HIGH PERFORMANCE MINERAL DRAG RACING OIL

Mineral based engine oil designed to enable maximum power while providing ultimate protection under the most severe race conditions.

• Unique friction modifier system enables maximum power output

• “Stay-in-place” chemistry and 2X Zinc anti-wear system provide lasting protection

• High quality base stocks enable effective ring seal

• Advanced, proprietary additive system keeps your engine clean

• Designed to prevent separation caused by fuel dilution

• Available in 50WT, 60WT & 70WT

EDITOR-IN-CHIEF

CHRIS BIRO editor@rpmmag.com

V.P. MARKETING/CUSTOMER RELATIONS TRISH BIRO trish@rpmmag.com

EVENT MEDIA events@rpmmag.com

EVENT SUBSCRIPTIONS COORDINATOR SHERRIE WEBER sherrie@rpmmag.com

ART DIRECTOR .......................................................... JIM McHARG

Photographic Contributions: Mark - Godragracing.org, George Pich, Louis Fronkier, Blake Farnan, Jerry Garrison, Eddie Maloney, Wes Taylor, Steven Taylor and Amber Hynes

RPM Magazine is a REGISTERED TRADEMARK of Revolution Publishing & Media Inc. RPM Magazine is a worldwide motorsports publication distributed online.

To subscribe to RPM go to www.rpmmag.com or email Trish Biro at trish@rpmmag.com, or call 519752-3705.

The focus of RPM is to bring a diverse mix of high performance street and race automobiles to life within its pages including race cars, muscle cars, hot rods and street legal machines with an emphasis on the “EXTREME,” including fast doorslammer and outlaw forms of drag racing. Not familiar with these types of cars? They are considered to be the top-shelf of the industry and are on the edge with regard to design, performance, and power!

RPM Magazine does not sell its mailing list or share any of the confidential information regarding its subscribers.

Editorial Contributions:

Chuck Scott, Mark-Godragracing.org, Tim Biro, Stan Smith, George Pich, Jay Misener, Eddie Maloney, Wes Taylor, Steve Baur

Technical Writing Contribution: Chuck Scott, Shane Tecklenburg, Tim Biro and Jay Misener

For advertising information contact

TRISH BIRO ............... 519.752.3705 ................ trish@rpmmag.com

Special Events Manager: Chris Biro events@rpmmag.com

Special Events Sales: Trish Biro: 519-752-3705 trish@rpmmag.com

Subscriptions/Address Changes: Circulation circulation@rpmmag.com

General Inquiries: 519.752.3705 info@rpmmag.com

RPM Magazine has been a world leader in motorsports publishing for 26 Years and has support locations in Ontario, Canada, Alabama, Texas, and Virginia, along with contributing writers and photojournalists worldwide.

If you have a story that may fit within the focus and scope of RPM Magazine’s coverage, please email our Editor In Chief at editor@rpmmag.com. Submission of an article does not guarantee that it will be published.

Revolution Publishing & Media Inc. (RPM) / RPM Magazine IS NOT responsible for errors or omissions in ANY advertisement or article. Advertisements may be rearranged or altered at the sole discretion of RPM to allow the ad to fit in the space purchased by the advertiser.

WE RESERVE THE RIGHT TO REFUSE ANY ADVERTISING WHICH WE CONSIDER TO CONTAIN MISLEADING, OFFENSIVE OR FALSE INFORMATION. REPRODUCTION OF ANY INFORMATION HEREIN IS STRICTLY PROHIBITED WITHOUT PRIOR WRITTEN CONSENT.

I remember growing up, seeing my dad and mom race, both at the track and on the street...

