MAR/APR 2023 AFSA42PLANS TOBEMAGICAL SPRINKLERAGE VOL 42/02 FIRE PUMPS OFFICIAL PUBLICATION OF THE AMERICAN FIRE SPRINKLER ASSOCIATION

Approved up to 400 psi reliablesprinkler.com/prv PERFORMANCE UNDER PRESSURE

PRV Pressure Regulating Valve

Model PRV is a compact, diaphragm-type valve that reduces and regulates pressure in

flowing and nonflowing conditions.

no trim connections to the

of

valve,

PRV

to install, maintain, and service. USA Manufactured in the with Globally Sourced Parts

Model

The

both

With

face

the

the

is simple

Safety is at the forefront of every action we take as a company. To reduce risk and promote consistency, we take advantage of automatic welding technology when creating fire protection products for customers across the nation.

©2021 Ferguson Enterprises, LLC 0021 000000 VISIT US ONLINE AT FERGUSON.COM/FIRE

©2022 Ferguson Enterprises, LLC 0022 000000

Through

with Xaap

Xaap’s mobile and web-based applications were designed to help streamline the process to maintain, track and ensure system compliance, and manage inspection reporting needs. With Xaap, we make the inspection process easier.

Save time and increase accuracy with standardized templates that follow all current fire code requirements and collaborate with team members more effectively using one source of truth.

Expand your inspection capacity and increase customer satisfaction with easily shared reports and insights.

Get

Learn how Xaap can help you digitize your

reporting process: www.xaapbuildings.com Visit our site and schedule your customized demo today.

easier, smarter building compliance

inspection

Facility manager

one centralized view, access inspection reports 24/7 giving you insights into the health of your fire and life safety systems.

Service provider Inspector

5 SPRINKLER AGE | MAR/APR 2023

FEATURES 12 | EXPERIENCE THE MAGIC! AFSA42 OFFERS CEUS AND CONNECTIONS IN ORLANDO 16 | DIESEL-DRIVEN FIRE PUMP SYSTEMS CALCULATION AND INSTALLATION ISSUES ARE OFTEN MISSED 19 | TRAINING MADE EASY NEW VIRTUAL INSTRUCTION PROGRAM LAUNCHES WITH GREAT SUCCESS 20 | TUNE INTO FM 101: AFSA ROCKS ITM TRAINING ROLE OF FACILITIES MANAGEMENT IN ITM 22 | THIRTY YEARS OF EXCELLENCE CATCHING UP WITH PAST NATIONAL APPRENTICE COMPETITION COMPETITORS 27 | DEVELOPING DESIGNERS NEW PROGRAM OFFERS SCHOLARSHIPS 28 | SUPPORTING FIRE PROTECTION SYSTEMS NFPA 200 IS ON THE HORIZON 30 | ONE-STOP CEU SHOP LIVE AND ON-DEMAND WEBINARS OFFER CEUS, CPDS, AND CAL FIRE-APPROVED COURSES 33 | NEW MEMBERSHIP CATEGORIES ADDED WELCOMING A&E DESIGN FIRMS AND FACILITY MANAGERS 6 CHAIR’S MESSAGE 8 PRESIDENT’S REPORT 10 FLASHPOINT 36 HIGHER STANDARDS 37 TECHNICAL CHALLENGES 38 AFSA NEWS 38 CALENDAR OF EVENTS 39 CHAPTER NEWS 39 ASSOCIATION NEWS 40 AFSA CHAPTERS 41 NEW MEMBERS 42 U.S. CONSTRUCTION 43 PRODUCT NEWS 45 PEOPLE IN THE NEWS 46 INDUSTRY NEWS 46 INDEX OF ADVERTISERS MAR/APR 2023 VOL 42/02 SPRINKLER AGE, (ISSN 0896-2685) is published bimonthly for $33.95 per year by the American Fire Sprinkler Association, Inc., 1410 East Renner Road, Suite 150, Richardson, Texas 75082. Periodicals postage paid at Dallas, Texas and additional mailing offices. POSTMASTER: Send address changes to SPRINKLER AGE, 1410 East Renner Road, Suite 150, Richardson, Texas 75082. Follow us on

ON THE COVER: Fire pumps photo courtesy of Poole Fire Protection, Olathe, Kansas. Also in this issue: AFSA42.

CHAIR’S MESSAGE

Iam hoping by the time you read this, that you all had a great Q1 and are off and running into the 2023 calendar year! Based on the previous edition of Sprinkler Age , the economic experts (which I’m not one of) stated that 2023 should be another solid year for our industry. I know I’ve said this before and will most probably say it again, but we need to feel blessed to be in this outstanding industry at this moment in time. On top of the business opportunities we have, we are also providing a benefit to our communities by offering a service that saves lives. However, we must not forget that people are still dying from fires every day in their unsprinklered homes. For us to truly be successful, we must continue to push to have our systems installed where the people spend most of their time—in their homes. AFSA will be working on a training program to assist companies in learning how to estimate, design, and install NFPA 13D systems while working with other industry associations to push for legislation to mandate all single-family homes be equipped with a fire sprinkler system throughout our great country. Besides pockets scattered around in various states, California and Maryland are the only two states that have statewide initiatives that require new single-family homes to be sprinklered. I was heavily involved in passing the Maryland law and have high hopes over time that we can be successful in other states as well. Please think about offering support where you can for this initiative.

AFSA recently concluded our Q1 committee and Board meetings. One of the most exciting topics that I listened to was the planning for AFSA42. AFSA42 will be held at the Signia by Hilton Orlando Bonnet Creek in Florida September 6-9. AFSA At-Large Director Chris Johnson, president and CEO of Piper Fire Protection, is this year’s Convention Committee chair. He, Marlene Garrett, and the other committee members are planning a tremendous event. Not only will it take place utilizing the beautiful grounds of this resort, but it will also include portions of Universal Studios, making AFSA42 an event the entire family will enjoy! The exhibit floor plan will be unlike any other we’ve had in the past. The National Apprentice Competition will be in the center of the exhibits and not along the edge of the convention floor as in the past. Since the apprentice competition will be the center of attention that day, it only makes sense to have them show their skills in the center of the exhibits! I’ve been the Convention Committee chair twice and never thought of that… great job, team!

AFSA has also just kicked off its new fire sprinkler apprenticeship training program, featuring live virtual instruction. The first class had 26 first-year apprentices attend to begin Book 1. This is an excellent start to this program, and I believe that most contractor members will find this program to be very beneficial. Not only will there be professional instructors teaching the classes, but the cost will be less than doing it in-house as well. If you do nothing else, please take a look at this program and compare it to the method you’re utilizing now … assuming you are, in fact, training your apprentices!

Remember that training is imperative to growing our industry and minimizing our liability. I always hear Bob Caputo’s response when a company tells him that they don’t have time to train and that they feel that after their employees are trained, they’ll leave. His response is always, “What if you don’t train them and they stay?” Spot on, Bob!

May God continue to watch over this association today and throughout 2023. May He also bless you always and in all ways. n

EDITORIAL: 214-349-5965

BOB CAPUTO, CFPS, Publisher, ext. 124 bcaputo@firesprinkler.org

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

ADVERTISING: 214-349-5965

SYDNEY RICHARDSON, Communications Specialist, ext. 134 srichardson@firesprinkler.org

CIRCULATION: 214-349-5965

D’ARCY G. MONTALVO, Editor, ext. 115 dmontalvo@firesprinkler.org

AFSA BOARD OF DIRECTORS

JACK A. MEDOVICH, P.E., Chair, 804-222-1381

LINDA M. BIERNACKI, First Vice Chair, 318-841-0330

PAUL DELORIE, Second Vice Chair, 603-432-8221

ROD DIBONA, Treasurer, 605-348-2342

JEFF PHIFER, Secretary, 803-438-2994

TED WILLS, Immediate Past Chair, 610-754-7836

LYLE HALL, 858-513-4949

CHRIS JOHNSON, 727-581-9339

R. DONALD (DON) KAUFMAN, 505-884-2447

MICHAEL F. MEEHAN, 757-213-3660

E. PARKS MOORE, P.E., 251-473-6000

JAY STRICKLAND, 301-474-1136

WAYNE WEISZ, 209-334-9119

AFSA LEADERSHIP

BOB CAPUTO, CFPS, President, ext. 124

LAVERNE DAVIS, Vice President, Finance & Administration, ext. 112

JOHN AUGUST DENHARDT, P.E., FSFPE, Vice President, Engineering & Technical Services, ext.121

MARLENE M. GARRETT, CMP, Vice President, Meeting & Education Services, ext. 118

LESLIE CLOUNTS, Director, Education Services, ext. 130

ROGER GRAGG, Director, Marketing & Information Technology, ext. 116

Sprinkler Age is devoted to the professional development of the fire sprinkler industry. Deadline is 1st of the month preceding publication.

Published by American Fire Sprinkler Association, 1410 East Renner Road, Suite 150, Richardson, TX 75082. Call (214) 349-5965, FAX (214) 343-8898, or email sprinklerage@firesprinkler.org for information.

Copyright © American Fire Sprinkler Association, Inc. All rights reserved. PRINTED IN USA. Unless expressly stated otherwise, all editorial and advertising material published is the opinion of the respective authors and/or companies involved and should not be construed as official action by or approved by Publisher or the Association.

Sprinkler Age is a membership benefit, provided free of charge to AFSA members. For information on non-member and/or foreign subscription rates, call (214) 349-5965.

ABOUT AFSA MEMBERSHIP

AFSA annual membership dues are a sliding scale for Contractors and Associates and a flat fee for Authorities Having Jurisdiction. (Members receive a free subscription to Sprinkler Age.) Write or call AFSA for membership information. See AFSA’s website at firesprinkler.org.

6 SPRINKLER AGE | MAR/APR 2023

JACK A. MEDOVICH, P.E. AFSA BOARD CHAIR

SimplifyingCorrosionPreventionindry-pipe andpre-actionfiresprinklersystems. Designed • Engineered • Built in the USA generalairproducts.com Protected by Vapor Pipe Shield Untreated Compressed Air After Two Years of Continuous Testing Fully mechanical & piped directly in-line between the air compressor and the dry pipe valve, Vapor Pipe Shield makes preventing corrosion simple, efficient, and highly cost-effective. How it Works

For a very long time, I owned a 1983 Jeep CJ7 Renegade, which is now in the possession of my daughter and son-in-law, who enjoy weekends in the desert. I bought that vehicle in early 1990 from a Marine who was deploying and it’s since been driven by multiple friends, visitors, and my adult children over the years and with a few exceptions, has been relatively bulletproof in terms of cost to maintain. I actually sold it to a friend who took it to Washington state for his cabin, and after about five years, asked if we wanted it back—which is how my daughter ended up with it. About now, some readers should be asking, “What does this have to do with fire sprinklers?” For those of you still reading, I’m getting there. (By the way, both my daughter and son-in-law work for an AFSA member fire sprinkler company, as do two of my other adult children, so it should be noted that I have contributed directly to industry recruitment efforts.)

If memory serves, I paid that Marine what he asked for, $2,500. It had about 80,000 miles on it at the time, but it wasn’t in bad shape and was an original AMC Jeep (so the dealership wouldn’t work on it any longer since they were now a part of the Chrysler Group). Now, in 2023, this vehicle has at least 150,000 miles on it and is not even listed in the Blue Book, so it’s hard to place a sales value on it, should one want to sell it. But how does anyone define value?

The reality is that the value of anything, tangible or perceived, is really what someone is willing to pay for it. In fact, I believe people, especially businesspeople, are willing to spend money on things that will add value. Case in point, when we go to the grocery store, most people will pass up the savings of store brands in favor of known brands at a higher price because of perceived value or quality. Let’s get back to that 40-year-old Jeep CJ7 for just a moment. Would you believe that a search of the Autotrader.com has a number of similar vehicles (same year) for sale between $5,000 and $40,000? Remember, the Kelly Blue Book site doesn’t even list a suggested price for a 1983 Jeep (or any other 1983 vehicle). So, where is the value? Why would anyone pay $40K for something that originally sold new, off the showroom floor for a fraction of that? Well, some things stand the test of time, and there is a very specific interest group of people who enjoy the off-road experience—a targeted audience.

Again, what does this have to do with the fire sprinkler industry? We are no different than the off-road community in terms of being a very specialized group of people, a targeted audience of people who are willing to part with our hardearned cash for things that add value. We invest in tools and vehicles with no hesitation, and we almost never purchase the cheapest product, but rather spend the extra money on those

products proven to be of better quality and last longer. These tools make us money in the long run, so we’re willing to invest in quality products. That said, what is the most important tool we need? Clearly, that answer is people. We can buy tools, trucks, and materials all day, but we’re all constrained by the number of people we can hire and train to do the work, do it right, and limit our liabilities and exposures.

Your membership in the American Fire Sprinkler Association (AFSA) is one of those decisions that clearly represents an investment in quality and added value. I think we can all agree that developing people is the double-edged sword of our businesses. Sometimes we invest in people who let us down in some way, but that can never stop us from investing in people who we need to develop and grow our businesses and our industry. AFSA’s training programs are unparalleled in delivering quality and value-added services to our members. Beginning and Intermediate Design Schools, ITM Technician Training, and our apprenticeship program and the new Virtual Classroom (with plans to simulcast in Spanish in the future) are just the tip of the iceberg in terms of our value-added propositions. Your access to AFSA’s Engineering & Technical Services Department may be the easiest service we point to as member value, especially from those members who tell us that a single engagement has more than paid for their annual dues.

