24 minute read

CCT

from SPN Sep 2021

by spnews.com

Taking the lid off traditional jars

Recently SPN received a moving story from a packaging company that decided that it would ‘make a difference’ having been inspired by a lady suffering from cancer. This has resulted in a valuable packaging solution. CCT tell their story via the list of questions that we created for the company.

Advertisement

What is the background to CCT and what have been its milestones?

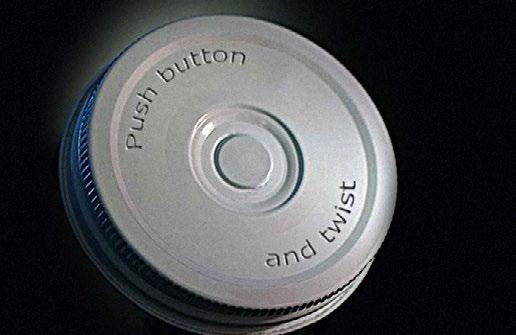

CCT is an innovative packaging solutions company and the creator of the EEASY Lid – the first jar lid innovation in over 75 years. The development of the EEASY Lid was inspired by a friend to CCT who was being treated for cancer. She struggled to complete everyday tasks, including opening packing like vacuum-sealed jars. CCT took on the challenge of inventing a jar lid that was easy for anyone to open. The team spent the next eight years developing the EEASY Lid, ensuring its packaging was accessible to everyone – no matter age, gender or physical capability.

Company milestones include the following :

• CCT announced the launch of the EEASY Lid on November 12, 2020, making opening a vacuum-sealed jar up to 40% easier with just the push of a button. • The EEASY Lid hit store shelves at Pennsylvania-based Boyer’s Food Markets on January 6, 2020. Incorporated on its Darci’s brand pasta sauce, Boyer’s became the first grocer in the country to use the EEASY Lid. • In February of 2020, CCT partnered with North Cliff Consultants to run a consumer testing study to assess the difficulty people have in opening a traditional vacuumsealed jar. The study found nearly 50% of consumers struggle to open jars, proving how ease of use affects purchasing decisions.

• On May 4, 2020, CCT announced the results of the first use of the EEASY Lid over a three-month test period in Boyer’s Food Markets. Results showed that the first use of the EEASY Lid boosted Boyer’s private-label pasta sauce sales by over 300%. • CCT announced its partnerships with The Affinity Group and Trade Consult on August 3, 2020. These partnerships assist CCT in expanding the EEASY Lid’s domestic and international reach.

• Just earlier this year on March 8, CCT introduced the world’s first aluminum lug lid, as it is now producing an aluminum lug version of its EEASY Lid in its new state-of-the-art technology center.

Can you describe your product portfolio and any unique applications within the packaging industry? (EEASY Lid?)?

CCT makes the EEASY Lid, the first jar lid innovation in over 75 years. The EEASY Lid comes in both a continuous thread (CT) version and a lug version. CCT’s EEASY Lug Lid is the world’s first aluminum lug lid ever made. The EEASY Lid works by simply pressing a button on the lid. After use, the lid is reclosed by pressing the button from the inside of the lid to help keep the product fresh and prevent spills. Research found the EEASY Lid reduces the amount of torque needed to twist off a jar lid by more than 40% compared to standard CT lids and 58% for traditional lug lids.

What differentiates CCT from its competitors and do you offer any added-value customer services?

First and foremost, CCT and the EEASY Lid were established to bring further inclusivity within the packaging industry, something you don’t see a lot of in today’s world. The EEASY Lid makes opening jars accessible to everyone despite age, gender, disability or physical ailment (carpel tunnel, arthritis, etc).

CCT has also raised industry standards when it comes to jar lid packaging. Both CT and lug versions of the EEASY Lid are made of aluminum (with the lug version of the EEASY Lid being the world’s first aluminum lug lid). Most other lids in the market – specifically all lug lids – are made of steel. The aluminum CCT uses offers an unmatched combination of strength, lightweight and corrosion-resistance material, in addition to being more desirable when it comes to recycling than steel.

How sustainability aware would you say that your company is and what recent measures have you taken to improve your overall contribution to the circular economy?

