WE HARNESS THE FIRE TO CONTROL THE SEA

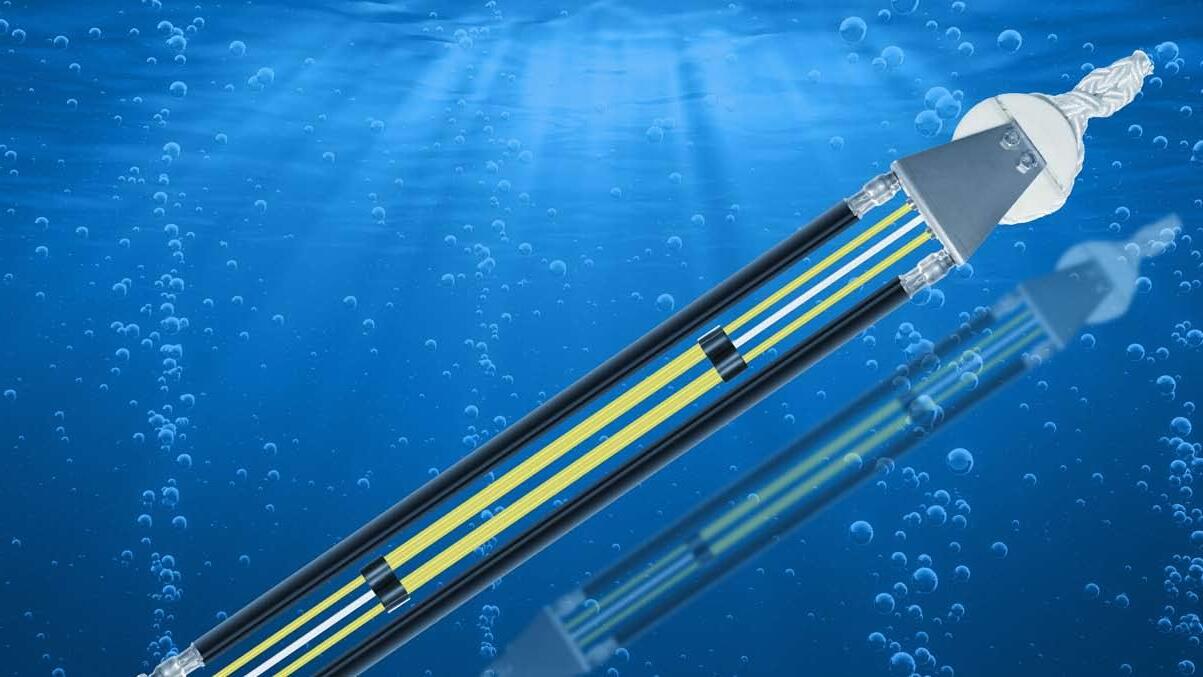

WHAT WOULD HAPPEN IF WE COULD REPLACE STEEL AS REINFORCEMENT WITH SOMETHING NON-CORROSIVE?

A couple of years ago we asked ourselves this question and a long process was started. After a couple of years of development, a patent was applied for covering a new production method using Basalt as reinforcement. Basalt is volcanic rock formed from the rapid cooling of lava. Basalt Rebar reinforcement is an alternative to steel for reinforcing concrete, basalt rebar is tough, stronger than steel and has a higher tensile strength. Basalt rebar is naturally resistant to alkali, rust and acids, therefore perfect for Marine environments.

Charlotte Niemiec looks at highlights around the world in 2017

Marina Planning & Design

Dubai’s ambitious Marasi project includes four distinct marinas. Oscar Siches reports

Abell Point Marina in Australia underwent a swift rebuild after Cyclone Debbie

Windermere Quays Marina, now reconfigured and extended, is better able to welcome

a UK tourist spot

Alamitos Bay Marina in California was the subject of an ambitious rebuild.

Lagoon Marina in Ras Al Khaimah supports the first phase of the Mina al Arab development.

On the cover: In 2005 Alamitos Bay Marina had 1,962 slips in seven different basins. In a project which lasted 13 years, the City of Long Beach, California, refurbished it entirely, reconfiguring to 1,655 slips with optimum slip sizes. Read more p. 39

Marina World

HEAD OFFICE MAILING ADDRESS & SUBSCRIPTION ENQUIRIES

Loud & Clear Publishing Ltd,

School Farm, School Road, Terrington St. John, Cambridgeshire PE14 7SJ, UK

Editor

Carol Fulford

T: +44 (0) 1945 881018 F: +44 (0) 1621 855 867 E: carolfulford@marinaworld.co.uk

Deputy Editor

Charlotte Niemiec T: +44 (0) 1945 881018 E:charlotte@marinaworld.co.uk

Advertisement/Commercial Director

Julia Hallam

T: +44 (0) 1621 855 890 F: +44 (0) 1621 855867 E: juliahallam@marinaworld.co.uk

Administration Manager

Corinna Francis T: +44 (0) 1621 855 890 E: corinnafrancis@marinaworld.co.uk

Finance Manager

Magdalena Charman T: +44 (0) 1403 733678 E: accounts@marinaworld.co.uk

Advertisement Production

Nick Hing T: +44 (0) 1323 490384 E: adstudio@marinaworld.co.uk

NORTH AMERICAN OFFICE

Sales Director Americas

Philippe Critot

PO Box 29759, Los Angeles, CA 90029-0759, USA

T: +1 323 660 5459 F: +1 323 660 6030

E: pcritot@marinaworld.com

FRENCH OFFICE

Publisher’s Representative Catherine Métais T: +33 6 60 17 75 81 E: c.metais@parisrai.com

ITALIAN OFFICE

Advertisement Representative

Ediconsult Internazionale srl piazza Fontane Marose 3, 16123 Genoa, Italy

T: +39 010 583 684 F: +39 010 566 578 E: genova@ediconsult.com

CHINESE OFFICE

Publisher’s Representative Simon Ding

Bridge International Holding, Rm. 401, Building A, No. 55 Jinyu Road, Minhang District. 201103 Shanghai, China

T: +86 21 33231328 F: +86 21 33231366 E: simon@chcbiz.com

Marina World (ISSN 1471-5856) is published bi-monthly by Loud & Clear Publishing Ltd, School Farm, School Road, Terrington St. John, Cambridgeshire PE14 7SJ, United Kingdom. The 2018 US annual subscription price is $160. Airfreight and mailing in the USA by agent named Air Business Ltd, c/o Worldnet Shipping Inc., 156-15 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA.

Periodicals postage paid in Jamaica NY 11431. US Postmaster: Please send address changes to MARINA WORLD, c/o Worldnet Shipping, Inc., 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA.

Subscription records are maintained at Loud & Clear Publishing Ltd, School Farm, School Road, Terrington St. John, Cambridgeshire PE14 7SJ, United Kingdom. Air Business Ltd acts as Loud & Clear Publishing’s mailing agent.

Marina World is available on subscription at the following cost:

1 year (6 issues) - £80.00 Sterling ($160)

2 years (12 issues) - £140.00 Sterling ($280)

No part of this publication may be reproduced without the prior permission of Loud & Clear Publishing Ltd, the copyright owners. Upon application, permission may be freely granted to copy abstracts of articles on condition that a full reference to the source is given.

Printed in the UK by Stephens & George

© 2018 Loud & Clear Publishing Ltd

Views expressed by individual contributors in this issue are not necessarily those of Loud & Clear Publishing Ltd. Equally, the inclusion of advertisements in this magazine does not constitute endorsement of the companies, products and services concerned by Loud & Clear Publishing Ltd. The publisher reserves the right to refuse advertising.

Death by plastic

The BBC’s biggest TV hit for 2017 was Blue Planet II, a documentary narrated by Sir David Attenborough that explored the increasingly challenged life in our oceans. The series was popular not just in the UK, where it attracted over 14 million viewers, but worldwide. According to The Sunday Times, 80 million watched in China alone; slowing down the internet.

Attenborough – who has at least 15 natural species named after him and a volume of awards and honorary titles – has become increasingly involved with environmental projects and given greater prominence to environmental messages over his many decades as the UK’s best known naturalist. His message in Blue Planet II, reinforced by disturbing (and controversial) images, that plastic is now the biggest threat to the sea and creatures who live in it or rely upon it, will be one of his most important legacies. Destroy our oceans and we destroy our world.

The facts make stark reading. We produce nearly 300 million tons of plastic every year, half of which is for single use; over eight million tons is dumped in the sea every year; a plastic bag has a ‘working life’ of 15 minutes; over the last ten years we have produced more plastic than during the whole of the last century (plasticocean. org).

