The past year has been a whirlwind of economic and technological activity, and a period of growth at the Southwest Regional Manufacturers Association (SRMA). Has it all been good? Depends on who you ask.

Let’s address the elephant in the room and buzz word of the year: tariffs. Some manufacturers love the concept, others not-so-much. Some are feeling positive effects – increased sales due to onshoring efforts and are expanding production to accommodate. Others, however, have faced challenges such as unstable and rising raw material prices, leading to lost business and tightened budgets. Despite these hurdles, manufacturers are united in their desire for a positive outcome, though the journey to get there is causing many headaches. The key is to plan for various scenarios, ensuring readiness to act swiftly when needed.

Next on the list is artificial intelligence (AI). While AI has been around for some time, its impact has surged over the past year. Tools like ChatGPT, CoPilot and Gemini have become mainstream, enabling users to complete tasks more efficiently. There is a fear AI might replace human jobs, but initially, people who harness AI for increased productivity will replace those who do not. Manufacturers must embrace AI on the shop floor to boost productivity, a crucial key performance indicator (KPI) for profitability.

In our region, there has been a strong focus on expanding manufacturing education, a catalyst for attracting high-tech careers to Southwest Florida. Initiatives like the new CNC (Computer Numerical Control) Machining program at Fort Myers Technical College and the Space Florida Academy Program at Charlotte County high schools are prime examples. Over the years, I’ve learned skilled workers must be available for manufacturers to move to a region, not the other way around.

At the SRMA, we’ve welcomed Allison Evanitz as our membership experience manager, dedicated to reaching more manufacturers in our region and ensuring we provide the services and benefits our members need. Our business advisor, Pavel Kuviarzin, has been busy evaluating applicants for the Small and Large Manufacturer of the Year Award in partnership with Lee County Economic Development Office and the Horizon Foundation. This new process of determining finalists and winners brings benefits to all applicants, providing a comprehensive analysis for each manufacturer. This is in addition to bringing valuable training and operational resources to the manufacturers and finding funding to assist

“In our region, there has been a strong focus on expanding manufacturing education, a catalyst for attracting high-tech careers to Southwest Florida. ...

Over the years, I’ve learned that skilled workers must be available for manufacturers to move to a region, not the other way around.”

with those costs. We continue to offer plant tours at our member facilities, sharing best practices for all manufacturers to use, no matter what they make. Lastly, as referenced above with AI adoption, automation will also be a key focus for the SRMA. Revenue per employee is the primary metric we’ll be looking at and encouraging our members to do the same.

The SRMA is here to assist with any of these topics and more. Let us know how we can help. For membership, event and resource information, visit srma.net or email exec@srma.net. Join the SRMA today.

Rob Harris has been serving as the SRMA’s Executive Director since June 2021. The SRMA is a part of the FloridaMakes network.

