The technical magazine for those involved in the design, construction and refit of superyachts

EDITORIAL

EDITOR IN CHIEF

EDITOR | HOW TO BUILD IT

EDITORIAL CONTRIBUTOR

FEATURES EDITOR

FEATURES WRITER

NEWS EDITOR

WRITER

CONTENT CREATOR

CONTENT CREATOR

Francesca Webster

Justin Ratcliffe

Charlotte Thomas

Leona Caanen

Enrico Chhibber

Sophie Spicknell

Andrea Pefianco

Nick Smits

Fabio Lima

DESIGN PRODUCTION

CREATIVE DIRECTOR

GRAPHIC DESIGNER

Ivo Nupoort

Beatriz Ramos

INTELLIGENCE

HEAD OF INTELLIGENCE

RESEARCH ANALYST

DATABASE MANAGER

Ralph Dazert

Adil Zaman

Syrine Mellakh

SALES & ADVERTISING

HEAD OF SALES

SALES MANAGER

SALES MANAGER

SALES MANAGER

SALES MANAGER

CLIENT SERVICE MANAGER

SALES ITALY

Marieke de Vries

Mitchell Cassee

Charly van den Enden

Nuri Ozkaya

Sabine van Hooidonk

Johanna Borreli

info@admarex.com

CORPORATE

FOUNDER & DIRECTOR

TECHNOLOGY DIRECTOR

FINANCE DIRECTOR

COMMERICAL DIRECTOR

Merijn de Waard

Fabian Tollenaar

Laura Weber

Bart Beemsterboer

SuperYacht Times B.V. Silodam 256, 1013 AS, Amsterdam, The Netherlands 31 (0) 20 773 28 64 info@superyachttimes.com www.superyachttimes.com

Cover Images:

Project Zembra by Justin Ratcliffe

REV Ocean by Justin Ratcliffe Pendennis by Rupert Pearce

How to Build It is published by SuperYacht Times B.V., a company registered at the Chamber of Commerce in Amsterdam, The Netherlands with registration number 52966461. The magazine was printed in October 2025.

Heinen & Hopman’s HVAC&R solutions seamlessly integrate into your yacht’s design, delivering silent, precise comfort in every space. Our systems ensure optimal air quality, temperature, and humidityallowing you to enjoy every journey in effortless comfort.

GET IN TOUCH WITH OUR TEAM OF SPECIALISTS

The yachting industry is increasingly subject to environmental, economic and geopolitical pressures. In this scenario, the one theme that keeps coming up is rethinking the fundamentals – a central topic of this issue of How to Build It.

At one end of the scale, Antonini Navi in La Spezia is proving that bold thinking isn’t only reserved for the biggest boats. As demand grows for robustness, custom design and fast delivery, this young yard with a background in the oil and gas sector is betting on metal construction and modular platforms in a size bracket usually dominated by GRP.

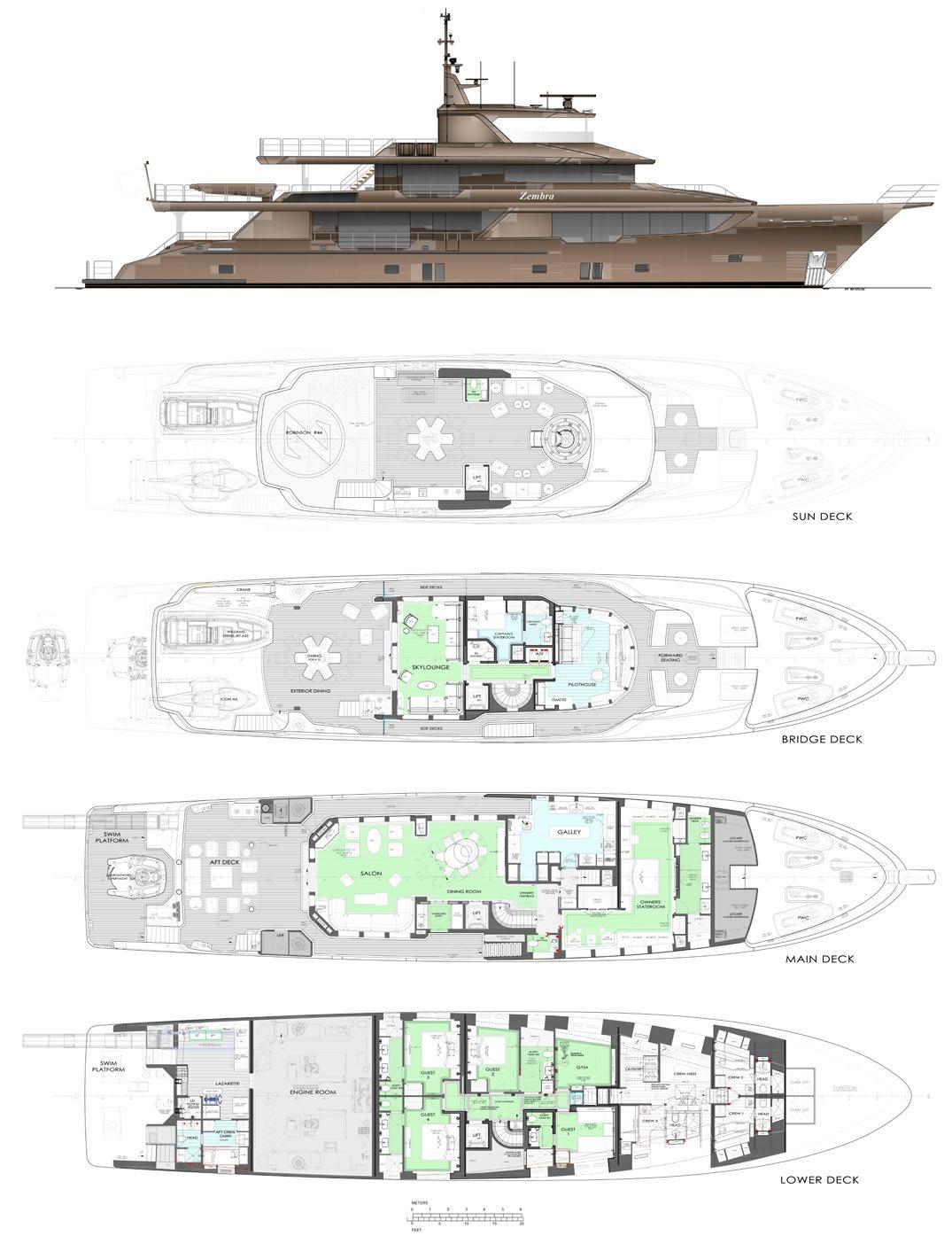

Meanwhile, Delta Marine’s Project Zembra takes an adventurous approach to what an explorer yacht can be – in this case a 48-metre yacht built in composite with the payload of a much larger vessel. Able to carry everything from a mini sub to a seaplane, it’s a reminder that with a little creative design and engineering you can pack an awful lot into a compact package.

At the opposite extreme is REV Ocean. A decade in development, this 195-metre research vessel and superyacht represents the confluence of luxury, science, and environmental advocacy. A reminder that true innovation often happens on long timelines, she is being built thanks to the resources and patience of a man who could afford to wait for the right solutions, which are rarely the fastest ones.

Avant-garde projects don’t always reach the water. Our revisit of Neonemo, a 2008 concept for Tom Perkins by Ken Freivokh in collaboration with naval architect Patrick Bray, reveals a technical design that was ahead of its time. Though shelved due to circumstance, its innovations remain relevant today and we’re reminded how some of the best ideas aren’t always the most visible.

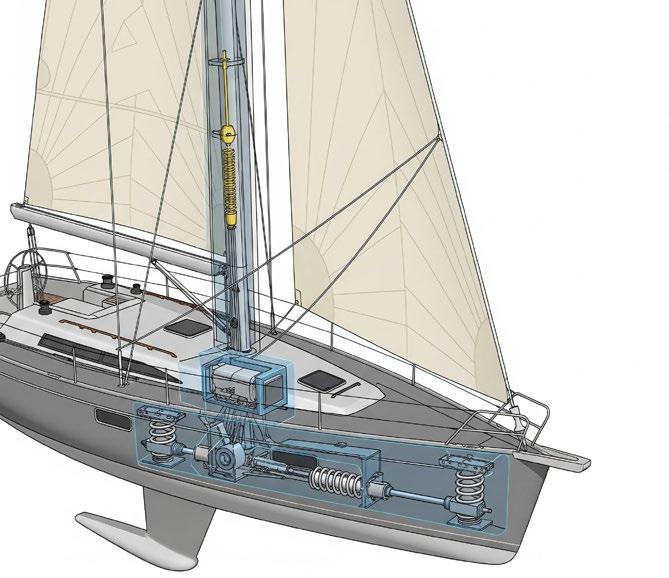

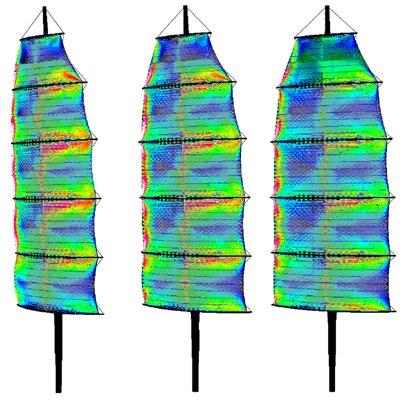

We also take a look at developments in rig design. Masts and spars on sailing boats or sail-assisted motor yachts are no longer just sail carriers: they can also be power generators, ventilation systems, and testbeds for materials science.

The common thread in all these stories is a willingness to rethink convention. Technical design, when well-executed, doesn’t need to shout. It’s in the structure, the integration and the way a yacht works – or doesn’t – when far from shore.

Justin Ratcliffe - Editor

For generations, we have been realizing the most extraordinary living spaces with dedication and expertise. On water and on land. As a leading international partner in interior+ outfitting, we turn visions for living into reality – for both indoor and outdoor areas.

We are crafting visions.

Some

19 Supplier Spotlight: Multiplex

At the 1986 Admiral’s Cup in Cowes, Jan Reiners turned a rudder failure into the spark for Multiplex – a company that recognised early on the power of carbon fibre.

22 CEO in Conversation: Toni Salom of Nautipaints Group

Toni Salom on the family firm’s evolution from Mallorca’s first yacht chandlery to a full-service refit powerhouse as the group plans to move into new builds.

27 Business Brief: Masters of Versatility

From classic renovations to custom tenders, a visit to Falmouth reveals how Pendennis has blended rebuilds, refits, and new-builds into an ongoing success story.