Plastic is everywhere: tiny fibres, microbeads, fragments and chemical by-products that infiltrate every aspect of daily life. It’s in the air, it floats like pollen in sunlight. It’s thick in rivers and oceans, it’s in seafood and salt and in millions of wild animals; it has contaminated tap water samples from around the world. It defies wealth and geography and scientists suspect plastic can leach toxins once inside the human body (orbmedia.org).

According to ecowatch.com, we currently recover just over 5% of the plastics we produce; the Great Pacific Garbage Patch off the coast of California is the size of Texas with plastic pieces outnumbering sea life by six to one; there is more microplastic in the ocean than there are stars in the Milky Way.

The Guardian newspaper takes up the theme: “Every minute one rubbish lorry’sworth of plastic is dumped into the sea. If we continue at this rate, some estimate that our oceans will contain more plastic than fish by 2050.”

The task to clean up our oceans is monumental and, although we can make a big difference, we will only ever achieve a modest improvement. Our very best policy is prevention; to make any and every effort not to litter and pollute the sea; to avoid buying ‘throw away’ plastic where we can; and to remember that ‘recyclable’ plastic is only more virtuous if it is actually recycled.

The Marina World team was delighted that the floating rubbish collector, Seabin, won the DAME design award in the Marina Equipment category at Metstrade 2017 (see p. 47). Not only is this product worthy of such a prestigious accolade but its accompanying education programme boosts public awareness of how polluting the sea has become a dire and undisputed global threat.

Carol Fulford Editor

BTI plans Tampa marina

USA: Florida-based property developer BTI Partners has revealed plans for a 150-slip deep water marina facility in Tampa’s Westshore Marina District, a 52 acre (21ha) mixed use waterfront development on the Tampa side of the Gandy Bridge.

The $10 million facility will be the largest new marina to be built in the Tampa Bay area in many years and will have slips ranging from 35-100ft (1130m). Boaters will have unobstructed deep water access to the Bay and the Gulf.

Ideally located within walking distance of Westshore Marina District’s planned retail outlets and restaurants, the marina will have a broad range

Marina proposal at North Harbour

AUSTRALIA: A proposed marina with associated shoreside facilities is currently going through the approvals process with local and state government for the North Harbour development in Brisbane.

North Harbour is a new master planned residential community developed by Port Binnli, the team behind Mackay Marina Village & Shipyard. It will include 1,000 acres (404.6ha) of open space and parkland. Two parks are already open and an AU$3 million Heritage Precinct is under construction with additional parks and recreational areas proposed for future development.

of services and amenities including a ship store, fuel dock and concierge services.

BTI has retained Moffatt & Nichol to design the marina facilities and construction is expected to begin this year and complete by 2020. The developer will also be building luxury condominiums with high end amenities and services to a similar construction timeframe.

SUTL wins China contract

CHINA: According to The Business Times (Singapore), SUTL Enterprise – owner of the One°15 brand – has secured a 10-year management contract for an upcoming integrated marina at Sanshan Island in Taihu Lake, Suzhou.

The contract was awarded by the project’s master developer Suzhou Taihu SanShan Island Marina, which holds land and water rights. The project will comprise a private marina, yacht club, marina facilities and a potential clubhouse.

SUTL Enterprise executive director and CEO Arthur Tay told the newspaper that Sanshan Island attracts more than a million visitors every year, with visitor numbers increasing “more than 10% year-on-year”.

The world leader in mooring systems

The marinas of the future ask for versatile systems that stand the test of time; products that can adapt to the developing demands and protect

How does it work?

SEAFLEX® is an elastic mooring solution that expands and retracts with each tide and wave, taking on and dampening the forces

the most modern, sleek, state of the art

With 45 years of research and development, SEAFLEX® is the most technologically advanced mooring option in the world, anchoring thousands of marinas, wave

Research your options, give your marina the mooring solution it deserves! for

® Rope

SEAFLEX® is custom made to handle the

With the system in place, the moored application is secured in all directions, throughout wind, waves and

SEAFLEX

Further boost to marina portfolio

USA: Suntex Marina Investors LLC has acquired two properties on the Trinity Lake reservoir in California.

Cedar Stock Resort Marina is a fullservice facility that is operated under permit from the Forest Service. It caters

for a broad range of vessel types with rentable slips, and offers fishing boat, cruiser, powerboat, PWC and ski boat

Metstrade 2017: a record breaking 30th

NETHERLANDS: The 30th Metstrade event (14th-16th November 2017) broke new ground in terms of exhibitor and visitor numbers. Unique visitor figures were the highest ever recorded at 16,307 (5% up on 2016) and the overall total, at 24,856 visits, rose by the same percentage. Organisers RAI Amsterdam were particularly pleased to see a boost to geographical reach as visitors arrived from 116 different countries (107 in 2016), and 68% of overall visitors came from outside the Netherlands.

Exhibitors in the Marina & Yard Pavilion (MYP) were impressed with the quality of visitors, reinforcing the benefit of a dedicated product pavilion in a niche market area.

“This anniversary edition was a success because it was conducted in a vibrant atmosphere where exhibitors and visitors alike enjoyed excellent business,” said RAI Amsterdam’s maritime director Irene Dros. “There

was also a great deal of appreciation for the exceptionally high number of new and innovative products on display.”

One of these innovations was Seabin, a floating debris recovery product that won the prestigious DAME design award in the Marina Equipment category! Read more about Seabin and other Metstrade marina product highlights on pages 47-52.

NEW EDITION Marina World Suppliers & Services

March 2018 – February 2019

If you are a supplier of products and services to marinas and did not have a FREE entry in the 2017/18 edition of MWS&S, please complete your entry form before end of January 2018 on marinaworld.com

rentals. Holidaymakers can also book vacations on houseboats or mountain cabins.

The second property, Trinity Center Marina, is an all-new marina that will be operated under the same permit arrangement. Planned to open in June this year, it will tentatively have around 20 boat slips and fuel facilities.

Trinity Lake Resort has a water area of 16,000 acres (6,475ha) and a 154mi (248km) shoreline, which is best known for its irregular shape that features three separate arms and dozens of secret tree-lined coves.

With bald eagles dipping into the lake and the monumental backdrop of the Trinity Alps, it is one of the most scenic reservoirs in the state.

Superyacht Summit

DUBAI: P&O Marinas and Fabmar will run the Dubai International Superyacht Summit from 28th February - 1st March 2018.

The theme for the year is ‘The Emirati Riviera: A New World Hub for Yachting’. With many marina developments currently under construction, the UAE is becoming an increasingly popular part of the superyacht cruising circuit and offers an alternative wintering homeport for traditional destinations.

Contact: Fabiana Maccarini, f.maccarini@fabmar.net

Marina Life by

• ELECTRIC VEHICLE CHARGING

• LIGHTING

• PRE-PAYMENT SYSTEMS

• SMART METERING

• ELECTRICAL DISTRIBUTION

• ACCESSORIES

• INSTALLATION

• TESTING & INSPECTION

Years’

Head office contact:

t: ++44 (0) 1205 724754

f: ++44 (0) 1205 724876 rolec@rolecserv.co.uk

We have been very happy with the service we have received from Rolec over the years, and this time too. The installation went really well and the products are excellent.

Grahame Armer Managing Director, Windermere Aquatic Limited

The (Rolec) system has been so well designed, and is so slick, that it has transformed both the customer experience and operational side for us.

Michael Prideaux Managing Director, Dean & Reddyhoff

Swift action saves football party

USA: At the end of October last year over 150,000 college football fans converged on Jacksonville for the annual Florida vs. Georgia game, affectionately known as The World’s Largest Cocktail Party. Fans usually start docking their boats at Metropolitan Park Marina (Metro Park) on Friday so as to spend the weekend celebrating with in-water tailgating. But last year the Metro Park fixed docks were completely wiped out by Hurricane Irma’s storm surge.

With roughly 600 people needing the docks for game day, City officials contacted Bellingham Marine and fortunately, Bellingham had an inventory of temporary timber docks waiting in a nearby plant.

“The docks were built for the National Marine Manufacturers’ Association (NMMA) as part of an expansion project for the Miami International Boat Show,” explained Steve Ryder, Bellingham manager of project

development. “NMMA officials graciously agreed to allow the City of Jacksonville to rent the docks as part of their rental inventory programme.”

On 24th October, Bellingham began a two-day installation of 640ft (195m) of floating timber docks and thus provided the much-needed temporary moorage for the big game. With a bit of luck and some quick action on everyone’s part, fans were able to enjoy all the festivities to the full.

