HIGH PERFORMANCE MINERAL DRAG RACING OIL

Mineral based engine oil designed to enable maximum power while providing ultimate protection under the most severe race conditions.

• Unique friction modifier system enables maximum power output

• “Stay-in-place” chemistry and 2X Zinc anti-wear system provide lasting protection

• High quality base stocks enable effective ring seal

• Advanced, proprietary additive system keeps your engine clean

• Designed to prevent separation caused by fuel dilution

• Available in 50WT, 60WT & 70WT

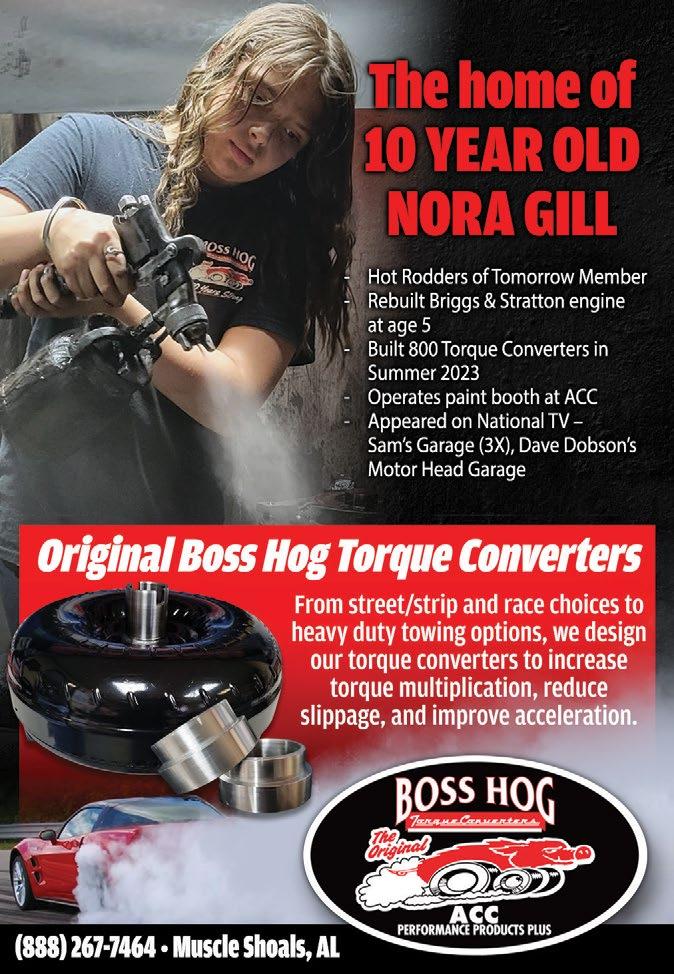

EDITOR-IN-CHIEF

CHRIS BIRO editor@rpmmag.com

V.P. MARKETING/CUSTOMER RELATIONS TRISH BIRO trish@rpmmag.com

EVENT MEDIA events@rpmmag.com

EVENT SUBSCRIPTIONS COORDINATOR SHERRIE WEBER sherrie@rpmmag.com

ART DIRECTOR .......................................................... JIM McHARG

Photographic Contributions: Mark - Godragracing.org, George Pich, Louis Fronkier, Blake Farnan, Jerry Garrison, Eddie Maloney, Wes Taylor, Steven Taylor and Amber Hynes

RPM Magazine is a REGISTERED TRADEMARK of Revolution Publishing & Media Inc. RPM Magazine is a worldwide motorsports publication distributed online.

To subscribe to RPM go to www.rpmmag.com or email Trish Biro at trish@rpmmag.com, or call 519752-3705.

The focus of RPM is to bring a diverse mix of high performance street and race automobiles to life within its pages including race cars, muscle cars, hot rods and street legal machines with an emphasis on the “EXTREME,” including fast doorslammer and outlaw forms of drag racing. Not familiar with these types of cars? They are considered to be the top-shelf of the industry and are on the edge with regard to design, performance, and power!

RPM Magazine does not sell its mailing list or share any of the confidential information regarding its subscribers.

Editorial Contributions:

Chuck Scott, Mark-Godragracing.org, Tim Biro, Stan Smith, George Pich, Jay Misener, Eddie Maloney, Wes Taylor, Steve Baur

Technical Writing Contribution: Chuck Scott, Shane Tecklenburg, Tim Biro and Jay Misener

For advertising information contact

TRISH BIRO ............... 519.752.3705 ................ trish@rpmmag.com

Special Events Manager: Chris Biro events@rpmmag.com

Special Events Sales: Trish Biro: 519-752-3705 trish@rpmmag.com

Subscriptions/Address Changes: Circulation circulation@rpmmag.com

General Inquiries: 519.752.3705 info@rpmmag.com

RPM Magazine has been a world leader in motorsports publishing for 26 Years and has support locations in Ontario, Canada, Alabama, Texas, and Virginia, along with contributing writers and photojournalists worldwide.

If you have a story that may fit within the focus and scope of RPM Magazine’s coverage, please email our Editor In Chief at editor@rpmmag.com. Submission of an article does not guarantee that it will be published.

Revolution Publishing & Media Inc. (RPM) / RPM Magazine IS NOT responsible for errors or omissions in ANY advertisement or article. Advertisements may be rearranged or altered at the sole discretion of RPM to allow the ad to fit in the space purchased by the advertiser.

WE RESERVE THE RIGHT TO REFUSE ANY ADVERTISING WHICH WE CONSIDER TO CONTAIN MISLEADING, OFFENSIVE OR FALSE INFORMATION. REPRODUCTION OF ANY INFORMATION HEREIN IS STRICTLY PROHIBITED WITHOUT PRIOR WRITTEN CONSENT.

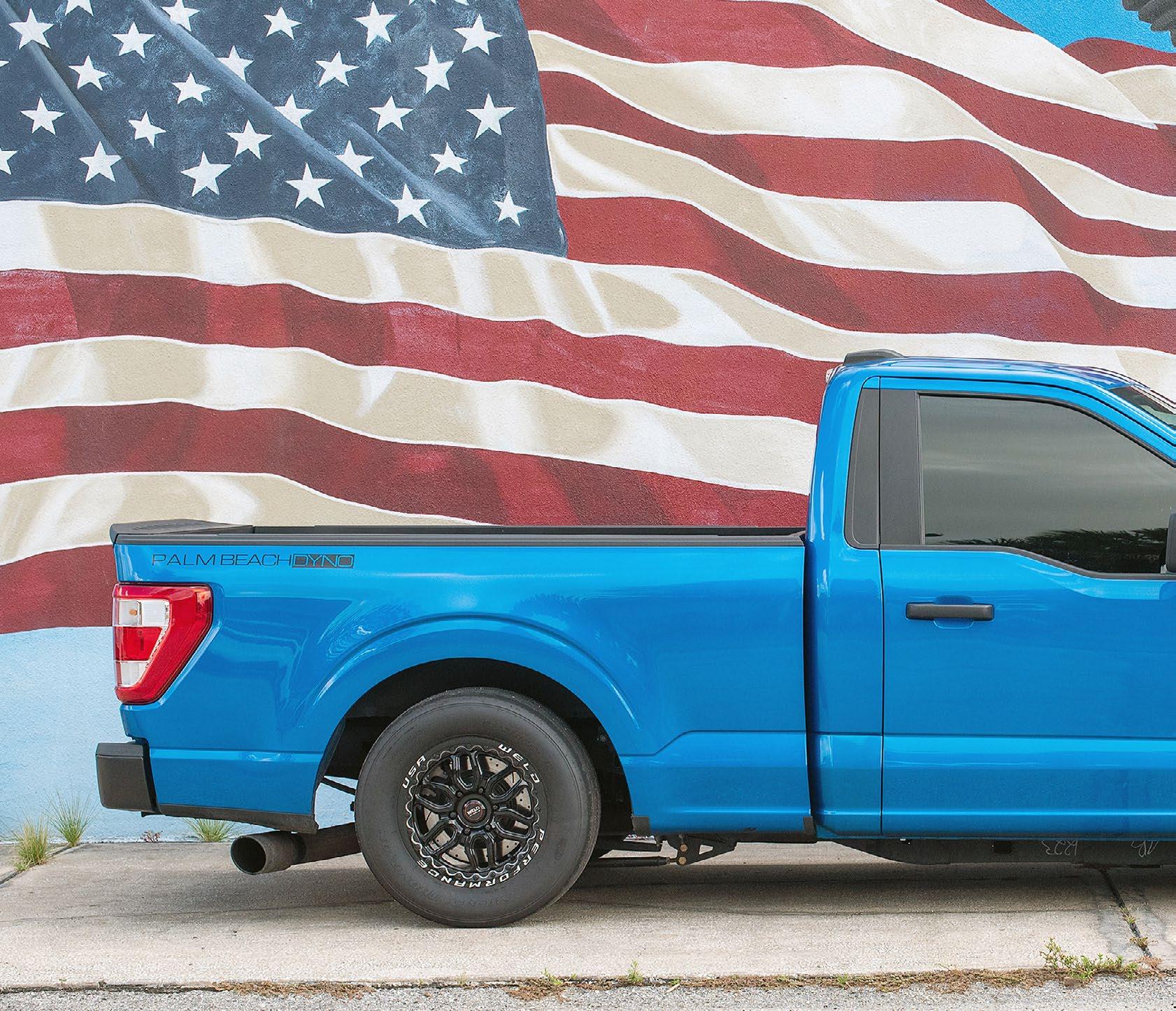

Along with building a highly modified, lightweight and crazy quick and fast car or truck, there’s the segment of the performance and drag race market that prefer very select modifications to a vehicle they really like. These folks want to maintain street drivability and creature comforts while extracting every single digit of horsepower out of their stock, or close to stock engine. Enter Florida’s Mike Marcoccia.

With a love for cars and trucks that started at the age of 16, Mike worked his tail off to save for his first car. “It was a 1992 Mustang GT and I began adding the usual bolt-ons,” he explained. “I would go and drag race with this car to the Orlando Speed World track and drive it home.” That first Mustang set in motion a chain of events that has included owning over 40 Mustang Fox Bodies over the years. “I currently have three

that I like to work on: an ’89 Vortech V3 GT, a ’91 Vortech V1 triple black convertible, and a 1991 Coupe currently under rebuild.”

From a truck standpoint, Mike isn’t stuck on just his regular cab short box 2 wheel drive F150. Included in his stable of Fords he also has a 2016 Hellion twin turbo F150 due to hit the street and strip in the next few weeks. But back to his daily driver.

In 2021 Mike ran across an ad on Craigslist for the truck. An older gentleman had driven it just 7,200 miles and when gas prices got high, he wanted to get out of a V8 truck. It was bone stock, with a barely broken-in Coyote 5.0L engine. Keep in mind, if you had said 25 years ago that a virtually stock engine in a heavy, well-optioned pickup truck

could run easy 9-second passes with bolt-on parts… you’d be called a witch and burned at the stake, but that’s exactly what Mike Marcoccia set out to do.

As you can imagine, there’s not much to tell about the truck aside from it being mostly stock with some suspension mods and, obviously, some witchery performed under the hood.

Ford Velocity Blue paint covers the factory body of the 2021 regular cab short box F150. A Cervini’s ram air hood was paint-matched and installed to help air flow under the hood, plus it looks killer. Ford Performance front fender vent trim was also added along with a Palm Beach Dyno decal on the box side.

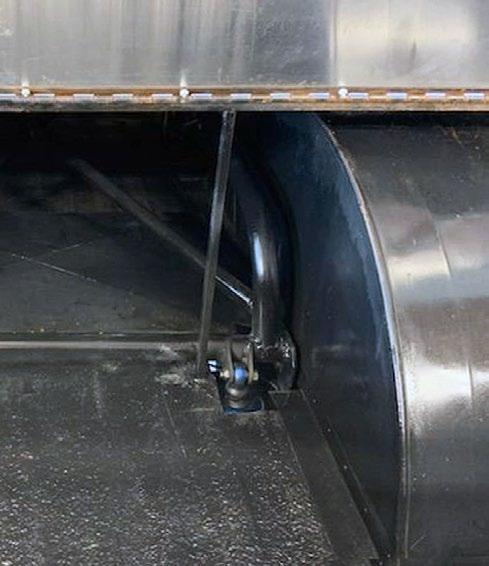

The trucks low stance is thanks to a VAS 3/5 drop kit with traction bars, Kelltrac shocks and coilovers.

Turn your LS into a legend in its own time with Trick Flow GenX® 280 HIP cylinder heads. These ultra-performance HIP’d (Hot Isostatic Pressed) castings are significantly stronger than regular heads, and include many other outstanding features such as:

• Industry-leading airflow

• 280cc CNC Competition Ported intake runners

• 87cc CNC Competition Ported exhaust runners

• Manley 2.165" Severe Duty intake/1.600" Inconel Extreme Duty exhaust valves

• Trick-Alloy™ powdered metal valve guides

• Trick Flow by PAC Racing dual valve springs

• Clearance for 3/8" pushrods

• .750" decks

• 6-bolt-per cylinder mounting

• LS3 rocker stands included with assembled heads

Track Max® Camshafts

Engineered for Performance! New heads are just one part of the Serious Horsepower formula. To complete it, you’ll need some more components.

• Dyno proven to significantly increase power

• Made from premium billet steel blanks

• Available in several hydraulic roller designs up to 230°/238° duration and .625"/.625" of lift

R-Series Intake Manifolds for GM LS3

• Bring carbureted-style aspiration to LS3-style engines

• 3,500-7,500-plus RPM range

• Available in carbureted and carb-style EFI versions

Variable Valve Timing Delete Kits

• Removes VVT so your engine makes big power with aftermarket parts

• Available with 1- and 3-bolt cam gears

• Includes cam/crank timing gears; timing chain and damper; LS2/LS3 timing cover with bolts, seal, and gasket; cam sensor, harness, and bracket; water pump gaskets; and cam, cam sensor, and balancer bolts

Each month we host some of our past issues of RPM Magazine in this section. If you haven’t read them yet, they are new to you! If you have, maybe there’s a favourite car/story you want to read again….here they are!

CLICK A COVER OR SCAN A QR CODE TO GO BACK IN TIME!

Body wise, it’s all factory panels with the exception of a Cervini’s ram air hood which Mike had painted to match the factory Ford Velocity Blue paint.

Ditto for the interior; all factory.

You might, however, notice

the F150 sits a bit different from factory and that’s because Marcoccia installed a VAS 3/5 drop kit along with Kelltrac shocks and coilovers with traction bars out back to get the required hook once the power level was increased.