Like that branded product on your grocery store shelf, AFSA provides that higher-quality product where the added value is worth the price! Get the most value for your membership dollar by taking advantage of AFSA’s training programs, supporting services, and active participation at the local chapter level. We are stronger together! We can help grow your people and increase their value with programs that are practical, applicable, and current. As we prepare to occupy our new offices and training lab here in Dallas, we look forward to delivering “knock-your-socks-off” level services that add value and make your membership worth the spend. n

BOB CAPUTO, CFPS AFSA PRESIDENT

8 SPRINKLER AGE | MAR/APR 2023

PRESIDENT’S REPORT

Oxeo Extinguishing Systems from Viking

Protect High-Risk Areas from Fire with Inert Gases

New cULus Listed and FM Approved Oxeo extinguishing systems offer a unique solution for protecting damage-sensitive areas with the naturally occurring inert gases Nitrogen and Argon. These gases leave no residue on electronic equipment and result in no secondary damage or negative environmental impact, making them perfect for data centers and similar applications. Learn more on our website at vikinggroupinc.com.

To learn more about Viking’s Oxeo extinguishing systems, including tank capacity, pressure ratings and more, please visit vikinggroupinc.com or scan the QR code.

FLASHPOINT

Iam sitting in California in early February as I write this column. The AFSA Board of Directors is meeting, and I have the opportunity to present the status of work in progress and answer questions regarding the Engineering & Technical Services Department. To prepare for this discussion, my department generates a report on our activities and what services our members are utilizing.

Last year was a busy one for my department. Our Technical Review service gives our members access to our engineering staff to ask questions on specific technical issues. Depending on the question, we provide answers by email, letter, or phone. In 2022, we addressed approximately 650 Technical Reviews, with an average response time of less than one business day. About 65 percent of the questions were related to NFPA 13, with the remainder divided between NFPA 14, 20, 22, and 25. A few questions referenced other miscellaneous standards and publications by other organizations. While most geographical areas our members are operating in are governed by previous editions of the referenced standards, most responses are based on the latest edition of the standard. Where requested, we do review previous editions of the standards and provide documentation of any changes as well as the rationale behind changes in the standard over the years.

The number of reviews is heavily based on the size of the requesting company. Our smaller category members (Categories 1 to 5) have asked almost 50 percent of the questions, while our designer category asked nearly 20 percent of the questions. This service occupies approximately 1,000 hours of staff time each year. If your company is not utilizing the Technical Review service, try us out.

AFSA is well represented on the NFPA Technical Committees. We have 118 seats on 55 different technical committees. Our volunteers and staff cover 44 codes and standards. We are also involved in 12 different UL standard technical panels. These panels set the standards that equipment must meet to be Listed by UL. We bring a contractor’s perspective to this process.

With a new year, changes do occur. I am disappointed to announce John Johnson has left AFSA for another opportunity that does not require travel. His employment with AFSA was very beneficial to our members. John’s ability to reach and interact with our students in the ITM programs we offer was outstanding, and we wish him the best. Who knows, he might assist us in the future by giving selected presentations. Josh McDonald, MSET, CFPS, CWBSP, WBITM, manager of technical services, will assume John’s role. We will not miss a step as Josh is a natural with ITM.

I am also very proud to announce the addition of Veronica Westfall to our staff as a technical development specialist. In her previous position, she authored all four levels of the new AFSA Sprinkler Fitting curricula, so she is very familiar with our program and the needs of our trainees. With all the training programs we create, having her on our team will make us much more efficient. Welcome aboard, Veronica!

My goals for this year can be summarized by the following three points:

• Ensure our training for AFSA members is the best it can be. We will be updating and modernizing our current offerings to ensure we are instructing to the latest developments in the standards and current industry practices while presenting the material in a manner that today’s students expect. We will expand our offerings based on members’ needs and desires. We all require a qualified workforce, and AFSA is here to serve that need as the leader in training for the sprinkler industry.

• Ensure our membership and chapters get to know the AFSA Engineering & Technical Services staff. We will be out visiting the chapters and our members. We will be presenting in person where we physically can. There is nothing better than the direct interactions we have with our members. Look for us, introduce yourselves, and ask us questions. My entire staff enjoys this type of interaction.

• Build a state-of-the-art classroom and lab in our new Dallas office to better serve our members by offering the very best hands-on training on a variety of fire protection systems. Our new lab is being designed and constructed early this year. Several manufacturers and suppliers have generously offered their assistance. We will also need fitters to help with the installation. If you would like to participate, contact Josh McDonald at jmcdonald@firesprinkler.org. Stay tuned for more information as it takes shape!

I have been involved with AFSA since 1994 as a volunteer and for the last three years as an employee. What a fantastic ride it has been. I appreciate all the AFSA Board of Directors does for the association and in allowing me the honor of representing them as the vice president of the Engineering & Technical Services Department. Thank you! n

