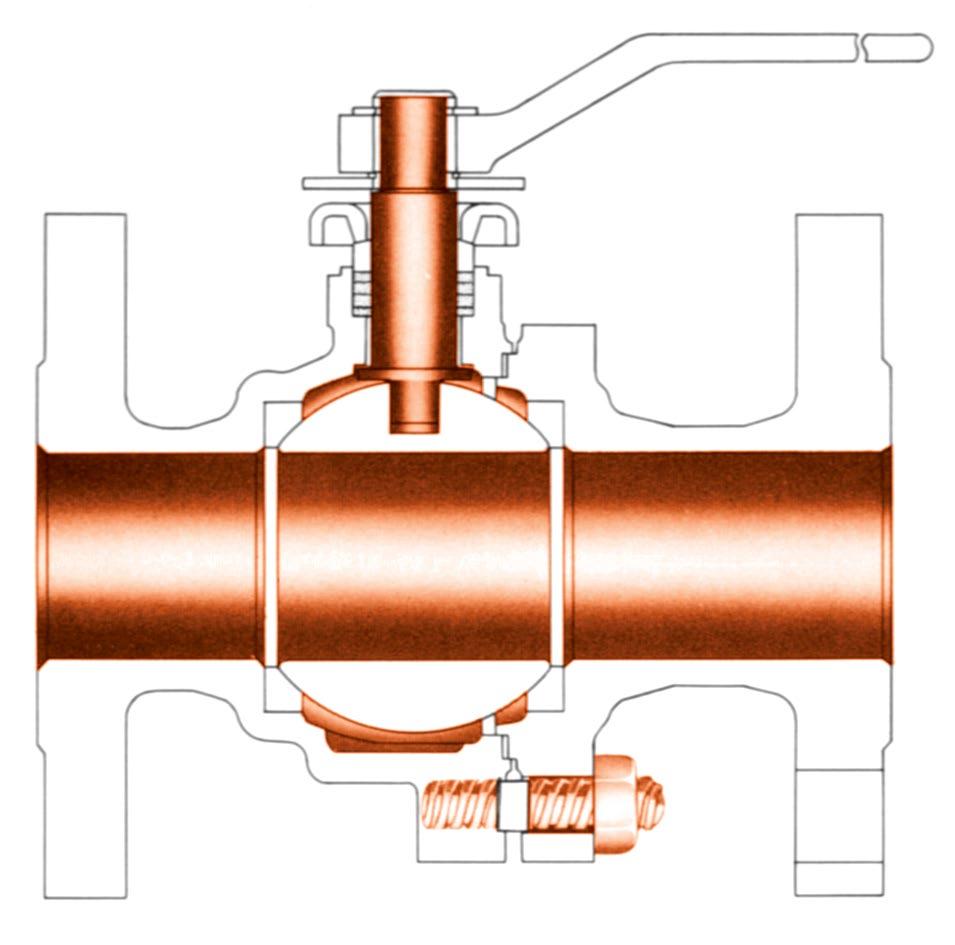

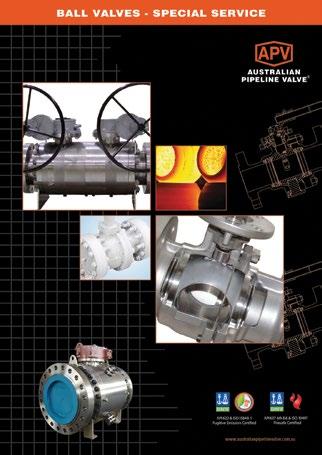

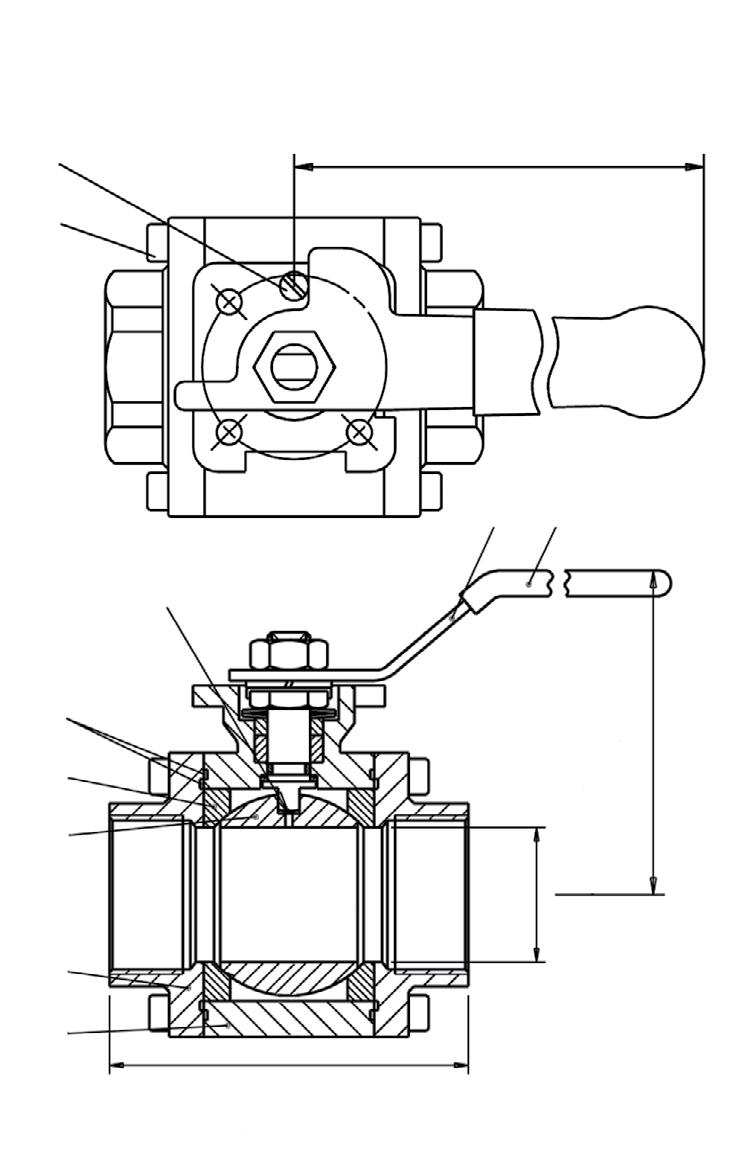

• High Cycle Triple Barrier Stem Seal System

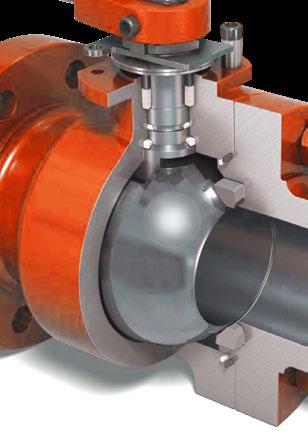

• True Swing Out Centre

• V-Type Packing for Maximum Stem Sealing

• Full Port DN 8NB~50NB (1/4”- 2”)

• 2000PSI (13790 kPa) for 25NB 1500PSI (10342 kPa) for 32~50NB

• Long life for Actuated Valve Applications

• Belleville Washer Set for Automatic Compression of Stem Sealing

• Direct Mount Pad (ISO 5211)

• Inside Bolting

• TA Luft Fugitive Emission Compliant

• Precision Investment Cast Heavy 3 Piece Body

• Blow-Out Proof Stem

• Antistatic Design

• Various End Connections Available (NPT, BSP, SW, BW etc.)

PRESSURE/TEMPERATURE RATING

Full Bore - 2000 PSI (8~25NB) 1500 PSI (32~80NB)

FEATURES

• High Cycle Triple Barrier Stem Seal System

• Full Port DN 65NB~100NB (2 1/2”- 4”)

• 2000PSI (13780 kPa) 65NB~80NB 1500PSI (10335 kPa) 100NB

• Long life for Actuated Valve Applications

• Belleville Washer Set for Automatic Compression of Stem Sealing