We agree, it looks factory stock! Whipple designed the Gen5 Stage 2 3.0 Liter blower to fit under a stock hood and look factory, so that’s why it does. But make no mistake, this monster brings the factory horsepower to the neighborhood of 775 and toque up to 685 ft-lbs! And, as they say, the proof is in the pudding, as Mike has those 9-second time slips to prove it.

Body & Paint:

Factory body, 2021 Velocity Blue with Cervini’s ram air hood.

Chassis Modifications:

No chassis mods.

Suspension (Front & Rear):

VAS 3/5 drop kit with traction bars, Kelltrac shocks & coilovers.

Engine:

Stock

Rotating Assembly: Stock.

Cylinder Heads: Stock.

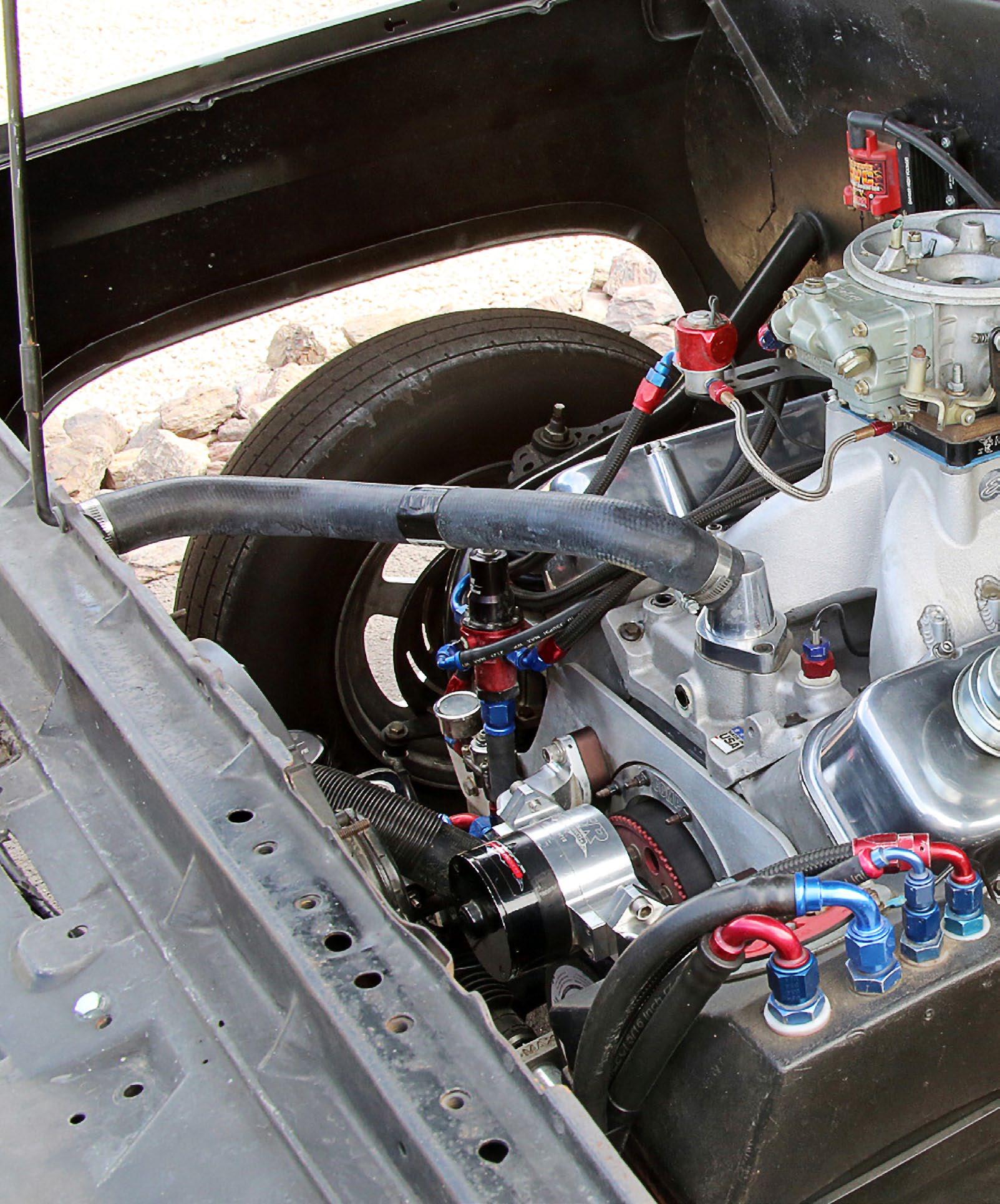

Induction & Fuel Delivery:

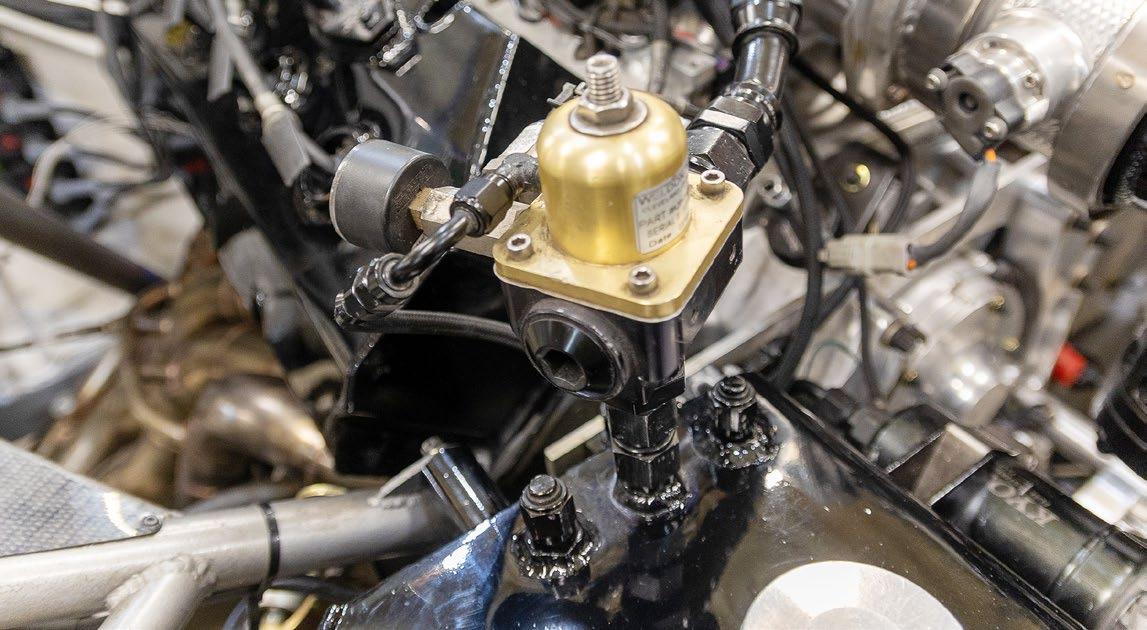

Fore fuel system with dual pumps, 1050 injectors.

Power Adder:

Whipple gen5 stage 2 with 3.25 pulley

Transmission:

RSA Stage 2 build 10R80 transmission with Circle D converter.

Rear End:

Yukon LSD with 3.31 gears.

Brakes:

TBM XS3 brakes.

Tires & Wheels:

315/50/17 Mickey Thompson Street Radials on 17x10 Weld Laguna Beadlocks on the rear and Toyo Proxes ST III 235/65/17 17x7 Weld Lagunas up front.

Interior:

Stock.

ET & MPH:

Best of 9.78 at 144 MPH in the ¼-mile.

Most Memorable Experience(s):

2024 Mod Nationals win in True Street 10 second class in Bradenton.

2025 Spring Break Shootout win in True Street class at South Georgia Motorsports Park.

Most Unique Feature(s):

I would say I’ve yet to see or hear of a 2021 stock engine Whipple F150 2wd run quicker than my 9.78.

Thanks To:

Palm Beach Dyno team and Ken Bjornes on the tuning.

Now for the fun stuff.

Mike installed a Whipple Gen5 Stage 2 twinscrew 3.0 Liter blower with 3.25 pulley. The blower comes equipped with an integrated intercooler and the kit is designed to fit

under a stock hood, but Mike added the Ram Air hood to increase air flow. Although there’s no dyno sheets available, the blower is advertised to push your stock F150 Coyote up over 775 street-legal horsepower

Insidethetruckitis completelyfactoryandit looksandsmellslikenew!

Purchased in 2021 with the odometer reading 7,200 miles, Mike now has close to 15,000 miles on the truck, many of them ¼-mile hit at a time!

at the flywheel. And since the truck does run 9.70s in the quarter, we’d say that’s pretty accurate. Now you can’t just bolt on a beast like this and go racing or you will be throwing parts into the cow pasture. To go along

with the blower, Mike also installed a Fore fuel system with dual pumps and 1050 injectors to provide adequate amounts of high octane fuel to the now muscular mill, but he didn’t stop there.

Along with the suspension parts, Mike beefed up the factory rear differential with a Yukon posi unit and 3.31 gears

17x7 Lagunas are installed up front with Toyo Proxes ST III 235/65/17 tires.

Weld Laguna 17x10 wheels with beadlocked 315/50/17 Mickey Thompson Street Radials reside on the rear of the truck. Looking from the side, you can see that the upsized rear meats sit just flush with the outer edge of the rear wheelwell.

An RSA Stage 2 10R80 transmission with Circle D converter was bolted in place behind the Coyote and the 8.8 rear end was beefed up with a Yukon limited slip posi unit, axles and 3.31 gears.

The slammed F150 rides on Weld Laguna 17x10 wheels on the rear with 315/50/17 Mickey Thompson Street Radials beadlocked in place and 17x7 Lagunas up front with Toyo Proxes ST III 235/65/17 tires.

The Original Patented CalTracs Traction System

Complete bolt on system: no mods, cutting, welding, most applications

Keeps axle from rotating, maintains pinion angle

Eliminates spring wrap up

Pre-load adjustability

Durable powder coated finish

Detailed Illustrated Installation Guide

Custom sets available, call

Mike with his ’21 Supercharged F150 after a good night at the rack running 9-second passes. Time to load up and drive it home!

Stopping duties are provided by TBM XS3 brakes all ’round.

“I started getting into the trucks for the simple reason I’m getting older and fatter and they are much easier to get in and out of, ” Mike joked. But the truth is that even with Mike driving, the truck easily runs well into the 9-second

zone, with a best to date of 9.78 at 144mph.

And as far as truckin’ in his F150 on the street and strip with reliability, Mike had this to say about that; “The project took about 6 months to complete in all and the truck has close to a 125 quarter-mile passes on it now, with not one issue.”

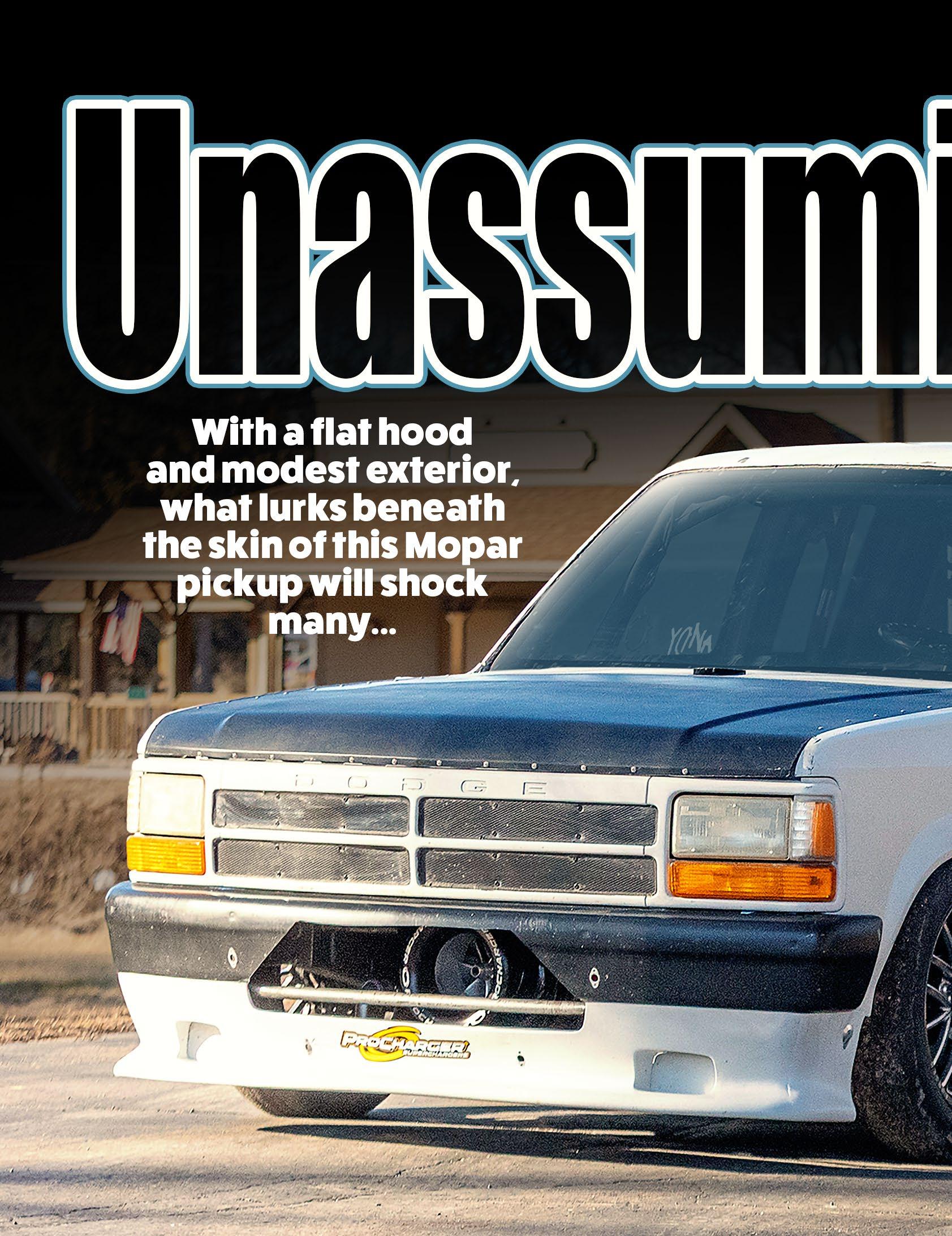

smoke and mirrors; or in drag racing terms, ,the sleeper,. ..