ANDY HOLLEMAN

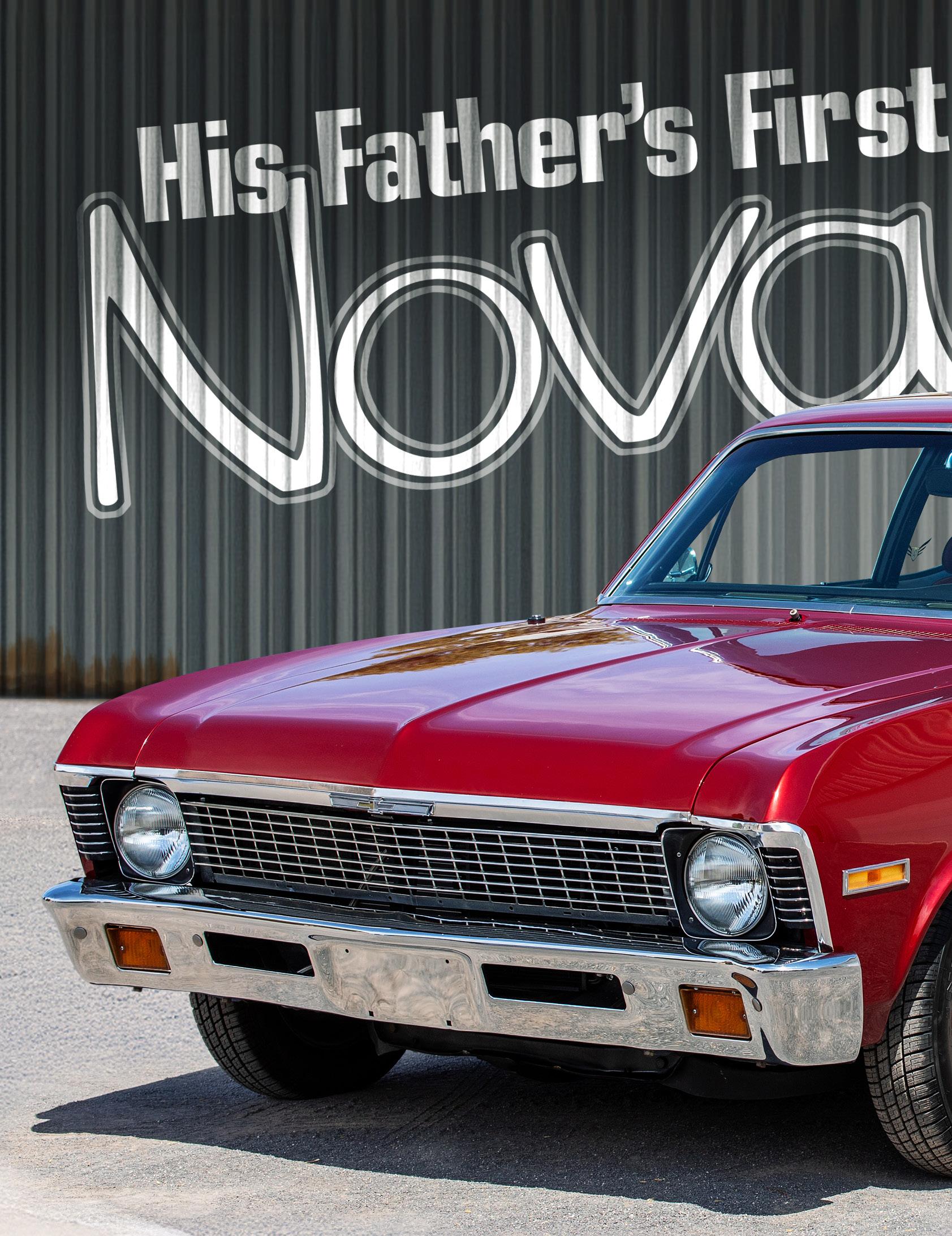

The Nova you see here was the first one Andy Holleman’s father ever built.

His father finished it when Andy was just four years old and eventually sold it to a customer who continued to have the Hollemans service it. Years later, the Chevy was involved in a minor collision and Andy Holleman was able to buy it back and return it to the family.

Raised in his father’s hotrod shop, Andy Holleman

got his first taste of the culture while rolling around in his playpen in the office. Being homeschooled allowed Holleman’s automotive education to start very early. From the playpen he graduated to cleaning and sweeping at the shop and then took on small technical jobs by the age of 14 while his father showed him the basics like rebuilding carburetors and differentials, and performing electrical work.

