Australia’s Leading Trade Show for Intralogistics, Robotics and Automation, Warehousing, Supply Chain Management and Materials Handling 22-24 July 2025 | The Dome, Sydney Olympic Park

Drop by the SCLAA stand to meet the incredible, passionate, and driven committee team. You’ll also have the chance to connect with NSW Director Julian Brancaccio, Independent Director Cathy-Anne Jones, and other inspiring supply chain professionals.

SCLAA is proud to host the CeMAT Knowledge Theatre 22-24 July 2025

It’s your chance to experience the latest innovations and technologies shaping the future of warehousing and logistics, all in one dynamic, hands-on environment. Come join the SCLAA team, connect with industry professionals, share ideas, and participate in conversations shaping the future of supply chain and logistics in Australia.

Sue Tomic, FGIA, MAICD

SCLAA Board Chair

Managing Director for Chain Consulting Services.

Appointed to the Board in 2019.

Australia’s Supply Chain Under Pressure: Resilience in an Age of Volatility

Its halfway into 2025, and like most of us, economists looked forward to the end of 2024 and towards the new year with hope and also trepidation. Yet so much has changed and what is likely to keep us awake at night as this year continues?

There is no doubt Australia’s supply chains are under pressure - not from a single event, but from a convergence of ongoing disruptions that are increasingly structural in nature. Geopolitical instability, economic uncertainty, infrastructure gaps, and a deepening workforce crisis have made unpredictability the norm rather than the exception.

We’ve moved beyond isolated shocks. We’ve entered an era where volatility is the baseline - and supply chains need to be rebuilt around that reality.

Globally, the rules of trade are shifting fast. Tariffs between the US and China are changing in real time. Exemptions are floated and then repealed. As global trade flows become more reactive, Australian operators, even at a distance, are impacted. Delays, congestion, and route changes are placing pressure on importers and exporters alike, complicating logistics planning and undermining reliability in freight timelines.

The suddenness and immediate effects of trade policies between two of the worlds largest economies, continue to cause imbalances and bottlenecks in trade routes. The impact has been evident in recent months in Australia. The great thing in our land of droughts and flooding rain, particularly the latter, is bumper agricultural exports. Being an island, our farmers and regional exporters rely on incoming container trade to capitalise on the current boom in regional exports. The disparity between seasonal container demand and container supply continues to be a challenge in the Australian marketplace.

The global climate is the great disruptor but has also seen some positives for the Australian businesses.

It has spurred the government in fast tracking the Fair trade agreement with the EU

Australian agricultural exporters are experiencing more demand from our Asian trading neighbours as they swing away from US agricultural imports.

New trade opportunities are emerging for some Australian agricultural industries.

The $2.5 billion US Beef export market to China ground to a halt during April.

Australia’s cattle industry is enjoying a surge in demand from China for grain-fed beef and is filling the gap.

Statistics from Meat and Livestock Australia (MLA) show Australian grain-fed beef exports to China have ramped up significantly, with 21,885 tonnes shipped in February and March - up nearly 40 per cent on the same period last year. Last month, Australia exported more than 127,000 tonnes of beef, a record for April.

The biggest customer was the United States (37,213 tonnes), followed by China (21,572 tonnes).

Australia’s almond export to China has burgeoned as well, from 0.77 per cent of Chinese almond imports a few years ago to nearly 70 per cent this year.

The Chinese market had been the source of the majority of grower revenue for the last few years and this the expectation is that Californian growers, who hold 80% of the worlds almond export market share, will see a decline. Likewise, there is an opportunity for any Australian export commodity that does not have a tariff attached, to take advantage of international market opportunities.

Exporters need to be mindful that these opportunities and growth are occurring in a volatile international market. The old saying “don’t put all your eggs in the one basket” remains even more relevant now, than it did during Covid. The opportunities can be negated with a slowing Chinese economy and the recent 90 day moratorium on Chinese tariffs as announced last week.

The other benefit to Australia is that import prices here may fall in the short term if China has a surplus of goods and pivots to other markets as a response of decreased US demand.

Container volumes into the US have already dropped dramatically, but price benefits require a longer lead time to measure any expected benefits.

At best, the supply/demand situation will continue to be unpredictable at port level as US shippers either pivot to non Chinese markets for imports or try to move as much product as possible before the 90 day moratorium expires. Container carriers may be ramping up blank sailings to our Pacific region to cater for surging demand elsewhere

So with all the volatility globally, the question remains on how Australia will increase freight efficiency domestically to retain competitiveness?

Locally, policy ambition hasn’t yet translated into operational change. The Federal Budget’s focus on local manufacturing and freight strategy is important, but real-world outcomes remain elusive. Freight diversification, particularly the shift from road to rail, has been a consistent government talking point, but continues to lack fast-tracked delivery….sorry, not sorry for the pun. Rail freight and Intermodal transport remains underutilised, despite being an obvious lever for congestion relief, emissions reduction, and resilience. Without decisive infrastructure and policies favouring modal integration, operators are left relying on increasingly fragile road corridors and grappling with rising labour and compliance costs. For small to medium businesses in particular, this landscape creates compounding challenges. Many are now operating in survival mode, adapting reactively rather than planning proactively. That’s a risky position in an environment where cost blowouts and scheduling volatility can’t be easily absorbed.

The road freight market continues to experience mergers, acquisition or outright business collapse in the wake of global and local cost pressures and demand volatility. Contracts negotiated for a period of years become commercially unviable in a matter of months. Cashflow imbalance pressures where some freight supply chain service providers impose short credit trading terms and shippers are increasingly requesting 60 and sometimes up to 90 day credit terms, is untenable for the majority of freight carriers. Only the largest are able to survive. We all know what lessening of competition means to our industry.

This is not just an infrastructure or freight issue. It’s an issue of imbalance and disparity across the freight supply chain.

But, its also a capability issue.

Technology is advancing at pace — from automation to predictive analytics and AI-enabled logistics tools — but implementation is still inconsistent. Many businesses simply aren’t ready to unlock the potential of these systems. It’s not the tools that are lacking, but the human capability to embed and use them effectively.

This brings us to what is arguably the defining issue of our time in supply chain: workforce readiness.

The labour shortage we face isn’t just about numbers. It’s about strategic capability. It’s about whether the people leading our freight, procurement, warehousing, and planning systems are equipped to think differently, lead change, and work across evolving platforms and processes. Warehouse and distribution centre operators have embraced the available automation and predictive technology much more so than others. Transport carriers in particular, all too often rely on the dreaded excel spreadsheets and legacy systems rather than exploring current market capabilities or focussing integration of data rather than duplication.

Too often, career development in this sector is undefined. There’s a lack of clarity in progression pathways. There’s a mismatch between training systems and the actual demands of modern logistics roles.

Australia’s talent pool is deep, but under-supported. We must move away from treating skills development as a reactive fix and start viewing it as core infrastructure. That means:

• Strengthening partnerships between industry and education

Prioritising training that adapts to emerging technologies and methods

Providing clearer, modular career paths that support long-term leadership growth

Supply chain leadership isn’t confined to the boardroom. It lives in planning teams, shift supervisors, freight coordinators, and analysts. It’s the ability to make confident, informed decisions under pressure, to adapt, recalibrate, and keep goods moving even when conditions change without warning.

The State of Supply Chain in Australia today is one of tension, transition, and potential. Our systems are stretched but not broken. Our people are capable but in need of support. And our national ambition is real — but it needs sharper execution.

This isn’t about getting back to stability. That may no longer be realistic.

It’s about building supply chains that can function without it. That can absorb pressure, adapt fast, and move forward in the face of uncertainty. Because in today’s world, resilience is no longer a competitive edge, it’s the baseline.

In a landmark moment, the Supply Chain & Logistics Association of Australia (SCLAA) joined forces with Automate-X to host the very first NZ Networking Event, and what an unforgettable evening it was!

Australia and New Zealand may be known for their fierce rivalry, from rugby fields to netball courts, but this week, that spirit took a back seat to something far more powerful: shared vision, professional camaraderie, and industry momentum.

Hosted at the character-rich Stanbeth House in Auckland, with outstanding service and first-class catering. It was an inspiring night where long-standing industry relationships were rekindled and brand-new connections sparked.

A massive thank you to the incredible sponsors, Auckland Racking & Shelving and Face Consultants Ltd, whose support made the event possible.

meaningful industry ties across the ditch. The energy in the room was electric, and the most common question of the night? “When’s the next one?”

This is just the beginning. Watch this space.

SCLAA was proudly represented by Rakesh Bandipelli and Natalie Wallace, who were honoured to be part of Huge kudos to the exceptional team at Automate-X, Ben Haughey, Jordan McFall, Mark Pringle, and Kayla Brall

Events like these are what the supply chain industry is all about: sharing insights, exchanging ideas, and building

SCLAA welcomes our newest Platinum National Partner, Vstrong. As a not for profit Industry Association, run by members for members, our ability to support the SCLAA infrastructure and to expand is highly dependent on our National Partners. We ask all our members to support our valued National Partners where they can.