Regardless of what you call it, it’s the oldest trick in the book, but it still works! Show a person one thing to make them believe what you want them to believe, then hit them with reality.

Hailing from Genesee Depot, Wisconsin, Andy Straley grew up going to

the drag strip with his father, older brother and sister. He inherited the Jr. dragster that his siblings both honed their talents in and forged his own path down the 1320 that ultimately led him to the supercharged 1995 Dodge Dakota you see here.

When Andy bought the truck it had mosquito control lettering and graphics on it, remnants of which can be found under the rear wing.

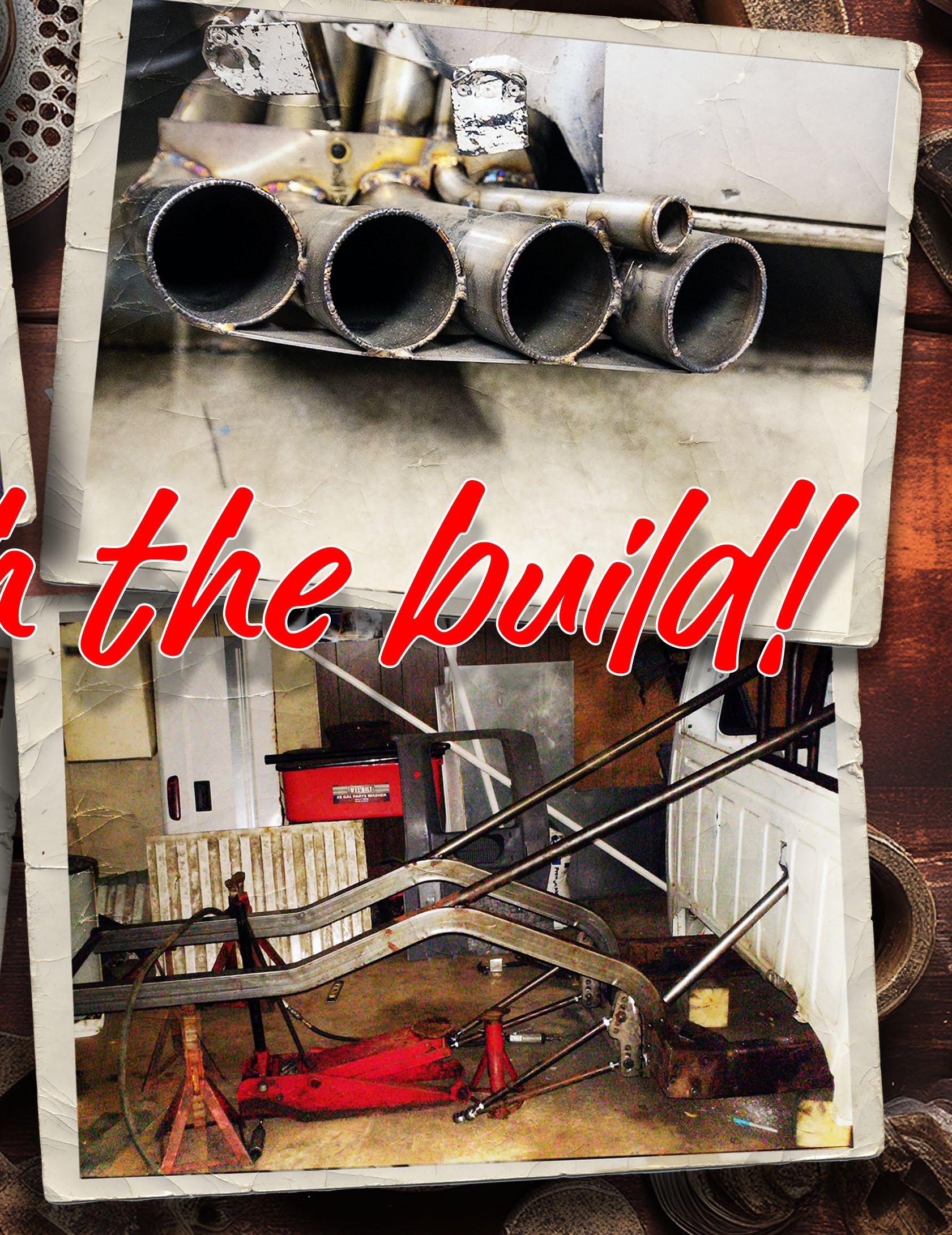

With a flat hood and unassuming exterior, Andy Straley’s Dodge Dakota is the perfect grudge race sleeper, aside from the zoomie exhaust exiting the front fenders and wing hanging off the rear, of course.

“It all stemmed from our dad’s passion for speed,” Straley said. “We spent countless hours in the garage with him as he built his car among countless other people’s cars. We all had the opportunity to be bitten by the speed bug at a young age. Because of that, we all race now.”

As it happened, the Straley’s needed an alignment on their

father Tim’s Dodge Daytona racecar that brother Dan was now piloting and dropped it off to another shop, K.R Auto, owned by Kevin Ribbens.

“I was just 18 at the time,” Straley explained. “As they worked on the car, I spotted a white extended-cab Dakota with mosquito control lettering on it in his shop.

By this time, I had already owned a 4x4 V-6 extended-cab Dakota and I asked Kevin for the deal on it.”

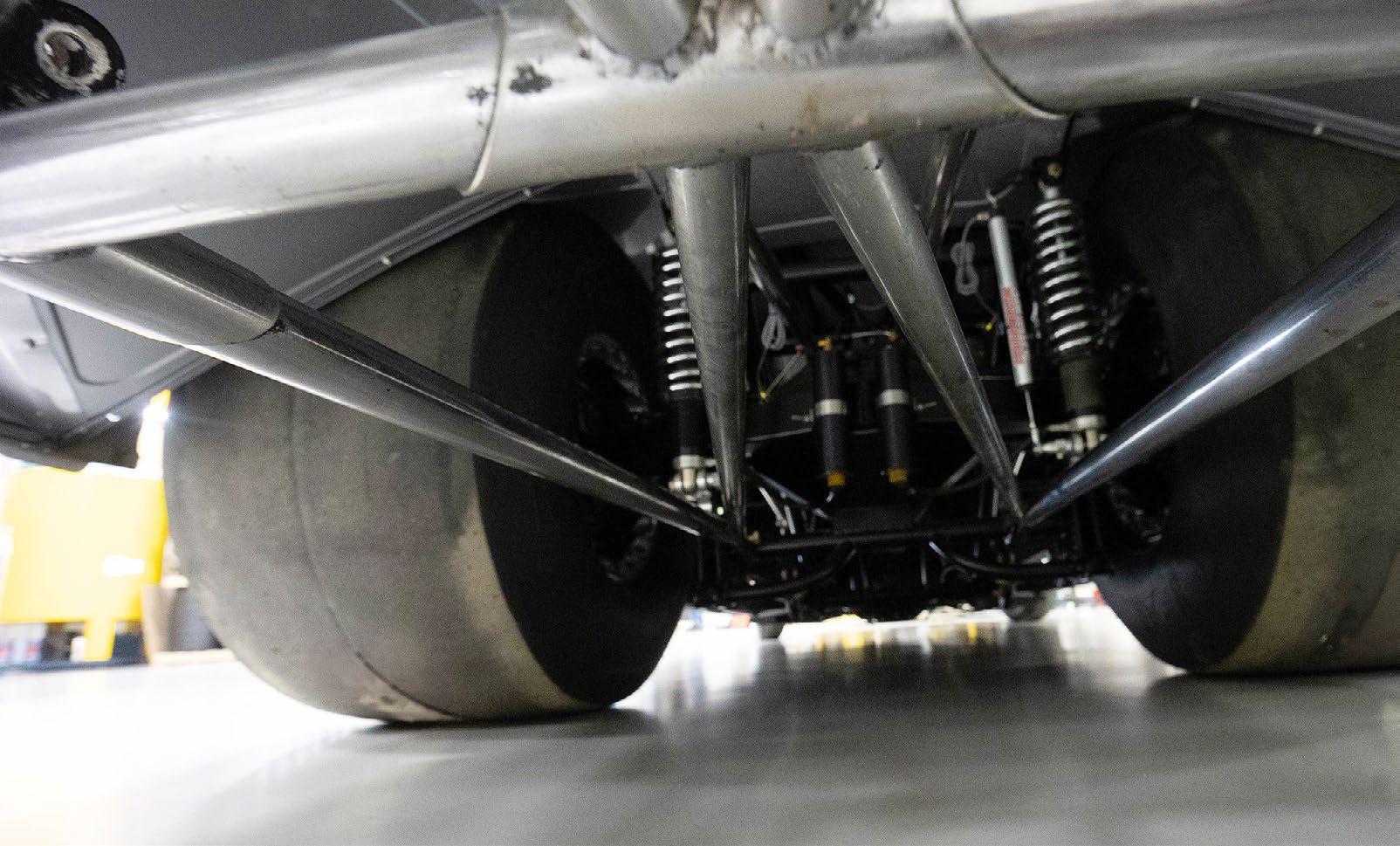

With a loan from his father, Straley brought the Dakota home for just $400 with plans to make it his first racing machine and it didn’t take him long to start cutting on the V-6-powered, midsize pickup. Initial plans called for narrowing the stock rearend, but Straley’s brother suggested going straight to back-halving the truck and so they installed a 2x3 rear frame kit and 4-link suspension from Chassis Engineering from which they hung a Ford 9-inch rear packed with an aluminum center section, spool and axles and 3.89 gears.

The Dakota started its life with Straley in 2008 as a beaten up abandoned 10.5-tire project with stock 235/75r15 tires up front. The back window was broken out and the 3.9 V6 and auto trans were well used up. He and his family got right to work in making it into a formidable drag truck.

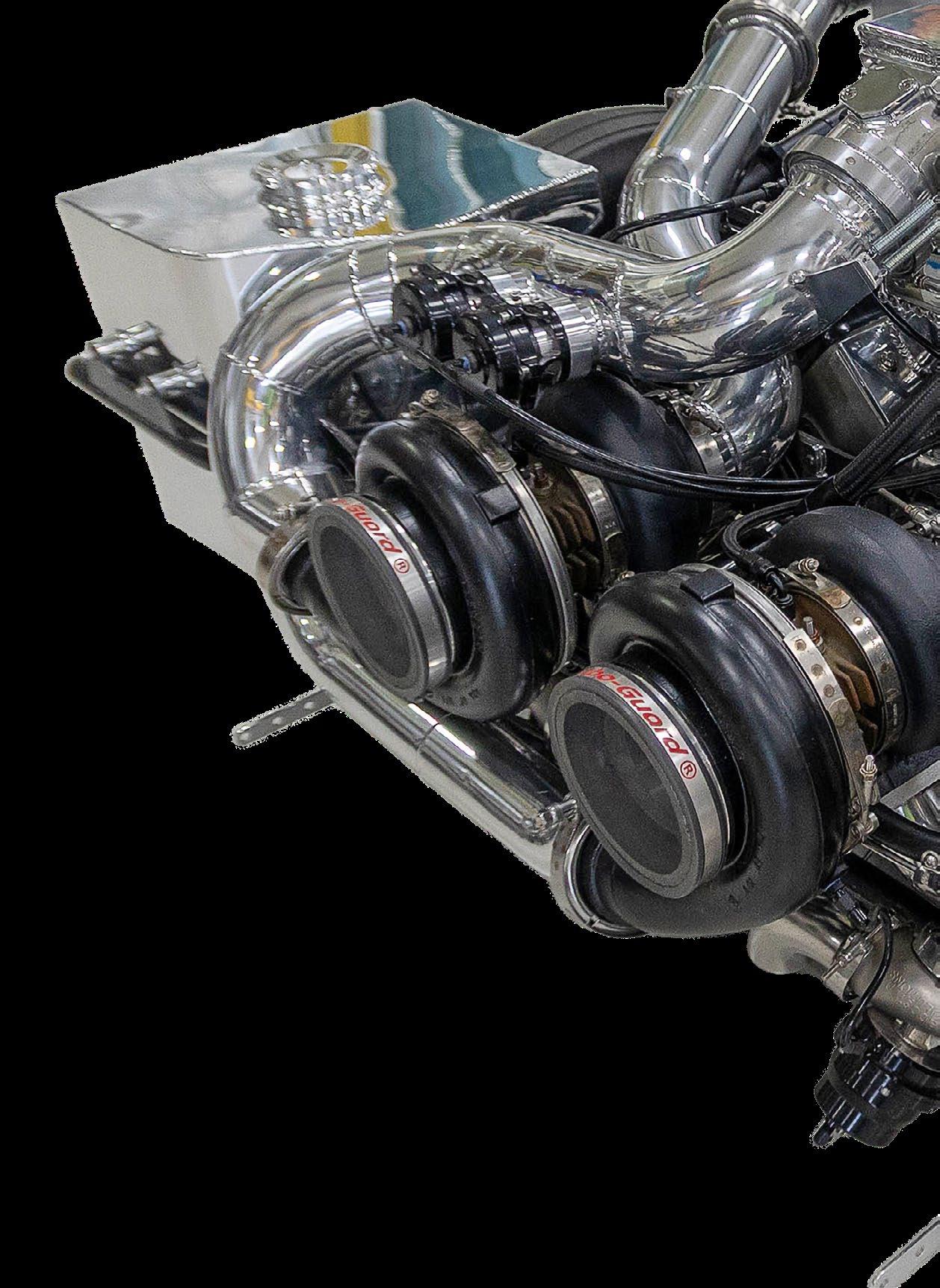

Straley updated the blower to an F-3X-140 ProCharger during the recent HEMI build.

Next up was the roll cage and Straley put time in researching who he might have perform the work, but his father had a plan of his own.

“My dad and brother were at the track for a bracket race, and I had to come later in the morning,” Straley said. “I got to the track and my dad says to open the trailer and help unload the car. I opened the door and a complete 12-point cage was stacked on a pallet! My dad said, ‘Here’s your graduation present, get to work,’ so I did just that.”

To get the Dakota moving down the track, Straley grabbed the 500 cubic-inch big-block Mopar powerplant from his father’s Daytona, as his father had retired from racing and no longer needed it. The engine, topped with Mopar Performance Parts Stage 6 heads and intake manifold, was backed by a TorqueFlite 727 transmission and the combination proved potent enough for 10.20 index racing. Later, Straley bolted on a nitrous oxide plate—a gift from then girlfriend and now wife Samantha—and was able to dive into the 9.50 index classes.