Harvey and Irma –counting the costs

USA: Boat Owners Association of the United States (BoatUS), the nation’s largest advocacy, services and safety group for recreational boaters, estimates that more than 63,000 recreational boats were damaged or destroyed as a result of both Hurricane Harvey and Hurricane Irma last year.

A combined dollar damage has been estimated at $655 million (boats only). The numbers are strikingly close to 2012’s Hurricane Sandy, which remains the single largest industry loss with more than 65,000 boats damaged and more than $650 million in estimated losses.

Breaking down the 2017 season storms, Hurricane Irma damaged or destroyed 50,000 vessels with approximately $500 million in recreational boat damage. About 13,500 boats were damaged or lost costing $155 million in boat damage as the result of Hurricane Harvey.

“These two storms were as different as night and day,” said BoatUS marine insurance program vice president of claims Rick Wilson. “The boats that were hit the hardest by Harvey were located on a relatively small slice of Texas coast, while we saw damage to recreational vessels from Irma in every corner of Florida.”

“While Hurricane Irma’s losses are

significant, it could have been much worse,” added Wilson. “Irma ultimately travelled up Florida’s west coast and not the east, which was initially forecast. And while locations in the right front quadrant of the storm such as Big Pine Key and Marathon were hit hard with a Category 4 storm, Irma lost strength as it approached the mainland and swept up Florida. As the storm passed east of Tampa Bay, waters receded and came back gradually, also lessening surge damage.”

CLARIFICATION

In the November/December issue, we reported on a handful of marinas affected by the devastating US hurricanes. We would like to clarify that the six marinas in the IGY Marinas portfolio that sustained damage remained fully open and were taking reservations whilst repairs were made.

Hurricane Recovery Forum

IMBC – 31st January – 2nd February New Orleans, USA

The International Marina & Boatyard Conference (IMBC) has added a Hurricane Recovery Forum to its 2018 conference agenda. The twohour session, scheduled for Friday 2nd February will finalise the two-day conference.

The forum will focus on hurricane recovery efforts and risk management with topics covering employee and electrical safety, insurance claims, design and engineering and (US) federal disaster loans. The session will also include lessons learned and a first-hand account of the recovery of a local marina devastated by Hurricane Katrina.

“Although our agenda was complete, we knew this was a topic that had to be addressed, given the historical storms we have experienced this year,” said Association of Marina Industries (AMI) chair, Brad Gross CMM last November. “Our goal is to provide our industry with information from industry-leaders to help them successfully and safely deal with their recovery efforts.”

IMBC, organised by the AMI, will be held at the Ernest N. Morial Convention Center. Further information at www.marinaassociation.org/imbc

Floating pontoons

Aluminium on concrete: luxury on steady basis

Let’s shape together your new marina

Tel. +39 0422 702412 info@ingemar.it www.ingemar.it

Made in Italy

Pontoons, breakwaters, piers for super yachts, floating bridges and constructions: the best solutions for connecting sea and land by means of strong and reliable structures, in aluminium, concrete or steel, standard or tailor made.

Pontoons and constructions over the water

Aqaba - Jordan: 7,000 sqm of pontoons and fingers for Ayla Marina on the Red Sea

GLOBAL REVIEW 2017

A year of firsts

Over the course of 2017, Europe took centre-stage in terms of new marinas, expansions and refurbishment, North America continued both to build and to consolidate, and countries in Southeast Asia launched world-class marinas and superyacht docks. Charlotte Niemiec selects some highlights.

Developments were busy across Europe and, in the UK, seemingly at an all-time high. In London, the refurbishment of all three basins at St Katharine Docks completed at the beginning of the year, giving them a “new lease of life”. The Poralu docks can now accommodate a wider range of boat sizes up to 40m (131ft). Meanwhile, a new 146-berth marina opened within the Harleyford Estate on the River Thames - a site regarded as one of the most beautiful private country estates in the south of England - and Tingdene Marinas completed a £1 million investment in new pontoons and shoreside facilities at Racecourse Marina in Windsor, expanding capacity by 50% to 262 berths. Walcon Marine and Rolec Services worked on the projects.

Outside of London, Marina Projects began reconfiguration and extension of Windermere Quays Marina on Lake Windermere in Cumbria. Phase one saw the marina reconfigured from 180 to 260 berths (see p. 35 for more). Premier Marinas announced it had earmarked £7.5 million for the start of a £75 million project to redevelop Noss on Dart Marina. The project

will commence with the rebuild and expansion of the marina to include 232 berths, a new boatyard, hard standing for up to 100 boats and a drystack. The company will also reconfigure a third of the mooring system at Port Solent, Portsmouth, for boats up to 33m 108(ft).

Much further north, in Scotland, a £2.5 million transit berthing facility opened in Oban. It comprises 15 finger berth pontoons, three hammer heads and 12 fully-serviced floating concrete breakwaters. The project was managed and delivered by Gael Force Marinas and Pontoons, which also installed 40 berths at James Watt Dock Marina in Greenock as part of an expansion and

To become the largest marina in the Middle East and North Africa region, Dubai Harbour will have a 1,400 berth marina.

refurbishment programme currently in progress by the marina’s newly appointed long-term operator Marina Projects.

A new “marina of true excellence” was announced for Monaco. This will have over 170 berths for vessels of 6.5 to 60m (21 to 197ft), 400 car parking spaces, a maintenance yard and around 3,800m² (40,903ft²) of commercial space. Landside work includes traditional nautical and tourist services, shops, restaurants, green spaces and a beach. As Monaco marinas currently turn away between 20 and 30 superyachts every day, the new development is set to offer additional and much needed mooring opportunities.

In Italy, work completed on the new Capo d’Orlando marina in Sicily, offering 552 berths for boats up to 40m (131ft) in length. The marina is formed of two large Ingemar piers connected to the wharf and a series of mooring fingers and has Plus Marine dockside equipment. Another iconic marinaMarina d’Arechi - also completed; and ranks as one of the most impressive tourist facilities ever built in the Campania region. It has an impressive sweeping 1.2km (0.7mi) breakwater, arched restaurant buildings and 1,000 berths, 80 of which are for superyachts of 25 to 100m (82 to 328ft). The marina is complemented by an extensive boatyard, shops, bars and restaurants along a 3,000m (8,842ft) long quayside promenade whose central buildings feature upper storey space for a yacht club and restaurant likely to open in January 2018. A further 1,000 berths

Bear Lake State Park Marina in Garden City, Utah, USA boosted slips to 380 with completion of a second phase.

POWER to Protect

Lighthouse Power Pedestal

One of our most popular units, the allpurpose Lighthouse pedestal has a wide range of features.

Lighthouse-SS Power Pedestal

The Lighthouse-SS offers the same features and options as the standard Lighthouse, but is made with high quality stainless steel for superior durability and performance.

Mega Yacht Powerpoint

Admiral-SS Power Pedestal

Truly the flagship of our unitized pedestal line, the Admiral-SS possesses amperage capabilities and receptacles to serve nearly any size Mega Yacht.

From the company that is known for its high quality innovations, Eaton is the only company to offer a selfcontained dual-phase megayacht unit.

Ground Fault Pedestal SMART Notification

The Michael Cunningham Act (WV)

Samantha Chipley Act (KY)

Noah Dean & Nate Act (TN)

GLOBAL REVIEW 2017

for yachts up to 75m (246ft) are expected to be built in the country in 2019, growing the network to over 4,000 berths.

In the Netherlands, Holland Marinas in the Maasplassen lake district in the south east of the country expanded its berth capacity from 520 to 600, increasing the size of fairways and introducing larger berths with finger piers. Single berths were designed to accommodate vessels in specific ranges and were generously sized to comfortably take the maximum boat length in each category. When half of the dredging work had been completed, the existing pontoons were moved aside and 70 steel piles were removed. A month later, 88 new steel piles were positioned and the pontoons transferred to their new location. Nine new gangways were installed and building began on a main pier approximately 330m (1,083ft) long.

Elsewhere in Europe, the Sovren House Group soft opened a megayacht marina on the island of Ibiza in the western Mediterranean. The marina, called Sovren Ibiza, offers 16 berths for superyachts between 60 and 185m (197 and 607ft) at fixed docks. The marina specifically caters for yachts up to 185m (607ft) in length. In Malta, plans for Valletta Marina were set to regenerate the waterfront. When complete, it will offer 270 berths for

vessels of 10 to 28m (33 to 92ft) and have additional space for superyachts up to 50m (164ft). In Montenegro, Marina Portonovi, an essential element of the €650 million upmarket Portonovi Resort, was completed. It is set to become a key nautical destination in the Mediterranean and a seasonal hot spot for superyachts. On completion, the resort will feature nearly 300 luxury villas and apartments. The marina design provides a range of berthing options including a number of smaller berths reserved for the exclusive yearround use of residents. The remainder will be available for visiting boats and

superyachts up to 70m (230ft). The outer fixed breakwater can also be used for seasonal mooring of vessels up to 200m (650ft) in length.