A trusted logistics system integrator, Vstrong delivers tailored automation solutions powered by advanced software and equipment. Headquartered in China with offices in Australia, Singapore, and Malaysia, we’ve completed 700+ projects across industries like e-commerce, pharma, and retail. Provides end-to-end consulting, we help clients streamline operations and embrace intelligent logistics.

SCLAA welcomes our newest National Partner, Airstack Intralogisitcs As a not for profit Industry Association, run by members for members, our ability to support the SCLAA infrastructure and to expand is highly dependent on our National Partners. We ask all our members to support our valued National Partners where they can.

Airstack Intralogistics Pty Ltd is an Australian company specialising in warehouse automation solutions tailored to meet the evolving needs of supply chain and logistics operations.

As the exclusive partner of CIMC Pteris Global, a world leader in intelligent logistics systems, Airstack brings proven global technology to the local market.

Our core solutions include:

– Automated Storage & Retrieval Systems (AS/RS)

– RGVs, AGVs, and Conveyor Systems

– Mini Load Systems

– Sorting Systems

With labour shortages, rising costs, and growing demand for speed and accuracy, automation is no longer optional—it’s essential. Airstack helps clients reduce manual handling, increase throughput, and optimise space without overhauling their existing infrastructure. We’re proud to be a member of SCLAA and are keen to connect with like-minded professionals to explore how automation can improve operational efficiency across the sector.

Let’s talk about how Airstack can support your next project or help future-proof your operations.

SCLAA welcomes our newest National Partner, OPTUS. As a not for profit Industry Association, run by members for members, our ability to support the SCLAA infrastructure and to expand is highly dependent on our National Partners. We ask all our members to support our valued National Partners where they can.

For more than 30 years Optus has helped organisations of all sizes to transform their customer and employee experiences.Trusted by Australia’s largest enterprises and government departments, Optus helps businesses improve employee retention and engagement, boost

customer satisfaction and drive operational efficiency. With Optus as your partner, you can expect technology solutions curated to meet your business challenges, backed by unique mobile-led capabilities, a secure managed network and a best-in-class partner ecosystem.

Who doesn’t love a behind-the-scenes look at one of Queensland’s most critical logistics hubs?

This week, the Queensland division of the Supply Chain & Logistics Association of Australia (SCLAA) proudly hosted a sold-out Port of Brisbane tour, and what an incredible day it was!

Attendees were treated to an exclusive, guided exploration of the Port of Brisbane Pty Ltd’s worldclass facilities, thanks to the insightful and engaging commentary from James Wardle and Ed Harwood

A huge thank you to both for sharing their time, knowledge, and passion for the port’s operations.

Our members were captivated by the scale and sophistication of the port’s infrastructure—from the automation of container handling equipment to the

strategic navigation of large vessels through intricate canal systems. For many, it was a first-time opportunity to witness the inner workings of this vital logistics artery up close.

The Port of Brisbane plays a pivotal role in Queensland’s economic engine, handling millions of tonnes of cargo each year. Learning about its long-term developmental goals, future expansion plans, and the role of technology in optimising operations sparked some fascinating conversations among attendees.

Events like this are at the heart of what the SCLAA stands for—bringing professionals together to connect, learn, and grow through shared experiences and exclusive access to industry knowledge.

On June 19th, members gathered at The Incholm by Ode Hotels in Spring Hill for a well-attended and thought-provoking evening focused on the challenges and opportunities facing our industry. Attendees heard from Natalie Wallace, SCLAA Vice Chair and Chief Growth Officer at Netlogix, alongside Chris Josey, SCLAA QLD Vice President and Regional Head ANZ for Falcon Autotech.

The conversation ranged from macroeconomic influences to emerging technologies, with candid insights into the skills and capabilities organisations will need to stay competitive. The event provided a valuable platform for dialogue and connection among supply chain professionals across the region.

On June 19th, SCLAA QLD committee members Natalie Wallace, Monica Vorhauser, and Chris Josey joined over 350 business and community leaders in Brisbane for the 2025 Vinnies CEO Sleepout.

This powerful and humbling evening offered firsthand insight into the experiences of people facing homelessness. Through simulations and storytelling, it became clear that access to stable housing is the most critical lever to break the cycle—yet demand continues to far outweigh supply.

Vinnies has committed to building 500 homes over the next five years in Queensland, with construction already underway at one site and two more scheduled to break ground this year. We encourage our members to consider joining the Sleepout next year as we continue supporting this important cause.

The experience is not only a fundraiser—it’s a stark reminder that homelessness can happen to anyone, and that we all have a role to play in driving change.

Site Visit: Tuff Trailers - from steel to screenFriday, 18 July

Join SCLAA members for an exclusive behind-thescenes tour of Tuff Trailers, a leader in Australia’s heavy fabrication and logistics manufacturing sector. Since 1995, this family-owned Crestmead-based business has been engineering trailers tough enough for the country’s harshest conditions—from low loaders and tilt decks to wideners and road trains.

This is a rare opportunity to see how digital tools and lean practices are transforming traditional manufacturing environments from the ground up. Don’t miss it! BOOK NOW

22nd - 24th July 2025

– Congratulations to Monica Vorhauser & hubby Josh & dishlicker “Daisy” on the purchase of their new home.

– Congratulations to Chris Josey & wife Joanne on their 27th Wedding Anniversary

– Ozan Anilan – we miss you, come home soon.

– George Hodgson is participating in the 2025 Mystery Box Rally to be held in August to raise funds for Cancer Council. A wonderful cause –for more information please visit https://www. mysteryboxrally.com.au/

Monica Vorhauser

QLD Division President monica.vorhauser@sclaa.com.au

When you choose the Logistics and Supply Chain major in the Bachelor of Business at RMIT University, you’ll develop in-depth knowledge and skills in contemporary issues central to the logistics and supply chain management industry.

Tailor your learning

Undertake in-depth study in Logistics and Supply Chain, complemented with a choice from 14 majors and 32 minor areas

Industry informed Partner with industry as part of your studies and get a head start on your career.

Prepare for future success

Demand for logistics and supply chain professionals is expected to grow 30% over the next decade.*

supply chain and logistics management department of university in Australia.

Procurement specialist

Logistics manager

Supply chain analyst

Logistics planner

Warehouse manager

Chief operations officer

Supply chain executive

*Source: U S Bureau of Labor Statistics

Scan to learn more about the Logistics and Supply Chain major

In mid-May, Sam Craddock, now State Manager at Fremantle Freight & Storage, but previously a key driving force behind Silk Contract Logistics’ impressive new Kenwick facility hosted an SCLAA WA visit the site, to see an outstanding showcase of sustainability in action.

Attendees at the fully subscribed event were given a firsthand look at one of the few warehouses in Australia to earn the prestigious Green Star certification.

Recently winning MHD magazine’s Sustainable Warehouse Mercury award ahead of some highly

credentialed competitors, and spanning 24,000sqm, with a container-rated hardstand and sizeable canopy, the site features over 33,000 pallet spaces and is situated in close proximity to a new rail head.

Sam shared valuable insights into the building; the momentum that COVID-impacted supply chain issues gave to its evolution; it’s lithium battery powered MHE fleet, and how staff wellbeing was a key consideration throughout the design.

All present thoroughly enjoyed the event, evidenced by the lively post tour Q&A and networking.

Later in the month we were pleased to greet AutogenAI, an SCLAA National Partner, who hosted an evening entitled ‘AI, Networking and the Future of Supply Chain’. At this informal gathering our members and contacts were able to explore how AI is transforming the way businesses respond to tenders and RFPs; cutting response times, improving win rates, and reshaping the future of procurement and logistics.

With the 2025 Mentoring Program about to start, SCLAA WA is proud to announce that mentee registrations have already reached double figures. Exciting times are ahead as Dan Green, the WA Mentoring Lead, coordinates what is always an extremely rewarding event for all involved.

Brian Lynn

Nearly five million MC9000 Series ultra-rugged mobile computers have streamlined processes in ports and yards, manufacturing, warehousing and retail. With every

From May 21st to 22nd, the ICC Sydney once again became the vibrant hub for professionals across the supply chain and logistics sector as we gathered for the 3rd Supply Chain Week. Despite the rain, the enthusiasm and energy were unstoppable - proving once again that passion for supply chain excellence never takes a day off.

The event brought together an impressive turnout of professionals, creating an engaging environment where ideas, experiences, and perspectives were actively exchanged over meaningful conversations, accompanied by excellent food and beverages. More than just a conference, it was a platform where the industry’s thought leaders, practitioners, and innovators came together to share insights that will shape the future of our field.