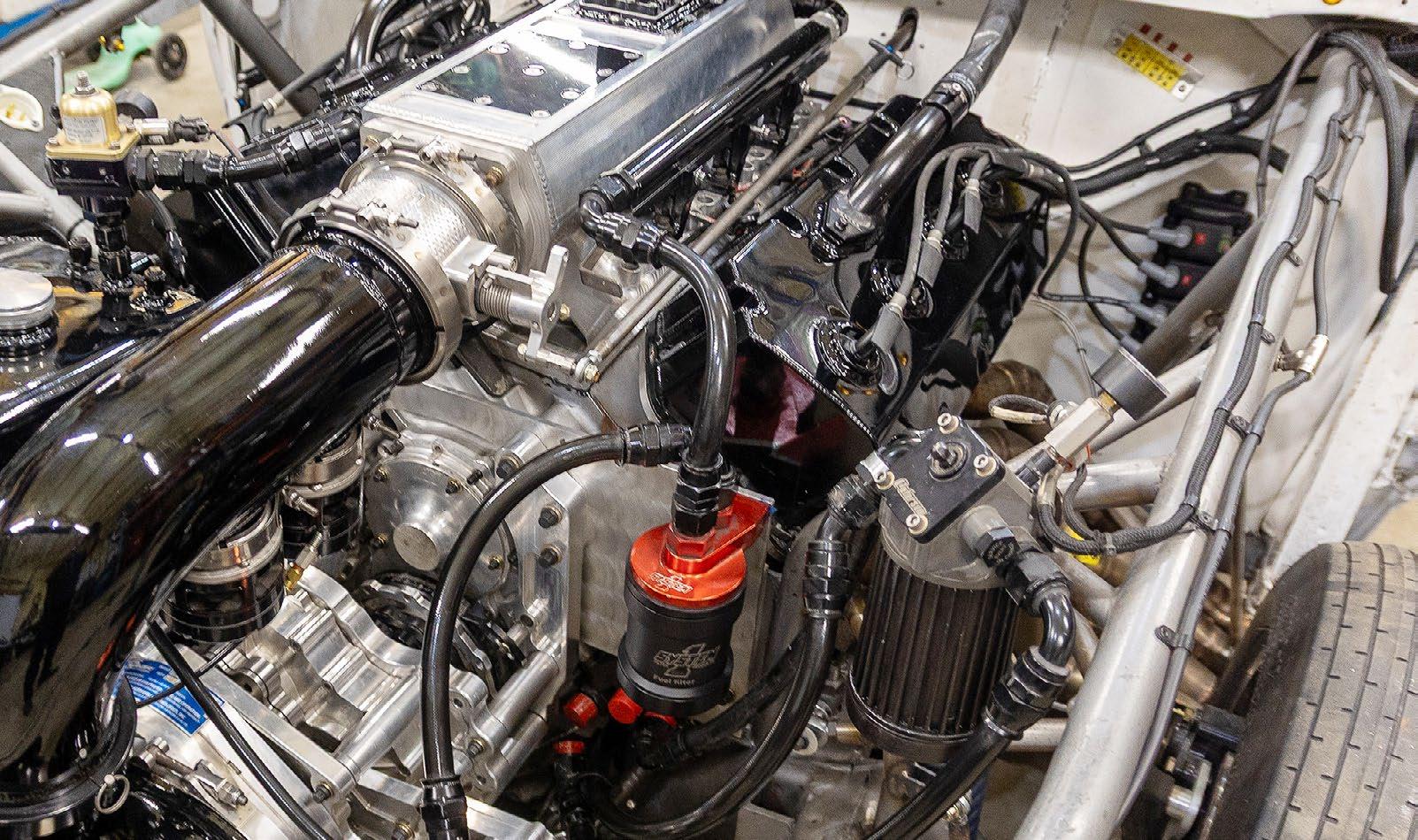

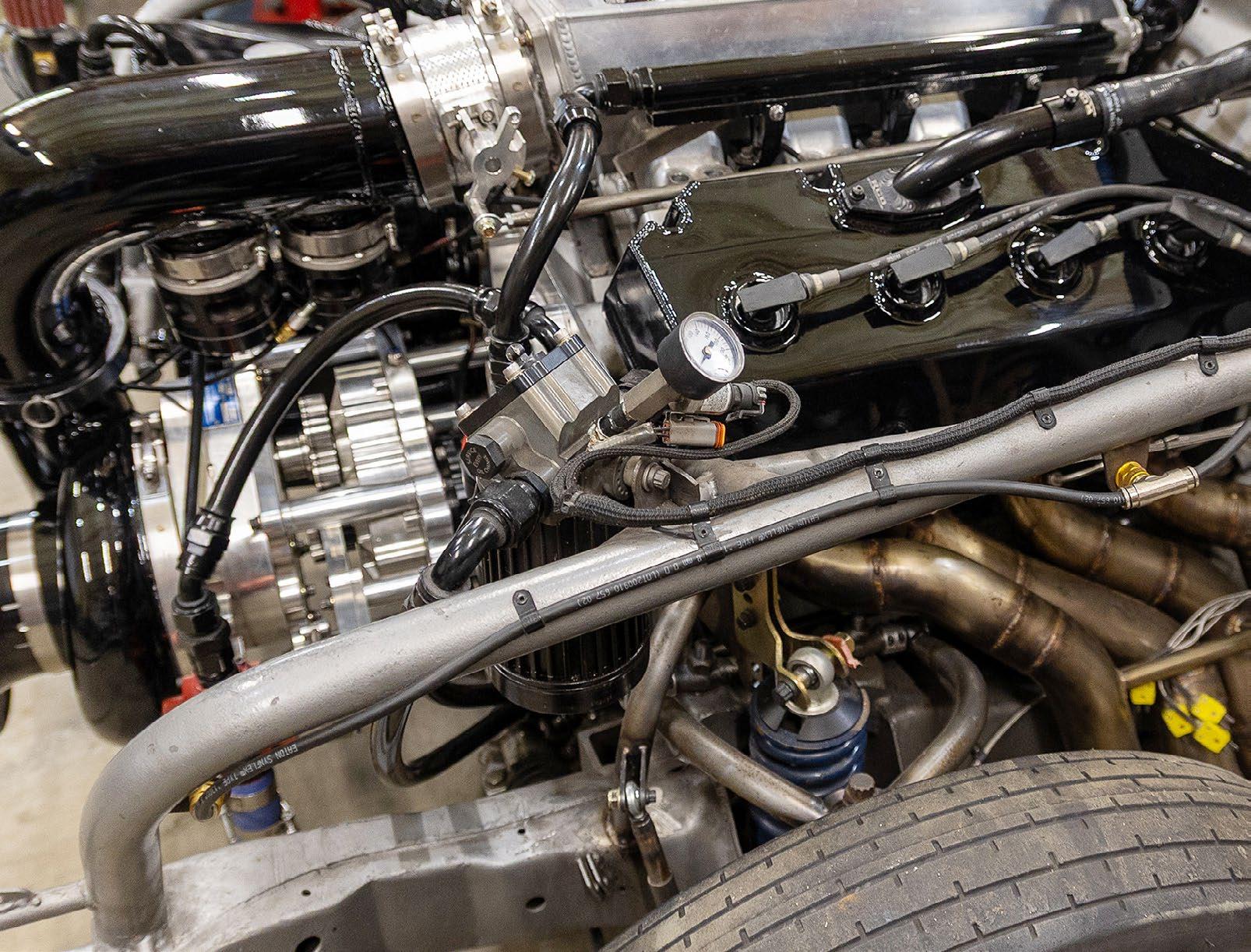

The blown HEMI, built by AES Racing, works out to 510 cubic-inches. The aluminum block was filled with GRP billet connecting rods, a billet steel Bryant crankshaft and forged Diamond Racing boost-spec pistons and is topped with a Hogan’s fabricated intake.

“After Index racing, we got to the no-prep, no-time phase—this is where the fun really started,” Straley told us. “We went to a KOTs (King of the Street) event and were immediately hooked. The atmosphere of the racing was 180 [degrees] from what I was used to, but definitely fit what I was looking for.”

Straley competed in a few events, but a tuning error that resulted in engine damage ended his campaign. He regrouped, however, and upgraded to an all-aluminum, 540 cubicinch Mopar with an F-2 ProCharger blower and a robust Turbo 400 transmission.

...We have only scratched the surface on this setup. We have a total of 4 passes on the new combo and set a new personal best on the 2nd run…by a lot!...”

Andy Straley

Straley bought the truck for just 400 bucks and before long built it into drag truck, making it better, stronger and quicker each time he swapped out the engine, finally ending up with the ProCharged 510-inch HEMI now set between the framerails.

Chassis & Suspension:

4-link rear, stock style up front, custom built upper arms and shock mounts.

Body & Paint:

Mostly factory paint with a few areas of touch up. Glasstek hood and fiberglass front bumper, everything else is steel.

Engine:

Currently a 510 ci aluminum HEMI, billet GRP rods, billet Bryant crank, Diamond forged boost-spec pistons.

Induction:

Hogan’s billet intake with 600 and 850pph injectors.

Power Adder:

F3X140 ProCharger

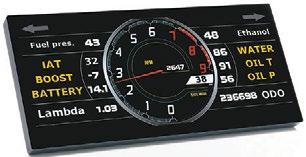

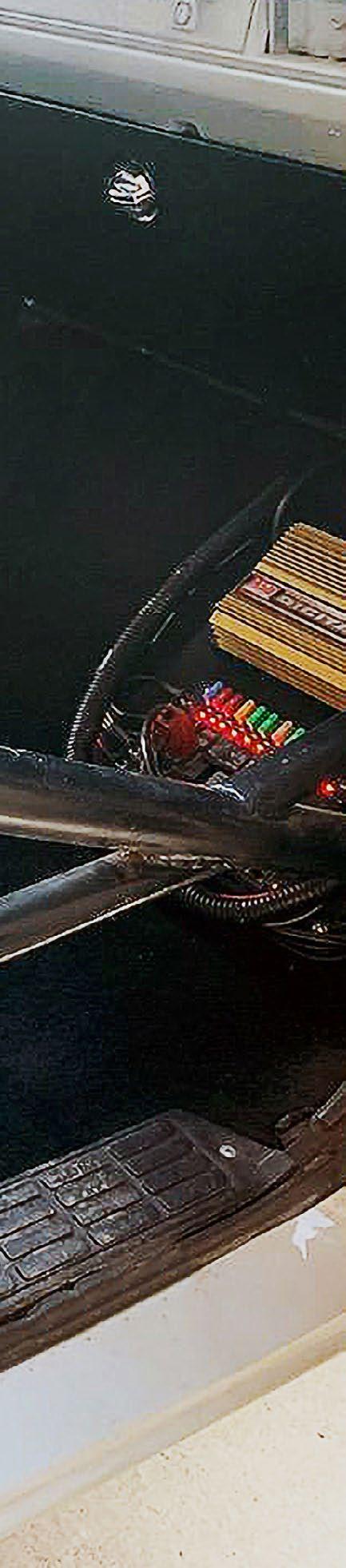

Electronics:

Holley Dominator, MSD Pro 600 ignition and coils, Holley 8 channel egt, Holley injector driver, Leash relay boards, Holley 7-inch dash,

Transmission & Converter:

2 speed TH 400 by Dave Klaput at Proformance Racing Transmissions, PTC bolt-together converter.

Rear differential:

Ford 9” with an aluminum bolt-through case, spool and axles and 3.89 ratio gears.

Tires & Wheels:

Fronts are billet 17” ATC forged and rears are 15x13 Holeshot wheels with a Macfab beadlock conversion.

Interior:

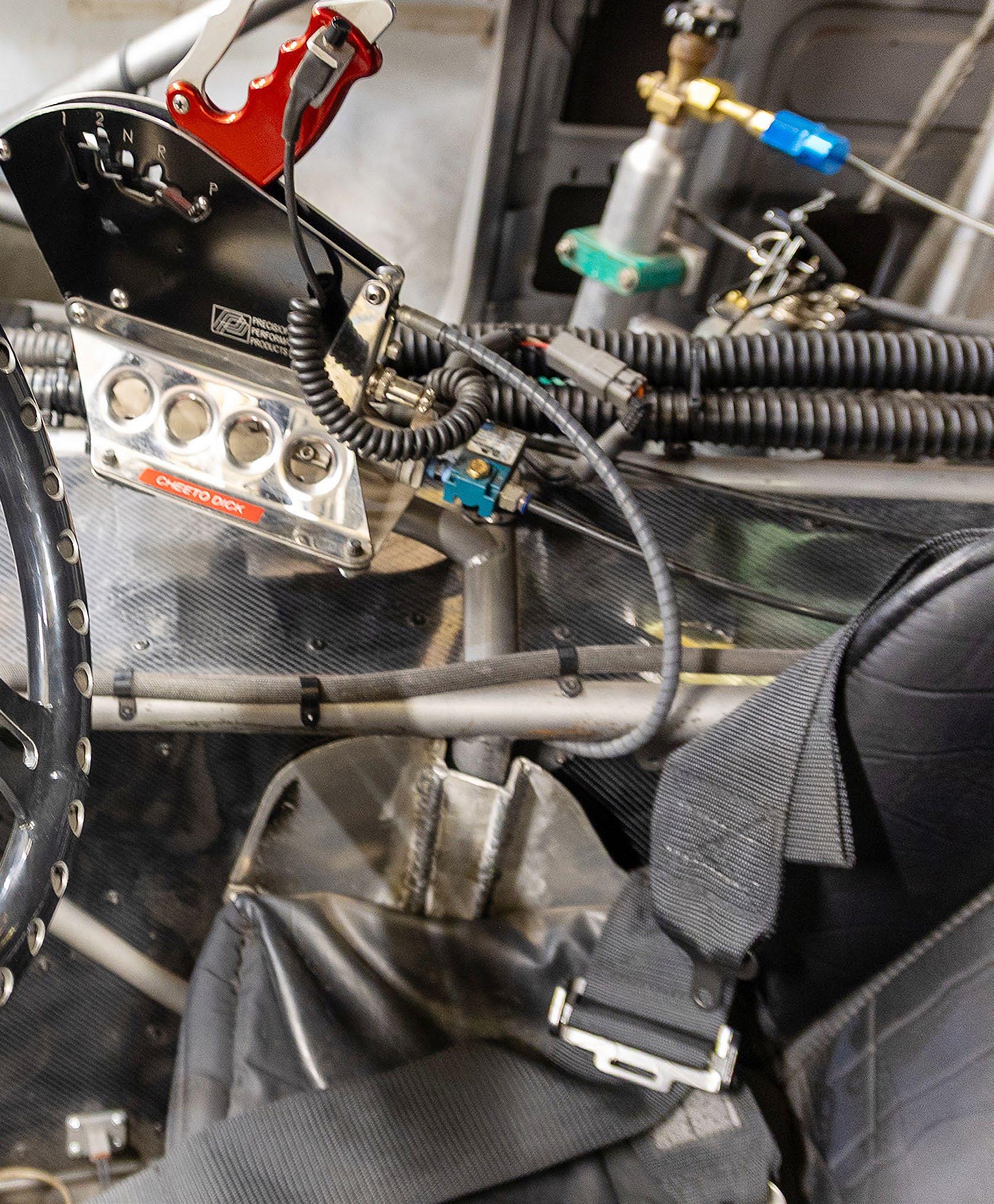

Precision shifter, PRO 1 harnesses, Lifeline Zero 360 fire system.