JOHN AUGUST DENHARDT, P.E., FSFPE AFSA VICE PRESIDENT OF ENGINEERING & TECHNICAL SERVICES

10 SPRINKLER AGE | MAR/APR 2023

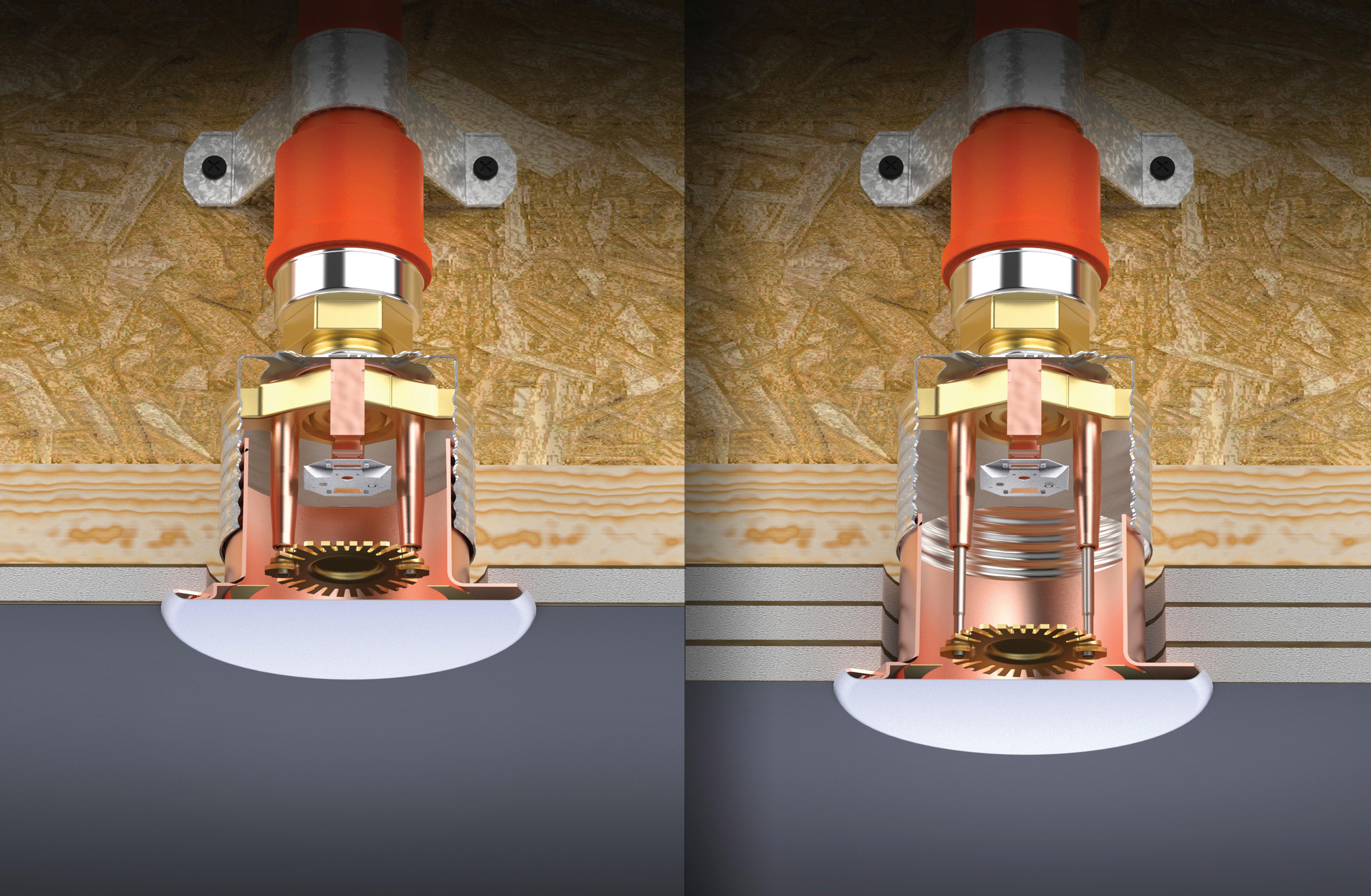

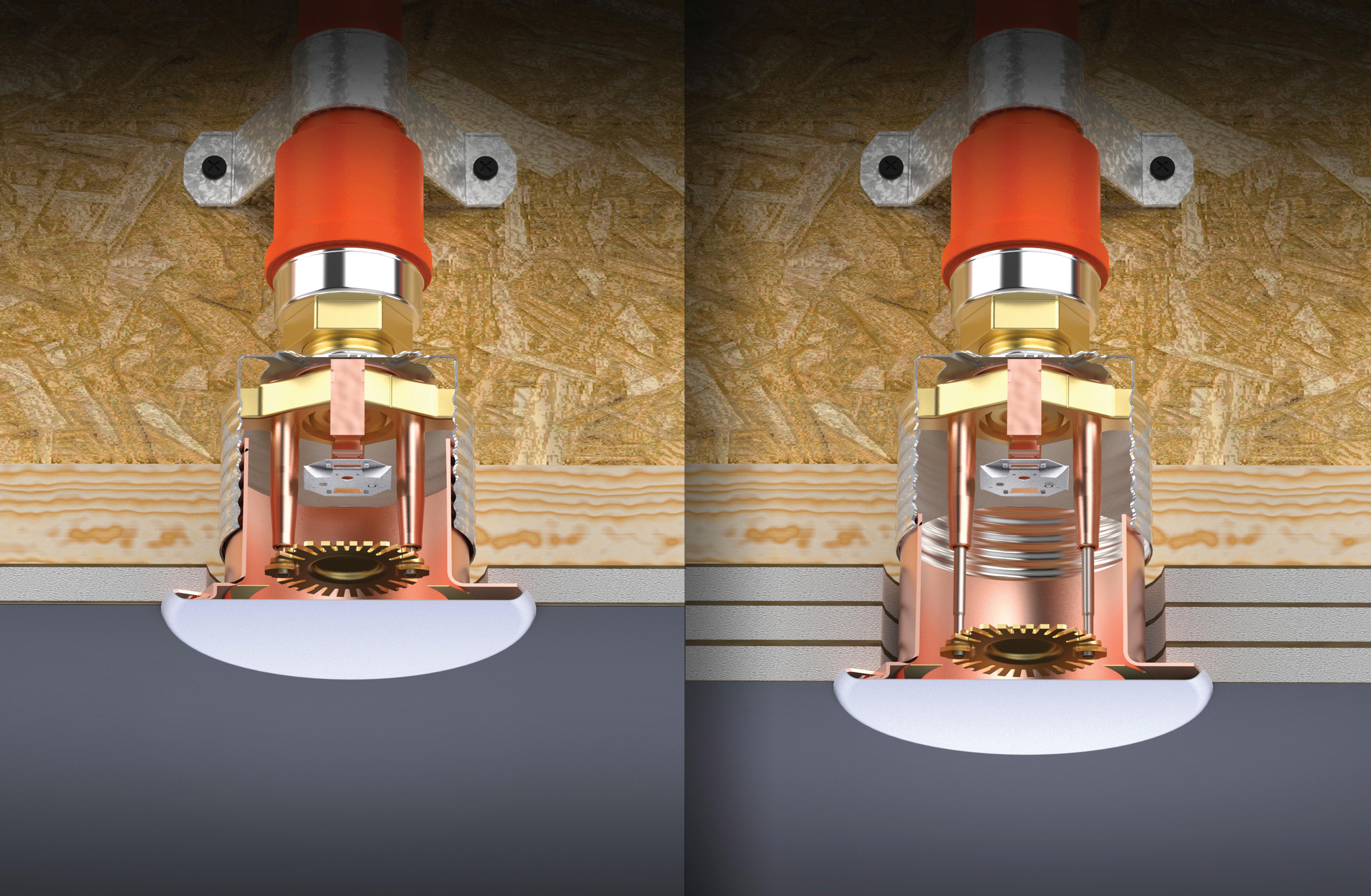

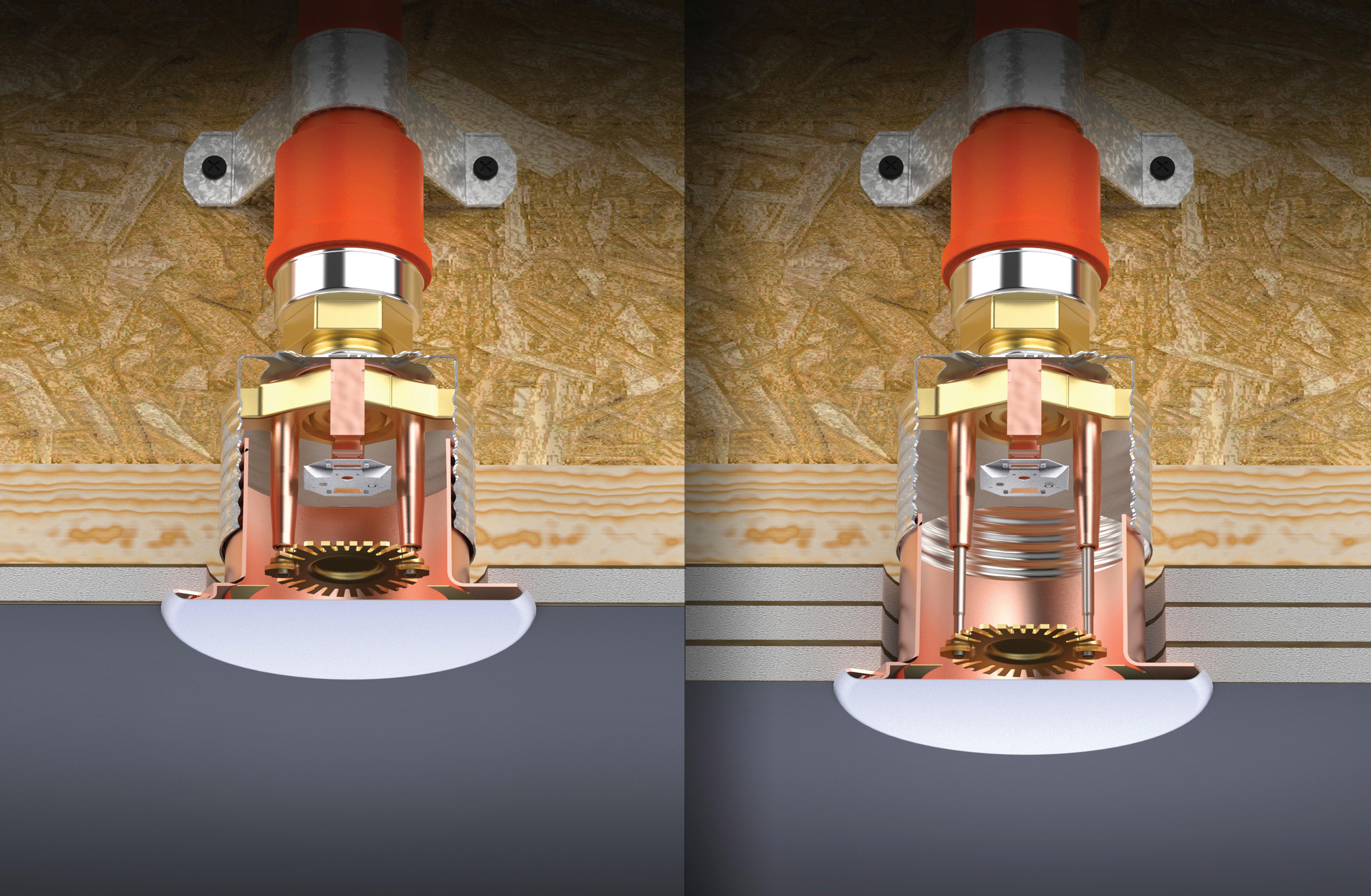

STYLE VS2

STANDARD COVERAGE SPRINKLER

The only flexible, UL Listed K5.6 Standard Coverage sprinkler with no equivalent length calculations needed past the branch line.

STYLE VS2

• One assembly with one field connection

• No equivalent length of pipe to calculate

• Reduced pipe preparation and field work

HARD PIPE, ELBOWS, K5.6 SPRINKLER

• Multiple components and connection points

• Must calculate to account for frictional resistance of pipe and fittings

• Must measure, cut and thread hard pipe

SCAN TO LEARN MORE © 2023 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

EVERY DAY, ON EVERY PROJECT, WE WORK FOR YOU.

EXPERIENCE THE MAGIC!

AFSA42 OFFERS CEUS AND CONNECTIONS IN ORLANDO

SYDNEY RICHARDSON | AMERICAN FIRE SPRINKLER ASSOCIATION

When many think of Orlando, Disney World and Universal Studios usually come to mind. While memories of Mickey Mouse or heart-racing roller coasters might be floating around in your mind, we hope to rewrite that top-of-mind recall this year at AFSA42: Convention, Exhibition, and Apprentice Competition, September 6-9, 2023, at Signia by Hilton Orlando Bonnet Creek! The American Fire Sprinkler Association’s (AFSA) annual convention returns to Orlando, and excitingly enough, it’s also the 30th anniversary of the National Apprentice Competition (NAC). AFSA42 encourages newcomers while invigorating growth and prosperity for members with expert education, top training, and numerous networking opportunities

“AFSA42 is going to be a magical experience. Prepare yourself to experience cutting-edge technology, first-class training, and unforgettable evening events,” comments AFSA Vice President of Meeting & Education Services Marlene Garrett, CMP. “Experience the magic. We can’t wait to see you in Orlando!”

PERFECTLY PACKED SCHEDULE

AFSA42 will offer four days of managerial and technical seminars filled with education, training, and networking led by industry experts. Educational seminars over seven tracks cover all aspects of the industry: Install/Design, ITM, Other Technical, Fitter, NextGen, AHJ, and Business Management— hours of CEUs, CPDs, and Florida-Approved credits. AFSA’s exhibition provides an opportunity to meet with leading manufacturers and suppliers of the latest products and services offered in the fire sprinkler industry. The unopposed exhibit hours allow attendees and exhibitors to visit without interruption, and the second day of exhibits also features the finals of AFSA’s 30th National Apprentice Competition (NAC). For apprentices interested in competing, see page 31 of this issue or visit www.firesprinkler.org/competition/.

Convention spotlights include the Exhibition Grand Opening reception, general session, two evening parties, and social events, as well as a chance to relax with friends new and old during the networking meals hosted for attendees who are fully registered in AFSA’s room block at Signia by Hilton Orlando Bonnet Creek. This year’s convention will kick off with an opening party on Wednesday, September 6, at the Wizarding World of Harry Potter™– Hogsmeade™ at Universal Studios. Guests will begin the evening with an exclusive dinner at Universal CityWalk™, where

guests enjoy a variety of themes and cuisines. After dinner is presented by an award-winning culinary team, guests are free to explore an eclectic mix of venues, including: Bob Marley – A Tribute to Freedom SM, Pat O’ Brien’s® Orlando, and CityWalk’s Rising Star™. The streets will stay alive with music from a DJ and stilt walkers. Then, guests will be escorted to the Wizarding World of Harry Potter™– Hogsmeade™ where they will experience a one-of-a-kind event filled with magic and excitement. A delectable dessert selection and bountiful beverage service will be offered, followed by free reign to experience Harry Potter and the Forbidden Journey™, Hagrid’s Magical Creature Motorbike Adventure™, and Flight of Hippogriff™. If that’s not enough, guests will also be entertained with scheduled performances by the Frog Choir and Triwizard Spirit Rally, and can visit Ollivanders™ wand shop, and the train conductor.

Convention comes to a bittersweet end with the crowd-pleasing Awards Party to be held on the final night of the convention—Saturday, September 9. This year, our Awards Party has the exciting theme of “Magic and Illusions”! Guests will enjoy a night of dancing and dining amid strolling magicians, an illusionist, and a contortionist at the Pavilion at Signia by Hilton Orlando Bonnet Creek. Come celebrate with AFSA and find out who will win the apprentice competition!

PLAY WHILE YOU STAY

The hotel rooms and suites at Signia by Hilton Orlando Bonnet Creek offer a sophisticated elegance creating a relaxing

12 SPRINKLER AGE | MAR/APR 2023

The newly renovated Signia by Hilton Orlando Bonnet Creek will host AFSA42, offering an elevated experience for attendees.

ambiance for AFSA42 attendees to unwind and recharge. From the luscious, green Florida views to the various amusement parks at your feet, stays are anything but ordinary. Signia by Hilton Orlando Bonnet Creek offers luxurious rooms, fine dining, Waldorf Astoria Spa, a state-of-the-art fitness center, the top-rated Waldorf Astoria Golf Club, FunZone arcade, and a lagoon-style pool complete with private cabanas and a waterslide! Did we mention the complimentary transportation to all four Walt Disney World® Theme Parks and Disney Springs®?

The AFSA group rate for Signia by Hilton Orlando Bonnet Creek is $199 per night plus tax and includes complimentary internet in guest rooms. Reservations may be made online during the convention registration process at www.firesprinkler.org/book. Group rates are available for stays from September 2-12, 2023, but reservations must be made by Friday, August 4, 2023, to secure AFSA convention group rates. After August 4, room rates are based on availability.

HOTEL RESERVATION & ATTENDEE LIST ALERT

AFSA is made aware of third-party vendors soliciting AFSA exhibitors and attendees posing as our housing vendor or attendee list distributor. These companies mislead you into thinking they are working on our behalf. Companies that use this tactic include Exhibitor Hotel Reservation Services (EHR), Global Housing, and National Travel Associates. They are not endorsed by or affiliated with AFSA or its show. Entering into financial agreements with such companies can have costly consequences, such as no hotel reservations, no free networking meals, no complimentary internet access, or a mailing list. To receive full AFSA hotel benefits, book directly with the

hotel by phone or using the link found on AFSA’s convention website, www.firesprinkler.org/AFSA42. Please note attendee lists are distributed onsite complimentary. AFSA does not use outside services to sell attendee lists.

SPONSORSHIP OPPORTUNITIES

AFSA42 is expected to attract over 600 decision-makers from all corners of the country, many of whom are looking for innovative products and services to help make their companies more competitive. From the Diamond to the Bronze level package, AFSA has sponsorships to fit every budget. AFSA42 sponsors enjoy visibility, recognition, and access to convention attendees. Benefits are provided throughout the convention with online exposure, increased visibility, and face-to-face opportunities. Some of these benefits include:

• Priority booth selection for sponsors at the Diamond, Platinum, Gold, and Silver levels (AFSA members only). Booth selection will be based on the current point system within each sponsorship level, from Diamond to Silver.

• Room-access key cards. Diamond sponsors will have their logo featured on hotel room key cards.

• Recognition at Awards Party. Diamond sponsors will receive special recognition during the final-night Awards Party, where AFSA crowns its newest National Apprentice Competition champion! New benefits are available for Diamond sponsors for 2023! Diamond sponsors will have added exposure with:

• Company branding at the Awards Party,

• Company branding on highly visible wall wraps at Signia by Hilton Orlando Bonnet Creek, and

13 SPRINKLER AGE | MAR/APR 2023

Signia by Hilton Orlando Bonnet Creek is an Official Walt Disney World® Hotel, welcoming guests into a blend of inspired hospitality and exceptional amenities. From a brand-new lobby to elevated guest rooms, signature dining and innovative meetings, guests can enjoy memorable experiences and best-in-class travel in iconic Orlando.

• Company branding at the Universal Studios CityWalk Opening Party.

AFSA offers several “a-la-carte” options for companies, including pre-event email press releases, pre-event sponsored blog posts, convention app rotating banner ads, and networking meal tables. These sponsorships range in cost from $250 to $2,500. More details can be found online at www.firesprinkler.org/sponsorship.

EXHIBIT AT AFSA42

The schedule for AFSA42 is specially designed to create multiple opportunities for attendees to visit the exhibit hall and network. This gives exhibitors ample time and as much personal interaction with customers as possible. AFSA ensures traffic in the hall through:

• Unopposed exhibit hours. AFSA carefully schedules each day of the convention to avoid seminars and social events conflicting with exhibit hall hours.

• National Apprentice Competition (NAC). AFSA’s NAC is held each year in the exhibit hall. This popular event draws convention attendees to view the installation portion of the competition and puts them within your reach.

• Exhibition Grand Opening Reception. AFSA’s Chair of the Board of Directors hosts this popular evening event, allowing convention attendees to tour the exhibit hall and enjoy hors d’oeuvres and a cash bar.

• Free passes for the second day of exhibits. AFSA invites local Authorities Having Jurisdiction (AHJs) and exhibitor-invited guests to visit the exhibit hall.

Sponsors also enjoy exhibitor benefits at AFSA42. Diamond and Platinum sponsorship levels include one 10-ft x 20-ft booth, and Gold sponsorship level includes one 10-ft x 10-ft booth.

Additional booths are available for purchase to expand the size.

Diamond sponsors receive three all-access registrations and six exhibit-hall-only registrations (a $8,260 value). Platinum-level sponsors receive two all-access registrations and four exhibit-hall-only registrations (a $6,000 value). Gold sponsors receive one all-access registration and two exhibit-hall-only registrations (a $3,000 value).

