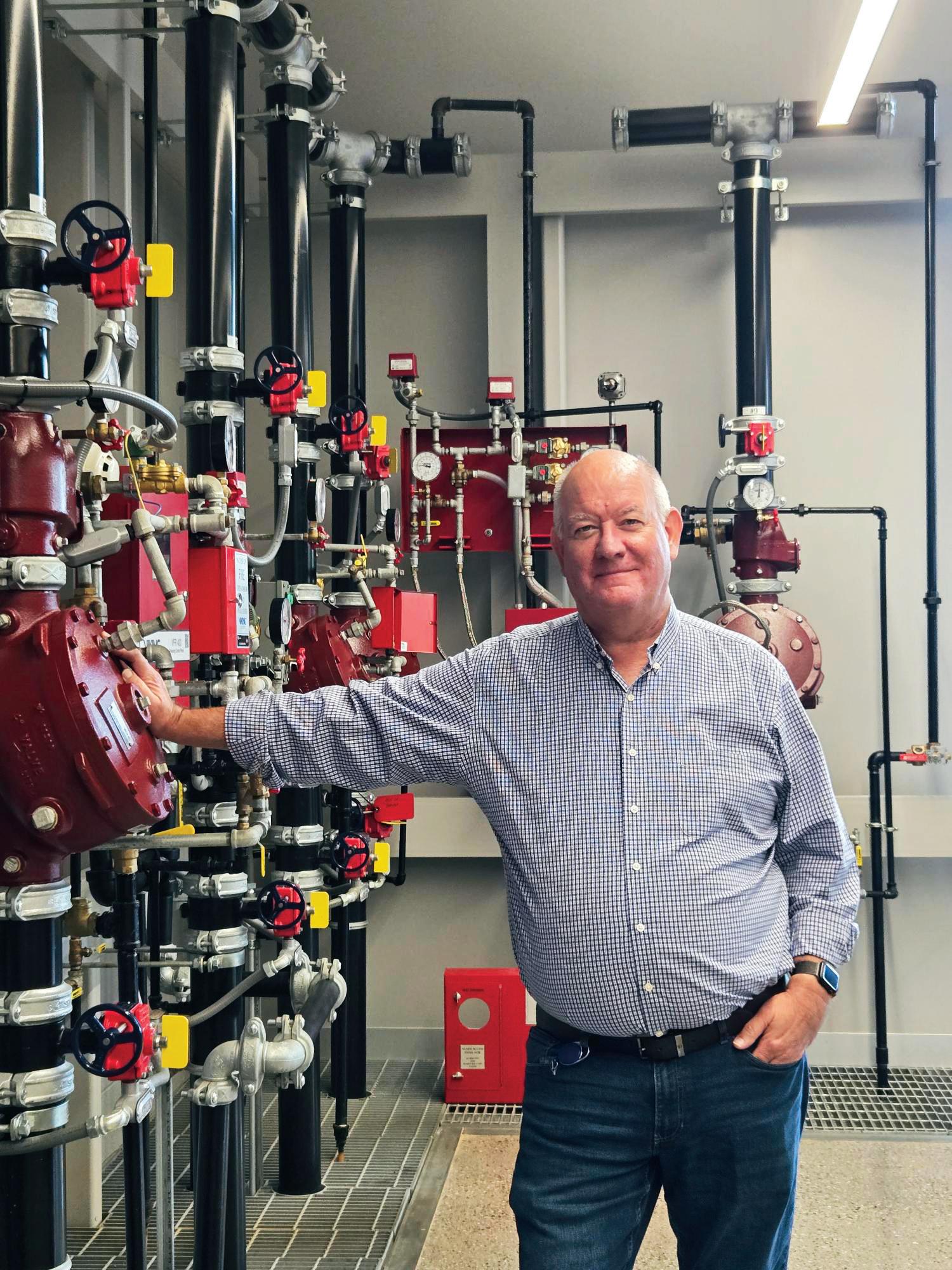

MARTIN WORKMAN

2025 PARMELEE AWARD RECIPIENT

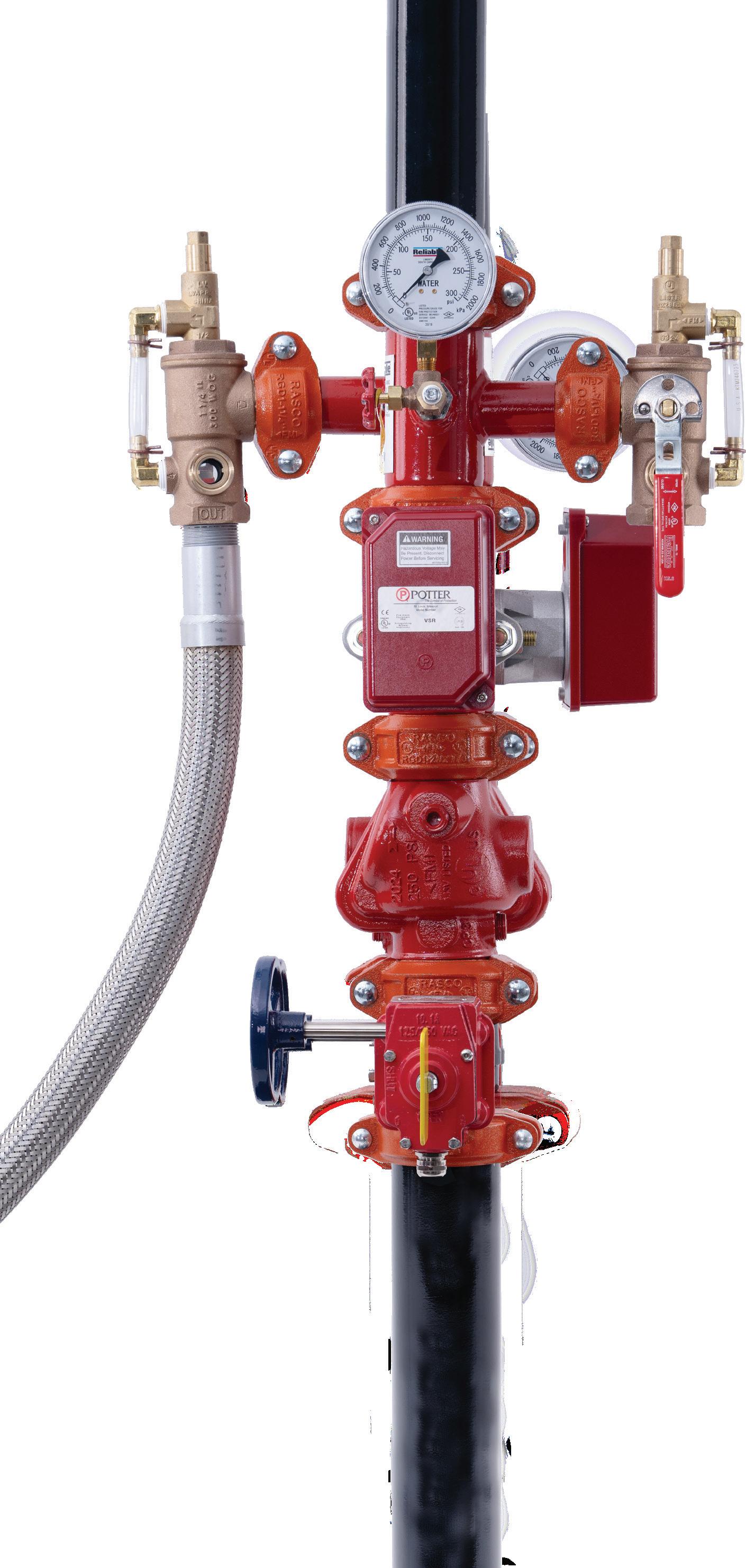

Commercial Riser (can

2025 PARMELEE AWARD RECIPIENT

Commercial Riser (can

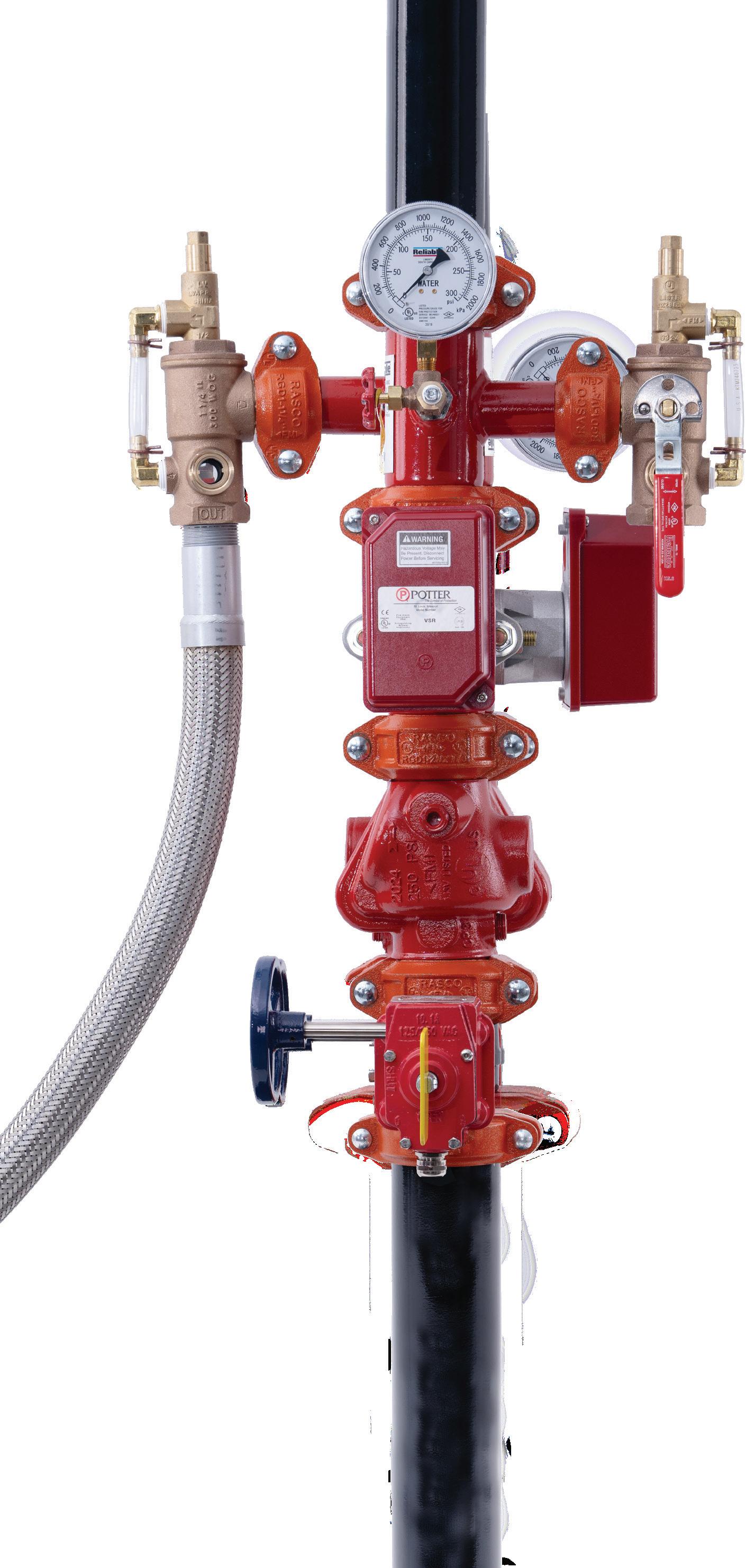

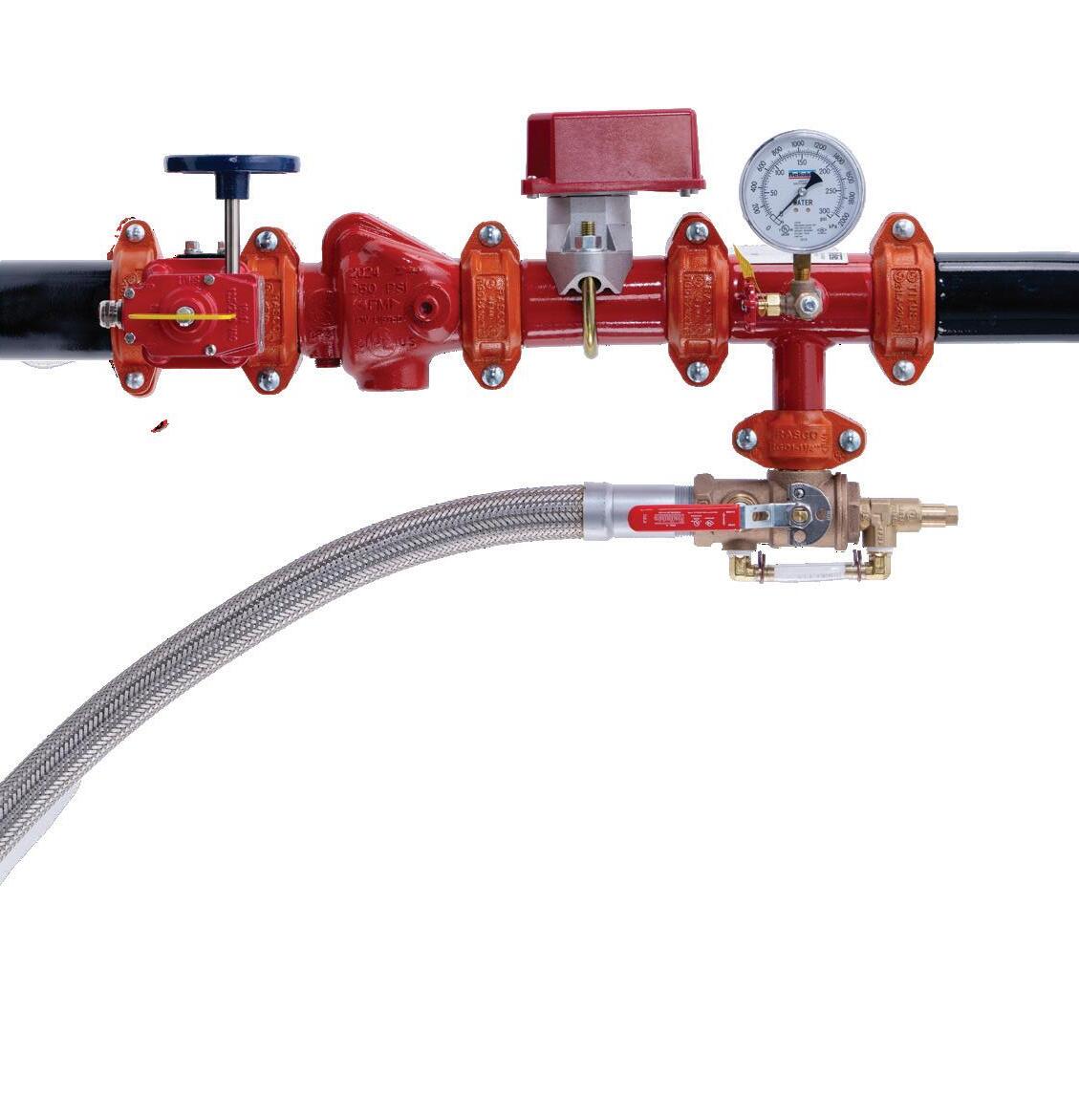

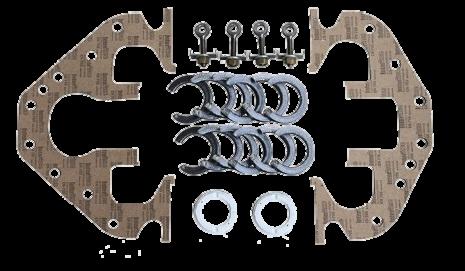

THE FCA2 FLOOR CONTROL ASSEMBLY FITS JUST RIGHT Test & Drain

Potter Water Flow Detector available in Explosionproof and automatic test versions

The Model FCA2 is cULus Listed in all sizes and FM Approved in 2"–8". The FCA2 is designed for optimal configuration for any installation scenario. With 360° rotation of each modular component, this versatile assembly adjusts to the trickiest corners.

All the components required for a complete floor control assembly. Available in sizes from 11/4"–8".

One PO. One Box. One Installation.

Our new mill expands our overall product capabilities, giving us the most comprehensive range of sprinkler pipe in the industry:

• Diameters from 1” to 10” NPS.

• Schedule 10, 30, 40, and Eddy Flow (size dependent)

• Lengths up to 25’, with custom lengths available

Plus a variety of finishing options — not to mention our exclusive EddyGuard II® MIC antimicrobial coating to help ensure reliable flow for years.

It’s all available to you from a single, responsive supplier…making your pipe selection job much easier.

The best-in-class tool for in-air or power driven field fabrication of 1 – 12" OGS and 1" IGS pipe in various pipe materials.

› Groove diameter adjustment

› Manual or power driven

› Interchangeable roll sets

› Simple depth setting procedure

› Adjustable ratchet

› Lightweight and portable

› Collapsible for tight spaces

› Rugged design

› Plastic tool case protects the tool and organizes accessories

› Strong enough for field fabrication

Includes a full package of components for operation and service

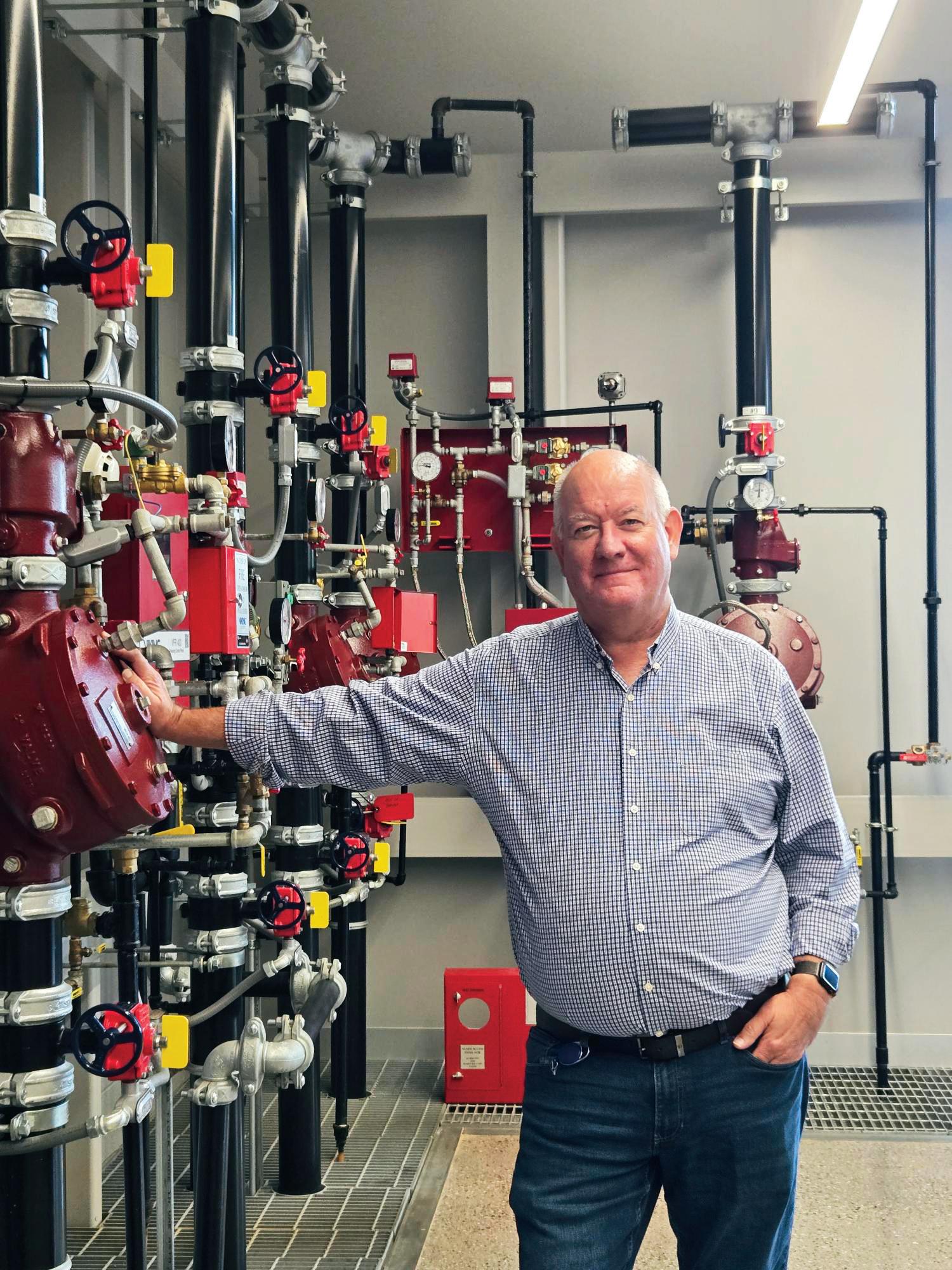

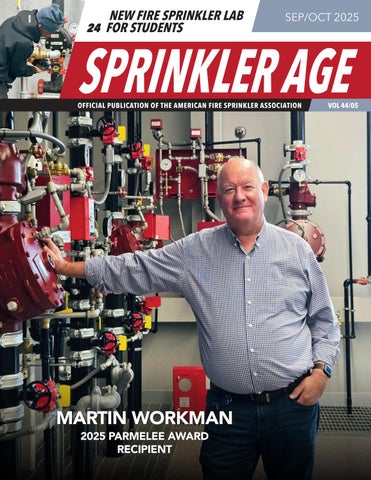

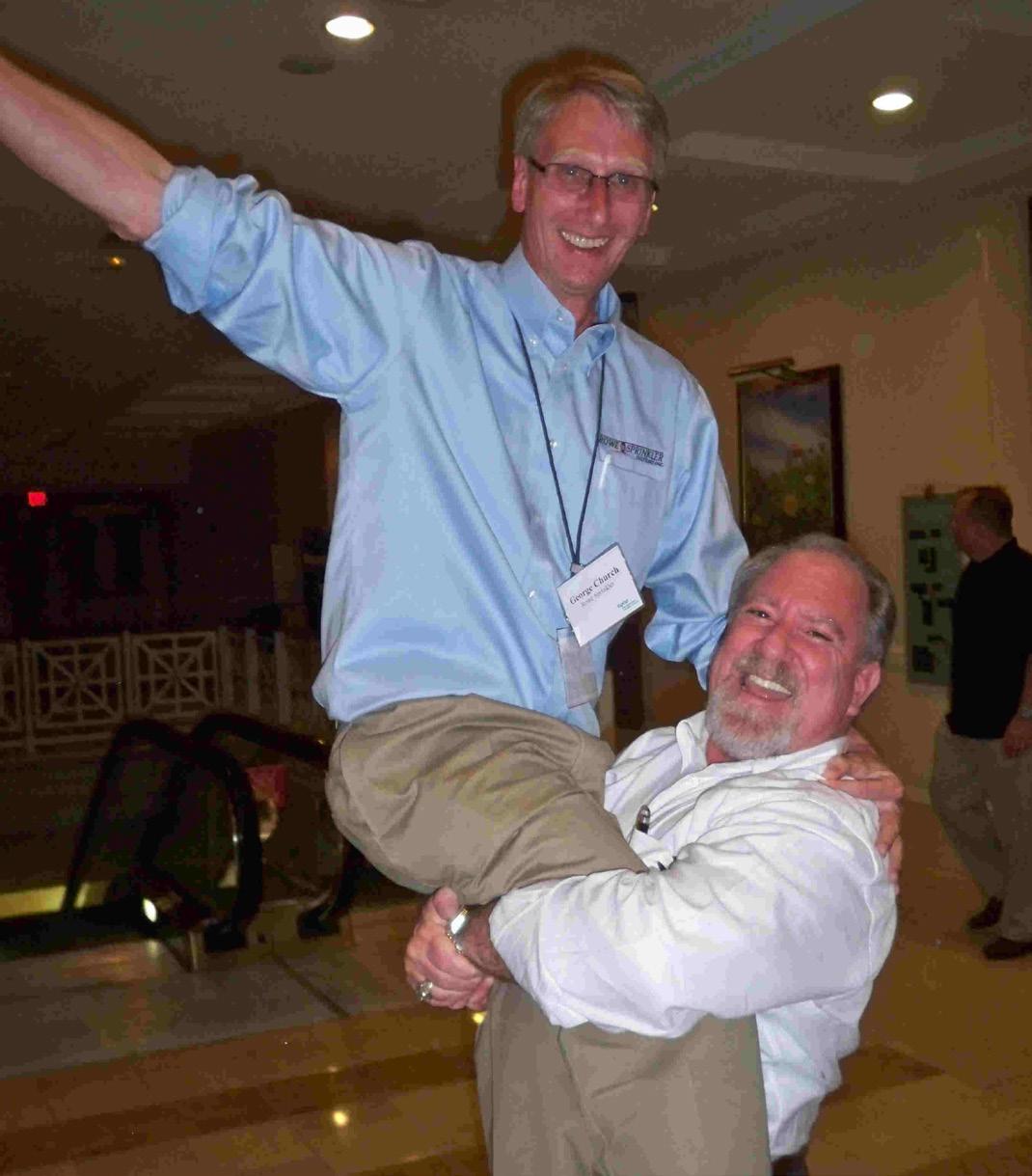

THE COVER: Martin Workman, senior vice president of product development for The Viking Corporation, Inc., is AFSA’s 2025 Henry S. Parmelee Award recipient. Also in this issue: NFPA 13.

