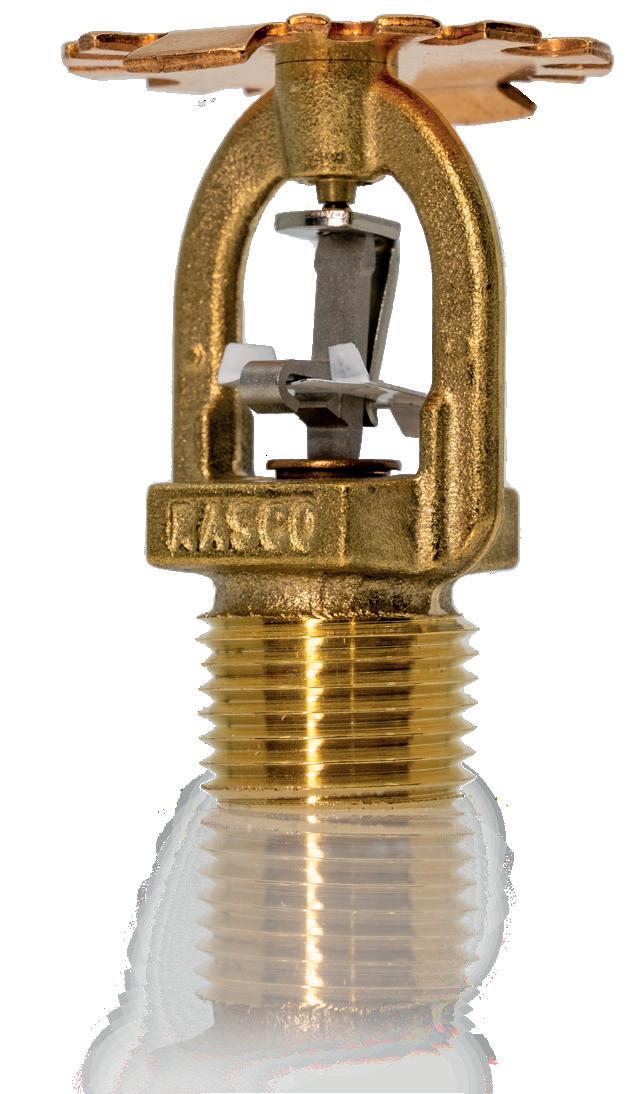

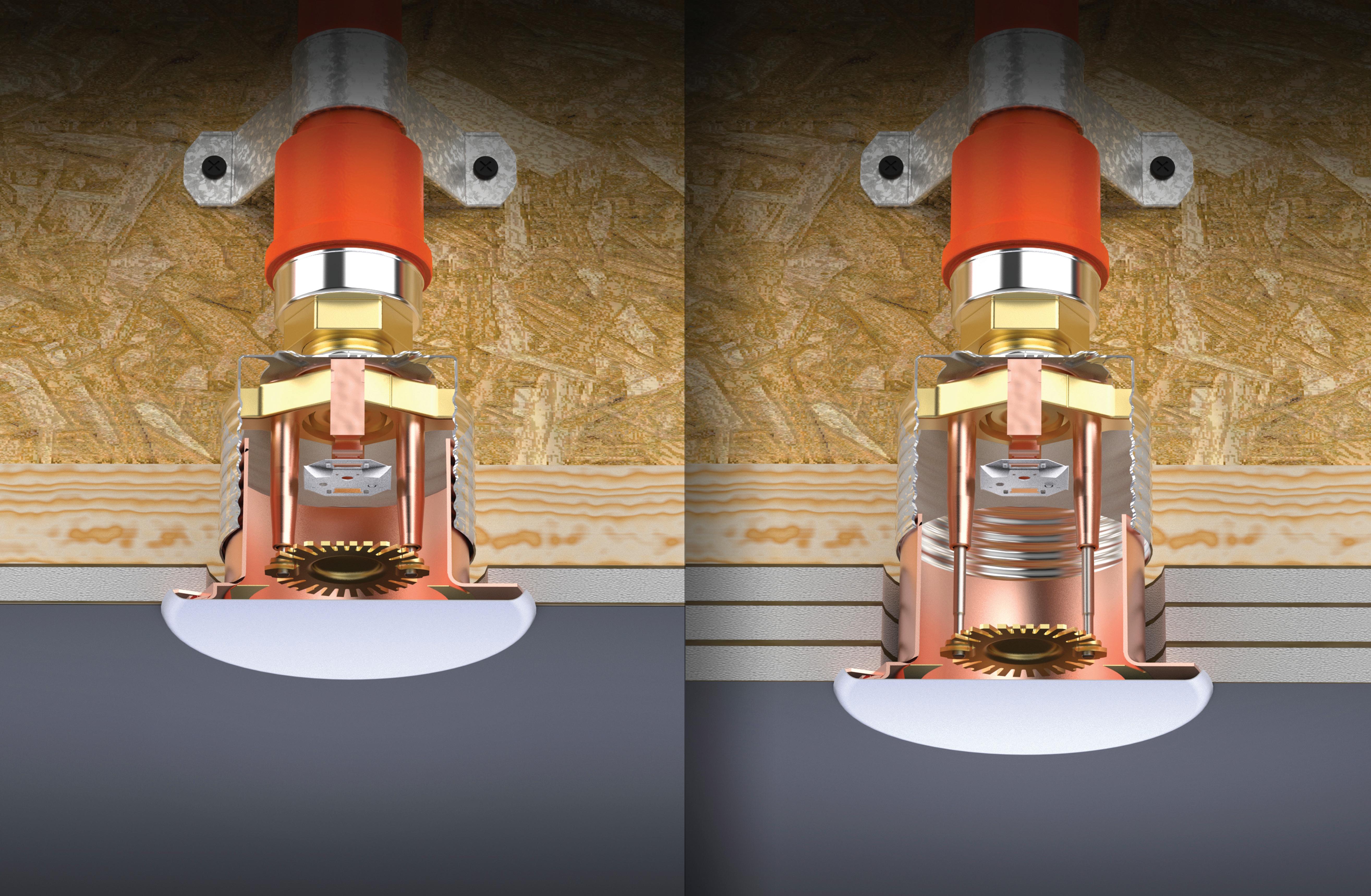

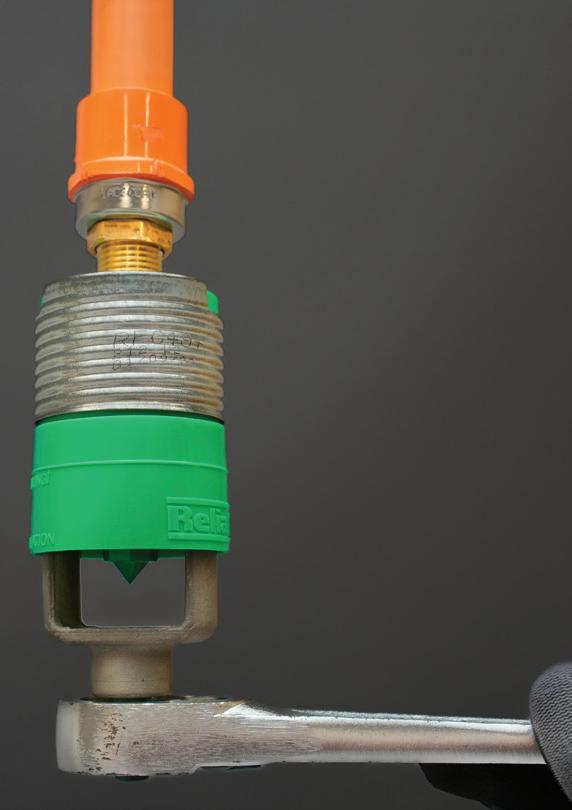

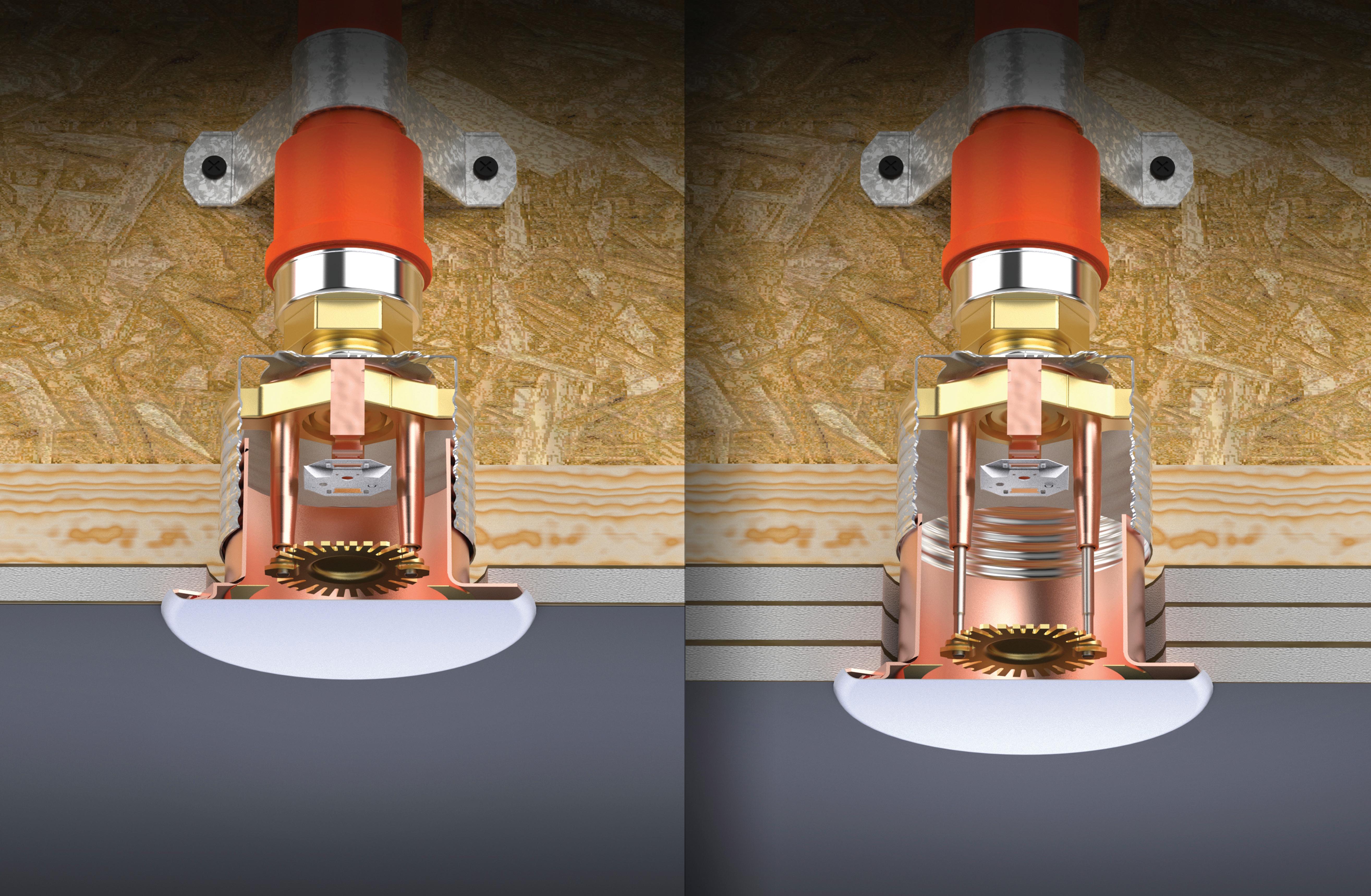

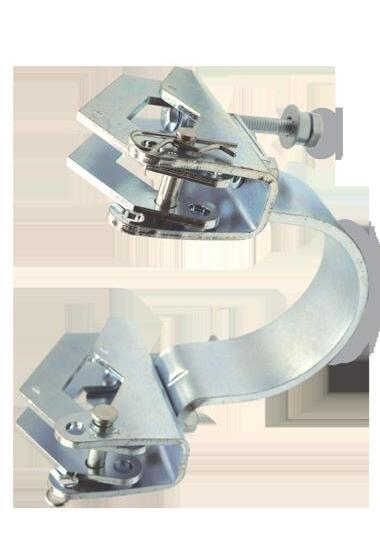

The Reliable Model KFR-CCS Sprinkler is designed for the protection of specific light hazard combustible and noncombustible concealed spaces requiring sprinkler protection. Its high, flat spray pattern provides ideal coverage of these spaces and its rugged 212° F fusible link design requires no shipping protector. The KFR-CCS is suitable for installation with CPVC pipe (wet systems) or steel pipe (wet, dry or preaction systems).

