BALL

Quality is Our First Priority.

Consistent product quality and a proven track record makes Australian Pipeline Valve a dependable choice where total reliability is the number one concern.

Since its founding, APV’s philosophy has been focused on quality. Our valves are manufactured in full compliance to worldwide standards (such as ASME/ANSI, API, EN, ISO, BS, AS).

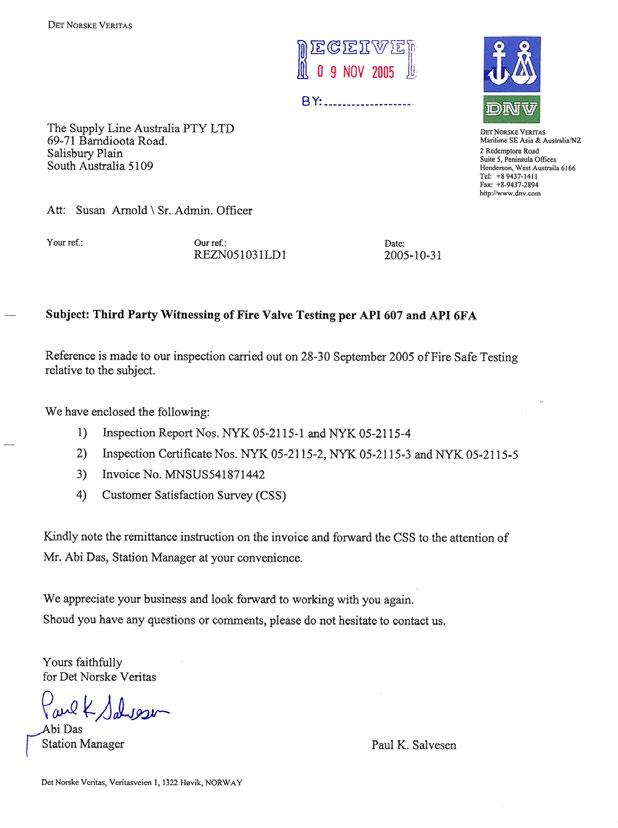

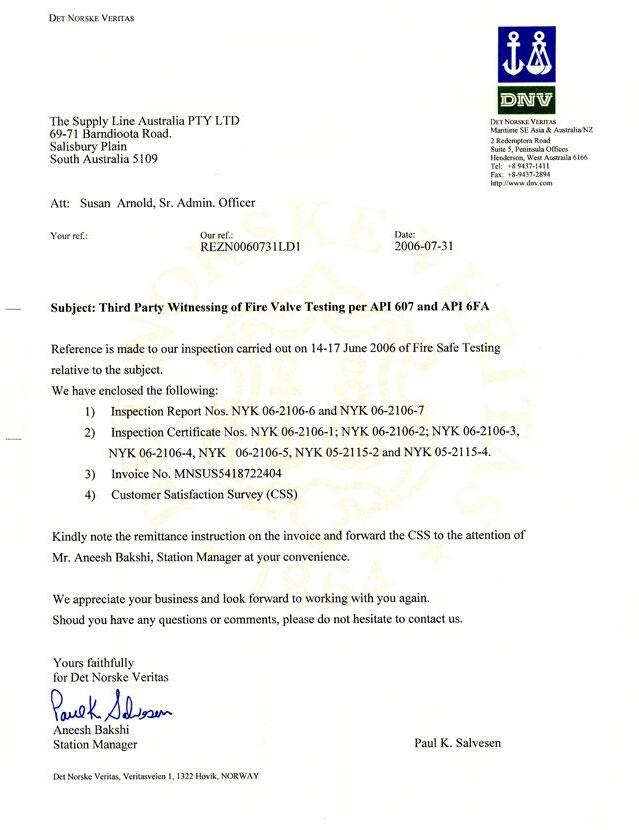

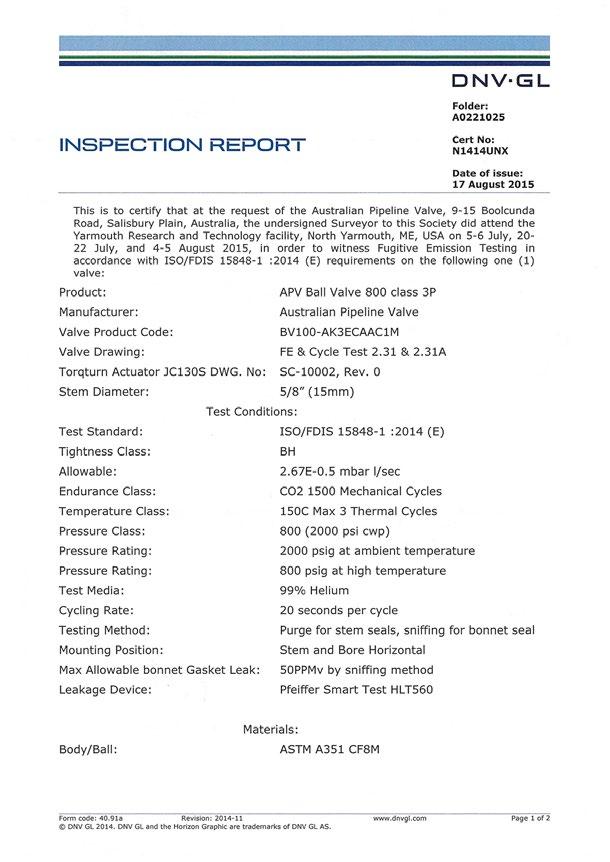

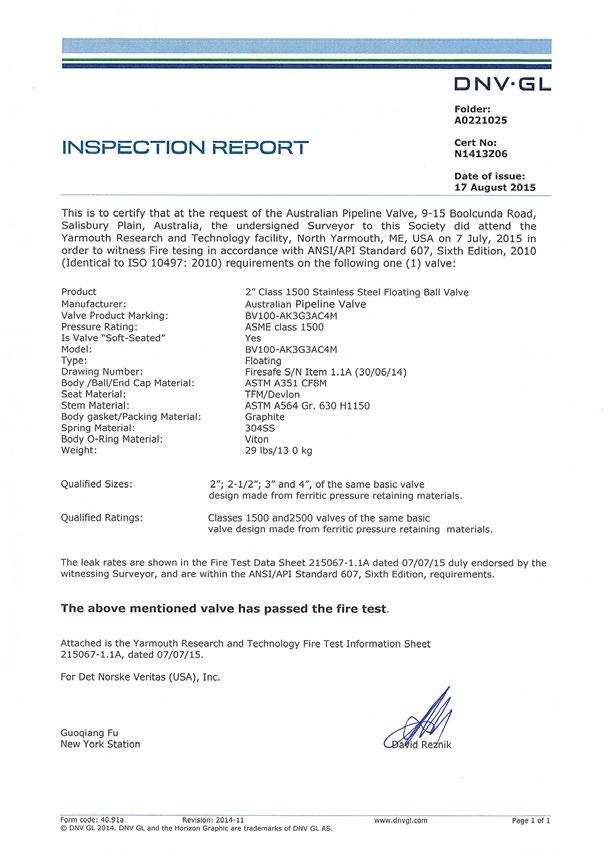

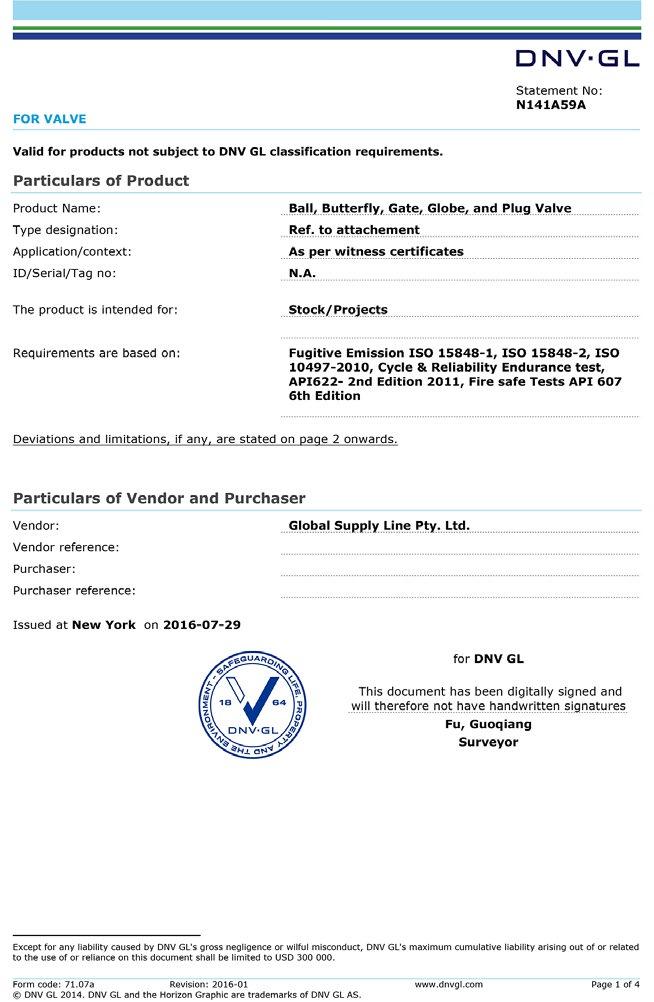

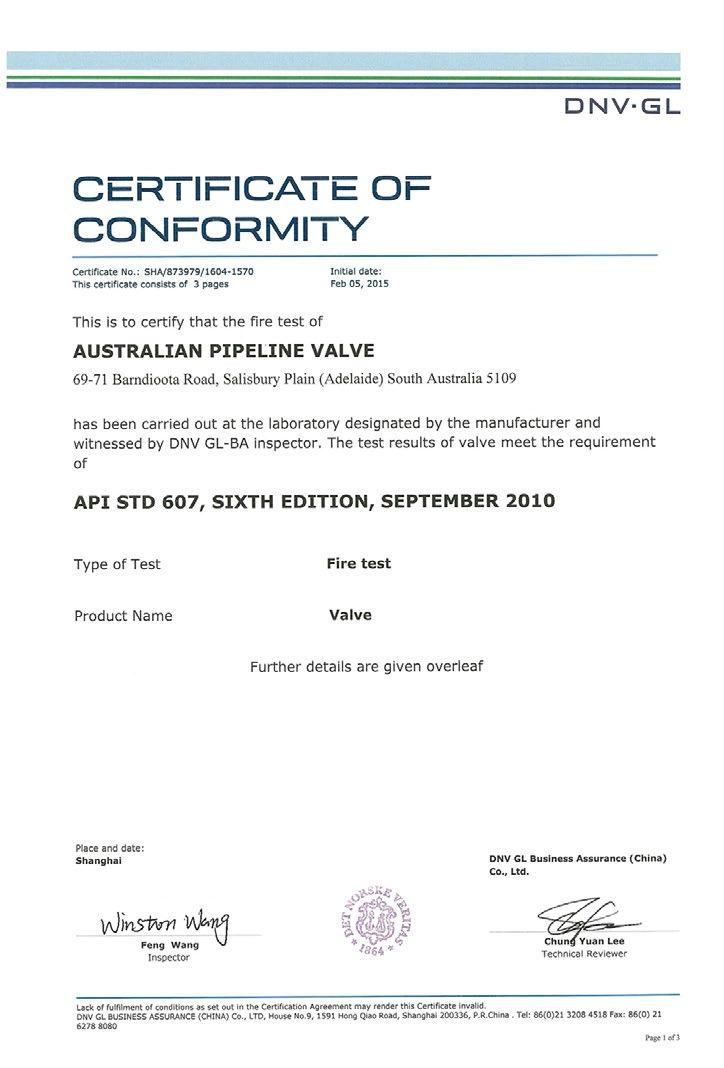

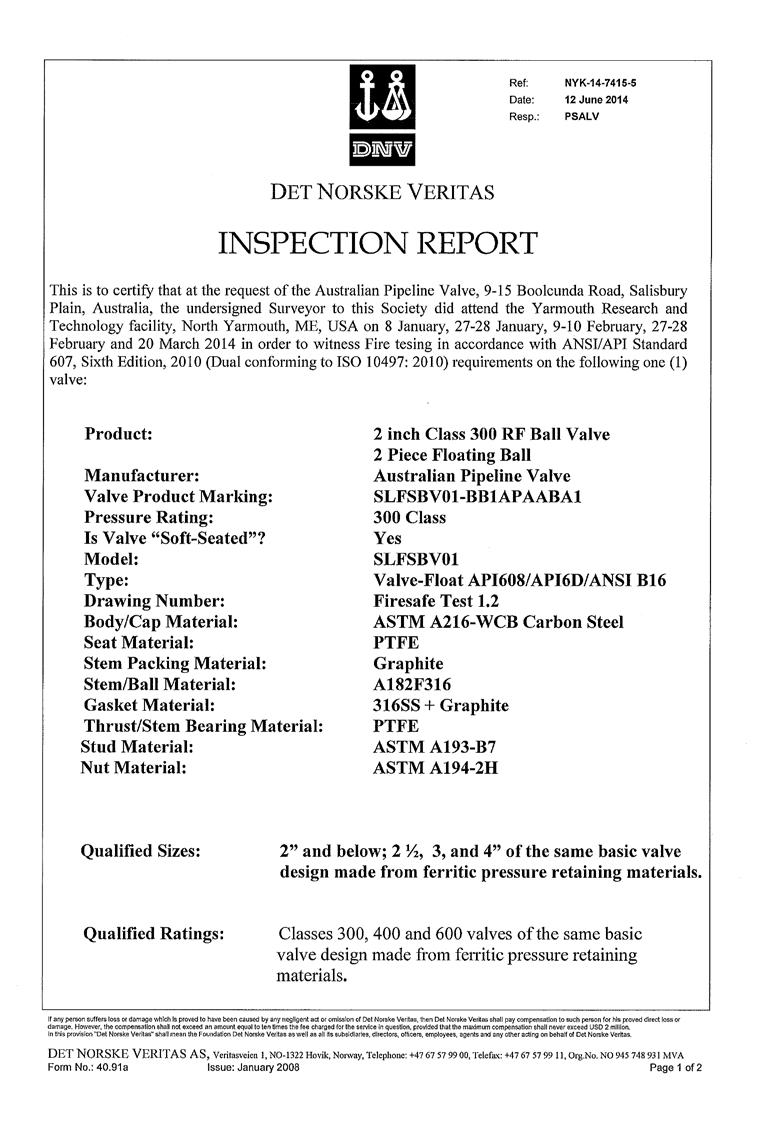

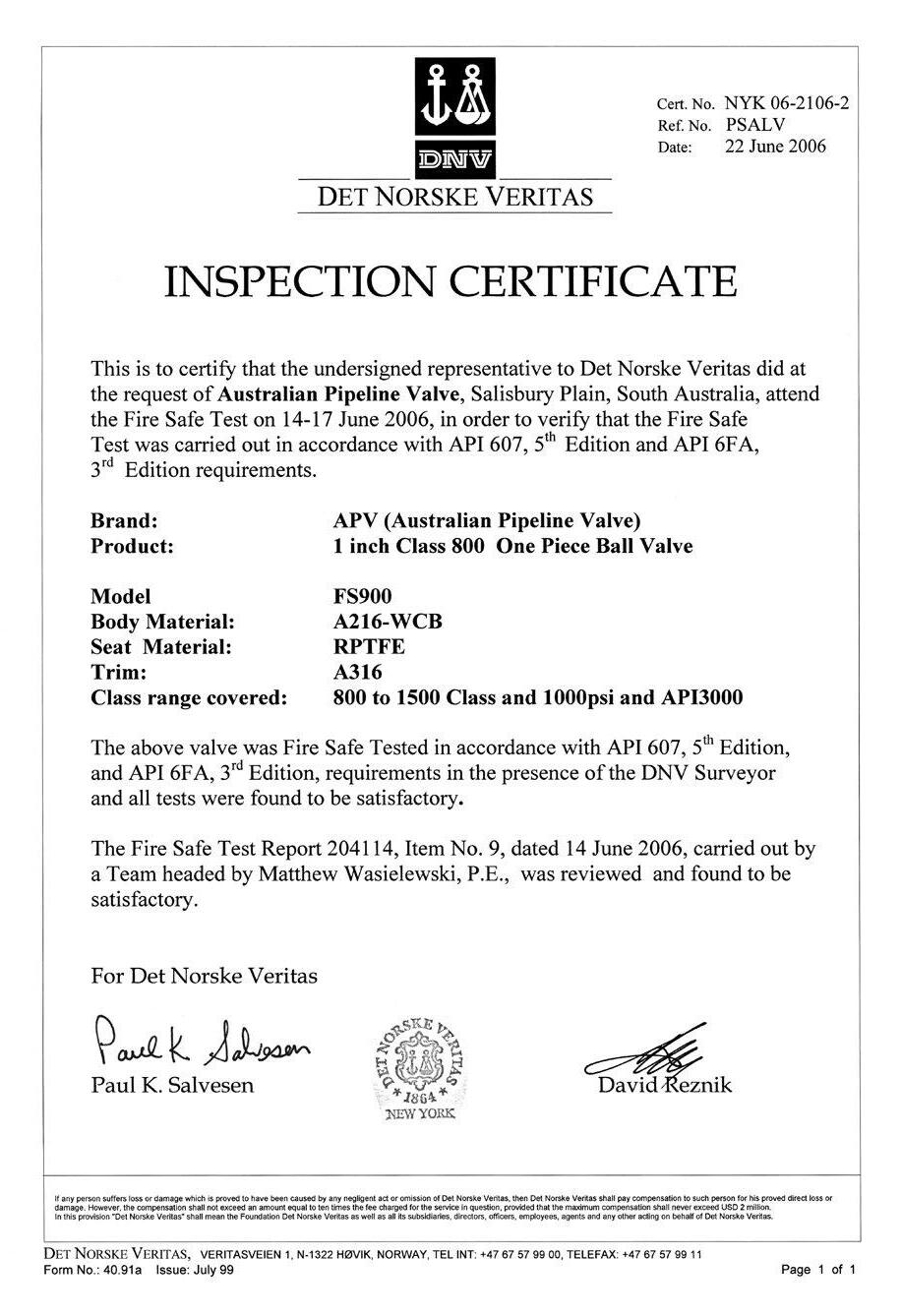

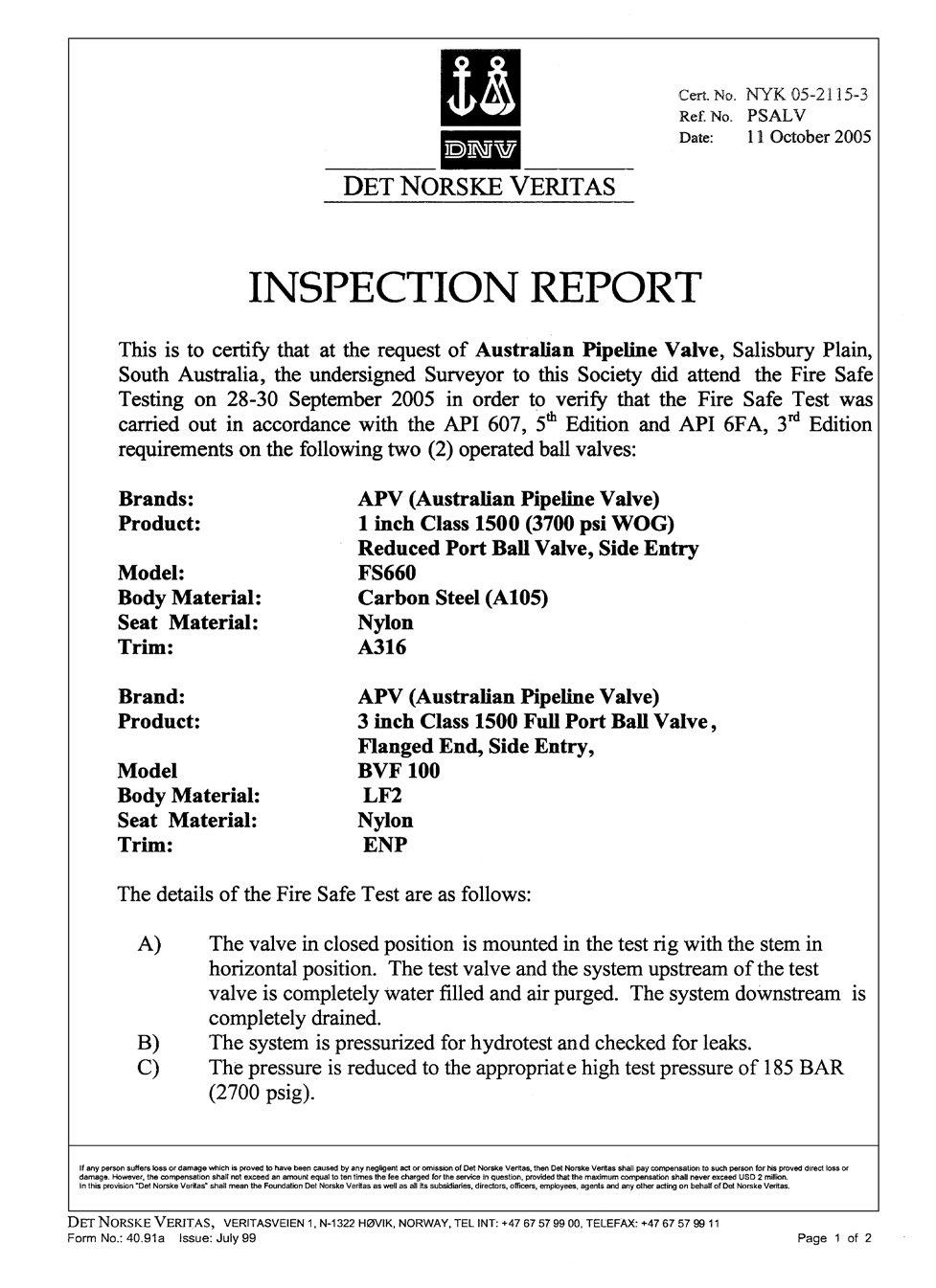