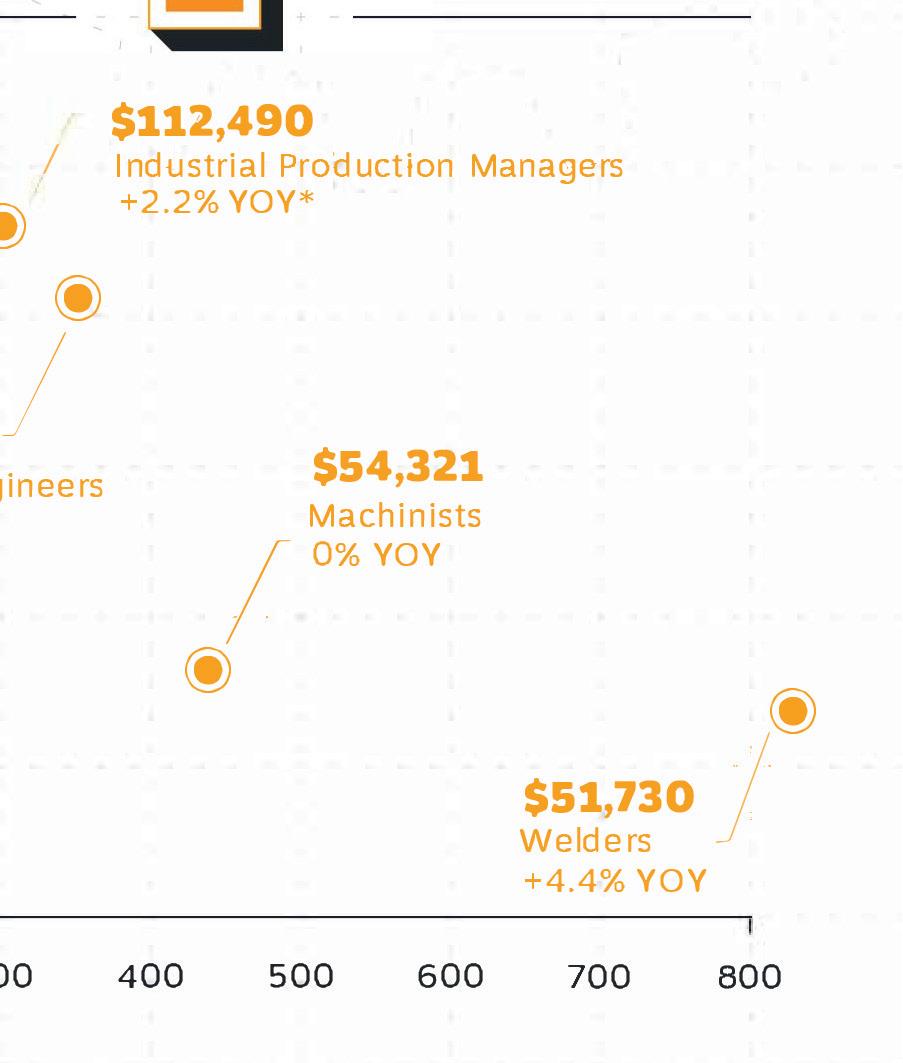

Manufacturing in Lee County continues to play a vital role in creating a resilient economy through job creation and providing residents with meaningful, high-wage careers. From early industrial roots to current technological advancements, this sector has helped define the region’s growth in workforce development to position Lee County as a hub for innovation and long-term economic stability.

From advanced medical devices and aerospace components to cutting-edge software and sustainable materials, Lee County’s manufacturers are creating products that reach markets across the globe. Manufacturing is significant for diversifying Lee County’s business climate, contributing $1.4 billion annually and supporting over 8,000 local jobs. With average annual earnings in manufacturing well above the statewide average, this industry provides career pathways that support families and strengthen the community.

Lee County is home to a growing number of small and large manufacturers, such as Paragon Machine Co., Foley Products, Addman and e2Companies, that benefit from a collaborative system of workforce training and business support. These companies represent the diversity and innovation that drive Lee County’s manufacturing sector in areas such as precision machining, infrastructure components, advanced additive manufacturing and clean energy solutions.

Partnerships with Florida Gulf Coast University (FGCU), Florida SouthWestern State College (FSW), Fort Myers Technical College and Cape Coral Technical College are helping to produce a pipeline of skilled talent prepared to meet these evolving industry standards. FGCU and FSW also continue to expand digital badge and micro-credential offerings to adapt with the region’s workforce expansion. Post-secondary career and vocational training will be offered through two upcoming technical colleges: The Heights CareerTech Institute and Lehigh Technical College. These institutions will offer credentialed programs in high-demand manufacturing fields to help create a skilled workforce while also improving access to hands-on learning in historically under-served communities.

Lee County is a prime destination for manufacturing with its direct access to major highways, rail lines and the Southwest Florida International Airport while also being conveniently located between the Port Miami, SeaPort Manatee and Port of Tampa. This strategic location enables manufacturers to efficiently move raw materials into the region and distribute finished

products to domestic and international markets. This transportation infrastructure is a key asset for manufacturers that rely on timely supply chains and distribution networks to help reduce costs, shorten lead times and improve product reliability. This seamless connectivity not only supports the daily operations of existing manufacturing companies in Lee County but also enhances the region’s appeal for new manufacturers looking to expand into the area.

The Lee County Economic Development Office (EDO), under the leadership of the Lee Board of County Commissioners, is proud to support this vital industry through initiatives and partnerships with the Southwest Regional Manufacturers Association and other targeted workforce development programs. As Lee County looks toward the future, manufacturing will remain a core driver of economic growth and resiliency throughout the region. The Lee County EDO is committed to strengthening this sector and celebrating the manufacturers that are helping to shape the success of tomorrow through innovation, growth and resiliency.

John Talmage, Lee County Economic Development Office Director, has more than 20 years’ experience in City government and Economic Development. Contact him at (239) 533-6800 or jtalmage@leegov.com.

Lee County’s manufacturing sector continues to expand and adapt to the industry’s technological advancements, offering more career opportunities.

Visit LeeCountyBusiness.com to learn how the Lee County Economic Development Office (EDO) can assist with business expansion and retention for all manufacturing needs. The Lee County EDO is also a proud partner of the Southwest Regional Manufacturers Association (SRMA).

Since its founding in 2012, D3 Glass, a family-owned business based in Fort Myers has followed a remarkable path of steady growth and innovation. This year marks the third consecutive time the company has been named to the prestigious Inc. 5000 list of America’s fastest growing privately held businesses—an achievement that reflects both its entrepreneurial spirit and community impact.

Founded by the Daubmann family in a modest 10,000-square-foot facility in southern Lee County with just 10 employees, D3 Glass has expanded into a state-of-the-art 60,000-squarefoot manufacturing plant off Alico Road. The company now employs more than 53 local residents and has also established a distribution warehouse in Charlotte, N.C.

While D3 Glass is best known for supplying the family’s other ventures—10 MY Shower Door locations and MY Architectural Glass—it also serves numerous regional glass companies throughout the South-

eastern United States. Their excellence in manufacturing earned them the title of “Manufacturer of the Year” from the Horizon Council of Lee County, recognizing their economic and community contributions.

The company’s community engagement extends beyond business.

D3 Glass regularly hosts facility tours for groups such as the Economic Development Council, the Bonita/Estero Board of Realtors, Local High School STEM students, Florida Gulf Coast University’s Lutgert College of Business and local homeschoolers through the BIZ KIDZ Entrepreneurship Group.