The KFR-CCS recently received an enhanced cULus Listing:

• Protection of concealed spaces with trusses without requiring draft curtains.

• Protection of concealed spaces with trusses up to 60 inches in height.

• Maximum sprinkler spacing up to 16 feet in concealed spaces with trusses or noncombustible insulation-filled joists.

• Matches industry leading hydraulic requirements for wet systems.

Assembled & Rigorously Tested in Liberty, SC

Proper sprinkler application made easier with designer-friendly bulletin 044.

reliablesprinkler.com/ccs

SPRINKLER AGE, (ISSN 0896-2685) is published bimonthly for $33.95 per year by the American Fire Sprinkler Association, Inc., 1410 East Renner Road, Suite 150, Richardson, Texas 75082. Periodicals postage paid at Dallas, Texas and additional mailing offices.

Welcome to AFSA42!!! There has been a tremendous amount of preparation by AFSA42 Convention Committee Chair Chris Johnson, Piper Fire Protection, Inc.; his entire Convention Committee; and, of course, AFSA staff led by Marlene Garrett, AFSA’s convention chief in charge! I hope everyone takes advantage of the seminars, networking meals, and all the magic surrounding us in Orlando! Solidifying your network by visiting with old friends and making new ones should be a goal you set for yourself. This is the greatest benefit of attending AFSA’s conventions and exhibitions. Make sure you also attend the general session. There will be patriotism, association/industry updates, and plenty of awards—all mixed in with a bit of magic and fun!

One of the awards being handed out will be AFSA’s highest honor, the Henry S. Parmelee Award. This award is given in recognition of an outstanding individual dedicated to the professional advancement of the fire sprinkler industry and fire safety through the use of automatic fire sprinklers. The Board of Directors considered this year’s nominations at its July Board Meeting. This year’s recipient is Dr. James A. Milke, Ph.D., P.E., FSFPE, from the University of Maryland’s Fire Protection Engineering (FPE) Department. I have known Jim for many years, too many to count. We started as friends, golf buddies (that didn’t go so well), professor/student, and ultimately as a mentor of mine as I watched him progress through the ranks of the FPE department all the way to becoming its director in 2011. Jim follows in the footsteps of many tremendous past winners of this award, including the 1991 recipient Dr. John L. “Prof” Bryan, the founder of the FPE department at Maryland. Prof was all of our mentors, including Jim’s. I was worried when Prof retired. I was concerned whether there could ever be someone to take over the department in that same humble, mentoring way that Prof did … then came Jim. Please read the article on Jim featured in this issue to learn about all of his accomplishments, including the work he has done advocating and proving the life safety benefits of the automatic fire sprinkler. It will be my greatest honor to present Jim with this award during the general session Friday afternoon at AFSA42.

At the conclusion of AFSA42, my term as Chair of this tremendous association will come to a close. The two years have gone by faster than I ever could have imagined. I’ve loved this association since first getting involved with it in 1989 and have continued to love it even more as the years have gone by. I will serve my next two-year term as Past Chair before retiring from the AFSA Board at that time, so you’re not totally getting rid of me quite yet. The Board of Directors (past and present), committee members, and all other volunteers have made this association the best industry association in the country! Thank you for all of your efforts. It would be a shame if I didn’t mention the outstanding staff we have within AFSA in Dallas. They work tirelessly each and every day with the sole purpose of making you and your company better. As each one of us improves, our entire industry improves as well. That is the goal of AFSA!

They say we receive more in giving than the actual act of receiving itself, and how true that has been for me. I have been honored to serve you as your Chair and will continue to serve you always in any way that I can. THANK YOU!! May God continue to watch over this association today and for many years to come. May He also bless you and your companies always and in all ways. n

EDITORIAL: 214-349-5965

BOB CAPUTO, CFPS, Publisher, ext. 124 bcaputo@firesprinkler.org

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

ADVERTISING: 214-349-5965

SYDNEY RICHARDSON, Communications Specialist, ext. 134 srichardson@firesprinkler.org

CIRCULATION: 214-349-5965

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

AFSA BOARD OF DIRECTORS

JACK A. MEDOVICH, P.E., Chair, 804-222-1381

LINDA M. BIERNACKI, First Vice Chair, 318-841-0330

PAUL DELORIE, Second Vice Chair, 603-432-8221

ROD DIBONA, Treasurer, 605-348-2342

JEFF PHIFER, Secretary, 803-438-2994

TED WILLS, Immediate Past Chair, 610-754-7836

LYLE HALL, 858-513-4949

CHRIS JOHNSON, 727-581-9339

R. DONALD (DON) KAUFMAN, 505-884-2447

MICHAEL F. MEEHAN, 804-459-2200

E. PARKS MOORE, P.E., 251-473-6000

JAY STRICKLAND, 301-474-1136

WAYNE WEISZ, 209-334-9119

BOB CAPUTO, CFPS, President, ext. 124

JOHN AUGUST DENHARDT, P.E., FSFPE, Vice President, Engineering & Technical Services, ext.121

MARLENE M. GARRETT, CMP, Vice President, Meeting & Education Services, ext. 118

MEDA MERRITT, Senior Director, Membership Services & Chapter Support, ext. 133

MELISSA ATHENS, Director, Finance & Administration, ext. 112

LESLIE CLOUNTS, Director, Education Services, ext. 130

ROGER GRAGG, Director, Marketing & Information Technology, ext. 116

Sprinkler Age is devoted to the professional development of the fire sprinkler industry. Deadline is 1st of the month preceding publication.

Published by American Fire Sprinkler Association, 1410 East Renner Road, Suite 150, Richardson, TX 75082. Call (214) 349-5965, FAX (214) 343-8898, or email sprinklerage@firesprinkler.org for information.

Copyright © American Fire Sprinkler Association, Inc. All rights reserved. PRINTED IN USA. Unless expressly stated otherwise, all editorial and advertising material published is the opinion of the respective authors and/or companies involved and should not be construed as official action by or approved by Publisher or the Association.

Sprinkler Age is a membership benefit, provided free of charge to AFSA members. For information on non-member and/or foreign subscription rates, call (214) 349-5965.

AFSA annual membership dues are a sliding scale for Contractors and Associates and a flat fee for Authorities Having Jurisdiction. (Members receive a free subscription to Sprinkler Age.) Write or call AFSA for membership information. See AFSA’s website at firesprinkler.org.

This issue of Sprinkler Age magazine is the convention issue, so let me join our Board Chair in welcoming everyone attending AFSA42 to Orlando. Our Board of Directors and AFSA staff have prepared another amazing schedule of events at an incredible location. This convention continues to be the largest fire sprinkler event in the world and this year we have sold out the exhibit hall. That is a very encouraging trend for our industry because it shows that we really are breaking free of the COVID-19 pandemic’s impact on our daily lives and the growth and interest in AFSA’s development and programs.

One thing I know for sure is that being a first-time attendee of a function celebrating 42 years can seem daunting at best. To make new attendees feel more comfortable, we will be hosting a short cocktail hour for first-timers and their guests. (Please check your registration packets for time and location.) In addition, first-time attendees will be identified by a badge ribbon so if returning attendees see one, please reach out to make them feel more welcome. Share the secret handshakes and show off AFSA’s “We’re all in it together!” spirit.

I am proud to report on the progress AFSA staff continues to deliver for our members and our industry. Under the leadership of John Denhardt, P.E. (and a bunch of other letters after his name), our technical services department has grown exponentially along with AFSA’s positive reputation across the industry. Technical Reviews (formerly Informal interpretations) of codes and standards continue to be turned around in one day, helping our contractor and AHJ members resolve issues together for the benefit of projects in every stage of work. Our technical services team is working with members and committees to develop new training materials and update existing programs, webinars, and reference materials. Our project list continues to grow as members and chapters provide feedback on the trends and needs for training, recruiting, and retaining the workforce needed to grow our business and our industry. Our team of subject matter experts includes Kevin Hall, Josh McDonald, Eric Andresen, Veronica Westfall, and Victoria Valentine. When you see them during the convention, be sure to ask them your burning questions.

In addition, our administrative support team is also knocking it out of the park behind the scenes. Linda Wee, Maricarmen Martinez, and Christina Sales keep the flow with support of seminars, webinars, and training to ensure attendees have room, food, and drink, in addition to CEUs and records of training. With Leslie Clounts and Marlene Garrett leading training programs and meetings/convention, we continue to deliver better and better experiences for your needs.

Membership and Chapter Development is a huge focus for this team, and the return of Meda Merritt has already shown a return with increased membership and retention numbers. Dominick Kasmauskas is working as hard as his name is to spell. He puts more miles on his car each month visiting members than I put on my truck each year. Our focus moving forward is chapter support, especially for those chapters where activities have fallen off a bit. If you’re not hearing from us, we want to hear from you! After all, you are the reason we’re here.

Our marketing team and especially the work that goes into publishing this magazine in print and electronic formats also deserve

kudos. Roger Gragg and his team with Josh Fisher, D’Arcy Montalvo, and Sydney Richardson are doing a great job of increasing our social media presence as well as making our direct contacts with membership a better engagement experience. In fact, we’ve onboarded a new software program just for that purpose.

We all know the competition for workers in the construction trades continues to be fierce, and we appear to be coming up short in appealing to candidates over other construction trades. We need to change that equation locally and nationally. We cannot do what we’ve always done and expect better results. Let’s get together and see how we can better retain our industry’s best and brightest while appealing to a new breed of recruits. The fire sprinkler industry has great job opportunities for every interest level with good pay and benefits. This is one of the most important challenges facing us today. The AFSA staff wants to help engage in solutions, and we’re open to new ideas. We’re planning an engagement program with a local high school to introduce its students to the fire sprinkler world. Let’s think about how we can do that everywhere.

