The Marinas22 conference and exhibition, held on the Gold Coast in May, welcomed over 320

The Marinas22 conference and exhibition, held on the Gold Coast in May, welcomed over 320

HEAD OFFICE MAILING ADDRESS & SUBSCRIPTION ENQUIRIES

Loud & Clear Publishing Ltd,

School Farm, School Road, Terrington St. John, Cambridgeshire PE14 7SJ, UK

Editor

Carol Fulford

T: +44 (0) 1945 881018

E: carolfulford@marinaworld.co.uk

Advertisement/Commercial Director

Julia Hallam

T: +44 (0) 1621 855 890

E: juliahallam@marinaworld.co.uk

Administration Manager

Corinna Francis T: +44 (0) 1621 855 890

E: corinnafrancis@marinaworld.co.uk

Finance Manager

Magdalena Charman T: +44 (0) 1403 733678

E: accounts@marinaworld.co.uk

Advertisement Production

Charlotte Niemiec T: +44 (0) 7446 056473

E: adstudio@marinaworld.co.uk

NORTH AMERICAN OFFICE

Sales Director Americas

Philippe Critot

PO Box 29759, Los Angeles, CA 90029-0759, USA

T: +1 323 660 5459 F: +1 323 660 6030

E: pcritot@marinaworld.com

FRENCH OFFICE

Publisher’s Representative

Catherine Métais T: +33 6 60 17 75 81

E: catherinemetais@marinaworld.com

ITALIAN OFFICE

Advertisement Representative Ediconsult Internazionale srl

piazza Fontane Marose 3, 16123 Genoa, Italy

T: +39 010 583 684 F: +39 010 566 578

E: genova@ediconsult.com

ASIA PACIFIC OFFICE

Publisher’s Representative Suzanna Kovacevic

T: +61 438 22 46 09

E: suzanna@marinaworld.com

Marina World (ISSN 1471-5856) is published bimonthly by Loud & Clear Publishing Ltd, School Farm, School Road, Terrington St. John, Cambridgeshire PE14 7SJ, United Kingdom.

The 2022 US annual subscription price is $160. Airfreight and mailing in the USA by agent named WN Shipping USA, 156-15 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA.

Periodicals postage paid in Jamaica NY 11434. US Postmaster: Please send address changes to MARINA WORLD, WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA.

Subscription records are maintained at Loud & Clear Publishing Ltd, School Farm, School Road, Terrington St. John, Cambridgeshire PE14 7SJ, United Kingdom.

Air Business Ltd is acting as our mailing agent.

Marina World is available on subscription at the following cost:

1 year (6 issues) – £80.00 Sterling ($160)

2 years (12 issues) – £140.00 Sterling ($280)

No part of this publication may be reproduced without the prior permission of Loud & Clear Publishing Ltd, the copyright owners. Upon application, permission may be freely granted to copy abstracts of articles on condition that a full reference to the source is given.

Printed in the UK by Stephens & George

© 2022 Loud & Clear Publishing Ltd

Views expressed by individual contributors in this issue are not necessarily those of Loud & Clear Publishing Ltd. Equally, the inclusion of advertisements in this magazine does not constitute endorsement of the companies, products and services concerned by Loud & Clear Publishing Ltd. The publisher reserves the right to refuse advertising.

If you need inspiration to pursue environmentally aware, transformational projects, this is your issue. From one side of the globe to the other, new marina developments are emerging that, although involving a patient and determined journey through planning and approvals, are delivering landmark marinas:

• Dana Point Harbor – a huge municipal marina in California crying out for improvement is now, via a PPP, being redeveloped into a vibrant hub for locals and visitors, with top notch marina services and infrastructure, dining, retail and hotel accommodation.

• Queenstown Marina – set amidst stunning scenery and positioned on an environmentally sensitive lake in New Zealand’s South Island, Iraj Barabi’s dream-come-true facility merges seamlessly into the lakefront scene and has a touch of nostalgia in the mix.

• Dinner Key Marina – massively damaged in 2017 by Hurricane Irma, this municipal marina – the largest on the US eastern seaboard – has benefited from robust repairs and upgrades while remaining open to the public.

• Adelaide Pointe – visionary owners Ryan and Emily Leestma have flipped the traditional model on its head to create a marina, hotel, retail and residential development on Muskegon Lake, USA. Key elements include an open plan approach that is accessible to the local community, soft shorelines, natural materials and green energy.

These, together with Marina Punta del Faro (featured on the cover) and examples of many special marinas in our Advertisement Feature A-Z Guide to Pontoon & Decking Manufacturers, make this September/October issue of Marina World a celebration of modern marina design.

Our annual A-Z Guide, which features 22 companies, is a valued reference source for anyone looking to develop, rebuild or expand a marina facility.

Start planning!

Carol Fulford Editor

Don’t miss Mooring Post – Marina World’s new digital newsfeed. Sign up at www.marinaworld.com for free to receive this and a heads up on each print issue of Marina World

We understand the water. We have the products and the knowhow to move away from old fashioned methods like piles, chain, or cables.

applications like marinas, wave-attenuators, buoys,

accomodate for the depth.

Contact us at

SEAFLEX SWE +46 90 16 06 50

SEAFLEX US +1 (310) 548-9100

back to provide constant stability.

Sustainable materials that ensure

from a company that cares.

USA: Further to a five-year planning process, the town of Bristol on Narragansett Bay in Rhode Island has completed a large-scale harbour expansion project. The centrepiece of the work is an SF Marina floating concrete breakwater and pontoon system.

After removing Bristol Harbor’s aging fixed wave fence, local company Reagan Marine Construction installed 12 SF500 Series (5.2m/17ft wide) floating breakwater pontoons. These are virtually unsinkable, exceptionally stable and are coupled in a way that absorbs and distributes stress loads. The pontoons are anchored using 48 16-strand Seaflex mooring hawsers.

“The breakwater works great,” said harbour master Gregg Marsili. “Not

Don’t miss our new digital newsfeed. Sign up for free at www.marinaworld.com

Highlights from August/September:

• Ibiza: new superyacht yard development

• Maldives: floating boating community wins approval

• UK: Council seeks funding for Barry Docks

• USA: preliminary submissions for Seaport San Diego

• Cyprus: town planning approval for Larnaca

only does it protect the marina, but also the shoreline, our other marina at Rockwell Park, the fuel pier on State Street and the Prudence Island ferry dock.”

The 790ft (240m) long structure includes an interior dock array for a total of 34 tapered fingers. Bristol Harbor has 22 transient slips for boats up to 39ft (12m) in length and an additional 499ft (152m) of dock space for vessels up to 197ft (60m).

• Qatar: M3 to develop Pearl yacht club

• USA: Suntex buys The Wharf in Marathon, Florida

• USA: Freedom Boat Club expands to Chula Vista

• New Zealand: Westhaven Marina –first in country for Gold Anchor

• Croatia: Marina Rijeka – new marina, new standards

BONUS: Refresh your reading on the thorny topic of leases and concessions with our archive articles, sign up now.

PierPump – Trouble-free disposal of waste and bilge water from boats and yachts.

When installing a wastewater management system harbor operators have to make several decisions depending on the location, number of berths and size to find the optimal system.

The Vogelsang PierPump is a customer-oriented high-performance solution, which is easy to operate and allows bilge water or black water to be pumped directly into the sewage system. The integrated rotary lobe pump means that the PierPump is resistant to foreign matter, so that the vacuum extraction process does not come to stop if the wastewater contains foreign matter. Wastewater tanks are vacuum extracted in a very short time, and the voyage can continue.

VOGELSANG � LEADING IN TECHNOLOGY vogelsang.info

USA: MarineMax, the world’s largest recreational boat retailer, has entered into a definitive agreement to buy Island Global Yachting (IGY Marinas).

MarineMax will acquire IGY Marinas for US$480 million in cash, with an additional potential payout of up to $100 million two years after closing, subject to the achievement of defined performance metrics. IGY is projected to generate over $100 million in revenue in 2022.

The deal is expected to close in the first half of 2023 and Tom Mukamal, CEO of IGY Marinas, and the existing IGY management team will continue to lead the growth and operations of the business.

“We are delighted to announce our acquisition of IGY Marinas, a transformative transaction for MarineMax, that significantly strengthens our ability to provide the best customer experience to yacht owners around the world,” said W Brett McGill, CEO and president of MarineMax. “The addition of IGY Marinas positions MarineMax as the

BELGIUM: A declaration on “developing common rules for truly European nautical tourism” was launched in Brussels in July at a European Parliament Intergroup on Seas, Rivers, Islands and Coastal Areas event.