Looking ahead, D3 Glass is developing two groundbreaking innovations aimed at enhancing glass safety and

visibility—advancements expected to further elevate its role in the industry.

From humble beginnings to national recognition, D3 Glass continues to embody the values of innovation, quality and community investment, serving as a model for sustainable growth in Southwest Florida’s manufacturing sector. Bill Daubmann is President and Founder of MY Shower Door, D3 Glass, and MY Architectural Glass. Visit MYShowerDoor.com. Contact (239) 596-3255 or info@myshowerdoor.com.

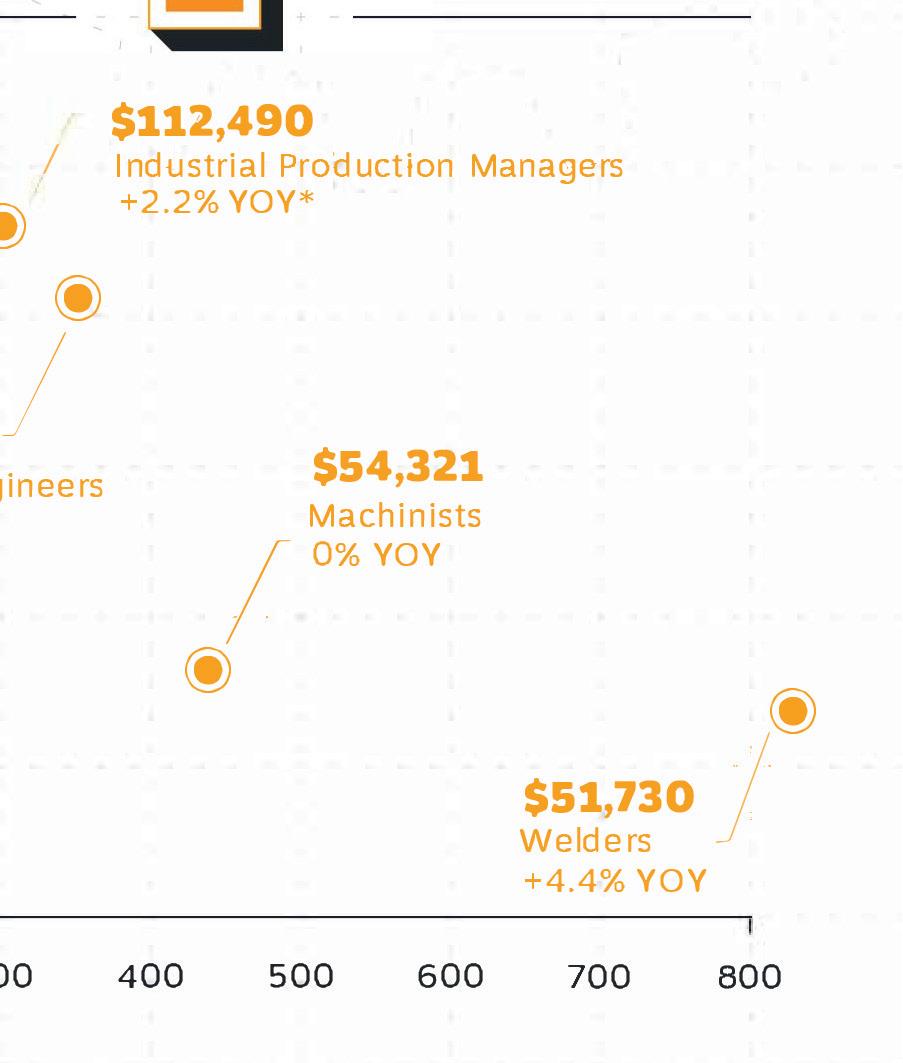

Traditionally known for its agricultural industry, it may surprise most to learn that there is an active and growing manufacturing community in Hendry County, producing a variety of products from food to space exploration products. This growing industry is influenced by the county’s agricultural heritage, strategic location and cost advantages to attract businesses seeking alternatives to more congested and expensive coastal areas while maintaining access to major Florida markets.

Just south of Lake Okeechobee, Hendry County is located between Lee and Palm Beach counties. Its central location has made it ideal for many businesses looking for expansion locations, especially from the Miami-Dade area. Along the U.S. 27 corridor, Hendry’s location not only sees the movement of freight from the seaports, but it offers ease of access west via Highway 80.

In the eastern portion of the county, the City of Clewiston and the surrounding area has several industrial parks ideal for manufacturing. In LaBelle, The Jack Paul Industrial Park offers 600 acres of opportunity along State Road 29. A short line railroad, SCFE, that is well run and ready to move freight via CSX and Norfolk Southern is available in Clewiston and offers a trans load site about 12 miles from LaBelle.

This year, we welcomed several new manufacturers producing goods for residential and commercial structures, a manufacturer who will be producing metals

from sulfide mineral concentrates, and a 100,000-squarefoot food production facility.

Food processing continues to be a fast-growing sector in Hendry. It represents a natural evolution of Hendry County’s agricultural base, adding value to raw agricultural products and creating a more diversified economic foundation.