One of the standout aspects of this year’s Supply Chain Week was the diverse and comprehensive range of topics covered. The sessions spanned critical areas such as strategic supply chain management, ESG and sustainability practices, building resilience across global networks, people development, and integrated business planning. Each session offered unique insights and practical knowledge that attendees could take back to their organisations.

A particular highlight was the growing focus on artificial intelligence and its transformative potential within supply chains. The discussions explored not just the emerging applications of AI but also how technologies such as robotics, digital twins, and advanced analytics are rapidly redefining how we plan, execute, and optimise logistics operations. The combination of technology and human expertise showcased throughout the event truly reflected where the future of supply chain is headed.

We also want to extend our special thanks to our dedicated SCLAA NSW committee members - Alice Brimicombe, Michael Farragher, Cathy-Anne Jones, Riaz Haque, Rae Su, Drew Mckinnel and Hans Tobbe -

for their time, energy, and effort. Their support ensured that SCLAA was well-represented throughout the entire event, delivering a professional presence that reflected the values and capabilities of our association.

To everyone who stopped by to say hello - thank you! And to those who are just getting to know SCLAA: we encourage you to stay connected. We are committed to continuing to bring valuable activities, events, and learning opportunities to the supply chain community.

SKUTOPIA hosted a site tour for SCLAA in mid-June, providing insights into how a smart combination of advanced software and hardware made a difference for their customers as a 3PL in the heart of Sydney. Attendees ranged from members to non-members, industry users to consultants. A special thank you to Talea Bader, the founder of SKUTopia, for presenting and hosting the tour.

Events as such are not just educational, showcasing high industry standards of technology, but also attract new interest from people new to the industry and talents outside the supply chain wanting to explore new opportunities in SCLAA. This is truly encouraging as we expand the horizons of many into this fast-changing world of logistics.

Thank you to Jason Wu and Julian B for organizing and coordinating the site tour.

What’s Coming Up at SCLAA NSW?

As always, there’s plenty more on the horizon! Here’s a snapshot of what’s ahead:

Joint event of recruiting and Mentoring Program Launch (July): Our annual mentoring program officially kicks off in July, offering members the opportunity to learn from experienced leaders and build valuable industry relationships that support professional growth. https://www.sclaa.com.au/wa-event/future-proof-yourcareer-trends-talent-transformation-in-supply-chainand-logistics/

CeMAT Exhibition (July): We will once again be present at CeMAT Australia, the country’s largest logistics and supply chain exhibition. Visit our booth to discover the latest industry trends and learn more about SCLAA’s activities and membership benefits.

Taco Tuesday Networking (July): Our popular Taco Tuesday networking event returns, providing a relaxed and enjoyable environment to meet fellow professionals and grow your connections across the supply chain community.

PetBarn Site Tour (August): Take part in our upcoming PetBarn site tour to explore supply chain solutions in practice. See firsthand how retail operations are optimising their fulfillment processes and technologies. Keep an eye on ‘Upcoming Events’ on the SCLAA website.

Cybersecurity Webinar (August): As cybersecurity grows increasingly important, our expert-led webinar will cover emerging risks and provide practical guidance on how to strengthen your organisation’s cyber resilience.

Rae Su NSW/ACT Division Committee irene.martinezgonzalez@sclaa.com.au

The team had the opportunity to visit Galipo Foods, hosted by Nathan Narayanan and Mann Barinder. We were inspired by their stories of growth, innovation, and unwavering commitment to customer satisfaction.

As a future focused company, Galipo were the first food distributor company to implement robotics technology within its distribution warehouse. Witnessing this innovation firsthand was a highlight of the visit, and a true testament to the company’s forward thinking approach.

With an extensive SKU range, the group observed the highly efficient voice to pick system, robotic automation, and in-house fleet management that power Galipo’s complex supply chain. It was a privilege to see such and iconic South Australian food distribution company in action.

DHL Supply Chain is a global contract logistics provider with operations in over 50 countries. They have a network of warehouse and distribution centres worldwide with 1,600 warehouses worldwide with over 17 million square meters of storage space.

Members have rare opportunity to see DHL’s Adelaide central warehouse to witness their process inventory management, state of the art sorting, digital innovation and smart warehousing.

Sara-Ann Dixon SA/NT State President Sara-Ann.Dixon@sclaa.com.au

Coming out of another solid IWD event, the team focussed on helping our partners with webinars and events.

The Beyond The Cab: Winning Driver Trust & Protecting All Road Users with Bestrane was super positive. Understanding how fleets adopt AI powered solutions with ever changing laws and regulations I think gives us insight in how AI will change how supply chain operates.

The SCP Virtual summit will be taking place on 14 July 2025. It is promising to be a huge event led by our own Stephen Lakey. The audience is APAC wide so make sure you tune in!

Solid number of registrations for this year’s mentoring program. Closing date was extended to June 22 due to the registrations coming in. We are planning for the formal launch in July 10 so keep an eye out. This is a unique opportunity to be partnered with a Supply Chain leader if you’re a mentee and a fantastic way to pass on what you’ve learned over the years as a supply chain leader in our region!

Our state End Of Financial Year event has been locked in. The venue will be Oxford – 427 Swanston St, Melbourne. Thankful to VStrong, a new SCLAA National member sponsoring this event. This is a great night to network, let your hair down and celebrate the close to the financial year. Seems like it comes quicker every year!

Team is also driving the ASCL Awards in parallel. Keep an eye out for the special offer before month’s end!

Archival Garcia VIC/TAS Division President archival.garcia@sclaa.com.au

Renowned for his razor-sharp wit and effortless delivery, Jimeoin’s role as MC promises a fast-paced evening packed with off-the-cuff brilliance and perfectly timed punchlines.

From opening remarks to spontaneous one-liners, this won’t be your standard industry dinner. It’s the supply chain and logistics’ night of nights — with world-class comedy keeping things fresh, sharp, and unforgettable.

ASCLA 2025 held in Melbourne - Venue TBA

This is an opportunity to align your brand with excellence, innovation, and leadership. Showcase your organisation, strengthen brand awareness to industry leaders and be an Ambassador of Excellence by recognising the highest achievers in the supply chain and logistics Industry. Solidify your position as a champion of progress and innovation; a partner driving our industry forward.

Sponsorship inclusions and inclusion quantities vary between packages.

NOMINATIONS ARE OPEN FOR THE AUSTRALIAN SUPPLY CHAIN & LOGISTICS AWARDS

The annual ASCL Awards recognise the outstanding achievements of Supply Chain & Logistics professionals and organisations across Australia, celebrating industry excellence and championing collaboration, innovation, and success.

The ASCLA are the industry’s longest running and most prestigious awards. Join us in recognising and cheering on individuals and companies that have contributed to the advancement of the Supply Chain and Logistics industry in Australia, this November.

LEARN MORE NOMINATE BY 28 AUGUST

Showcase your organisation, strengthen brand awareness to industry leaders and be the Ambassador of Excellence by recognising its highest achievers by sponsoring an Award for only $5500 + GST.

ASCL INDUSTRY EXCELLENCE AWARD

Dedicated to Mike Munns, FAIMM Award Inaugurated 1987.

ASCL SUPPLY CHAIN MANAGEMENT AWARD

Dedicated to Doug Beattie Award Inaugurated 1984.

ASCL FUTURE LEADERS AWARD

Dedicated to Vince Aisthorpe Award inaugurated 2009.

ASCL AUTOMATION, ROBOTICS OR EMERGING TECHNOLOGY AWARD

Award Inaugurated 2021.

ASCL TRAINING, EDUCATION & DEVELOPMENT AWARD

Dedicated to the late Professor Peter Gilmour Award Inaugurated 2002.

ASCL INTERNATIONAL SUPPLY CHAIN AWARD

Award inaugurated 2016.

ASCL ENVIRONMENTAL EXCELLENCE AWARD

Dedicated to Mr Ken Pike, Award Inaugurated 1966.

ASCL BIG DATA, IT & BUSINESS INTELLIGENCE (BI) AWARD

Award inaugurated 2021.

ASCL START-UP AWARD

Award inaugurated 2021.

ASCL WORKPLACE HEALTH AND SAFETY AWARD

Award inaugurated 2024.

ASCL TRANSPORT LOGISTICS EXCELLENCE AWARD

Award inaugurated 2024.

VIEW AWARD CRITERIA SUBMISSIONS

Don’t Miss out!

2 MONTHS TO NOMINATE! SUBMISSIONS CLOSE

AUGUST 2025

Why settle for one membership when you can unlock double the value? As an SCLAA member, you now receive a complimentary Supply Chain Partners membership — giving you two powerful networks for the price of one. Stay connected with Australia’s largest community of supply chain professionals and gain exclusive access to global insights, resources, and collaboration opportunities through Supply Chain Partners.

