SUSTAINABLE PACKAGING NEWS

Circular Economy

SPN looks at how the packaging industry is adopting sustainable circular practices

Plastic Packaging

Challenges and sustainable innovations

Corrugated Packaging

Bottles vs Cartons

Printing Solutions

Taking the lead in sustainability

Sustainable Revolution

The shift towards reusable packaging is gaining momentum, promising a greener future

Issue 24:2 - April 2024

15th & 16th May 2024 The NEC, Birmingham, UK PRE-REGISTER FOR FREE ENTRY! 15TH & 16TH MAY 2024 REGISTER FREE AT WWW.CHEMICALUKEXPO.COM 2 Packed Days 500+ Exhibitors Process & Plant Engineering Chemicals & Materials Sourcing Laboratory Innovation Operations & Logistics 100+ Speakers Supporting Media Partner The UK’s largest EXPO for the Chemical, Laboratory & Process Industries FREE ENTRY WHEN PRE-REGISTERED Supporting Partners include:

Welcome to

Dear Readers,

I hope that all is well with you and yours and that everyone is off to a good start as summer beckons!

Despite the dreadful on-going war in Gaza and the continuing conflagration in Ukraine, our industry is not only surviving, but thriving! That is according to our feedback and the confirmation of business optimism throughout the National Press.

In any event, the industry’s commitment to improving efficiency and sustainability is driving the green agenda forward and meeting the demands of an ever-growing call by consumers for less waste and greater sustainability.

This awareness of our responsibilities at every stage of our manufacturing processes, has helped us to significantly improve productivity and achieve savings not only in logistics, but also in basic commodities and raw materials. What’s more, following the recent alarming news that the earth is warming faster than anyone has ever predicted, there is yet another imperative to be more innovative and resourceful and so helping to protect our planet.

In our latest issue, we offer some major insights into optimising resource efficiency and the circular economy. We also reveal packaging’s latest digital print solutions as well as the benefits to be considered in relation to the use of Bottles vs Cartons. Our coverage of the forthcoming DRUPA Packaging Trade Show in Dusseldorf is another feature well-worth investigating!

In the meantime, we wish you all success and hope that you continue to find SPN your most valuable source of up-to-the -minute news and thought-provoking solutions.

Sincerely,

SUSTAINABLE PACKAGING NEWS

spnews.com Philip Yorke ( Editor ) April 2024 SUSTAINABLE PACKAGING NEWS 3 SUSTAINABLE PACKAGING NEWS Sustainable Revolution 1. The shift towards reusable packaging is gaining momentum, promising a greener future Circular Economy SPN looks at how the packaging industry is adopting sustainable circular practices Taking the lead in sustainability Issue 24:2 - April 2024 Corrugated Packaging Bottles vs Cartons Plastic Packaging Challenges and sustainable innovations Printing Solutions news_packaging WELCOME TO SPN MAGAZINE linkedin.com/company/ sustainable-packaging-news/ Director Editor Writers Designer Kevin Gambrill Philip Yorke Dominy Jones, Steven Gislam Dom Thorby

4 SUSTAINABLE PACKAGING NEWS Contents CONTENTS REGULAR FEATURES TOPICS SUPPLY-CHAIN SLEUTHS 6 Get Supply Chain Sustainability BOTTLES V CARTONS 12 Kingsland Drinks - It’s in the bag! 13 Syntegon - Tunnel Vision 14 Elopak Elevates Brands REUSABLE PACKAGING 16 The Sustainable Revolution RESOURCE EFFICIENCY 34 Rethinking Resource Efficiency CIRCULAR ECONOMY 22 Zero Waste - Redefining the Circular Economy 26 KP Films - Looping the Loop 28 Metal Packaging Europe - Circular Solutions 30 Bpacks - Barking up the right tree 32 PakTech Pioneering the Circular Economy CORRUGATED PACKAGING 37 RH Fibreboard - Child’s Play INDUSTRY 4:0 38 The next phase in digitisation PLASTIC PACKAGING 18 Plastic – the slow toxin 8 20-20 VISION 7 Britvic unlocks 5.4m Sustainable Results 8 Giant leap! - DS Smith takeover DIGITAL DIGEST 9 Advancing Digital Design RETAIL ROUND-UP 10 M&S Takes Rapid Action 11 Going Soft on Plastics PRINTING SOLUTIONS 40 NOMOQ - Greater sustainability EVENT NEWS 42 Drupa 2024 44 ACHEMA 2024 46 CHEM UK EXPO 9

SUSTAINABLE PACKAGING NEWS 5 CONTENTS 18 38 13 42 22 40

Supply-chain Sleuths

Get Supply Chain Sustainability

We believe that all SPN readers can significantly improve their overall supply chain efficiency and benefit from some of these recent IBM insights! IBM told Sustainable Packaging News that with today’s solutions ranging from supply chain partner data exchange, to procurement and inventory planning, as well as to end-to-end transparency, major improvements can be made quickly and efficiently.

To which can be added the orchestration of intelligent omnichannel order-fulfilment optimisation, where IBM® offers a complete portfolio of next-generation products and services to solve any company’s supply chain management needs. Furthermore, it is possible to improve the company’s bottom line and help to provide a greater competitive advantage. Companies can always make their supply chain smarter, more resilient and more sustainable with IBM’s unique state-of-the-art Supply Chain Solutions.

Increase overall cost-effectiveness and efficiency by taking advantage of the following IBM offers: Get The Guide to Generative AI for Supply chain efficiency, and build a more sustainable, resilient supply chain. The many benefits include greater cost savings, ability to exceed customer expectations, and the advantage of differentiating the brand.

Get your customers what they need—when and where they need it—while preserving business continuity by reducing supply chain disruptions.Improve forecasting by enabling intelligent, end-to-end global supply chain visibility and transparency.

Get real-time intelligence and actionable recommendations to reduce disruption mitigation-time from days to hours. Sense and respond to changes on demand—as they occur. Also evolve supply chain planning and processes to reduce operational silos, respond to market disruptions, mitigate risk and maintain business continuity.

6 SUSTAINABLE PACKAGING NEWS

SUPPLY-CHAIN SLEUTHS

Britvic unlocks 5.4m Sustainable Results 20-20 Vision

LineView Solutions has unlocked £5.4M in capacity increase at Britvic’s factory in Rugby, UK through its Line Balancing Optimisation programme. (LBO). LineView worked with the leading British beverage manufacturer to execute a comprehensive LBO training project over a two-week period. The programme achieved an immediate capacity increase of £2.9M, directly impacting Britvic’s profitability, whilst revealing a further £2.5M in capacity gains through enhanced control optimisation.

LineView was tasked with upskilling the Britvic controls engineering team with the necessary skills and knowledge to identify and implement LBO opportunities across the business. With constant pressure to optimise production, LineView’s industry experts worked in collaboration with the team to implement practical improvements and enable the lines to fulfil market demand for summer can volume.

The tailored LBO training equipped eight Britvic team members with skills to effectively balance operator and machine time. This focus included improving control, accumulation, speed, start-up, and run-out times across can lines, enabling the team to identify and implement LBO opportunities across the entire organisation. As a result, they are now positioned to unlock additional capacity increases across multiple lines, while also fostering sustained production efficiency through a commitment to continuous improvement.

Paramjeet Pahdi, Rugby Site Director at Britvic PLC, expressed his satisfaction with the project, stating, “I’m hugely impressed with LineView. We’ve unlocked significant capacity for our plant and reduced the impact of minor stoppages on our production lines. Most importantly, we’ve equipped our people to be able to go hunt down these opportunities throughout our business. LineView delivered not only an engaging course but also ensured we have full understanding and confidence to take ownership of this process moving forwards!”

LineView Solutions is a global leader in manufacturing optimisation solutions, dedicated to empowering manufacturing companies to achieve excellence and operational efficiency through its advanced software and expert consulting services. With a focus on innovation, technology, and customer-centricity, its solutions help manufacturing organisations enable data-driven decision-making to improve their environmental footprint and product quality.

