WF to HSS Shear

• Single-plate

• WT

• Single angle HSS to HSS Shear

• Coped beam

• Exterior plates

• Through bolt & coped beam

WF to HSS Moment

• Flange plate

• WT

• Wrap-around ...and more!

This invaluable — soon-to-be indispensable — and complimentary online resource will save design time by eliminating the need for developing and maintaining custom spreadsheets. Fabrication-friendly typical HSS details are an excellent starting point for design while corresponding calculators enable design completion.

Teams can streamline the design process and enhance collaboration directly on HSS Connections Hub. Engineers can quickly create HSS connection calculations based on the most recent design manual and specific code requirements. Fabricators will receive connection designs that meet requirements and are fabrication-friendly, eliminating back-and-forth revisions.

• Access a growing library of HSS connection calculators and fabrication-friendly typical HSS details, each available with a wide range of options.

• Hub calculators automate and confirm connection designs in real-time based on the AISC Steel Construction Manual, 16th edition.

• Clear and concise results indicate whether the designed connection is efficient and it meets specified requirements.

• Full transparency: Review and verify your calculations against specific code references with a simple click.

• Download or share detailed connection drawings, including dimensions, bolt sizes and other relevant information for easy communication with fabricators.

• Request support from Atlas Tube’s engineering experts on your project.

Sign up today and start using the HSS Connections Hub.

connectionshub.atlastube.com

Watch the how-to video. Currently available connections:

subscriptions@structuremag.org

Chair John A. Dal Pino, S.E. Claremont Engineers Inc., Oakland, CA chair@STRUCTUREmag.org

Kevin Adamson, PE Structural Focus, Gardena, CA

Marshall Carman, PE, SE Schaefer, Cincinnati, Ohio

Erin Conaway, PE AISC, Littleton, CO

Sarah Evans, PE

Walter P Moore, Houston, TX

Linda M. Kaplan, PE Pennoni, Pittsburgh, PA

Available Only at

On the Cover: The Hangzhou Century Center, also known as “The Gate of Hangzhou,” is a prominent urban development situated in the Xiaoshan District of Hangzhou, China. This iconic development comprises two high-rise towers, each reaching a height of 310 meters, connected at their base by a 60-meter-span steel arch bridge.

Nicholas Lang, PE Vice President Engineering & Advocacy, Masonry Concrete Masonry and Hardscapes Association (CMHA)

Jessica Mandrick, PE, SE, LEED AP Gilsanz Murray Steficek, LLP, New York, NY

Brian W. Miller

Cast Connex Corporation, Davis, CA

Evans Mountzouris, PE Retired, Milford, CT

Kenneth Ogorzalek, PE, SE KPFF Consulting Engineers, San Francisco, CA (WI)

John “Buddy” Showalter, PE International Code Council, Washington, DC

Eytan Solomon, PE, LEED AP Silman, New York, NY

Executive Editor Alfred Spada aspada@ncsea.com

Managing Editor Shannon Wetzel swetzel@structuremag.org

Production production@structuremag.org

Director for Sales, Marketing & Business Development

Monica Shripka Tel: 773-974-6561 monica.shripka@STRUCTUREmag.org

Sales Manager Audrey Schmook Tel: 312-649-4600 Ext. 213 aschmook@ncsea.com

Today’s multi-family residential construction design calls for maximum ceiling height with minimal floor-to-floor depth, enabling developers to fit more into multi-story buildings.

To address those demands, Vulcraft-Verco has re-engineered its Dovetail Floor Deck to provide more strength, fire resistance and acoustical performance with as little as 5 ½ inches of deck depth, giving you the design flexibility to create a project that is both economical and practical.

HANGZHOU CENTURY CENTER: ENGINEERING A LANDMARK

By Jin Chen, PE, SE

By Anantha Chittur, SE, PE and Steven Baldridge, PE, SE

Innovative, unconventional solutions abound in a concrete high-rise hospitality project in India.

A suspended steel grid structure connects two towers in this iconic development in Hangzhou, China.

20

By David Fields, PE, SE, and Alex Wiley, PE, SE

An eccentric cantilever and stepping perimeter columns allow a Chicago luxury apartment tower to dramatically capture space at height.

By Eric Grusenmeyer, PE

A phased approach to major renovations at the New Orleans stadium allowed it to remain fully functional and continue to host major sports and entertainment events, ensuring a steady stream of revenue and minimal disruption to schedule.

By Michael A. Tecci, P.E., Brooke H. Shannon, Ph.D.

Wesleyan University endeavored to build a state-of-the-art science complex to expand its reach and grow multiple programs. 42

CAST CONNEX ® Diablo Bolted Splice™ (DBS) is a cast steel fitting that enables unobtrusive field bolted splices in circular hollow structural section (HSS) members.

Effortless to use as it eliminates field welding, and expertly designed such that the bolted connection is inboard of the outer diameter of the HSS.

Seamless DBS splice connectors are offered with thin-gauge plates to conceal the splice, although they can be left uncovered.

Easy to Specify pre-engineered solution, available in sizes to fit a range of HSS/Pipe. Datasheets and sample specification language available at: www.castconnex.com.

Photography by Dustin Williams

By Luke Lombardi, PE and Lauren Wingo, PE (SE 2050 Co-Chairs)

Nabih Youssef

By William L. Coulbourne, PE, Jessica Mandrick, PE, SE, and Adam Reeder, PE, CFM

By Andrew Sundal, AIA, PE; Dave Martin, SE; Emre Toprak, Ph.D, PE; and JohnMichael Wong, Ph.D, SE

Tara Flaherty, EIT

By John Dal Pino, David Seward, Anders Carpenter, Ruth Todd, Maria Flessas, and Dan Bech

By Luke Lombardi, PE and Lauren Wingo, PE (SE 2050 Co-Chairs)

Structural engineers adapt design and construction methods that change with economics, materials, and current research available to shape the built environment—quite literally. From the carved stone used to build the pyramids to the concrete dome of the Pantheon, our profession has answered the evolving needs of society with ingenuity and resolve. And in the wake of disasters, like the 1994 Northridge earthquake, we respond with creative solutions to keep our communities safe. We observe, gather data, calculate risk, develop design formulas, and establish code changes. As storms grow and disasters worsen, our capabilities are needed and we are called to act.

Today, we stand on the brink of another major shift and face a new defining challenge. One that isn’t sudden but accelerating. The science is clear: our development systems use up vast resources, disrupt ecosystems, and create an imbalance of greenhouse gases destabilizing our climate. Concrete and steel, principal materials that define our profession, are among the most carbon-intensive on Earth—contributing upwards of 15% of global emissions. That is six times that of aviation! Continuing to build as we have will use up remaining carbon budgets needed elsewhere.

And yet, at this existential threshold is an incredible opportunity.

Material advancements, smarter design strategies, and emerging policies are opening the door to better collaboration and more efficient, lowerimpact structures. This shift needs structural engineers, and embracing this challenge is a way towards purpose and resilient business practice.

The Structural Engineering Institute’s (SEI) SE 2050 Commitment Program was founded to support structural engineers in this pivotal moment. The vision of SE 2050 is to lead a transition of the structural engineering profession towards a net zero future. Since SE 2050 was established in 2020, the topic of embodied carbon has gone from rogue to vogue to California code. While structural engineers were traditionally left out of sustainability discussions, that is quickly changing as the environmental impacts of structural materials become better understood.

Addressing embodied carbon in the built environment is an opportunity to show the societal value of our profession and advance our other core principles: economic and sustainable use of resources, the use of innovative technologies, and the creation of inspiring structures.

Now in its fifth year, SE 2050 has over 150 firms of all sizes across more than 30 states signed on to the commitment. These Signatory Firms are showcasing an evolution of the structural engineering profession and sit at the forefront of

adopting efficient design approaches and build ing technologies.

It’s important that structural engineers use our voice because we’re often the only ones that know what we know on a project. It’s structural engineers like Fraser Reid at Buro Happold who can evaluate the inefficiency of column transfers. It’s structural engineers like Alexis Feitel at KL&A who can say that steel can be salvaged. It’s structural engineers like Anthony Dente at Verdant inventing very lowcarbon straw panels. And it’s structural engineers like Don Davies at Davies-Crooks Associates that specify the performance characteristics of concrete. All of these structural engineers are members of SE 2050 Signatory Firms, amongst many others showcasing advancement of the profession. Engaging on embodied carbon puts front and center the importance of several themes:

practices—are available on the website, se2050.org. Another key resource published this year is the SE 2050 Commitment Program: 2023 Data Analysis and Findings Report. The findings provide insights on design parameters that most greatly influence embodied carbon.

• Efficiency and Cost Savings: Optimizing designs to reduce material use, engineers lower project costs while reducing embodied carbon. This puts engineers at the table earlier in the design process.

• Adaptive Reuse and Existing Buildings: In 2022, architects made more revenue from renovations than new builds. There’s growing potential in retrofitting and repurposing existing structures.

• Circularity and Material Reuse: Developing skills in deconstructing and reusing materials from existing buildings creates new revenue streams and value-added services.

Lastly, beyond the rational engineering assessment, this work has a resounding positive impact on people. Nearly two out of three people in the U.S. have a sense of personal responsibility toward climate change, but over half don’t know where to take action. For firm leaders, the power to influence our industry towards a better future offers a lasting legacy. And for young engineers, this work is an opportunity to grow in a career developing solutions to address the generation’s biggest challenge. SE 2050 is building a culture of collaboration that recognizes everyone has a role.