ONLINE COMMUNITY PLATFORM

COMPREHENSIVE MEMBER DIRECTORY

Effortlessly look up and directly connect with other expert members, industry experts, and potential business opportunities. Strengthen your network and grow your business within the industry.

PROFESSIONAL BUSINESS STOREFRONT/ MEMBER PROFILE

Set up a professional member profile and/or business storefront with links to your products, services, articles, videos, case studies, events and more.

DEDICATED SUPPLY CHAIN & LOGISTICS JOBS BOARD

Post job vacancies or that you are open for work to a highly engaged and qualified supply chain audience. This platform is designed to help attract top talent in our industry, streamlining recruitment and job search processes, ensuring the right job opportunities reach the right professionals in the industry.

ENHANCED COLLABORATION

Participate in forums, discussions, and events to exchange knowledge, share experiences, and collaborate with like-minded professionals.

If you haven’t activated your complimentary membership yet, now’s the time to unlock more value out of your SCLAA membership.

GET YOUR CODE

The 2025 Supply Chain Partners Virtual Summit is here to reignite the global conversation on supply chain excellence, transformation, and resilience.

This July, the most prominent online summit for B2B business and supply chain professionals returns with more insights, more experts, and more global connections than ever before. With rising tariffs, regional conflicts, and the imperative for digital transformation, supply chain leaders must be equipped with the latest strategies and tools to build resilience and drive growth.

Join us to gain actionable insights from industry experts, connect with a global network of professionals, and position your organisation at the forefront of supply chain innovation. Don’t miss this opportunity to future-proof your operations and lead with confidence in an era of unprecedented change.

1 WEEK TO GO! In partnership with: 9 JULY 2025 10:00 AM - 4:15 PM AEST

15 Speakers | Speed Networking | Free Event NOT AN EVENT TO BE MISSED | REGISTER NOW

Successful deployment of autonomous sortation robots by New Zealand logistics specialist enables rapid ROI, staffing stability and new client acquisition across apparel and footwear sectors

DSL Logistics, one of New Zealand’s fastest-growing third-party logistics providers, has achieved a 30% improvement in processing efficiency following the deployment of Infios’ AutoSort Mobile robotics at its Auckland distribution centre. The successful implementation was completed in time for peak season and is expected to deliver a full return on investment within 4 years.

The automation initiative has strengthened DSL’s position as the country’s leading 3PL for apparel and footwear brands. DSL, which has doubled in size over the past five years, operates from six facilities in Auckland and serves a roster of clients including major fashion and sporting brands.

Faced with increasing labour shortages, wage pressures and surging eCommerce demand, DSL adopted Infios’ autonomous mobile robots to modernise its sortation process. The system utilises tabletop sortation robots that bring items to stationary staff at ergonomic sorting stations—eliminating time-consuming travel and streamlining throughput.

“Struggling with attendance, reliability and rising wage costs meant we needed to innovate beyond traditional manual processes,” said Aaron Hobbs, Operations Director at DSL. “The fact that we pulled the trigger 18 months ago has put us a couple of years ahead of the competition. We’ve built the confidence and integration, and now we’re ready to automate more.”

Implemented in August 2024, the project was fasttracked to go live ahead of DSL’s busiest season. Its modular design has enabled the company to handle inventory for 40 different clients using one centralised solution, with items shuttled from five warehouse sites into the robotic sortation system.

The robots have also enhanced DSL’s flexibility in managing returns and producing custom ratio packs— pre-configured product sets designed to match retailer-specific size and style allocations. “The system is remarkably intuitive—we can train new staff in just five minutes, which proved invaluable during the seasonal ramp-up,” Hobbs added.

DSL Logistics integrated the Infios robotics solution with its proprietary warehouse management system (WMS), creating a seamless, highly accurate process that has maintained near-perfect order fulfillment rates.

“DSL exemplifies how the right automation technology can overcome operational constraints while enabling business growth,” said Andrew Leslie, Head of AMR APAC at Infios. “This implementation showcases the adaptability of our autonomous mobile robots for 3PLs supporting complex, multi-client environments.”

Following the success of the sortation rollout, DSL plans to expand its automation journey by piloting additional Infios innovations, including 3D sortation modules and Layer Picker technology to further boost performance in its eCommerce fulfillment operations.

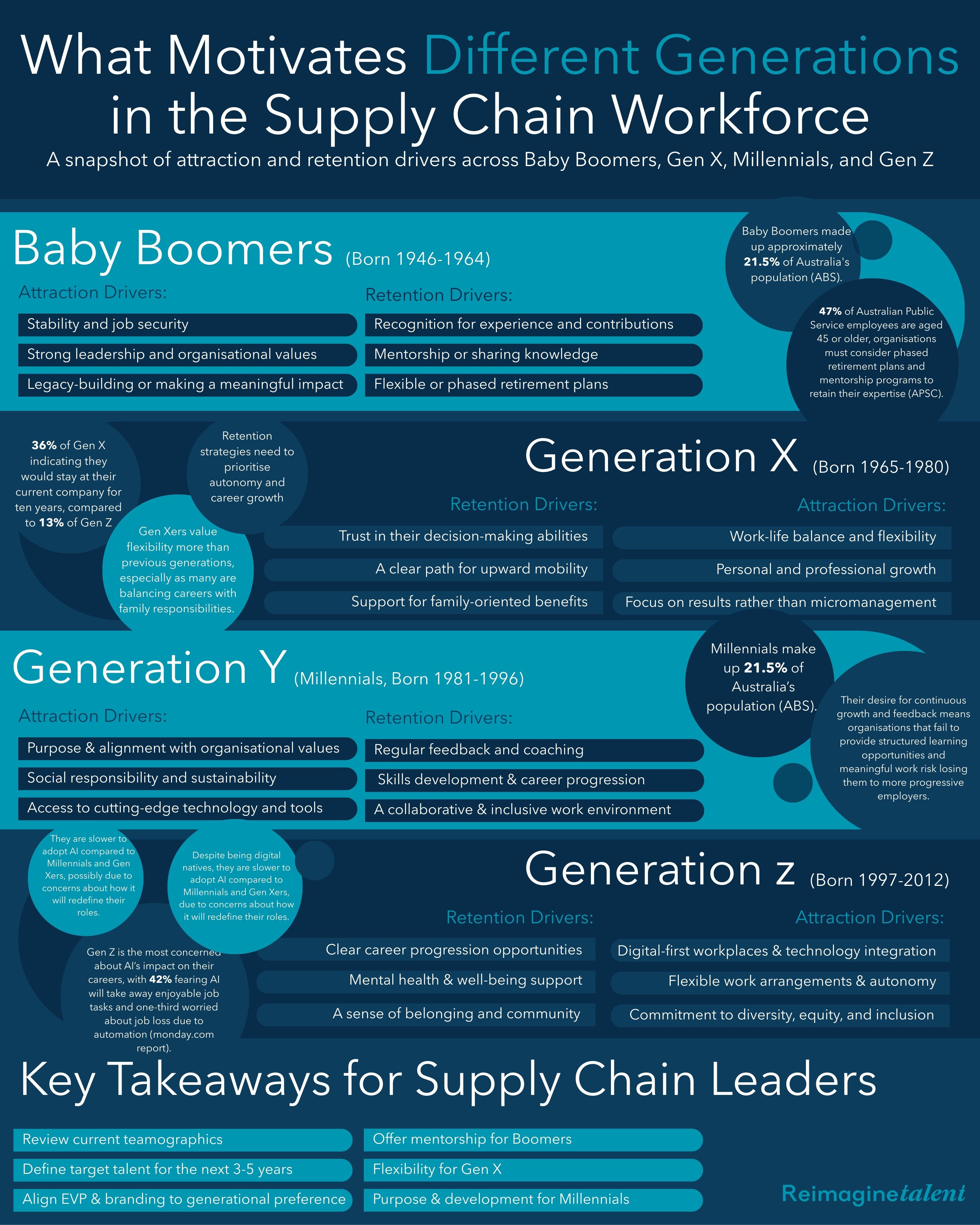

Attraction is the process of positioning your brand as an employer of choice within a specific market segment or the broader market. It involves creating a compelling value proposition that draws potential employees to your organisation. Factors influencing attraction include:

– Company Culture: The actual or perceived environment and values of the organisation.

– Salary and Benefits: Competitive remuneration packages that meet market standards.

– Work-from-Home Agreements and Flexibility: Options for remote work or flexible hours.

– Career Opportunities: Clear pathways for advancement within the organisation.

– Learning and Development Opportunities: Support for skill-building and professional growth.

– Social Causes: A commitment to sustainability or other meaningful initiatives.

– Leadership Perception: The belief that the company has effective and inspiring leaders.