AFSA is not resting on our laurels. We’re already up and running with design school and other classroom training programs at our new headquarters, and we are nearing the grand opening of our new hands-on lab. The lab will never be “complete,” as we continually update the technology and show off new equipment. This lab will prove to be the best-in-class of any independent lab facility with the ability to flow sprinklers, show obstructions to spray patterns, and flow test fire pumps, standpipes, and fire hydrants. With 22 operable risers and a variety of fire alarm panels, we look forward to providing a tactile, hands-on training experience for our members at every level and interest. Yes, it has been a busy year for Team AFSA from top to bottom. We have recently been asked to partner with a few international fire sprinkler associations, including those in the United Kingdom and Latin America. We are looking closely at how to introduce our printed training manuals in the Spanish language.

While I am happy to report the progress we’re making, I am even more excited about AFSA’s near and long-term plans. I want to challenge every member to reach out to recruit a new member this year. We all want educated competitors, and we all need a little help from time to time. Training programs are our way of providing the help you need to grow your businesses… and your competition, too.

For those of you attending AFSA42, I hope you will enjoy our time together in Orlando. For those of you who will not be attending, you will be missed, and we hope to see you at a chapter meeting soon. Remember, we are all AFSA, and we’re all in it together. n

BOB CAPUTO, CFPS AFSA PRESIDENT

• UL 1450 Listed for Fire Protection

• Fastest Installation and Set Up Saves Big On Your Time

• Minimize Maintenance with Included Auto Tank Drain

• Set Compressor for Low, Standard or High Pressure Applications by pressing a button!

UL Listed Digital Pressure Switch Features:

• View Holding and Set Pressures

• View and Record Run Hours

• View Running Amperage

• View and Record Compressor Cycles

The ADVANCE Series from General Air Products is the most technologically advanced fire protection air compressor on the market. Installed in a flash compared to standard models, the UL Listed digital pressure switch is wired out of the box for all standard pressure settings. The ADVANCE series is also the only fire protection air compressor available that will automatically drain the tank of water. Use this

Vapor Pipe Shield from General Air Products is the newest product for corrosion mitigation in Dry and Pre-Action fire sprinkler systems. Utilizing VpCI Vapor Corrosion Inhibitors that have been mitigating corrosion in industries around the world for over 40 years, Vapor Pipe Shield will save you significant amounts of time and money compared to existing technologies.

Simplifying Corrosion Prevention.

Iam writing this column as I’m traveling to Kansas City for the second draft meetings for the 2025 edition of NFPA 13, Standard for the Installation of Sprinkler Systems . The months of June and July were extremely busy but exciting. I feel invigorated about the sprinkler profession and the positive impact of AFSA on the industry.

The 2023 NFPA Conference & Expo that I wrote about in the last issue could not have gone better. Walking the exhibit floor reminded me of our association’s reach. Exhibitor after exhibitor stopped me to talk about AFSA. As our new sprinkler and valve lab in Richardson is under construction, many of the exhibitors offered equipment and assistance in creating a state-of-the-art facility. They want to be a part of it. The NFPA annual Technical Meeting also had individuals talking to the AFSA technical team. Attendees wanted our thoughts and position on several issues. Kevin Hall led our efforts and spoke on an issue of importance to our members. Victoria Valentine was also in attendance but had to remain neutral and not offer any opinions. Her role was to observe the process in case she needed to rule on an issue. This was because she was appointed to the NFPA Standards Council a few months ago. What an honor for her and AFSA. Congratulations, Vicky!

The AFSA Board of Directors’ meeting was held in mid-July in South Dakota. The committee meetings were packed with people from throughout the United States. Many issues were debated and with a diverse group of people, opinions varied. In the end, numerous issues were resolved, and an approach to move forward was agreed upon. Watching this process never fails to impress me. The time and dedication these volunteers show for our association is truly remarkable.

Speaking of volunteers, AFSA holds 116 seats on NFPA Technical Committees. Many of these seats are held by volunteers who represent AFSA in this process. Our involvement would not be possible at this level without the support of our members. With this much activity, I want to announce that Kevin Hall and I are working on the relaunch of the AFSA Technical Advisory Committee (TAC for short). For those who have been around for years, you will recall that TAC was used to develop AFSA positions on technical issues. This group met regularly to ensure we fully understood the technical issues from the perspective of our members before we attended NFPA Technical Committee meetings. I served on TAC when I worked at Strickland Fire Protection. Over the years, this group became inactive, but we see the potential for real value in reviving it. The new TAC concept has been approved by the Board of Directors and AFSA At-Large Director E. “Parks” Moore, P.E., has been appointed as the first chair. Parks, Kevin, and I are developing the guidelines

and membership rules for TAC. At AFSA42, we will have a meeting to discuss its goals. If you are interested in this group, please join us for the conversation.

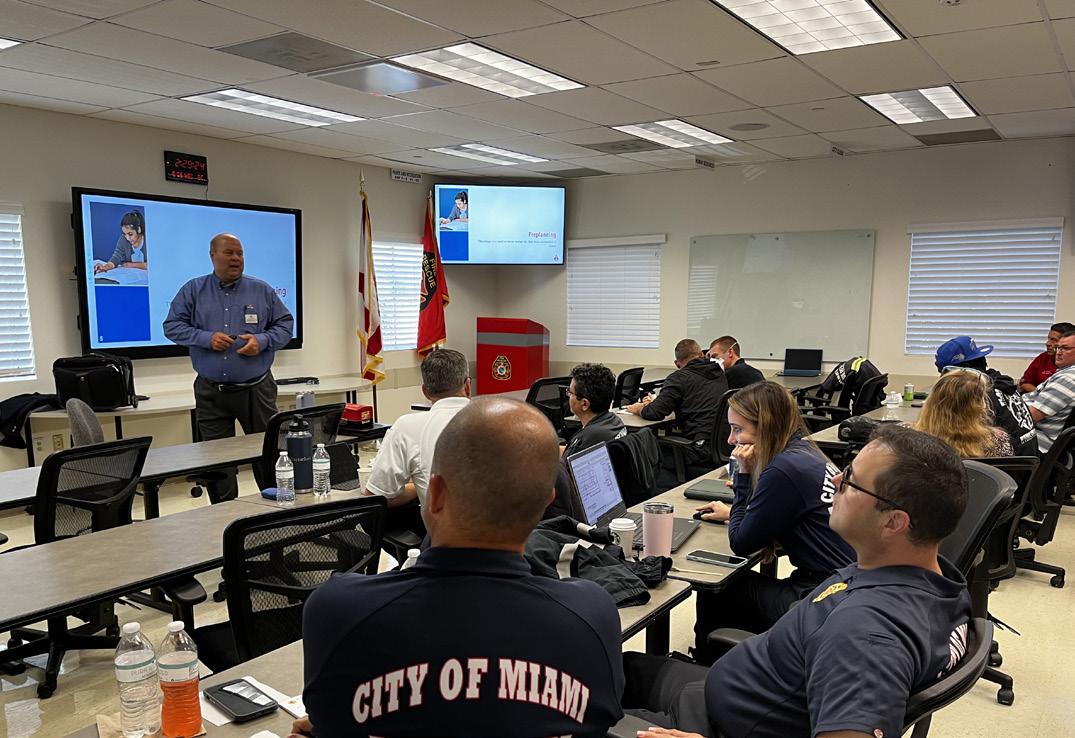

In the last year or so, our training classes have been sold out. Our staff has been adding additional classes to our training schedule to try to accommodate the growing need. Our in-person training at the chapter level has exceeded my wildest imagination. Traveling around the country, the excitement and desire for training has kept me invigorated. We have also expanded our membership and training offerings for Authorities Having Jurisdiction (AHJs). Numerous AHJ training classes have been held this year. The feedback from the attendees shows us the need for AHJ training is real.

The 2025 NFPA 13 second-draft meetings went well. Our AFSA representatives prepared, listened attentively, and discussed, agreed, or where necessary, argued for our members’ interest. Seeing how the “sausage” (the standard) is made with our input, makes me smile knowing that our involvement ensures our contractors’ interests are protected along with ensuring good fire protection. The Technical Committee on Hanging and Bracing met virtually. Kevin Hall and Victoria Valentine serve on that committee. The Technical Committee on Private Water Supplies also met virtually. Bob Caputo and Josh McDonald are members of that committee. The Sprinkler System Installation Technical Committee met in person. Jason Gill, Mike Meehan (current AFSA Region 6 Director and past AFSA Chair of the Board), and Parks Moore serve on that committee. Brett Heinrich, Kevin Hall, Josh McDonald, and I attended as guests. The Discharge Technical Committee also met in person. James Fantauzzi, Steven Scandaliato, Kevin Hall, and I are members of that committee. Josh McDonald attended as a guest.

This industry makes me proud, and being a staff member of AFSA makes me prouder. Team AFSA! n

JOHN AUGUST DENHARDT, P.E., FSFPE AFSA VICE PRESIDENT OF ENGINEERING & TECHNICAL SERVICES

Safety is at the forefront of every action we take as a company. To reduce risk and promote consistency, we take advantage of automatic welding technology when creating fire protection products for customers across the nation.

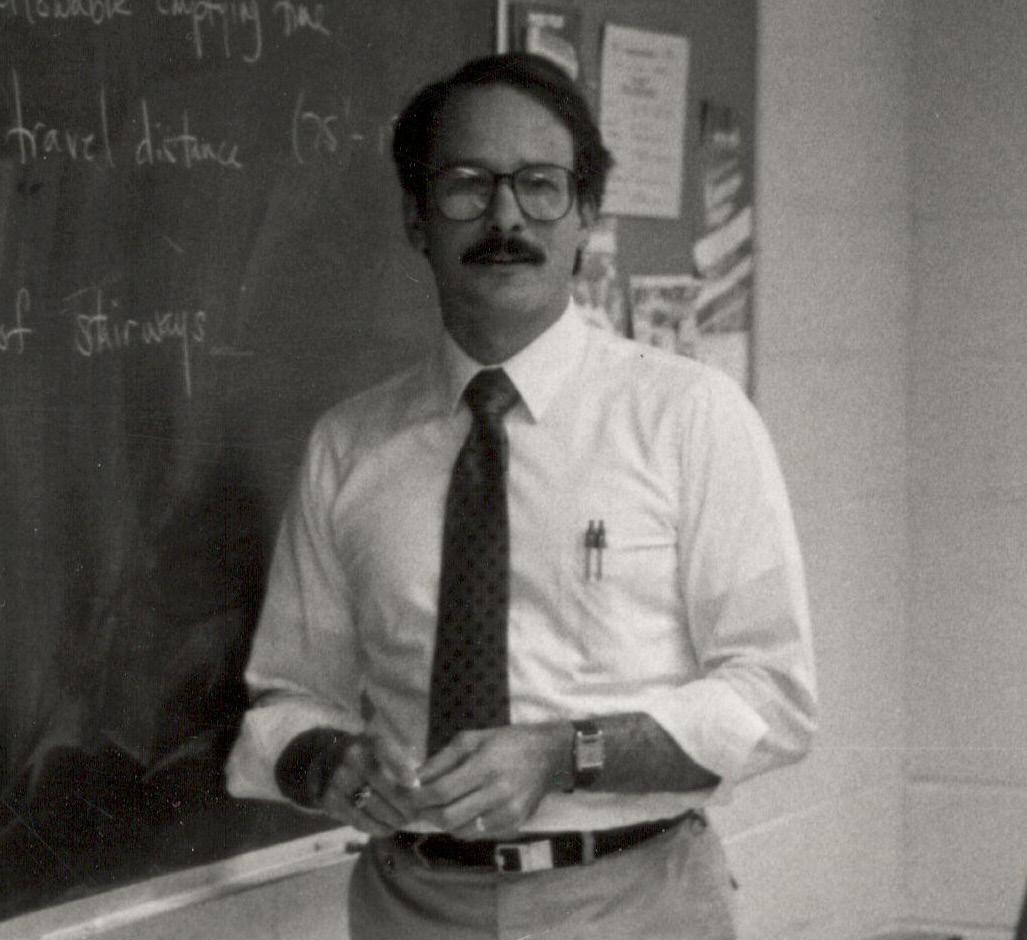

In 1983, the American Fire Sprinkler Association (AFSA) created its highest honor, the Henry S. Parmelee Award, to recognize an outstanding individual who has dedicated himself or herself to the fire sprinkler industry and the goal of fire safety through automatic sprinklers. The recipient of this year’s award has dedicated over 40 years of his life to the industry and its people and perhaps, more importantly, its students. He is an educator, mentor, leader, and above all else, a well-respected professional in the fire protection industry. For AFSA, it is an honor to recognize Jim Milke, P.E., Ph.D., FSFPE, chair of the Department of Fire Protection Engineering (FPE), University of Maryland (UMD), with the 2023 Henry S. Parmelee Award.