“I remember growing up seeing my dad and mom race, both at the track and on the street,” Holleman recalled.

With a slightly lower-than-stock raked stance, flat hood and custom dog dish hubcaps, the Nova presents a tame appearance, but make no mistake, Holleman can run single digit ¼ mile hits with ease.

The Original Patented CalTracs Traction System

Complete bolt on system: no mods, cutting, welding, most applications

Keeps axle from rotating, maintains pinion angle

Eliminates spring wrap up

Pre-load adjustability

Durable powder coated finish

Detailed Illustrated Installation Guide

Custom sets available,

Turn your LS into a legend in its own time with Trick Flow GenX® 280 HIP cylinder heads. These ultra-performance HIP’d (Hot Isostatic Pressed) castings are significantly stronger than regular heads and include many other outstanding features such as:

• Industry-leading airflow

• 280cc CNC Competition Ported intake runners

• 87cc CNC Competition Ported exhaust runners

• Manley 2.165" Severe Duty intake/1.600" Inconel Extreme Duty exhaust valves

• Trick-Alloy™ powdered metal valve guides

• Trick Flow by PAC Racing dual valve springs

• Clearance for 3/8" pushrods

• .750" decks

• 6-bolt-per cylinder mounting

• LS3 rocker stands included with assembled heads

Engineered for Performance!

New heads are just one part of the Serious Horsepower formula. To complete it, you’ll need some more components.

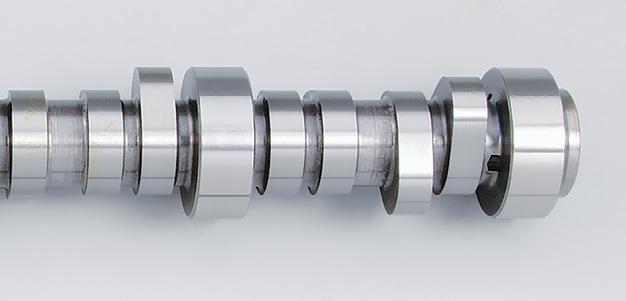

Track Max® Camshafts

• Dyno proven to significantly increase power

• Made from premium billet steel blanks

• Available in several hydraulic roller designs up to 230°/238° duration and .625"/.625" of lift

R-Series Intake Manifolds for GM LS3

• Bring carbureted-style aspiration to LS3-style engines

• 3,500-7,500-plus RPM range

• Available in carbureted and carb-style EFI versions

Variable Valve Timing Delete Kits

• Removes VVT so your engine makes big power with aftermarket parts

• Available with 1- and 3-bolt cam gears

• Includes cam/crank timing gears; timing chain and damper; LS2/LS3 timing cover with bolts, seal, and gasket; cam sensor, harness, and bracket; water pump gaskets; and cam, cam sensor, and balancer bolts

