SPRINKLERAGE

FIRE MUSEUM OF MARYLAND

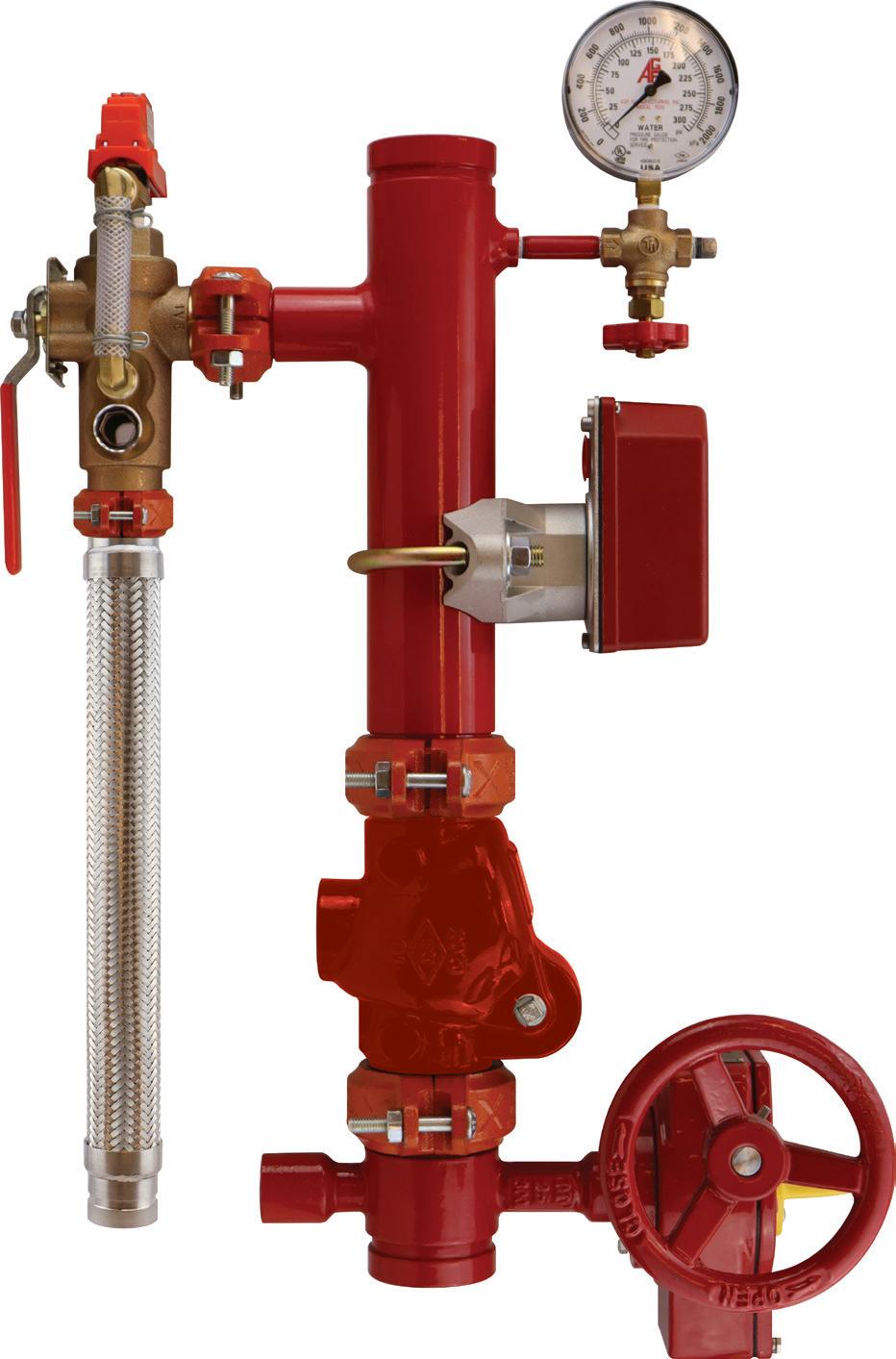

Commercial Riser (can

BACKED INTO A CORNER?

THE FCA2 FLOOR CONTROL ASSEMBLY FITS JUST RIGHT Test & Drain

Potter Water Flow Detector available in Explosionproof and automatic test versions

The Model FCA2 is cULus Listed in all sizes and FM Approved in 2"–8". The FCA2 is designed for optimal configuration for any installation scenario. With 360° rotation of each modular component, this versatile assembly adjusts to the trickiest corners.

All the components required for a complete floor control assembly. Available in sizes from 11/4"–8".

One PO. One Box. One Installation.

Our new mill expands our overall product capabilities, giving us the most comprehensive range of sprinkler pipe in the industry:

• Diameters from 1” to 10” NPS.

• Schedule 10, 30, 40, and Eddy Flow (size dependent)

• Lengths up to 25’, with custom lengths available

Plus a variety of finishing options — not to mention our exclusive EddyGuard II® MIC antimicrobial coating to help ensure reliable flow for years.

It’s all available to you from a single, responsive supplier…making your pipe selection job much easier.

with the best-in-class Installation-Ready™ rigid coupling for fire protection

Eliminate guesswork and mitigate risk with fully defined metal-to-metal contact at the install indicator

Install with ease, accuracy and speed when tightening with one touch per bolt

Simplify installations with robust gasket tabs that provide proper groove engagement and alignment

Prevent spinning bolts and pinching fingers with extended track neck bolt design

victaulic.com

CHAIR’S MESSAGE

Ibelieve AFSA is the GOLD standard for training and educating the industry while promoting fire protection systems that save lives and property. This core mission brings our association the best of the best talent to our staff. Our newest superstar to join our team is Matt Klaus, as executive vice president and COO. I would like to extend a warm welcome to Matt and look forward to collaborating with him on our many projects. Also, congratulations to Josh McDonald, director of operations and training, for passing his P.E. exam! I am so proud of his hard work and dedication to accomplish this major step in his career. Fantastic job, Josh!

President Bob Caputo and I had a successful fire sprinkler international conference in Salzburg, Austria. As I mentioned in my last Chair’s Message, AFSA was invited to participate, as well as Bob presenting a seminar on NFPA 13. This was an excellent opportunity for us to introduce the many training programs we offer. The event brings all the European countries together for one common goal: to advocate and adopt fire sprinkler standards. This was an outstanding event that brought our countries closer together. Thank you to our hosts, Alan Brinson, European Fire Sprinkler Network executive director, and Chris Stason, Victaulic UK Ireland fire protection manager, for welcoming AFSA to Europe.

Our second quarter committee and Board meetings held April 28-30 were another dawn-to-dusk work session. The Legislative Committee, chaired by Mike Meehan, prepared and approved a position paper on NFPA 25 ITM regarding AHJs requiring ASSE certification versus NICET II ITM certification. The subcommittee’s position is clearly requesting equal consideration for acceptance of NICET II certification or ASSE certification. If you have a jurisdiction requiring only ASSE certification, the position paper is located on AFSA’s Legislaive webpage, firesprinkler.org/legislation. If you need our assistance, please contact Kevin Hall (khall@firesprinkler.org) or Bob Caputo (bcaputo@firesprinkler.org). Board Member Chris Johnson testified at the Florida House Career and Workforce Subcommittee, allowing our apprenticeship curriculum to be accepted under Florida guidelines, which gives funding back to the Florida Chapter providing the training. This is a big win for Florida, AFSA, and additional open-shop states. Thank you, Chris and AFSA Florida Chapter Executive Director Jessica Cox, for your time and dedication. Now, all that is needed is Governor DeSantis’ signature.

I am calling for all owners, presidents, and COOs to encourage your AFSA apprentices to start testing for the seven coveted spots in the National Apprentice Competition to be held during AFSA44 at the Gaylord National in Washington, D.C. Our current Apprenticeship & Education Chair and incoming Board Chair Paul DeLorie requested, and the Board approved, to increase the prize money for the apprentice competition winners. Now, the prizes are $10,000 for first place, $7,500 for second place, $5,000 for third place, and $2,500 for each remaining apprentice finalist. Paul emphasized this as “what AFSA is all about… training our apprentices.” The competing apprentices will be highlighted at our Awards Party on October 18. We have the best-of-the-best open-shop contractors; let us continue to show the country we have the best-trained fire sprinkler apprentices!