SUSTAINABLE PACKAGING NEWS 7

20-20 VISION

Giant leap! STOP PRESS

DS Smith, the UK packaging giant, has agreed a takeover by US rival, International Paper that values the company at £5.8bn. The all-share deal would see DS Smith shareholders own just over a third of the combined firm. The FTSE 100 listing would not disappear from the London Stock Exchange altogether, as the larger group plan to seek a secondary listing in the UK.

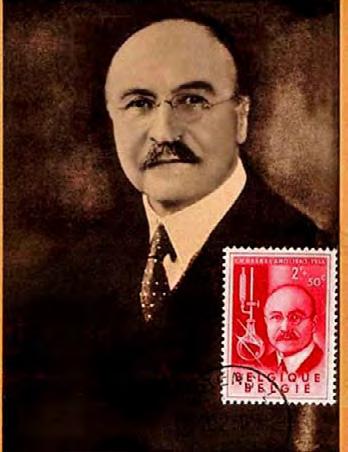

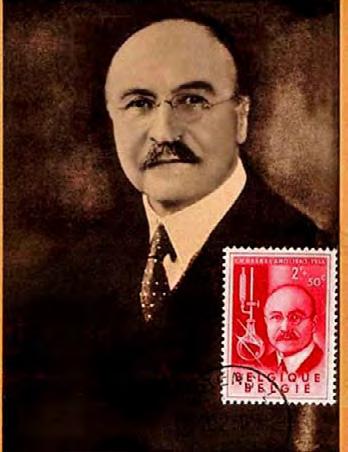

Mark S Sutton CEO International Paper USA

Mark S Sutton CEO International Paper USA

The proposed deal was announced ahead of a deadline for offers imposed by the City’s Takeover Panel of 23 April. UK firm Mondi had been among the other potential suitors. Its all-share offer had valued DS Smith at just over £5.1bn. It still has time to make a counter bid but DS Smith said International Paper was in a position to proceed, adding that it would recommend shareholders back the deal on the table. Subject to that and regulatory approval, it would expect to close late this year. The value placed on DS Smith represents a 47.7% premium to the closing price of its shares in February before Mondi’s initial interest came to light.

As part of its plans, International Paper said around 400 roles across the combined company could be at risk, but added that any layoffs would be subject to review. DS Smith’s long-serving chief executive Miles Roberts, who had already announced his plans to retire, commented: “The combination with International Paper is an attractive opportunity to create a truly international sustainable packaging solutions leader that is well positioned in attractive and growing markets across Europe and North America”.

8 SUSTAINABLE PACKAGING NEWS 20-20 VISION

Miles Roberts CEO DS Smith

Image Courtesy International Paper USA

Digital Digest

Advancing Digital Design

The evolution of packaging through digital printing means that major players gain a competitive advantage in the market as digital printing redefines industry standards with its versatility, customisation options, and sustainability advantages, said research group Smither.

Digital printing enables brands to craft genuinely distinctive packaging designs that distinguish them from others. Digital printing may be relatively new to packaging, but it is fast becoming a key player in the highly competitive packaging market, say experts.

Ohio, USA-based market research company, Smithers, says digital will be the fastest growing print technology for packaging from 2022 to 2027. Indeed, a study published by USA consultants Towards Packaging, a sister firm of Precedence Research, said the digital printing packaging sector is valued at more than $24.15m in 2023 and is estimated to reach $56.03m by 2032. In 2022, North America was the largest market with a 31.15% share, followed by Europe at 29.47%. Major players include American majors QuadGraphics Inc, Hewlett Packard (HP), Eastman Kodak and the WS Packaging Group, plus Britain’s Mondi Plc, the research states.

Digital Printing Drives Innovation

Without doubt, this innovative technology offers design and production flexibility, with fewer stages than ‘traditional’ printing’s application of ink to plates or screens that stamp the packaging. In digital packaging, a digital file, typically a PDF or JPEG, is transferred to a printer to apply designs or information and/or designs on to packaging materials.

The most common use of digital printing is inkjet with electrophotography and thermal transfer, with nano-graphic printing also gaining ground. Here, ultra-small particles of wet ink are jetted onto a conveyor blanket, drying there before being transferred onto packaging paper.

- Contributed by Smithers Research. March 7th 2024

SUSTAINABLE PACKAGING NEWS 9 DIGITAL DIGEST

Retail Round-up

M&S Takes Rapid Action

New M&S investment is driving its plans to become a fully ‘net zero business’ by 2040. This will be achieved by working in partnership with its long-standing and new suppliers to take rapid action towards net zero through a series of innovation projects.

A series of investments designed to tackle scope 3 emissions are driving M&S’ plans to help it become a ‘net zero business’ across all its operations and entire value chain by 2040. Eight new initiatives have been funded by M&S’ £1m Plan A Acceleration Fund which supports projects addressing challenges and supporting innovation that will help the retailer reduce emissions. Separately, the retailer is also investing £1m in changing the diet of the pasture-grazed cows to reduce the amount of methane being produced and released into the atmosphere.

“ I talk a lot about the ‘magic of M&S’ – a key part of this is our commitment to innovation ”

In a first for the UK, the initiative will see M&S working with all 40 of its Select dairy farmers, removing around 11,000 tons of greenhouse gas emissions from the atmosphere each year, and cutting its fresh milk carbon footprint by 8.4% “I talk a lot about the ‘magic of M&S’ – and a key part of this is our commitment to innovation,” said M&S CEO Stuart Machin “It’s in our DNA and, along with our unique model of own brand, long term supplier partnerships, it’s how we deliver the quality and trust our customers expect from us.”

- 9th April 2024

Jacqui Parr

10 SUSTAINABLE PACKAGING NEWS RETAIL ROUND-UP

Courtesy M&S

Going Soft on Plastics

Tesco rolled out recycling points for soft plastic packaging to all large its large stores not long ago and it has proved to be a major success! Customers can now recycle soft packaging such as bread bags, salad bags and crisp packets.

The supermarket made the move after a successful trial of recycling points across 171 stores allowing customers to recycle plastic including bread, salad and vegetable bags, crisp packets and sweet wrappers. Tesco said 85% of customers at trial stores in Wales and south west England said it helped them recycle more than they would otherwise have done, and shoppers also liked the convenience of combining recycling with their shop.

Once collected by Tesco, the old soft plastic is sent for recycling, where it is washed, sorted and as much material as possible is recycled into new products and packaging. The leading retailer said that in a recent sampling, it was able to recover more than 80% of the plastic returned by customers, and is now working with recyclers to see what can be done with the remaining 20% which is sent for incineration to generate energy.

“We’re rolling out collection points to the whole of the country so even more customers can help us stop plastic from going to waste, said Tesco’s director of quality, Sarah Bradbury.

“Soft plastic packaging such as the clear film to wrap meat and fish, crisp packets and fruit and veg bags is not commonly collected by local councils from homes for recycling so it usually went in the waste bin”.

The retailers roll-out of collection points, has allowed it to collect and recycle over 1,000 tonnes of plastic last year.

SUSTAINABLE PACKAGING NEWS 11 RETAIL ROUND-UP

Courtesy Tesco Plc

Kingsland Drinks

It’s in the bag!

At Kingsland Drinks, we have always made it a priority to continually improve the sustainability of our products. Physical improvements (such as glass light weighting and corrugate improvements, where Kingsland Drinks has been at the forefront for decades) and developments in bag-in-box technology (more recyclable EVOH bags) are examples of this.

Brands are under pressure to reduce their environmental footprint, which includes addressing issues related to singleuse plastics, excessive packaging waste, and carbon emissions. Finding eco-friendly packaging solutions without compromising the product’s integrity can be challenging but some brands are doing it well, especially within the wines and spirits sector.

Environmentally conscious consumers are seeking out products with eco-friendly packaging, sustainable sourcing of ingredients, and responsible production processes which is why we have invested in a state-of-the-art bag in box production line which supplies formats of 1.5L, 2.25L and 3L to some of the UK’s biggest retailers, as well as contract packed products for multiple national brands and our own consumer facing brands.