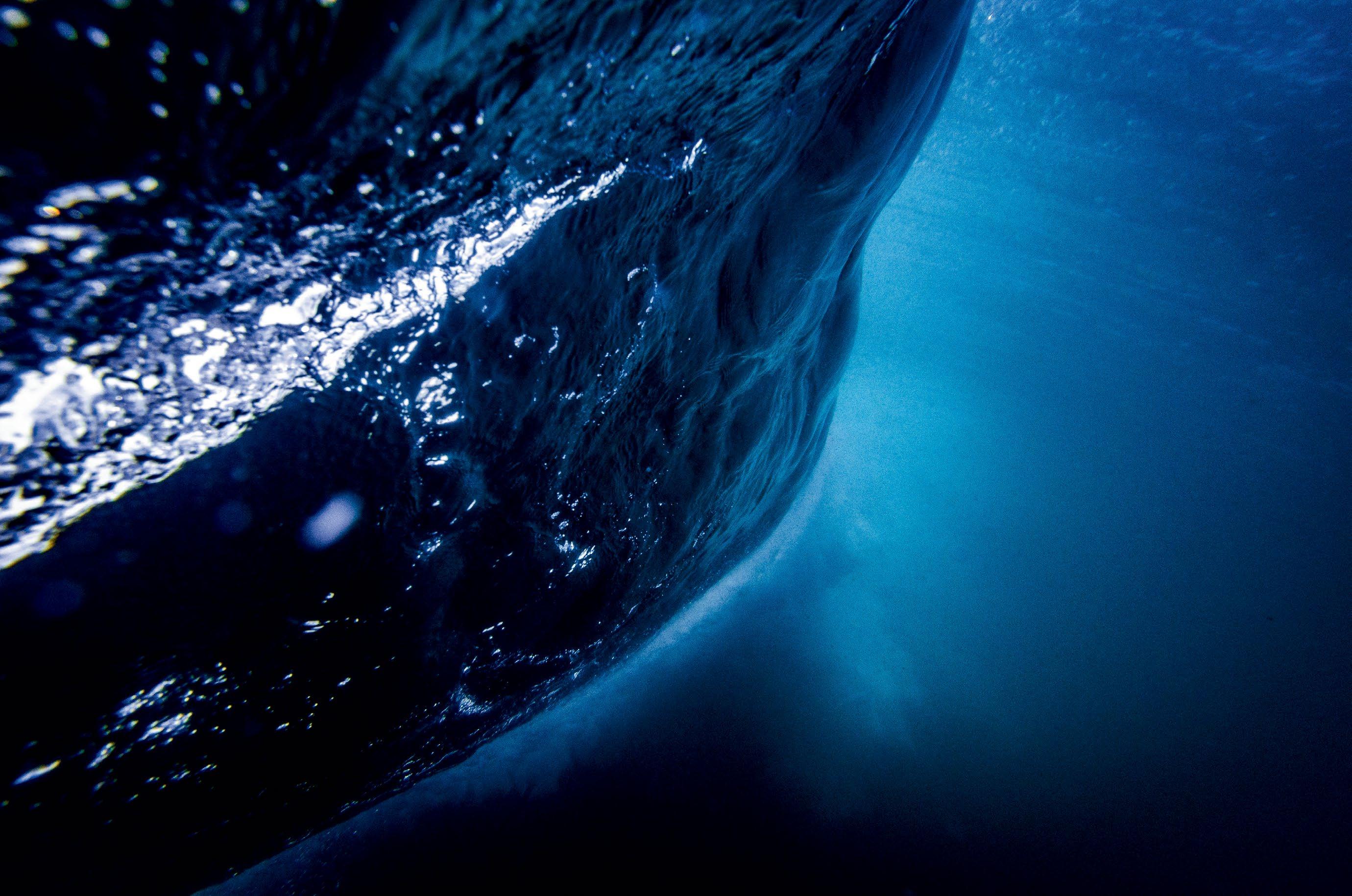

40 Build Report: Quite a Journey

We step aboard 195-metre REV Ocean, the groundbreaking blend of research vessel and superyacht designed to push the boundaries of marine science and sustainability.

53 Concept in Focus: Ahead of Its Time

In 2008, a British designer and a Canadian naval architect collaborated on a forward-thinking explorer concept for an American venture capitalist. Although it was never built, the design remains cutting-edge to this day.

62 Industry Events: Metstrade 2025

Metstrade has been the stage for marine innovation since 1988, and this year’s edition set to break records. We take a look at just some of the new products being showcased in the Superyacht Zone.

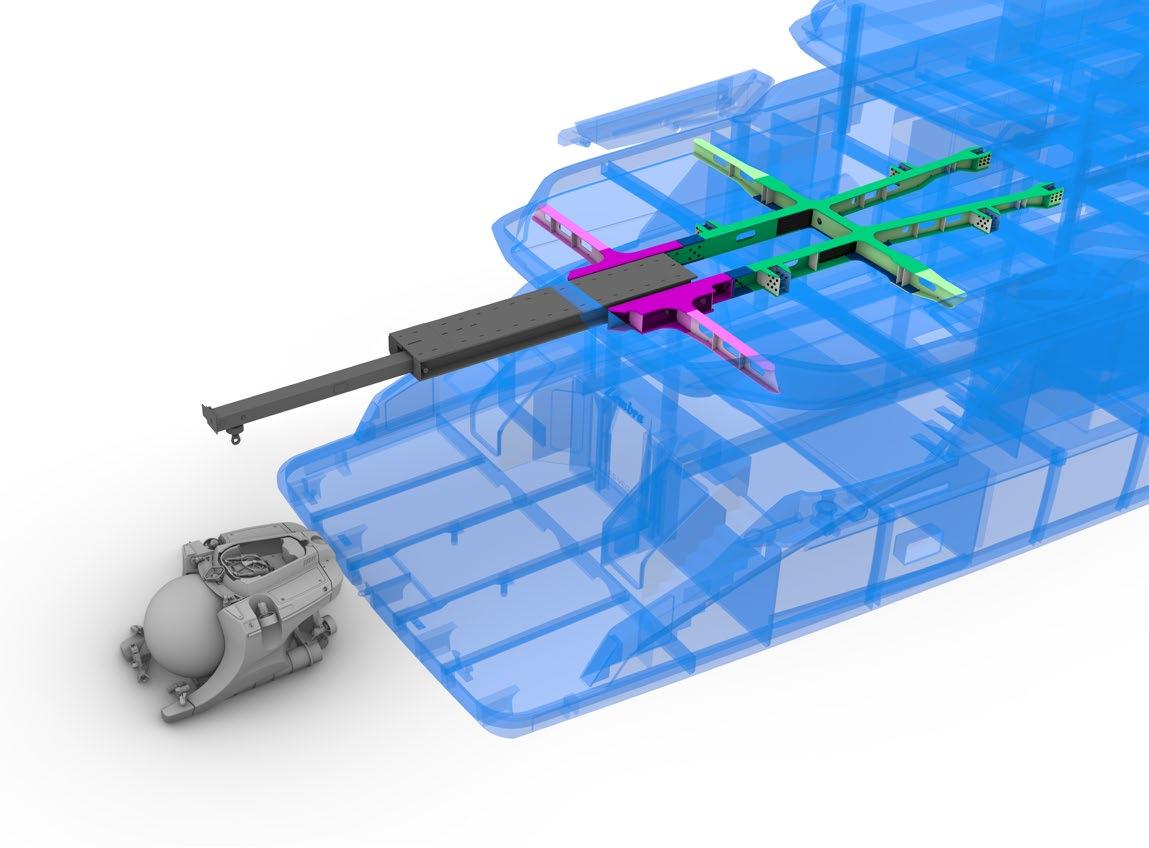

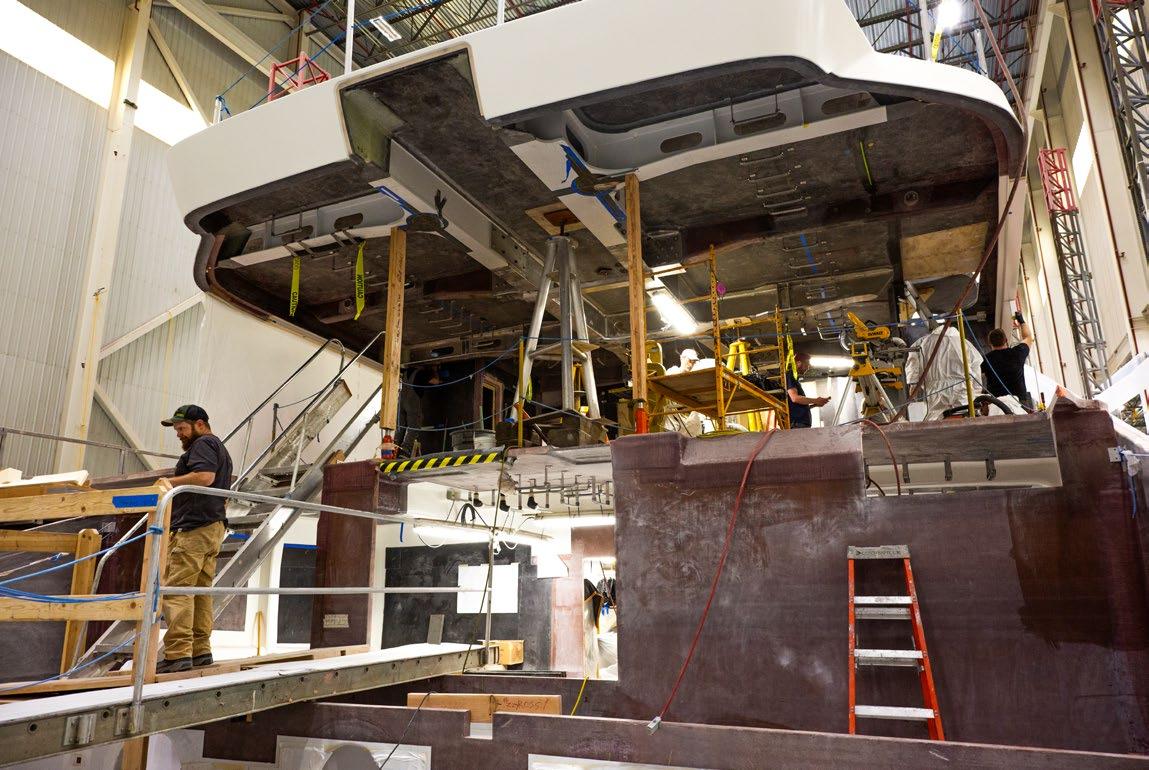

76 Build Report: Carry That Weight

Project Zembra, Delta Marine’s 48-metre composite explorer, is a showcase example of how an ambitious brief has been met with innovative design and engineering.

88 Inside Angle: Sailing Meets Strategy

From teenage sailing instructor to round-the-world skipper, Arrow Monaco COO James Allen brings his hands-on experience and leadership skills to yacht management.

93 Onboard Systems: Waste Not, Want Not

As environmental restrictions tighten, modern superyachts must integrate advanced wastewater treatment from the design stage. We look into what needs to be taken into account.

105 Spars & Appendages: Mast, Present & Future

Over the last two decades, innovations in advanced composites have pushed the limits of what’s possible and transformed the masts and spars of today’s super-sailing projects.

114 Build Report: Proof of Concept

Young shipyard Antonini Navi is going head-to-head with composite builders by targeting the sub-300GT market with two steel-hulled sister ships due to launch shortly.

127 Industry Insight: The Hidden Energy Ogre

Accounting for half of onboard energy use, HVAC systems are evolving from 25-year-old standards to connected, intelligent solutions, says Patrick Voorn of Synergy | The HVAC Consultancy.

