The technical magazine for those involved in the design, construction and refit of superyachts

EDITORIAL

EDITOR IN CHIEF

EDITOR | HOW TO BUILD IT

EDITORIAL CONTRIBUTOR

NEWS EDITOR

FEATURES EDITOR

FEATURES WRITER

WRITER

SOCIAL MEDIA MANAGER

CONTENT CREATOR

Francesca Webster

Justin Ratcliffe

Charlotte Thomas

Sophie Spicknell

Emma Dailey

Enrico Chhibber

Ellen Ranebo

Marina Vargas

Nick Smits

DESIGN PRODUCTION

CREATIVE DIRECTOR

GRAPHIC DESIGNER

Ivo Nupoort

Beatriz Ramos

INTELLIGENCE

HEAD OF INTELLIGENCE

RESEARCH ANALYST

DATABASE MANAGER

YACHT HISTORIAN

Ralph Dazert

Adil Zaman

Syrine Mellakh

Malcolm Wood

SALES & ADVERTISING

HEAD OF SALES

SALES MANAGER

SALES MANAGER

SALES MANAGER

SALES MANAGER

CLIENT SERVICE MANAGER

SALES ITALY

Marieke de Vries

Justus Papenkordt

Daniel Van Dongen

Charly van den Enden

Nuri Ozkaya

Johanna Borreli

info@admarex.com

CORPORATE

FOUNDER & DIRECTOR

TECHNOLOGY DIRECTOR

FINANCE DIRECTOR

Merijn de Waard

Fabian Tollenaar

Laura Weber

SuperYacht Times B.V. Silodam 256, 1013 AS, Amsterdam, The Netherlands 31 (0) 20 773 28 64 info@superyachttimes.com www.superyachttimes.com

Cover Images:

Amer 41 by Amer Yachts

Volvo Facility by Volvo Penta Leapher Yachts by Justin Ratcliffe

How to Build It is published by SuperYacht Times B.V., a company registered at the Chamber of Commerce in Amsterdam, The Netherlands with registration number 52966461. The magazine was printed in October 2024.

With the Cannes, Monaco and Fort Lauderdale shows behind us, November means it’s time for METSTRADE. Indeed, this issue of How to Built It is timed to coincide with the start of the 36th edition of the keystone B2B event in Amsterdam. In anticipation, we’ve gathered a selection of the latest product innovations from companies exhibiting at the ever-growing Superyacht Pavilion in an extended products section starting on page 85.

We have an intriguing double bill of in-build reports for you. Leapher Yachts is a recent brand in the Netherlands aiming to build its first 60-metre explorer yacht of 1,750 gross tons in just 26 months. I went along to the shipyard on the banks of the Rhine to check on progress and find out how it plans to complete the build so quickly.

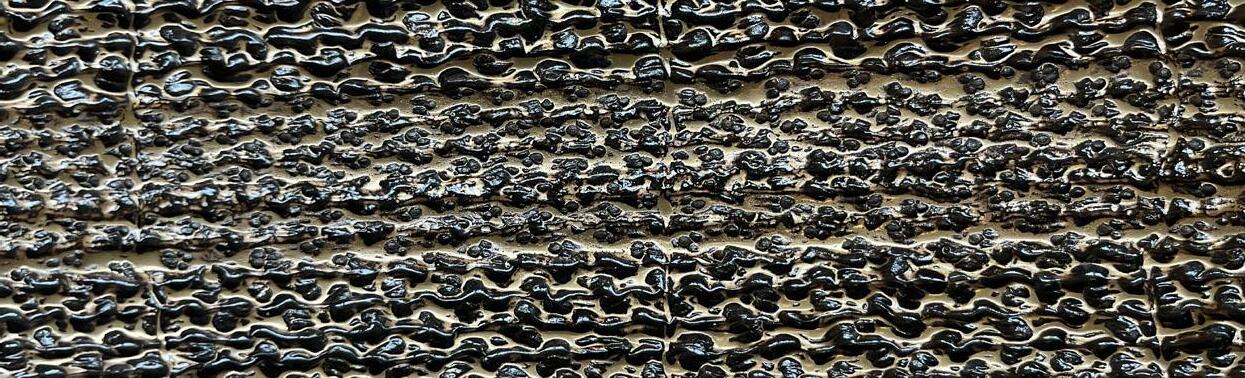

The second report comes from Plymouth, UK, where two brothers have embarked on an enterprising journey to transform a 50-year-old GRP sailing yacht in hideous condition into a luxury charter vessel. What’s more, they are doing it by employing the latest sustainable materials, technologies and build processes.

Just before the inaugural Asia-Pacific Superyacht Summit in Hong Kong last June, I popped over to Taiwan to visit Ocean Alexander. The composite builder has historically designed its yachts specifically with American users in mind and the US is by far its biggest market. But is the brand looking to widen its client base with the new Puro series by Italian designer Giorgio Cassetta?

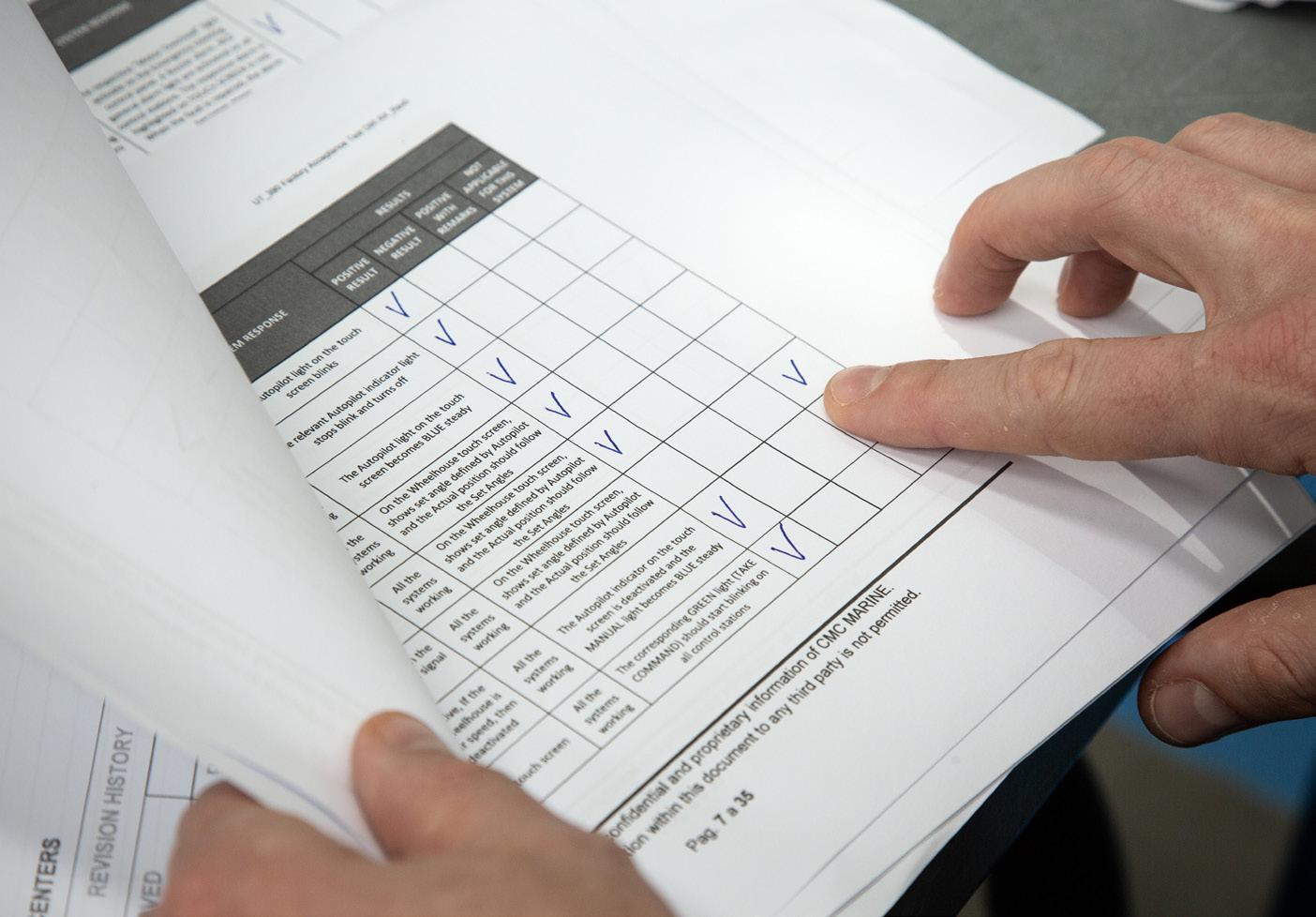

Back in Europe, we call in on CMC Marine near Pisa. The supplier of electric stabilisation and steering control systems has long dominated the domestic superyacht scene, and continues to expand with strategic partnerships and a new production site near Naples. Furthermore, since setting up a branch in the UK it has started to make inroads into the tough north European market.

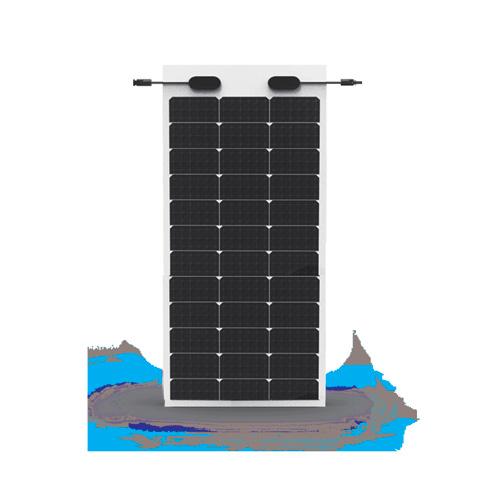

With winter fast approaching and summer holidays a distant memory for most of us, to finish off we thought we’d inject a little sunshine into your life by taking a look at solar energy. More specifically, at the current status of solar tech and why shipyards are happy to install it on the roofs of their facilities but rarely on their superyachts.

Enjoy!

Justin Ratcliffe - Editor

24 Business Brief: Eastern Promise

Asian shipyards have become a force to be reckoned with and Ocean Alexander in Taiwan regularly figures among the top 10 superyacht builders.

CEO in Conversation: Farsounder

Since founding FarSounder in 2001, Matthew Zimmerman has driven the technical development

and navigate

36

Build Report 1: Turning A New Leaf

Leapher Yachts in the Netherlands is rethinking engineering and production processes along commercial shipbuilding lines to build its first steel explorer yacht more quickly and efficiently.

51 Concept in Focus: Ulstein Thor

Since first unveiling is Thorium-powered Ulstein Thor design in 2022, the Norwegian company has continued to update and develop the concept. But will a nuclear-powered superyacht ever be feasible?

58 Build Report 2: Say it In Steel

We take a closer look at the 41-metre Amer Steel, the smallest in the new superyacht range from Permare that will be the first to carry Volvo Penta’s new IPS40 professional platform.

69 OEM: Control My Ride

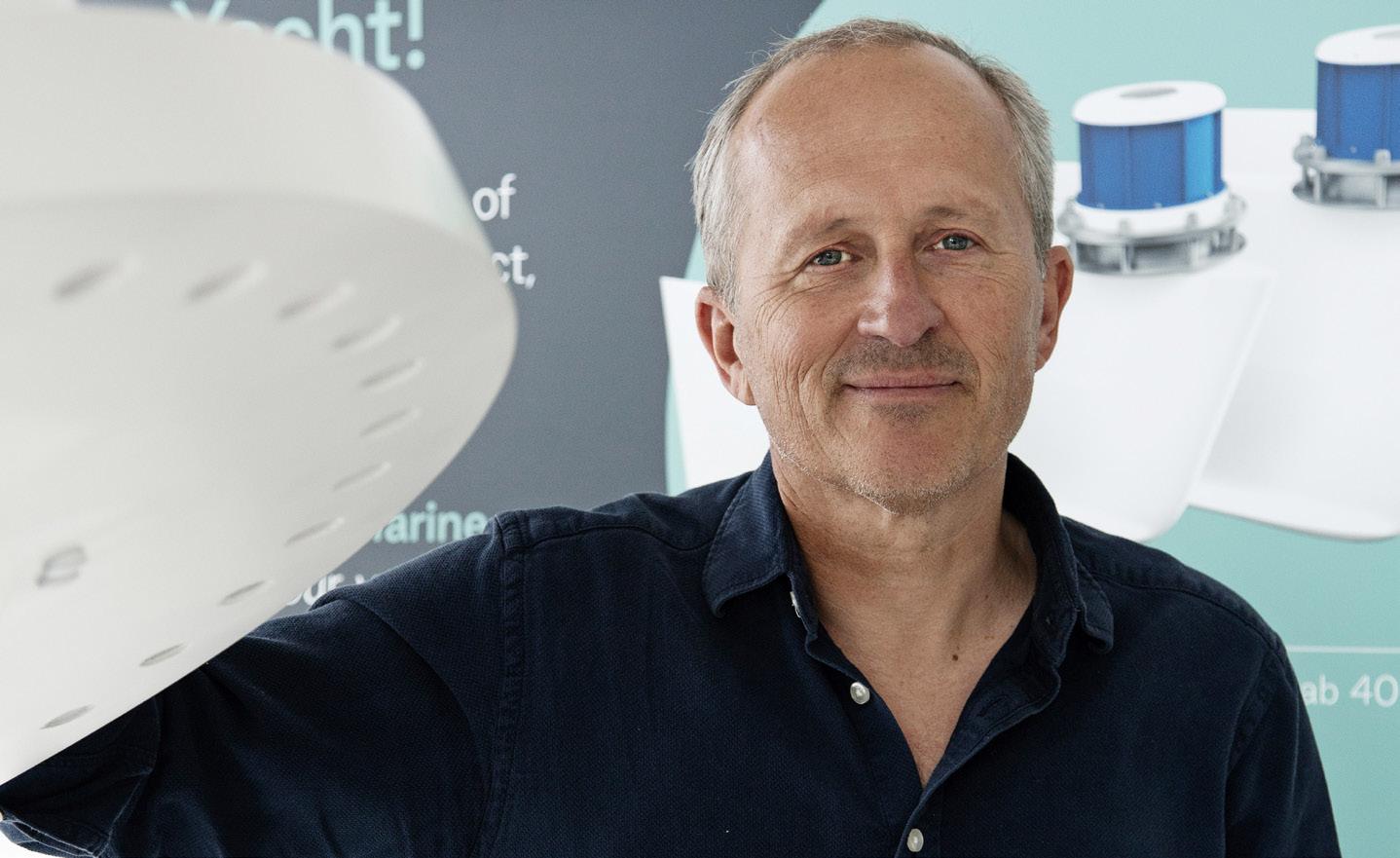

Celebrating its 20th anniversary next year, CMC Marine in Italy is 12 months into a three-year investment and expansion strategy centered around product innovation, production capacity and market offering.

79 Inside Angle: Jan-Pieter Braam

Owners’ rep, project manager and technical advisor Jan-Pieter Braam of JPMarine BV believes in effective communication, meticulous planning and strategic team management.

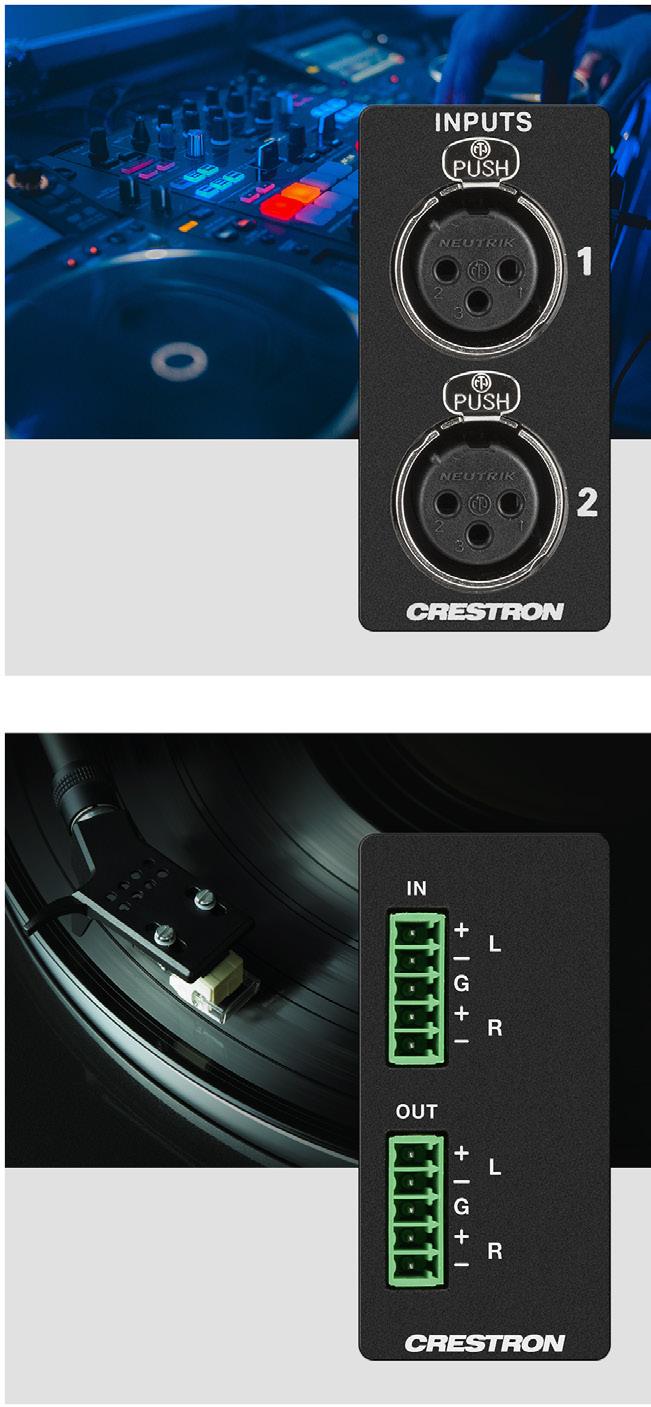

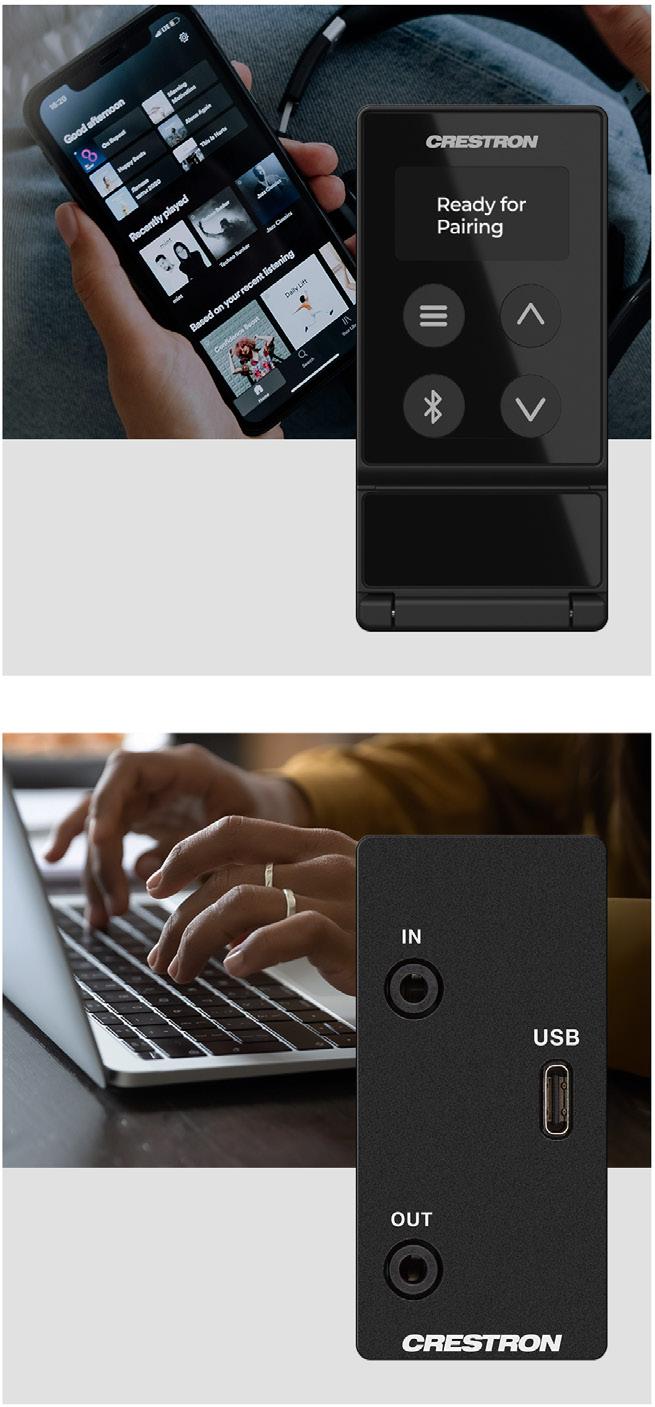

85 Industry Events: Superyacht Pavilion Spotlight

Just some of the innovative new products to watch out for at the 36th edition of METSTRADE in Amsterdam.