Retention, on the other hand, focuses on keeping employees engaged and committed over the long term. While attraction and retention often share common roots, the factors that initially draw someone to a company may evolve as they become part of the organisation.

Why Understanding Attraction and Retention Drivers Matters

Your success as an employer hinges on these two factors. Attracting and, more importantly, retaining top talent is essential for the sustained success of any business. High turnover can lead to increased costs, knowledge loss, and a negative impact on morale, whereas engaged employees drive productivity and innovation.

In Australia and globally, employees’ expectations about work and career progression are changing rapidly. A study by the Australian Public Service Commission highlights that employees across generations are seeking more flexibility, inclusive workplaces, and a greater sense of purpose. Traditional operating models are being challenged, and technological advances require rapid adaptation to the future of work.

Baby Boomers (Born 1946-1964)

Attraction Drivers:

– Stability and job security.

– Strong leadership and organisational values.

– Opportunities for legacy-building or making a meaningful impact.

Retention Drivers:

– Recognition for their experience and contributions.

– Opportunities for mentorship or sharing knowledge.

– Flexible retirement options or phased retirement plans.

As of 2021, Baby Boomers made up approximately 21.5% of Australia’s population (ABS). With an ageing workforce, where 47% of Australian Public Service employees are aged 45 or older, organisations must consider phased retirement plans and mentorship programs to retain their expertise (APSC).

Generation X (Born 1965-1980)

Attraction Drivers:

– Work-life balance and flexibility.

– Opportunities for personal and professional growth, including lateral project-based movements.

– A focus on results rather than micromanagement.

Retention Drivers:

– Autonomy and trust in their decision-making abilities.

– A clear path for upward mobility.

– Support for family-oriented benefits, such as childcare options.

Gen Xers value flexibility more than previous generations, especially as many are balancing careers with family responsibilities. With 36% of Gen X indicating they would stay at their current company for ten years, compared to just 13% of Gen Z, retention strategies need to prioritise autonomy and career growth (monday.com report).

Generation Y (Millennials, Born 1981-1996)

Attraction Drivers:

– A strong sense of purpose and alignment with organisational values.

– Emphasis on social responsibility and sustainability.

– Access to cutting-edge technology and tools.

Retention Drivers:

– Regular feedback and coaching.

– Opportunities for skill development and career progression.

– A collaborative and inclusive work environment. Millennials, like Baby Boomers, also make up 21.5% of Australia’s population (ABS). Their desire for continuous growth and feedback means organisations that fail to provide structured learning opportunities and meaningful work risk losing them to more progressive employers.

Generation Z (Born 1997-2012)

Attraction Drivers:

– Digital-first workplaces with seamless technology integration.

–

Flexible work arrangements and autonomy. –

A strong commitment to diversity, equity, and inclusion.

Retention Drivers:

– Clear career progression opportunities.

– Mental health and well-being support.

A sense of belonging and community.

Gen Z is the most concerned about AI’s impact on their careers, with 42% fearing AI will take away enjoyable job tasks and one-third worried about job loss due to automation (monday.com report). Despite being digital natives, they are slower to adopt AI compared to Millennials and Gen Xers, possibly due to concerns about how it will redefine their roles. With Gen Z accounting for 18% of Australia’s population, understanding their concerns about job security and progression is crucial for long-term retention (ABS).

More than half of businesses across the UK, US, Canada, Germany, and Australia now employ three or more generations simultaneously (ABC). This diversity can be an asset when managed effectively, but it also poses challenges, particularly in aligning expectations and communication styles. Employers must tailor their attraction and retention strategies to each generation’s unique priorities, ensuring an engaged and motivated workforce.

As a Supply Chain Leader, it is crucial to first review your current team demographics and assess whether the company is effectively addressing the key retention drivers. If not, internal discussions should be held to determine how these can be improved.

Attraction and retention strategies must evolve with the workforce. Organisations that understand generational preferences and invest in tailored initiatives—such as mentorship programs for Baby Boomers, flexibility for Gen X, purpose-driven work for Millennials, and AI training for Gen Z—will be best positioned for long-term success. The future of work is multigenerational, and companies that embrace this reality will thrive in an ever-changing business landscape.

I would argue that you need to understand where you are currently and who your audience is now, as well as who you want your audience to be in 3-5 years. Will you be targeting Gen Z and beyond, or will you recruit the skills of more senior professionals from Gen Y? Knowing and understanding both the current state and future state of your workforce is critical to positioning your company with the essential workforce skills needed not only to survive but to thrive. For talent attraction, understanding your target talent market will allow you to strategically position your Talent Acquisition efforts and refine your brand messaging to effectively engage your audience.

West, Founder & Principal, Reimagine Talent

In this series of articles, Argon and Co shares our insights into the future of supply chain planning. In part one, we looked at the overarching themes. In part two, we explore the future of the planning role itself and the evolution of the supply chain orchestrator.

If you ask about the future of supply chain, the answer is likely to revolve around technology – but the most significant change is not the tools themselves—it’s the shift in roles, skills, and culture that teams must undergo. As companies move towards more integrated, data-driven supply chains, the traditional role of the planner is evolving into that of a supply chain orchestrator. Systems are simply the enabler for this transformation.

The previous article highlighted the increasing need for agility and the expanding scope in future supply chains. For teams to manage the speed and breadth required, we must challenge existing operating models and roles and understand how we can drive value more effectively with the tools we have available.

The traditional supply chain planning role

Historically, supply chain planners have been the backbone of operations, focused on demand forecasting, inventory management, and coordinating manufacturing schedules. Their work was largely siloed, with each function of the supply chain—sales, procurement, manufacturing, logistics—managed independently. This separation was effective when supply chains were simpler, demand was predictable, and external disruptions were minimal.

However, today’s supply chains are far more complex, globalized, and susceptible to disruptions, which means that this fragmented approach is no longer sufficient. To thrive in this environment, businesses must embrace end-to-end coordination and cross-functional integration—a shift that is redefining the traditional role of supply chain planners.

Supply chain orchestrators and the operating model

The evolution from supply chain planner to orchestrator reflects the need for a more holistic approach to managing supply chains. Orchestrators go beyond just planning for demand or managing inventory and then handing off responsibilities to the next person in the chain; they are responsible for integrating and synchronizing every aspect of the supply chain, from procurement to manufacturing to delivery. They ensure that all parts of the supply chain work together seamlessly, creating a system that is agile, efficient, and resilient.

This shift is enabled by advanced technologies—such as AI, real-time data analytics, control towers and IoT— that provide orchestrators with the real-time insights and visibility needed to make informed decisions faster. However, while technology plays a vital role, it is not the limiting factor. The biggest challenges are human-centric: organizations must cultivate the right skills, foster collaboration across departments, and build a culture that embraces this new approach.

The change enables and requires a rethink of the operating model design. The operating model may need to evolve several times as technical and human capability builds. Supply chain orchestrators need a broad perspective to influence the entire supply chain, but in some businesses this role will be an evolution of the end-to-end planner role; in others, it may sit above or to the side of the more traditional planning teams initially, until the full change enables much of the transactional work to disappear.

While the technology supporting supply chain orchestration is rapidly advancing, the most significant barriers to this transformation are people capability and culture. As businesses seek to move from traditional planners to orchestrators, they must confront the need for:

1. New skills and expertise: The orchestrator role requires a diverse set of skills that go beyond what traditional supply chain planners are used to. Orchestrators must understand cause and effect in every part of the end-to-end supply chain, be adept at data science and analysis, possess strategic thinking, and manage cross-functional teams. They need to be comfortable working with emerging technologies such as AI and machine learning, but also have the leadership skills to foster collaboration across multiple functions.

Developing these capabilities requires significant investment in training and upskilling. The role of an orchestrator is more strategic and requires professionals who are not only operationally proficient but can also see the bigger picture, anticipate disruptions, and make decisions that benefit the entire supply chain ecosystem.

2. Cross-functional collaboration: Orchestration demands planners work across multiple functions, including procurement, manufacturing, logistics, sales, and finance. Traditional silos between these

departments must be broken down to ensure that all teams work towards common goals. This requires a cultural and operating model shift—departments that previously operated independently now need to integrate data, align their objectives, and collaborate in real-time.

Creating a culture of collaboration is not easy. It requires leadership to actively promote open communication, trust, and shared accountability across the organization and relies on an updated supply chain operating model. Without this cultural foundation, even the best technology and planning systems will fail to deliver the full benefits of orchestration.

3. Strategic leadership and decision-making: Unlike traditional planners who focused on short-term, operational tasks, orchestrators must be strategic leaders. They are responsible for making high-level deci-

sions that impact the entire supply chain, balancing efficiency, cost, sustainability, and resilience. This requires a shift in capabilities and mindset—from focusing solely on immediate concerns like manufacturing schedules or inventory levels to thinking about long-term goals such as sustainability, risk management, and customer satisfaction.