Bag-in-Box wine more efficient

Bag-in-box wine is more efficient to transport versus individual glass bottles, resulting in a lower carbon footprint when moving around the UK and can be a more sustainable alternative to glass. We have also moved from an unrecyclable inner to a bag that can be recycled with soft plastics in most supermarkets to ensure the packaging is as sustainable as possible.

We have developed and introduced bag-in-box wine options for two of our successful retail brands, Campaneo (featuring Spanish wines from the Campo de Borja region) and Andrew Peace (highlighting Australian wines from the Victoria region. While these wines are already well-received in 75cl bottle format, we identified a market demand for quality bag-in-box wines. Both ranges are known for being popular and affordable high street wines, but the newly introduced 2.25-litre bag-in-box formats now offer sustainability-focused choices in the wine market.

Both retailers and consumers are switching on to wines in this format, so we must embrace what they offer; recyclability, affordability, and longer lasting wine. New consumers to the bag-in-box category realise the positives in terms of convenience, freshness and quality, and there’s real appetite for formats that offer environmental and sustainability benefits.

We’re expecting even more innovations and developments in bottled and bag in box wines. Expect to see a more canned drinks, bag in box wines and cocktails, paper-based bottles, and light-weight glass on shelf in the very near future.

- Taylorson, head of marketing and product management, Kingsland Drinks

12 SUSTAINABLE PACKAGING NEWS BOTTLES V CARTONS

Courtesy Kingsland

Syntegon/Ampack

Tunnel Vision

Syntegon told SPN that Flexibility is essential when it comes to dealing with Nutritional trends such as liquid meals, but also the requirements of consumer groups like patients and infants favour the marketing of bottled food. Regardless of whether they are a short-lived hype or a vital necessity, manufacturers are faced with the pressing question of how to fill liquid products safely, in large quantities, and in different bottle formats and materials. Versatile filling and sealing machines in aseptic executions are a viable option.

Liquid food manufacturers mainly rely on injection-molded, pre-sterilised bottles made of HDPE as well as PET and PP. Due to its particularly high barrier properties, HDPE is primarily used for highly sensitive products such as clinical and infant formula. The easily recyclable PET options are the bottles of choice for everyday products such as milk- or plant-based drinks, dairy products, and soups.

Besides the materials, bottle formats vary and are as useful as they are challenging during filling. If more than one bottle format or material is to be filled and sealed efficiently on the same line, there is no way around fast changeovers.

Bottle transport is key

One possible option for bottle transportation in the food industry are machines that grip bottles at the bottom. Neck handling simply reverses the principle and ensures particularly effective transportation. Instead of at the base, the machine grips bottles at the neck, ensuring faster changeovers and minimal adjustments.

Ampack, a Syntegon company, has developed neck-handling further for the new FBL filling and sealing machine displayed at Anuga FoodTec. With this innovation, the company is expanding its portfolio for flexible and aseptic filling of liquid food products. “With the FBL, we offer manufacturing companies the option of filling HDPE, PET, and PP bottles on one machine,” explains Oguz Karcier, Product Manager at Ampack.

No hiding place for germs

Manufacturers must further achieve high disinfection rates to ensure maximum product protection and a long shelf life both inside and outside the cold chain. The FBL meets the highest safety requirements in this respect, as aseptic filling is one of Ampack’s core competencies.

“All bottle materials can be effectively decontaminated thanks to the FBL’s new sterilization system,” continues Karcier. This versatility is needed for good reason. PET, for example, is more temperature-sensitive than other materials and is more prone to absorbing the hydrogen peroxide (H2O2) used for sterilisation. Thanks to precise temperature control, the FBL can handle each of the materials and ensures reliable sterilisation – for safe products and even safer consumers.

For more information visit: www.syntegon.com

SUSTAINABLE PACKAGING NEWS 13 BOTTLES V CARTONS

Thanks to its flexible handling and sterilisation system, the FBL fills different bottle formats and materials without damaging the product

The FBL’s sterilisation and double chamber system ensures the highest standards of hygiene

Elopak

Elopak Elevates Brands

“ Consumers don’t only buy products; they buy brands that reflect their values ”

The modern world is revolving around plastics. Every minute, people around the world buy 1 million plastic bottles. But now it’s time to change. Regulations are increasing and consumers are looking for ways to make environmentally friendly choices without compromising on quality.

Changes in consumer priorities and habits call for innovative solutions. In order to attract consumers, brands have to think outside the box and dare to be different. The appetite for more sustainable consumption habits is there. By opting for fiberbased packaging for your home and personal care products, you are embracing a natural alternative to plastics.

Unique and innovative

Packaging is the most effective way of communicating brand values. Since the majority of all purchasing decisions are made at point of sale, it’s crucial that your product is presented in a container that immediately grabs the consumers’ attention.

A recent consumer study clearly shows that D-PAK™ cartons from Elopak, specifically developed as refill for non-food products, is seen as a more unique and innovative form of packaging compared to alternative packaging options. It offers a 360-degree communication space, allowing you to devote more space for product information and the benefits of the packaging, both which are perceived as increasingly important for the consumers. This will in turn help to elevate your brand. The carton is also helping your product to stand out in a crowded shelf, currently dominated by plastic packaging.

14 SUSTAINABLE PACKAGING NEWS ELOPAK

Convenience is key

We know however, that it takes more than just pretty packaging to get noticed. The natural look and feel of our fiber-based cartons, in addition to its convenient features, offer a premium consumer experience that alternative packaging can’t match. The consumer study revealed that consumers find the D-PAK™ carton superior to pouch alternatives in terms of opening, pouring and re-closing. As many as 97% of the respondents prefer it for refill and it is considerably better liked by consumers than alternative packaging options.

A natural alternative to plastics

Plastic is a serious problem for the planet, not just in terms of litter, but also because of the greenhouse gas emissions from plastic production and disposal. We cannot simply recycle our way out of this issue. We need to drastically reduce plastic production across the board. This includes addressing our reliance on plastic in the packaging industry.

“ Thinking realistically, if we are going to reduce the amount of plastic in our packaging systems, we need a solution that shoppers are willing and happy to adopt. ”

- Thomas Körmendi, Elopak CEO

The good news is that shoppers in Europe are already primed towards reducing their plastic use. According to Deloitte’s Sustainable Consumer survey, 64% of UK consumers actively tried to limit the amount of plastic they used in 2023. Also, 91% of respondents from a second study commissioned by Elopak, state that reducing plastic use is important to them in choosing a refill. Another good reason for choosing cartons, since they are primarily made with wood fibres, containing less plastic than alternative containers. We are continually working to reduce the plastic content in our packaging, and you can also go fossil-free with renewable and bio-circular polymers.

For over a century, we have developed our cartons to be the most sustainable packaging on the market. With leading design features and by constantly improving our use of materials, our cartons are optimized for recycling and reducing emissions.

Companies are taking their responsibility seriously, and the D-PAK™ carton is now helping some of the world’s most recognized brands within home and personal care to reduce plastics and become more sustainable. Perhaps this is worth considering the next time you make a packaging decision?

- Kantar quantitative test and face to face interviews December 2023, 150 participants in Sweden.

- Absolute Research, survey conducted December 2023, 1,025 respondents in UK and Germany.

ELOPAK SUSTAINABLE PACKAGING NEWS 15

Sustainable Revolution is driving a Greener Future

By Dominy Jones

In a world grappling with environmental concerns, the spotlight is increasingly turning towards sustainable practices, and one of the key players in this movement is reusable packaging. As we confront the challenges of climate change and excessive waste, the shift towards reusable packaging is gaining momentum, promising a greener and more eco-friendly future.

Reusable packaging stands as a beacon of hope in the fight against single-use plastics and excessive waste. Traditional packaging, often designed for one-time use, contributes significantly to pollution and resource depletion. In contrast, reusable packaging offers a sustainable alternative, reducing the environmental impact associated with packaging materials.