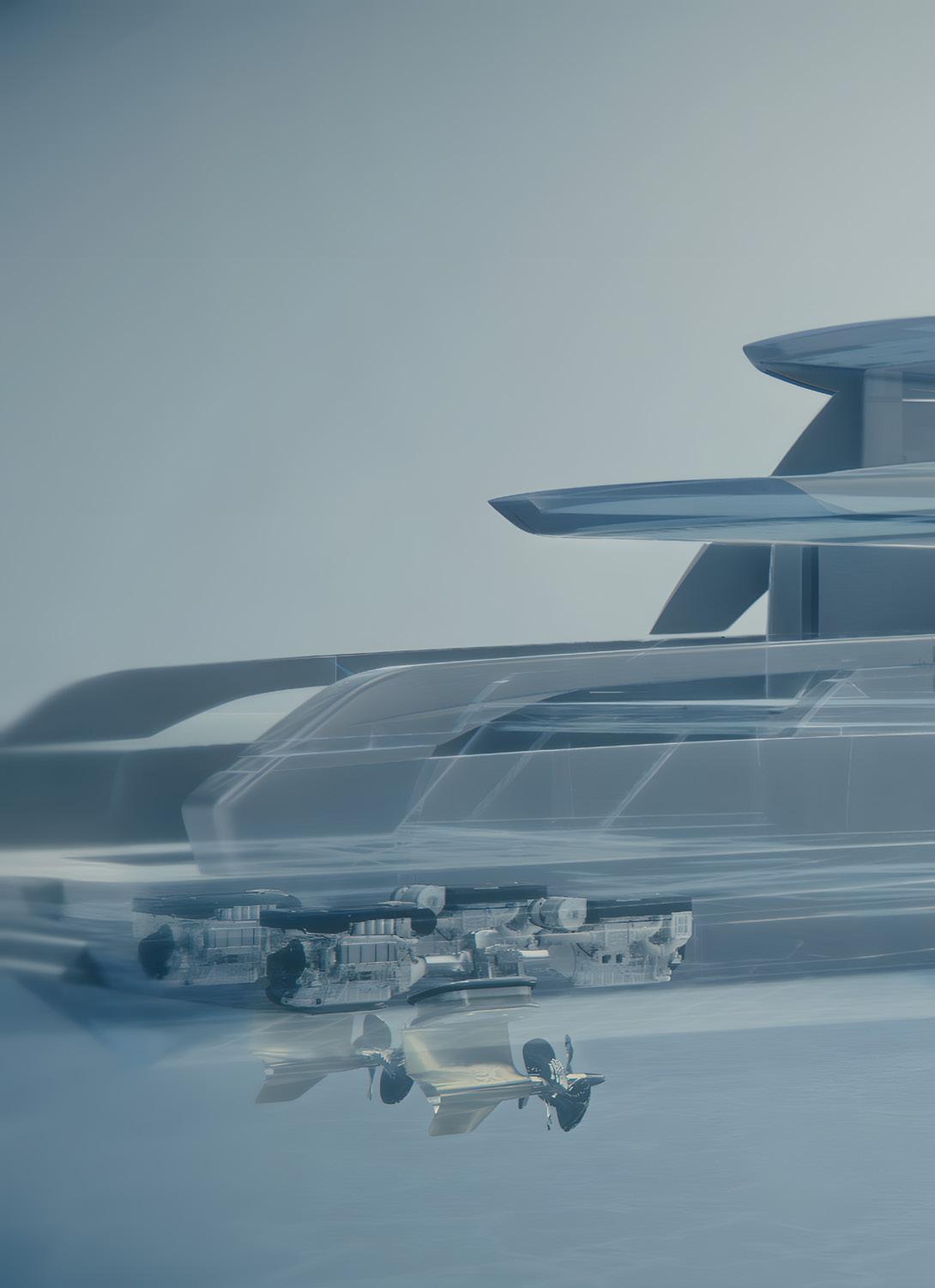

99 New Tech: Going Pro

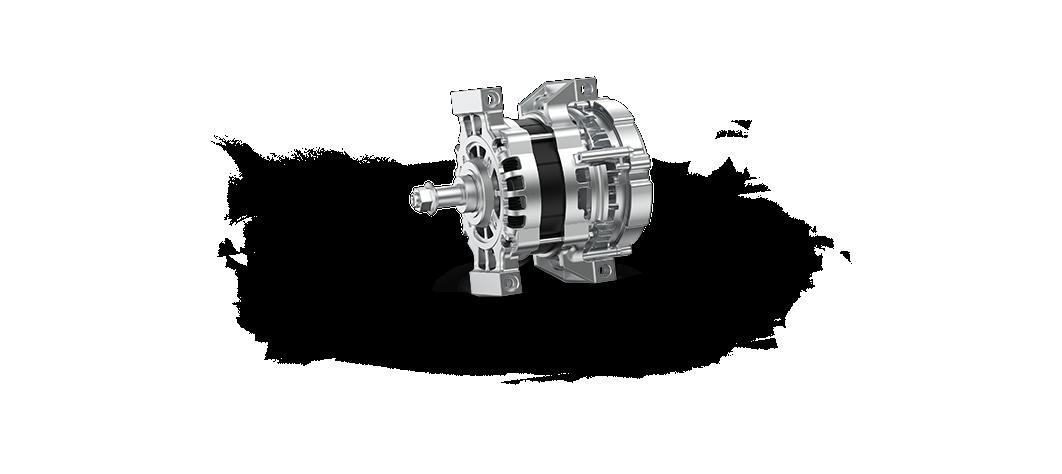

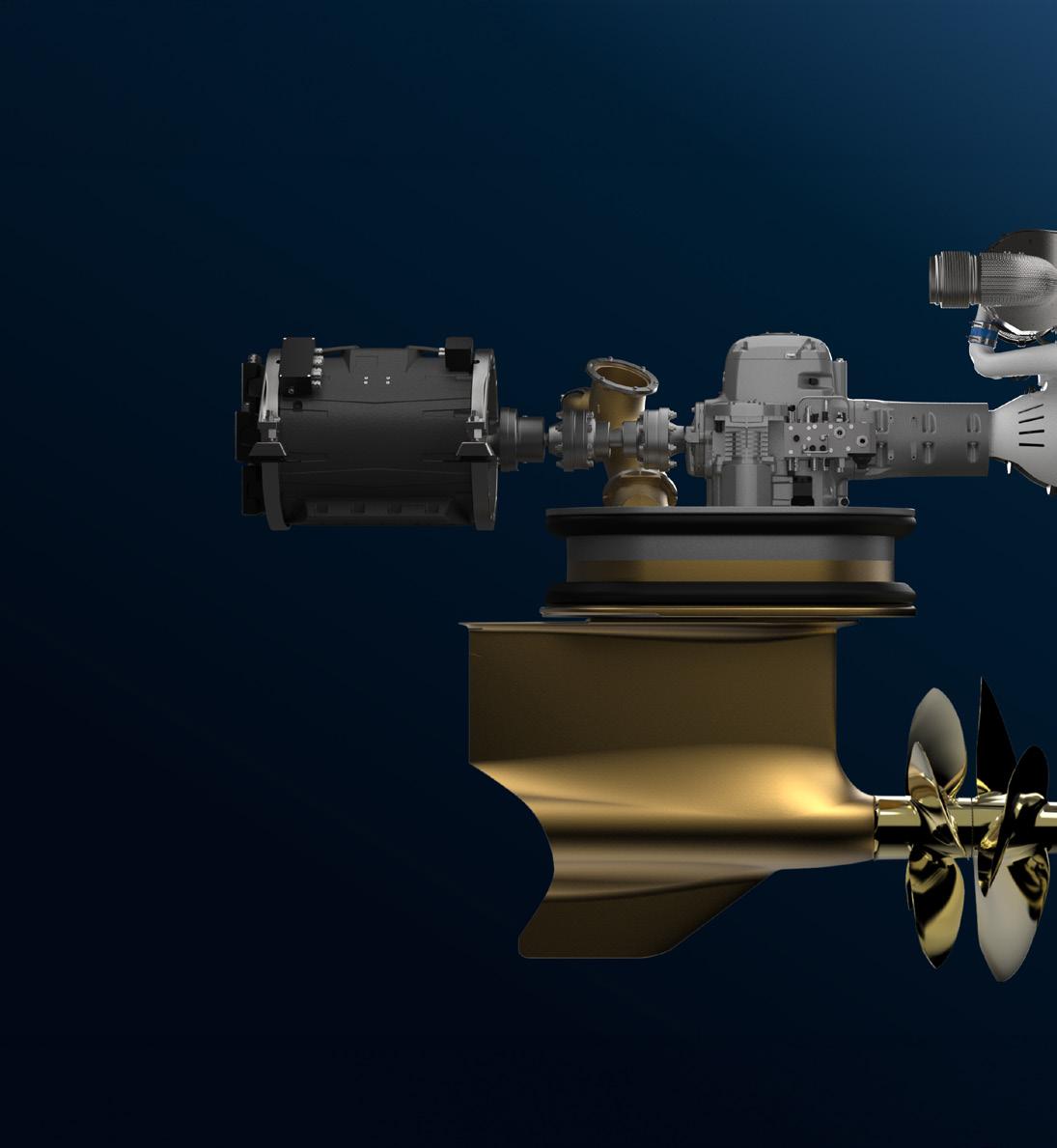

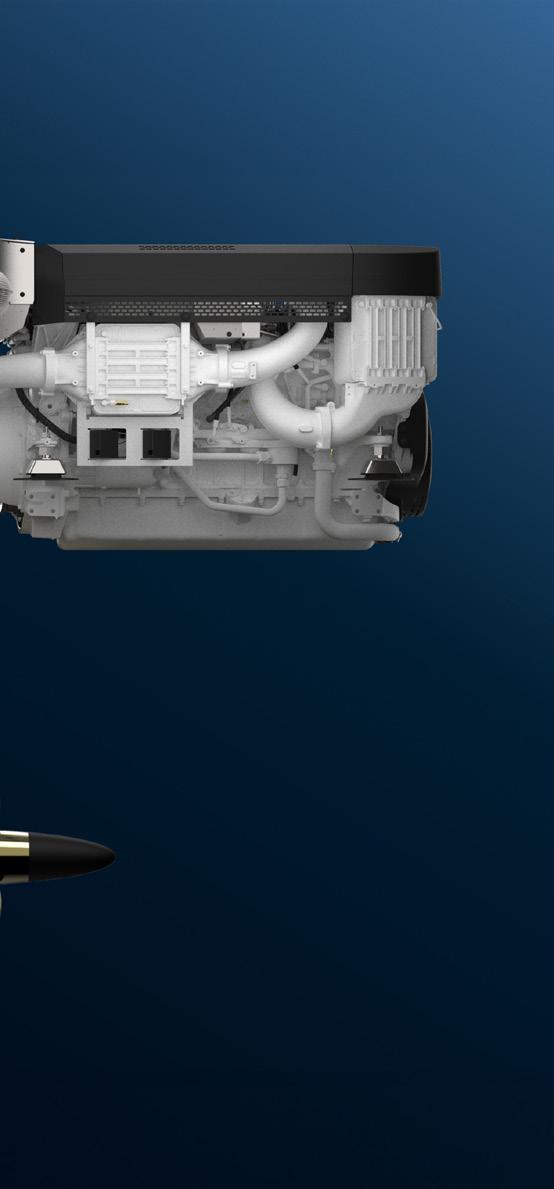

Volvo Penta’s new IPS professional platform takes the original concept, beefs it up for commercial use and aims it at yachts in the 40- to 60-metre size bracket.

107

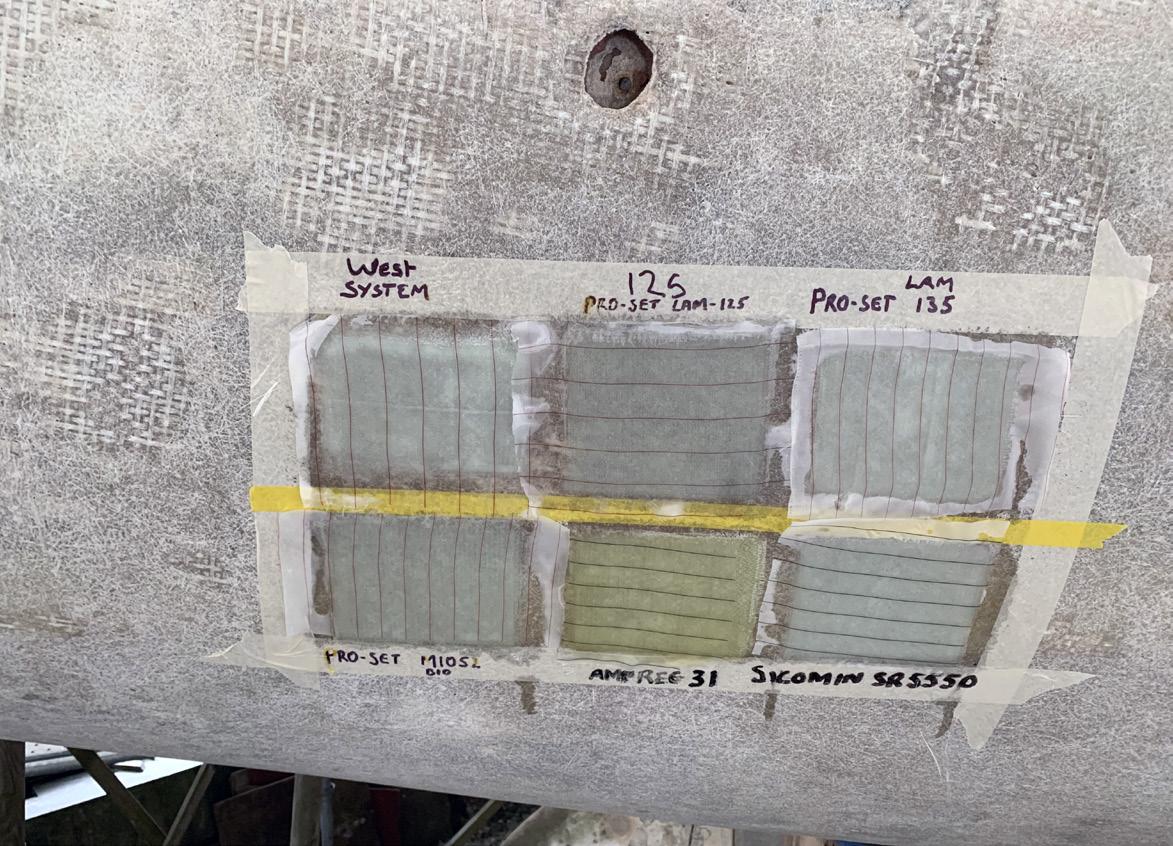

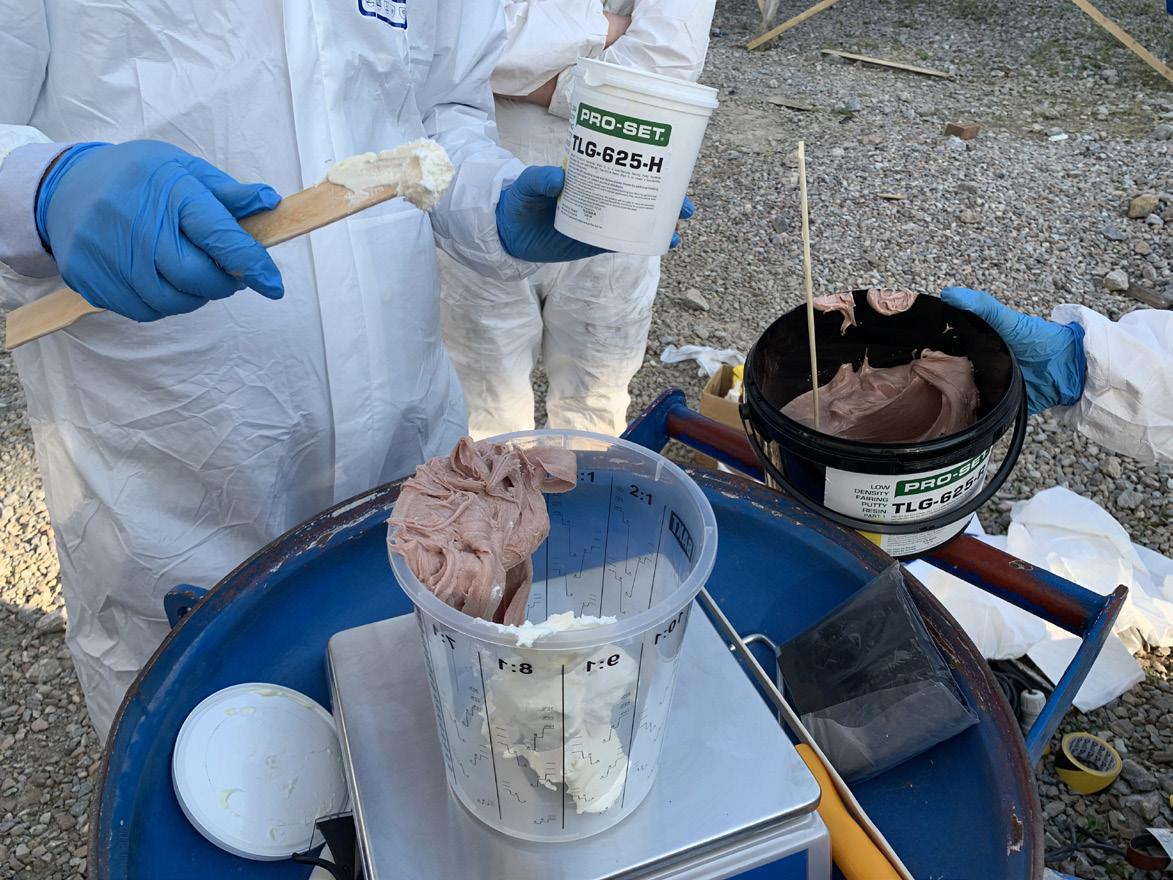

Refit & Conversion: A Voyage of Discovery

How do we deal with fundamentally eco-unfriendly GRP? The bold rebuild of a 22.77-metre sailing ketch in Plymouth, UK, is coming up with some innovative answers.

117 Rules & Regs: Builidng to the REG Code

Julian Smith, Principal Surveyor for Cayman Islands Shipping Registry and Red Ensign Group Yacht Code Secretariat, summarises the revised yacht code that came into effect on 1 July this year.

