PAUL DELORIE

CHAIR, AFSA BOARD OF DIRECTORS

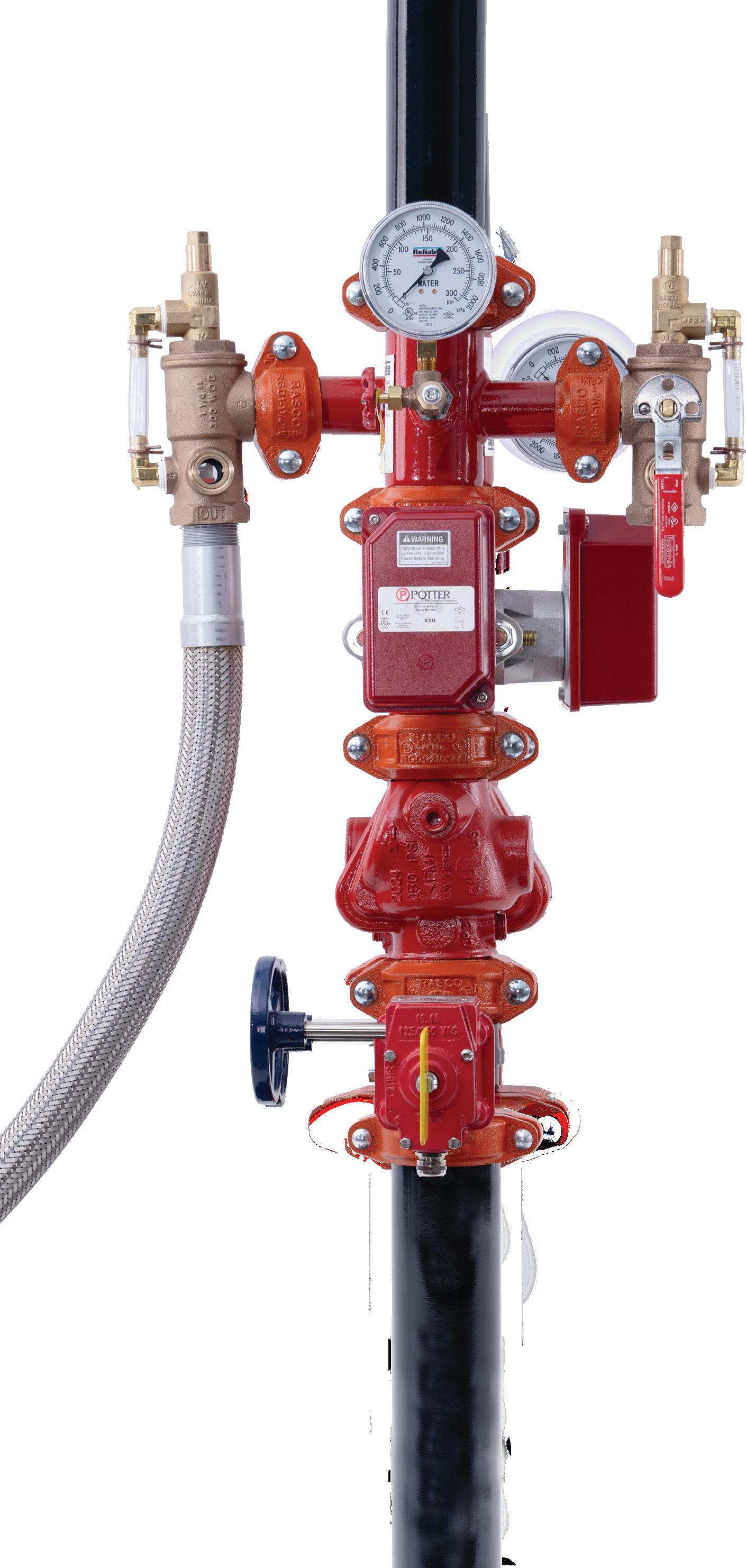

Commercial Riser (can

BACKED INTO A CORNER?

THE FCA2 FLOOR CONTROL ASSEMBLY FITS JUST RIGHT Test & Drain

Potter Water Flow Detector available in Explosionproof and automatic test versions

The Model FCA2 is cULus Listed in all sizes and FM Approved in 2"–8". The FCA2 is designed for optimal configuration for any installation scenario. With 360° rotation of each modular component, this versatile assembly adjusts to the trickiest corners.

All the components required for a complete floor control assembly. Available in sizes from 11/4"–8".

One PO. One Box. One Installation.

Fire Protection Air Compressor Listing Requirements in NFPA 13 & UL 1450, Supplement SC

General Air Products is proud to offer a complete line of UL listed & NFPA 13 Compliant Fire Protection Air Compressors.

NFPA 13 (2025) now states:

“8.2.7.5.2 - Where an air compressor is dedicated for the sprinkler system, the air compressor shall be listed for fire protection.”

Because of the NFPA 13 update, UL added UL 1450, Supplement SC to clarify and standardize what qualifies as a listed Fire Protection Air Compressor.

Going forward, listed Air Compressors for Fire Sprinkler use will be marked as follows:

“This Air Compressor Has Been Evaluated for Fire Sprinkler Use According to UL 1450, SUPPLEMENT SC”

Compressors that are not tested to UL 1450, Supplement SC cannot imply suitability for use in Fire Sprinkler Systems.

A few requirements of UL 1450, Supplement SC Compressors:

Complete compliance with NFPA 13

Provided with a means to be hardwired and permanently connected (No plug in cord)

Pressure-regulating control switch (pressure switch) must operate for 100,000 cycles under rated load

Relief valve tested at 5x maximum setting

Scan the QR Code to learn more about what the changes mean for Contractors & Engineers

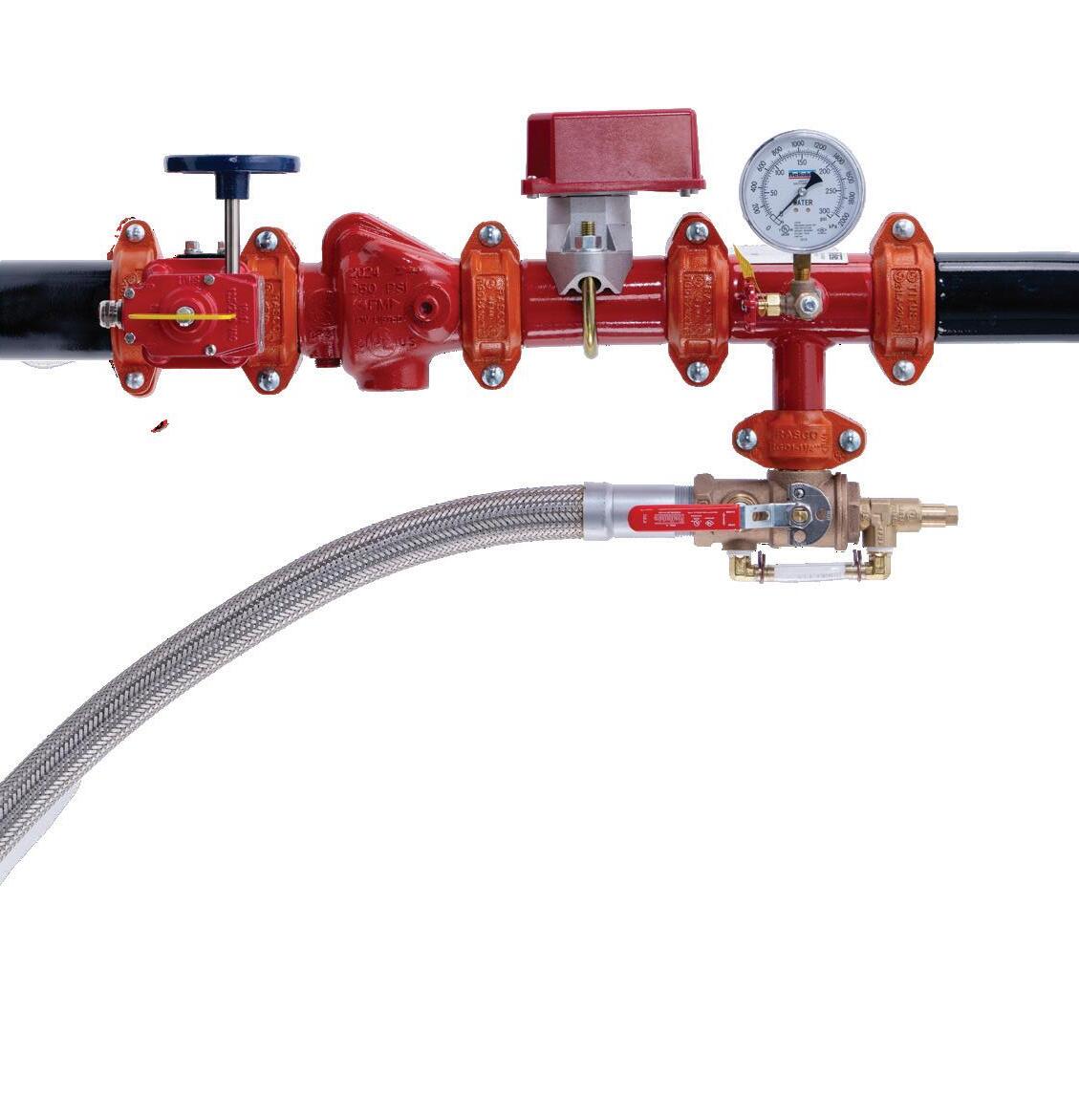

KEEP WATER WHERE IT BELONGS

- AWAY FROM YOUR CRITICAL EQUIPMENT

• Gain peace of mind by keeping water away from racks and protect critical equipment from accidental water damage

• Navigate dense ceilings with 2" UL Listed bend radius and versatile brackets for every configuration

• Minimize facility downtime during upgrades and eliminate extended shutdowns in 24/7 operations

• Experience 100% kink-resistance that guarantees consistent flow characteristics and NFPA compliance SERIES

CHAIR’S MESSAGE

As I step into the role of Chair of the Board of Directors for the American Fire Sprinkler Association (AFSA), I am both honored and excited to serve an organization that has been instrumental in advancing the merit shop fire sprinkler industry for over four decades. The trust you have placed in me is humbling, and I am committed to upholding our shared mission of safeguarding lives and property.