The influential cross-party Intergroup, co-organised by European Boating Industry and the Conference of Peripheral and Maritime Regions, brought together 107 MEPs from 23 different member states and six political groups.

The main measures highlighted in the declaration are the recognition of private boaters’ licences, the mutual

preeminent leader in the superyacht industry – the only company able to offer an integrated experience coupling high value superyacht berthing and marina services in premier locations with exclusive superyacht service offerings. Moreover, this investment continues to diversify our business mix with not only higher margins, but also a larger geographic footprint, especially in highly desired destinations in the Mediterranean and Caribbean.”

McGill continued: “We are very pleased to strategically expand with IGY Marinas and have tremendous respect for their outstanding management team for building a high-quality real estate portfolio of luxury marinas with extraordinary growth potential. IGY has experienced significant recent growth, as its brand has become sought-after by yacht owners, as well as public and private marina owners worldwide.”

recognition of skipper qualifications, the sustainable development of pleasure ports and inland recreational navigation, and the alignment of reduced VAT rates across the tourism sector to ensure a level playing field.

With close to 200 registered participants, the event featured some of the highest-level players from the European Commission and European Parliament, as well as the German Ministry of Transport and Digital Infrastructure.

Speaking for the industry were Roberto Perocchio (Assomarinas and Confindustria Nautica), Olivier Albahary (Globesailor and FIN) and Harald Kuhnle (Kuhnle Tours and BVWW). They highlighted that the rules for landbased activities need to be replicated for the water. Boater licences, for example, should be treated in the same harmonised way as car driving licences.

All speakers agreed on the need for a more European approach to tackling the issues flagged up at the event. In a thriving sector, this would push sustainable growth of nautical tourism and manufacturing in coming years.

GREECE: According to the Hellenic Republic Asset Development Fund (HRADF), four interested parties have submitted Expressions of Interest for the sub-concession of the right to build, operate, manage and maintain a megayacht marina on the island of Corfu.

The parties are: a consortium of Avax and Aktor Concessions; D Marinas Hellas; Lamda Marinas Investments; and Tekal. All are being evaluated to determine whether they qualify for the second phase of the tender (binding offers).

The Corfu megayacht marina will

be located on the east coast of the island, to the west of the existing commercial port and adjacent to the cruise terminal. As such, it will enjoy all the benefits of being on the Ionian coast, be close to many tourist attractions and just 3km (1.8mi) from an international airport.

USA: Windward Marina Group has undertaken a radical lifts and docks renovation programme at its Jacksonville Beach Marina (Beach Marine) on the Intracoastal Waterway in Florida. The marina has over 180 wet slips and drystack for 300 boats.

The project called for 15 Golden aluminium four-post boat lifts with 28,000lb (13,000kg) capacity, and a further ten for vessels up to 40,000lbs (18,140kg). It also involved the installation of 25 customised Golden Marine Systems 9-Series aluminium walkways, configured as fixed docks, for access to each lift.

Each dock measures approximately 44ft (13.4m) long x 3ft (1m) wide and is built from fully welded 6061 T6 marine grade aluminium with stainless steel components, topped with an attractive Endeck composite decking.

“We’re seeing a new trend of marinas upgrading to lift slips,” said Michael

Shanley, president Golden Marine Systems. “Especially for larger vessels that push the limits of indoor storage, lifts keep the boats out of the water and safe from the elements. They also provide owners fast and easy access, while reducing the need – and expense – for marina staff to be involved in every launch. In addition, marina owners are realising premium rates for lift slips with fast return on investments.”

Allen ‘Gus’ Gustafson, Beach Marine’s director of marina operations, gives positive feedback: “Our customers have been happy with the unrestricted access to their boats that the lift slips offer. We’re pleased with the product and currently working with Golden on adding more lifts in the future,” he confirmed.

Windward Marina Group is also in the process of upgrading Beach Marine’s shoreside power offering.

La Valletta Loano Hammamet Stora Palau

Fiskardo Aqaba Dubai Port Gogek Khiran

Castellammare di Stabia Lefkas Tripoli

Venezia Spalato Maratona Salerno Piskera La

Maddalena Gouvia Muggia Maratea Gedda

Capo d’Orlando Tremezzo Doha Tivat Trani

Lixouri Procida Al Fintas Carrara Brissago

Genova Rodi Dammam Sistiana Locarno

Cagliari Atene Lacco Ameno Palermo

Manfredonia Novi Vinodolski Montecarlo

Viareggio Rab Alassio Farasan

Budva Ravenna Portorose Bari

Villasimius Taranto Biograd Cala di Volpe Trieste

Jesolo Savona Lisbona Portovenere Novigrad

Bisceglie Aiaccio La Spezia Portoferraio

Lustiça Montecarlo Santa Manza Riva del

Garda Castiglioncello Kastela Al Faw Portofino

S. Margherita Ligure Volme Methoni Livorno

Haquel Napoli Marsaxlokk Jesolo Aci Trezza

Taranto Mgarr S. Teresa di Gallura Grado

Rovigno Chioggia Vibo Valenza Mitilene

Imperia Como Agios Kosmas Monfalcone

UK: Walcon Marine has completed the first phase of a two-stage project to replace berthing facilities at Windermere Village Marina in the north of England’s Lake District.

The marina is undergoing a complete transformation, with a new layout that will accommodate 335 boats of up to 15m (49ft) in length at floating pontoons as opposed to fixed timber jetties.

Designed and project managed by Marina Projects, the new marina will take full advantage of available space, with back walkways following the contours of the shoreline and encircling five piers.

All work is being done in two off-seasons. The 2021/22 phase began with Walcon removing much of the old infrastructure, including around 700 piles, so as to allow local contractor Jetties &

Walcon System 2000 pontoons have so far been used to create some of the back walkway and three piers. Bespoke bowspring bridges for berth holder access to and from the shore have also been installed.

The marina is also renewing all power pedestals and adding deck-level lighting and fibre internet connections.

Windermere marina manager, Dan Fairweather, speaks positively about the progress to date. “It has been great to work with Walcon. The project was a number of years in the making and they were very patient and have worked well with our staff and local contractors,” he says. “There was a lot of boat moving as the old jetties were removed and with Marina Projects they planned and handled that very efficiently. We are very happy with the results so far and look forward to having it completed.”

Walcon will recommence work this October with completion scheduled for March 2023.

Steel pipe floating breakwater systems

Towed, self-propelled, and highway trailers

Range of designs backed by scale-model testing

Sling lift trailers and boat hoists

Available with or without decking and fingers

Remote control hydraulic trailer tugs

Steel or HDPE pipe floating dock systems

Galvanized boat storage stands

Full range of options and accessories available

Simple operation, rugged durability, flexible features

Conolift hydraulic equipment including lifts and trailers

We also supply floating docks and breakwaters

FRANCE: Poralu Marine is to supply and install floating docks for the 2024 Paris Olympic Games dinghy, catamaran and keelboat competitions at Roucas-Blanc Marina in Marseilles (CGI below). The contract follows its successful bid in June 2021 to upgrade the rowing basin and sprint race course on Vaires Torcy Lake in Vernes-sur-Marne.

At Roucas-Blanc, Poralu will build 405m (1,330ft) of floating docks (including 15 footbridges) and 18m (59ft) of overhanging docks (attached to the quay). Delivery will be in the third quarter of this year.

For Vaires Torcy, the company removed and recycled former rowing installations, improved the slipway, built, supplied and commissioned new international standard floating installations, and supplied and installed automatic starting gates.

Poralu is very familiar with work for rowing competitions and the Olympics. It designed and built infrastructure for the 2012 London Olympic Games and Paralympic Games, the 2010 Singapore Youth Olympic Games, the 2001 Rowing World Championships in Lucerne, Switzerland, the 2009 Junior Rowing World Championships in Brivela-Gaillarde and the 1997 Rowing World Championships on Lake Aiguebelette.

USA: Construction of the new marina at Dana Point Harbor in Dana Point, California has begun. Over the next five years, it will be rebuilt by Bellingham Marine in 15 phases with an extra two phases in the outer basin.

Although revitalising the marina has been under consideration for over two decades, turning the dream into reality has been down to Supervisor Lisa Bartlett and her vision and commitment to a Private Public Partnership over her eight-year term.