It’s never too early to start planning your marketing strategy. AFSA42 is at the pinnacle of reaching your customers! To take full advantage of all the publicity available to sponsors, sign up by April 15, 2023. For more details, visit www.firesprinkler.org/ sponsorship or contact Marlene Garrett via email at mgarrett@ firesprinkler.org or phone at (214) 349-5965 ext. 118 to discuss how your company can make the most significant impact.

EXPERIENCE THE MAGIC AT CONVENTION

Stay up to date with the latest from AFSA and AFSA42, including news, deals, discounts, and offerings. Get real-time updates on the association’s official happenings sent to your desktop or wireless device by subscribing to or “following” AFSA social media, and use our official hashtag #AFSA42.

• TikTok: tiktok.com/firesprinkler.org

• LinkedIn: linkedin.com/company/american-fire-sprinklerassociation-afsa-/mycompany/

• Facebook: facebook.com/firesprinkler.org

• Instagram: instagram.com/firesprinklerorg

• Twitter: twitter.com/AFSA

• YouTube: youtube.com/user/AmerFireSprinkAssn

Plan your Orlando getaway with AFSA today! Bookmark AFSA’s convention website at www.firesprinkler.org/AFSA42 and check back frequently as online registration opens soon. n

14 SPRINKLER AGE | MAR/APR 2023

The magnificence of Hogwarts castle takes shape above Hogsmeade at The Wizarding World of Harry Potter ™. Hogwarts is the home of the thrilling, new, state-of-the-art attraction—Harry Potter and the Forbidden Journey—that uses ground-breaking technology to bring the magic, characters and stories of Harry Potter to life in ways never before experienced. HARRY POTTER characters, names and related indicia are © & ™ Warner Bros. Entertainment Inc. J.K. ROWLING`S WIZARDING WORLD™ J.K. Rowling and Warner Bros. Entertainment Inc. Publishing Rights © JKR. (s18)

INDUSTRY LEADING TRAINING

P P P P �P P

FIRE SPRINKLER FITTING

APPRENTICESHIP TRAINING SERIES LEVELS 1-4

AFSA Members SAVE

over

30%

Recognized Curriculum in all 50 states

Online Testing with 24/7 access

No More Retake Codes

Virtually Proctored Tests

Now with Fewer Tests

The Fire Sprinkler Fitting Apprenticeship Training Series, written from a contractor’s point of view, includes nearly 600 training hours and online access to student history and grades and is customizable to fit your company’s needs.

www.firesprinkler.org/fitter

DIESEL-DRIVEN FIRE PUMP SYSTEMS

CALCULATION AND INSTALLATION ISSUES OFTEN MISSED

JOHN AUGUST DENHARDT, P.E., FSFPE | AMERICAN FIRE SPRINKLER ASSOCIATION

Diesel-driven fire pump systems are economical, reliable, and a proven method when an increase in water pressure is required for fire protection systems where reliable normal electrical power is not available. In accordance with NFPA 20, Standard for the Installation of Stationary Pumps for Fire Protection , 2022 edition, all diesel drivers must be Listed for fire protection service. In the United States and other countries, these drivers must comply with applicable emission standards. While the diesel engine has been around since the early 1900s, the modern diesel driver is more fuel efficient and produces fewer emissions than ever before.

For a diesel-driven fire pump system to operate as intended, several design and installation calculations or considerations must be completed during the design and shop drawing. These include:

• Operation ambient temperature of the diesel driver,

• Elevation above sea level of the diesel driver,

• Combustion ventilation requirement,

• Room ventilation requirements based on the type of driver cooling,

• Floor drain sizing,

• Fuel tank sizing,

• Battery sizing and voltage,

• Battery cable sizing,

• Controller incoming voltage,

• Block heater incoming voltage, and

• Exhaust piping sizing.

OPERATION AMBIENT TEMPERATURE

The maximum operating ambient temperature at the engine air inlet connection is limited to 120°F. The minimum room ambient temperature is 70°F if the diesel engine is not equipped with an engine block heater or 40°F if equipped. However, every diesel engine manufactured for the U.S. market is equipped with an engine block heater. The upper limit of 120°F is specified by NFPA 20 and the listing of the diesel engine. The temperature limitation of the diesel engine is determined by considering the engine’s full load operating conditions at the location’s highest expected outside temperature. This requirement is not an easy requirement to satisfy in warmer locations without a large ventilation system or an air conditioning system. For operating air temperatures above 77°F, NFPA 20 requires a derating of the

output of the diesel engine (horsepower). In the real world, how many existing fire pump rooms (enclosures) are over 77°F when the diesel engine is operating under full load? I’m sure the engineer of record, the designer, or the plan reviewer ensured the diesel engine’s power was derated.

ELEVATION

NFPA 20 requires a derating of the output of the diesel engine (horsepower) for all elevations above 300 feet above sea level. This derating accounts for the lower oxygen level in the combustion air as less oxygen results in less power.

COMBUSTION VENTILATION

As part of the listing, the diesel engine manufacturers specify the minimum quantity of combustion air needed for the diesel engine to operate properly at full load operating conditions. The combustion air must always be available with the room at normal operating conditions. Think about the fire pump operating test you witnessed. Was the door to the outside chocked open? A public input was submitted for the 2025 edition of NFPA 20, which will require all operational tests to be conducted with the room at normal conditions—3:00 a.m. on a Sunday when no one is around.

16 SPRINKLER AGE | MAR/APR 2023

This diesel-driven fire pump serves a 750,000-ft2 distribution center in Amsterdam, New York. Photo courtesy of Poole Fire Protection, Olathe, Kansas.

ROOM VENTILATION

The fire pump room (enclosure) must have sufficient ventilation to ensure the diesel engine is operated at the design temperature and radiant heat does not raise the temperature in the room. If the diesel engine is cooled with air through a radiator, ventilation must be supplied with sufficient air to allow proper cooling with the diesel engine under operating under full load conditions. Think of a generator installation. The amount of air flow required is huge. In addition, the room temperature must be kept over the minimum under all air flow conditions even when the incoming air temperature is very cold.

FLOOR DRAIN

A floor drain is required by NFPA 20 and usually is provided. However, is it sized correctly? The drain must handle normal drips and packing glands, but with a diesel engine that uses a heat exchanger, the heat exchanger will need to discharge sufficient water to keep the engine cool under full operating load. The diesel engine manufacturer can supply the required water flow rate.

FUEL TANK SIZING

The method to determine the capacity of the fuel storage tank for diesel-driven fire pump systems has changed over the years. When I started in this business in the mid 1980s, the minimum fuel tank capacity was determined by the following formula: 1 pint of fuel per horsepower of the driver multiplied by 8 hours run time plus 5 percent for sump plus 5 percent for expansion. A basic example: A 50 Hp driver: 1 pt x 50 Hp x 8 hours x 1.10 = 440 pints = 55 gallons.

With the 1983 edition of NFPA 20, the formula was modified. However, this modification did not change the results. The change only made the formula easier to use: 1 gallon of fuel per horsepower plus 5 percent for sump plus 5 percent for expansion.

Using the example above of a 50 Hp driver, 1 gallon x 50 Hp x 1.10 = 55 gallons. So, the capacity of the fuel tank has been essentially the same until the 2022 edition of NFPA 20. During the 2022 revision cycle, a public input was submitted to change the formula to: Driver’s fuel consumption rate at rated Hp multiplied by 8 hours run time plus 5 percent for sump plus 5 percent for expansion.

This public input was resolved by the Technical Committee. The Technical Committee provided a substantiation for their decision that, in my humble opinion, did not make sense. It is well known that diesel fuel, when stored for long periods, will degrade unless proactive steps are employed to slow down the degradation. Modern diesel drivers are much more fuel efficient than previous drivers. Heck, look at my father’s vehicle in the 1970s, a 1974 Ford County Squire station wagon. In real-world driving, that vehicle was lucky to get 10 miles per gallon. A modern Ford Expedition can easily obtain 20 miles per gallon. This improvement in fuel efficiency has resulted in the need for the capacity of diesel driver fuel tanks to be reduced. In the automotive world, manufacturers engineer the fuel tank to match

the fuel efficiency and desired driving range. So why in the world would the Technical Committee not use the same approach?

NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, has long realized diesel fuel quality is an issue. Specific monitoring, testing, and correction language for fuel quality is included in NFPA 25. In reality, many owners do not have these services completed.

During the 2022 revision cycle public comment period, a public comment was received which requested the Technical Committee reconsider this approach. The submitter provided a rationale for the reconsideration like the points made above. The Technical Committee did change their direction. The resulting new formula is as follows: Driver’s fuel consumption rate at rated Hp multiplied by 12 hours run time plus 5 percent for sump plus 5 percent for expansion.

Let’s cover some of the confusing language. In fact, the Technical Committee had the incorrect language during the second draft ballot process. A Technical Interim Amendment (TIA) was processed by NFPA to correct the language. One will see the following terms used in the industry:

• Fuel Supply Rate – the amount of fuel supplied to an engine while the engine is in the operating condition.

• Fuel Return Rate – the amount of fuel returned to the fuel tank while the engine is in the operating condition.

• Fuel Consumption Rate – the amount of fuel the engine consumes in the operating condition. For fire pump driver

17 SPRINKLER AGE | MAR/APR 2023

applications, this value is the consumption rate at full load condition. By definition, the fuel supply rate minus the fuel return rate equals the fuel consumption rate.

Almost all modern gasoline and diesel engines use the above method in delivering fuel to the engine. The fuel that is returned to the tank is filtered and, in some cases, preheated. This method helps ensure the fuel in the tank is kept cleaner and when preheated, will aid in the combination process. When sizing a diesel fuel tank for fire pump service, the fuel consumption rate can be determined by reviewing the diesel driver manufacturer’s listing literature. The data sheet for the driver will list the fuel consumption rate. From there, apply the new formula as stated above. If, for some reason, the fuel consumption rate is not known, the original formula is allowed to be utilized. However, in almost every situation I have reviewed, the new formula will produce a minimum capacity fuel tank smaller than utilizing the original formula.

It should be noted, with the original formula, diesel drivers are designed to operate at least 5 hours and 20 minutes since the low fuel alarm is designed to operate at the twothirds level of a full fuel tank (8 hours x 2/ 3). With the new formula, a 12-hour time was chosen by the Technical Committee in lieu of the recommended 8 hours. While I do not fully understand the Technical Committee’s justification for the 12-hour duration requirement, it is now in the standard. Thus, utilizing the new formula, under maximum load, the driver will have sufficient fuel to operate 8 hours (12 hours x 2/ 3). For comparison purposes, the longest time duration I have ever designed for was 4 hours. In this specific case, the diesel fuel tank at the two-thirds level will double the water supply time duration. The fuel supply time duration seems an overkill to me, but the Technical Committee decided on this. Maybe this requirement can be changed in a future edition. This requirement will not change for the 2025 edition of NFPA 20 as no public inputs were received on this topic, but for the 2028 edition of NFPA 20 it is a possibility. In any case, if the engineer of record or owner of the project feels a larger fuel tank is desired, they can specify one.

Correctly sizing the fuel tank will assist the owner in providing sufficient fuel for the required duration without having so much fuel, which could lead to stale and compromised fuel. A smaller-sized fuel tank will fit in a room easier, present a lower fire hazard, and cost less in terms of equipment and fuel.

BATTERY SIZING AND VOLTAGE

The diesel engine manufacturer will have several options for battery sizing in terms of capacity and voltage. These available options should be reviewed to ensure the best option is chosen for the specific installation. While larger capacity batteries are more expensive, they might offer a better value for the client.

BATTERY CABLE SIZING

The battery cables need to be of sufficient length and diameter to ensure proper operating conditions. Where are the

batteries going to be located? Based on the length and load, is the proper wire size being provided?

CONTROLLER INCOMING OPERATING VOLTAGE

Controllers are available with several incoming voltage choices. Has the electrical correlation been made between the design and installation team?

BLOCK HEATER OPERATING VOLTAGE

Diesel engine block heaters are available with several incoming voltage choices. Has the electrical correlation been made between the design and installation team? Higher voltage heaters will draw less amps and might be a better choice for the installation.

EXHAUST PIPE SIZING

The backpressure applied to a diesel engine will negatively affect performance of the engine. The length, number of fittings, and the type of silencer (muffler) will affect the backpressure. Increasing the exhaust piping size might be required to allow the backpressure to be in the acceptable range. The engine manufacturer will provide the maximum backpressure allowed for a specific diesel engine. Silencers with greater noise reduction will cause more backpressure.

EXHAUST TEMPERATURE

The diesel engine manufacturer will provide the discharge exhaust temperature under full operating load. Modern diesel engines with emission controls will typically operate at a higher temperature. These temperatures need to be reviewed to prevent personal injury due to contact and radiant heat loads need to be considered. Properly rated insulation can assist with the exhaust temperature concerns.