I am a fire protection contractor, and I started out in our industry by chance. Forty years ago, I was hired to work as a sales trainee at a fire sprinkler company. A childhood friend worked as a successful sprinkler fitter at the company, and he had put in a good word for me with the owner. I got the job, and I started in the fabrication shop. Eventually, I was a field helper, designer, estimator, and project manager. I didn’t have the skills to be a sprinkler fitter! Now, I am senior vice president of Hampshire Fire Protection Co., based in Londonderry, N.H. I am primarily involved in system installation. I especially like design-build projects. I am proud to work in our noble fire protection industry. Our AFSA membership provides vital benefits for our company.

As Chair, my priority is to sustain our great educational offerings and technical services to our members. Over many years, particularly in the last six years, we have improved and built up a robust Sprinkler Fitting training program, design school, technical webinars/workshops, and our ITM Inspector Development Program. We constructed a fantastic training facility and lab at our headquarters in Richardson, Texas. Many thanks to the vision and drive of our president, Bob Caputo, for this success. Our programs and services are developed and maintained with the expertise of our talented staff at AFSA. The expression “best in class” describes them perfectly.

We will continue to promote workforce development and foster collaboration and camaraderie among contractors, manufacturers, suppliers, design professionals, and Authorities Having Jurisdiction. I am dedicated to ensuring that AFSA remains a forward-thinking association, responsive to the needs of our members and the communities we serve.

As our industry evolves with new fire protection challenges, technologies, regulations, and market demands, AFSA remains steadfast in supporting our members with the resources, training, and representation needed to thrive.

I want to extend my thanks to the previous Board Chair, Linda Biernacki, for her leadership and to all Board members for their commitment to AFSA. Our successes are built on the collective effort of many, and I am confident that our continued partnership with our members will strengthen the fire sprinkler industry for years to come.

I want to extend my sincere gratitude to Larry Thibodeau, president of Hampshire Fire Protection Co., for his unwavering support of AFSA and the opportunities he has afforded me.

I encourage you to reach out, share your ideas, and stay engaged with AFSA. Together, we can shape a safer future and further our mission of protecting lives and property from fire.

Thank you for your trust and support. I look forward to working with you as we embark on this new chapter. n

EDITORIAL: 214-349-5965

BOB CAPUTO, CFPS, Publisher, ext. 124 bcaputo@firesprinkler.org

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

ADVERTISING: 214-349-5965

CLARISSA RIOS, Communications Coordinator, ext. 134 crios@firesprinkler.org

CIRCULATION: 214-349-5965

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

AFSA BOARD OF DIRECTORS

PAUL DELORIE, Chair, Region 10, 603-432-8221

JAY STRICKLAND, First Vice Chair, Region 6, 301-474-1136

CHRIS JOHNSON, Second Vice Chair, Region 7, 727-58219339

TOMMY CLEMENTS, Treasurer, Region 9, 804-459-2218

JEFF PHIFER, Secretary, Region 8, 803-438-2994

LINDA M. BIERNACKI, Immediate Past Chair, Region 5, 318-841-0330

BROOKS BAYNE, Region 1, 503-692-9284

HUNTER BRENDLE, At-Large, 334-270-8571

MINDY BUCKLEY, At-Large, 770-925-9099

R. DONALD (DON) KAUFMAN, Region 3, 505-884-2447

MICHAEL F. MEEHAN, At-Large, 804-459-2200

WAYNE WEISZ, Region 2, 209-334-9119

AFSA LEADERSHIP

BOB CAPUTO, CFPS, President, ext. 124

MATT KLAUS, Executive Vice President & COO, ext. 139

MELISSA ATHENS, Vice President, Finance, ext. 112

LESLIE CLOUNTS, Vice President, Education Services, ext. 130

JOHN AUGUST DENHARDT, P.E., FSFPE, Vice President, Engineering & Technical Services, ext.121

MEDA MERRITT, Vice President, Membership & Chapter Development, ext. 133

Sprinkler Age is devoted to the professional development of the fire sprinkler industry. Deadline is 1st of the month preceding publication.

Published by American Fire Sprinkler Association, 1410 East Renner Road, Suite 150, Richardson, TX 75082. Call (214) 349-5965, FAX (214) 343-8898, or email sprinklerage@firesprinkler.org for information.

Copyright © American Fire Sprinkler Association, Inc. All rights reserved. PRINTED IN USA. Unless expressly stated otherwise, all editorial and advertising material published is the opinion of the respective authors and/or companies involved and should not be construed as official action by or approved by Publisher or the Association.

PAUL DELORIE AFSA BOARD CHAIR

Sprinkler Age is a membership benefit, provided free of charge to AFSA members. For information on nonmember and/or foreign subscription rates, call (214) 349-5965.

ABOUT AFSA MEMBERSHIP

AFSA annual membership dues are a sliding scale for Contractors and Associates and a flat fee for Authorities Having Jurisdiction. (Members receive a free subscription to Sprinkler Age.) Write or call AFSA for membership information. See AFSA’s website at firesprinkler.org.

Introducing the Figure C9 The Fastest, Easiest to Verify Rigid Coupling Available

• Visual and Tactile Installation Verification

• All-new Patent-pending Design

• CenterLOK™ Gasket Enables Two-handed Installation

• Simplified Tightening

• Ready-for-installation

PRESIDENT’S REPORT

I’m a pretty old guy. Well, ok, I’m an old guy who isn’t very pretty, but I’ve been around long enough to know the world around me is changing at a more rapid pace than the experiences my father had while visiting this planet. When we look up the word “culture,” we will find it defined as the set of shared attitudes, values, goals, and practices that characterize an institution or organization.

I always like to ask people how they got into the fire and life safety industry, and in many cases, it’s nepotism. Most people have a relative, neighbor, or friend in the industry. I never met Albert Einstein, so for today, let’s call this Bob’s theory of relativity. By the way, AFSA is working to increase the interest and awareness of young students toward career opportunities within the fire and life safety industry, but that’s a discussion for another column. For this column, let me focus on the cultural changes I’ve observed during my 47-year journey, which has led me to share these random thoughts.

I should note that I understand that younger people often dislike hearing older people talk about how life was better, or harder, or whatever, back in their day. I hate that, too, and that’s not where I’m headed with this. Let’s all agree that change isn’t always bad; it’s just change.

Like many of us older individuals, when I entered this industry, the “red book” (aka NFPA 13) fit in my back pocket. It was 1970 something, but I have a 1961 version in my collection, and many of the rules and figures from that edition are still in the current edition in one form or another. When starting out, back when a terabyte meant a pterodactyl bit you (teh·ruh·dak·tl), it was impressed upon me by almost every person I worked with to understand the importance of our work. People were passionate about saving lives and property, and there was a great sense of pride in knowing that what we were doing mattered. We were mostly self-policed, and we needed to do things right no matter who was watching or who might miss something in a plan review or during an inspection.

Of course, there were always a few competitors in every market who were just there to make a buck, but they never participated in industry social or association events. Most of us wanted all our competitors to be knowledgeable and successful. Even when we lost a job, there would be another one around the corner—enough work for everyone. When I look around the industry today, I fear we have lost some of that cultural drive and the pride that went with it. It seems our culture has shifted, with a greater emphasis on making money than on doing things right. Don’t get me wrong, I understand that business exists to make a profit—any business. There is no other reason for a company to exist, even our “not-for-profit” association has to make money to pay bills. However, most of us have always made money doing what we do and doing it right, regardless of who was watching. Making money was the result of what we did and

why we did it. I think that is missing or at least fading from our industry, and it needs to be recaptured.

I do not believe the cultural change is driven by corporate ownership, mergers, and acquisitions we’ve seen in past years, or even next-generation ownership of family businesses. We’re still saving lives and property, but now, there appears to be more pride in EBITDA (Earnings Before Interest, Taxes, Depreciation, and Amortization) than in the altruism of what we’re doing and why. People seem to be more focused on the ROI than the value proposition our industry offers in terms of a safer world.

Most firefighters can tell you how many people they’ve saved from a burning building or car, or how many babies they’ve delivered on the side of the road. None of us will ever meet the people we’ve saved by installing fire sprinklers in the built environment, but I promise you, it’s in the thousands. You should take exceptional pride in this fact and cherish this wonderful industry, knowing that what we do every day truly matters. We save lives and property. Fire sprinklers save lives. What you do saves lives, and you get paid to do it. Did you hope to have an impact on your world? In this industry, you do. Make as much money as you can—we believe in free enterprise and capitalism, but let’s prioritize putting fire protection first. n

BOB CAPUTO, CFPS AFSA PRESIDENT

FLASHPOINT

AFSA44 was an unbelievable event. What a wonderful time we all had, and, if you missed it, hopefully you can join us in San Antonio at AFSA45 September 27-30, 2026. The training opportunities and networking were vast. The list of presenters throughout the event was the Who’s Who of the industry. The “Ask the Experts” panels were packed with experts from all areas of the field. In fact, we were limited to 10 seats on the panel and, looking around the audience, many other experts were in the room. The call for presentations for AFSA45 has been issued with a deadline of January 9, 2026. Based on the number and quality of submissions we received for AFSA44, we expect the submissions for AFSA45 to be top-notch once again

The end of the calendar year is the perfect time to look back while also looking forward to the future. Why do this? It helps you identify what you did well, what you did not do so well, and what needs to be continued, changed, or dropped. In my role at AFSA, I need to be honest with my team to see what needs to happen. The great news for me is that my technical team is hitting it out of the park. For this column, I reviewed my November/ December 2024 Flashpoint column. We have accomplished everything I set out for 2025 and then some. For 2026, most of my goals have been set for me. Our leaders, Bob Caputo and Matt Klaus, along with the AFSA’s Board of Directors, want the technical team to keep the pedal to the floor with our current items, and they want us to add related training. The addition of inspection and testing of fire alarm systems, releasing systems, fire extinguishers, clean agent systems, kitchen extinguishing systems, exit and emergency lights, fire dampers, and fire doors are all being considered. These additions will happen, but it will take time and effort. The Board of Directors has committed the financial resources to this goal. Our current training facility in Richardson, Texas, is nearing full capacity, with the 2026 calendar filling up quickly. Our contractor, manufacturers, suppliers, associates, AHJs, designers, and engineering members are flocking to our classroom and lab for training. The attendees complete a course evaluation after each program, which I personally review. The goal of these evaluations is to identify areas for improvement and recognize our strengths. The great news for me is the overwhelming positive comments we receive. Although I receive only a few negative comments, I take each one to heart. However, I occasionally come across a humorous review. I wanted to share two of the ones I reviewed. “During break, you only had Diet Coke for me to drink. I prefer Coke Zero.” My favorite, “The t-shirt you gave me was only available in red. I prefer blue t-shirts.” We are doing well if these are the type of negative comments I am reading!