As the first pile was pulled at C Dock on 4th August to mark the start of the construction, Bartlett said: “Our beloved harbour has served our community well for over 50 years. As we embark on the harbour revitalisation, I am excited for all the improvements that are coming that will enhance the experience for all the citizens of greater Orange County as well as for visitors to our harbour from near and far.”

“As a partnership, we have been committed to having Dana Point Harbor set a new standard for marinas on the West Coast,” said Bryon Ward, president of Burnham Ward Properties and partner in Dana Point Harbor Partners (DPHP). “We immediately embraced Bellingham Marine’s concept of a non-ferrous dock system not only to enhance longevity but to also reduce the number of pilings in the harbour. This method aligns with the partnership’s goal to create a more environmentally conscious harbour as it also eliminates the need for treated lumber.”

“The new dock system will be enhanced in almost every aspect,” added Joe Ueberroth, founder of Bellwether Financial Group (partner in DPHP) and owner of Bellingham Marine. “The new design addresses both ADA accessibility and public access, the guest services will set a new standard for the West Coast, and the electrical and pump-out systems

The latest CGIs show the vibrant scope of the rebuild plans for Dana Point Harbor, which will become a community asset and visitor attraction.

will meet the needs of boaters for generations to come.”

Bellingham held a pre-construction meeting with County and City officials and staff describing phasing plans, building Best Management Practices (BMPs), and construction logistics.

“The Bellingham team will be a fixture in the harbour for the next five years,” explained Eric Noegel, general manager of Bellingham’s southwest division. “Working for a client that is truly dedicated to the development of a marina that protects the environment while having the longevity to serve the community through its entire leasehold has been inspirational to our R&D, manufacturing and installation teams,” he added.

DPHP has spent millions of dollars and countless hours behind the scenes over the last four years to get to the point where construction is visible in the harbour. “It is difficult for most people to imagine the heavy lifting that takes place during the years prior to commencing construction. We now enter a fun period where the installation teams go to work and the community can witness the transformation of the marina in its 15 phases while we continue to operate as the largest marina on the West Coast,” Ueberroth noted.

DPHP comprises three property development firms who are working in partnership with Orange County.

Burnham Ward Properties is responsible for stewarding the harbour’s commercial core activities, e.g. retail, restaurants, office and parkscapes; Bellwether Financial guides the marina operations including the boat slips, boater facilities, dry boat storage, dayboat mooring, guest slips and launch ramp areas; and R D Olson Development leads the hotel redevelopment.

The partnership has developed a master plan that connects the harbour’s landside and waterside to become a cohesive waterfront experience.

Marinas are rarely built in New Zealand’s beautiful South Island and rarest of all in the south west – where the Southern Alps give dramatic backdrop to Queenstown and the dog leg-shaped Lake Wakatipu. Developing Queenstown Marina has been a long thought through and challenging process but the result is a new community hub for the lake with unique features and room for expansion.

Marina owner Iraj Barabi of Lakes Marine Projects thinks back to 2010 and the early planning stage. “It seems like ages ago now. I had almost forgotten how painful the approval process was – thanks for reminding me,” he smiles. “This is a very exceptional area and Lake Wakatipu is a highly sensitive environment. It is understandable and actually encouraging that the Queenstown Council, Otago Regional Council and Land Information New Zealand (LINZ) would scrutinise every detail and aspect of the project with insistence to oversee the development.”

“As frustrating as the process was, looking back we had great support from all government agencies and the local community. Seemed everyone liked the idea. Knew it was needed but wanted it done right. And that is understandable as two previous attempts to build a marina at the site had failed miserably,” he adds.

Queenstown Marina – at first phase – currently offers 80 berths for a mix of vessels of 8 to 18m (26 to 59ft) and a second phase is at design stage.

Bellingham Marine New Zealand (BMNZ) completed phase one and is collaborating regarding the second

Iraj Barabi

stage. Berths are leased primarily to locals and New Zealand residents, and all moored boats are motor boats. Barabi is working to accommodate a couple of electric boats.

“Considering the circumstances, COVID and border lockdowns, the interest and the uptake in the berths has been exceptional,” Barabi says. “The 8m berths are fully occupied. There are still a handful of 10m berths available. Considering the lack of historical data and an existing marina, I would say we got the mix of the berth sizes pretty right. We also sized the marina well for the demand.”

The project scope for Bellingham Marine was to provide an engineered turnkey design and build solution for new piers and attenuator, confirms BMNZ general manager Chris Lamont. The marina site is exposed to a 3.9km (2.4mi) fetch from the south west, with a wind generated wave reaching a maximum height of 1.8m (6ft). Platforms for floating buildings were also in the project brief.

Electric Service Pedestals

Electric Vehicle Charging Units

Electric Boat Charging

Electric & Water Management Systems

It’s no secret that the world is steering towards cleaner and greener modes of transport. As world leaders in providing service pedestals and associated products for marina and waterside destinations, and with over 10 years’ experience in the electric vehicle charging industry, Rolec are able to provide a solution to suit your electrification needs. Enabling you to offer your visitors a seamless charging experience, whether it’s for electric vehicles or electric boats.

“This project was unique in that it was the first substantial marina to be built on the lake, which is a gem on the New Zealand tourism circuit and fiercely protected in its waterfront development,” Lamont explains. “The location in the middle of the Southern Alps, with no port access and restricted road access, required us to look at other options outside of casting in our own manufacturing plants for the larger pontoons required for the attenuator and floating building platforms.”

A satellite casting yard was set up in Cromwell, 50km (31mi) from the site, where there was a good supply of concrete. Challenges had to be overcome as casting was undertaken during the winter to allow for installation in the summer. Winter temperatures were often below 0°C so heating and blankets were utilised to help with curing and hot water was added to the concrete mix.

Visual impact is very important in such a sensitive environment. “BMNZ proposed an engineered telescopic pile solution during the consenting process as our preferred option,” Lamont says. “This system has been used successfully in a number of attenuators in Australia and the USA. The ‘plunger pile’ is connected to the pontoon using a pin connection and hangs inside the larger bottom driven into the lakebed.”

The attenuator pontoons measure 4m (13ft) in width with skirts, and the first 30m (98ft) has trenches for fuel and sewage pump-out lines. Unifloat marina pontoons were used to create four building platforms of 9m x 20m (29ft 6in x 66ft). They are timber walered and post-tensioned using GRP rods and

have Fibre Reinforced Polymer (FRP) through bolts and glass-filled nylon nuts to reduce maintenance and corrosion. Walkways, platform and attenuator pontoons are ducted for power, water and data, and pontoon fingers have rounded boat-friendly ends. The pier walkways have a nominal width of 2.4m (8ft).

A Keco pump-out and fuel pumps offering petrol and diesel (available for marina guests and the general public) are located on the breakwater. All berths have power (16-32 amps) and water via a combination of M-Tech Sterling and Platinum pedestals. Fire hose reels with lifebuoys and fire extinguishers in M-Tech fire stations are also installed. Wi-Fi can be provided to all berths if needed.

One of the most striking features of Queenstown Marina is its array of floating sheds, which add colour and character and a yesteryear ambience. “It is very unique, blends in with the environment, and is very nostalgic,” Barabi says, but uptake has been hampered by the restrictions of the pandemic. “The completion of the marina coincided with the outbreak and the border closures. Fortunately, Lakes Marina Projects was in a position to absorb the costs associated with delays in occupancy. Currently, there are many interested parties intending to lease the floating buildings but we are selective in who will occupy these buildings as we want the proper ecosystem.” An art gallery in the floating buildings for Spike, a well known marine artist, has already become a community favourite. One of the three land-based buildings

The marina’s nostalgic array of floating sheds is one of its most striking features and is perfect for a wide range of commercial purposes.

is occupied by K-Jet (jet boat rides) as anchor tenant and the other two will be for food and beverage. Other amenities, including shower rooms and toilets, and enhanced car parking facilities are underway.

All plans, on land and water, take the sensitive lake environment fully into account. “Our detailed environment policy is focused on ensuring the marina and the watercraft do not adversely affect the lake. This is done by policies, advanced equipment, such as fuel reservoir, lines and pumps, mitigation and routine inspections to ensure functionality of systems and structures plus regular lake bed inspections for invasive weeds.”

There are no further plans to develop any landside structures but the design phase of stage two is progressing. “With the data generated since the marina became operational and the input we have received from the boaties, we are finalising the berth size mix. Stage two will complement and expand the berth offerings by another 100 berths. We expect construction to begin next year with a completion date of 2024.”