Best ET & MPH:

We are racing small tire slick/radial No-Time for now, so we can’t share the truck’s capabilities. Let’s just say we annihilated our old personal best with this combo and have some big plans and ideas for the 2025 season! Keep an eye out for us.

You don’t see many Dodge Dakotas this radical. Most of the time it’s S-10s or GM trucks and there are really only a hand full of fast Dodge trucks out there that are Chrysler powered! So the truck in general, and that it’s got a HEMI!

Reason For Build:

Just my love for the Dakota trucks.

Build Timeline:

Have had it since 2008 and haven’t stopped.

Most Memorable Experience:

The first pass with it when I got in done the first time!

Thanks To:

Tony Schroeder at AES -Engine builder https://aesracing.net/news.htm

Dave Klaput at Porformance Racing Transmissions https://www.proformanceracingtransmissions.com/ Procharger superchargers

Jake Malek at Strange Engineering

Nicholas Layo- Sponsor https://www.smartmachinetool.com/recaptcha/

Larry Meyers- Sponsor https://www.elect-techinc. com/

Tim Straley, Father

Dan Straley, Brother

Brittany Straley, Sister

Joey Rabiola, Brother in-law

Samantha Straley, Wifey

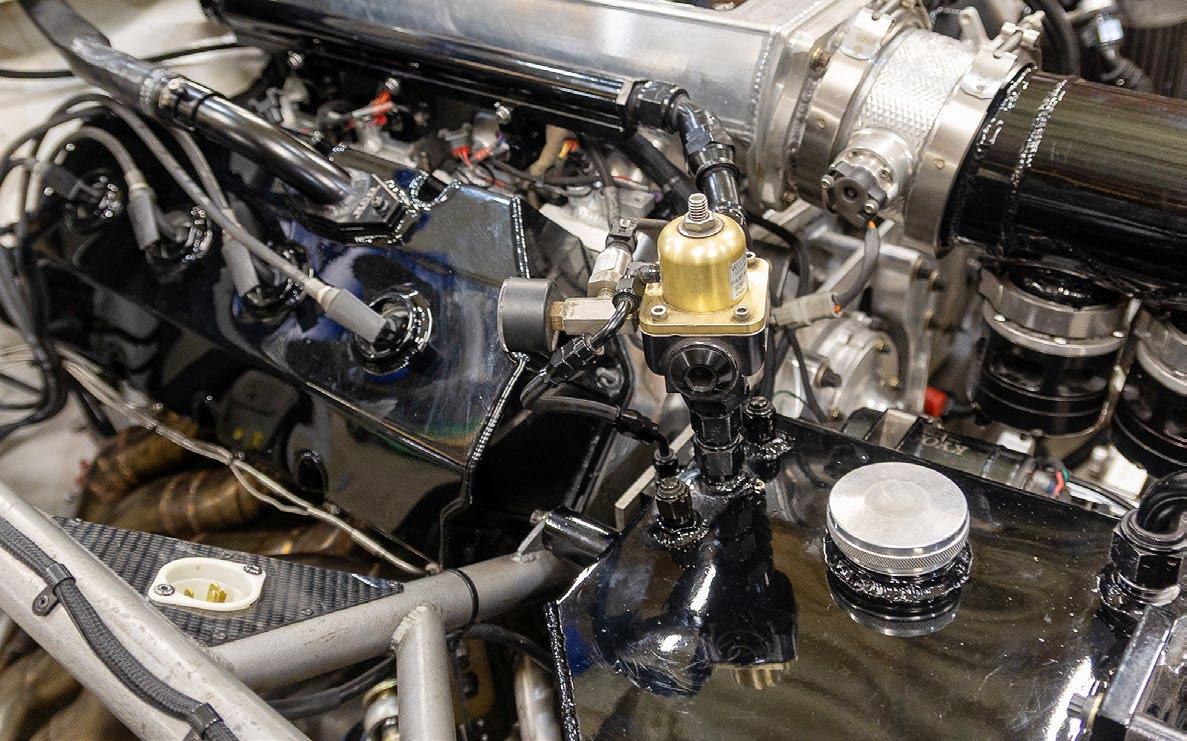

The new engine program also included a switch to C16 fuel and Holley electronic fuel injection. Thankfully, his sister Brittany’s boyfriend, Joey Rabiola, happened to tune EFI and jumped in to handle the engine management.

The blown 540 was good for 1,400 rearwheel horsepower and low 5s in the 1/8 on a non-prepped track. Straley raced it for

two seasons before an aluminum connecting rod got angry with him, but that gave him the opportunity to switch things up and move to a HEMI engine.

“We have only scraped the surface on this combo,” Staley said. “We have a total of four passes on the new package and set a new personal best on the second run, by a lot.

A Precision Performance Products shifter commands the two-speed Turbo 400 and, to protect the occupant in the event of the unthinkable, there’s also a Lifeline Zero 360 fire suppression system. Straley also installed some tunes for long waits in the staging lanes. Watch out for this

Putting the HEMI in the truck was challenging, but definitely worth the effort. I think the most challenging thing was building the zoomies. Having a stock frame up front, I had to make a lot of bends to get them to lay right.”

The HEMI also signaled Straley’s move to using a dedicated engine builder, in this case, Tony Schroeder at AES Racing in Elk Grove Village, Illinois, putting together the 510 cubic-inch aluminum engine with

GRP billet connecting rods, a billet steel Bryant crankshaft and Diamond Racing pistons.

The ProCharger was updated, too, with Straley changing to an F-3X-140 unit blowing into a Hogan’s fabricated intake manifold. Billet Atomizer 600 and 850PPH injectors provide the fuel and MSD’s Pro 600 ignition and coils light the air/fuel mixture. Leash Electronics relay boards keep the juice steady, and Holley’s 7-inch dash provides the data.

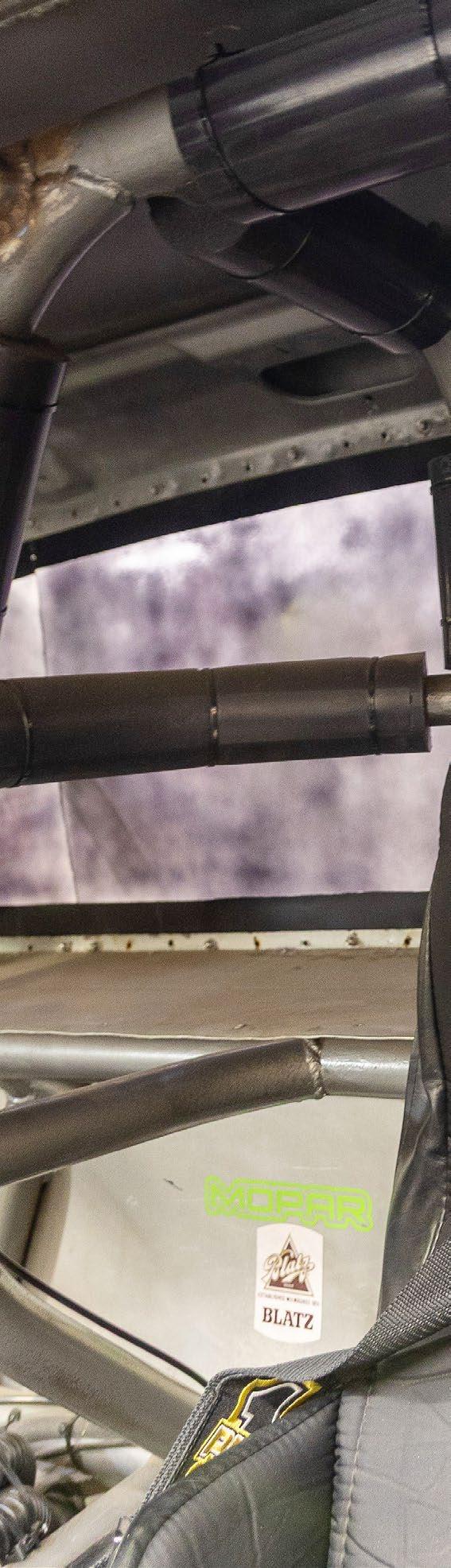

The interior of the blown HEMI Dakota follows the exterior with very little hype and only the equipment and tools necessary for drag racing. A cage surrounds the driver and the interior is finished with a combination of tin and carbon panel work. A basic steering column is paired with a removable billet steering wheel and a 7-inch dash provides the data.

Inside the Dakota’s Spartan confines you’ll find a Precision Performance Products shifter to control the Dave Klaput/Proformance Racing Transmissions-built, twospeed Turbo 400 and PTC torque converter, as well as a Pro1 racing harness to keep Straley strapped into his seat. There’s also a Lifeline Zero 360 fire suppression system and a sound system to keep Straley

both protected and entertained.

The long and sleek extended-cab body rolls on billet 17-inch ATC forged wheels up front and 15x13 Holeshot rear hoops with beadlocks by Mac Fab Performance out back. Lightweight disc brakes reside on all four corners.

The body is still largely covered in the factory white hue and Straley has lightened the pickup

up with a Glasstek hood and fiberglass front bumper. The fact that his ride of choice is a Dodge Dakota is something he’s proud of and something he says you don’t generally see at this level of performance.

“There are really only a handful of fast Dodge trucks out there that are Chrysler-powered!”

Car enthusiasts and racers are often creative creatures and this can usually be seen in the types of modifications they make, the style of build they do, or even in the cars they choose to drive.

For Oak Lawn, Illinois’ Pat Powers, he had a distinct vision of his El Camino when he first set eyes on it, but that didn’t keep him from changing it several times.

As a young teenager, Powers helped his father and brother

build a 1967 El Camino that eventually became his daily driver.

“It was this car that started my passion of muscle cars and wanting to know more about how everything works,” Powers told us.

Extensive factory trim and lighting was used on the exterior of the car to ensure it still looks and works like an original El Camino. Joining the party are a number of race-necessary items such as the fender- exit exhaust dumps, wing, wheelie bars and twin ’chutes.

An all steel OEM shell that Powers has had for a number years was completely reworked and joined by a one-off Glasstek fiberglass front end and set of full-frame doors (all were the first ever produced by Glasstek for a ’70 El Camino) and Eric Eisenbeis laid down GM’s Switchblade Silver after witch a vinyl top was added to maintain a classic muscle car look.

A few years later, he parted ways with that car to build a ’69 Camaro that became a back-halved racing machine capable of high 8s while competing in the Chicago Outlaw Super Stocks. Powers sold it and began his next project, a ’67 Chevy II Nova that followed the exact same route, from the type of build, to the

type of racing, to being sold when the right offer was made for it.

Throughout the years, Powers put his automotive savvy to work by building parts and cars for other people to fund his own projects. Having that knowledge, he wasn’t afraid to tackle the major project that was his next build, a 1970 El Camino.

“A neighbor had bought a blue ‘70 El Camino, but it had a black front end on it,” Powers recalled. “He explained to me that the car was hit, and they took the front end off a black car to put on the blue car to sell. I asked him what they were

doing with the black car, and he said he would find out. A few weeks went by and a flatbed truck with the black El Camino with no front end shows up all the way from Georgia. Steve, my neighbor, said here’s your car—total price for the car… $300!”

The front end was designed to accept factory headlights as well as a Sunoco-style 5 inch hood. Glasstek also provided the front spoiler and a rear bumper that’s been wrapped in chrome vinyl, and Powers fabricated the rear wing.

“Everythingabout itjustflows...”

Powers immediately envisioned its completed look and stripped the El Camino down in order to create his vision. Eventually, he finished the build with a ProCharged smallblock powerplant and a clean white paint job with “some crazy graphics on it.” Think-

ing it was all that at the time, he began conjuring up a different vision of what the Chevy should look like. He sold the drivetrain and reworked the suspension so the El Camino would ride a bit lower, but when his home caught on fire, the project was put on hold.

A near bulletproof 9.5-inch rearend was fabricated by Powers and fitted with an Ultra Case, 3.90 gears, and 40-spline axles and is suspended by a custom 4-link/coilover setup. And yes, up front that’s a factory frame section…on steroids! Penske front coilover shocks were used along with TRZ drop spindles and tubular upper and lower control arms and rack and pinion steering.

“All my side work came to a temporary halt as did the build,” Powers said. “My brother offered me some space to continue working, which I took him up on. At the same time, a new picture of the car drew itself in my head.”

Powers stripped the El Camino once more and Eric Eisenbeis laid down GM’s Switchblade Silver on the one-off Glasstek fiberglass front end and the stock steel body panels. A vinyl top was added to enhance that classic vibe.

A 415-inch small block Chevy built around an Oldsmobile Rocket block was designed by Andy Jensen and built by Powers, while Joe Priola put the finishing touches on it.

“I worked closely with Robert at Glasstek and he made me the first one-piece fiberglass front end for a ‘70 El Camino,” Powers explained. “He also made me the first set of full-frame doors.” The front end was designed to

accept factory head lights as well as a Sunoco-style hood with a 5-inch rise. Glasstek also provided the front spoiler and a rear bumper that’s been wrapped in chrome vinyl, and Powers fabricated the rear wing himself.