We have a great program, seminars, networking, along with a fabulous location, so mark your calendars for AFSA44, October 15-18, 2025. Hope to see you all there! n

EDITORIAL: 214-349-5965

BOB CAPUTO, CFPS, Publisher, ext. 124 bcaputo@firesprinkler.org

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

ADVERTISING: 214-349-5965

CLARISSA RIOS, Communications Coordinator, ext. 134 crios@firesprinkler.org

CIRCULATION: 214-349-5965

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

AFSA BOARD OF DIRECTORS

LINDA M. BIERNACKI, Chair, Region 5, 318-841-0330

PAUL DELORIE, First Vice Chair, Region 10, 603-432-8221

JAY STRICKLAND, Second Vice Chair, Region 6, 301-474-1136

ROD DIBONA, Treasurer, Region 4, 605-348-2342

JEFF PHIFER, Secretary, Region 8, 803-438-2994

JACK A. MEDOVICH, P.E., Immediate Past Chair, At-Large, 804-222-1381

BROOKS BAYNE, Region 1, 503-692-9284

HUNTER BRENDLE, At-Large, 334-270-8571

MINDY BUCKLEY, At-Large, 770-925-9099

TOMMY CLEMENTS, Region 9, 804-459-2218

CHRIS JOHNSON, Region 7, 727-5821-9339

R. DONALD (DON) KAUFMAN, Region 3, 505-884-2447

MICHAEL F. MEEHAN, At-Large, 804-459-2200

WAYNE WEISZ, Region 2, 209-334-9119

AFSA LEADERSHIP

BOB CAPUTO, CFPS, President, ext. 124

MATT KLAUS, Executive Vice President & COO, ext. 139

MELISSA ATHENS, Vice President, Finance, ext. 112

LESLIE CLOUNTS, Vice President, Education Services, ext. 130

JOHN AUGUST DENHARDT, P.E., FSFPE, Vice President, Engineering & Technical Services, ext.121

MEDA MERRITT, Vice President, Membership & Chapter Development, ext. 133

Sprinkler Age is devoted to the professional development of the fire sprinkler industry. Deadline is 1st of the month preceding publication.

Published by American Fire Sprinkler Association, 1410 East Renner Road, Suite 150, Richardson, TX 75082. Call (214) 349-5965, FAX (214) 343-8898, or email sprinklerage@firesprinkler.org for information.

Copyright © American Fire Sprinkler Association, Inc. All rights reserved. PRINTED IN USA. Unless expressly stated otherwise, all editorial and advertising material published is the opinion of the respective authors and/or companies involved and should not be construed as official action by or approved by Publisher or the Association.

LINDA M. BIERNACKI AFSA BOARD CHAIR

Sprinkler Age is a membership benefit, provided free of charge to AFSA members. For information on nonmember and/or foreign subscription rates, call (214) 349-5965.

ABOUT AFSA MEMBERSHIP

AFSA annual membership dues are a sliding scale for Contractors and Associates and a flat fee for Authorities Having Jurisdiction. (Members receive a free subscription to Sprinkler Age.) Write or call AFSA for membership information. See AFSA’s website at firesprinkler.org.

Improving America’s Emergency Response Connections

HARRINGTON METAL FACE STORZ —EXPANDING THE NATIONAL STANDARD—

HPHA

The “Permanent Hydrant Adapter Standard” was first established in 1975. The “Harrington Permanent Hydrant Adapter (HPHA)” has been preserving and maintaining this standard since 1990. Metal Face Storz. No Locks. ANY THREAD. Dependable and tamper-resistant.

HIHS

The “Harrington Integral Hydrant Storz (HIHS)” was invented by Harrington in 2001. The HIHS maintains the established HPHA Standard in an Integral Storz Nozzle. Metal Face Storz. No Locks. ANY HYDRANT. Dependable and tamper-resistant.

HFDC (NPT) & 150# FLANGES

HARRINGTON IS PROPOSING THE ELIMINATION OF THE ADAPTER GASKET AND ALL LOCKS ON PERMANENT OUTDOOR INSTALLATIONS*. Metal Face Storz. No Locks. ANY PIPE.

Dependable and tamper-resistant.

*NOTE: Harrington currently provides NPT Storz & 150# Flange Storz “with lock and gasket”. These adapters are not designed for permanent outdoor installation. The gasket and lock will fail at the hands of time, or vandals.

PRESIDENT’S REPORT

Isuspect almost everyone in the fire protection community has heard that Matt Klaus has joined Team AFSA as our executive vice president and chief operating officer. Matt joins us after 15 years with NFPA and, more recently, NFPA Global. Like most, I regard Matt as an industry icon, with whom I have had the privilege of working and teaching with for many years. The fact that Matt has decided to join AFSA speaks in no small way to the growth and development of this association and the opportunities we all see ahead. I want to acknowledge the wisdom and foresight of AFSA’s Board of Directors for their decision to bring Matt aboard, as he grows into the new role. With great pride, I assure the membership that we are in great shape to continue delivering best-in-class training and education programs for the fire sprinkler industry.

Supporting people with professional development pays longterm dividends in more ways than most consider. The construction industry can be fun, and the fire sprinkler business is even more fulfilling with opportunities for anyone interested in saving lives and property. Every coin has two sides, and with opportunity comes risk. We rarely hesitate to invest in vehicles, tools, and equipment, but often ignore investing in our people. Every rule has an exception, and the exception in small businesses is usually investment in family members. While not always bad, this practice sends a message to non-family employees that the runway for them is short.

We receive regular calls from members asking if we know any designers who might be available. When we suggest putting someone in our Beginning Design School, we always hear, “We’re looking for five to eight years of experience.” I always laugh when I hear this because more designers are aging out of the industry than those being trained to take their place. AI will not fill the gap, at least not soon enough to meet the needs of our industry.

The solution is simple. Put a candidate in the field for six to eight months, then, if they prove they’ll show up on time with a positive attitude and an aptitude for mechanical systems, send them to Beginning Design School. We’ll send you back someone ready to learn and produce with an understanding of what they’re doing and why they’re doing it. Of course, you could send them to a design school first, but starting with a picture in their mind makes more sense.

The training programs at AFSA are designed to go beyond just the technical aspects of design, installation, ITM, estimating, or project management. Our programs help deliver technically capable people, and we also focus on business practices and discuss limiting liability for your companies. AFSA instructors discuss the importance of documenting issues related to inspections and claims-related concerns. We train candidates in best practices, communication with customers, and share real-life experiences. Most of us know industry problems are universal—only the accents change.

One example is ITM training, where we address how to talk to an angry customer when something breaks during a test performed, when all we did was expose a problem that would have occurred during a fire event. We revealed the issue, which is the reason for

the inspection and testing requirements in the first place. We encourage inspectors and technicians to use NFPA 25 section A.3.3.8 as a tool to discuss deficiencies and how they should be handled in the case of impairments.

Participants in our beginner design courses learn about verifying project specifications and requirements to help avoid the embarrassment of having issues that should have been addressed early in a project. Simple things can be verified up front, like buying American material requirements, requiring sprinklers to be in the centerline of ceiling tiles, or even identifying sprinkler types or brands.

With service technicians, we discuss not having loose materials in the back of open trucks, double-checking their ladders, and ensuring that tools and materials are secure before leaving a job site. We also discuss the importance of safe driving and other safety issues. We discuss checking in and out with your customers and verifying central station alarm issues. Things that eliminate last-minute cancellations and increase customer satisfaction by improving communications and setting expectations.

As enrollment in our VIP sprinkler fitter apprenticeship program grows each month, we continue to hear great reviews from the participants and company owners alike. We attribute this to the experienced instructors who make this program work. Their willingness to share work experiences with the next generation of sprinkler fitters and supervisors ensures the future of our industry.

AFSA staff and chapter leaders are focused on recruiting new talent by exposing our industry’s opportunities to people who have never heard of fire sprinklers. We’re reaching out to high schools and community colleges and offering our sprinkler fitter book 1 (at no charge) to any school interested in sharing opportunities in our industry with their students.

I hope to encourage all AFSA members to take advantage of our training programs in Richardson (Dallas) or invite us to deliver training in your region. We promise to make your good people better!

Please share your stories with us, let us know how we’re doing for you as members, and tell us what we need now to ensure your success in the future. We’re looking forward to seeing many of you in October in our nation’s capital at AFSA44! Last year’s convention was a record breaker, and we hope to do it again in Washington, D.C.! n

BOB CAPUTO, CFPS AFSA PRESIDENT

The VK970 Quick Response Sprinkler and Flexible Hose Assembly is a next‐generation fire protection solution engineered to simplify installation processes by eliminating the need for recalculations of hydraulic requirements. The VK970 is pre‐calibrated with a K-factor of 5.6 (80.6 metric), ensuring accurate system design without the complications of equivalent length adjustments—an essential benefit in retrofit projects where original system data may be lacking.

Learn more on our website at vikinggroupinc.com.

5pk

Packaged in boxes of five (complete with five recessed escutcheons)

2 in.

The hose has a 2” minimum bend radius and may have up to four bends

K5.6

Contains a K-factor of 5.6 and is available in hose lengths of 48” (1.2m) and 60” (1.5m)

Viking’s revolutionary Sprinkler Selector ensures that you can find the right sprinkler for the job — every time. Get started by visiting webtools.vikingcorp.com/sprinklerselector

FLASHPOINT

Someone once told me that you know you are getting old when you start receiving praise and awards for things you like to do. Retirement is right around the corner, they explained. Well, I am not ready to retire, and I still love what I do, so God willing, you are going to have to keep putting up with me for a while. So, what is the point of this column? “Standing on the shoulders of giants” is my statement.