Strategic decision-making is often hampered by a lack of coordination between departments or outdated mindsets that prioritize short-term gains over longterm benefits. Orchestrators must challenge this way of thinking, encouraging a more forward-looking and holistic approach to supply chain management.

Read the rest of the article online here: https://www.argonandco.com/en/news-insights/articles/the-future-ofsupply-chain-planning-series-part-2-from-planner-toorchestrator/

As global supply chains grow more complex and volatile, organisations in Australia are increasingly turning to artificial intelligence (AI) to future-proof their operations and remain competitive. A new IDC InfoBrief, sponsored by Blue Yonder, reveals that AI-powered orchestration is becoming central to how Australia and New Zealand (ANZ) businesses manage disruption, improve productivity, and meet rising customer expectations.

The IDC InfoBrief, titled AI-Driven Orchestration for the Modern Supply Chain, draws insights from 742 business leaders across the Asia-Pacific region. It paints a clear picture; AI is no longer a futuristic add-on — it’s a core capability that’s enabling real-time decision-making, greater visibility, and operational agility right across the supply chain.

According to the IDC InfoBrief, 99.5 percent of supply chain leaders across Asia-Pacific see visibility as a top priority, while 99.7 percent highlight the importance of agility. These capabilities are critical in today’s environment of frequent disruptions, from extreme weather events and geopolitical tensions to unexpected shifts in consumer demand.

AI is increasingly seen as the engine behind both. Through predictive analytics, AI can help businesses anticipate potential problems such as supplier delays or demand spikes. With this foresight, organisations can act faster and more strategically, whether that means rerouting shipments, adjusting stock levels, or reallocating resources.

“ANZ businesses are responding to a new era of supply chain complexity by leaning into AI-driven orchestration,” states Antonio Boccalandro, president for APAC at Blue Yonder. “They are building smarter, more connected ecosystems that can see, analyse, decide, and act in real time.”

The IDC InfoBrief also identifies other areas of growing AI adoption, including:

• Worker productivity: AI-driven tools are helping to schedule shifts, allocate tasks, and predict labour needs more accurately.

Procurement: Algorithms can assess supplier performance, manage risk, and suggest better sourcing strategies.

• Supply chain design: AI supports long-term planning by simulating different supply scenarios and modelling the impact of disruptions.

Australian company Silk Logistics is one example of how AI is being put into practice. By automating parts of its warehouse operations, Silk has improved service delivery and streamlined workflows - a model that many other Australian organisations are now looking to emulate.

At the heart of this shift is the idea of orchestration - integrating data, processes, and tools across departments and external partners. AI enables this orchestration by making it possible to unify fragmented systems, automate routine tasks, and optimise complex decision chains.

“Organisations across the region must adopt scalable AI solutions, cloud platforms, and collaborative ecosystems to future-proof their supply chains,” said Stephanie Krishnan, associate vice president at IDC Asia/Pacific. “Those who can unify their data and orchestrate their networks in real time will lead in performance, resilience, and innovation.”

While not highlighted directly in the IDC InfoBrief, agentic AI is reshaping supply chains by embedding intelligent decision-making into every layer of operations — from warehouse floors to delivery routes and network-wide coordination. In warehouse environments, the agentic AI can act as an assistant helping leaders respond dynamically to real-time changes. It intelligently reallocates labour as priorities shift, optimises layouts using predictive demand and supply insights, and identifies outbound risks early to prevent delays. It is also capable of streamlining highstakes activities like trailer docking and unloading, based on content urgency and staffing availability, all while proactively ensuring compliance with on-time, in-full (OTIF) targets. This enables greater agility, higher throughput, and more reliable service.

Working in tandem, advanced tools such as logistics operations agents can support the broader supply chain by monitoring conditions, suggesting smarter routing to avoid delivery disruptions, and automating scheduling changes to reduce delays and costs. Meanwhile, a network operations agents bring visibility across a company’s multi-enterprise networks, enabling realtime collaboration, predictive insights, and automated execution across supply, logistics, and fulfilment. These AI agents transform static supply chains into adaptive, self-optimising ecosystems.

The message from the IDC InfoBrief is clear: AI is no longer a nice-to-have. It is a strategic imperative for supply chains operating in a world of unpredictability. As ANZ organisations embrace AI-driven orchestration, they are setting the foundation for more agile, intelligent, and competitive supply networks.

Creating a safety-first culture isn’t about adding more safety posters or checking off compliance boxes, it’s about making safety part of every action and decision. For fleet operators, it’s about ensuring that safety is everyone’s responsibility, from the depot to the cab.

So, how do you build a safety-first culture that sticks? Here are five practical ways, with a focus on the people, processes, and technology that make it happen.

1. Build trust

Before you roll out the next training session or toolbox talk, take a step back. Does your team trust you? Trust is the foundation of any strong safety culture. Without trust, your team won’t feel comfortable reporting hazards or speaking up about safety concerns. Start with genuine conversations. Ask about their weekend, share your own stories, and take an interest in their lives. When you connect with your team on a personal level, safety discussions become much easier and more effective.

2. Listen to understand

When a driver raises a concern, your first job isn’t to fix it, it’s to understand it. Effective safety cultures are built on two-way conversations. That means truly listening, even when you don’t immediately agree. Ask questions, dig into the detail and show that their perspective matters. Taking the time to unpack concerns and explore the root cause builds trust and accountability. And when people feel heard, they’re far more likely to speak up again, which is exactly what you want in a safety-first environment. It builds buy-in, and that’s where continuous improvement starts.

3. Empower managers to lead safety

When managers actively lead on safety, it sends a clear message: safety isn’t optional, it’s expected. And because they’re closer to day-to-day operations, they’re in the best position to influence behaviour and drive engagement.

Encourage them to:

– Recognise and reward safe behaviour

– Nominate team members for peer recognition

– Run informal safety talks or share personal stories

– Host BBQs or casual lunches around safety and wellbeing themes

This kind of bottom-up engagement helps shift safety from something reactive to something people participate in and take ownership of.

4. Safety is everyone’s job

Safety doesn’t sit with one person or department; it’s a shared responsibility. From drivers and dispatchers to schedulers and senior managers, every decision made has a knock-on effect. The Chain of Responsibility (CoR) is more than a best practice; it’s a legal requirement under the Heavy Vehicle National Law (HVNL). It ensures that anyone who influences transport operations is held accountable for safety, not just the driver behind the wheel. That means everyone in your supply chain, from operations and logistics to executive leadership, has a role to play. When each team member understands how their actions impact others, accountability naturally follows. A collective effort leads to better safety culture and improved outcomes.

5. Empower teams with the right tools

Building a safety-first culture isn’t just about what people say or believe, it’s also about what they can see and do. The right technology gives both drivers and managers the visibility they need to act, build accountability and drive long-term behaviour change. Microlise offers a range of Safety, Health & Compliance solutions that can help transport operators make this happen:

– Driver Performance Reporting: With Fleet Driver Performance, track trends in speeding, harsh braking, idling, and more. Guide coaching and monitor progress over time for continuous improvement.

– AI Distraction Cameras: AI Distraction Cameras reduce risky behaviours like mobile phone use, fatigue, and unfastened seatbelts with real-time alerts and high-definition video reviews, supporting proactive safety management.

– Fleet Camera Systems: Fleet Camera Systems provide video evidence of incidents, helping improve driver accountability and safety awareness.

– Fatigue Compliance & Electronic Work Diary (EWD): Powered by Logmaster, this solution digitises driver work and rest data, streamlining safety monitoring and compliance with smart alerts and cloud-based record access.

– Incident Analysis: Capture detailed information before and during an incident with an in-vehicle recording device. The system records control functions four times a second for 30 seconds before and after an event, sending the data securely for analysis.

These tools don’t just gather data, they also create real change. With real-time feedback and a focus on continuous improvement, you build a proactive safety culture. Operators using these solutions, along with regular coaching and performance reviews, have seen ewer safety incidents, better fuel efficiency and more engaged drivers. When these solutions are built into onboarding and development, they support a culture where safety is owned by everyone and driven by data.

Building a safety-first culture goes beyond rules and regulations. It’s about trust, relationships, and consistency. When you combine this with the right tools and shared responsibility, you create lasting change.

Ready to take your fleet’s safety to the next level?

See how the right tools and processes can help strengthen your safety culture from the ground up. Find out more.

Do the new Fairwork and HR regulations make it feel like all too much?

Want a hand?

A Group Training Organisation is the best hand you will find, and with the newly announced GTO Reimbursement Program, partnering with Squad has never looked better.

Find out your eligibility and contact Squad for a free chat at www.squad.org.au/For-Business

Keeping freight on the move – and cash flowing – has been at the heart of more than two decades of success for Global Trade Logistics.