At CCT, we are very aware when it comes to the type of materials we use to create the EEASY Lid. We knew we wanted to use aluminium on our lids instead of steel (which is what the rest of the industry uses) due to it being more recyclable.

80% of the jar lid industry uses lug lids compared to CT lids. While there have been aluminium CT lids circulating, the jar lid industry had yet to see an aluminium lug lid. With many years of research and development in the making, CCT set out to create the first aluminium lug EEASY Lid. This opens the jar lid market up to more sustainable options for manufacturers and grocers all over the world.

What are the key drivers for change in your industry sector and how is the current demand for sustainability and recycling affecting your products and productivity?

“The packaging industry is constantly being driven by consumer needs. Many brands are forced to evolve their packaging as consumer needs and wants are changing. Currently, sustainability is a huge driving factor when it comes to consumer purchase decisions. Shoppers are looking to buy products that have some sort of benefit or positive impact on our environment. While many companies are updating new packaging protocols, the jar lid industry has been using the same types of lids and materials for the past 75 years. We believe the EEASY Lid – especially the new aluminium lug lid – will give companies even more flexibility when it comes to a sustainable focus”.

Are you planning the launch of any new packaging products in the foreseeable future that you can tell us about?

“We are currently focusing on expanding the EEASY Lid to more manufacturers and grocers across the globe. CCT is currently in talks with major retailers and national brands to potentially start incorporating the EEASY Lid on products to soon be available to consumers”.

How has the Covid 19 Pandemic affected your production and manufacturing processes - and future ambitions?

“One of the biggest impacts of COVID-19 that we experienced was on our production facility. Along with creating the world’s first aluminium lug lid, we needed to create a custom state-of-the-art technology centre to produce a product that is a first of its kind. We saw a slight delay in getting some machinery and equipment used to produce the EEASY Lid, but we are proud to say we are officially up and running with production.

Aside from minor production delays, consumers are buying food and jarred products at a higher rate during the COVID-19 pandemic – putting even more pressure on the supply chain. With that in mind, our progress has continued full steam ahead in terms of getting the EEASY Lid on potential products and in stores”.

What inspired you to make a general statement about the importance of working with partners across their supply chains?

“Sustainability is more than just reducing the use of plastics in products. It involves doing anything that we can to improve the world that we live in, and no one company can solve the challenge by itself. Rather, it takes everyone pushing in the same direction to make a true impact.

Additionally, consumers are continuing to push brands to further invest in sustainable efforts, and studies have shown that consumers will pay more for products from companies that take sustainable measures during production. For us, the EEASY Lid can be a piece of the puzzle that helps brands improve their sustainable efforts. So, for brands to think holistically about their supply chains, it behoves them to evaluate all the partners they currently or will work with to see where more sustainable changes can be made across the supply chain.

This can include changing the materials used for production or packaging to be made of recycled material, working with transportation partners who work to limit their emissions or cut down on less-than-truckload shipments or even going as far as educating consumers about how they can help with limiting food waste or encouraging them to recycle”.

How do you plan to educate the food industry sector, in order to get them to rethink their packaging options in the light of increasing demand for greater sustainability from consumers?

“In the food and beverage industry, companies are well aware of consumers’ buying habits, and sustainability has been trending as one of the main reasons consumers buy one product over another. As much as brands have been changing their packaging to reduce plastics and use alternative materials to become more sustainable, there are other things we can all do to ensure that there are natural resources for future generations. From reducing waste during the manufacturing process to working with partners across the supply chain, the little efforts each company takes to do better makes a difference in the grand scheme of things”.

What do you consider to be the best way forward in promoting greater awareness of what consumers can do to incentivise converters?

“We think consumers are doing their part in incentivizing brands to switch to more sustainable practices, as this is reflected in sales and market shares for a company’s products. And while it will never be 100% of consumers who go out of their way to buy products from more sustainable brands, the near 70% of consumers who do will continue to push brands to implement more best practices in hopes of attracting those consumers to buy their products. Now, it’s just up to the companies to recognize that this is a trend that will continue, and it will be up to them if they want to participate or not. Here at CCT, we planned for this to be a part of our product roadmap and developed the world’s first aluminium lug lid, which aims to be a part of that puzzle that helps brands improve their sustainability efforts”.