Now that my goals are set, what about your team and your personal goals? If you lead a team, are your fellow

employees properly trained? I hear all the time from contractors, “We need more designers.” Well, that might be a difficult task, but what about investing in the designers you currently have on your team? Are they certified? NICET’s Level III in Water-Based System Layout or NFPA’s Certified Water-Based Systems Professional (CWBSP) should be the minimum goal for all designers. ITM technicians should also strive to be certified. NICET’s Level III in Inspection and Testing of Water-Based Systems (ITWBS) or NFPA’s Certified WaterBased Systems Inspection, Testing, and Maintence (WBITM) System Professional should be the minimum goal for all ITM technicians. Additionally, field installers should strive to complete an apprenticeship program. AFSA has programs designed to provide the necessary education for your people.

For seasoned employees, what about continuing education? Even if your local AHJ does not require continuing education, it is the right thing to do. Failing to train employees on the latest changes in installation standards or available products can compromise quality and have severe financial consequences. Liability for inferior designs, installations, or inspections can lead to legal action. Training is an opportunity, not an expense. Again, AFSA has programs designed to provide the necessary continuing education for your people. Set goals for both your employees and yourself, and follow up on their progress.

As I complete my fifth year of employment with AFSA, we have changed and moved forward in a positive way. I am proud to lead the most technically competent team in the industry. Kevin, Josh, Eric, Hayden, and Victoria all bring their specific strengths to my team. I always like to remind my team about the AFSA mission statement—“AFSA is the voice of the merit shop fire sprinkler contractor. We educate and train the industry while promoting fire protection systems to save lives and property.” My take on this statement is to train, train, train, and train some more. No one has ever claimed they are too educated in their chosen profession. Hell, I am still learning every day.

Having two grandchildren, I can only pray that I will be able to train them to be the best they can be. God, please help me! n

JOHN AUGUST DENHARDT, P.E., FSFPE AFSA VICE PRESIDENT OF ENGINEERING & TECHNICAL SERVICES

InstaSeal’s revolutionary “Torque-Assist” cap allows for handtightening, while InstaSeal gaskets seal the connection upon sprinkler installation. This exciting process completely eliminates the need for wrenches and sealants, meaning fitters can maximize their efficiency. InstaSeal fittings are now available in 1/2”, 3/4” and 1” sizes for your next project!

Select Viking sprinklers are compatible with the advanced InstaSeal technology through the addition of new “Torque-Assist” caps.

Look for the compatibility icon to ensure the correct sprinklers are being ordered for a job requiring InstaSeal technology.

No sealants needed

InstaSeal technology eliminates the need for messy traditional sealants like thread tape or pipe dope

Hand-Tightening encouraged

Wrenching is no longer required!

Maximize sprinkler fitting efficiency with hand-tightening

Torque-Assist cap

The protective “Torque-Assist” sprinkler cap makes it a truly seamless experience for contractors to hand-wrench

Listed and Approved

A growing number of products within the InstaSeal family are FM Approved and UL Listed with Viking sprinklers

MEMBERS ELECT 2025-2026 BOARD OF DIRECTORS

DELORIE ELECTED CHAIR OF THE BOARD

D’ARCY MONTALVO | AMERICAN FIRE SPRINKLER ASSOCIATION

The American Fire Sprinkler Association (AFSA) held its 2025-2026 officer elections during the October 2025 Board meeting. Paul DeLorie, Hampshire Fire Protection Co., Londonderry, N.H., was elected Chair of the Board. Jay Strickland, Pye-Barker Fire & Safety, Forestville, Md., was elected First Vice Chair; and Chris Johnson, president and co-founder of Piper Fire Protection, a Fortis Brand in Clearwater, Fla.,was elected Second Vice Chair. Jeff Phifer, Crawford Sprinkler Company of South Carolina, Lugoff, S.C., was elected Secretary; and Tommy Clements, president and CEO of VSC Fire & Security, Richmond, Va., was elected Treasurer.

In addition, Clements, Johnson, Don Kaufman, Mike Meehan, and Jeff Phifer were re-elected to another three-year term.

DELORIE ELECTED CHAIR

Region 10 Director and Chair of the Board Paul DeLorie is senior vice president of Hampshire Fire Protection Co., based in Londonderry, N.H. Hampshire Fire Protection is one of the largest merit shop fire sprinkler companies in New England.

“I am honored to be Chair and work alongside dedicated and talented Board members who have great industry experience and passion for our cause,” DeLorie comments. “Our directors make a lasting impact on our communities and the success of our members. They are championing fire safety and supporting our industry’s growth, innovation, education, and training. That’s what AFSA is all about.”

DeLorie is a 1984 graduate of the University of New Hampshire and has over 40 years of experience in sprinkler design, estimating, sales, project management, and senior management. He was a board member and treasurer of the AFSA Patriot Chapter, now the New England Chapter. He served on the board of Associated Builders and Contractors (ABC) for the New Hampshire/Vermont Chapter for many years and was the board chair. DeLorie joined the AFSA Board in 2014. Since then, he has chaired several national committees and served as treasurer for AFSA’s Board of Directors for four years.

DeLorie is excited about the association’s innovative and expanding training programs. “Our Level 1, 2, and 3 VIP

[virtual instruction path] fitter series is taking off and making a difference in a trained workforce,” he says. “I look forward to the completion of Level 4 in early 2026, which will complete the VIP project. I believe that this complete series will really make a big difference for our contracting companies and their fitters.”

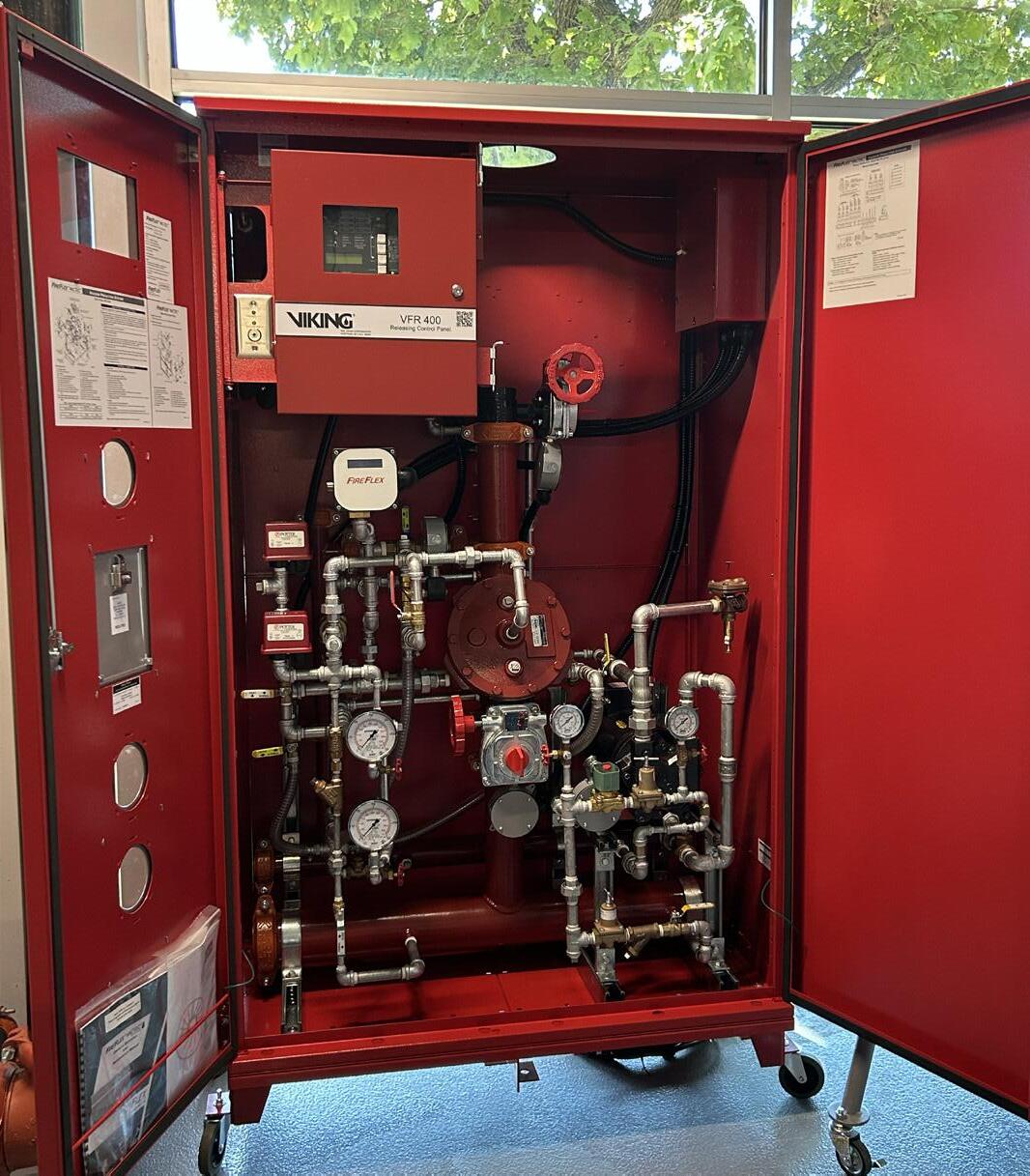

DeLorie is also pleased with the growth of AFSA’s training lab. “I’m inviting all members to experience AFSA’s lab. It has an impressive number of valve stations that operate in real-world conditions for hands-on training with our expert staff. There are all makes, models, and types of valves to work on. The lab has a large array of branch lines with various types of flowing sprinkler heads. You can see the interruption of the water spray due to obstructions. There are even window sprinklers to check out.”