If you feel motivated to act, join SE 2050! SE 2050 Signatory Firms publicly share their accomplishments through annually updated Embodied Carbon Action Plans, which outline each firm’s approach to staff education, project impact tracking, reduction targets, and advocacy for embodied carbon-conscious design. These action plans—alongside free resources for advancing design and specification

You can also join us in person. Later this month, the Towards Zero Carbon 2025: Summit and Symposium will be held in Boulder, Colorado. This event will take education into action, bringing together firms collaboratively working to advance structural engineering towards best practices and technologies that foster sustainable, efficient resource use.

This year’s Towards Zero Carbon Summit will include three key tracks:

• Embodied Carbon Bootcamp—Ideal for engineers beginning their embodied carbon education journey.

• SE 2050 Signatory Firm Summit—A first-ever in-person gathering of SE 2050 Signatory Firms to exchange ideas and shape the program’s future.

• Firm Leader Roundtable—A collaborative space for leadership to drive sustainable transformation in our industry.

These tracks ensure structural engineers of all experience levels can engage, whether they’re just starting their sustainability journey, seeking deeper connections within the SE 2050 network, or guiding their firm’s evolving strategy.

The structural engineering profession is being shaped by the societal shifts occurring as a result of a warming world, while also influencing changes to advance design and construction practices towards a net zero future. SE 2050 provides a framework, and its Signatories show a path forward with tools available now. Whether you’re optimizing a new design or reimagining an old one, this is structural engineering’s moment to lead.

Nabih Youssef, a leading California-based structural engineer and seismic design expert and pioneering advocate of steel plate shear walls in areas of high seismic risk, passed away on July 12, 2024, at the age of 80. Born in Egypt, Youssef, SE, F ASCE, FAIA, received a bachelor’s degree in structural engineering from Cairo University in 1967. After emigrating to the United States, he received a master’s degree from California State University, Los Angeles, in 1974 and then a postgraduate diploma in earthquake engineering from UCLA.

As the founder, chair, and CEO of his eponymous firm Nabih Youssef & Associates (NYA), he was a revered expert in the development of earthquake engineering codes and standards. Today NYA is an internationally recognized structural engineering firm with offices in Los Angeles, San Francisco, San Diego, Irvine, South Carolina, and beyond. Youssef’s visionary leadership, innovative engineering, and profound kindness left an enduring mark on the design and construction community. Youssef was a co-author of foundational documents for Performance Based Seismic Design (PBSD), which is a fundamental part of contemporary earthquake engineering.

NYA became known for undertaking landmark projects that had immediate and lasting effects on our communities. His accomplishments were many but those most important are:

• The base isolation of Los Angeles City Hall, a monumental effort to preserve the legacy of the historic tower after the effects of the Northridge earthquake.

• The 54-story LA Live project cited by the American Institute of Steel Construction for special achievement for the use of an innovative steel shear wall system. LA Live’s Ritz Carlton Tower pioneered new applications of PBSD and helped reimagine tall building seismic engineering in high seismic regions.

• The Broad, which houses 2,000 works of art collected by Eli and Edythe Broad, whose prominent collection is now encased in a “veil and vault” concept. To protect the artwork, light filters into the space through a creative honeycomb facade that covers an acre of column-free galleries.

• The base isolation of Our Lady of the Angels Cathedral earned Youssef and team recognition from ENR as Top Seismic Project of the 20th Century in 2006. After the historic Saint Vibiana Cathedral was damaged in an earthquake, the Los Angeles archdiocese commissioned a new $200 million cathedral. The base isolation system consists of 149 rubber bearings and a separate set of 47 steel sliders. The cathedral’s thin concrete walls and alabaster panels allow diffused light to pour inside in a modern take on stained glass windows. Youssef was thrilled to help realize Rafael Moneo’s vision for this contemporary deconstructivist design.

Youssef delighted in historic landmarks and breathing new life into buildings. He saw value in preservation to help neighborhoods thrive, show respect for their past, and bring vibrancy to communities. A few of his passion projects included the restorations and expansions of the Ace Hotel, the Harold Examiner building, the Los Angeles Memorial Coliseum, Dodgers Stadium, and Transbay Terminal in San Francisco. He helped retrofit and restore the Getty Villa, worked on the Walter E Washington Convention Center in DC, and innovated a glass canopy structure to enclose a new atrium supported by the new addition wing of the Cleveland Museum of Art.

A registered civil and structural engineer, Youssef was one of the world’s leaders in earthquake engineering and seismic design and the development of associated standards. His position as the Chair of the Vision 2000 Committee and the Seismology Committee for the Structural Engineers Association of California heavily contributed to the enactment of PBSD, a major conceptual breakthrough for the engineering community. Youssef also chaired the City of Los Angeles’ Mayor’s Blue Ribbon Seismic Hazard Reduction Committee. He authored many technical papers, and taught classes at multiple universities, including lectures on engineering concepts and analysis for high-rise buildings. He served on the University of California Seismic Advisory Board, was part of the Building Seismic Safety Council “NEHRP” Special Programs of the National Institute of Building Sciences in Washington DC and was an Associate Editor for the publication “The Structural Design of Tall & Special Buildings” published by Wiley. He was a pioneer in the use of base isolation to protect structures seismically. His dedication to his work and collaboration with peers were leading aspects of his character.

The catastrophic failure of the Olive View Hospital and Sanitarium during the momentous Sylmar temblor of February 9, 1971, was one of the most important early influences on Youssef’s career. A graduate student in structural engineering at California State University in Los Angeles at the time, he had never felt an earthquake. “It was my first awareness of the severity of Mother Nature,” Youssef recalled to Downtown LA News in 2004. The structural failure of the hospital led to two of the 14 fatalities in the Sylmar quake despite the facility’s state-of-the-art design. This underscored the fact that

earthquake engineering was “an open field and earthquake codes were not fully developed. That’s what caught my creative interest and led to my decision to immerse myself in the field,” Youssef said. While Youssef made his name working on construction projects, his most lasting contributions could ultimately come from work that took place out of public view. Youssef sought to transform the entire philosophy underlying traditional earthquake codes. As chair of the Seismic Safety Committee of California’s Buildings Standards Commission, and as a member of many other panels, Youssef investigated the performance of buildings constructed to code standards before the 1994 Northridge earthquake. The investigation showed that steel-framed structures built to the most demanding specifications at the time were not immune to catastrophic failure during a big event. That finding added momentum to an ongoing shift away from force-based code prescriptions that lay out a list of generalized strength features that every building must have. Youssef and others urged regulatory agencies to adopt PBSD standards, which set goals ranging from preventing collapse to protecting property at various seismic intensity levels and performance objectives.

California’s State Historical Building Code is an example of standards that incorporate performance-based guidelines. “While not compromising life safety, it still allows alternative, creative methods of interventions which limit the intrusion and help protect the historic fabric of old buildings,” Youssef said. This transformation in thinking about earthquake safety deserves a good deal of credit for the downtown Los Angeles renaissance, especially along the Historic Core. People widely regarded Youssef as one of the leading thinkers among structural engineers within the adaptive reuse movement. When it came to historic structures, such as steel frame/brick

infill buildings, Youssef wanted to take advantage of the quality of the original designs. “The common view … was that masonry walls had no value. Retrofitting them required tons of shear walls and foundations, which was not feasible,” Youssef said. In fact, the intrusive intervention required under older codes sometimes did more harm than good, he added, not only to the historic character of old buildings but to their structural integrity. A better way to retrofit historic buildings, Youssef said, is to supplement the inherent strength of masonry walls with reinforced concrete frames, carbon fiber mats and other unobtrusive, lightweight materials. Those are also the most cost-effective methods.

Youssef played a key role in the booming reuse of beautiful historic buildings in the downtown, historic core of Los Angeles. Redevelopment was possible because of an improved partnership between developers and city officials who were receptive to novel approaches to earthquake design. “I wouldn’t use ‘flexible’ to describe their approach. Building officials feel guilty about that word,” Youssef said. “But I would say we now have much better collaboration between the city and leading engineering firms and practitioners. That has allowed us to implement cost-effective, elegant solutions, and in a timely manner too.”

Youssef was a husband and father of three. He created a national educational charity for children in need, https://www.copticedu.org/, and co-founded several schools. He changed the lives of countless people with opportunity, and more often with kindness.

With generosity and creativity, Nabih Youssef transformed structural engineering forever, leaving the profession better than he found it. His spirit of innovation and compassion will continue as his firm’s guiding principle as they carry his legacy forward into their next chapter. ■

With more than 65 years of thoughtful product innovation and leadership in structural engineering, Simpson Strong-Tie offers smart solutions for mass timber to meet this industry’s unique demands. Our connectors, fasteners, adhesives and mechanical anchors are rigorously tested to provide strength and design flexibility. Along with a nationwide supply network that delivers exactly what you need when you need it, our solutions and expertise can help you build mass timber projects faster, stronger and easier. For the latest information on our growing line of mass timber products, visit strongtie.com/masstimber.

The new revisions were primarily influenced by the need to make the standard compatible with ASCE 7-22 Supplement 2 and ten years of post-disaster flood assessments.