For a smaller freight-forwarding company to compete with international behemoths, Global Trade Logistics founder Gary Coutsoudis knows he and his team must out-perform.

That includes crucial factors, such as delivering exceptional customer service and playing it smart with financing. On the service front, he is proud of the culture the company has created – built around personalisation, flexibility and relationships – as it handles air and sea freight, customs clearances, warehousing and distribution services.

“From the smallest client to the big multinationals, they all want service. We’re very good at that and it’s something I’ve instilled in the staff from the very beginning,” says Gary, who leads the team of 15 at Global Trade Logistics (GTL), which has offices in Sydney and Brisbane servicing every port and location throughout Australia, as well as agents in Asia, Oceania, Europe and the United States.

The service-led approach has paid off. Operating for more than two decades as a family business, GTL has an enviable reputation across Australia, Asia, Europe and the US for transporting goods from food and wine to furniture, stone, tiles and marble products, oversized machinery, plus vehicles and automotive products.

One memorable instance demonstrates the benefit of great service for Gary. Many years ago, another freight forwarder opted out of an air-freight shipment for its client, a Hungarian based water-treatment company. So, GTL stepped up, did the job and impressed the client, securing its business.

“Unbeknown to me, they were just about to be bought out by a big multinational” Gary recalls. “That relationship has since grown from one small shipment into a multi-million-dollar client.”

GTL’s pledge is to ensure businesses safely and costeffectively navigate an increasingly dynamic trade environment. Being smaller and more agile helps. For example, having multiple independent agents in China is advantageous when setting freight rates. “We can pick and choose rates from different agents, whereas the big guys have to stick to rates set by their head office.”

Financing has been another vital area of focus for Gary since he set up the business in 1999, following a split from a previous long-term business partner.

After that upheaval, money was initially tight. Relying on a simple cheque account and not having property as collateral for bank financing, GTL was operating on a “shoestring” budget that restricted growth. “For the first three or four years, I just had to rebuild,” Gary recalls.

Key to the turnaround is the banking relationship he initiated with Westpac that’s become a 20+year partnership. “They’ve helped us all along the way with home loans and business facilities. They’ve been very, very supportive,” Gary says.

GTL’s biggest challenge in the early days was cash flow. Fortuitously, in 2008, Gary’s accountant recommended invoice finance – aka debtor finance – and it’s been a game-changer.

“I would highly recommend this facility to others,” Gary says. “If they’ve got a good client base, but their cash flow is tight, you just can’t beat it.”

How does it work? In essence, invoice finance is a flexible line of credit linked to and secured by outstanding accounts receivable. The Westpac facility allows businesses to use unpaid invoices to unlock up to 85%

of their value, boosting cash flow for operating expenses and growth opportunities – and it’s a tool that can grow with a business. The more invoices issued, the more funds that can be accessed.

Westpac also offers a 24/7 self-serve portal, enabling the business to upload invoices in seconds and draw down funds in minutes, which helps reduce paperwork and administration.

Today, GTL has a very large invoice finance facility with Westpac. This means GTL can confidently service its global partners and support global trade as goods are moved quickly and seamlessly. Gary says it has been crucial to GTL’s growth.

There’s no waiting for invoices to be paid. Gary explains that with a multinational client, one invoice alone could be worth hundreds of thousands of dollars.

“If you are operating just on an overdraft, you’ve got to wait 30-90 days to get that money.” However, with invoice finance, GTL gets 85% of the invoice up front, freeing up cash to service the client and funds to run the business.

“Just like an overdraft though, its crucial you stay on top of your collections,” he says.

It’s created cash flow for GTL to expand beyond traditional markets such as Australia and the US into fast-growing locations across Spain, Turkey and China, with the Asian powerhouse being a strong growth region.

With GTL performing well in multiple markets, Gary is confident of ongoing success.

The business’s experience and service ethic will hold it in good stead, he believes, and it’s in sound hands with son Christopher following in his footsteps, supported by GM Daniel Jovanovic, CFO Toufic Khoury and a fabulous team.

Invoice finance has also been key to the business’s expansion to date and Gary anticipates his long-term relationship with Westpac will ease any financing needs as the business seeks further growth, with hopes to open a Melbourne office soon.

The bank has also helped with mortgages to purchase several commercial properties. “They’ve been brilliant,” he concludes.

This information is general in nature and has been prepared without taking your personal objectives, circumstances and needs and into account. You should consider the appropriateness of the information to your own circumstances and, if necessary, seek appropriate professional advice. Consider the terms and conditions for the product before making any decision.

Inventory blowouts aren’t a warehouse problem. They’re a strategy problem.

When inventory issues persist, the problem isn’t stockit’s what happens upstream.

In supply chain management, persistent inventory blowouts rarely involve the stock itself. They’re a red flag. A signal that something deeper isn’t working, such as poor visibility, reactive planning, or disconnected decision-making.

Those signals get louder when businesses scale rapidly, as Bondi Sands did.

When organisations ask, “Why is our inventory still out of control?” they often look in the wrong place. The core issues typically lie upstream:

Manual, reactive demand planning processes

• Low forecast accuracy due to poor modelling

• Siloed systems and misaligned departments

• Data quality issues across ERP and spreadsheets

A lack of scenario planning and risk visibility

Until these fundamentals are fixed, any inventory ‘solution’ is just window dressing.

Bondi Sands, an Australian self-tanning brand, is distributed in over 45,000 stores worldwide, including physical stores in 14 countries and online stores in 95 countries.

Despite strong sales, they were held back by:

• Excel-driven forecasts and planning

• Lack of real-time visibility

• Frequent stockouts and planning gaps

An overburdened ERP system with manual order flows

Recognising these challenges, Bondi Sands partnered with DMS to conduct a complete supply chain transformation.

Together with DMS, Bondi Sands implemented a digital supply chain platform focusing on demand, inventory, and supply optimisation. This enabled them to:

Shift from manual to algorithm-driven forecasts

Establish a single source of truth across the business

• Integrate multiple internal and external data streams

• Drive real-time KPIs and smarter, more responsive decision-making

• Optimise stock placement using multi-echelon inventory optimisation

The impact was immediate and measurable:

• 37% reduction in days of inventory in just 8 months

• Transparent, real-time inventory visibility

• Smarter supply decisions tied to margin and profitability

• Alignment between sales, finance, and operations

• Voted a top three vendor for shelf availability by a major retail partner

“We created a slick and seamless integrated worldwide network that works smarter, not harder.”

– GM Global Operations, Bondi Sands

Inventory issues are not isolated - they’re symptoms of bigger problems.

If you’re still chasing inventory issues, it’s time to shift the conversation from stock to strategy.

Start here:

1. Benchmark your current planning capability – tools like the Supply Chain Maturity Score can help

2. Comprehensive supply chain maturity assessment - designed for organisations seeking complete alignment across people, process, data, and technology. Reach out to start the conversation

3. Align cross-functional teams - get sales, finance, and supply chain using the same assumptions

4. Focus on process and data before platform - technology supports change, but it won’t drive it alone

Bondi Sands didn’t just cut inventory; they realigned their entire planning process to enable scalable, data-driven growth.

If you still treat inventory as the problem, it’s time to look upstream.

Their transformation, recognised with the 2023 ASCLA International Supply Chain Award, proves that real change starts with strategy – not stock counts.

The future of supply chain isn’t about reacting faster – it’s about seeing further.

What’s holding yours back?

Consillion is a global, independent manufacturer and supplier of cash management solutions, including self-service devices, smart safes, cash counters, sorters, and software. Headquartered in Sydney, the company is designed to help businesses minimise costs and eliminate inefficiencies associated with handling cash.

“NetSuite’s made acquiring customers much easier because our responses to tenders and RFPs are now backed up by robust data.”

- Stephen Basford, General Manager of Software and Systems, Consillion

The B2B distributor, founded in 1984, started seeing significant growth several years ago after it earned the business of several large banks. This phase of growth saw the company expand its workforce by 60%, establish subsidiaries in Singapore and New Zealand, and acquire a dedicated manufacturing facility in the UK.

Consillion’s global expansion and success exposed the inadequacies of its old tech stack, which consisted of separate finance, inventory, and service management platforms. Manual reporting processes made it difficult and time-consuming to deliver the required data to clients in the heavily audited banking sector. Furthermore, sales reps had divergent processes and leaders had no visibility into sales cycles, leading to missed business opportunities.

The company brought together all business data in one system, simplifying financial and operational management across subsidiaries, with NetSuite OneWorld. Additionally, NetSuite CRM’s unified sales processes boost efficiency and deliver timely insights into pipelines and forecasts. Accessible and up-to-date data has also helped with strategic purchasing and supply chain management, reducing procurement lead times by 30%.