CONCLUSION

In summary, a diesel engine driver is a great choice for a fire pump system. However, the above items need to be considered to ensure a properly designed and installed system. If any one of these is missed, the system could fail when it is needed. Always refer to NFPA 20 and the diesel engine manufacturer’s literature to ensure compliance. n

ABOUT THE AUTHOR: John August Denhardt, P.E., ET, CWBSP, FSFPE, is the vice president of engineering and technical services for the American Fire Sprinkler Association (AFSA). He is responsible for strengthening AFSA’s engineering and technical approaches to meeting member, industry, and operational priorities, with an emphasis on service, quality, and integrity. Denhardt is a registered professional engineer (P.E.) in the District of Columbia and the states of Delaware, Maryland, Pennsylvania, and Virginia. He is NICET Level III certified in water-based systems layout, NICET Level III certified in inspection and testing of water-based systems, and a certified water-based system professional through NFPA. Denhardt is a member of the NFPA 13 technical committee on sprinkler system discharge criteria, a fellow in the Society of Fire Protection Engineers (SFPE), a member of the SFPE Board of Directors, a member of the Board of Trustees for NFPA’s Fire Protection Research Foundation and sits on the University of Maryland Department of Fire Protection Engineering’s Board of Visitors. A native of Maryland, Denhardt holds a Bachelor of Science degree from the University of Maryland College Park in fire protection engineering. Prior to this role, Denhardt was employed by Strickland Fire Protection in Forestville, Maryland, since 1994, overseeing large-scale projects and assisting with design and installation technical issues.

18 SPRINKLER AGE | MAR/APR 2023

TUNE INTO FM 101: AFSA ROCKS ITM TRAINING

ROLE OF FACILITIES MANAGEMENT IN ITM

JOSHUA MCDONALD, MSET, CFPS, CWBSP, WBITM | AMERICAN FIRE SPRINKLER ASSOCIATION

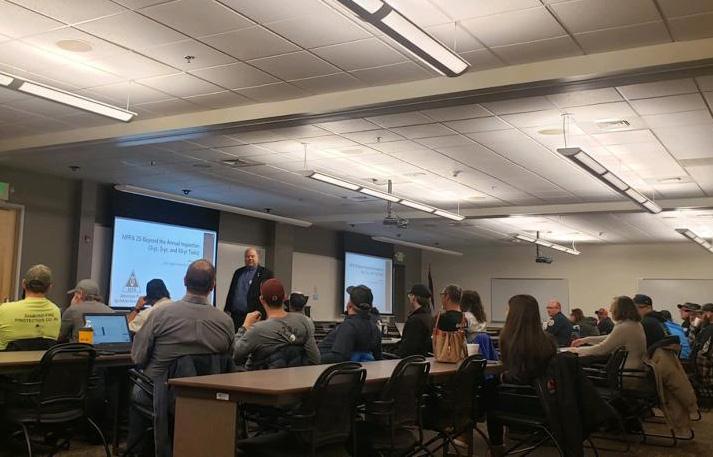

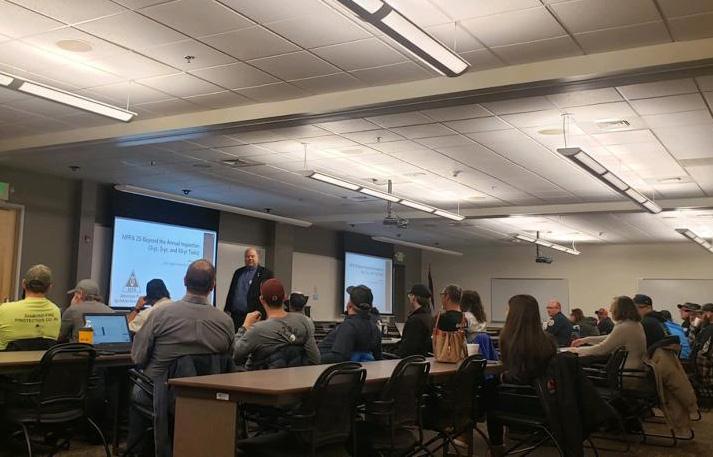

The inspection, testing, and maintenance (ITM) of water-based fire protection systems is ultimately up to the building owner or designated representative (DR). Building owners may need help understanding the systems themselves, let alone the importance of NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems , and what the required frequencies are for each inspection and test. Yes, the installing sprinkler contractor provides NFPA 25 to the building owner after installing the system. Still, over time and with staff turnover, that information tends to get stuck under the files. Realistically, the sprinkler system is only one of many systems that the building owner or designated representative is responsible for maintaining.

Many large commercial properties have trained, mechanically savvy staff—sometimes referred to as facilities maintenance, facilities management (FM), property maintenance/ management, or the engineering department—performing regular preventative maintenance (PM) on the systems within their capabilities. The basic weekly inspections are typically within the facility management staff’s capabilities, and the more in-depth monthly, quarterly, semi-annual, and annual ITM is contracted out as allowed per the operational budget. These systems sometimes do not get the necessary attention following a contractor’s NFPA 25 ITM. Required tests or maintenance is often pushed back or disregarded, resulting in life safety and property protection deficiencies and impairments. Realistically, the owner’s budget determines what gets fixed. A better understanding between the contractor and the building owner is required to alleviate the frustration as to who is responsible for completing each task. Often, the best way to accomplish this is through education of the onsite FM team. The FM team needs to know exactly what they are responsible for, how the systems operate, and how to complete the tasks correctly.

EDUCATING THE OWNER

Before celebrating the completion of another successful installation, take the time to sit down with the owner and/or designated representative to identify what their team can

accomplish, such as weekly valve inspections. During this conversation, the customer will realize that some tasks are within their capabilities, while others require the assistance of a fire protection contractor. For example, few owners have the technical ability onsite to complete an annual fire pump flow test and analyze the results. Communicating everything that goes into a pump run is not only good service but also creates the potential for a future ITM contract. It also allows the owner or DR to have a better understanding of what they are paying for, what they should expect to be done, and that the work they are contracting is being appropriately conducted. The critical parts and pieces then can be triaged due to the inevitable budgetary concerns, ultimately leading to peace of mind that the protection in place is adequate.

The onsite FM team needs to understand what they are responsible for as the building owner’s designated representative per NFPA 25. NFPA 25 requires that all ITM tasks be performed by qualified personnel in accordance with the standard and manufacturer’s instructions. NFPA 25, 2023 edition states:

4.1.1* Responsibility for Inspection, Testing, Maintenance, and Impairment. The property owner or designated representative shall be responsible for the proper inspection, testing, maintenance, and impairment management of waterbased fire protection systems in accordance with this standard.

4.1.1.3 Inspection, testing, and maintenance shall be performed by qualified personnel.

…

4.1.1.5* Where the property owner or designated representative is not the occupant, the property owner or designated representative shall be permitted to delegate the authority for inspecting, testing, maintenance, and the managing of impairments of the fire protection system to a designated representative.

A.4.1.1.5 Examples of designated representatives can include the occupant, management firm, or managing individual through specific provisions in the lease, written use agreement, or management contract.

EDUCATING THE FM TEAM

It is essential to understand that when things are not cleared off the deficiency and impairment list, it is the responsibility of

20 SPRINKLER AGE | MAR/APR 2023

the owner or DR—not the contractor—as they did not approve or contract the work. A lot of responsibility is placed on the shoulders of the FM team. The FM team may be qualified to complete some of the required ITM activities, but not all. Either way, experienced and knowledgeable people need to get their eyes and hands on the equipment, and it needs to be fixed appropriately. The General Requirements also state that the building owner or DR must have an impairment coordinator and have communications with the alarm company (including putting the system on alarm test). This is discussed thoroughly in our classes and, many times, both contractors and building owners do not realize who is responsible and later find that they have been taking on an unwarranted liability.

Many FM workers are only missing the education to truly qualify them to complete basic sprinkler system ITM. Jurisdictions typically allow for the building owner or DR to complete their own work for certain tasks. NFPA 25 states:

4.1.1.3.1* Qualified personnel shall meet at least one of the following qualifications:

(1) Meets the requirements and training for a given field acceptable to the authority having jurisdiction

(2) Is certified by a nationally recognized fire protection certification organization acceptable to the authority having jurisdiction

(3) Is registered, licensed, or certified by a state or local authority to perform inspection, testing, and maintenance of water-based fire protection systems

3.3.35* Qualified Personnel. Competent and capable individual(s) having met the requirements and training for a given field acceptable to the AHJ.

Weekly or monthly valve inspections include a visual confirmation that the pipe is in good shape, the control valve is open, and the gauges are reading as expected. The inspection is not too in-depth. However, it is beneficial for the person completing the task to understand the status of the system in order to recognize when it requires assistance from an outside fire protection contractor. Most FMs are not expecting or wanting to do the more skilled work (e.g., rebuild a dry valve, complete a preaction trip test, repack a fire pump, or complete an annual fire pump flow test). Instead, they would like to utilize their team to its fullest potential and complete the more common inspections properly, such as weekly/monthly inspections, no-flow pump tests, drain drum drips, etc. An additional benefit of FM team training is that the more familiar they are with the system in both normal and abnormal conditions, the less downtime and money will be lost when pipes burst, or other issues arise.

HOW AFSA CAN HELP

This information must be shared with the FM community, starting with us as contractors. AFSA’s NFPA 25 HandsOn ITM three-day course is designed for contractors, FM team members, risk management entities, engineers, and building officials. We have already had FMs come through the

class and walk away with a lot of instantly usable information. In addition, the discussions between the FMs and contractors were invaluable in appreciating the different perspectives, ultimately helping to ensure that those who safely enter a building without a thought can leave without a thought because of our joint efforts behind the scenes. For more information on this course, visit www.firesprinkler.org/ programs/nfpa-25-hands-on-itm.

The addition of AFSA’s training lab (currently under construction) will be vital to give ITM technicians and FMs the practical hands-on experience required to complete ITM tasks and adequately structure a contract to get the job done right. The indoor lab will include the following:

• Sprinkler demonstration area,

• Functional risers of all types (wet, dry, preaction, and deluge),

• Air and nitrogen supplies,

• Flowing hydrant,

• Standpipes,

• Fire pumps, and

• Both new technology and old to prepare trainees for anything they might see in the field.

AFSA staff have observed training labs around the country and incorporated aspects of each one into the layout of this training space to offer the best learning experience possible for AFSA members and attendees.

The best part of the lab is that there is no concern about breaking something that will cost your facility monetarily, the learning is fun, and real-world scenarios will be simulated. We appreciate the opportunities we have been given to use the General Air Product training facility (located in Exton, Pennsylvania) and the Johnson Controls, Inc. training facility (located in Cranston, Rhode Island) for our ITM training. We have also visited other labs around the country, including the Viking Group Inc. training facility (located in Caledonia, Michigan) and the Reliable Training Facility (located in Liberty, South Carolina), as well as others. We will continue to use these labs to supplement training and make it more accessible to members in those regional areas.

The AFSA lab is one of many exciting new developments in the sprinkler pipeline. Stay tuned for more updates, as we are constantly creating new content and grooming existing programs for improved presentation in virtual, classroom, and hands-on environments. n

ABOUT THE AUTHOR: Joshua McDonald, MSET, CFPS, CWBSP, WBITM, is the manager of Engineering & Technical Services, where he is responsible for developing, updating, and delivering technical content. He has experience in all areas of training for fire protection industry professionals, including web-based and hands-on learning. As a manufacturer, McDonald has been involved in the research and development of new fire protection products and has experience with risk engineering applying to the installation of fire protection systems. He received his Bachelor of Science degree in fire protection and safety engineering technology and a Master of Science degree in Fire Safety and Explosion Protection from Oklahoma State University. McDonald is a member of NFPA and SFPE.