The story of Milke is one of happenchance. He didn’t pursue fire protection in the most obvious of ways that are encountered in this industry—because of family, a professor suggesting it to him, or even because he himself had a burning desire to work with fire. Rather, Milke stumbled upon fire protection as a manner of fate.

Milke’s journey began when he was a student attending Ursinus College in Collegeville, Pennsylvania, as a physics undergrad student. “I chose physics out of high school because I knew nothing about engineering. I don’t recall guidance counselors telling me to study engineering. I didn’t have any family mentors who were engineers that could talk about it, so I just picked physics because that’s something I knew from high school,” Milke recalls. “My freshman year, I went to a really small school. When fire alarms went off in the dorms, I was intrigued by the array of equipment the firefighters brought in to deal with a small fire or an overheated hot plate. I was curious, so I went down and volunteered as a firefighter at Collegeville Fire Department in December of my freshman year.”

Indeed, Milke’s curiosity would serve as a guiding direction that would later present new opportunities. “Come my sophomore year, I began to wonder, ‘What in the world am I going to do with this physics degree?’ I didn’t want to teach high school physics, and I didn’t want to go to graduate school for physics. I came to find out about fire protection engineering at an NFPA (National Fire Protection Associa -

tion) conference in Philadelphia. The fire department paid the registration fee for me to attend.”

As Milke walked around and attended presentations, he realized he was feeding his curiosity. “I was thinking, ‘Wow, this is great!’ I learned about fire safety and realized it’s a huge field. Then I happened to find a brochure on the University of Maryland on a table in this empty hallway. I picked it up, read it, and thought to myself, ‘This is perfect!’ And that’s how I got into the field.”

Following the completion of his bachelor’s degree in physics in 1974, Milke transferred to the University of Maryland and earned his bachelor’s degree in fire protection engineering in 1976. After graduation, Milke left for Fairfax County, Virginia, where he would serve as a fire protection engineer at the Fire Marshal’s Office. Simultaneously, Milke began teaching part-time in community colleges. “I got a taste of teaching and found that I enjoyed it.”

As Milke continued performing code and plan reviews by day and teaching by night, chance would present a new opportunity. “One of my past professors from Maryland had a research contract and invited me to come back and do research with him. It was just a year contract; there was no guarantee it was going to continue beyond that.”

Though working at the University of Maryland wouldn’t be the only opportunity offered to Milke. “As I’m filling out personnel papers

for Maryland as a research assistant, a faculty member says, ‘You know, you ought to take a grad class. It’s part of your fringe benefits here.’ That’s how I got into grad school!” Milke says with a laugh.

Timing would prove itself serendipitous for Milke once more. As Milke completed his master’s degree in mechanical engineering, Dr. Jack Watts, the original faculty member who had invited Milke to return to the university, left to start a consulting business. “Prof Bryan, the department chair at the time, asked me, ‘How would you like his position?’ As I thought about how I had enjoyed my time at the university, he said, ‘You know you’re going to need to get your Ph.D. if you do this.’ So, I said, ‘All right, I’ll do it.’”

Who was ‘Prof’? ‘Prof’, or Dr. John L. Bryan, was the department chair at the University of Maryland Department of Fire Engineering. Notably, he was also the recipient of AFSA’s Parmelee Award in 1991. “[He] was my initial supervisor, a mentor, and treated me very early on as a colleague and not as someone who reported to him. I appreciated all the guidance he gave me, it’s just amazing. Professionally, I would lean to Prof number one,” says Milke.

Bryan would encourage Milke to get involved within the industry as much as possible. “He wanted all students, class alum, and students in the FPE department to get involved—sit on standards committees. That’s where you learn what’s behind the curtain. Through his encouragement, I got involved with NFPA and was a member of the smoke control management and fire tests committees.”

In the 1980s, Milke was asked to participate in the NFPA

technical committee that were just expanding in the area for smoke control in high-rise buildings, atrium malls, and similar structures. He is recognized as one of the leading experts in the theory of smoke control system design.

Milke was also invited to be a part of NFPA’s Standards Council in the early 2000s. “Serving on the Standards Council was

a very interesting role to fill for the seven years that I was involved. It was an incredible opportunity to get connected and really see how these committees operate. Prof also encouraged me to join SFPE [Society of Fire Protection Engineers] and other professional societies. I served as president of our local SFPE chapter in the ‘80s, and then was elected to the SFPE board of directors and served as president of SFPE during that time. I served for ten years in total. I was also involved with ASTM [American Society for Testing and Materials] and participated in its standards and committees.”

In addition, when Prof stepped down from the Underwriters Laboratories’ (UL) Fire Council to become part of its board of directors, he nominated Milke to fill his spot, and he continues to serve on several UL committees to this day.

Over the course of 34 years, Milke has also been involved with the American Institute of Steel Construction (AISC), American Fire Sprinkler Association (AFSA), American Society of Civil Engineers (ASCE), and Institution of Structural Engineers (IStructE).

Milke credits Bryan’s advice for making his career more fulfilling. “I like being involved, seeing what really goes on, and understanding how you make that ‘secret sauce.’ I tell my students that you can’t just complain about the codes and standards. You need to get involved, make a difference. Don’t just sit on the sidelines whining. That’s been a part of my role, too, helping to improve the situation however I can through my participation.”

Milke also offers additional advice to his students. “Be open to opportunities! When I look at my career path, I didn’t have this grand vision or this grand plan. There were things that basically fell in my lap. But the fact that I was open to it and that I was looking and listening to these opportunities is a piece of it. Also, not being afraid to pursue some opportunities, and pursue some initiatives, was key to that. Don’t be afraid to volunteer and step up. We need to encourage the next generation of people to be ambitious, to pursue opportunities, and don’t settle for ‘good enough’!”

While Milke has been heavily involved in numerous associations over the years, he hasn’t limited his reach to just within the industry. Milke; Nicole Hollywood, the FPE department’s lead recruiter and advisor; and other members of the FPE department created the Fire

Protection Engineering Design Challenge (FPEDC) or “The Challenge” for high school students. Now in its ninth year, The Challenge allows high school teams to design and construct a two-room model apartment that includes innovative and effective detection, notification, and fire suppression systems. Schools that participate receive a local FPE alumni/professional in the field as a mentor. In recent years, the program has had as many as ten high schools participating in the final competition called “Burn Day,” which is now housed at the ATF Labs located near College Park. This year, AFSA supported FPEDC as a main sponsor and will continue to be a sponsor for the next five years.

“Recruiting high school students to our department to study fire protection engineering is an ongoing challenge and has been since the start of the program,” Milke states. “We must let people know that fire protection engineering exists and then help them understand what it is. Students don’t want to just sit in a classroom and listen to people drone on. So, what can we do to get them engaged and get them active?”

“It’s been a good competition,” Milke continues. “The selfish goal is to have students come and study fire protection engineering, and we get some, but that’s not the only reason why we’re doing this. If we can get students excited about STEM, then that’s a win.”

When asked why he believes most people do not pursue education in fire protection engineering, Milke explains, “I think it’s principally an awareness problem—that this field exists and knowing how much of a difference fire protection engineers make. I think that’s a key selling point that isn’t necessarily appreciated.”

He continues, “A lot of high-school-aged students are attracted to the bright, shiny thing and whatever that fad is right now—AI, drones, etc. There are fire protection aspects to that, and we try to get people to understand them. But saving lives and property, saving the environment, and all the good that comes from that is a strong selling point for us. We tell students, ‘You’re going to be doing something where people matter. You’re doing things to help people and companies at all levels! You’re dealing with populations of disadvantaged people and providing fire-safe housing in a cost-effective way. Sprinklers are a big part of that. I think we’re just trying to raise awareness of the incredible good that can happen from a career in fire protection engineering.”

“Jim has been the faculty lead and topical expert for The Challenge,” comments Jack Poole, P.E., FSFPE, principal, Poole Fire Protection, Inc., Olathe, Kansas, and one of Milke’s students during his time at UMD. “Since the inception of the program, Jim has been vital in creating the curriculum; determining challenge parameters; writing the rubric and rules which he later helped to edit into an eBook; serving as one of the early instructors who presented material at schools; creating videos and video lectures; serving as a judge during the Burn Day final competition; locating and securing sponsorship on multiple levels; and, most importantly, recruiting and expanding the fire protection engineering program.”

While a professor at UMD, Milke has taught classes on heat transfer, codes and standards, risk analysis, structural fire protection, fire suppression systems, smoke control, and life safety to more than 1,000 undergraduate students and hundreds of graduate students who have made considerable contributions to the fire sprinkler industry. He has conducted many research projects, written numerous research papers, and co-authored three books on smoke control with John Klote, D.Sc., P.E., Fellow ASHRAE.

“When I arrived at the university in 1977, Jim was working with Prof Bryan’s leading research called Project People and I continue to reference that research today,” comments William E. Koffel, P.E., FSFPE, SASHE, Senior Director, Special Projects, Koffel Associates, Columbia, Maryland “It has impacted the codes and engineering guides that practicing fire protection engineers use today. I have also incorporated lessons learned from that research in the work that I do helping clients prepare emergency plans and to train occupants and employees in how to respond to fire emergencies.”

Early in his career, Milke conducted research directly helpful to the fire sprinkler industry such as an examination of the quality of water in fire sprinkler systems. He was involved with many water quality research projects around campus to address the quality of water in sprinkler systems as well as determining the water supply for residential sprinklers. This work in the 1980s helped clear the way for Prince George’s County to pass its mandatory fire sprinkler ordinance for single-family homes in the early 1990s.

Later in his career, Milke was asked to be one of the experts in the NIST World Trade Center investigation after the events of September 11. He helped to study the performance of systems in the twin towers and adjacent buildings. His work helped to make sprinklers an expected system in almost all high-rise buildings.