By William L. Coulbourne, PE, Jessica Mandrick, PE, SE, and Adam Reeder, PE, CFM

ASCE 24 was last revised in 2014, over a decade ago while major flood events have caused severe damage to the nation’s building inventory and infrastructure. This standard, titled Flood-Resistant Design and Construction was first published in 1998 and was revised in 2005 as well as in 2014. ASCE 24-14 has been adopted into the International Building Codes by reference and is used across the country to guide building and re-building in areas designated as floodplains. This latest revision, ASCE 24-24, has been submitted for consideration in the 2027 IBC and is intended to improve building performance during floods by requiring higher elevations for buildings in floodplains and by strengthening many provisions that address how to construct buildings subject to flooding. This revision also aligns flood design requirements with the recent changes made to ASCE 7-22, Supplement 2 as they relate to more stringent standards being applied to flood load design. This standard revision provides a resource for the practice in the form of a Commentary section that provides examples of buildings in floodplains to illustrate how to use the new provisions, especially as they relate to the new elevation requirements.

Previous versions of ASCE 24 had minimum elevation tables that required a minimum elevation to the Base Flood Elevation (BFE) plus

some amount of freeboard. The BFE is FEMA’s regulatory minimum elevation or the elevation of the 1% annual chance flood, which is used for the National Flood Insurance Program (NFIP). Freeboard is an additional elevation that provides a margin of safety above the BFE minimum elevation. The NFIP requires communities to adopt minimum construction standards and in exchange makes flood insurance available for properties. In ASCE 24-14 and prior editions, the required amount of freeboard was dictated by the Flood Design Class (FDC) of the building; the higher the class (from 1 to 4), the greater the amount of freeboard generally. ASCE 24 uses FDC to distinguish building use types instead of Risk Categories used by ASCE 7; while the FDC aligns closely with Risk Category, FDC provides more specificity on the use types in each class.

ASCE 24 strives to meet or exceed the NFIP requirements. The elevation requirements in ASCE 24-24 are now driven by the Design Flood Elevation (DFE) which is determined by applying the higher of the locally mandated elevation requirements and a Mean Recurrence Interval (MRI) flood event. The MRI flood event is different for each FDC. FDC 2 buildings (most commercial and residential buildings) require a minimum elevation to the 500-year flood level; FDC 3 buildings require a minimum elevation to the 750-year flood level; and FDC 4 buildings require elevation to the 1,000-year flood level. Since there is very little information about the elevation of 750- and 1,000-year floods, there are scaling factors provided to help designers estimate those higher flood levels. The 500-year flood level is often provided in Flood Insurance

Studies (FIS) and the extent shown on FEMA Flood Insurance Rate Maps (FIRMs). Table 1-2 from the new standard is shown above slightly modified as Table 1 here.

The DFE is calculated as the DFE = FE com or (FEMRI + ΔSLC) where

• FE com = Flood elevation established by the community, and

• FEMRI = Flood elevation based on the required minimum MRI for the flood design class of the building or structure (500-year for Class 2, 750-year for Class 3, 1000-year for Class 4), and

• ΔSLC = Relative sea level change which shall not be taken as less than 0 As noted previously, flood elevations are generally available for 10-, 50-, 100- and 500-year flood events and are shown in the FIS and/or FIRM for the flood source of interest. The needed elevations for 750and 1,000-year elevations are almost never available unless a site-specific study has been performed. Therefore, two new tables were added that designate how to find the needed flood elevation when only certain pieces of information are available. The methods in these tables accommodate the range of flood data available on reports and maps throughout the country and are listed in order of most commonly available. One table describes the methods for noncoastal flood sources, and one describes the methods for coastal flood sources. The noncoastal flood source table (Table 1-3 in the standard) has five possible methods for each of the four FDCs. Table 2 is a slightly modified version of Table 1-3. The coastal flood sources table (Table 1-4 in the standard) has four possible methods for each of the four FDCs. Table 3 is a slightly modified version of Table 1-4. Tables 1-5 and 1-6 of the standard list the scaling factors necessary to calculate for higher return period events for coastal flood sources when the FEMRI information is not available. The intent of including Tables 2 and 3 shown here is to provide a minimum elevation for the structure that will elevate the structure above the MRI flood event and generally limit the MRI flood loads imposed on the structure per ASCE 7-22, Supplement 2. One example of this comparison is provided in this article in the Example Elevation Section.

There are worked examples for finding the correct minimum elevation for the nine cases (five noncoastal and four coastal) in the ASCE 24-24 Commentary for Chapter 1. The examples use various FDCs, and thus various design associated mean recurrence intervals to provide a range of possible approaches to obtaining the correct DFE. Since in each case, there is a minimum required elevation of either the BFE + freeboard or the DFE, there is a comparison in each example of which is higher—the BFE + freeboard or the DFE.

The elevation requirements carry over into other sections of the standard instead of being repeated and only slightly modified. The previous versions of ASCE 24 had separate elevation tables for Chapter 3 (primarily A zones), Chapter 4 (primarily V Zones and Coastal A Zones), Chapter 6 (Dry and Wet Floodproofing), and Chapter 7 (utilities). Those tables have been removed in ASCE 24-24 and the elevation requirements for these flood subjects are covered fully by Chapter 1 and Table 1-2. The other chapters now simply refer to Table 1-2 when elevation requirements are mentioned in each chapter. To further simplify the determination of the minimum elevation requirements, a web-based tool has been developed by the committee and the LSU AgCenter that will be released in conjunction with ASCE 24-24 in order to aid design professionals and local officials with minimum elevation determinations. Sections 2.3 and 4.4 of ASCE 24-24 on Elevation Requirements are measured consistent with ASCE 24-14 in that the minimum required elevation for buildings in noncoastal and coastal areas with small waves is for the top of the lowest floor to be elevated to or above the elevation established in the new Table 1-2 (shown here as Table 1), and in areas where the 100-year wave heights are greater than 1.5 feet, the bottom of the lowest horizontal structural member of buildings must be elevated in accordance with the same Table 1-2 requirements. Tables 2 and 3 shown here describe for the practitioner how to achieve the requirements of Sections 2.3 and 4.4 for different conditions related to the flood elevation data available.

elevations (SWEL) available

Method C: Only 100-year flood elevation available

Method E: 100-year flood elevation not available

1 100-year FE100 FE100 FE100 100 com

2 500-year FE500 SWEL500+ [CMRI_100(FE100-SWEL100)]

3 750-year FE750

4 1,000-year FE1000

CMRI_500(SWEL500-Zdatum) + [CMRI_100(FE100-SWEL100)] + Zdatum

CMRI_500(SWEL500-Zdatum) + [CMRI_100(FE100-SWEL100)] + Zdatum

CMRI_100(FE100-Zdatum)+Zdatum

CMRI_100(FE100-Zdatum) + Zdatum

CMRI_100(FE100-Zdatum) + Zdatum

CMRI_100(100com -Zdatum) + Zdatum

CMRI_100(100com -Zdatum) + Zdatum

CMRI_100(100com -Zdatum) + Zdatum

Where SWELMRI represents the stillwater elevation at a specified MRI and CMRI_xxx represents the scaling factor from Table 1-5 or 1-6 (in the standard) depending on the MRI. Zdatum is permitted to be zero for the Gulf of Mexico and all other coastal sites. For Great Lakes and all other coastal lake sites, the Zdatum is the chart datum or low water datum.

The determination of the DFE must now include consideration of sea level change in coastal flood locations. The standard requires that a building service life of 50 years be considered into the future, and that the amount of sea level rise be based on the historic rate of change (over the previous 40 years) at the building site location times the 50-year service life. A sea level change value of less than zero is not allowed. There is information in the commentary that discusses how to find the sea level change for many locations around the country. Data developed and provided by the USACE and NOAA covers many coastal locations around the country. There is no requirement that a site-specific study must be conducted in order to find the rate of sea level change at a specific project site. This requirement to include consideration of sea level change is in line with the requirements in ASCE 7-22, Supplement 2. Designers and owners may wish to consider a greater amount of sea level rise based on projections of future conditions, but such predictions are not required by ASCE 24-24.

Example Elevation Determination Comparison: ASCE 24-24 and ASCE 7-22, S2

Givens:

Building is FDC 2 located on the Gulf Coast Community has adopted ASCE 24-24 and requires 1 foot of freeboard FIRM Map indicates the BFE = 13 feet which is to the top of the wave at this coastal location

FIS at transect of interest indicates SWEL100 = 10.8 feet and SWEL500 = 15.1 feet

Rate of historic sea level rise is 0.015 feet/year and is to be used for a 50-year building life

Elevation at the site taken as 0 feet which is the coastal datum

Find the required minimum elevation in accordance with ASCE 24-24 and the equivalent elevation for loading in ASCE 7-22, S2. Since the FE100, SWEL100 and SWEL500 are all known, use Method B from Table 3 above to find the elevation required by ASCE 24-24.

1. The required minimum elevation to meet the community regulation (see Table 1) = FE100 = 13 feet+1 feet = 14 feet

2. The elevation required to comply with ASCE 24-24 for FDC 2 buildings = SWEL500+[CMRI_100(FE100-SWEL100)] = 15.1 + 1.35 (scaling factor from Table 1-5 in standard)*(13-10.8) = 18.1 feet

ΔSLR must be added to this elevation to determine the final FE500 for DFE comparison, so 18.1 feet + 0.015*50 = 18.9 feet

3. Compare FEcom to FE500 to determine the DFE and then compare to minimum elevation requirements. FEcom = 14 feet < FE500 = 18.9 feet = DFE. DFE = 18.9 > BFE + 1 feet (13 + 1 foot = 14 feet).