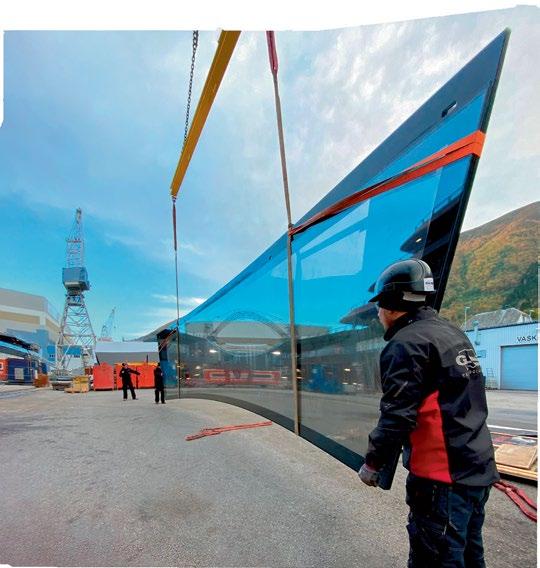

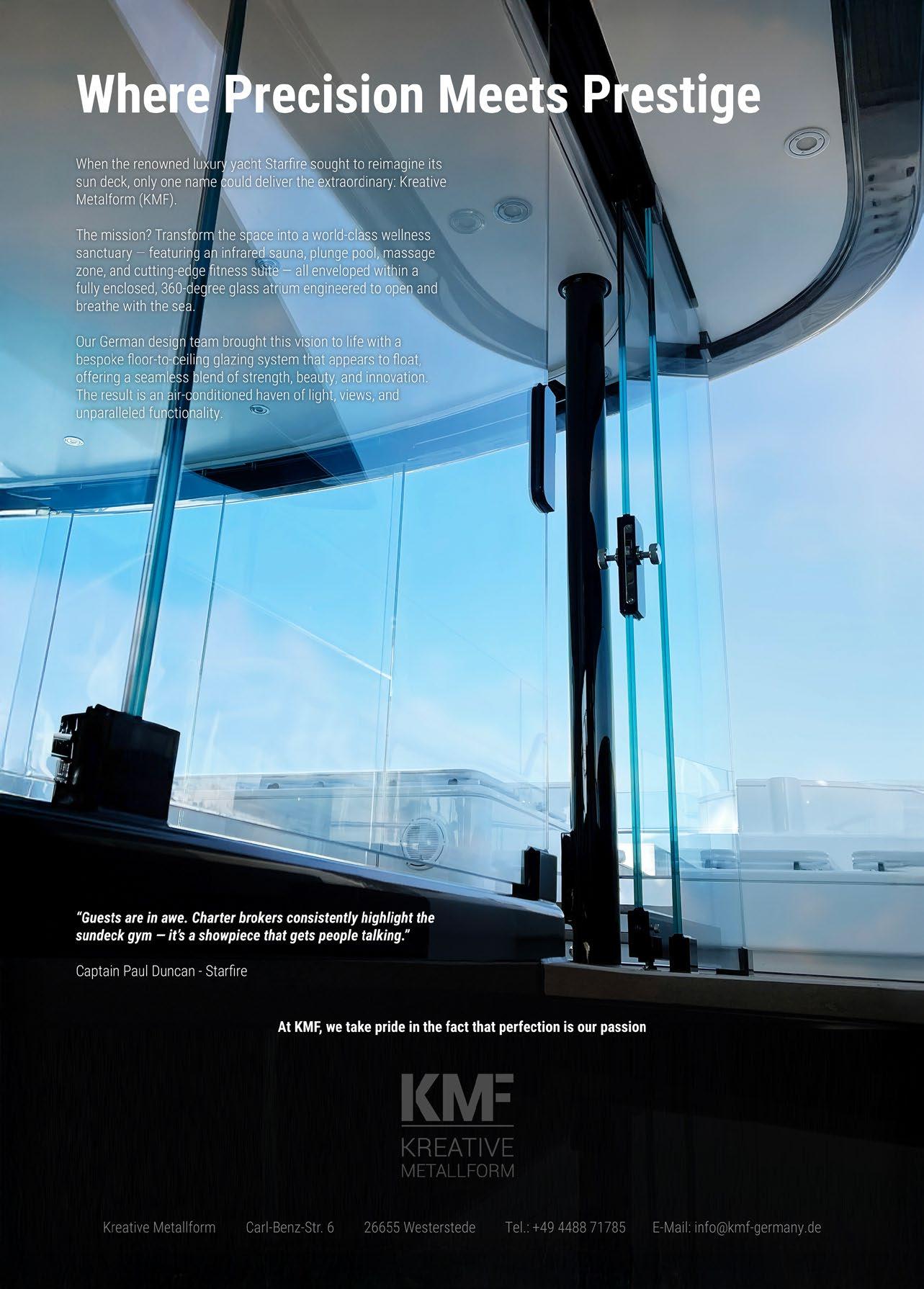

Two of Europe’s leading marine glass manufacturers, Yachtglass (Germany) and Hard Glass (Italy), have joined forces to launch Ocean Glass, a new joint venture aimed at revolutionising glazing solutions for the global superyacht market.

Ocean Glass brings together German engineering and Italian design at a time when demand for highspecification marine glass is surging. With the increasing use of expansive glazing on both the exteriors and interiors of luxury yachts, the new venture is poised to deliver precision, safety, and innovation at scale. Both companies will continue to operate independently and

maintain their existing customer relationships, but Ocean Glass will serve as a dedicated platform to develop new markets and deliver innovative solutions to emerging shipyards around the world.

“This partnership merges our strengths to serve new markets and deliver custom solutions where quality matters most,” said Silvia Buck, CEO of Yachtglass. “We’re especially focused on Turkey, the Middle East, and Asia.”

Fiorenzo Furlan, President of Hard Glass, adds: “Ocean Glass sets a new benchmark for performance and aesthetics in marine glazing. Together, we’re building the future of glass at sea.”

Alfa Laval has announced the appointment of Martijn Bergink as President of its Marine Division. He will also continue in his current roles as President of Business Unit Pumping Systems and Managing Director of Framo, an Alfa Laval-owned company.

Bergink, who joined Alfa Laval in 1998, has held several senior leadership positions within the Marine Division. In his new role, he will join the Group Management team. He succeeds Sameer Kalra, EVP and current President of the Marine Division, who is retiring after leading the business through significant growth and its transition toward decarbonization.

“I am honoured and excited by the opportunity to lead the Marine Division,” said Bergink. “I look forward to further developing the business to meet future customer needs as we continue the decarbonization journey and seize the opportunities ahead.”

The Marine Division, which accounted for 40 percent of Alfa Laval’s order intake in 2024, employs 6,300 people and focuses on energy efficiency, decarbonization, digitalisation, and environmental compliance.

No matter what the age or what vibe you’re looking for on a cruise, keep the suds in the tub with our high performance, MAGLift™ Rotors.

An absolute dream at slow or zero speed™. Spread the word!

Castoldi, known for its waterjet drives and series tender production, has announced a new Jet Tender 34 Limo, its first venture into the limousine segment. The Italian brand has worked with the Nauta Design studio to deliver a sophisticated ship-to-shore guest experience for a fleet of ultra-luxury cruise ships operated by the Aman Group, currently under construction at the Mariotti Shipyard. With the hull mould already complete, the first unit of the Castoldi Jet Tender 34 Limo is scheduled for delivery at the end of 2025.

The clean-cut design incorporates generous headroom, multiple boarding options, a configurable cockpit with a range of seating arrangements and wrap-around windows, plus a dual-purpose pantry and bathroom area. The customisable platform can be evolved to suit different superyacht requirements, including Open Limo and Support Vessel versions.

“This collaboration between Castoldi and Nauta has ensured that the design didn’t just look beautiful but performed at the highest level,” says Giacomo Castoldi, CEO of Castoldi. “We’ve integrated technical systems in a way that enhances both comfort and aesthetics, creating an experience where innovation and luxury go hand-in-hand.”

Green Energy Storage (GES), an Italian innovator in the field of green energy storage, has signed a framework agreement with RINA, the multinational engineering consultancy, inspection and certification group, to develop a new hydrogen battery. The first prototype is scheduled to be presented in December 2025.

Horizon Group has completed a state-of-theart shiplift system at its Premier Shipyard in Kaohsiung, Taiwan, after two years of development. The yard, which spans 24,000 square metres and 200 metres of waterfront, is designed to accommodate yachts over 70 metres. Its new Pearlson Shiplift System measures 160 metres by 13.7 metres and can handle up to 1,800 metric tons. The installation follows Horizon’s $15 million expansion of the facility in 2021.

The company says the upgrade cements Premier Shipyard’s reputation as a destination for refits and maintenance The yard has serviced more than 30 yachts globally, including projects on vessels up to 69 metres and brands such as Feadship and Riva.

“We are very excited about this latest upgrade with the new Pearlson Shiplift System, as it marks a significant step in the Horizon Group’s ongoing expansion,” says John Lu, CEO of Horizon Group. “The shiplift provides our shipyard with vastly increased capabilities and capacity, helping to fulfill unprecedented demand for global superyacht owners.”

The battery is based on a hybrid hydrogen/liquid technology that uses a manganese-based liquid electrolyte. The system integrates hydrogen production and re-absorption in a closed cycle, eliminating the need for external tanks. This approach combines green chemistry, with abundant, non-toxic and recyclable active materials, with a modular and scalable design in which the energy and power components are independent, allowing the system to be expanded up to the megawatt scale. Its life cycle is expected to exceed 12,000 cycles, equal to about 15 to 20 years of use.

The collaboration with RINA marks a strategic step in guiding GES from a laboratory-scale prototype to a market-ready product. RINA will play an active role in validating the technology and facilitating the entry of the technology into the energy sector.

Sam, Electrical

1 OF 500 SKILLED CRAFTSPEOPLE

Whether refit, restoration or build, every Pendennis project is a true team effort. Our time-served tradespeople are experts in their field, crafting precise and perfect work at every step of the way.

www.multiplexgmbh.com

New projects in early stages of construction that present opportunities for OEMs, suppliers and subcontractors.

The fully custom yacht will be constructed by Lynx Yachts and features a masculine exterior design by Weel Sluijter. With a beam of 8.85-metres, a draft of 2.25-metres and a gross tonnage of 199 GT, she has been tailored to a highly specific brief. Below deck, two 14.5 square-metre rooms can be adapted to suit the owner’s requirements. Meanwhile, a 62 squaremetre lazarette, located aft of the engine room, provides generous storage for inflatable toys, surfboards, canoes and scuba-diving equipment.

LENGTH: 32.55metres BUILDER: Lynx GT: 199 GT COUNTRY OF BUILD: The Netherlands DELIVERY YEAR: 2027 NAVAL ARCHITECTURE: Diana Yacht Design EXTERIOR DESIGNER: Weel Sluijter INTERIOR DESIGNER: Julian Moore Design

The commission marks the largest project in the yard’s history and was sold in cooperation with 26 North Yachts as build broker, with Arrow Monaco acting as the owner’s representative and new build management team. With an 11.6-metre beam and a volume of 1,513 GT, Project YN258 can accommodate up to 14 guests across seven staterooms, including two dedicated owners’ suites, one located on the bridge deck and the other occupying an entire private owners’ deck.

LENGTH: 70.1-metres BUILDER: Royal Hakvoort GT: 1,513 GT COUNTRY OF BUILD: The Netherlands DELIVERY YEAR: 2029 NAVAL ARCHITECTURE: Diana Yacht Design EXTERIOR & INTERIOR DESIGNER: Sinot Yacht Architecture & Design

Vard has announced its partnership with USbased marine research organisation Inkfish for the design and construction of the 100-metre custom-built research vessel RV6000, based on the Vard 9 33 design. The contract is valued at over €200 million. Fincantieri, owner of Vard, will also be involved in the project and RV6000 will join the Inkfish fleet alongside vessels Hydra and Dagon .

LENGTH: 100-metres BUILDER: Vard Group AS GT: C.6,000 GT

COUNTRY OF BUILD: Norway DELIVERY YEAR: 2028

NAVAL ARCHITECTURE: Vard Group AS EXTERIOR DESIGNER: Vard Group AS INTERIOR DESIGNER: Unknown

In July Maiora, part of the NEXT Yacht Group unveiled its latest project, the 42-metre Exuma with the first hull already sold. All guest accommodations are located on the main deck, with the main saloon and entertainment areas located on the upper deck. The yacht offers two engine configurations: twin Volvo Penta engines delivering a cruising speed of 16 knots and a top speed of 20 knots, and triple MTU engines providing a cruising speed of 26 knots with a top speed of 30 knots.

LENGTH: 42.49-metres BUILDER: Maiora Yachts GT: 430 GT COUNTRY OF BUILD: Italy DELIVERY YEAR: 2027

NAVAL ARCHITECTURE: Maiora EXT. DESIGNER: Cassetta Yacht Designers INT. DESIGNER: Carlo Colombo of A++ and Elie Saab

As the inaugural model in the series, she also represents the first in-build yacht sale for the Tureddi Group. Azzurra will be constructed in steel and aluminium and will feature naval architecture penned by Van Oossanen Naval Architects, with exterior design from Giamboi Designs. Azzurra’s general arrangement focuses on liveable spaces and onboard comfort.

LENGTH: 36.7-metres BUILDER: Cantieri Navali Tureddi GT: 350 GT

NAVAL ARCHITECTURE: Van Oossanen Naval Architects

COUNTRY OF BUILD: Italy DELIVERY YEAR: 2027

EXTERIOR DESIGNER: Giamboi Designs INT. DESIGNER: N/A

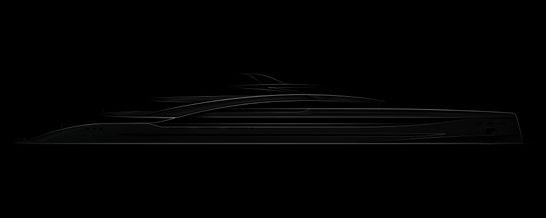

Described as a “grand coupé of the sea,” the ISA 100m Custom combines a sleek, automotive-inspired profile with the shipyard’s iconic ISA arch, reinterpreted with a strikingly dynamic strength. A fusion of power, elegance and functionality, the yacht features a steel hull and aluminium superstructure, 2,999 GT of interior volume and a certified helideck.

LENGTH: 100-metres BUILDER: ISA Yachts GT: 2,999 GT

NAVAL ARCHITECTURE: Palumbo Superyachts

COUNTRY OF BUILD: Italy DELIVERY YEAR: 2029

EXTERIOR & INTERIOR DESIGNER: Team for Design - Enrico Gobbi

At a volume of 499 GT and being built with a steel hull and aluminum superstructure, the NL 47 Plus XL offers accommodation for 10 guests across five staterooms, supported by crew cabins for up to nine. The design blends timeless exterior lines with contemporary interiors that can be fully customised to each owner’s preferences.