The processing facilities support both local agricultural production and serve broader regional and national markets. Producing a variety of products from yogurt and sugar to tortillas, manufacturers find the transportation network appealing. Since most destination locations are roughly within an hour’s drive, distributing perishable goods to either coast offers opportunities to increase customer bases.

To support and encourage additional growth in this sector, Hendry is hiring a consultant to evaluate 300 acres owned by the county for the development of an Agricultural Innovation Park to include a Food Innovation Center. As agricultural practices continue to adopt AI technology and the use of robotics, Hendry is exploring ways in which it can support and encourage these technology advancements.

To support the workforce pipeline in the industry, the Hendry County School District received $1.7 million from the Florida Workforce Development Capitalization Incentive Grant (CAP Grant) program in May 2025. This grant will be used to support Agritechnology, Technical Agriculture Operations and Food Science programs within the district. They have also expanded the offerings at the Workforce Development and Adult School to include more class and program options. This increase has accelerated Hendry to become a leader amongst rural counties in the state as the number of certifications awarded continues to outpace other areas.

The county’s commitment to innovation—from the planned Agricultural Innovation Park to cutting-edge workforce training programs—demonstrates that Hendry is not merely adapting to economic change, but actively shaping its future. As businesses increasingly seek alternatives to congested coastal markets while maintaining competitive advantages, Hendry County stands ready to support the next generation of manufacturing enterprises that will drive Florida’s economic growth for decades to come.

Keitha Daniels is the Director for the Hendry County Economic Development Council. She has worked for the Board of County Commissioners over the past seven years with a focus in economic development. To contact her, email keitha@hendryedc.com.