The cosmetics industry is wholeheartedly embracing reusable and refillable packaging. Leading glass packaging firm, Croxsons, has produced primary packaging for London-based refillable skincare essentials brand, Necessary Good. When consumers begin to run low on their Necessary Good products, they can simply order a 100% biodegradable refill pouch and transfer its contents. The company firmly believes that compostable, bio-based and biodegradable packaging presents the ideal solution for addressing waste issues within the beauty industry.

Baralan, a consolidated player in primary packaging for the cosmetics and beauty industries, has introduced a new series of Inner Cups. Available in two sizes, the Inner Cups can be combined with Baralan’s glass Maria Jars to create a refillable packaging option, offering an environmentally conscious approach to skincare packaging.

“ numerous innovative solutions have emerged within the realm of reusable packaging ”

Substantial long-term savings

The economic benefits of reusable packaging cannot be understated either. While the initial investment in reusable containers may be higher than their disposable counterparts, the long-term savings are substantial. Businesses can cut costs associated with constant replenishment of single-use packaging, waste disposal, and potential fines related to environmental regulations. Consumers, in turn, can enjoy cost savings by investing in reusable alternatives that withstand the test of time.

16 SUSTAINABLE PACKAGING NEWS REUSABLE PACKAGING

Refillable skincare brand packaged by Croxsons

New Inner Cups for Refillable Glass Jars from Baralan

In recent years, numerous innovative solutions and designs have emerged within the realm of reusable packaging. This surge in creativity not only addresses environmental concerns but also caters to the growing consumer preference for sustainable products. A bespoke 14 litre HDPE reusable container designed and manufactured by Berry Global is playing a central role as the vessel for a new refill packaging solution from the Refill Coalition.

“Designing for reuse is one of the key elements of Berry’s Impact 2025 sustainability strategy and commitments. This innovative refill solution demonstrates what can be achieved when all parts of the supply chain work together and we are very proud to have partnered with the Refill Coalition to bring it to life.” commented Edward Arnold, who has co-ordinated the project for Berry.

Growing appetite for refill

The appetite for refill shopping is clearly high. Research shows most people are willing to change their long-established shopping habits. Despite having grown up in a single-use packaging world, between 67% and 85% of us say we would try refilling if it was more widely available in supermarkets. Almost three-quarters (73%) would be willing to try refilling for their online purchases. Catherine Conway, Director at Go Unpackaged, certainly believes that refill models are the future – but acknowledges that achieving this will take a concerted effort from the packaging industry to shift away from the single-use model that has served it for so long.

“We need a seismic shift towards reuse and refill if we’re to stem the tide of the amount of single use packaging waste going out into the world. It’s not a solution for everything but there are certain contexts where this reuse and refill packaging actually thrives and makes a difference.”

In conclusion, the adoption of reusable packaging is a pivotal step towards building a more sustainable and environmentally conscious world. As consumers become more aware of the impact of their choices, businesses are responding by embracing reusable alternatives. By reducing waste, promoting the circular economy, and offering economic benefits, our choices today positively influence the world we leave for generations to come.

REUSABLE PACKAGING SUSTAINABLE PACKAGING NEWS 17

Plastic Packaging

Plastic – the slow toxin

From the desk of Steve Gislam

Plastic – no other man-made packaging material causes quite the same level of division. This once indispensable wonder-material which played an important part in ushering humanity into the modern age is simultaneously the scourge of the seven seas, as it clogs waterways, kills wildlife and poisons us all with every breath we take. It is both our saviour - and our slow toxin.

Two decades into this century, and plastic’s reputation is seriously on the ropes. Which leads to the question: how can we continue to enjoy the myriad benefits of this flexible and versatile material, whilst also protecting public health and the environment?

How did we get here?

The history of plastic is a fascinating journey marked by innovation, technological advancements, and widespread adoption across various industries until it reached every household throughout the world.

Natural materials such as rubber, shellac, and cellulose had been used for centuries, but the concept of synthetic plastics began to emerge in the 19th century. In 1862, Alexander Parkes demonstrated Parkesine. Made from cellulose treated with nitric acid and a solvent, Parkesine was a kind of proto-plastic that could be moulded when heated and retained its shape when cooled. Thus, the foundations for modern plastics were laid.

18 SUSTAINABLE PACKAGING NEWS PLASTIC PACKAGING

In 1907, Leo Baekeland invented Bakelite. Bakelite was used for a wide range of applications, including electrical insulation, automotive parts, and consumer goods.

In 1907, Leo Baekeland, a Belgian-American chemist, invented Bakelite, the first synthetic plastic made from phenol and formaldehyde. Bakelite was durable, heat-resistant, and electrically non-conductive, making it suitable for a wide range of applications, including electrical insulation, automotive parts, and consumer goods. Bakelite’s commercial success paved the way for the rapid growth of the plastics industry in the early 20th century. It was widely used in manufacturing throughout the 1920s and 1930s

In 1935, Wallace Carothers and his team at DuPont developed nylon, the first synthetic fibre, which revolutionised the textile industry. Nylon stockings became immensely popular, symbolising the era’s modernity and progress. During World War II, plastics played a crucial role in military efforts. Materials such as polyethylene and polystyrene were used in aircraft canopies, helmets, and other military equipment, demonstrating the versatility and utility of plastics in wartime applications and arguably helping the right side win the war.

In the latter half of the 20th century, concerns about the environmental impact of plastic began to emerge. The accumulation of plastic waste in oceans, landfills, and ecosystems raised awareness about the need for sustainable waste management practices. Efforts to promote recycling and reduce single-use plastics gained momentum in response to environmental concerns. Initiatives such as recycling programs, eco-friendly packaging alternatives, and regulations aimed at reducing plastic pollution became increasingly common.

Today’s challenges

Perhaps the most pressing challenge facing the plastic packaging sector is its environmental impact. Single-use plastics, in particular have garnered significant negative attention due to their persistence in the environment and harmful effects on wildlife. One need only look to the Great Pacific Garbage Patch in the eastern Pacific, an accumulation of plastic materials, brought together by Gulf Streams and currently roughly the size of Mongolia.

“ microplastics can be found in the deepest oceans, the highest mountains, the bellies of animals and even in our blood streams ”

Then there are the negative health impacts of microplastics, which are now so ubiquitous they can be found in the deepest oceans, the highest mountains, the bellies of animals and even in our blood streams. Heightened awareness among consumers about the health and environmental consequences of plastic packaging has led to increased demand for sustainable alternatives.

Brands are under pressure to respond to consumer preferences and demonstrate their commitment to environmental stewardship.

PLASTIC PACKAGING SUSTAINABLE PACKAGING NEWS 19

“ The plastic packaging sector is at a critical juncture, facing both significant challenges and exciting opportunities for innovation and sustainability ”

Innovation brings hope

One promising avenue for addressing the environmental impact of plastic packaging is the development of sustainable alternatives to traditional plastics, such as biodegradable plastics. Bioplastics, derived from renewable sources such as corn starch or sugarcane, break down more quickly in the environment, reducing the long-term accumulation of plastic waste and offer potential solutions to mitigate the environmental impact of plastic production and disposal.

Advances in packaging design and technology have led to the development of packaging that is easier to recycle. Innovations such as SEE’s new space-saving bubble wrap inflator produce on-demand cushioning and wrapping with a higher degree of recycled plastic and save space and thus transportation costs and associated emissions. Similarly, advances in recycling technologies, such as chemical recycling and improvements to mechanical recycling, offer promise for improving the efficiency and effectiveness of plastic recycling and aim to close the loop on plastic.

Working together

Many companies in the plastic packaging sector are now wholeheartedly embracing the principles of the circular economy, and prioritising recycling, reuse, and waste reduction. By redesigning products and packaging for recyclability and incorporating recycled materials into their supply chains, these companies are actively working to create a more sustainable future for the entire sector.

Addressing the complex challenges of plastic packaging requires collaboration right across the value chain. Companies are partnering with suppliers, customers, and other stakeholders to develop innovative solutions and drive collective action.