LENGTH: 47.6-metres BUILDER: Mengi Yay GT: 499 GT

NAVAL ARCHITECTURE: Ginton Naval Architects

COUNTRY OF BUILD: Turkey DELIVERY YEAR: 2027

EXTERIOR & INTERIOR DESIGNER: Nuvolari Lenard

The story of Multiplex begins in Cowes, England, at the 1986 Admiral’s Cup. Battling fierce winds during the regatta, keen sailor and boat builder Jan Reiners experienced issues with his boat’s rudder blades. Frustration turned to inspiration when he reached for a then little-used material in yachting: carbon fibre. Strong, light, and resilient, it solved his performance problems and sparked the idea for an innovative company with a product portfolio based entirely on carbon composites.

BY GEORGIA TINDALE

Jan Reiners

Nearly four decades later, the German composite specialist is a global leader.

From humble beginnings, multiplex products – ranging from gangways and swim ladders to fenders, awnings, and stairs – are now found on around 80 percent of the world’s largest sailing and motor superyachts.

“Multiplex began with basically nothing,” recalls CEO and founder Jan Reiners. “I had a 40-foot container with an oven inside, which I heated up to 130 degrees. Nowadays, we have our 2,500-square-metre facility in Bremen, which uses all of the latest cutting-edge techniques to produce the parts we need.”

The early years were a period of experimentation. Multiplex even ventured briefly into yachtbuilding, producing a tender, a 50foot day sailor, and a 72-foot high-performance sailing yacht. But Reiners quickly realised the future lay in perfecting components, not whole boats. The company has streamlined its focus to a tight but growing portfolio of seven product lines – all crafted from carbon fibre.

While the catalogue has remained largely unchanged for more than 35 years, the yachts themselves have not. As superyachts have grown in scale, so too have the Multiplex systems. Reiners points to his first product, the multiflap gangway, which has been in production for over 35 years, but over that time the scale of it has changed completely to match the growing size of yachts. Notwithstanding this scaling up of products, however, they never exceed 25 kilograms in weight. This is because ease of operation for the crew is a top priority.

“Everything is still completely manually operated,” Reiners explains. “There is no pushbutton system. The crew need to grab a swim ladder or a gangway the moment the owner or guests ask for it – so it has to be light, reliable, easy to handle, and of high quality.”

A watershed year for the company came in 2019, when Reiners chose to expand the company’s project capacity six-fold – from 20 to 120 – in one fell swoop. It was a bold gamble, requiring a major shift in operations, staffing, and supply chain management. Manufacturing and engineering moved partly out of house, which required new focus on project oversight and quality control.

“It was absolutely the right decision,” says Reiners. “We now have it entirely under control and are running 87 projects simultaneously. At peak season, I expect we’ll reach 120 or even 130. In five years, the aim is to be handling 130 to 150 projects. But we don’t want endless growth – we’re not in the automotive industry.”

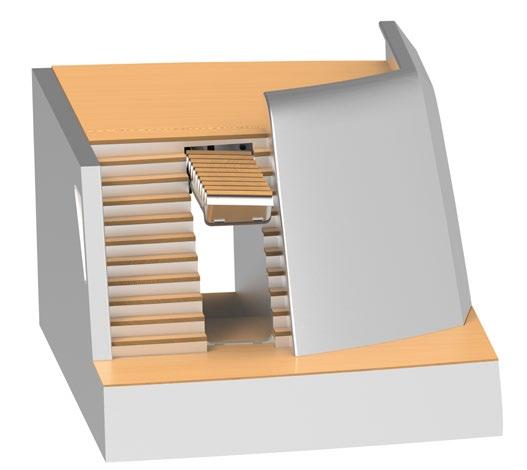

Recent acquisitions, such as German filament-winding specialist Vinco, have strengthened Multiplex’s ability to deliver at scale while freeing up its in-house team for innovation. New products are already on the horizon, with several due to be unveiled at this autumn’s Metstrade show.

With sun awnings accounting for around 50 percent of production, its most technically complex standard product is the multistair, a fully carbon fibre, extendable and foldable side-boarding ladder of up to 14 steps, which has a production time of 8-12 weeks. But Multiplex also breaks ground with bespoke solutions on occasion. One such is a fully integrated steering station made entirely of carbon for a 38-metre yacht, for which the company was responsible for the complete production and project management. Behind the scenes, the team is developing new products and refining existing ones, with some set to debut at this year’s Metstrade show.

For Reiners, the journey has never been about chasing scale for its own sake. Instead, it has been about identifying problems, creating lightweight, durable solutions, and ensuring they can be deployed quickly and effectively on board. That ethos – born out of a rudder issue in Cowes nearly 40 years ago – remains at the heart of Multiplex today.

YOUR BEST CHOICE FOR NEWBUILD AND REFIT.

After starting life as Nautipesca Can Miguel, Mallorca’s first yacht chandlery in 1971, the family-run Nautipaints Group now spans superyacht painting and refinishing, hull and tank maintenance, marine supplies and, as of this year, scaffolding and containment. Following a recent spate of heavyweight refit projects – including Black Pearl and Maltese Falcon – CEO Toni Salom talks us through the company’s planned move towards new builds, how COVID-19 pushed it to embrace e-commerce, and how the tide has turned on electrostatic spray guns.

BY GEORGIA TINDALE

Nautipaints Group is a family affair. How important is that to you?

I saw the growth of the yachting industry in Mallorca from a few small fishing boats in the early 1990s to the huge yachts we have today. In recent years, my children, Maena (General Manager of Nautichandler) and Joan (Deputy General Manager of Nautipaints) are already starting to be group’s driving force. I’m still the CEO, but the company now has a third generation in the business, and I feel extremely proud of that.

How are you looking to grow the business going forward?

To increase our business, we need to target the new-build sector and the idea is to have an established position in the market within the next three years by consolidating our presence on mainland Spain, in the South of France, and northern Europe.

Over the last 20 years, Nautipaints has completed more than 250 full refit paint projects in 13 different locations, which reflects the scale and reliability of our operations. As part of a three-year strategic plan, we aim to continue expanding all four divisions of Nautipaints Group beyond Mallorca, while also developing our presence in the new-build sector. This year, for example, we began collaborating on the construction of a 25-metre catamaran in Spain, a project that represents the direction in which we’re heading.

What is the biggest obstacle you’ve faced while growing the company?

COVID-19, without a doubt. We were lucky because my team managed to support each other and adapt during some very difficult moments, and come out stronger on the other side. It also gave me an inspirational idea. I was sitting at home and noticed that Amazon drivers were some of the only people working, and this inspired me to develop the e-commerce side of our supply business, which today is a key part of the group: a platform with worldwide shipping, from which we have already delivered to over 70 countries.

What have been the major technological developments you’ve seen in your sector over the past 50 years?

In general, we’re still working with the same products we’ve always worked with, although the quality of these have certainly improved over time. For example, primers have been developed that contain more solids to fend off corrosion. The choices available have also expanded – you can now choose from a huge array of different paint colours, for example, and we also have our own machines in-house to mix the paint ourselves.

Another major change has been our adoption of electrostatic spray guns, which we started using around five years ago. These are a great tool because they help us to really reduce our wastage. A few years ago, we were hesitant about training our guys in how to use them because clients were demanding that we use conventional airspray guns instead. Now it’s the total opposite. Beyond these specific examples, our focus is on the continuous incorporation of new developments and innovations that enhance efficiency, safety, and quality across all our projects.

Finally, what have been the most memorable or complex yacht projects you’ve worked on to date?

The most complex was probably the tank treatments we recently did for Black Pearl. We carried them out with the boat in the water, which nobody had ever attempted before. We had to strictly control the humidity and all of the environmental conditions, and passed all of the pipes through the boat itself, which was unusual. We also had to factor in the very real risk of explosion, which meant there was a lot of pressure around the project. Overall, though, it was a very successful project.

Again, with the work we did on Maltese Falcon, we were working in very complicated conditions. We completed the work in Italy in winter between November and April, so it was very rainy and windy at the time. Both were brilliant projects for us and helped show the industry what we’re capable of.

BY LEONA CAANEN

Starting Vyva Fabrics 35 years ago, it was just Carol Driessen, a 150 metres of Sunbrella acrylic and a passion for creating, using fabrics and colours. Based in Amsterdam, The Netherlands, Carol and her team are both textile visionaries and trendsetters, working with sustainable fabrics and Flexiteek before it was popular. Establishing their expertise early on, it’s now almost impossible to find a superyacht without a touch of Vyva Fabrics.

The yachting world has always felt like home for Carol, founder, owner and CEO of Vyva Fabrics. Growing up in a marina owned by her parents, Carol’s life has revolved around yachting. It should therefore come as no surprise that, in the early days, if a ship needed a refit or new outfitting, Carol would do it all herself.

The first few years, there was little she didn’t do. Carol held the title of warehouse manager, accountant, sales representative, shipping manager, booth builder, and general manager. Her maritime roots have given Carol a very straight forward, no-nonsense business mentality: creating the right fabric for the right project. While Carol has grown her team, she still enjoys being involved in all elements of the business, with help from her daughter, Karlijn.

Carol’s business has always had an element of family, with much of her inspiration, knowledge and network coming from growing up in her parents’ marina. While there have been many highs and lows over the course of 35 years, there isn’t a trace of hesitation when Carol notes her favourite moment: Karlijn joining the business. Working together for eight years already, the motherdaughter duo are now co-owners.

Another high in Carol’s career has been relocating to their current office in the industrial north of Amsterdam. While Carol immediately loved the feeling of the empty lot sitting right by the water, it took some motherly convincing to purchase it. The exclusive location, right across from the Damen Yachting Shipyard, would be able to serve both as an office and a warehouse. Even Carol’s 80-year-old mother, who went to have a look early on a Sunday morning, felt the area and its marine atmosphere was the right place for Vyva Fabrics.

While the maritime industry was Vyva Fabrics’ main focus for many years, Carol eventually expanded into other sectors, including hotels, hospitality and healthcare. Each new sector brings an assortment of challenges and opportunities regarding the fabrics Carol chooses to work with. Not only that, but working in the different sectors has shown Carol how versatile her fabrics truly are. Such as 4 Outdoor Fabrics, which is frequently used for outside furniture on superyachts, but is also more than ideal for hotels and hospitality: settings all requiring a certain level of comfort, as well as resistance to deep cleaning and need to be resistant to bleaching, whether from alcohol based cleaning solutions, chlorine or lying in the sun all day. Yet what makes Vyva Fabrics so unique is not just their knowledge or experience, but their desire to create something beautiful and durable. In each project, whether for a hospital, hotel or superyacht, the purpose of the fabric is deeply analysed. Carol, Karlijn and their team will sit with the architect, client or project manager, and inquire what

the desired fabric is for. Clients tend to have a vision of what they want, but lack the knowledge of how versatile some fabrics are and what they can best be used for. Many textiles still have the misconception of being non-versatile. Customers have a hard time imagining that a fluffy outdoor fabric exists, or that, because of its sensitivity to decoloration, linen isn’t ideal for outside. No matter what textiles are used, Vyva Fabrics tries to always be topped up on their stock, which sits tucked below their first-floor office. The entirety of their stock is digitalised, and Karlijn highlights how this has helped them deal with the numerous orders that come in each day. The ease of having the warehouse below the office, is that the company can ensure a quick delivery time. Two days for the Netherlands and Belgium, and 3-5 days for the rest of Europe. Even when a roll of fabric is out of stock, there’s a maximum wait of two weeks.

The digitalised stock and attention to detail for each project stem not only from Carol’s passion for her work, but also tie in with her desire to be sustainable. Carol draws a lot of her inspiration for textiles, colours and marketing campaigns from her love for nature and food. Focusing on sustainability and caring for the environment through distinguished use of certain fabrics is an ode to her source of inspiration. Throughout the last 35 years, all of Vyva’s fabrics have some extent of recycled materials, are mostly PFAS-free and always high quality. Such as Dinamica, made of discarded PET-bottles and polyester clothes, or REVYVA, made of 100% postconsumer plastic bottles.

Another way in which Carol has introduced recycled, durable products into her work, and which is considered to be another highlight of her career, is Flexiteek. When Carol started selling Flexiteek, everyone thought she was crazy, claiming no one would want synthetic wood on their yachts. Yet Flexiteek is engineered to last about 20 years, and is especially designed to be durable in a harsh marine environment and withstand the chartering world: sun, stains, scratches and salt. Carol’s vision was ahead of her time; now you can’t think of a superyacht without thinking about alternative teak decking, such as Flexiteek.