• Direct Mount Pad (ISO 5211)

• Precision Investment Heavy 3 Piece Cast Body

• Blow-Out Proof Stem

• Available in Carbon Steel or Stainless Steel

• Various End Connections Available (NPT, ISO 7/1, ISO 228/1, BSP, SW, BW, etc.)

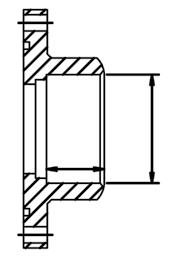

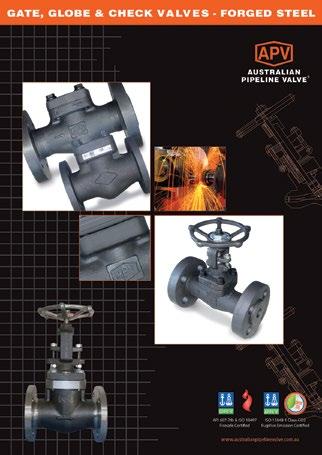

• Screwed end, socket weld end to ASME B16.11, butt weld end to ASME B16.11

• True swing-out centre

• Design to ANSI B16.34/API 608

• High Cycle Triple Barrier Stem Seal System

• V-Type Packing for Maximum Stem Sealing

• Full Port DN 8NB~50NB (1/4”- 2”)

• 2000PSI (13790 kPa) for 8~50NB

• Belleville Washer Set for Automatic Compression of Stem Sealing

• Direct Mount Pad (ISO 5211)

• 3 Piece Enclosed Bolting Design

• Precision Investment Cast Heavy 3 Piece Body

• Antistatic design to API 608

• Vacuum service (PTFE Seat) down to 20 microns (133 pascals)

• Firesafe Certified Version Available

• Blow-Out Proof Stem

• Various End Connections Available (NPT, ISO 7/1, ISO 228/1, BSP, BSPT, etc.)