“ companies are wholeheartedly embracing the principles of the circular economy ”

Consumer demand for transparency is growing rapidly, and the internet has facilitated this shift. As such companies are increasingly accountable for their environmental impact. By providing information about their packaging materials, sourcing practices, and recycling efforts, companies can build trust and credibility with consumers.

Where to now?

While plastics have revolutionised numerous industries and improved our quality of life, the environmental challenges associated with plastic production and disposal underscore the need for sustainable solutions and responsible consumption practices in the 21st century.

The plastic packaging sector is at a critical juncture, facing both significant challenges and exciting opportunities for innovation and sustainability. By embracing new technologies, collaborating across the value chain, and prioritising environmental stewardship, companies can navigate this evolving landscape and contribute to a more sustainable future.

20 SUSTAINABLE PACKAGING NEWS PLASTIC PACKAGING

PACKAGING MACHINES DESIGNED TO HANDLE SUSTAINABLE MATERIALS.

SO FLEXIBLE TO BE READY FOR TOMORROW’S CHALLENGES.

Raw material costs and their availability, national and international regulations - everything changes so fast, making the future increasingly unpredictable.

IMA Ilapak’s HFFS horizontal flow wrappers, VFFS vertical baggers and Stand-Up pouch machines offer limitless flexibility to handle the new sustainable and recyclable packaging materials.

With IMA Ilapak, the future is in your hands.

SUSTAINABLE PACKAGING NEWS 21

Zero Waste - Redefining the Circular Economy

SPN asked Future Market Insights (FMI) to provide us with an up-to-the-minute status of trends in delivering the Circular Economy. Here is their response dedicated to our readers.

True to its name, Circular Economy is a system designed and promoted as a rotational type of system in which each component acts as a part that can be reduced, reused and recycled in such a way that the component stays in the loop throughout. Essentially, the circular economy advocates for closed-loop system designs and circular resources so that raw materials stay in the supply chain, or the system on the whole.

Using more effective methods that take into account a component’s whole lifecycle, circular economies eliminate waste through design. This ensures that the waste that does arise is as high-quality as possible, allowing natural resources to be reused.

The Concept

The concept of a Circular Economy first surfaced in 1960 when concepts related to non-linear and closed systems, like the ones found in nature, were being discussed by policy makers such as ecologists, economists and academics. This was the first time that the existing linear economies that were being followed and promoted by manufacturers and the government were being challenged. Up until then, a uni-directional economic model was being followed which involved the production, consumption and deportation of products and components in the economy. The concept of circular economy on the other hand believed that the parts of an economy should stay in circulation as long as possible, thereby using the full potential of resources until they are perished.

In addition to using many of the waste prevention techniques that we currently use, such as reduction, repair, and recycling, a circular economy looks to nature for inspiration when creating robust, adaptive, feedback-rich systems that support sustainable functionality and allow resources to regenerate.

22 SUSTAINABLE PACKAGING NEWS CIRCULAR ECONOMY

It also places a strong emphasis on controlled water systems and clean, renewable energy to support thriving ecosystems. A worldwide system where we can mostly rely on resources we have previously collected, as opposed to neglecting recycling and exploiting raw materials, is the ultimate goal of a circular economy.

“Zero waste is primarily focused on eliminating or reducing the waste generated by various economic activities. It is defined as the conservation of resources by methods of responsible production, usage, consumption and reuse of products and materials without disposing them in a way which is harmful for the environment and in turn the human health. Zero waste is a concept introduced so that corporations and governments focus on policies and economic structures whose end product is causing little to no trouble for the environment in the form of hazardous landfills, unhealthy burning and dumping in the oceans etc.” - Ismail Sutaria, Future Market Insights

Although recycling and resource conservation have long been popular concepts, the phrase “zero waste” and the movement as it is known today emerged in the 1970s when people realized how many resources were being disposed of in landfills. Over the following few decades, what started as a grassroots movement to reduce landfilling and incineration turned into reforms in local government policy as well as international law. Over the past ten years, the term zero waste has gotten more and more popular, partly because it has measurable and defined goals and it aligns well with the sustainability movement, particularly with customers. This indicates that a lot of businesses have made commitments to demonstrate their sustainability by going “zero waste” within a specific period.

Zero waste is an advocate for a pollution free environmentrather a garbage free environment. If the waste is not produced, the process of harmful disposal of it using methods like burning and throwing it in landfills does not arise at all.

Zero Waste - the ultimate aim

The circular economy has had a significant influence on zero-waste thinking since its ideas preceded the zero-waste movement by several decades. It is reasonable to argue that the circular economy takes into account the whole current consumption system, whereas the zero-waste movement is a subset of circular thinking that primarily targets businesses and individuals that wish to minimize waste.

CIRCULAR ECONOMY SUSTAINABLE PACKAGING NEWS 23

Zero waste can be considered as the ultimate aim or goal for the circular economy. The concept of a circular economy believes that the components of an ecosystem should stay in the loop for the longest time possible and eliminate the need of disposing it. Zero waste is the answer to the question - How can economies be run without the end product residue harming the environment. It can therefore be inferred that zero waste is a part of the objectives of the circular economy. It is like a cog in the wheel of a circular economy - a very important part and aim.

Zero waste is a workable approach, as demonstrated by creative practitioners, social entrepreneurs, forward-thinking legislators, and cooperatives of recyclers and other waste management professionals in cities and regions throughout the world. Zero waste solutions, as opposed to the process of burning waste, safeguard the environment and public health while also generating jobs and saving money.

These initiatives complement extended producer responsibility, clean production, and waste minimization plans for hazardous and difficult-to-recycle commodities. When combined, these processes offer some of the most convenient options for lowering greenhouse gas emissions and preserving natural resources and energy. They offer tremendous potential for the growth of regional economies, working towards the ultimate goal of achieving zero waste in a circular economy.

Hindrances and Challenges

Infrastructure : It will need a large amount of money and coordination to build the sorting, recycling, and reprocessing facilities, trash collection services, and other facilities needed to sustain a circular economy.

Technological Restrictions : Because of certain materials’ technological restrictions, recycling or reusing them can be expensive or complex. Creating new technology to get around these restrictions can be difficult.

Behavioural Change : Because of ingrained habits and ignorance, it can be difficult to persuade individuals, organizations, and governments to embrace new practices that emphasize recycling, reuse, and waste reduction. The scalability and comparability of circular initiatives might be hampered by the lack of established definitions, metrics, and certifications for circularity.

Supply Chain Complexity : From product design and manufacture to consumption and disposal, cooperation and coordination are needed throughout the supply chain to achieve a circular economy. It can be difficult to coordinate these initiatives, particularly in international supply networks.

Policy and Regulation : The transition to a circular economy may be hampered by insufficient or inconsistent laws and rules related to resource usage, recycling, and waste management. It is essential to articulate laws and offer rewards for circular activities.

Resource Scarcity : The availability of particular resources gets scarcer as the world’s population and consumption levels rise, making it difficult to manage resources sustainably and circularly.

Complexity of Materials : Because of their complexity, certain materials, including composite materials or polymers with several layers, are difficult to recycle or reuse. A circular economy requires finding practical uses for these resources.

24 SUSTAINABLE PACKAGING NEWS CIRCULAR ECONOMY

Closed Loop Systems

The Circular Economy encourages closed-loop systems that minimize waste through design by reducing, reusing, and recycling components to keep resources in circulation. It was first introduced in the 1960s and opposes linear economic models by promoting sustainability and resource conservation that are modelled after natural systems. Zero Waste is a concept that first surfaced in the 1970s and has since gained popularity because it sets quantifiable targets for minimizing waste produced by economic activity through responsible production, usage, and reuse. Zero Waste falls in line with sustainability efforts that are put forth to reduce harm on the environment.

“ Zero waste solutions have proven successful in protecting the environment, creating jobs, and saving resources despite obstacles ”

The ultimate goal of the circular economy is zero waste, which tries to reduce trash disposal and maintain components in circulation. In addition to clean production, waste minimization, and enhanced producer responsibility, it provides easy ways to reduce emissions and conserve resources.