The required elevation for ASCE 24-24 = 18.9 feet

4. The elevation for loading in ASCE 7-22, S2 is determined using Equation 5.3-1 (ASCE 7-22) or df = (SWELMRI-Ge) +ΔSLR where df = design stillwater flood depth, Ge = ground elevation and ΔSLR = change in sea level elevation. In this example, df = (15.1 – 0) + 0.75 feet = 15.85 feet

We do not know the wave height for the FE500 event; we only know the SWEL500. Therefore, we must find the FE100 wave height and use a scaling factor from Table 5.3-3 (ASCE 7-22).

We must find the top of wave elevation so the result can be compared to the ASCE 24-24 result. The controlling wave height above the SWEL100 is the BFE = 13 – 10.8 feet = 2.2 feet and the controlling wave height above the SWEL is 70% of the total wave height so the total controlling wave height for the FE100 = 2.2/0.70 = 3.1 feet

The total controlling wave height (HC500) for the 500 year MRI = 3.1 feet*1.3 (scaling factor) = 4 feet The wave portion above the SWEL = 0.70*4 feet = 2.8 feet so the DFE (FE500 elevation equivalent) = 15.85 feet + 2.8 feet = 18.7 feet

5. Therefore the required minimum elevation using ASCE 24-24 is 18.9 feet which is greater than 18.7 feet (ASCE 7-22 DFE) and so it may not be necessary to increase the minimum elevation of the building to minimize loading.

If the ASCE 7-22 DFE was greater than the ASCE 24-24 required minimum elevation, then a designer may consider elevating the floor system to minimize the flood loads on the building.

In addition to changes in required elevations for structures, there were changes to several other important sections in ASCE 24-24. These changes primarily deal with flood proofing methods other than elevation and materials used for flood-prone structures. The change in minimum elevation also required addressing the extent of the 500-year floodplain.

ASCE 24-24 expanded the floodplain from the requirements of the previous

version. ASCE 24-14 only required the provisions of the standard to apply to the delineated Special Flood Hazard Area (SFHA) or the 100-year floodplain as shown on FIRMs. A significant change was made to ASCE 24-24 to expand the floodplain to also include the Shaded X Zone (500-year floodplain) where it is mapped. The standard also allows communities to delineate their own floodplain if it is more restrictive than the SFHA and Shaded X Zone shown on the FIRM. This brings ASCE 24-24 further into alignment with ASCE 7-22 Supplement 2.

Significant language is added regarding the use of materials in salt-laden environments and expanded on materials and material standards that should be consulted when the building is to be located near a coastline where salt exposure is prominent. Steel and concrete material especially received additional discussion, particularly as it relates to metal connectors and reinforcing steel for concrete or masonry. Two new ASTM standards are discussed regarding flood damage-resistant materials. ASTM E3075-24 is a Standard Test Method for Water Immersion and Drying for Evaluation of Flood Damage Resistance, and ASTM E3369-24 is a Standard Specification for Determining the Flood Damage Resistance Rating of Building Materials. This is the first time that such an evaluation method for flood damage-resistant materials has been available to designers. This will help address the NFIP requirement that all materials installed below the minimum elevation be resistant to flood damage. It will also provide manufacturers with a method of certifying that new products are indeed flood-damage resistant.

The requirements for dry floodproofing are allowed in only A Zones (primarily riverine flood areas) and Shaded X Zones (500-year floodplain areas) and similar noncoastal locations and require flood opening barriers to have passed the tests and be certified as described in ANSI 2510, American National Standard for Flood Mitigation Equipment. This means that in order to be used in flood mitigation projects that require compliance with ASCE 24-24, all opening barriers such as shields, flood barriers, closures over doors and windows must meet the ANSI 2510 standard. That also means that designers who will certify compliance, must assure themselves of such compliance.

Designers who certify compliance with the dry floodproofing requirements will need to make sure flood barriers have been tested to the flood depth required of a specific design; they will need to know how the flood barriers are to be installed and design attachments for such flood barriers; they will need to conduct a flood vulnerability assessment of an existing structure where flood barriers are planned and specify how to seal up any other small openings that might exist in the structure’s exterior walls. There is more specific information provided about what type of shields are allowed for each FDC for both new construction and for

substantial improvements. Additionally, more discussion is provided about the use of dry floodproofing techniques for non-residential buildings and non-residential space in mixed-use buildings. Distinctions are made between a barrier for a building opening (i.e. door or window) and a “temporary floodwall.” Floodproofed wall systems must be marked to indicate the level of floodproofing sealant to minimize the potential for unsealed penetrations to be made through a sealed wall system, which would compromise the floodproofing.

There are new inspection, maintenance, and operations plans required to be filed with the

Authority Having Jurisdiction (AHJ), and actual deployment of equipment and exercising the operations plan is required annually (or as stipulated by the AHJ). Post-disaster assessment indicates that most flood damage to dry floodproofing systems occur because of poor design, poor installation, not knowing where the floodproofing shields or devices are located, and the owner or support personnel not knowing how to install measures properly. There are maximum times allowed for the deployment of active dry floodproofing systems based on Flood Design Class. For wet floodproofed buildings, exceptions were added for the location of flood vents based on restrictions imposed by the geometry of the spaces with only one exterior wall and on sloped sites.

Additionally, two other changes were made to the standard based upon post-disaster assessments. The standard now addresses elevating existing slab-on-grade buildings, which has been a common practice in some parts of the country as a way to elevate the lowest floor of a house and bring that house into compliance with the NFIP. However, there have been structural slab failures when this has been done, since most slabs have minimal thickness and minimal to no reinforcing steel. Additional language has been added in ASCE 24-24 to make sure the existing slab is assessed for strength, strengthened as needed and connected properly to the new foundation to be able to resist uplift and buoyancy as required. There were also changes to the standard to require that when there is an entrance from the elevated building into an enclosure below the building that the door must be an exterior grade door. This was added based upon elevated buildings being damaged during flood events due to the failure of doors leading into enclosures, leaving the buildings open and unable to be secured.

The new revisions to ASCE 24-24 were primarily influenced by the need to make this Flood-Resistant Design and Construction Standard compatible with ASCE 7-22 Supplement 2 and ten years of post-disaster flood assessments. Many users will recognize the increase in the floodplain extent and the additional elevation requirements. The committee considered the use of the standard for both design and floodplain management in development of the requirements. Engineers will need to consider the minimum elevation requirements in ASCE 24-24 and the minimum elevation for flood load consideration in ASCE 7-22 Supplement 2 and should use that when determining how high to elevate buildings. The material, slab, and enclosure access provision should further reduce damage to elevated buildings. Innovations in the dry floodproofing requirements should reduce the potential risks for both new and substantially improved floodproofed buildings. The changes are viewed as a major improvement to flood resistant design and are intended to reduce flood losses with increased building flood protection and increased national resiliency. ■

Full references are included in the online version of the article at STRUCTUREmag.org .

Stronger Reinforcement and Cost Savings from the Geotechnical Foundation to the Superstructure

DYWIDAG THREADBAR® Reinforcing Steel ASTM A-615 (Grade 75/80 & 100)

• Enhanced Strength

Utilize higher grade steel for increased usable space and stronger reinforcement.

• Material Efficiency

Use less material to reduce job-site congestion, handling, and your carbon footprint.

• Lightweight and Practical

Ideal for prefabricated cages, our lightweight reinforcement assemblies simplify transportation and installation.

• Easy Installation

Save labor with our robust threaded bar, coupler system, and accessories. Eliminate the need for lap splices or on-site thread cutting.

• Melted and Manufactured in the U.S.A.

• Versatile Options

Available in a wide range of sizes, from #6 to #32, to suit your specific project needs.

• Superior Durability

Hot rolled for exceptional strength and long-lasting durability.

• Protective Coatings

Choose from epoxy coating or galvanized options for added protection.

• Custom Lengths

Available pre-cut to your required length, ensuring convenience and precision.

A suspended steel grid structure connects two towers in this iconic development in Hangzhou, China.

By Jin Chen, PE, SE

The Hangzhou Century Center, also known as "The Gate of Hangzhou," is a prominent urban development situated in the Xiaoshan District of Hangzhou, China. Positioned between the Hangzhou International Expo Center to the east and the Olympic Sports Center Training Hall to the west, the project is envisioned as a striking gateway to the city. This iconic development comprises two highrise towers, each reaching a height of 310 meters, connected at their base by a 60-meter-span steel arch bridge. The surrounding commercial blocks form a dynamic mixed-use complex, offering office spaces,

With a total construction area of approximately 526,000 square meters—370,000 square meters above ground and 160,000 square meters below— the twin 63-story towers are designed to resemble the letter "H," a symbol of Hangzhou's identity. A suspended steel grid structure connects the two towers starting at the 21st floor, creating an expansive public space above the bridge, enhancing both the functional and architectural scope of

Hangzhou is located in a region of moderate seismic activity and medium wind pressure. The lateral design of the towers’ structural system is primarily governed by seismic effects. The structural system itself is a highly efficient and robust integration of distinct yet complementary components. It is designed to leverage the stiffness, mass, and damping characteristics of a rigid central core and a ductile perimeter moment frame, optimizing resistance to dynamic wind forces while efficiently dissipating seismic energy.