A newbuild marina and the restrictions of a global pandemic were not a happy mix but, once opened, operation has been smooth. “The marina management is relatively pain free, mostly due to our top notch team. Our main challenge has been to keep focus on our vision and goals to keep this marina as an inviting and functioning hub that adds another dimension to this truly exceptional part of New Zealand despite external and unexpected challenges that have restricted movement and access during the last two years. And once we have accomplished our goal of building the best marina in New Zealand, the challenge of course would be to keep it at the top.”

Queenstown Marina is a stunning complement to one of New Zealand’s most scenic towns and an iconic reference for Bellingham Marine. Embraced by the local community as an additional lakeside destination and as a much-needed boating facility, it has already merged seamlessly into the lakefront scene. The future looks bright. “It is a great feeling to know people will be enjoying this marina for generations to come,” Barabi says.

The recent acquisition of Marina Punta del Faro Resort in the Italian region of Friuli Venezia is potentially the first step in an expansion process for leading premium marina operator and marina consultant D-Marin. CEO, Oliver Dörschuck, tells us more.

At the most extreme point of Lignano Sabbiadoro where the magical colours of the Adriatic Sea merge into the fresh water of the Marano Lagoon, Marina Punta del Faro Resort is seen as a ‘pearl of pleasure’ in the Upper Adriatic. Its 1,200 moorings are supported by a high level of assistance and services, and there are many leisure opportunities on site and in the local area.

The marina resort is a perfect acquisition for a group that is renowned for service, quality and the offering of unique experiences, and it expands the portfolio into completely new territory while bringing the tally to 16 marinas. These are based in Greece (where D-Marin has its headquarters), Turkey, the UAE, Montenegro and Croatia.

Punta del Faro is a 25-year-old tourist port that offers privacy, safety, tranquillity and beauty in a well-tended environment with special features, such as the splendid swimming pool inspired by the archaeological finds in the ancient Roman colony of Aquileia. It

has a sandy beach and a neighbouring pine forest, protected and recognised as a Site of Community Importance.

Sports infrastructure includes a tennis court and a five-a-side football pitch, a Technogym gym and a sporting club, which opened in May. And the classics of a good modern marina are all present: 24-hour mooring assistance; pump-out; dining service; golf buggies; internet corner; disabled access; electric car charge points etc.

Leisure offerings are complemented by the technical, with yard services

spread over an area of 2ha (5 acres). This gives space for external storage, and for the shipyard, where boat haul and transfer takes place using an 80 tonne boat hoist, a 4 tonne selfpropelled crane with extendable arm (up to 25m/82ft) and a 20 tonne selfpropelled trolley.

Covered storage sheds include the sail loft, the joinery and carpentry department, and mechanical workshops for the installation and repair of electrical and electronic systems. On-site operators include Nautimotor Toniutto (Yanmar and Lombardini Marine workshop and Yahama dealership), Motornautica Casasola (Volvo Penta workshop) and Piccoli Giuseppe Falegname (nautical carpentry, interior fittings etc).

Marina guests can spend leisure time in various bars, restaurants and retail outlets, can join water aerobics courses and have swimming or diving lessons on site and in the surrounding area. Various sport and sailing school activities are also offered via the Lignano Yacht Club, whose regattas start in April with the Regata dei Due Golfi and end in November and December with the Campionato Autunnale della Laguna, held in 2022

The METSTRADE Show is the happening meeting place in Amsterdam where the international leisure marine community gathers. In a hospitable and safe environment, we make you feel at home to meet and mingle with the entire industry. Feel connected and charge yourself to optimise your business.

This year’s show will be back in most of its original shape with more companies and more marine equipment on the floor. More side events and a comprehensive content program will enhance the METSTRADE experience and offer more value in terms of knowledge exchange and networking opportunities. METSTRADE will be back as the largest global B2B event on leisure marine equipment and we are receiving very positive feedback that the industry is eager to attend the show in November!

During this year’s show, the dedicated METSTRADE Theatre will host an insightful discussion about building sustainable marinas, as well as diving deep into the transition to e-handling – both sessions powered by Marina World.

concentration of exhibitors from the marina and boatyard industry in a businessto business environment, complemented by key training and networking events for marina professionals.

Are you a marina owner, operator, developer or supplier? Then this year’s METSTRADE will have plenty in store for you!

The 2022 HISWA Marina Symposium will focus on market developments for marinas. HISWA Holland Marine Industry organizes this symposium exclusively for its members, both inside and outside the marina industry. Participants can apply by registration via HISWA-Recron. And as every year, the dedicated Marina & Yard Pavilion will bring together the world’s largest

The Marina & Yard Pavilion will be located in Hall 5, making it the go-to hall for building and managing a marina, hosting marina owners, operators, developers and suppliers from around the world.

We hope to welcome you on 15-17 November. Don’t forget to register for your free ticket now. See you at METSTRADE!

METSTRADE will be held at the RAI Convention Centre in Amsterdam and will run from 15-17 November 2022.

Get your free ticket, go to www.metstrade.com/tickets

for the 47th and 33rd year respectively.

All facilities and event programmes have been developed without losing sight of the need to protect the marine environment and to meet the criteria of the Blue Flag status it has held for many years.

Specific environmental attention is paid to the disposal and separation of used oils and batteries, and the maintenance of clean water. A Seabin has been installed near one of the central piers for the collection of microplastics and small scraps of floating waste. Due to the currents, it collects around 1.5kg (3lb 5oz) of waste per day, which equates to 500kg (1,100lb) per year. The Seabin installation is the result of a collaboration with Lifegate, an environmental consulting company that fosters sustainability in the workplace and boasts a community of over five million people.

Aside from plentiful nearby attractions, Punta Faro Marina is just an hour or so away from Venice by car or train and is a unique experience by boat. In just over two hours, you can reach Cortina d’Ampezzo, one of the most renowned ski and mountain resorts in the Alps, and also enjoy relaxing breaks in the Collio hills, famous for the vineyards producing Tocai, Pinot, Sauvignon, Cabernet and Merlot wine.

And the marina is the start of things to come for D-Marin, according to Oliver Dörschuck:

“Punta Faro is our first marina in Italy and becomes the 16th marina in the D-Marin group. We’re really excited to enter the Italian market. Our acquisition

of Punta Faro enables us to extend the sailing destinations we can offer both our new and existing clients and is the ideal complement to our marinas in nearby Croatia,” he says.

“Our goal is to build a premium marina network, particularly across the Mediterranean Sea. We are looking forward to welcoming new marinas to our family in Italy and are currently discussing several opportunities.”

Q: What attracted you most to this particular marina?

A: We are very selective about the marinas we add to our network. Indeed, Punta Faro is an excellent addition. It is a large marina, is well-run and offers all the services and facilities like great restaurants, dry dock, gyms, tennis courts and a pool. We look for marinas with similar values to us that offer high quality services, delivered by a team that is committed and truly cares about its customers.

As people are the real differentiator, we look for teams with the right innovative mindset that fits our purpose.

Q: What are the main advantages for

Around 1,200 berths are located throughout the site.

you and for Punta Faro Marina Resort?

A: Our purpose is to enrich yachting experiences and provide our clients with first-class experiences whether they use their boat for sports or exploring. A key advantage to welcoming Punta Faro to the D-Marin family is it enables us to offer more choice to our customers, opening up new destinations for them to explore with us thanks to our reciprocal berthing programme. D-Marin already has a high brand loyalty. From time to time, customers choose a new yachting location, but most of them we welcome to one of our other D-Marin marinas in a different location. Punta Faro will get new customers from the D-Marin customer pool.

In addition, Punta Faro will benefit from the innovative digital services, which will improve the experience for customers, making it even easier to visit Punta Faro. Given our scale, Punta Faro will also benefit from our presence at boat shows and our strong D-Marin website.

Q: Are you planning to make changes to services, infrastructure, personnel and internal management? If so, which ones and why?

A: Our main focus will be the introduction of our quickly appreciated digital services at Punta Faro. I am convinced the digital experience exists to make our lives quicker, easier and more effortless and complements the overall yachting experience in Punta Faro.

Clients are able to create online profiles where all documents can be uploaded, check-in can be completed online, and booking and paying for a specific berth takes only a couple of

Plan your participation in this unique global marina event

The biggest meeting of the recreational boating industry

The sporting club, which opened in May this year, complements a gym, tennis court and five-a-side football pitch.

minutes. And there is more to come. We keep innovating and designing new services and processes.