I have never done what I do for praise or recognition. I just enjoy passing my knowledge on to others. I encourage all the people I interact with to do the same. We need to aid those less experienced in a particular topic to excel. With practice and patience, I believe all of us can be the best at whatever we choose to do, given our God-given ability. Not doing your best is not in my mindset. As a very clever technical writer once said to me, “good enough is not good enough.” It might be good enough to get by, but we should strive to do our best at all things we take on. In the real world, time constraints, budget concerns, and other work and family obligations can push us, but we should always strive to do our best.

Where did I learn these life and work lessons? As a young boy, I watched my father work two jobs so he could support our family. We lived humbly, but his drive to send us to a private Catholic school was his push. My sister and I were kept in line by a loving but heavy-handed mom. She expected no less than perfection. A 98% on a test was a reason for studying harder, not praise. My grandmothers, aunts, and uncles expected the same. My schoolteachers from grade school through college expected the best in me, and each of them would do anything necessary to ensure I did my best. My football coaches saw my potential and never let me give up on myself, especially during two-a-day summer practices. In the work environment, the owners of the companies and supervisors I have worked for have all been supportive. The one place I worked where I was not pushed was the worst job I ever had. Not that the work was difficult or not in my wheelhouse. I just realized no one cared enough about me to do my best. “Good enough” was acceptable. That job did not last long for me. I could not handle that situation. I really thought I had something wrong with me. I could not bring myself to go to work and just put time in doing “okay” work.

During my involvement with my high school, Mount Saint Joseph in Baltimore, I got to know Brother James Kelly of the Xaverian Brothers. “Standing on the shoulders of giants” was one of his sayings. I never really understood what he meant. But as I grew older, I sure did know what he meant by that saying. My success is based on the giants who came before me. They helped shape who I am today. From my parents, family, schoolteachers, employers, friends, coworkers, and other presenters I have listened to, I am in fact standing on the shoulders of giants.

At my mother’s funeral, I requested that the song “Wind Beneath My Wings” be performed. My mother was my biggest supporter. I have had so many supporters in my life, I could not list them all. While writing this, I am thinking about my wife,

daughters, my grandson Zachary, and the rest of my family. My thoughts then go to all the supportive teachers I have had. Dr. John Bryan and Dr. James Milke both shaped my professional career into what it is today. (Interestingly, both fine gentlemen have received the AFSA’s highest award, the Henry S. Parmelee award.)

Ronald M. Brave took me on as a new graduate and showed me how to work hard. Even though I just graduated from college, I still had a lot to learn. Manning Strickland (another Henry S. Parmelee award recipient) and his son Jay Strickland shaped me by showing and letting me do what I needed to do at a sprinkler contractor company to manage complex projects for secure government facilities. I learned the right way to work in those environments to make our projects successful while ensuring the quality of our work spoke for itself. I learned the three items of any project: speed, quality, and cost. You never get all three. Pick two, and the project will be successful. My quality was all first-class, so pick speed or cost—the client’s choice.

My current and last employer, AFSA, is led by Bob Caputo. Bob’s advice and push are perfect. Anyone who knows Bob knows what I am talking about. Matt Klaus has recently joined AFSA, but I have known him for a long time. In his new role, I already know what I am going to get—a man who will always help me do my best while pushing AFSA in the proper direction. I would be lacking if I did not mention William Koffel, Russell B. Leavitt, and Russell P. Fleming as great presenters from whom I have each “stolen” something.

I’ve only named a few people who have supported and mentored me; I apologize that I can’t list more. Hopefully, in the future, others might say that they are standing on the shoulders of giants. They might even think of me as one of their supporters. I promise I will always push anyone I come into contact with to be their best. I know my wife, daughters, and especially my grandson can count on me if I am on this Earth. n

JOHN AUGUST DENHARDT, P.E., FSFPE AFSA VICE PRESIDENT OF ENGINEERING & TECHNICAL SERVICES

The birthday boy, Zachary, turned 1! Enjoying his cake made me so proud and happy.

Vapor Corrosion Inhibitors Outperform 98% Purity Nitrogen in Mil Loss Testing.

More Effective

Less Expensive

Easier Install

MODERN PROTECTION FOR A FIRE HISTORY MUSEUM

AFSA MEMBERS DONATE, INSTALL SPRINKLER AND FIRE ALARM SYSTEMS

D’ARCY MONTALVO | AMERICAN FIRE SPRINKLER ASSOCIATION

The Fire Museum of Maryland in Lutherville is one of the largest fire museums showcasing the history of firefighting in America. It grew from the Heaver family’s private collection of more than 40 years. Previously unprotected, this important and comprehensive museum is finally safe from the ravages of fire, thanks to the American Fire Sprinkler Association’s (AFSA) Chesapeake Bay Chapter, where members came together and helped install sprinkler systems.

Chesapeake Bay Chapter Executive Director Danielle Fowler has loved and visited the museum for over two decades. “I remember taking my kids here when they were little—and now they’re grown! It’s just a wonderful place full of fascinating history and equipment. It must be protected and shared with our community and future generations.”

COMING TOGETHER FOR A GREAT CAUSE

The project began when Marty Smith, SET, CFPS, president & CEO, ATS Advisors, LLC, learned about the museum and its needs. About 10 years ago, the museum asked the company for help with a new fire alarm system. Smith and his brother Jeff owned Alarm Tech Solutions, LLC at the time. “I toured the museum, and it was filled with so many interesting artifacts. Being a fire alarm guy more than a sprinkler guy, I loved the fire alarm office!”

Marty and his brother, Jeff, designed the fire alarm and emergency communication systems for the museum. Because it

wasn’t protected by sprinklers, they worked with GamewellFCI to donate the equipment and had one of Alarm Tech’s electrical contractor customers, Freestate Electric, install a fire alarm, with complete area smoke detection, and a speakerbased emergency communication system.

“It was tricky working around all of those artifacts,” remembers Smith. “We got lifts donated because of the elaborate collection of fire trucks and other large items that you have to work around and on top of that can’t be moved.”

As that project was nearing completion, Smith was asked to serve on the museum’s board. One of the first projects he decided to take on was a much-needed sprinkler system since the museum was not protected. He had the initial design done but then sold their business.

That’s when Smith connected with AFSA’s Chesapeake Bay Chapter and briefly talked about the project at one of its meetings. “Before I even sat down from presenting the project, I had two emails from vendors offering to help,” he remembers.

“Our chapter members are always looking to give back to our community and not just be members of it,” says Fowler. “We held a chapter meeting at the museum so everyone could see what the project was all about and that all of these amazing artifacts weren’t protected. That really lit a fire to get them more involved. I don’t think there was one naysayer in the group. Everyone was on board!”

Tim Parham, from Everon (formerly ADT Commercial), Columbia, Md., volunteered to spearhead the project. “All of

Chesapeake Bay Chapter members came together to protect the museum.

The project was a joint effort between museum staff and AFSA volunteers.

the materials and installation were donated by AFSA member companies, including JCI, Strickland Fire Protection and Absolute Fire Protection, both a part of Pye-Barker Fire & Safety and Castle Sprinkler & Alarm. AFSA was huge in getting the community involved.”

Parham notes. “Kevin Galligan from JCI did the design, and his field team did the install in the annex, including the riser. They also did riser installation in the east wing/addition to the main building, and up to the office space.”

The museum comprises two buildings; the largest one is the main space, housing a large exhibit hall, function rooms, archives, and offices. A second building is a four-bay garage used for storage called the “annex.”

“We were required to sprinkler both buildings,” comments Smith. “We put a wet system in both and a preaction system in the mezzanine level of the main building for the archives and library. We replaced the existing air sampling smoke detection system with a new air sampling smoke detection system that is a part of the preaction system to replace the obsolete system.”

AFSA’s Vice President of Engineering and Technical Services, John August Denhardt, P.E, FSFPE, was the liaison between the museum and Baltimore County to help move things along.

The new systems were the star of a Donor Celebration Luncheon held December 3, 2024. Steve Heaver, co-founder, executive director, and curator of the museum held guided tours and attendees were able to also explore the exhibits on their own. Mission BBQ donated a hearty and delicious lunch.

“I really appreciate everyone coming together for their help and support. The luncheon was fun and the perfect setting to celebrate this great accomplishment together,” comments Fowler.

Chapter Chair Jason Martin agrees. “The dedication that Steve Heaver and his team put into the Fire Museum of Maryland to tell the stories of how fire protection improved since the 18th century, and preserve the machines that kept us safe, is just magnificent. When it was brought to our attention the museum needed a sprinkler system to protect the history of the fire service, our chapter members jumped right in to make it happen.”