Each tower features a centrally located reinforced concrete core tube, which transitions from an elongated octagonal shape at the base to a rectangular form by the 44th floor. The core resists the majority of lateral seismic and wind loads. The perimeter frame is a composed of reinforced concrete beams and composite SRC columns which could provide the excellent ductile for seismic and minimize the sizes. The perimeter moment frame is proportioned to ensure effective load sharing, maximizing efficiency as the second defense system for seismic.

The towers’ oval-shaped floor plans taper along their height, resulting in a highly dynamic, aerodynamically optimized massing with a rounded corners and tapered shape, highly integrated with architectural layouts. This shape helps to disrupt wind vortex shedding, thereby reducing wind-induced vibrations and loads, leading to significant material savings.

The floor system consists of one-way reinforced concrete beams and slabs within and beyond the core. Although cast-in-place concrete floors typically extend construction timelines, the contractor was able to implement a three-shift work schedule per day for concrete construction, whereas steel construction was limited to one shift per day due to local regulations. As a result, the concrete system did not delay the schedule while simultaneously achieving structural material cost savings.

The steel arch bridge spans 62 meters between the two towers, elevating 34 meters above the ground. Comprising six parallel arch trusses aligned with the tower columns, the bridge is supported by rigid connections at the ground level, where it integrates with the steelreinforced concrete columns of the towers. The horizontal thrust of the bridge is transferred to the core tubes of the towers via the continuous floor slab system at the ground level, ensuring stability and load distribution.

The bridge serves dual functions: a pedestrian walkway at the 6th floor and a banquet hall at the 3rd floor. The arches of the bridge are defined by the Funicular form-finding to minimize the bending moment under gravity. The diagonal braces are incorporated to enhance lateral stiffness since this building-type bridge still needs to meet with building structural control ratios. The bridge’s natural frequencies are 1.23 seconds

in the X-direction, 1.18 seconds in torsion, and 0.99 seconds in the Y-direction, ensuring its stability under dynamic loads and providing a resilient structure for varied use.

The suspended roof structure spans approximately 60 meters between the two towers, hanging from the 21st floor. It is composed of bidirectional steel grid members with vertical curvature optimized through the catenary geometry concept; each segment of the grid is straight with the H section. The horizontal curvature is carefully designed to simplify node connections and enhance the architectural aesthetics. Horizontal restraint systems located on the 18th, 14th, and 11th floors provide lateral stability for the suspended roof and incorporate tension cables and compression struts. Vertical steel members support the side walls of the suspended structure, hanging from the edge beams of the roof. These vertical members are laterally restrained at the 6th and 3rd floors of the bridge but are free to move vertically, accommodating differential displacements.

The drape roof is one of the project’s most innovative features, drawing inspiration from the natural shape of a hanging chain, which forms a catenary curve under its own weight. This geometry ensures the roof predominantly carries axial forces to minimize bending moments and optimize material efficiency, which contributes to both structural performance and sustainability.

The initial geometry of the longitudinal drape grid was derived from the classic catenary equation. However, this equation assumes uniform segment lengths and constant gravity loads per segment. Given the varying segment lengths and loads in the drape grid, iterative calculations and adjustments were required to account for the actual gravity loads at each node. This process ensured the final catenary geometry efficiently supports its self-weight

The integration of the steel grid roof and glass panels was a key design challenge, demanding precise coordination to balance structural integrity with aesthetic refinement. The objective was to maintain the majority of the glass panels in a flat configuration while accommodating the doubly curved geometry of the draped roof.

To achieve this, the roof's surface was designed using a scaled-translational approach, beginning with defining a central catenary curve, which is then subdivided into multiple straight-line segments based on the target glass panel dimensions. Due to the tapered form of the tower and different hanging ends, adjacent catenary curves span slightly longer distances. These adjacent curves are generated by scaling the central catenary—preserving the segmentation—and translating it to its designated location. This procedure is repeated to generate the series of catenary curves across the surface. Finally, corresponding division points between adjacent curves are connected with straight lines, forming a quadrilateral grid, which defines the layout for the glazing panels. This method ensured that the glazing panels remained perfectly flat while conforming to the overall curvature of the structure. Each glass panel was supported by a quadrilateral steel grid, with panel edges precisely aligned to the grid lines. The flatness of the panels was meticulously controlled through careful geometric calibration of the grid and strategic orientation of the steel members.

The optimized geometry allows 97% of the grid members to use standard H-section steel (HN300x150x6.5x9), with localized reinforcement (H300x150x10x25) at stress concentration areas. The total steel weight of the roof, including nodes, is approximately 700 tons. The sidewall of the drape roof connects the edge of the drape, which

Each grid node consists of a steel tube with four H-section members connected to it.

The steel bridge was finished in 6 months and the steel drape roof and side walls were constructed in 11 months during the pandemic time.

is straight in plan, to the edge of the bridge structure, which is curved in plan. It also meets the towers along a line angled in elevation. The hanging mullions of the sidewall are designed to be as evenly spaced as possible while maintaining a funicular shape under gravity to minimize bending.

To achieve these design constraints, 3D graphic statics were employed. In this approach, force magnitudes within the structure are represented by the lengths of lines in a force diagram, while equilibrium at each node is ensured by the closure of force polygons. By imposing geometric constraints on these diagrams, a 3D funicular structure in equilibrium was developed.

Although the structural logic of the sidewall precludes the use of entirely flat glass panels, the relatively shallow curvature ensures that cold-bent glass panel warping remains within acceptable limits, even under wind-induced deflections.

The grid nodes of the suspended roof are designed to simplify construction and ensure structural efficiency. Each node consists of a steel tube with four H-section members connected to it. The flanges of the H-sections are welded to circular plates at the top and bottom of the tube, ensuring continuity of the load path. The orientation of the I-section member axes is carefully specified to ensure that the webs of every I-section intersecting at a node align along a common line, known as the "node axis." This eliminates geometric torsion and simplifies detailing and documentation. The sidewall connections were designed as hinged joints, allowing for construction tolerances and accommodating differential displacements while maintaining structural integrity.

Wind tunnel testing was conducted to determine the wind loads on the suspended roof and side walls. The tests provided eight wind load cases for the structural design, with wind pressures ranging

from -2.27 kPa to 1.73 kPa. The natural frequency of the suspended roof was controlled to be around 1 Hz to ensure accurate wind load predictions.

The maximum deformation of the suspended roof under wind loads is 132 millimeters, which is acceptable for a 60-meter span. The lateral deformation of the side walls at the connection points with the towers is 47 millimeters inward and 68 millimeters outward, within the allowable limits for the curtain wall system.

The deformation of the twin towers under wind and seismic loads has a minimal impact on the suspended roof due to the high stiffness of the towers relative to the roof structure. In the integrated structural model, the lateral deformation of the towers at the connection points with the roof is 30 to 50 millimeters, which has a negligible effect on the overall behavior of the grid roof. The porous grid roof reduces wind loads while promoting natural ventilation at the concourse level.

The deformation of the suspended roof is controlled to ensure the safety and functionality of the glass panels. The out-of-plane deformation of the panels is limited to 1/50 of the diagonal length, while the in-plane shear deformation is controlled by designing the panel connections to allow for relative displacements.

The structural performance of the suspended roof was evaluated using finite element analysis. The analysis considered gravity loads, wind loads, and seismic loads, as well as the interaction between the suspended roof and the twin towers. The results confirmed that the roof meets all design requirements, with sufficient stiffness and strength to withstand extreme loading conditions.

Following the completion of the foundation and basement, construction of the two towers commenced simultaneously from ground level. A climbing formwork system was utilized for the reinforced concrete shear wall core, which progressed approximately two floors ahead of the column, beam, and slab floor system. The typical construction pace averaged six days per floor. Upon reaching level 24, construction of the steel bridge began. The two cores were engineered to resist the thrust forces from the steel bridge. Each bridge arch was prefabricated in two segments at the shop, with the six steel arches erected first, followed by the installation of steel braces, columns, and floor members. The superstructure construction for both towers was completed in 13 months.

The construction of the drape roof presented several challenges, including the need for precise positioning of the grid members and the installation of the glass panels. The construction of the suspended roof involves the following steps:

1. Complete the main structures of the twin towers and the steel bridge.

2. Install temporary scaffolding system on the 6th floor of the top of bridge up to the 20th floor.

3. Assemble large segments 2x2, 2x3, 3x3 grid modules of the roof grid steel in the shop and lift them into position using cranes.

4. Install grid roof steel segments from the lowest mid strip of the roof.

5. Connect the edge beams of the roof to the side walls and install the vertical steel members.

6. Install the horizontal restraint systems at the 18th, 14th, and 11th floors.

7. Install the glass panels on the roof and side walls, ensuring uniform loading.

The Hangzhou Century Center project demonstrates the feasibility of using catenary geometry and advanced structural analysis techniques to design long-span suspended structures. The project’s success provides valuable insights for future projects, particularly in the design of lightweight, efficient, and aesthetically pleasing structures.

The successful realization of the Hangzhou Century Center project would not have been possible without the dedication and expertise of the entire project team. Special acknowledgment is due to structural team members William Baker, Dane Rankin, Toby Mitchell, Han Ding, Max Cooper, and Ben Johnson for their innovative approach to architectural integration and structural aesthetics. Their collective efforts and seamless collaboration were pivotal in transforming this ambitious vision into a tangible landmark.