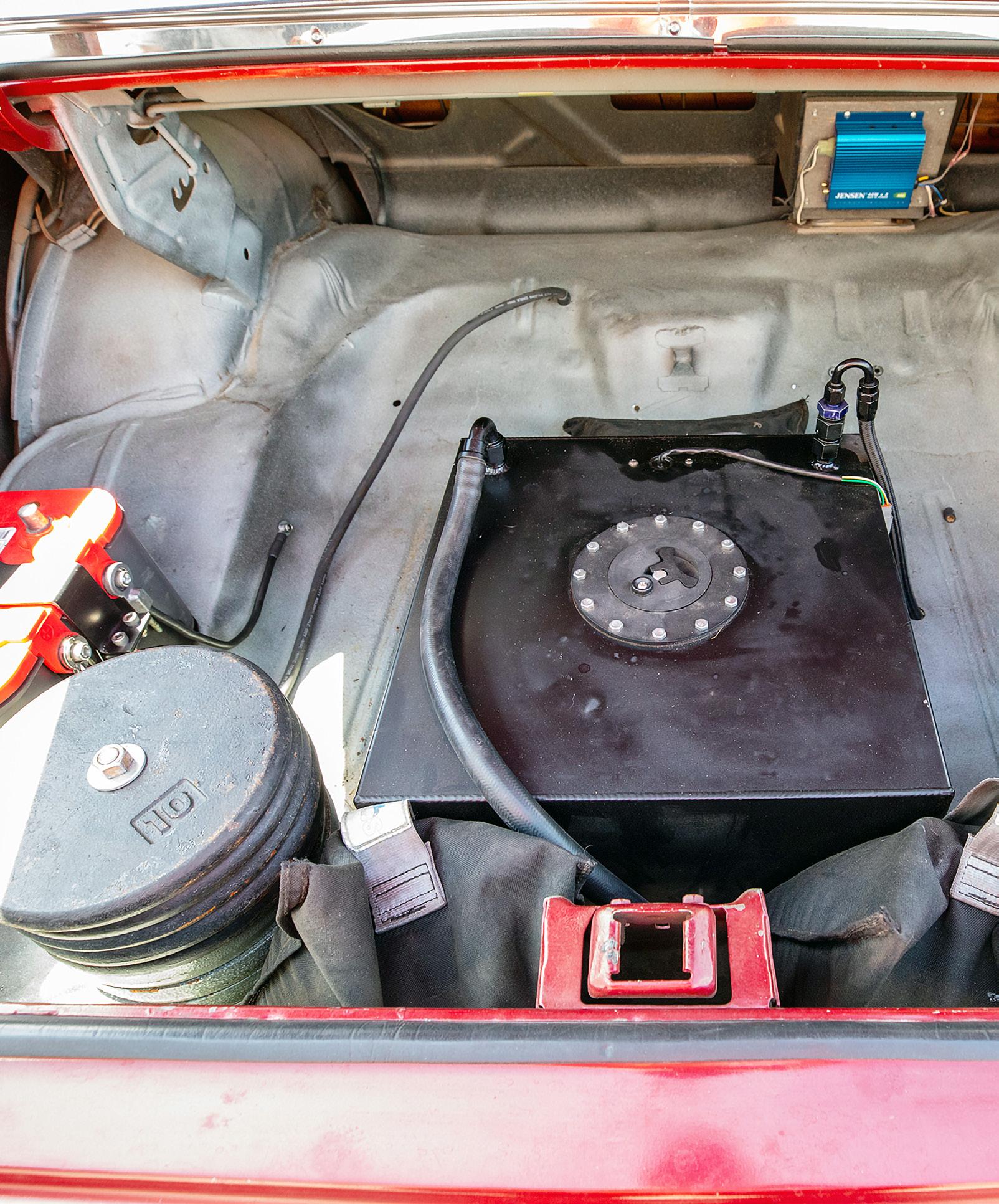

Ballast weight, check. Battery, check. Fuel cell, check. Full Nitrous bottle, check. Tunes…gotta have ’em!