A new high-tech marina designed to set new standards in the Baltic was built in Kakumäe, 10km (6 mi) from the centre of Estonia’s capital city Tallinn. Offering wet berths for 300 vessels and additional superyachts, the marina will have a well-equipped boatyard, heated storage for a further 250 boats and many on-site amenities. A private 4m (13ft) wide VIP pier is also built to accommodate up to 16 megayachts in the 40 to 60m (131 to 197ft) range. All vessels have access to a pump-out dock, fuel dock with four pumps and a selfservice boat washing station. The dry storage building will hold vessels up to 130 tons.

In Cyprus, the ministry of energy, commerce, industry and tourism awarded a 125-year lease to PMV Holdings for the development of a marina in Paralimni in the Famagusta district. The concession includes a marina of around 300 berths, administration buildings, residential, commercial and hotel development.

US redevelops and consolidates

In Florida, Loggerhead Marina sold 11 of its marinas throughout Florida to Suntex Marina Investors LLC. The

Marina d’Arechi on the Amalfi coast has boosted berths in southern Italy and is seen as a symbol of regional success.

Kakumäe Marina, just west of Tallinn, was largely completed in 2017 and will also have impressive shoreside infrastructure.

GLOBAL REVIEW 2017

transaction included over 2,300 wet and dry slips and multiple restaurants. The sale illustrates the current trend towards consolidation in the US. Dana Point Harbor Partners (DPHP) was announced as the master developer for the Dana Point Harbor revitalisation plan. The Florida marina was built in the early 1970s and is in need of significant modernisation. The programme proposes 2,296 wet slips, 388 drystack spaces and valet boater slips; commercial and retail space; two hotels; offices; and a surfing museum. Further details will be available later this year.

Bellingham Marine added 15 slips to the five-star Tarpon Point Marina in Florida and, in California, was also contracted to engineer, design and manufacture a new concrete floating dock system for the Blu Harbour community development in Redwood City. It includes a 64-slip marina, 402 apartments, a human powered watercraft launch dock and a saltwater pool.

In Utah, Oklahoma-based marina company Meeco Sullivan completed a second phase of redevelopment at Bear Lake State Park Marina. The project encompassed 218 boat slips and 440ft (134m) of dock walkways with 12in (30cm) galvanised steel frames and composite decking. The arrangement has end ties and three gangway

landings. Slips are all single loaded and range in size from 20-48ft (6-15m).

The marina now has approximately 380 slips with longer side ties for 48ft+ (15m+) boats.

The new Hyatt Marina opened at the Hyatt Hotel, Newport, in Rhode Island. The marina has been designed to accommodate vessels of over 200ft (61m) in length at a 30in (76cm) freeboard mega berth and moor up smaller vessels of up to 60ft (18m) at additional slips.

In Massachusetts, Provincetown Marina at the tip of Cape Cod completed phase two of redevelopment, which comprised an 8ft (2.4m) deep, 900ft (274m) long, 20ft (6m) wide

Marina di Valletta, Malta, soft opened in June 2017 and attracted immediate interest from potential berth holders.

floating breakwater – one of the widest and deepest on the East Coast. It includes in-slip pump-out and 480 3-phase power.

Plans for an impressive waterfront project, The Wharf, were shored up. The US$2.2 billion project encompasses 50 acres (20ha) of water and 24 acres (9.7ha) of upland improvements. It will feature 3,000,000ft² (287,709m²) of new residential, office, hotel, retail, cultural and public space. The waterside will include waterfront parks, promenades, piers, docks and three new marina facilities. The first marina component is the Market Pier Day Docks with 30 slips and 1,000ft (305m) of side tie. Moving southeast, or downstream, the next structure is the fixed Transit Pier with attached Transit Taxi Dock, also a concrete floating dock. The longest pier in the project is called District Pier where large vessels will moor. New floating dock marinas are replacing two existing facilities. Bellingham Marine has completed a 100-slip facility at the members-only Capital Yacht Club. Next to the yacht club will be a new 200-slip marina with 2,520ft (768m) of side tie. The Wharf Marina will be completed in Phase 2 and is planned to have heavy-duty floating docks and power to accommodate megayachts, including

Marina Portonovi in Montenegro has a sheltered marina basin for a variety of vessel sizes.

GLOBAL REVIEW 2017

high-end services and crew facilities.

In New York, one of the first major inter-coastal waterfront revitalisation projects for the city of Buffalo, New York, was completed in just over a year. Lake Erie Marina is now the largest full-service marina in the New York State Parks system, with 1,063 slips. The refurbished marina also features a new fuel pier and courtesy docks with ADA access; modern fuelling stations and a new ship store; a new PWC dock; a renovated fullservice restaurant; renovated on-site operations, management and boater services office; and a 400ft (122m) long attenuator at the mouth of the harbour.

In Central America, IGY Marinas took over ownership and management of Red Frog Beach Marina in Panama, which currently offers 12 megayacht berths and can accommodate vessels in excess of 300ft (90m) lengths. Guests can enjoy the amenities of the associated resort and spa; shuttle bus access to a beachfront restaurant; and an impressive line-up of recreational activities. IGY is exploring plans to

add on-site food and beverage outlets.

Finally, in the Caribbean’s British Virgin Islands, a new outer marina opened at Nanny Cay in Tortola. When fully complete, it will almost double the dock facilities to 300 slips, split between the inner and outer marina. The 6.5acre (2.6ha) outer marina peninsula will also have eight new condo blocks, each with three four-bedroom and four three-bedroom condo units; enhanced walkways and recreation areas; a new restaurant; gym and wellness centre; a new commercial retail and service space.

Many marinas in the Caribbean, Florida and the Gulf Coast were

Motuoapa Marina on Lake Taupo in New Zealand was radically redesigned to create a great public resource.

affected by hurricanes Irma, Jose, Harvey and Maria. Damage varied widely but impressive efforts were made to affected marinas to restore business swiftly.

Middle East typically ambitious

A 310-berth marina was completed in Al Fintas, Kuwait, while Bahrain Marina Development Company unveiled the master plan of Bahrain Marina, scheduled to complete by 2020. It includes a 5-star hotel, serviced hotel apartments, seafront hotel villas and a residential tower with freehold apartments. It will boast berths for vessels of various sizes.

The jewel of the year was undoubtedly the plans for Dubai Harbour. Styled as an iconic waterfront destination that extends over 460 acres (186ha), it will include a 1,400-berth marina as well as a cruise ship port and terminal, a shopping mall, events arena, luxurious residential buildings, hotels, offices, retail stores, restaurants, cafés and the Dubai Lighthouse. Expected to be completed in four years, the destination will expand Dubai’s mooring capacity by nearly 50% from its current 3,000 berths and will offer moorings for vessels up to 85m (279ft) in length. Also in Dubai, APCC Piling won a US$45 million contract to build six marinas in ‘Deira Islands’. The marinas will have a total of 614 berths for yachts up to 60m (197ft) in length

Marina Projects took over management of James Watt Dock early in 2017 and has already improved infrastructure.

GLOBAL REVIEW 2017

and construction is set to finish in two years. Deira Islands is a new coastal city that will add 40km (25mi) to Dubai’s coastline and house a population of around 250,000.

Elsewhere in the region, Marinas Performance installed a 152-berth pontoon system on Dalma Island, 42km (27mi) off the coast of Abu Dhabi, and ART Marine was appointed marina operator of the first of four new marinas in the Al Zorah development in Ajman. The company will manage berthing facilities for vessels of 8-40m (26-131ft).

Asia ramping up

Developments in Southeast Asia didn’t lag behind. Nongsa Point Marina & Resort in Batam became the first marina in Indonesia to earn Global Gold Anchor accreditation and the prestigious 5 Gold Anchor status. The international marina has 65 berths, including two for vessels up to 130ft (40m). Marina Industries Association president Andrew Chapman said the marina provided the benchmark for marina development in the country.

In Cambodia, the first phase of Princes Private Club Marina on the Mekong River in Phnom Penh completed with the installation of three superyacht berths. The project is seen as a significant milestone for tourism in the country and may be the first of several likely superyacht berthing projects.

Installation of a 650ft (198m) long breakwater was a major element in a second phase redevelopment project at Provincetown Marina in Massachusetts, USA.