“Throughout the project, it was a showing of sprinkler competitors working together to complete a quality job that protects this history for future generations to enjoy,” Martin notes. “As the Chapter Chair, I have such a great appreciation for our AFSA Chesapeake Bay Chapter members who made this project happen!”

Some of the historical firefighting apparatus at the museum include an 1856 Agnew hand engine (left) and an 1899 American steam engine.

Left Photo: The chemical engine was one of the major innovations in firefighting since the introduction of the steam pumping engine. Shown here is an 1881 Holloway Chemical Fire Engine. Right photo: Fire trucks on display include this meticulously restored 1927 Maxim.

LEARNING ABOUT FIRE

The museum, founded in 1971, is a leading institution in preserving, restoring, and interpreting the history of the urban fire service in the United States. It is open to the public and houses a world-class collection of historic hand engines, horse-drawn, steam-powered, and motorized vehicles. Exhibits include firefighting tools, antique toys, the Great Baltimore Fire of 1904, a working fire alarm office, a cast-iron building facade from Baltimore’s Engine Co. #8 built in 1871, and a children’s discovery room. The museum features curriculum-based educational tours in science, history, and technology. It also participates in community events, hosts an annual steam show, and rents out meeting space and vehicles.

Heaver, who has led the museum for many years, recently moved to a curator and director emeritus role. Jeff Buchheit has joined the museum as its new director. Others on staff include Tom Miller, assistant curator; Aaron Lippincott, educator; and Amy Landsman, public relations. Nate Davis is responsible for facilities, Lee Smith handles mechanical projects, and Ed Burgee oversees collection maintenance.

The museum’s apparatus on exhibit ranges from 1806 to the present. Many of its restored apparatus are working road vehicles. The crown jewels in its firefighting history are an 1856 Agnew hand engine, an 1899 American steam engine, a 1905 Hale water tower, a 1918 Mack ‘Bulldog’ ladder truck, a 1913 Ahrens-Fox model A pumping engine—the only one left in the world, and a 1947 Mack Floodlight Wagon. In 2024, the museum welcomed more than 15,500 guests, its second-highest attendance to date.

COMMITMENT TO THE COMMUNITY

Now protected, the Fire Museum of Maryland continues to educate the public and increase awareness of firefighting and the fire protection industry. Future plans for the museum include displaying the east wing risers behind plexiglass instead of drywall so the public can see them and learn more about the sprinkler system.

“Thanks to so many generous people and so many generous companies, we now see the project through to completion,”

The museum’s fire alarm office with an antique watch desk display the history and technology of emergency communications from 1860 to present.

summarizes Smith. “We really appreciate having worked with so many wonderful people and companies to get the sprinkler, fire alarm, and emergency communications systems added to help protect the history of this great industry.”

The museum is never resting on its laurels to acquire, refurbish, and display new items, including a fire boat currently being renovated. Chapter members are also not done helping the museum. “We are also working to raise the last bit of funds to offset the $9,500 that the museum has paid out-of-pocket for $250,000 worth of equipment,” states Smith. Anyone wishing to donate can reach out to Museum

Director Jeff Buchheit or visit the museum’s donation webpage at museumfiremuseummd.org/donate.

“When someone needs something and we have the ability to help, we’re there,” comments Fowler. “This was a fantastic endeavor for our chapter to get involved with, and I encourage other chapters to seek out similar projects in their area.”

For more information about the Chesapeake Bay Chapter, its projects, and events, visit afsachesapeakechapter.org or contact Fowler via email at daniellef@pottersignal.com.

The Fire Museum of Maryland is open on Saturdays year ‘round and Wednesday-Friday in June, July, and August. Group

Left Photo: The museum’s tour begins with an exhibit on Benjamin Franklin, widely credited with laying the groundwork for the modern American fire service. Right Photo: The museum acquired a 104’ decommissioned fire boat that had to be cut down to 38’ for preservation in Lutherville.

The key plan/work areas used for the sprinkler system installation project at the Fire Museum of Maryland.

The riser for the main building will be protected by removable Lexan panels that will display some basic instructional materials for younger visitors. To its left will be the master list of donors.

tours and special events can be arranged. Have an item, picture, or document that you would like to donate to the museum? Email details and pictures to collections@FireMuseumMD.org.

The museum depends on individual donors and corporate sponsors for new projects and exhibits, operational costs, and other ongoing events. It receives funding from Baltimore County, donors, members, planned giving, admissions, and visitors. For more information on the museum and to donate, visit firemuseummd.org. n

FIRE MUSEUM OF MARYLAND DONORS

PLATINUM SPONSORS: INSTALLATION LABOR & MATERIALS

Tim Parham, Everon (formerly ADT Commercial)

Kevin Galligan, JCI

Jay Strickland, Pye Barker (formerly Strickland Fire Protection

Dan Mathias, Pye Braker (formerly Absolute Fire Protection)

Jason Martin, Castle Sprinkler & Alarm

GOLD SPONSORS: INSTALLATION MATERIALS

Roo Barletta, Ferguson Fire Protection

Kyle Curran, General Air Products

Mike DeCecco, General Air Products

Chris Dickman, Wheatland Tube

Daneille Fowler, Potter Global Technologies

Jim Hanzsche, Mechanical Sales

Chris Haywood, Victaulic

Trey Kistler, GE Tignall

Heather Lutton, Kidde Global Solutions

Michael Moss, Brecco/Lansdale

Scott Munroe, Zurn

Vince Palmeri, Honeywell

Anthony Roy, JCI Tyco Fire Products

Scott Sack, Windy City Wire

Taylor Smith, Space Age Electronics

Joe Solomon, Core & Main

Steve Tajer, ASC Engineered Solutions

Dennis Wech, JCI Tyco Fire Products

SILVER SPONSORS: SERVICES & MISCELLANEOUS

John August Denhardt

Chuch Fusco, BFPE

Anna Gavin, Fireline

Frank Hauf

Mission BBQ

OVER SIXTY SENSATIONAL SEMINARS AT AFSA44

LEARN MORE AND EARN MORE WITH CEUS, CPDS, AND CONTACT HOURS

This year, the American Fire Sprinkler Association’s (AFSA) annual convention heads to the nation’s capital for expert instruction, entertainment, networking, and North America’s largest fire sprinkler exhibition. Join AFSA in Washington, D.C. for the premier sprinkler industry event—AFSA44: Convention, Exhibition, and Apprentice Competition, to be held Oct. 15-18, 2025, at the Gaylord National.

Offering over 60 seminars and over 70 hours of education, this year’s seminars provide CEUs, CPDs, and Contact Hours. AFSA44 sessions will include ICC and Florida Contractor CEUs where applicable.

SEMINAR HIGHLIGHTS

This year, seminars are organized by specialty, making it easy to customize schedules and maximize learning experiences. Sessions are grouped in areas such as sprinkler technology, standards updates, special occupancies, business management, dry systems, design and project management, and hydraulics.

AFSA’s ITM sessions focus on forward flow testing of backflow preventers, component action (the “other” NFPA 25 tables), field sprinkler system testing statistics and ITM in NFPA 25, and NFPA 25 inspection reports. “Changing How We Classify System Conditions in NFPA 25, 2023 Edition” by Russ Leavitt, SET, The Telgian Corp, examines the changes to Table A.3.3.8 and associated text to assist service providers in providing the best information to the system owner while limiting liability. NFPA 25 intends service providers to use their judgment and knowledge in assigning classifications such as non-critical and critical deficiencies or impairments. It is necessary to understand the intent of the standard as explained in the revised annex material to comply with these expectations.

The seminars on updates are always popular during AFSA’s annual convention, and this year’s line-up will be no different the NFPA 13, NFPA 14, NFPA 20, NFPA 25, NFPA 200, and NFPA 420 standards covered. One seminar of interest is “Suppression Research From FPRF.” The FPRF (Fire Protection Research Foundation), NFPA’s research affiliate, conducts several suppression-related research programs to answer some of the industry’s most challenging questions. This session will provide an update on the types of Automatic Storage Retrieval Systems (ASRS) and sprinkler protection guidance, address the latest test results for sprinkler protection guidance for electric vehicles, multiple row racks, elevated walkways, parking garages, and car stackers.

In the Sprinkler Technology grouping, seminars include Electrical Requirements for Fire Pumps, Introduction to BIM, The Cut and Dry of Dry Sprinklers, Tech Top Five, and Extended Coverage, Beyond Ordinary. “Interfacing Fire Sprinkler Systems to the Fire Alarm” by Tom Parrish, CFPS, SET, PSP, GROL, with Telgian Corp. will explain the different components of the sprinkler system that need to be monitored by the fire alarm system. This system could be a building fire alarm system or a dedicated function sprinkler monitoring system. The requirements for air supervisory, tamper switch position, flow switches, and even low-temperature sensors will be explained. Determina-

tion of what is an alarm, a trouble, or a supervisory will also be covered. This is a good session for all skill levels and provides basic knowledge, a nice review, and even an update on changes that have been made in NFPA 72.