Under Milke’s leadership as chair of UMD’s FPE Department, his vision for an improved department led to many programs and activities that have benefited the sprinkler industry, including:

• Creating a professional track tenure position at the UMD FPE Department that focuses on teaching aspects of the industry that are specific to suppression and other fire protection systems.

• Improving relationships with many sprinkler manufacturers and contractors joining the UMD FIRE Center.

• Partnering with AFSA to provide a live side-by-side dorm room burn at UMD to show students and others the importance and value of automatic fire sprinkler systems.

If you think Milke plans to slip into a traditional retirement— think again. Milke plans to continue working part-time at UMD. “I don’t plan on evaporating and not touching fire protection again. I’ll still help with the department, teach a couple of classes, maybe take on a special project here or there. Otherwise, I’d love to stay involved with the standards committees that I’m on now.”

Perhaps his drive to continue working ties back to his pride in his students. “This is going to sound sappy, but when I would hear Prof Bryan talk during his time here, he’d say, ‘The greatest feeling you can have as a professor is to see what your previous students have gone on

to achieve.’ That’s something I’ve really come to appreciate. To see the John Denhardts, the Jack Medovichs, and others, and see where they’ve placed themselves in their organizations and their companies… being a part of that is huge! I think that’s got to be number one of all the things that I have done. It’s not one paper, one book, or anything like that; it’s the whole collection of people with whom I’ve been involved.”

“There was an event in May that recognized my time at the university, and someone tallied that around 80 percent of the undergrads who have come out of this department have been in a class I’ve taught. Among our graduate students, 100 percent of them who have graduated during my time here at Maryland have been in a class that I’ve taught. To have that much of an impact—that broad of a population that I have been able to touch—I may not be everyone’s best instructor, but just being able to be a part of that development and now to see where they are, it’s really impressive! It’s such a great feeling.”

AFSA will present Milke with its 2023 Henry S. Parmelee Award at AFSA42: Convention, Exhibition, and Apprentice

Competition to be held September 6-9, 2023, at the Signia by Hilton Orlando Bonnet Creek. The presentation will be the highlight of the general session as indicated by the accolades of this year’s honoree.

“I have known Jim for many years, and he has always been a mentor for me,” comments AFSA Chair of the Board Jack Medovich, P.E., senior vice president, Summit Companies. “He has worked to advocate for and prove the benefits of automatic fire sprinklers and has educated the current and future field of fire protection engineering professionals. He has left a lasting legacy on the fire protection industry, and it will be my greatest honor to present Jim with this award.”

“Throughout his more than 45-year career as a fire protection engineer and a professor at UMD, including the last 12 years as chair of the FPE department, nobody has done more to train fire protection engineers in the support of fire sprinkler systems than James A. Milke. I cannot imagine anyone with a better resumé to receive this award,”

comments Kenneth E. Isman, P.E., FSFPE, clinical professor of fire protection engineering at UMD.

“Dr. Milke has made significant contributions to the fire protection engineering and the fire sprinkler industry through his outstanding research, leadership, and advancement of the industry,” comments Poole. “I congratulate him on receiving this well-deserved award and in following the footsteps of Dr. John L. Bryan (Prof).”

“Jim has been a mentor for me throughout my career,” comments AFSA Vice President of Engineering and Technical Services John A. Denhardt, P.E., FSFPE. “He was not only one of my professors, he was a true leader who people wanted to follow by his example on how to work in a professional and responsible manner. I will always be grateful for my lifelong learning under Jim.”

Milke is quick to name others for supporting him. “I must mention the unconditional support I’ve had from my wife, Judy, and our children, Lauren and Jason. Their support was key so that I could pursue various professional activities, which sometimes required travel and time away from our home and family. I would also give a shout-out to my parents, who started me on this road—instilling a work ethic, encouraging me, and supporting me to go to college. Certainly, I couldn’t have done it without them.”

He concludes, “I think it’s already been conveyed, but I’ve had an incredibly enjoyable career. It’s something I couldn’t have even imagined when I was graduating from Maryland with my undergrad degree. There’s no way I could have planned this out to be this level of enjoyment and the flow of activity has just been phenomenal.”

George Couros recently wrote, “Your legacy as an educator is always determined by what your students do.” In this case, Milke’s legacy will continue remarkably for quite some time. n

EDITOR’S NOTE: Do you know someone who should be nominated for AFSA’s highest honor, the Henry S. Parmelee Award? AFSA is proud to recognize those individuals who have dedicated themselves to the professional advancement of the fire sprinkler industry and to the goal of fire safety through automatic sprinklers. AFSA accepts nominations year-round at www. firesprinkler.org/afsa-awards. (Member login required.)

1983 John M. Rhodes, FM Global Research Corp.

1984 William J. Meyer, Central Sprinkler Corporation

1985 C. B. Hall, American Automatic Sprinkler Co.

1986 Harold L. Black, Central Fire Protection, Inc.

1987 Edward J. Reilly, Ed Reilly Associates

1988 Richard T. Groos, The Viking Corporation

1989 Ron Coleman, Chief, Fullerton Fire Dept., CA

1990 Frank J. Fee III, Reliable Automatic Sprinkler Co., Inc.

1991 Dr. John L. Bryan, University of Maryland School of Fire Protection Engineering

1992 W. D. (Dave) Hilton, Chief, Cobb County Fire Department, GA

1993 J. Frank Riseden, AFSA President 1983-1991

1994 Haden B. Brumbeloe, Publisher, FPC Magazine

1995 Edward H. Smith, H.F.P. Corporation

1996 Tom Waller, Viking Fire Protection of the SouthEast

1997 Chester W. Schirmer, Schirmer Engineering Corp.

1998 Tom Siegfried, Retired Chief, Altamonte Springs, FL

1999 Donald D. Becker, Midland Automatic Sprinkler Co.

2000 Robert L. McCullough, AllSouth Sprinkler Company (awarded posthumously)

2001 Buck Buchanan, Central Sprinkler Corporation

2002 Frank M. Winiecki, General Sprinkler Corporation

2003 Jack Viola, H.F.P. Corporation

2004 Lowell Gillett, Fire Engineering Co., Inc. (retired)

2005 Joe Hankins, FM Global (retired)

2006 Art Cote, National Fire Protection Association

2007 Tom Groos, The Viking Corporation

2008 William E. Corbin, Mutual Sprinklers, Inc.

2009 Lloyd Ivy, AFSA Director of Membership (1986-2008)

2010 Marty Giles, VSC Fire & Security

2011 Willie Templin, American Automatic Sprinkler, Inc.

2012 Bob Rees, Sunland Fire Protection

2013 Russ Leavitt, Telgian Corporation

2014 James Golinveaux, Tyco Fire Protection Products

2015 George Wagner, Worsham Sprinkler Company

2016 Steve Muncy, AFSA President (1991-2016)

2017 Robert (Bob) G. Caputo, Fire & Life Safety America

2018 Kraig Kirschner, AFCON

2019 Manning Strickland, Strickland Fire Protection

2021 George DiMatteo, Ferguson Fire & Fabrication

2022 Kevin T. Fee, Reliable Automatic Sprinkler Co., Inc.

2023 Dr. James A. Milke, P.E., University of Maryalnd, Department of Fire Protection Engineering

EVERY DAY, ON EVERY PROJECT WE WORK FOR YOU.

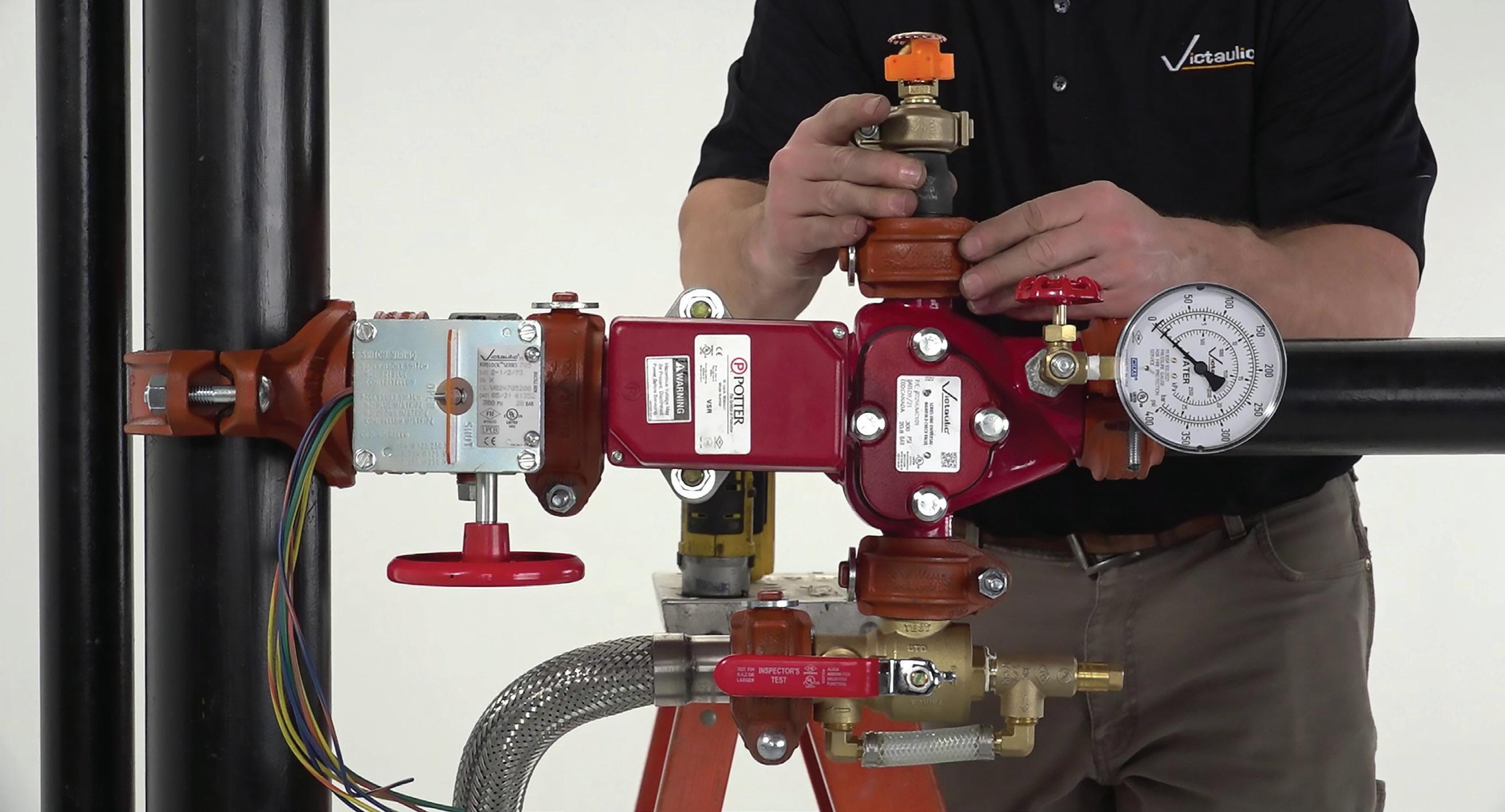

CONTROL VALVE | Allows shut off for maintenance, inspection or renovation

FLOW SWITCH | Transmits an alarm signal that the sprinkler system is active

TEST & DRAIN | Allows the water flow switch to be tested and the system to be drained for maintenance and inspections

CHECK VALVE WITH REMOVEABLE COVER PLATE | Allows the system to retain pressure over time

REQUIRED SYSTEM GAUGE(S) | Assesses loss of pressure over time during testing and verifies water pressure

FLEXIBLE DRAIN HOSE | Includes groove-by-groove captured coupling connections for labor savings

The comedian Bill Engvall made the saying “Here is your sign” well-known. When he said it, it was directed at someone who just said something that was obvious or just plain stupid. One story I remember Engvall telling at a comedy show was about a gentleman who was using a coat hanger trying to unlock his car. Another person walking past looked at the gentleman and asked, “You locked your keys in the car?” The gentleman responded, “No sir, I’m just trying to hang my car up to dry.” Here is your sign. So, what does this have to do with sprinkler systems? Failure to include the required signage is an obvious mistake that can be costly. Numerous signs are required by NFPA 13, Standard for the Installation of Sprinkler Systems, and other standards; however, many sprinkler designers, installers, and inspectors are not familiar with the signs they are required to provide. We all know about the requirement for control valve and main drain signs, but what about the rest? This article will discuss required signs and explain why they are critical to the safe operation of a fire protection system.