FEATURES

• True Swing-out Centre

• Elastomer & Graphite Free

• High Cycle Triple Barrier Stem Seal System

• V-Type Packing for Maximum Stem Sealing

• Full Port DN 8NB~50NB (1/4”- 2”)

• 2000PSI (13790 kPa)

• Long life for Actuated Valve Applications

• Belleville Washer Set for Automatic Compression of Stem Sealing

• Direct Mount Pad (ISO 5211)

• Inside Bolting

• TA Luft Fugitive Emission Compliant

• Precision Investment Heavy 3 Piece Cast Body

• Blow-Out Proof Stem

• Various End Connections Available (NPT, BSP, SW, BWeld, etc)

High Cycle Elastomer Free Energised Stem Seal Thrust Seal Stem Area

ADJUSTABLE PRELOADED GLAND - ELASTOMER FREE

Ensures even packing adjustment without need for continuous adjustment.

GLAND PLATE

HANDLE NUT

LOCKING CAP

7. PTFE V-Ring Stem Packing Set

Secures gland nut position BELLEVILLE SPRING SET

PACKING

Moulded packing set

ANTI-STATIC STEM DEVICE

Triple barrier stem seal system combined with live loaded packing utilising a Belleville Spring set provides assurity of low emissions and low maintenance.

DIMENSIONS (MM)

FEATURES

• Full Port

• Size - DN 8NB~65NB (1/4”- 2 1/2”)

• Threaded ends to ANSI B1 20.1, BS 21 BSP

• Blow-out proof stem

• -46ºC to 220ºC (CF8M/CF8)

• -29ºC to 220ºC (WCB)

• Carbon Steel, Stainless Steel

Mounting Pad ISO 5211 as option

M Mounting Pad

2-1/2”

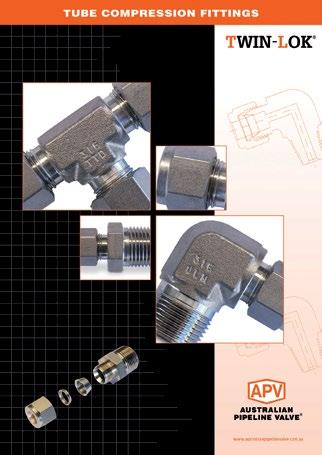

FEATURES

• Temperature From -20 to + 80ºC

• Pressure 210 bar as a maximum

• Application Fields Hydraulics, pneumatics, general industrial installations

• Threaded Ends Female according to BSP / UNI-ISO 7/1 (UNI EN 10228) Also available in NPT

• Anti blowout design Triple barrier stem seals, 2 self adjusting cone shape PTFE seats, O-ring and PTFE packing

CAPACITY AND LOSS OF HEAD DIAGRAM The Kv is the index port capacity expressed in cubic metres per hour, causing a pressure drop of 1 bar with water at 15ºC.

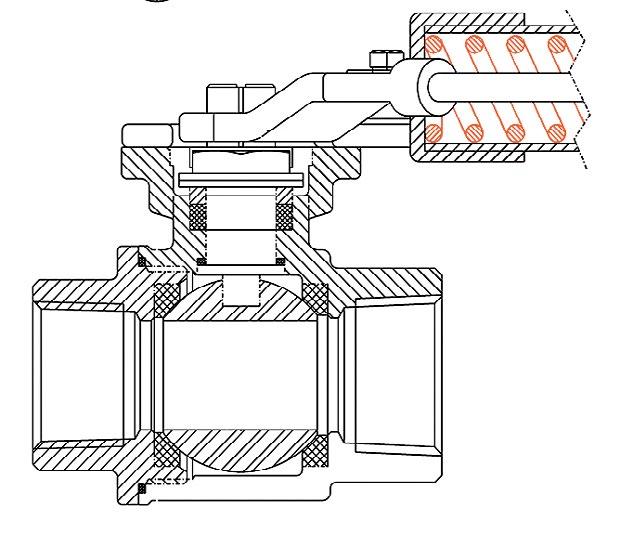

• Full Port DN 8NB~80NB (1/4”- 3”)