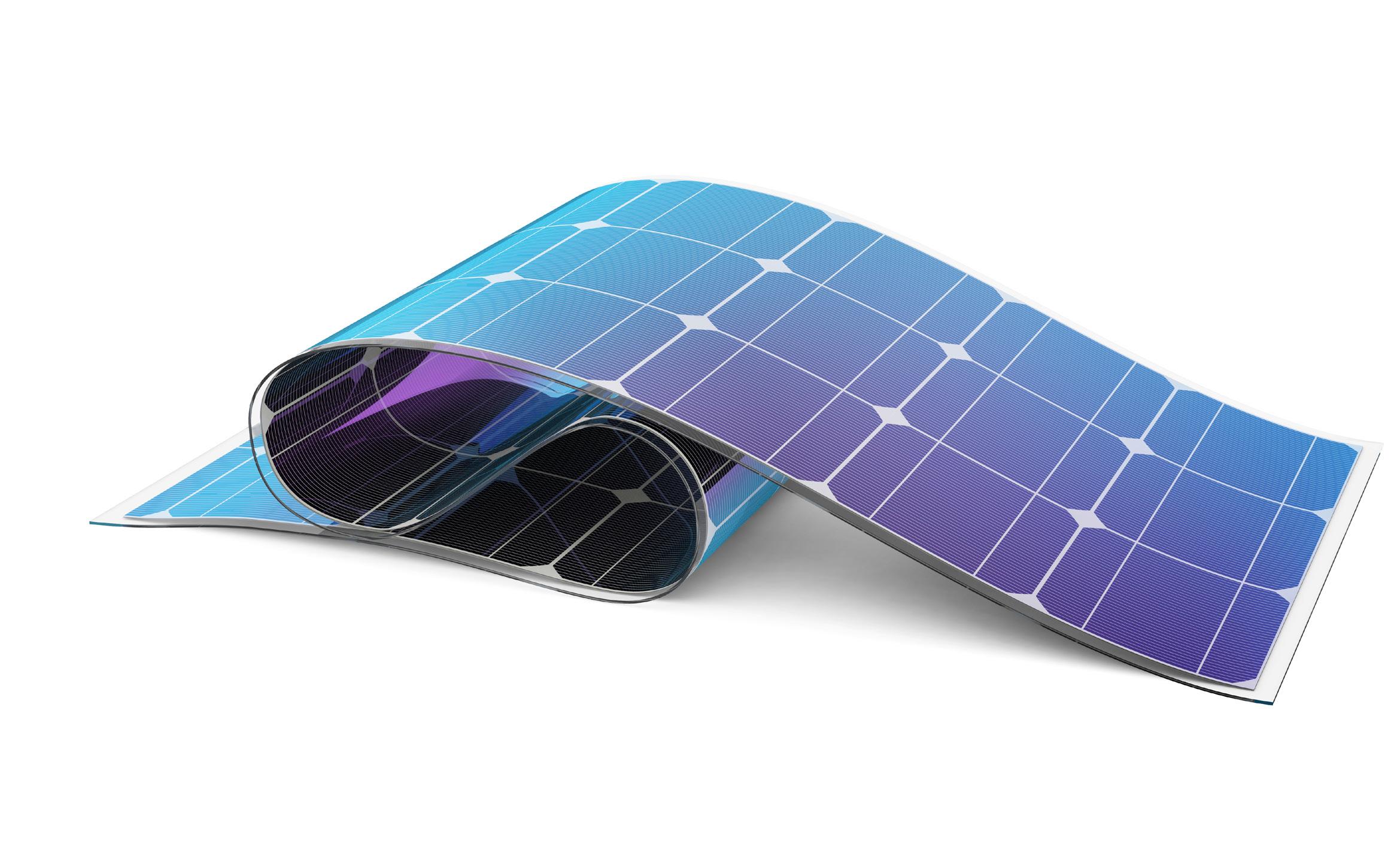

123 Sustainability: Let It Shine

What is the current status of solar tech and will it ever have its moment as a renewable source of energy aboard superyachts?

Volvo Penta has unveiled its helm-to-propeller hybrid-electric package, with delivery set to begin at the end of 2025. The D13 IPS hybrid-electric package comprises an electric motor and diesel engine that works in parallel on the same drive shaft, allowing for smooth Pure Electric drive mode, Hybrid mode, and seamless automatic power transitions. In Cross-Over mode, one diesel engine propels both drives to optimise efficiency and extend engine maintenance. Depending on the chosen drive mode, the system automatically controls whether the boat should be powered by the electric motor, the combustion engine, or both.

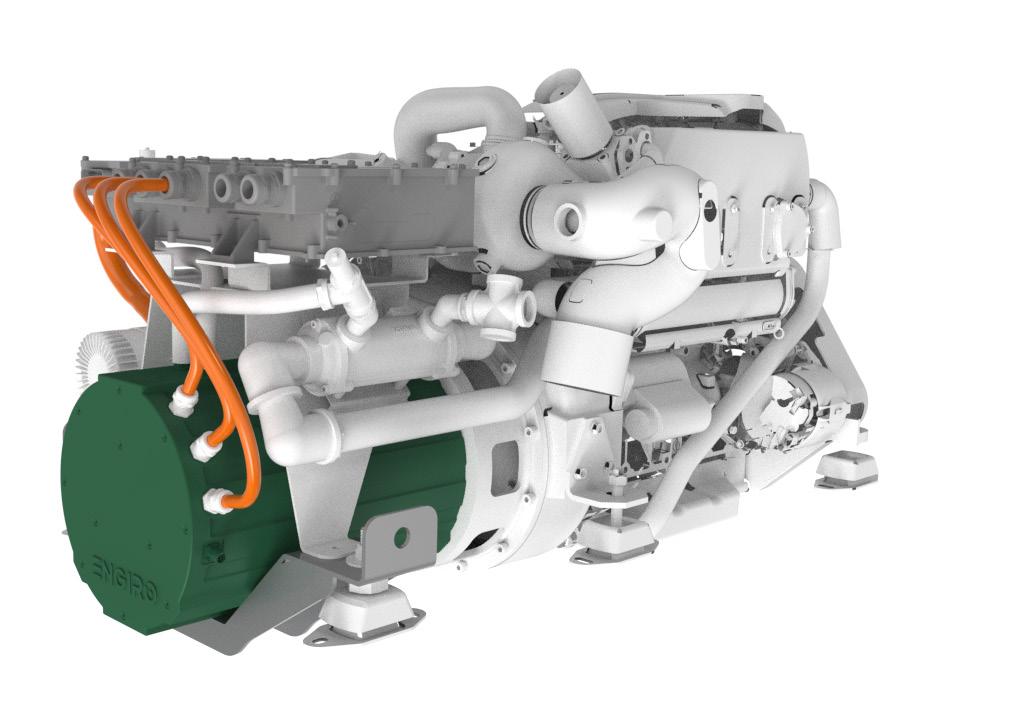

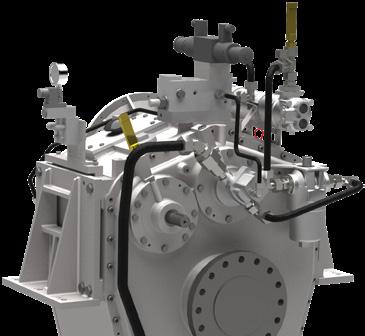

Volvo Penta also debuted its long-awaited IPS Professional Platform at the 2024 Monaco Yacht Show. Designed to deliver enhanced efficiency and performance, it is engineered with the flexibility to accommodate a range of power sources, including the potential for electric and hybrid configurations.

MIT.EQ (Marine Innovation Technology Equipment Expo) is a new international trade fair event for professionals in the marine industry with a focus on sustainable development and innovation in the sector. Designed as a meeting and networking place for shipyards, technology companies, accessories, services and solutions for the marine industry, the first edition will be held at the Rimini Exhibition Centre from 5-7 March 2025 in conjunction with KEY - The Energy Transition Expo dedicated to integrated technologies and solutions for energy efficiency and renewable energies in the Mediterranean area.

“The marine industry is a strategic sector for Italy and we believe there is room for a new vertical event dedicated to the entire industry,” says Marco Cecchini, Business Development Manager Italy & EU of Italian Exhibition Group (IEG).

“MIT.EQ will not only be a B2B trade fair, but also a speaking-platform to elevate the national and international debate on sustainable innovation in the sector.”

MAN Engines first presented its new MAN V12X engine series to a global audience at the Cannes Yachting Festival 2022. The newly developed V12 engine for yacht applications is now in serial production. For the first time the new series offers an output of 2200 hp (1618 kW) from 30 litres of displacement. Compared with the previous most powerful yacht engine from MAN Engines – the MAN V12-2000 with 2000 hp (1471 kW) – the displacement of the MAN V12X has been increased by more than five litres and the maximum torque from 6500 Nm to 7350 Nm.

A new coolant pump and a new thermostat housing provide the MAN V12X with an optimised coolant supply for long service life. The engine is also optionally available with an outer-skin cooling system instead of the closed coolant circuit. The cylinder head of the MAN V12X, which has also been optimised in terms of flow and cooling, is designed to meet the same development goal. In addition, the oil supply has also been modified by using new oil pumps and new oil coolers, as well as optimising the flow.

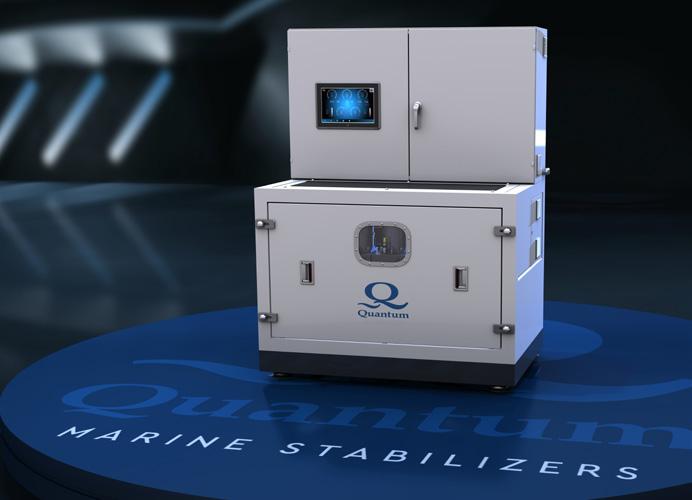

Quantum hopes to introduce a breakthrough in powering stabilisers with its new patent-pending F45 – Electric/ Hydraulic Hybrid Power System that draws on the best attributes of a traditional hydraulic power unit and the cleaner advantages of a direct electric drive system. After almost five years in development and months of testing, the first F45 System was installed on a refitted 47-metre Feadship.

Lloyd’s Register, RINA, DNV, Bureau Veritas, and ABS, announced the formation of the Yacht Safety and Environmental Consortium (YSEC) at the Monaco Yacht Show 2024. The consortium aims to enhance safety and environmental standards within the yacht industry, with a focus on yachts over 24 metres in length.

The new consortium is committed to driving forward the safety and environmental performance of yachts, promoting and advising on achieving the best practices in the industry. The yacht sector has a considerable need for a unified consortium of class societies, as yachts are not covered by the International Association of Classification Societies (IACS) in the same way other vessels are.

Stabilisers are big consumers of power, particularly at zero speed, with an operational profile that often generates large power fluctuations, causing a strain on the generators and the power grid. The F45 is able to manage power fluctuations, as well as store and recover power, through a proprietary flywheel solution called MESS (Mass Energy Storage System). Furthermore, excess energy from fin deceleration (zero speed) or hydrodynamic force (underway) can be recovered and stored for future use through Dynamic Energy Recovery. At the 2024 Monaco Yacht Show, Quantum also showcased the E-Fin, its first fully electric stabilisation system. “The product is designed for a fin size in the three to five-metre range, which we refer to in terms of fin square-metres, and can be easily retrofitted to a Quantum XT.” says John Allen, owner of Quantum Marine Stabilizers.

“LR is proud to work with our class peers to establish the Yacht Safety and Environmental Consortium,” says Engel-Jan de Boer, global yacht segment director at Lloyd’s Register . “The collaboration is a shared vision that will enable the industry to address safety and environmental challenges more effectively. By working together, we can set new benchmarks and ensure best practice across the industry.”

Following the successful launch of the Awlgrip® 3D Color Visualizer, AkzoNobel has added two further digital capabilities to its technical service offer. The new innovations include RealWear, a camera headset that will change the way applicators worldwide can access support, and Virtual Reality (VR) Spray Gun technology. Both RealWear and the VR Spray Gun are compatible with the Awlgrip, Interlux®, International® and Sea Hawk® brands and will help train and upskill both the current and future generation to deliver superior yacht finishes, globally.

The RealWear camera headset is a safe and hands free visual assistant tool that connects applicators directly to the AkzoNobel team for real-time technical support. Users wearing the RealWear glasses can stream video and take pictures, allowing the AkzoNobel technical team to observe issues and offer support in real time from anywhere in the world. The software can be used via mobile and is compatible with both Apple and Google operating systems.

Tijssen Elektro, the yachting navigation and communication specialist, part of the Alewijnse Group, is opening a dedicated service location in Palma de Mallorca to service motor and sailing yachts of all sizes. The new facility will complement the Barcelona and La Ciotat service facilities.

The long term partnership between MB92 and the yacht paint specialist GYG Limited has taken another step with the announcement that MB92 intends to acquire the company. GYG Limited operates primarily under the brands Pinmar, Pinmar Yacht Supply and Technocraft, and has worked with MB92 on various refits for the past three decades. MB92 announced that the decision was made in order to enhance its in-house capabilities in a competitive market and to ensure the highest quality of service.

GYG Limited will continue to operate under its established brand names, with the integration into MB92 aiming to strengthen its growth potential.

In addition, Ronald Bunders, nav-com designer and installer, has returned to the company after a period with A+T Instruments and will be joining the Palma facility. “Palma de Mallorca is the best place to provide services to large yachts, particularly sailing yachts, in the Mediterranean region,” explains Robert Brugman, General Manager at Tijssen Elektro Zeeland. “With its strategic location off the Spanish coast, there is constant demand for servicing and refits on sailing and motor yachts, with peaks in the spring and autumn. After the Monaco Yacht Show, which takes place in late September, many yachts dock in Palma de Mallorca. There they can either finalise preparations before crossing the Atlantic to the Caribbean or stay there for the winter for maintenance or larger refits. Then, in the spring, this trend goes into reverse.”

New projects in early stages of construction that present opportunities for OEMs, suppliers and subcontractors.

The explorer yacht will feature exterior and interior design, as well as naval architecture by Marcello Penna. As for accommodation, she will have six staterooms for guests and four for crew members. The owner’s suite features a private terrace that is strategically positioned on the main seck. This deck also hosts a full-beam VIP cabin, while the four guest staterooms are located on the lower deck. The captain’s suite is ideally situated on the bridge deck adjacent to the wheelhouse. Additionally, a massage room on the upper deck serves dual purposes, functioning as an optional single cabin for crew members or guests.

LENGTH: 37.5-metres BUILDER: Cantieri di Pisa GT: 385 GT COUNTRY OF BUILD: Italy DELIVERY YEAR: 2026

NAVAL ARCHITECTURE: Marcelo Penna EXTERIOR DESIGNER: Marcelo Penna

INTERIOR DESIGNER: Marcelo Penna

The first ISA Viper 120 motor yacht sold to an American client in July, with Zarpo Yachts introducing the buyer. With a hull and superstructure in composite with carbon fibre reinforcements, the ISA Viper 120 yacht features a sea-level beach club fitted with a multipurpose transformer serving as both a bathing step ladder and gangway. Located two side steps away is a spacious sun pad facing aft as well as a lounge consisting of sofas and a coffee table.

LENGTH: 37.7-metres BUILDER: ISA Yachts GT: 300 GT COUNTRY OF BUILD: Italy DELIVERY YEAR: 2026

NAVAL ARCHITECTURE: ISA Yachts EXTERIOR DESIGNER: Fulvio De Simoni

INTERIOR DESIGNER: Fulvio De Simoni

Baltic Yachts have unveiled the details of their first multihull project, a 32.9-metre blue water cruising catamaran, which was sold in June of this year. She is due to begin construction in October and will be delivered to her owner in the summer of 2027. The full carbon yacht will have the ability to regenerate electricity through her propeller when under sail and will feature pivoting centre boards that allow for exploration through shallow waters.

LENGTH: 32.9-metres BUILDER: Baltic Yachts GT: 250 GT COUNTRY OF BUILD: Finland DELIVERY YEAR: 2027 NAVAL ARCHITECTURE: Berret Racoupeau Yacht Design EXTERIOR DESIGNER: Berret Racoupeau Yacht Design INTERIOR DESIGNER: Jamie Bush & Co

She is the first yacht from the new Turkish that has a range of aluminium yachts spanning from 24-metres to 56-metres in length; the brand’s first 42-metre model, the GX42 RPH, is currently in-build. She will feature a hybrid propulsion, a smart hull design and solar charging. Construction of the first 42-metre GX42 is underway, as the keel laying ceremony took place on 1 June 2024, and more than 50 percent of her hull has already been welded.

LENGTH: 42.1-metres BUILDER: GX Superyachts GT: 353 GT COUNTRY OF BUILD: Turkey DELIVERY YEAR: 2026 NAVAL ARCHITECTURE: NAMES by Francesca Rogantin EXTERIOR DESIGNER: Marco Casali Too Design INTERIOR DESIGNER: Marco Casali Too Design

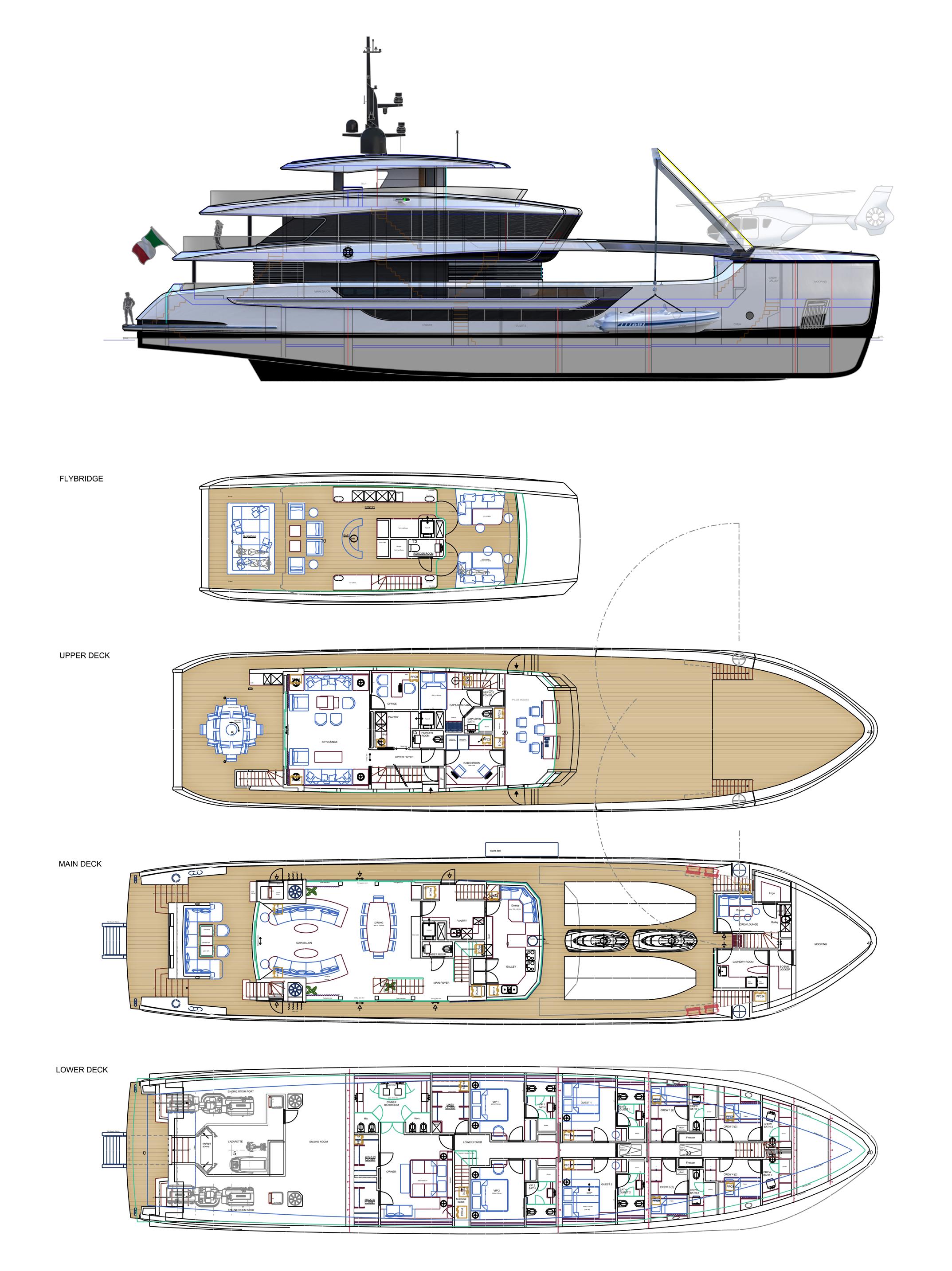

Announced during Cannes with the first hull sold before the show, the tri-deck explorer features a bold, yet strong exterior design, geometrical aesthetic. The yacht can accommodate up to 10 guests across a five stateroom configuration, with her owner’s suite situated on the main deck and her remaining four staterooms located on the lower deck. RAW will be powered by twin Caterpillar IMO tier III engines, with an expected top speed of 13 knots and a cruising speed of 11 knots.