Rather than following trends, Carol has always been an innovator in the field of textile. Her expertise, insight and passion for her work, along with her maritime background, has made her the best in the business for the larger part of four decades. With a solid vision and foundation to build on, Carol looks excitedly towards the future and getting to share it with her daughter Karlijn, who will eventually take over the business. For now, the two work together effortlessly, each an expert in different creative and organisational elements of the business. Vyva Fabrics has been and will remain a household name in the textile industry, on superyachts and beyond.

Craftsmanship that lasts. Protection that goes beyond.

At De Koninggroep we protect what’s precious. With over three decades of expertise in blasting, coating, and preservation for the superyacht industry, we deliver lasting quality, down to the finest detail. Innovation where it matters, craftsmanship that endures. Today, tomorrow, and far beyond.

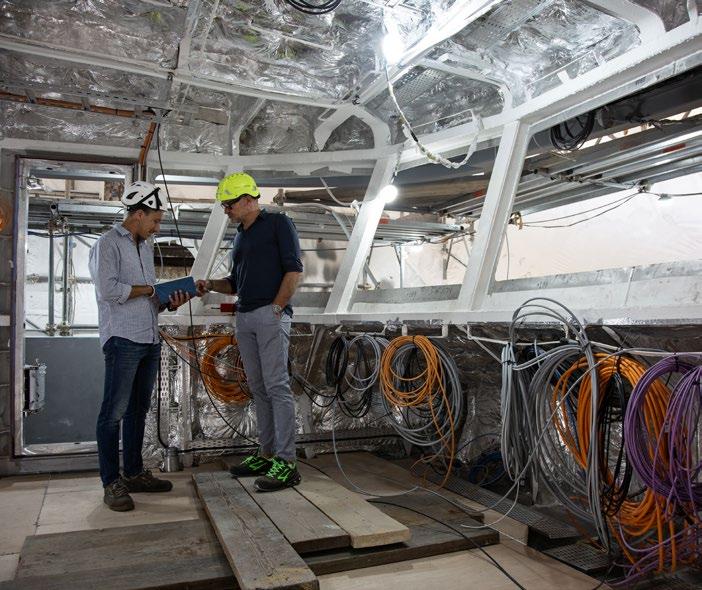

On a recent visit to the Pendennis facility in Falmouth, Cornwall, the breadth of work underway in a single shed was striking: a 50-metre Turquoise in refit, a custom Cockwells tender nearing completion, a classic Westsail 32 cutter fresh from maintenance, and a 10-metre motor boat receiving a new coat of paint. With a mix of refit, rebuild and new-build at the heart of the yard’s identity, our visit was an opportunity to explore the strategy and structure that have shaped the company’s success to date.

BY FRANCESCA WEBSTER

Below: 85.6-metre Aquila (ex-Cakewalk) in the 150-metre dry dock at Pendennis in Falmouth.

Facing page: The basin functions as a controlled arrival, commissioning and trials area.

Pendennis Shipyard was established in 1988 by British entrepreneur Peter de Savary to provide a dedicated facility for both yacht construction and refit. Its first new-build was delivered in 1991, the same year that the three-masted, gaffrigged schooner Adix underwent a major restoration. This dual focus on building and refitting, which has remained at the heart of the yard’s operations for more than three decades, continues to define Pendennis today. Over the past year alone, the yard has delivered the new-build motor yacht Fox, completed the major rebuild of the 1950’s explorer Seawolf, undertaken refits of the sailing yachts Ghost, Hetairos and Adix and built the Thames electric passenger vessel Silver Raven. Alongside these headline projects, a steady stream of refits, maintenance works and smaller commissions ensure the yard is as active as ever.

The Pendennis Group has expanded significantly in recent years, building a portfolio that extends beyond its home base in Falmouth. Alongside the shipyard’s core activities the group also owns Cockwells, known for its bespoke superyacht tenders, and Norfolk Interiors, a specialist in fine joinery that complements the yard’s interior projects. Pendennis Vilanova has strengthened its Mediterranean presence with a dedicated refit and service facility near Barcelona that provides continuity of care for its fleet. Together, these businesses create a diverse yet interconnected network that supports the group’s strategy of combining British craftsmanship with international outreach.

The Pendennis Group is guided today by a four-strong board of Directors – Toby Allies, Charlie Ross, Stephen Hills and Ian Granville – each bringing distinct expertise to the table as well as dividing responsibility to support and provide strategic direction to the subsidiaries, Norfolk Interiors, Cockwells and Pendennis Vilanova. Rather than a rigid hierarchy, they operate within a deliberately flat management structure, meeting weekly to coordinate activities across the group.

Co-founder Mike Carr is the Chairman of the Group and his role is complemented by nonexecutive directors providing governance and external perspective. Beneath this tier, individual companies within the group have their own management teams, ensuring both continuity and a clear pipeline for succession. It is a model that reflects Pendennis’s philosophy of shared responsibility and empowerment.

As Allies explains: “It’s a structure designed to balance ambition with resilience, ensuring the business continues to evolve without losing the family-minded culture that has long defined it.”

In parallel with its new-build activities, Pendennis has earned a reputation as one of the industry’s foremost refit and rebuild yards.

While Pendennis is perhaps best recognised for its major refit and restoration work, the yard also has a rich pedigree in newbuild construction dating back to the late 1980s. Its first new-build was the 37.4-metre sailing yacht Taipan of Wales, a project that set the tone for the yard’s commitment to craftsmanship and innovation in the sailing yacht sector. This debut firmly positioned Pendennis within the competitive custombuild market and laid the foundation for a tradition of complex, bespoke construction. By 1999, Pendennis had extended its newbuild credentials to motor yachts with the delivery of Moatize. This milestone broadened the shipyard’s scope beyond sailing yachts and underlined its ability to apply the same precision and attention to detail to motor yacht construction. Subsequent builds, including Ilona and Steel, showcased its capacity to tackle large-scale motor yacht projects with the same expertise as its sailing yachts.

In parallel with its new-build activities, Pendennis has earned a reputation as one of the industry’s foremost refit and rebuild yards, having completed over 120 significant projects alongside its 22 newbuilds. The early restorations of Adix, Adela and Fair Lady established the company’s methodology: anchoring long-term, technically demanding projects within its order book while balancing these with shorter service works.

The yard has since become the natural home for J Class yachts, with Shamrock V, Velsheda, Ranger and Lionheart among those entrusted to its care. Notably, many crew returning with their yachts encounter the very same craftsmen involved in earlier restorations – a continuity made possible by Pendennis’ longstanding apprenticeship programme, which ensures expertise is passed seamlessly between generations. Pendennis’ sailing yacht heritage is second to none, yet the yard has consistently applied those same skills to motor yachts.

“The close-quarters craftsmanship demanded by sailing yachts, with their cambers, sheer lines and tightly engineered spaces, enhances the workforce’s adaptability when tackling the vast scale of an 80-metre motor yacht,” says Allies. “This dual expertise allows Pendennis to keep its order book broad, ensuring resilience against fluctuations in either segment of the market.”

Acquired in 2024, the local Cornish yard Cockwells Boatbuilding provides the Pendennis Group with a dedicated capability in tenders and small craft. While its expertise is applied to Pendennis projects, Cockwells also serves external clients and other yards worldwide. This parallel activity broadens the group’s commercial reach. Innovation is another area where the two companies align. Cockwells has been active, for example, in developing hybrid propulsion solutions and composite techniques.

“Cockwells gives us the ability to support clients beyond the mothership,” says Stephen Hills. “A refit or new-build might also need a tender and by keeping that in-house we can ensure it meets the same standards and integrates smoothly into the project.”

Pendennis acquired Norfolk Interiors – a long-term Pendennis partner – in 2021 as a joinery and fit-out arm of the group, delivering interior outfitting for yachts alongside bespoke furniture and cabinetry for residential and commercial projects. For the yard, this provides greater control over quality and schedules without having to rely entirely on subcontractors. The company’s activity across both marine and landbased sectors is a deliberate strategy. Norfolk Interiors is also involved in training and apprenticeships, supporting the development of skilled tradespeople within the group.

“We’re conscious of the need to sustain craft skills,” continues Hills. “By having Norfolk Interiors in-house, we can provide real pathways for people to learn joinery and furniture making at the highest standard.”

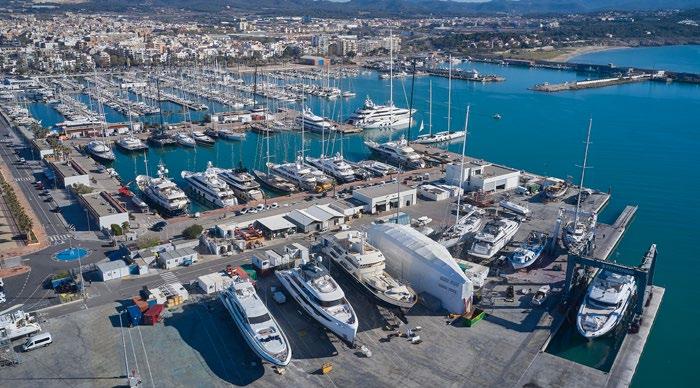

Pendennis Vilanova was founded in 2018 at Vilanova Grand Marina, near Barcelona, as the group’s Mediterranean service base. The site now offers 30,000 square metres of hardstanding, a 620-tonne travel lift, and berths for yachts up to 130 metres. A significant portion of the superyacht fleet spends much of its time in the Mediterranean, which meant establishing a base here was a natural evolution. The yard works in tandem with Falmouth, offering maintenance and warranty support after major refits.

“When I arrived, it was still seen as a marina with a small lift,” says General Manager Miquel Lliteras, who joined in 2021, and has overseen the site’s transformation. “Today we can haul up to 55-metres and usually operate at close to full capacity.”.

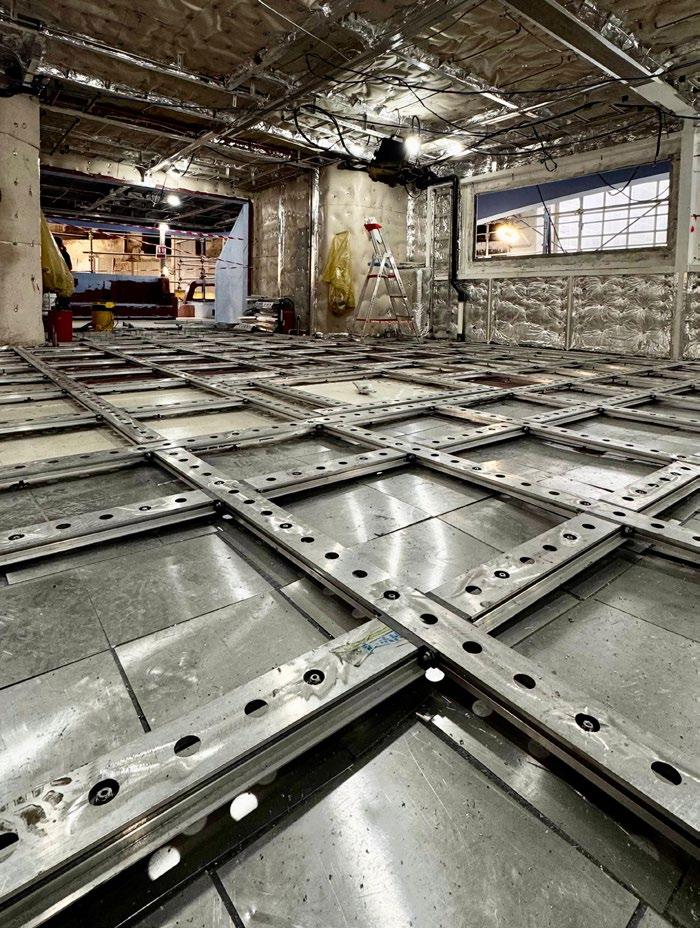

From its earliest years, Pendennis has consistently invested in flexible, engineering-heavy infrastructure rather than fixed production lines, enabling the yard to complete a variety of projects despite its limited physical footprint. A 150-metre dry dock is the backbone of the site, enabling large-scale restorations and bespoke newbuilds to run alongside seasonal service work that keeps its 500-strong workforce busy. Early spend focused on core trades –joinery, metalwork, electrical and paint – so the yard could self-perform critical paths and control quality from day one.