Ask not what you can do for AFSA, ask “What can AFSA do for you?” (a little play on words from JFK). Convention is here, and we are so excited to have over 1,200 attending AFSA44 in Washington, D.C. I would like to thank all the sponsors who support this endeavor, and for whom we would not be able to provide such a FIRST-CLASS convention without. Diamond Sponsors include ASC, Ferguson Fire & Fabrication, Reliable, Victaulic, and Viking.

The second Women in the Industry panel is on Wednesday, October 15, from 3:30-4:30 pm, with a short mixer after. The panelists include me, Lisa DiRienzo with Impact Fire Services, Meaghen Wills with Anchor Fire Protection, Jacqueline Wilmot, P.E. with Brooks Safety Solutions, and our moderator will be our very own Meda Merritt, AFSA’s Vice President of Membership and Chapter Development. Panelists will share their hard-fought stories and experiences that have shaped them into the successful women they have become in a male-dominated field. Last year, it was standing-room only. Don’t be shy, gentlemen—this panel is for men and women. See you all there!

The National Apprentice Competition is always the highlight of the convention. Congratulations to the finalists and their companies. I want to point out that a female apprentice is in the competition this year. I wish for all the finalists to do their best, but I must say I have a little extra “show them how it’s done” for Leona Ball with Piper Fire Protection from Region 5. Good Luck to ALL!!! You have earned your way here, and each of you has the opportunity to become the AFSA44 Apprentice 2025 Champion!

As I write my last Chair’s Message, I am traveling to the AFSA Florida Chapter for its Legislative Conference. This is an exciting opportunity to experience firsthand the work sessions that formulate important legislation for fire sprinkler contractors for the upcoming state legislative session. Accolades to the Florida Chapter board of directors, especially AFSA At-Large Director and Chapter Board Member Chris Johnson, and Chapter Executive Director Jessica Cox, for working tirelessly to obtain legislation regarding our apprentice training.