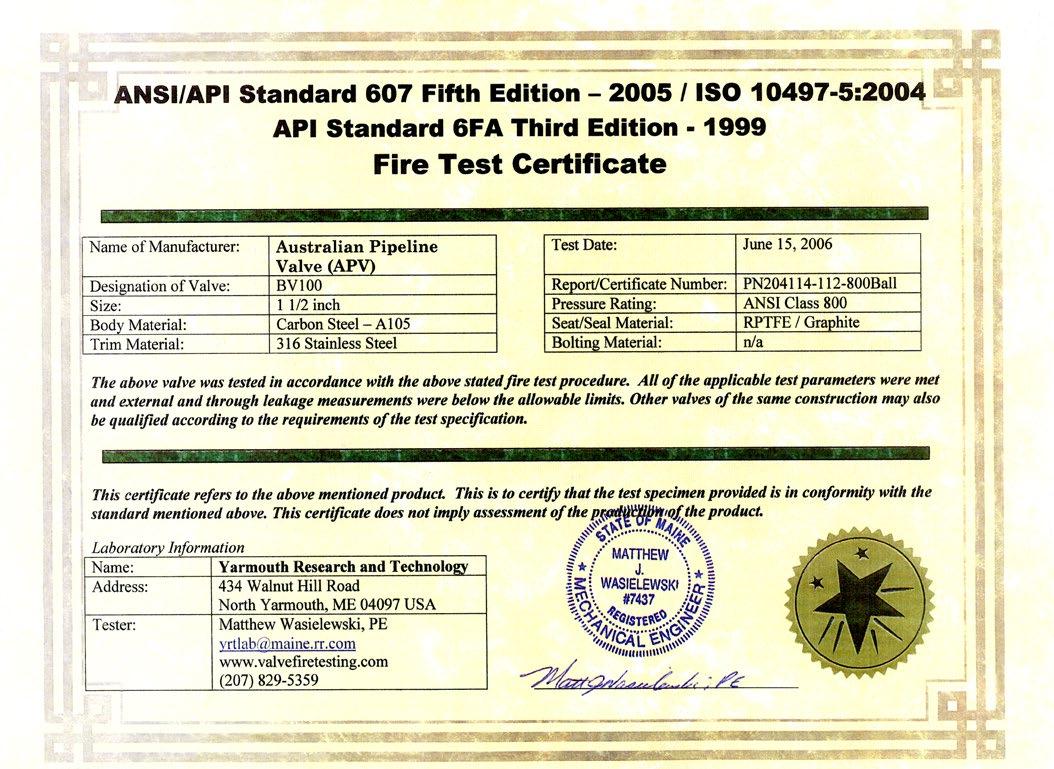

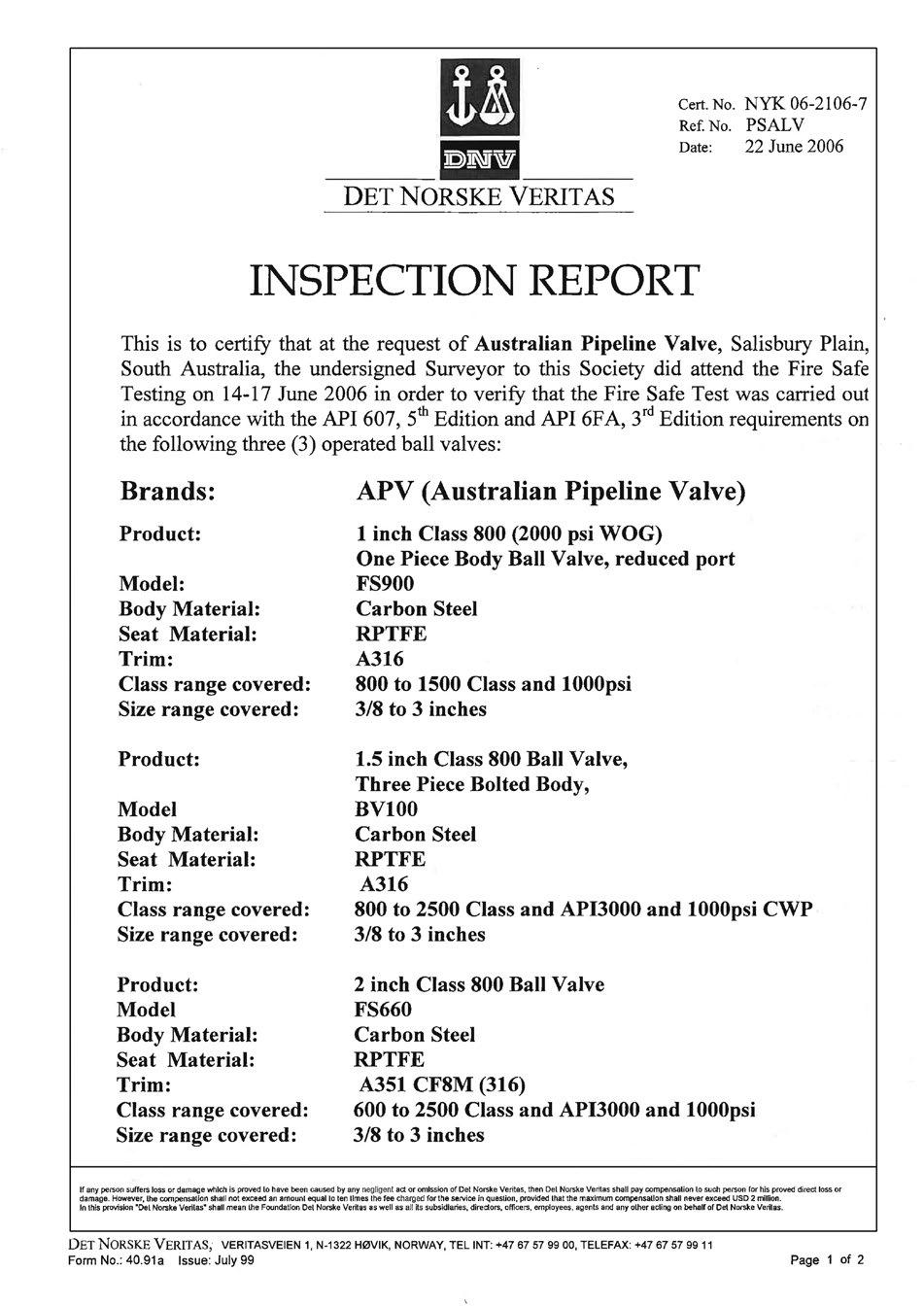

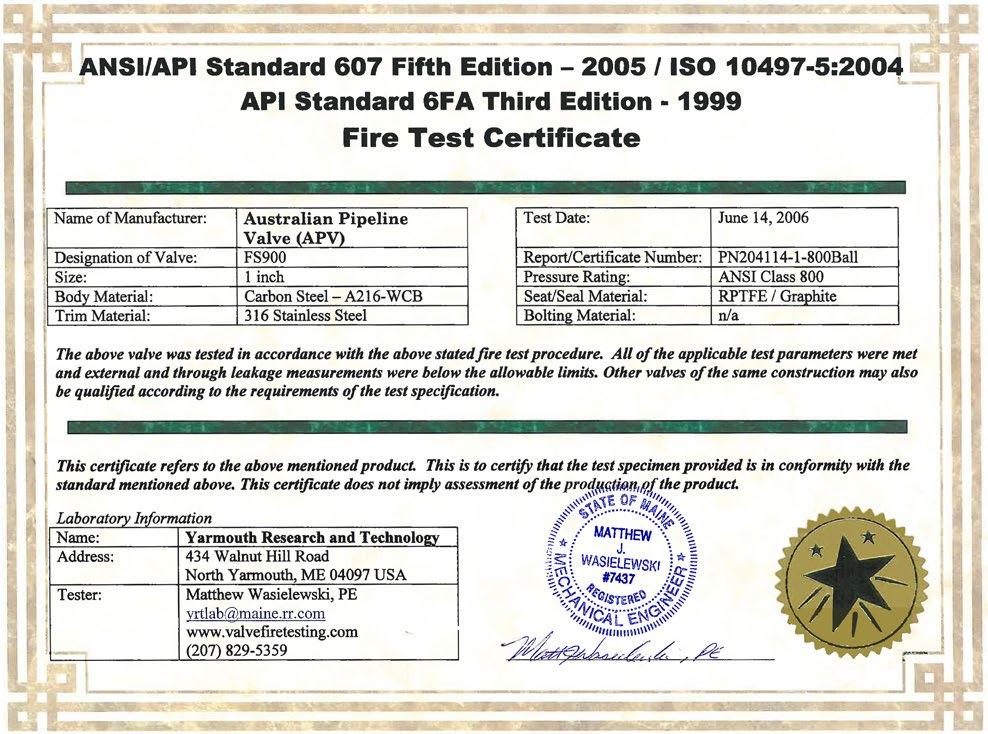

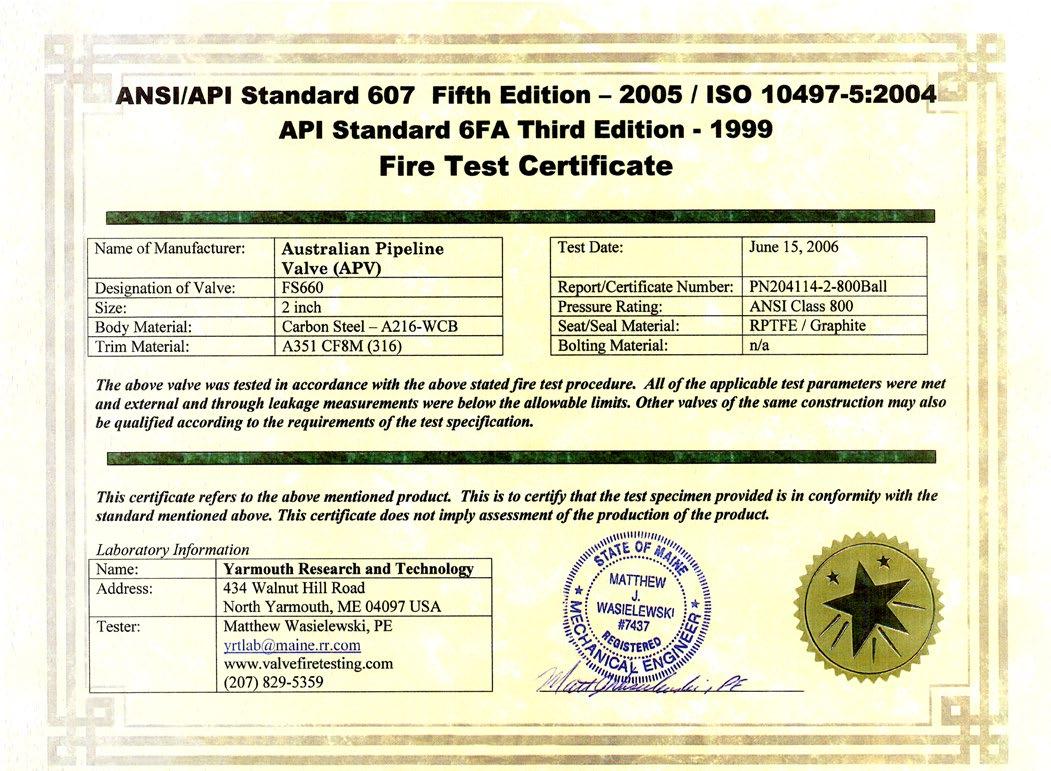

Australian Pipeline Valve is one of a small number of companies in the world to hold firesafe certification to the latest 5th & 6th edition of API 607 as well as the latest edition of API 6FA.