LENGTH: 31.08-metres BUILDER: CdM GT: 250 GT COUNTRY OF BUILD: Italy DELIVERY YEAR: 2026 NAVAL ARCHITECTURE: N/A EXTERIOR DESIGNER: Cassetta Yacht Designers INTERIOR DESIGNER: N/A

Project Iron Man is primarily characterised by her dedication to spacious outdoor entertaining spaces to support a multi-generational family, and allow for scenic surroundings similar to that of the family’s current Benetti yacht.

LENGTH: 80-metres BUILDER: Benetti GT: 2,050 GT COUNTRY OF BUILD: Italy DELIVERY YEAR: 2028

NAVAL ARCHITECTURE: Benetti EXTERIOR DESIGNER: Cassetta Yacht Designers INTERIOR DESIGNER: N/A

Riva’s largest ever yacht, sold in the summer and unveiled at the Monaco Yacht Show, will be delivered in 2028. The yacht has a steel hull and aluminium superstructure. Defined by her technologically advanced solutions, Riva 70 Metri will feature the latest generation hybrid propulsion, heat recovery technology and a PTO/PTI system, setting an example for ecofriendly yacht production for the Ferretti Group.

LENGTH: 70.5-metres BUILDER: Riva GT: 1,350 GT COUNTRY OF BUILD: Italy DELIVERY YEAR: 2028 NAVAL ARCHITECTURE: Riva

EXTERIOR DESIGNER: Officina Italiana Design (Mauro Micheli) INTERIOR DESIGNER: Officina Italiana Design (Mauro Micheli)

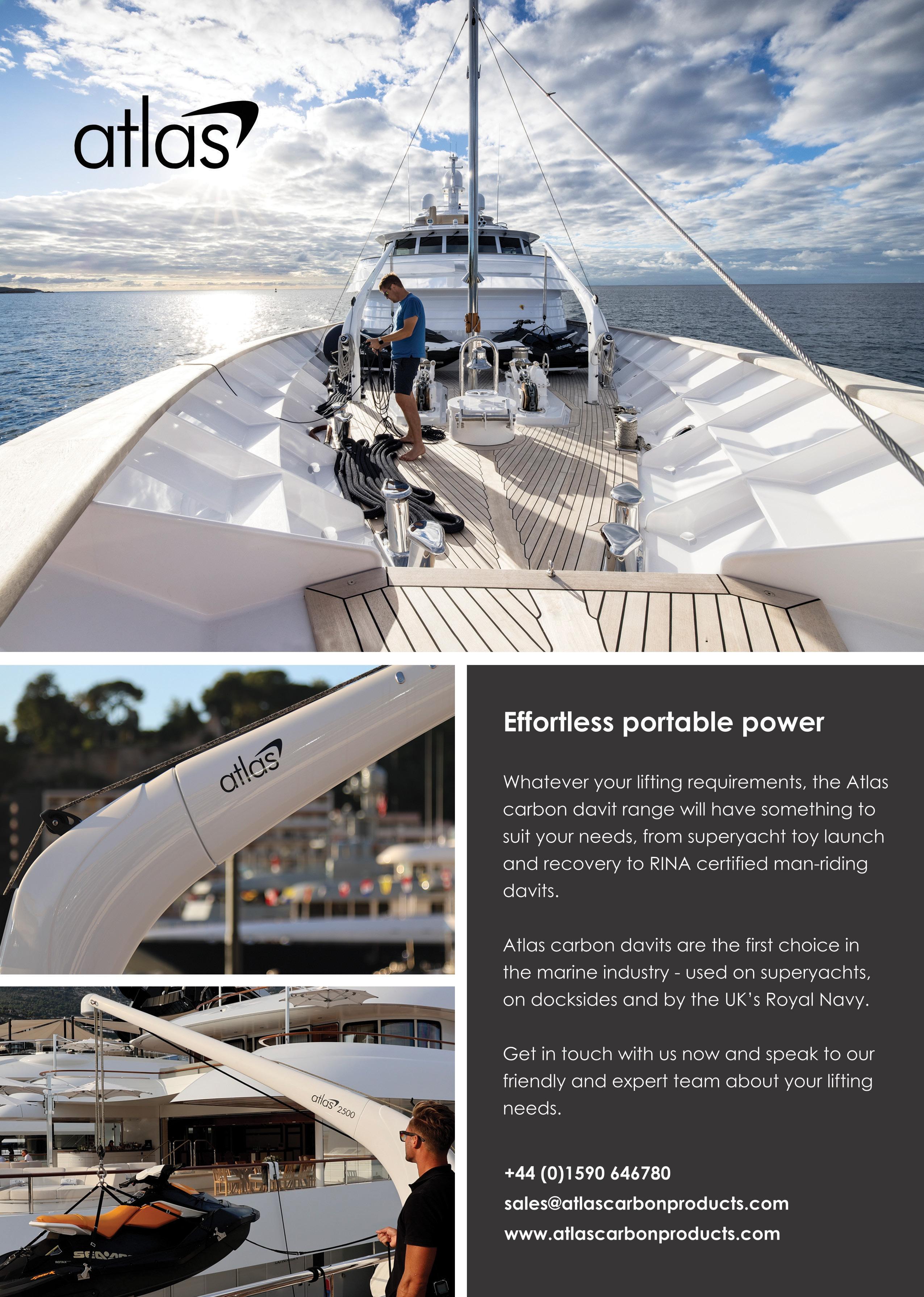

Advertisement

The marine stabilisation industry has made significant advancements in recent years, with Quick Group leading the way through its MC² brand. Andreas Karlsen, Quick Group’s Chief Commercial Officer, shares how MC² is transforming boat stabilisation technologies.

MC² originated when Quick Group acquired a small company that developed gyro stabilisers. Building on this foundation, Quick Group expanded the MC² line to include a wide range of gyro stabilisers named Quick Gyro, two series of trim tabs, Intercepta IN Series trim tabs and Intercepta X Series trim tabs, and Viator fin stabilisers. Together, these technologies create an integrated solution for yacht stabilisation, setting MC² apart in the marine industry.

The unique strength of the MC² system is its ability to integrate multiple stabilising technologies. Whether the yacht is in motion or at anchor, the system uses AI-driven algorithms to anticipate and adjust to changing conditions, optimising fuel efficiency and overall performance across the three stabilisation methods.

Karlsen emphasises the main advantage of MC² lies in its integration: "Our goal is to make gyro stabilisers, interceptors, and fins work as a unified system," he says. “Unlike competitors, MC² is the only system that combines all three stabilisers, resulting in better performance and smoother boating, aided by advanced algorithms and artificial intelligence” and continues "When interceptors, gyros, and fins work together, the result is a significantly improved experience. Our algorithms ensure all systems communicate and respond as one, enhancing stabilisation and efficiency."

This approach addresses the growing demand for integrated solutions rather than standalone technologies. Since the launch of the first Quick Gyro stabilisers in 2017, interest in MC²’s system has increased among customers seeking comprehensive systems for both refits and newbuilds. The integration of these technologies not only improves stabilisation but also enhances fuel efficiency and vessel performance.

A key innovation in the MC² line is its interceptor technology, which has two ranges: the Intercepta IN Series trim tabs and the Intercepta X Series trim tabs. The IN series is designed for easy installation and it has an integrated electric actuator, while the X Series allows for customisation in size, making it ideal for bespoke builds and the motor is mounted inside the hull.

A standout feature of the MC² Intercepta is its versatility in standard or custom installations depending on the series chosen, designed specifically to provide more installation options. For production shipyards, the IN Series offers a straightforward, easy-to-install solution. In contrast, the X Series is fully customisable, both in length and in engine position, catering to the specific design and performance needs of larger or more complex vessels.

"In large-scale production, the MC² Intercepta Series provides a consistent and reliable solution," says Karlsen. "For high-end, custom yachts, the X Series is customisable to meet the exact requirements of each vessel."

The official mass-market release of the MC² Intercepta is planned for late 2024, following months of extensive testing and final refinements. While still in development, the product has already attracted significant interest from the marine industry.

"Since we introduced the MC² Intercepta at the METS Trade Show, we’ve seen a lot of excitement from the market," says Karlsen. "There’s real demand for integrated systems, and we’re eager to launch a product that will enhance vessel performance worldwide."

Quick Group's dedication to quality is reflected in its thorough testing process. The company owns two demo boats, a Nimbus T11 and a Falcon 80, where they rigorously test all MC² systems in real-world conditions. This ensures the products meet the highest performance and reliability standards.

"Testing is critical for us," says Karlsen. "We don’t just rely on internal evaluations; we work closely with customers, whose feedback helps us refine and improve our products."

Quick Group's MC² line stands at the forefront of marine stabilisation technology, offering an integrated solution combining Intercepta trim tabs, Viator fin stabiliser, and Quick Gyro Stabilizer. With a strong focus on innovation, customisation, and system integration, the MC² brand is set to revolutionise the marine industry.

To find out more: https://quickgroup.com/mc2/

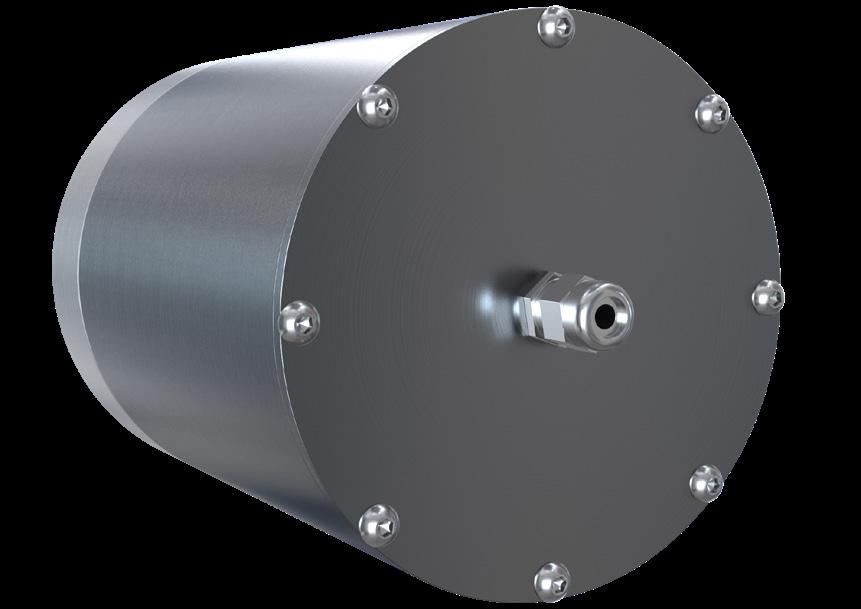

Specialising in azimuth thrusters, bow thrusters, and control systems, Veth Propulsion in the Netherlands has become a trusted name in the maritime sector by offering custom-engineered propulsion solutions. Founded in 1951 and acquired by American firm Twin Disc in 2018, Veth has expanded its global reach, working across multiple sectors including yachting, inland shipping, and offshore services. The luxury yachting segment, however, accounts for 1520% of the company’s business. Diesel-electric superyachts equipped with Veth thrusters include Rossinavi’s 59.4-metre Akula, Admiral’s 75-metre Kenshō, and Feadship’s 84.2-metre Obsidian

At the 2024 Monaco Yacht Show, Veth Propulsion showcased their ELITE™ thruster series, its latest range of thrusters designed to meet the needs of superyachts.

The 360° thruster combines Veth’s Contra Rotating technology, Rolla's class S propellers with the successful Integrated L-drive thruster, distributing power between two propellers, reducing the overall diameter and minimising noise and vibration – two key concerns for yacht owners who prioritise comfort and quietness onboard. The thrusters are compatible with yachts from 30-120m+ and have a power output range from 150 up to 2000 kW per thruster. On top of that, Veth is exploring the possibilities for a bigger model, providing 2800 kW per thruster.

“We have adapted and refined a concept we've successfully utilized for decades in commercial applications—our contra-rotating propellers—to specifically meet the performance and noise reduction standards of the yachting industry.” says Navneet Chadha, Veth’s R&D hydrodynamic engineer. While not exclusive to Veth, this contrarotating propeller system is what differentiates its thrusters, with the configuration improving thrust efficiency by reducing the rotational energy in the water flow that is typically lost in conventional single-propeller thrusters. This results in a more efficient propulsion system, particularly at higher speeds, while the CFD-optimised strut and customised propellers enhance overall efficiency.

Veth’s commitment to reducing onboard noise has been a key driver in the development of the ELITE™ thruster series. This was made possible, in part, through a collaboration with Rolla SP Propellers, a leading manufacturer of propellers that meet the stringent "S" Class

over Underwater Radiated Noise (URN) and its effects on marine ecosystems. The company is actively investigating its Elite systems to ensure they operate quietly, both onboard and in the surrounding waters, reducing their environmental impact.

"We have undertaken comprehensive testing, including both simulations and real-world trials," says Navneet. "Our thrusters have been thoroughly model-tested at several leading European research institutions and are now undergoing validation on full-scale yachts. Additionally, we have carefully compared the results from our simulations with actual performance data gathered from these trials to ensure accuracy and reliability."

Unlike the commercial marine sector, yachts have unique demands in terms of available space for technical areas, more so now that beach clubs have become a staple of yacht design, limiting the volume available for the technical deck below. The ELITE™ thruster series has been specifically designed with a compact build-in height to free up space.

Looking ahead, Veth is investing in real-time monitoring and optimisation systems working closely with owners’ teams regarding noise and vibrations. These optimisations have resulted in the minimisation of pressure pulses caused by the rotating propeller blades as they pass near the hull of the vessel, which are one of the main causes of noise and vibration. Known as "hull-excited vibrations," Veth’s research engineers have also optimised the shape of the propeller and components, such as the headbox, to reduce these pulses, resulting in quieter operations.

With a commitment to providing bespoke solutions, Veth Propulsion works closely with designers, naval architects, and engineers to ensure its products meet the unique requirements of each yacht. This approach enables the company to offer customisable options, from propulsion power to aesthetic considerations.

In response to the growing focus on sustainability, Veth Propulsion has also been working to integrate electric technologies into its product range. “As hybrid propulsion becomes more widespread,” says Simon Langstraat, teamlead sales at Veth, “Veth thrusters are designed to integrate with a range of power sources – from diesel-electric to emerging hydrogen and methanol systems that may become standard in the future.”

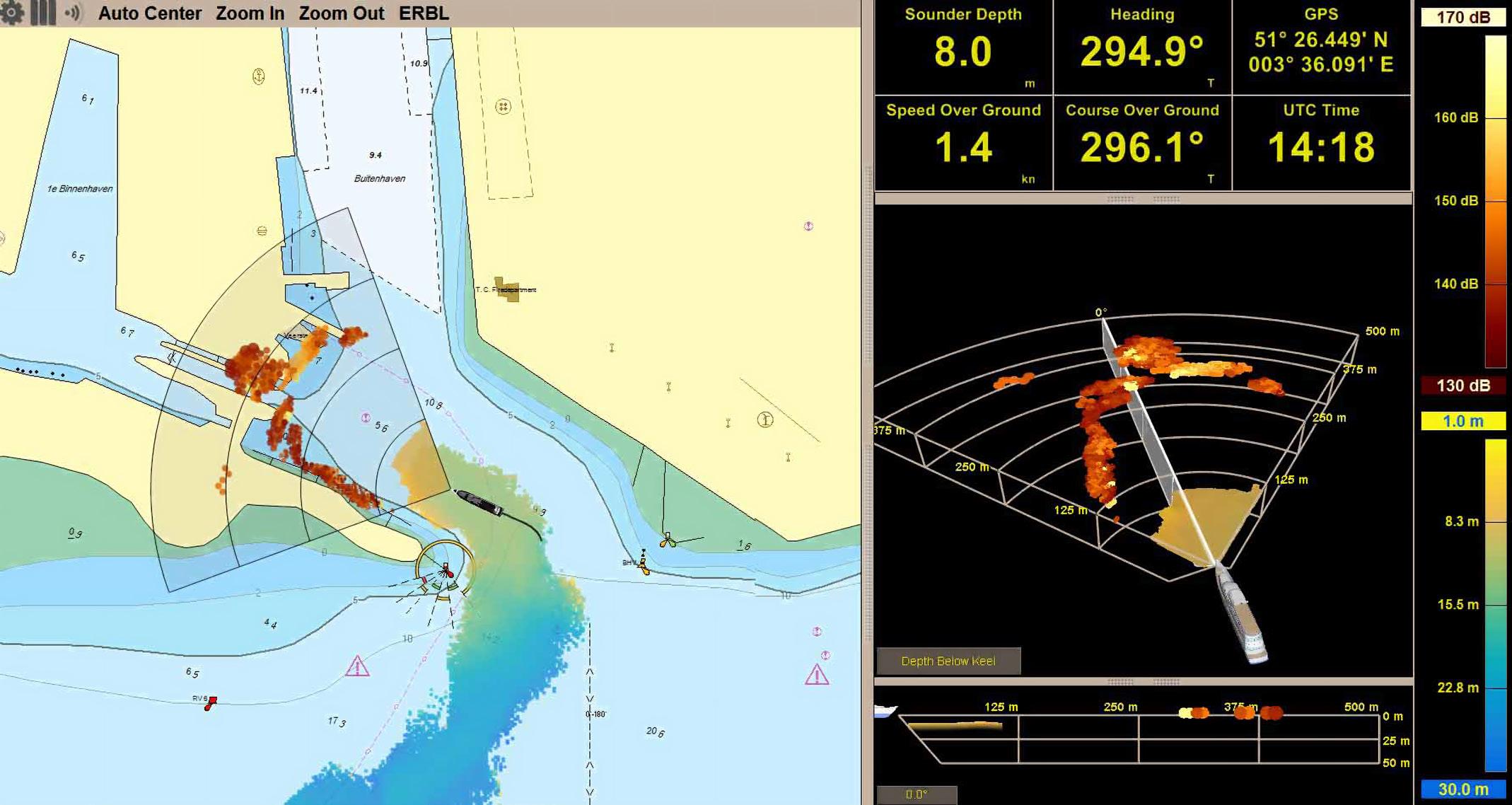

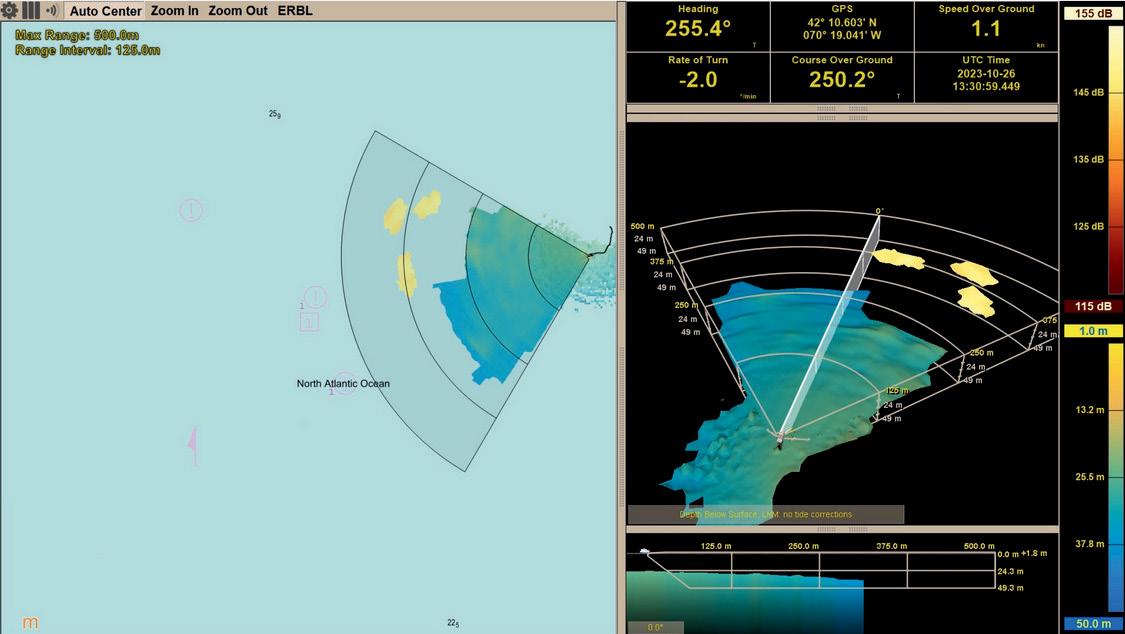

Rhode Island-based sonar technology developer FarSounder set out with the mission to reduce whale strikes by yachts and superyachts. Over the last 23 years it has expanded the scope of its capabilities, recognising the value of Forward Looking Sonar (FLS) in uncharted or poorly charted regions. CEO Matthew Zimmerman shines light on how the technology has developed.