Digital services not only reduce administration for customers, but they also save our team time too, leaving more time available to spend with clients, especially those who prefer more face-to-face-contact.

Punta Faro is already well cared for, but we will certainly continue to invest to improve the services and facilities we offer our customers. We are ready to invest and upgrade the marina.

Q: D-Marin claims to support the social, cultural, environmental and economic development of local communities and regions. Where will your focus be at Punta Faro Marina?

A: The D-Marin network is very much aligned on our Environmental, Social & Governance (ESG) strategy; we are developing a concept to support a stringent ESG approach across marinas in six countries. However, most of the activities will be implemented

locally and we will develop a Punta Faro specific concept with the local team. We like to be good neighbours and integrate well in the local communities and preserve the environment. A few examples of activities our teams have been involved in include collecting and recycling sails, investing in solar panels to produce clean energy and supporting

local youth training facilities.

We recently received the silver medal from EcoVadis for our ESG activities last year, which ranks us in the top 30% of all leisure companies (see Products & Services). This is a great achievement we are very proud of, but we will continue to seek ways we can improve our ESG efforts further.

by Cat Olnick

October marks one year since the reopening of Dinner Key Marina and its restoration to original operating capacity since suffering disastrous hurricane damage in 2017. Located in the Coconut Grove neighbourhood of Miami, Florida, Dinner Key Marina is the largest wet slip facility on the eastern United States, and Florida’s largest marina with 587-slips.

Hurricane Irma was an enormously powerful storm that caused extensive destruction throughout Florida and parts of the Caribbean. When it made landfall in the USA on 10th September, the wind speed, storm surge and wave impacts caused considerable damage to all of the marina’s nine piers. Vessels from the mooring field and anchorage outside the marina chaffed through and snapped mooring lines under the extreme forces resulting in vessels crashing into the marina. The damage was devastating, impacting 60% of the dockage.

After the completion of planning and permitting work in 2019 led by Moffatt & Nichol, the City began working with the Design-Build (D-B) team to repair the damaged marina and make significant upgrades to the facility. The D-B team was led by Kearns Construction Company and included Cummins Cederberg as the lead marine engineer overseeing the engineering design of structures and utilities, as well as

supporting the ultimate construction.

A short walk from the heart of Coconut Grove village where you will find retail and entertainment, the marina serves as a destination for South Florida’s tourism economy with

Dinner Key Marina, with 587 slips, is the largest marina on the eastern US seaboard.

overnight and monthly accommodations.

Dinner Key Marina is the City of Miami’s flagship municipal marina, generating valuable revenue. This restoration project included repairing or replacing structural elements for nine piers totaling over 7,200ft (2,190m) in length and restoring full utility services along with system upgrades.

Remaining operational during construction was a challenge the D-B team had to face.

The ability to keep the marina operational was a crucial element of the timeline. Cummins Cederberg worked closely with the Kearns Construction team to sequence the approach and minimise operating disruptions to the marina.

“The project phasing was really a fluid challenge for the project team to work through and coordinate during the entire construction operation,” says Kearns Construction team lead, Brock Sullivan. “Not only did our D-B team have to physically divide the work areas and staging locations, but we worked

Since 1963 Walcon has proven itself to be a worldwide leader in the design, construction and installation of marinas and berthing facilities, with renowned

with the existing upland utilities to ensure service was uninterrupted for active slip users and dockmaster staff.”

The core of the structural work consisted of replacing the concrete access piers with a more slender profile consisting of two pre-cast beams laid parallel. This improved section provides more robust resistance to future wave impacts and allows easier access to utilities if future repairs are needed. Cost-efficient concrete repairs were performed to other existing walkway spans, pile caps and select piles in lieu of replacement.

As part of the D-B team’s efforts during pre-construction and active construction operations, opportunities were identified to optimise the construction scope and project budget. Cummins Cederberg and Kearns Construction performed multiple walkthroughs with the City to identify components that could be salvaged by means of repair, allowing funds to be reallocated to other improvements, such as replacing mooring piles or dock piles.

The D-B team, in collaboration with the City, made the strategic decision to raise all the finger piers during the reconstruction to not only reduce future storm surge impacts but resist increasing seasonal water levels. Subsequently, at the end of construction, the 2021 ‘king tides’ provided record high water levels. The

recently renovated piers experienced no flooding, while the existing docks in place during renovation were under water.

The original scope for the timber dock piles included a mixed approach of replacing all framing and decking in certain areas, while other locations called to only replace select framing and dock piles. By performing design level inspections prior to and during construction, the team found more dock piles could be salvaged than in the original plans.

“There’s another layer when seeing the project in real time versus on paper,” states Cummins Cederberg senior project manager, Rasheed Muslimani. “By

Left: old finger piers were underwater during 2021 ‘king tides’ but new piers experienced no flooding. Below: hurricane damage in 2017 affected 60% of the dockage.

performing continual inspections, we found more opportunities to optimise the budget for the City and in this situation some dock piles didn’t need to be replaced, making it possible for all docks to receive new framing and decking.”

The D-B team’s optimised dock improvement scope provided new framing and decking for all timber docks – creating a consistent look, stability and access.

Given most of the utility fixtures or supply feeds sustained damage from the storm, the scope included full overwater replacement of all utility systems including domestic water, fire protection, wastewater, electrical and low voltage. With MEP (Mechanical, Electrical and Plumbing) design led by Basulto & Associates and fire suppression design led by REDI

Do you need to be supported in marina design, business planning or operational matters?

Do you require a strong expertise in outsourced marina management?

Do you have a marina project and look for an investing and operating partner?

Marina Management & Consulting by Poralu Marine offers a 360° service to increase the attractiveness of your investment. We offer fully integrated services: from conception and construction to operation, your project is handled in-house by our experienced and knowledgeable teams

Our expertise in retail management, our focus on activity diversification and marina activation, will help you maximize the profitability of your premises. Determining the best value offer within your property is key in strengthening your community, diversifying and optimizing your streamline of revenue, while ensuring a successful integration of all your marina related facilities.

Our sustainable solutions and practices distinguish us from our peers, our focus throughout the process will be to reduce the impact of your marina installations and activities on local ecosystems.

To guarantee the maximum return on investment, MM&C works with you from concept studies to management and operation, efficiently implementing your business model based on a risk and profit sharing approach.

Learn more : www.marinamanagementconsulting.com

Cascais, PORTUGAL

+351 214 692 024

Barcelona, SPAIN

IF IT’S ON WATER WE HAVE A SOLUTION

+34 933 601 101

Rio de Janeiro, BRAZIL

+55 21 3942 8828

Engineering, the team overcame many constructability challenges to address re-using existing upland utility feeds, adapting the design to meet current code requirements and maintaining service in phases.

A significant milestone was the successful acquisition of a City of Miami code variance to design and install seven submersible electrical panels to protect the electrical system from future flooding during a hurricane event without having to position them 11 feet (3.3m) above the existing ground surface. The variance required not only a state-level review from the Florida Building Code Board, but also created a new operating policy for the Dinner Key dock master operations team.

New utility components were installed to provide a state-of-the-art user experience for both the marina staff and slip users. New security cameras were installed throughout the piers, along with Wi-Fi towers, and remote pedestal monitoring to track water and power consumption.