David Reznik

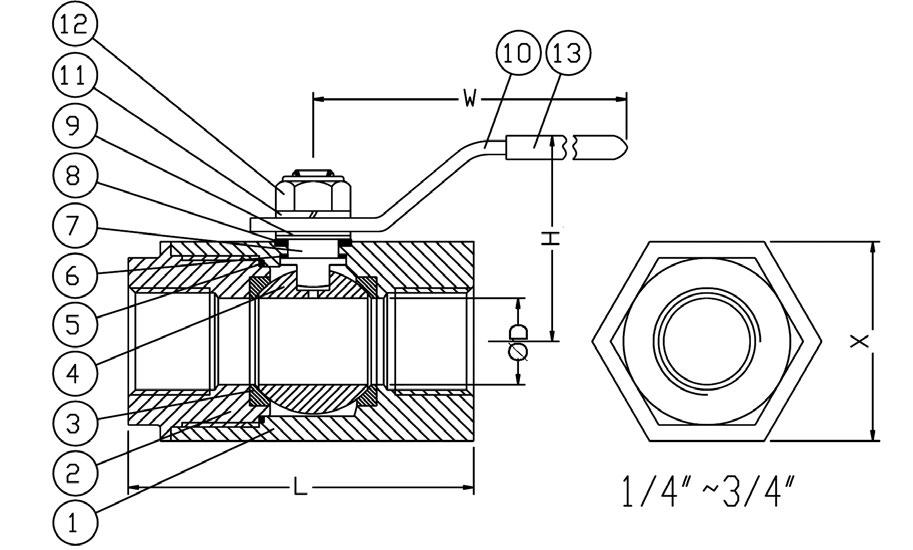

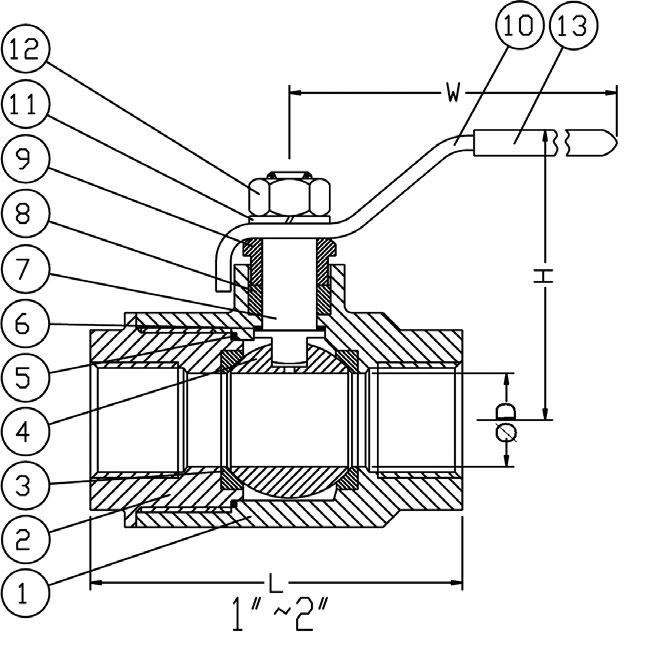

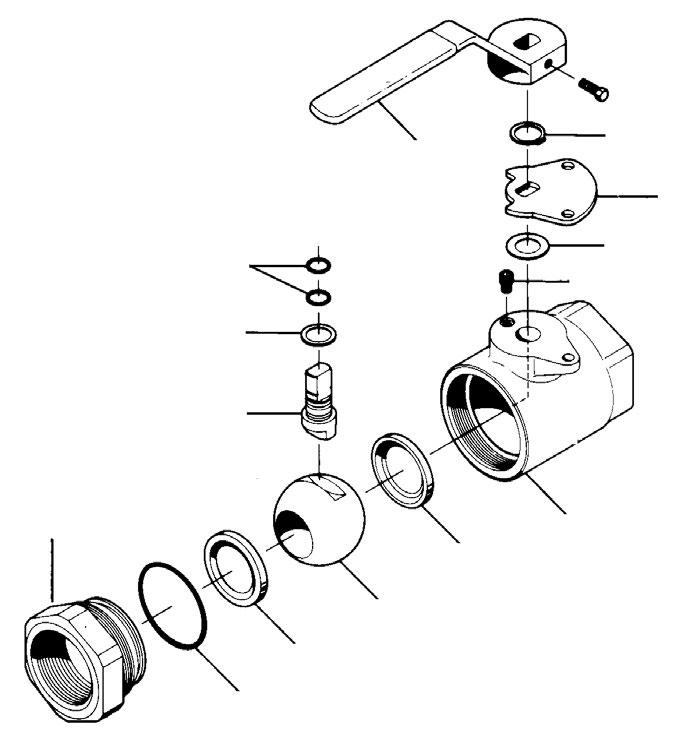

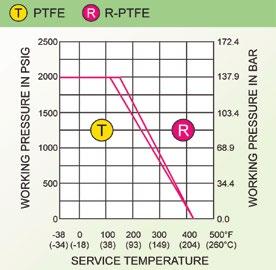

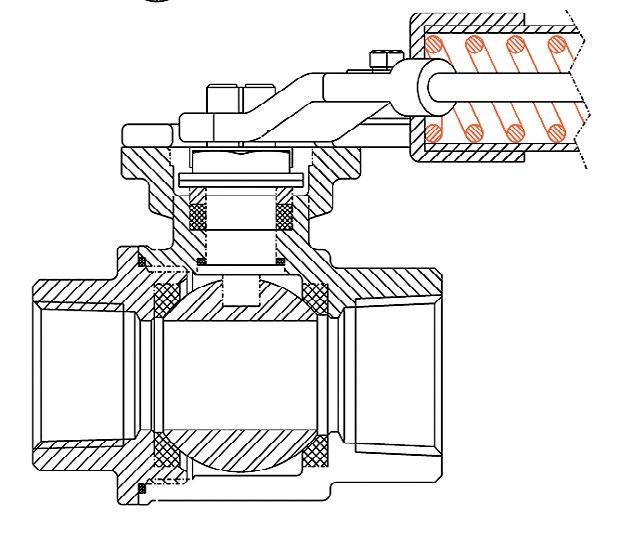

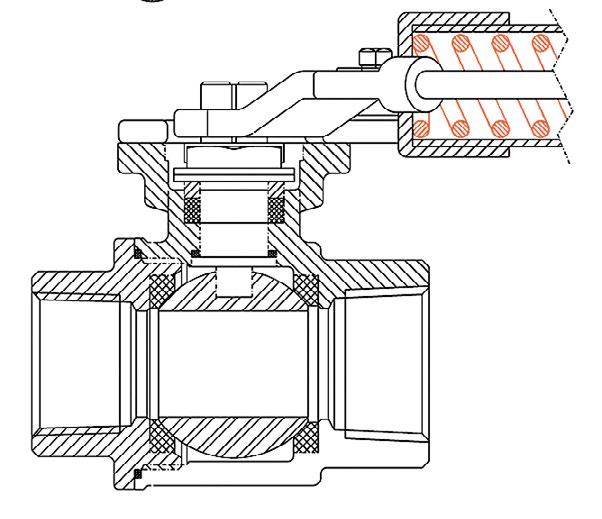

• 2000psi CWP.

• Single Piece design.

• Reinforced TFE seats and stuffing box ring.

• NACE MR-01-75 available.

• Compact.

• Firesafe Certified API 607 5th edition.

• Reinforced TFE seats increase durability.

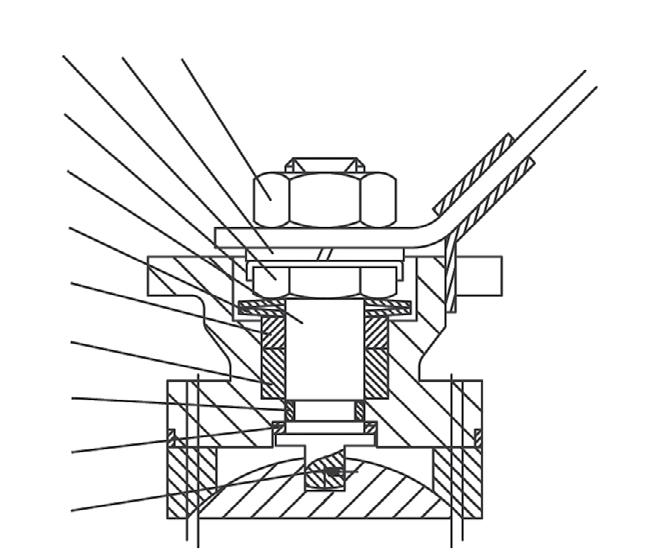

• Separating packing nut and handle nut ensures NO STEM LEAKAGE even when the handle is removed.

• Belleville washer assures leak-free seal on cool-down & as packing wears.

• Bottom-loaded blow-out proof stem.

• Basic design complied with ANSI B16.34 and MSS SP-110.

• NPT threaded ends complied with ANSI B 1.20.1.

• BSP threaded ends complied with BS21.

• Graphite gasket & stem packing prevent post-fire external leakage.

• Post-fire metal-to-metal seal prevents internal leakage after fire.

• Tested according to MSS SP-110/API 598.

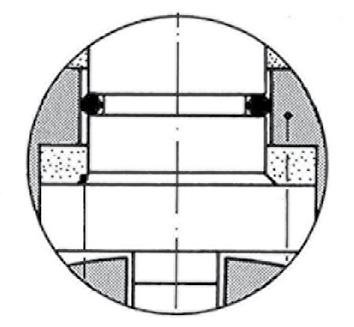

• Ball includes Pressure Equalisation Hole to prevent trapped pressure in body cavity which prevents seat damage due to thermal cycling.

L Locking Device

M Tapped Mounting Pad

V Vented Ball

FEATURES

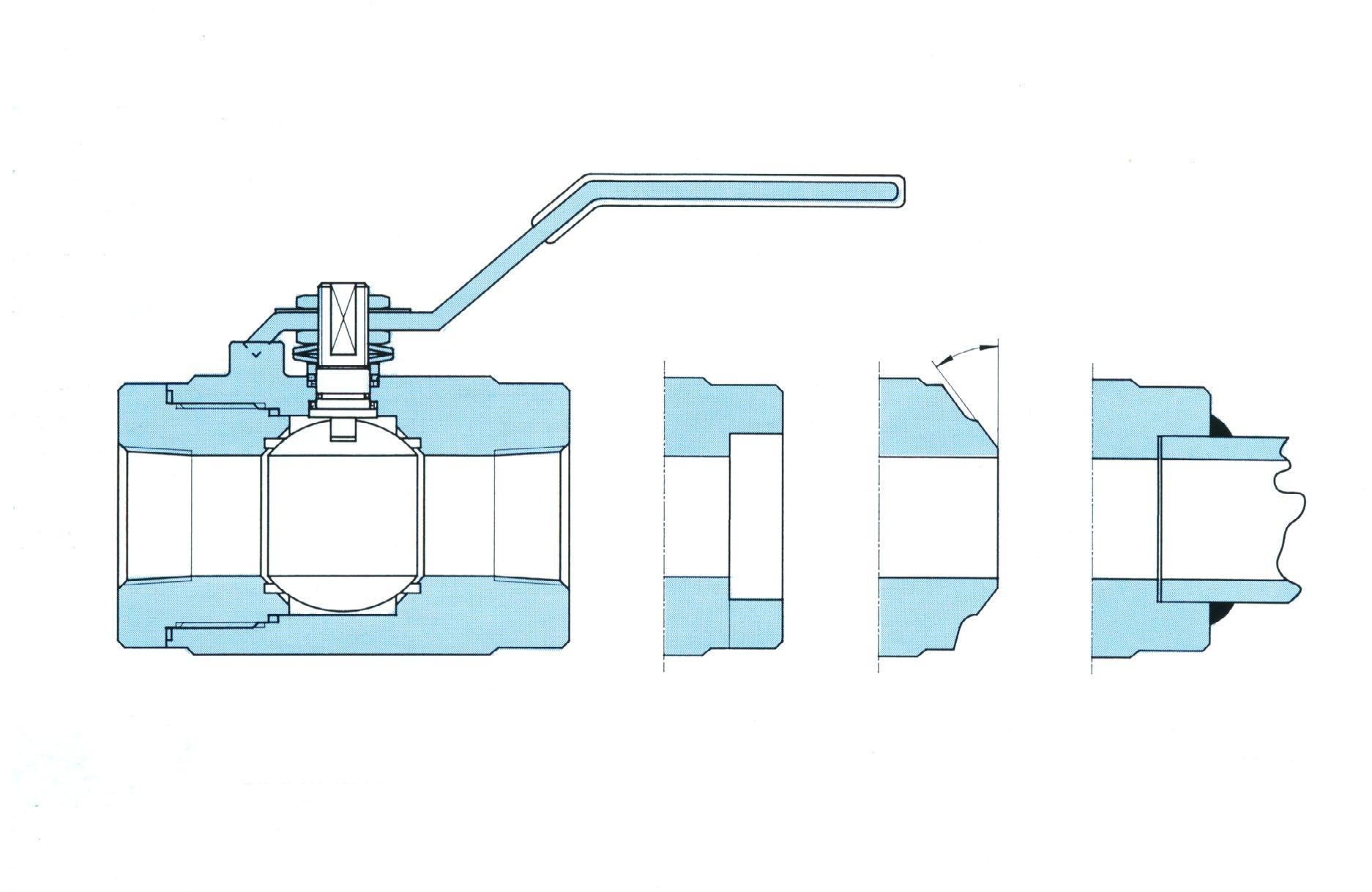

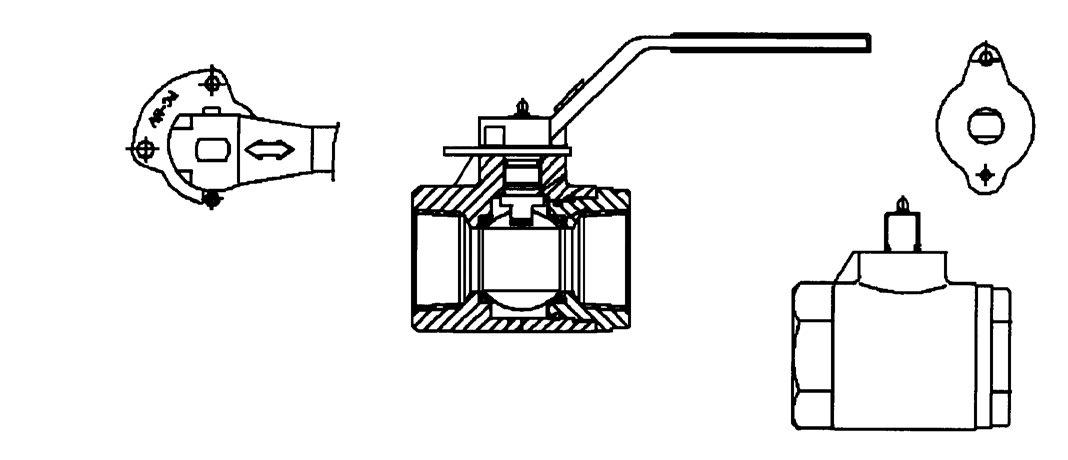

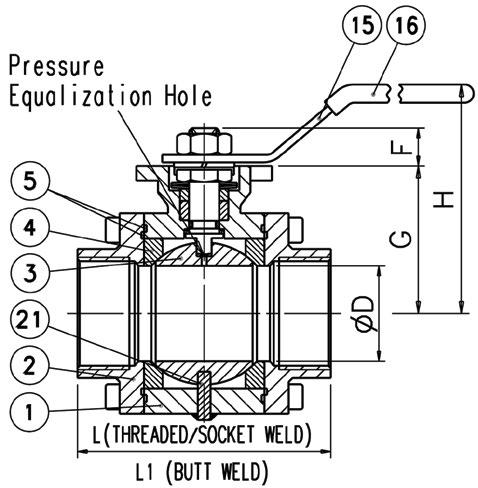

• 1000 PSI CWP

• Reinforced TFE seats increase durability. Adjustable packing gland.

