SUSTAINABLE PACKAGING NEWS

Bio-Based Packaging

What exactly is bio-based packaging? SPN looks at the advantages

What exactly is bio-based packaging? SPN looks at the advantages

Pure-Pak® eSense. An aluminium-free carton made with sustainably sourced paperboard and an innovative polyolefin barrier. It unlocks the potential of a fully renewable aseptic carton and reduces the carbon footprint with up to 50%*

The season for International Expo’s is upon us and in May we will be focussing on the interpack Trade Fair in Dusseldorf. This year almost 3,000 companies will be represented covering every aspect of the packaging industry. Once again, interpack will be offering the packaging and related process industries the most extensive overview of the global packaging market yet.

This optimistic look at global markets is encouraging considering that the world is not only having to face unprecedented natural disasters but also a war in Europe that has created a sharp rise in global inflation.

However, the resilience of the packaging industry is legendary and somehow it seems to be able to maintain its onward drive for increased sustainability, whilst at the same time, promoting the circular economy. Innovation is also alive and well at interpack across the entire spectrum.

In this bumper issue, SPN covers a number of key areas that are of special interest. These range from new Luxury Packaging advances to the latest developments in the Pharma and Cosmetics sectors. We also have some independent, in-depth contributions from Ecoveritas and from Mondi’s director of eCommerce, Nedim Sisic. In addition, there is a feast of engaging topics throughout this latest issue and due to popular demand, our regular feature, ‘Retail Round-Up’ continues to bridge the gap between the consumer, the manufacturer and the converter.

In any event, we trust and hope that everyone will stay well and safe throughout this turbulent period. In the meantime, we send our thoughts and condolences to all those who are suffering such deprivation in Ukraine and in the Turkey/Syria earthquake disaster.

Sincerley,

Philip Yorke ( Editor )

“In the future, waste will become a precious commodity”. The climate emergency makes the switch to a circular economy ever more urgent. At the same time, we must acknowledge that complex problems do not have easy solutions. In the six years between headline-grabbing climate conferences, the global economy consumed 70% more than the Earth can safely replenish. Thus creating an additional half a trillion tonnes of virgin materials.

Two-thirds of the resources we take from the Earth are discarded. Ever since the Industrial Revolution, we have been accelerating a linear take-make-waste model that assumes an infinite supply of resources. Now, a new circular economy proposes something more regenerative.

The circular economy is much more than recycling or just redesigning our products. It’s about transforming the way our economy works - moving from taking, making, and wasting to eliminating, circulating, and regenerating. The opportunity is clear and sizeable, but ambition alone is not enough, and translating purpose into action will require the unfurling of a series of coordinated efforts.

“ The circular economy is about new ways of creating value via innovation, new business models, and future-proofing your business models ”

Our generation has the unique opportunity to reconcile the paradox between progress for all and a sustainable future for our planet, thanks to a step change in efficiency. We believe that waste will come to be seen as a precious commodity, shaping new business models and defining commercial opportunities. That’s why we are helping business leaders to rethink their propositions and scale up their circular solutions.

The circular economy is about new ways of creating value via innovation, new business models, and future-proofing your business models in an increasingly resource-constrained world. It’s about the need to unleash materials’ true value and potential, whether in their beginning-of-life, utilisation, or end-of-initial-life phases. The business case for the circular economy is crystal clear. Whilst many are already realising value from the concept, our world is still only 9.1% circular.

Transferring linear operations into a circular economy is no easy feat. It involves dynamically changing approaches to manufacturing, knocking out planned obsolescence and setting goals to minimise material and energy waste.

We must acknowledge that while materials may inevitably degrade, they do not disappear. Degraded materials can be captured and plugged into our economy in their transmuted forms. We talk a lot about reducing consumption, buying less and buying better quality products when it is necessary to make a purchase. And a less-throwaway life is the holy grail for those prioritising quality over quantity.

Businesses like ours exist as a vital resource for those looking to understand how to connect materials with manufacturing and the means of distribution and consumption. We help companies harness the power of knowing what they don’t know regarding environmental compliance data.

Reduce, reuse, and recycle is the standard cradle-to-grave manufacturing model dating back to the Industrial Revolution that we still follow today. Extended Producer Responsibility proposes that we should strive to create value instead of minimising waste. This is the essence of Cradle to Cradle: waste need not exist at all.

Despite a backdrop of uncertainty, the packaging industry has continued to innovate, create and try things that could impact the future. With brands and retailers showing no signs of relaxing their sustainability targets, it’s been up to packaging specialists to respond – and they have done just that.

“ a less-throwaway life is the holy grail for those prioritising quality over quantity ”

“The Long-awaited Government Environmental Improvement Plan is disappointing and falls short” says Dr Adam Read, chief external affairs and sustainability officer for SUEZ UK recycling and recovery.

Read told SPN: “The Government’s Environmental Improvement Plan has been long-awaited, and we fully support its holistic approach. That said, whilst commitments to improve wildlife and people’s access to nature are the focus of the news headlines, our first look at the delivery plan for reducing waste and maximising resources has left us somewhat disappointed.

There is very little that is new in relation to the way we manage waste and resources in the UK – the delivery plan references the reforms to extended producer responsibility, consistent collections and a deposit return scheme that have been underway now for two years, and the new programme to maximise resources and minimise waste could well be a repackaged version of the draft waste prevention plan consulted on last year.

Dr Adam Read

“ whilst commitments to improve wildlife and people’s access to nature are the focus of the news headlines, our first look at the delivery plan for reducing waste and maximising resources has left us somewhat disappointed ”

The material specific waste reduction targets are a step in the right direction when it comes to understanding and measuring the impact of policy reforms on our future performance, but still take a weight-based approach rather than looking at carbon impacts. We welcome the proposed call for evidence on a plan for moving remaining biodegradable waste out of landfill by 2028 and this needs to be progressed without delay, so that any guidance on how we make this transition is available in time to have an impact.

In the five years since the 25 Year Environment Plan was published, our ambitions have moved on – focussing on downstream interventions will only take the UK part of the way on its journey to a more resource efficient, decarbonised, circular economy. To truly move the dial, we need to re-think consumer habits and a potentially game-changing target for resource productivity was a notable omission from the document.

Some delays to the flagship policies to reduce waste and increase reuse and recycling as a result of covid were understandable, but we are now reaching a point where commitments to announce the detail of reforms ‘in due course’ are wearing thin and hampering investment in the infrastructure and services we will need to take the reforms from the page into real life.”

SUEZ has signed a contract with three Kent councils to deliver waste and recycling services from 2024, worth £152 million over the life of the eight-year contract.

The contract was awarded by Ashford, Maidstone and Swale councils after a detailed tender process and incorporates the provision of waste collection and recycling services across the three boroughs’ nearly 200,000 households, as well as street cleansing in Ashford and Swale, whilst Maidstone’s will remain in-house. It will begin in March 2024.

Blending consistency with innovation, fortnightly collections of waste and recycling will continue, with a single wheeled bin for dry recycling, alongside weekly food waste collections. At the same time, SUEZ will introduce a new fleet of lower emission vehicles using electric bin lifts funded by each council, alongside improved technology for vehicle tracking, routing and managing customer service requests. Together, these improvements will lower the carbon footprint of the service and provide the councils and residents with up-todate service information.

The new contract also includes proposed improvements to the level of cleansing in rural and residential areas, and quicker response times for the removal of fly-tipping. John Scanlon, Chief Executive Officer for SUEZ recycling and recovery UK, said: “We’re delighted that the Mid-Kent Waste Partnership has entrusted SUEZ to deliver essential services to their residents from 2024.”

Tesco announces a new initiative to help keep our seas blue. Over 80% of plastic in the ocean originates on land! The move, in partnership with Keep Sea Blue, will see around 500 tonnes of discarded plastic prevented from entering the oceans.

Plastic waste such as drinks bottles which is at risk of getting into the sea, is now being collected and recycled and used again in Tesco’s fresh fish packaging. Next week sees many of the supermarket’s fresh Salmon, Haddock, Cod and Sea Bass lines sold for the first time in trays that contain at least 30% Recycled Coastal Plastic collected from beaches, coastlines, and coastal communities around the Mediterranean Sea. The move into the new packaging is expected to remove around 500 metric tonnes of plastic from the environment each year and reduce the amount of ‘virgin plastic’ required in the packaging.

Tesco will use discarded plastic collected from coastal areas in the Mediterranean for its fresh fish packaging. The move, in partnership with Keep Sea Blue, will see hundreds of tons of discarded plastic prevented from entering the oceans

Plastic waste such as drinks bottles which are at risk of getting into the sea, is now being collected and recycled and used again in Tesco’s fresh fish packaging.

The plastic waste consisting of Polypropylene, PET, Polyethylene, and other types of plastic, is collected from atrisk coastal areas such as beaches, and coastal communities within 10 km from the sea, thus prevented from entering the Mediterranean Sea by wind, rain or floods. Collection and processing is undertaken with full transparency and traceability and certified by the non-profit organisation Keep Sea Blue which works with and connects organisations across the supply chain from collection to reuse in new packaging.

The plastic is recovered initially by a network of collectors across the Mediterranean, including volunteer groups involved in beach clean-ups, local authorities, non-profits, and the private sector. The PET share of the waste is then carefully sorted, grinded, washed and recycled and goes back into foodgrade packaging materials. Through its customised Blockchain Platform, powered by Oracle Blockchain technology, the organisation monitors and certifies the circularity of plastics ensuring full material traceability.

Sarah Bradbury, Tesco Quality Director, said: “Where we can, we are reducing the amount of new plastic we use in our business. Re-using coastal plastic in our fish packaging is one way we can do that and at the same time keep it out of the oceans.”

Lefteris Bastakis, Founder, Keep Sea Blue: “Mismanaged plastic waste can only be solved by many partners working together. We are glad that Tesco is making a meaningful and active contribution to this programme towards protecting the Mediterranean Sea from plastic pollution and building a more sustainable future.”

“ Mismanaged plastic waste can only be solved by many partners working together ”

There has been a growing interest in how digitalisation can improve efficiency, reduce costs and improve the interface between the brand and the consumer. The recent report from Forrester underscores the increasing importance of digitalisation and its role in advancing the cause of greater sustainability and the circular economy. Philip Yorke takes a closer look at its conclusions.

Changes that came about in the packaging industry in response to the pandemic, resulted in a major shifting of consumer preferences, and supply chain disruptions. Unfortunately, these are likely to remain relevant well beyond 2023. However, digital transformation in the packaging industry can help overcome disruptive shut-downs, offer greater operational agility, improve operational efficiency and lower costs. SPN looks at some of Forresters’ recent conclusions.

Forrester said: “The process of designing new packaging, typically involves dozens of design concepts before arriving at the perfect solution. It’s not uncommon for packaging development departments to wait days and weeks before each prototype is ready, which can be extremely time-consuming. Which is why packaging brands turn to 3D printing to speed up packaging development through faster and more economical production of design variations.

This is possible because 3D printing is a digitally-controlled technology that doesn’t require moulds or other tools for production. It uses a design file sent to a 3D printer and manufactured within several hours. Another benefit of 3D printing is that it can create prototypes with the finished product’s features, colours, and materials. This enables packaging companies to test the final product’s look and feel, whilst keeping the costs low. For example, Thermos, a manufacturer of insulated food and beverage containers, has been using 3D printing for packaging prototypes since 2006.

Switching from outsourcing prototyping jobs to in-house 3D printing reduced the lead time for a prototype from five days to several hours. The company states that prototyping with 3D printing allowed them to optimise the fit of the cap stopper and pouring performance of their best-selling Thermos mugs.

Whilst 3D printing enables faster packaging designs, smart packaging technologies make packages more communicative and individualised, by using tags, QR codes or sensors that embed information onto packaging, which smartphones and other devices can read.

One example of smart connected packaging comes from a leading UK university that developed a solution that enables spirits traders to authenticate bottles of rare vintage whisky. This is achieved by using their smartphone to tap an anti-tamper NFC bottle closure that connects to a digital certification record held on a private blockchain.

In addition to the food and beverage industry, pharmaceuticals can also benefit from smart packaging. From the customer perspective, pill bottles with smart packaging can help patients understand product usage, safety, and dosage information which has the added environmental benefit of reduced paper usage. From the supply chain perspective, smart packaging can provide visibility on every medical product’s location, making inventory management and quality control more efficient.

Expanding on the supply chain point, using intelligent packaging with radio frequency identification sensors (RFID) enables a more efficient supply chain for packaging manufacturers and distributors.

Companies can collect data and track packages connected to a network. For example, RFID tags allow tracking of the location of a package throughout warehouses. This is because the RFID tags are automatically scanned by the RFID reading device upon entering and exiting the warehouse.

What is the best part of RFID tags within an inventory? The fact that individual manual scanning of each package is not necessary. Through radio-frequency monitoring, the RFID reader knows immediately when the package has entered or left the warehouse. Not only does the use of RFID tags for packaging minimise human error, but they also help to enhance the delivery time and increase the rate rate of packaging productivity.”

“ smart packaging technologies make packages more communicative and individualised ”

“ packaging brands turn to 3D printing to speed up packaging development through faster and more economical production

The shape of supply seems to be changing in every conceivable way. It’s becoming less chain-like and more network-based, as businesses seek the sophistication needed to thrive in an uncertain world. Supply chains themselves are also shrinking, with organisations beginning to move away from the cheap-labour strategies that have fuelled the manufacturing boom and rapid industrialisation in South East Asia for the past 40 years.

But those days seem to be drawing to a close, because supply chains that span the globe are too vulnerable to disruption in today’s volatile, uncertain world. Increasingly, firms are looking to reshore and nearshore both manufacturing and sourcing to reduce their exposure to risk.

A recent Reuters Events whitepaper shows just how strong the reshoring trend has become. Produced in conjunction with A.P. Moller-Maersk, the giant Danish shipping company, the paper – called ‘A generational shift in sourcing strategy’ – is a global deep-dive into near-sourcing, nearshoring and reshoring in the post-pandemic world. It looks at how companies across the world are looking to rebalance their supply chains, reduce risk, increase visibility and improve sustainability.

The paper shows that the countries with the two largest manufacturing workforces, Germany and Poland, are the most attractive sourcing and reshoring locations. But the authors also add that there’s a “broad-based commitment” among businesses to source more from within both East and West Europe to reduce the distance to end-market and meet the increasing need to draw on pools of skilled labour.

In the foreword to the paper, Mikkel Søndergaard Rasmussen, Regional Head of Logistics and Services, Europe A.P. MollerMaersk recounts the chaos and disruption of the past two years, including the pandemic and war in Ukraine. “Global markets have been fragmented and this has left supply chains exposed,” he says, adding: “Little wonder, then, that companies hold supply chain resilience in increasingly high regard, because the ability to deliver products reliably and on time is increasingly important to their customer-value propositions.”

Rasmussen observes that this has seen sourcing strategies “come under the microscope for many” as the bid for resilience gathers pace. He says: “Resilience doesn’t come without its costs but when set up correctly, logistics can be seen as a business enabler and potential source of competitive advantage, instead of being a financial hindrance.” The paper concludes: “Future supply chain logistics will undoubtedly look different from today’s offerings, as supply chains start to move closer to the end consumer, with fewer intermediate parts traded over long distances.”

Paper or plastic? Once upon a time, it was an innocuous question asked by staff at the supermarket checkout regarding your preference of a grocery bag. Today, the once simple question has taken on a different edge, as our understanding of climate change has widened.

Whilst common wisdom systematically holds up paper as the better of the two environmentally, is it really as cut and dry as “paper good, plastic bad”? And is such a binary perspective even relevant for such a complex topic? Plastic has an image problem Plastic was first invented in 1907, but it wasn’t mass produced until after the Second World War. At the time it was lauded as a wonder material. Its main pro being that it is cheap and easy to produce, which is a major reason why it has become such a universally popular packaging material worldwide.

Other benefits of plastic packaging include its versatility, durability and lightweight qualities, making it ideal for transporting goods safely.

In recent years however, a steady flow of media reports has brought to light the negative impact plastic is having on the environment, and public opinion has shifted as a result.

With such a high volume of plastic ending up in the oceans, this is hardly a surprise. One high profile example of this is the Great Pacific Garbage Patch - an “island” between California and Hawaii comprised of pieces of floating plastic brought together by ocean currents. The Patch is now estimated to cover 1.6 million square km, making it slightly larger than Mongolia. To put that in perspective, if it were a sovereign country, it would be the 19th largest in the world, just behind Iran.

And this is just the tip of an iceberg that won’t melt away. More pernicious even than floating plastic landmasses is the problem of microplastics – tiny pieces of plastic which have been found in the deepest oceans and on the highest mountains. This fact alone has led to some scientists claiming that plastic’s ubiquitous presence can be considered as the start of the Anthropocene – a new epoch where every aspect of life on Earth is shaped by human activity. And let’s not forget, all this has happened in less than a century.

Virgin plastic also requires fossil fuels – particularly oil – for its manufacture. In a world attempting to move away from oil extraction and dependency, this puts the material in a difficult position. And while images of dead sea animals with bellies full of plastic are an emotive way of highlighting a very real problem, and a sure sign that something needs to change, they can serve to over-simplify a complex issue and obfuscate a more pertinent and difficult-to-answer question: What needs to change exactly? While we can certainly reduce the amount of plastic we use, we can’t stop using it completely. So where is the line?

“ More pernicious even than floating plastic landmasses is the problem of microplastics ”

From the perspective of the packaging sector, the paper vs. plastic debate is especially poignant, and no more so than in food packaging. While plastic has certainly been overused as a material, the negative reports tend to mean we forget the multitude of benefits that plastic provides. Indeed, its use in the food sector has revolutionised the industry.

Plastic protects food products from contamination by moisture, humidity, bacteria and insects, among other things. It also helps reduce food waste by preserving its contents for longer, meaning out of season fruit and vegetables are more readily available all year round. Its light weight makes it easy to transport and allows food to travel greater distances, and in terms of production, it is cheap to make, meaning lower prices for consumers.

What’s more, being wood-based, paper is ultimately a sustainable material, so long as the forests from which it comes are themselves managed sustainably. Indeed, properly managed forests can aid in carbon sequestration, removing CO2 from the atmosphere and storing it inside the wood.

However, proponents of plastic packaging have begun fighting back against the negative publicity of late with claims that manufacturing paper packaging produces more carbon emissions and requires more energy than manufacturing plastics. While statistics on this vary, it is generally thought to be the case that paper requires three times as much energy to make as plastic. Plus, paper’s heavier weight also means higher vehicle emissions and fuel costs for transportation.

It’s not just the food industry that plastic has revolutionised. It can easily be said that plastic has saved lives. So much medical equipment is made from plastic because it allows for a more sterile, hygienic environment by offering one-time-use products and eliminating the need for sterilisation. Plastic also offers a higher comfort level than the alternative metal options and is hypo allergenic.

The advantages of paper are well-known. Paper is biodegradable and therefore poses much less risk to the environment in that regard. It is also one of the easiest materials to recycle, and consumers are very aware of this. As a result, paper boasts a far better reputation amongst the public, which is why so many companies are cutting plastic and switching to paper.

“ It’s not just the food industry that plastic has revolutionised. It can easily be said that plastic has saved lives ”

So, if paper isn’t as good as its reputation, and plastic is more sustainable so long as we keep it out of nature, where does this leave us? In a world where plastics are a necessity, paper and cardboard can take over to some degree. Certainly, it would be wise to eliminate unnecessary and excessive packaging of all kinds – whatever it is made of. Nonetheless, the Paper v. Plastic debate itself is something of a moot point because it doesn’t allow much room for nuance. It also fails to consider nascent technologies that could change the game entirely.

Perhaps a better approach, on top of cutting down on excessive packaging, would be to invest more heavily in chemical recycling. Unlike mechanical recycling – where used plastics are separated and then physically ground down - its chemical counterpart can break all kinds of plastic down into the oils and chemicals from which they were made. The technology acts like molecular scissors, snipping the long-chain hydrocarbon bonds down into shorter-chain hydrocarbons.

This essentially creates a “good-as-new” product, the same quality as fossil-based hydrocarbons, which are then ready to be used to create born-again virgin-grade plastics, with no limit on the number of times the material can be recycled.

As promising as the technology is, the bad news is that it’s likely to take another decade before it can be scaled up sufficiently to meet demand for a truly circular plastic economy. In recent years, we have seen several large companies, like BASF, ExxonMobil and Total investing in the technology, which is promising.

Nonetheless, developing an infrastructure for a closed-loop circular plastics economy will take time to implement on a global scale. The OECD estimates that, at present, only 9% of plastic waste is recycled globally, with 22% being mismanaged. While it is the case that recyclable plastic is – despite public perception - the most sustainable form of packaging, without concerted action towards innovations in waste reduction, designing better alternatives, improving waste management, and investing in chemical recycling, that perception is unlikely to change any time soon.

Every participant that entered our 2022 Annual Sustainability Awards was a winner. However, the biggest winner of all was our planet – and, of course, the consumers who inhabit it!

The video of the SPN virtual awards ceremony is available to watch at: www.spnews.com

“This competition was unique in many ways, but in particular the large number of entries represented the highest levels of dedication to sustainability and to technological innovation that we have seen to date. Thus making the task of selecting winners all the more difficult for our panel of eminent judges.

There were new, fresh ideas and approaches to be found around every corner - and throughout all six categories! We therefore congratulate all those who participated in the competition this year and submitted concepts that will certainly continue to make a major contribution to sustainability for many years to come!

Thank you everyone for a great effort all round!!” (SPN team)

Mondi have developed EcoVantage paper for Tesco shopping bags, with the aim of closing the loop on carrier bags made from its own paper waste.

Sealed Air have created Mail Lite® PickPack format, a shipping package for recycle-ready Mail Lite mailers®, which reduces the amount of packaging weight by 60%

Recover Packaging developed a customer-made PET Laminate with the mono-layers bonded by FDA approved adhesive.

To enter visit:

www.spnews.com/awards-submission/

PakTech products are renowned for their unrivalled efficiency and quality. That means greater sustainability, and ease of use thanks to their ergonomic design. Created and built in-house, the company uses a meticulous production process that ensures its applicators meet and exceed any multi-packing challenge. Countless Premium brands rely on Paktech applicators and they do for good reason!

By investing in high-quality, high-output machinery, owners of Paktech applicators are able to keep labour costs down and the efficiencies of their processes high. Many PakTech Applicators offer a quick return on investment, in fact, most in less than three years. You can review the company’s ROI flyer here, in order to see its significant monthly recoup results.

High quality also means durability, and durability means they’re built to last, thus providing an impressive life-cycle and strong resale values. Many of PakTech’s machines have been running for well over 15 years! Ultimately, all that matters is that each tailormade product serves the unique needs of each client – ensuring a substantial positive impact on their bottom line.

Whenever a customer has a question or problem to resolve, PakTech understands that your business doesn’t have hours or days to wait. Along with cutting-edge technology, PakTech applicators also come with a readily available customer service team to ensure that your machine stays up and running at maximum efficiency.

The company’s team of expert technicians and engineers are available 24/7 and are ready to provide support to see you through any challenges that you may encounter. PackTech’s Rockwell and Fanuc-certified staff have many years of expertise between them and come with specialised, in-depth knowledge that guarantees a swift return to normal production.

One of PakTech’s greatest accolades goes to its versatility. For example, its CCA line of applicators is capable of multipacking a broad range of can types such as Standard, Sleek, and Slim etc. In addition to offering fast change-over times to accommodate the different heights of cans.

PakTech’s MPA line of applicators are equipped with multiproduct functionality and capable of handling everything from beans and salsa containers, to lighter fluid and cooking oil, and from mouthwash and soap to beverages.

The company also creates client need-based customised applicators to partner with its custom-designed PakTech handles. Therefore, no PakTech customer goes unserved when it comes to applicator versatility.

Safety is paramount at PakTech. That’s why, when you get a PakTech applicator, you can rest-assured that you have true state-of-the-art machinery with built-in best-in-class safety circuits. With Lexan guarding, operator safety, and doors that lock when closed and prevent running when open, means that teams can operate safely and effectively without worrying that either them or their machines can be compromised.

A PakTech spokesperson told SPN, “At PakTech, we’re extremely proud to offer applicators that we all believe in. They offer a tried and true, turn-key solution that our clients can attest across every aspect of how we design and implement our products. Great brands deserve great processes, and that’s precisely what PakTech is here to provide.”

For more information visit: https://paktech-opi.com/

“ At PakTech, we’re extremely proud to offer applicators that we all believe in ”

SPN spoke to two companies, Philadelphia-based packaging giants Crown, and New Jerseybased sustainable waste management experts TerraCycle - both leaders in their respective fields - about the measures they have taken towards better sustainability and in creating a circular economy along their value chains.

How ‘sustainability-aware’ would you say your company is, and what recent measures have you taken to improve your overall contribution to the circular economy?

Crown is strongly committed to advancing a Circular Economy in terms of our products & our processes. In 2020 we launched our Twentyby30 program, which includes 20 measurable sustainability goals to be completed by the end of 2030, all set against a 2019 baseline.

Our latest 2021 Sustainability Report outlines the progress we have made towards the goals we set out in 2020. These include reaching 75% renewable electricity by 2030 and 100% by 2040, in line with our Net-Zero goal via The Climate Pledge.

To advance our transition to a Circular Economy, 60% of our total annual R&D spend is on sustainability projects. As a result, we have already achieved a 4% global average reduction in the standard 12 oz. (330ml) can weight.

We also became a member of the Ellen MacArthur Foundation and have recently completed its Circulytics assessment aimed to reveal the extent to which a company has achieved circularity across its entire operations.

“ To advance our transition to a Circular Economy, 60% of our total annual R&D spend is on sustainability projects ”

Crown

What have been your most important milestones in relation to sustainability?

In September 2022, we co-hosted the first Global Aluminium Can Sustainability Summit, bringing together over 100 aluminium supply chain representatives. The event facilitated important discussions to drive actionable progress toward the industry’s sustainability goals.

Our GHG emission reduction targets are approved by the Science Based Targets initiative. 30% of our total electricity used in 2021 was consumed from renewable resources, bringing us closer to reaching our goal of 75% renewable electricity by 2030 and 100% by 2040.

In line with our Twentyby30 program, we empower every employee to be an active participant in our sustainability journey, creating meaningful connections between their daily tasks, their personal lives and the impact they can make on the environment and society.

Can you describe your product portfolio and its sustainability credentials?

Crown produces metal packaging, which is perfect for a Circular Economy. In fact, it is possible for recycled aluminium cans to return to store shelves as new beverage cans in as little as 60 days.

In your opinion what have been the most significant developments in terms of recycling and bio-degradable packaging?

Deposit return schemes are a great way to encourage consumers to recycle aluminium cans—the world’s most recycled package. In 2021, we set new goals to advance recycling rates, including reaching 70% in the U.S. and 80% in EMEA—all by 2030.

How much is the on-going pressure for greater sustainability and recycling affecting your productivity?

As public concerns over plastic pollution grow, brands are seeking packaging options with superior green credentials. Metal packaging is infinitely recyclable, making it increasingly appealing to environmentally conscious consumers.

As we are keen to understand more about the latest trends shaping the packaging industry in your sector, what do you consider to be the most significant recent developments?

Around 75% of new beverage launches in North America now appear in cans thanks to the format’s sustainability credentials, an increase in off-premises consumption, and consumer demand for new beverage options (energy drinks, seltzers) where cans are the preferred package.

How ‘sustainability-aware’ would you say your company is and what recent measures have you taken to improve your overall contribution to the circular economy?

TerraCycle was built around sustainability. We create solutions to recycle hard-to-recycle waste - items that would otherwise be destined for landfill, incineration or the environment. We also created Loop, our global platform for reusable packaging.

Our free recycling programmes are our most popular solutions. We partner with brands that cover the costs of transporting and processing various waste streams, as well as a charitable incentive for the members of the public that collect on the programmes. We recently launched programmes with Paula’s Choice to enable consumers to recycle their skincare product packaging, and Sistema, to recycle used food storage containers and reusable drinks bottles.

For any waste stream that we don’t offer a free recycling programme for, businesses and individuals can purchase a Zero Waste Box, the price of which covers the costs of transporting, sorting, and recycling the waste.

We have also launched new platforms in recent years aimed at expanding our reach and increasing our positive impact. In 2019, for example, we unveiled Loop in the UK, a platform for reuse that allows any brand to create reusable versions of their product packaging and for any retailer to make those available to consumers.

What have been your most important milestones in relation to sustainability?

In 2007 TerraCycle launched our first brand-sponsored recycling solutions. Since then, key milestones include expanding from the US to the UK in 2009, developing the first solutions for waste including cigarette butts and medicine blister packs, and introducing our reuse platform Loop in 2019.

“ TerraCycle was built around sustainability. We create solutions to recycle hard-to-recycle waste - items that would otherwise be destined for landfill, incineration or the environment ”

In your opinion what have been the most significant developments in terms of recycling and bio-degradable packaging?

The introduction of front-of-store flexible recycling in supermarkets across the country is one significant development that has been industry-driven. We’re also seeing some of the most comprehensive environmental legislation being introduced including the Plastic Packaging Tax, EPR, and Deposit Return Scheme.

TerraCycle has also been at the forefront of recycling innovation, launching first-of-their kind solutions for previously unrecycled waste streams including crisp packets, medicine blister packs and coffee capsules. We’re proud that these innovations have made the importance of recycling impossible to ignore and have contributed to new schemes being developed that help make complex packaging recycling more accessible.

What do you consider to be the most promising market opportunities for your company at this time?

There are plenty of products and packaging on the market that are considered “unrecyclable” simply because nobody has tried to find a solution, and TerraCycle is always on the lookout for new waste streams to tackle and new ways to recycle.

What are the key drivers for change in your industry sector and how much is the on-going pressure for greater sustainability and recycling affecting your productivity?

Consumer behaviour, company commitments and legislation are all driving change in the recycling industry. Another change we want to see is increased transparency in the industry. We partnered with Evreka on new waste management tracking software to be at the forefront of this change.

Another driver for change in the recycling industry is the demand for more widely accessible recycling solutions for hard-to-recycle materials like flexibles and mixed material packaging. As experts in this field, we are regularly approached by brands and manufacturers looking for a ready-made solution for their products, while they work on making their packaging widely recyclable in the long term.

We have everything covered, regardless of whether your new project is for polyolefin or PET recycling. Each of the individual process steps is perfectly tuned to ensure that what you get in the end, is what you were expecting from the beginning. The right sorting and washing equipment, the most suitable water treatment, the perfect extruder. Get the best results from EREMA Group‘s decades of experience in plastics recycling.

“ We’re proud that these innovations have made the importance of recycling impossible to ignore and have contributed to new schemes being developed ”Engineering and integration services Turnkey projects Feasibility and pre-invest studies

Beverage cartons offer several distinct sustainability advantages over plastic bottles, however within the aseptic segment different packaging types have varying levels of environmental benefits, largely as a result of their composition. The use of aluminium in aseptic beverage cartons has resulted in a higher carbon footprint than their fresh counterparts. Extracting and refining aluminium is an energy intensive processes and aluminium is also a finite resource, which does not replenish over time – unlike paper.

At Elopak, we have therefore invested to deliver a solution that ensures the packaging of aseptic products can be as sustainable as for those in the fresh segment. The result is the Pure-Pak® eSense carton: a more environmentally friendly aseptic carton made without an aluminium layer.

Using technology from our fresh portfolio, we replaced the aluminium in the Pure-Pak® eSense carton with a polyolefin blend barrier. It simplifies the recycling process as the new polyolefin structure enables a one operation separation of the fibers and the polyolefin layers. This result in a carton with an up to 50% lower carbon footprint compared to a standard aseptic carton.

Although no longer containing an aluminium layer, the PurePak® eSense carton remains rigid and convenient, ensuring that the product inside stays fresh for longer.

Nowadays, consumers are looking for ways to reduce their environmental footprint – without having to compromise on quality. By rolling out the Pure-Pak® eSense carton, Elopak offers its customers more sustainable packaging for a wider range of products, while still playing a vital role in protecting

Elopak’s ambitions is to promote a net zero circular economy for packaging: driving the transition from plastic bottles to fully renewable, low carbon cartons. It also makes sense for our customers with aseptic products, many of whom produce environmentally friendly products and want a packaging option that supports their ethos.

Elopak partnered with García Carrión for this launch and their famous Don Simón brand is the first in the world to be launched in the new aluminium-free Pure-Pak® eSense carton, featuring six different plant-based drinks.

The Pure-Pak® eSense carton is available in a range of sizes and with various environmental features, such as the Natural Brown Board. The Natural Brown Board is unbleached. An unbleached paper board has stronger fibers and less wood is needed to create the paperboard. This results in unique, natural-looking cartons which effectively communicate a commitment to sustainability and instantly stands out on the shelves.

Introducing a more environmentally friendly carton for the aseptic market.

“ Elopak’s ambitions is to promote a net zero circular economy for packaging ”

SPN invited CCT’s president Brandon Bach for his vision concerning the drivers for change in sustainable packaging and the growing role of aluminium in the global circular economy. Here are his answers to our questions.

How ‘sustainability-aware’ would you say your company is and what recent measures have you taken to improve your overall contribution to the circular economy?

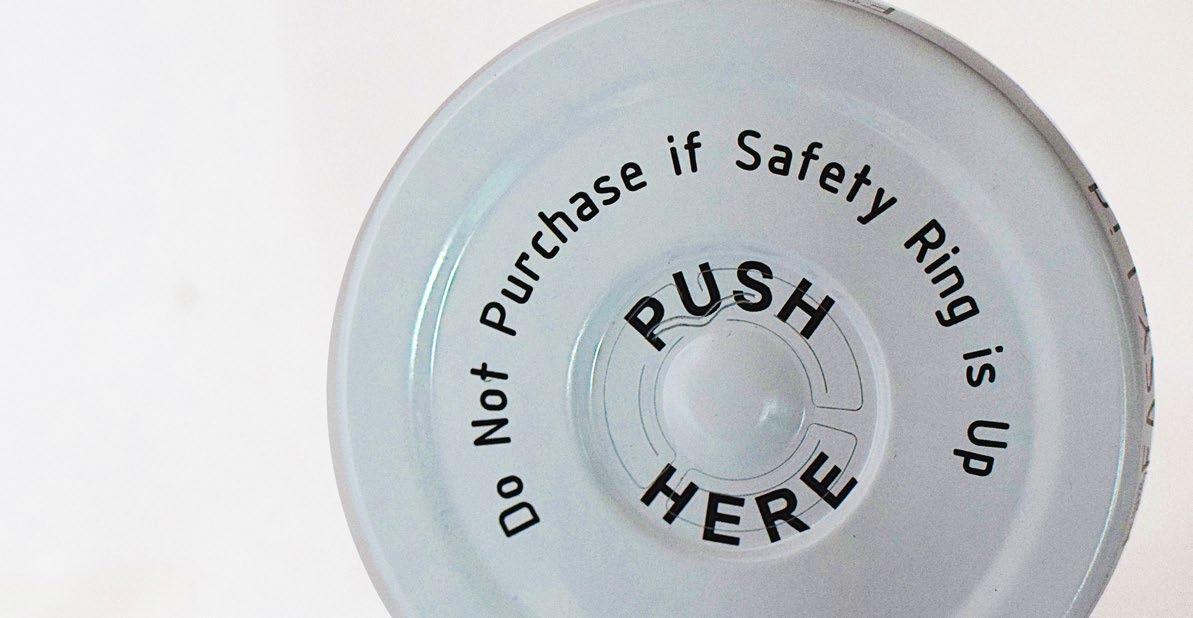

Consumer Convenience Technologies (CCT) created our aluminum lug EEASY Lid after eight years of R&D. Aluminum is easily and infinitely recyclable without a significant reduction in the integrity of the material, helping to promote a circular economy.

In relation to sustainability, what would you say have been your most important milestones?

While traditional jar lids are made of steel, the EEASY Lid is the world’s first aluminum lug lid, setting a new precedent for sustainability in the industry. We recently expanded our capabilities to include manufacturing line assessments for brands looking to accommodate the EEASY Lid, helping companies across the globe become more sustainable.

What do you consider to be the most promising market opportunities for your company at this time?

CCT is currently in talks with major grocers, brands and manufacturers across the globe, looking to expand EEASY Lid availability. In October, Boyer’s Food Markets became the first supermarket chain in the U.S. to use the EEASY Lid on its new in-house pasta sauce line. The EEASY Lid boosted Boyer’s pasta sauce sales by 104%.

What are the key drivers for change in your industry sector and how much is the on-going pressure for greater sustainability and recycling affecting your productivity?

The key driver for change in our industry is consumer demand. A recent survey by Retail Insight found that 67% of consumers believe retailers have more work to do to boost their sustainability credentials. Inclusivity is also huge – consumers of all ages/abilities benefit from enhanced designs that allow them to use products without assistance.

As we are keen to understand more about the latest trends shaping the packaging industry in your sector, what do you consider to be the most significant developments recently?

Sustainable and inclusive packaging innovations are all around us. Kraft is testing the brand’s first recyclable fiberbased cup for its Mac & Cheese and paper bottles for its ketchup. Olay recently unveiled an easy open winged lid for people with disabilities. Rare Beauty uses rounded tops on products for those with limited upper limb mobility.

Can you describe your product portfolio and its sustainability credentials?

The demand for sustainable packaging continues to rise. Aligned with brand strategies aimed at improving product packaging and shifting to greener packaging, our innovative EEASY Lid made of recyclable aluminum protects the environment and enhances consumer experience one jar lid at a time.

Are you planning the launch of any new products in the foreseeable future that you can tell us about?

As of right now, CCT offers the EEASY Lid in the 63 mm size, which is the size of an average pasta sauce jar. We eventually would like to produce additional jar lid sizes for other food products. Our goal is to have as many consumers as possible experience the benefits of the EEASY Lid on whatever jarred product they like.

How has the Covid 19 pandemic affected your production and manufacturing capabilities?

Soaring inflation has led us, and other companies, to focus on lightweight packaging materials to create cost efficiencies in the supply chain and decrease waste. For example, 63 mm aluminum lids weigh 57% less than traditional steel lids. The lower weight of aluminum can decrease fuel consumption and emissions, vehicle maintenance and road repair.

How do you see the future evolving in your sector?

The start of 2023 marks another year that grocers and retailers must find ways to make themselves competitive and attract customers. Companies can do this by elevating their product packaging to include the EEASY Lid, making the product more accessible. Future product packaging will evolve to be more sustainable, inclusive and innovative.

The success that CCT has enjoyed since the launch of its EESYLID device, has added significantly to the packaging sector’s move towards growth in the use of aluminium closures in the food industry. SPN applauds the contribution made by CCT towards increased sustainability and the circular economy.

“ Our innovative EEASY Lid made of recyclable aluminum protects the environment and enhances consumer experience one jar lid at a time ”

“ Our goal is to have as many consumers as possible experience the benefits of the EEASY Lid on whatever jarred product they like ”

Ahlstrom

Ahlstrom continues to advance its base-paper development to achieve its unique, sustainable barrier properties. These are fundamental to unlocking the sustainability benefits that paper brings to flexible packaging. The majority of flexible packaging solutions require highly sophisticated barrier properties in order to function efficiently and to preserve a diverse range of food contents.

The primary requirements for these applications are typically oil and grease barriers, and moisture barriers. These specialized barrier properties are not inherently present in paper structures, but by engineering the production processes and additives used, paper can clearly exhibit these properties and enable barrier coatings to work more effectively.

Ahlstrom is the global leader in fiber-based specialty materials, and their purpose is to Purify and Protect Every single Fiber for a Sustainable World. Ahlstrom serves five growing and distinctive end-markets which form the basis for its five divisions: Food and Consumer Packaging, Healthcare, Filtration, Building Materials, and Technical Materials. Sustainability, innovation, and quality are all central in their solutions, from compostable and recyclable food and beverage packaging materials, to protective medical fabrics.

Today, consumers and brand owners are demanding more sustainable solutions that reduce their impact on the environment and have a positive end-of-life product story (recyclability, compostability, and biodegradation as examples). Ahlstrom has a specific philosophy around this journey of innovating more sustainable products. This is Ahlstrom’s ‘from Plastic to Purpose’ journey and this campaign is raising awareness regarding the possibility of fiber-based solutions as a renewable packaging options.

Small fibers can make a big difference, and a key focus area remains on utilizing fibers and other renewable materials to develop replacement solutions for current non-renewable packaging, such as plastics and films. Ahlstrom has a unique set of capabilities and a wide breadth of technical applications, to allow it to develop some of the strongest performing base-papers available. Highly developed base-papers are key to solving the barrier requirements in flexible packaging, whilst still utilizing the inherent product’s end-of-life benefits that paper provides.

Paper is an ideal material for flexible packaging applications, and already has a broad field-of-use from good flexibility and folding characteristics to print-ability. Paper is easily sealable and glue-able, laminating well to other structures. In addition, paper functions effectively through the challenging converting processes.

Manufacturers, brand owners, and consumers all have their own individual requirements concerning sustainability and regeneration goals. Paper packaging can meet these specific goals and be customized to the end-use objective. Ahlstrom is ready to work with partners who are aligned with our goals and guiding principles to secure a more sustainable future.

For more information about Ahlstrom’s barrier technology, advancements and their ‘from Plastic to Purpose’ initiative, visit: https://bit.ly/BoundlessBarriers

“ Ahlstrom has a unique set of capabilities and a wide breadth of technical applications, to allow it to develop some of the strongest performing base-papers available ”

At SPN we regulary invite captains of the packaging industry for their insights and observations concerning sustainability, from a company perspective. On this occasion, we invited Nedim Nisic, Mondi Group’s eCommerce director, to expand on where the company is now, and where it plans to be, moving forward.

SPN asked Nedim the following wide-ranging questions: How ‘sustainability-aware’ would you say your company is and what recent measures have you taken to improve your overall contribution to the circular economy?

As a leading manufacturer of sustainable packaging and paper solutions, we can offer our customers a multi-material portfolio of fit-for-purpose eCommerce packaging solutions that support their sustainability goals by optimising their packaging.

Our Mondi Action Plan 2030 (MAP2030) sustainability framework sets out our commitment to creating circulardriven solutions, driven by empowered people, taking action on climate.

In our work to create circular solutions, our target is for 100% of our packaging and paper to be reusable, recyclable or compostable by 2025. We also have targets to eliminate waste in landfills as well as demonstrate progress with our partnerships to eradicate unsustainable packaging.

“ our target is for 100% of our packaging and paper to be reusable, recyclable or compostable by 2025 ”

In relation to sustainability, what would you say have been your most important milestones?

Following Mondi’s commitment to Net-Zero by 2050, we recently had our Net-Zero targets validated by the Science Based Targets initiative, building on our long-term commitment to take action on climate change. Mondi has already made significant progress by reducing our greenhouse gas emissions by almost 45% against our 2004 baseline.

Our recently developed Path to Circularity Scorecard provides us with a framework to assess the circularity of our portfolio and apply harmonised criteria and thresholds across our packaging and paper product groups.

What do you consider to be the most promising market opportunities for your company at this time?

In addition to opportunities around our sustainable solutions, we know from our eCommerce customers that they are navigating the dual pressures of high demand and potential manual labour shortages in their fulfilment centres. We can help ease that pressure by consulting on automated machine solutions and optimising their eCommerce operations. For example, the eComPack machine is a compact and simple solution for automating Mondi’s EnvelopeMailer, the preferred corrugated mailer in eCommerce fulfilment.

What are the key drivers for change in your industry sector and how much is the ongoing pressure for greater sustainability and recycling affecting your productivity?

The increasing demand for sustainable eCommerce packaging motivates us to push the boundaries of what is possible in our industry. We consider the environmental impacts of our products at each stage of the value chain. This involves reviewing the sourcing of raw materials; material efficiency; product design; sustainable end-of-life and product safety.

Our approach is to use paper where possible and plastic when useful, keeping the customer’s needs in focus at all stages of the design process.

As we are keen to understand more about the latest trends shaping the packaging industry in your sector, what do you consider to be the most significant developments recently?

Our recent research looked at online shopping patterns and consumer attitudes; its outcome supports us in guiding brands towards more sustainable solutions in line with consumer demands towards eCommerce packaging.

Our latest insights find that the top consumer demand trends are:

1. Protection of goods and environmental considerations continue to be two of the most vital customer requirements

2. Overpackaging costs more than expected

3. The unboxing moment matters

4. Consumers are increasingly willing to pay a small premium for packaging that meets their needs

5. The behaviour & trends of Millennials are driving the market

Can you describe your product portfolio and its sustainability credentials?

Our eCommerce portfolio offers tailored, creative solutions that are specially designed to minimise waste and protect goods being delivered with packaging that is the right size and convenient for the end consumer. Our wide range of eCommerce packaging solutions, from kraft paper to converted solutions such as MailerBAGs and corrugated solutions, makes it easy for our customers to find ideal packaging for their needs.

Are you planning the launch of any new products in the foreseeable future that you can tell us about?

We continuously explore new ways to improve packaging, focusing on sustainability, functionality and cost-effectiveness for our customers. Our innovative approach continues to be recognised, including a recent WorldStar Packaging Award, for setting new standards in secure and sustainable eCommerce packaging with our innovative corrugated solution.

How do you see the future evolving in your sector?

Consumers are increasingly mindful of the impact of products they purchase and our customers are relying on us to lead the way in resource efficiency, waste reduction and recyclability. Younger generations, and Millennials in particular, are the driving force for online shopping and they are looking for brands that put sustainability at the heart of the experience. It’s why understanding our customers’ needs and innovating together to address consumers’ expectations is so important.

For more information visit: www.mondigroup.com

Packaging is a ubiquitous part of life in the 21st century, and it plays a crucial role in the protection and preservation and transportation of goods, in particular food and drinks. However, the production and disposal of packaging can also have a significant impact on the environment.

On top of that, packaging requires significant amounts of resources and energy to manufacture, thus pushing up the sector’s greenhouse gas emissions, not to mention the myriad other environmental impacts.

The packaging industry as a whole has a critical role to play in the development of the circular economy, largely due to the vast amounts of waste it creates and the significant amounts of resources it uses. Packaging accounts for a high proportion of worldwide municipal solid waste. According to the United Nations Environment Programme (UNEP), an estimated 36% of plastic packaging is single-use, with 85% of that ending up in landfills.

What’s more, the UNEP estimates that 98% of single-use plastics used in the manufacture of packaging are produced from fossil fuels or virgin feedstock. According to the organisation’s forecasts, the level of greenhouse gas emissions connected with the manufacture, use and disposal of fossil-fuel-based plastic is set to grow to 19% of the world’s carbon budget by 2040.

Establishing a circular economy in the packaging industry would result in increased resource efficiency, less waste going to landfill and lower greenhouse gas emissions. Creating such a system however would require a major paradigm shift which would see all stakeholders moving away from the traditional linear model of “take-make-waste” towards a closed-loop system in which materials and resources are kept in use for as long as possible.

By closing the loop on material use, we can create a more sustainable and responsible industry that benefits the environment and the economy. Here’s a closer look at why the circular economy is so vital for the future of the packaging sector and what it can bring to the table.

“ 98% of single-use plastics used in the manufacture of packaging are produced from fossil fuels or virgin feedstock ”

“ By closing the loop on material use, we can create a more sustainable and responsible industry that benefits the environment and the economy ”

One of the biggest benefits that creating a closed-loop circular economy would have for the packaging sector is waste reduction. Not only is waste reduction better for the environment, but it can also save companies money on materials and on waste disposal.

Packaging makes up a large portion of the waste produced across the world, and a large proportion of it ends up in landfills or leaking out into the environment – usually the oceans - as pollution. By reusing the materials we have, as opposed to constantly producing new ones, companies can cut down on waste and help do their bit for sustainability and the environment.

Another major benefit of the circular economy is that it makes things more efficient. Instead of using resources to create new materials and products, we can reuse what we already have. This saves time, energy, and money, and helps to create a more efficient and effective system across the value chain.

Making the circular economy a reality in the packaging industry can also aid in the reduction of greenhouse gas emissions. Packaging manufacture uses a lot of energy, and by using recycled materials and creating closed-loop recycling systems, we can reduce the energy consumption and emissions associated with packaging production simply by not having to manufacture them again from scratch. This has a positive impact on the environment and helps to address the issue of climate change, as well as cutting overall costs.

Finally, establishing a circular economy has the potential to create a plethora of new jobs and economic opportunities for the packaging sector. By increasing the use of recycled materials and developing closed-loop recycling systems, we can create a new industry around recycling and waste management, with businesses popping up to fill the increased demand. This can bring new jobs and economic benefits to communities and help to create a more sustainable and responsible future.

While all of this sounds great on paper, there are plenty of hurdles to be overcome if the packaging sector is to make a circular economy a reality.

“ Making the circular economy a reality in the packaging industry can also aid in the reduction of greenhouse gas emissions ”

A lot of people, both consumers and producers, simply don’t understand what a circular economy is or why it’s so vitally important. This makes it difficult to get everyone on board and working towards the same goal. Public support for such systems is vital if we are to truly change our systems and make them more sustainable.

What is needed is a raising of awareness and more widespread education about the benefits a circular economy can bring. This way, both the private and public sectors, as well as the general public, can all do their part to make it a reality.

Another challenge is the lack of the necessary infrastructure and technology to support a circular economy. Businesses need to work with governments at a national and local level to develop and roll out effective collection and recycling systems, as well as for procuring the new technologies needed for recycling different types of packaging materials. These systems also need to be easily understood by the public at large. Without these, the creation of a circular economy in the packaging industry will remain nothing more than just a pipe dream.

Finally, we need supportive government policies and regulations in order to make a circular economy a reality. This includes policies that encourage the use of recycled materials, the development of closed-loop recycling systems, and the reduction of waste and emissions associated with packaging production and disposal.

Without these, it will be difficult to create the changes needed within the packaging industry. While there has been some progress in this area, such as the European Union’s Circular Economy Action Plan and the UK’s Circular Economy Package, both of which aimed to tighten the rules in this area, critics have said that it does not go far enough.

The creation of a closed-loop circular economy in the packaging industry has the potential to bring significant environmental and economic benefits. By reducing waste, increasing resource efficiency, and lowering greenhouse gas emissions, a circular economy would help to create a more sustainable and responsible packaging industry.

It’s a big idea with a lot of potential benefits, but there are still many challenges to overcome as well. The implementation of a circular economy in the packaging sector requires the support of consumers, manufacturers, and policy makers, as well as the development of effective collection and recycling systems and the continued availability of new technologies, that are affordable to businesses of all sizes.

“ Businesses need to work with governments at a national and local level to develop and roll out effective collection and recycling systems ”

IFE Manufacturing provides a one-stop-shop for the food and drink manufacturing industry by bringing you the latest innovations from top suppliers from across the food and drink supply chain.

Get ready to discover the solutions that will help you upscale, launch or optimise your offering and deliver high quality and effective business connections in 2023 and beyond.

If you’re responsible for sourcing products and solutions across the food and drink supply chain such as ingredients, packaging solutions, processing and packing technology and manufacturing services, then you need to be at IFE Manufacturing, the UK’s only dedicated showcase for end-to-end food and drink manufacturers.

ifemanufacturing.co.uk

IFE Manufacturing 2023 is co-located with:

SPN is pleased to report that UPM Raflatac has received many recognitions and accolades from RecyClass for its multiple label products* that utilise diverse, advanced adhesive technologies.

The granted recognitions expand UPM Raflatac’s portfolio of RecyClass recognised PE (polyethylene) label materials and extends the portfolio to include PP (polypropylene) label materials. Both the PE and PP materials are recognised to be recycling compatible with coloured HDPE (High Density Polyethylene) and PP packages. This means that the PE and PP labels can be recycled either in PP or HDPE coloured recycling streams. The recognition for the PP recycling stream compatibility is first of its kind in the world.

“ The recognition for the PP recycling stream compatibility is first of its kind in the world ”

“At UPM Raflatac, we are working towards a more sustainable and circular future. One big part of this is making consumer plastic packaging recyclable. We are proud that we are the first self-adhesive label company to provide RecyClass approved recycling compatible labelling solutions for PP packaging. According to extensive, independent testing done by Plastics Forming Enterprises (PFE), our unprinted labels have had limited impact on the recycling quality on both PP and HDPE coloured recycling streams. This proves that our labels don’t hinder the recycling process or recyclate quality,” says Katja Kivelä, Business Director, Food and HPC, Films & Specials SBU EMEIA, UPM Raflatac.

In the past, the traditional drivers of plastic packaging design have been functionality and brand appearance, while the endof-life management of the packaging has been disregarded. Today it is expected that companies develop and offer solutions that are designed for recyclability.

“Today’s consumers and brand owners demand product solutions where the sustainability aspects, including packaging recyclability, are considered thoroughly, and in the future the demand will be even higher. We are well prepared for the market demands, as our labelling solutions for fastmoving consumer goods (FMCG) products are by default designed to support the recycling compatibility,” Kivelä says.

RecyClass is an initiative driven by the interest of brands, retailers, converters, raw material producers and recyclers to advance the recyclability of plastic packaging to improve recyclability and recyclate quality.

With its scientific approach, RecyClass enhances and evaluates the recyclability of plastic packaging by developing methodologies and guidelines necessary to assess the recyclability of a package.

“It is not only the composition, but also the components of packaging that make it recyclable. That is why labels play a crucial role in determining the compatibility of the designed product with the available recycling streams,’’ says Fabrizio di Gregorio, RecyClass Technical Director.

“The UPM Raflatac innovation is a very good example how this compatibility can be ensured. It is also worth noting that the RecyClass endorsement is valid for the coloured stream only. Furthermore, since the labels were tested unprinted the printing inks applied on labels could impact the recyclability,” di Gregorio concluded.

“ We are proud that we are the first self-adhesive label company to provide RecyClass approved recycling compatible labelling solutions for PP packaging ”UPM Raflatac strengthens its manufacturing Capabilities in Poland with the latest Label & Narrow Web production facilities

Gary Seward, Managing Director at Pulse Roll Label Products, talked to SPN about the latest labelling waste reduction solutions. The key is that it is possible to reduce waste significantly by using fixed Anilox printing.

Seward told SPN: In a world of reducing lead times and short print runs, it’s becoming more important than ever to find new sources of efficiency. Combined with the growing demand for sustainability among brands and consumers alike, it’s no surprise that in 2023, many label printers are thinking about how they can reduce waste in their workflow operations.

Let’s go back. These days, we are all aware of how important it is to minimise our packaging and labels’ impact on the planet. From cutting emissions to using more recycled content, the tried-and-tested environmental strategies in printing are largely established throughout the industry. However, if we want to take sustainable labelling even further in this age of tight margins and compressed lead times, we need to start looking for new solutions.

The growing complexity of label designs mean that many jobs now need multiple spot colours or half tones, which in turn leads to regular anilox changes. Each change eats up time and resources, as well as increasing the potential for waste.

From printing control patches to excessive ink consumption, there are a myriad of ways in which resources used in flexo can go to waste – and every little bit adds up to a create a bigger environmental problem. The solution to this seems simple on paper: reduce your waste to improve your environmental impact.

However, doing so, while remaining at the level of quality that is expected, is a more complicated challenge. The answer could lie in Fixed Anilox Printing. The idea behind Fixed Anilox Printing is simple. This process takes manual steps out of the print workflow to standardise production, increase capacity, reduce waste, and ultimately save time and money. In essence, it enables the production of any spot colour using just one anilox volume – thus removing the need to change anilox between jobs.

The secret to Fixed Anilox Printing is the PureTone® ink range, which has been specially formulated for strength and balance levels that let it produce all colours using one anilox. Its unique chemistry, with high-strength single-pigment bases, means less ink is needed to achieve the vibrant colours that are currently in fashion.

This strength also makes colour matching simple. When combined with the Pulse bespoke mixing database, the reduced pigment content in the ink leads to cleaner colours with less risk of metamerism occurring. This makes it easy to achieve a Delta E of less than two.

Using Fixed Anilox Printing, it is simple to achieve lower film coating weights, using less ink to achieve the outstanding results you expect. The high strength of the ink means less is needed to achieve the bold, vibrant tones so popular with brands – in fact, Fixed Anilox Printing can reduce ink consumption by up to 30%, helping to minimise waste, conserve resources, and reduce the emissions footprint of ink production and transportation, with the net result of lowering your environmental impact.

Taking action on sustainability might not be the number one priority for printers in today’s market. But with the right systems in place, it’s becoming easier than ever to reduce waste whilst also making businesses more efficient.

“ Fixed Anilox Printing can reduce ink consumption by up to 30% ”

For far too long now, recyclers have needed to go through the extra step of removing labels from PET bottles during the recycling process.

This extra step consumes vast quantities of water, energy and time, thus resulting in material that will ultimately need to be disposed of. This step does not help support the Circular Economy. However, that has all changed now with the introduction of SmartCycle® the latest heat-shrink-sleeve label films from kp.

SmartCycle® from Klockner Pentaplast (kp) is a unique PET label film that, when used with washable inks, allows recyclers to completely skip the de-labeling process. It can be run through the entire recycling process, right along with the PET bottle or container to which it is attached. SmartCycle® label films have no negative effects on the recycling process, such as clumping or slowing down the line.

The result is a major reduction in the disposal of packaging materials, and a greater yield of post-consumer recycled material. Thereby increasing the amount of post-consumer recycled material available to the market, whilst at the same time, decreasing demand for virgin materials. In addition, it eases the pressure on non-renewable resources.

This increased amount of PCR material can then be used for production of new PET products such as bottles, containers, and label film itself and a major announcement on this topic is due soon from kp.

The ‘Sustainable Protection of Everyday Needs’ is more than just the company’s motto. It is woven into the very fabric of everything they do and part of its kp’s commitment as featured in its their innovative ‘Investing In Better’ strategy. Recently kp was awarded a gold rating in sustainability from EcoVadis in 2022. This accolade places it within the top 3% of global plastic manufacturers.

All SmartCycle® heat shrink label films have excellent shrinkrate properties which allows them to be used with virtually any geometry bottle currently in production. Furthermore, as they have superior printing capabilities there is also no need to limit colour options. This in turn opens the door to 360° branding opportunities. Many major global brands have already employed SmartCycle® films to their advantage and kp are keen to help other companies to achieve their sustainability goals by utilising this high performance label-film today.

“ Sustainable Protection of Everyday Needs is more than just the company’s motto ”

Having to write off even a small percentage of the products you ship can cost thousands of pounds. In fact, depending upon the value of the goods, this can often amount to very much more. In addition to this obvious cost, there are also other factors to consider which are equally important.

For example, when considering consumer packaged goods, damage during transit will lead directly to reduced on-shelf availability. This equates to loss of sales.

Damage caused to items during shipping not only incur a monetary cost (with returns / replacements), but also creates a negative perception amongst your customers. Besides this, everyone knows the frustration of receiving damaged goods. This is especially acute when they are critical to your business or operations. Add this to the admin associated with returning items and the costs of dealing with this and it can very quickly lead to unhappy clients.

Happy customers tend to be loyal customers who spend more and will recommend you to colleagues and friends. Customers frequently receiving damaged items won’t come back for more! The impact on your business and its potential growth can be severe.

When it comes to performance, we look to GWP for the answers. The company often works with companies that are experiencing such diverse problems. However, by analysing the product and the type of damage in detail, and then applying its considerable experience and knowledge of transit packaging design, a business can have great success in solving such problems. GWP’s solutions regularly not only engineer-in the right level of protection for the product but also engineerout the cost. In many cases, using less of the right material is both more cost effective and more efficient in terms of protection, than using more of the wrong material.

Whilst damage to items in transit can occur in a number of ways, there are three which are most common across the majority of industry / market sectors. Firstly, and perhaps the most frequently observed, is that of prolonged vibration or sudden impact during shipping. Depending on the fragility of the product and type of packaging used, this can either occur suddenly (breakage) or from prolonged or repeat handling in transportation (failure).

With the average ecommerce order having around 10 touch points prior to delivery, it is essential packaging can withstand the rigours of the chosen courier. Also fairly common is damage resulting from poor pallet or load stability. This can be caused in transit by a vehicle cornering or sudden breaking, or even by stacking packaging too high, which can result in crushing or “bursting”.

Finally, and often overlooked, is damage caused to surfaces by abrasion. This can be through excessive vibration and surface contact between product and packaging - or even by product touching product, which typically affects printed, polished or painted surfaces.

Perhaps the single biggest threat to any business when considering packaging, is that of transit damage. It can also be amongst your most significant packaging costs! In fact, alongside the cost of returns and replacements, it can have an extremely negative impact on your customers’ satisfaction level. This in turn can lead to poor brand perception, and eventually limit a business’s potential for repeat sales and customer loyalty.

Whilst much of this may appear to be common sense, it is surprising how many examples of expensive items being damaged in transit on a daily basis! By following GWP’s expertise and practical knowledge, you can certainly minimise the risks - or even eliminate them!