As Chair of the Board, DeLorie leads the AFSA Board of Directors, which is comprised of 10 Regional Directors (one for each of the 10 membership regions), At-Large Directors, and the Immediate Past Chair. The Board has a wide array of expertise, experience, and education that provides strong support to both the Chair and the association as a whole.

The members of the 2025-2026 Executive Committee are (l to r): Chair Paul DeLorie; First Vice Chair Jay Strickland; Second Vice Chair Chris Johnson; Secretary Jeff Phifer; Treasurer Tommy Clements; and Immediate Past Chair Linda Biernacki.

REGIONAL DIRECTORS

Region 1 Director Brooks Bayne is co-owner and vice president of operations at AFP Systems, Inc. in Tualatin, Ore. He started in the fabrication shop working for his uncle, AFP Systems founder Jim Bayne, after graduating from McQueen High School. After earning his journeyman license through the AFSA apprenticeship program, Bayne worked in the field as a foreman before becoming superintendent in 2007.

Bayne was inspired to go further in the industry, learning sprinkler system design, estimating, and project management. In 2017, he stepped into the roles of co-owner and vice president of operations after working 20 years alongside his uncle. AFP Systems has been an AFSA Contractor member since 2012. The company has provided service throughout the Pacific Northwest for over 36 years and is a proud member of ABC’s Pacific Northwest Chapter and ABC Inland Pacific Chapter, Inc.

Region 2 Director Wayne Weisz started his career in the fire sprinkler industry in 1979. He started as an apprentice and quickly worked his way through the ranks as a foreman and then general superintendent with American Fire Systems in Lodi, Calif. In 1986, Weisz, along with his brother Byron, founded Cen-Cal Fire Systems, Inc., also in Lodi. In 1997, the brothers established D-M Fabrication, which ran as an independent pipe fabrication facility supplying fire sprinkler piping throughout the western United States. Cen-Cal Fire became a member of AFSA in 1987. In 2021, Cen-Cal Fire Systems became a part of the Sciens family of companies.

Weisz became a member of the AFSA Board of Directors in 2005. He has chaired multiple AFSA national committees over the years and in 2017-2018 served as AFSA Chair of the Board. In 2018, he was appointed by the California State Fire Marshal’s Office to serve on the State Automatic Extinguishing Systems Advisory Committee. Weisz is active in California apprenticeship issues and sat on the CAFSA apprenticeship board of directors for over 21 years. He is a founding member of and active in the

AFSA Sacramento Valley Chapter.

Region 3

Director is Don Kaufman, president of Kaufman Fire Protection, Albuquerque, N.M. With over 49 years in the sprinkler business, Kaufman was instrumental in starting AFSA’s New Mexico Chapter and is a past president of the chapter. On the national level, Kaufman served as the Chair of the Board and has chaired several committees. He also served as chair of the New Mexico State Board for Professional Engineers and Surveyors, three terms as chair of the New Mexico State Apprentice Council, and served on the New Mexico Construction Industries Commission. He is an active member of ABC, past president of ABC’s New Mexico Chapter, member of the American Society of Professional Estimators, and past charter president of Albuquerque Rotary Del Sol. Region 5 Director Linda M. Biernacki is the founder/president of Fire Tech Systems, Inc., with three offices—its main location in Shreveport, La., and branch offices in Monroe, La., and Oxford, Miss.—is an AFSA Quality Contractor, ISNetworld Certified, and is licensed in six states (Alabama, Arkansas, Louisiana, Mississippi, Oklahoma, and Texas). With over 34 years of experience, Biernacki provides industry experience, knowledge, and background. She is past chair and current member of the NICET board of governors (June 2022-June 2023), past board member and current member of the National Society of Professional Engineers (NSPE) board of directors, past president and current board member of the Louisiana Fire Sprinkler Association (LFSA), and is past AFSA40 Convention Committee and Membership & Chapter Development Chair. She represents AFSA on the NFPA 232 Committee for Protection of Records. Biernacki is certified in NICET Level III Fire Protection Engineering Technology Water-Based Systems Layout and is certified by the Women’s Business Council Gulf Coast. She is a member of Associated Builders and Contractors (ABC), American

Society of Certified Engineering Technicians (ASCET), Louisiana Automatic Fire Alarm Association (LAFAA), and Louisiana Associated General Contractors (LAGC).

First Vice Chair of the Board Jay Strickland serves as Region 6 Director. He is the vice president of business development for Pye-Barker Fire & Safety. Strickland has been involved in the fire protection industry for 42 years. He is certified in NICET Level II, Fire Protection, Water-Based System Layout. He is a past chair of the AFSA Chesapeake Bay Chapter.

He served on the board of Anne Arundel Community College (AACC) Foundation, a 501(c)3 corporation. The organization’s mission is to secure and steward private funds to enhance the educational endeavors of the college. This includes creating a new pathway to earn a college degree that many skilled craftsmen and women may have never considered as an option. A new Associate of Applied Science (AAS) degree program at AACC enables students who have completed apprenticeship programs to earn credits for their hard work. This includes pre-apprenticeship and apprenticeship programs. The degree is part of the school programming to ensure that students have the resources to pursue lifelong careers and that local businesses have a pipeline of employees ready for roles from entry-level through upper management.

Region 7 Director and Second Vice Chair Chris Johnson is president and co-founder of Piper Fire Protection, a Fortis Brand in Clearwater, Fla. He has led Piper since 2002. Johnson is a NICETcertified fire protection Engineering Technician, holding a level III certification in fire sprinkler design. He has served AFSA’s Florida Chapter since 2011 as Education and Legislative Committee

BAYNE WEISZ KAUFMAN

chair as well as vice chair, chair, and immediate past chair of the chapter. Johnson has served on the board of ABC for the Florida Gulf Coast Chapter since 2015, and is a past chapter chair. He has also served on the ABC Florida State board as well as the ABC National board. Johnson was elected and sworn into office as Largo City Commissioner in November 2022. His mission is to utilize his time, treasure, and talents to advocate for the fire sprinkler industry throughout Florida. He holds a Florida Fire Protection Contractor I License and Fire Equipment Dealers’ Licenses Class A and D. Chris is our AFSA National Committee Chair of the Legislative Committee.

Region 8 Director and Secretary of the Board Jeff Phifer is president and CEO of Crawford Sprinkler Company of South Carolina, based in Lugoff, S.C., one of the oldest family-owned and continuously operated fire sprinkler contractors in the nation. Crawford celebrated its 100th year in 2020. Phifer has been at Crawford for 46 years, working as a fitter, service technician, and in administration. In 1999, he became the third generation to be president and chairman of the board at Crawford Sprinkler Company.

Region 9 Director and Treasurer Tommy Clements is the president and CEO of VSC Fire & Security based in Richmond, Va. He joined the company in 2017 following VSC’s acquisition of Arkansas Automatic Sprinklers/United Fire Suppression, where he had served as the CEO since leading a sponsor-backed acquisition in 2009. Following Markel’s acquisition of VSC, Clements relocated to Richmond to assume the role of COO and was promoted to president in 2022. He took on the additional role of CEO in 2023.

Clements is a former Nuclear Submarine Officer for the US Navy, having served onboard the USS Alabama ballistic missile submarine and in Navy Recruiting as head of enlisted recruiting in the Southeast United States. After his military service, Clements worked as a program manager on satellite defense and space shuttle programs before

entering the construction industry as a development consultant to owners of casinos, resort hotels, and residential properties. Clements has a degree in Electrical Engineering from Mississippi State University and an MBA from the Stetson School of Business and Economics at Mercer University.

Serving as Ex-Officio (non-voting) members of the Board:

• Dwight E. Bateman, VSC Fire & Security, Inc., Houston, Texas;

• Don Becker, AFSA Life Member, Dallas Center, Iowa;

• Bob Rees, API, High Point, N.C.;

• Manning Strickland, Pye-Barker Fire & Safety LLC, Forestville, Md.;

• Willie Templin, American Automatic Sprinkler, Fort Worth, Texas;

• Larry Thibodeau, Hampshire Fire Protection Co., LLC, Londonderry, N.H.;

• Jack Viola, JFV Engineering, LLC, South Hadley, Mass.; and

• Ted Wills, Anchor Fire Protection/Sciens Building Solutions, Perkiomenville, Pa.

AT-LARGE DIRECTORS

The Board has retained three At-Large Director positions, held by Hunter Brendle, Mindy Buckley, and Mike Meehan.