Implementing a circular economy is challenging due to the requirement for infrastructural development, technological barriers to material recycling, and difficulty in supply chain coordination. Obstacles also include material complexity, scarce resources, inconsistent policies and regulations, and behavioural shift.

Zero waste solutions have proven successful in protecting the environment, creating jobs, and saving resources despite obstacles. In the process of moving toward a circular economy with zero waste, they present opportunities for local economic growth. In general, zero waste is seen as an essential component of the goals of the circular economy, acting as a cog in the wheel of sustainable resource management.

CIRCULAR ECONOMY SUSTAINABLE PACKAGING NEWS 25

KP Films

Looping the Loop

From Cecilia Guardado, Marketing Director, Trays at kp (Klöckner Pentaplast)

KP Films told SPN: “We must get serious about closing the tray material loop! As the global demand for packaged goods continues to rise, so does the urgency to address the environmental impact of packaging waste. One of the fundamental challenges we face in food tray recycling is the inefficiency recovery of PET materials. Despite efforts to promote recycling and heavy global investment in infrastructure, a significant portion of valuable food contact-approved tray material is wasted during the recycling process, ending up in secondary applications”.

“While still giving new life to recycled material, this inefficiency results in industries such as fresh protein and produce still heavily relying on virgin materials, exacerbating the strain on natural resources and stalling the journey towards a robust circular economy.

To truly address this issue, we must shift our focus from simply recycling trays to reaching the next step and firmly closing the loop on the packaging lifecycle. We need to look at not only how plastic food trays are recycled, but how we’re making new packaging designs. It’s going to be a question of creating innovative solutions that enable tray materials to be reused and recycled more efficiently, thereby preserving their value and reducing reliance on virgin resources.

We must ask how we can create a more coherent, connected loop that keeps valuable PET material circulating as trays rather than downcycled into other product categories.

Our team at kp asked this very question when creating kp Tray2Tray®. This is our initiative designed to rewrite the recycling rulebook for tray packaging and ensures the future of the packaging format is as tough and durable as the trays themselves. We are on a mission to recover used food packaging and turn it back into more of the same, as safe, and fully recyclable rPET food packaging. Over time, trays have been developed with ever higher percentages of recycled material from trays and we currently include up to 35% RecyClass certified content. However, we are on the verge of becoming the first company to provide a full 100% kp Tray2Tray® food tray, composed entirely recycled PET material from trays.

This milestone will mark a significant moment in the evolution of the food tray production industry, and points towards the future of the industry. It also underscores the importance of investing in innovative solutions that enable closed-loop systems for tray packaging, where materials are continuously recycled and reused without becoming lost to other applications. We are setting a new standard for the industry and inspiring others to follow suit in the journey towards a more circular economy in food tray production”.

26 SUSTAINABLE PACKAGING NEWS CIRCULAR ECONOMY

Cecilia Guardado

KP Tray2Tray®

SmartCycle® Close the loop with our recyclable, heat shrink sleeve films produced with 30% post-consumer recycled content! Sustainable Label Films

Samples

Metal Packaging Europe

Delivering Sustainable Circular Solutions

By Krassimira Kazashka, CEO, Metal Packaging Europe

As industries focus on improving their sustainability and adopting circular practices, the issue of greenwashing has become more prominent. European governments are taking significant steps to address this challenge. Meanwhile, increasingly, consumer purchasing is driven by environmental considerations. Social responsibility remains as important as ever.

Alive to all these factors, brands, retailers, and manufacturers continue to drive innovation, developing more sustainable packaging solutions to minimise food and packaging waste. But the fact is, if a packaging format such as a food or beverage can was invented today, it would be hailed as a breakthrough packaging design. Rigid metal packaging is a well-established, ready-made solution and the perfect partner to deliver a more circular economy.

Consumers rightly expect a lot from their products and the benefits of metal packaging include its long shelf life, its prevention of waste and the superior protection it offers from external factors. Significantly, for food products, metal packaging also helps to preserve nutritional value and cut food waste in the home which is a major contributor to climate change. In the EU around 88 million tonnes of food waste are generated annually with associated costs of 143 billion euros.

Today, a key challenge for every industry is to reduce dependence on raw materials. Rigid metal packaging is a model example of circularity as it is a permanent material. Regardless of the number of times metal is recycled, its inherent properties do not change. Once produced for the first time and properly collected, sorted, and processed at the end of its life, metal packaging becomes a valuable, circular resource for continuous production loops.

Easy and economical to sort and separate from non-metallic materials and recycle at scale, rigid metal packaging contributes some of the highest recycling rates among all packaging materials. In 2021, 78.5% of steel packaging was recycled in Europe. This figure corresponds to the amount of packaging that is really recycled and not just collected, aligning with the progressive approach adopted by the EU. At the same time, 76% of aluminium beverage cans were recycled in Europe.

28 SUSTAINABLE PACKAGING NEWS CIRCULAR ECONOMY

“ Metal Packaging Europe will continue to serve as the unified voice for Europe’s rigid metal packaging industry ”

The total amount of aluminium recycled from cans reached a record level of 570,000 tonnes, an increase of 60,000 tonnes from the previous year. This result represents a total Greenhouse Gas (GHG) emissions saving of 4.7 million tonnes of CO₂ – equivalent to the annual amount of GHG produced by a European city of more than half a million inhabitants.

In 2024 and beyond, Metal Packaging Europe will continue to serve as the unified voice for Europe’s rigid metal packaging industry. Our efforts will centre on helping the value chain achieve net zero by 2050, continuing to deliver the social and environmental benefits we know rigid metal packaging provides, and a process of driving continual improvements in transparency. By championing sustainability, reducing reliance on raw materials, and maximising the circular economy benefits of metal packaging, MPE aims to deliver a more sustainable future for all citizens.

Metal packaging actively contributes to the Circular Economy and supports numerous value chains and applications, like beverages, food, fish, chemicals, paints, aerosol, and others. For further information visit: https://metalpackagingeurope.org/

Odour optimised, energy efficient, recyclable. And for specific applications: super clean and food contact compliant. Recycled pellets of the future can do more. Get more out of your post consumer material flow with innovative EREMA technologies featuring digital assistance systems. More quality, more productivity. For a better end product. Take the new energy saving dual filtration solution INTAREMA® TVEplus® DuaFil ® Compact, for example, as well as proven ReFresher anti odour technology and the smart predictive maintenance tool Predict:On. Enter this future right now with EREMA. Enter the new era of recycling.

CIRCULAR ECONOMY

erema.com/thenewera

CHOOSE THE NUMBER ONE. YOUR LOCAL EREMA CONTACT EREMA NORTH AMERICA INC. www.erema.net VISIT US @NPE ORLANDO | FLORIDA, USA

– 9 MAY 2024 WEST HALL, BOOTH W4471

6

Bpacks

Barking up the right tree

Bpacks Launches World’s First Bark-Based Packaging Technology to Seamlessly Replace Plastic Materials. The company’s new technology is fully compatible with existing production streams and targets the $384 billion global plastic packaging market.

Bpacks, a sustainable packaging startup, announced the launch of the world’s first bark-based packaging technology. The new materials seamlessly integrate with current equipment used for all kinds of plastic rigid packaging production, facilitating the shift to eco-packaging. This is especially important, as the European Union’s policy directives have mandated the transition to biodegradable packaging within the next five years.

Bpacks’ 300 square meters R&D centre, which is based in Belgrade, Serbia, enables the production of both finished packaging and granules as substitutes for plastic pellets.

“ our packaging is 100% bio-based, with up to 75% of materials sourced from production waste ”

The bark-based pellets’ production process closely resembles that of polymers and doesn’t require capital investments to begin moulding, since the manufacturing process mirrors that of plastic production.

The Bpacks’ production process starts with compounding, followed by the creation of pellets or sheets, and concludes with the casting of solid packaging, which takes place either by injection moulding or thermoforming techniques. The material should fully decompose in moist soil within one to two months. Nowadays, the most common biodegradable polymers such as PLA or PBAT eventually decompose into water and carbon dioxide in compost. However, neither of these adds useful material to it. Bark-based material, on the other hand, turns into compost within a week in an active environment, and enriches the compost with valuable nutrients.