In September, I will attend the AFSA Virginia Chapter’s 32nd Annual Burn Survivors’ Golf Tournament. Last year set a record with over $100,000 raised for the Burn Survivors Foundation! Then, it is off to convention at the Gaylord National in Washington, D.C. At the AFSA44 General Session on October 17, I will turn the gavel over to our 2026-2027 Board Chair, Paul DeLorie. Paul will be an excellent Board Chair and serve the association and its members well. Post convention, I will squeeze in the AFSA Georgia Chapter Golf Tournament on October 24, and then I’m off to my AFSA Louisiana Chapter Social and Golf Tournament, October 27-28, in Baton Rouge. No time for work!

In closing, I want to thank everyone for their hard work and dedication to support my goals for AFSA, the Board, committee chairs and members, AFSA team, and my Fire Tech Systems’ team. None of this would have been possible to achieve without your support and desire to move AFSA forward for the betterment of its members. See you all at convention to celebrate all the great things that are happening at AFSA for its members. It has been an honor to serve you as Board Chair these last two years! n

EDITORIAL: 214-349-5965

BOB CAPUTO, CFPS, Publisher, ext. 124 bcaputo@firesprinkler.org

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

ADVERTISING: 214-349-5965

CLARISSA RIOS, Communications Coordinator, ext. 134 crios@firesprinkler.org

CIRCULATION: 214-349-5965

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

AFSA BOARD OF DIRECTORS

LINDA M. BIERNACKI, Chair, Region 5, 318-841-0330

PAUL DELORIE, First Vice Chair, Region 10, 603-432-8221

JAY STRICKLAND, Second Vice Chair, Region 6, 301-474-1136

ROD DIBONA, Treasurer, Region 4, 605-348-2342

JEFF PHIFER, Secretary, Region 8, 803-438-2994

JACK A. MEDOVICH, P.E., Immediate Past Chair, At-Large, 804-222-1381

BROOKS BAYNE, Region 1, 503-692-9284

HUNTER BRENDLE, At-Large, 334-270-8571

MINDY BUCKLEY, At-Large, 770-925-9099

TOMMY CLEMENTS, Region 9, 804-459-2218

CHRIS JOHNSON, Region 7, 727-5821-9339

R. DONALD (DON) KAUFMAN, Region 3, 505-884-2447

MICHAEL F. MEEHAN, At-Large, 804-459-2200

WAYNE WEISZ, Region 2, 209-334-9119

BOB CAPUTO, CFPS, President, ext. 124

MATT KLAUS, Executive Vice President & COO, ext. 139

MELISSA ATHENS, Vice President, Finance, ext. 112

LESLIE CLOUNTS, Vice President, Education Services, ext. 130

JOHN AUGUST DENHARDT, P.E., FSFPE, Vice President, Engineering & Technical Services, ext.121

MEDA MERRITT, Vice President, Membership & Chapter Development, ext. 133

Sprinkler Age is devoted to the professional development of the fire sprinkler industry. Deadline is 1st of the month preceding publication.

Published by American Fire Sprinkler Association, 1410 East Renner Road, Suite 150, Richardson, TX 75082. Call (214) 349-5965, FAX (214) 343-8898, or email sprinklerage@firesprinkler.org for information.

Copyright © American Fire Sprinkler Association, Inc. All rights reserved. PRINTED IN USA. Unless expressly stated otherwise, all editorial and advertising material published is the opinion of the respective authors and/or companies involved and should not be construed as official action by or approved by Publisher or the Association.

LINDA M. BIERNACKI AFSA BOARD CHAIR

Sprinkler Age is a membership benefit, provided free of charge to AFSA members. For information on nonmember and/or foreign subscription rates, call (214) 349-5965.

AFSA annual membership dues are a sliding scale for Contractors and Associates and a flat fee for Authorities Having Jurisdiction. (Members receive a free subscription to Sprinkler Age.) Write or call AFSA for membership information. See AFSA’s website at firesprinkler.org.

On behalf of the AFSA team, it is my great pleasure to welcome you to AFSA44. We are delighted to have you join us for what promises to be an inspiring and unforgettable event. Our shared commitment to advancing fire protection, life safety, and our mission of protecting people and property provides a unique opportunity to connect, learn, and grow together. With a diverse lineup of educational sessions and an exhibit hall showcasing the latest innovations in our industry, we are confident you will find new ideas, valuable tools, and fresh perspectives to bring back to your teams and communities.

Equally important, this convention is about relationships— strengthening the bonds that make our association a family. Whether you are a first-time attendee or a long-time member, we encourage you to take full advantage of the networking events, share your experiences, and collaborate with colleagues who share your passion for fire and life safety. Together, we will explore emerging technologies, evolving codes and standards, and the future of fire protection in a rapidly changing world. Thank you for being here and for the role you play in advancing our industry and our association, as well as for the lives and property we save through the work we love doing. We also wish to extend our deepest gratitude to our sponsors and partners, whose generous support has helped make this event possible. We look forward to a memorable convention filled with learning, inspiration, and fellowship. Welcome, and let’s make this our best convention yet!

For those of our members who are not fortunate enough to be able to attend this year’s event, let me take a few paragraphs to talk about what you can expect to see from your association as we move into 2026. First and foremost, we are proud to announce that our Virtual Instruction Program (VIP) for Fire Sprinkler Fitter Apprenticeship is growing rapidly. The latest Phase One class, which was recently started, has over 60 registered apprentices from across the country, and our ever-growing cadre of incredible instructors is increasing with it. For those of you unfamiliar with this program, it allows your apprentices to attend the required classroom sessions remotely, from anywhere with a live instructor via connected devices. This is a benefit for those companies and apprentices working in remote locations, as well as those where traffic makes attending an actual classroom difficult after an eight-hour workday.

Our 20-month ITM program is easily the most well-enrolled, and the last few classes have had 100% pass rates for NICET Level II test takers. Attendance in our programs for layout technicians and fire pump testing has also seen a sharp rise, and the feedback we’ve been receiving is an indicator of great successes for our instructors and the participants who have attended. Our lab space is being booked almost every week with open registration and private training programs.

But that’s not where the success stories end. AFSA staff, under the guidance of our Board of Directors, have plans to expand our lab and our training programs to include ITM for fire alarm (low voltage), kitchen hoods, fire extinguishers, fire doors, and dampers to help

me

increase opportunities for our members to add services and for AFSA to become your one-stop shop for training and education for your staff. I invite everyone to visit our website, firesprinkler.org, and click on the Education & Training tab to see the many options at your disposal.

As we’ve noted in the recent past. AFSA would love to hear and publish your story in Sprinkler Age. How did you get into this industry? Why are you a member of AFSA? Is there something our Engineering & Technical Services Department has done to save you time or money? What’s next for your region or this industry? We want to know, so please tell us your story so we might share it with others.

Finally, I’d like to say thank you to Linda Biernacki, who has served as Chair of the Board these past two years. Linda brought her unique style and panache to the role, while keeping everyone on their toes and helping to guide the Board and the staff to reach a little further and accomplish their goals. Enjoy the convention, and don’t forget to have a little fun! n

We offer a complete lineup of intermediate level in-rack sprinklers, accessories and installation tools— featuring over 20 FM Approved and/or UL Listed configurations—designed to meet the demands of today’s toughest storage environments.

From standard racking to automated storage and retrieval systems, our sprinklers, guards and watershields are engineered for performance and flexibility designed to avoid obstructions while maximizing coverage.

Viking’s entire intermediate level in-rack offering includes InstaSeal® compatibility, allowing the flexibility of hand-tightening without using a wrench, tape or dope.

Learn more on our website at info.vikinggroupinc.com/in-rack.

Over the last few months, I have attended several NFPA technical committee meetings and the SFPE Storage Symposium. One thing became evident: many times, we do not know what we don’t know or what we should know. What do I mean?

Look at the hazard classification of a typical automotive parking garage. The annex to the 2025 edition of NFPA 13 lists a typical automotive parking garage as Ordinary Hazard Group 2 (OH2). Now let’s add electric charging stations and maybe vehicle stackers to the typical parking garage. Does that change the hazard classification discussion? Some local plan reviewers and AHJs are classifying any parking garage with electric charging stations as Extra Hazard Group 2 (EH2). Are they out of their minds? NFPA 13, 2025 edition defines an EH2 as “3.3.148.2 Occupancies or portions of occupancies with moderate to substantial amounts of flammable or combustible liquids or occupancies where shielding of combustibles is extensive.” I’m not sure EH2 is correct, but we need more data.

So, what do we do as an industry? We look at loss history, field experience, and fire testing to attempt to answer this question. Several organizations have been looking at this issue critically for automotive parking garages. The NFPA Research Foundation has an ongoing parking garage research project that AFSA proudly sponsors. They are working on Phase 3 of the report, and as a technical panel member, I’ve seen some of the testing. There were public inputs to NFPA 13, 2028 edition to modify the requirements. Unfortunately, only minor changes were accepted during the first draft meeting without more data being provided. The second draft meeting should offer more changes. NFPA 88A, Standard for Parking Structures, 2027 edition is currently under second draft. There are public comments moving forward to address the sprinkler criteria. We will see what shakes out, but one thing I know for sure, we do not know what we do not know. Also, remember, just because design criteria get into a standard does not make it gospel. In many cases, it is an educated guess based on the data the technical committee has to review.

Our industry has changed substantially in the last decade. New technologies, products, storage arrangements, tighter deadlines, and many other items come to mind. What is one to do? Stay informed, ask questions, and hold on because the pace is furious, and I do not think it will slow down anytime soon. For example, who would have ever thought NFPA would develop a standard on cannabis, NFPA 420, Standard on Fire Protection for Cannabis Growing and Processing Facilities, a code to address battery safety, NFPA 800, Battery Storage Code, or add fall prevention to the scope of NFPA 101, Life Safety Code,® which has rules for grab bars and other items.

Just as the industry has changed, has your company changed? Are you looking at new lines of work? Are you doing more ITM activities? NFPA 25’s scope includes water storage tanks, water spray systems, water mist systems, foam systems, underground piping and valves, and fire hydrants. Have you thought about adding these services? ITM activities also could include fire extinguishers (NFPA 10), kitchen hood systems (NFPA 96), carbon dioxide systems (NFPA 12), clean agent

systems (NFPA 2001), hybrid fire suppression systems (NFPA 750), fire alarm and signaling systems (NFPA 72), dry chemical extinguishing systems (NFPA 17), fire doors and windows (NFPA 80), wet chemical fire extinguishing systems (NFPA 17A), and emergency exit lights (NFPA 101). The need for experienced inspectors to perform these inspections is huge. You might want to look at your competitors, as many of them are expanding their service to include these requirements in their offerings.

Where is this industry going? Your guess is as good as mine. But I can tell you that if you keep your head down, you might miss the opportunity to keep up.

I also want to remind all that the responsibility for performing a service comes with liability if your team does not perform the service professionally and in full compliance with the terms of the contractual agreement. This means you need trained and experienced field inspectors and administrative staff who can write a proposal to cover your company’s exposure. Let me give you a real-world example. You enter into an agreement to perform annual ITM service on one 1,000 gpm at 100 psi-rated diesel-driven fire pump system in accordance with NFPA 25, 2023 edition. Your inspection team does a complete flow test, and the documentation is perfect. All items passed, and all is great. Did your contract specifically exclude all the required inspections, testing, and maintenance on the diesel driver? If it did, did the client have the same understanding? Does the AHJ understand you did not do a complete ITM on the diesel driver? What if the driver has an issue a month after you were onsite because you did not change the fuel filters? Who is going to get the blame? Even if you had excluded the work, finger-pointing would occur if all parties involved were not on the same page.

The bottom line is that all staff involved in any part of sales, inspections, and administration of the work must be trained on what is important and what can happen if items are missed. We do not know what we do not know, but “we do not know” is NOT a legally defensible answer. Standardized procedures with proper training can assist in making sure your company succeeds.

AFSA is looking at what the future brings. We have come a long way since our start, especially in the last five years. We want to serve our members as they move forward. Do we need to offer training in some of the areas I discussed, or should we stay focused on what we’ve been doing? Our technical team is up for the challenge; are you? Let me know what you think about AFSA expanding our scope of training. I want to hear your thoughts. Feel free to reach out to me directly at jdenhardt@firesprinkler.org. n

JOHN AUGUST DENHARDT, P.E., FSFPE AFSA VICE PRESIDENT OF ENGINEERING & TECHNICAL SERVICES

When facing tight physical and logistical windows, it helps to have a dedicated hand at the wheel to ensure everything goes smoothly.

Our Project Management service provides expert support and organization at every step of the process; from design to fabrication to the complete package arriving on the jobsite, we’ll anticipate your needs and provide focused, experienced assistance.

“Leading by example” is often touted yet not always accomplished. Hallmarks of this leadership style include acting with integrity, demonstrating accountability, fostering trust, and modeling best work ethics and values. Leaders who embody these traits inspire others to achieve their best. One member of the fire protection industry who lives this principle is Martin Workman, senior vice president of product development for The Viking Corporation, Inc. Because of his commitment and dedication to education, training, and the betterment of the industry, the American Fire Sprinkler Association (AFSA) is pleased to recognize Workman with its highest honor, the Henry S. Parmelee Award.

Workman joined the fire protection industry when a friend’s father offered him a job in western Michigan, if “he didn’t mind getting dirty.” Workman was working at an auto parts store and was happy to accept, as he was paying his way through college. “I didn’t really understand what I was doing at first,” he remembers. “I unloaded pipe mostly.”