On Vietnam’s south-east coast, construction began on Ana Marina in Nha Trang. When complete, it will be the country’s first world-class marina, initially offering 60 berths for vessels of 20-40m (66-131ft) and extra wide berths for catamarans. Future phases will include a superyacht dock for six yachts up to 70m (230ft) in length and an additional 100m (328ft) berth is under construction. Landside developments include a swimming pool, restaurant, yacht club bar and ballroom, gym, spa, and a boatyard with hardstand, drystack, slipway and workshops. Ana Marina was designed by Camper & Nicholson Marinas and features Marinetek pontoons.

Across the water in India, plans were floated for two landmark waterway projects. They include a marina at

Belpaur, providing a waterfront of 1.8km (1mi) hosting floating restaurants, yacht clubs, aquariums and activities on land. The project plans are for a berthing facility of 30 berths minimum and comprehensive services.

Quieter in Australia and New Zealand

It was a comparatively quiet year for Australia and New Zealand. In Australia, Ardent Leisure Group made headlines by selling the d’Albora Marinas portfolio to a special purpose vehicle jointly owned by Sydney-based Balmain Corporation and Goldman Sachs for AU$126 million and, in New Zealand, renovations completed at Motuoapa Marina. Work included excavation and removal of an island and reclamation of part of a lake. The marina’s new Bellingham Unifloat pontoons are arranged in a 158-slip configuration, with power pedestals and potable water available.

Also in New Zealand, Kennedy Point Boatharbour was given the go-ahead to build a 186-berth floating marina at Kennedy Point in Putiki Bay, Waiheke Island. In addition to the floating berths, the marina will have up to 19 pile moorings, 30 public day berths and storage for kayaks and standup paddleboards. Finally, Lyttleton Port of Christchurch began building a new marina at the inner harbour pile mooring site in Lyttleton Harbour in the first stage of a wider regeneration plan to improve public access and amenities in the area. The marina, to be called Te Ana to reflect Kiwi cultural values, will be Canterbury’s only floating marina and will feature up to 200 berths.

The marina at Blu Harbor, a community development in Redwood City, California, was redesigned and rebuilt.

Dubai International Boat Show

MARINA PLANNING & DESIGN

Marasi Business Bay: from mirage to reality

Building one of the most innovative marina designs in a hot desert climate and working with a multitude of different cultures, materials and time-scales is proving challenging but rewarding. Oscar Siches gives an update on Dubai’s ambitious Marasi project, set to complete in 2023.

While the marina and nautical industries have grown in parallel, development and innovation in marinas has always trailed behind yacht design as the industry is conservative and reluctant to implement change. For example, marinas only began offering electricity in the 1970s, when yachts fitted fridges and air conditioning. They offered Wi-Fi in the early 2000s when laptops became ubiquitous. Marina designers and operators tend to drag on proven facts and only improve when clients make a specific request. They do not, in general, innovate.

But the Marasi project in Dubai is breaking with that safe but negative tendency. The project began in 2015 when Dubai Properties, the state land development company in Dubai, approached Homeport FZA, a European marina design and management company established in the Emirates, to create the design concept for the Marasi project. As the project engineering firm, Homeport engaged International Waterfront Consultants (IWC), which has good

experience in the region. When complete, Marasi Bay will have a group of four marinas within the Dubai Canal, a 7.4km (4.6mi) artificial waterway dug from the tip of Dubai Creek back to the Persian Gulf, 4m (13ft) deep at low tide and with an average width of 120m (394ft). The canal runs through the highly-developed Business Bay and downtown Dubai areas, among towers of unusual design, four hotels and under six bridges (three for vehicles, three for pedestrians), providing an 8.5m (27ft) air draft for vessels to sail through at high tide.

The Marasi promenade features 450 restaurants, seating areas, cafés and parking. With completion expected in 2023, Dubai looks set to achieve another architectural and engineering feat.

Dubai Properties had three firm principles for the design: it must not be standard, it must not

CGI of Marasi Bay at night highlights the range of berth sizes and public spaces.

be boring, and it must be sustainable. All four marinas were to be designed in a canal section of 2.8km (1.7mi). Homeport was chosen to design and manage the project because of its experience and involvement in Anchor Marina at Palm Jumeirah and Festival Marina.

As concept designer, I was quick to recognise the similarity between the canal section and parts of the Intercoastal Waterway in Florida, US. In the South Florida section, it becomes a lively waterway full of marinas, condominiums, restaurants, boatyards and bars. It is possible to set a few days’ sailing programme without having to sail to the open sea.

The Dubai Canal may become a smaller version, but with plentiful traffic proving an attraction for passers-by. Ferry stops are being added and new ferry schedules drawn up, for fast and slow vessels. The four marinas are grouped around a 60m (197ft) wide channel that runs through the centre.

Four distinct marinas

The marinas have been designed for all types of visitor, with consideration of the potential use of nearby upland. The first, called Park 3, was ready in December 2017 at the Business Bay circle. With 176 berths from 8 to 35m (26 to 115ft) and located 700m (765yd) away from the Burj Khalifa building and near Dubai Mall, this marina will feature two floating restaurants. Nine floating houses are located nearby, connected by gangways to a 250m (820ft) long, 5m (16ft) wide pontoon. Another, almost

Stainless steel pedestals, custom-made by Plus Marine, and Septech floating pontoons were installed within a tricky timeframe.

MARINA PLANNING & DESIGN

symmetrical marina, will be positioned on the other half of the Business Bay circle and feature approximately the same number of berths.

The restaurants of Park 3 will be located at one edge of the traffic canal approximately 150m (492ft) off the sea wall and at the base of the crescent. Both will be accessible via a 9m (29ft) wide floating promenade and lined with two rows of 4m (13ft) high palm trees. These trees are one of the unusual innovative features of these marinas, creating a floating forest effect, providing natural shadow and breaking the barren look of concrete pontoon surfaces. The planters are fitted every 15m (49ft) throughout the marina, with the edge of the plant pots designed to be used as a seat.

The second marina could be described as a floating amusement area. Four very large barges anchored 50 to 60m (164 to 197ft) offshore will house a bar with a swimming pool (beach club type), which will be surrounded by a visual barrier for full discretion, a shisha palace, a standard restaurant and a second restaurant consisting of electric-powered boats fitted with a pantry, table and lavatory facilities. While sailing through the canal, an onboard chef will cook and serve to hosts and guests, making it a genuine sail-and-dine experience.

The third marina is being constructed in an inlet in a densely-inhabited area. It is intended for the use of residents who enjoy boating activities and who own

yachts. The fourth marina will be the largest, with around 400 berths, located in a wide-open bay of the canal. It will feature a ramp across from the top to a circular restaurant built on the water.

Challenges and opportunities

Such an ambitious project – in such a short time scale – is not without its challenges. The process of building is far removed from the image of finished high rises, top accessory brands and glitzy shopping malls that Dubai evokes. Working with different cultures and with many different people is hugely exciting, but requires true understanding and patience.

Left & below: palm trees provide natural shade and break the barren look of concrete pontoon surfaces.

In this project the mid- and upperranks of companies and consultants involve people from the UAE, Egypt, Palestine, UK, USA, Lebanon, Argentina, Germany, Bulgaria, Canada, the Czech Republic and Australia. Blue-collar workers include those from India, Pakistan, the Philippines and Bangladesh. Major religions must be respected: Islam, Buddhism and Christianity.

In any project, delays are inevitable. In this case, shortly after construction permits were granted in April 2017, the holy month of Ramadan began and the working schedule changed. During this time, work begins at 5.00am and stops at 12 noon. While contracts had been agreed with suppliers ahead of time to maintain speed of production, suppliers had suppliers themselves who adhered to the slower pace of all the Muslim population and the whole chain was disrupted.

Septech, the appointed builders, mixed engineering and management with magic and kept up an unusually fast pace given the situation. The marina had to be floating and assembled by September. Pontoon modules needed to be transported from a factory over 150km (93mi) away in Abu Dhabi to the construction site, but heavy trucks were only allowed to use the roads from midnight to 5.00am, giving a short half-hour’s leeway to

unload or deal with any emerging problems. Trucks usually arrived at 4.305.00am, the cranes start working at 6.00am and, just as work was ramping up, workers were often asked to leave the site they were working on to begin excavation on another building.

Moods fluctuate throughout Ramadan. Workers work on empty stomachs until sunset; Muslim women cannot touch any men during the month; any exchange with a female banker, office worker or lawyer must be limited to a nod of the head and those of different cultures must fight the automatic urge to extend an arm for a handshake.

MARINA PLANNING & DESIGN

– actions that will only prove wise or otherwise a couple of weeks later.