• Bottom-loaded blow-out proof stem.

• Low operating torque to reduce automation costs.

• Optional mounting pad complies with ISO 5211 for ease and interchangeability of actuation.

• Basic design complies with ANSI B16.34 & MSS SP-110.

• NPT threaded ends complies with ANSI B 1.20.1.

• BSP threaded ends complies with BS21 (ISO 7-1 RC). Buttweld ends also available.

• Graphite gasket & stem packing prevent post-fire external leakage.

• Tested according to MSS SP-110/API 598.

* For 4” refer to separate drawing

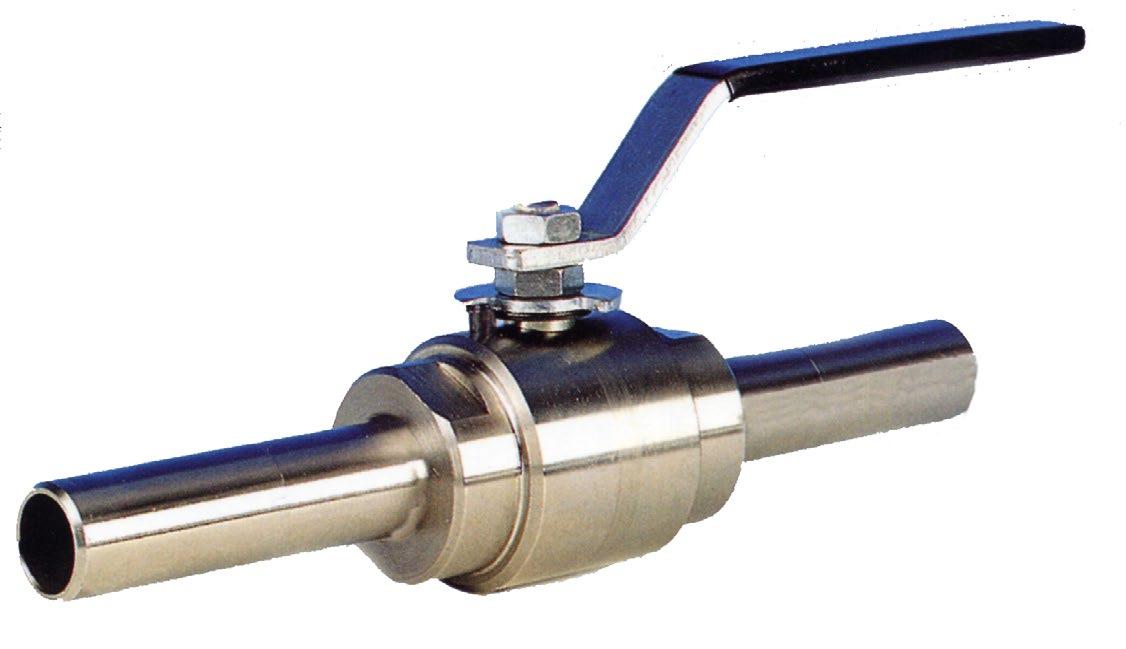

Buttweld Ends MATERIALS LIST

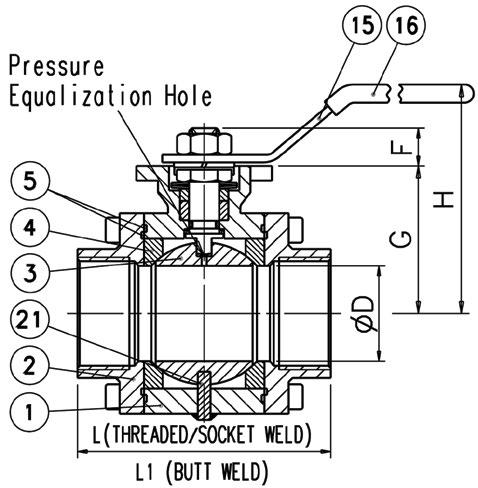

• 2000 psi CWP (800 Class) with RPTFE seats. (Up to 50NB)

• 2220 psi CWP (900 Class) with Delrin/RPTFE seats. (Up to 50NB)

• 1500 psi CWP 65NB to 100NB (seal welded body) with Delrin or RPTFE seat.

• Reinforced TFE seats increase durability.

• Adjustable packing gland.

• Bottom-loaded blow-out proof stem.

• Low operating torque to reduce automation costs.

• Optional mounting pad complies with ISO 5211 for ease and interchangeability of actuation.

• Basic design complies with ANSI B16.34 & MSS SP-110.

• NPT threaded ends complies with ANSI B 1.20.1.

• BSP threaded ends complies with BS21 (ISO 7-1 RC).

• Graphite gasket & stem packing prevent post-fire external leakage.

• Tested according to MSS SP-110/API 598.

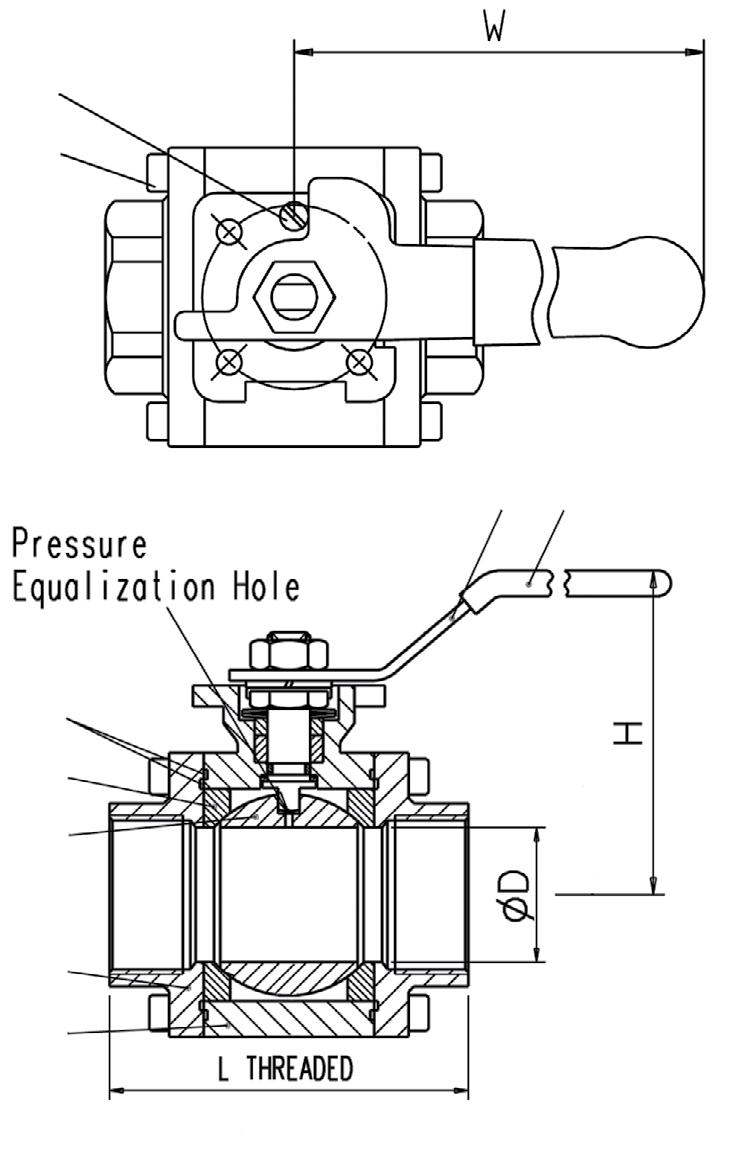

• Ball includes Pressure Equalisation Hole to prevent trapped pressure in body cavity which prevents seat damage due to thermal cycling.

DIMENSIONS

* 2 1/2” to 3” see separate drawing and separate pressure/temperature chart. *2 Mount pad is optional and dimensions can vary. This catalogue is general in it’s nature and design and can vary at any time. This catalogue is to be used as a guide only.

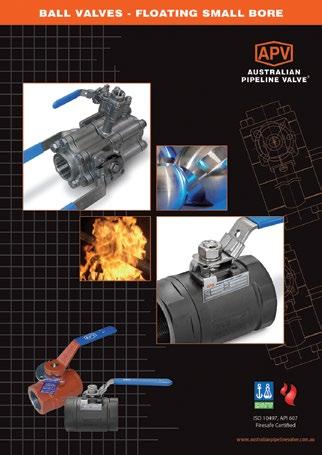

• 2000PSI (13790 kPa) 8~25NB. 1500PSI (10342 kPa) 32~80NB.

• Full Port DN 8NB~80NB (1/4”- 3”)