At-Large Director Hunter Brendle is president of Brendle Sprinkler Company, Inc., based in Montgomery, Ala. He began working in the shop as a teenager, working in the field as a helper and apprentice, and later transitioning into the office. Brendle is a proud third-generation in fire protection. He is past president and current board member of the Alabama Fire Sprinkler Association, board member for the Tony Bice Memorial Golf Tournament, and serves on AFSA’s National Convention, Membership, NextGen, and Public Education & Awareness committees. He holds a NICET Level III in Water-Based

Systems Layout, Florida Fire Protection Contractor II, and is a graduate of AFSA’s Apprenticeship Training Series.

At-Large Director Mindy Buckley is CFO and co-owner at Allsouth Sprinkler Company, Buford, Ga. She has over 20 years of experience at Allsouth in all aspects of the company. Buckley has been active with the Georgia Fire Sprinkler Association since 2016 and serves as Treasurer on its board of directors. She is also the Chair of AFSA’s Public Education & Awareness and Education committees, a member of and Membership & Chapter Development and a member and Board Liaison for the Next Generation workgroup. Buckley also works closely with the Office of the Commissioner of Insurance and Safety Fire Public Education Department to educate children on fire prevention.

At-Large Director Michael F. Meehan is chairman of VSC Fire & Security, headquartered in Richmond, Va. A 1981 graduate from George Mason University in Fairfax, Va., Meehan began his fire sprinkler career working summers as a pipefitter apprentice. He is a NICET Level IV Certified Engineering Technician in Water-Based Systems Layout and has more than 46 years of experience in sprinkler design engineering, estimating, project management, and senior management. Meehan is a past AFSA Chair of the Board and represents installing contractors and AFSA on the NFPA 13 committee.

RETIRING DIRECTORS HONORED

At-Large Director and Immediate Past Chair Jack A. Medovich, P.E., and Region 4 Director Rod DiBona are retiring from the Board. Medovich is with Summit Companies out of Men -

MEEHAN BRENDLE BUCKLEY

dota Heights, Minn. A 1983 graduate of the University of Maryland School of Fire Protection Engineering, he served three years as fire marshal of Fairfax County, Va., before joining the fire sprinkler industry 39 years ago. He has been active in AFSA since 1991, is a past chair of the Chesapeake Bay Chapter, and served the Virginia Chapter as chair and as a member of the board of directors for many years. He represents AFSA on the Correlating Committee on Automatic Sprinkler Systems, encompassing NFPA 13, 13R, 13D, 24, and 291. In the past, he has served as a member of the following NFPA committees: NFPA 14, 20, 25, 101, 750, and 5000.

“Jack was one of my most ardent supporters on the Board, comments AFSA’s Immediate Past Chair Linda Biernacki. “He said he is retiring from the voting Board, but his influence on our industry will stay with us for years to come. Thank you, Jack, for your mentorship and friendship. I wish you well in your new endeavors!”

Region 4 Director Rod DiBona is the executive vice president for PyeBarker Fire and Safety, with branches throughout the United States. He lives in Rapid City, S.D. DiBona entered the fire protection industry in 1990 and started in the AFSA apprenticeship program in 1991. In October of 1993, he was asked by Marty Hammon to join him, his son, and his son-in-law to create Rapid Fire Protection. In 1995, DiBona was a Top 7 finalist in the AFSA National Apprentice Competition. In July of 2021, Rapid Fire joined the Pye-Barker Fire and Safety family. DiBona is a NICET Level III Certified Engineering Technician in Water-Based Systems Layout.

“Rod has been an energetic Board member whose focus has been on protecting the open shop contractor,” comments Biernacki. “I remember Rod had brought some of his family last year and his daughter introduced herself at a dinner and said she wanted to be president of the company one day. We all loved that and cheered. You go, girl!”

CALL UPON THE BOARD

AFSA’s Board of Directors is strongly committed to the continuance of the merit shop philosophy, the promotion of property and life safety through the use of automatic fire protection, and the continued development of training for fire sprinkler fitters, layout technicians, inspectors, and management.

AFSA members are encouraged to ask questions or voice suggestions with any Board member or staff. If you have a question or comment, please see the list of Board members and key staff on page 6 of every issue of Sprinkler Age or visit the Board of Directors’ webpage on the AFSA website at firesprinkler.org/ board-of-directors or the staff webpage at firesprinkler.org/afsa-staff. n

Day Shipping

CA (800) 458-3492 • info@bavco.com

- San Antonio, TX (866) 318-0274 • txinfo@bavco.com East Coast - Charlotte, NC (844) 202-1618 • ncinfo@bavco.com

AFSA44 HITS EVERY MARK IN THE NATION’S CAPITAL

AFSA CELEBRATES CONVENTION, EXHIBITION, AND APPRENTICE COMPETITION IN WASHINGTON, D.C.

CLARISSA RIOS | AMERICAN FIRE SPRINKLER ASSOCIATION

Washington, D.C., set the stage for AFSA44, the American Fire Sprinkler Association’s (AFSA) annual Convention, Exhibition, and Apprentice Competition, Oct. 15–18. Drawing over 1,500 fire sprinkler contractors, manufacturers, suppliers, architects, designers, facility managers, Authorities Having Jurisdiction (AHJs), to the Gaylord National Resort & Convention Center for four days of networking, education, and fun!

“At AFSA44 you could almost feel the magic in the air—the energy, the learning, the people!” comments AFSA44 Convention Chair Jay Strickland, vice president of business development M&A, Pye-Barker Fire & Safety. “You could see how much our industry is growing and how committed everyone is to raising the bar. That passion proves we’re not just maintaining standards—we’re scaling up, innovating, and inspiring the next generation to protect what matters most. It’s an exciting time to be part of this industry.”

Attendees had the opportunity to participate in 64 seminars and explore a sold-out exhibit hall featuring 108 exhibitors promoting the latest technology and products in the industry. AFSA also offered AHJs a free morning of seminars and a chance to explore the industry’s largest exhibition.

AFSA IN ACTION IN D.C.

AFSA44 opened on Wednesday, October 15 with a full slate. That morning, AFSA chapter leaders came together for its annual Leadership Conference at convention. One highlight was the presentation of awards to chapters. The Chapter Impact Award, recognizing a chapter that has shown significant growth and improvement over the past year by enhancing member engagement through expanded training programs and meaningful networking opportunities, was presented to the Tennessee Chapter. The Chesapeake Bay Chapter received the Preservation Excellence Award for their efforts to protect the Fire Museum of Maryland. The award honors a chapter that has made outstanding contributions to its community by helping preserve historic landmarks and treasured buildings through the installation of fire sprinkler systems. The Collaboration Excellence Award was presented jointly

to the Louisiana, Arkansas, Alabama, and Georgia Chapters to recognize their successful teamwork in launching the Southern Sprinkler Summit—a regional training program and tradeshow.

Wednesday afternoon was packed with technical seminars, a new member/new attendee orientation, and Women in the Industry panel. That evening, everyone gathered in the Harbor Social sports bar and garden atrium to enjoy duckpin bowling, darts, bocce, music, and great food and drinks. George Washington and Teddy Roosevelt even made an appearance!

Thursday was a day full of learning and earning education credits in seminars covering technology, standards updates, special occupancies, business management, dry systems, design and project management, and hydraulics. After all that training, a little fun was needed and found with The K Factor podcast hosts! Inspired by the hit YouTube show “Hot Ones,” Eric Andresen, Kevin Hall, Josh McDonald, and Nate Williams took on a gauntlet of increasingly hotter wings while answering a mix of technical fire protection questions and fun, personal ones. The guys definitely took the heat and succeeded in finishing all the wings, while providing laughs and insights.

Martin Workman, senior vice president of product development for The Viking Corp., received the 2025 Henry S. Parmelee award from 2023-2025 AFSA Chair of the Board Linda Biernacki.

Friday offered more seminars followed by the general session. AFSA 2023-2025 Chair of the Board Linda Biernacki, Fire Tech Systems, Inc., Shreveport, La., presented the 2025 Henry S. Parmelee award to Martin Workman, senior vice president of product development for The Viking Corporation Inc., for his dedication to education, training, and development of fire protection standards.

Two additional honors were presented at the event. Mac Beaton, director of career and technical education (CTE) for Henrico County Public Schools in Virginia, received the 2025 Fire Sprinkler Advocate of the Year award for his outstanding efforts to educate the next generation and raise public awareness about the fire protection industry. Madison Wolf, Victaulic regional sales manager, was named the 2025 Joe Heinrich Young Professional of the Year for her commitment to empowering the next generation and supporting future professionals.

Attendees heard inspiring speeches from the award recipients and learned that a donation was made on their behalf, in lieu of a convention souvenir, to the Kerr County Flood Relief Fund. This donation will support both urgent relief and long-term rebuilding efforts after the devastating floods in Kerr County, Texas, on July 4, 2025.

Members also recognized retiring At-Large Director Jack Medovich, P.E., and Region 4 Director Rod DiBona for their years of service to the association. Finally, everyone joined in celebrating the seven finalists competing in the 32nd National Apprentice Competition—complete with confetti canons! After the general session, attendees were invited to the exhibit hall for the Exhibition Grand Opening Reception with a first look at this year’s exhibiting companies along with heavy hors d’oeuvres and cocktails.

“AFSA44 was truly inspiring! Seeing so many passionate professionals come together reminded me why I love this industry. The energy, the conversations, and the shared commitment to fire safety made this event unforgettable,” comments Biernacki. “Our convention committee and the AFSA staff, did an outstanding job making everything feel seamless.”

On Saturday, seminars were held during the morning hours, and the exhibits opened to great success. Attendees enjoyed learning about new products and services for the fire sprinkler industry and networking with fellow industry professionals. During the afternoon exhibition, the nation’s top seven fire sprinkler fitter apprentices

Madison Wolf, regional sales manager for Victaulic, was presented with the 2025 Joe Heinrich Young Professional of the Year award by AFSA NextGen Initiative Chair Katie Meehan.