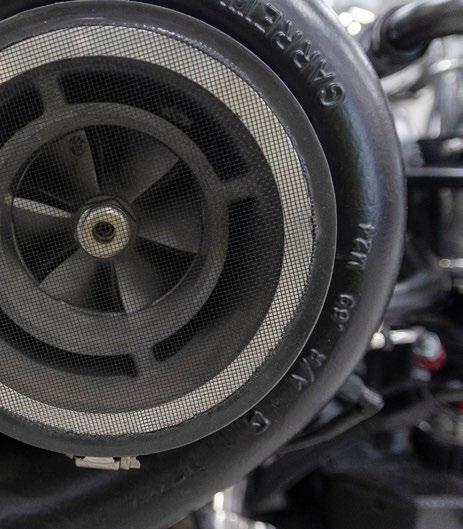

Twin Garret 88mm turbochargers compress the atmosphere before it enters the engine. The combination is managed using Big Stuff EFI, a Hyperaktive boost controller, and an MSD Pro 600.

Chassis & Supsension:

Fire wall Back 25.2 chassis built by Pat Powers

Stock front frame rails modified for coil over shocks

TRZ 1.5” drop spindles for spindle mount wheels

TRZ upper & lower control arms

TRZ rack and pinion

Penske front shocks built by Adam Drzayich

McAmis 4 link frame brackets

Hammer Concepts & Design rear end 4 link brackets

Hammer Concepts & Design shock mounts

Penske Rear Shocks built by Adam Drzyich

McAmis wheelie Bars

Body & Paint:

Steel roof, quarters and tailgate

Quarters stretched 5”

Glasstek 1 piece front end modified to fit stock headlights and grille

Glasstek 5” sunoco hood

Glasstek doors

Glasstek bumper

Glasstek chin spoiler

Custom wing and mounting built by Pat Powers

Front window from pro glass

Side and rear window from Optic Armor

Paint is GM Switchblade silver by Eric Eisenbeis

Final buff and shine by Paul Giebudowski

Bumpers wrapped chrome

Aluminum bed cover powder coated by Loko Coatings Oak Lawn, Il.

Factory vinyl top

Engine:

Andy Jensen designed 415” small block Chevy assembled by Pat Powers, finished by Joe Priola

Olds Rocket block machined my lSM Waterford Township, MI.

Steffs dry sump oil pan

Magnus dry sump pump

Peterson dry sump tank

Rotating Assembly:

Winberg 3.76 stroke crank

GRP aluminum rods

Diamond pistons

Diamond wrist pins

King bearings

Custom ground Bullet Racing cam

Jesel belt drive

Jesel keyed lifters

ATI damper

Cylinder Heads:

Brodix canted valve heads machined by BES, Guilford, IN.

2.25 Titanium intake valve

1.60 Inconel exhaust valve

Pac valve spings

Manton 7/16” tapered pushrods

Jesel rocker arms, 1.65 intake 1.5 exhaust

Power Adder:

Twin Garret 88mm turbos

Pat Powers Big Tire Twin Turbo Small Block 1970 Chevrolet El Camino

Induction:

Older Visner sheetmetal intake converted over to fi, top hat fabricated by Pat Powers

Accufab 102mm throttle body

Atomizer 250 and 550 injectors

Electronics:

Big Stuff TPM

MSD Pro 600

Hyperactive boost controller

Racepak v300

Transmission & Converter:

Lenco 4 speed built by Larry Coglianese (owner of the Chi Town Hustler funny car)

10” dual disc clutch built by Cale Aronson (Black Magic Clutches)

Rear Differential:

Fabricated 9.5” rearend built by Pat Powers

9.5” case, 3.90 gear, 40 spline axles

Tires & Wheels:

16x16 Delta 1 wheels on rear with Mickey Thompson 34x17x16

V series spindle mount fronts with Mickey Thompson 27x 4.5x1

Interior:

Glasstek fiberglass dash wrapped by Rage Wraps

Racepak UDX-BS3 dash

Aluminum seats powder coated by Loko Coatings

Factory tilt column

Custom billet steering wheel by RBZ Billet

Factory carpet, door panels, and headliner

Necksgen 6 point harness

Tin work by Pat Powers

Best ET & MPH:

Brand new car. Will know something come August but hoping it’s faster than it looks!

Most Unique Feature(s):

It’s an El Camino, not many people build them, and I believe this one has all the right looks and color to it. Everything about it just flows.

Reason For Build:

I wanted to build something outside the box. I started with a shell and a clean slate to let my vision come to life. Plus the fact that my brother and I both drove El Camino’s growing up.

Build Timeline:

Too long. There were too many changes along the way and too many pauses through the years.

Thanks to:

I don’t even know where to begin.

I have had so many people step up and help me through the build process.

My wife, son and daughter.

My brother for lending me the space to do what I do.

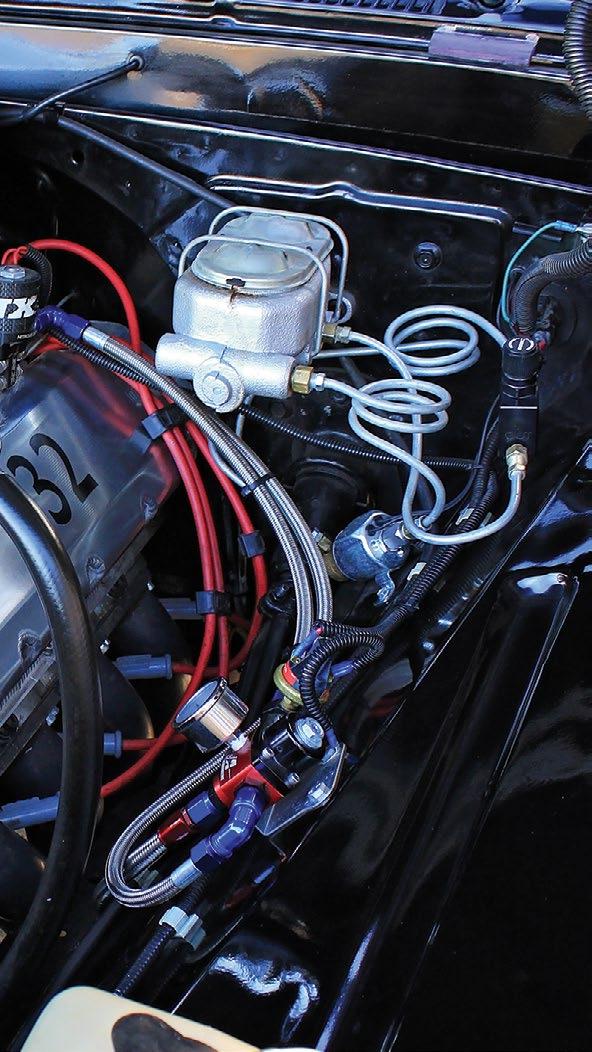

Racetronix, they supplied all the hoses and fittings to plumb the fuel and oiling system.

Ben at Big Stuff TPM.

John at Loko Coatings.

Bob at Coating Specialties. David at High Performance Lubricants.

Robert, Tori, and Chloe at Glasstek. Vincent at Mayeda Motorsports. That’s just the tip of the iceberg. There are so many friends and companies to thank. I’m just thankful that I have that many who are willing to help.

Pro Glass and Optic Armor provide the view inside the El Camino where you’ll find plenty of bars to meet the 25.2 SFI-certified chassis. Powers had Rage Wraps cover the Glasstek fiberglass dash that houses a Racepak UDX-BS3 dash which he views while strapped in

his aluminum seats that have been powder-coated by Loko Coatings. A Necksgen six-point harness keeps Powers planted in the driver’s seat while a factory GM tilt steering column with a custom billet steering wheel by RBZ Billet provides comfort on the drive.

Trimming out the interior is a stock-style carpet, door panels, and headliner, with tin work by Powers.

Rolling on V Series spindle mount wheels shod with Mickey Thompson 27x 4.5x15 tires up front and Weld 16x16 Delta 1 wheels out back with some big Mickey Thompson 34x17x16 rear rubber,

A pair of Brodix canted-valve cylinder heads that were prepped by BES Racing Engines were studded in place and a Visner Engine Development sheet metal intake manifold was modified for fuel injection. Powers fabricated the upper plenum and bolted an Accufab 102mm throttle body to it.

the El Camino sits low and mean thanks to stock front frame rails that have been modified for Penske front coilover shocks. Powers utilized TRZ 1.5-inch drop spindles as well as the company’s upper and lower control arms and steering rack to complete the front suspension.

Rage Wraps wrapped the composite dash while factory door panels, carpet and headliner honor the origins of the once production line truck. While a factory tilt column was also used, long gone are the original gauges and controls and a Racepak dash now relays all vital signs to the driver.

Shoring up the rear suspension are McAmis 4-link frame brackets and wheelie bars, and Hammer Concepts & Design rear end 4-link brackets and shock mounts. Adam Drzyich refined the Penske shocks out back as well as up front, and Powers relies on custom disc brakes to keep the powertrain in check. Powers hadn’t put any laps on the El Camino at the time this was written, but the powertrain is ready to move mountains and it all starts with 415 cubic inches of Andy Jensen-designed small-block Chevy muscle. Powers assembled the combination while Joe Priola put the finishing touches on it.

LSM in Waterford Township, Michigan, machined the Oldsmobile Rocket block that was fitted with a dry-sump oiling system consisting of components from Peterson Fluid Systems, Steffs, and Mangus Motorsports.

Inside the block you’ll find a Winberg crankshaft spinning in King bearings and slinging GRP aluminum connecting rods and Diamond Racing pistons. A Jesel belt drive spins the custom camshaft from Bullet Racing Cams and an ATI Super Damper quells the harmonics.

Pat rows through the gears courtesy a manual 4-speed gearbox from Lenco built by Larry Coglianese. The 10-inch dual-disc clutch was built by Cale Aronson of Black Magic Clutches. And to keep that nostalgia vibe, Power’s pulls gears through the custom individual shifter levers.

The 25.2 SFI-certified cage surrounds Powers and windows have been replaced by Pro Glass and Optic Armor pieces. Aluminum race seats have been powder-coated by Loko Coatings and a Necksgen six-point harness and RBZ Billet steering wheel round out the bulk of race parts inside the El Camino.

The foundation of the induction system is a pair of Brodix canted-valve cylinder heads that were machined by BES Racing Engines and feature 2.25inch Titanium intake valves and 1.60-inch Inconel exhaust valves operated by PAC valve springs, Manton 7/16inch tapered push rods and Jesel rocker arms. Powers procured a vintage Visner Engine Development sheetmetal intake manifold that was modified for fuel injection. He fabricated the upper plenum and bolted an Accufab 102mm throttle body to it.

A combination of Billet Atomizer 250 and 550 injectors provides copious amounts of fuel and for good reason, as Powers mounted up twin Garret 88mm turbochargers to compress the atmosphere before it enters the engine. The combination is managed using Big Stuff EFI, a Hyperaktive boost controller, and an MSD Pro 600.

Powers perhaps went a bit old school with a tried-and-true

manual gearbox from Lenco. Larry Coglianese (owner of the Chi Town Hustler Funny Car) built the 4-speed that was fitted with a 10-inch dual-disc clutch built by Cale Aronson of Black Magic Clutches.

Beneath the El Camino’s bed you’ll find a 9.5-inch rearend that Powers fabricated and fitted with an Ultra Case, 3.90 gears, and 40-spline axles.

Paul Giebudowski put the final

buff and shine on Powers’ raceready El Camino.

“It’s an El Camino, not many people build them, and I believe this one has all the right looks and color to it,” noted Powers. “I can sit back and say that I built ninety-eight percent of this car with my own two hands. If I really need to thank anyone, it is my family. My wife, son, and daughter have had to deal with

everything I do for almost 30 years. They get all the thanks in the world from me!”

Powers most memorable experience with the Chevy to date was when he rolled it out of the trailer to debut it at Chicago World of Wheels. The procurement/fleet manager plans to run the Chevy in Outlaw 10.5, Big Tire, and Builders Brawl classes in the near future.

Article first appeared in the February 2023 digital issue.

RPM MAGAZINE Reprint IN Print!

RPM MAG’s commitment to features that appeared digital-only since June 2020.