Siegwerk

Defeating today’s down-cycling challenges

Accredited as the first technology of its kind by the Association of Plastic Recyclers (APR), Siegwerk has developed a unique washable ink-technology that defeats today’s on-going, down-cycling spiral. The new technology enables de-inking of UV/ LED printed PET shrink sleeves, thus allowing for the post-recycling of sleeves, along with PET plastic bottles.

Today there is a greater awareness than ever of the need for recyclable packaging. This in turn has created the development of special materials in order to develop new packaging formulas. However, there are a number of key challenges that need to be overcome in order to make 100% circular packaging possible.

Different plastic types cannot be separated or mechanically recycled in order to yield a useful recyclate. Furthermore, avoiding multi-material structures is not always possible in respect of shelf-life and other technical aspects of the packaging. In addition, current recyclate quality is typically poor. This is due to the unpleasant visual appearance, as well as the odours that can be emitted from different types of recyclates following extrusion. These problems can also be related to ink-degrading and unwanted traces remaining in the recyclates. This process unfortunately stimulates and enforces down-cycling.

The importance of inks and coatings in designing packaging fit for recycling cannot be over-emphasised. Ink used on packaging can either hinder or help in facilitating true circularity and avoiding the down-cycling of packaging.

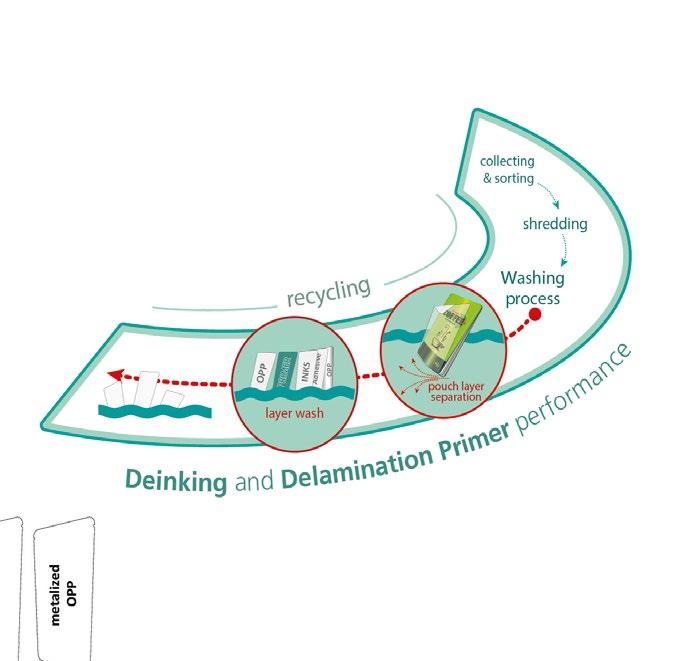

To address these problems the leading ink manufacturer, Siegwerk has developed de-inking and delamination technology that enables the creation of high-quality recyclates.

The de-inking and delamination primer are printable layers sensitive to an industrial hot washing progress. Inks and coatings are removed quickly and effectively, leaving clean, separated plastic layers. The remaining high quality recyclates can be used in new packaging materials. Plastic laminates do not always need to end up in the landfill or incinerator. This break-through technology from Siegwerk is compatible with a wide variety of packaging structures, whilst packaging specifications remain unchanged. Most importantly, use of the de-inking and de-lamination technology aids in achieving 100% recyclability, which is an essential component in achieving a truly Circular Economy. One example of the application of this technology is the use of de-inking primers for cPET sleeves in combination with certified ink systems. This allows for the removal of printed layers within defined de-inking process conditions. This new technology finally avoids the down-cycling of rPET in the textile industry.

Whilst this technology may significantly enhance circularity, collaboration and close cooperation within the corresponding value-chain is key to establish a commercially successful recycling process. Therefore, Siegwerk is seeking partnerships from those in the packaging value-chain who wish to take a leading role in pioneering circular solutions for the future.