Let’s start by looking at NFPA 13, 2022 edition. Table A.16.17 is a summary of the signs that must be provided and was developed to make it easier to identify what signs are required by the body of the standard.

Section 16.9.11 requires all control, drain, venting, and test connection valves be provided with permanently marked weatherproof metal or rigid plastic identification signs. The identification signs must be secured with corrosion-resistant wire or chain. The control valve signs need to identify the portion of the building served. Figure 1 shows the front and back of a typical control valve sign that meets these

requirements. Systems that have more than one control valve that must be closed to work on a system or space are required to have a sign referring to the existence and location of the other control valve. Not providing this sign cost one building owner over $500,000 in property damage. In an emergency situation at this facility, all the control valves could not be turned off in a timely manner as no onsite personnel knew the location of the second control valve.

Section 8.6.1.4 requires that for all antifreeze systems that are remote from the system riser, a placard must be mounted on the system riser that indicates the number and location of all remote antifreeze systems supplied by that riser. Section 8.6.1.5 requires a placard at the antifreeze system control valve that indicates the manufacturer type and brand, volume, and minimum use temperature of the antifreeze solution used in the system.

Section 16.10.5.3.7 has a requirement that most are not aware of. Even though this requirement has been in NFPA 13 since the 2007 edition, I seldom see this sign provided. All auxiliary (low-point) drains on dry pipe systems or preaction systems require a sign at the dry pipe or preaction valve indicating the number of low-point drains and the location of each individual drain. Failure to provide this signage has caused numerous installing contractors to lose legal claims that were brought against them when systems experienced freeze damage. In one case, a maintenance crew drained all the low points they saw, but the system still experienced pipe damage due to freezing. There were seven low points, but two of them were not obvious. The low points were shown on the “as-built” drawings, but because the required signage was not provided, the installing contractor was still found liable for damage that occurred long after the system was completed. Luckily this claim was small, but it could easily have been much different. We have found that providing an 11-in. x 17-in. outline of the system indicating the

number and location of the low-point drains and the inspector’s test connection has satisfied this requirement. We usually install the outline in a picture frame and mount it near the dry or preaction valve. We also include this outline in our Operation and Maintenance manuals. This sign ensures that important information about the system is posted for future use and reference.

Section 16.12.5.8 covers the requirements for signage at the fire department connections (FDCs). Each FDC must include a sign having raised or engraved letters at least 1-in. high on a plate or fitting reading the type of systems served. If any system served requires 150 psi or more, a sign must be provided indicating the system demand pressure. Where an FDC serves only a portion of a building, a sign should be provided indicating the portion(s) of the building served.

Section 29.4 requires a Hydraulic Design Information Sign, sometimes referred to as a Hydraulic Data Nameplate. Like the valve identification signs required by Section 16.9.11, we all should be familiar with this sign since it has been around for years. However, over the years, a few modifications and new requirements have been added to this sign. Every hydraulically calculated system is required to have this sign. This means that if a multistory building has multiple systems, each system that has a water supply source, control valve, waterflow alarm, and drain requires its own signage. The sign must be placed at every alarm valve, dry pipe valve, preaction valve, or deluge valve supplying the corresponding hydraulically designed area unless the Authority Having Jurisdiction (AHJ) approves an alternate location. In addition, NFPA 13 requires signage at every system riser and floor control assembly. The Hydraulic Design Information Sign must include the location of the design area or areas, size (area) of or number of sprinklers in the design area, the discharge densities over the design area(s), the required flow and residual pressure demand at the base of the riser or fire pump (if applicable), the occupancy classification or commodity classification and maximum permitted storage height and configuration, the hose stream allowance included in addition to the sprinkler demand, and the name of the installing contractor. Where a system has been designed using the pipe schedule method, Section 29.5 requires a Pipe Schedule Design Information Sign or nameplate located on the corresponding system riser. Section 29.6 requires a General Information Sign. Even though this requirement has been in NFPA 13 since the 2007 edition, it is often missed. The installing contractor must provide a General Information Sign that can be used to determine system design basis and information relevant to the inspection, testing, and maintenance requirements of NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems. The General Information Sign must be placed at each system control riser, antifreeze loop, and auxiliary system control valve. It needs to include the following information: name and location of the facility protected, occupancy classification, commodity classification, presence of high-piled and/or rack storage, maximum height of storage planned, aisle width planned, encapsulation of pallet loads, presence of solid shelving, flow test data, presence of flammable/combustible liquids, presence of hazardous materials, and presence of other special storage. In addition, the sign must include the location of venting valve(s), location of auxiliary drains and low-point drains on dry pipe and

preaction systems (note that this is also required by Section 16.10.5.3.7), original results of the main drain flow test, original results of the dry pipe or double interlock preaction valve test, and name of the installing contractor or designer. The sign must also indicate the presence and location of antifreeze or other auxiliary systems. Where injection systems are installed to treat corrosion (including microbiologically influenced corrosion or MIC), the type, concentration, and disposal requirements of the chemical must be shown. Finally, the sign must indicate the presence of nitrogen when used to allow for an increased C-factor in dry or preaction systems.

For marine systems, Section 31.2.7.5 requires an 18-in. x 18-in. sign displaying the applicable symbol for an FDC as shown in Table

5.2 of NFPA 170, Standard for Fire Safety and Emergency Symbols, 2024 edition. The symbol must be placed at the connection so that it is in plain sight from the shore access point.

Section A.16.11.2 suggests installing a sign near the local alarm device required by Section 16.11.2. (Remember, the annex contains material that explains or clarifies the body of the standard but is not legally enforceable.) The sign should be located near the device in a conspicuous position and include wording such as: SPRINKLER FIRE ALARM—WHEN BELL RINGS CALL FIRE DEPARTMENT OR POLICE.

While not necessarily classified as a sign, Section 16.2.7.7 requires a list of the sprinklers installed in the property to be posted in the spare sprinkler cabinet. This requirement was added during the 2007 revision to NFPA 13. This list needs to include the following information: the Sprinkler Identification Number (SIN) or the manufacturer, model, K-factor, deflector type, thermal sensitivity, and pressure rating; general description; quantity of each type to be contained in the cabinet; and issue or revision date of the list.

In this section, we will cover the signage requirements in NFPA 13D, Standard for the Installation of Sprinkler Systems in One- and Two-Family Dwellings and Manufactured Homes, 2022 edition; NFPA 13R, Standard for the Installation of Sprinkler Systems in Low-Rise Residential Occupancies, 2022 edition; NFPA 14, Standard for the Installation of Standpipe and Hose Systems, 2024 edition; and NFPA 20, Standard for the Installation of Stationary Pumps for Fire Protection, 2022 edition.

NFPA 13D – This standard has only one requirement for a sign, and that is for a multipurpose piping system, which is defined by Section 3.3.13.3 as: “A piping system intended to serve both domestic needs in excess of a single fixture and fire protection needs from one common piping system throughout the dwelling unit(s).” This is not the typical independent sprinkler system most sprinkler contractors are installing. This is a combined domestic water/ sprinkler system for the dwelling unit(s). In accordance with Section 6.3.4, when a multipurpose piping system is installed, a warning sign with minimum 1/4-in. letters is required to be affixed to the main shutoff valve and states the following:

WARNING: THE WATER SYSTEM FOR THIS HOME SUPPLIES FIRE SPRINKLERS THAT REQUIRE CERTAIN FLOWS AND PRESSURES TO FIGHT A FIRE. DEVICES THAT RESTRICT THE FLOW OR DECREASE THE PRESSURE OR AUTOMATICALLY SHUT OFF THE WATER TO THE FIRE SPRINKLER SYSTEM, SUCH AS WATER SOFTENERS, FILTRATION SYSTEMS, AND AUTOMATIC SHUTOFF VALVES, SHALL NOT BE ADDED TO THIS SYSTEM WITHOUT A REVIEW OF THE FIRE SPRINKLER SYSTEM BY A FIRE PROTECTION SPECIALIST. DO NOT REMOVE THIS SIGN.

The intent of this sign is to warn the unknowing homeowner or residential contractor about the need to consider the sprinkler system before adding any device to the combined water system.

NFPA 13R – Section 5.2.14.4 requires all control, drain, and test connections be provided with permanently marked weatherproof metal or rigid plastic identification signs. The identification signs must be secured with corrosion-resistant wire, chain, or other approved means. The control valve signs need to identify the portion of the building served. Systems that have more than one control valve that must be closed to work on a system or space are required to have a sign referring to the existence and location of the other valves.

Section 6.11.3 requires signage for FDCs. Each FDC to a sprinkler system must be indicated by a sign having raised or engraved letters at least 1 in. in height on a plate or fitting indicating the type of system(s) served (e.g., AUTOSPKR., OPEN SPKR., or STANDPIPE).

While not necessarily classified as a sign, Section 11.1.7 requires a list of the sprinklers installed in the property to be posted in the spare sprinkler cabinet. This requirement is similar to the NFPA 13 requirement. The list must include the following information: the Sprinkler Identification Number (SIN) or the manufacturer, model, K-factor, deflector type, thermal sensitivity, and pressure rating; general description; quantity of each type to be contained in the cabinet; and issue or revision date of the list.

NFPA 14 – Section 7.10 requires that all required signs be permanently marked and constructed of weather-resistant metal or rigid plastic materials.

Section 8.7.1 has numerous requirements for signs. It requires that all main and sectional system control valves, including water supply control valves, be equipped with a sign indicating the portion of the system controlled by the valve. In addition, all control, drain, and test connection valves must be provided with signs indicating their purpose. Where sprinkler system piping supplied by a combined system is supplied by more than one standpipe (“loop” or “dual-feed” design), a sign must be located at each dual or multiple feed connection to the combination system standpipe to indicate that to isolate the sprinkler system served by the control valve, an additional control valve or valves at other standpipes must be shut off. The sign must also identify the location of the additional control valves. Where a main or sectional system control valve is in a closed room or concealed space, the location of the valve must be indicated by a sign in an approved location on the outside of the door or near the opening to the concealed space. Where hose connections are not located in exit stairways, signs must be provided in accordance with NFPA 170 to identify the location of the hose connection in an approved manner. Valve cabinets, where provided, must be marked to indicate the contents. Lettering must be red with a white background and 21/2 in. in height. Annex section A.8.7.1.5 suggests that it might be necessary to mount hose connection signs parallel, perpendicular, or at an angle to the plane of the mounting surface on which the sign is located. The point is that the sign must be readable in an emergency by responding personnel. Dry systems with low-point drains must have a sign at an approved location indicating the number of low-point drains and each individual drain. Where a fire pump is provided to supply an automatic standpipe system, Section 8.7.2 requires a sign at the pump indicating the minimum pressure and flow required at the pump discharge flange to meet the system demand.