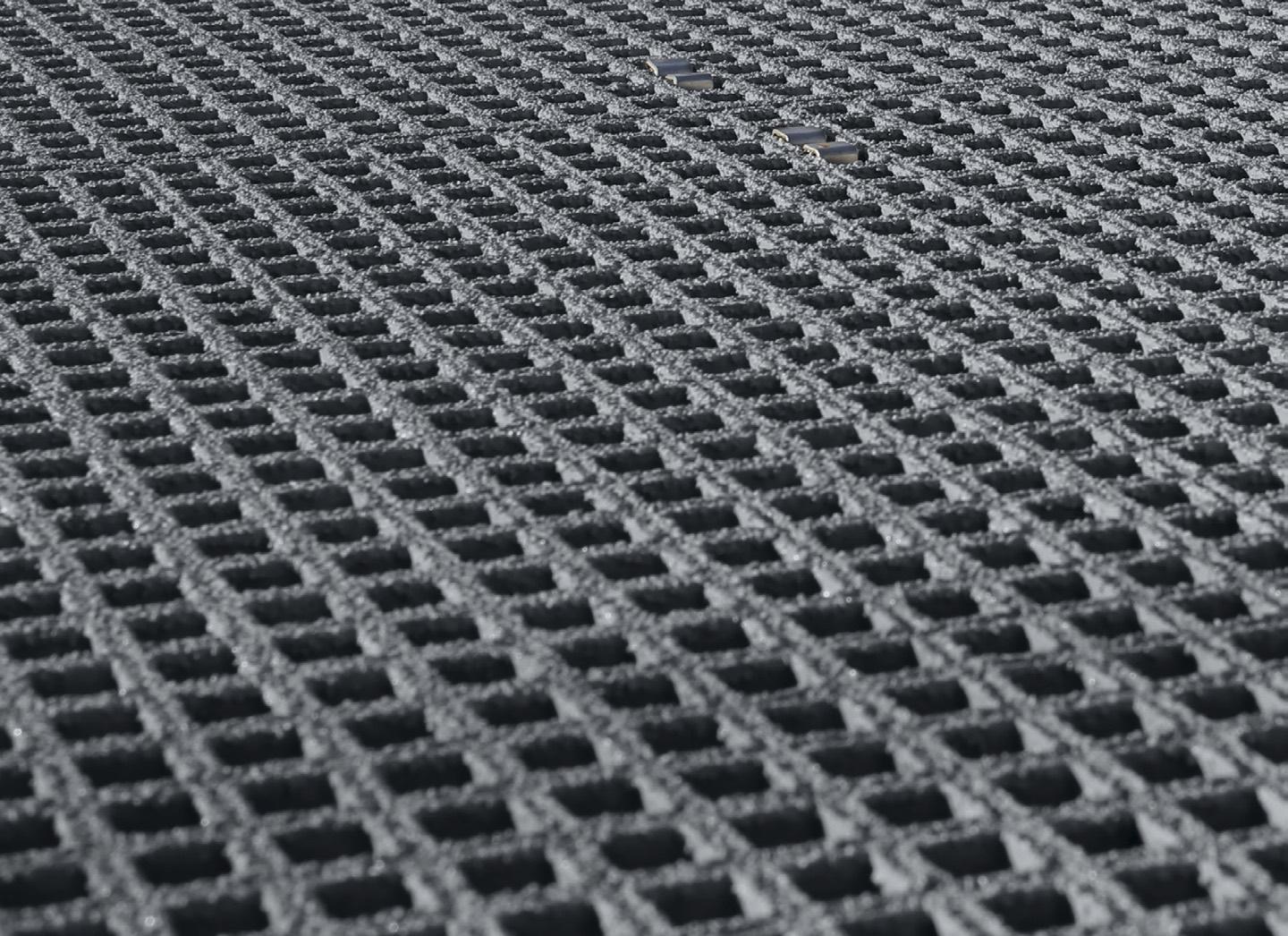

One of the functionality improvements incorporated by the D-B team was to replace the pier walkway surface with a fibre-mesh grating with a mid-span support beam instead of the previous pultruded glass fibre grating. This robust system provides greater stiffness under foot and support for golf carts

Left: new fibre-mesh grated decking is non-slippery, safe under load, and allows sunlight to filter through to preserve marine life. Above: the scope of the project included full overwater replacement of utility systems.

and other operational equipment, as well as increased sunlight transmission through the pier to promote the health of underlying marine resources.

On Wednesday 20th October 2021, the City of Miami celebrated the completion of this comprehensive repair and upgrade project to the Dinner Key Marina, and it remains fully operational one year later. Funding for the marina repairs came through the Florida Inland Navigation District (FIND), the Federal Emergency Management Agency (FEMA), and revenues generated by the marina and other City funds.

Today, Cummins Cederberg continues work with the City of Miami to protect this $22.5-million investment by enhancing the protective spoil islands surrounding the marina. These enhancements will include a mix of hard and soft protection measures, such as rock breakwaters and naturebased enhancements as well as increased recreational opportunities to support the community friendly atmosphere prevalent in the region of Dinner Key Marina.

Cat Olnick is marketing manager for Cummins Cederberg, a professional engineering firm working exclusively in the coastal and marine environment. Its team of coastal and marine engineers, scientists, and regulatory experts, specialise in marina design, coastal dynamics, biological monitoring and environmental permitting.

www.cumminscederberg.com

by Greg Weykamp

For most developers in the United States, the path to success when building on the waterfront has been focused on securing a prime parcel and immediately setting about creating an exclusive, fenced off private enclave behind gates and guardhouses. Value creation was based on limiting access and manufactured scarcity, with little thought or only lip service to environmental protection and long term sustainability. For Ryan and Emily Leestma, the visionary owners behind Adelaide Pointe, an entirely new approach that flipped the traditional development model on its head was the only path they ever considered.

The City of Muskegon was once a very wealthy community of lumber barons providing much of the timber used to rebuild Chicago after the great fire. Located along the sandy beaches of Lake Michigan, Muskegon Lake is a large inland water body that is still home to commercial shipping, along with interstate ferry services and world class recreational boating. After the lumber mills came paper mills and steel foundries, and a local economy based largely on industry while the rest of the West Michigan shoreline communities shifted to tourism and recreation.

The Adelaide Pointe project is located on a 29.7 acre (12ha) site that was

Mass timber multi-family and mixed use buildings along the lakefront have been designed and constructed with sustainability in mind. Image: Korb & Associates (architects).

formerly home to a steel foundry, munitions plant and warehousing facilities. Over many decades, the steel foundry dumped hundreds of thousands of cubic yards of used foundry sand into the lake, creating a peninsula that

Aerial CGI highlights the scope of a site that was once a fenced off marine facility.

will soon become home to over 400 units of mixed-use residential, hotel and retail uses, alongside a new 270berth marina protected by a 980ft (300m) breakwater.

While permitting a project of this scale would have been relatively easy decades ago, today there is a much greater focus on protecting public trust waters that requires much greater care and creativity in order to complete the entitlement process. With a passion for the environment and a deep love of Muskegon Lake, the Leestmas decided to build the most sustainable waterfront community they could imagine, and share it with as many people as possible.

Rather than putting up gates, they began the project by taking down fences and inviting the nearby Nims neighbourhood residents to enjoy the waterfront. In partnership with the City of Muskegon, this new waterfront community will make every inch of the waterfront open to the public forever under permanent dedicated public use easements, resulting in 1 mile (1.6km) of new public trails and over 2.5 acres (1ha) of new public waterfront park space.

The breakwater includes an access trail and fishing overlooks to support deep water fishing for the public, and a peninsula of City land with a derelict marina facility that has been

behind fences for decades will soon be cleaned up and opened to the public at the developer’s expense. In addition to public trails and open space, Adelaide Pointe aims to make boating on Muskegon Lake accessible for everyone in the community regardless of income by offering affordable paddle craft rentals, boat rentals, boat clubs and dry rack storage on site.

While traditional shoreline treatments for lake environments with 3.4ft (1m) wave heights rely heavily on armouring, the Adelaide Pointe project has committed to utilising soft shorelines wherever possible. As a result, over 82% of the shoreline will be a native wetland restoration very carefully designed by fisheries and wetlands biologists. Creation of the marina basin will require dredging of over 2,300,000 ft³ (65,000m³) of foundry sands and 353,000ft³ (10,000m³) of contaminated organic sediments.

While dredging at this scale would usually be a significant environmental impact, in this case the removal of the foundry spoils will expose the original lakebed, which has been proven to greatly improve aquatic habitat. The dredged sand materials will be used to raise the site to final grades, and organic materials amended where possible and reused in the parks and landscape areas. Where stone armouring is absolutely necessary, as in the breakwater, the traditional quarried limestone armour stone will be covered with a layer of native Michigan fieldstone below the water in order to provide much

better habitat value for invertebrates and native plant and fish species. When complete, the interior shore of the Adelaide Pointe marina basin will be a fully restored native wetland protected by a conservation easement forever.

Moving inland, the development proposes a series of six storey, high density multi-family and mixed use structures organised in a walkable neighbourhood connected to the nearby downtown and Lake Michigan beaches by a regional trail network. Surface parking is intentionally limited, with the majority of parking below structure, creating a waterfront district where residents and visitors leave their cars behind as soon as possible.