Business management staff will find value in seminars on increasing profits through better design, attracting and retaining the next generation of leaders, bidding projects, historical development of our industry, leveraging your network to boost your business brand, jobsite organization, women in the industry, small business operations, and more. “Need Employees? High School CTE is Your Answer!” by 2025 AFSA Fire Sprinkler Advocate of the Year Award Recipient Mac Beaton, director of Career and Technical Education for Henrico County, Va. Public Schools, will be offered as part of the Business Management grouping. In this course, attendees will learn how the AFSA Virginia Chapter and Henrico County Public Schools have partnered together to create a tangible pathway for businesses to find their next employee. This partnership has allowed for the creation of the first high school program designed to prepare students to enter the profession with skills and certifications. Discover how AFSA’s Virginia Chapter has gone from a career fair of about 25 students to now over 300 students in attendance. The value of “planting the seed” early will be highlighted along with the return on the investment.

Those attending the Special Occupancies seminars will learn about the evolution of data center fire protection, retrofitting sprinklers for historic properties, fire protection for distilleries, and protection of aircraft hangars. Scott Golly, P.E., with Jensen Hughes will present a deep dive into the chemistry of lithium-ion batteries during his “Fire Protection Challenges for Li-Ion Batteries,” discussing the uses of lithium batteries, including battery energy storage, micromobility, and data centers. Fire protection challenges presented by this battery technology, fire protection strategies, and associated codes available that are trying to address these lithium battery fire protection challenges will also be discussed. Case studies and examples of successful and failed protection strategies will be provided.

AFSA44 Schedule-At-A-Glance

Wednesday, 10/15

10:00 am – 8:00 pm Registration

10:00 am – 12:30 pm Leadership Conference (Invitation Only)

1:00 pm – 4:30 pm Seminars

1:30 pm – 3:00 pm New Attendee Orientation

3:00 pm - 4:30 pm AFSA Design Training Project Info Session

3:30 pm – 4:30 pm Women in the Industry Panel Discussion

7:00 pm – 10:00 pm Opening Party

Thursday, 10/16

7:00 am – 8:30 am Grab-and-Go Breakfast

7:30 am – 5:00 pm Registration

8:00 am – 11:30 am Seminars 11:30 am – 1:00 pm Networking Lunch

1:00 pm – 5:00 pm Seminars

2:00 pm – 10:00 pm Exhibitor Move in 5:30 pm – 6:30 pm Hot Ones Challenge/The K Factor Podcast

Friday, 10/17

7:00 am – 8:30 am Grab-and-Go Breakfast

7:00 am – 6:00 pm Registration

8:00 am – 2:00 pm Exhibitor Move In

8:00 am – 11:30 am Seminars

11:30 am – 1:00 pm Networking Lunch

1:15 pm – 2:45 pm General Session

3:00 pm – 3:30 pm Exhibitor Appreciation (Exhibitors Only)

3:30 pm – 7:00 pm Exhibit Grand Opening

Saturday, 10/18

7:00 am – 8:30 am Grab-and-Go Breakfast

7:30 am – 3:30 pm Registration

8:00 am – 9:30 am M/S Council Meeting

8:00 am – 11:30 am Seminars 11:30 am – 1:00 pm Networking Lunch 12:30 pm – 3:30 pm Exhibit & Apprentice Competition Finals

In the Design & Project Management sessions, topics include field labor management and estimating and bidding best practices by AFSA President Bob Caputo, CFPS. In addition, “Good Listing Processes and Jobsite Organization” by Sam Harbert, Driven Fire Consultants, will discuss how keeping listing in mind during the design phase can directly influence the organization of a jobsite. Breaking up listing areas, among other considerations, can minimize mobilization times for your field staff and get the project started on a timely and positive note. The session aims to prompt added discussion within companies, suppliers, and fabricators to look at how mobilization and jobsite organization isn’t just a field issue, but a team issue.

3:30 pm – 9:30 pm Exhibitor Move out 5:30 pm – 6:30 pm Awards Rehearsal 7:00 pm – 10:00 pm Awards Party

Sunday, 10/19

7:30 am – 10:00 am Exhibitor Move Out

Always a popular educational and entertaining discussion, the “Ask the Experts” panel discussion will be held in two parts on the final day of the convention, Saturday, Oct. 18. This panel will feature representatives from industry-leading organizations and aims to encompass varying perspectives, such as research and

development, enforcement, manufacture and supply, codes and standards, and design and install applications. Got a hot topic to discuss? Submit your questions in advance (https://fs8.formsite. com/AFSA/4nakcg1qkm/index) or bring them to the seminar to have them answered once and for all!

A DAY DESIGNED FOR THE AHJ

AFSA44 has designed a full day of education and exhibits for Authorities Having Jurisdiction (AHJ). On Friday, Oct. 17, the day begins with seminars “Fire Service Demand Tariff,” “An AHJ Guide for Inspection and Testing Sprinkler Systems, and “Is It Engineering or System Layout?” Afterwards, a free lunch is provided to AHJs in attendance, and they are invited to attend AFSA44’s General Session. This is followed by the Exhibit Grand Opening Reception to view the latest products and services for the sprinkler industry.

AHJs are also welcome to attend the “Ask the Experts” panel discussion on Saturday, Oct. 18, and tour the exhibition for a second day. An added bonus on Saturday is the opportunity to observe the top seven fire sprinkler apprentices in the nation vie for first place at AFSA’s 32nd National Apprentice Competition (NAC), which will be held in the middle of the exhibit hall.

MORE ROOMS FOR AFSA44

Due to increased attendance at AFSA’s annual convention, a block of rooms at the Residence Inn National Harbor has been

secured in addition to the AFSA44 headquarters hotel, the Gaylord National. Group rates are available at both hotels.

The Gaylord National offers an extraordinary blend of sophistication and warmth on the enchanting Potomac River. Immerse yourself in the 19-story lush garden atrium, indulge at the Relâche Spa, and relax in cozy rooms and executive suites. Worldclass service and top-tier dining options cater to every palate! The AFSA group rate for the Gaylord National Resort & Convention Center is $269 per night plus tax for single/double rooms.

Relish the comfort and style of the Residence Inn National Harbor, located across the street from Gaylord National. Enjoy picturesque views of the Potomac River and rest well in contemporary hotel suites. The rate at the Residence Inn is $249 per night plus tax for a standard room.

Guests are welcome to stay at either hotel from Oct. 14-19. Reservations must be made by Wednesday, Sept. 10, to secure the convention group rate. After Sept. 10 or until rooms are sold out, group room rates are based on availability. Be sure to book your stay with the hotel directly using the link on the AFSA convention website, firesprinkler.org/afsa44, to receive the correct group pricing.

AFSA is not represented by travel agencies or housing companies, such as Global Housing, that may try to book your room outside of our room block. Be aware of third-party vendors soliciting AFSA exhibitors and attendees, posing as our housing vendor. These companies mislead you into thinking they are working on our behalf, but are NOT endorsed by or affiliated with AFSA. Book directly with Gaylord National or Residence Inn National Harbor using the links on AFSA’s website to ensure your reservation is guaranteed.

A CAPITAL CELEBRATION!

The grand celebration of the fire sprinkler industry and AFSA begins on Wednesday, Oct. 15, with an unforgettable evening full of excitement and entertainment as AFSA takes over the Gaylord National Resort’s Harbor Social Sports Bar and beautiful atrium. Guests will experience a vibrant atmosphere, delicious food, and unique activities. Try your hand at darts, bocce, and duck pin bowling, all while networking with fellow attendees from across the country.

���� Wings. Fire Protection. Rapid-Fire Questions. Regret. ����

Brace yourselves for the spiciest session of the week—”The K-Factor Podcast Presents: Hot Takes Under Fire!” on Thursday evening, Oct. 16. Inspired by the hit YouTube show “Hot Ones,” this live forum brings the heat as podcast hosts Josh McDonald, Eric Andresen, Kevin Hall, and Nate Williams take on a gauntlet of increasingly hotter wings while answering a mix of technical fire protection questions and fun, personal ones.

Moderated by AFSA’s Director of Program Development & Special Programs Victoria B. Valentine, P.E., FSFPE, the session will also feature live questions from the audience, so come ready to put your favorite hosts in the hot seat—literally!

And to help the audience keep their cool, there will be a cash bar available throughout the event. Grab a drink, enjoy the show, and see who can stand the heat! Don’t miss the laughs, the insights, and the inevitable spicy meltdowns!

AFSA44 offers two hotel options this year, including the stylish and comfortable Residence Inn National Harbor.