Mac Beaton, CTE director for Henrico County, Va. Public Schools, accepted the 2025 Fire Sprinkler Advocate of the Year award from Legislative Committee Chair Mike Meehan.

Retiring Directors Jack Medovich (left) and Rod DiBona (right) were honored during AFSA44’s general session.

The National Apprentice Competition finalists won cash prizes, tools, and a commemorative plaque.

installed mini-sprinkler systems before a packed crowd. That evening, at the annual Awards Party, the winners of the 32nd Annual National Apprentice Competition (NAC) were announced. Raul Larios, Hiller Companies, Calif., won first place and $10,000; Leona Ball, Piper Fire Protection, Fla., won second place and $7,500; and Christopher Redman, J.G. Tate Fire Protection Systems, Poway, Calif., placed third and won $5,000. Honorable mentions and $2,500 were awarded to Stephen Dolan, Rieve Fire Protection, Conn.; Corbin Rogers, Rapid Fire Protection, Inc., S.D.; Kyle Strickland, Marmic Fire & Safety, Ark.; David Walencewicz, Impact Fire Services, Conn. All competition winners received a commemorative award and tools.

“AFSA44 was another fantastic success, with a record turnout at every level of participation,” comments AFSA President Bob Caputo.

“I cannot express my gratitude enough to our members, associates, and staff, whose hard work and dedication continue to make AFSA’s annual convention the premier event in our industry. From the volunteers who represent our regional chapters to the speakers who presented, and everything in between, this convention was fun and exciting from start to finish.”

To see photos of this year’s event, visit flickr.com/afsa.

A BIG TEXAS WELCOME!

Grab your cowboy boots and strut on down deep in the heart of Texas next fall for AFSA45, September 27-30, 2026. Stay up-to-date on next year’s event and the 33rd NAC through AFSA’s website at firesprinkler.org. n

AFSA44 at the Gaylord National Resort & Convention Center in Washington, D.C., offered education, technical training, networking, a packed exhibit hall, and the 32nd National Apprentice Competition.

AFSA44 was an All-American celebration of the fire protection industry with professionals from across the globe enjoying seminars, exhibits, socials, and meals in the nation’s capital.

VACUUM SYSTEMS

LANGUAGE ADDED TO NFPA 13, 2025 EDITION

JONATHAN ROGER | FIREFLEX SYSTEMS

The new edition of NFPA 13, Standard for the Installation of Sprinkler Systems , makes important changes for dry and preaction systems and officially recognizes negative pressure systems, also known as vacuum systems, as an accepted way to slow or prevent corrosion. Although vacuum technology has been around for many years, the language added in the 2025 edition of NFPA 13 will help guide users and designers in better adopting this method of supervising pipe networks for dry and preaction systems.

CORROSION CONTROL: TACKLING AN OLD PROBLEM WITH MODERN SOLUTIONS

Corrosion has always been one of the main problems for dry and preaction systems. Oxygen and moisture trapped inside the pipes eat away at the steel over time. The results are leaks, blockages, and rough pipe interiors that affect system performance.

The 2025 edition of NFPA 13 takes this problem seriously. It now recognizes vacuum systems as an accepted way to slow or prevent corrosion.

• Vacuum systems solve the problem differently. By keeping the pipes under negative pressure, oxygen and water are significantly reduced. Without them, the corrosion cycle simply does not start.

This recognition is also tied directly to design. Steel pipes in dry and preaction systems now default to a C-factor of 100, which reflects rougher pipe conditions over time. But if vacuum technology is used, designers are allowed to apply the higher 120 value. In practice, that means smoother calculations and better flow assumptions for systems designed with corrosion protection in mind.

VACUUM SYSTEMS: WHERE TECHNOLOGY MEETS LONGEVITY

Vacuum technology is one of the most interesting parts of the 2025 update because it moves from being “innovative’’ to being formally recognized in NFPA 13.

Corrosion Control: The main advantage of vacuum systems is their ability to eliminate both oxygen and water from the corrosion equation. With those two elements gone, rust can not form. Studies show vacuum systems slow corrosion significantly compared to traditional air-filled systems and perform similarly to even nitrogen-filled systems.

Fast Set-up and Instant Performance: One of the key features of vacuum systems is that the process is natural, environmentally friendly (green), and very quick. We are simply using basic laws of physics to reduce the amount of oxygen and water

moisture in the pipe, therefore reducing the amount of energy in the system, making it practically inert. We are talking about achieving corrosion resistance in mere minutes even for larger networks. Once the proper vacuum is achieved in any piping network we are sure that the entire network is being protected as the reduction in oxygen and air moisture is achieved uniformly.

Peace of Mind: There is no external monitoring required with vacuum systems. As soon as the piping network for a dry or preaction system is under negative pressure, we know the system is performing as it should. Similar to a positive air-filled system, if there is a leak in the piping network, a vacuum pump will ensure the proper vacuum level is maintained, and if, for some reason, the network is compromised, a supervisory signal will be sent to the panel for further investigation. This peace of mind is inherent to the system, like any standard dry or preaction installed today.

Freeze Protection: Vacuum systems also cut down on the risk of ice plugs. In cold climates, condensation inside pipes can freeze and block water delivery. Negative pressure minimizes condensation by reducing the amount of oxygen, water moisture, and removing energy in the system. This means that once

A FireFlex negative pressure system is in AFSA’s Training Lab.

MEET YOUR 2026 M/S COUNCIL MEMBERS

KAEMPFER ELECTED CHAIR, ENGLISH VICE CHAIR

CLARISSA RIOS | AMERICAN FIRE SPRINKLER ASSOCIATION

The American Fire Sprinkler Association (AFSA) is pleased to announce the results of the 2026 Manufacturers/Suppliers (M/S) Council election. After votes were cast and tallied, Andy L. Kaempfer, Safe Signal, will serve as chair, and Dave English, General Air Products, will serve as vice chair.

“Throughout my career I have worked hard to advance operational excellence, foster sustainable growth, and champion the development of local and global awareness of fire sprinklers and their efficacy at slowing the fire epidemic,” Kaempfer says. “As the vice president of suppression sales for the Americas at Potter Global Technologies, I have led initiatives that have strengthened industry collaboration, enhanced competitiveness, and promoted the adoption of cutting-edge technologies. As Chair of AFSA’s M/S Council, I will commit to working hard at guiding its members in its mission to support manufacturers and contractors through advocacy, innovation, and partnership ensuring our industry continues to thrive in an evolving global landscape.”

“I would like to express my sincere gratitude for being named vice chair for AFSA’s M/S Council,” says English. “I am deeply humbled by the trust and the confidence that the

Council members have placed in me. On behalf of the entire Council, I would like to thank Phil Schechinger for the tremendous job he has done over the last two years in solidifying our mission and moving the Council forward. As a Council, we are more than confident that incoming Chair, Andy Kaempfer, will continue to work diligently and collaboratively to keep the successful trajectory we are on. I can’t wait to work side by side with him and all the other Council members on the important work we do for the AFSA and this incredible industry!”

ELECTION RESULTS

In addition to the newly elected Chairs, three individuals will commence their newly elected terms on Jan. 1, 2026. James Yost, TALCO; Lainey Liotta, Blazemaster; and Sara Hiers, Watts Fire, Waterworks, and Irrigation; will each embark on a three-year open term that is set to expire on Dec. 31, 2028. Additionally, Mandy Giesbrect, NUCOR, has been elected to a one-year open term, expiring Dec. 31, 2026.

Members of 2026 M/S Council include Andy Kaempfer, Safe Signal; Dave English, General Air Products; Derek Allen, Core & Main; Jason Allen Burley, Johnson Controls; Mandy Giesbrect,

NUCOR; Sara Hiers, Watts Fire, Waterworks, and Irrigation; Tate Hitzeman, Potter Electric Signal Company; Scott Howser, Victaulic; Jeff Key, Ferguson Fire and Fabrication; Lainey Liotta, Lubrizol Advanced Materials; Jim McHugh, AGF Manufacturing; Terry Pickvet, Winsupply; George Rabideau, Wheatland Tube; Jason Allen Burley, Johnson Controls; Phil Schechinger, Viking Group; Rex Schwendiman, Reliable Automatic Sprinkler Company; and James Yost, Talco Fire Systems.

COUNCIL COMPOSITION

The M/S Council is comprised of both appointed and elected representatives. Each device manufacturing company that holds AFSA membership at category 8 or above is allowed one seat, with the representative to be appointed by the individual company, and three appointed seats on the Council are reserved for distributors/ fabricators in dues-paying category 7 or above with a national scope. In addition, there is one domestic pipe manufacturer seat for category 7 and above. There are eight elected representatives, and persons serving in these positions may represent any supplier or manufacturer company that includes, but is not limited to, suppliers, other manufacturers, or manufacturer’s representatives as long as the company is an AFSA member in good standing.

AFSA members are encouraged to contact Council representatives with questions or ideas. If you are interested in becoming more involved with AFSA, consider investing in the future of your industry. Please also consider the time and financial commitment required to attend meetings and work on AFSA programs.

The M/S Council will meet during the AFSA Board and Committee quarterly meetings in 2026: Jan. 20-22 in Palm Springs, Calif.; April 28-30 in Savannah, Ga.; July 28-30 in Portland, Maine; and Sept. 27-30 in San Antonio, Texas.

All companies represented on the M/S Council, whether the position is appointed or elected, must maintain their status as an AFSA member in good standing. Currently, to run for an elected seat on the M/S Council, nominees must attend at least one M/S Council meeting and exhibit at the AFSA Exhibition within the prior year. Members interested in serving should contact Denhardt at jdenhardt@firesprinkler.org. n

From left to right: Dave English has been elected M/S Council Vice Chair and Andy Kaempfer has been elected M/S Council Chair.