21 SPRINKLER AGE | MAR/APR 2023

THIRTY YEARS OF EXCELLENCE

CATCHING UP WITH PAST NATIONAL APPRENTICE COMPETITION COMPETITORS

SYDNEY RICHARDSON | AMERICAN FIRE SPRINKLER ASSOCIATION

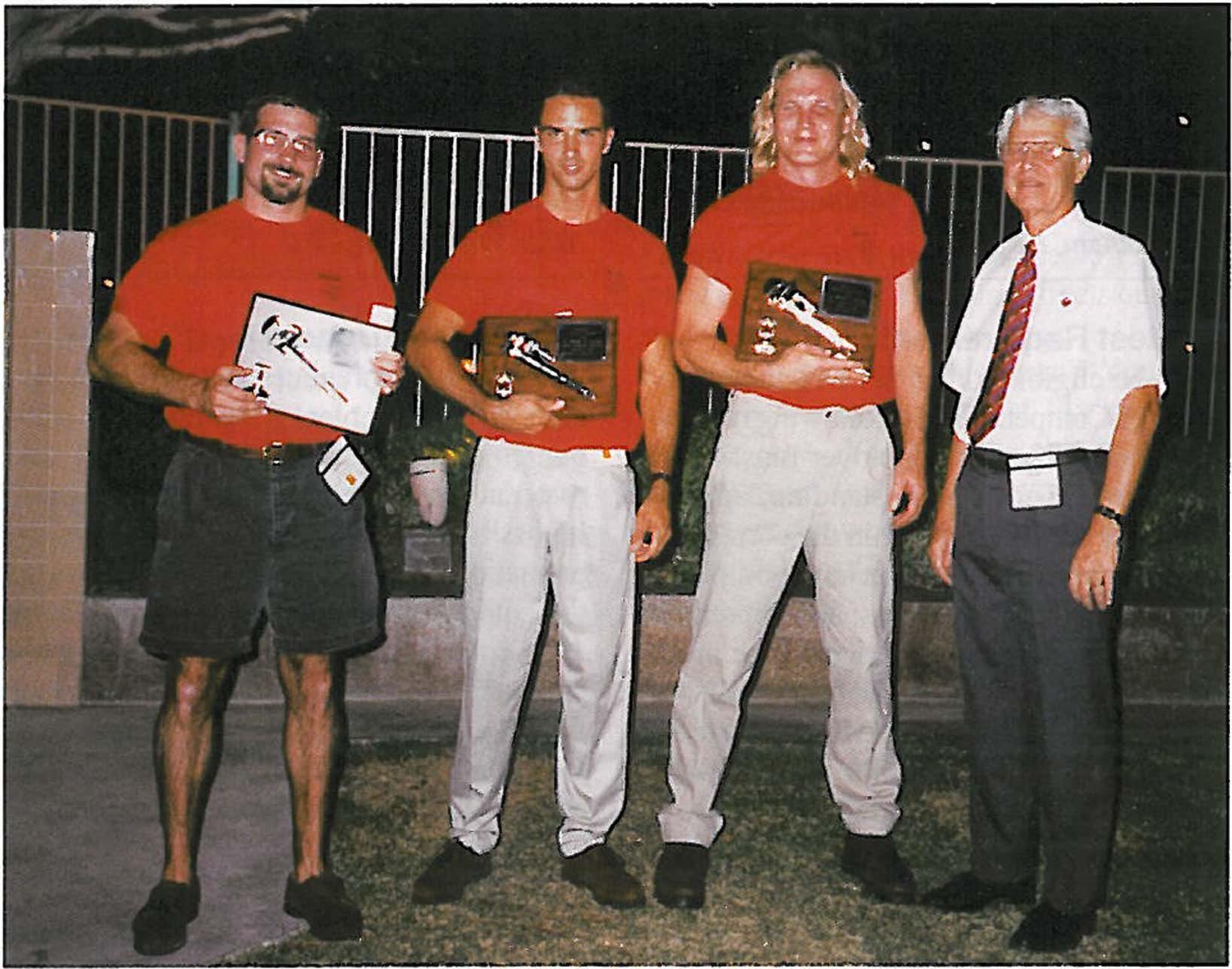

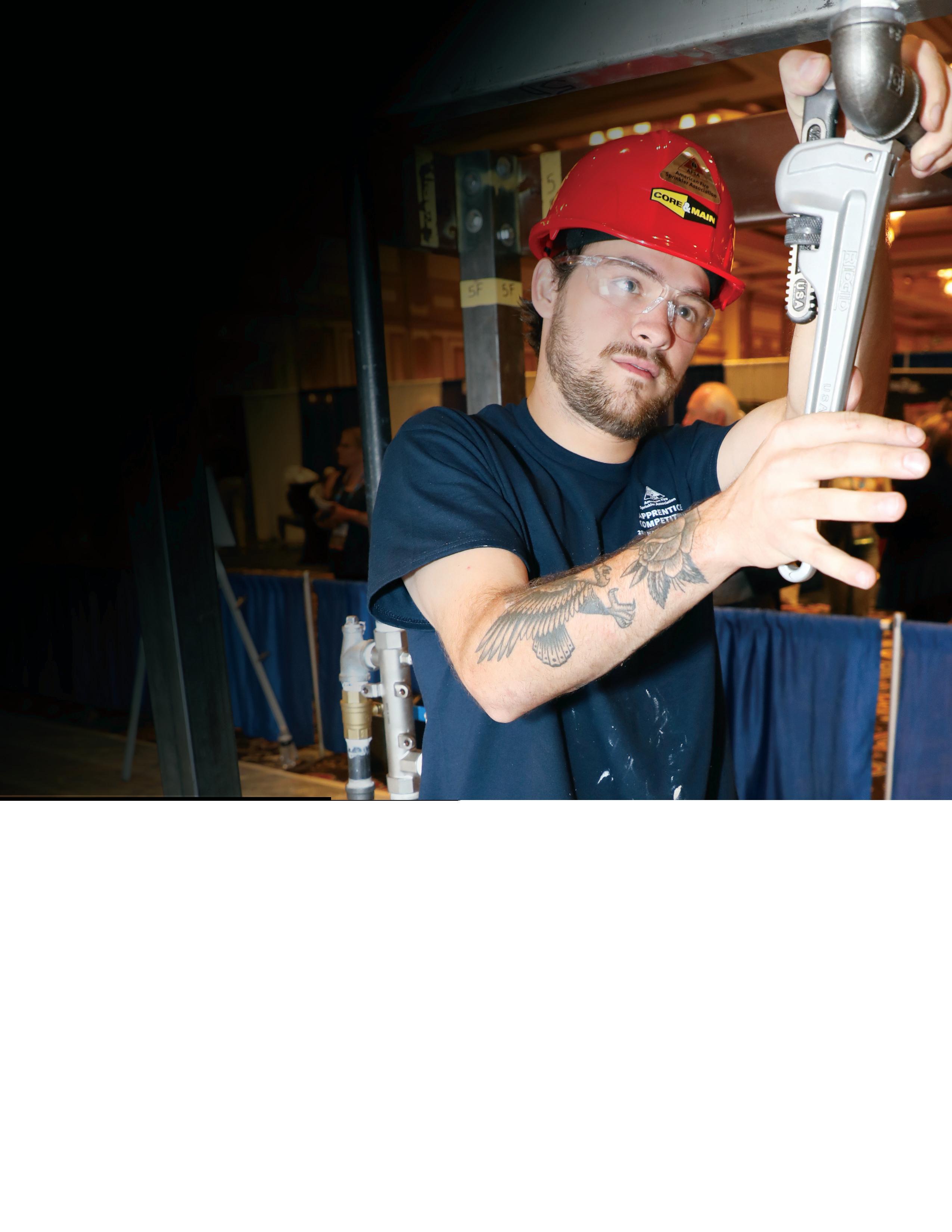

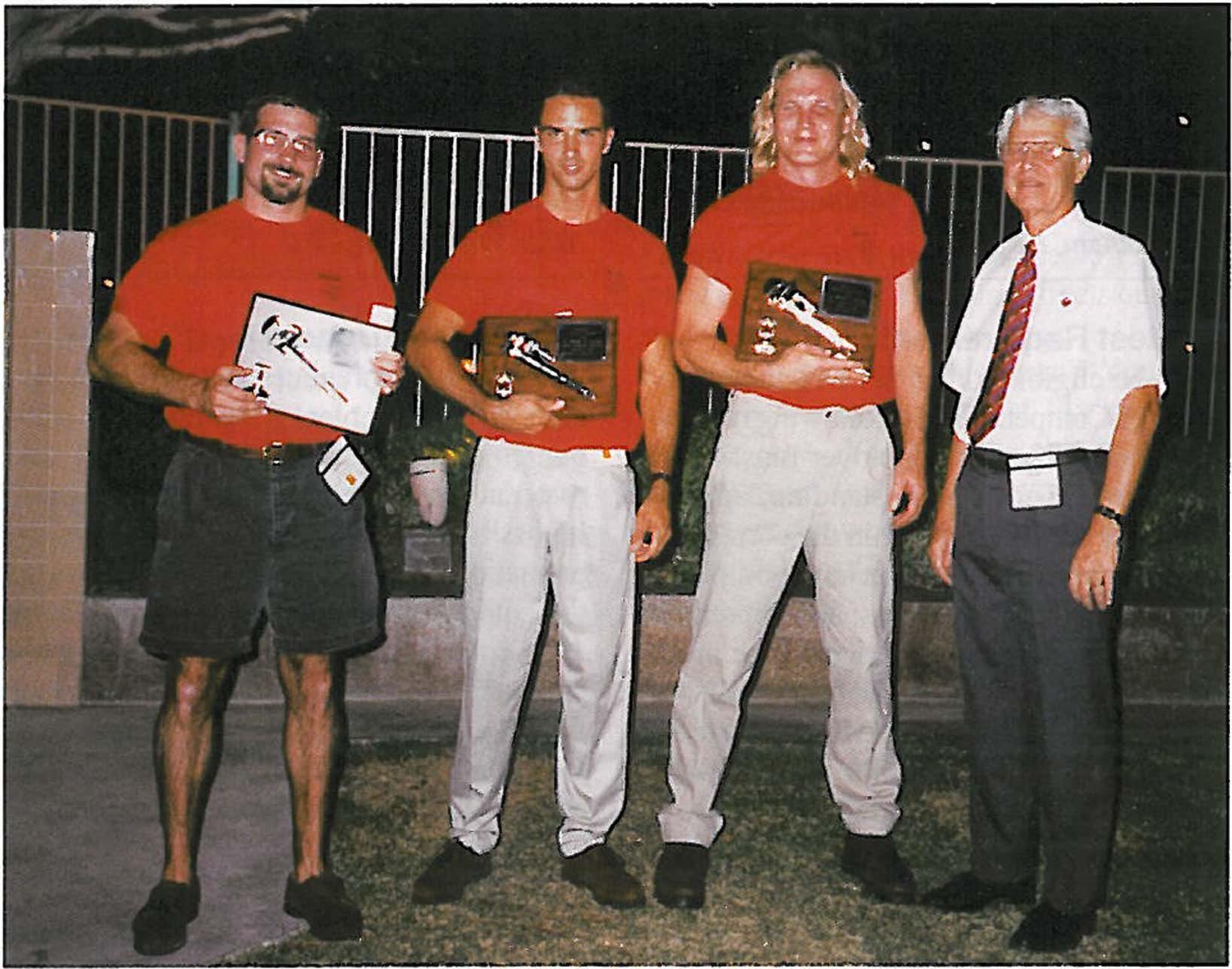

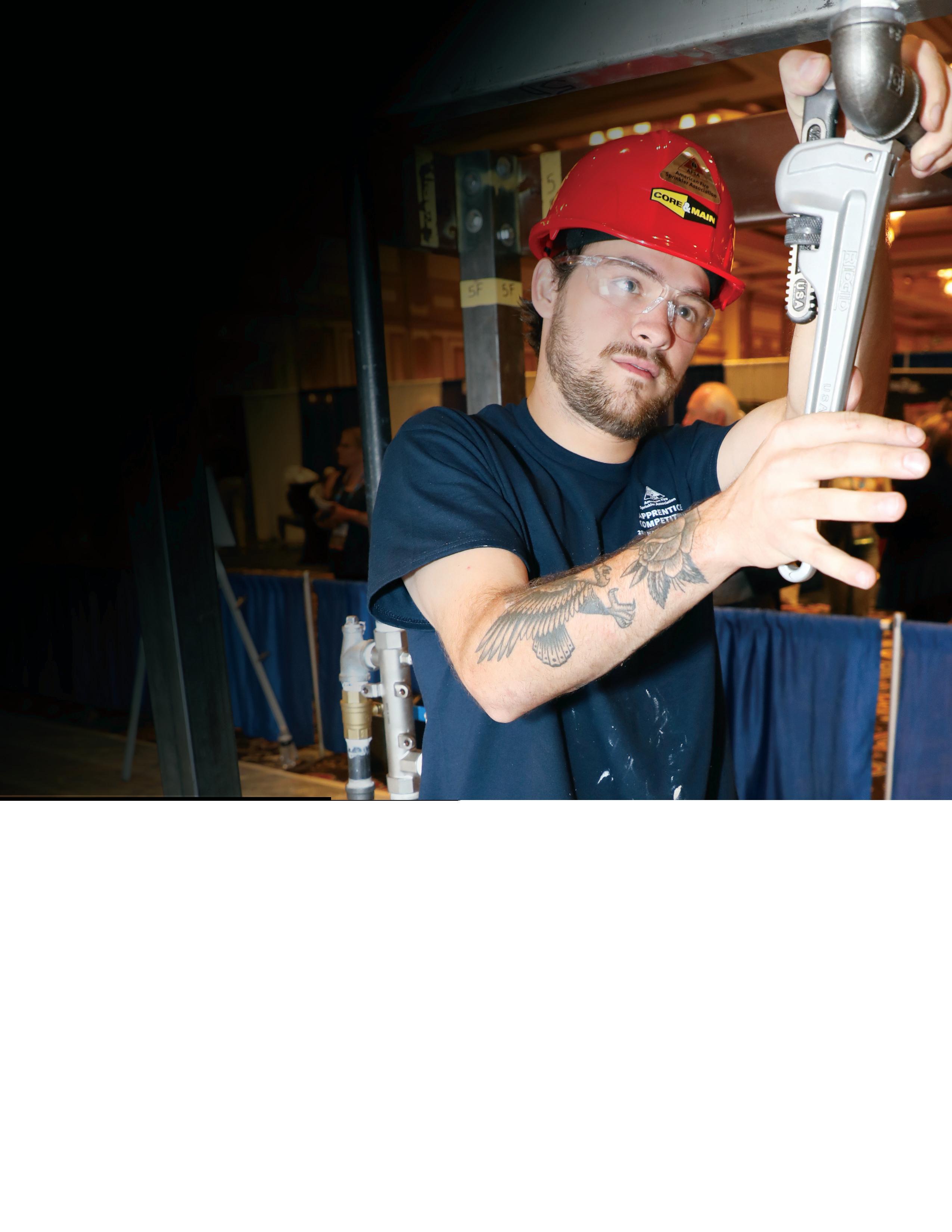

Thirty years ago, the American Fire Sprinkler Association’s (AFSA) launched the National Apprentice Competition in 1994 at the 13th Annual AFSA Convention & Exhibition in Fort Lauderdale, Florida. That inaugural year, the competition was well represented, with seven apprentice finalists from member companies nationwide, all competing to be crowned the champion apprenti ce.