• 2000PSI (13790 kPa) for 25NB 1500PSI (10342 kPa) for 32~80NB

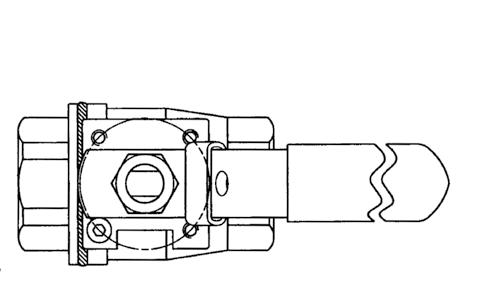

• Spring Return Handle (Dead Man Handle) for Auto Default Position

• High Cycle Triple Barrier Stem Seal System

• V-Type Packing for Maximum Stem Sealing

• Belleville Washer Design for Automatic Compression of Stem Sealing

• Direct Mount Pad (ISO 5211)

• TA Luft Fugitive Emission Compliant

• Precision Investment Heavy Hex 2 Piece Cast Body

• Blow-Out Proof Stem

• Available in Carbon Steel or Stainless Steel

• Various End Connections Available (NPT, BSP, ISO 7/1/ ISO 228/1, BW, etc.)

• All components of lever are stainless steel

• Operating torque should be sized according to valve torque, media, pressure and safety.

• Can be fitted on 1P, 2P, 3P valve

• Available in ISO F03 to F07

• 55CrSi Spring Material

*Available unmachined

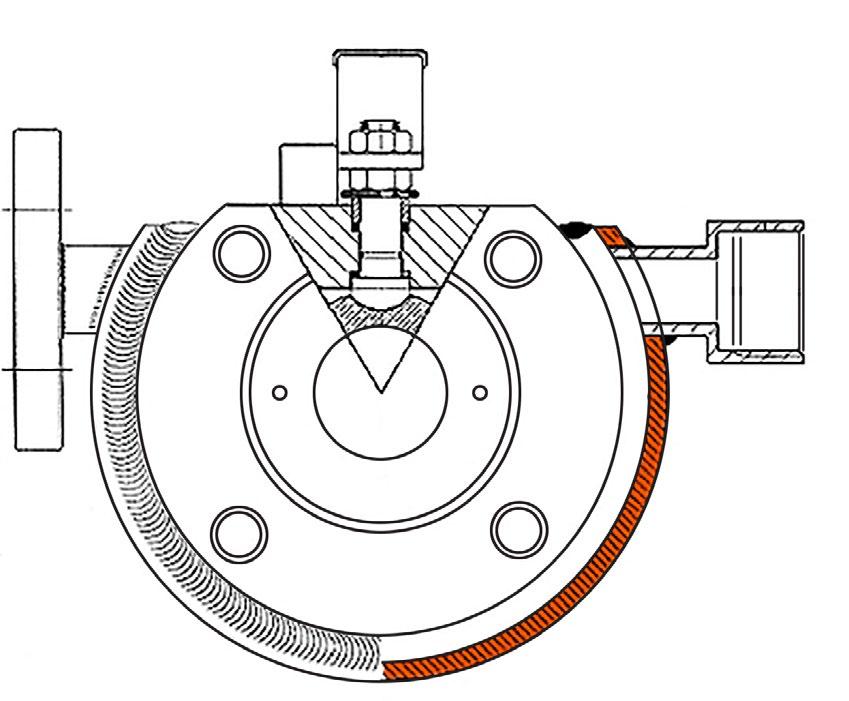

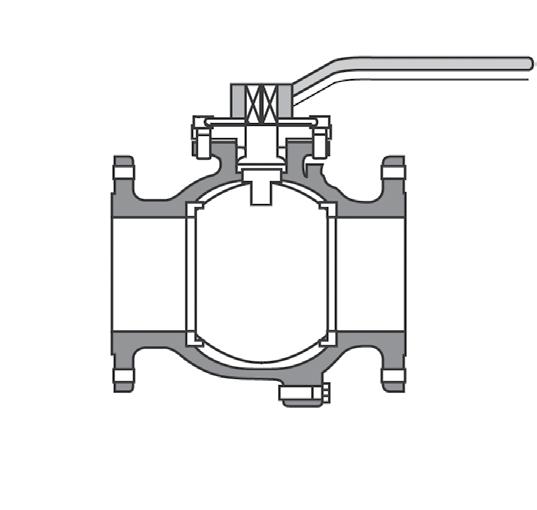

FEATURES

• Wafer jacketed ball valve

• Jacket connections - threaded, flanged, oversized (on request).

• Oversized and /or special jackets in carbon and stainless steel.

• Adjustable packing gland.

• Also available in 150 to 600 class

• Bottom-loaded blow-out proof stem.

• Low operating torque to reduce automation costs.