As the refit business accelerated, the yard added enclosed refit halls at the head of the dry dock, creating a weatherproof, yearround environment. Subsequent re-planning of the waterfront introduced a sheltered basin that functions as a controlled arrival, commissioning and trials area. Yachts can come alongside, enter refit halls or dock down without disrupting neighbours – effectively a two-lane workflow that separates heavy works from soft-commissioning and sea-trials logistics. In addition, the yard’s position at the entrance to Falmouth Harbour means that yachts can leave the basin and immediately start sea trails in a sheltered environment, heading out to open sea if necessary and return without having to navigate through challenging systems.

The £22 million development in 2015 was a decisive reset of site layout, including services and energy management. Electrical distribution, compressed air, extraction and fire systems were upgraded in parallel so multiple large projects could run safely at once. Environmental performance was improved with better containment, filtration and lighting, lifting finish standards while reducing rework. The programme also strengthened craneage, doors and access routes for taller rigs and broader beams, opening the door to larger sailing yachts and complex rebuilds.

Pendennis’ mobile lift capacity has progressed in lockstep with the fleet. The yard moved from the original 60-tonne travel hoist to 400 and 640 tonnes, before commissioning an 800-tonne lift in 2019. The former 640-tonne unit now serves at Pendennis Vilanova, giving the group a consistent haul-out methodology between Cornwall and the Mediterranean. Paired with the dry dock, this creates a clear split: up to 800 tonnes by hoist, beyond that via dock; maximising utilisation and minimising bottlenecks.

The 2025 launch of Silver Raven, a hybrid-electric Thames passenger vessel, demonstrates just how far Pendennis’ project capability has evolved. Entirely built in aluminium by Pendennis in Falmouth, with design and power profiling by Vulkan UK and an EST Floattech Octopus Series battery bank, the vessel can carry more than 300 passengers between Greenwich and Tower Bridge, recharging in just 15 minutes at each terminal.

Although far removed from a traditional superyacht, the project embodies Pendennis’s trademark qualities: exacting aluminium fabrication, complex systems integration and a collaborative relationship with an innovative ownership team.

Just as importantly, it demonstrates the transferability of knowledge gained on hybrid propulsion refits such as Seawolf into a different maritime sector.

“We’ve always embraced challenging projects, from ferries to architectural structures,” says Allies. “If it excites us and stretches the workforce, we are up to the challenge.”

What unites projects like Silver Raven, the J Class fleet and modern rebuilds is the Pendennis approach to project development. Each commission is treated as a bespoke exercise, managed not against a template but against the requirements of the vessel and its owner.

Pendennis has consistently invested in flexible, engineering-heavy infrastructure rather than fixed production lines, enabling the yard to complete a variety of projects despite its limited physical footprint.

The Digital Manufacturing Centre (DMC) is the newest pillar in the investment story –and an employee-led one. Proposed by the engineering team, the DMC brings rapid, on-site manufacture of critical parts into the heart of the yard. By consolidating processes such as precision machining, waterjet cutting and smallbatch fabrication in stainless steel, aluminium and bronze, the facility gives Pendennis the ability to deliver components on demand.

One of the greatest benefits is the speed from design to part. Engineers can work directly with captains and surveyors to model improvements, then produce and fit bespoke solutions without relying on external suppliers. For heritage yachts, the DMC has proven invaluable, allowing for the faithful recreation of fittings and fixtures no longer available, preserving historical integrity while ensuring safety and reliability. On modern performance sailing yachts, the facility also supports innovation, producing custom hardware to reduce weight, increase stiffness and enhance handling under sail.

“The DMC ultimately embodies our philosophy of retaining control over quality and schedule,” says Stephen Hills, Commercial Director at the Pendennis Group.

“By reducing downtime, eliminating freight delays and ensuring components meet the yard’s standards, the centre not only strengthens technical capability but also delivers a measurable return on investment.”

Investment has extended beyond Falmouth. Pendennis Vilanova provides Mediterranean haul-out, paint and pit-stop capability, giving clients continuity of people, process and documentation between refit cycles. The integration of Norfolk strengthens interior capacity for large projects, while Cockwells brings deep tender expertise that dovetails with Vilanova’s service offering. Each move targets pinch points – joinery throughput, tender servicing, regional access – rather than growth for growth’s sake.

Taken together, these investments have created a yard that can carry one or two anchor projects, a full-custom build or a multiyear restoration, while executing a balanced slate of seasonal refits and smaller projects. For owner representatives, project managers, captains and surveyors, the net effect is tangible: fewer hand-offs, tighter schedules and work that stands up to scrutiny long after a yacht has passed Falmouth’s Black Rock and headed out to sea.

www.reintjes-gears.com

Quick Nautical Equipment, brand of Quick Group, has launched its latest addition – the 140 kilogramme Olympic anchor. Designed and manufactured entirely in Italy, the new model underscores the brand’s focus on super highholding power, innovation and customer-driven development.

The decision to create a 140 kilogramme anchor came directly from client demand. One customer had purchased a 100 kilogramme model and required a larger version for the same yacht. “Given the way we designed the product, scaling up the range was a natural step,” explained Andreas Karlsen, CCO of Quick Group.

Positioned as an upper-range solution, the new model is suited for yachts between 30 and 40 metres with a displacement of up to 170 tonnes.

What sets the Olympic series apart is its blend of engineering precision and robust build. The design prioritises holding power, vital in increasingly demanding anchoring conditions. “Owners want peace of mind when they leave the vessel at rest,” said Karlsen. “The Olympic anchor delivers superior security, ensuring it sets rapidly and holds firmly.”

Unlike conventional cast anchors, the Olympic range is built from welded stainless steel sheets. Both the interior and exterior are welded, creating a structure as strong as a forged piece but with advantages in balance and seabed penetration. In the 140 kilogramme model, additional mass concentrated in the fluke enhances its ability to dig deeply, securing the yacht with greater reliability. The series has obtained the SHHP classification by RINA which testifies the great anchoring efficiency of this series which has a holding power at least double of an HHP anchor.

Manufacturing in Italy also allows Olympic Anchors to maintain tighter quality control and shorter lead times compared to standard cast anchors often produced in the Far East or South America.

The 140 kilogramme model also incorporates features tailored to contemporary yacht design. A shortened shank increases compatibility with modern bow rollers and retractable systems, aligning with the growing trend of concealing anchors within the hull.

An optional Olympic swivel, sold separately, ensures the anchor always returns upright when retracted, preventing chain twist and ensuring smooth operation – a key benefit for yachts with automated systems. Internal cavities help the anchor consistently settle on its fluke side, ensuring reliable setting every time.

The 140 kilogramme anchor crowns a line that begins at just seven kilograms for tenders and smaller craft, extending through 80 and 100 kilogramme models to cover a wide spectrum of vessels.

Launched in 2023, the Olympic range has already delivered several hundred units, with growth expected to accelerate. Quick Group’s global distribution network supports visibility across all major yachting markets. “We are still in the early stages of building the dealer base for this niche product, but the response has been strong from both shipyards and the retrofit market,” Karlsen added.

For Quick Group, the Olympic anchor reflects how yacht equipment can combine technical sophistication with discreet design integration. As anchoring systems become more concealed and safety ever more critical, demand for high-holding anchors that are both reliable and adaptable will only grow.

With its combination of Italian craftsmanship, strength and compatibility with modern systems, the 140 kilogramme model is positioned to meet that need. “Our aim is always to listen to our customers, adapt quickly, and deliver equipment that gives owners and crews confidence,” Karlsen concluded. “The Olympic anchor is very much a product of that philosophy.”

Meet the Quick Group team at Metstrade 2025: info@quickgroup.com Metstrade Quick Group Booth 01.153 | 01.251

REV Ocean, the brainchild of Norwegian billionaire Kjell Inge Røkke, is a one-of-a-kind project that brings together innovative engineering and cutting-edge technology in a powerful commitment to environmental stewardship. We went aboard the 195-metre research vessel and superyacht earlier this year at the Vard Søviknes shipyard in Norway shortly before she departed for Damen Shiprepair in the Netherlands where final outfitting is taking place.

BY JUSTIN RATCLIFFE

Right: REV Ocean at the Vard facility in Norway. Note the 22-metre hatchway in the hull for access to the main hangar and moonpool.

Facing page, top: The custom Seaonics crane on the aft helideck. Centre: The container deck looking forward.

Bottom, from left: Lawrence Hislop, REV Ocean Communication Director; Eva RamirezLlodra, Science Director; CEO Nina Jensen; Oystein Mikelborg, Operational Director.

Approaching Vard Søviknes by boat on a very cold but sunny winter’s day, the huge bulk of REV Ocean dominates the bay. With the top of her mast almost 40 metres above sea level, she dwarfs a 171-metre cable-laying vessel moored alongside. Built to Polar Class 6 for navigation in medium first-year ice with machinery specified to ICE 1C, REV Ocean will spend most of her time as an oceanic research platform for teams of scientists and conversationists. But she will also function as a unique charter yacht for up 24 guests in the luxuriously appointed forward part of the vessel arranged around a central atrium over five decks with glassencased elevator and suspended staircase. At 19,235 GT she is easily the biggest superyacht in the world.

No one has ever attempted to build such a vessel before. Indeed, REV Ocean’s CEO and marine biologist Nina Jensen admits it’s been “quite a journey” with unexpected hurdles along the way, not least rebuilding the observation lounge in aluminium to remove topweight and extending the hull by 12 metres to meet stability criteria. This in itself was a vast undertaking accomplished by cutting through the hull in front of the container deck at frame 115, adding a new mid-section, and reconnecting the kilometres of piping and cabling. By the time the vessel is delivered next year, she will have been in build for close to a decade.

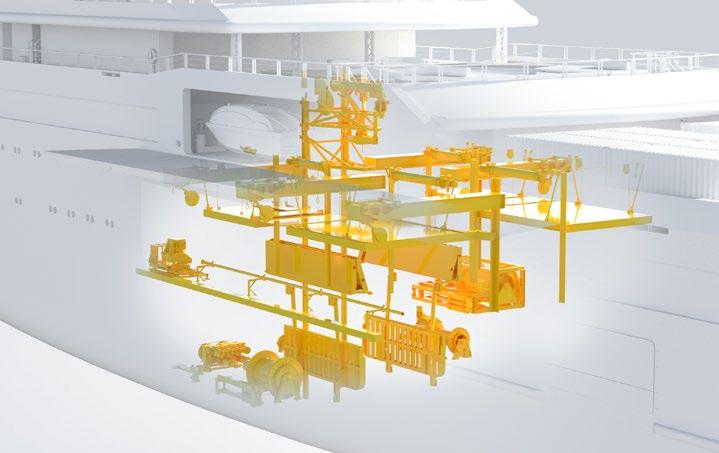

Despite the unwanted delay, the hull extension proved positive in other ways. The container deck was designed to take containers for storage, or as containerised laboratories in addition to nine dedicated wet and dry science labs, but a new deck hatch now provides direct access to the hangar below that houses all the sub-sea equipment. This means the 30-tonne capacity custom crane by Seaonics on the aft helideck can manoeuvre heavy loads – including whole containers – in and out of the space quickly and efficiently from above rather than the side.

There is also a new CTD (Conductivity, Temperature, Depth) water sampling room, dedicated storage for the submarine, a media editing suite, and a 3D printing lab, which allows the team to make and test new tool solutions or do vital repairs and maintenance out at sea. These are in addition to the preexisting survey control room, conference hall, 36-seat auditorium, executive boardroom, and various offices. There are 400-plus Wi-Fi access points around the vessel.

Tankage for fuel also increased – a major boon according to REV Ocean’s operations director, Øystein Mikelborg, who spent 20 years at the Norwegian Polar Institute taking part in expeditions to the Arctic and Antarctic. “We had a saying that you can never have enough fuel – unless you’re on fire,” he jokes dryly. With a top speed of 16.8 knots, at an economical 12 knots projected range is over 8,000 nautical miles, with almost as much urea for the SCR units to last as long as the fuel. The vessel will be able to remain at sea without refueling or reprovisioning for up to two months.

“I never thought it would be possible to just cut a ship in half, insert a section, and then reassemble it,” says Nina Jensen. “That’s an oversimplification, of course, but the added space has made a significant difference in terms of scientific upgrades and operation. Even though it took time, the 12-metre extension has ultimately resulted in a much better and more capable ship.”

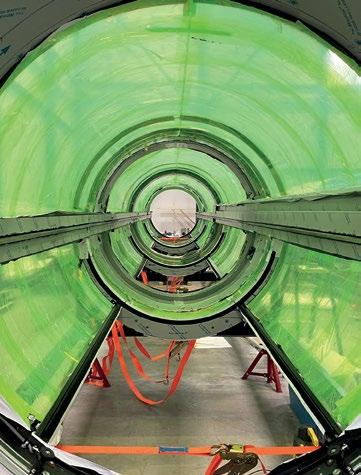

The moonpool in the main hangar for launching and recovering a three-person submersible and a ROV is open to the water at the base of the hull. The entire REV Ocean concept was developed around this space.

