Insulated panels offer

for roofing and cladding across various building types.

Insulated panels offer

for roofing and cladding across various building types.

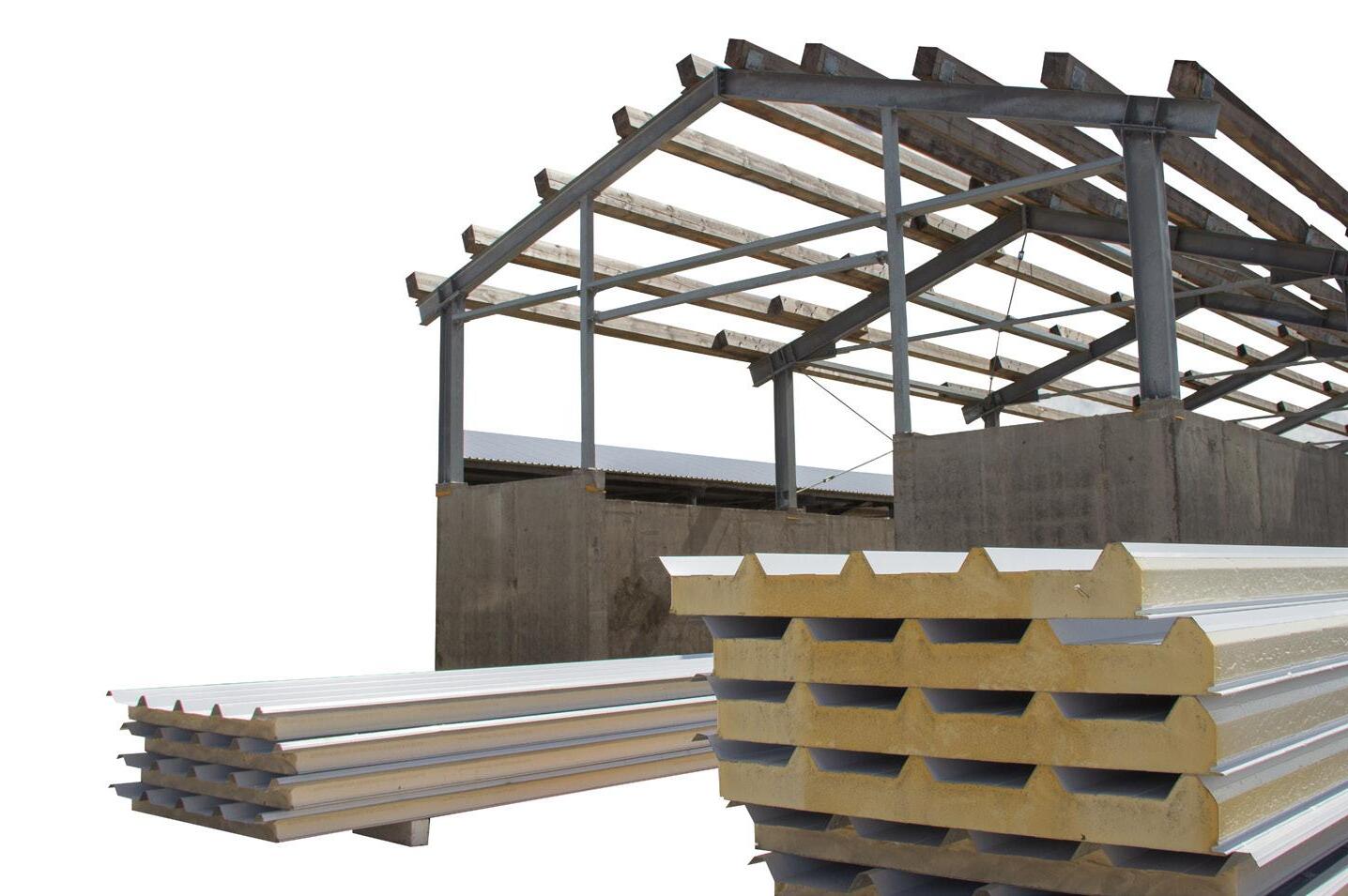

Insulated panels are an advanced roofing and cladding product often used for commercial buildings designed for thermal efficiency and durability. Also known as ‘all-in-one’ or ‘sandwich’ panels, they are comprised of two 0.5mm thick steel sheets with a core of PIR (polyisocyanurate) insulation. Available in various thicknesses, insulated panels protect against moisture ingress and temperature variation and provide fire resistance. The outer steel layer offers robust protection against the elements, while the inner surface has a white liner that acts as the finished ceiling, enhancing light reflection and providing a clean, modern look.