Section 8.7.3 requires a Hydraulic Design Information Sign to identify the basis of the system design. The sign must be located at the water supply control valve for automatic or semiautomatic standpipe systems and at an approved location for manual systems. The sign must indicate the location of the two hydraulically most remote hose connections, the design flow rate for the connections, the design residual inlet and outlet pressures for the connections, the design static pressure, the design system demand (i.e., flow and residual pressure) at the system control valve or at the pump discharge flange where a pump is installed, and at each FDC.

Section 8.7.4 requires that all pressure-regulating devices be equipped with a sign that indicates the static and residual inlet and outlet pressures and flows. Section A.8.7.4 states that the sign can be mounted on the valve or in the vicinity of the valve as long as it is visible during periodic tests and inspections.

Section 9.9 has requirements for FDC signage. Each FDC must be supplied with a sign labeled STANDPIPE with letters at least 1-in. high that allows the sign to be read from the street. For manual systems, the sign must also indicate that the system is manual and that it is either wet or dry. If automatic sprinklers are also supplied by the FDC, the sign or combination of signs must indicate both designated services (e.g., STANDPIPE AND AUTOSPKR or AUTOSPKR AND STANDPIPE). A sign must also show the pressure required at the inlets to deliver the standpipe system demand if over 150 psi. Where an FDC serves multiple buildings, structures, or locations, a sign must be provided indicating the buildings, structures, or locations served.

Section 12.11 requires the installation of signs required by this standard to be verified at system acceptance.

NFPA 20 – For positive displacement pumps, Section 8.4.10 requires a permanently marked weatherproof metal or rigid plastic sign affixed to the system that indicates the required time to achieve the system design pressure. The sign is required for acceptance testing and future periodic testing.

Section 10.1.2.5.2 has a requirement for electrical fire pump systems when multiple pumps serve different areas or portions of the facility. In these applications, an appropriate sign must be conspicuously attached to each controller indicating the area, zone, or portion of the system served by that pump or pump controller. Section 12.1.3.3.2 has the same requirement for engine-driven controllers.

Section 11.4.2.4 requires a method to avoid overfilling diesel fuel tanks. One method that is allowed is the installation of a permanent sign at the fill point with the tank calibration chart and instructions for the filling procedure, which includes having the person performing the fill operation determine how full the tank is prior to filling and calculate the quantity of fuel (in gallons or liters) that it will take to get the tank to 90 percent of its capacity. Where climatic conditions are such that the sign could be obscured by ice or snow, weathered beyond readability, or otherwise rendered unreadable, the fill procedure and chart can be stored in an office window, lock box, or other location accessible to the person filling the tank.

In summary, the installation of signs is often ignored or thought of as unimportant. However, the need for signs is clear. Failure to provide

the required signage can cost valuable time in an emergency and leave the installing contractor liable for damages. Additionally, NFPA 25 requires that many of the required signs be checked during required inspections, and if missing, they must be replaced. Specifically, the Hydraulic Design Information Sign must be replaced if missing. This could result in the installing contractor receiving a telephone call from the property owner asking, “Where’s my sign?” Having another contractor develop a Hydraulic Design Information Sign without the benefit of the as-built drawings can be expensive. No matter what type of system you are installing, make sure you follow all the requirements for proper signage. Don’t make this obvious (and often expensive) mistake. You need to be able to say, “Here is your sign!” n

ABOUT THE AUTHOR: John August Denhardt, P.E., ET, FSFPE, is AFSA’s vice president of engineering and technical services. He is a member of the NFPA 13 Sprinkler Discharge Committee and is a Fellow of SFPE. Denhardt is an NFPA Research Foundation trustee, sits on the University of Maryland (UMD) Department of Fire Protection Engineering’s board of visitors, and is a member of the SFPE board of directors. Denhardt holds a Bachelor of Science degree in fire protection engineering from UMD in College Park.

EDITOR’S NOTE: This article first appeared in two parts in the January/February 2017 and March/April 2017 issues of Sprinkler Age. As one of the most-read Sprinkler Age articles to date, it was revised to reflect the latest editions of the applicable standards and reprinted in this issue.

IMPORTANT NOTICE: The article and its content do not represent a Formal Interpretation issued pursuant to NFPA Regulations. Any opinion expressed is the personal opinion of the author and presenter and does not necessarily represent the official position of the NFPA and its Technical Committee.

The American Fire Sprinkler Association (AFSA) welcomes its members to Orlando, Florida, for AFSA42: Convention, Exhibition, and Apprentice Competition. This year is also the 30th anniversary of the National Apprentice Competition (NAC), and its seven competitors represent the best of the fire sprinkler industry. This competition allows apprentices representing member companies from across the country to compete in two phases of testing, written and hands-on, for the chance at national recognition and cash prizes.

AFSA’s National Apprentice Competition, started in 1994 by the late Robert (Bob) L. McCullough, then chair of the Apprenticeship & Education Committee, was created to promote apprentice training and give recognition to the apprentices who are actively enrolled in the AFSA Apprenticeship program. Now celebrating its 30th year, the competition continues to attract more fire sprinkler apprentices from AFSA local chapters and member training programs from all corners of the United States, bringing them together annually for the fire sprinkler industry’s foremost showcase of training excellence.

Eligibility for apprentices to compete is based on the following criteria: their employer must be a member of AFSA in good standing, the apprentice must actively be participating in the AFSA apprenticeship courses or enrolled in the NCCER/AFSA Fire Sprinkler Fitting Training Series, and they must have at least one year of field experience with a minimum of six

months combined hands-on experience in cutting, threading, and installing steel pipe and CPVC pipe. The first competition phase consists of a 100-question multiple-choice exam provided by AFSA. The test is proctored online, making it accessible to contestants from all 50 states. The results of this test will determine who will go on to participate in the live competition at AFSA42.

The top seven apprentices in Phase I receive the following: a full registration to the convention and a second full registration for their employer; an expense-paid trip to AFSA42 to compete; accommodations at the Signia by Hilton Orlando Bonnet Creek; and a brand-new set of hand tools to use in Phase II.

Phase II entails a more thorough written exam given at the convention, followed by a live practical installation in the exhibition hall at AFSA42. The Phase II exam is based on all four levels of the AFSA/NCCER Contren® Learning Series Sprinkler Fitting curriculum. Following a written exam, apprentices must cut, thread, and install a steel and CPVC piping system with sprinkler heads and perform a water pressure test. Participants are graded on accuracy, craftsmanship, and safety.

The combined results of the Phase II written and hands-on tests determine the winner. A lot is on the line for these apprentice hopefuls as prizes are awarded based on finishing rank: first place takes home a $5,000 cash prize, second place receives $3,000, third place receives $2,000, and all other finalists receive $1,000.

This year the nation’s top seven apprentices will travel to Orlando to try their luck at becoming the next AFSA NAC champion. Sprinkler Age caught up with each finalist for a quick Q&A to help you

get to know the finalists before cheering them on during the live competition.

Samuel Callison, Titan Fire Protection Inc., Vista, CA

Why did you choose to pursue a career in fire protection? I have family in the trade, and it has treated them well. I want to provide my family with the same financial security that I grew up with.

What advice would you give someone thinking about entering the fire protection trade? Pay attention in class, do what your foreman says, show up on time.

Matthew Comp, Diamond Automatic Sprinklers, Inc., Mt. Holly Springs, PA

Why did you choose to pursue a career in fire protection? I have always had a passion for working with my hands. When I saw an advertisement from Diamond looking for an apprentice, I was intrigued and started doing some research. After seeing all the different tasks it takes to install and maintain a sprinkler system, I knew that this industry would be an ideal fit for me.

What is the key ingredient to your success? I believe the key ingredient to my success is my adaptability. Being able to quickly and effectively switch between multiple tasks and maintain focus on each one is such a strong skill in this profession.

Daniel Coticchio, Piper Fire Protection, Clearwater, FL

What do you enjoy most about the work you do? I love to work with my hands and create something. It also brings me joy to say I help prevent fires and save lives.

What does the future of the industry look like to you? A lot more innovative ideas will come together to make the trade better. It wasn’t long ago that it was 4-in. threaded pipe and back-breaking work.

Timothy Farley, Allied Fire Protection, Fargo, ND

Why did you choose to pursue a career in fire protection? I lucked out after the

local plumbing union denied me for its apprenticeship. I consider myself to be lucky to be here after being hired on with zero experience.

What does the future of the industry look like to you? To me, it looks solid, and more people are interested in fire protection and are taking fire protection more seriously. There’s plenty of oppor tunity to advance my career.

Armonie Jones, Aqueduct Fire Protection Systems, Williamstown, NJ

What do you enjoy most about the work that you do? What I enjoy the most is coming across new places, buildings, warehouses, and coming up with a game plan like a checklist, and then running pipe through them from the starting building point at times until finished down to the pump room with (all systems normal) and being able to say I piped that building.

What advice would you give someone thinking about entering the fire protection trade? When I started, I didn’t understand the process or introduction-like steps, but the further I got, I realized you needed to have knowledge on how all the pieces of a system work in order to only install it correctly, but save you trouble, manpow er, and water chaos. Been there!

Andrew Lynch, Johnson Controls, Colorado Springs, CO

Why did you choose to pursue a career in fire protection? I was at a point in my life where I was looking for a career that I could grow with instead of just another dead-end job. I’ve always enjoyed working with my hands, so when I heard that Johnson Controls was hiring sprinkler fitter apprentices, I thought it would be a good fit.

What does the future of the industry look like to you? Fire protection has a bright

future filled with potential. This new technology being developed and policies being put in place to keep people and

until I got into the plumber’s union. I started to love the work I was doing and progressed quickly. Then I was offered

From l to r: Samuel Callison, Matthew Comp, Daniel Coticchio, Timothy Farley, Armonie Jones, Andrew Lynch, and Brian Otto are the seven finalists for AFSA’s 30th Annual National Apprentice Competition, to be held during AFSA42 in Orlando.Do NFPA 13D and NFPA 13R systems need relief valves? The short answer to this question is “No.” A longer answer would be that you only need to install a relief valve on an NFPA 13D, Standard for the Installation of Sprinkler Systems in One- and Two-Family Dwellings and Manufactured Homes, or NFPA 13R, Standard for the Installation of Sprinkler Systems in Low-Rise Residential Occupancies, system if the piping is designed and installed in a gridded arrangement and alternative provisions have not been made to accommodate thermal expansion of the water in the piping. This article will be a short history of this subject and how we got to the point where this question needed to be asked.