“No other research vessel has a trawling system like ours. Trawling is usually a blunt tool, but the fish recognition system collects only what’s necessary for research purposes.”

At the heart of REV Ocean’s capacity for deep-sea exploration is a 7.7m x 5m moonpool in the main hangar. Designed for launching and recovering a three-person submersible and a remotely operated vehicle (ROV), it is open to the water at the base of the hull so passengers can be disembarked inside the vessel and crew aren’t exposed to the elements on deck in high seas or subzero conditions.

Although there is a closing mechanism to prevent excessive water ingress during transit or in rough seas, the moonpool is designed to be always full of water. This required careful design to ensure overall stability – as an opening in the hull, it effectively reduces the amount of water the vessel displaces by several hundred tonnes. Located in the centre of the vessel least prone to rolling and pitching, baffles around its edges absorb wave energy for a relatively calm working environment even in rough seas. A massive hydraulic hatch measuring 22m x 6m on the port side opens the full length and height of the moonpool hangar. Additional handling systems allow the deployment of water sampling systems and coring devices. In addition to the moonpool, five boom cranes handle over-the-side operations.

The set-up is a more sophisticated version of the moonpool aboard Kronprins Håkon, Norway’s largest ice-breaking polar research vessel. Øystein Mikelborg led the construction of the Kronprins Håkon and brought his knowledge into the new vessel, along with additional capabilities that the research ship doesn’t have.

By way of example, Mikelborg points to the trawling gear, which is among the most advanced ever installed on a research vessel and was personally developed by Kjell Inge Røkke, drawing on his knowledge of fishing trawlers (see sidebar). Housed under the helideck in the stern are two 35-tonne winches for 3,000 metres of trawl wires and a massive net storage drum, requiring extensive structural support in the deck.

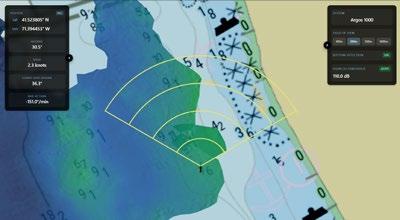

Trawling is essential for sampling at specific depths, especially 1,000 metres down in the mesopelagic or ‘twilight’ zone, but it can also be destructive. To avoid indiscriminate netting, REV Ocean uses Simrad PX FX sonars and Scantrol software for selectively sampling specific fish species and sizes, which are delivered direct to the main wet lab by a vacuum system.

“No other research vessel has a trawling system like ours,” says Mikelborg. “Trawling is usually a blunt tool, but the fish recognition system collects only what’s necessary for research purposes. It’s basically an ecoharvesting system that releases non-target species back into the ocean unharmed.”

REV Ocean has a diesel-electric propulsion package comprising 4 Wärtsilä generators of 2.7MW each and two 3,200kW Ingeteam electric motors coupled to conventional drive shafts, plus a 3MWh Corvus lithiumion battery pack for peak shaving and silent running under batteries alone for limited periods at two knots during research missions.

“The vessel is built to the IMO’s Safe Return to Port (SRtP) regulations for redundancy of critical systems in the event of accident or damage,” adds Captain Nils Baadnes, who has been involved in the project since metal cutting began at Vard Tulcea in Romania.

“That means we have two separate engine rooms, two ballast systems, two switchboard rooms, two propulsion rooms, an emergency bridge, an emergency galley, duplicate fixed fire-fighting systems, and so on.”

The submersible DSV Aurelia by Triton Submarines is fitted with an array of scientific sensors, tools, cameras, and sampling equipment. With a dry weight of 11,200kg, it is the deepest-diving threeperson acrylic submersible in production, able to reach a depth of 2,300 metres and remain submerged for 10 or more hours (rather unnervingly, the pressure at such depths means the interior volume of the acrylic viewing sphere shrinks by 150 litres).

REV Ocean’s other deep-sea vehicle, ROV Aurora, is a Supporter 6000 manufactured by Kystdesign in Norway. It can accommodate up to 24 hydraulic tooling functions, 16 scientific sensors and 10 camera connectors. It successfully dove the Malloy Deep and the Gakkel Ridge in the Arctic Ocean (3800m), sampling hydrothermal vents for the first time.

Backing up sub ops and other missions is a whole fleet of auxiliary vessels, including a 14-metre work boat built entirely from extremely durable but recyclable polyethylene (PE), two 8.5m work boats, two 6.5m Fast Rescue Craft and four Zodiacs, among others.

Eco-friendly waste management systems are designed to reduce the vessel’s carbon footprint in line with her environmental mission. A pyrolosis incinerator, for example, allows materials – including plastics – to be burned at high temperatures, minimising the release of noxious gases and producing only limited char. This reduces the need to offload plastic waste to shoreside facilities, particularly in countries with limited recycling infrastructure.

There is heat recovery on the Tier III-compliant generators (fitted with both SCR and Diesel Particulate Filters) for feeding back into hot water circuits and HVAC, as well as generating fresh water through an evaporation plant. In addition, a “free cool” system in sea water temperature below 10°C further reduces power demands on the HVAC system.

All the onboard systems are monitored by VARD’s SeaQ Green system, so the crew can run the ship in the ‘cleanest’ way and keep COx, SOx and NOx emissions to a minimum.

Exterior decking throughout will be Tesumo, a composite product derived from sustainably cultivated wood that has the appearance, dimensional stability, weather resistance and natural durability of teak.

Studies have clearly shown the detrimental effects of underwater noise on marine mammals and propellers and REV Ocean has been designed to be as quiet as possible under tough DNV-GL SILENT-R notation. The hypothetical task test for SILENT R notation is to be able to approach a cod fish within 100 metres without being detected. Propellers, rather than engines, tend to be the primary sources of underwater radiated noise. The shape of the hull significantly influences the water flow to the propeller and achieving an optimal inflow is crucial for reducing wake and noise (REV Ocean’s hull was initially tank tested at the Hamburg Ship Model Basin). Instead of electric pods – and despite the vessel’s 46-metre drive shafts – Konsgberg variable pitch propellers designed for seismic research vessels proved the quietest option. These vessels require high thrust to tow the heavy seismic gear and at the same time operate under strict requirements to minimise acoustic emissions. REV Ocean is kitted out with its own hydrophone system, as well as a fixed gondola just behind the bulbous bow is housing sub-bottom profilers and twin multi-beam echosounders for 3D mapping the seabed down to 8,000 metres. Further aft are twin, 16-tonne drop keels equipped with biological echo sounders, sonars and Acoustic Doppler Current Profilers.

Designed by Espen Øino with interior styling by H2 Yacht Design, REV Ocean is privately funded by Kjell Inge Røkke, the majority owner of Aker ASA, a Norwegian industrial investment company listed on the Oslo Stock Exchange. As a teenager, Røkke began working on commercial fishing boats in Alaska and built his fortune through ventures in fishing, seafood, shipping, and offshore industries. REV Ocean began in 2016 when he signed The Giving Pledge, vowing to donate more than 50% of his fortune to philanthropic causes. Delivery is expected in Q1 of 2027. Røkke also spearheads the non-profit foundation HUB Ocean that provides fit-forpurpose ocean data to help decision-makers and industry leaders steer a course to improve ocean health. “Data needs to be available in the most efficient form,” he says. “Today, you will spend the lion’s share of time finding the data, compared to the time you spend actually working on and driving new insight from data.”

"Given this was a first-of-its-kind vessel – a research vessel that also serves as a superyacht – with a unique build strategy, it was always going to be complex."

George Gill has been the project director and owner’s representative for the REV Ocean vessel since the beginning. Having served as chief engineer on Røkke’s previous 66-metre sailing yacht Aglaia, his technical expertise and close collaboration with the owner helped shape the original design brief, which became the cornerstone document to launch the project.

How did REV Ocean get off the ground?

George Gill: I was working on another sailing yacht project for the owner when he called to say he was switching to power. He’d always wanted to build a motorboat and was inspired by the Ulysses projects constructed at the Kleven shipyard. The first two Ulysses demonstrated a different way of building large yachts – one that didn’t rely on the traditional superyacht yards. As a shipyard owner himself, the owner was intrigued by this new approach and saw the potential to innovate beyond the usual channels. I visited the first Ulysses in Barcelona in May 2016 to see the concept firsthand, which had a significant influence on REV Ocean

How did the shipyard selection and development process proceed?

GG: As a Norwegian, the owner wanted to draw attention to the Norwegian maritime cluster on the country’s west coast, so my brief was to utilise Norwegian expertise wherever possible in the project. This meant it became a choice between two Norwegian shipyards: Kleven and Vard. I spent a lot of time working closely with both, developing general arrangements, onboard systems, and features such as the laboratories and the moonpool. Initially, the vessel length was set at 140 metres but quickly increased to 145 metres and beyond. We eventually signed the contract with Vard in March 2017 and metal cutting started at its facility in Tulcea, Romania, in February 2018 with the keel laid in April.

What has been the most complex part of the design and construction process for you as project director and owner’s representative?

GG: It’s difficult to single out one area – there have been many challenges! What I believe

sets this project apart is the build strategy. Normally, a shipyard manages the entire project – timeline, risk, contractors – all for a fixed price. Here, the owner’s team managed all those aspects across multiple suppliers and yards. This approach demands intense risk and schedule management, but it also reduces bottlenecks caused by contractual disputes because we’re not operating under strict delivery deadlines with penalties. We’ve aimed to support this through transparent communication to ensure no one gets caught out, allowing everyone to have their say on the design process and price their work based on full and accurate information.

Looking back, what would you have done differently?

GG: Given this was a first-of-its-kind vessel – a research vessel that also serves as a superyacht – with a unique build strategy, it was always going to be complex. We wanted to balance the number of consultants to ensure that development was swift and avoid getting bogged down in dialogue. But in hindsight I would have put more safeguards in place, especially during the early planning stages. That’s on me. More contingency measures and risk management protocols to handle the unprecedented scope and complexity would have helped smooth the process. Ultimately, however, this is a unique project and some lessons can only be learned by doing.

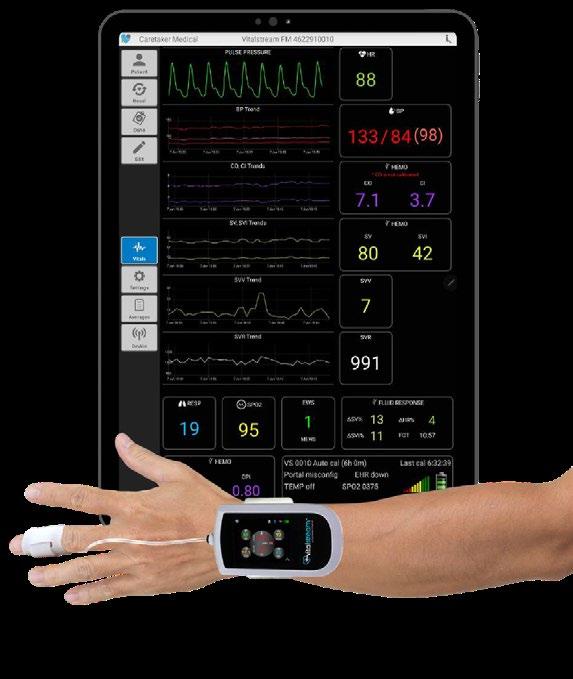

systems

Bottom: The dieselelectric drive has a 3MWh battery bank for peak shaving and silent running at slow speed.

When completed, REV Ocean will offer the potential for significant discoveries in marine biology, oceanography, and environmental science. Despite her hightech, research-oriented mission, the fact she will also carry fee-paying guests as a commercial superyacht reflects a growing awareness of the importance of the oceans to the planet’s health.

“This ship is unique and building something so complex takes time,” concludes Jensen.

“Despite the delays, our team has stuck with the project because we believe in the vision. It’s been tough at times, but the wait will be worth it.”