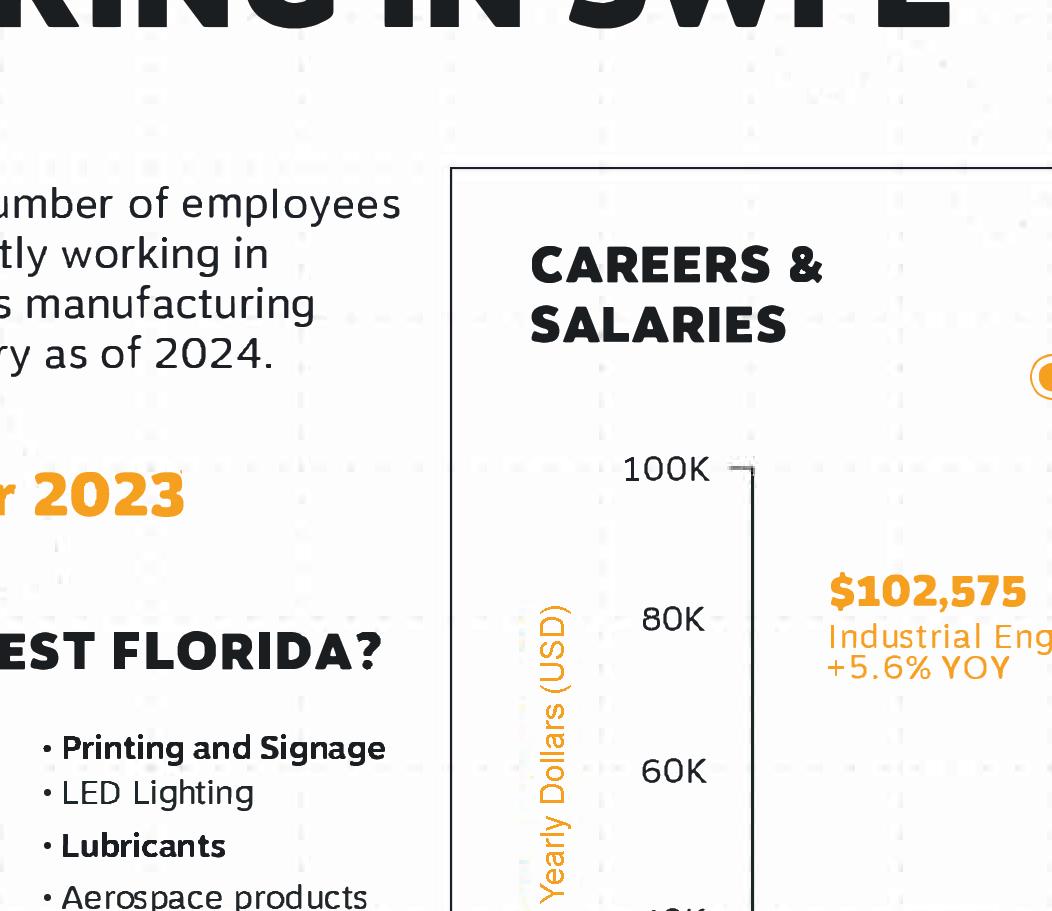

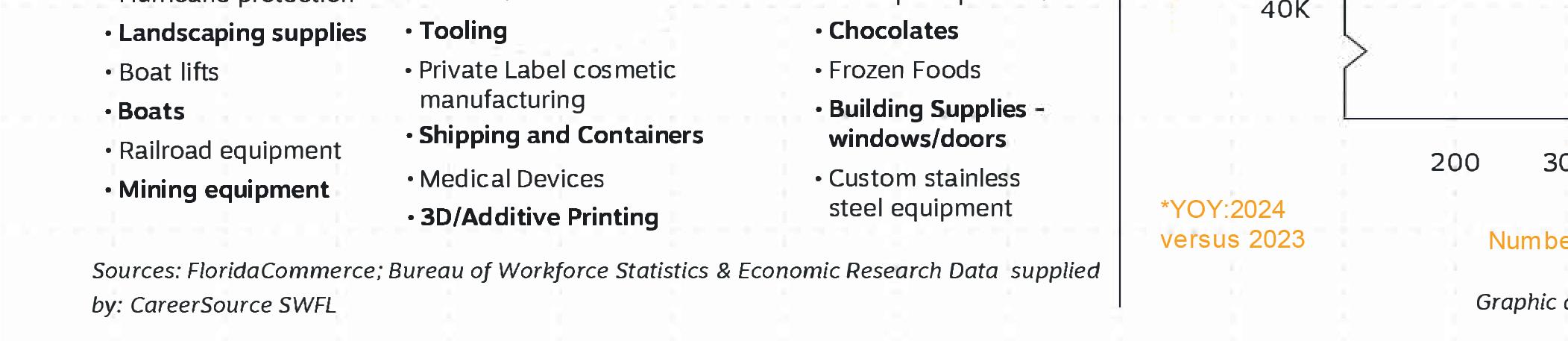

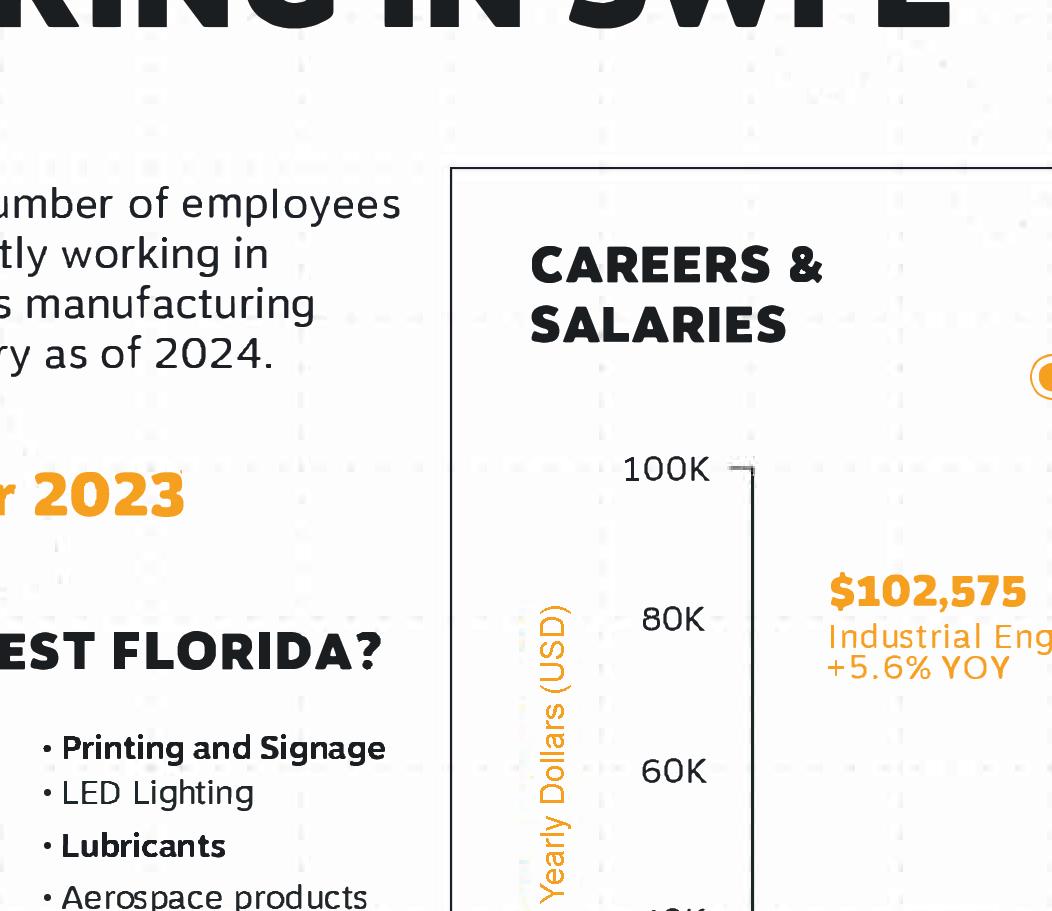

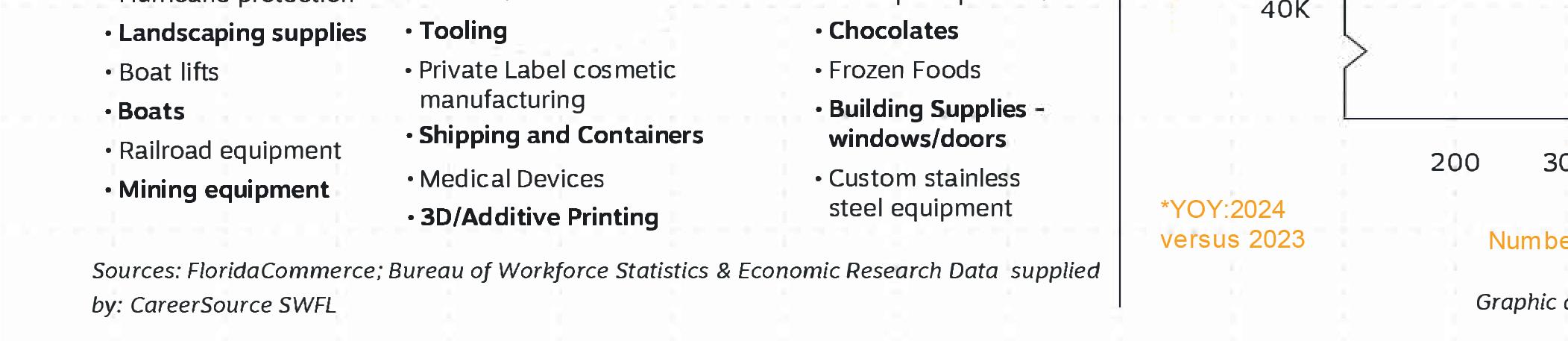

Manufacturing continues to tick upward with more and more manufacturers either locating to Southwest Florida or expanding in Southwest Florida offering lucrative careers and advancement than ever before.

CareerSource Southwest Florida is here to support manufacturing of all types and sizes in the Southwest Florida region. If you consider yourself a manufacturer, Let’s Talk!

CareerSource SW FL is a nonprofit organization so all of our services and programs come at no cost. We are partnered throughout Southwest Florida to assist manufacturers with hiring and training needs. Some of our partners include: Southwest Regional Manufacturers Association (SRMA), educational systems including the technical schools, the Small Business Development Center, Small Business Administration and other non-profit organizations.

Some of our services include: helping with job descriptions, recruitment and applicant pre-screening. We can assist with Job Fairs and hiring events. Utilize

BILL WELCH

CareerSource Southwest Florida’s five Centers for training or interviewing. We have access to the latest labor market information for manufacturers at our fingertips.

Some of the programs include “Work based Training Grants” including:

1. “Work Experience” grants similar to an internship where the individual is paid by CareerSource SW FL and covered by workman’s compensation to see if it is a fit for both the manufacturer and applicant before making an offer of employment.

2. Another grant is our “On the Job Training (OJT) program” for new hires that is not qualified or has a skills gap between the job description and resume/ application of the applicant. If the new hire is eligible then CareerSource SW FL will reimburse 50% of the

“Beyond business, Charlotte County offers the quality of life today’s workforce expects; waterfront living, excellent schools, low crime and abundant outdoor recreation. Whether a business is launching a new facility or expanding a national footprint, Charlotte County has the location, labor and leadership to support your success.”

Charlotte County is rapidly becoming one of the state’s most strategic locations for manufacturing and distribution. With a strong infrastructure backbone, available industrial space and a deep commitment to workforce development, we’re not just growing we’re outpacing the state.