The suspended grid steel structure of the Hangzhou Century Center stands as a remarkable achievement in contemporary structural engineering. Through the innovative application of catenary geometry, advanced wind tunnel testing, and meticulous construction planning, the project has produced a structure that is not only highly efficient but also visually striking. Its success offers valuable insights for the design and construction of future long-span suspended structures and supertall buildings, pushing the boundaries of engineering excellence. ■

Innovative, unconventional solutions abound in a concrete high-rise hospitality project in India.

By Anantha Chittur, PE, SE and Steven Baldridge, PE, SE

Mumbai, often referred to as India’s financial and commercial capital, is known as the “City of Dreams.” True to this reputation, the city's projects are often ambitious in both scale and vision. One such landmark development is Maker Maxity, a sprawling 20-acre integrated commercial, entertainment, and hospitality complex located in Mumbai's central business district, the Bandra Kurla Complex (BKC).

The hospitality component of Maker Maxity spans 1.2 million square feet and features two tower blocks, each comprising four interconnected towers. These towers, housing luxury-branded hotels, stand 16 stories tall with a combined total of 475 rooms. Beneath them lies a five-story podium stretching more than 800 feet from end to end—notably designed without expansion joints. The structure also includes three basement levels for back-of-house operations, parking, and services. Atop the podium, a roof deck offers a pool and restaurant

with views of the Mithi River. While the design accounted for a future vertical expansion of five additional floors, this plan was ultimately set aside during initial construction.

The project's schematic design was originally based on a structural steel system featuring staggered trusses. However, recognizing that structural steel is relatively uncommon in large-scale hospitality and commercial projects in India, where its use is typically reserved for industrial structures, BASE (the Structural Engineer of Record) and the general contractor, Leighton India Contractors Pvt. Ltd., proposed an alternative solution. They converted the structure into an all-concrete system without altering the original design intent. This revised approach employed long-span post-tensioned beams spanning the building’s width and a distinctive floor system combining composite metal decks with concrete topping supported by the beams. The hybrid system was chosen to reduce or eliminate the extensive

shoring and reshoring typically required in conventional concrete construction, ultimately accelerating the project’s timeline.

It's not often that a project begins with a firm "no expansion joint" directive from the client. Their decision was primarily based on the aesthetics of breaking up large open finished lobbies with expansion joints and their expression on the building elevation, in combination with high initial cost and long-term maintenance. Despite numerous discussions and requests early in the design process to incorporate an expansion joint at the podium levels, the response remained a resolute "No."

The podium, overlooking the Mithi River, gracefully follows the river’s flow with an elegant segmented shape. Each tower block comprises four distinct volumes, giving the exterior an architectural expression of independent buildings. The vertical transportation elements, such as elevators and stairs, were strategically clustered within one volume, with corridors extending to the remaining sections. This arrangement effectively reduced restraint to shrinkage and volume changes.

To further minimize restraint, the adjacent interconnected buildings primarily utilized planar shear walls oriented perpendicular to the

shrinkage direction. Perimeter beams spanning between the demising walls of hotel rooms, which also supported the tops of large glazed openings, acted as supplementary moment frames along the building's length. These frames offered less resistance to volume changes compared to shear walls, helping to manage structural movement.

To control initial shrinkage in each tower block, a designated shrinkage strip (marked red) remained open for 28 days in the tower and 56 days in the podium. Additionally, a long delay pour strip (marked green) was incorporated into the podium to allow each tower block to undergo long-term volume changes and reduce cracking (Fig. 2).

The contractor closely monitored the volume change during construction, and the long delay pour strip was closed shortly after the project was topped out.

In addition to shrinkage control, thermal loading was also considered in the design of the vertical and horizontal framing using a comprehensive 3D ETABS analysis model.

The podium's top at Level 5 was designed to accommodate various functions, including pre-function areas, ballrooms, convention spaces, and indoor pools. Achieving these large open areas using traditional flat

Owner: The Indian Film Combine (IFC)

Structural Engineer of Record: BASE

Concept Design: SOM India

Architect of Record: Archgroup Consultants (Dubai)

General Contractor: Leighton-Infra Joint Venture

Wind Tunnel Consultant: RWDI

slabs or one-way slabs would have required transfer girders at Level 6.

To address this challenge, a unique hybrid floor system was introduced starting at Level 6. This system featured long-span post-tensioned beams with clear spans of approximately 58 feet 6 inches, supporting a metal deck spanning roughly 15 to 16 feet, which served as sacrificial formwork. This one-way spanning metal deck hybrid slab was designed for the design loading with conventional reinforcement placed in the flutes. During construction, the metal deck was temporarily supported at mid-span or one-third points using post shores at a single level (Fig.3).

This hybrid system allowed the temporary shores to be removed within six days—significantly faster than traditional post-tensioned or reinforced concrete frames constructed in India, which typically require reshoring for 12 to 28 days. As a result, the system achieved

a 60-75% reduction in framing manpower.

Below Level 5 and in the basement levels, traditional two-way flat plate framing was used.

The podium levels beneath Tower 8, located at the southwest end of the project, extended beyond the tower's footprint. This area housed a large double-height ballroom, with one half positioned beneath the tower and the other half occupying the expanded podium. Above the ballroom, a spacious outdoor amenity deck offered impressive views of the city.

Supporting half the tower's weight with a traditional transfer girder,

as a result of single-span beams spanning the width of the building, proved challenging. The ballroom’s high ceiling requirements con flicted with the placement of a girder, and incorporating one at Level 6 interfered with the lobby’s space planning.

To address this, several design alternatives were explored. One option involved a Vierendeel truss extending from Level 6 to Level 20, while another proposed shallower transfer girders placed at four locations between Levels 6 and 20. However, both solutions resulted in beam and column sizes that clashed with the architectural facade, making them less desirable.

In parallel, a traditional transfer truss option was studied. This design featured a full-height transfer truss extending from Level 5 to Level 6, supporting the exterior columns from Level 6 to the roof (Fig. 4). The truss’s bottom chord spanned the entire floor height between Levels 4 and 5, which housed mechanical services. Openings were incorporated into the bottom chord to allow MEP ducts to pass through.

Ultimately, the transfer truss solution emerged as the most efficient option. It was also well-received by the client and architect, who embraced it as a striking design feature of the planned outdoor bar.

The basement levels of the project are situated below the surrounding water table, leading to significant buoyant forces. Based on seasonal fluctuations, the design water table level created a hydrostatic head of approximately 3 meters (10 feet). To manage the water table during construction, an extensive under-raft drainage system, including sumps and pumps, was implemented.

For the final condition, a hydrostatic slab was designed to withstand hydrostatic pressures of around 11.5 kPa (240 psf). The slab was designed to span between the footings, similar to how a reinforced concrete slab spans between drop panels. It was connected to the footing using pull-out dowels cast into the footing. These dowel bars were straightened during concrete placement for the slab, transferring the load from the slab to the footing (Figure 5).

To create a waterproofed basement (bathtub), a mud slab was laid as the bottommost layer, with a waterproofing layer placed on top. This waterproofing layer extended behind the basement retaining walls (on the soil side) up to the ground floor. The stitch slab and footings were installed above this waterproofing layer.

To reduce the hydrostatic head the slab had to support, a ballast layer of compacted fill was added beneath a slab-on-grade (Fig. 5). This fill layer also accommodated various subgrade plumbing, pipes, and other MEP conduits, facilitating easier installation and future access for maintenance or repairs within the waterproofed "bathtub."

The slab-on-grade was 100 millimeters (4 inches) thick and lightly reinforced, while the stitch slab was reinforced similarly to a two-way reinforced concrete slab, with the reinforcement placed in reverse to address uplift loads.

Turning ambitious visions into reality requires comprehensive analysis, careful planning, and purposeful execution. These elements were pivotal in achieving the client's goal. Various structural design solutions were thoroughly explored, with the final selections—including the hybrid floor framing, transfer truss, and stitch slab—chosen through a methodical process of evaluation and continuous collaboration with the architect and contractor. ■

Anantha Chittur, PE, SE, is Principal at BASE and is based in its Chicago office. He can be reached at achittur@baseengr.com.

Steven M. Baldridge, PE, SE is President at BASE and is based in its Honolulu office. He can be reached at sb@baseengr.com.

An eccentric cantilever and stepping perimeter columns allow a Chicago luxury apartment tower to dramatically capture space at height.