All of the buildings will be constructed using mass timber, a method that relies entirely on laminated wood structural panels, posts and beams for all components. This makes every structure far less carbon intensive, with significantly reduced steel and concrete than typical buildings. The lighter weight of the buildings requires much lighter foundations, resulting in significant savings, faster construction, and a more sustainable structure that harks back to the historic lumber mill uses on the site. Continuing the use

Left: Soft shorelines have been adopted for over 82% of the project. Below: A floating timber dock system, manufactured locally, reflects the preference for natural materials.

of native plant materials throughout, each building will incorporate intensive green roof systems focused on habitat creation for pollinators and migratory bird species.

As the Leestmas also own a commercial solar business, Adelaide Pointe will incorporate extensive use of solar energy generation throughout the project. All new and existing structures will incorporate rooftop solar, and the 10ft (3m) wide waterfront trail system will have solar panels in the pavement. The marina will be constructed using a locally manufactured floating timber dock system with solar panels mounted to the walking surface of the main piers, offsetting a significant percentage of the marina’s electrical use.

As early adopters of electric vehicles, it made sense to the developers to install over 20 Level 2 Destination EV chargers, a Level 3 DC fast charger, and EV charging capacity at each residential parking space in the development. Looking towards the future of electric boating, the marina will offer high speed chargers for electric boats on the water today, and design

Fisheries and wetlands biologists very carefully undertook a native wetland restoration project.

the marina electrical system to allow for in-slip charging in the future.

As you might imagine, this very unconventional approach to sustainable and accessible waterfront development has garnered broad community support, including unanimous city planning approvals and the support of local environmental organisations such as the Muskegon Lake Watershed Partnership. Customers have also responded positively, with the first 50-unit residential building securing enough buyers to commence construction in only a few months, the first commercial/retail structure fully leased, and roughly 20% of the marina berths leased even before construction has begun. The idea of living and working in an environmentally sound yet vibrantly active and connected waterfront is clearly attractive to many buyers.

Another major benefit resulting from the focus on community access, public waterfronts and environmental

stewardship is significant funding support from the US Fish and Wildlife Service, the State of Michigan and local brownfield remediation TIF funds. By working together with the Michigan Department of Natural Resources and the City of Muskegon, Adelaide Pointe is a model public private partnership and a great example of commercial

success based on doing the right thing for the environment and the community. Gregory Weykamp is president of Edgewater Resources, LLC, specialists in delivering real-world solutions for complex coastal and waterfront projects. Edgewater acted as consultant for the Adelaide Pointe project. www.edgewaterresources.com

With the APP “Service Mobile” we manage preventative and corrective maintenance actions.

Client Portal. A platform providing up-to-date crane information that both GH and the client can access.

Remote monitoring of the crane’s operating data in real time. Making prevenptive and corrective maintenance more efficient.

motion@ghcranes.com www.motion.ghcranes.com

The Marinas22 international conference and trade exhibition reaffirmed its place as one of the largest marina industry conferences in the world after welcoming over 320 attendees across two days to the Australian Gold Coast 23rd-24th May.

The conference was opened by the Hon. Michael Healy, Queensland Assistant Minister for Tourism Industry Development, a strong supporter of the industry who highlighted the measures in place for future sector growth. An economic overview, forecast and implications for industry was delivered by Tapas Strickland, NAB chief markets economist, before Ashley Fell, demographer and social researcher and director of advisory at McCrindle Research, outlined the changing consumer and demographic trends and the opportunities ahead for the marina industry.

Andrew Chapman, MIA president, released the findings of the 2021 Health of the Australian Marina Industry Survey (HAMIS), which presents a resilient and strengthened industry but challenges operators and governments to provide additional storage capacity to support the boating boom.

Joe Ueberroth, president and owner of Bellingham Marine, delivered a thought-provoking presentation on how marinas could maximise their returns. The conference hall buzzed, with delegates busy re-evaluating their current business practices to take on board some of the ideas presented.

With the macro picture painted and the industry opportunities examined, the first afternoon presented delegates with a choice of specialist subjects to examine. Conference committee chairman, Mike Harvey, commented: “The Marinas22 programme was designed to allow delegates the opportunity to delve into topics by choosing between two workshop streams, each with a panel of experts. Day one included innovation, the environment and decarbonisation, boatyard evolution, marketing and marina events.”

The Innovation Showcase was the highlight, and showcased five new products, four of which were environmental initiatives. A live poll was taken from over 150 delegates in attendance and the Man Overboard Marina Alarm System was announced as the winner in a tightly contested result. In receiving his award, product creator Paul Williams explained the genesis of his

Below (clockwise): The Hon. Michael Healy; Joe Ueberroth; and Ashley Fell.

idea: “It was conceived after a near drowning incident in a marina where my boat is moored. A woman had fallen into the marina late at night and by the time her cries for help were heard she was suffering serious hypothermia as well as other injuries. I went home that night and came up with a solution that has consumed my life ever since.”

Day two of the conference focused on encouraging delegates to look internally at their operations to further capitalise on the recent industry growth. This was led by Darren Vaux, vice president of ICOMIA and managing director of Empire Marinas Group. He provided delegates with insights, and discussed opportunities on how the industry could engage with new and old boaters as we move into a post-COVID environment. Suzanne Davies, Marina Industries Association (MIA) CEO, provided an overview of the MIA, outlining how it is supporting industry and following a strategic direction. Davies then introduced Ed Shute, membership and programmes manager, who explained the importance of the environmental and accreditation programmes the MIA administers, along with the industry training and educational programmes. New industry support initiatives including My Marina Guide and Marine Jobs were also presented. In closing, Shute commented, “it is our business to help members grow theirs,” – a sentiment embraced by the room.

Day two workshops delved into topics and key pain points, such as insuring against and managing risk, legal issues facing marinas and creating an engaged, productive and

Specialists in the design, fabrication and installation of customized aluminum and timber floating dock systems, fixed piers and gangways for marina projects worldwide. From project design and management to manufacturing, installation and maintenance, Bluewater Marine competes globally with fabrication facilities in Hawaii, California and North Carolina.

Contact our team today for a consultation and quote on your next project!

West Coast: San Diego, CA619 499 2007

East Coast: St. Petersburg, FL727 209 7110

The smart system has been created to support marinas in managing the services o ered to their customers and add value to the port structure and its boats places. Our multi-platform solution is able to remotely control from PC and Smartphone the columns, making the systems integrated.

high performing workforce through training and development.

Lyndon Turner, CEO Nautilus Marine Insurance, chaired a panel of experts who discussed current market conditions and provided delegates with useful guidance on key risk areas affecting their marinas.

During the ‘Lessons and Learnings’ session, Scott Finsten, harbour master Ocean Marina Yacht Club in Thailand, described a recent boat fire at his facility, explaining the key takeaways and best practices that need to be in place to avoid disaster. Panel chair,

Andrew Chapman, commented: “It’s these first hand experiences that help build knowledge amongst the industry and in the long run will reduce the number of catastrophic accidents occurring.”

The conference programme concluded with Jonathan MacDonald’s keynote address: ‘Inspiring Success’. MacDonald invigorated the room to embrace innovation. Suzanne Davies summed up: “Jonathan gave our marinas a lot to think about, changing their mindset of the business they think they are in and shifting this to the business they are truly in. When we selected Jonathan to be our keynote speaker, we were drawn to his ability to invoke deeper thinking and inspire an audience to challenge the status quo.”

• Jellyfishbot from IADYS is an on-water robot. It is the size of a small suitcase and collects floating solid and liquid waste floating on the water surface.

• Collect’Thor from The Searial Cleaners is fixed to the edge of a marina or seawall where it attracts and contains waste floating on the water surface. It is totally silent and can collect and store up to 100kg (220lbs) of waste before being cleaned.

WINNER: The Man Overboard Alarm System, developed by Paul Williams, enables a casualty to simply pull a cord under the pontoon decking to sound an audible alarm. This not only raises attention but also gives marina management the location of the person in distress.

• Sucoil from Sustainable Oil Recovery is a cost-effective, recyclable solution to removing hydrocarbons from water. Deployed on a sponge, the spill attracts the hydrocarbons, which can be squeezed from the sponge and recycled. The sponge can be reused and repurposed, reducing landfill.

• Seavolt is an electric charging network for ports and waterways – soon to be installed in Empire Marinas Group marinas.

And finally, the ‘blue carpet’ was rolled out for the Gala Dinner. The evening provided an opportunity for the industry to celebrate achievements and recognise some of the industry’s long-serving members: Colin Bransgrove for his 13 years of service as MIA CEO, and Phil McGowen CMM, marina manager of Birkenhead Point Marina, for over 14 years of service volunteering and providing his knowledge, skill and time in the creation and delivery of many industry courses.