Charlotte County’s manufacturing sector has experienced job growth approximately 15% higher than the state average (Lightcast, 2024). Additionally, from 2007 to 2024, the county’s transportation and warehousing sector expanded by nearly 232%, significantly outpacing Florida’s statewide growth of 88% during the same period (Florida Department of Economic Opportunity, 2024). These results highlight the impact of strategic planning, targeted investments in logistics infrastructure and workforce development, and a consistently pro-business environment.

Our industrial growth is anchored by the Punta Gorda Airport (PGD) and the adjacent Enterprise Charlotte Airport Park (ECAP) a 4,300 acre logistics and manufacturing district easy I-75 access, supporting thousands of high-wage jobs.

For companies ready to move now, Charlotte County offers new spec space ready for lease, including:

• Florida Gulf Coast 75 Logistics Center: Up to 306,000 square feet of divisible light industrial space with 49 loading docks, 64 trailer parking spaces, threephase power and high ceilings.

• PGD Industrial Park: 40,000-square-foot (divisible) units for light manufacturing with dock-high and drivethrough loading, available for immediate occupancy.

• Other spec buildings in ECAP: Ranging from 10,000 to 40,000 square feet, ready for customization.

Our “Cleared 4 Takeoff ” initiative streamlines permitting and reduces red tape. Developers and end- users benefit from direct access to County staff,

fast-tracked reviews, and coordinated utility and zoning support.

Charlotte County is also investing heavily in workforce development. Our large veteran population brings discipline and experience to the logistics and manufacturing sectors. We work closely with programs like the Honor Foundation and Department of Defense’s SkillBridge program to help service members transition into highdemand jobs.

At the K–12 level, Charlotte County Public Schools leads with innovative Magnet Programs in aerospace, advanced manufacturing, cybersecurity and robotics. Students gain hands-on experience in fields aligned with local industry needs and continue into technical certification programs at Charlotte Technical College, Florida SouthWestern State College and Florida Gulf Coast University, creating a full pipeline from classroom to career.