Visit www.siegwerk.com or contact boc@siegwerk.com to create circular solutions for your packaging.

Evertis Squaring the circle for PET trays

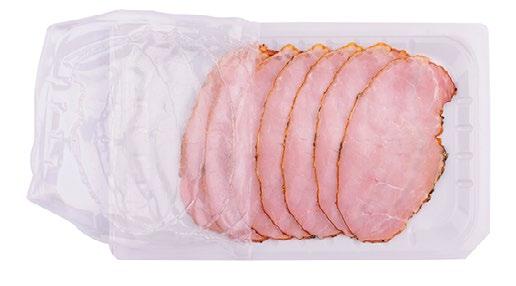

Evertis is a modern-day success story, especially when it comes to PET tray packaging. For it not only plays a crucial role in food preservation, both in terms of safety and hygiene, but also in the minimisation of food waste. This makes it today’s material of choice in terms of circularity. When it comes to the circular economy, Evertis, is the leading global supplier of PET-based films, and the one that sets the industry standard.

Pioneering the incorporation of recycled content in their films for the food packaging industry since their foundation in 1959, and with the establishment of their own recycling unit in 2003, Evertis have been giving their customers the option of offering more environmentally friendly products long before there was any directives or targets in place. Evertis currently target an average incorporation of 50% post-industrial and post-consumer recycled content in their films.

Extending tray life

Evertis give post-industrial and post-consumer multilayer trays a new life, thus proving that a circular economy for trays can be a reality. The firm’s partnership with a company that has a unique technology that permits incorporating recycled PET obtained from a delamination process of multilayer waste, means that it can be reintroduced as secondary raw material in their film production processes.

Evertis uses raw materials and production processes, such as water-based lamination, that allow the delamination of multilayer materials during the recycling process, so that they can be reincorporated back into their films. The Evertis film production process has an EREMA reactor which allows for up to 100% of recycled content to be included in their films for food contact applications with EFSA food contact approval.

Fully recyclable PET streams

The prominent levels of recycled content is not the only ambitious goal that Evertis has successfully achieved in terms of circularity, ‘Design for recycling’ is one of the top issues the company tackles together with their customers, as they view this as an opportunity to boost their film’s ability to close the loop.

To the company, ‘Eco-Design’ means the development and production of products that follow all legislation and regulations regarding food contact, whilst protecting and assuring the proprieties of the packaged product. However, of extreme importance to Evertis is delivering packaging solutions that after usage, can be recycled and reincorporated once again into new materials. To Evertis, eco-design means a circular economy.

In the last few years Evertis has focused on developing innovative solutions that are fully recyclable in the PET stream. Given the close collaboration with their sistercompany Selenis, a producer of specialty polyester solutions, they have the possibility of developing resins with improved properties that can enhance the behavior and effectiveness of their films when compared with standard solutions.

Their ECOSEAL™ film, produced with Selenis Bondz MM 510™ resin, allows brand-owners to package their products in fully recyclable APET packaging trays, by replacing the usual PE layer with this specialty polyester, the need for a multilayer in the bottom web is eliminated. Furthermore, the ECOSEAL™ film’s enhanced sealing properties are compatible with universal sealing lidding films, ideal for Form-Fill-Seal packaging. Other fully recyclable solutions that Evertis has recently launched are their IR BLACK™ films, formulated with an NIR Black masterbatch that is detectable by the current sorting technology in recycling processes. This new development is a sustainable alternative that is carbon-black-free, thus improving the recyclability of the material and the final packaging.

All this is good news from SPN’s perspective, as well as for all companies that are planning to meet the 30% requirement for recyclable films and are dedicated to the circular economy. When it comes to FMCG packaging in particular, Evertis appears to have “Squared the Circle” for PET trays.

Albea Tubular step-by-step success

When it comes to questions about plastic tube recycling, the answers can vary over time. New manufacturing techniques and product innovation can create additional milestones, resulting in more regulations and increased legislation. Albea believes that a clearly defined and specific methodology is crucial to achieving improved recycling results.