By David Fields, PE, SE, and Alex Wiley, PE, SE

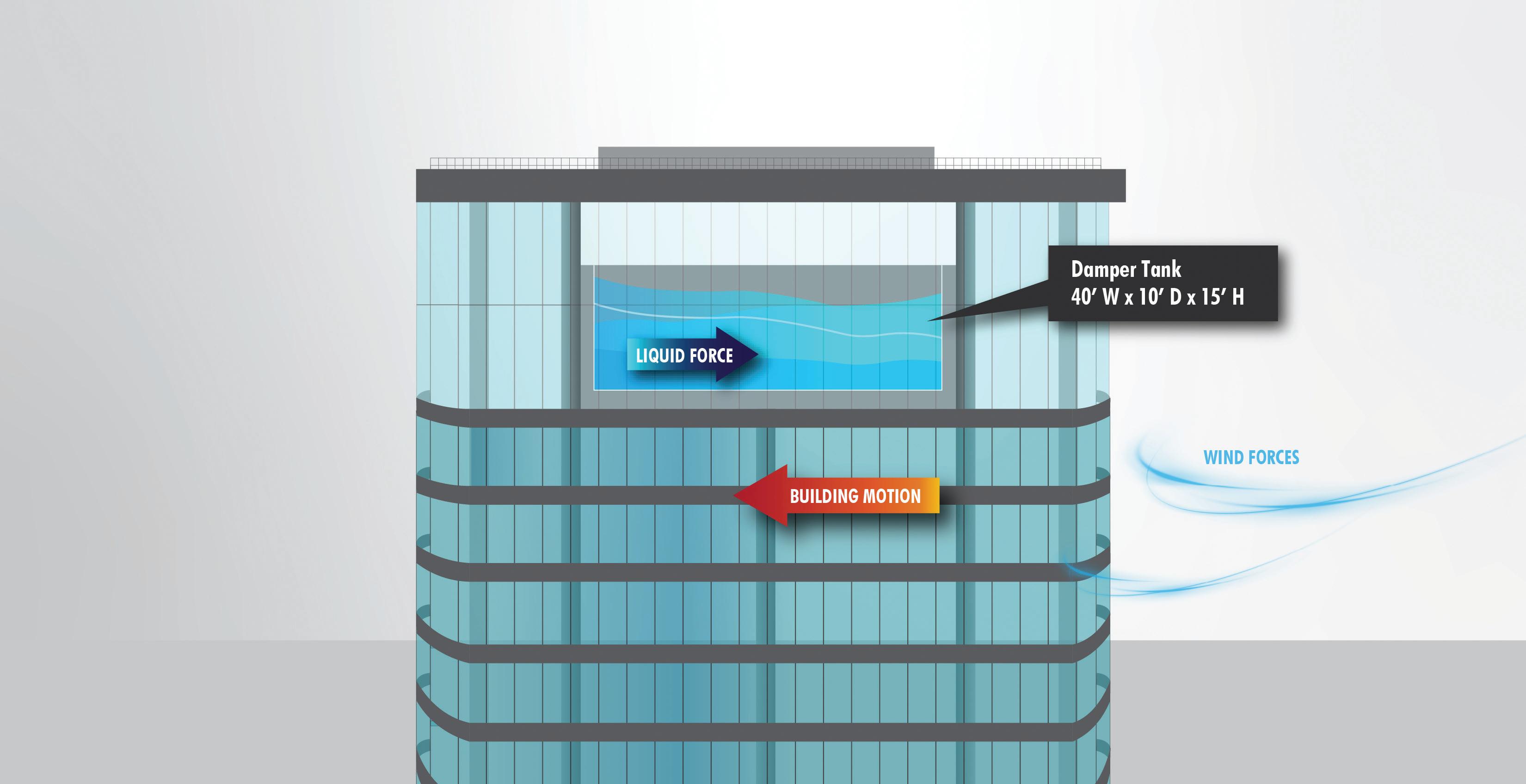

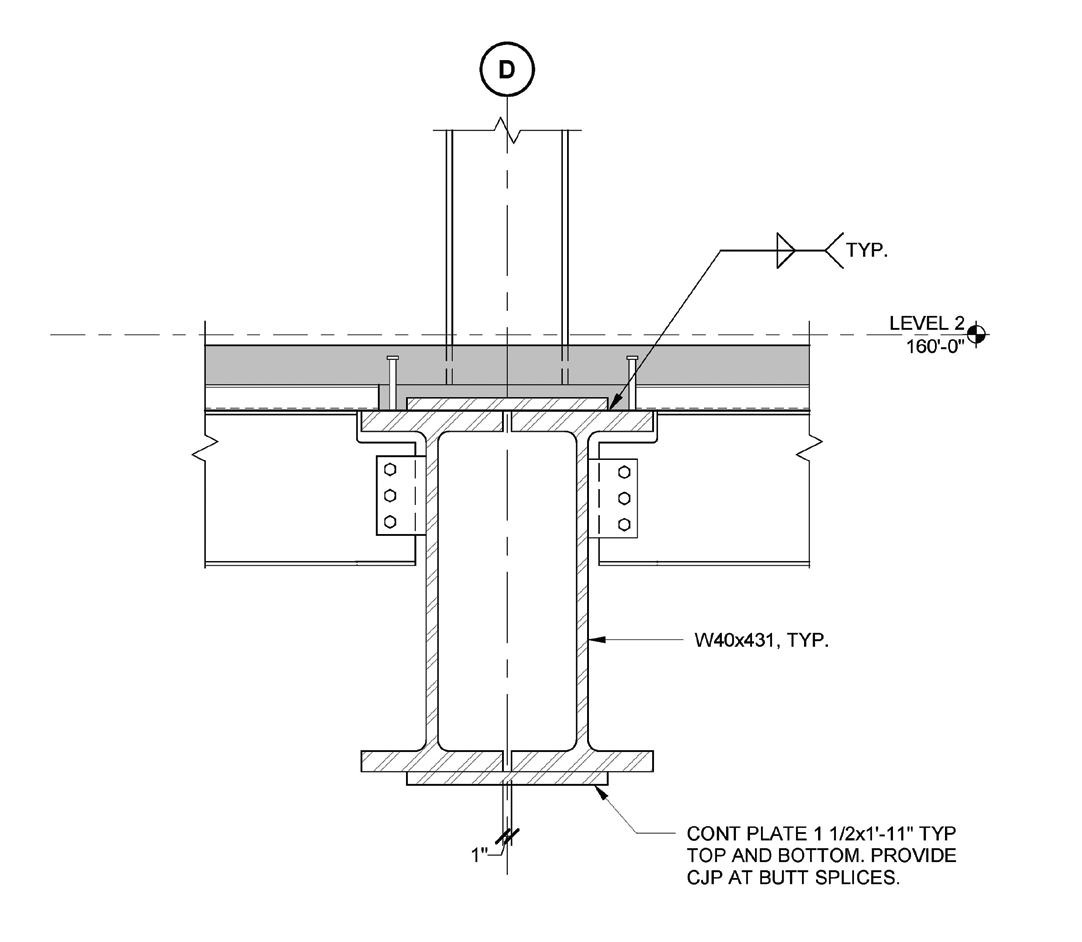

Floating high above the sea of historic mid- and high-rises framing Grant Park in Chicago’s South Loop neighborhood, 1000M—Helmut Jahn’s final and tallest Chicago tower project—is a masterclass in found space. The 788foot, 73-story luxury apartment tower at 1000 South Michigan Avenue opened in June 2024. Magnusson Klemencic Associates’ (MKA) straight, vertical, and orthogonal design of the tower’s initial 10 floors provides stability to the more structurally complex, space-reclaiming features above, including a cantilever that extends over a neighboring building and incrementally increasing floorplates that create an expanding twist in the building with height. Dual-purpose water tanks located on the tower’s rooftop level serve to dampen the structural response and provide the fire suppression water reservoir.

The development team behind 1000M had the luxury of owning two adjacent sites—1000 South Michigan, where the tower sits, and 1006 South Michigan, home of the eight-story Leightner Building. The 1000M site, only 100 feet wide, abuts that of the Leightner

Developer: Time Equities, JK Equities, and Oak Capitals

Architect: Helmut Jahn, Jahn/

Structural Engineer: Magnusson Klemencic Associates

Contractor: James McHugh Construction

Interior Design: Kara Mann

Building, its neighbor to the south. Tearing down the smaller building to increase 1000M’s footprint was not viable due to Leightner’s landmark-protected status. Instead, the development team set its sights on the air rights above and capturing space at height.

Jahn proposed a unique solution to widen the tower above the Leightner and create more space: a south-facade cantilever that slopes gently over the 100-foot Lightner Building, claiming air rights to maximize leasable floor area and unit count. MKA designed an allconcrete structure to suit, with primarily flat plate floors and lateral stability provided by a central core buttressed at its base.

McHugh Construction, its in-house concrete subcontractor McHugh Concrete, and concrete formwork supplier Peri Formwork Systems collaborated to build the 18-foot, MKA-designed sloped building extension, continuing each floor farther south over the floor below via

continuously evolves as it rises above the podium structure. (Image credit: MKA)

sloping columns between Levels 11 and 20. At Level 11, a 19-foot “fire lid” slab extends over the neighboring Leightner Building, serving as a four-hour fire separation, protecting the 1000M building from potential heat from the roof of the Leightner Building should a fire break out.

At Level 20, where the steeply sloping southern columns resume a vertical path, 1000M’s appearance changes. The building’s lower floors, an aesthetic nod to the Historic Michigan Boulevard District and buildings of 200-foot scale, give way to a slender, carved tower designed to look at a distance like a separate building, complete with differentiating color and sheen.

Unlike the rectangular shape of the building’s base, the upper tower’s form begins in plan with symmetrically curved east and west faces and a flat aspect to the north and south. Diagonal planes then emerge from these straight north and south facades as each floor’s perimeter columns “walk” away from the center of the building to further expand the tower. This expansion continues at each of the top 50 stories of 1000M, growing the exterior bay dimensions from 30 to 43 feet and increasing the individual floorplate area by 900 square feet.

To accommodate the lengthening spans, MKA’s engineers designed a series of increasingly thicker flat slabs to maintain a flat soffit and avoid costly and intrusive beams extending beneath the slab.