Workman was on a prevailing wage job, and his new boss wanted him to join the company’s apprentice program. Workman agreed and quickly advanced through the trade. “As a second-year apprentice, I was running jobs,” Workman remembers. He eventually left the field to pursue design, but spent most of his time in contracting at Peninsula Fire Protection in Grand Rapids, Mich. In 1994, Workman was named vice president and part owner.

Workman was also involved with training at Peninsula. One night, he filled in for the regular instructor on the design and hydraulics section. “That one night turned into five years,” he laughs. Workman found he had a knack for teaching and connecting with the apprentices and began instructing for all levels of the program.

That same year, AFSA and Associated Builders and Contractors (ABC) agreed to establish AFSA’s Training for Excellence correspondence courses as the national standard for sprinkler fitter apprenticeship training. Ken Huber at ABC asked Workman if he’d be a Subject Matter Expert (SME) on the committee. “I initially

said no because I didn’t consider myself an expert,” says Workman. “I’d never even heard of the term ‘Subject Matter Expert!’”

However, Huber convinced Workman that his input would be valuable. “The day I flew into D.C. for my first set of meetings, I was clueless!” Workman recalls. “I am so grateful to the people I met there— Danielle Dixon, Lenny Hollis, Janet Knowles, Bob McCullough, John McDonald, Doug Rice, Manning Strickland, Jack Viola—all are very special to me, and I know there are others I am forgetting to mention. They were outstanding mentors who taught me much about business, the trade, and people.”

Viola was impressed with Workman’s work and dedication to the project. “Not only did Martin generously share his expertise, but he also single-handedly wrote critical chapters that have become foundational to the program’s continued success. His willingness to go above and beyond for the rewrite committee was evident throughout every phase of the project.”

Those meetings were long and intensive. “It was all about being together and working,” comments Workman. Weekends away from home were required because most committee members were business

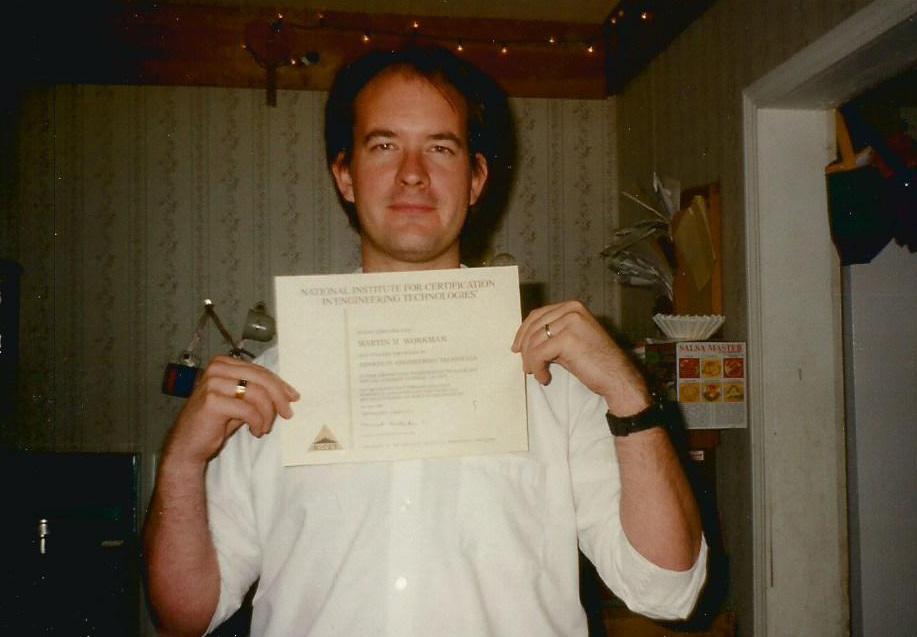

Workman proudly shared his first NICET certification in 1992.

owners who had to return to their companies. Workman soaked up all the knowledge he could. “Being from Michigan and not having traveled much, it was fascinating to learn what was required for the different regions around the country, like minimum bury for underground pipe due to freezing.”

“Jack, Bob, and Manning were very welcoming to me as a young guy,” says Workman. “After I met Bob, he would ask me why Peninsula wasn’t a member of AFSA. I told him we did our own thing in Michigan. He then paid for my wife, Tracy, and me to attend the convention and see what AFSA was all about.”

He continues, “Bob was so committed to the training of the industry. He had a true passion for it. I was lucky to understand that early on. The more you gave of yourself or to the trade, the more you’d see it come back. Bob would say, ‘The better you train your people, the better you train your competition, and that’s good for business.’ He was good that way.”

Peninsula joined AFSA as a contractor member, and the combined training debuted thanks to the committee’s dedication and unselfish energy. Eventually, ABC’s craft training curriculum spun off into a new independent non-profit organization, the National Center for Construction Education and Research (NCCER). AFSA’s partnership with NCCER continues today, providing the industry with best-in-class apprenticeship training.

Retired AFSA staff member Janet Knowles, AFSA’s communications director at the time, served as AFSA’s staff liaison to the review committee and worked closely with the SMEs throughout the four-book revision. “Martin committed a significant investment in time and always came prepared and was willing to step up when needed,” she says. “Although I retired from AFSA nearly a decade ago, I still like to look through Sprinkler Age magazine online. When I see an article written by Martin or a note that he will be speaking at an upcoming convention, I know that he is still delivering on his promises to further the goals of the fire sprinkler industry and AFSA.”

Viola agrees. “Martin’s unwavering commitment to the writing and upgrading of the curriculum has been instrumental in raising the standards for fire sprinkler apprentices nationwide. His tireless efforts and deep knowledge have helped ensure that AFSA’s curriculum remains the benchmark for excellence in the field.”

Workman takes the principles of mentorship and giving back to heart. It’s been the foundation for all he’s done on both the contractor and manufacturer/supplier sides of the industry. “The people I talked about who mentored me while we were developing apprenticeship training didn’t charge me for it, and I have the responsibility to do the same. People have always given to me. I’ve advanced my career because of it and been able to do many things other people haven’t. These guys were teaching me a craft. Very few people aren’t willing to teach you everything they know, and they do it willingly in this industry. You lead by example. And the examples I’m giving you are true leaders.”

Workman has also written for the United Association’s (UA) apprentice curriculum and judged its apprentice program. “Training is training,” he says.

Working on the national apprentice training committee was Workman’s first introduction to AFSA and the start of a decadeslong relationship. After attending that first convention in Atlanta in 1996, Workman joined and became involved in many of AFSA’s projects and initiatives.

Workman served as a judge for several National Apprentice Competitions (NAC). When AFSA established its scholarship essay contest to educate the public and high school students about sprinkler systems and the industry, Workman volunteered to serve as a judge for several years. That required him to read many batches of essays written by students. “I enjoyed reading the essays. I was surprised by how many there were. Workman comments. “It was gratifying to see the attention the trade was getting from young people.”

Workman was invited to represent AFSA on the NFPA 30, Flammable and Combustible Liquids Code, committee in the late 1990s. That led to serving on numerous committees, including NFPA 30b, Code for the Manufacture and Storage of Aerosol Products; NFPA 13, Standard for the Installation of Sprinkler Systems; NFPA 11, Standard for the Low-, Medium, and High Expansion Foam; NFPA 401, Standard on Aircraft Hangars; NFPA 415, Standard on Airport Terminal Buildings, Fueling Ramp Drainage, and Loading

Walkways; NFPA 423 Standard for Construction and Protection of Aircraft Engine Test Facilities; NFPA 502, Standard for Road Tunnels, Bridges, and Other Limited Access Highways. He has served as a principal member on all the committees except for NFPA 502, where he is an alternate member.

Workman also served on AFSA’s Technical Advisory Council (TAC), which was established to address technical issues and NFPA codes and standards related to the fire sprinkler industry. Forty contractors, designers, and engineers from around the country served on the TAC during this time, comprised of AFSA representatives on NFPA technical committees, sprinkler manufacturers from AFSA’s Manufacturers/Suppliers (M/S) Council, and AFSA staff.

“It’s impressive to see such a large contractor presence in the TAC, says Workman. The members are very committed to their craft and profession,” says Workman.

Workman is also a member of the National Fire Protection Association (NFPA), National Fire Sprinkler Association (NFSA), and Society for Fire Protection Engineers (SFPE). He has served as a presenter, author, and trainer for ABC, AFSA, and NCCER. Workman is NICET Level II Special Hazards and Level III Sprinkler Layout certified and is considered an SME for NCCER.

“Martin has been a staunch advocate for fire sprinkler systems. His involvement with industry associations demonstrates his commitment to advancing life safety systems,” comments James Golinveaux, chairman of the board for The Viking Group. “Through his participation with NFPA, he actively contributes to the development and refinement of fire protection standards, ensuring they meet the highest safety and efficiency criteria.”

Peninsula Fire Protection was a customer of Mike Bosma’s at Viking, and in the mid-90s, that relationship changed the trajectory of Workman’s path in the industry. “He asked if I’d ever be interested in working for Viking, but I was happy at Peninsula,” Workman remembers. “By 1997, though, I was ready for a change.”

Bosma, currently president of Viking SupplyNet, notes that Workman always had a real passion for the business. “I felt we needed someone with that contractor perspective, and we’ve

benefited greatly from Martin’s passion for the industry, customer service, and training. Many of our products today have his fingerprints all over them, especially on the valve and special hazards side. He was instrumental in developing dry ESFRs, new versions of dry valves, and integrated systems.”

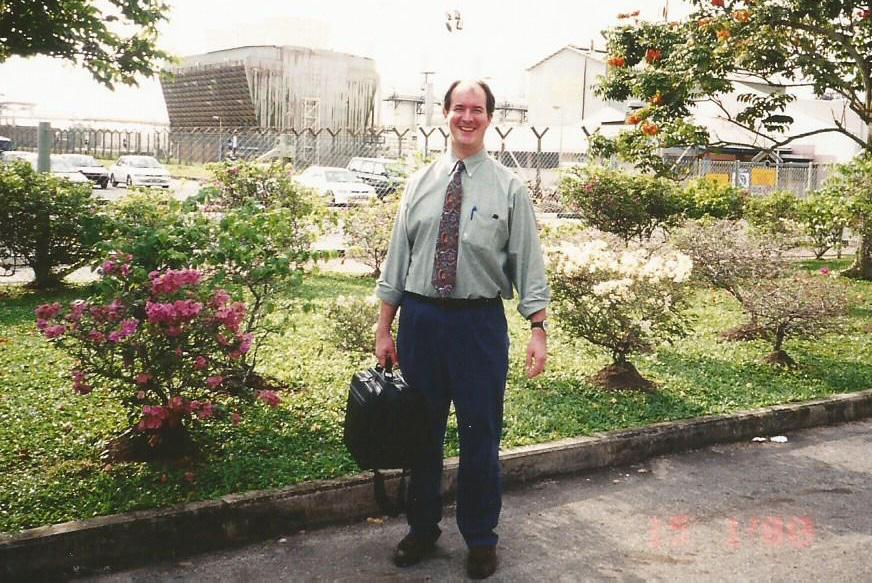

When Workman started at Viking, he created many training presentations covering wet, dry, deluge, special hazard, and preaction systems. “We had to create all that curriculum,” Workman notes. “Traveling globally, you’re leaving those presentations about good fire protection everywhere,” Workman notes. “Viking has a long history of commitment to training. Dick Groos taught our very first training program!”

One of Workman’s tasks was to travel with the salespeople to meet customers and bring back feedback. From that first trip out of Michigan to Washington, D.C., Workman has now traveled the globe—throughout North and South America, Europe, Asia, the Middle East, Australia, New Zealand, South Africa—and was able to see how the installation of fire sprinklers differed from the U.S.

Going on sales calls to customers and sharing information were highlights from those days. “If you have a great idea, it’s nice, but if no one else likes it, it doesn’t work,” Workman notes.

He says those sales calls were where he saw his efforts pay off. “As I’ve traveled the world, I’ve been able to share trade experience with others. Viking has often been asked for assistance, and we’ve been able to contribute to many country and global standards. I’m lucky to be at a company supporting that willingness to help. It’s hard when you’re at other companies that don’t see value in training and volunteering.”

Workman rose to product manager at Viking, overseeing its entire product line. One of his responsibilities was chairing an internal New Product Development (NPD) group, which identifies new products and prioritizes projects for research and development. In 2010, Workman rose to vice president of product management, which recognized his role in product management and new product development for Viking. He continued to chair the new product development team and manage the Viking product line, and became instrumental in setting up and managing its non-water-based system products. He was also a significant factor in the continued development of the Viking seminar and numerous training efforts within the company and the sprinkler industry.

In March 2021, Workman was promoted to senior vice president, product experience, where he continues to develop products, business, digital initiatives, special hazard sales, training, and technical services for Viking. He also continues his involvement with research and development, manufacturing, and marketing to develop products for the industry.

All his roles at Viking have required Workman to travel extended periods away from home and family. He was on the road for many years, and then COVID hit. “We all stopped traveling for a while, but it happened at a good time when I needed to be home,” Workman says.