• Optional mounting pad complied with ISO 5211 for ease and interchangeability of actuation.

• Tested according to MSS SP-110/API 598.

HEATING JACKET FLANGE CONNECTION

HEATING JACKET THREADED CONNECTION

MATERIALS

HEATING CHAMBER JACKET

Stem Gasket

Gland Stainless steel

Handle Zinc Plated Carbon Steel*

Lever and Gland Nut Zinc Plated Carbon Steel*

Socket Springs Zinc Plated Carbon Steel*

Stop Pin Zinc Plated Carbon Steel*

Stop Plate Zinc Plated Carbon Steel*

* Or Stainless Steel on request.

DIMENSIONS 150 & 300 CLASS

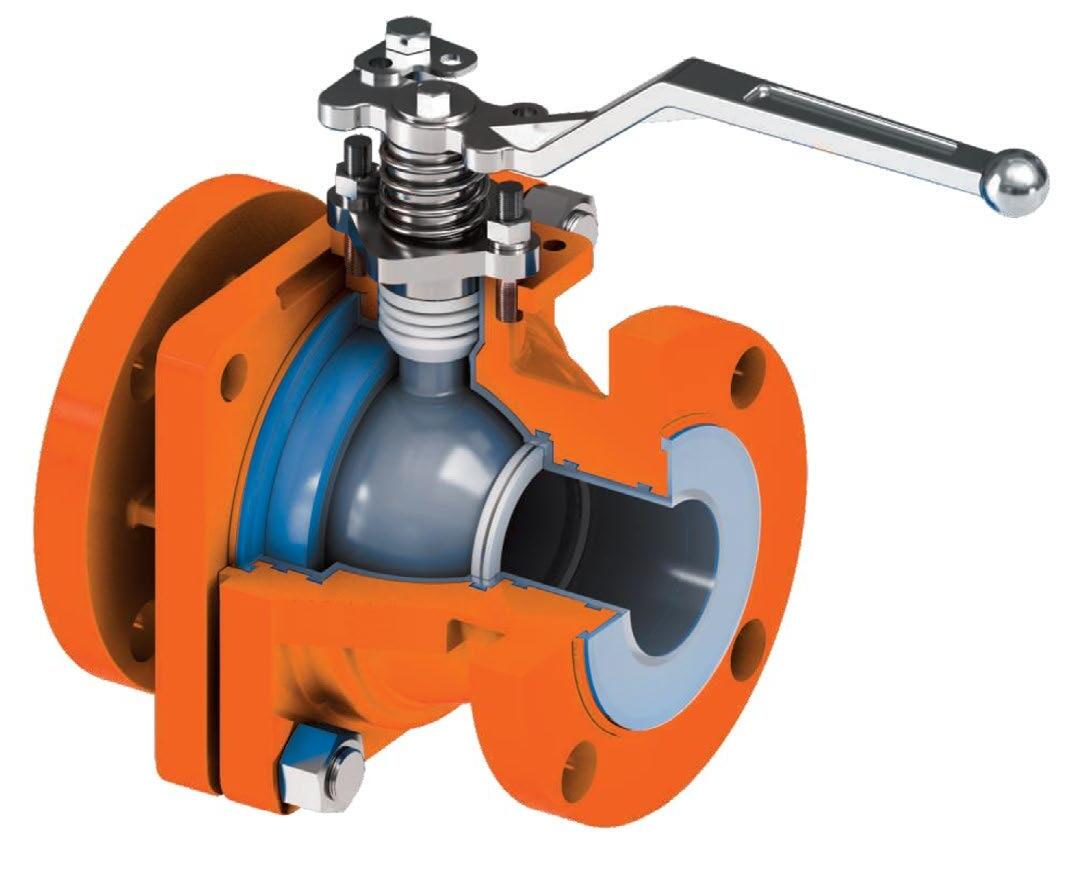

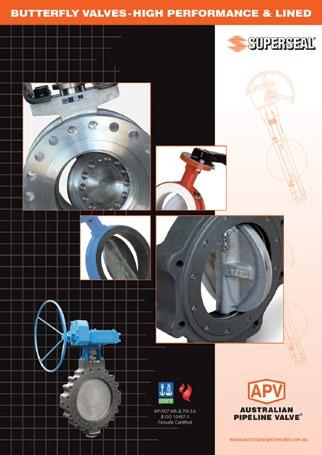

The Superseal RFFL lined ball valve utilises PFA lining which has the same chemical inertness as PTFE. Due to its chemical composition, PFA retains a high amount of mechanical strength at elevated temperatures. Up to 200°C (400°F).