BY FRANCESCA WEBSTER

What was the origin concept of FarSounder?

During my university studies there was a major oil spill incident caused by a barge hitting a rock near Rhode Island, and around the same time I became aware of the high number of whale deaths being caused by ship strike. I began to think that there must be a technology to prevent vessels from hitting rocks and whales, but after reviewing the market discovered that there was no existing product designed for that application. Vessels have many sensors onboard – GPS, radar and depth sonar being the most common – none of which give you accurate real-time information about transient objects or shifting underwater scapes such as sandbanks. So we set out to develop a product that filled that gap.

Did you lean on pre-existing technologies when developing the FarSounder FLS?

It was more complex, more expensive and took longer than we initially thought. Globally there are very few individuals with expertise in sonar and marine acoustics development outside of the military and academia. Even then, most of the developments are incremental changes to legacy systems, but no one ever set out to use sonar to solve issues relating to shallow-water navigation. Everything had to be developed in-house, from circuit board design, software development and engineering to firmware and the mechanical design of the products. We contract manufacture of all of the components from US suppliers, but do all of the final assembly and testing in-house. Although the company was founded in 2001, we didn’t start supplying our products until 2005, which tells you a bit about the complexities.

What is the sonar made from and how is it installed on yachts?

We offer three different models, and their sizes vary based on the model. Our largest model, which has the longest range, features a transducer array that's approximately 9 inches tall and 14 inches wide. The housing for this model is made from 316 stainless steel, a strong and durable material that’s also quite expensive. We chose this material because we want to create ship-grade equipment, not recreational or cheap plastic products, for robustness and long-term reliability. Inside, we use standard off-the-shelf electronics similar to what you'd find in cell phones, but they’re integrated into custom-designed circuits and boards. These boards are assembled in the US and shipped to us for testing and final assembly. The transducers, which convert acoustic energy into electrical energy, are made from ceramic – an industry standard for marine acoustics.

How long does it typically take to retro-fit one of your systems?

The installation process can be relatively quick, especially when compared to something like hull painting, which requires weeks of planning. For instance, on a commercial vessel, we've seen installations completed in as little as 48 hours, from cutting the metal to launching the boat. For a yacht refit, we’ve had installations done in about three days. While it may not be as visually polished as a longer installation, it is fully functional and gets the job done without being highly disruptive during the refit process. Integrating the fairing onto the hull is key so as not to interfere with the vessel’s performance.

FarSounder is a partner of Seabed 2030 to better map the seabed – how do you protect yacht privacy?

We’ve been contributing in two ways. For the past five or six years, we’ve sent USB hard drives to select customers who are interested in collecting data. This helps us improve our algorithms by gathering data from various environments and vessels, and it also enables us to troubleshoot any issues they may encounter. Some of these customers allow us to contribute their data to Seabed 2030.

About six months ago, we launched a pilot program to share data anonymously across our FarSounder fleet. This allows us to create an aggregated map of the seabed data and contribute it anonymously on behalf of our users to Seabed 2030. Importantly, the data is stripped of any identifying information – it only includes a unique randomised ID tied to the sonar, not to the vessel itself. The truth is, with AIS and satellite tracking systems, it's almost impossible to fully obscure a vessel’s location anymore, so the concern about FarSounder’s data revealing a boat’s location is somewhat outdated.

What other types of data are you collecting and contributing through this program?

In addition to bathymetry (sea floor depth), we’re soon launching new functionality to allow our users to contribute other valuable data, such as whale sightings and floating trash observations. We’ve already set up the cloud service that connects depth measurements through our servers for Seabed 2030, so we thought, why not facilitate the collection of other meaningful data? For the trash observations, we’ll be passing the information on to Eyesea, a nonprofit focused on mapping marine debris. It’s an exciting way for our users to contribute to the global understanding of marine ecosystems.

Asian superyacht shipyards have become a force to be reckoned with and Taiwan is the region’s leading producer. Just prior to the start of the inaugural Asia-Pacific Superyacht Summit in Hong Kong last June, we travelled to the Taiwanese city of Kaohsiung to visit Ocean Alexander, which regularly figures among the top 10 superyacht builders.

BY JUSTIN RATCLIFFE

The story goes that Ocean Alexander was born when founder Alex Chueh was approached by a close friend seeking financial assistance for his failing shipyard. Apocryphal or not, from humble beginnings as a small boat builder in 1978, Ocean Alexander is now among the best-selling superyacht brands in the US. At the same time, it has helped to establish Taiwan as a yacht production powerhouse.

The US has been Ocean Alexander’s primary market since day one. In fact, although its yachts have long been built in Taiwan, the brand’s corporate headquarters were originally in Seattle, a city that has always had strong trading links with Asia, and the US head office is still based there. Around 85 percent of production goes to the US and just shy of 20 yachts were delivered to American customers last year, with six sales in the last quarter alone. Nearly all the rest finish up in Australia.

“The past two decades have been our period of most consistent growth,” says Dan Mundy, Ocean Alexander’s head of global operations. “That really coincides with two tipping points in the company’s history: Johnny Chueh taking over the reins from his father, and the launch of the first Ocean Alexander 100.”

Perfectly at home in both Asian and Western cultures, Johnny Chueh studied finance and economics in Australia and the US. In the early 2000s he set about restructuring the company along industrial lines. The Ocean Alexander 100 designed by London-based Evan K. Marshall built on the success of its 90-foot predecessor and marked the brand’s entry into the 30-metre-plus segment when it was introduced at the 2014 Fort Lauderdale International Boat Show. It was followed by a 112 and 120-foot series.

“This was all part and parcel of a wider expansion drive,” continues Mundy. “The market was changing, motoryachts were becoming bigger and bigger, and the company focus was anticipating the future market trends and preparing to move in a new direction. We realised we needed to expand our distribution out of Seattle and the Pacific Northwest. We already had a dealer in California – and the Great Lakes region for a time – but now we wanted representation in Florida to become a coastto-coast concern.”

Ocean Alexander became part of the parent company Alexander Marine International and the outlets it owned on the West Coast were rebranded as Alexander Marine USA. MarineMax became the exclusive East Coast dealer for Ocean Alexander yachts and in 2017 Alexander Marine USA acquired MarineMax’s San Diego office (for MarineMax, the dealership meant it could enhance the diversity of its offering by introducing larger yachts to its small to medium-sized product portfolio). Ocean Alexander then set up its own strategic service and commissioning centres on both coasts.

“The difference between manufacturers and retailers is always an interesting one,” says Mundy. “The manufacturer thinks they can do some things better than the retailer, and the retailer thinks the same about the manufacturer. But we just said to MarineMax, ‘Tell us how you see the the needs of the market’, and since that collaboration started we have seen an absolute spike in sales of around 50 percent.”

That surge has been helped by progressive expansion of the Kaohsiung facilities to increase production capacity and sales have now stablised at pre-Covid levels following the post-pandemic peak. Construction of a new state-of-the-art facility adjoining the current main assembly site is due to start shortly that will further boost production and enable projects over the current 40 metres.

“We study data, we study the industry, we study the market, and that serves to really have our finger on the pulse.”

Facing page: Checking windows and seals for watertightness in the yard’s test tank.

Below: 20 yachts were in various stages of construction at the time of our visit.

Bottom: A 30R ready for delivery.

As a semi-production builder, Ocean Alexander manufactures pre-designed models with customisable features and takes a very methodical approach to what might be interpreted as market trends – Mundy calls it responding instead of reacting to the marketplace. In practice this means that it can ramp up or slow down production of certain models quite quickly without disrupting production schedules.

“We study data, we study the industry, we study the market, and that serves to really have our finger on the pulse,” says Mundy. “What we’ve learned over a long period of time is that a saturation point does not lead to a termination; it only leads to a reduction. As soon as the market starts to feel that reduction, demand goes up again because of scarcity. So we’re responding to these trend cycles more than we’re reacting to them.”

At the time of our visit, there were 20 yachts on the factory floor at various stages of a 16 to 19-month build cycle. All were ‘sold’ in the sense that they have a first client, which may be MarineMax, Alexander Marine USA or Alexander Marine Australia.

About a quarter of those units had a final customer already signed up, a figure that may be as high as 60 percent by the time the yachts are completed. Conversations with owners usually happen within the last 12 months after hull and deckhouse have been connected, but still in time to let clients put their personal stamp on the interior. Each yacht goes through full quality controls and sea trials before leaving the factory in Kaohsiung. The interior is then dismantled, wrapped for protection and stowed on board for transport to the US or Australia, where it will go through another six-week commissioning period. This effectively means the whole QC process is carried out twice.

Some semi-custom builders offer more than one layout, but Ocean Alexander prefers not to mess with general arrangements as it makes it harder to stick to production schedules and can lead to further customisation requests. Instead, it aims to utilise the same spaces in different ways by taking stock of customer requests and engineering alternative iterations into the initial design. Mundy recalls one customer for a 27R who wanted a second master suite, for example. The layout already provided for two VIP cabins forward of the engine room, which could be easily turned into a full-beam master stateroom without any structural modifications.

“We’re not putting the information out there that, hey, we’ll do anything you want us to do,” he explains. “We’re pre-thinking what somebody might want and we can affect those changes well into the production cycle, which again speeds up the whole process. In the past five years I can think of just one example where we reconfigured bulkheads for a client.”

Although yachting in Asia-Pacific is on the rise, the region is not a market for Ocean Alexander. This is largely explained by the difference in usage between American

and Asian owners. Americans are often owner-operators who undertake long-range voyages, racking up hundreds of hours on engines and generators (last June the San Juan archipelago off Seattle hosted Ocean Alexander’s annual West Coast Rendezvous attended by yachts that travelled from far and wide to get there). It stands to reason that they appreciate sturdy construction, quality engineering, plenty of living and storage space, and comfortable but functional interiors – features that resonate less with Asian owners who are more inclined to take short day trips, or even enjoy the boat without leaving the marina.

“We build in Taiwan, but we use American thinking behind our construction methods and remain focused on the dominant US market,” Mundy told the audience during the Asia Pacific Superyacht Summit in Hong Kong. “As we expanded our distribution opportunities and the service side of the industry, we just found ourselves completely consumed. So we’ve been fortunate to never have a moment in time where we’ve had to stop and say, okay, where’s the broader market? Where do we begin to expand further?”

According to the Asia-Pacific Superyacht Market Report 2024 prepared by SYT iQ, as of the start of 2024 builders from AsiaPacific (including Australia and New Zealand) accounted for 509 out of 5,787 operating yachts over 30 metres in the world, a share of 8.8 percent. Of those 509 yachts, 163 were built in Taiwan. If we then look at developments over the last 10 years, the share of builders from the region has gone up to 9.9 percent, as Asia-Pacific builders delivered 159 out of 1,604 yachts completed between 2014 and 2023.

The region is now in second place after Europe, as the role of North American has declined and Taiwanese builders in particular took over a large part of the US market for motoryachts up to 40 metres. Of the 659 superyachts over 30 metres under construction as of mid-May 2024, 40 yachts (6 percent) are under construction in AsiaPacific countries: 23 in Taiwan, 13 in China, and the remaining four spread over four other countries.

Founded by Alex Chueh in Seattle, Ocean Alexander specialises in building fibreglass superyachts from 27 metres up to 40 metres (soon to be 45 metres). Of six production sites owned by the company in the city of Kaohsiung in southwest Taiwan, four are active in front-end manufacturing and two are responsible for back-end assembly (a yard in China that was building smaller yachts closed in 2013). A new facility adjoining the main assembly site in Kaohsiung represents an investment of more than US$60 million and is expected to be operational next year.

Supported by its retailing partnership with MarineMax, over the past decade the brand has broadened its presence to Florida and the East Coast, but also Australia with an office in Brisbane. A rare blip in business was a joint venture in 2009 with Christensen Shipyards in Vancouver to produce the 120 Megayacht. A mould was shipped across the Pacific and the first hull was launched in 2012, but with Christensen’s subsequent financial collapse two other hulls were transported to Taiwan for completion.

Early Ocean Alexander models were designed by Ed Monk Jr, son of the legendary naval architect Ed Monk Sr and a top-notch designer in his own right. Ed Monk Jr created the brand’s classic combination of sturdy construction, seaworthy lines and practical amenities that appeal to American owner-operators. But like other legacy brands, Ocean Alexander has had to balance well-loved looks with the need to innovate. The classic lines and flared bow of the Legend series by Evan K. Marshall, for example, draws on the brand’s Northwest heritage, but the Revolution series by the same designer with its near-vertical bow introduced a more modern aesthetic. The Puro 35M designed by Giorgio Cassetta is the latest addition to the fleet that adds a new flavour to the mix and targets a global clientele.

“We asked Giorgio for Italian – or better still, European – design with American sensibility.”

JUSTIN RATCLIFFE

That moment may be now. The first 35M Puro designed inside an out by Giorgio Cassetta with naval architecture by Italybased NavalHEAD made its debut at the 2024 Palm Beach International Boat Show to wide acclaim. Six more units in the series are in build, production of a 40-metre Puro has started and a 45-metre, sub400GT version is in development. The Puro brings a distinctly Italian flavour to what is commonly perceived as a stolidly American brand, which suggests Ocean Alexander is looking to expand its appeal beyond its traditional borders.

“We asked Giorgio for Italian – or better still, European – design with American sensibility,” says Mundy. “We wanted something that is stunning, beautiful and sexy to look at, but then we’re going to build it so it actually lives up to the expectations of our clients. Yes, Europe is of interest and we have a very specific strategy how to approach that market, but it will be executed as a marathon and not a sprint.”

The new facility in Kaohsiung will allow Ocean Alexander to build up to 45 metres and beyond, but the brand has no intention of going over 500GT, which is nearing the limits of GRP construction and would pit the brand against steel and aluminium builders. However, competitive advantage is just one consideration: just as important is remaining true to its roots and a client base with a 40 percent return rate.

“We are very much in tune with the market that we serve and the best thing is that at 40 or even 45 metres, we’re still dealing directly with the client and not with a representative or family office,” concludes Mundy. ”We love building yachts for people, not for entities.”

As the longest-established personal submersible manufacturing company, SEAmagine has been setting industry benchmarks for manned submersibles since 1995. SEAmagine’s fleet has completed over 13,500 dives with a perfect safety record, a figure representing more dives than all other submersible manufacturers combined.

Based near Los Angeles, SEAmagine has cultivated long-term relationships with its yacht clients, including one superyacht owner who recently returned for a third submersible. This loyalty stems from two key factors: first, SEAmagine’s submersibles are designed and customised to fulfil the owners’ dreams. Second, the subs’ proven reliability and performance, along with the company’s 24/7 international support, alleviate captains’ concerns, allowing the underwater vehicles to seamlessly integrate with other onboard activities.

“Many yacht owners, captains and yachting professionals are unfamiliar with the distinctions between well-designed and poorly designed submersibles, as this technology comes from a different marine sector,” explains Charles Kohnen, co-founder and chairman of SEAmagine. “Our subs, which are sized and built specifically for yachts, prioritise design features that enhance the owner’s diving experience while ensuring ease of maintenance and operation. The difference SEAmagine’s design makes in terms of owner and captain satisfaction for their sub is like night and day.”

The first key factors a yacht must consider when selecting a submersible are its passenger capacity, maximum depth rating and launch weight limit. These parameters determine the sub’s size and weight, but additional considerations are equally important. One key purpose of a sub on a yacht is to provide an unforgettable underwater view for the owners. This is best achieved with a panoramic bubble design, unobstructed by a hatch on top, which can significantly block the overhead view. The difference in experience between a sub with an overhead hatch and a SEAmagine sub is undeniable.

Anyone who has had the opportunity to dive in both will attest to this. SEAmagine designs its submersibles with a unique rear hull section that houses the hatch, pilot station and equipment, allowing the front bubble to maintain an unobstructed panoramic view while offering passengers a more spacious interior. Space aboard a sub is premium real estate, and SEAmagine subs offer more room within their launch weight category than any other sub on the market. This additional space allows SEAmagine subs to include larger, more comfortable leather seats and maximised personal space for all aboard.

Another standout feature is the cabin’s quiet interior. All SEAmagine subs are equipped with powerful propulsion thrusters that operate without gearboxes, eliminating loud noises from the motors that could startle marine life or create an annoying hum. To further enhance the tranquil atmosphere, SEAmagine has designed a quiet air conditioning system and fans, prioritising a peaceful environment. SEAmagine has also optimised the boarding and disembarking process to ensure comfort while the submersible is floating on the water’s surface. The patented design features a horizontal top deck with handrails, allowing passengers to board through the rear hatch and descend a short staircase to their seats. This extra-large hatch design improves convenience and safety.

These are just a few of the distinguishing factors that contribute to an exceptional submersible. The resulting superior designs are only possible due to SEAmagine’s experience gained over thousands of dives and nearly 30 years of dedicated submersible development.