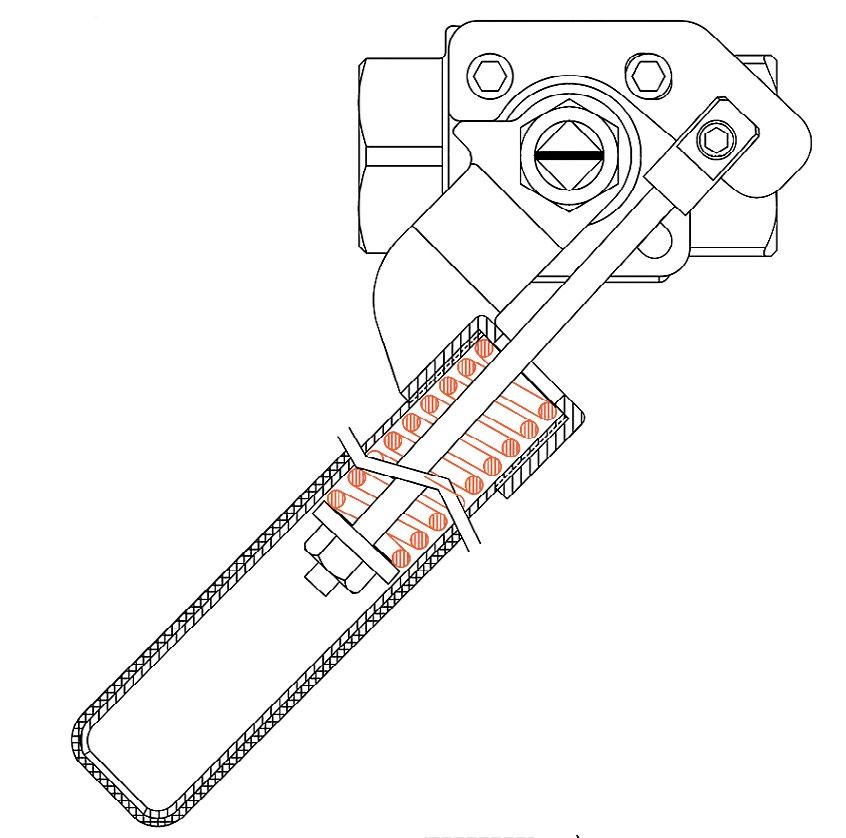

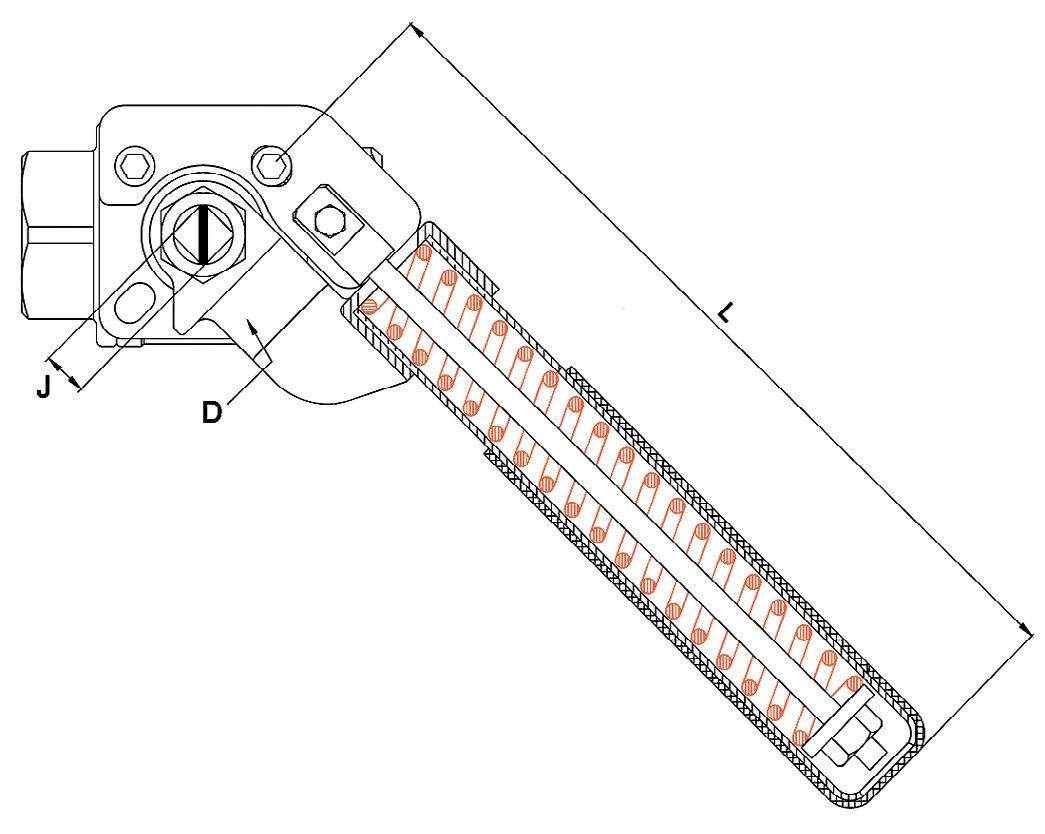

• Longlife for Actuated Valve Applications.

• Belleville Washer Set for Automatic Compression of Stem Sealing.

• Blow-Out Proof Stem.

• Graphite Gasket & Stem Packing Prevents Post-fire External Leakage.

• Tested according to API 598.

• Direct Mount Pad (ISO 5211).

• TA Luft Fugitive Emission Compliant.

• Precision Investment Heavy 2 Piece Cast Body.

• Available in Carbon Steel or Stainless Steel.

• Casting Approved by TUV AD 2000-Merkblatt W0.

• Various End Connections Available (NPT, ISO 7/1, ISO 228/1, BSP, DIN 2999, DIN 259, etc.).

• Basic design complies with ANSI B16.34 & MSS SP-110.

• Ball includes Pressure Equalisation Hole to prevent trapped pressure in body cavity which prevents seat damage due to thermal cycling.

Bore: 2000 PSI (8~25NB) 1500 PSI (32~80NB)

(MM & NM)

FEATURES

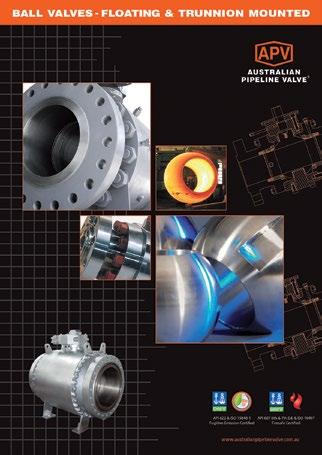

• ANSI 900 (2200psi) and ANSI 1500 (3700psi)

• API 3000 also available.

• Graphite stem packing.

• Blow-out-proof stem design.

• RTFE and Devlon seats.

• Bolted adjustable packing gland.

• Heavy duty handles.

• Reg. Port and Full Port available.

• NACE MR-01-75 can be supplied.

• Fire safe design API 607 & API 6FA.

• Locking Kits available

• Heavy construction.

• Enlarged bottom-loaded blow-out proof stem.

• Special design of gasket ensures NO LEAKAGE between body & cap.

• Basic design complies with ANSI B16.34 and MSS SP-110.

• NPT threaded ends complies with ANSI B1.20.1.

• Ball includes Pressure Equalisation Hole to prevent trapped pressure in body cavity which prevents seat damage due to thermal cycling.

STANDARD EXECUTION

• Fire safe.

• Threaded ends: ANSI B1.20.1 - API 6A / UNI ISO 7.1.

• Extended Socket Weld - Butt weld ends also available.

• Materials: A105 / WCB - AISI 304/L - AISI 316/L.

• Gaskets: PTFE, Graphite

• Identification: Valve size - Rating - Material

CLASS 900 - 2220 PSI WOG

Max Working pressure: 153 bar a 38ºC - 2220 psi @ 100ºF seat RPTFE/Delrin

CLASS 1500 - 3700 PSI WOG

Max Working pressure: 255 bar a 38ºC - 3700 psi @ 100ºF Seat Nylon/Delrin

API 3000 - 3000 PSI WOG

Max Working pressure: 210 bar a 38ºC - 3000 psi @ 100ºF Seat Nylon/Delrin

Other special materials are available for seats: PTFE + 316; Carbon Graphite; Vespel, Delrin, PEEK Technical information upon request.

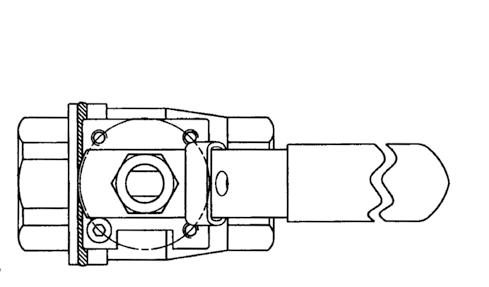

FEATURES

• Two Piece Body Screwed Ends

• Investment Cast Body

• Blow Out Proof Stem / Floating Ball

• Fire-Safe API 607 5th Edition, API 6FA 3rd Edition

• Adjustable Packing Gland

• Standard Locking Handle

• Actuator Mounting Pad

• Ball includes Pressure Equalisation Hole to prevent trapped pressure in body cavity which prevents seat damage due to thermal cycling

• Threads conform to ANSI B1.20.1, BS21, DIN259/2999

• Mount Pad

API 3000 - 3000 PSI WOG

Max Working pressure: 207 bar @ 38ºC - 3000 psi @ 100ºF

Seat Nylon / Delrin

CLASS 2500 - 6000 PSI WOG

Max Working pressure: 413 bar @ 38ºC - 6000 psi @ 100ºF

Seat Nylon / Delrin

Other special materials are available for seats: PTFE + 316; Carbon Graphite; Vespel, Delrin, PEEK Technical information upon request.