At 9.00am every Tuesday there is a project meeting and all workers are reminded of the importance of reaching deadlines on time. This is followed by a rush out to the factory, to the site, to the administration offices, a re-arrangement of tasks and trimming of processes

The hard work never ceases. The pontoon quality is inspected two or three times a week – top finishing, monolithic casing, manholes, rod ducts. As concrete cannot be cast or left to dry in the average 46°C (115°F) outside, units must be covered with rags and made permanently wet. The expanded polystyrene voids are reinforced and brought to the waiting empty moulds

Integrating into the ‘cityscape’.

while everyone hopes the truck delivering the concrete will arrive on time as concrete has to be poured from the truck within two hours of delivery.

Launching and assembling marina sections is big news and attracts quite a crowd. When the first pontoon was launched, a high directive of Dubai Properties, press reporters and distinguished guests attended. The crowd watched as a crane swung a pontoon module and placed it delicately into the water. A set of five pontoons, including one with the palm tree in place, was towed towards the event area. The mirage turned into reality before everyone’s eyes.

That night, workers celebrated at an Indian restaurant and, at 5.15am the next day, arrived back at the site to monitor the unloading and launching of the 14,000kg (14t) block anchors arriving from the Sharjah (desert) factory. The marina was completed with less than a month’s delay.

MARINA PLANNING & DESIGN

Superior delivers speedy rebuild after Debbie hits Abell

Point

When Cyclone Debbie hit the Australian Whitsunday islands on Tuesday 28th March 2017 it was a Category 4 with 275km (171mi) winds and was unusually slow moving. But, although it was slow to build, when the eye passed over, winds swung from the north and made the storm significantly more destructive. Given the severity of the cyclone, there were relatively few vessels in the area that actually sank but many sustained damage. Pontoon infrastructure at award-winning Abell Point Marina (APM) took a battering.

Berths on H, J, K, F, G and A arms at APM were deemed non-salvageable, resulting in a direct and dire impact on many of the 80-plus independent commercial businesses which operate from the hardest hit North Marina. With tourism demand at its highest in the tropical northern Queensland winter, time was of the essence in order to minimise negative impact on these businesses and the local Airlie Beach community.

APM owner, Paul Darrouzet, had Superior Jetties on site within 48 hours of the cyclone and, in conjunction with the APM management group, an immediate ‘make safe’ campaign was instigated and undertaken. This was swiftly followed by commencement of a marina rebuild.

Maria Dwyer from Oceanic Marine Risk Insurance, as the CGU

representative, was instrumental in facilitating expeditious insurance responses which enabled quick action. A destroyed 30m (98ft) gangway was lifted from L arm fuel dock on Monday 3rd April and a loan unit installed to allow fuel business to be restarted in under a week.

The Superior team on the Gold Coast worked to establish the logistics, scheduling, material and personnel requirements to ensure that the

Craning in pontoons to replace G arm berths at Abell Point Marina.

rectification project would happen in record time. Superior’s Ryan Hogan was appointed project manager and he arrived in Airlie Beach to help the BIA volunteer group with emergency work in the community in the first week after the cyclone.

Hogan then set up a project office at the marina and pontoon manufacture commenced at Superior Jetties’ facilities on the Gold Coast in less than four weeks. Pontoon deliveries were made every Monday throughout the project without fail.

The demolition and re-piling programme was undertaken quickly and efficiently by Pacific Marine Group, which has worked with Superior on a number of occasions in the past.

The on-site team completed the project in sections to enable the marina team to accommodate ever increasing numbers of winter visitors prior to full arms being completed. This was achieved through a complex project services plan and the dedication of sub-contractors such as Orca Marine, Proserpine Electrical and Whitsunday Drainage Contractors. The entire project was completed in August 2017 with only some minor ongoing repairs outstanding for local contractors to handle.

The ‘Abell Point Marina Cyclone Rectification Project’ was a wonderful example of focused efforts by many parties to rebuild a resilient community, and Superior Jetties is extremely proud to have been a part of the process.

New berths on A arm after the originals were deemed non-salvageable.

on the water and everywhere

La Paz, Mexico, 5 October,

A hurricane state of emergency is declared by the Mexican authorities

MANUFACTURER OF PONTOONS AND MARINA EQUIPMENT

"In Lower California, marinas are exposed regularly to tropical storms"

Tropical storm «Norbert», which started life last week in the Eastern Pacific, has gathered force in the last few hours. On the Saffir-Simpson hurricane scale, it should reach the Mexican area of Lower California (the La Paz area) on Friday evening, by which time it will certainly have grown in strength to category 3 (out of 5 categories), with gusts of wind reaching over 210 km/h, according to the National Hurricane Center in Miami.

Each component of the pontoons, as well as the Marina anchoring, must be absolutely perfect to resist extreme climatic conditions. Our Marina has already weathered several hurricanes, without any damage to the equipment supplied by Poralu. We are absolutely satisfied with their reliability.

Andres Barrera Peralta Manager, Marina Escale Nautique

MARINA PLANNING & DESIGN

Redesign completes at Windermere Quays

Lake Windermere in Cumbria, the largest natural lake in England, is one of the country’s prime tourist spots. Surrounded by mountain peaks and picturesque villages, over time the lake has become a magnet for watersports enthusiasts. Windermere Quays Marina, originally built in the Lake District National Park’s key town of Bowness-on-Windermere from 2004 to 2006 by Walcon, has now been reconfigured and extended in a development designed and managed by Marina Projects.

“The increasing size of boats on Windermere as well as greater overall demand required us to update our marina,” said Grahame Armer, managing director of Windermere Aquatics, the parent company of Windermere Quays Marina. “We have increased the number of berths from 184 to 260, with an emphasis on having more capacity for boats in the 9 to 15m (30 to 50ft) range. The overall footprint, including the moorings, has doubled to allow more space for the larger boats to manoeuvre.”

Construction work followed an extensive design and approvals process undertaken by Marina Projects to secure the necessary consent, including the negotiation of a new lease for the extended marina. The planning approval required the implementation of a detailed consultation strategy with key stakeholders and regulators, as well as the undertaking of specialist studies into navigation, marina design and viability.

The scope of work handled by Marina Projects included the marina design and specification of the marina equipment that was installed as part of the reconfiguration. In addition, Marina Projects managed the procurement

With its new pier and reconfigured original mooring system, Windermere Quays Marina now meets the needs of existing and future customers.

and contract negotiations with the selected contractors, and the project management and contract administration of the works from award through to completion.

The marina’s existing Walcon System 21 finger pontoons and piers were refurbished before being redeployed. Walcon Waliflote wave attenuating pontoons were also added at each end of the marina to improve the wave climate within the confines of the marina basin. Other aspects of the project included extraction of the existing piles and driving of new ones to conform with the new layout. Notable design improvements were made to pile restraints to accommodate extreme water levels. The swing moorings were also relocated.

Rolec – the selected supplier of pedestals for the 2006 marina - was contracted to manufacture, supply and install over 100 silver anodised aluminium Quantum marina service pedestals and other accessories. The pedestals feature electricity metering, water taps and LED lighting. Anti-frost protection was also included via Rolec’s heat trace tape system.

Windermere Quays also installed over 50 Rolec energy efficient LED deck combi lights in blue and white, shore electrical system isolation panels,

Rolec Quantum pedestals and Walcon pontoons provide ample full service berths.

WHAT TO DO, WHEN YOU HAVE WATER BUT NO LAND?

Let’s take your waterfront to the next level

Bluet is a Finnish company, specializing in profitable waterfront development with special floating solutions. We offer design, consulting, project management, delivery and supervision services around the world. We create, coordinate and oversee the project in co-operation with the best local contractors.

When you’re considering building on water, take a look at what we can do: www.bluet. . We will make your floating idea real!

The Future is Floating

a number of distribution units and Quantum SOS pedestals. All of the under deck pipework was lagged to provide extra frost protection.

All work involved relocating berth holders as the project progressed over eight piers.

Armer was full of praise for the contractors and the end result.

“This project has created a worldclass marina and visitor attraction at Bowness-on-Windermere,” he said. “The development has introduced a new marina that provides our customers with an unrivalled level of facilities and services [on the lake].

Marina Projects has tailored the design to our specific requirements, ensuring the business meets the needs of present and future boating markets.”

Marina Projects managing director, Mike Ward, commented: “Having been involved in this project since its inception, it is pleasing to see the marina extension complete. We have worked closely with our client to overcome all of the challenges that have been faced, including delivering the works throughout the busy 2017

MARINA PLANNING & DESIGN

Aquatic team.”