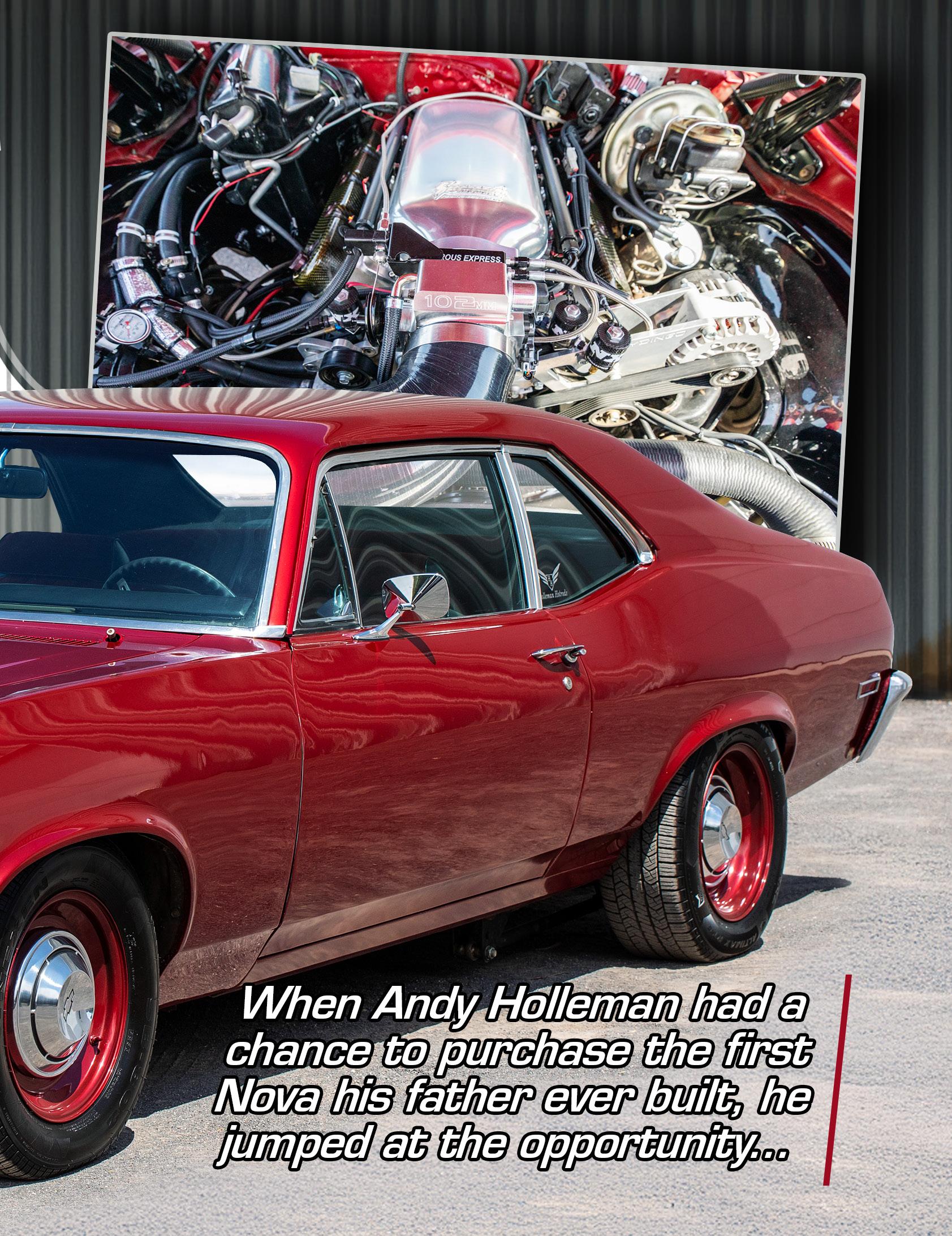

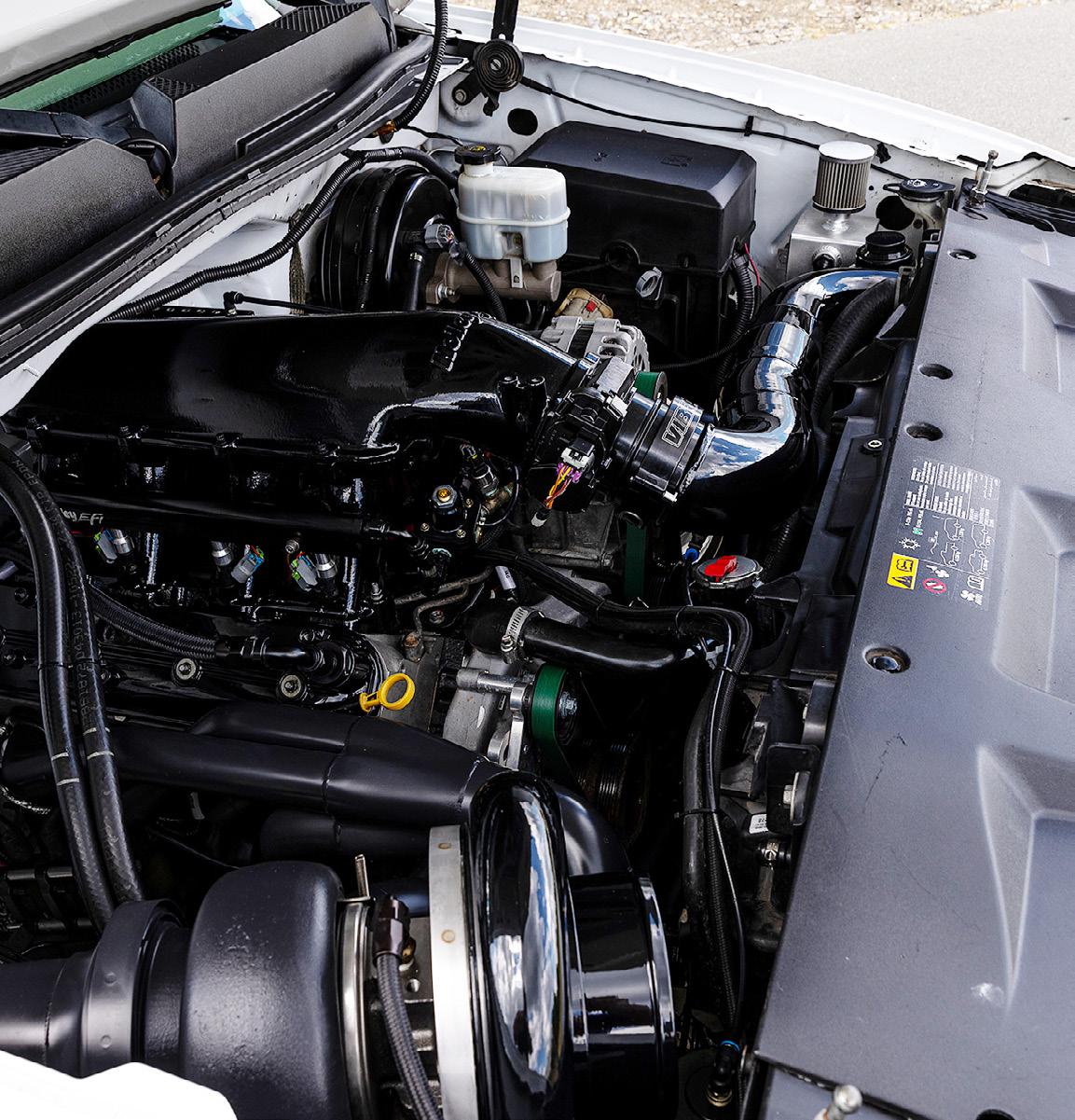

The powerplant starts with an LS6 block and it was fitted with an LSA crankshaft, Manley Performance connecting rods, and Icon forged aluminum pistons. A Lil Johns Motorsports Solutions custom camshaft that optimizes engine performance for nitrous oxide use was installed, as was a set of LS7 lifters.

The induction system starts with a pair of Dart aluminum cylinder heads that deliver a 12.5:1 compression ratio. The valve train has been upgraded for increased durability and performance and the chosen components include upgraded trunnions in the factory GM rocker arms, PAC valve springs, Trick Flow push rods, and Ferrea valves.