Gilles Swyngedauw, VP Sustainability & Innovation at Albea told SPN: “Europe is driving the way towards a more sustainable future with the Green Deal and its new Circular Economy Action Plan, which focuses on 6 key areas, among these are climate change, clean and circular economy and zero pollution. In a very short time, the EU and France voted and implemented new regulations on packaging waste. And there is more to come with the revision of the Packaging and Packaging Waste Directive which will start shortly and will become the cornerstone of Sustainability in Packaging.

The targets are clearly defined: In 2025, 50% of plastic packaging should be recycled, in 2030 55%, and 100% of packaging will have to be reusable, recyclable or compostable by 2035. Still, to be claimed as recyclable, all packaging needs to be collected, sorted, regenerated, and used again as a material for a viable application, which implies a multistage process”.

Gilles Swyngedauw VP Sustainability & Innovation at Albea

At Albéa, we have defined an effective methodology based on 4 concise steps:

Step 1 defines the packaging to assess. A tube is made of the tube, a seal and a screw cap. To assess the product, the seal has to be removed and disposed. It is therefore not considered as a component of the packaging when assessing the recyclability of the tube. On the other hand, to assess the product, the cap will be unscrewed and screwed back on after each use. For the assessment, the formula should also be considered as some formulas can disqualify the recyclability of the tube.

Step 2 is about defining an existing recycling stream as well as the recycling family of material the tube belongs to. Where Extended Producer Responsibility is in place, the Producer Responsibility Organizations (PROs) are managing the collection and sorting the packaging by families of materials. The material making up more than 50% of the tube weight defines the family – and the appropriate recycling stream. Once the family is defined, a local recycling stream needs to be found. Finally, it should be ensured that the packaging entering the stream is not going to interfere with this one.

Step 3 is about the sorting of the tube packaging and its recognition in a “materials recovery facility” (MRF). For example, black carbon or full metallised layer on surface will hinder the sortability.

Step 4 starts when moving from the MRF to the Regenerator plant. The compatibility of the various components with the recycling stream of its main materials family is evaluated to guarantee that nothing hinders the recyclability: Alu foil or some additives such as fibres are not compatible and can downgrade the regeneration. Some components may not impact the overall recyclability but may reduce the amount of recycled material available like PET Caps in HDPE streams.

Recycling-ready tubes and caps

Greenleaf 2 laminate tubes

Recognised by both the Association of Plastic Recyclers (APR) in the US and RecyClass in Europe, Greenleaf is a patented, simplified web production process that generates a 100% recyclable laminate range with high barrier properties.

First cap in PE launched in February 2020

The SLIM Cap (flip-top) in PE is one of the lightest caps on the market, an eco-designed model combining weight reduction with recyclability.

First extruded plastic tube & cap is recycling-ready in Europe

Recognised by RecyClass, the tube is a mono-material, downgauged web with white masterbatch that leverages the unique Thinwall™ technology and assembled with a HDPE shoulder. Both tube ranges can be regenerated into HDPE bottles and integrate the HDPE bottles recycling stream.

Guidelines on recyclable tubes:

• As mono-material as possible • Tube body in HDPE • Cap and tube body in same material • Barrier layer as thin as possible • Optimized decoration

Certified sustainability at Sihl

Your product in individualised packaging? Quickly available, ideally in your own design and in small quantities? With ARTYSIO, we not only offer flexible and individualised packaging solutions, but can also meet your sustainability requirements!

At Sihl, we combine economic success with environmental protection and social responsibility. Economy and ecology go hand in hand so that we actively contribute to a more liveable future. Environmental, social and corporate governance is our guiding principle and it sums up what we do. That is why we create products and solutions that make the best possible use of existing resources and whose sustainability has already been confirmed by various certificates.

In the area of PACKAGING, recyclability is a priority for us. Three years ago, the environmental services provider Interseroh launched its “Made for Recycling” assessment procedure and thereby set a groundbreaking standard for the recycling capability of packaging.

The renowned company was commissioned to put the flexible packaging film 5552 ARTYSIO PACKAGING 5552 NW P&P PP M FFS 74 W to the test on the basis of its scientific assessment methods. Interseroh developed this fundamental testing standard together with the bifa environmental institute and it was then certified by the Fraunhofer Institute for Process Engineering and Packaging IVV.