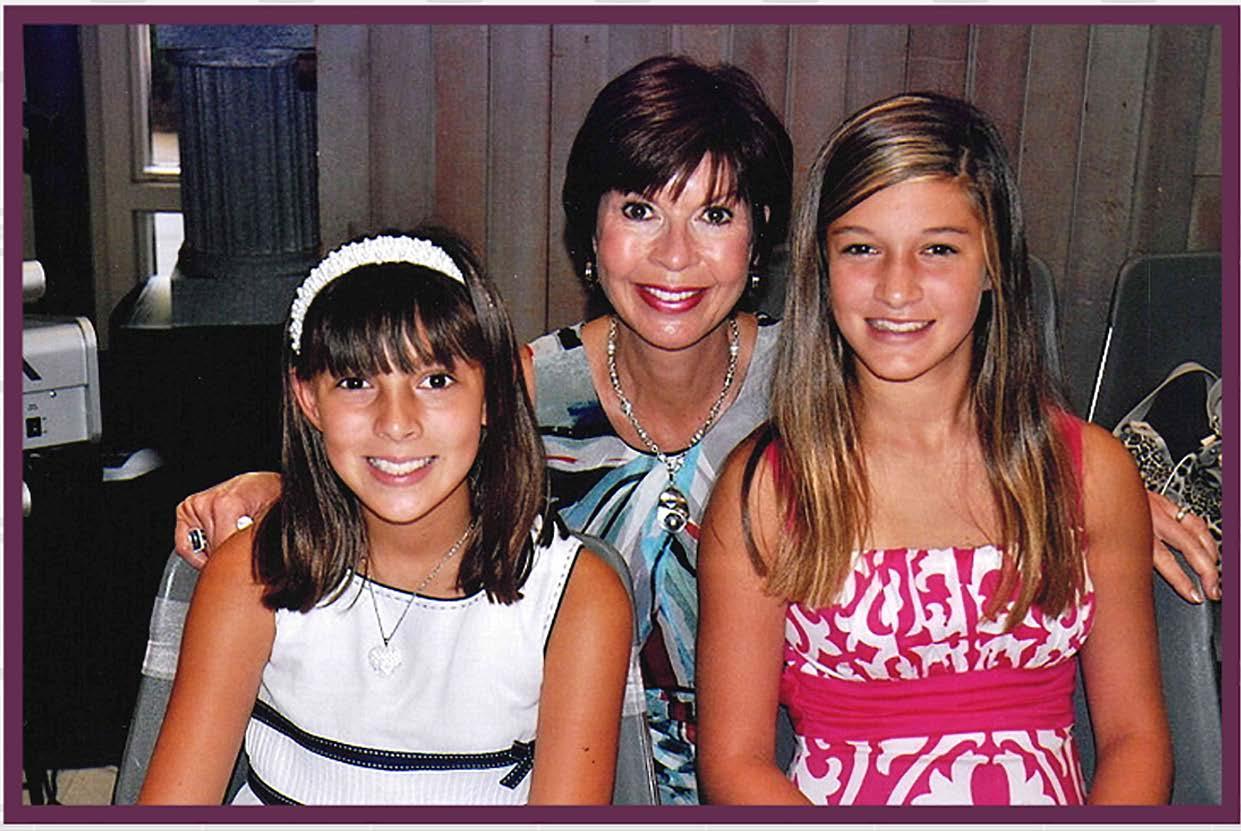

Family is extremely important to Workman. His wife, Tracy, has been by his side from the beginning, always supportive and just as committed to the industry and its people. “I remember when I was still fitting pipe, and I had some work release individuals working on a job. I shared my lunch with some of them when we broke for lunch because they had nothing. I was telling Tracy about it that night. The next day, I opened my Igloo, and she had also made lunch for them. From then on, she made lunches for all those men who worked for me.”

Tracy was also instrumental when Workman was developing the national apprenticeship training materials. “I’d have the dining room table covered in papers and books,” Workman remembers. “If Tracy came in and read what I’d written and could understand it, then I knew the apprentices would, too,” Workman remembers. “If she came with me to a trade show, she would help man the booth. She knows what I’m talking about because she’s been involved with this industry right along with me.”

The couple had four children along the way—Jessica, Martin II, Emily, and Kaleigh—and Workman gives Tracy all the credit for raising them while he constantly traveled. “I wasn’t home a lot of nights, and she’s made a lot of sacrifices for me. I really appreciate her and the kids for all they’ve done.”

The Workmans’ children have grown up and had families of their own. Daughter Jessica has three children, Jacob, Emilia, and Lucas; son Martin II and wife Candance have one daughter, June; daughter Emily and her husband Gredual have three children, Oliver, Lydia, and Emma; and daughter Kaleigh and her husband Francisco (Frankie) also have three children, Frank Martin and Edison.

The Workmans’ wedding day, August 29, 1986, with lifelong friends David Hickox and Julie Hooper by their sides.

Tracy was initially diagnosed with cancer in 2015. After surgery, it appeared she was good. In 2017, she was diagnosed with cancer again and is undergoing various treatments. In 2024, Tracy was diagnosed with chemotherapy-induced leukemia in 2024. “I seriously thought about retiring when Tracy battled that first bout of cancer, and she said I’d drive her and myself crazy if I did,” Workman remembers with a smile. “Our children have been wonderfully supportive, and her doctors are great,” comments Workman. “Cancer really changes your perspective,” he notes, “but we’re going on 39 years together, ready for our 40th, and pushing towards our 50th!”

The couple currently resides in the country outside of Delton, Mich. Workman isn’t planning to retire anytime soon, but is setting that up for the long term. “It’s always time to move on at some point,” he notes. “I’ve thoroughly enjoyed being

involved in the fire protection industry, but I’m looking forward to more time with Tracy, the kids, and grandkids.”

What are Workman’s thoughts on the future of the sprinkler industry? We’re behind. “Industry always seems to be 20 years ahead of product development in fire sprinklers. What we once knew in storage is now changing at a fast pace, and the standards are having a hard time keeping up with it. We will soon have warehouses without aisles, and maybe no people. Automated retrieval storage racks and robotic top-loading and side-loading storage are here today. At the moment, NFPA 13 has to say these facilities are out of its scope.”

Boat storage is one example. Workman notes that Michigan has more lakes than any other state, and boat storage abounds and has been built with sprinkler protection. Yet NFPA 13 doesn’t cover that.

“Going forward, we will see more dependence and reliance on manufacturers for testing,” Workman notes. “Customers don’t listen to us like they used to. We’ll say, ‘Don’t use plastic,’ and they say, ‘That’s what we use.’ ‘Don’t store with automatic retrieval systems,’ and they say, ‘Well, that’s how we store.’”

He continues. “The future is exciting to me because of new technology and new needs,” Workman says. “We’ve disproved what we thought we knew from much of the storage testing we did decades ago. I can see us going back to doing more in-rack sprinklers with a smaller K-Factor because you need them in more spaces. There are definitely some challenges for the industry, and they always come from the contractors. Oftentimes, they are plowing the new trail. ‘Sprinkler per 13’ is the norm, but when it’s out of scope, you get involved with insurance and local Authorities Having Jurisdiction (AHJs).”

Workman sees the residential area as the biggest growth market, with the most significant opportunity. “That’s where I think we run into the people problem—not enough of them to fulfill the public’s safety needs. Most people end up here accidentally, and a few are born into the trade. The trade found me, yet I didn’t know I was lost!”

Workman sees recruitment as a continuing challenge for this industry. “How do we make the trade interesting? I don’t think people really understand that this industry is not a place you end up; it’s a launch pad.”

To that end, Workman and Viking work with the AFSA Virginia Chapter in its recruitment efforts. During the chapter’s annual career fair, Brian Berkley with Viking travels down with virtual-reality (VR) headsets that introduce the industry in a gaming-type experience for students. “It gives the upcoming generation a taste of the trade and lets them know about our great opportunities,” comments Workman. “I’m a perfect example of how far someone can go in this industry. I started at $3.50 an hour and didn’t know much of anything. This trade rewards you if you have an above-average work ethic.”

Workman is calling for industry professionals to get involved. “The more we can promote our trade, the better, because it’s such a positive one. I always tell people that the result of what I do saves lives and property. We install sprinklers in buildings according to a prescriptive code, which means it’s been tested and approved.”

He continues. “I also want to really encourage everyone to participate in the NFPA process. So many think it’s an old boys’ club, and it’s not. Anyone can submit a change, and it must be read. All Underwriters Laboratories’ standards are also consensus documents,” he notes. “If you don’t like something, you want to contribute. Simply reach out to someone, and they’ll help you. The entire trade is full of people who want to enable each other. Once you submit a public input, the organization must tell you what they did with it.”

In 1983, AFSA created its highest honor, the Henry S. Parmelee Award, to recognize an outstanding individual who has dedicated himself or herself to the fire sprinkler industry and the goal of fire safety through automatic sprinklers. AFSA will present this year’s award to Workman during AFSA44: Convention, Exhibition, and Apprentice Competition, to be held Oct. 15-18 at the Gaylord National in Washington, D.C. The presentation will be the highlight of the general session on Friday, Oct. 17.

“Martin embodies the essence of the Parmelee Award,” says Golinveaux. “His leadership within The Viking Corporation and the broader fire protection industry, relentless advocacy for fire sprinkler systems, and unwavering dedication to education and training make him a worthy recipient of this prestigious honor. Martin’s contributions have not only advanced protection technology and standards but have also inspired and educated the next generation of professionals dedicated to fire safety.”

“This year, we had a great group of nominations. When it came to Martin’s bio, involvement with AFSA, his commitment to training, and glowing recommendations from James Golinveaux [past award recipient] and Janet Knowles, one of my mentors when I joined the Board, he was an excellent choice!” comments AFSA Chair of the Board Linda Biernacki, president of Fire Tech Systems, Inc., Shreveport, La. “I am so pleased that we will honor his

The COLLECTanDRAIN Model 5500 prevents system freeze ups by enclosing the dry fire sprinkler system’s auxiliary drain in a temperature controlled environment, and it features automated supply and drain valves that automatically maintain the auxiliary drain according to NFPA 13. Install them now and be ready for winter!

KEVIN HALL, M.ENG., P.E., ET, CWBSP, PMSFPE | AMERICAN FIRE SPRINKLER ASSOCIATION

The 2025 edition of NFPA 13, Standard for the Installation of Sprinkler Systems , introduces key updates to the hydraulic calculation requirements for supplemental sprinklers. These sprinklers, installed under obstructions, ensure adequate water distribution when ceiling-level sprinklers are blocked by wide obstructions below. The new requirements clarify when and how these sprinklers should be included in system calculations, preventing unnecessary overdesign while maintaining fire protection effectiveness.

NFPA 13 specifically defines a supplemental sprinkler as “a sprinkler that is installed below an obstruction.” While this definition could be broadly applied to many sprinklers in a layout based on their positioning, the intent is to apply the requirements for supplemental sprinklers that are added below wide obstructions completely below the level of the sprinkler deflector, and there is full coverage above from the sprinklers installed at the ceiling level. It is not the intent to apply these requirements to sprinklers added below obstructions at the ceiling level to account for sprinkler discharge pattern development.

For the characteristics of the sprinkler itself, the layout technician has more options. Regardless of the type of sprinklers installed overhead, the supplemental sprinkler is only required to have a fast-response thermal element and be ordinary temperature rated. It is preferred that they match K-factor and orientation of the ceiling sprinklers, but it is not necessary if the supplemental sprinklers are calculated. If another sprinkler makes sense based on hydraulics or economics, it can be used as long as it is calculated.

As stated in previous editions of NFPA 13, it is not the intent to calculate supplemental sprinklers when the sprinkler matches the characteristics of the ceiling sprinklers and the piping supplying the supplemental sprinklers matches the sizing pattern of the branch lines. Where differing characteristics are necessary or desired, the supplemental sprinklers need to be calculated. NFPA 13 now clearly states that when the supplemental sprinklers are calculated, they are calculated separately and independently from the sprinklers installed

Discharge requirements for supplemental sprinklers are based on the hazard directly below the obstruction. This can benefit the designer, allowing them to use less restrictive discharge criteria for lower ceiling elevations.

at the ceiling level overhead—no balancing. This allows for more flexibility when designing systems with supplemental sprinklers.

If the piping configuration does not match the branch line sizing pattern, hydraulic calculations must be conducted to confirm that pipe sizes can adequately support the supplemental sprinklers. To calc or not to calc? Prior editions of NFPA 13 fell short after this simple guidance. How many supplemental sprinklers do you calculate? What is the design area? The number of supplemental sprinklers included in the calculation depends on the arrangement of sprinklers under the obstruction, and the standard offers two options:

1. If there is a single line of supplemental sprinklers, calculations must include four adjacent sprinklers on the same branch line. 2. If there are multiple lines of supplemental sprinklers, calculations must include two sprinklers on two separate branch lines.

The next missing piece of information is the area of coverage of the supplemental sprinkler. In density/area-based applications, the area of coverage for each supplemental sprinkler must only include the footprint of the obstruction it protects. This prevents the calculation from incorporating unnecessary coverage areas beyond the obstruction, as the supplemental sprinklers are only intended to operate when there is a fire directly below the wide obstruction; otherwise, the ceiling-level sprinklers provide adequate protection.

The discharge criteria are simplified even further by only requiring the hazard directly below the obstruction to be considered.

For density/area applications, the design must comply with section 19.5, which defines water density requirements based on hazard classification. While there probably isn’t a different occupancy classification in such a small space, the benefit of this requirement is that it permits ceiling height to be considered at the bottom of the obstruction. This could allow for other adjustments, but it is probably more beneficial when you consider the storage application. If Control Mode Specific Application (CMSA) or Early Suppression Fast Response (ESFR) sprinklers are used as supplemental sprinklers, their discharge pressure must comply with section 20.16.4, ensuring their proper function within the system. Again, that discharge pressure would be based on a lower ceiling height at the bottom of the obstruction which could decrease the hazard. As an example, an ESFR system protecting 15 ft of storage in a 30 ft building requires a minimum end-head pressure of 52 psi for K-16.8 sprinklers. If sprinklers were installed below a wide obstruction with the bottom of the obstruction only at 25 ft, the minimum end-head pressure for K-16.8 sprinklers could be reduced to 35 psi allowing for smaller pipe sizes to be used.