The £1 million marina project at Windermere Quays is part of a wider regeneration strategy for the Bowness-

on-Windermere area and is the first phase of comprehensive development proposals for the site. Further phases will primarily focus on the adjacent landside area and include provision of a new visitor centre, restaurants, retail outlets and a hotel.

boating season. The finished project is a credit to all involved, including both Walcon and Rolec but also the Windermere

As completed in 2006, Windermere Quays before the 2017 extension.

Gold Anchor scheme has provided an excellent template to inform our planning and investment priorities during the development of our newly completed marina.”

www.tyha.co.uk www.marinas.net.au

“The

Darren Finkelstein, Marina Manager, Wyndham Harbour Marina, Melbourne, Australia. Gold Anchor rating: 4 Gold Anchors

MARINA PLANNING & DESIGN

An epic rebuild at Alamitos Bay Marina

Embattled by rising maintenance costs, Alamitos Bay Marina initiated a programme in 2005 to rebuild all 1,962 slips in seven different basins. The timber docks dated from the 1960s and were 20 years past their projected life span. No one at the City of Long Beach, California, imagined it would take the next 13 years to complete the project. Robert Wilkes reports

The marina is south of Los Angeles and enjoys a uniquely loyal customer base. There are tenants who have been there for decades whose children and grandchildren are also renting slips. Over time, neighbouring tenants have formed tight communities.

The City’s marinas are operated by the Marine Bureau, part of the Department of Parks, Recreation and Marine. Three City-owned marinas total 3,337 slips: Alamitos Bay Marina, Long Beach Shoreline Marina and Rainbow Marina. Alamitos Bay is the largest marina in the US. The rebuild project started in 2005 and has been undertaken in phases. The final phase will be completed in mid-2018.

Reasons for the length of the project are size, environmental compliance and the timing of funding. Elvira Hallinan is the Marine Bureau manager. “Most operators have a marina the size of one of our basins,” said Hallinan. “We had seven basins to rebuild. It wasn’t a project, it was a journey.” Delays caused by the Environmental Impact Review (EIR) were unanticipated. Contractors were ready to begin when

the requirement for a full EIR delayed the start of construction.

Start-stop-start scheduling

Incremental funding created a number of starts and stops. Unable to fund the work, the City applied for and was awarded loans from the Division of Boating and Waterways of the California Department of Parks and Recreation. The loans were parcelled out corresponding to project phases. Construction would halt until the next loan was awarded. In 2015 the Marine Bureau leapfrogged the financing problem and construction has been continuous since.

Reconfiguring for the market

In the original marina slips started at 20ft (6m) in length. Boating evolved and smaller slips went unrented, but California

The operators of Alamitos Bay Marina, just south of Los Angeles in California, have undertaken a ‘journey’ to rebuild slips in seven different basins.

Coastal Commission regulations protect the rights of small boat owners. The problem was resolved by trading small slips for two dry storage facilities, one with 164 racks and a soon to open facility with 100 more.

After many design/build conferences to determine the optimum configuration, wet moorage slips now total 1,655, from 15 to 115ft (4.5 to 35m). The most common slip size went from 30ft (9m) [429 slips] to 40ft (12m) [359 slips]. The number of slips over 80ft (24m) has gone from one to ten.

The Bellingham Marine concrete docks include rounded finger ends and wood trim at the triangle frames. All-new Eaton electrical utilities and power pedestals provide 30A to 50A power. The marina offers pump-out receptacles within reach of every boat and individual receptacles for slips 40ft (12m) and above.

A design-build team

“Most public marinas are designed by an engineer, put out for bid, and the low bidder is selected,” said Eric Noegel, manager of project development for Bellingham Marine. “We call that the design/bid/build methodology. We used a design/build approach for this project - a much better option.”

The design/build method is based on the concept of a single entity who accepts full responsibility for designing and constructing a project from conception to completion. The more experience the firm has in the required disciplines (design, manufacture and

Installing final elements in the design/build process.

MARINA PLANNING & DESIGN

construction), the more value it is able to create for clients. From the outset of the project, design, manufacture and construction expertise is brought to bear upon all components. Constructability and operating expense are evaluated against initial cost to optimise lifecycle costs.

Very few public agencies are able to utilise a design/build approach. The charter of the City of Long Beach, however, allows the City to use a best-value selection process when the project involves a revenue-producing asset. The City has used this process with parking garages, so it recognised the value of a design/build contractor. Price was part of the scoring, but so were experience, product longevity, schedule, financial strength and warranty. “It turned out that we were the low-price bidder as well,” said Noegel, “but the City’s ability to evaluate the entire proposal, not just price, sets this project apart.”

Design/build provides two advantages: a streamlined organisation and the flexibility to respond to changes and unanticipated events. These attributes enabled the team to solve

Rounded finger ends, smart dock boxes, Eaton power pedestals and an attractive combination of concrete and timber give Alamitos Bay a radical new look.

problems, make timely decisions and keep the project on track.

Hallinan was the team leader. The team praised her management and communications skills and plain hard work. Everyone credited good teamwork for the project’s success. Ed Heaton was Bellingham Marine’s project manager early in the project. “What stands out,” said Heaton, “is the close interaction that came out of the design development process. If we thought it would help, Bellingham would suggest, ‘this might work out better,’ or, ‘here’s where your costs are.’ The others would listen and work with us to get the end product the City wanted.”

Encouraging teamwork

The City hired TranSystems Corporation as project manager and to manage the RFP process. TranSystems and the City of Long Beach saw the benefits of the best-value bid process and wrote the RFP accordingly. Long product life and low maintenance were important because the City wanted to avoid rebuilding again for as long as possible. The subs included the engineer of record, Moffatt & Nichol, the dock system engineer, Redpoint Systems, and the key construction sub, Manson Corporation for dredging and pile driving.

Bellingham Marine was selected as prime, in part for their design/build capabilities. “Not many contractors can perform that function on a project that

includes both landside and waterside improvements,” said Steve Schmucker, senior project manager at TranSystems. “Bellingham Marine could definitely handle it. It was a timely choice and made good sense financially.”

Work scheduling was critical. During the transition from smaller to larger slips Bellingham Marine’s engineering staff maintained control of the design and determined feasibility, provided layout options, checked clearances in fairways and came up with workarounds for environmental matters. Decision-making flexibility extended to the colour of shoreside toilet facilities. When local homeowners saw the planned exterior colour they rebelled. The team let them submit ideas and a colour proposed by the homeowners was adopted.

Dredging and disposal

The challenging aspect of dredging was where to dispose of sediment. Clean material can be barged out to sea and deposited in a controlled, unconfined area on the sea floor. If the material is contaminated or hazardous, options narrow. Drying the material and hauling it to a hazardous waste facility is costly.

Mercury found in some sediment was in all likelihood from nearby industrial run-off. Luckily for Alamitos Bay, the Port of Long Beach owned a Confined Disposal Facility (CDF) and agreed to take the material within a limited time window. The stops and starts put the City in danger of losing access to the CDF. Josh Burnham of Anchor QEA, the project’s environmental consultant, helped negotiate additional access to the CDF.

Providing independent and bespoke services to clients worldwide

Masterplanning

Feasibility studies and market research

Business planning

Marina and Marina Club design

Investment appraisal

Tender and project management

Environmental and legislative advice

Legal and property consultancy services

MARINA PLANNING & DESIGN

Imaginative financing

By 2015 the City realised it was in a position to sell revenue bonds to pay for the project. “Because the bonds were collateralised by revenues from the marina,” said Hallinan, “I had to sell my marina to investors through road shows with Morgan Stanley. Preparation took six months. A couple of investors actually came out to the marina and we took them on a tour to see the old and new docks. The quality of the new marina and the loyalty of the customer base were factors in our successful financing.”

The City originally thought it might be able to sell $30-40 million, but the entire offering ($114,015,000) sold out in half an hour. The City paid off previous loans leaving a budget of $49 million to complete inwater construction and $3 million for landside improvements. Careful environmental mitigation

A marine biologist and an ornithologist guided the City’s environmental compliance. A mitigation site was created in marine stadium to plant eel grass beds to compensate for dredging and construction losses. Migratory sea birds and nesting sites were monitored and protected. Starfish clinging to old docks were returned to the water.

YOUR NEXT AD COULD DIE FROM POOR CIRCULATION.

Long project - happy tenants

The truth hurts. An advertisement that doesn’t reach its market hurts your budget. As an advertiser, we believe you need accurate, up to date and independently verified circulation figures for the publications in which you choose to advertise. That’s precisely what an ABC Certificate of Circulation provides.