In order to set the stage, we need to go back to the 1960s. In the mid-1960s, all fire sprinkler systems were either laid out as tree systems or loop systems. The overwhelming majority of fire sprinkler systems were tree systems with the pipes sized using a pipe schedule. A small number of fire sprinkler systems used hydraulic calculations to size the pipe, with some of these having a simple loop. This was the most complicated piping arrangement that could be reliably calculated by hand, and computer programs for hydraulic calculations were not yet on the market (although Art Cote was working on one at this time while a student at the University of Maryland).

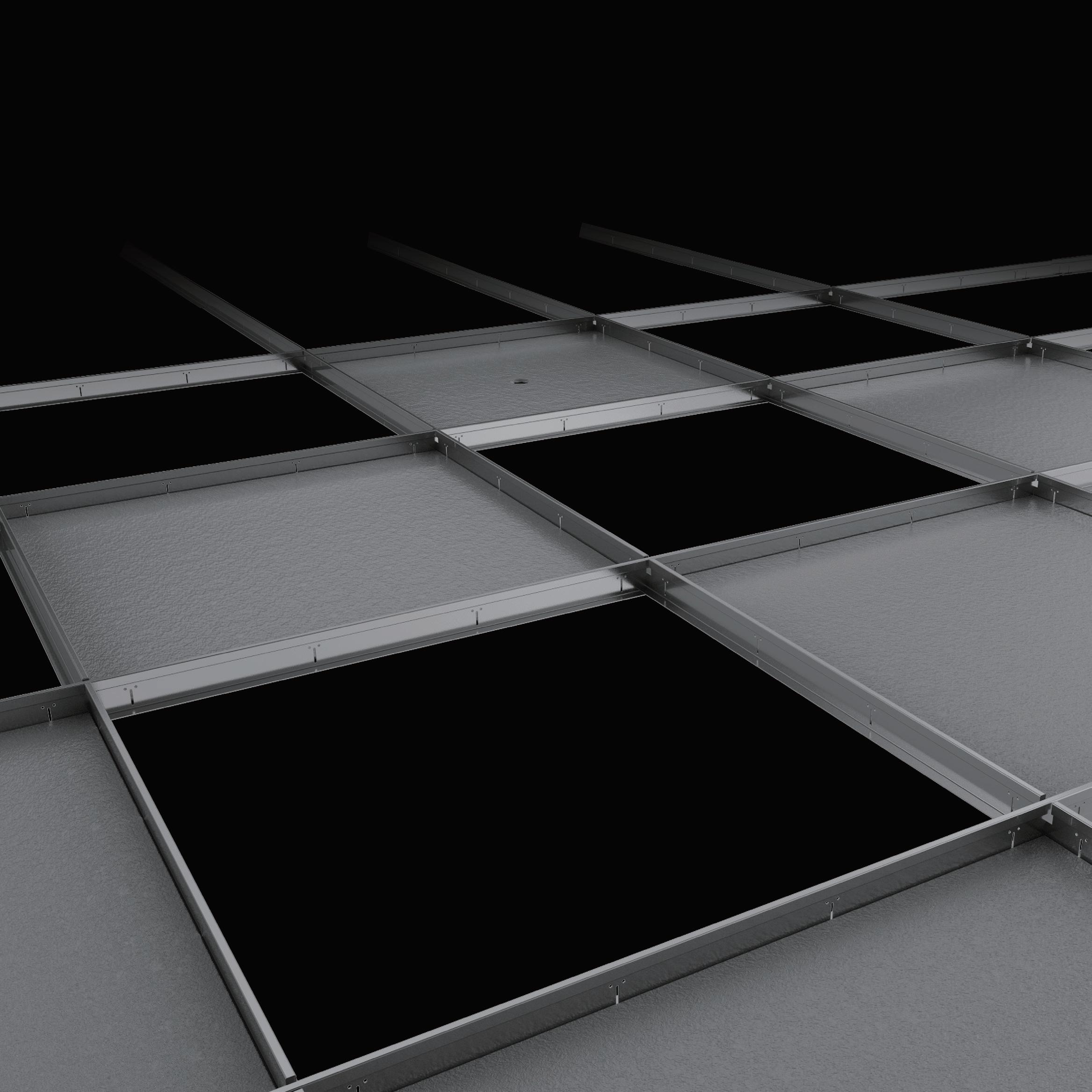

By the late 1960s, a few engineers were using the time they could get on large mainframe computers to do the hydraulic calculations for gridded sprinkler systems to size the pipe and ensure that the water supply would be sufficient. When these first gridded systems were installed, a common problem emerged that wasn’t foreseen by these engineers: the pressure in these systems got very high during hot summer months, and in some of these early systems, ruptures occurred because the system was unable to withstand the pressure caused by the change in temperature.

The problem was that gridded systems do not trap air like tree and loop systems. When tree and loop systems are first filled with water, air is pushed to the ends of the branch lines and compressed until the air pressure equalizes with the water pressure. If the water temperature rises, the pressure will go up, and the water will expand into the air space, compressing the air a bit more until the pressures equalize again. The air pockets create space for the water to expand.

Consider the following example. A wet-pipe tree sprinkler system with a total volume of 500 gallons within the piping [starting with the air at 0 psig (14.7 psia)] that is initially filled with water with a temperature of 50°F and a maximum pressure of 50 psig (64.7 psia). Using Boyle’s Law (the pressure times the

volume within a system is a constant as long as you consider the absolute pressure, not the gauge pressure), we can calculate that the water will fill 386 gallons of the piping and compress the air in the branch lines until the total volume of compressed air is 114 gallons (500 x 14.7/64.7 = 114; 500 – 114 = 386).

When water warms up from 50°F to 120°F (as it might during the summer), it expands by about 1 percent in volume. In our example, this would cause the water to go from 386 gallons to 390 gallons, which would compress the air from 114 gallons to 110 gallons. Using Boyles Law again, we can calculate the effect that this has on the air pressure (64.7 x 114/110 = 67; 67 – 14.7 = 52. 3). The air pressure would go up to 67 psia, which is a gauge pressure of 52.3 psig. So, in a tree system, where the water has somewhere to expand, the effect of expansion due to thermal changes is negligible (from 50 psi to 52.3 psi in this case).

But in a gridded system, there is no trapped air after the system has been filled and tested a few times. When the water temperature goes up, the water pressure goes up, and the water tries to expand, but there is no place for the water to go, forcing the pressure to go up exponentially since water is an incompressible fluid. The water quickly gets to a pressure that exceeds the rated pressure for the pipe, valves, and fittings, and eventually, a rupture can occur at a weak point in the system.

By the early 1970s, many engineers were designing gridded systems with a relief valve to combat this problem. It was not until the 1985 edition of NFPA 13, Standard for the Installation of Sprinkler Systems, that a requirement was added to the standard to require a relief valve on all wet-pipe systems where the piping was arranged in a grid with an exception allowing for the relief valve to be omitted if the system had “auxiliary air reservoirs” (see Proposal 1329 in the Fall 1984 Technical Committee Report). The relief valve needed to be set to open at 175 psi or 10 psi lower than the maximum system pressure, whichever was greater. Wet-pipe sprinkler systems worked well for more than 100 years, with only gridded systems being required to have relief valves (if they did not have the air reservoirs, and such reservoirs were not very common).

In the early 2000s, corrosion of steel pipe in wet-pipe fire sprinkler systems was receiving a great deal of scrutiny. For reasons that have never fully been explained, steel pipe in fire sprinkler systems was no longer lasting for the number of years that building owners expected. Whether due to microbiologically influenced corrosion (MIC) or just plain oxidation, corrosion became a significant problem. Engineers started to add air vents to sprinkler systems to minimize corrosion, and

there were concerns that tree and loop systems with air vents would suffer the same concerns for bursting as gridded systems. In the 2010 edition of NFPA 13, Standard for the Installation of Sprinkler Systems, the section requiring relief valves (7.1.2.1 in that edition) was changed from requiring them on gridded systems to requiring them on all wet-pipe systems (unless they had air reservoirs). Part of the substantiation for the change was “the growing popularity of venting trapped air from metallic wet pipe systems to inhibit corrosion activity increases the importance of protecting all wet pipe systems from over-pressurization.”

Unfortunately, the people who submitted the proposed new language for NFPA 13 and the NFPA committee in accepting this language did not differentiate between wet-pipe systems with steel piping (which might suffer from corrosion) and wet-pipe systems with non-metallic piping or copper tube (which might not have any corrosion issues). Therefore, since the 2010 edition of NFPA 13, all wet-pipe systems have required a relief valve unless they have air reservoirs designed to absorb the pressure increases that might occur with thermal expansion. The air reservoir exception is important to note since it allows the designer an alternative to a relief valve.

In the 2016 edition of NFPA 13, the standard added a requirement for an air vent to be installed at a high location in all wet-pipe systems using metallic pipe in order to vent trapped air (see Section 7.1.5 in that edition). This makes it all the more important to have a relief valve on the system since it is less likely that there will be air to absorb the expansion of the water due to thermal changes.

It is important to note that the requirements for relief valves and air vents only exist in NFPA 13. The residential standards,

NFPA 13R and NFPA 13D, do not have similar requirements because it is rare to find steel piping in such systems, and it is even rare to find gridded systems. In addition, these systems tend to be smaller so that the effect of thermal expansion is minimized. Tree and loop systems tend to trap air, which allows for the thermal expansion of the water and engineers have not been adding air release devices to NFPA 13D or NFPA 13R systems because the pipe that they tend to use is more resistant to corrosion.

NFPA 13D and NFPA 13R systems have been successfully installed for more than 30 years without air release mechanisms and without relief valves, and the experience with these systems has been very good. Reports of such systems rupturing due to thermal expansion of the water inside the piping have not surfaced. There are no requirements for air release mechanisms or relief valves in either NFPA 13D or NFPA 13R. While NFPA 13R does refer back to NFPA 13 for some installation rules, the intent has not been to pick up the requirements for a relief valve for tree or loop systems. For those purists who want to make sure that every system meets every single word of the standard, you can point to the air reservoir exception for tree and loop systems and perform a simple analysis of the volume, pressure, and temperature as was performed above to show that the trapped air in such systems is sufficient to leave the relief valve off of the system. n

ABOUT THE AUTHOR: Kenneth E. Isman, P. E., FSFPE, is a clinical professor at the University of Maryland in the Fire Protection Engineering Department, where he teaches classes on fire protection system design, life safety analysis, and performance-based design. He worked in the fire sprinkler industry from 1987 to 2014 and has been a member of the NFPA Committee for Residential Sprinkler Systems since that committee was first formed in 1998 and is currently the committee chair.

Did you hear the circus music? The barker calling out, “Get your ticket for the greatest show”? The Southern Fire Sprinkler Summit host chapters (Alabama, Arkansas, Georgia, and Louisiana) welcomed guests to its Great Sprinkler Summit June 13-16, 2023, at The Lodge in Gulf State Park, Orange Beach, Alabama. The schedule included seminars, welcome reception, vendor expo, bazaar, and networking meals.

“We wanted registrants to engage in training and education, networking, and most of all—fun!” says event co-organizer Ellen Ballard, LFSA executive director.

“Everyone embraced the theme and joined in the fun, which made everything amazing!”

An estimated 225-275 people attended the summit, including over 100 seminar registrants and 37 vendors. Major sponsors included Core & Main, Ferguson Fire & Fabrication, Reliable, SPP Pumps, Victaulic, Viking SupplyNet, and Winsupply.