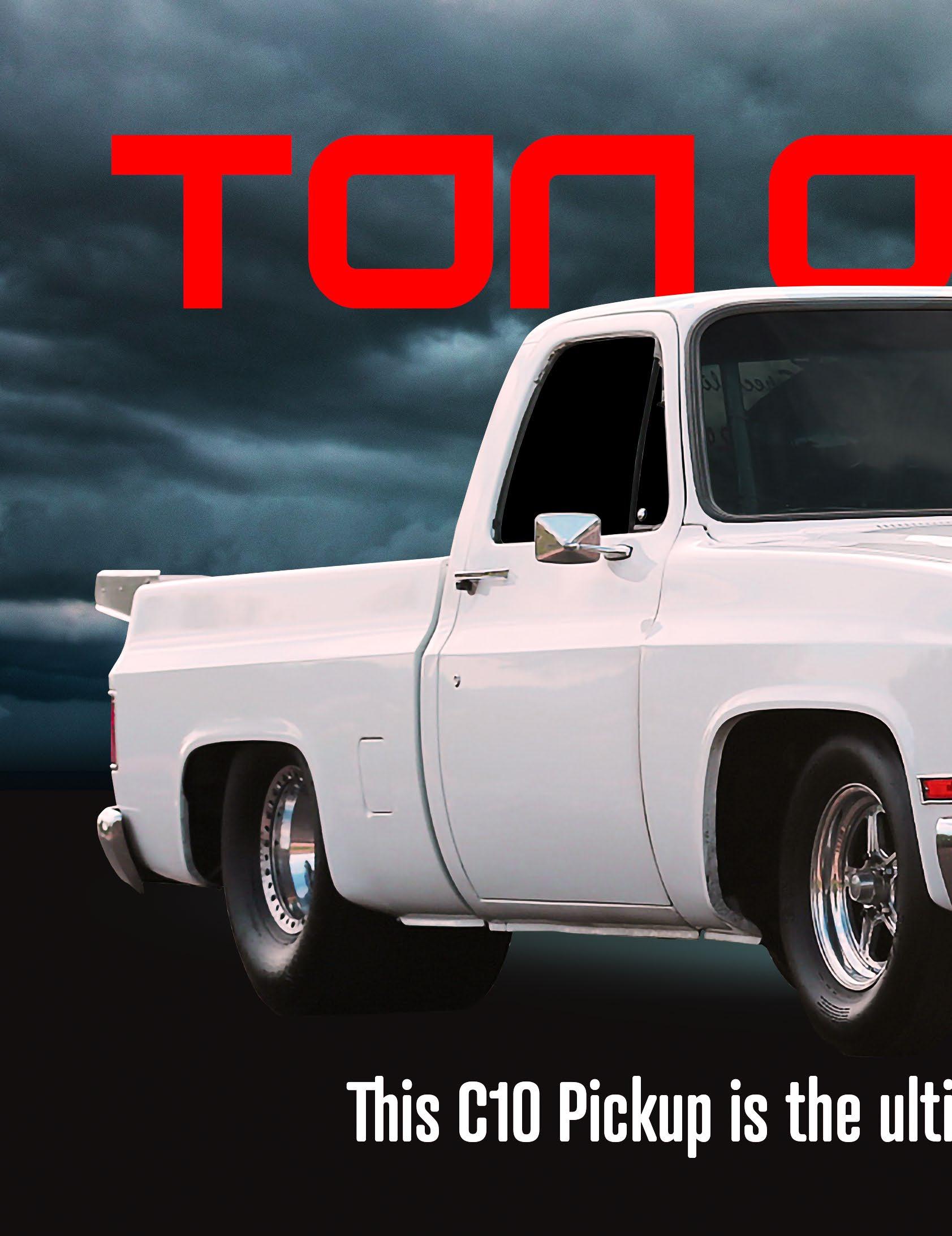

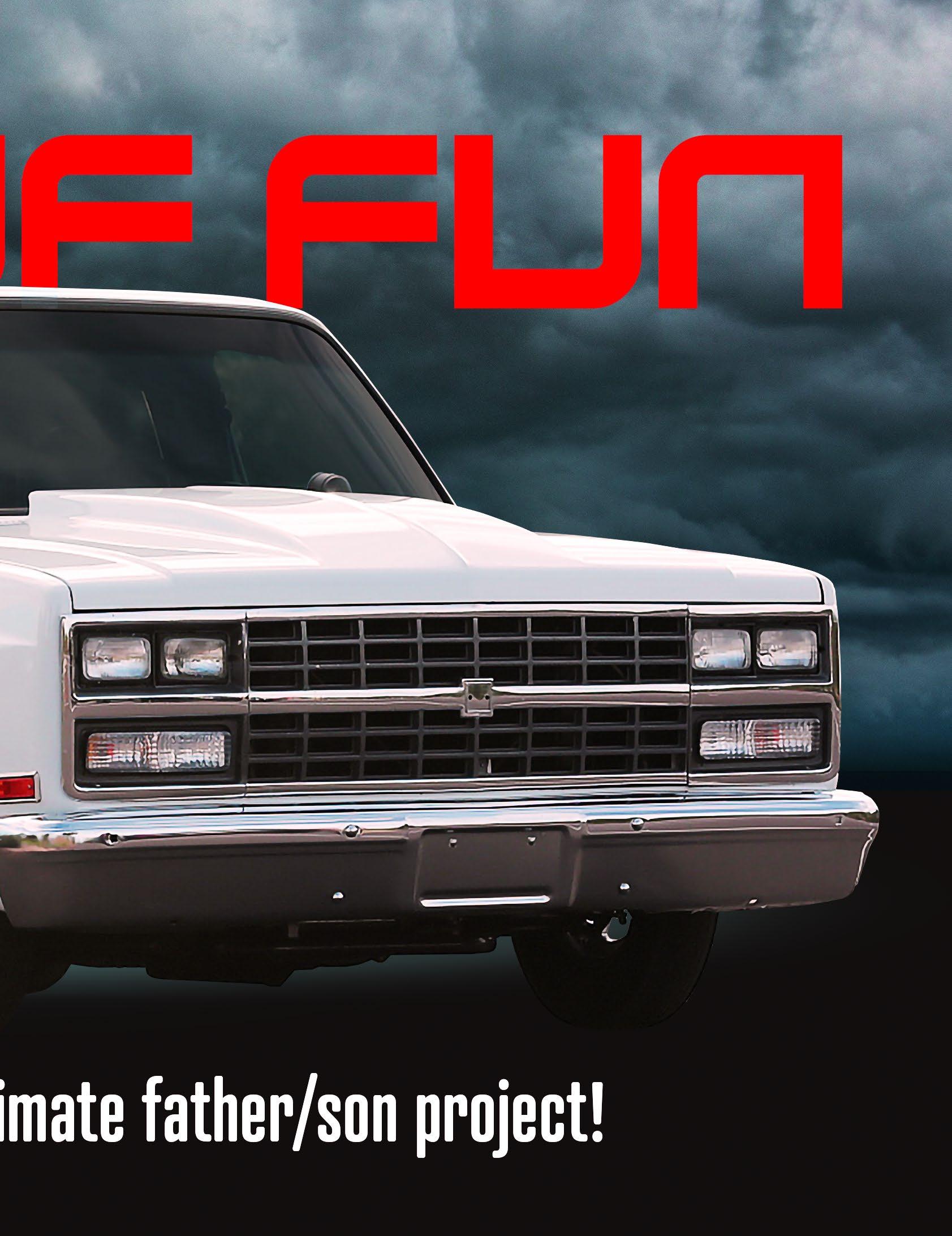

With over 40 years of horsepower in his blood, Willie Wray shows no signs of slowing down (pun intended).

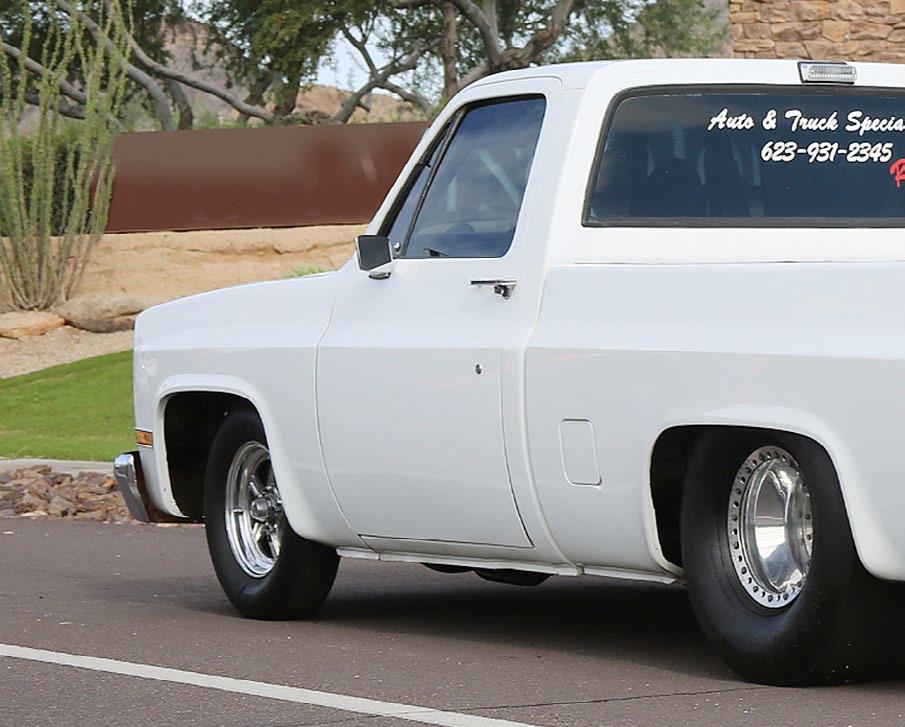

Wray was turning wrenches as soon as he could hold one and grew up at the drag strip watching his mom and dad race, until he could finally get behind the wheel himself. “I have been drag racing since I was 16,” he said. “I started building cars and square body Chevys in my teen years while helping my dad run his transmission shop, until I opened my own auto repair shop when I was 25.”

Throughout his life, building, repairing and racing cars has been Willie’s passion and he has passed that passion on to his youngest son, Hunter, who started helping him with builds.

“Hunter was 15 when we built his first truck, a 1987 Chevy C10, and he has been hooked ever since. He helped me with the build of this truck 3 years ago, and having my son work alongside me has brought me such joy and pride.”

Building power and racing spread through the Wray family and Willie’s wife took the wheel in 2008 and Hunter, now 21, is also a regular at the drag

An occasional street cruise in the C10 has a habit of turning heads....

While the truck needed quite a bit more work than expected, Willie and his son got right down to business and had it done in just 4 short months. Many of Wray’s past builds had been street oriented, but with his passion for both building and racing he decided to build this square body C10 for the strip first and foremost. However, while it’s not regular practice, you might just see the truck cruising the streets of Glendale, Arizona as it is tagged with “Historic” plates. As we all know, the C10 truck is not the most practical choice for drag racing. Weight and wind resistance are the first things that come to mind – it’s heavy, and shaped like a brick – but Willie isn’t out to set records and prove anything other than to himself and his family.

They set out to build a truck that could handle anything they could throw it power wise, yet be dependable and safe for the whole family.

The body on the C10 is all steel, even the cowl hood is an aftermarket steel version, and all the windows are still

OEM glass. Again, Willie wasn’t aiming for a lightweight ride but he did shave weight where he could without compromising the original vibe of the truck itself. And anyone who knows Willie, knows he likes the clean look of a classic square body.

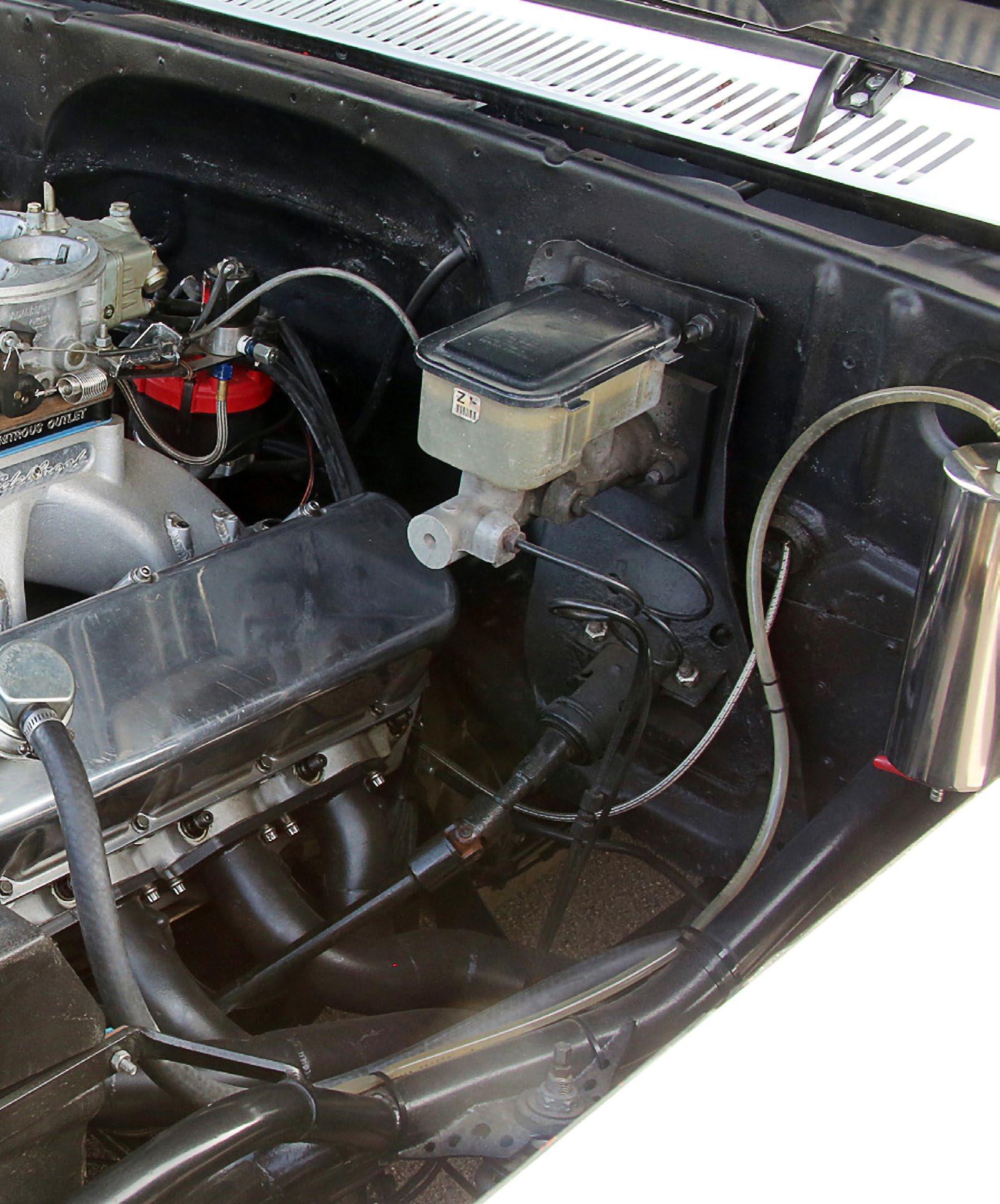

The interior was kept simple with a factory dash and a few necessary gauges to relay info. A 7.50 SFI certified Funny Car style cage protects the driver. Electronics are mounted to the passenger side firewall for easy access.

The frame consists of the x-braced factory mid and rear sections with a double rail chromoly front with tubular a-arms, struts and rack and pinion steering. A ladder bar coilover setup was used out back. Cage bars meet the rear coilovers in the bed area of the truck between the massive wheel tubs.

To make the engine compartment more accessible, they did however modify the stock front clip to make it into a removable one-piece unit and also pinned the stock front bumper for easy removal.

The healthy pickup tips the scales at 3,150 pounds with

driver, which is surprisingly trim for a vehicle of this size. On the aerodynamic shortcomings of the C10…they are part of its identity, so there’s nothing Willie could or wanted to do about that. The body and paint work was completed by Willie and Hunter.

A simple but effective big block started with a World aluminum block and ended up with 582 inches. Dart 360 heads, a Super Victor intake and Dominator carb make up the top end. The truck hauls to 9.20’s in the quarter to date, on motor alone. There is a plate nitrous system installed but it has not been plumbed for use…yet.

The chassis is overbuilt for the current power level, mostly because Wray chose to run it naturally aspirated, for now anyway. The cage carries a 7.50 certification and up front a double rail chromoly chassis

section was fabricated to work with the factory mid and rear frame and includes a chromoly X brace underneath. Afco struts were used along with custom tubular A-arms, rack and pinion steering and aftermarket disc brakes.

Body & Paint:

All steel body with 2” steel cowl hood. Body and paint done by Willie and Hunter Wray.

Chassis & Suspension/Modifications:

Double rail chromoly strut front end with tubular A-arms and rack and pinion steering. Stock mid and rear frame sections braced and equipped with ladder bars and Afco double adjustable coilovers. 7.50 cert Funny Car style cage.