Beyond business, Charlotte County offers the quality of life today’s workforce expects; waterfront living, excellent schools, low crime and abundant outdoor recreation.

Whether a business is launching a new facility or expanding a national footprint, Charlotte County has the location, labor and leadership to support your success. We’re not just open for business, we’re built for it.

For more information about the benefits Charlotte County Florida can offer a manufacturing business, contact Kay Tracy, Business Recruitment Manager at: (941) 764-4944 or Kay.Tracy@CharlotteCountyFL.Gov.

wages for a period of time to offset training costs for that person.

3. CareerSource SW FL also offers 50% reimbursement costs of a manufacturer up-skilling their current entry level workforce to make them more productive and allow them to advance in their careers. This grant is called “Customized Training.”

Talking about customization – since each manufacturer is different and each one has different needs, CareerSource SW FL customizes our relationships to meet those individual needs. Give us a call to start a conversation on how CareerSource SW FL can be of assistance to your manufacturing ongoing growth & success.

Bill Welch is the Business Services Director with CareerSource Southwest Florida with 20+ years of experience in staffing and consulting employment services. assisting business to grow and prosper. Contact (239) 9318200 or wwelch@careersourcesouthwestflorida.com.

At a facility tucked into the industrial corridors of Southwest Florida, a team of engineers, assemblers and quality control technicians is quietly transforming how our communities are lit. Their work doesn’t make headlines often, but it touches nearly every part of our daily lives, from the glare-free lights in local classrooms to the safe glow lining city streets and neighborhood parks.

The company, Energy Harness, has been designing and building high-performance LED lighting systems in Southwest Florida for over 15 years. While many manufacturers have outsourced or off-shored their operations, Energy Harness has kept its roots firmly planted in the region, betting on the power of local talent and hometown pride.

“We’re not just building lights,” said one longtime technician on the production floor. “We’re building things that help our kids see better in school, that make it safer to walk at night, that save our local governments money. That’s something to be proud of.”

Founded in 2010, Energy Harness began as a small engineering outfit focused on energy-efficient lighting. Over the years, the company expanded into full-scale manufacturing, building a vertically integrated process that includes everything from product design to assembly and testing, much of it done by hand, in-house.

Energy Harness technicians take pride in their contribution to the success and growth of the company.

Today, it designs luminaires and control systems used in schools, healthcare facilities, municipal buildings and industrial sites across Florida and beyond. But what sets the company apart isn’t just its technology; it’s the local footprint.

By keeping production close to home, Energy Harness has created skilled jobs in the region while giving clients the kind of responsiveness and customization that’s hard to find in mass-produced imports.

“We work with the people who use our lights,” ex-

plained a project engineer. “Teachers, city planners, facilities managers, they tell us what they need and we build around that.”

Building lighting for Florida is no simple task. Between the humidity, heat and salty coastal air, many products fail faster than expected. That’s why every Energy Harness fixture undergoes rigorous testing, from thermal stress to optical performance, to make sure it can stand up to real-world conditions.

“We simulate the worst-case scenarios,” said one quality inspector. “If it can survive here, it’ll survive anywhere.”

Products include everything from UV-C systems that purify indoor air to classroom lighting that adjusts color temperature to reduce eye strain and improve focus. Some of these innovations were born out of necessity during the COVID-19 pandemic; others came from direct feedback from teachers and health care workers.

One standout example is their C-LEC Classroom Control System, a simplified lighting control panel designed with teachers in mind. Instead of confusing switches and complex programming, it offers intuitive settings to adjust brightness and color temperature for different learning tasks.

ENERGY See page 13

At the Greater Naples Chamber, we recognize the important role the manufacturing sector plays in our local and regional economy.

Manufacturing has a significant impact on Southwest Florida’s overall economy. There are more than 600 manufacturing operations in the five-county region, which contributed approximately $2.9 billion to the local and regional economy in 2024.

Closer to home, Collier County boasts about 200 manufacturing operations, in industries ranging from medical devices to cables and wires. These businesses collectively contributed about $1.2 billion to Collier’s economy in 2024.

More of this is on the horizon. The Florida Chamber has identified manufacturing as one of the top areas for growth, with the goal of seeing Florida in the Top 5 states for manufacturing jobs by 2030. Statewide, we’re already seeing progress. A July 2025 report from the Florida Chamber showed that the Sunshine State was

ranked No. 1 for manufacturing job growth, adding 90,000 sector jobs statewide over the past 10 years.

Our region is expected to benefit from the push to bring more manufacturing to the state, with Southwest Florid projected to see 12% growth by 2029. In Collier County, we’re anticipating 14% growth in these jobs over the next four years.

While the industry outlook is positive, there are still challenges to overcome. Southwest Florida has more individuals in the field approaching retirement age than the national average, highlighting the need for a qualified, well-trained workforce.

The Greater Naples Chamber is proud to partner with organizations throughout our region, including the

Southwest Regional Manufacturers Association, FutureMakers Coalition and Collier County Public Schools to ensure the long-term success of the industry by creating pathways for students and workers to attain the necessary training for these high-wage and high-skill jobs.