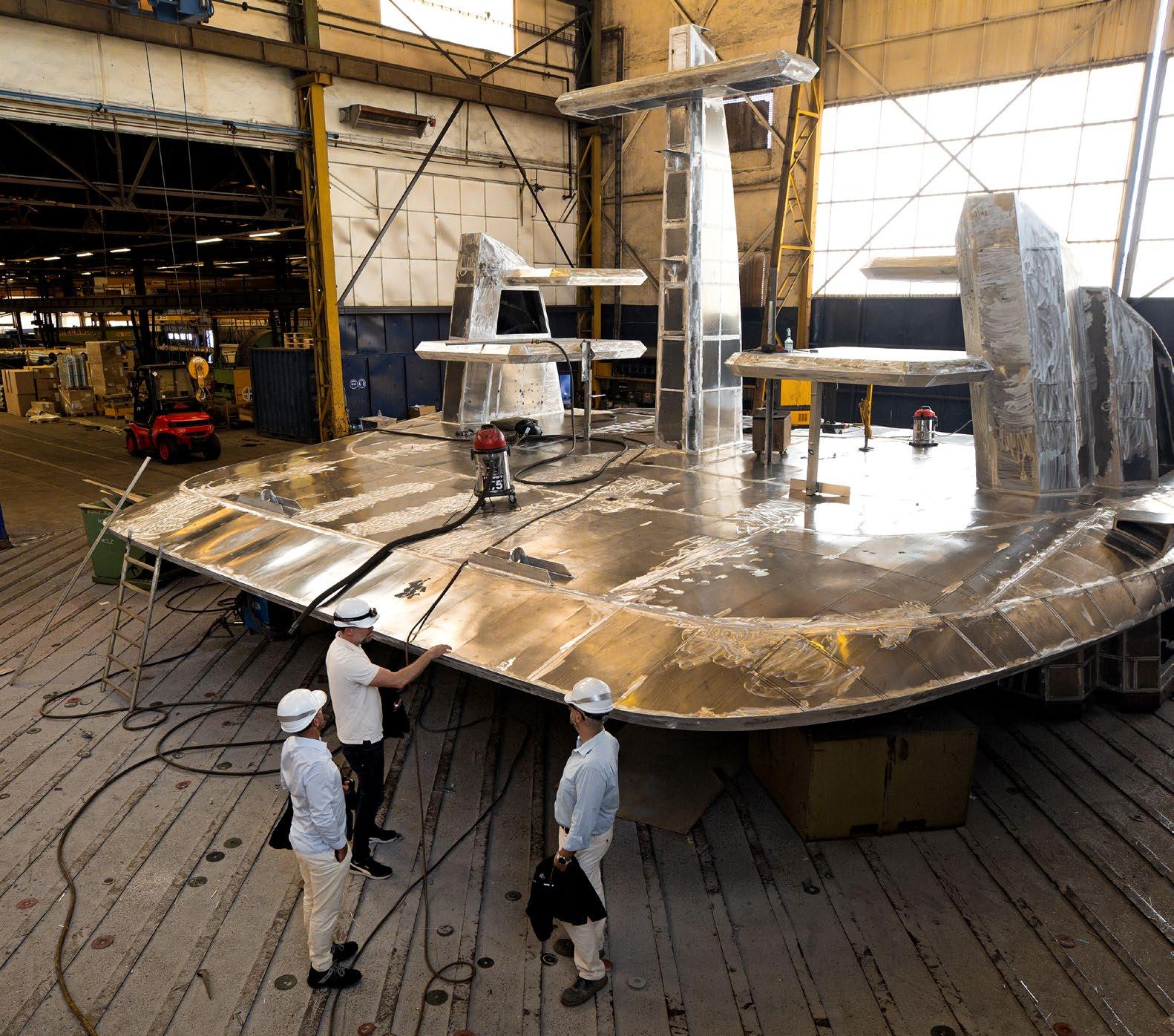

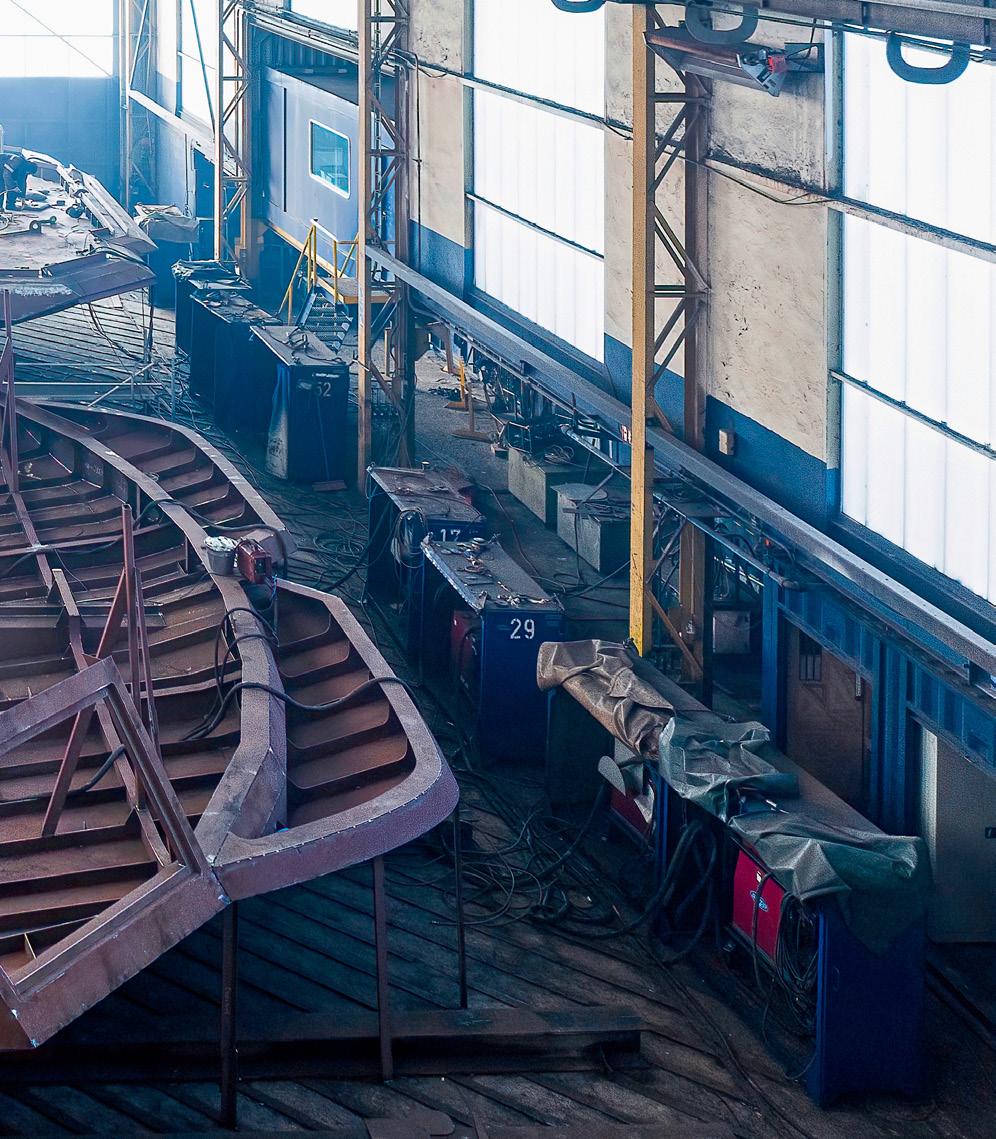

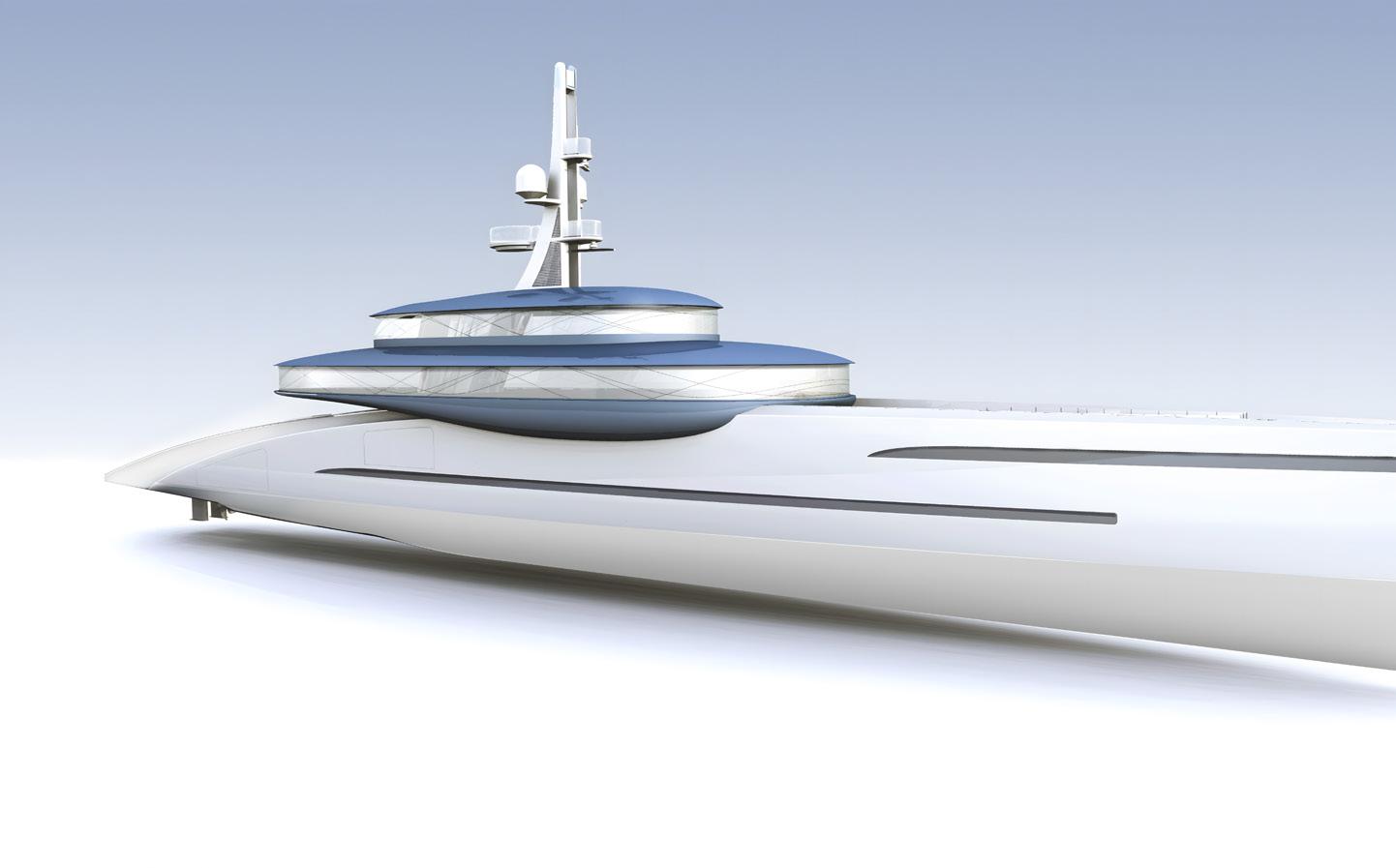

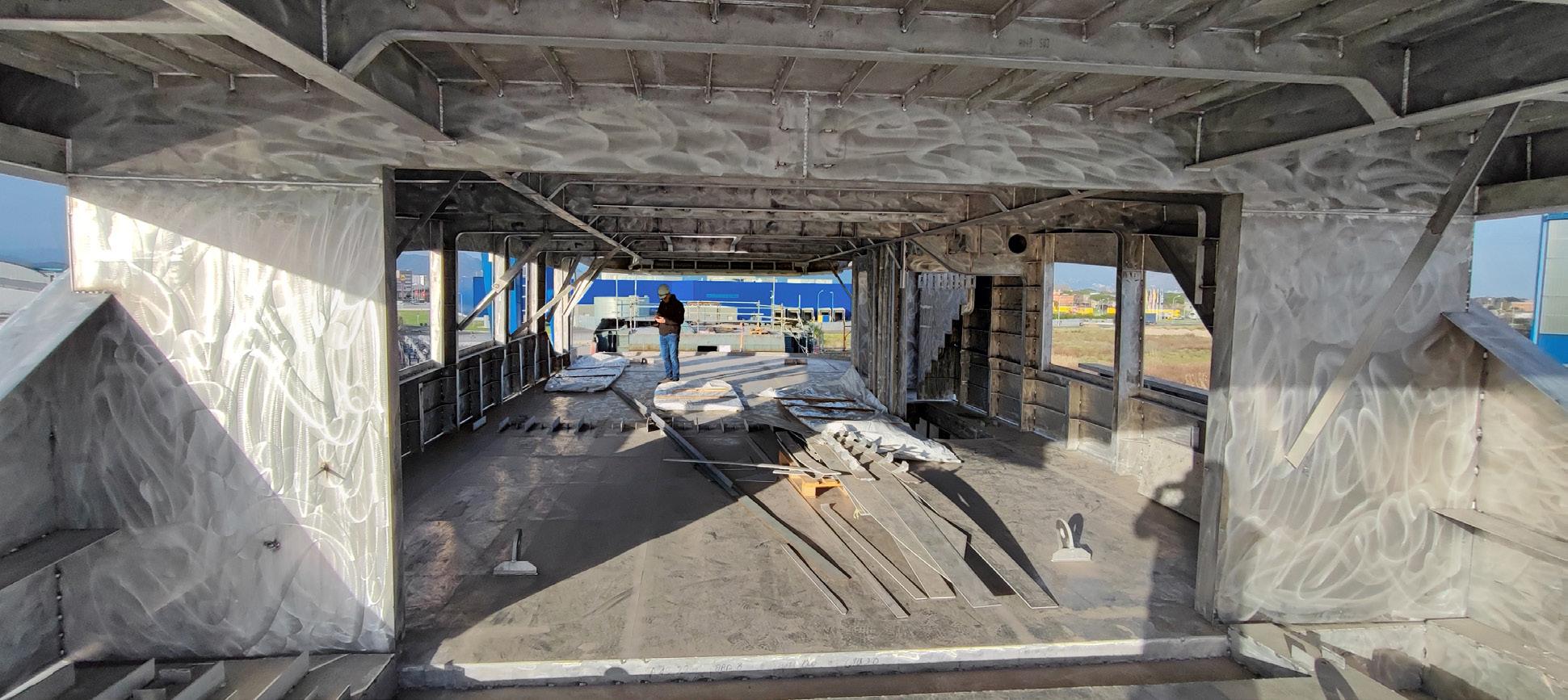

Leapher Yachts is a new and innovative brand that aims to complete Horizon, an Ice Class explorer yacht of 60.5-metres and 1,750 gross tons, in just 26 months by rethinking the design, engineering and production processes along commercial shipbuilding lines.

BY JUSTIN RATCLIFFE

Yiannis Andriotis, founder of Leapher Yachts in the Netherlands, is a man on a mission. The former professional sailor and owner of the Odyseas Marina on the Ionian island of Meganisi has spent a decade immersing himself in the superyacht world, spending time with owners, guests, captains and crew to find out their likes and dislikes, preferences and pet hates. Now he is putting what he learned into practice.

“I started cherry-picking solutions to the many issues the sea can throw at you and together with a like-minded client we set out to design the ideal explorer,” he begins.

“Everything pointed to a steel-hulled yacht and Horizon, the first in our Navix explorer series, is the result of bringing all those ideas together. I believe it offers the best balance of what people want in terms of space, comfort, efficiency, flexibility, operability and servicing.”

The next stage was to find a shipyard to build it. Although the cheaper option would have been Greece, Turkey, Italy or Spain, his search focused on the Netherlands because of the country’s legacy of building both yachts and special-purpose working vessels. Cor D Rover, the Dutch designer of the Leapher range, suggested the family-owned De Hoop Shipyard, a builder of compact expedition cruise ships and subcontractors for the likes of Damen with production sheds, quay cranes and construction slipways on the Rhine in Tolkamer. An opportunity arose when the 135-year-old company closed its doors in the wake of the Covid-19 pandemic. Leveraging the shipyard’s knowledge, experience and proven designs, Leapher formed a strategic partnership with the former De Hoop team in late 2022.

Leveraging the shipyard’s knowledge, experience and proven designs, Leapher formed a strategic partnership with the former De Hoop team in late 2022.

It is not just the design, layout and makers’ list that defines Leapher’s focused approach to yacht building; it also aims to emulate commercial shipbuilding practices to speed up production and contain costs.

“Building a good boat is one thing – building a financially successful boat is another,” says Leapher founder Yannis Andriotis. “To do that you need to build in as little time and with as few extra costs as possible. That means designing for fast production scheduling, because when you make a decision about equipment and its installation, it also affects engineering and production.”

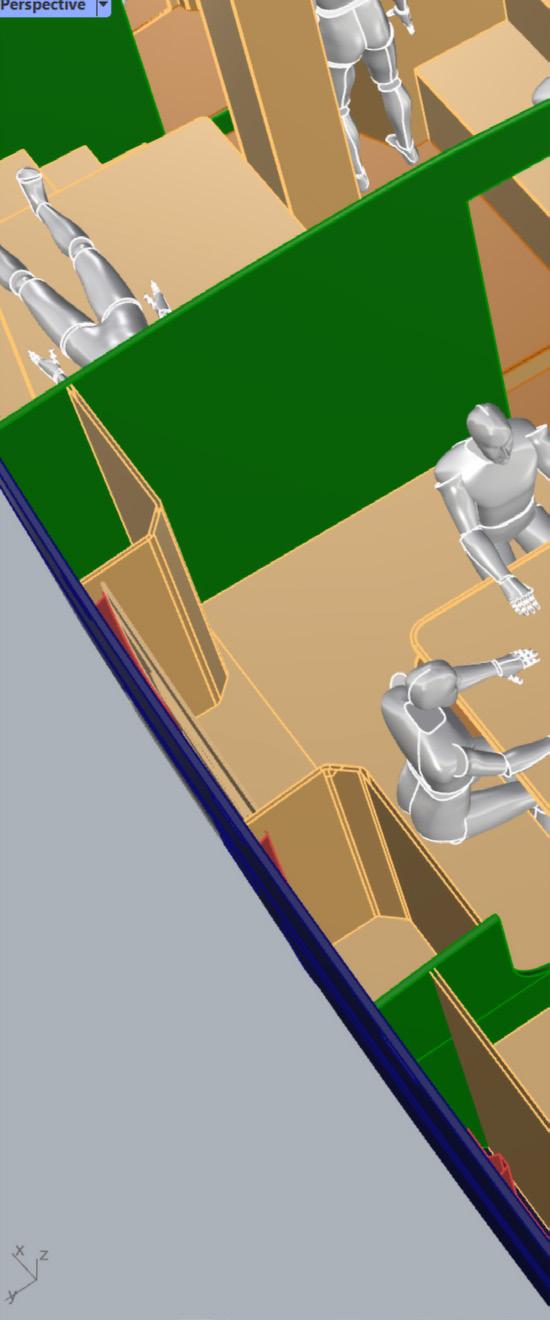

Leapher’s production process is structured so workers can carry out their trades –welding, fairing, carpentry, and so on – in adjacent spaces on board at different stages of the build process. This is achieved by firstly preparing the blocks as much as possible in advance with cable trays laid and piping penetrations completed, so that by the time they are brought to the slipway, aligned and welded, installation of equipment can start while the vessel is still being built. “In this scenario volume is our friend,” says Yiannis, “because having the space makes it easier for different processes to be going on side by side.”

Although the shipyard has its own flatbed plasma cutter, for the time being it is quicker to have a subcontractor cut the metal and deliver it ready-shaped, although Leapher may bring more processes in-house in the future. To further save production time, even the piping sections are laid out individually inside one of the hangars ready for installation so they don’t get scratched and have to be repainted.

“The goal was clear: to merge maritime offshore technology with luxury superyacht features and quality into a single package.”

Horizon’s naval architecture is by 07 Designers with hull optimisation by Van Oossanen, but the former De Hoop engineering team has also brought its experience and expertise to the project. A closer look at the scale models of De Hoop vessels lining the Leapher offices reveals why: all of them have diesel-electric propulsion.

“The reason why these ships are full dieselelectric has nothing to do with fuel economy,” says Yiannis. “It’s because they are robust, efficient and proven systems offering very high torque and manoeuvrability. Our decision to go with shafts and propellers instead of Azipods again comes down to practicality and reliability: if you have an issue with a pod in a remote location, you could be in trouble, but if you prang a prop you can get it fixed in most places in the world.”