Consillion tracks every sales team interaction, from opportunity management to sales forecasting to order fulfillment, through NetSuite CRM’s sales force automation capabilities. This visibility has freed up time previously dedicated to administrative work so sales teams and leaders can focus on building relationships. Furthermore, NetSuite provides the data required to build more compelling tenders and RFP submissions, helping Consillion win new customers.

CTA:

Interested in learning more? Contact tania.large@oracle.com for exclusive SCLAA member offers

Are you aware that Australia is currently wasting an estimated $4.5 billion worth of unsold and returned goods every year?

That’s not a typo. That figure, uncovered in a recent report by Deloitte Access Economics and commissioned by Good360 Australia, lays bare the staggering cost of waste clogging our supply chains. The report highlights how the boom in e-commerce and no question returns is fuelling a silent crisis, one that is expensive, unsustainable, and entirely avoidable.

Good360 Australia is a not-for-profit organisation on a mission to repurpose surplus durable goods from furniture to clothing and hygiene products, by connecting businesses with their network of 5000 charities and high need schools across the country. Think of it as a logistics solution for good, transforming what was once a write-off into a win-win for business, people, and planet.

If you’re holding onto stock including clothing, personal care items, office supplies, toys, and homewares, that no longer serves a commercial purpose because it is obsolete, excess, seasonal or returned, Good360 can help you turn that problem into purpose.

We’re calling on supply chain professionals, procurement leads, and inventory managers:

Don’t let good products go to waste. Instead, redirect them to where they’re needed most.

- Read the full Deloitte report here

- Learn more at good360.org.au

- Contact Good360: 0450 063 778 / 02 85943600

Reach out to Vanessa Hood for

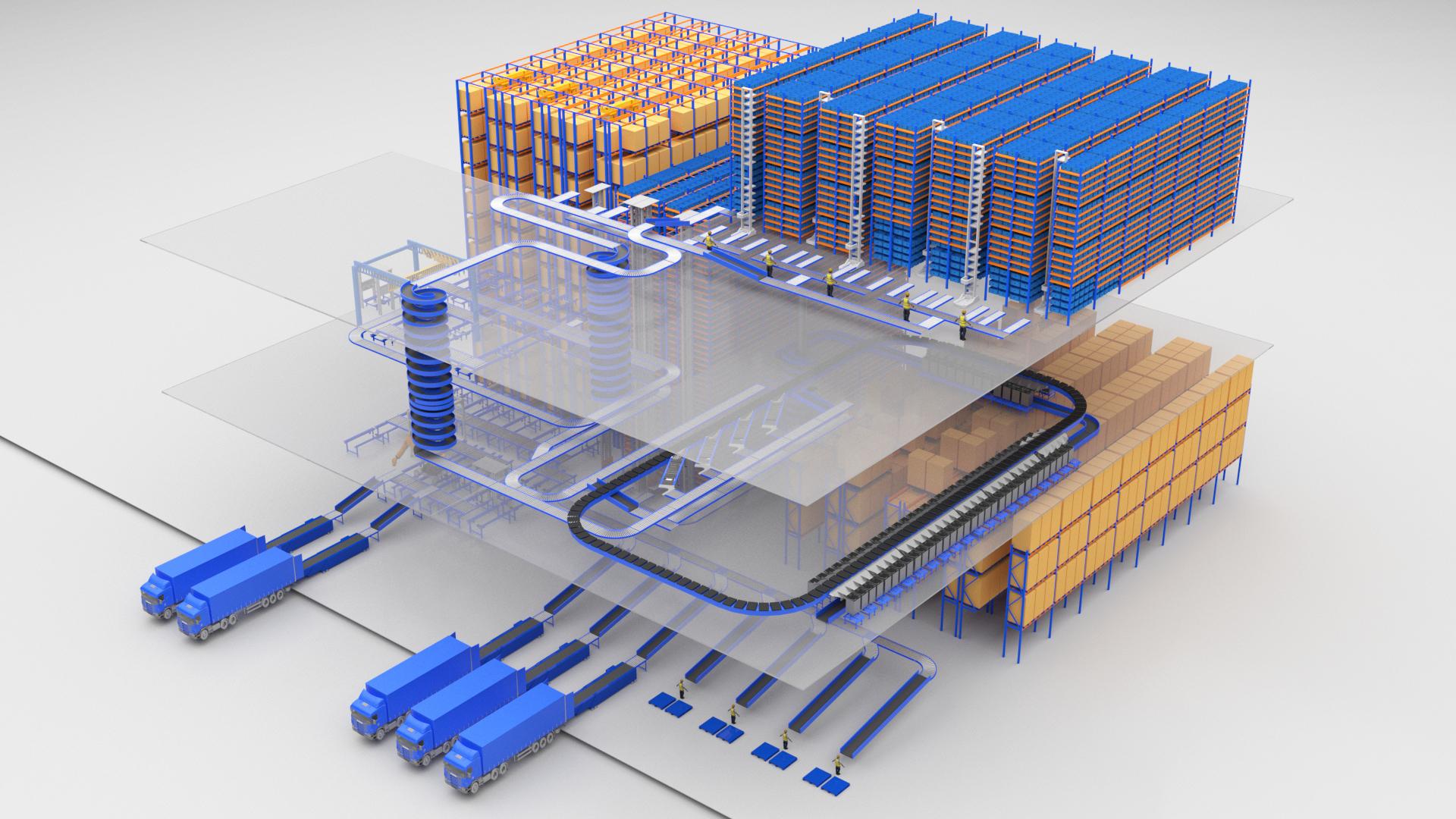

Swisslog will be displaying its end-to-end warehouse automation solutions as it exhibits at CeMAT this year in Sydney, July 22-24, at Stand A9.

This year, Swisslog will focus on its multi-temperature warehouse automation solutions, including ambient, chilled, and cold storage. With 250 deep freeze projects worldwide, Swisslog has a pedigree in cold storage solutions that are compliant, energy-efficient, and protect workers from harsh environments.

Keeping cool with cold storage solutions

“Low temperatures make refrigerated warehouses harsh environments, where it is recommended that humans should spend minimal time to avoid hypothermia and other health and safety risks,” says Swisslog Managing Director, Australia and New Zealand, Dan Ulmamei.

“An automated high-bay chilled warehouse can reduce the energy load by as much as 20% compared with conventional more labour-intensive alternatives,” he adds.

Technologies on display at CeMAT this year include:

– PowerStore pallet shuttle system for high density warehouses, designed to maximise space utilisation and throughput. The modularity of the PowerStore pallet shuttle system enables storage of up to 60% more pallets compared to manual systems. It can also be individually tailored for all shapes and sizes of warehouse buildings. –

AutoStore grid-based Automated Storage and Retrieval System (ASRS), for which Swisslog is one of the top integrators globally. AutoStore is a unique and simple solution that uses robots and bins to quickly process orders. It provides better use of available space than any other automated system thanks to its unique design that enables direct stacking of bins on top of each other and storage of multiple SKUs in a single bin. Over time, the system naturally learns which products have a higher rotation, storing them on the top layer to ensure faster picking times.

– SynQ software, Swisslog’s proprietary warehouse automation software which can perform the role of a Warehouse Management System (WMS), Warehouse Execution System (WES) and Warehouse Control System (WCS). SynQ provides total visualisation of the system in real-time, and allows for efficient and accurate troubleshooting, as well as optimising performance over time. It can, for example, position faster-moving products nearer the front of the storage system, for quicker access. Live demonstrations of SynQ software will be performed during CeMAT.

Experience automation in action at CeMAT

“We encourage logistics industry professionals at CeMAT to visit Swisslog at Stand A9 for live demonstrations that show how intelligent, end-to-end automation solutions can unlock greater warehouse efficiency, productivity, and sustainability,” says Ulmamei.

To speak to a Swisslog expert, or book in a site visit, please click here

The e-commerce boom isn’t slowing down any time soon, and heightened customer expectations are putting immense pressure on retailers and the supply chain to deliver more parcels faster than ever before.

20.1% of all retail purchases in 2024 are expected to take place online; with the global e-commerce market expected to total over $7.9 trillion by 2027 1 *

Today’s customers expect to receive or pick up their orders in record time, including same-day and two-hour windows. This expectation is blurring the line between warehouses and retail stores, with orders no longer being fulfilled from warehouses alone, but increasingly from the back of stores and micro-fulfilment centres located closer to customers.

Picking has also become a full-time job. To keep up with demand, workers must fulfil orders faster and faster, meaning the speed and accuracy of workflows have never been more important.

So, how are businesses coping with these ever-increasing demands? The answer is technology.

Warehouse and logistics leaders are always looking for ways to give their workers an instant productivity boost, process more orders, increase order accuracy, and meet the fastest delivery times, and one area seeing a huge investment is wearable technology.