RECALLED PRODUCTS A BLAST FROM THE PAST

BOB CAPUTO, CFPS | AMERICAN FIRE SPRINKLER ASSOCIATION

The recent loss of life fire at the Gabriel House Assisted Living facility in Fall River, Mass., has been attributed to the presence of recalled sprinklers installed in that facility. The Massachusetts State Fire Marshal has described this as a ticking time bomb, following an investigation that revealed other local systems may also have recalled products installed that have not yet been discovered, identified, or replaced. There can be no question that closer examination of facilities nationwide, if not globally, could reveal similar results and problems.

While not all the facts related to the Gabriel House fire are yet known, we do know that recalled products, including sprinklers, are still out there and must be identified and replaced.

NFPA 25, Standard for Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, 2026 edition, section 4.1.6.1.1* states that upon discovery of any component and equipment under recall or replacement programs by the owner’s maintenance personnel, designated representative, or contractor, the owner shall be notified in writing. As noted in the enhanced content of this section in NFPA LiNK, paragraph 4.1.6.1.1 raises awareness of the importance of handling recalled products or components if they are discovered. This requirement does not necessitate that the owner’s maintenance personnel, designated representative, or contractor have specific knowledge of recalled products or components. However, if they do identify recalled items installed in a system, they must notify the owner so that the owner can take corrective action.

There are a few challenges in practice related to this requirement:

Recalled Central Omega sprinklers. CPSC alleges that, on average, between 30 and 40 percent of Omegas removed from various locations across the country for testing failed to activate as they should. CPSC is warning consumers that they are at risk of bodily injury or death and should have Omegas replaced as soon as possible.

• Periodic inspections of sprinklers, pipes, and fittings, etc., are conducted from the floor level, so it can be difficult to identify components that may be affected by a recall, which may not be visible even to the trained eye.

• Many of the sprinklers on the recall list were manufactured and installed between 1982 and 1999. Many younger inspectors may never have heard of the recall event or visited the sprinkler recall website pages.

This might also apply to building and facility managers, as well as property owners, who are ultimately responsible for the systems they own or manage, along with compliance with inspection and testing requirements. One solution lies in increasing public awareness and education across the board. If the Fall River fire marshal is correct in the assertion that recalled fire sprinklers and other recalled products represent a ticking time bomb, we need a concerted effort to inform everyone

associated with maintaining these life safety systems.

Recalled sprinklers include the following:

• Omega sprinklers – Central GB and Omega brand sprinklers, manufactured from the 1970s to 2000, featured O-ring seals that could degrade over time, preventing the sprinklers from activating. These sprinklers were recalled in March of 1998 after tests revealed a 30-40% failure rate in lab activation tests. Overall, the recall included 35 million sprinklers.

• Star sprinklers – Manufactured by Mealane Corp., approximately 1 million Star sprinklers manufactured from 1961 through 1976 were recalled in 1999 when tests showed a 67% failure rate.

HOW TO IDENTIFY RECALLED SPRINKLERS

1. Locate the sprinkler: Find the brand name (Central or Star, or others) and model number stamped on the sprinkler head.

2. Check for the date: Look for the date of manufacture, which will be a four-digit year stamped on the base, deflector, or arm.

3. Verify with the U.S. Consumer Products Safety Commission (CPSC) or other site: Compare the identified model and date against the recall information at cpsc.gov.

Fire sprinkler systems are required to have spare sprinklers provided on the protected premises, typically located in a cabinet near the system control riser or elsewhere on the property. These spare sprinklers are provided to enable the prompt replacement of activated or damaged sprinklers. A sign should be located inside this cabinet indicating the make, model, type, and number of sprinklers required to be present. It is common for these spare sprinklers to be identical to those installed in the system, so one place to look for evidence of recalled sprinklers is to examine these devices. The spare sprinkler may not be identical to those installed in every case, but it can be a helpful starting point in the process.

Building owners, property managers, homeowners, and others should immediately replace all sprinklers that are painted, corroded, leaking, damaged, or known to be recalled. Municipal and contracted inspectors should be trained to help identify recalled products and the actions to take when they are known to be present. Anyone needing assistance identifying recalled fire sprinklers, or other recalled products discovered in their water-based fire protection systems, can contact AFSA’s Engineering & Technical Services Department for guidance by emailing questions to technical@firesprinkler.org or the technical services department of any fire sprinkler manufacturer.

Our members who provide inspection and testing services must provide training and information to their inspectors and have procedures in place to document their findings related to deficiencies, recommendations, and the discovery of recalled fire sprinklers or other recalled products that may have been installed in a system. Remember to document everything to avoid being

pulled into litigation or other costly processes. Most importantly, remember that your firm provides inspection and testing services, during which problems may be revealed that require attention. It is always the owner’s (or their designated representative’s) responsibility to facilitate necessary repairs and identify changes in building use that may impact the ability of installed fire protection systems to control or suppress a fire as intended. Fire sprinklers save lives and property. Let’s protect our image and the excellent record we’ve established as an industry. n

Recalled “Star” brand sprinkler. According to CPSC, these sprinklers could fail in a fire, exposing the public to bodily injury or death.

ABOUT THE AUTHOR: Bob Caputo, CFPS, is president of the American Fire Sprinkler Association (AFSA).

EMBRACING TECHNOLOGY

INNOVATIVE FIRE PROTECTION PRODUCTS BENEFIT OWNERS AND CONTRACTORS

JIM MCHUGH | AGF MANUFACTURING, INC.

When it comes to fire protection, codes and standards provide the baseline: reliable systems designed to save lives and protect property. But for building owners, simply meeting minimum standard requirements doesn’t always address the everyday challenges of operating and maintaining these systems. Increasingly, the fire protection industry is embracing technologies and product designs that go beyond compliance to deliver added value through convenience, cost savings, and peace of mind.

BUILDING STANDARDS: THE STARTING POINT, NOT THE FINISH LINE

Standards are essential, but they’re written to ensure safety, not to optimize building operations. They don’t always account for factors like maintenance labor, service costs, or the risk of incidental water damage. Manufacturers and contractors are stepping in to fill that gap by offering products that streamline maintenance, reduce nuisance issues, and provide owners with tools for smarter management of their fire protection systems. For example, AGF’s Flood Eliminator is a product designed to allow condensate water to collect normally in a standard drum drip but then, if presented with the flow that would result from a failed drum drip, automatically trip to cut off that flow, eliminating the flooding and damage that would result from the system’s failure.

THE OWNER’S PRIORITIES BEYOND COMPLIANCE

For building owners, the value of a fire protection system often extends

beyond compliance. Convenience and efficiency are important, since owners want to minimize the time and disruption required for inspections, testing, and maintenance. Cost control is also a priority, with an emphasis on avoiding expensive service calls, reducing the risk of water damage, and extending the lifespan of the system. Finally, owners place high importance on visibility and confidence. They want access to real-time data and reassurance that their system is operating as intended. These priorities are shaping demand for products that provide more than basic functionality and that make ownership easier, more cost-effective, and more reliable.

THE ROLE OF IOT IN FIRE PROTECTION

One of the most meaningful advancements in fire protection system maintenance has been the integration of Internet of Things (IoT) technology for targeted system monitoring. AGFConnect is designed specifically to monitor auxiliary drains and alert building personnel via text message, app notifications, and emails when maintenance is required. By tracking condensation levels in real time, AGFConnect identifies when water has accumulated, prompting timely service before ice damage occurs. Contractors can also leverage this technology to offer proactive maintenance programs for their customers, receiving alerts when a drain requires attention and performing service

AGFConnect sensor and gateways wirelessly monitors for real-time auxiliary drain maintenance alerts.

only when needed to prevent freezing or accidental system trips. This focused, proactive approach reduces unnecessary site visits and manual maintenance while ensuring that critical low points remain operational. As a result, facilities can maintain compliance and system readiness with greater efficiency and confidence, and contractors can offer data-driven maintenance programs.

SMARTER MAINTENANCE-FRIENDLY PRODUCTS

Innovation is also improving the way systems are maintained. Auxiliary drains, for example, have long been a source of nuisance trips and accidental discharges. Dry and preaction systems are especially vulnerable in unheated areas where condensation in auxiliary drains can freeze and compromise the system. Traditionally, freeze protection required constant vigilance and manual intervention from contractors or facility personnel. Today, heated cabinets have been developed by AGF Manufacturing to house auxiliary drains and protect them against freezing. In addition, AGF’s Model 5450 self-maintaining and Model 5500 auto-draining cabinets are available, which continuously manage condensation without manual effort. These solutions lower the risk of freeze-related failures, reduce slip and fall liability due to ice during cold weather, and give owners confidence that their systems remain reliable year-round.

Corrosion protection has also become a priority, since corrosion can shorten the life of a system and lead to unexpected leaks or failures. Automatic air vents, such as the AGF Model 7900AAV, are being used as a proactive approach to remove trapped air, a major contributor to corrosion in wet systems. In addition, CORRINSITE corrosion monitors with sight glasses provide owners with real-time insight into the condition of their piping, allowing them to address issues before they become expensive water damage. CORRINSITE is for wet, dry, or preaction sprinkler systems manufactured from the same mild carbon steel as the system’s piping. The plug’s surface sits at the same depth as the pipe wall and therefore corrodes at the same rate as the pipe. When

the monitor’s plug corrodes beyond its limit, moisture penetrates the sealed chamber and transforms the brilliant white sight glass to a fluorescent orange color, indicating a corrosion problem and a need for further pipe inspection. These tools help owners extend the service life of their systems while reducing the likelihood of disruptive and costly failures.

THE CONTRACTOR’S ROLE: GUIDING OWNERS BEYOND STANDARD

Fire sprinkler contractors play an important role in helping owners understand the difference between meeting standard and optimizing system performance. By presenting clients with options that enhance convenience, reduce costs, and provide better visibility, contractors can demonstrate added value and position themselves as trusted advisors. New technologies also create opportunities for contractors to expand their services. For example, remote monitoring solutions allow contractors to provide ongoing oversight, alerts, and data analysis that go well beyond traditional inspection schedules. By offering these additional services, contractors not only help owners maximize system performance but

also create stronger, long-term partnerships built on proactive support.