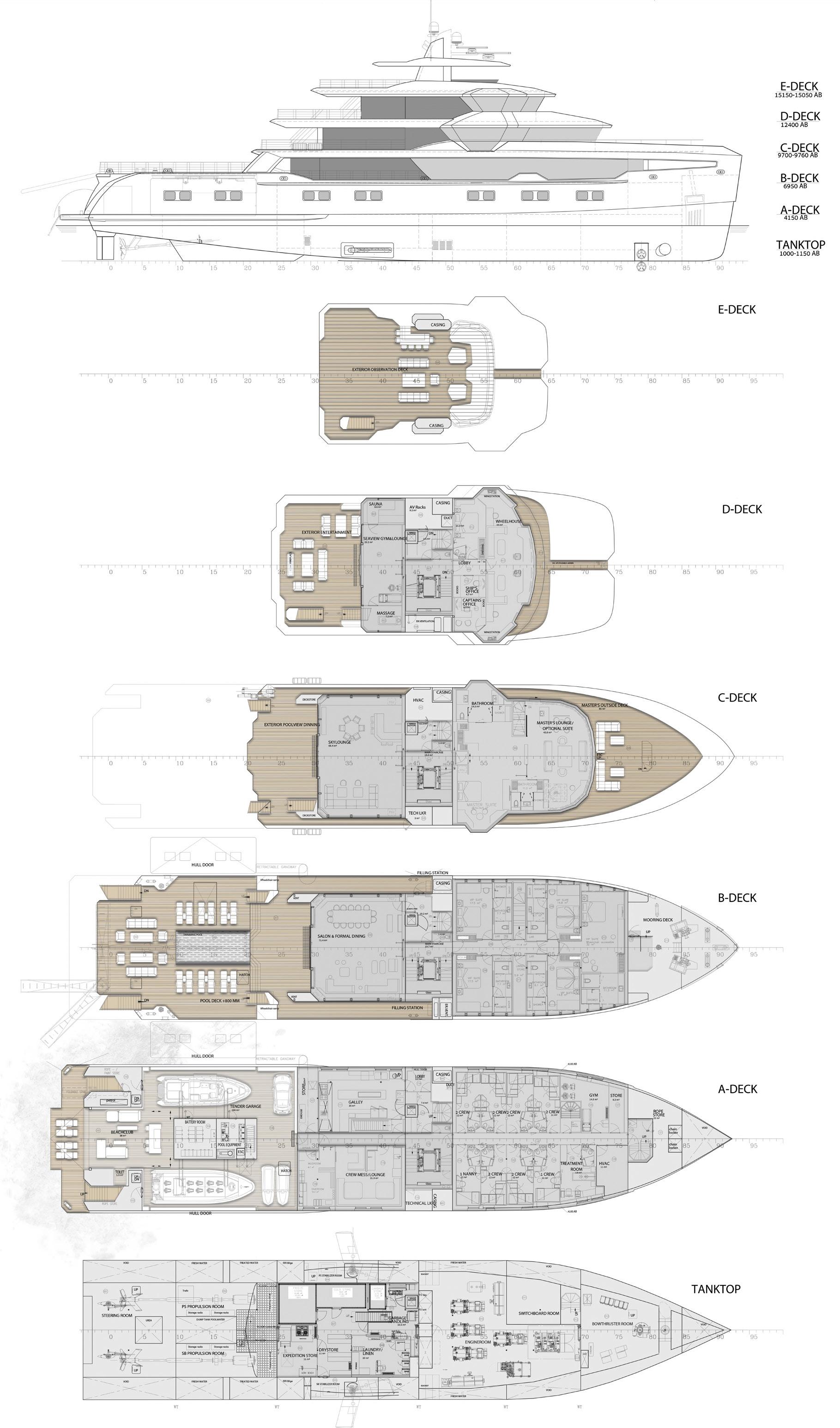

It is indicative of Leapher’s ship-like approach that the GA of Horizon refers to A-deck, B-deck, C-deck, D-deck and E-deck instead of lower, main, upper, bridge and sun decks. The whole of the tanktop deck is devoted to technical spaces and includes the propulsion, generator and switchboard rooms, a dry store, walk-in freezer and cold rooms, and a garbage handling room for up to 40 days’ autonomy with zero discharge (see sidebar p.47). A large laundry provides a comfortable and functional working space for crew instead of being crammed into a corridor, and an expedition store serves as a multifunctional space that can be equipped as a research laboratory.

Diesel-electric propulsion is not the only feature derived from De Hoop’s example. The four Tier III compliant, Scania DC16 generators (456kW each with both SCR and DPF units) and Stamford alternators were chosen with easy repair and maintenance in mind. Coupled with the low-noise electric motors (700kW each) from Drivewerx and low-vibration 5-blade propellers by Blokland, the yacht will have a top speed of 12 knots and a massive range of up to 10,000 nautical miles at 10 knots when it burns just 150 litres of fuel per hour. For safety and redundancy purposes, the generators, propulsion gear and switchboards are divided into two independent systems that can function in tandem or separately. If there is a critical issue with one propeller or shaft line, for example, one half can be shut down and the watertight propulsion compartment sealed while the vessel runs on the other two generators and remaining prop in ‘get home’ mode.

The yacht also carries 600kWh of lithiumion batteries for peak-shaving, silent running at anchor and an emission-free range of 15 nautical miles at 6 knots in full electric mode. The A60 battery room on the lower deck is equipped with Novec fire suppression and sprinkler systems, but its position between the pool and the dump tank provides boundary cooling to help dissipate heat in case of fire (together with Lloyds, the build team is looking into being able to flood the compartment with water from the pool).

Two Veth bow thrusters, tunnel and retractable, provide redundancy and enhance DP capability together with Becker flap rudders for transverse thrust. Unusually, the retractable stabiliser fins are by SKF Marine, which has been equipping ocean-going vessels for over half a century. The fins are housed completely inside the hull without any protrusion, reducing drag and fuel consumption. Another relatively unknown brand in yachting is HatenboerWater for the watermakers that supplies the Royal Netherlands Navy. The HVAC system is based on Heinen & Hopman engineering that has been customised to meet the specific requirements of the yacht.

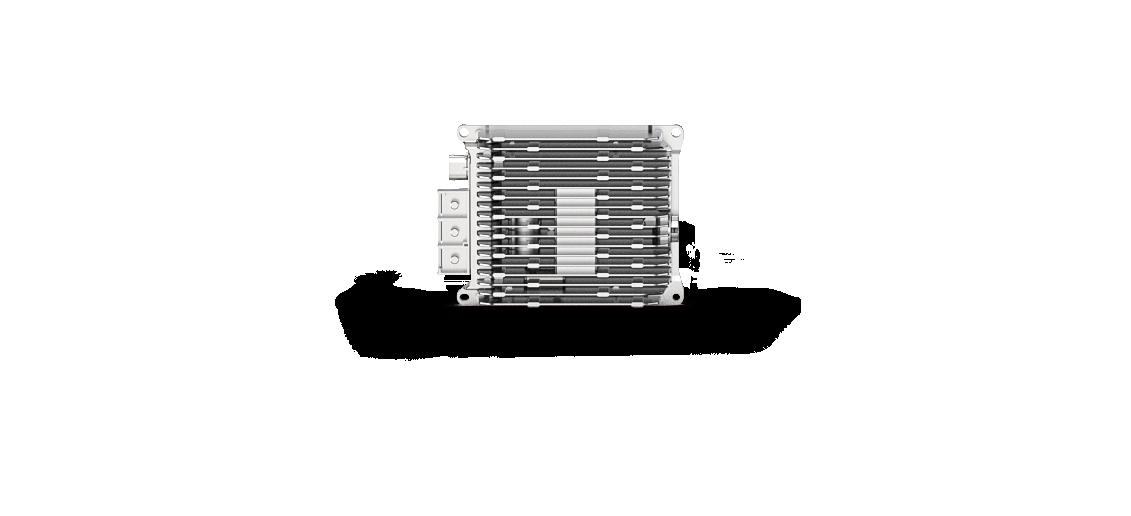

Low tech but efficient box coolers are mounted in the hull below the waterline. Like a radiator on a car, the coolant in the system transfers heat to the seawater before it returns to the engines. Often seen on ships, the closed-circuit cooling system eliminates the need for seawater to enter the vessel as well as the associated raw water pumps, strainers and high maintenance of opencircuit systems.

“The goal was clear: to merge maritime offshore technology with luxury superyacht features and quality into a single package,” says build captain Tobias Leigh-Oberholzer. “This approach, along with excellent seagoing capability, offered cost benefits as commercial equipment is often more durable, less maintenance-intensive and more costeffective than yacht-specific equipment.”

One of the key design criteria was to have two 10-metre tenders based on military-spec hulls used by the British Royal Navy, one of which is fully enclosed for colder climates. Housed in a garage on the lower deck (A-deck), there is room left over for four PWCs and even a small car or mini sub. These are launched through hatches by a 2,500kg-capacity crane with an 11-metre reach that is built into the upper deck overhang, where the steel fashion plates and superstructure have been engineered to provide a rigid tripod effect. The same crane can be used to launch a seaplane from the raised aft deck where the pool has a lifting floor.

“Originally we had a helicopter hanger instead of the pool and that’s still an option on future builds, but this time we favoured a seaplane because of the limited range of helicopters,” says Yiannis. “We calculated that the longest trip could be from the Ross Sea in Antarctica to somewhere like South Georgia. That’s over 1,000 nautical miles, which is too far for a helicopter in an emergency.”

Every effort has been made to make life on board as comfortable and efficient as possible for the crew, so opposite the pro-spec galley is a very large crew mess, the crew cabins have a floor area of fully 12 square-metres, there is a crew gym and a full-size service lift that travels from the garbage handling room on tank top level up to the bridge deck.

The main deck (B-deck) follows a more conventional layout with a main saloon and indoor dining, four guest suites and a fullbeam VIP suite forward. The guest suites are exactly the same size with mirrored layouts, which means furniture and fittings can be standardised for fast, semi-custom production. A simple but smart design feature is that the walk-around sections on all the decks have railings instead of solid bulwarks – a cost-effective solution that allows for easy boarding from the dock in case of extreme high and low tides around the world.

“You can only design the boat once, so you need to pre-engineer as much as possible and look ahead as many moves as you can.”

Below: All the painted pipe sections are laid out carefully on the floor ready for installation to avoid scratching them. Facing page: At the time of our visit the build was waiting to be covered prior to deck levelling.

“The vessel’s design evolved from a rough workboat concept to a high-class, expedition-style yacht with everything from dynamic positioning and hybrid propulsion, fully kitted out dive and mud rooms, garbage handling room and onboard medical facility, to a heated pool with a contra-flow system, sauna, massage room, observation lounge, gym, and a fire-pit,” says Captain Tobias.

The forward-facing master stateroom occupies fully half the interior volume on the upper deck (C-deck) and is 14.4-metres wide from window to window, which extend beyond the maximum beam. However, the layout has been designed to offer various options and the owner’s lounge can also be closed off to serve as an extra suite with a drop-down bed, an office or family room. All the guest areas and passerelles are wheelchair friendly.

“You can only design the boat once, so you need to pre-engineer as much as possible and look ahead as many moves as you can,” says Yiannis. “Take the wheelchair access, for example. This a boat for private use but it’s being built to commercial class. If you can add something without seriously affecting cost, complexity or production time, why not do it?”

The wheelhouse with enclosed wing stations and top-end equipment such as Hatteland monitors used by offshore and naval vessels, is another XL space designed for guests to be be involved in the navigation process when the yacht is traversing the Northwest Passage or cruising the fjords of Greenland. One of the guest couches will have a monitor that can display charts and 3D scans of the seabed.

The former De Hoop facility has plenty of covered buildings at its disposal, but these are mostly low-rise production sheds. The actual assembly work takes place outside on the slipway – unusual for a yacht builder in northern Europe. At the time of our visit and with the hotworks complete, the shipyard was preparing to cover Horizon prior to deck levelling and fairing (instead of sandblasting, it is also testing an innovative laser system that Andriotis calculates saves several weeks’ production time) and is being creative in how it uses its facilities. A hangar that served for assembling the steel plates, for instance, will be converted into a temporary, climate-controlled hangar for painting large components like the aluminium hardtop and tender garage doors.

It seems that Leapher’s bold strategy is going to plan and Horizon is progressing on schedule since construction began in June 2023. But what began as a pared-down series project has taken on more custom characteristics and everything will have to continue to run smoothly if the team is to meet the target of showcasing the yacht in Monaco next year. Before leaving, I ask Yiannis whether his 26-month build schedule for a yacht of 1,750-plus gross tons might be a touch too ambitious?

“We’re a new shipyard with new people, but I think we can build this very complex yacht in the allotted time,” he replies with only the slightest hesitation. “The most important thing right now is that we continue to test ourselves and focus on delivering a great boat.”

“We’re a new shipyard with new people, but I think we can build this very complex yacht in the allotted time.”

Horizon is equipped with a biological sewage plant. Based on 12 guests and 16 crew at 250 litres per day, the system can produce 7,000 litres of clear water per day of which three percent goes into a sludge tank and rest into treated water tanks with a capacity of over 86,000 litres. The more limiting factor is the sludge, but Captain Tobias calculates the tankage capacity still provides zero-discharge autonomy in protected areas for up to 40 days at full capacity. The pool water is first de-chlorinated before passing through the biological sewage system. Space has also been left to retro-fit an evaporation unit if needed.

A food waste disposal unit macerates waste food and dehydrates it (the water is cycled into the sewage plant). Along with a glass crusher and industrial compactor, there is storage space for waste in the refrigerated garbage room for more than 40 days at sea.

Because there is no seawater passing through the vessel, the closed box cooling system further reduces environmental impact. A heat recovery system on the generators and box coolers pre-heat all the hot water on board, and can be used for heating the interior and decks in cold weather.

On superyachts the hull fairing usually extends a short distance under the waterline, but that makes little sense on an Ice Class vessel where even brash ice will quickly strip off the fairing compound. Instead, the fairing on Horizon will stop where the ice belt starts and below will be treated with self-cleaning, biocide-free, silica-based anti-fouling that offers better protection from ice, but also improves fuel consumption by reducing resistance through the water.

An issue associated with being autonomous for long periods is the availability of fresh fruit and vegetables. Captain Tobias is looking into installing in the dry store a system that its maker describes as “the world’s first autonomous vegetable grower.” Specifically designed by Agwa for use at sea, the AI-based system calculates and generates precise growth plans tailored to each plant’s requirements, from leafy greens to fruits, in special vertical cabinets.

Ulstein began its thorium-powered Thor concept with a question: What if we could design and build a vessel with an abundant emission-free energy source able to support other vessels with clean fuel? There are some 160 vessels worldwide with nuclear reactors, nearly all of them military ships or submarines, but will we ever see a nuclear superyacht?

BY JUSTIN RATCLIFFE

“We’re starting to see micro reactors and associated systems that can be scaled to fit on bigger superyachts.”

Ulstein first unveiled its 149-metre Thor concept in 2022 together with the full-electric cruise ship concept Sif. With carbon emissions and alternative fuels in the spotlight, the disruptive project garnered considerable industry interest and last year the Norwegian group was invited to join a panel of class societies and flag states to discuss nuclear energy at the Superyacht Forum during METSTRADE in Amsterdam.

“What was interesting was that each session was given 45 minutes before breaking for lunch, but ours had a record show of people and lasted one-and-a-half hours,” says Øyvind Gjerde Kamsvåg, Chief Designer at Ulstein

International. “Most people were sceptical about nuclear power at first, but many were converted by the end of the session.”

The clever thing about Thor from a superyacht perspective is that it is categorised as a Replenishment, Research and Rescue (3R) vessel and conceived as a floating power and charging station. Equipped with a Micro Modular Reactor (MMR) or a thorium-powered Molten Salt Reactor (MSR), it would be able to generate 20MWe of clean, safe electricity for recharging a new breed of full-electric vessels at sea, with the potential to also be plugged into the renewable energy grid.

“Thor would be able to satisfy a variety of different needs in the market,” continues Kamsvåg. “So you can use it as a first responder, you can use it as a scientific research hub, you can use it as an energy replenishing unit. It can serve so many functions once we start to explore the nuclear energy infrastructure.”

The alternative to a mobile charging station like Thor is installing a nuclear reactor on board the yacht itself, which comes with other potential advantages. As the fuel is contained within the reactor there are no fuel tanks, combustion air intakes or exhaust stacks that take up valuable space.

Besides being emission free, nuclear reactors require no regular maintenance and provide extremely long intervals of operation before refueling. The latest reactors on submarines, for example, are designed to last the lifetime of the ship, during which time they circumnavigate the globe many times.

“Superyacht clients like the idea of Thor because the reactor is separate from the yacht itself,” says Kamsvåg. “But we’re starting to see micro reactors and associated systems that can be scaled to fit on bigger superyachts. That is still a bit further up the road, but I think both scenarios are equally interesting.”

Feadship considered the question with its Relativity concept back in 2012 and concluded that “technically speaking, a nuclear fission reactor design could be made, customised to fit the available space on a yacht and dimensioned to allow for all operating conditions.” Like Ulstein, thorium was envisaged as fuel in a high-temperature, low-pressure molten salt reactor. The heat output would then be converted to mechanical power using high efficiency, closed-cycle Helium gas turbines to drive the generators. But the technology was not readily available and issues associated with insurance and port controls rendered the idea compelling but ultimately impractical.

More recently, a 2023 joint study between the Feadship R&D department and Delft University tackled the topic again. The study identified that a IV generation Micro Modular Reactor using a uranium, carbon and oxygen fuel kernel might be the best fit for the load profile of a superyacht. A fraction of the size of a conventional nuclear reactor, MMRs can be factory-assembled and transported as a unit for installation. Both Feadship and Ulstein have looked into the volumetric requirements of installing such reactors on board and found they would occupy less space than alternative fuel systems. However, the Feadship study underlined the massive weight implications of the lead and concrete shielding materials required. Depending on the size and power of the reactor, the whole installation could weigh over 2,300 tons, more than doubling the weight of an 80-metre yacht!

This is just one reason why Feadship believes a more realistic role for maritime nuclear power would be to make green hydrogen or methanol either onshore, or close to shore, for use as carbon-free fuels. This view was backed up by Ronno Schouten, Design Manager at Feadship, at the Alternative Fuels conference during the 2024 Monaco Energy Boat Challenge:

“Yes, a nuclear-powered yacht will be technically feasible sometime in the future, but why integrate an MMR with an average onboard load of about 10 percent, when you can put it to better use onshore making green fuel like methanol for multiple yachts at maximum power?”

“The regulatory bodies and flag states all agree that nuclear will play a role if we want to go into emission free or more sustainable shipping.”

Although technically possible, onboard nuclear power faces other hurdles. Public perception of the danger of radioactivity, heavily influenced by high-profile accidents like the Chernobyl and Fukushima disasters, is a major concern although sometimes overstated. The latest nuclear technology makes leakage or meltdown highly unlikely, but checks need to be put in place to prevent accidents due to grounding, impact, collision, machinery damage, fire, explosion, and other causes. Last but not least is the near total lack of maritime legislation, insurance policies and flag state rules covering nuclear reactors on yachts.

Left: Thor is essentially a multi-purpose recharging station equipped with a Micro Modular Reactor that dissolves thorium, an abundant and naturally occurring metal with low radioactivity, in molten salt.

Bottom: Feadship’s Relativity concept in 2012 first mooted the topic of a nuclear powered superyacht.

“The regulatory bodies and flag states all agree that nuclear will play a role if we want to go into emission free or more sustainable shipping,” says Jose Jorge Garcia Agis, managing director at Ulstein International. "The main challenge today is that the international regulations for nuclear-powered ships are outdated and based on old nuclear technology. This makes it very difficult to implement them on modern vessels. Ship design is heavily influenced by regulations; we work within the rules. Without clear rules, we have to define our own framework and then seek approval, rather than designing around an existing framework."