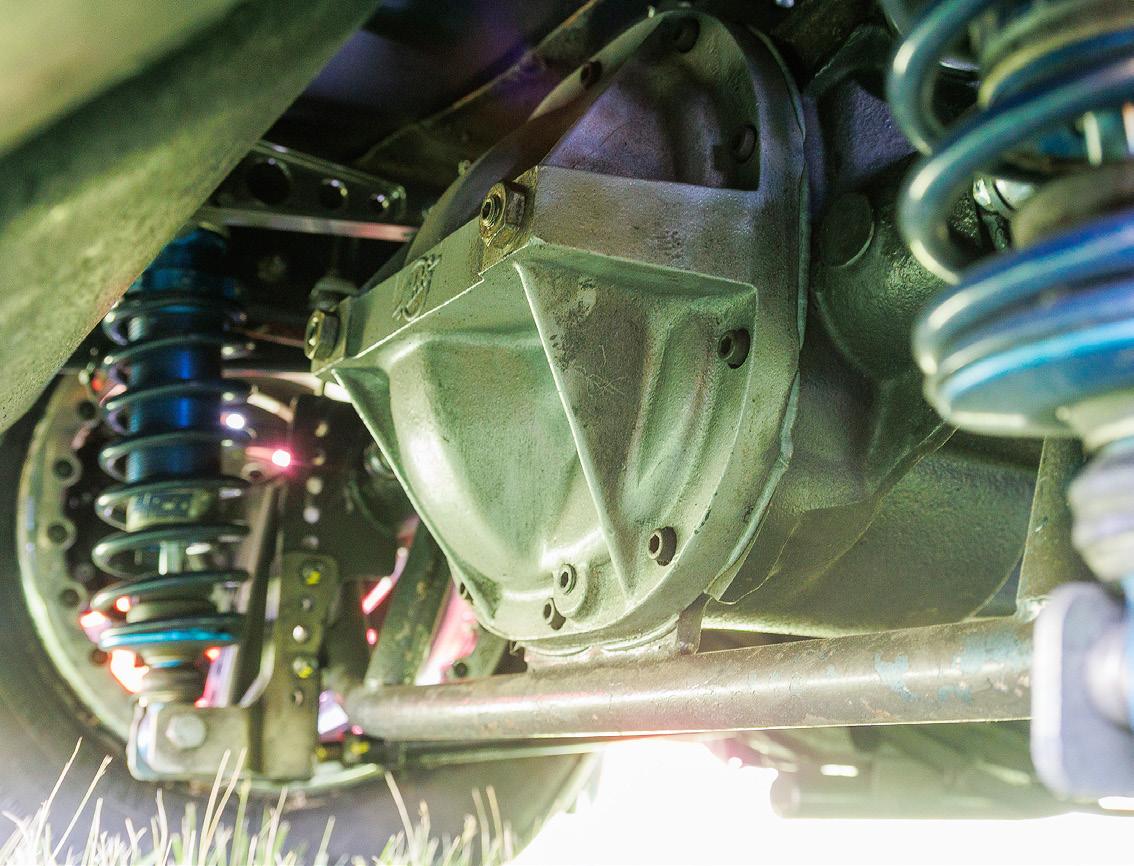

A Ford 9-inch rearend was built for the Nova with 31 spline axles, and since it is a true street/strip machine, an Auburn limited-slip unit was installed along with the 4.11 gears. Suspension wise, out back the Nova is still sprung with leafs, but they have been upgraded to Calvert Racing split mono-leaf springs and paired up with a set of legendary CalTrac bars and a pair of QA1 shocks. Holleman added only Landrum coil springs and QA1 double-adjustable shocks up front, otherwise everything else is factory.