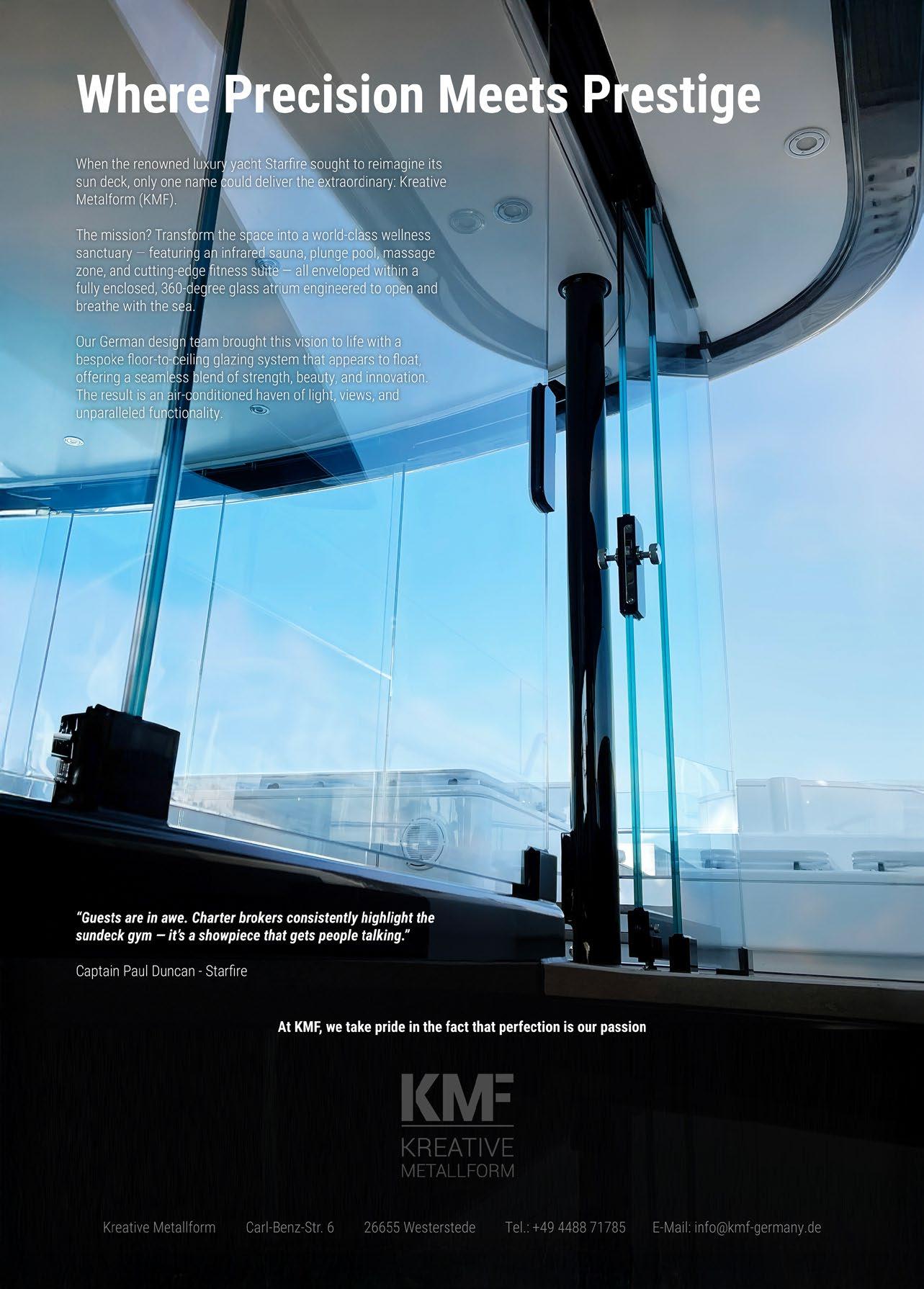

A billionaire venture capitalist, a Canadian naval architect, and a British superyacht designer – this was the cast of players behind Neonemo, an avantgarde yacht concept dating back to 2008 that in terms of aesthetics and technical design is still ahead of its time.

BY JUSTIN RATCLIFFE

It was early summer 2008 and Canadian naval architect Patrick Bray was on his way to the airport when he received an unexpected phone call from Ken Freivokh. The UK-based designer explained he was working on a new project with Tom Perkins, the owner of Maltese Falcon, who wanted to meet him. A meeting eventually took place aboard the classic motoryacht Atlantide, also owned by Perkins, in Vancouver’s Coal Harbour.

“It turned out Perkins wanted to build an exploration yacht to carry his two-person submarine,” recalls Bray. “Over the next month or so and several discussions later, the various responsibilities were agreed upon and Perkins signed a design agreement with us in July 2008. Basically, we would handle the naval architecture and Ken the exterior and interior design. I remember he liked the idea that the time difference between Ken and I meant that someone would always be working on his project!”

The sub in question was a winged Deep Flight Super Falcon manufactured by California-based Hawkes Ocean Technologies. Perkins bought the very first 6.7-metre Super Falcon model that could dive to a depth of 120 metres and remain underwater for about four hours on a single battery charge.

“For a while Tom kept the sub on the deck of Maltese Falcon, which was never designed for the purpose.”

The following September another meeting took place, this time aboard Maltese Falcon in San Francisco. The idea was that Bray could meet the crew, including the then captain Justin Christou, to get a better idea of Perkin’s preferences and how he would use the vessel. From these meetings several key criteria for an all-aluminium vessel emerged, including massive storage space for the sub and auxiliary craft; a floating rotodock system; a heavy-duty deck crane able to swivel though 360 degrees; a machine workshop; fixtures for a possible towing kite; controllable pitch propellers; 10 knots cruising and 16 knots top speed, as well as advanced appendages for fuel saving. The preference was to build in North America and Perkins was in talks with fellow billionaire and superyacht owner Dennis Washington, whose family holding included the commercial Seaspan shipyard in Vancouver.

“For a while Tom kept the sub on the deck of Maltese Falcon , which was never designed for the purpose, so the whole concept was meant to give him the freedom to explore the world in a way that was both functional and comfortable, with the submersible taking centre stage,” says Ken Freivokh. “The design challenge was balancing function with style, ensuring that the yacht could carry all of Tom’s equipment for his adventures, while also providing the comfort and performance expected of a luxury yacht.”

Based on space planning and payloads, a vessel with an overall length of 42 metres emerged and was dubbed Neonemo Freivokh’s exterior lines were rugged and stylish, but not overly polished and had a subtle retro twist. Penned at a time when the ‘crossover’ trend was still to emerge, they still look fresh today.

The layout offered accommodation for 10 guests in four lower deck cabins and an owner’s suite on bridge deck. The main deck comprised the saloon, galley and crew quarters forward with direct access to the crew mess, laundry and store rooms on the deck below. An observation deck was included for extended visibility when navigating unknown waters. But the raison d'être for a vessel designed for adventure was the expansive main deck aft with its two hydraulic hatches that covered a large garage below for housing the submersible and a large tender that could also serve as surface support during sub ops.

Meanwhile, Bray was working on the hull form. At the time he was researching the benefits of fixed midship and stern bulbs to reduce resistance. Like a bulbous bow, these hull appendages or blisters modify the overall wave train through their own small wave and pressure patterns, and it is this interaction that can reduce the overall resistance. The consequent reductions in power and fuel consumption allow for further reduction in vessel weight. Furthermore, by influencing the wake field around the propeller, stern bulbs can improve propeller efficiency and reduce vibrations.

“Being the kind of person he was, Perkins was intrigued by the science and the plan was to tank test the hull we’d developed for him,” says Bray. “Sadly, before that could happen the project was cancelled when he was diagnosed with cancer – he felt he couldn’t afford the time it would take to design and build a yacht from scratch.”

Instead, Perkins converted a 37-metre Japanese fisheries vessel his carry his submersible. He embarked on several South Pacific expeditions with Dr. No before selling the yacht shortly before his death in 2016.

“Being the kind of person he was, Perkins was intrigued by the science and the plan was to tank test the hull we’d developed for him.”

But the Neonemo story – and Bray’s research – did not stop there. At the 2016 Monaco Yacht Show, Rossinavi and Freivokh presented the Argo 48M explorer concept. Apart from being six metres longer, the renders revealed a carbon copy of Neonemo, right down to the Deep Flight Super Falcon sub sitting on deck. In addition to the original shaft-line propulsion, a diesel-electric version was also proposed.

“After Tom Perkins passed away, we thought the concept project should not be buried in the drawers of the design office,” said Scandinavian Marine, project developer for the Argo 48M at the time. “We agreed with Ken that a reassessment of TP’s mission by growing the original project size to a 499 GT volume should better allow the realisation of some of the latest energy-friendly technologies, while keeping the operational cost of this yacht under a well-balanced canopy.”

Right, from top: Bray’s CFD analyses and tank tests of a 45-metre hull form with bulbous bow, as well as side and stern bulbs, showed significantly less resistance than an un-appendaged hull.

Bottom: Neonemo’s underwater profile superimposed on Freivokh’s original render.. Note the ‘blister’ amidships.

“After Tom Perkins passed away, we thought the concept project should not be buried in the drawers of the design office.”

Weirdly, no mention was made of Bray’s “energy-friendly” hull bulbs, which he had developed further through a series of research programs. The first was an in-water scale model of a 45-metre hull at the ITU Ata Nutku Ship Model Testing Laboratory in Istanbul. After the tests, Associate Professor Emin Korkut, Superintendent of the University Faculty of Naval Architecture and Ocean Engineering, congratulated Bray on the results: “I should tell you that your hull form has been one of the best forms tested recently in our towing tank,” he wrote. This was followed up with a computational fluid dynamics program, and a third more extensive CFD program at the National Research Council of Canada’s Ocean, Coastal and River Engineering Research Centre (OCRE). The un-appendaged hull in these CFD analyses revealed 23–26 per cent more resistance over a range of 12–20 knots.

“That’s a difference of over 1,100 horsepower at 20 knots,” Bray points out. “This is really significant and translates into considerable fuel savings, as well as a much lower carbon footprint, flatter wave train, and lower underwater noise signature. For electric propulsion, it also means smaller electric motors and less draw on the battery system.”

Last year, Bray unveiled the Bahamas Explorer, a 34.3-metre concept designed for long-range expeditions that draws on his years of research and development into fuelsaving appendages. By including a bow bulb, midship bulb, and stern bulb, the Bahamas Explorer could reduce fuel consumption by 25 percent, meaning smaller fuel tanks and engines to achieve its top speed of 18 knots and 6,000 nautical mile range at 12 knots. In the conclusion to his latest research, Bray wrote: “We feel there are numerous ship applications – including yachts – for these appendages in reducing consumption of fossil fuels and the impact of vessel wake on shorelines, as well as reducing the quantities of raw materials required to construct these more efficient and therefore lighter weight vessels.”

Although the results of Bray’s studies have been published, it remains a mystery why no shipyard to date has picked up on his findings, which promise significant advantages using inexpensive, low-tech, low-maintenance solutions. Similarly, and sadly, one of the coolest concepts of its kind remains “buried in the drawers” of Freivokh’s design office.

BY LEONA CAANEN

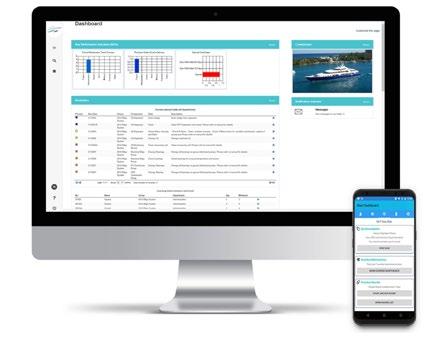

For more than 25 years, SuperYacht Spares (SYS) has gone beyond traditional yacht provisioning, acting not as a supplier but as a dedicated service provider — an extension of your team. Each year, SYS equips over 20 newbuild projects (50m and above) and supports more than 450 operational yachts around the globe, ensuring they perform flawlessly from day one and throughout their lifetime. Their mission is simple yet ambitious: “We are here to ensure you never need to compromise on the pleasure of yachting.”

From the first drawing of a new build to the daily operations of an established yacht, SYS provides seamless support. Each project is guided by a personalised dedicated team of specialists who assist you from start to finish, regularly visiting the yard, working alongside your crew, and ensuring every system and detail on board runs flawlessly.

SYS doesn’t just deliver equipment; they deliver confidence. With hands-on expertise and clear communication, their team becomes part of yours, anticipating needs before they arise and ensuring every challenge is met with precision and care.

SYS has developed a unique data-driven approach that brings structure and clarity to even the most complex projects. Every yacht SYS supports is backed by a custom digital inventory, allowing full transparency and control.