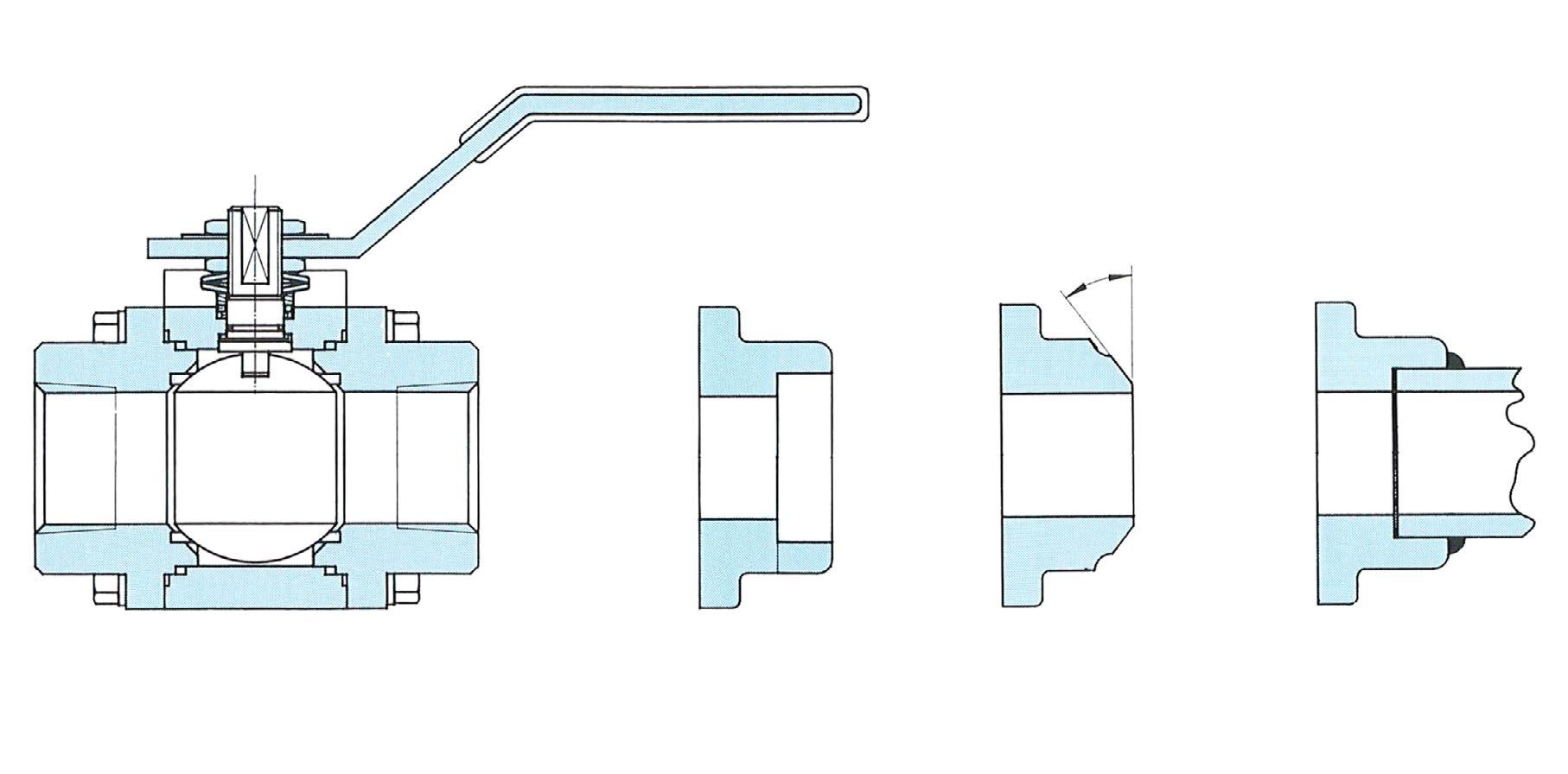

FIRESAFE CERTIFIED API 607 5TH

EDITION AND API 6FA 3RD EDITION

• Refer to non extended FS660 data sheet for main valve specification

• Class 800, 1500, 2500

• Design and Manufacture per ANSI B16.34, BS5351, API 608

• Thread per ANSI B1.20.1

• Socket per ANSI B16.11

• Test and Inspection per API 598

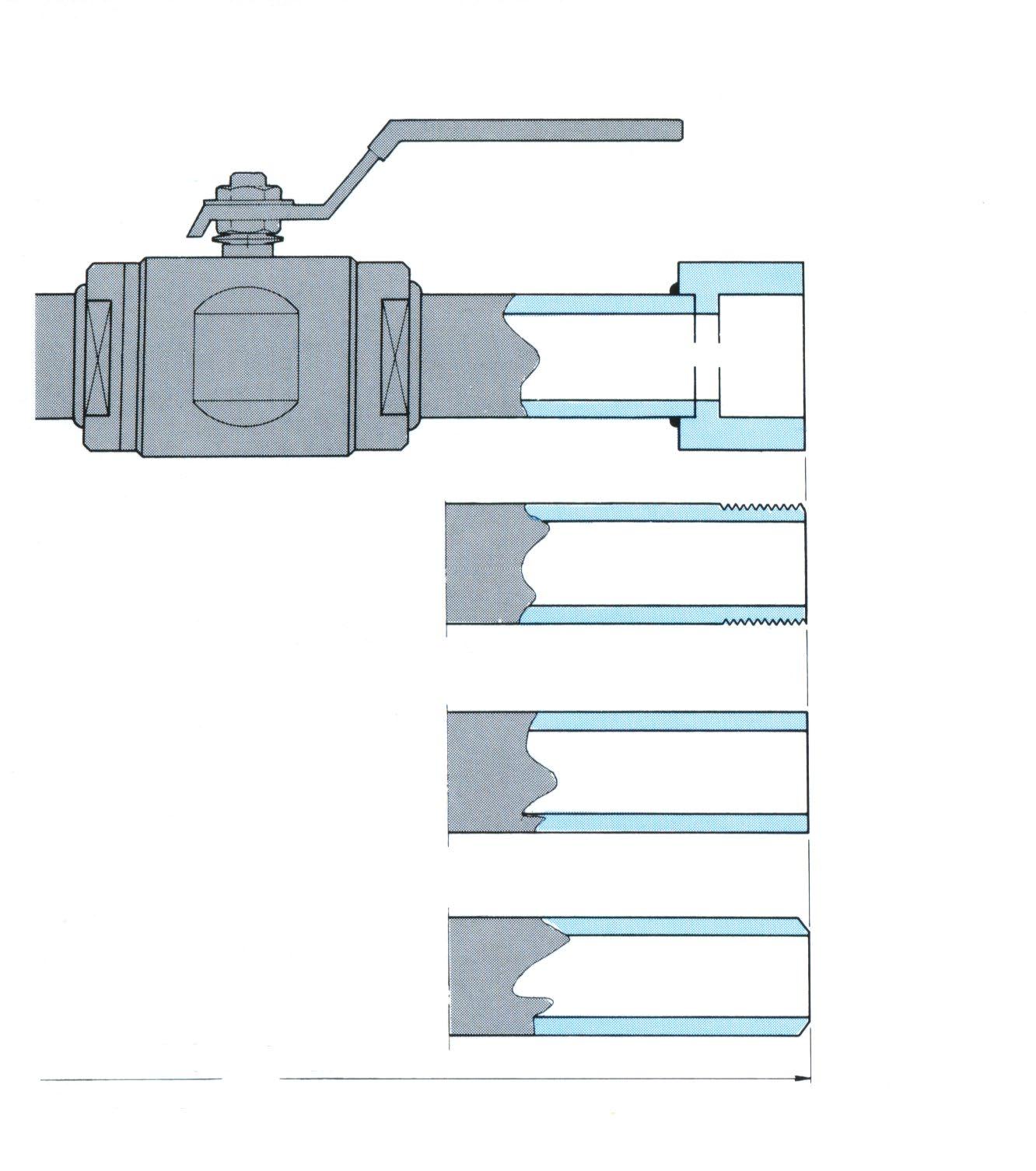

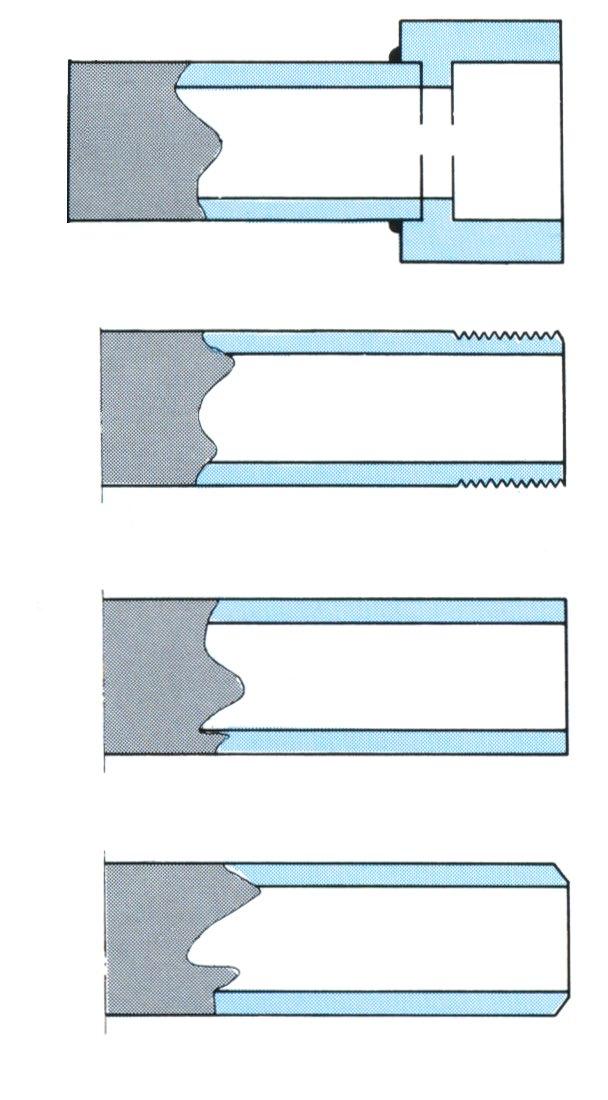

Integral or weld-on extended ends

* Optional pup lengths available as per manufacturing drawing

TYPE SOCKET WELD

TYPE THREADED

TYPE PLAIN

TYPE BUTT WELD

L2 Normal extended ends pattern L1 Special extra long pattern

FEATURES

• 3,000 PSI cold, Non-shock

• Proven Design

• Full Port (2” size is full port to schedule 160)

• Nylon or Delrin seats, PTFE or graphite seals

• Heavy duty handle

• Stainless ball and stem

• 2 piece body

• Ball includes Pressure Equalisation Hole to prevent trapped pressure in body cavity which prevents seat damage due to thermal cycling.

• Threaded ends NPT ANSI B 1.20.1 - API 6A

OPTIONS

• Padlocking device

• Steam trim

• BSPT BS21/ISO 7-1 ends

DIMENSIONS

* The Cv factor is the gallons of water per minute that the valve will pass with 1 PSI pressure drop. 2 1⁄2” & 3” 3000 psi also available.

• Size Range DN15~25 (1/2”~1”)

• Pressure Rating 10,000 PSI

• End Connection Female pipe thread to NPT, DIN259/2999 or BSPT/BS21/ISO 7-1

• Temperature Range -20°F to 428°F (-29°C to 220°C) with PEEK seats

DIMENSIONS

Size C D

2C (Brown)*

(2160 PSI)

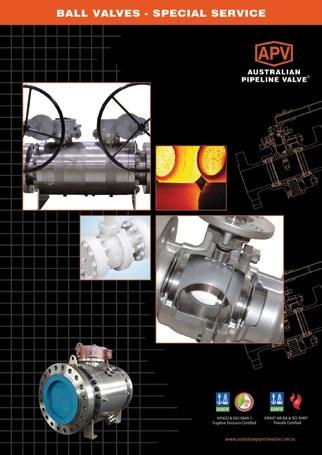

FEATURES

• 2 Piece, Full Port and Reduced Port

• Bolted Construction

• Blowout-Proof Stem with O-Ring • Anti-Static

• Conforms to ASME B16.34

• Screwed end, socket weld end to ASME B16.11, butt weld end to ASME B16.11, flanged end or any combination available

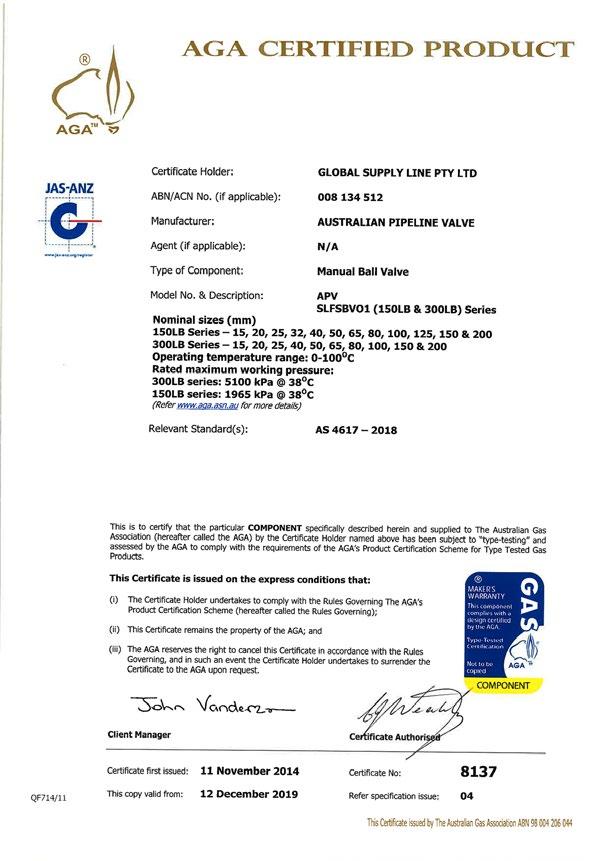

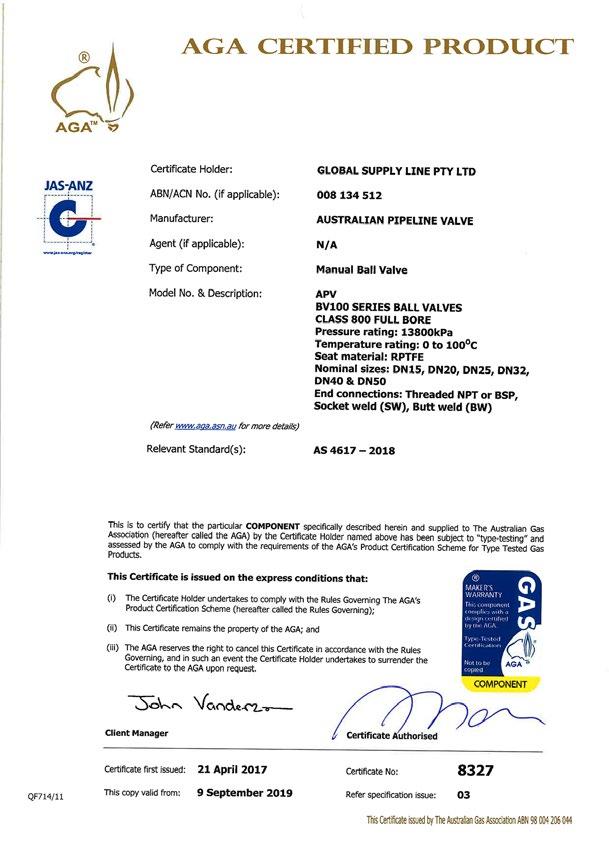

• AGA approved for AS 4617, AS 4629.1 & AS 4629.2

• Swing-out centre (800 Class)

• Firesafe to API 607 6th edition and API 6FA

• High cycle triple barrier stem seal system

• Design to ANSI B16.34

• Class 600 to 2500 and API 3000

• Three piece, enclosed bolt design

• Investment cast or forged

• Anti-blowout stem

• Full bore for minimum pressure drop

• Adjustable packing nut to compensate for tension loss

• Locking handle

• Antistatic design to API 608

• Testing to API 598

• Actuator mounting pad to ISO 5211

• Vacuum service (PTFE Seat) down to 20 microns (133 pascals)

8NB (1/4) 10

10NB (3/8) 10

15NB (1/2) 12

20NB (3/4) 35

25NB (1) 68

32NB (1-1/4) 105

40NB (1-1/2) 150

50NB (2) 290

No safety factor is included. When conditions below apply, then calculate torque using the following application factors:

DIMENSIONS - ANSI-600LB

DIMENSIONS - ANSI-600LB

*150 x 111mm standard bore also available. Refer to drawing.

DIMENSIONS - ANSI-900/1500LB

Forged 3 Piece 600~2500LB

2500lb Refer to drawing. Also see BVF100-F26 (Special Service Ball Valves) for floating 1500NB 900/1500lb. Also see model BV100 3 piece.

NPT/SW/BW (Short / Standard Ends)

EXTENDED END TYPES (Fully Integral or Weld on)

INTEGRAL FLANGED (150 to 2500 Class)

The BV100 Series (7500 PSI Version) valve structure and wall thickness conforms to ASME B16.34 standard.

The BV100-7500 Series is full bore in all sizes and is also available with a V-ball slot in 15°, 60° or 90° for different flow rate requirements.