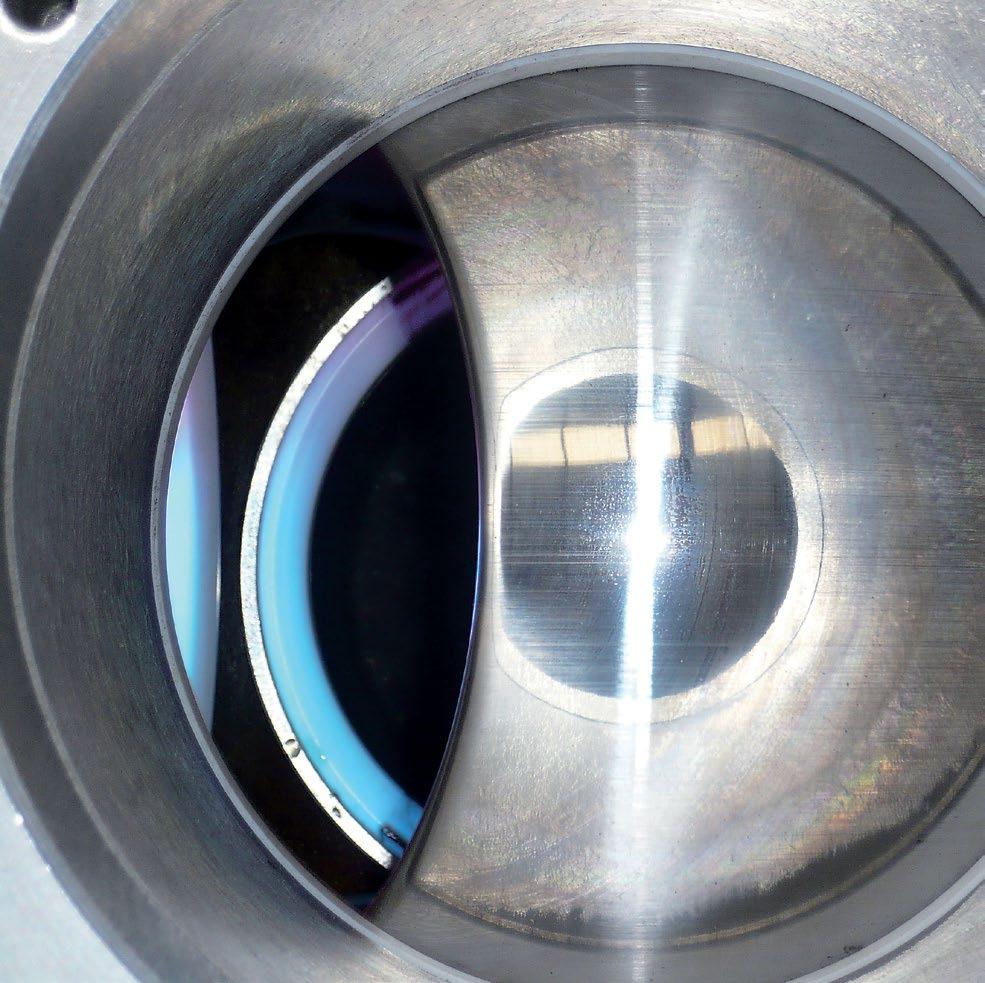

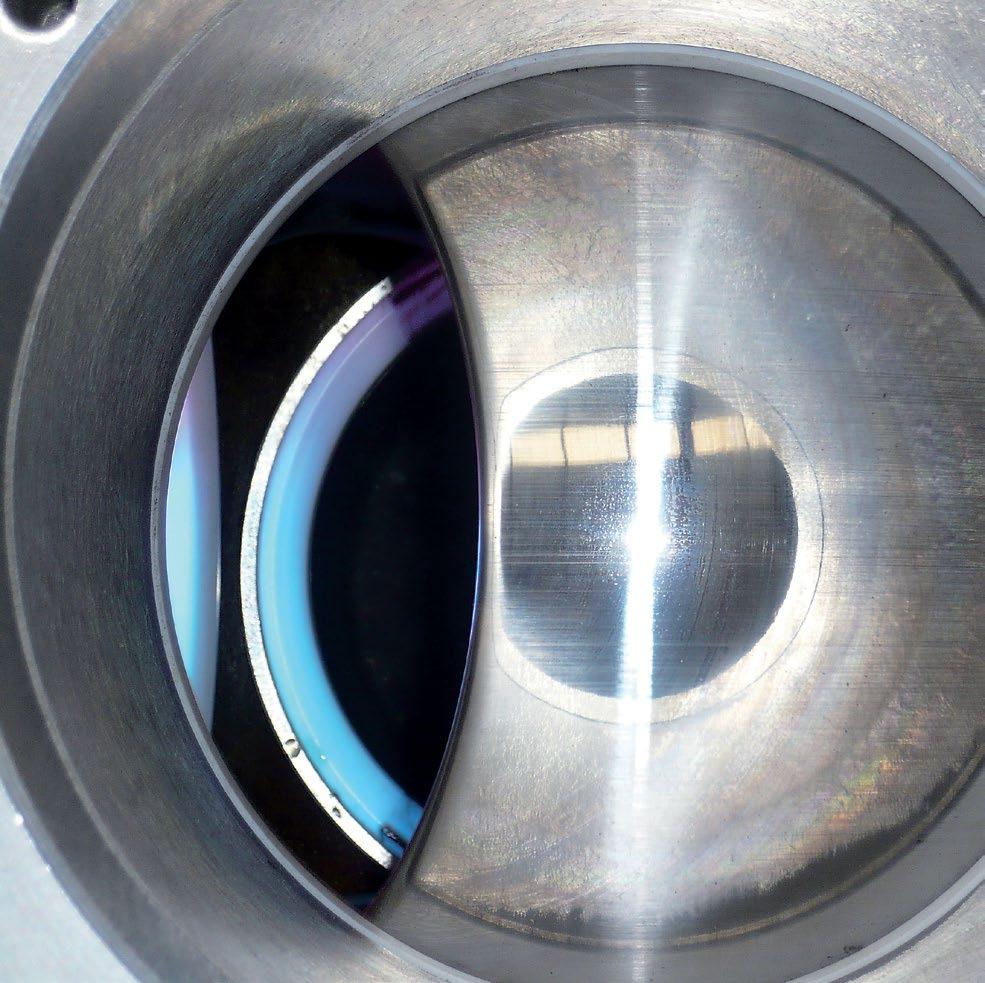

The Superseal Model RFFL Energised Flexible Seat gives the ball a light loaded cushioning effect in all positions. The line pressure against the floating ball further energises the seat. Therefore the higher the pressure the tighter the seal, whilst at low pressures the valve is easier to turn than other brands.

The inherent lubricity properties of the PTFE seat give the Ball a cushioning effect and this combined with the PTFE coated Ball & integral stem ensures no jamming or stem breakage. The resilient cushioning effect also extends the life of the valve. Traditional 2 piece ball & stem design, with ‘Flat’ teflon seats place more strain on all components. In larger sizes a trunnion mounted ball is also available to further ensure no stem or seat leakage, caused by the operator forcing the ball off axis due to particulates jamming the seating area.

MATERIALS

End

Ball with Integral Stem Teflon Coated DI/WCB/316

Seat Ring - Energised PTFE

Stem Bearing PTFE

Gland Box

Ductile Iron Bush PTFE

Gland Packing PTFE

Gland Nut ASTM A 276 Type 316

Gasket PTFE Lever Holder

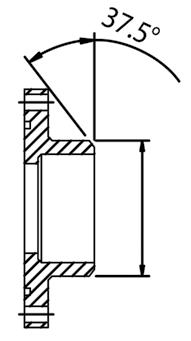

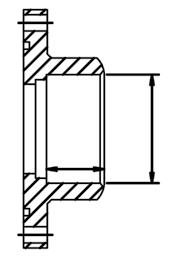

L = Face to Face

N# = Number of Holes

OD = Flange Diameter

HS = Size of Hole

TH = Flange Thickness