Visit: www.abc.org.uk

No boat owner was without a temporary slip as new docks were being built. The closely bonded marina tenants came into the office to see if their temporary moorage could be near each other. They wanted to return to the new docks the same way. While

there were complaints about the long wait, the feeling in the marina is sheer happiness. The tenants love the new docks and the neighbourhood is better than ever.

Robert Wilkes writes about the marina industry from his home in Bellevue, WA, USA.

marine@ghcranes.com www.ghcranes.com

MARINA PLANNING & DESIGN

Lagoon Marina meets growing berth demand in RAK

With hundreds of small boats and a long tradition of sailing and fishing as its foundation, Ras Al Khaimah is now evolving into one of the yachting hubs in the United Arab Emirates and the Arabian Gulf. Often overshadowed in the news by Dubai or Abu Dhabi, RAK – as it is called locally – is only now starting to develop its nautical potential. RAK is located halfway between Dubai and the Musandam Peninsula in Oman, bridging also the highest-energy cosmopolitan urban centres and the purest natural coastal landscapes in the region. David Canfield reports

One of the recent marinas in this northern emirate, which is providing new berths for the growth of its recreational navigation and nautical tourism, is The Lagoon Marina at the Mina al Arab project. This marina is part of the first phase of a large-scale US$2.7bn master planned project, which is the largest of its kind in RAK. Mina al Arab is presently under development by RAK Properties, the preeminent real estate developer in the area. The roles of marina consultant and engineer were performed by ATM, a company that specialises in marina projects and has over 12 years of uninterrupted presence in the UAE.

Plans and development

The final master plan for Mina al Arab was conceived in 2006 and construction started immediately. The project is a 250ha (618acre) development with

about 80ha (197.6acre) of ecological reserve. By the time the global financial crisis impacted the project schedule, all major earthworks and bulkheading of canals had been completed.

Within the framework of the available infrastructure, the master plan was updated for re-launching of works after the crisis. The master plan now includes eight resorts, an Arabian souk and thousands of residences including villas, townhouses and apartments. Upcoming hospitality components are supported by tourism data that shows that more accommodation is needed in the emirate, which is particularly well known for its natural landscapes. The new approach also adds emphasis to environmental features and incorporates the value of the wetland reserve through two eco-hotels.

The completed initial phase of the

The simple symmetrical layout of Lagoon Marina mirrors the central plaza of the high-density residential development.

master plan development includes villas, residential towers and the marina. The developer is enthusiastic about the current surge in activity at the site, including two hotels under construction that are scheduled for completion in 2018, and the outlook for completion of the master plan build-out in the near future.

Design and development team

ATM was founded in 1984 in Florida and started major involvement in Dubai in 2005. In the early nineties, the company set up a dedicated marina team. Originally focused on environmental and coastal engineering services, it quickly evolved into a comprehensive and integrated practice. For over 20 years, ATM’s marina services have encompassed market studies, marina planning, economic feasibility and business plans, coastal engineering modelling, marina engineering design, environmental studies, regulatory permitting, operations consulting, due diligence, tender services and construction support services. The ATM team has worked on over 600 marina projects worldwide.

In the region, ATM has been involved in signature projects such as Dubai Marina Yacht Club, Palm Jumeirah Marina East and West, Jumeirah Beach Hotel Marina and Marasi Marina to name a few - before, during and after the recession - and is one of the few locally licensed companies to process marina No Objection Certificates (NOCs) and permits in Dubai. In the Lagoon Marina project, ATM was involved in the marina planning, design, tender, approvals, construction supervision, support for the selection of the marina operator, and handover.

Marina development process

The Lagoon Marina at Mina al Arab is a 50-berth facility with Majestic Jetties pontoons and Rolec Seawave dockside pedestals. It supports the first phase of the project development and its simple symmetrical layout mirrors the central plaza of the high-density residential development. This location is opposite to The Harbour at Hayat Island, which will be developed in a future stage.

The Lagoon Marina is one of the

Features and Bene ts

Routes easily along or underneath docks. The Nylon 12 outer jacket is UV stabilized and salt water resistant; no chase pipe required. Can be supplied in extra long continuous lengths: eliminating transition sumps on the dock. Additionally, a double containment exible oating dock connector is available.

For custom lengths of up to 1000 feet please contact factory.

MARINA PLANNING & DESIGN

master plan elements intended to activate the first phase of development, especially The Lagoon Walk, a 1km (0.6mi) long promenade which is a signature feature of the development.

This is the second marina in Ras Al Khaimah dedicated to recreational navigation, as all other small craft facilities are primarily for fishing boats. Due to limited track record, permitting risk was a concern at the beginning of the marina project. However, the process went smoothly and all approvals were obtained in time.

The marina construction contract was awarded to Majestic Jetties & Marinas as a design/build after a private tender process. Providing full performance specifications and detailed plans, along with the tender documents, is a proven practice to obtain fair competitive pricing while clearly establishing the expected quality of the end product. This results in a ‘closely managed design/build’ process. In some parts of the world, establishing the right roles for the marine contractors, dock supplier and utility suppliers can make a major difference in the process and may affect the outcome.

Experience shows that achieving the expected quality in all project details is a challenging goal, one that needs to be pursued every day until the construction is completed. The dock suppliers know best about the detailed design and opportunities of their products, while the engineer and owner’s technical representative play a key role in protecting the owner’s interests and facilitating the contractor’s work flow. Throughout the world, across cultures and legal jurisdictions, this practice is proven to deliver projects efficiently and to a high standard.

One area of focus for Lagoon Marina was the owner’s interest in the aesthetic quality of elastic anchoring in order to avoid the piles that are a typical sight in most marinas. Elastic mooring solutions are increasingly popular but can present specific technical and operational challenges which are important for the engineer to review and assess prior to implementation. Key challenges may relate to inadvertent restrictions to draft of vessels and higher range of movement in docks compared to

Custom design

Built around your needs

traditional piling. The review of design calculations and shop drawings by the owner’s engineer is a valuable stage in a well-managed design/build marina contract. Contractors and dock suppliers often identify efficient solutions, but sometimes they can also inadvertently reduce the performance of the end product. The designs or product alternatives are evaluated in terms of compliance with specifications, but also in the context of the physical conditions and expected performance.

A Hazelett elastic mooring system was deemed to be an effective way to meet the owner’s requirements for aesthetics and to be suitable for use in the given environmental site conditions.

The Lagoon Marina, which opened in early 2016 and is under ART Marine management, is the first within the Mina al Arab master plan. Future facilities within the project and elsewhere in the Northern Emirates will allow the growth of recreational navigation and nautical tourism in the region.

David Canfield ME, PE is a director of ATM and is based in Dubai. He can be reached on dcanfield@appliedtm.com

slipways, Wise Boat Hoists can travel throughout the boat yard or marina. They can even load trailers and trucks. At Wise we utilise only the best materials in the construction of all hoist components. Particular emphasis is made on increasing durability and reducing maintenance costs.

METSTRADE 2017 - PRODUCT HIGHLIGHTS

Seabin wins a 2017 DAME design award

The first commercial version of the V5 Seabin – an innovative marina-based collector of floating rubbish – was displayed by Poralu Marine in the Marina & Yard Pavilion at Metstrade 2017. The product not only attracted a continuous stream of visitors but secured a much coveted DAME design award in the Marina Equipment category.

Seemingly simple but nonetheless innovative and forward thinking, Seabin was developed by two Australian surfers Pete Ceglinski and Andrew Turton. Their awareness of the importance of clean oceans and increasing concerns about marine pollution set them into inventor mode; although not just to create a product but also to launch a philosophy.

Seabin, not surprisingly, is a bin that sits in the sea. It is fixed to a floating pontoon, submerged, and connected to a low power electric pump which creates a continuous current to attract floating waste to the collector. The waste is recovered in a bag, which is emptied and replaced by maintenance personnel as required. Each bag has a maximum sensible lifting load of 20kg (44lb).

A fine catch

As can be seen in any Seabin video – and the launch video in 2015 that attracted crowd funds for the first year of development has been viewed more than 200 million times – the product is a magnet for all kinds of floating debris. What is less obvious is that, in the midst of the daily rubbish, Seabin captures micro plastics; tiny 2mm

fragments of pollutants that are likely to escape most other systems.

Designed for sheltered waters in marinas, clubs and ports, the product should be strategically positioned in specific debris problem areas where wind and currents will push the flow of rubbish towards the bin. It should be checked twice a day. A percentage of oil can also be captured with simple oil absorption technology if the catch bag is customised for this purpose. As the technology develops, the amount of oil each Seabin can capture will increase.

Around the world