RAISING THE STANDARD

Sprinkler systems will always be designed first to meet the requirements of the standards. Yet as technology continues to advance, the industry has an opportunity to raise the standard by delivering solutions that serve owners more directly. Going beyond standard means offering convenience, preventing system downtime, and providing confidence. In the end, going beyond standard isn’t just about better products. It’s about advancing the industry with better outcomes for the people who rely on these systems every day n

ABOUT THE AUTHOR: Jim McHugh is president of AGF Manufacturing, a family-owned company dedicated to improving the industry through innovation and quality. Following in the footsteps of his father, company founder George McHugh, he has continued AGF’s tradition of engineering practical, forwardthinking solutions for contractors and building owners. Under his leadership, AGF has expanded its product lines to include advanced technologies while maintaining a strong commitment to American manufacturing and customer support.

Above photo: AGF Model 5500, fully automatic auxiliary drain with integrated heating and self-draining capability. Right photo: AGF Model 5300A with FloodEliminator to protect against accidental flooding.

AIR SUPPLIES IN NFPA 13 AND 14:RECENT UPDATES

DRY AND PREACTION SPRINKLER AND STANDPIPE SYSTEMS

RAY FREMONT, JR. | GENERAL AIR PRODUCTS, INC.

Sprinkler contractors, engineers, and Authorities

Having Jurisdiction (AHJs) should be aware of some significant updates regarding air supplies in dry and preaction sprinkler systems. Changes in this edition—concerning air compressors, nitrogen generators, and Vapor Corrosion Inhibitors (VCls)—deserve your attention due to their impact on system reliability and compliance.

AIR COMPRESSORS MUST NOW BE LISTED FOR USE IN SPRINKLER SYSTEMS

NFPA 13, Standard for the Installation of Sprinkler Systems, now mandates that any air compressor used in a dry or preaction sprinkler system must be listed specifically for fire protection service. This change eliminates ambiguity and formally brings air compressors into alignment with the listing requirements already in place for nearly every other system component.

To support this change, UL 1450, Motor-Operated Air Compressors, Vacuum Pumps, and Painting Equipment, Supplement SC was developed to establish clear, enforceable performance and construction standards tailored to sprinkler system demands. Unlike the generic UL 1450 listing and listings like it, which cover a wide range of industrial and consumergrade compressors, Supplement SC outlines the specific criteria for the fire protection application, including:

• Pressure Switch Endurance Testing: Pressure-regulating control switches must perform under full load for 100,000 cycles with no more than a 5% calibration drift,

ensuring long-term reliability and preventing system pressure issues that can lead to failures or false trips. Unlisted air compressor pressure switches have no cycle standard, and generic UL 1450 and listings based on UL 1450 criteria (non-Supplement SC) only have a 30,000 cycle requirement. The lower the cycle requirement, the more frequent failures are likely.

• Permanent Wiring Connection: UL 1450, Supplement SC compressors must be permanently connected to a wiring

system, disallowing the use of plug and cord connections commonly found in retail quality compressors. This requirement enhances safety by reducing the risk of malfunctions and accidental system trips due to someone flipping the light switch. (Also must be installed in accordance with NFPA 70, National Electric Code, Article 430; and be placed on its own dedicated electrical circuit).

• Testing at 5x the Maximum Relief Valve Setting: This ensures structural integrity

Figure 1. 8.2.7.5.2 Where an air compressor is dedicated for the sprinkler system, the air compressor shall be listed for fire protection.

2. Note the label: “This air compressor has been evaluated for fire sprinkler use according to UL 1450, Supplement SC.”

under extreme conditions, even at maximum operating pressure. Safety relief valves also ensure that air compressors comply with industrial safety standards, such as those set by OSHA and ASME.

• Clear Markings of the Maximum Rated Operating Pressure: pushing any air compressor beyond its listed pressure range can not only be dangerous, but also affects NFPA 13’s required 30-minute system fill requirement. More pressure = less flow, and less flow= more time your system will take to reach that higher pressure. Sprinkler air compressors are sized to meet this 30-minute fill requirement, and the pressure ratings of each compressor must be followed in the field.

• Proper Labeling: every UL 1450, Supplement SC sprinkler air compressor will include labeling stating: “This air compressor has been evaluated for

sprinkler use according to UL 1450, Supplment SC,” giving inspectors, contractors, and Authorities Having Jurisdiction (AHJs) clear confirmation of compliance in the field.

This listing ensures that compressors are purpose-built for the fire protection environment—rated for the required 30-minute system fill time, pressure range, and installation method. Contractors, engineers, and AHJs should now expect—and require—UL 1450, Supplement SC compliance on all new dry and preaction system installations. It’s a step forward in reliability, safety, and enforceable code compliance.

PROTECTION AGAINST LEAK RATE ISSUES FOR NITROGEN GENERATORS

The new edition provides a significant revision regarding nitrogen generators, this equipment is now required to be sized to a

in accordance with the Hazen-Williams formula

C values from Table 28.2.4.8.1 as follows: (16) In new systems, an increased C value of 120 shall be permitted where a vapor corrosion inhibitor is provided in accordance with 8.2.11.

minimum leakage rate of 1.5 psi (0.1 bar) per hour (NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, allowable rate), while maintaining 98% concentration throughout the entire sprinkler system. This change stems from feedback indicating that many nitrogen generators were unable to sustain the required flow necessary for corrosion mitigation as system leak rates grow over time. Consequently, many systems either failed or were left in an air “bypass” mode after a low-air alarm, leading to increased costs and corrosion issues for both contractors and building owners.

This updated standard compels manufacturers to design nitrogen generators that can perform at and beyond the NFPA 25 permissible pressure leak rates from day 1 commissioning. Producing 98% purity nitrogen on-site is an inefficient process and difficult to maintain long-term. For contractors, this means careful consideration must be given to the sizing and selection of nitrogen generators. Ensuring that these units are capable of meeting these demands from the outset is crucial for avoiding future failures.

VAPOR CORROSION INHIBITORS: THE MOST EFFECTIVE APPROACH TO CORROSION MITIGATION

The 2025 standard has also formally adopted language defining

Figure

Figure 3. 8.2.10.2. The nitrogen generator shall be capable of supplying and maintaining at least 98% nitrogen concentration throughout the system at a minimum leakage rate of 1.5 psi (0.1 bar) per hour.

Figure 4. 28.2.4.8.1 Pipe friction loss shall be calculated

with

VCls or Vapor Corrosion Inhibitors and given instruction on their use and delivery method in dry and preaction sprinkler systems.

The three aspects that the new edition calls out regarding the use of VCls include:

• The Vapor Corrosion Inhibitor shall be from a listed assembly (such as Vapor Pipe Shield) that is permanently installed on the system.

• The Vapor Corrosion Inhibitor shall be maintained in accordance with the manufacturer’s instructions.

• In new systems, a C value of 120 shall be permitted where a vapor corrosion inhibitor is used.

The new edition of NFPA 13 highlights the role of Vapor Corrosion Inhibitors (VCI) in optimizing system design and reliability for the long term, while offering significant cost

savings compared to more conventional methods of corrosion control like nitrogen generators. n

ABOUT

THE AUTHOR: Ray Fremont, Jr. has worked at General Air Products for over 25 years. Now, as president of General Air Products, he represents the fourth generation of his family’s air compressor and industrial equipment manufacturing company. Fremont has spent the last 10 years educating the fire protection industry about the nuances of the spaces where air supply equipment is installed and serviced.

“YOU CALLED ME, RIGHT??” DECECCO RETIRING AFTER 42 YEARS OF CUSTOMER SERVICE

Here is a statement that I know to be true: if you have needed assistance with a fire sprinkler air compressor any time in the last 42 years, then you have been assisted in some way by Ray DeCecco.

I think it is amazing that one person has had a hand in helping fire sprinkler contractors solve problems so singularly and for so long. When industry experts like John Denhardt, Martin Workman, Jim Dooley, or Terry Victor have questions about fire sprinkler air compressors, they call Ray DeCecco.

Ray has worked in sales and customer service at General Air Products for almost his entire career. He was introduced to the fire sprinkler industry through my father, who he has known since they met in kindergarten. Ray and my dad were friends through grade school and high school, and worked side-byside until my dad passed away in 2021.

Ray’s professionalism has been a cornerstone for the values that General Air Products’ customer service and sales staff work to embody as we serve the industry. Everything I have learned about customer service comes from Ray D (as we all call him). Asking questions, applying expertise with confidence, always remembering that the customer is in a jam and looking for help—even when they get hot about it. These are pivotal to good service.

That said, one of the best things I’ve learned from Ray is that customer service is a two-way street. It requires earnestness and honesty from everyone involved. Patience in

this process has its limitations, and for good reasons. Ray D is an incredibly patient person with customers. If Ray’s patience runs out it is because the person on the other end of the phone is not ready to be helped. In modern terms, they are still in the “feelings” stage of the issue.

When I worked as an inside sales rep, I knew that Ray’s patience was at its end on a call, when I would hear him say, “Wait, wait wait… You called me, right?” What a great phrase—full of Philadelphia attitude.

Ray D, being earnest and honest, used the phrase sparingly and only as a means to wake up a customer. After going back and forth with a customer who called for help, after arguing over each step in the troubleshooting process, Ray D said, “Wait, wait, wait… You called me, right?” and he waited until they answered the question. At that point, a customer could continue to “passionately express” their frustration. If they chose that path, Ray would tell them, “Call me back when you cool off and I will be happy to help you.” Then he’d hang up on the customer. He would hang up on them because they forgot that when they made the call, they were looking for his help. Help that he cannot give if they are not ready to work together with him.