ULTIMATE CONTROL

FLOOR CONTROL ASSEMBLIES

RiserPACK Ultimate Floor Control assemblies feature a steel manifold (2”-8”), butterfly valve or check valve (or both), 4” Model 7500 pressure gauge, 3-way universal gauge valve, TESTanDRAIN valve with drain line, waterflow alarm switch, and a Model 7000L pressure relief valve with drain trim. They are the ultimate solution for every floor control.

LEARN MORE

FIRE PUMP DRIVERS

SELECTION OF POWER REQUIREMENT FOR THE DRIVER

JOHN AUGUST DENHARDT, P.E., FSFPE | AMERICAN FIRE SPRINKLER ASSOCIATION

Most of us realize NFPA 20, Standard for the Installation of Stationary Pumps for Fire Protection , requires drivers of fire pumps to be listed and be of the electric motor, diesel engine, or steam driver type. What most of us do not understand is how the manufacturer sizes the driver. Most Professional Engineers and Authorities Having Jurisdiction (AHJs) are also unaware of the process. The language in the body of NFPA 20 is clear as mud. However, the annex language to this section gives direction, even though I disagree with this language.

4.7.6* The driver shall be selected in accordance with 9.5.2 (electric motors), 11.2.2 (diesel engines), or 13.1.2 (steam turbines) to provide the required power to operate the pump at rated speed and maximum pump load under any flow condition.

A.4.7.6 For centrifugal and turbine pumps, the maximum brake horsepower required to drive the pump typically occurs at a flow beyond 150 percent of the rated capacity. For positive displacement pumps, the maximum brake horsepower required to drive the pump typically occurs when the relief valve is flowing 100 percent of the rated pump capacity. Pumps connected to variable speed drivers can operate at lower speeds, but the driver needs to be selected based upon the power required to drive the pump at rated speed and maximum pump load under any flow condition.

Enhanced Content: The maximum power can be determined from a pump curve. A certified pump curve is not available until the pump is manufactured,

but a generic pump curve can be obtained from the pump manufacturer to determine the maximum horsepower demand.

This language has not significantly changed over the years; however, the listing agencies’ interpretation of it has changed.

Let me start by saying I never want a driver to fail in any condition we expect the fire pump system to perform. All fire pumps are designed to perform anywhere from churn condition (no flow, 0 gpm) to 150% of the pump’s rating. For example, a 1,000 gpm-rated fire pump must deliver 65% of the fire pump’s rated pressure at 150% of the fire pump’s rated flow. The maximum flow we ever expect for this fire pump to provide is 1,500 gpm. Following NFPA 20, the incoming water supply must be sized to provide at least the rated flow and not less than the largest connected fire protection system water flow rate demand, whichever is greater. I always like seeing the incoming water supply capable

of providing positive pressure to at least 150% of the fire pump rated flow, but that does not always work in the real world. (Size the underground supply piping correctly. Table 4.28 of NFPA 20 shows the smallest allowed pipe size, not the required pipe size, as this can only be determined through a hydraulic analysis. In any case, the water supply should be the limiting factor in the system design up to the 150% flow rating.

However, the listing agencies and some of the NFPA 20 technical committee members have a different approach to the language. Their interpretation is that a fire pump driver should NEVER FAIL at any possible flow rate the specific fire pump COULD deliver if enough water was available and, in some cases, be forced into the suction of the fire pump. This has caused the manufacturers of fire pumps to review how they sized the required drivers for their specific fire pumps. This process

Tim “The Tool Man” Taylor isn’t always right; sometimes more power doesn’t make sense.

started around seven years ago and began to show its ugly side. Many manufacturers had to increase the power rating of the drivers to handle the “what-if” scenario. What if we had all the water flow rate possible under good pressure, and something happened to cause the fire pump to work at 200% or even 300% of its rated flow capacity? My answer is easy—who cares!

In most cases, we will never have this amount of water flow rate, and even if we did, the boost in pressure would be so low it would not matter. Fire pump systems are designed to be sacrificial. If they burn up or melt down doing everything they were designed for, we can live with that. Life is full of compromises and decisions. To force every project to size the drivers of their fire pump systems for an unplanned “what if” situation is not good fire protection.

Proposals to NFPA 20 in the last two cycles have brought this issue to the technical committee and to the NFPA annual Technical Meeting. I have been screaming from the top of any place to express my frustration with this issue. I have no problem if a client wants to oversize their driver for what ifs, but is that what we want in a consensus standard? I do not think so. What are some of the issues this causes? Let us look at a few examples.

SITUATION NUMBER 1

A customer has an existing 500 gpm fire pump system that, when installed, required a 50 Hp driver. The existing fire pump had mechanical issues and must be replaced in lieu of repairs due to the damage. The exact same fire pump by the same manufacturer now requires a 60 Hp driver. If this is an existing electric driver, does this mean the electric wiring and service now needs to be reviewed and upgraded for the larger driver? What if there is a generator set providing auxiliary power? Is the generator still adequate? All of this because of a “what-if” scenario.

SITUATION

NUMBER 2

An engineer has specified a 1,000 gpm fire pump system with a 75 Hp driver. You

have found a suitable fire pump; however, due to the driver requirement, the manufacturer had to shape the internals of the pump so that at 1,300 gpm, the pressure curve drops (steeply) quickly compared to a similar pump with a flat pressure curve. The flatter the pressure curve, the higher power driver needs to be. Using the steep curve takes away the pressure that the connected fire protection system could have used.

As Tim the Tool Man (played by Tim Allen) in the television show “Home Improvement” would often say, “More power, you can never have too much power!” But just like the television show, sometimes, more power does not make sense. Let us set the minimum driver size power to cover any needs up to 150% of the specific fire pump rated flow. Larger power-rated drivers add cost in terms of the driver itself, an increase in wire and equipment size in an electric driver application, and a fuel tank with a diesel engine application. The project owners are required to cover the increased cost with little benefit. Let us stop this ridiculous overdesign. As I stated earlier, I want good fire protection, but I will not accept stupidity because of “what-if” scenarios. At last year’s NFPA Technical Meeting, those in attendance overwhelmingly

supported my thoughts above. However, the technical committee ignored the vote and did not clarify the language. Hopefully, for the 2028 edition of NFPA 20, we can return normality to the technical committee. Watch for future updates as the code cycle progresses and ensure your thoughts are heard. n

ABOUT THE AUTHOR: John August Denhardt, P.E., ET, CWBSP, FSFPE, is the vice president of engineering and technical services for the American Fire Sprinkler Association (AFSA). He is responsible for strengthening AFSA’s engineering and technical approaches to meeting member, industry, and operational priorities, with an emphasis on service, quality, and integrity. Denhardt is a registered professional engineer (P.E.) in the District of Columbia and the states of Delaware, Maryland, Pennsylvania, and Virginia. He is NICET Level III certified in water-based systems layout, NICET Level III certified in inspection and testing of water-based systems, and a certified water-based system professional through NFPA. Denhardt is a member of the NFPA 13 technical committee on sprinkler system discharge criteria, a fellow in the Society of Fire Protection Engineers (SFPE), a member of the SFPE board of directors, a member of the board of trustees for NFPA’s Fire Protection Research Foundation and sits on the University of Maryland Department of Fire Protection Engineering’s Board of Visitors. A native of Maryland, Denhardt holds a Bachelor of Science degree from the University of Maryland College Park in fire protection engineering. Prior to this role, Denhardt was employed by Strickland Fire Protection in Forestville, Md., since 1994, overseeing large-scale projects and assisting with design and installation technical issues.

Figure

KLAUS JOINS AFSA

ASSOCIATION WELCOMES INDUSTRY EXPERT AS EXECUTIVE VICE PRESIDENT, CHIEF OPERATING OFFICER

The Board of Directors of the American Fire Sprinkler Association (AFSA) has announced the unanimous selection of Matthew (Matt) Klaus as the association’s executive vice president/chief operating officer (COO). Established in 1981, AFSA serves as North America’s largest fire sprinkler industry organization. Klaus’ tenure began on April 1, 2025

“Matt Klaus is an industry leader with a broad base of global industry knowledge and experience that would be hard to match. Having Matt join Team AFSA secures long-term growth and development for our association and its members,” says AFSA President Bob Caputo, CFPS. “Matt rounds out an already strong staff of fire and life safety professionals and makes AFSA the unsurpassed technical powerhouse in the fire sprinkler industry.”

As executive vice president/COO, Klaus will oversee daily operations, ensure operational efficiency across all departments, and collaborate with AFSA’s experienced team of engineers and other professionals to serve its members and set and meet association goals. Klaus will also represent the association and foster relationships with industry partners to increase the visibility and value of the fire sprinkler industry in support of AFSA’s mission to be the voice of the merit shop fire sprinkler contractor, educating and training the industry while promoting fire protection systems to save lives and property. Klaus has been involved with AFSA for many years, serving as a convention seminar speaker and member of AFSA’s Legislative and Public Education & Awareness Committees.