The company’s assessment method measures packaging against a very high standard. Only packaging that scores at least 18 points from a total of 20 is awarded the “Made for Recycling” certificate. The seal of quality is thus a meaningful indicator of the sustainability of an item of packaging. The assessment process determines whether the packaging can be easily allocated to the right capture system, how the packaging behaves during sorting and whether the packaging is suitable for material recycling. The more points the packaging scores on a scale of 0 to 20, the easier and better it is to recycle. In addition, the “Made for Recycling” service meets the requirements of the minimum standard for assessing the recyclability of packaging of the Central Agency Packing Register (ZSVR) that has been in force since 1 September 2019.

Our monomaterial for flexible packaging, 5552 ARTYSIO PACKAGING 5552 NW P&P PP M FFS 74 W, has undergone this rigorous testing process and has been awarded the certificate of recyclability! 5552 ARTYSIO PACKAGING is an aqueous inkjet printable, white PP-based film that is manufactured in compliance with GMP guidelines and therefore qualifies as flexible primary packaging for food & non-food applications. The design of the product and the very fast fixing of the waterbased ink makes ARTYSIO Packaging 5552 particularly suitable for print&pack applications, where packaging is printed and filled inline in a single production step. The machinability of the monomaterial has been designed both for use on horizontal FFS systems for the filling of bulk goods and on vertical systems for the filling of free-flowing products, which hugely extends the usage possibilities of ARTYSIO Packaging 5552.

With a sealing and barrier coating, ARTYSIO Packaging 5552 has excellent sealing qualities for maximum product safety, very high sealed seam strength and superb machinability on production systems. ARTYSIO Packaging 5552’s “easy opening” function also makes it simple to open in a controlled way. The excellent water vapour and aroma barrier makes the product suitable as primary packaging for products such as cereals, chocolate products, confectionery or tea.

What more could you want? Benefit from our know-how, our partnerships and our ongoing support and contact us today at artysio@sihl.com