W = Lever Length

FR = Raised Face Diameter

G = Gear Length

T = Raised Face Thickness

C = Centre of Flange to Height of Body PCD = Pitch Circle Diameter

Stopper Plate

Break - Away Torque

- 60% of B.A.T. Close - 80% of B.A.T.

When the ball rotates into closed position, the minute gap between the body and the seat further energises the seat against the ball, ensuring the ball and stem are not tilted on an angle (which can cause seat & stem leakage) giving the ball a trunnion like effect during closing and once closed.

DIMENSIONS 150LB

*Gear Operator

Design Standards

Design Standard BSEN ISO 17292:2004 / BS 5351

Testing Standard EN 12266-1 & 2 (2003) / API 598

Face to Face ASME B 16.10, DIN/EN 558-1

Top Flange ISO 5211

AF Series - Lining / Body Join

Dovetail groove for better grip of lining.

‘V’ Groove for zero leakage.

Lining Specifications

Lining Thickness 3.0 to 5.0

Spark Test 15 KVDC

Service Temperature Max. 200°C A variety of liner material is available - FEP, PP and ETFE

The DO Series ball valves are ideally suited for corrosive applications, requiring reliable performance, tight shutoff, and constant torque The valves successfully handle a multitude of corrosive applications in industries such as chemical, petrochemical, pharmaceutical, pulp and paper, foundries and mining like sulphuric acid, etc.