These panels offer significant advantages compared to traditional roof systems comprising of multiple built-up layers. They simplify installation by combining insulation, structural support, and weatherproofing in one step, reducing construction time and labour costs. Consistent factory-controlled manufacturing of the panels ensures reliable thermal performance and a tight seal, which minimises air leakage and improves energy efficiency. Unlike built-up systems, which can require a complicated installation process, insulated panels provide a straightforward, durable solution, making them an ideal choice for energy-efficient building projects.

Panels can be supplied precisely cut to the specific length you require. Simply specify the exact panel lengths needed (up to a maximum panel length of 20 metres) and panels are cut to these dimensions, ensuring that each piece fits without additional adjustments.

Key benefits of cut-to-length panels:

• reduces on-site cutting

• minimises waste and labour time

• lessens the risk of errors during installation

Cut-to-length insulated panels are usually produced in 2 to 4 weeks, depending on stock availability and specific requirements. This can vary based on demand and production schedule.

We also provide a take-off service, assisting you with measuring and quantifying the materials needed for your project. Whether you’re working from architectural drawings or a quick sketch, we can help you stay on schedule and within budget.

Installation guidance is also available, giving you access to expert advice tailored to the specific needs of your project, whether you are a seasoned contractor or new to installing insulated panels. We can provide step-by-step instructions and best practice tips to ensure your panels are installed correctly, maximising their performance and longevity. With our support, you can avoid common pitfalls, reduce installation time, and enhance the overall quality of your build.

A cut-back refers to the end of the panel where the insulation and liner sheet are factory cut at a shorter length than the top steel sheet. Cut-backs can be made at different lengths and need to be specified at the time of order.

There are two purposes for cut-backs:

1. To create a drip edge on the panel that ensures water run-off into a gutter. Gutter cut-backs are usually produced from 50mm to 75mm long.

2. To ensure a watertight overlap where two sheets join end-to-end. This could be two panels fastened together or where an insulated panel joins a rooflight sheet. We recommend a minimum end lap cut-back length of 150mm.

Please note: The overall length of the sheet is determined by the length of the top sheet rather than the liner sheet length, which will be shorter.

Insulated panels can be installed either from left to right or right to left. Each panel is manufactured with a side lap detail where the top sheet projects beyond the insulation and liner sheet; this will then lap onto the crown of the previously laid panel. Left to right or right to left handing must to be specified at the point of order. Panels should be installed with the overlaps facing away from the prevailing wind. This will determine the handing of the panels.

For standard-pitched roofs, it is common practice to order the panels ‘50% handed’; half laid left to right and half laid right to left.

Once installed, the Platinum® Plus system guarantees 25 years of coverage for the entire system, ensuring that all components, including roofing and cladding, are fully integrated and designed to work together. This guarantee only covers commercial installations. To activate this guarantee, your project details must be submitted to Tata Steel. This will ensure that all components used are pre-approved and meet the required standards for the 25-year system coverage.

The Confidex® Guarantee offers up to 40 years of protection for the pre-finished steel surfaces, such as Colorcoat HPS200 Ultra® or Colorcoat Prisma®, depending on the location and environmental conditions, safeguarding against corrosion, weathering, and fading. This guarantee only covers commercial installations. To activate this guarantee, your project must be registered with Tata Steel.

Please note: Guarantee application forms are provided at the time of purchase, but it is the customer’s responsibility to complete and submit the application.

Stock holding depot

South East

Hill Place Farm, Turners Hill Road, East Grinstead, West Sussex RH19 4LX

Tel: 01342 315 300

Saint Hill Farm Business Park, West Hoathly Road, East Grinstead, West Sussex RH19 4NG

Tel: 01342 315 300

Midlands

Unit 4a and 4b

Wymeswold Business Quarter, Burton Lane, Wymeswold, Leicestershire LE12 5BS

Tel: 01509 380 283