Of course, getting to compete was an accomplishment in and of itself. Apprentices began by preparing for the exams given by AFSA, all of which were based on AFSA’s Training for Excellence apprenticeship training course. Apprentices first had to take a 70-question written exam to qualify to compete and were scored within their state. After receiving the top score for their state, the apprentices then had to take another longer test to qualify as best in their region. Though the testing didn’t stop there—after getting through the first two rounds of testing, the top seven apprentices would take their final three-hour written test at the convention, which would follow with an installation thereafter. Apprentices would install a mini fire sprinkler system as hundreds of AFSA convention attendees, members, and guests watched. Grading for these miniature systems was determined by accuracy, craftsmanship, and safety.

While the testing and qualifying procedure has changed over the years, the excitement and anticipation of competing continue to grow. As AFSA celebrates its 30th anniversary, we’re checking in with past competitors. What have they been up to since competing, and how have their lives changed since participating in the NAC?

JOE HEADRICK, 2019 CHAMPION

Joe Headrick learned of the fire protection industry through a family friend. Headrick still works for Rapid Fire Protection in Bismarck, North Dakota, as he was when he competed just a few years ago. Headrick notes, “The NAC helped me prove something to myself and my employer [which] has helped me advance in the fire protection industry.” Additionally, Headrick

points to a variety of techniques for fire sprinkler installation. “The competition gave me the ability to see how other people working for other companies do the same work and how different their styles and approaches are.” Headrick ended with a promising sentiment of networking opportunities, stating, “It was a great experience employment-wise and for personal growth. The other apprentices at this competition were just outstanding people, and it was great to work beside them.”

CONNOR JONES, 2021 2ND PLACE FINALIST

Connor Jones became familiar with the industry from his neighbor, who he worked for just out of high school. Jones’ journey officially began when he worked for Mr. Fire Sprinkler in Colorado, which focused on remodels and assisted living. Jones later went on to work for Rapid Fire Protection, the company he represented at NAC in 2021, and, since then, he has become a foreman for them.

Jones reflects on NAC, “A big advantage of the competition is getting noticed, both by your employer and others. It’s a great confidence boost. Getting there also shows you opportunities you may not otherwise realize exist. The last advantage it gave me was to realize how many other highly qualified, competent, and passionate young people there are in the industry. I can’t advance until someone can fill the role I already do. It helped me realize a large portion of my focus should be helping others increase in knowledge and ability.”

Jones continues, “The advice I’d give my younger self and young people getting in the workforce is something Mike Rowe of ‘Dirty Jobs’ fame has often talked about. When looking for a job or career, don’t focus so much on what your ‘passion’ is. Go where your skills are, where you can succeed, look for opportunities, and bring your passion. If I’d followed my high school passion, I’d be a broke musician. I wasn’t passionate about sprinklers in high school and college, but I sure am now.”

22 SPRINKLER AGE | MAR/APR 2023

CHANCE M C COLLISTER, 2017 CHAMPION

Chance McCollister started in the fire sprinkler industry after learning about it from his father, a general contractor, which eventually led to him getting a job with a fire sprinkler company. Some time passed after his championship, and McCollister was offered a job for another company that was starting up where he lived. McCollister says he took a leap of faith and has been working at Austin Fire Systems for the past four years, where he is the lead sprinkler fitter. While there, the company has also supported McCollister in earning his NICET Level II certification and several licenses.

“The National Apprentice Competition, along with a lot of supportive people, helped me mature and look deeper into myself,” McCollister reflects. “I feel like the competition further increased my motivation to be the best at what I do as a career.”

McCollister also notes that the NAC was advantageous for him because it helped him be more decisive when troubled with roadblocks and made him more confident in his ability to excel in his career. He adds, “Never hold back. Know what you want to achieve, and don’t give up until you are satisfied with the results! There is always something you can do better or learn, so stay humble.”

JOE MIENTKIEWICZ, 2016 3RD PLACE FINALIST

Joe Mientkiewicz first learned about the fire sprinkler industry through his church. In 2013, his church was building an addition, and the company they had originally hired to install the sprinklers was a no-show. His church then hired SimplexGrinnell (now Johnson Controls, Inc.), and Mientkiewicz volunteered his time to help. He worked closely with the company learning the ins and outs of sprinkler installation. Having yet to graduate high school, he was offered a job upon graduating. Mientkiewicz notes that seeing the action in person helped him to decide to follow this as his career. Mientkiewicz went on to compete in the NAC in 2016, and since placing third, he has been working as a fire sprinkler fitter/ technician. Most recently, he has become a fire alarm technician and is working toward NICET certification.

“The NAC helped me get to where I am today by bolstering my confidence in my abilities. I feel as though I have a good knowledge/understanding and some credibility from doing the competition.” He continues, “I have talked to people from other companies, and a lot of them expressed interest in hiring me, partially because of my attending the competition.”

Mientkiewicz further notes that the NAC and AFSA helped get him to where he is today. “AFSA has helped my career by providing good, standardized training that I other -

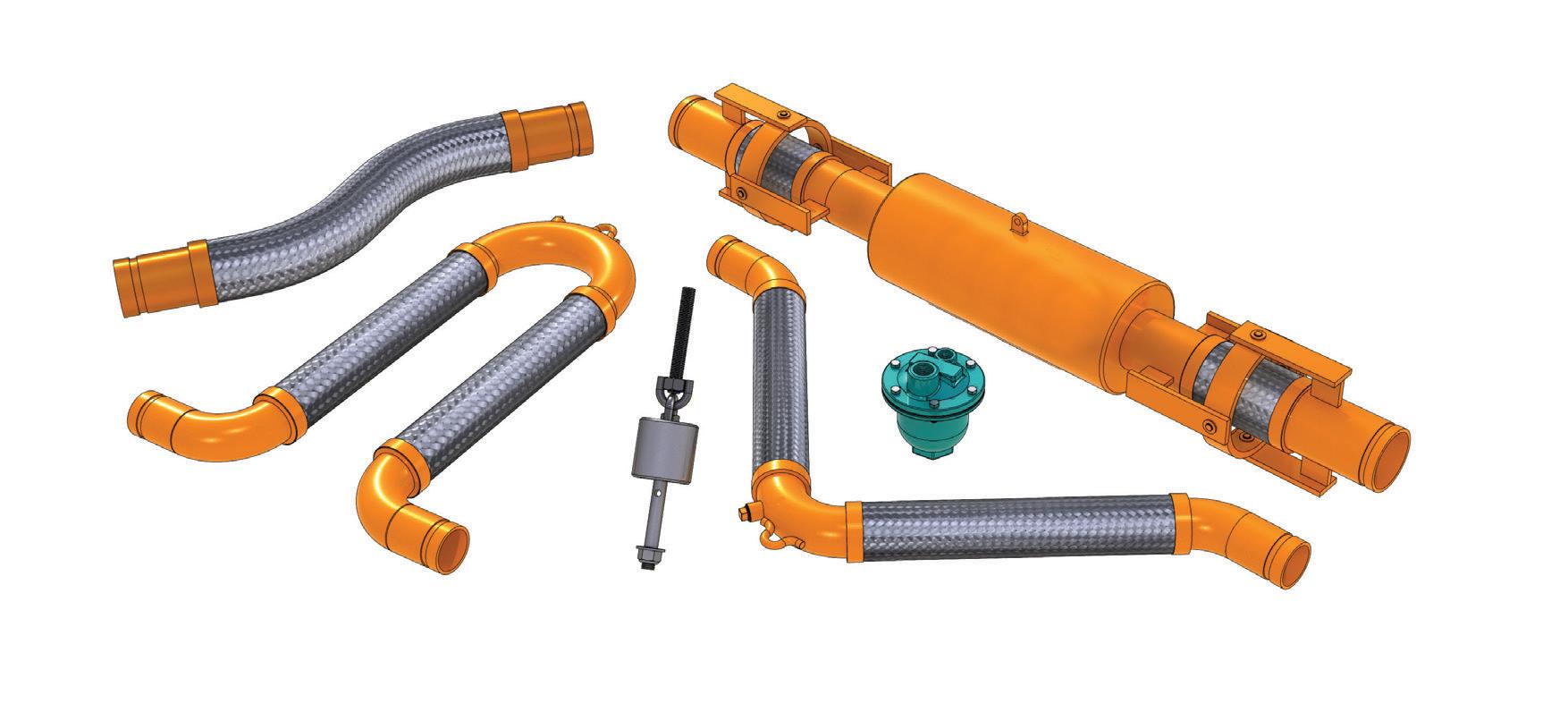

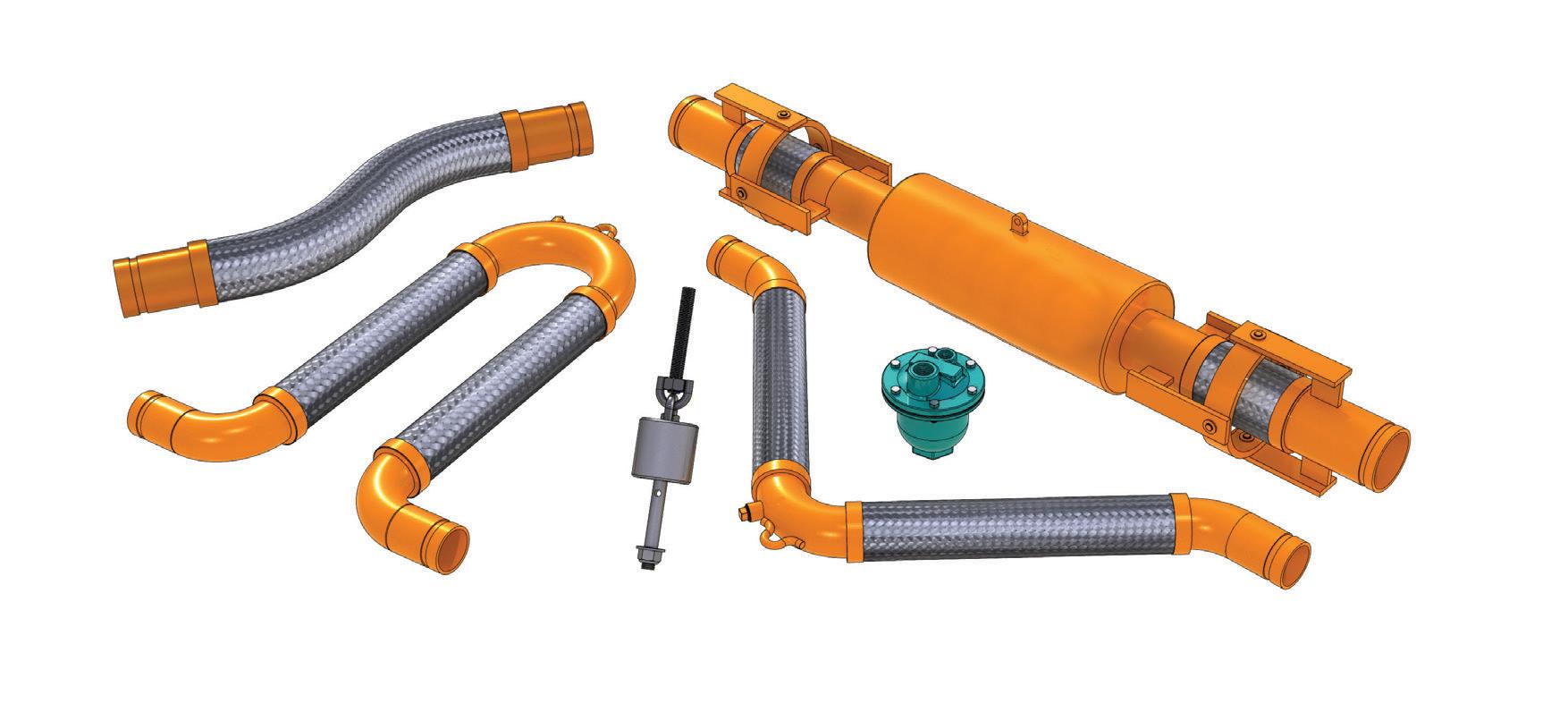

SEISMIC SOLUTIONS FOR FIRE SPRINKLER SYSTEMS

For more information, or to view the complete Fire Protection Product Line, visit www.Metrafire.com

Ensure full-rated protection against seismic activity with Metraflex Fire Protection Division. Manufactured in Chicago, Illinois, Metraflex has the sizes you need, the movements you require, and custom solutions for the perfect fit.