Locked-out standard on valves

Adjustable nuts and studs for packing adjustment with valve inline

lnnovative ”maze type” packing (elastic, moves with the stem, maintaining a constant seal ).

Epoxy coating paint

Thick liner 100% inspected at 14000 VDC for defects is made from highly corrosion resistant

Metal to metal contact (ensures that no part of lining can be deformed)

DIMENSIONS

Size 1/2” -12”

Pressure Class 150

Design Standard API 608

Connection Flanged, ASME B16.5

Testing API 598

P/T ASME B16.34

Body Material ASTM A216 WCB, A351-CF8, Ductile Iron, etc.

Lining Material PFA, PTFE, FEP, ETFE

Anti-static spring

ISO 5211 universal mounting pad permits easy automation even with the valve in the pipeline

Lined one piece type ball & stem (anti-blowout prevents stem blowout even in the event of topworks disassembly)

Lined securely locked into the body by ”T” slots and locking grooves,completely encapsulated ball and stem permits vacuum services

PTFE seats (easy to replace pop-out & pop-in seats)

Multiple international standards flange available

A. Valve size 15A (1/2”) to 25A(1”)

B. Valve size 40A (-1/2”) to 65A(2-1/2”)

C. Valve size 80A (3”) to 100A(4”)

D. Valve size 125A (5”) to 250A(10”)

Carbon PTFE will do higher temperatures. PEEK, bronze PTFE and metal seat also available.

DIMENSION LIST

• Full or reduced bore, solid ball

• 2 piece split body design

• Temperature range -25 to 220°C

• Lever operated

• Floating Ball design, bidirectional sealing

• Vacuum service to 20 microns (133 pascals)

• ISO mount pad available.

• Also available in flanged AS 2129 Table D/E, AS 4087 PN10, PN14, PN16, PN25 and EN 1066-2 PN10, PN16, PN25

* Torque is

a 20% safety factory

DIMENSION LIST

Indicative bill of material only. Refer as built drawing. * Style shown Bolted Gland. Gland nut style also available. Direct Mount Pad version also available, refer as built drawing.

* Torque is maximum breakaway at maximum differential (running

Only a 20% safety

is

† Over 150NB (6”) are gear operated.

HYGIENIC VALVES

A variety of options are available in weld ends, screwed ends or wafer “flangeless” type. Trim is teflon and stainless but for hygienic service the ball / disc can also be coated with teflon or polished (or lined if required). 2 way, 3 way, 4 way & 5 way available. A detailed data sheet can be supplied on items of interest.

TYPE FV01

TYPE FV02

Ball valve, 3 piece, available in Buttweld (tube or pipe), BSP or socket weld. For extra cost valves can be supplied to hygienic specification.

TYPE FV03

Hygienic ball type available with various end connections.

Hygienic Butter-ball. Does the same job as the traditional food / wine ball valve but at a lower cost. Available in special male threads as well as in flangeless configuration.

TYPE FV04

3/4 way ball valve traditional milk valve style.

TYPE FV05

Standard 3-4 or 5 way ball valve, (also available in flanged ends in larger sizes).

TYPE FV06

Hygienic ball valve.

WAFER STYLE 2014

Flangeless (wafer style) teflon lined butterfly valve. Also available in lugged.

“Australian Pipeline Valve produces isolation, control and flow reversal protection products for severe and critical service media in utility, steam, pipelines, oil & gas and process industries. APV valves and pipeline products form the most competitive portfolio in the market.”

FEATURES

• True Swing-out Centre

• Elastomer & Graphite Free

• High Cycle Triple Barrier Stem Seal System

• V-Type Packing for Maximum Stem Sealing

• Full Port DN 8NB~50NB (1/4”- 2”)

• 2000PSI (13790 kPa)

• Long life for Actuated Valve Applications

• Belleville Washer Set for Automatic Compression of Stem Sealing

• Direct Mount Pad (ISO 5211)

• Inside Bolting

• TA Luft Fugitive Emission Compliant

• Precision Investment Heavy 3 Piece Cast Body

• Blow-Out Proof Stem

• Various End Connections Available (NPT, BSP, SW, BWeld, etc)

High Cycle Elastomer Free Energised Stem Seal Thrust Seal Stem Area

ADJUSTABLE PRELOADED GLAND - ELASTOMER FREE

Ensures even packing adjustment without need for continuous adjustment.

GLAND PLATE

PEEK

HANDLE NUT

LOCKING CAP

7. PTFE V-Ring Stem Packing Set

Secures gland nut position BELLEVILLE SPRING SET

PACKING

Moulded packing set

ANTI-STATIC STEM DEVICE

Triple barrier stem seal system combined with live loaded packing utilising a Belleville Spring set provides assurity of low emissions and low maintenance.