Engine:

582 inch big block Chevrolet. World Products aluminum block, Callies crank and rods, forged pistons. Reher Morrison solid roller cam, Jesel belt drive, Dart 360 heads, Edelbrock Super Victor intake and Holley Dominator carb.

Power Adder:

Nitrous Outlet plate nitrous system – not currently plumbed for use.

Transmission:

Owner built Powerglide with Hughes 5500 converter. Hurst 1/4 stick shifter.

Rear End:

Ford 9”, 35 spline, Strange center section with spool and 4.56 gears.

Brakes:

Wilwood disc brakes all around.

Tires & Wheels:

Sanderson rear 15x14 single beadlocks wrapped in 16x33x15 Hoosiers. 15x4 Billet Specialties wrapped in 26x4x15 Hoosiers on the front.

Elapsed Time:

All steel, all stock glass, weighs 3150 with the driver and runs 9.20 @ 140mph in the 1/4, all motor.

Thanks To:

• My wife, Neva Wray for supporting me in doing this build.

• My youngest son Hunter Wray for helping with the build.

• AZ Differential Specialists, Dave Leyba.

• Hughes Performance.

Out back, the stock rear frame was equipped with a ladder bar setup with Afco double adjustable coilover shocks. Mounting points for the coilovers are between the massive wheel tubs in the truck box, where multiple chassis and cage bars meet. A Ford 9-inch with 35 spline axles, spool, Strange center section and 4.56 gears send power outward to the Sanderson 15x14 beadlocked wheels wrapped in 16x33x15 tires.

The roomy interior was equipped with a factory dash pad with aftermarket gauges installed. One race seat with harness accommodates the pilot who shifts through the Powerglide trans via a Hurst Quarter Stick.

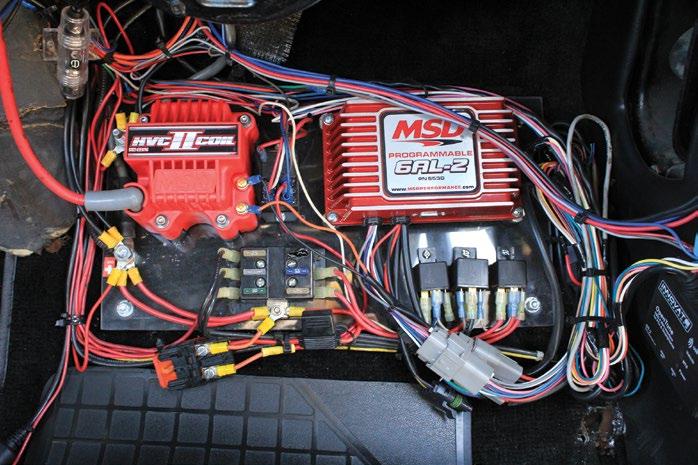

Door panels are fabricated and painted black and custom black carpet provides a clean finished look. Electronics, including the fuse and relay panel and MSD Digital 7 box, are affixed to the passenger side firewall area.

The pair built a 582 inch big block Chevrolet to sit between the rails that started life as a World Products aluminum block.

A Callies crank rotates Callies rods with forged pistons, and a solid roller Reher Morrison cam is kept in check by a Jesel belt drive. Dart 360 heads were reworked and fitted with a host of parts and a Super Victor intake with Dominator carb tops off the capable Rat. Being a transmission guy, Willie also built and installed

a Powerglide with a trans brake and a 5500 Hughes converter. All in all, it’s a tried, tested and true, dependable setup. A Nitrous Outlet plate nitrous system is installed, but no lines have been run to it as yet as the pair want to hit the max effort with the all-natural combo before moving on.

Excited about the finished product and how it performed during some shakedown miles, with all systems go, it was track time, but there was one challenge left. Willie didn’t realize the bulky Chevy would be such a tight fit in his 24 foot car hauler. Unable to open the truck door when it was boxed up, and having pinned the window in place after removing the regulator, there was no escape

once it was in the trailer. Willie and Hunter devised a way to make the steel driver’s door into a removable piece using the stock hinges for loading/unloading the truck. At last it was go time!

Naturally aspirated, the truck turns 9.20s in the quarter-mile with ease and mid to low-eights are expected with a conservative hit of nitrous. Racing as a family is fun and the truck definitely catches attention when it shows up at the track, but Willy says the most memorable experience with it to date has to be the fact that he built it with his son, and that’s what makes it truly special!

Article first appeared in the March 2018 issue.

There was little doubt that Waterdown, Ontario Canada’s Mark Robert would be wheeling some sort of fast car on the street—and eventually the dragstrip—as soon as he was old enough to drive.

“I can remember my dad bringing a transmission into our apartment living room to rebuild it, and he was repairing

and rebuilding cars constantly,” tells Robert. All through his childhood and into his teens Mark remembers his dad having some sort of fast car that he raced on the street and he even keeps a photo album filled with cars that he had lost, won, or bought over the years.

As Mark grew older, he took an interest in anything mechanical, and could often be

How can you not love the look of the early production pickups? Mark Robert’s C10 shortbox stepside is all GM and the only lightweight body panel is a Harwood glass hood. Robert’s example has all the factory trim, including bumpers still installed. Sure it adds to the weight, but this is a street truck that needs to look good, too!

No chute or wheelie bars add to the incognito look of the grudge/ no-time street driven truck. Big—but not over the top big—rear Mickey Thompson Drag Radial Pros hook the sizeable pickup.

There’s no shortage of cool original bowtie and classic speed parts on this street/strip warrior.

found taking things apart just to see what made them tick. When it came to anything motorized he had, it wouldn’t stay stock very long.

“I remember the first snowmobile I bought brand new. Three days later it had new pistons, clutch, pipe, and a re-jetted carb, all because I had lost a race,” he recalled with a grin.

It was at the pre-driver’s license age of 15 when Mark bought and built his first car and says that he would spend his nights just looking at it completed and waiting for his 16th birthday.

After high school, the now car-crazy Robert went to work at Supreme Auto and Collision where he eventually became the painter. On top of regular collision work, the shop became known for quality restorations and Mark would witness many high quality rides pass through the paint booth doors, but one in particular stuck in his head, a 1966 Chevy shortbox.

Inside, Mark chose to keep as much of the OEM look of the C10 as possible and added the race equipment such as an array of under-dash mount gauges and switches, a monster tach and large nitrous pressure gauge and billet B&M shifter as needed.

The original “Temp” “Gen” and “Oil” warning lights just wouldn’t cut it for Mark’s build.

The truck, once completed, would go on to win numerous awards at Motion, which at the time was Canada’s largest indoor car show in Toronto.

A few years later, after moving an hour or so down the road, Mark spotted a truck, wheels off sitting on cinder blocks in a side yard and it was, of all things, a 1966 Chevy shortbox step-

side. “I drove up to the house and asked if the truck was for sale,” he explained. “But very politely the owner said that he and his brother were going to ‘fix it up’.” Mark had to see the truck regularly during his drive to and from work and would check back with the owner every once in a while, just to see if he had changed his mind.

Finally, after the

Most of the work on the truck including the 8.50 SFI certified cage was designed and installed by Mark along with help from members of Stash Racing Team. The box floor was redone in hardwood strips and stainless steel.

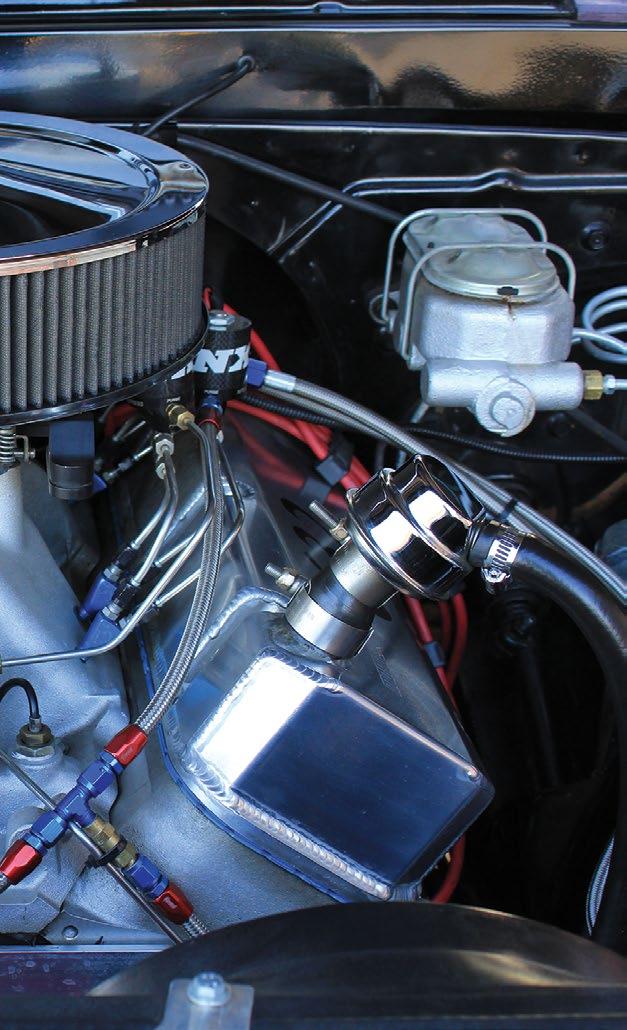

632 inches of Dart block, Musi/Edelbrock headed big block fill the more than spacious engine bay. A Nitrous Express Shark direct port nitrous kit is capable of delivering 600 extra ponies to the big block.

fourth or fifth visit, the owner started to see just how bad Mark wanted the truck. “He said to me, ‘you really want the truck, how much would you gimme for it?’ And after a short chat we decided on $1200 dollars.”

Mark and his father had just opened a new

business, Road Equipment Service Co. Ltd., and the truck was hauled off to the new shop. The time constraints of helping with a new family business took precedent over the truck though, and once it was stripped down most of the parts hung up in the shop rafters for the next five years.

Chassis & Suspension:

Stock frame with motor plate and mid plate. Reinforced trailing arms, 12-point cage certified to 8.50. Front 3-inch lowering springs QA1 double-adjustable shocks. Rear 4-inch lowering springs with double-adjustable shock and antiroll bar. Modified and strengthened trailing arms.

Engine:

632 cubic inch with Dart Big M block, Pat Musi/Victor heads, Manley crank with center counter weight, Manley 10.5 -1 pistons, Oliver rods. Isky Red Zone lifters, COMP roller rockers and stud girdle. Crane cam (intake 737 advertised 314 deg duration exhaust 726 324 deg duration). Victor cnc intake with AED 1375 CFM Dominator style carb. ATI harmonic balancer, Moroso aluminum pan and valve covers, Meziere water pump, Powermaster alternator and custom 2 1/2-inch header to 4-inch collector.

Power Adder:

Nitrous Express Shark direct port nitrous system, 600HP.

Electronics & Ignition: Innovate Motorsports O2 gauge. Maximizer 4 progressive nitrous controller. MSD programmable 6AL-2, MSD Pro Billet distributor, Innovate Motorsports 0T-2 with wifi for data logging, Painless 6 switch panel, Autometer Sport Comp tach with shift light. B&M roll control.

Transmission:

TH 400 stock case with Ultra Bell. All internals upgraded- 300m shafts, aluminum drums, 4140 hubs, reverse manual valve body with transbrake, Mark Williams yoke, Coan 9-inch 3,500 stall custom nitrous converter.

Differential:

Shortened 12-bolt with 3.73 gears, Moser spool, 35-spline axles,Strange pinion yoke and Ultimate 12 cover with axle tube supports.

Body & Paint:

Original Chevy steel, 4-inch cowl fiberglass hood, Urethane Black paint. Wood and stainless box floor.

Tires & Wheels:

15 x 12 Centerline Convo Pro with 31.25 x 12.2 Mickey Thompson Drag Radial Pros out back with 15x 6 with 225/70 15 up front.

Performance:

All I can say is that the truck went 9.035 1/4 mile at 150.95 1.364 60 foot with a mild hit of nitrous…so if you want to line up…

The 327/3 on the tree installed in the truck when Mark got his hands on it was beyond repair so he built a healthy 350 with twin 4 barrel carbs backed by a Super T10 trans. Over time, that combination would change to a 377, 400, 408, and eventually to the current 632 with TH400.

The roomy Chevy Rat was assembled by Beatty and Woods in Mississauga, ON and is based around a tough-as-nails Dart Big M block. A Manley crank with center counterweight swinging Oliver rods pinned to Manley 10.5:1 gas-ported pistons fills the big Chevy. Mark says he is not too concerned about information sharing (as it takes more than a camshaft to make the total package work) and tells us that a Crane cam was used with 737 intake lift/314 duration and 726/324 on the exhaust side. Pat Musi prepped Edelbrock Victor heads were studded in place and equipped with COMP roller rockers and girdles, and a Victor CNC-ported intake is topped by an AED 1375 cfm Dominator style carb.

Paint and body, which is jet black and arrow straight, was handled by Mark personally. The TH400 transmission build, 12-bolt rearend build, mini tub and 8.50-cert cage design, fabrication and install, and installing the engine and most everything else were also owner-completed along with the help of Team Stash Racing members.

Don’t let the lack of bling under here fool you. There’s no need to do much frame work for strength, so the original frame was used and the focus was on lowering springs and adjustable shocks, and beefing up a 12-bolt rear enough to handle the hit.

“The main goal was to build a true street and strip truck that would turn some good ETs at the track, but be drivable most anywhere,” tells Mark. “Pump gas, true street that hurts feelings at the track,” he added with a smile.

Mark runs the truck in no-time drags with Ontario Street Outlaws and while it has won many awards and races, including the most recent Motorama 2016 Best Pro Street award, the most memorable moment to date is definitely an on-track experience. “Beating Dean Carmine off the trailer in his turbo LS Mustang known as “The Loaf” has to be the best time with the truck so far.” After that, Mark says, the streetability of the C10 is great, “I can drive it from Hamilton to Niagara Falls anytime, this is a true street truck!”

The fact that it’s a 3,500-pound pickup is unique in itself, however it is the 632 cubes with 600 shot of nitrous that helps those in the other lane understand just how unique the truck really is. Unfortunately, in grudge/no-time drag racing, your rep catches up with you quick once you lay the smack down a few times, and such is the case for Mark Robert and his Full Assault ’66 C10 Chevy.

“The cat is pretty much out of the bag now,” laughs Mark. “But it was a real shocker at the track for grudge cars not expecting a truck to be that fast.”