“I’m thrilled to join the AFSA team and to work closely with all of their members and staff who are focused on making the world safer,” comments Klaus. “The hazards that impact our society, including our buildings and their occupants, continue to evolve. I look forward to facing the challenge of mitigating the impact of these hazards with this amazing staff and dedicated membership base.”

Klaus is well known within the fire protection industry and joins AFSA after a 15-year tenure at the National Fire Protection Association (NFPA). At NFPA, he served as the Principal of the Global Advisors business line in the newly formed NFPA Global Solutions. Prior to that, Klaus served as a Senior Principal Fire Protection Engineer and the Director of Technical Services at NFPA, where he was responsible for products and services related to Fire Protection Engineering

“Matt is a great addition to our AFSA team. I have known Matt for over 15 years, and he is an outstanding leader who works hard and encourages those around him to excel,” states AFSA Vice President of Engineering & Technical Services John August Denhardt, P.E., FSFPE. “Matt’s experience and leadership skills will make AFSA stronger and a driving force in the sprinkler industry.”

Klaus has extensive international fire protection engineering consulting experience. He has served as the author/ editor of several handbooks on topics including fire sprinkler system design and installation, commissioning and integrated system testing, ITM (inspection, testing, and maintenance), and residential sprinkler system design and

AFSA is pleased to welcome Matt Klaus to the team.

installation. Klaus holds a Bachelor of Science Degree in Civil Engineering and a Master of Science Degree in Fire Protection Engineering, both from Worcester Polytechnic Institute and a master’s degree in business administration from the University of Massachusetts Amherst.

“On behalf of the Board, I would like to welcome Matt Klaus. We are thrilled to add one of the all-stars of our industry to our AFSA team,” says AFSA Chair of the Board Linda Biernacki, president of Fire Tech Systems in Shreveport, La. “This is an exciting time for our association and our members. Welcome, Matt. I look forward to an exciting year ahead.” n

We offer a variety of digital tools and services for fire protection pros on the go. From easy online ordering through the Ferguson app and real-time access to associate expertise with Text-2-Counter to precision fabrication schedules and quotes from Firelist, you’ll benefit from all our technology when you partner with us.

VIP TURNS THREE!

APPRENTICESHIP TRAINING THAT DELIVERS

CLARISSA RIOS | AMERICAN FIRE SPRINKLER ASSOCIATION

This marks the third year for the American Fire Sprinkler Association (AFSA)’s Virtual Instruction Program (VIP), and it’s making an impact within the industry. VIP is designed to deliver flexible, high-quality training to companies and apprentices within the fire sprinkler industry. “It is exciting to see five different courses running simultaneously right now,” says AFSA’s Director of Program Development & Special Projects Victoria B. Valentine, P.E., FSFPE. “The growth in our classes shows commitment and investment in the next generation of our workforce.”

Trio Fire Systems in Duncanville, Texas, is one example of a company taking advantage of all AFSA’s VIP program has to offer. For companies like Trio Fire, it’s proving to be a turning point in their training efforts.

DESIGNED FOR BUSY SCHEDULES

Field Superintendent Mark Clary, who oversees Trio Fire’s VIP apprentices, describes the program as exactly what they had been searching for. “We spent years trying to find something like this,” Clary says. “We’re AFSA members, and when this came up, it fit us like a glove.”

Clary currently supervises three Level 1 apprentices enrolled in VIP. He appreciates how the program gives him visibility into their progress through regular email updates. “My favorite part is being able to keep up with their progress. I get emails from the program, and it’s flexible. They [AFSA’s VIP team] understand we get busy in this business,” he explained.

Trio Fire started VIP in hopes of improving their team and enhancing overall job site performance. “We had the hands-on training part down, but

what we needed was the book knowledge to back it up,” Clary explains. “This program bridges that gap.”

The VIP training not only helps large contractor companies but also small ones, like Trio Fire, to better manage time and resources. “For smaller companies that don’t have time to train, this program is good,” Clary adds. “You don’t have to stay after hours going through books with the apprentices.” Using this training program can give supervisors their time back, all the while providing apprentices with the instruction they need.

With VIP, Clary’s apprentices are already gaining the skills and confidence to move forward. “Other programs just give you the books and you hope the guys read them.” VIP helps provide structure and accountability among apprentices. When asked about future VIP plans, Clary answered that he intends to continue putting his apprentices through the program.

AN APPRENTICE PERSPECTIVE

Hunter Flaishans is a Level 1 VIP apprentice. He joined the program in late 2024 after bouncing from one job to another. At Trio Fire, Flaishans found his footing. “My brother had been trying to get me to work here, and one day I decided to go for it. I haven’t looked back since.”

Flaishans appreciates the VIP program’s flexibility and the quality of instructors. “They’re very knowledgeable and always willing to help. If you miss a session or want to go back and review, you can. Then you take what you learned and apply it directly in the field.”

Flaishans never saw himself in this kind of role, but it turned out he enjoys the hands-on aspect of the job and the

Ready to Learn Like a VIP?

Level 1 Begins July 22:

Early bird registration: Feb. 27 – Jun. 7

Regular registration: Jun. 8 – Jul. 12

Late registration: Jul. 13 – Aug. 12

Level 2 Begins Aug. 5:

Early bird registration: May 6 – Jun. 20

Regular registration: Jun. 21 – Jul. 25

Late registration: Jul. 26 – Aug. 25

Level 3 Begins Oct. 7:

Early bird registration: Jul. 9 – Aug. 23

Regular registration: Aug. 24 – Sept. 27

Late registration: Sept. 28 – Oct. 28

Level 4 Coming Quarter 1 2026!

chance to build a career. “You get paid to learn and travel around and have new experiences. I like traveling and not going to the same office every day.” He encourages others to consider the fire sprinkler industry and the VIP path. “It can be easy, and it can be challenging. But that’s the beauty of it. It’s on you; you only have to apply yourself.”

MORE ABOUT THE PROGRAM

With AFSA’s partnership with the National Center for Construction Education and Research (NCCER), the curriculum texts—the Sprinkler Fitting series— have been updated and are now in its 4th edition. This version aligns with NFPA 13, Standard for the Installation of Sprinkler Systems, 2019 edition for VIP Levels 1 and 2, and the 2022 edition for Levels 3 and 4. Levels 1-3 are each provided with ten months of instructional education content to pair with the on-the-job learning (OJL)

conducted by the employer, with Level 4 set for 2026 release. The education content includes the Sprinkler Fitting textbooks, two live monthly sessions, performance tasks to reinforce the modules, self-study components, and assessments.

“Watching the students learn and grow into the professionals this industry needs to carry it forward is so rewarding,” comments Valentine. “With Level 3 underway, we are now starting to see that turning point that comes with experience.”

Participants are required to attend interactive sessions led by AFSA staff and industry experts. Each session is two hours long and allows time for group discussion. The mandatory sessions are held twice each scheduled day to accommodate different time zones. After registering, a calendar with specific session dates and details is provided.

Scott Pugsley, SET, FPET, professor/ industry coordinator for Seneca School of Fire Protection Engineering Technology in Toronto, Ontario, Canada, is one of AFSA’s VIP instructors. “Scott’s a great instructor who keeps me interested and

“WE SPENT YEARS TRYING TO FIND SOMETHING LIKE THIS. ... IT FIT US LIKE A GLOVE.”

intrigued by what we are learning. He keeps me on my toes yet is educationally entertaining,” says one student.

The performance tasks correspond with each lesson throughout the course, and the assigned supervisor (employer) ensures the completion of these tasks, which must be completed to advance to the next level. The self-study portion allows the apprentice to review relevant readings, videos, and articles as needed. Assessments will also be conducted through the learning management system and virtually proctored. For Level 1 and Level 2, there will be one exam per module. For Levels 3 and 4, the number of assessments will be reduced from those corresponding to the 3rd edition of the textbooks, but for subjects that warrant it, there may be more than one exam per module.

Goof-Proof

VIP CONTINUES STRONG

In just three years, AFSA’s VIP has become an essential asset for companies seeking a convenient and effective way to train apprentices tailored to their specific needs. For businesses like Trio Fire Systems and apprentices like Hunter Flaishans, it’s more than a training program but also a resource to advance their skills and grow in their careers.

Looking for a more flexible and efficient approach to train your apprentices? AFSA’s VIP is the solution! To learn more, visit firesprinkler.org/vip. For any questions or to learn more about AFSA’s education and training opportunities, email training@firesprinkler.org or visit firesprinkler.org/education. n

REDUCING RISK

EXPLORING PCI COMPLIANCE, EMV TECHNOLOGY, AND SURCHARGING

ASHLEY MARINO | SERVICE FIRST PROCESSING

Credit card processing has become essential to modern commerce as the world increasingly embraces digital transactions. To ensure smooth and secure payment experiences, businesses must understand key concepts and best practices in credit card processing. This article covers data security, advanced card technology, and an overview of surcharge programs. Understanding and addressing these will help to ensure secure transactions while reducing risk and potential liability to your business.