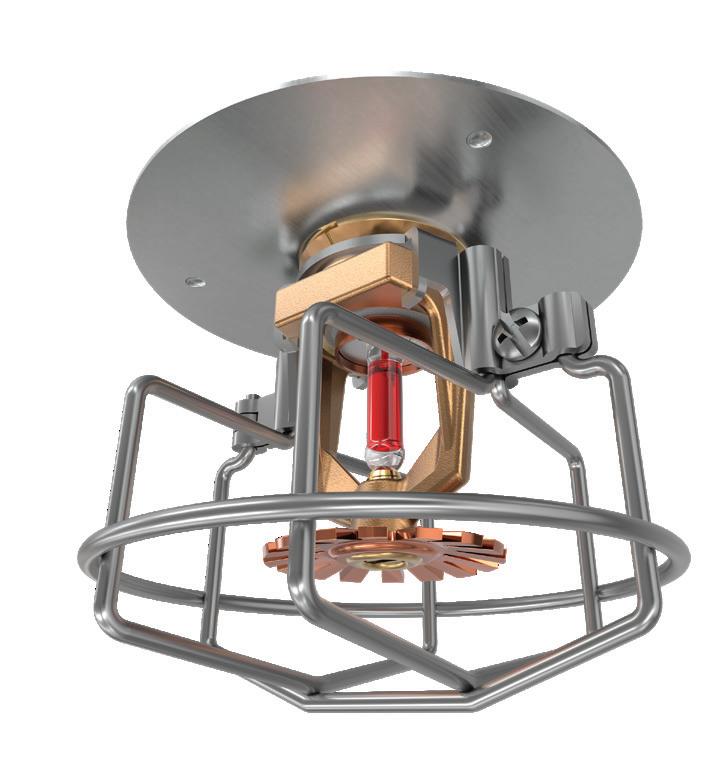

Beyond the hydraulic calculation requirements, the 2025 edition of NFPA 13 introduces additional installation requirements for supplemental sprinklers based on the shape and orientation of the obstruction. If supplemental sprinklers are installed under non-flat, non-solid obstructions, beyond the edge of an obstruction, or under open grating, they must be intermediate-level

rack-type sprinklers or provided equivalent protective measures to prevent cold soldering. While NFPA 13 did provide definitions for non-flat and non-solid obstructions, most designers should be able to figure that one out on their own.

The 2025 edition of NFPA 13 refines the requirements for supplemental sprinklers, clarifying when they should be included in hydraulic calculations and how many should be considered. Remember—NFPA 13 provides guidance in the annex that newer editions of the standard should be permitted to be used, in their entirety, through equivalency. Designers who take advantage of the technologies and methodologies in newer editions can design more efficient, codecompliant sprinkler systems that effectively address obstructions—and other issues—while avoiding excessive hydraulic complexity. n

ABOUT THE AUTHOR: Kevin Hall, M.Eng., P.E., ET, CWBSP, PMSFPE, is the director of engineering for AFSA. He is a member of several NFPA technical committees responsible for developing the model codes and standards, including NFPA 1 Fire Code, NFPA 13/13R/13D, NFPA 20, NFPA 25, and NFPA 200. Hall also represents AFSA on numerous UL technical committees responsible for revising and maintaining the product standards used in the sprinkler industry. He is a registered professional engineer in Delaware and Maryland, NICET III certified in water-based system layout, a certified water-based system professional through NFPA, and a professional member of the Society of Fire Protection Engineers (SFPE). He earned his Bachelor of Science and Master of Engineering degrees from the University of Maryland, College Park, in fire protection engineering. In 2021, he was recognized as one of SFPE’s “5 Under 35” award recipients. Prior to his association and committee work, Hall worked for Reliance Fire Protection in Baltimore, Md., as a project manager overseeing projects of various sizes and complexity.

Seven of the nation’s top apprentices will compete in the 32nd National Apprentice Competition (NAC) during AFSA44: Convention, Exhibition & Apprentice Competition, Oct. 15-18 in Washington, D.C. These finalists will put their skills to the test with a written and hands-on competition vying for cash prizes and national recognition. Showcasing the best talent in the fire sprinkler industry, this exciting event is one you won’t want to miss!

The National Apprentice Competition (NAC) was started in 1994 by the late Robert (Bob) L. McCullough, then chair of the Apprenticeship & Education Committee. The NAC was created to promote apprentice training and recognize apprentices who are actively enrolled in the AFSA Apprenticeship Program.

Eligibility for apprentices to compete is based on the following criteria: their employer must be a member of AFSA in good standing, the apprentice must actively be participating in the AFSA apprenticeship courses or enrolled in the NCCER/AFSA Fire Sprinkler Fitting Training Series, and they must have at least one year of field experience with a minimum of six months combined hands-on experience in cutting, threading, and installing steel pipe and CPVC pipe. The first competition phase consists of a

100-question multiple-choice exam provided by AFSA. The test is proctored online, making it accessible to contestants from all 50 states. The results of this test will determine who will go on to participate in the live competition at AFSA44.

The top seven apprentices in Phase I receive: a full registration to the convention and a second full registration for their employer; an expense-paid trip to AFSA44; hotel accommodations; and a brand-new set of hand tools to use in Phase II.

Phase II entails a more thorough written exam given at the convention, followed by a live practical installation in the exhibition hall. The Phase II exam is based on all four levels of the AFSA/ NCCER Contren® Learning Series Sprinkler Fitting curriculum. For the installation, apprentices must cut, thread, and install a steel and CPVC piping system with sprinkler heads and perform a water pressure test. Participants are graded on accuracy, craftsmanship, and safety. The combined results of the Phase II written and hands-on tests determine the winner. Prizes are awarded based on finishing rank: first place takes home a $10,000 cash prize, second place receives $7,500, third place receives $5,000, and all other finalists receive $2,500.

Seven of the nation’s top apprentices are heading to Washington, D.C, where they’ll compete on a national stage at

AFSA’s annual convention. Who will take home the grand prize and bragging rights? Sprinkler Age caught up with each finalist for a quick Q&A so you can get to know them before they hit the competition floor.

Leona Ball, Piper Fire Protection, FL

What’s your favorite part about the work you do? My favorite part is working with my hands and using tools to build fire sprinkler systems.

If you had a superhero power on the jobsite, what would it be? If I had a superhero power, it would be flight, so I can hang pipe without using lifts and ladders.

Stephen Dolan, Rieve Fire Protection, CT What advice would you give someone thinking about entering the fire protection trade? When you first start, your job is to make everyone else’s job easier and more efficient. Ask questions as you go, don’t try to be an expert.

What does the future of the industry look like to you? I see the maintenance side of things exploding in the next few years as AHJs implement automation to track and enforce deficiency solutions.

Raul Larios, Hiller Companies, CA

What’s the key ingredient to your success? My family. They always drive me and motivate me to better myself for them. They’re pushing me towards being successful.

What’s something you’ve learned in this trade that surprised you? The amount of people who don’t even know what a fire sprinkler is.

Christopher Redman, J.G. Tate Fire Protection System, Inc., CA Why did you

choose to pursue a career in fire protection? After being a firefighter, I loved putting fires out and wanted to do life-saving work. What advice would you give someone thinking about entering the fire protection trade? To remember you are doing life-saving work and don’t cut corners.

Corbin Rogers, Rapid Fire Protection, Inc., SD What’s your favorite part about the work you do? Besides saving lives, one of the main things I enjoy about the fire sprinkler industry is the puzzle of installing systems. Things like what is the best way to install this system or what rules and codes are applicable to what I am doing right now.

If you had a superhero power on the jobsite, what would it be? The power to communicate better. Information is power and being able to share ideas more effectively would be an incredible power to have.

Kyle Strickland, Marmic Fire & Safety, AR Why did you choose to pursue a career in fire protection? When I pursued this career, I was looking for a trade/ company that I could grow in. I take pride in my work and love seeing it operational.

What’s something you’ve learned in this trade that surprised you? I was surprised by all the different styles of systems and heads.

David Walencewicz, Impact Fire Services, CT What’s something you’ve learned in this trade that surprised you? One thing about working in this trade that surprised me is how tight-knit the fire protection community is.

What does the future of the industry look like to you? I envision our industry maintaining its unique, passionately dedicated work culture as it also advances and adapts to new technologies and infrastructures.

Get ready for an unforgettable showdown as the finalists go head-to-head in the nation’s capital in the heart of the exhibit hall at AFSA44. The excitement is building, and AFSA44 is bursting at the seams with education, training, and non-stop FUN. Whether you’re there to learn, network, or just soak it all in, there’s something for everyone. For more details and to register, visit firesprinkler.org/AFSA44. n

Fayette Pipe delivers with 100% hydrotested, American-made and melted pipe crafted by a veteran- and family-owned company.

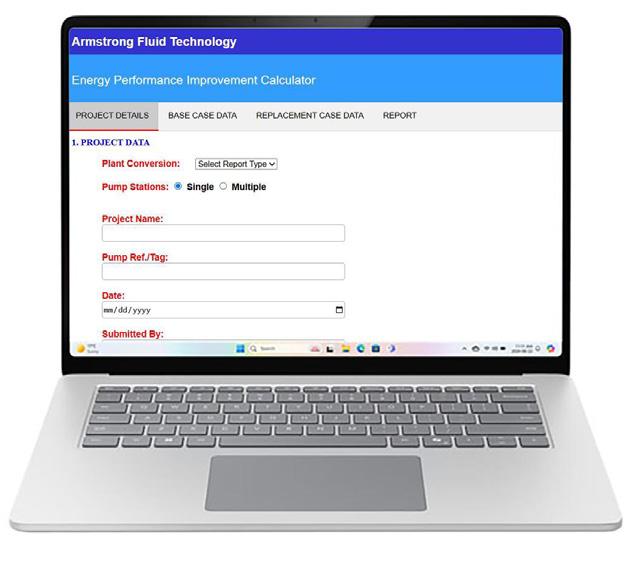

BOB CAPUTO, CFPS | AMERICAN FIRE SPRINKLER ASSOCIATION

For a few years now, I’ve been banging the drum, trying to convince others that we need to recognize an occupation for inspection and testing, separating it from installation as a matter of training and practice. What do I mean by that? It’s long been the practice of fire sprinkler contractors, whether signatory or open shop, to assign fitters to perform inspection and testing activities. I believe this is wrong and opens contractors up to serious liabilities.

[Your Company Letterhead]

[Date]

U.S. Department of Labor c/o AFSA

1410 E Renner Rd., Suite 150 Richardson, Texas 75082

RE: Letter of Commitment for an ITM Apprenticeship Program

Let’s compare this to automobile manufacturing and maintenance work. If I work on the assembly line at Ford or General Motors, building cars and trucks, does this qualify me as a service mechanic for those vehicles? Obviously no, because there is much more to ensure the safe functionality of the car than just knowing my part of the assembly process. The same is true for fire sprinkler systems.

Let’s consider experience and regional knowledge. Fitters in southern California, southern Florida, and other warm-weather

states install many wet pipe systems. Still, aside from coolers or freezers, they do not install many dry-pipe, pre-action, or deluge systems. I didn’t say they don’t see any of them, but surely not as many or as often as sprinkler fitters in Minnesota or Iowa. How about fire pumps? When I was a fire sprinkler contractor in San Diego, we installed systems in six-story buildings downtown without needing a fire pump. The water pressure in parts of San Diego County needs pressurereducing valves because the pressure is very high. Fitters in this region have installed very few fire pumps, unlike their counterparts in many other parts of the nation. Of course, the same can be said of inspection and testing opportunities, but in the course of a year’s worth of work, a dedicated inspector will see many more sites and conditions than would a fitter on construction sites.

[Your Company Name] is pleased to offer its full support for the proposed Inspection Testing, and Maintenance (ITM) Apprenticeship Program being developed by the American Fire Sprinkler Association (AFSA). We believe this program is a vital step toward developing a skilled talent pipeline for the fire sprinkler industry in the [Your City/Region] area.

As a leading employer in this region, we have identified a significant shortage of skilled ITM inspectors and technicians. We have been actively involved in developing the curriculum and standards for this program, and we are confident that it will produce highly qualified workers. We project that our company will have approximately [Number] openings for ITM inspectors and technicians in the next [Number] years. We commit to hiring graduates of this program and providing them with high-wage opportunities.

Our commitment to this program includes:

• Providing [Number] paid on-the-job training slots for ITM program apprentices.

• Allowing company mentors to assist with curriculum development and apprentice supervision.

• Donating [materials/equipment] to support the hands-on training component.

We are eager to continue our partnership with AFSA and the Department of Labor to ensure the success of this initiative. This investment will not only benefit our company but will also provide excellent career opportunities for local residents. Thank you for your consideration.

Sincerely,

[Your Name], [Your Title] [Your Email Address]

Inspection and testing of fire sprinkler systems should be a separate, stand-alone job because they require a distinct knowledge base and utilize a different set of rules. Specifically, NFPA 13 provides rules for designing and installing fire sprinkler systems. In contrast, NFPA 25 provides the requirements for inspection, testing, and maintenance of those and other water-based systems. NFPA 25 explicitly states that it is not the standard’s intent to have the inspector verify the adequacy of the installed system. The standard is based on a wear and tear approach to inspection and testing. It does not intend for the technician to have the knowledge base to determine if a system is installed correctly, designed for the current building use, or adequate for the current storage use or products. Nothing in the sprinkler fitter apprenticeship program prepares or trains fitters to perform inspection and testing activities. However, the knowledge of the equipment and system components can provide a great foundation.

Even if the training was modified to train sprinkler fitters to perform required inspections, few fitters spend enough time away from contract work to be knowledgeable or practiced enough to be effective and limit their employers’ liability. Moreover, let’s talk about the lack of manpower in our trade, as it has been in all construction trades.