SPECIFICATIONS

• Class range ANSI 3000 Class - 7500 psi 8NB ~ 25NB (1/4” to 1”) ANSI 2500 Class - 6000 psi 32NB ~ 50NB (1-1/4” to 2”)

• Adjustable stem packing

• Blow-out proof stem packing

• End connections: Threaded, Socket weld, Butt weld, Extended SW, BW

• ISO Mounting

• Full Port

OPTIONS

• Firesafe

• Spring handle (dead man handle)

• Oval handle

• Locking device

• V-Ball for control Valve

• Cryogenic option

• PTFE / PFA coating

• Special Alloy - Hastelloy C 276 / Super duplex / Alloy 20 / Monel 400

DIMENSIONS (mm)

*Optional

10,000 PSI trunnion version available in metal or soft seats.

• Size Range - 1/4” - 2” (DN8 - DN50)

• Pressure Rating - 2000 PSI (800 Class)

• End Connection - Threaded, Socket Weld & Buttweld

• Service Application - Slurries, Pulp Stock, Solid-Containing Fluids

• Firesafe API 607

DIMENSIONS

• Size Range - 2-1/2” - 4” (DN65 - DN100)

• Pressure Rating - 2000 PSI 2-1/2”~ 3” (65NB~80NB) 1500 PSI 4” (100NB)

• End Connection - Threaded, Socket Weld & Buttweld

• Service Application - Dirty Oils & Gas, Slurries, Pulp Stock, Solid-Containing Fluids

• Firesafe API 607

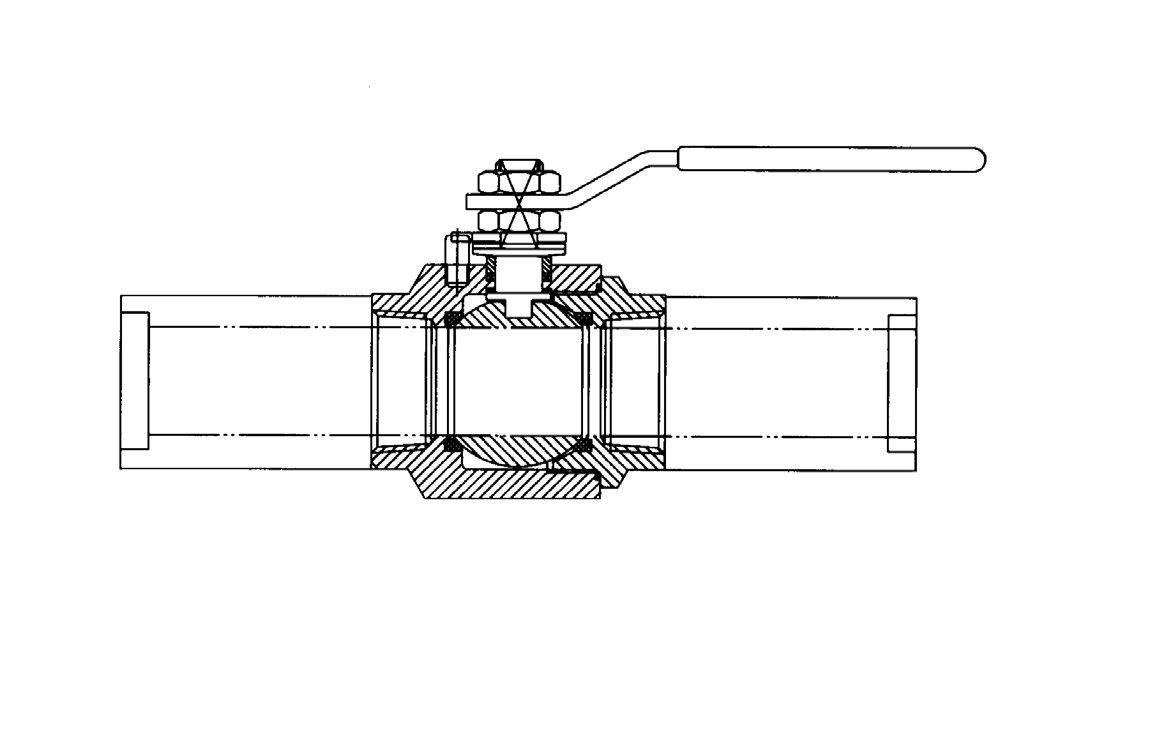

DB300-Z is available in 2160 psi (Class 900) and 3600 psi (Class 1500). Stainless steel, carbon steel or special alloy steel can be supplied.

All the valves on double block & bleed valve are with ISO 5211 direct mounting pad for automation. The 900 class valves are supplied with TFM1600, (Delrin), or RPTFE seats, 1500 class have PEEK 5004.

Valve construction & wall thickness is compliant with ANSI B16.34 wall thickness requirements. V-ball with 30°, 60°, or 90° port is available as an option for different flow rate pipe line designs.

FEATURES

• Body & end caps investment cast

• Full bore & Std. bore design

• Adjustable stem packing

• Blow-out proof stem design

• Locking device

• End types: threaded/socket weld/butt weld

OPTIONS

• Fire safe design

• Spring return handle (dead man handle)

• Steam jacketing

• Cryogenic bonnet

• Fugitive emission bonnet

• Hastalloy C/Super duplex/Alloy 20/Monel

Pipe CF8M 22 Bleed Ball Valve 23 Lever Steel Pipe 24 Gland CF8 25 Bolts SS 304 MATERIALS LIST

No. Parts Stainless

1 End Cap CF8M

2 Body CF8M

3 Ball SS 316

4 Seats PEEK/Delrin

5 Gasket PTFE/Graphite

6 Bolts SS 304

7.1 Thrust Washer PTFE/Graphite 7.2 Thrust Washer PEEK 8 Stem CF8M

9 Stem Packing PTFE/Graphite 10 Gland Washer SS 304 11 Disc Washer SS 301 12 Gland Nut SS 304 13 Nut Stop SS 304 14 Space Washer SS 304 15 Stop Plate SS 304 16 Stem Nut SS 304 17 Stop Pin SS 304

Lever SS 304 19 Lever Cover Vinyl 20 Block CF8M

• Full Port DN 8NB~80NB (1/4”- 3”)

• 2000PSI (13790 kPa) for 25NB 1500PSI (10342 kPa) for 32~80NB

• Spring Return Handle (Dead Man Handle) for Auto Default Position

• High Cycle Triple Barrier Stem Seal System

• V-Type Packing for Maximum Stem Sealing

• Belleville Washer Design for Automatic Compression of Stem Sealing

• Direct Mount Pad (ISO 5211)

• TA Luft Fugitive Emission Compliant

• Precision Investment Heavy Hex

2 Piece Cast Body

• Blow-Out Proof Stem

• Available in Carbon Steel or Stainless Steel

• Various End Connections Available (NPT, BSP, ISO 7/1/ ISO 228/1, BW, etc.)

• All components of lever are stainless steel

• Operating torque should be sized according to valve torque, media, pressure and safety.

• Can be fitted on 1P, 2P, 3P valve

• Available in ISO F03 to F07

• 55CrSi Spring Material

Buttweld pup

Plain pup end H Socketweld pup end

Flanged RF

Flanged

Electric Operator

Gear Operator

Lockable Lever

Lever Operator

Pneumatic Operated

C Carbon reinforced PTFE D Devlon

E Peek

F Pure PTFE / TFM1600

H Glass Reinforced PTFE (Glass Fibre Content 20%)

N Nylon

T Tefzel

U Delrin

V Viton X NBR Z Other A WCB

B A105/A105N

C LCB (low temperature ≥-46 C)

D LF2 (low temperature ≥-46 C)

E CF8 F 304

G CF8M

316 I CF3M

316L

CF3 L WC6 M WC9 N F51 / CD3MN / 4A O F55 / CE3MN / 5A P CE8M Z Other

/304L (Dual)

/ Viton

Graphite (GRP)

Graphite + Viton

Graphite + PTFE

Viton

Australian Pipeline Valve don’t consider in our design the following factors of risk:

1. Australian Pipeline Valve ‘Standard’ ball valves can be used in a temperature range between -28.8 to +200°C. (Note, pressure limitations apply above 38°C refer to Pressure/Temperature charts.) For service temperatures below -28.8°C ball valve construction materials shall be submitted to an impact test at the minimum service temperature. For temperatures outside of the range of -28.8°C to +200°C ball valves have to be provided with seats, seals and body material able to withstand the temperature degree required.

2. The onus is on the customer to specify all materials of construction and service conditions. Australian Pipeline Valve shall assume standard materials and conditions if not otherwise specified.

3. Australian Pipeline Valve ‘Standard’ ball valves are not equipped with devices suitable to avoid internal over-pressures caused by incorrect operations of process or by-fluids & liquids subjected to an increase of volume and/or pressure (these devices, such as the over-pressure hole in the ball or safety seats are available upon request).

4. Australian Pipeline Valve ‘Standard’ ball valves are not designed with special devices to withstand a sudden thermal jump (thermal shock).

5. In general Australian Pipeline Valve ‘Standard’ ball valves are not mechanically designed to bear overloads due to exceptional atmospheric or natural phenomenon’s (such as earthquakes).

6. In general Australian Pipeline Valve ‘Standard’ ball valves are not designed to bear loads on flanges, on pipe connections or pipeline.

7. In general Australian Pipeline Valve ‘Standard’ ball valves can’t withstand ice inside their bodies (in this case user must specify the optional stem extension for insulating, avoiding the presence of residual product inside the valve).

8. Australian Pipeline Valve ‘Standard’ ball valves are not suitable for low temperature service below -29°C (-20°F) unless provided with cryogenic stem extension and other modifications (available on request).

9. Australian Pipeline Valve ‘Standard’ ball valves are suitable for ‘industrial’ oxygen (not medical) service when supplied degreased and packed in polyethylene bags only.

10. The compatibility between ball valves construction materials and medium is selected by the user. The user is ultimately responsible for verifying the compatibility between medium and materials.

11. Abrasive or dirty service, high temperature service, low temperature service, vacuum service, near zero pressure service and other special applications should be clearly stated when requesting quotation.

Before installing the ball valve onto the pipe-line it is mandatory for the user to verify the compatibility of the ball valve with service conditions (medium, temperature and pressure). With reference to standard ball valves held in stock the reseller and end user will have to assure themselves of the compatibility with the use of conditions required by the customer. Australian Pipeline Valve ball valves must be only used for on-off (fully open/fully closed) service.

Before using the ball valve in a potential explosive atmosphere it’s necessary: -

• To verify the compatibility between the ball valve and the zone in which the ball valve should be installed.

• To foresee the pipe-line ground condition on which the ball valve should be installed.

• To check that the temperature of the ball valve surface is not higher than the flammable point of the atmosphere in which the ball valve is installed (in this case specify an insulating cover device for the valve and an extension for the wrench)

• Before installing ball valves with welding ends to make sure that the process of welding is carried out in accordance with all the safety requirements of the classified zone.

• To avoid mechanical knocks during the installation that may cause sparks.

STATIC ELECTRIC EFFECT The APV fire safe ball valves are provided with anti-static devices for ball-stem-body. When service conditions require electrical continuity to prevent static discharge, the user is responsible for specifying static grounding.

LIQUIDS WITH HIGH FLUID VELOCITY When ball valves are to be utilised on liquids with very high velocity, check with the valve distributor or manufacturer for appropriate advice to minimise the possibility of seat deformation, especially when they are highly pressurised on high temperature line.

THROTTLING SERVICE Ball valves are generally not recommended for throttling service, as both the fluid flow and the leading edge of the ball can damage or deform the resilient ball seats causing leakage. High fluid velocity or the presence of solid particles in suspension will further reduce seat life in throttling applications.

• Do not open the bonnet or cap when bearing pressure. Valve is not equipped with pressure access device. User should check it by other method through it’s piping system.

• Do not touch the surface of the valve on high temperature.

• Not allowed for unstable fluid, otherwise specified with category III in Declaration of conformity or/and in this user manual.

• Lock design on the handle to avoid the valve operated by non-related people is optional requested by the user.

Australian Pipeline Valve cannot be held responsible for damage caused by use of the product especially if it is improper use or modified.

“Australian Pipeline Valve produces isolation, control and flow reversal protection products for severe and critical service media in utility, steam, pipelines, oil & gas and process industries. APV valves and pipeline products form the most competitive portfolio in the market.”