30 SUSTAINABLE PACKAGING NEWS CIRCULAR ECONOMY

Mikhail Skalkin

Mikhail Skalkin

“Traditional bio packaging often struggles to compete with its plastic counterparts in terms of pricing and integration complexity. Our bio-based plastic substitute can be manufactured using existing plastic production equipment, eliminating the need for plastic factories to purchase new equipment.

This facilitates overcoming the market penetration challenges that most sustainable packaging startups are facing. Moreover, our packaging is 100% bio-based, with up to 75% of materials sourced from production waste. We also utilize pre-owned equipment, which helps decrease our CO2 emissions,” explained Mikhail Skalkin, Co-founder and CEO of Bpacks.

Utilising bark, waste of wood production, as its primary raw material, Bpacks ensures that forest resources are not further strained. With estimated bark production levels between 300 and 400 million m3 annually, the startup leverages this abundant resource to create environmentally friendly packaging solutions.

Furthermore, studies have highlighted the antimicrobial potential of bark extracts from various tree species, enhancing the functionality of Bpacks’ technology, which emits up to six times fewer CO2 emissions compared to traditional plastic production methods.

Founded by an experienced team of entrepreneurs and Ph.D. scientists, and backed by an international advisory board, Bpacks is a circular economy startup operating in Europe and the United Kingdom. The company’s CEO and co-founder, Mikhail Skalkin, has an extensive entrepreneurial background, including experience in M&A transactions involving large financial companies in Eastern Europe.

The founding team also includes Lev Bolshakov, who has a proven record in corporate finance, startup valuations, and M&A, and has closed deals surpassing $300 million in value, Nikolay Semenov, Ph.D., a researcher, engineer, and an expert in polymer materials science. Semenov is in charge of leading the firm’s R&D innovations together with Aleksandra Nešić, Ph.D., who has extensive experience obtaining and characterizing active substances from plants and organic materials.

Bpacks is backed by a strong advisory board of international scientists such as professor Maximilian Lackner, Ph.D., a process chemist and engineer with over 200 articles published.

“ Utilising bark, waste of wood production, as its primary raw material, Bpacks ensures that forest resources are not further strained ”

With the global packaging market reaching €1 trillion, and the sustainable packaging sector valued at $285.3 billion, Bpacks targets a very attractive and dynamic market opportunity. The firm aims to capture a slice of the $348.1 billion companies spend annually on plastic-based products, and which has spurred the emergence of novel materials and circular economy ventures, which offer biodegradable, compostable, returnable, and even edible sustainable packaging solutions.

SUSTAINABLE PACKAGING NEWS 31 CIRCULAR ECONOMY

Image courtesy Bpacks

Pioneering the Circular Economy with Innovative Packaging Solutions PakTech

PakTech is making waves in the packaging industry by championing the circular economy with their innovative and sustainable secondary packaging solutions. They exemplify that it’s possible to combine environmental responsibility with business success, offering products that are eco-friendly, functional and consumer preferred.

At the core of PakTech’s mission is the belief that the life cycle of packaging should be circular and shouldn’t end at the landfill. This is why they manufacture 100% recycled HDPE packaging handles made from recycled containers and design their products to be fully recyclable, encouraging a circular system that minimizes waste. By repurposing recycled plastic containers into high-quality packaging handles, PakTech is leading by example, through their circular economy model.

PakTech’s commitment to the circular economy extends beyond their product design. The company has set up over 800 recycling programs that encourage customers to return used handles, which are then recycled and made into new products. This initiative is a testament to PakTech’s dedication to sustainability, ensuring that materials are kept in use for as long as possible reducing the need for new resources.

Recently they reached the milestone of repurposing over a billion recycled containers into PakTech handles. PakTech is not just talking about environmental responsibility—they are putting their principles into action while their stats showcase their impressive sustainability story.

This achievement highlights the company’s role in reducing carbon and greenhouse gas emissions while saving energy, making a real difference in the fight against waste and climate change.

PakTech also takes their role in championing ESG goals seriously, using renewable energy for their manufacturing processes and supporting local recycling and educational programs. This holistic approach to sustainability shows that PakTech believes in a future where business and environmental goals are aligned.

In today’s world, where environmental sustainability is increasingly important to consumers and businesses alike, PakTech stands out as a trusted and proven market leader in sustainable packaging. By embracing the circular economy, PakTech is not just making a statement about their sustainable values—they’re paving the way for a more sustainable packaging industry.

32 SUSTAINABLE PACKAGING NEWS CIRCULAR ECONOMY

Rethinking Resource Efficiency

From the desk of Steve Gislam

In an age of electric cars, geopolitical turmoil, and billionaires in space, the phrase resource efficiency isn’t grabbing any headlines – which is a terrible shame because it’s probably more important to the average person’s everyday life than any of those things. Nonetheless, slowly but surely, humanity is beginning to face the fact that the resources that this planet – our only home - possesses are finite. We all know that if we don’t start fixing the roof of our home while the sun is still shining, things are going to heat up really fast.

Given that the effects of climate change are becoming ever more difficult to ignore, and consumers increasingly concerned, businesses across all sectors must strive to minimise their environmental impact. Those that fall behind are unlikely to survive the green transition. The packaging sector is no different. Crucial to reducing that impact and transitioning to green is resource efficiency which, if utilised effectively, can also aid waste reduction and improve the way in which resources are used.

What is resource efficiency?

While the phrase may be a new one, it is a concept as old as humanity itself. Since the earliest days of human settlement, there has been a drive to get as much as possible out of as little as possible. Sometimes this was driven by scarcity, sometimes by greed, but it’s always been there.

Fast forward to the 21st century and this drive comes from necessity as we face a worsening climate crisis. The good news is, though, that we are better placed to maximise resource efficiency than ever before.

Put simply, “resource efficiency” refers to the optimal usage of finite resources to achieve maximum output. It also incorporates waste minimisation, energy consumption and environmental impact. The word “resources” refers to anything a business uses such as raw materials, money, energy, water, and labour.

34 SUSTAINABLE PACKAGING NEWS RESOURCE EFFICIENCY

Key aspects of resource efficiency

Naturally, it goes without saying that there is quite a lot more to resource efficiency that than first meets the eye and it differs across different sectors. There are, however, a number of key aspects. Let’s dig a little deeper into some of those:

• Reduction of waste generation can be achieved with the take up of processes, technologies and practices that reduce material losses and emissions throughout the production and consumption cycle.

• Ensuring the effective and efficient use of resources without unnecessary consumption or depletion. This could be manufacturing products, delivering services, or providing infrastructure.

• Embracing principles of the circular economy. There’s a focus here on closing the resource loop through promotion of reuse, recycling, and remanufacturing to extract as much value as possible from materials as well as minimising resource extraction and disposal.

• Maximising energy resource productivity by employing energy-efficient technologies, processes, and systems to cut energy use and emissions.

• Implementing measures to reduce water consumption and water waste. Also adopting practices which enhance water reuse and recycling which can mitigate scarcity and environmental degradation.

• The streamlining of supply chains to minimise input of resources, transport distances, and inventory levels while still ensuring the timely delivery of goods and services.

• The promotion of sustainable consumption and production practices which prioritise resource efficiency, environmental stewardship, and social responsibility throughout the value chain.

• Embracing innovation and deploying advanced technologies to develop resource-efficient solutions, optimise processes, and improvements in productivity.

• The consideration of the entire lifecycle of products and services. This means everything from extraction of raw materials to end-of-life disposal or recycling and identifying opportunities for resource efficiency improvements at each of those stages.

• Engaging with stakeholders across the value chain including suppliers, retailers and consumers to foster collaboration, share best practices, and drive collective action towards achieving resource efficiency.

Strategies for enhancing resource efficiency

Given the importance of resource efficiency to the future of the climate as well as the longevity of a business, choosing the right strategy to achieve this can make all the difference. Here are a few of those strategies and technologies that can aid with resource efficiency in the packaging industry.