Five industry professionals were formally acknowledged as new Certified Marina Managers by the Global Marina Institute and One°15 Marina Sentosa

Cove, Singapore, was awarded Platinum 5 Gold Anchor accreditation.

The Gala Dinner concluded with presentation of an MIA Lifetime Achievement Award – the highest honour given by the association – to John Spragg, vice president MIA. The award, only three of which have ever been made, recognises individuals who have been major contributors to the marina industry over an extended period of time and for a majority of their professional life.

“John has been a true believer in what the MIA stands for,” said Andrew Chapman. “During his tenure at Bellingham Marine, John ensured that the MIA had the seed capital to operate while it was merely a volunteer organisation, through to today as the association’s Platinum Sponsor.

Without John’s or Bellingham’s involvement the MIA would not be the strong association it is today.”

The above article was first published in the June/July issue of Mooring Post

– Marina World’s digital newsfeed. Sign up to receive Mooring Post and a heads up on Marina World ahead of its print distribution at www.marinaworld.com

The EcoPile is a fully composite PVC/Fiberglass piling with a specialized internal trusssystem extruded on the inside for increased lateral and load bearing support. Coated in a highlyimpact res istant and UV stable compound, the EcoPile will stand up to the elements for decades withlittle to no maintenance.

The Conch Inn & Marina in Marsh Harbour felt the full force of Hurricane Dorian. The owners of the facility wanted to rebuild the property with the most environmentally friendly and longest lasting components. The Conch Inn is now a “Forever Dock” relying on composite EcoPile pilings and WearDeck’s composite dimensional boards and decking materials.

American Muscle Docks & Fabrication manufactures both floating and fixed boat dock systems, hardware, aluminium gangways and marina accessories. Everything is fabricated in-house in its USA factory so as to save costs, ensure quality and expedite custom orders.

American Muscle’s mission is to build stronger, simpler and more aesthetically pleasing dock products, and its name underscores its main focus: the ‘muscle’ that comes from more steel and more welds for high strength equipment that can well withstand harsh water environments.

Pile guides, timber dock hardware, steel truss hardware and frames, C-channel dock kits, ramps and jet ski lifts all have extra strength drawn,

where appropriate, from seam welding, corner gussets, horizontal and vertical supports, thicker male/female connection tabs and elongated pre-punched holes. After manufacture, all metal products are galvanised to help prevent rust, and powder-coated finishes are also available for stainless steel and aluminium.

manufacturing techniques to give its customers, whether commercial or residential, a unique and superior product for a better price.

American Muscle uses innovative

Bellingham Marine is a worldwide marina and waterfront design/build construction company with manufacturing facilities around the globe. The company is a leader in floating pontoon design specialising in floating dock systems, platforms and wave attenuators.

Bellingham Marine brings an extensive portfolio of products and widespread expertise to every project it undertakes. Its fully integrated service model, along with a design/ build methodology, provides clients with a low risk, cost effective and highly streamlined approach to their projects. The company maintains a strong financial base, instilling confidence in its clients that it can deliver everything it promises.

Having supplied over 25 million square feet of floating systems for clients around the world during its 60year history, Bellingham knows what’s been tried, what has worked, and what hasn’t. Time-proven construction methods combined with advancements in materials and an appreciation for value engineering are the foundation of

See advertisement p.56

an award-winning portfolio of projects. These can be seen around the world in diverse sites – from iconic harbours to public boat launches.

See advertisements p.7, 9 & 11

Established in 1997, Bluewater Marine and Dock Specialties is one of the premier dock manufacturers in the Pacific basin and beyond, specialising in the design, fabrication and installation of aluminium floating dock systems, fixed piers and gangways. Commercial dock system installations range from large scale marinas to small facilities.

The company’s low maintenance, flexible, modular designs include custom proprietary aluminium extrusions, stainless steel hardware and other recyclable materials. All products are fully engineered by an experienced team of licensed civil and structural engineers, are ADA compliant (where applicable) and are designed to meet site-specific environmental conditions.

All Bluewater Marine dock systems

are fabricated in-house and shipped to site ready for installation.

In 2001, the company built and installed 120 boat slips at the Waikiki Yacht Club. This project was the first aluminium floating dock system ever installed in the state of Hawaii. Following this success, Bluewater went on to develop a portfolio of innovative projects throughout Hawaii, California,

CA, USA

Micronesia, the Philippines and beyond, and now – with fabrication facilities in Hawaii, California and North Carolina –it implements projects globally.

See advertisement p.48

Clement Germany is a world leader in the design, manufacture and installation of large floating concrete structures. Its systems are some of the most innovative on the market, offering high quality, extreme durability, versatility and high functionality.

Clement uses German engineering and the most modern technology to produce floating heavy-duty high performance systems that are low maintenance with long lifespan to give a high return on investment. The loadcarrying capacity is ground-breaking, making it possible to float entire residential estates, holiday resorts and even multi-lane roads on bodies of water.

Dura Composites has over 25 years of experience in designing, manufacturing and supplying safer, stronger, faster and proven composite products for marine infrastructure projects.

Through its unique design, technology and manufacturing innovations, Dura Composites has developed a distinct range of Glass Reinforced Polymer (GRP) floor walkway grating, structural profiles, duct covers, ladders, hand railing and access platforms known as the d2 product range. All products offer customers a low life cycle cost and are a sustainable choice thanks to their long life expectancy and superb chemical and corrosion resistant

A policy of continuous R&D, enables Clement to offer advanced options, and every system sold is individually tailored down to the last tiny detail. Pontoon systems are very versatile and can be installed in challenging site conditions. As simple jetties or pontoons, elements are aesthetically pleasing but can also be combined with creative and

performance in waterside and marine locations.

Ostseeresort Olpenitz, Kappeln, Germany

architecturally demanding structures to create extraordinary floating solutions.

See advertisement p.34

For leisure environments, Dura also offers a range of clever lowmaintenance aluminium and composite timber decking and cladding.

In 2017 and 2020, Dura Composites earned a Queen’s Award for Enterprise in recognition of its achievement at the

Having spent over four decades perfecting and innovating its products and services to meet the demands of clients throughout the world, Golden Manufacturing has recognised a growing trend for the delivery of complete marine projects.

Its response to this is to offer a mix of award-winning products and an attractive ‘slip/boatlift combination’ to form a one-stop-package that generates a stronger bottom line for marina owners. Company founder, Bill Golden, believes that close attention to product detail and development, and forward thinking, are the cornerstone of Golden’s success and longevity. Golden uses modern methods, technology and skilled technicians, and delivers

systems that are safe, goodlooking, easy to operate and dependable.

Dura Grating 22mm Mini Mesh, Shepperton Marina, UK

forefront of composite product design. See advertisement p.31

Golden offers aluminium and concrete floating dock systems that are built to fit sitespecific needs. Systems are virtually maintenance-free and have a long lifespan.

The patented timber-free concrete

River Cove Marina, Miami, FL, USA

system comprises concrete decking, a patented aluminium whaler system and polyethylene UV resistant floats.

See advertisement p.14 &15

Horizon Marina is an accredited national high-tech enterprise in the marina construction field in China. With many years of experience in supplying floating dock solutions, and partnering with marinas to provide design, manufacture and installation, the company has delivered more than 300 marina references around the world.

Always focusing on quality and design, and on delivering the best customer service, Horizon Marina has become one of the main marina builders in China. The company has also accumulated project experience around the globe, not only with its aluminium systems but also with its concrete docks. In the past two years, for example, it has completed nearly 10,000m² (107,600ft²) of concrete

pontoon installations in Saudi Arabia.

Ranging from aluminium, concrete and steel pontoons, to breakwaters, floating houses and marina equipment, Horizon Marina provides clients with customised

Ingemar has over 40 years of experience in marine engineering and in the development of concrete floating structures. It is one of few companies in the sector to have its own independent production facilities, enabling it to carry out R&D in anticipation of market demands. The company is committed to quality, with ISO 9001 certification and SOA certification for public works up to €15.5 million.

The Ingemar product range includes modular all-concrete pontoons, discontinuous floating pontoons with galvanised steel or aluminium frames, hardwood decking and fibre reinforced concrete or roto-moulded polyethylene floats. It also offers fixed piers and a complete range of high quality concrete