or find out more at www.artysio-packaging.com

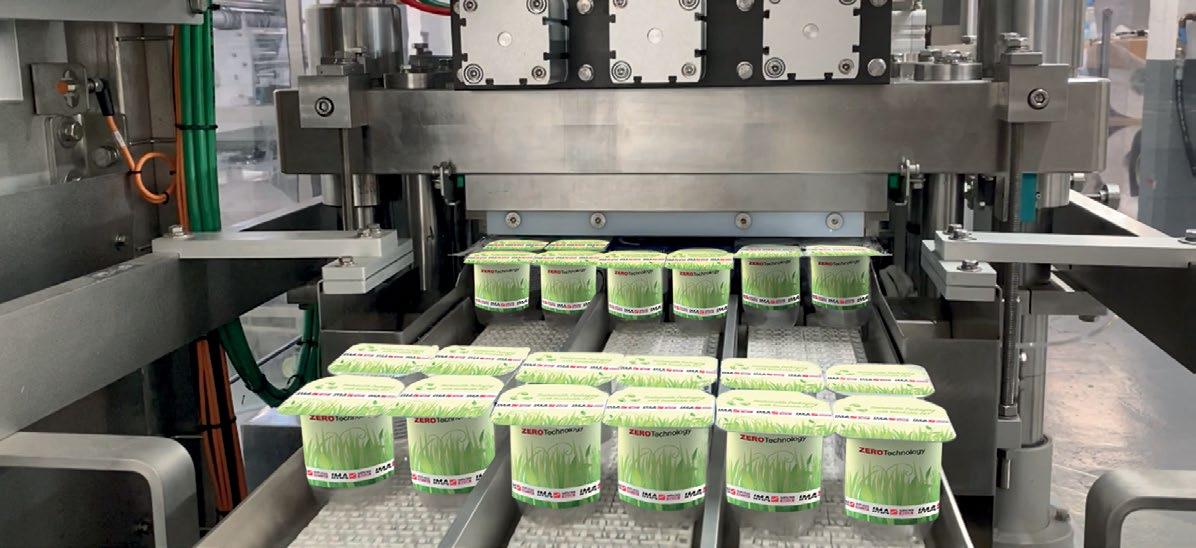

IMA DAIRY & FOOD Zero-in on new technology

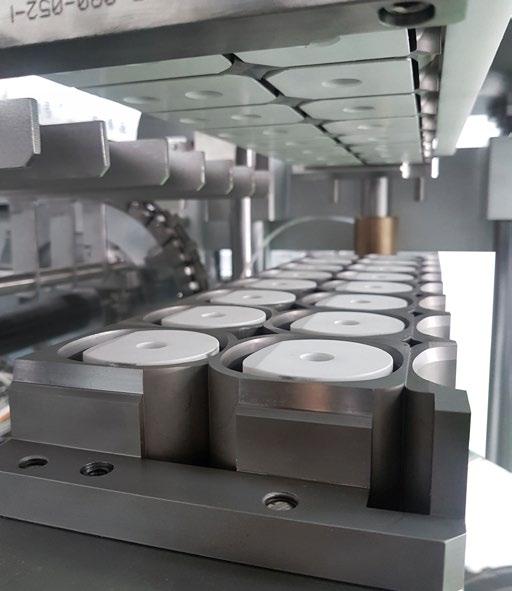

With its patented ‘ZERO Technology’ tools, IMA DAIRY & FOOD offers the perfect, sustainable solution for mono-materials packaging. These unique tools from the company’s ‘ZERO Technology’ range are the result of years of research and development and offer much more than simple solutions to save on materials, they also offer improved material characteristics and optimisation.

In today’s competitive marketplace, IMA DAIRY & FOOD is the perfect partner for achieving innovative and practical packaging solutions. From hygienic product protection, to communication with customers IMA DAIRY & FOOD says that packaging must fulfil a wide range of functions, including packaging design, ease of use, optimal logistics, and concise customer information. However, it must also be sustainable and guarantee the shelf-life of the product. Functionality and sustainability are equally important when it comes to packaging development. This must be taken into consideration when developing alternative packaging concepts with sustainable materials such as monomaterials, as well as materials from renewable resources.

When it comes to delivering a competitive edge, IMA DAIRY & FOOD’s advanced ‘ZERO Technology’ does just that. The new innovative technology can be applied to all cutting applications contained in any FFS machine. In addition it reduces maintenance costs whilst increasing the performance of the machine and provides longer punching time. By using these advanced tools, a quick switch from PS to more recyclable materials such as PET, PP and PLA can be achieved. Furthermore, customers now have the opportunity to use these materials for thermoformed products such as yoghurt cups. Only with its new, patented punching tools, can multipacks be made-up from these materials and be broken down into individual cups. In fact, this can just as easily be done as those for multipacks made from PS. Another benefit is that knives do not even have to be changed during this process using IMA DAIRY & FOOD machinery. Other special equipment in IMA DAIRY & FOOD’s ‘ZERO Technology’ range also includes special pre-heating plates, which can be easily dismantled for simpler maintenance.

Additional savings on materials can also be achieved by using the company’s special thermoforming moulds, which offer the advantage of using thinner base web materials (foil). The result is that IMA DAIRY & FOOD’s ‘ZERO Technology’ offers companies in the dairy or food industry the most innovative solutions possible when implementing more sustainable packaging materials. This is whether it is in existing form, fill and seal machines, or in new machines. What’s more, the improved recyclability of thermoformed products provides a significant reduction in ecological impact.

An IMA DAIRY & FOOD company spokesperson told SPN, “Our technological solutions have enabled plastic packaging to become increasingly lighter over the years whilst still offering the same packaging performance and rigidity. In order to offer advanced sustainable packaging solutions, we work in close partnership with our customers and suppliers from the very beginning, in order to develop practical solutions for saving packaging material and at the same time take into consideration the environmental wellbeing, as well as the customer‘s product and overall packaging concept.

“Together with our customers and material suppliers we rigorously test new packaging materials made from renewable or recyclable materials to ensure that the materials can be processed on our packaging machines and that the greatest possible machine output and optimisation can be relied upon at all times”