We all know our industry needs to attract more people at every level. This is especially true for qualified layout technicians, fitters, and inspectors. Many contractors tell us they could book more work if they could find more skilled people. Identifying inspectors in their own role will aid our industry and relieve some pressure on the need for more fitters. Inspection and testing do not require a four-year apprenticeship program to create qualified or certified workers. For starters, more wet pipe systems are installed than any other system type, and it doesn’t take more than six months to a year to train on these requirements. The NICET (the National Institute for the Certification of Engineering Technologies) water-based ITM Level 2 certification requires a candidate to have only two years of practical experience to sit for that test. The Level 3 certification requires five years of experience, which allows newly minted inspectors to work toward performing necessary inspections and testing on more complex systems, including dry-pipe, deluge, pre-action, fire pumps, and special hazard systems.

This role will attract more females, who currently only represent 3.1% of sprinkler fitters,¹ and others to the workforce, who may not be interested in pulling wrenches thirty feet in the air on a hot summer or cold winter day. Since most inspection and testing roles involve a lot of customer service interaction and are performed in existing, occupied buildings, the role will appeal to people who may be aging out of traditional installation roles, along with people from other service trades.

Unless you have been wearing blinders these past few years, many of the industry’s largest contractors have been focused on recurring revenue streams. Building their business book on inspection and testing while steering away from new construction projects. The consolidation, mergers, and acquisitions activities pervasive over the past

few years have offered much greater multipliers on recurring revenue streams than on the limited value of non-recurring revenue realized by a limited backlog of new construction work. It makes sense to the investment market, and our industry should read the tea leaves and respond to the trends by providing the workforce needed to meet the demand.

So, seriously. Our industry must create a new occupation category with well-trained, certified inspection and testing technicians. AFSA has been working toward getting the U.S. Department of Labor (DOL) to recognize this as its own occupation and create a DOL-approved apprenticeship program. Surprisingly, our application was

rejected the first time we submitted it. The process took over a year, and we are resubmitting the application with more support for the concept from the contracting community. If you agree with the need to recognize inspectors in our industry as a specific occupation, write a letter in support (see sample). Letters in .pdf form can also be emailed to valentine@firesprinkler.org. n

REFERENCES:

¹ “Sprinkler Fitter Demographics and Statistics in the US”, Zippia The Career Experts, zippia.com/sprinkler-fitter-jobs/ demographics, January 8, 2025.

ABOUT THE AUTHOR: Bob Caputo, CFPS, is president of AFSA.

On April 8, 2025, the Virginia Chapter of the American Fire Sprinkler Association (AFSA) conducted a board and members’ meeting at the Academy at Virginia Randolph located in Glen Allen, Va., to celebrate the grand opening of the new fire sprinkler lab and fire sprinkler curriculum at the school. The chapter meeting was a great success with 48 attendees and a delicious lunch expertly prepared by the HCPS culinary students.

Mac Beaton, director of workforce and career development, and Bev Cocke, M.Ed., administrative coordinaor of workforce development for Henrico County Public Schools (HCPS) presented a PowerPoint presentation on the genesis of the fire sprinkler lab and future projects moving forward with the chapter and HCPS. Virginia Chapter Board Member Mary Catherine Coyle, social media chair, prepared an excellent presentation on “How to Retain Employees” that was well received by the meeting attendees.

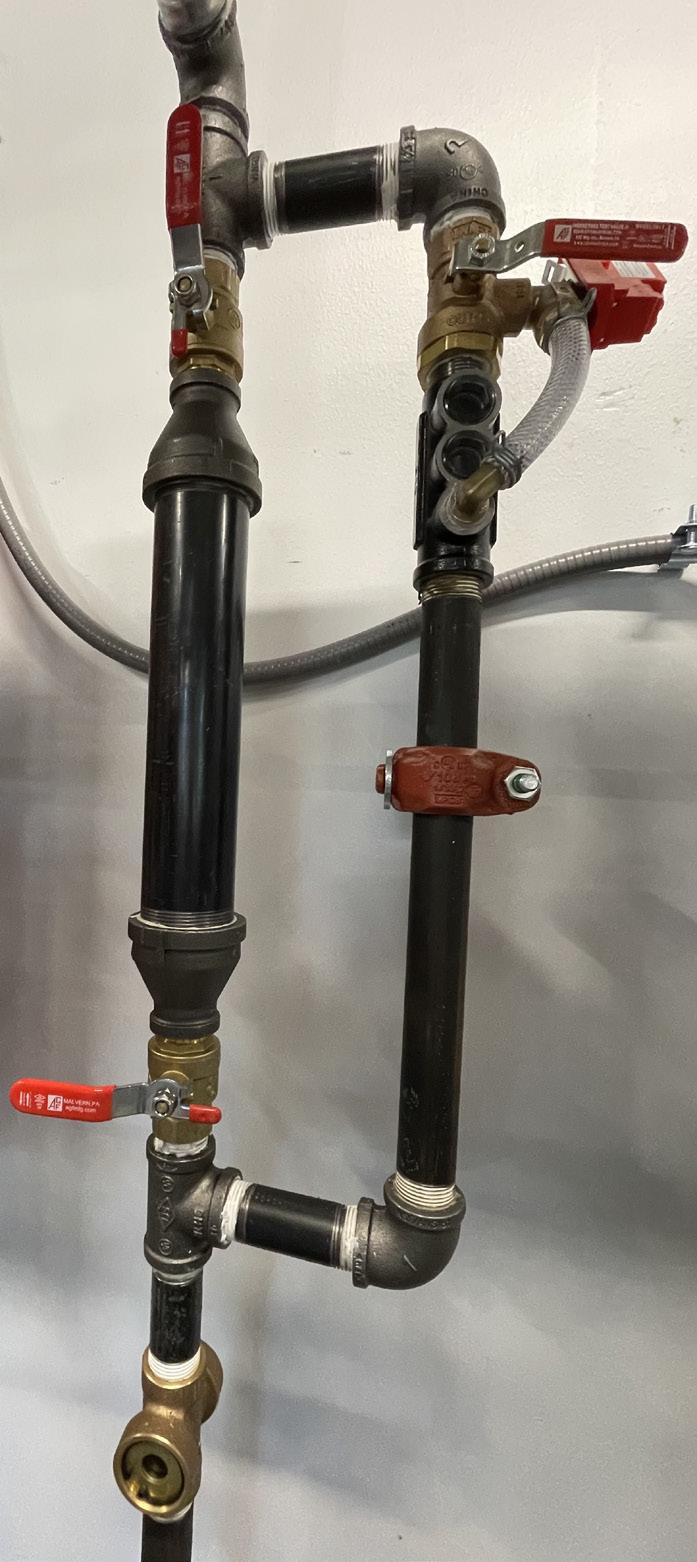

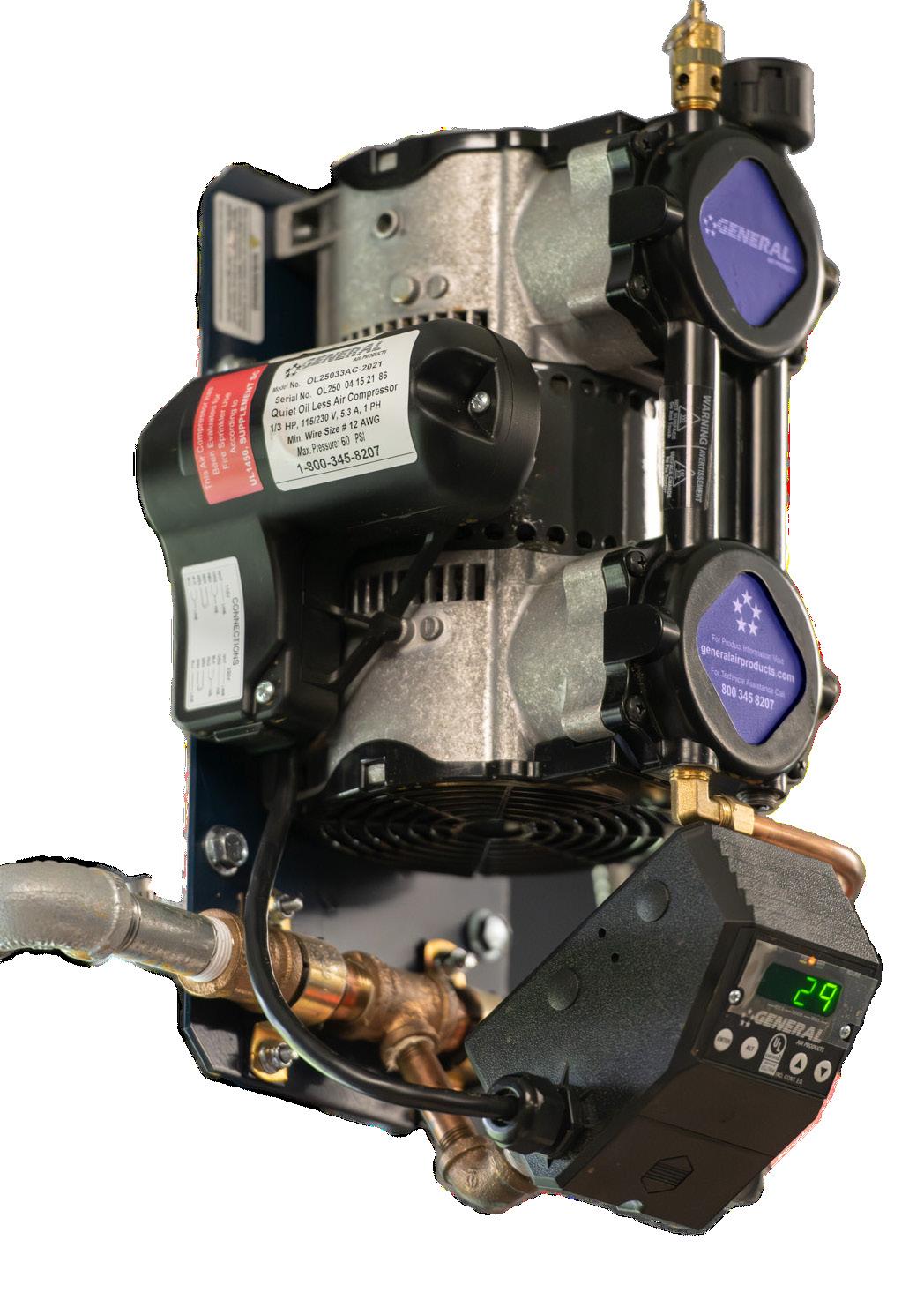

The fire sprinkler lab has active alarm, dry, pre-action and deluge valves for the students to use in training exercises during the semester. In addition, chapter vendor members donated an air compressor, backflow preventor, PRV valves, a fire alarm panel and a fire pump for additional training. Henrico County Public Schools also built out a glass-walled separate wet room with a large drain for the students to activate different types of fire sprinkler heads.

Jeff Lewis, chapter second vice president and education and apprentice chair led the effort with Beaton and Cocke to make these public private endeavors come to life. Lewis set this wildfire in a board meeting nearly four years ago and we have been trying to contain it ever since. We are looking forward to the next flare up!

Henrico County Public Schools approved and implanted a fire sprinkler curriculum that started last semester with four students and there are already 17 signed up for 2025-2026 school year. The new HCPS fire sprinkler program is utilizing the National Center for Construction and Education & Research (NCCER) sprinkler fitting training books for the instruction.

Chapter member Atlantic Constructors, Inc. provided an instructor to teach the class. Derek Zane has 25 years in the sprinkler industry as a new construction foreman and senior ITM technician. He brings his vast experience and enthusiasm to teach the next generation of sprinkler fitters and technicians.

The chapter is looking forward to providing the membership with opportunities to hire HCPS NextGen students for internships, part-time positions while in school, and eventually signing them on to full-time positions on HCPS Letter of Intent Signing Day.

The chapter greatly appreciates members who donated their time and talents for the HCPS fire sprinkler lab: Atlantic Constructors, Inc., Brooks Equipment Company, Ferguson Fire and Fab, Fire Pro, Inc., Johnson Controls, Inc., Reliable Automatic Sprinkler Company, Inc., VSC Fire & Security, Victaulic Company, Viking SupplyNet, and Zurn Industries. n

As a woman-owned business and having two young, goal-oriented women as p a r t of Fire Tech Systems and the fire sprinkler industry gives me hope for the next generation. I know that Emily and Nikki will create their path and engage i n amazing things at Fire Tech Systems and within our Industry. Pride and elation abound.

35 years and my greatest accomplishment yet has come to fr uition. My daughters, Emily and Nikki, have joined Fire Tech Systems. In 2023, Nikki joined me as the Director of Business Development and Manager of the Oxford, MS Branch office. T his year Emily joined us as Inspection Sales & Development, along with managing the new Texarkana, TX Branch.

1st Female Board Chair 2024-2025 1st Female Vice Chair 2022-2023 40th Convention Chair 2020-2021

- Board Chair 2022-2023 NFPA- 232 Committee Member LFSA- Past President, President, and Founding Member -Shreveport, LA 4 -Monroe, LA -Oxford, MS Locations -Texarkana, TX

CHRIS KACHURA, P.E. | VSC FIRE & SECURITY, INC.