Fostering growth in the manufacturing industry is critical to a healthy economy, and it is something we work hard to address every day. We look forward to continuing to support our regional manufacturing partners, serving as a valuable resource and advocate for the industry.

For more information about the Greater Naples Chamber, visit www.napleschamber.org or call (239) 262-6376.

Kristina Park is the president and CEO of the Greater Naples Chamber. Representing more than 1,000 members, the Chamber works to strengthen the local economy and promote the business community.

Geis Companies, with nearly 60 years of expertise in Northeast Ohio and a solid travelling construction success story for repeat clients, established its Bonita Springs office seven years ago to bring its client-focused, innovative construction solutions to Southwest Florida.

Building on a foundation of repeat client success, we’ve become a trusted partner for manufacturers, delivering highquality industrial and commercial facilities available for lease or sale. Our work with industry leaders like AXI and IPEX, along with past projects for Chromalloy and Princeton Tool, showcases our ability to design and construct spaces that boost operational efficiency and fuel long-term growth.

As dedicated members of the Southwest Regional Manufacturers Association (SRMA), Geis engages with a vibrant network of Southwest Florida’s 1,176 manufacturers, supporting over 13,500 local jobs. SRMA’s platform of workforce development, advocacy and networking events strengthens our ability to connect with regional businesses, helping them explore growth

Their lights can be found across Florida, illuminating Southwest Florida International Airport, Cape Coral city buildings and parks, guiding students through campus hallways in Collier and Charlotte counties and brightening corridors of our hospitals and medical centers throughout the region.

In one recent project, a school district retrofitted hundreds of classrooms with tunable white LED fixtures designed to enhance concentration and reduce glare. The upgrade not only improved learning conditions but also led to measurable energy savings, a win for students and taxpayers alike.

Another local project saw neighborhood park lighting replaced with LED systems that significantly improved visibility and safety while reducing mainte-

through facility expansions, space repurposing or new construction.

By leveraging SRMA’s resources, we deliver tailored solutions that save clients time and money while aligning with industry best practices and market trends. Leading our efforts in Southwest Florida is Jeffrey Martin, a 30-year Geis veteran with an engineering background and over 700 commercial and industrial projects to his name. His creative team tackles complex challenges, ensuring each project meets clients’ strategic goals.

Our complimentary pre-construction services provide free assessments to evaluate feasibility and op-

nance costs. The savings were reinvested in new playground equipment.

But perhaps the most lasting impact of Energy Harness’s work lies in its investment in people.

The company partners with local schools and technical colleges to provide internships and hands-on training in electronics and engineering. It also actively recruits veterans and mid-career professionals looking to shift into advanced manufacturing or skilled trades.

“We’re growing careers, not just filling positions,” said the company’s HR coordinator. “We want to create a place where people can learn, grow, and contribute to something meaningful.”

It’s a model that’s increasingly rare in an industry dominated by global supply chains, but one that’s proving resilient, especially as more organizations

timize plans—all it takes is a phone call to get started. Contact Jeffrey Martin at our Bonita Springs office (28100 Bonita Grande, Suite 103, Bonita Springs), by phone at (216) 218-3508 or via email at jm@geisco.net. With SRMA’s support and our proven expertise, Geis Companies is poised to help Southwest Florida manufacturers thrive.

As Chief Operating Office of Geis Construction, with more than 29 years with the company, Jeff Martin directs all aspects of the effort to design and build each company project.

look to shorten lead times and prioritize regional sourcing.

As communities across Southwest Florida continue to grow and modernize, Energy Harness remains a critical partner in that progress. Its locally built products light everything from sidewalks to stadiums, classrooms to clinics, spaces where we learn, live and come together. And in a time when so much of what we use comes from far away, there’s something uniquely hopeful about a company that chooses to stay close to home. If you travel thought Southwest Florida International Airport, you will see many energy harness lighting products.

For more information, contact sales@energyharness. com or (239) 790-3300, or sales@electroncharger. com or (239) 206-2935.

FOR 55 YEARS, GEIS COMPANIES HAS HELPED VISIONARIES GO FROM IDEA TO OCCUPANCY — FASTER, SMARTER, AND WITH FEWER SURPRISES

Geis Companies brings your project to life with our unique FullCycle Approach — a fully integrated design, construction, and delivery system that trims 25% off project timelines and eliminates the finger-pointing of traditional build.

From site planning to turnkey delivery, you get a partner who’s accountable from start to finish.

INTERIOR DESIGN

ARCHITECTURAL DESIGN

Full Service Construction

Design / Build Process

Reliable and On Time

Projects Maintain Budget

Proven Track Record

Construction & Design

Team Integration

OVER VIEW

PLANNING & FEASIBILITY

Site Assessment

A. DUIE PYLE TRUCKING TERMINAL 255K SF

Master Planning

Conceptual Design & Programming

Accurate Initial Budget

Agency Reviews & Approvals

DESIGN

Project Development Design

Renderings

Contract Development

Construction Documents

Interior Design

CONSTRUCTION

Project Scheduling

Subcontractor Selection

Project Management

Documentation

Quality Control

POST CONSTRUCTION

MERIDIAN BUSINESS PARK 218K SF

System Training & Start-Up

Owner's Manual

Warranty