23 SPRINKLER AGE | MAR/APR 2023

The Metraflex Company © 2022

Seismic Breakaway Hanger • Air Vents Seismic Expansion Joints • Flexible Connectors

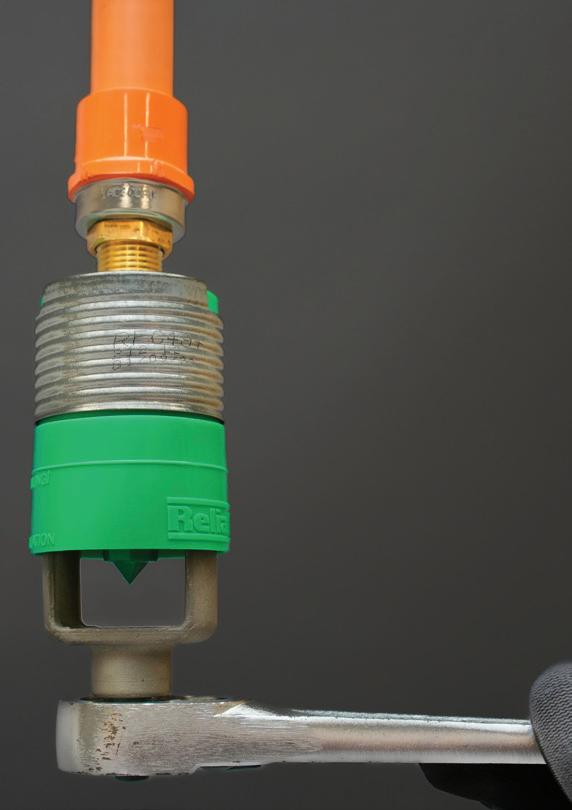

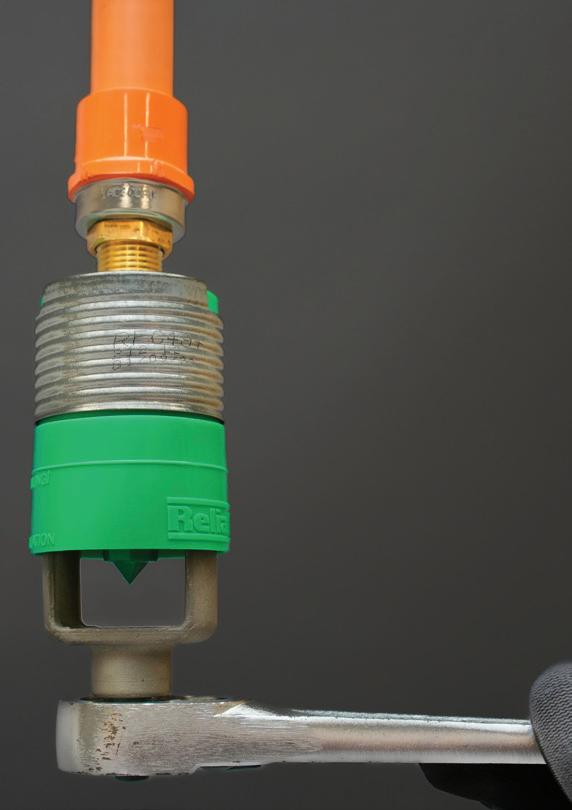

INSTALLER Now you can master the unexpected for whatever jobsite surprises might come your way. Introducing the Reliable ® RFC49plus Residential Flat Plate Concealed sprinkler. Great Reliable flows, now with a full 1" vertical cover plate adjustment. reliablesprinkler.com/RFCplus When you Expect the Unexpected Adjustme FULL25mm 212° 165° Ordinary Temperature Cap color indicates temperature Intermediate Temperature Wrenchable Cap

plus Adjustment FULL djustment 25mm

FRIENDLY RFC

wise wouldn’t have gotten and pushing me harder than I would’ve pushed m yself.” He continues, “The apprenticeship was especially helpful for keeping gaps out of learning. I also did a beginner design course in November of 2019 that helped me to be a better installer. I had been thinking about doing design. Since then, plans have changed, but going through NFPA 13 page by page with the instructors then and working through problems helped me be better prepared for issues that I may encounter out in the field. Having that design course under my belt also gave my supervisor confidence in me as well. I was only 23 when I completed it, and even though I was young, I was still able to have lots of responsibility to run new construction sprinkler projects as well as retrofit projects with Johnson Controls.”

What’s more, AFSA helped one of Mientkiewicz’s friends get a job as well. “On another positive note, I was able to take a friend with me to the competition. Consequently, he now works as an inspector for the same company I do. I have another close friend who just completed the apprentice program that I work with almost every day.”

“I’d like to add that I’d highly recommend that every apprentice should try to qualify for the competition,” Mientkiewicz concludes. “Even if you don’t qualify, the extra amount of study alone will greatly help you in your knowledge and understanding of your career, making you a more valuable asset to yourself and your company. Besides, it’s a great opportunity to have some friendly competition and a great time!”

ALEX SALEIK, 1995 2ND PLACE FINALIST

Alex Saleik got his start in the industry shortly after high school graduation with a job offer from Jay Strickland of Strickland Fire Protection, Forestville, Maryland. He started out in the fabrication shop for the first year, then went in the field for eight years, completing his apprenticeship program and competing in the NAC during this time.

Saleik stayed with Strickland Fire Protection and moved into design where he worked together on big projects for roughly 20 years with then Strickland Quality Control Manager/Senior Project Manager John August Denhardt, P.E., FSFPE (now AFSA’s vice president of engi neering & technical services). Saleik is now a design manager at Strickland and is NICET IV certified.

“The [NAC] motivated me to continue to work hard and provided me with a platform for other job opportunities in the industry,” Saleik says. “[AFSA] has provided me the opportunity to meet other talented people in the industry and learn from them. The classes being taught by AFSA, either through conven tions or webinars, are top-notch. They teach in a way that is entertaining and not boring. It’s nice to know that you can reach out to them any time with code questions.”

He continues, “The [NAC] provided me with the knowledge and confidence of doing things the right way, not taking shortcuts and sacrificing quality. It also helped me work under pressure. Competing in the [NAC] was a great experience for me. It was nice to see how all the key people in the industry made you feel important and offered support. It motivates you to do your best and make your company proud. I also have a son who is now in the apprenticeship program—man, I feel old,” Saleik says with a laugh. [John stated in response to Alex stating he is feeling old, “Alex, that is because you are old!”]

THE LEGACY CONTINUES

Calling all apprentices! If you haven’t competed, the time is now—and what better time to compete than during the 30th anniversary? This September, seven finalists will travel to Orlando to compete in AFSA’s 30th National Apprentice Competition. Apprentices will go through their first round of testing between May 15-June 16, 2023. Top test performers within their region will then receive an expense-paid trip to Orlando to compete, where they are dubbed as AFSA’s honorable guests, complete with a complimentary registration for their employer to attend, along with tools and cash prizes.

AFSA’s 30th National Apprentice Competition will take place on Saturday, September 9, at Signia by Hilton Orlando Bonnet Creek. Show us what you’ve got and submit an application form today at www.firesprinkler.org/competition. n

26 SPRINKLER AGE | MAR/APR 2023

(I to r) 1995 Apprentice Competition Winners Brian Rouleau. Alex Saleik awards from Bob McCullough during the Convention Party on the Patio.

DEVELOPING DESIGNERS

NEW PROGRAM OFFERS SCHOLARSHIPS

One challenge facing the fire sprinkler industry is the need for designers. The American Fire Sprinkler Association (AFSA) is pleased to announce a scholarship program for designers employed by AFSA Category 1-3 contractor members to help meet that demand. For 2023, a limited number of scholarships will be awarded for both AFSA’s Beginning and Intermediate Design Schools.

Each scholarship will cover registration fees and travel expenses, including airfare, hotel, and meals, for one of AFSA’s 2023 schools. Applications are submitted online and include questions for both the contractor and designer. A subcommittee of AFSA’s Public Education & Awareness Committee will review the applicants and award the scholarships. The retail value of each scholarship is $4,500.

“The AFSA Technical Services and Engineering team has revamped and revised our Design School offerings, and we’re proud to have this new scholarship program in the hope of helping to deliver more layout technicians to our members,” says AFSA President Bob Caputo, CFPS.

AFSA’s Beginning Design School presents a comprehensive, practical approach to preparing fire sprinkler system drawings. This class is designed for trainees and entry-level technicians with at least six months of experience as well as those with experience in the sprinkler trade looking to make the transition to system layout.

Experienced layout technicians will find AFSA’s Intermediate Design School useful to understand the tools they utilize in-depth and gain a deeper knowledge of layouts for standpipe systems, fire pumps, and seismic protection, along with the design requirements for general storage. This class is designed for competent trainees and technicians with at least one year of system layout experience. No prior Hydratec or Autodesk® Revit® experience is required. Students should be computer literate.

For more information on AFSA’s Beginning Design School, visit firesprinkler.org/design. For details on AFSA’s Intermediate Design School, visit firesprinkler.org/nextlevel.

APPLICANT ELIGIBILITY REQUIREMENTS

The AFSA Design School Scholarship is open to designers employed by Category 1-3 AFSA Member Contractor companies. Scholarship funds are payable to the designer’s employer; the designer must enroll within the calendar year.

Recipients will be ranked based on the level of demonstrated need deemed by the committee.

ENTRY DETAILS

Scholarship entries are accepted online only through the AFSA Design School Scholarship website at www.firesprinkler. org/designscholarship. Entrants must submit a completed entry form with all required information. Before design school scholarship funds are awarded, all information submitted on the entry form by the entrant will be verified.

NOTIFICATION

AFSA will contact each winner’s employer by email and phone. Once winners are confirmed, AFSA will send the appropriate forms to complete. AFSA will cover the design school registration fee, and a check will be issued to the employer to be used for travel expenses, including airfare and hotel. All forms and processes must be completed within sixty (60) days of the winner notification, or your scholarship is forfeited.

AFSA’s design school scholarships are only for contractor members in tier 1-3 categories. For more information and to apply, visit firesprinkler.org/designscholarship. Questions? Email scholarships@firesprinkler.org. n

27 SPRINKLER AGE | MAR/APR 2023

AFSA is helping Category 1-3 contractor members develop their designers and grow their design departments with its new design scholarship program.

SUPPORTING FIRE PROTECTION SYSTEMS

NFPA 200 IS ON THE HORIZON

VICTORIA B. VALENTINE, P.E., FSFPE | AMERICAN FIRE SPRINKLER ASSOCIATION

Installing any fire protection system has always included supports for the system to keep it in place over its lifetime. In the past, the guidance for supporting a system has been written by the experts for that type of system. Today, the information

has gotten more detailed and requires additional attention.

COMMITTEE FOR HANGING AND BRACING

Emphasis was put on the support of sprinkler systems when a task group was

put together in the mid-1980s within the NFPA 13 technical committee. In 1997, preparing for the 1999 edition of NFPA 13, the technical committee was reorganized to have multiple technical committees responsible for segments of the standard and all reporting to a correlating committee. One of these is the Technical Committee on Hanging and Bracing of Water-Based Fire Protection Systems. The scope for this committee is as follows: “This committee shall have the primary responsibility for those portions of NFPA 13, Standard for the Installation of Sprinkler Systems, that pertain to the criteria for the use and installation of components and devices used for the support of water-based fire protection system piping including protection against seismic events.”

As the information expanded within NFPA 13 for both gravity support and seismic protection, so did the references to the criteria. Other water-based systems such as standpipe systems (NFPA 14, Standard for the Installation of Standpipe and Hose Systems), fixed spray systems (NFPA 15, Standard for Water Spray Fixed Systems for Fire Protection), water mist systems (NFPA 750, Standard on Water Mist Fire Protection Systems), and others were also using the criteria found in NFPA 13 for hanging and bracing information. The committee aimed to address systems beyond sprinkler systems but often felt their content is in NFPA 13, and they were restricted from specifically calling out the needs of other systems. Yet, this is the group with the experts related to support and seismic protection.

Following many discussions and direction from the NFPA Standards Council, a new committee has been assembled to create

28 SPRINKLER AGE | MAR/APR 2023

PROPOSED CHAPTER TOPIC 1 Administration 2 Referenced publications 3 Definitions 4 General requirements 5 Hanging and support of sprinkler system piping 6 Seismic protection of sprinkler system piping 7 Hanging and support of water-spray fixed systems 8 Hanging and support of gaseous systems 9 Hanging, support, and seismic protection of gaseous fire suppression agent storage containers 10 Hanging and support of water mist systems 11 Seismic protection of water mist systems 12 Hanging and support of hybrid systems 13 Seismic protection of hybrid systems 14 Hanging and support of fire pump systems 15 Seismic protection of fire pump systems 16 Hanging and support of private fire water tanks 17 Seismic protection of private fire water tanks 18 Hanging and support of private fire service mains 19 Seismic protection of private fire service mains 20 Hanging and support of foam system components 21 Seismic protection of foam system components Annex A Explanatory details Annex B Supporting information on conformance with ASCE/SEI 7-22 Annex C Informational resources

1.

Table

Proposed subjects for the chapters of NFPA 200.