Sustainable design

Adopting eco-friendly materials and designing packaging with recyclability, reusability, and biodegradability in mind can significantly reduce resource consumption and waste generation. Sustainable design includes using materials such as recycled paper, cardboard, bioplastics, and compostable materials.

Lightweighting

Reducing the weight of packaging materials while maintaining the strength and functionality helps minimise resource consumption and keeps transportation costs down.

Lightweighting can involve using thinner layers of materials, optimising structural design, and employing advanced materials with high strength-to-weight ratios.

Source Reduction

Minimise use of packaging materials by optimising package sizes, eliminating unnecessary components, and using packaging designs that require fewer resources. This reduces the amount of material used while still providing adequate product protection.

RESOURCE EFFICIENCY SUSTAINABLE PACKAGING NEWS 35

Reusable Packaging

Implementing reusable packaging solutions, such as containers, bottles, and pallets, can significantly reduce the need for single-use packaging. Reusable packaging also helps decrease waste generation and resource consumption over multiple product cycles.

Recycling and Closed-Loop Systems

Use packaging materials that are widely recyclable and ensuring proper infrastructure for collection and processing. Implementing closed-loop systems, where packaging materials are recycled back into new packaging products, help conserve resources and reduce the need for virgin materials.

Biodegradable and Compostable Packaging

Utilise packaging materials that are biodegradable or compostable, which break down naturally into non-toxic components. This approach reduces waste and can even contribute to soil health when composted.

Supply Chain Optimisation

Streamlining packaging processes and logistics helps minimise resource consumption, energy usage, and emissions throughout the supply chain. This includes optimising packaging designs for efficient storage, handling, and transportation.

Investment in Innovative Technologies

Investment in emerging technologies such as 3D printing, nanotechnology, and advanced material science may be costly at first, but it does allow for the development of more sustainable packaging solutions and can even cut costs over time. These technologies can also allow for the creation of novel materials and packaging designs that are more resource-efficient and environmentally friendly.

Lifecycle Assessment

Conduct comprehensive lifecycle assessments to evaluate the environmental impacts of packaging materials and processes. It’s a more holistic approach that helps identify opportunities for improvements all along the value chain and informs decision-making towards improved sustainability.

Collaboration and Stakeholder Engagement

Fostering collaborations with suppliers, manufacturers, retailers, and consumers can help boost a culture of sustainability and also drive collective action towards improving resource efficiency across the packaging sector.

Engaging stakeholders throughout the value chain facilitates knowledge sharing, innovation, and the adoption of best practices. By implementing some or all of these strategies and leveraging innovative technologies, the packaging sector can enhance resource efficiency, reduce environmental footprint, and contribute to a more sustainable future.

An efficient conclusion

Resource efficiency is more a continual work in progress than a task that gets completed. Improvements in technology and broadening understanding of sustainable practices are ongoing, and as such keeping up with new trends and developments can bring rewards in this area.

While there is no quick fix, it is something that every company, not just those in the packaging sector, can benefit from financially, but also in terms of environmental impact. And as the green transition continues apace, can your company afford not to use its resources more efficiently?

36 SUSTAINABLE PACKAGING NEWS RESOURCE EFFICIENCY

RH Fibreboard

Child’s Play

Educating young minds concerning the importance of corrugated packaging and sustainability is of paramount importance. In 2019, the Sheet Plant Association was introduced to the TICCIT project (Trees Into Cartons, Cartons in Trees), an international outreach programme intended to introduce sustainability of paper-based products to Schools.

Avanti Primary

Steve Gabell (SPA sustainability committee member) and his employer RH Fibreboard Containers Ltd ran the project with local schools prior to the Covid Pandemic, which involved going into the school and teaching children about trees, paper, corrugated and sustainability benefits. At the end of the presentation, there is a practical session in which the children make up small boxes and plant a tree sapling into it. The children are gifted their tree saplings, which they then take home to plant the box directly into the ground. Over time the tree grows, and the box biodegrades into the soil.

Early this year Steve and RH Fibreboard have re-launched the school visits whilst at the same time encouraging members of the Sheet Plant Association to take up the ‘new look’ project, visiting schools and educating young minds about cardboard products, recycling, and manufacturing. So far this winter, 3 local schools have been visited with more planned and 100 trees have been donated.

“ The informative and engaging sessions not only taught us about the importance of tree planting but also instilled a sense of responsibility towards our environment ”

The presentation is an engaging open session for 7-9 year olds, and is designed to be interactive with lots of questions and answers. The children learn about nature, informative facts about trees, sustainable forestry, the high recycling rates of cardboard and why it’s a good packaging choice for our environment. The practical element of it demonstrates that even when cardboard does not go into the recycling loop, it still returns to the soil as it biodegrades.

The benefits stretch far beyond those which are directly related to donating trees to children. The project supports teachers with engaging sessions and materials.

Harry Penny, head teacher of Avanti Primary commented: “The team’s commitment to environmental education and sustainability left an indelible mark on our students. The informative and engaging sessions not only taught us about the importance of tree planting but also instilled a sense of responsibility towards our environment. The handson experience of planting trees not only enhanced our understanding but also created a lasting memory for everyone involved.”

It is also hoped that these sessions will inspire children in the future to look for a career in the industry and helps to look after the environment at the same time through promotion. Aligning businesses within a community help to build these fundamentally advantageous links with industry.

SUSTAINABLE PACKAGING NEWS 37 CORRUGATED PACKAGING

May the Fourth be with you

Industry 4.0 - also known as the Fourth Industrial Revolution or 4IR, is the next phase in the digitisation of the manufacturing sector. This is driven by disruptive trends including the rise of data and connectivity, analytics, human-machine interaction, and improvements in robotics.

The 21st-century industrial revolution is digital. Industry 4.0, the Fourth Industrial Revolution, and 4IR all refer to the current era of connectivity, advanced analytics, automation, and advanced manufacturing technology that has been transforming global business for years. This wave of change in the manufacturing sector began in the mid-2010s and holds significant potential for operations and the future of production. The recent McKinsey report excerpts offer some valuable insights.

What is the Fourth Industrial Revolution?

Steam propelled the original Industrial Revolution; electricity powered the second; preliminary automation and machinery engineered the third; and cyber-physical systems, or intelligent computers are shaping the Fourth Industrial Revolution.

Before 2014, the Google search term “Industry 4.0” was practically non-existent, but by 2019, 68 percent of respondents to a McKinsey global survey regarded Industry 4.0 as a top strategic priority. Seventy percent said their companies were already piloting or deploying new technology.

4IR builds on the inventions of the Third Industrial Revolution or digital revolution which unfolded from the 1950s and to the early 2000s and brought us computers, other kinds of electronics, the Internet, and much more. Industry 4.0 brings these inventions beyond the previous realm of possibility with four foundational types of disruptive technologies that can be applied all along the value chain:

1. connectivity, data, and computational power: cloud technology, the Internet, blockchain, sensors

2. analytics and intelligence: advanced analytics, machine learning, artificial intelligence

3. human–machine interaction: virtual reality (VR) and augmented reality (AR), robotics and automation, autonomous guided vehicles

4. advanced engineering: additive manufacturing (such as, 3-D printing), renewable energy, nanoparticles

Upskilling is key

Technology, however, is only half of the Industry 4.0 equation. To thrive in the Fourth Industrial Revolution, companies must ensure that their workers are properly equipped through upskilling and reskilling and then hire new people when necessary. Upskilling is key and means that employees learn new skills to help them in their current positions as the skills they need evolve. Reskilling is the real challenge: workers are retrained with new skills that will enable them to fill different positions within their companies.

“ companies must ensure that their workers are properly equipped through upskilling ”

This is increasingly vital as disruptive technologies transform job requirements, but the outlook on reskilling differs geographically. In Europe, 94 percent of surveyed executives believe that the balance between hiring and reskilling should be equal or tip toward reskilling, compared with only 62 percent of US respondents.

38 SUSTAINABLE PACKAGING NEWS INDUSTRY 4:0

Industry 4:0

Image courtesy McKinsey