PCI COMPLIANCE

Protecting cardholder data during credit card transactions is essential, and Payment Card Industry Data Security Standard (PCI DSS) compliance sets the security standards. Let’s delve into the key aspects of data security.

Understanding the scope of PCI DSS: PCI DSS applies to organizations that process, transmit, or store cardholder data. It encompasses maintaining a secure network, protecting cardholder data, implementing strong access controls, regularly monitoring and testing networks, and having an information security policy. Implementing security measures: Achieving PCI compliance necessitates implementing various security measures. Encryption ensures that cardholder data remains protected during transmission. Tokenization replaces sensitive data with unique identifiers, further enhancing data security. Network security measures, such as firewalls and intrusion detection systems, safeguard against unauthorized access. Access controls ensure that only authorized individuals can access sensitive data. Annual certification is required, and

based on how you process transactions, periodic vulnerability scans may be required for identifying and addressing potential security weaknesses.

Maintaining compliance: Data security is an ongoing process that requires continuous monitoring and assessment of security measures. Employee training is also essential in maintaining compliance, ensuring that all personnel involved in payment processing understand their responsibilities and adhere to security best practices.

EMV TECHNOLOGY

EMV (Europay, Mastercard, and Visa) technology is a global standard for credit and debit card payments that utilizes embedded microchips. Let’s explore EMV technology in greater detail.

How EMV Works: EMV cards securely store and process cardholder data using embedded microchips. When an EMV card is inserted into a compatible payment terminal, a dynamic transaction code is generated for that specific transaction.

Benefits of EMV adoption: Adopting EMV technology offers several advantages for businesses and customers. The primary benefit is a significant reduction in counterfeit fraud. EMV cards generate unique transaction codes for each payment, making it extremely difficult for fraudsters to replicate or use stolen card data for fraudulent transactions. Additionally, your processing cost may be affected. Check your statements for “EMV Non-Acceptance Fees.” Lastly, it is important to understand that you are more likely to lose a chargeback if a face-to-face transaction using a chip card was not run on an EMV device.

Implementing EMV: To accept EMV payments, businesses need to upgrade

their payment infrastructure. This involves using EMV-compatible payment terminals and/or point-of-sale (POS) systems that process EMV transactions. Additionally, staff may require training to familiarize themselves with the new processes involved in EMV transactions, such as card insertion and customer authentication validation.

SURCHARGING

Surcharging refers to the practice of adding an additional fee (surcharge) to customers who choose to pay with a credit card. While surcharging can help businesses offset credit card processing costs, it is important to understand how these programs work.

Considerations: The permissibility of surcharging varies across states and card brands may also impose limitations. It is important for businesses to be familiar with the laws and regulations governing surcharging in their operating jurisdiction.

Pros and cons of surcharging: Surcharging can provide businesses with a means to offset a portion of the costs associated with credit card processing. However, business should consider that surcharging may be viewed as a price hike by customers.

Implementing a surcharge program: For businesses considering surcharging, it is important to follow the applicable rules and regulations. Clear communication regarding the surcharge program should be provided to customers before the transaction occurs. This can be done through signage, disclosure on the website, or at the point of sale. n

ABOUT THE AUTHOR: Ashley Marino manages partner relationships at Service First Processing (SFP), a payment automation company, and has been with the company since day one. She’s focused on supporting associations and driving program success. SFP is an AFSA partner, offering discounts for AFSA members. Visit sfprocessing.com/afsa for details.

TESTING THE WATER

ANALYZING FIRE PUMP FLOW TEST RESULTS

JOSHUA MCDONALD, P.E., MSET, CFPS, CWBSP, WBITM | AMERICAN FIRE SPRINKLER ASSOCIATION

Fire pumps are utilized to provide pressure to fire sprinkler systems. The fire pumps are required to be no-flow tested weekly or monthly, depending on the scenario and the driver type. The no-flow test provides an opportunity to test the pump and check to see if the conditions are “normal.” The no-flow test does not test the performance of the fire pump based on the acceptance test, the manufacturer’s bench test, or the pump placard. The annual flow test provides a performance test to compare to the initial unadjusted field test curve or the data provided by the manufacturer. Unfortunately, many times, failed or deficient pump test data is due to manual error or a misunderstanding of the appropriate test data analysis. This article will discuss the importance of the annual fire pump test and proper analysis of the test results to inform those doing the test and the building owners who are ultimately responsible for the inspection, testing, and maintenance (ITM) of the fire pump systems.

Section 8.3.3 of NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-based Fire Protection Systems, 2023 edition, outlines the requirements for fire pump testing. It requires that technicians attempt to achieve 0%, 100%, and 150% of the rated capacity (flow) by physically flowing water for constant speed pumps, and the applicable data needs to be recorded and analyzed. In addition, variable speed pumps are subject to a flow test at 25% flow increments and at the constant speed settings stated earlier.

Knowledgeable, trained, and experience personnel are required to not

The annual flow test provides a performance test to compare to the initial unadjusted field test curve or the data provided by the manufacturer.

only perform the test but also analyze the test results. In many cases, the field personnel will record the data and more experienced personnel will review it to make determinations about pump performance, etc. (8.3.7.1.2 Qualified personnel shall interpret the test results.)

Accurately measuring and recording the test results and observations are required to conduct a fire pump test

properly. The results should not be looked at as black-and-white failure points, but the big picture of the fire pump test results, pump components, test history, and purpose of the fire pump should be taken into consideration. ITM technicians should not walk into pump tests looking for the pump to fail, but should look at the performance and whether the pump is doing its job.

Accurate test measurement is a vital task in analyzing a fire pump test appropriately. The analysis is useless without accurate data. NFPA 25 requires calibrated equipment to be utilized to help ensure the test results are accurate. The technician who is analyzing the results should be able to recognize when the fire pump flow test was not conducted appropriately or if the test results may not be accurate. Fire pump flow test points are measured with listed devices. The flow test data should be the amount of water flowing during the test and not the exact information on the placard. The number should be close, but many times, the actual numbers cannot be achieved with the commonly used equipment. For example, a 500-gpm pump requires flows at 0 gpm, 500 gpm, and 750 gpm. Many times, the actual flows based on the flow measurement equipment are more like 0 gpm, 504 gpm, and 756 gpm. It may not seem like a big deal that the test results were rounded to the pump flow points, but the pressures recorded are deficient by the standard with a 5% deduction. A 5% pressure reduction is not a lot of wiggle room, and the flow test results can be extrapolated at the exact pump flow points, even if they are a few gpm off, based on the logarithmic graph results, which are plotted to ensure the data collected reflects the test. The pump performance pressure (net pressure) is calculated by finding the difference between the discharge (system) pressure and the suction (supply) pressure.

Pdischarge - Psuction = Pnet

The amperage, voltage, and speed also must be recorded at each flow point. A calibrated tachometer and appropriate reflective adhesive are required to acquire accurate speed results. Due to the electrical hazards encountered when opening an enclosure, you are no longer required to take internal readings during a fire pump testing. (NFPA 25 Tentative Interim Amendment (TIA) #1287). However, where external readings are available, they must be recorded at the appropriate times during the test. The voltage and amperage are measured if there is an external readout, which may

need calibration based on the manufacturer’s instructions. Electrical supply issues typically show up in speed changes for legacy controllers that do not have electronic readouts. Voltage and amperage readings are not applicable for diesel-driven fire pumps for data collection and pump performance.

Upon completion of the fire pump test, the data needs to be analyzed. The gross fire pump curve and the net fire pump curve must be examined. The gross fire pump curve, or the discharge curve, includes the pump performance and the water supply and is utilized to ensure that the pump system can support the fire sprinkler demand. Pump tests are permitted to be acceptable if:

1. The fire pump meets the flow and pressure requirements of the ownerprovided system requirements.

2. The fire pump provides the rated flow.

3. The net pressure is required to be 95% at each flow point at the original manufacturer’s pump curve, the original unadjusted field curve (acceptance test), OR the curve generated from the fire pump nameplate.

4. Water supply can support the flow at the lowest permissible suction pressure.

Other considerations for electricdriven pumps are that the amperage cannot exceed the service factor times the full-load amperage of the motor, and the voltage is within 95-110%. The best curve to be measured against is the original unadjusted field curve. The test set-up should be as similar as possible to the test to compare the results to the system as it was installed. The 150% flow may not be met in some situations, and comparing the data to the acceptance test may show that the scenario has not necessarily been met in the entirety of the system’s lifetime. Leaving the test equipment in the back of the truck through the seasons is not the proper way to ensure that it is accurate enough to acquire the information needed. Many times, the technician gets into the habit of just looking at the pump placard. To limit liability and serve customers better, NFPA 25 does not have a category for a pump test “failure.” NFPA 25 does provide definitions for deficiencies