As is common in the greater Chicago area, suitable soil bearing to support such a tall tower is hidden below layers of fill and soft clay. To reach these soils, large diameter belled caissons were drilled to depths of approximately 75 feet to support elements primarily resisting gravity forces. Due to the narrow site and inherently narrow stance of the lateral system on the foundation, caissons resisting the building overturning were drilled and socketed into bedrock at a depth of approximately 100 feet to achieve their required capacities. The use of deep foundations was also advantageous in bypassing the existing nearby foundations, ensuring the 1000M structure did not surcharge the adjacent properties.

To utilize as much width as possible on the narrow site, the tower is supported by a continuous caisson-supported mat that carries all the tower columns. This solution engages the total dead weight of the building to minimize net uplift demands on the deep foundations, thereby reducing the depth, size, and quantity of expensive rock-socketed caissons.

A building of this height naturally captures enormous lateral wind pressures acting on its surface. Of equal importance was resolving the massive gravity-induced lateral forces created by the steeply sloped building columns, which induce significant horizontal thrusts on the building at the top and bottom of their slope extents. Resistance to these additional forces is provided by the same structural system that resists the wind forces.

A core-only solution to resolving the totality of the lateral forces was infeasible due to a tower height-to-core width aspect ratio of over 20:1. MKA considered two solutions to augment the core: buttress walls or an outrigger system, both of which engage the exterior of the building

to provide a much greater lateral stance.

An outrigger system was deemed too disruptive to the regularity of both the typical floor plan layout and the construction rhythm. Instead, the central concrete core engages with internal buttress walls aligned with core end walls and demise between apartments. The buttress walls extend to mid-height in the building and are end-capped by six-footsquare super-columns for the lowest 10 stories. The south-side sloping columns are tied to this system via heavy bands of high-strength reinforcing bars within the concrete floor slabs. As these heavy bands take up a large volume within the slabs and compete for space in the grid of post-tensioning tendons, a full-size mock-up was created to verify these elements could all be placed within a very tight area while maintaining the necessary configuration.

While the core and buttress systems were sized to ensure the building had all the necessary lateral strength, wind tunnel testing revealed the additional challenge of maintaining occupant comfort during significant wind events. The frequencies at which tall towers sway can resonate with occupants’ senses and lead to motion sickness. This effect is measured in minimal levels of acceleration, with an industry-accepted limit for residential occupancy at 18 milli-g during a 10-year storm. Rather than resolving the issue by adding stiffness through costly and space-taking increases in the size of the shear walls or super-columns, MKA employed two east-west oriented tuned liquid sloshing damper tanks strategically located on 1000M’s rooftop. Together, these dampers contain more than 33,000 gallons of water. These water tanks were tuned to the frequency of the building by careful measurement of as-built building motions and filling the tanks to a specific depth in relation to tank length, creating wave action matching those frequencies. The number and proportions

of tanks were selected to activate sufficient mass to impart meaningful changes to the building’s response to wind excitations. To minimize the impacts of the massive tanks on the roof slab and overall concrete volume, the tanks abut the central core shear walls. This solution utilizes the shear walls themselves as part of the tank enclosure while also relying on the core stiffness to cantilever the tank boxes off the core and stiffen the roof span condition.

In another example of found space at 1000M, the damper tanks double as the building’s fire water reservoir. In the event of a fire, the damper tanks will drain to provide water for firefighting crews. Unlike other damping solutions, a general contractor can build liquid sloshing dampers using materials and crews already mobilized on site. Rebar is tied, walls are formed and cast, and waterproofing liner is installed as it would in a rooftop pool. A case study of NEMA Chicago tower, a similar residential high-rise, found that adding sloshing dampers for a construction cost of $1.4 million saved just under $5 million relative to the next best wind management solution.

1000M is a study in shaking off the constraints of site. As large city lots grow scarce, consider taking advantage of found space using smart engineering solutions that do not massively disrupt the flow of construction. As evidenced by 1000M, small incremental changes can add up to large benefits. ■

Material strength

Welding efficiency

Supply chain assurance

Reimagine your project designs with Aeos™ ASTM A913 high-strength structural steel. It’s high strength-to-weight ratio and reduced welding pre-heat requirements make Aeos an efficient and sustainable design solution. As the only domestic producer of A913 and the largest steel manufacturer in North America, Nucor can help you optimize your supply chain and reimagine your next project.

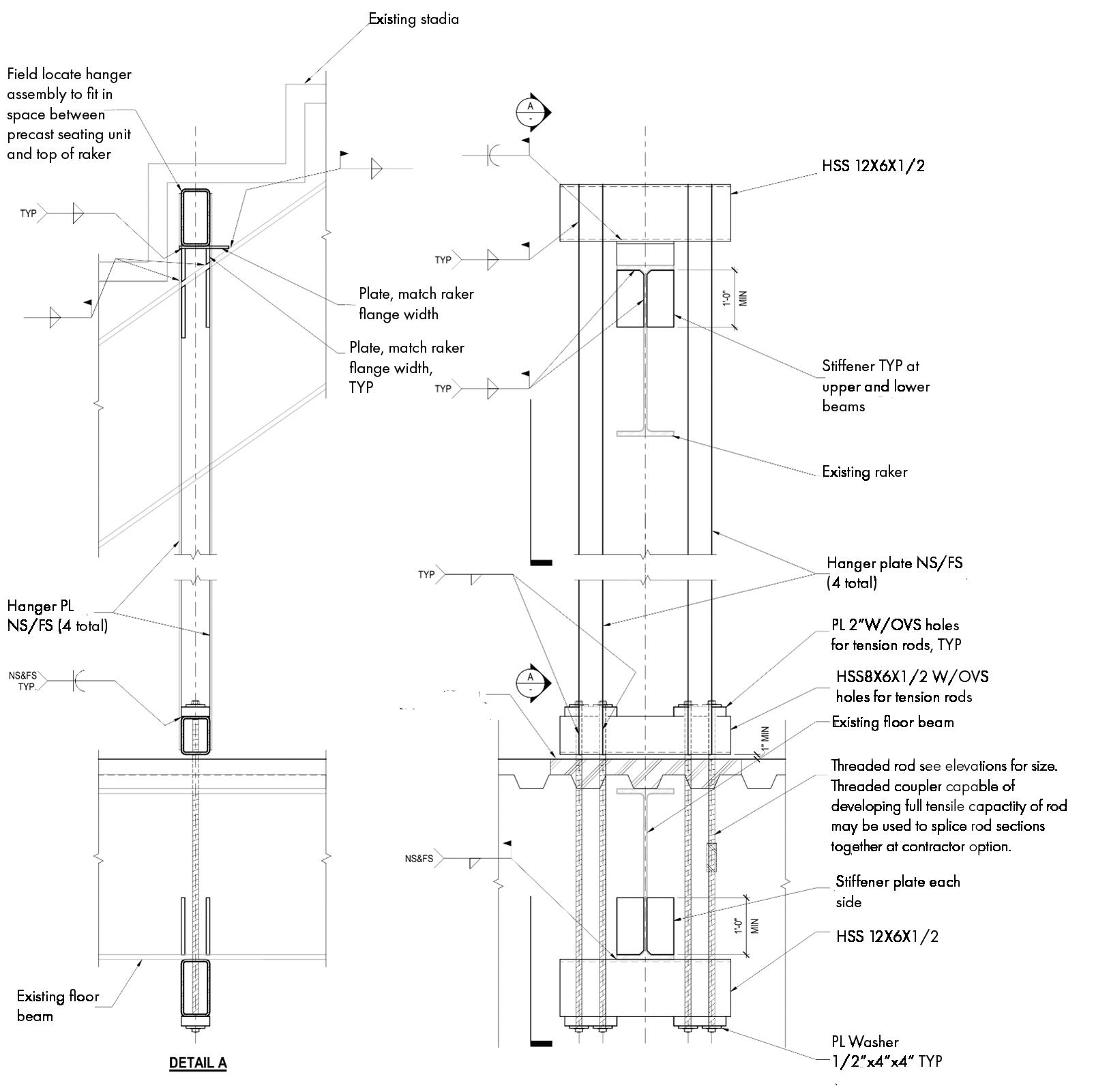

A phased approach to major renovations at the New Orleans stadium allowed it to remain fully functional and continue to host major sports and entertainment events, ensuring a steady stream of revenue and minimal disruption to schedule.

By Eric Grusenmeyer, PE

Caesars Superdome opened its doors in 1975, and with its innovative 680-foot clear span dome roof and iconic hourglass shape, it became a distinctive part of the New Orleans skyline. The Superdome, home to the NFL’s New Orleans Saints, is celebrating its 50th anniversary. But this is no ordinary sports venue. It hosted major concerts from the Rolling Stones in the ‘70s to three consecutive sold-out shows by Taylor Swift last year. The Superdome welcomed Pope John Paul II, Muhammed Ali, and the Republican National Convention and is also the home of the annual Essence Festival and one of the Mardi Gras parades. In addition to the Saints, the Sugar Bowl has been played there since it opened, and the stadium has held five NCAA football championships, six NCAA Final Fours, and eight Super Bowls including Super Bowl LIX in February 2025.

The Superdome is a major economic driver for the city, so when it sustained substantial damage during Hurricane Katrina in summer 2005, an extensive repair and renovation effort was fast-tracked. The building was rebuilt after the hurricane and hosted a home football game the following September 2006.