NFPA 13, Standard for the Installation of Sprinkler Systems , first included Early Suppression Fast Response (ESFR) sprinklers in its text in the 1989 edition. Its installation requirements were first introduced in section 9-3.3.1.2 of the 1989 edition, and it had a requirement of 1/ 4 in. per foot maximum roof slope requirement, not just for ESFRs, but for all methods of storage protection . Between the 1989 edition and the 1999 edition of NFPA 13, the slope requirements fluctuated before landing on the 2 in 12 slope, where it has remained since the 1999 release . Limiting warehouses to 2 in 12 has placed a constraint on the flexibility of warehouse design and construction. With the release of the 2025 edition of NFPA 13, that slope maximum has expanded to 4 in 12, which will provide greater flexibility in this design and construction process. The intent of this article is to look at these new slope considerations and the rules that apply when faced with these new options.

The road to the introduction of the 4 in 12 slope inclusion in the 2025 edition of NFPA 13 started with an indepth study by the Fire Protection Research Foundation (FPFR). The FPRF is an independent research affiliate of NFPA that was formed in 1982 to support the growing need for research that better informed the expanding body of NFPA codes and standards. In January 2016, the FPFR released its first report on sloped ceilings for ESFR, CMSA, and CMDA sprinklers entitled “Protection

of Storage Under Sloped Ceilings – Phase 1.” This was followed in October 2017 with its second report entitled “Protection of Storage Under Sloped Ceilings – Phase 2 – Test Matrix,” and a November 2017 report entitled “Protection of Storage Under Sloped Ceilings – Phase 2 –Measurement of Sprinkler Spray Patterns and Impingement Near Sloped Ceilings.” These reports include the test information that formed the basis for the 2025 edition of NFPA 13 new rules for sloped ceilings. These reports can be found online at nfpa. org/education-and-research/research/ fire-protection-research-foundation/ projects-and-reports/protection-of-storageunder-sloped-ceilings.

The new design requirements for storage under sloped ceilings can be found in section 20.9.1 of NFPA 13.

Section 20.9.1 still limits storage protection to a 2 in 12 slope except for the criteria listed in section 20.9.1.1. These protection requirement options are as follows:

1. In-rack sprinkler protection in accordance with one of the options in section 25.7, with no storage to be placed above the highest level of in-rack protection.

2. An installed horizontal false ceiling below the sloped ceiling that is capable of withstanding a 3 lb/ft² uplift force. False ceiling to have sprinklers installed in it.

3. Sprinklers to be installed per chapters 20 through 26 guidance, where slopes exceeding 2 in 12 are allowed.

4. Where the ceiling is obstructed, construction and it does not exceed 4 in 12 storage, shall be protected with a CMDA sprinkler approach and shall require sprinklers in every channel.

5. Where the ceiling is unobstructed construction and the slope does not exceed 4 in 12, storage shall be protected with a 50% increase in the design area requirements of chapter 20 through 26 for sloped ceilings.

6. Where the ceiling is obstructed construction, and it does not exceed a 4 in 12 slope, sprinkler system criteria specified in chapters 20 through 26 shall be used when all of the following criteria are met.

a. Purlins or beams for the roof framing run across the roof slope.

b. 18 in. maximum depth for the purlins or beams.

c. 5 ft or less on center for the purlins.

d. 40 ft on center maximum for bays created with solid structural members.

e. Blocking above each structural member is provided for purlin or beam channels.

CMSA sprinkler installation under a 4 in 12 maximum slope is addressed in section 13.2.6.1.2.3 of the 2025 edition of NFPA 13. This section is limited to obstructed construction only, with less than or equal to 50% of the ceiling structure open. This open consideration has to do with the structural members and the pockets that they create. This is important to the activation of the sprinklers. The intent of CMSA and ESFR sprinklers is to localize the sprinkler activation to the area over the fire to deliver the water discharge in the most effective manner. When the ceiling is to open, heat is allowed to roll up the slope, allowing heads outside of the fire area to activate. Per section 13.2.6.1.2.3, sprinkler installation shall be arranged in one of the two following arrangements:

1. Sprinklers shall be installed in each individual channel created by the roof structure and shall have a deflector depth below the ceiling/roof deck of 6-in. minimum and 12-in. maximum.

2. When channels are created by the roof structure by maximum 12-in. deep members and the channel volumes do not exceed 300 ft³, CMSA sprinklers shall be installed at a maximum 6 in. below the bottom of the structural member.

Section 13.2.6.1.2.4 states that CMSA installations where the slope is greater than 1 in 12 under obstructed construction with greater than 50% open structure shall be installed per the requirements of unobstructed construction, which is addressed in 13.2.6.1.1. It is important to remember that per item 5 in section 20.9.1.1, the design area for all ESFR design schemes is addressed in chapters 20 through 26. This 50% increase is due to the additional heat that may roll up the sloped ceiling, activating additional sprinklers.

ESFR sprinkler installation under a 4 in 12 slope is addressed in section 14.2.9.1.2.3 of the 2025 NFPA 13. Like the CMSA section, it is limited to less than or equal to 50% open for the ceiling structure for obstructed construction. Per section 14.2.9.1.2.3, sprinkler installation shall be arranged in one of the two following arrangements:

Sprinklers shall be installed in each individual channel created by the roof structure and shall have a deflector depth located below the ceiling/roof structure in accordance with 14.2.9.1.1, which states that K-14, K-16.8, K-25.2, and K-33.6 pendant sprinklers shall have their deflectors positioned a minimum of 6 in. and a maximum of 14 in. below the ceiling/roof deck.

When channels are created by the roof structure by a maximum 12-in. deep members running perpendicular to the ceiling slope, and the channel volumes do not exceed 300 ft³, ESFR sprinklers shall be installed at a maximum 6 in. below the bottom of the structural member.

Section 14.2.9.1.2.4 states that ESFR installations where the slope is greater than 1 in 12 under obstructed construction with greater than 50% open structure shall be installed per the requirements of unobstructed construction, which is addressed in section 14.2.9.1.1.1 It is important to remember that per item 5 in section 20.9.1.1, the design area for all

CMSA design schemes is addressed in chapters 20 through 26. For ESFR sprinklers, this will require the design area to include 18 heads as opposed to the standard 12-head calculation. The 18-head calculation arrangement is addressed in NFPA 13 section 28.2.4.4.1 and requires five heads on three branch lines and an additional three on the next line.

In addition to these changes for ESFR and CMSA sprinklers, the method of deflector orientation has been changed for slopes over 2 in 12. NFPA 13 has long required the sprinkler deflector to be aligned parallel to the slope of the ceiling. This requirement still exists for all slopes less than or equal to slopes of 2 in 12. However, NFPA 13 section 9.5.4.3 (3) indicates that for sloped ceilings exceeding 2 in 12 in storage occupancies, the deflector must be aligned parallel to the floor.

In conclusion, in the past, NFPA 13 has limited the installation of storagerelated sprinkler systems to buildings with a slope equal to or less than 2 in 12. In doing so, it has placed a constraint on the flexibility of warehouse design and construction. With the release of the 2025 edition of NFPA 13, the maximum slope allowed has expanded to 4 in 12, which will provide greater flexibility in the design and construction process of these storage occupancies. The new rules for both ESFR and CMSA sprinklers give a new set of tools for designers and design professionals to handle potential changes in new construction and modifications to existing buildings that in the past did not meet construction requirements for storage applications. n

ABOUT THE AUTHOR: Chris Kachura, P.E., is the Senior Fire Protection Engineer for VSC Fire and Security, Houston, Texas. He has a Bachelor of Science in Mechanical Engineering and Physics from Texas Tech University, and multiple licenses with the Texas Fire Marshal’s Office. Kachura is a registered P.E. in the State of Texas, Alabama, Arizona, Arkansas, Colorado, District of Columbia, Delaware, Florida, Georgia, Indiana, Iowa, Kansas, Kentucky, Louisiana, Maryland, Massachusetts, Mississippi, Missouri, Nevada, New Jersey, New Mexico, New York, North Carolina, North Dakota, Ohio, Oklahoma, Oregon, South Carolina, Tennessee, Utah, Virginia, West Virgina, and Washinton State. He is a member of the NFPA 30, NFPA 30B, NFPA 33, NFPA 34, NFPA 101, NFPA 1142, and NFPA 5000 Technical Committees and a member of AFSA, NFPA, and SFPE.

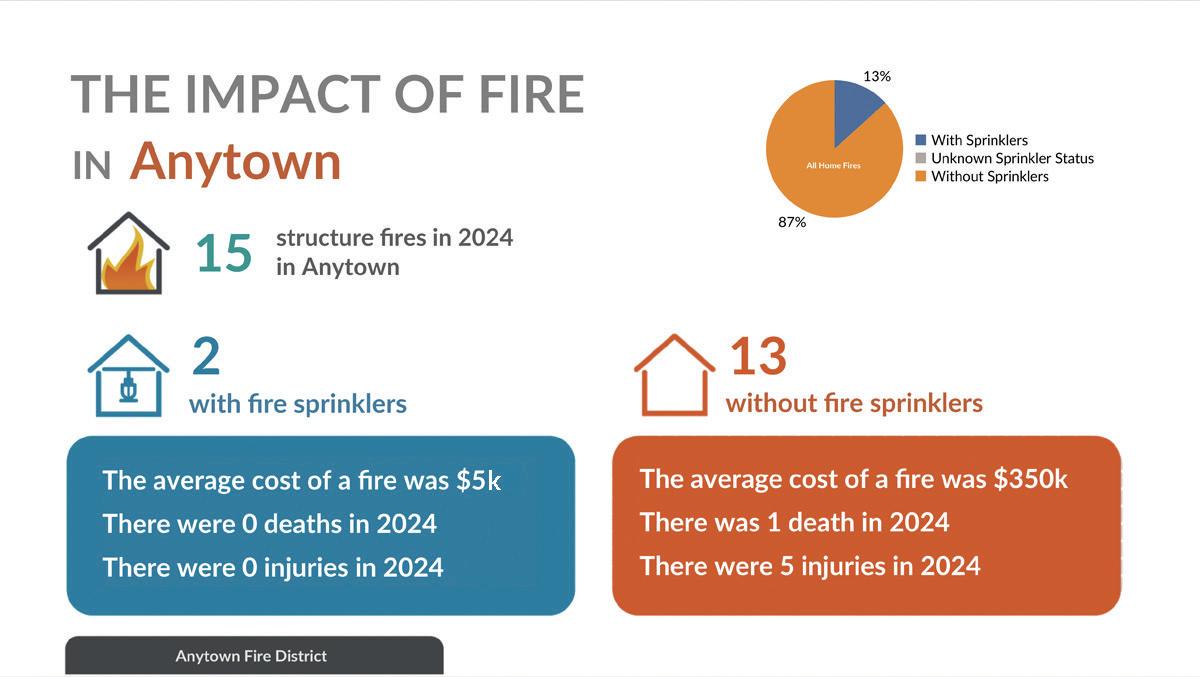

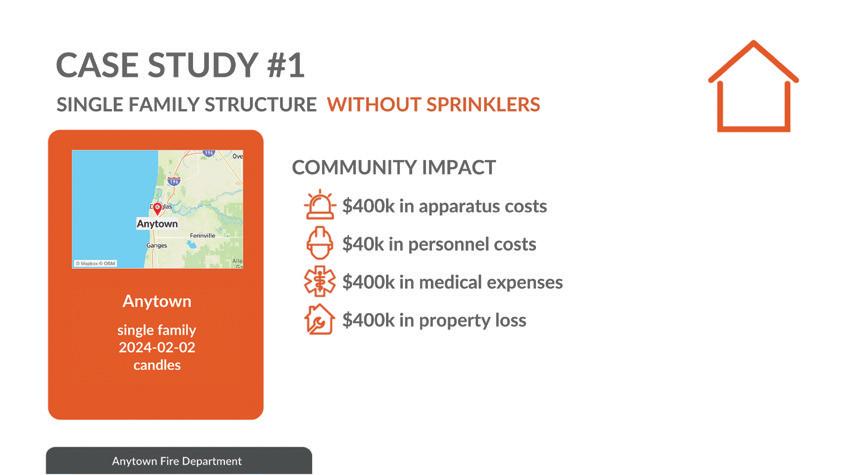

One- and two-family homes present the greatest fire risk to residents and responding firefighters. Home fires can become deadly in as little as two minutes because of modern construction methods, synthetic materials and furnishings and emerging technology, such as the increasing use of lithium-ion batteries. Home fire sprinklers are the only technology that stop a fire from becoming deadly.

For years now, national NFPA and ICC codes have required sprinklers in all new one- and two-family homes. Unfortunately, that life-saving sprinkler requirement is readily being removed from local codes across the country. Powerful lobbying efforts and misinformation from the home building industry, coupled with claims that installing sprinklers is too costly are driving this anti-code strategy.

One reason their anti-code strategy works is that local decision makers don’t understand the bigger, longer-term picture for their constituents: what is the cost of not protecting new homes? Removing sprinklers from the codes encourages substandard homes to be built.

Decision makers need to consider that when fire strikes these unsprinklered homes there can be significant consequences. The real cost of a fire in a home that’s not protected with fire sprinklers far outweighs the cost of installing home fire sprinklers. The real costs could include death, injury,

displacement and property damage. There is also a community impact on firefighter health and safety and fire department resources.

The result? Every new home built without fire sprinklers threatens Community Risk Reduction (CRR) for decades.

Battling back with education and information is the solution. This past June, a strategic response to the challenge was presented at the NFPA Conference and Expo. The Home Fire Sprinkler Coalition conducted a panel discussion titled “Proven Strategies to Help Decision Makers Choose Home Fire Sprinklers.” Each panelist highlighted successful approaches used in their

communities that resulted in entire developments being protected. Key in this approach was offering developer incentives and strategies that prevented sprinklers from being omitted when codes were being updated.

Kevin Bergstrom, deputy fire marshal, Camas Washougal Fire Department, talked about how the home fire sprinkler requirement failed in his jurisdiction because of strong opposition from builders in 2003. The city council did support negotiating incentives working with developers. He said it was