The commercial shipping industry is aware of what is at stake. Last year, Fincantieri and RINA signed an agreement with newcleo to carry out a feasibility study for applications in shipping for the nuclear tech company’s leadcooled, small modular reactors. In August Lloyd’s Register announced a project together with Core Power – a leading developer of floating nuclear technology solutions – and A.P. Mølle - Maersk to assess the viability of a nuclear-powered container ship that could be deployed in European waters. Lloyd’s Register further launched a new report at the Monaco Yacht Show in September entitled Fuel for Thought: Nuclear for Yachts that highlights its potential as a clean, powerful and long-lasting energy source.

“Nuclear energy offers the potential to be as transformational to shipping as the shift from wood to iron or from sail to steam,” says Engel-Jan de Boer, global yacht segment director for Lloyd’s Register. “Unlike alternative fuels that might serve as direct replacements for traditional oil-fired systems, nuclear power represents a fundamental shift that could redefine luxury yachting”.

Below: Newcleo’s LFR (Lead-cooled Fast Reactor) is a small nuclear battery producing a 30MW electric output. The nuclear tech company signed an agreement with Fincantieri and RINA last year to explore mini reactor applications for decarbonising the shipping industry.

The first nuclear-powered merchant ship, NS Savannah, was launched way back in 1959 by the New York Shipbuilding Corporation in New Jersey, USA, as one of only four nuclear cargo ships ever built. A demonstration vessel designed to serve also as a passenger ship, she was appointed with 30 air-conditioned ensuite staterooms, dining facilities for 100 passengers, a lounge that could be converted into a movie theatre, a swimming pool, veranda and library. However, high operating costs, low commercial value, limited port access and public concerns about safety led to her being taken out of service in 1971.

Sixty-five years after the launch of NS Savannah, the situation is very different. Nuclear technology is far more advanced, the reactors are much smaller and safer, and the IMO has doubled down on carbon-reduction ambitions by setting a net-zero emissions goal by 2050. Moreover, geopolitical tensions around the world are making the energy independence offered by the nuclear option an increasingly attractive proposition. In this scenario, another Norwegian research project, NuProShip (Nuclear Propulsion of Merchant Ships), is aiming to develop a commercially viable nuclear technology for ships that satisfies all stakeholders and requires no subsidies after the initial development process.

Heading up the NuProShip project is Jan Emblemsvåg, professor of ocean operations and civil engineering at the Norwegian University of Science and Technology (NTNU). He believes that given the poor energy density of other low- and zerocarbon fuels we might not have much choice but to embrace nuclear power for oceangoing vessels, and draws on a very graphic example to make his point: if hydrogen’s energy density was one metre long, uranium would be 32 kilometres long and thorium would be 38 kilometres long.

“This is what the green transition must be about,” he says. “We need to learn how to deal with these two atoms and then we should be just fine.”

The F45 Hybrid Power System is so efficient, you’d swear you were on a sailboat.

Quantum’s new F45 – Electric / Hydraulic Hybrid Power System is 60% more efficient at Zero Speed™ and recovers 80% of the energy in underway mode. Though it resembles the energy efficiencies of a sailboat, it’s designed for a motoryacht.

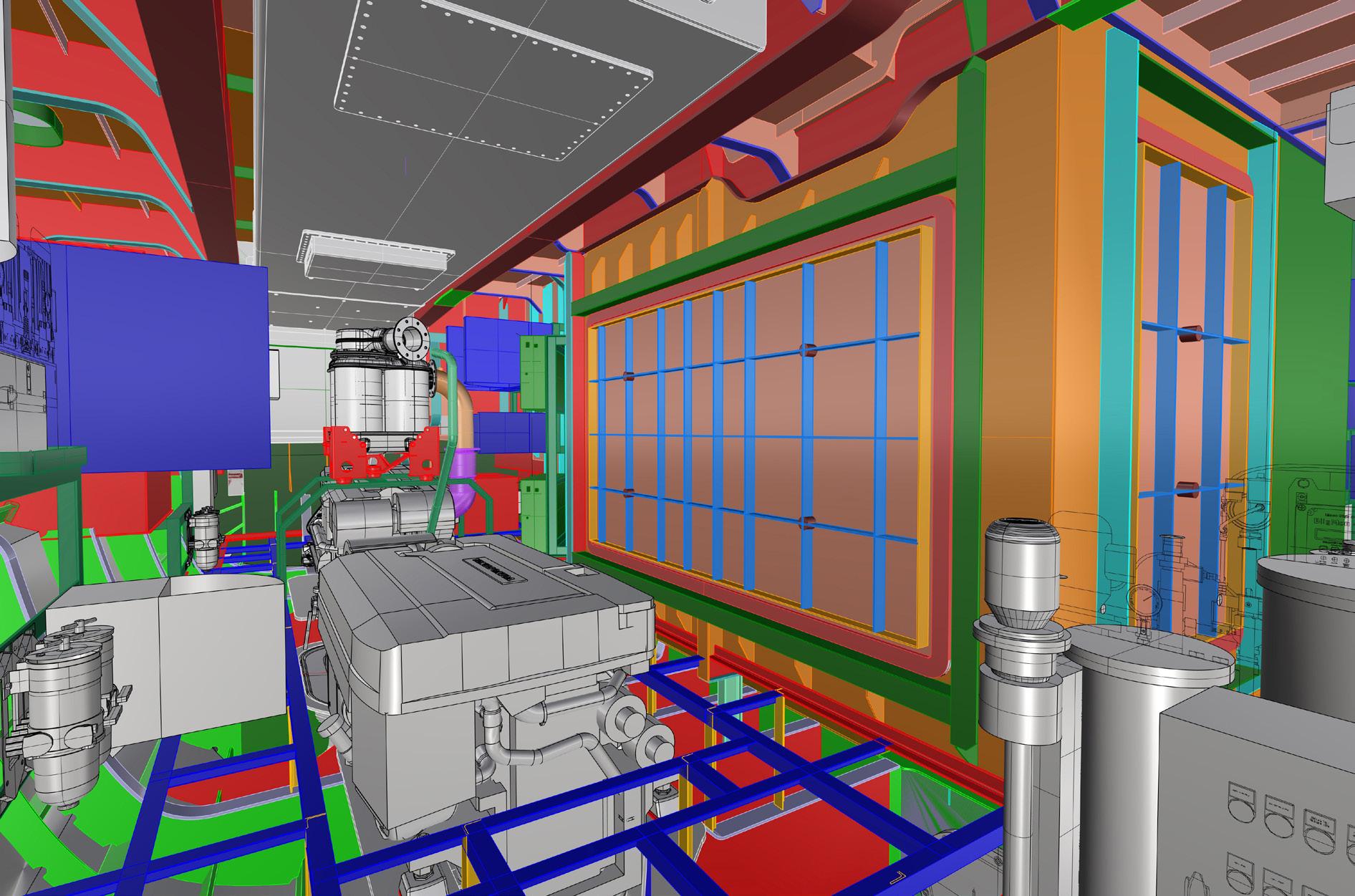

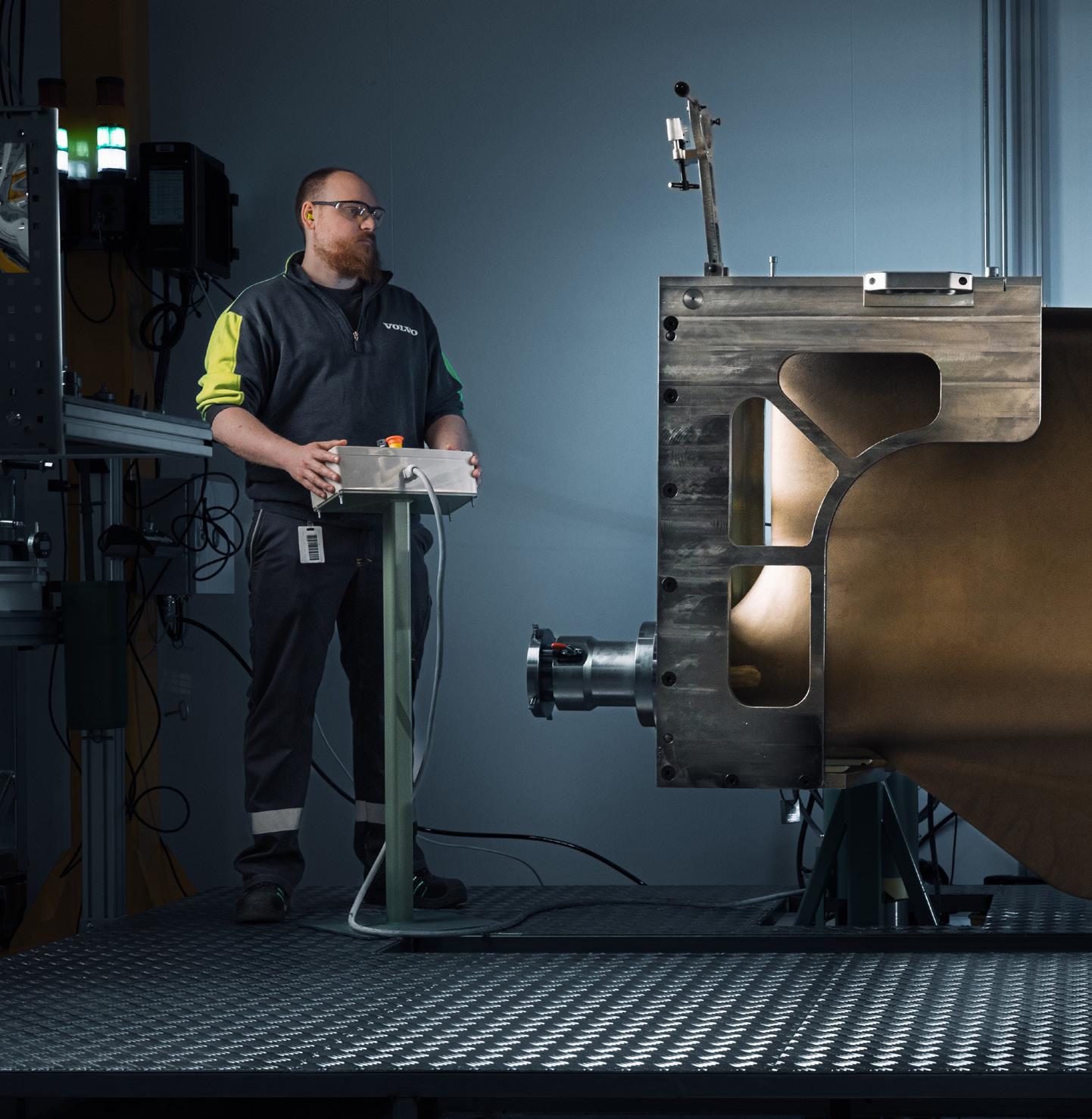

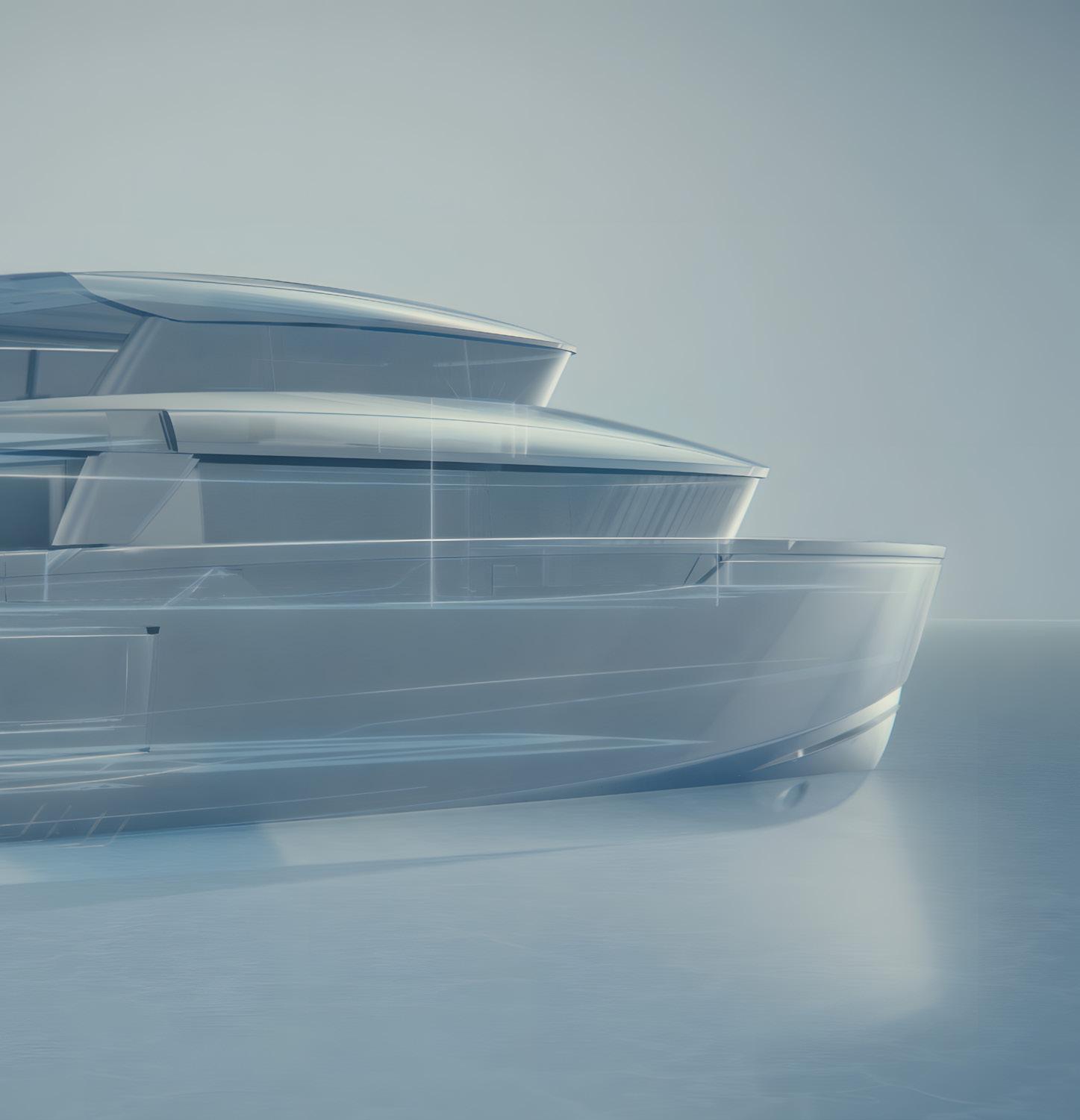

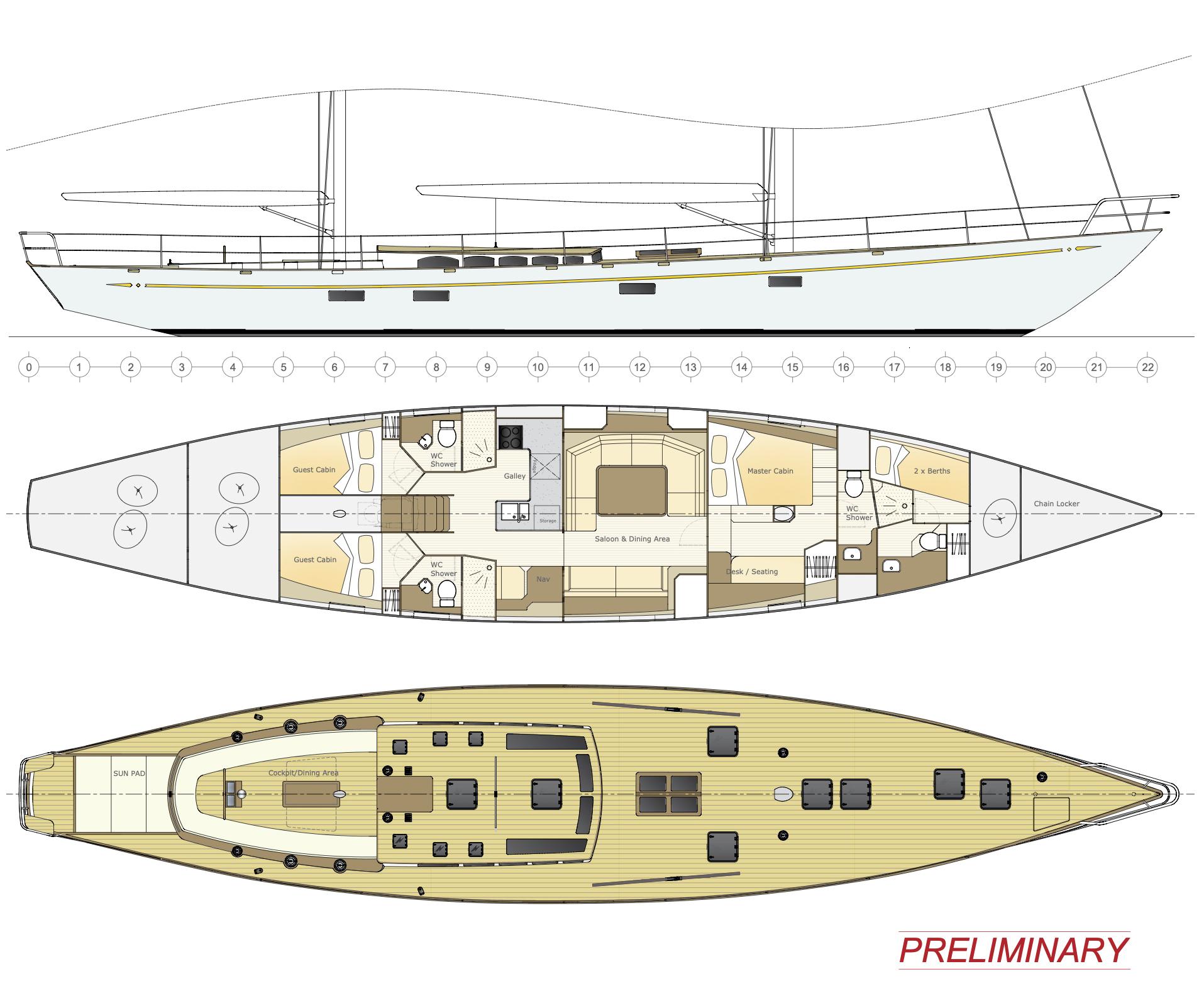

Eyebrows were raised when Italian fibreglass builder Permare announced construction had started on its first steel and aluminium superyacht. Two more Amer Steel projects followed in rapid succession. We take a closer look at the 41-metre explorer yacht, which will be the first to launch next year and the first steel hull to carry Volvo Penta’s new IPS professional platform.

BY JUSTIN RATCLIFFE

Two years ago when Permare started cutting steel on a 70-metre flagship, it represented a massive scaling up in size for the family-owned boatbuilder. The group has been building in fibreglass under the Amer Yachts brand for over 30 years and enjoys a loyal customer base, but the largest model in its composite range to date, the 36.5-metre Amer 120, is fully half the overall length and a fraction of the volume.

“It’s true we’re known for our smaller fibreglass boats, but Permare also has three refit shipyards in Liguria – Cantiere Sanremo Ship, Cantieri del Mediterraneo, and Cantieri del Ponente,” says Barbara Amerio, Permare CEO. “One refit was the complete restoration of Destiny S, a classic 1959 Camper & Nicholson, which involved rebuilding the riveted steel hull, so it’s not like we’re unfamiliar with the material and began building in steel overnight.“

However, Permare had no serious plans to start building new in steel until a satisfied refit customer approached them for the 70-metre project. That contract was quickly followed by another with an experienced client introduced by Luiz De Basto for a 41-metre explorer yacht, and a third sale for a 50-metre hull with a repeat client looking to upgrade from composite to metal. Although all are being built in rented hangars in Pisa, Permare is investing in a new state-of-the-art facility nearby that should be up and running by the end of next year (see sidebar).

Previous

Below:

Bottom: