Characterization and Quality Comparison of Liposome Formulations

Schwendeman, PhD

Anna

Disso America 2022 @AnnaSchwendy

on Complex

Center for Research

Generics http://www.complexgenerics.org https://www.youtube.com/channel/UCbF2EkiP5lbttBzsSu4eQRg @complexgenerics.org

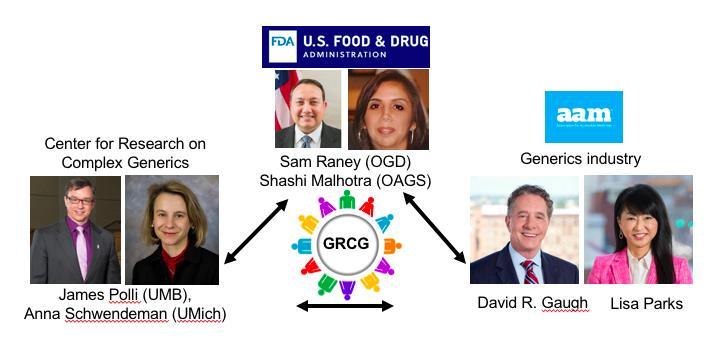

Access to newer equipment, methodologies, software, models

Support from FDA and AAM

3

Housed at UMICH and UMB Neutral ground for communication

Our Mission

“To increase access to safe and effective generic drugs through enhanced infrastructure/communication, education, and research collaboration across industry, academia and the FDA”.

CRCG Aims:

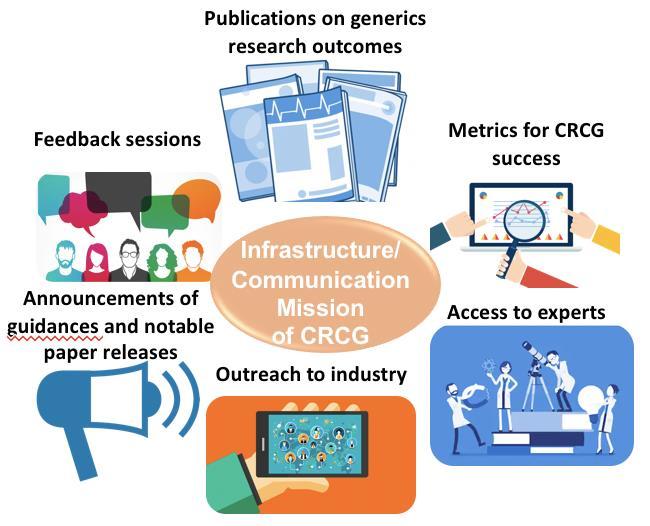

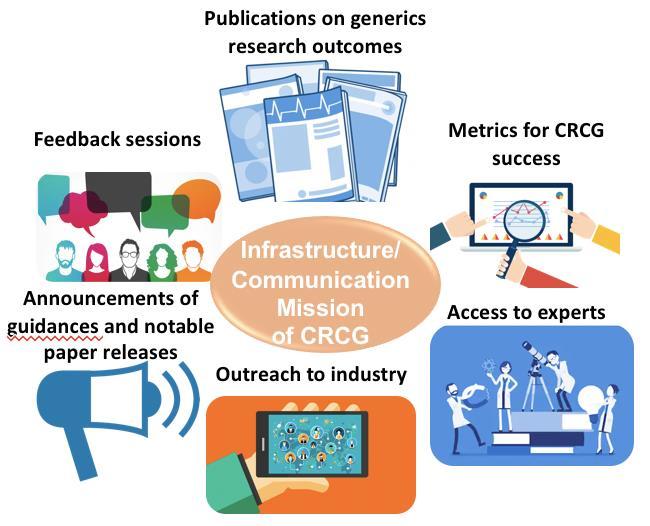

Communication: Establish core program infrastructure and gain the support of stakeholders to ensure CRCG success.

Education: Promote generic industry training through workshops, webinars and hands-on demonstration and engage fellows, students and public in complex generics research.

Research: Conduct collaborative research and technique development that facilitate complex generics.

4

Research Efforts in Complex Generics

Complex injectables, formulations and nanomaterials

Quantitative clinical

Complex mixtures and peptides

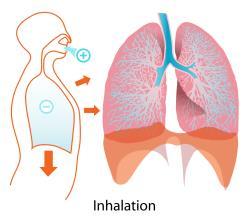

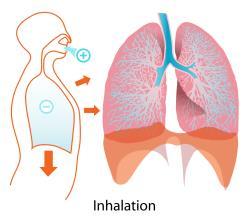

Inhalation and nasal products

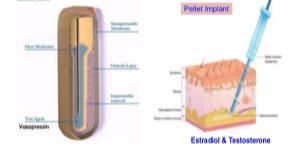

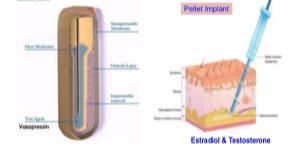

Long-acting injectables and implants

Drug-device combination products

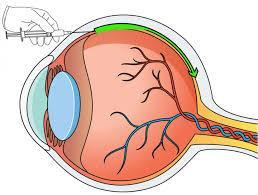

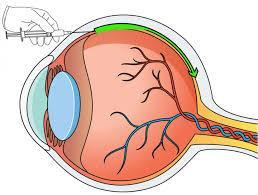

Ophthalmic products

Topical dermatological drug products

Patients substitution of generic drugs

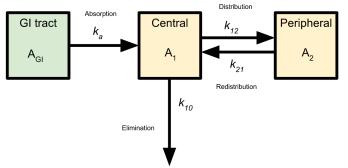

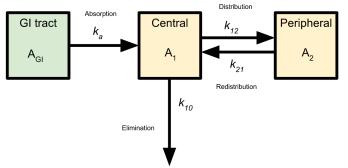

Locally-acting physiologically-based pharmacokinetics modeling

Data analytics

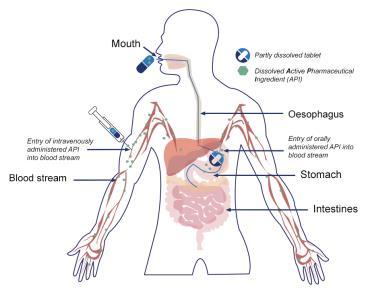

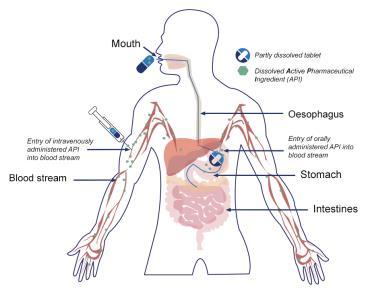

Oral absorption Models and bioequivalence

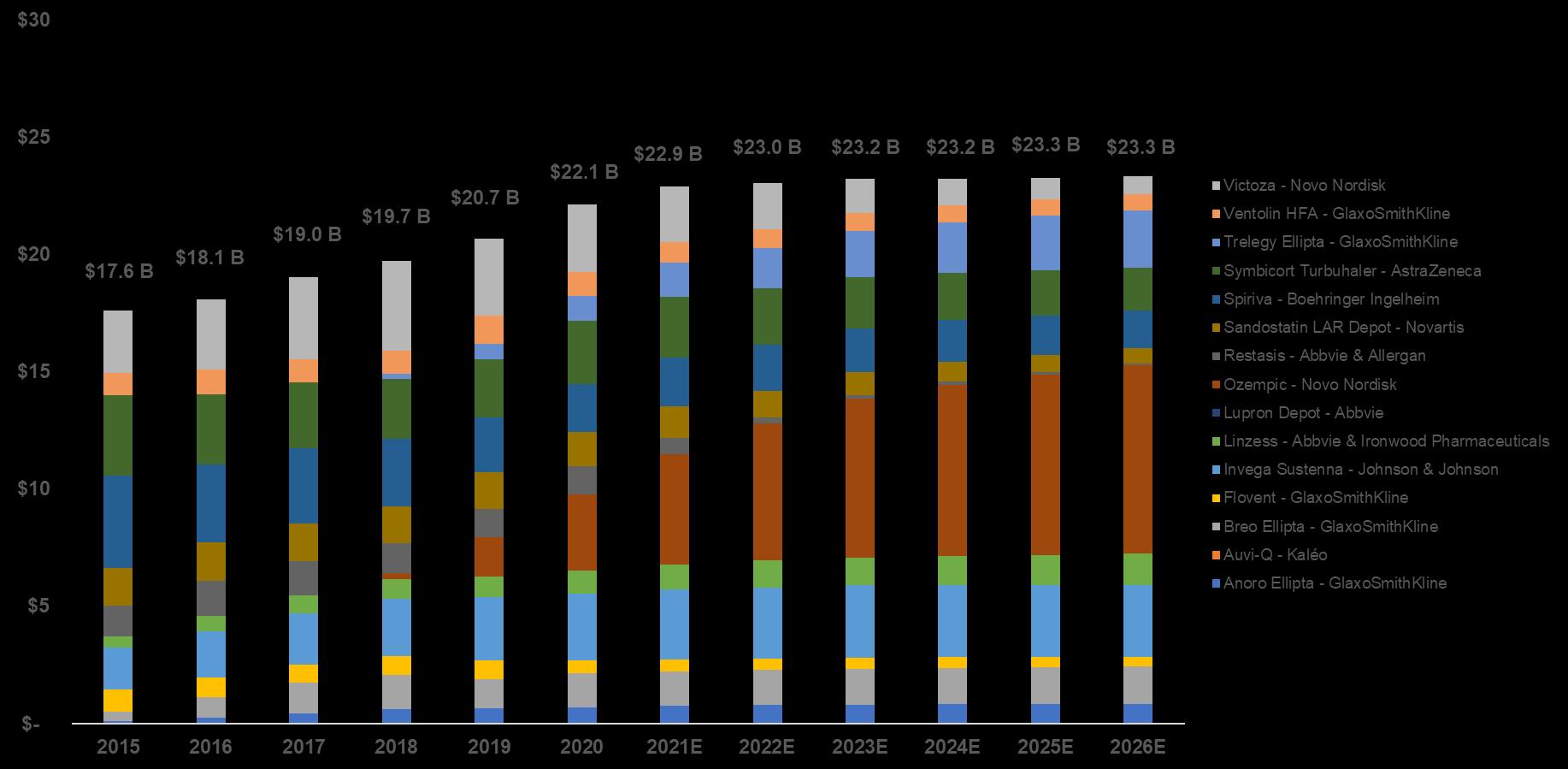

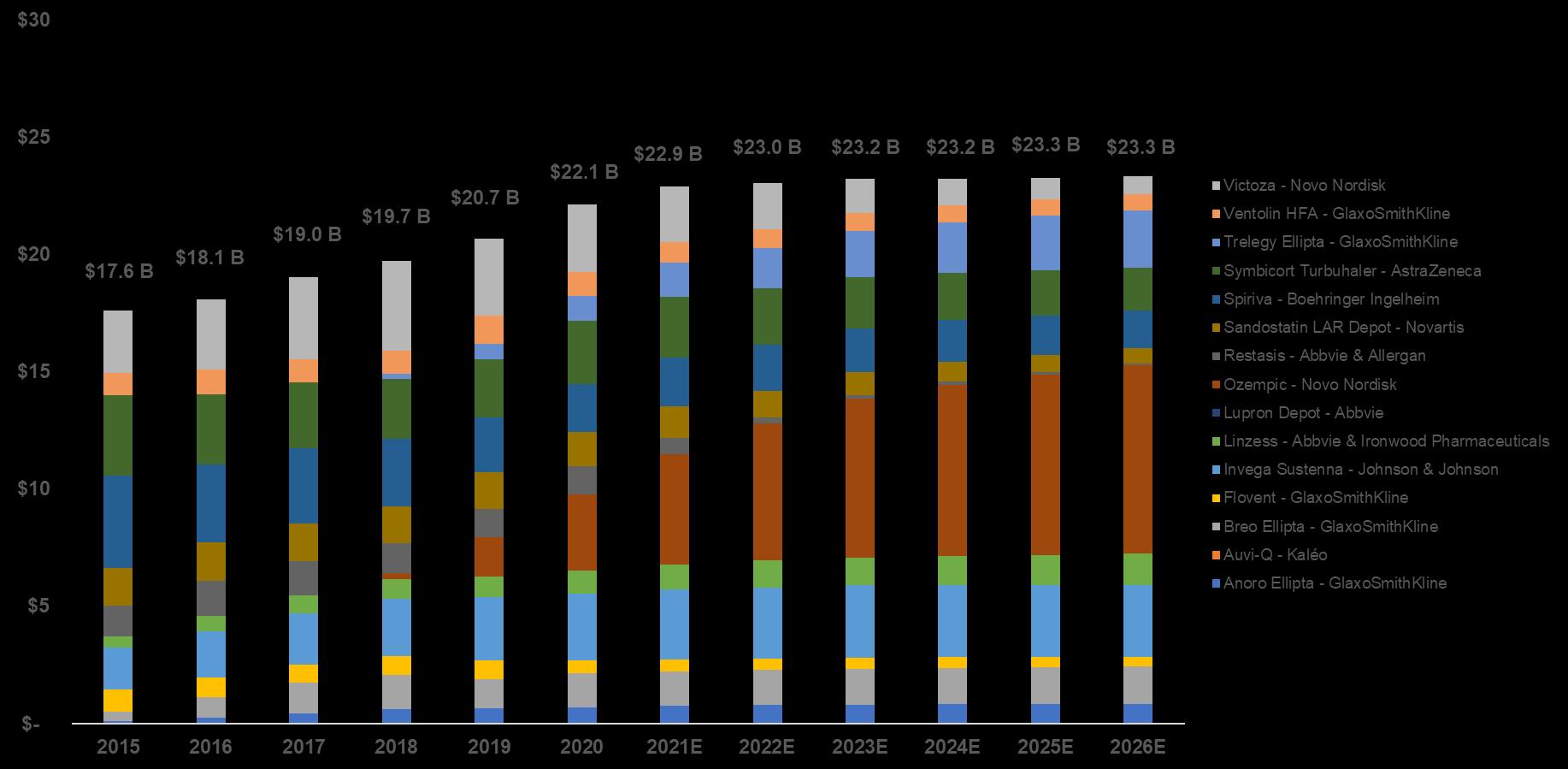

Top15 complex product worldwide annual net sales

Communication Mission

Injectables

Company Name Large Specialty Trade Org Type of products mentioned Perrigo X Oral, topical, inhalations, injectables Apotex X Oral, injectables, inhalations, drug-device combo Teva X All types of products Viatris X All types of products Sandoz X All types of products Fresenius Kabi X Injectables (lipid and polymer based) Cosette X Topical, locally acting orals, suppositories Solaris Pharma X Topical Nexus X Injectables Xellia X

AAM X Drug-device combo, orals, injectables PBOA X Drug-device combo, inhalations, orals, injectables Lassman Law X PSG for complex products SAAM X Oral, inhalations, ophthalmic

Training Mission

Research Mission

Development of Doxil® USP-4 IVR Assay

Case Study

Doxil® Shortage 2011-2012 Date Event Nov2011 BenVenuevoluntarysuspendsall manufacturing Dec2011 Congressionalcommitteehearing Nov2011–May 2012 FDAallowstemporaryimportationof drugs Nov2011–May 2012 FDAworkswithmanufacturersto expeditelotreleases Feb2012 “DrugShortagePreventionAct”is introduced May2012 FDAconditionallyapprovesLipodox

FDA RFA on Doxil® Dissolution Assay

Dr. Frank Szoka

Dr. Frank Szoka

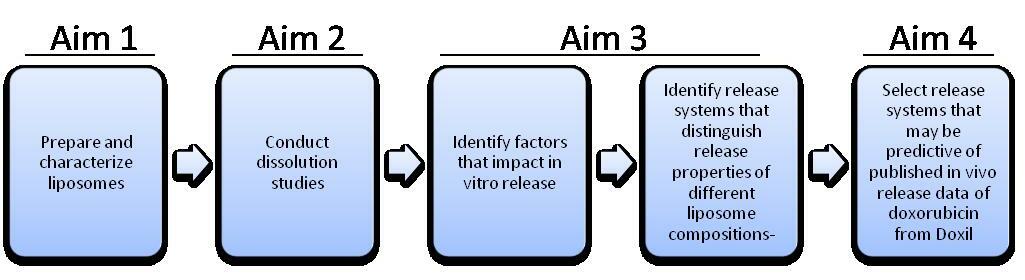

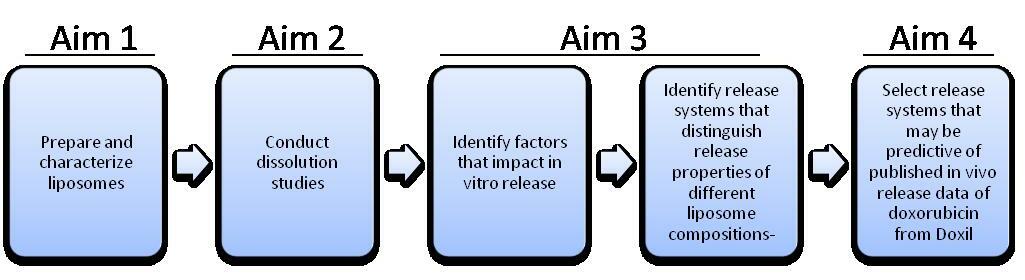

Project Objective

The objective of this project is to develop an in vitro release (IVR) assay for evaluating the biosimilarity of generic liposomal doxorubicin formulations to the innovator Doxil.

1

Liposome Formulation - performed by ZoneOne Pharma (Z1P) 0-4 months

2

Develop Release Conditions to performed by Z1P and UM 0-6 months

Aim

.

Aim

.

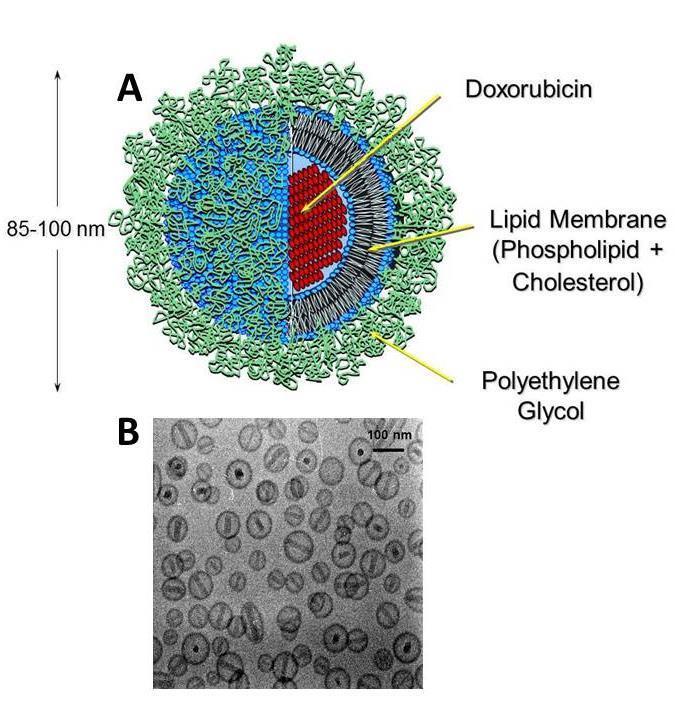

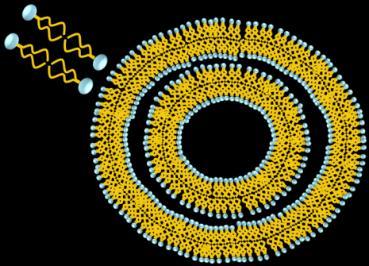

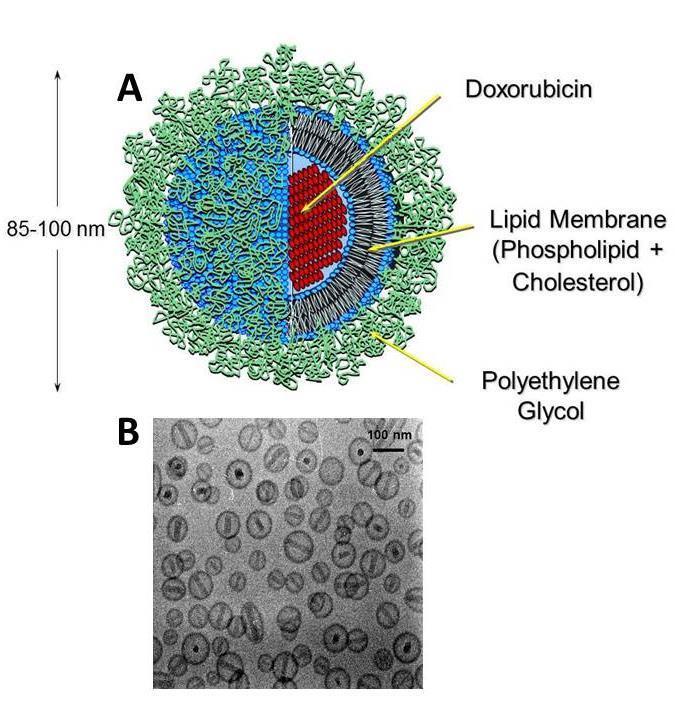

Composition of Doxil®

Doxorubicin

Crystals

Lipid

Membrane

Polyethylene

Glycol

Example of DOXIL® Manufacturing

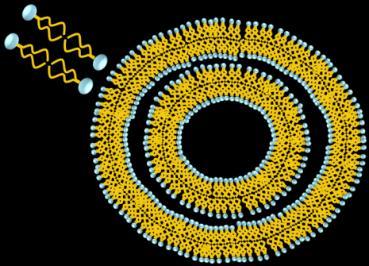

Varied liposome formation processes (red box) but not the composition www.doxil.com

Lipids

Dissolved in ethanol Mixed with aqueous solution

MLV formation

High Pressure Extrusion

Doxil® DOX loading

doxorubicin liposome PEG

Purification/ Sterilization

SUV formation

18

Importance and Challenges of Development In Vitro Release (IVR) Assays

• IVR performance is used to guide product and process development • IVR assay should be able to discriminate between formulations of the same compositions but different in vivo performances • Development of in in vitro-in vivo correlation (IVIVC) • Most approved nanomedicine products are incredibly stable and release drug after macrophage uptake

Most

set-ups for

assays

common

IVR

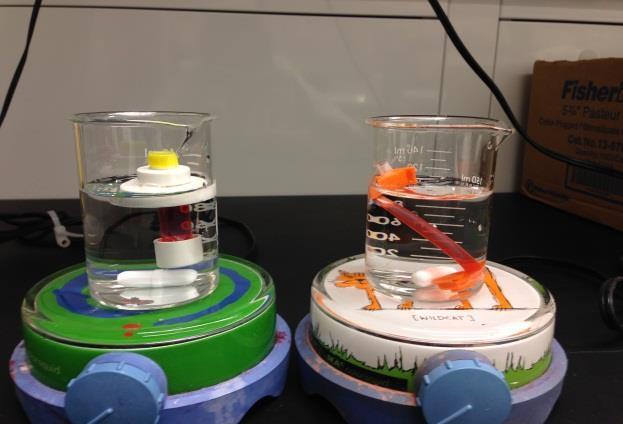

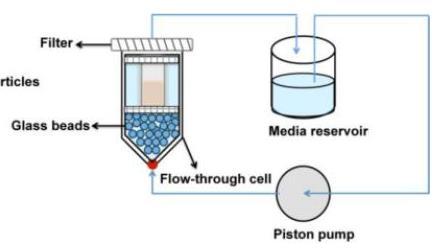

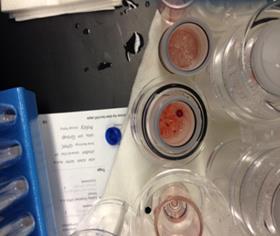

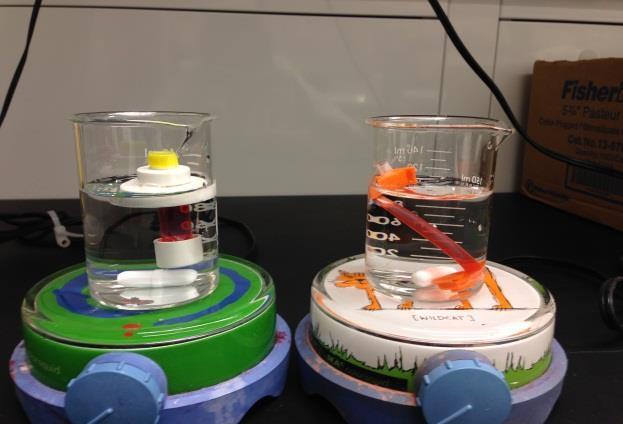

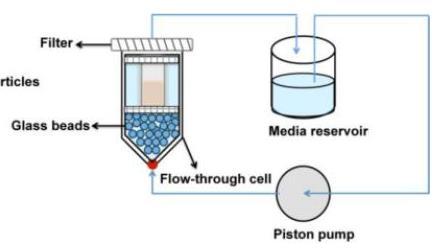

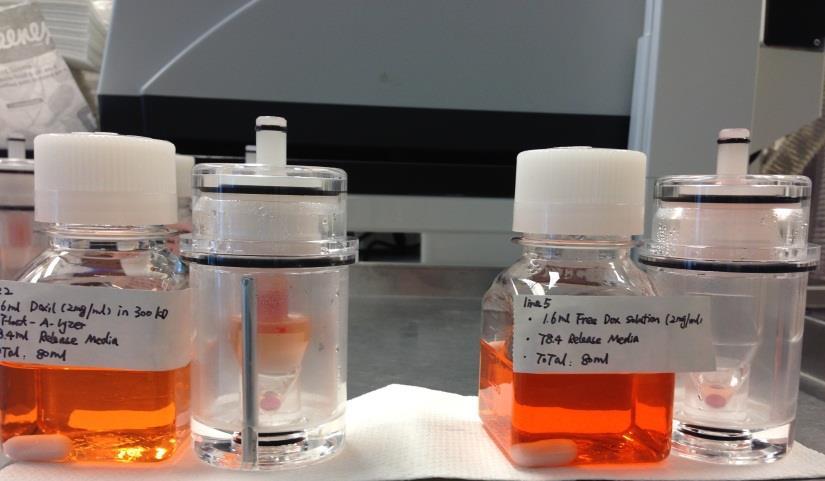

• “Sample and Separate” – Nanoformulation is mixed with release media – Samples removed, release media and nanoformulation separated and analyzed – Could be performed in centrifuge tubes (1 mL) or USP I/II apparatus (~1 L) • “Dialysis Bag” – Nanoformulation is separated from the media by dialysis membrane – Normal dialysis, reverse dialysis, side-by-side dialysis cell • “Flow Through Systems” – USP 4 apparatus with various adaptors to hold nanoformulation and flow media continuously Shen, Burgess, Drug Deliv Trans Res, 3(5): 409-415 (2013)

Consideration for Dialysis Bag IVR Assays

• Selection of dialysis bag type, molecular weight cut-off and membrane composition • Bag introduces diffusion barrier for the drug • Hydrophobic drug adsorbs to the bag • Maintain sink conditions – Media composition to avoid drug precipitation – Volume of the release media – Drug concentration in release media vs. limit of detection • The rate and type of agitation

impact of dialysis bag material

• CE Float-A-Lyzer adsorbs hydrophobic drugs No bag RC –bag (10 kDa) CE- Float-A-Lyzer (10 kDa)0.00% 20.00% 40.00% 60.00% 80.00% 100.00% 0 4 8 12 16 20 24 Time (h) University of 14 0 h 24 h Conventional Dialysis Method For Liposomes The

The Impact of Dialysis Membrane Pore Size

DOX(control)

0 20 40 60 80 100 0 4 8 12 16 20 24 Cumulative release (%) Time (h) 300kD CE 100kD CE 50kD CE 8-10kD CE Free

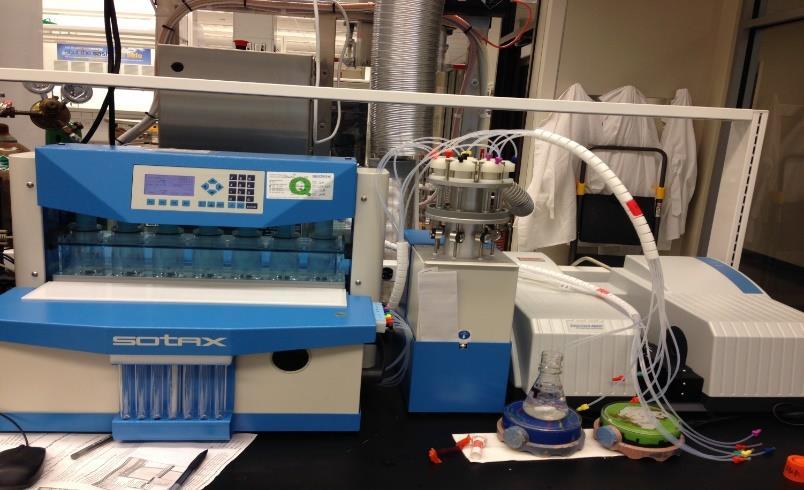

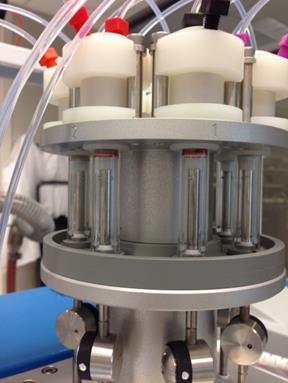

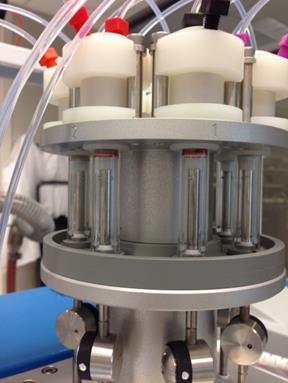

Flow Through Methods

Shen, Burgess, Drug Deliv Trans Res, 3(5): 409-415 (2013)

Consideration for Flow Through Methods

design of USP-4 cell

• The

• Open or closed system • Online or of-line detection • Flow rate • Media composition • Drug concentration in release media vs. limit of detection

No drug release from Doxil® PBS at 37oC

100% free DOX DOX solution in 100KD Float-ALyzer Doxil liposomePOPC Doxil® similar

0 0.2 0.4 0.6 0.8 0 4 8 12 16 20 24 Absorbance (AU) Time (h)

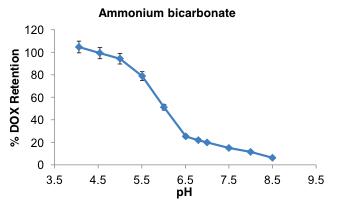

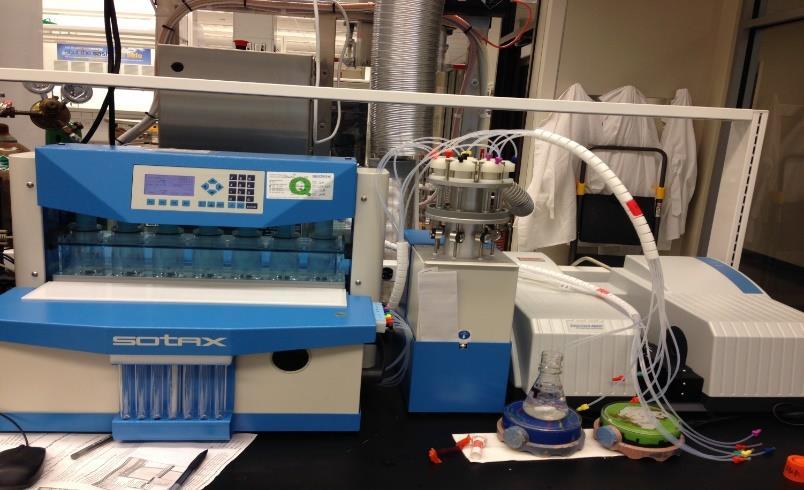

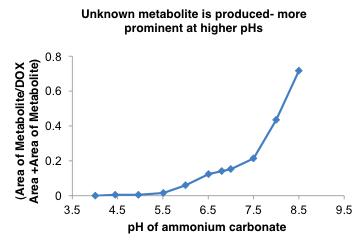

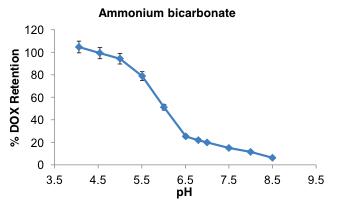

Ammonium Bicarbonate Induces Doxil® Release

Doxil® release in NH

at 37oC but precipitate in USP-4 System (Sotax)

liposome--

HCO

0 0.2 0.4 0.6 0.8 0 4 8 12 16 20 24 Absorbance (AU) Time (h) DOX

POPC Doxil® similar 100% free DOX control

4

3

Optimized

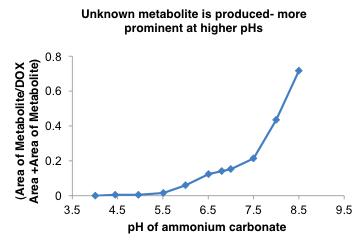

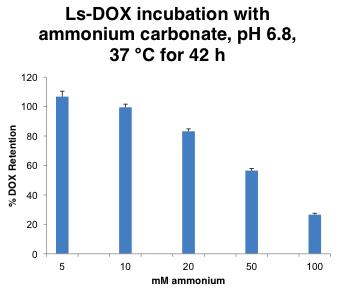

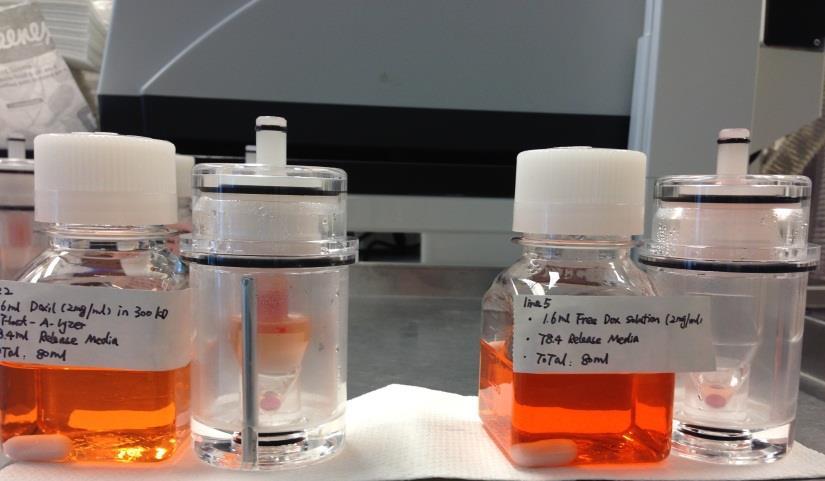

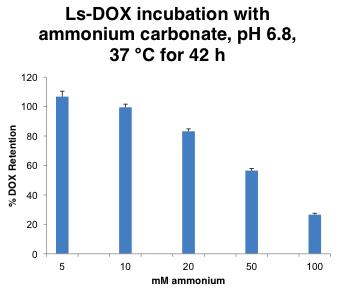

Release Media 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0 12 24 36 48 OD Time (h) Free DOX (control 1) Free DOX with stir bar(control 2) L-Doxil® in 300KD Float-A-Lyzer pH 5.998 pH 5.998 pH 5.998 pH 6.271 pH 6.306 pH 6.283 • Add acceptor HP-CD to avoid precipitation • Use NH4HCO3 to facilitate doxorubicin release from Doxil • Control of pH and OD by MES buffer (pH 6) • Adapt new release media to USP-4 IVR Yuan, AAPS J, 19(1), 2017

40.00%

30.00%

20.00%

Back to USP-4

Temperature Effect

–

0.00% 10.00%

50.00% 60.00% 70.00% 80.00% 90.00% 100.00% 110.00% 0 4 8 12 16 20 24 Release Time (h) No precipitation 55°C 45°C 37°C Yuan, AAPS J, 19(1), 2017

The effects of

release and assay reproducibility

conditions on

0 20 40 60 80 100 0 4 8 12 16 20 24 Cumulative release % Time (h) L-DOX 10µg/ml in total media L-DOX 20µg/ml in total media L-DOX 40µg/ml in total media

A0 20 40 60 80 100 120 0 4 8 12 16 20 24 Cumulative release % Time (h) 5% γ CD 5% HP-CD C 0 20 40 60 80 100 0 4 8 12 16 20 24 Cumulative r elease % Time (h) 1.5% γ-CD 1.5% β-CD 1.5% HP-CD B D

IVR

DOX

0 20 40 60 80 100 0 4 8 12 16 20 24 Cumulative release % Time (h) Day 1 Day 2 Day 3 Yuan, AAPS J, 19(1), 2017

0 20 40 60 80 100 0 4 8 12 16 20 24 Cumulative release % Time (h) POPC L-DOX Doxil® 23: 51-2(Homogenizer made) L-DOX (23:68-1) Optimized IVR assay distinguishes between different liposomal Dox formulations Media composition: 100 mM NH4HCO3, 75 mM MES, 5% w/v HP-CD 5% w/v sucrose, 0.02% w/v NaN3 (pH 6) Temperature: 45°C; Flow rate: 16 ml/min; Cell: Float-A-Lyzer, CE, 300 kDa Media volume: 80 mL; Dox concentration: 10 mg/mL f2 = 50 log 100 1+σ��=1 �� (����−����)2 �� n is number of time points, Rt is cumulative release for ref Tt is cumulative release for test Yuan, AAPS J, 19(1), 2017

Summary

• The developed USP-4 assay is capable of distinguishing between some liposomal doxorubicin formulations and predicts similarity for others.

• Due to high stability of Doxil ® and solubility limitations USP-4 assay is performed at 45oC in presence of HP-CD and ammonia bicarbonate.

• The USP-4 assay has difficulty in method validation due to large lotto-lot differences in Float-A-Lyzer and extensive maintenance required for equipment operating at 45oC.

• The developed assay is not physiologically relevant. It only a quality control and comparability assessment tool.

• Similar approaches had been utilized by us for development of IVR for AmBisome® , Exparel®, liposomal cyclosporin and other complex products.

@AnnaSchwendy

Univ of Michigan

Wenmin Yuan

Jie Tang Yue Yuan

Rui Kuai Zone One Pharma

Frank Szoka

Mark Hayes Charles Noble

Zhipeng Dai

Acknowledgements

Jiang

Nan

FDA Wenlei

Zheng

Dr. Frank Szoka

Dr. Frank Szoka