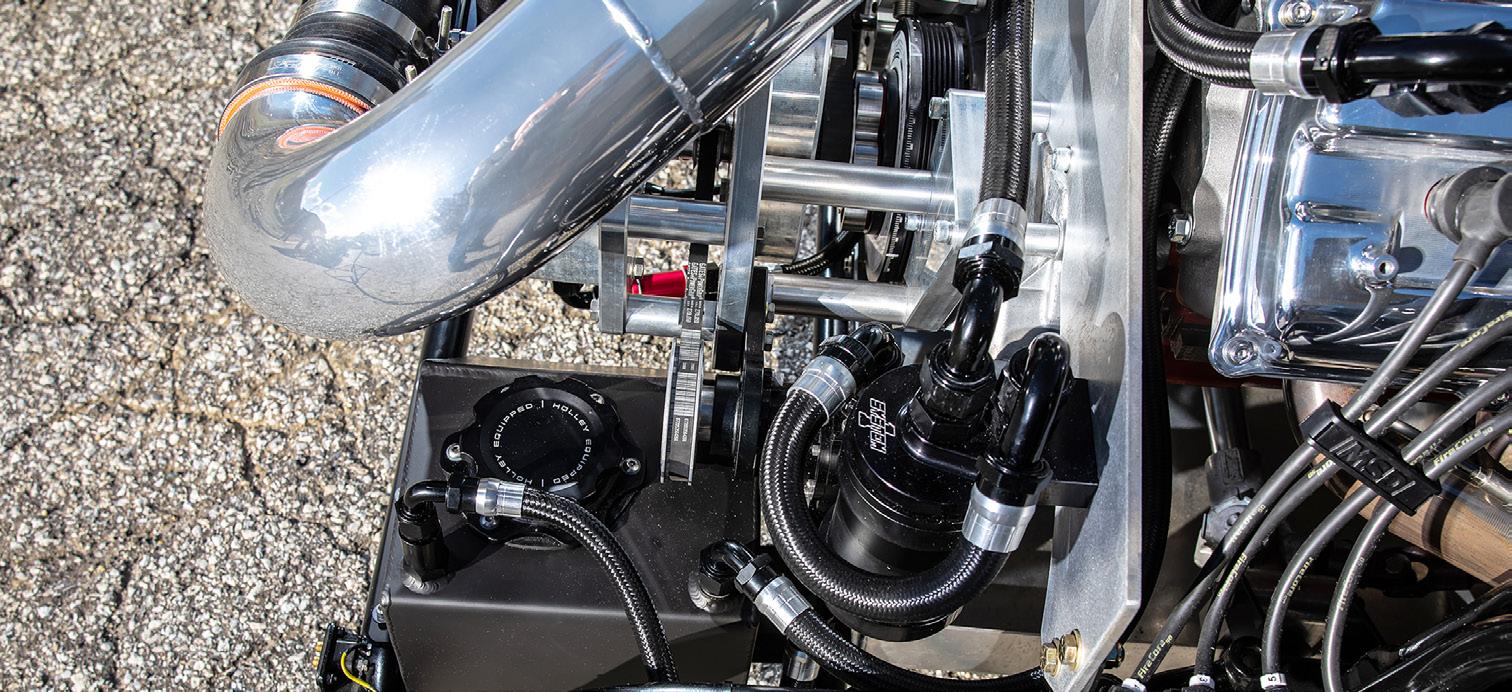

Feeding the Dart lungs is a Summit Racing fabricated aluminum intake manifold with a 102mm throttle body controlling airflow and RC fuel injectors managed by a Holley Terminator X providing the fuel to match. When it’s time to get rowdy, this sleeper Nova utilizes a Nitrous Express Maximizer 6 to progressively actuate the nitrous oxide plate kit.

A nitrous oxide-equipped LS engine is sure to increase the fun factor, but it doesn’t matter what’s under the hood if you can’t transmit the power to the rear of the car.

This stunning street/strip Nova was the first Nova Andy Holleman’s father built and he rode in it when he was just 4 years old. The car was sold, but years later Andy had the opportunity to buy it back and he didn’t hesitate.

To ensure all of the horses move this muscle car as intended, Holleman bolted in a beefed-up Turbo 350 automatic transmission that features a JW bellhousing, built internals, a manual valve body, and a custom PTC torque converter. With precise gear changes ready to de-

liver power on demand, the Nova needed a stout rearend to put the power down to the ground. To that end, Holleman em ployed a Ford 9-inch housing, and since it is a true street/strip machine, he installed an Auburn limited-slip differential and 4.11 gears.

Body & Paint:

My dad and my grandpa painted the car in 1992 with 1989 Corvette Brilliant Red paint.

Chassis & Suspension Modifications:

Factory frame and chassis. Front suspension is basically stock with custom Landrum front springs and QA1 double adjustable shocks. The rear suspension has Calvert split mono leafs with CalTrac bars and QA1 double adjustable shocks.

Engine:

The block is an LS6, 347 CID. The rotating assembly consists of an LSA crankshaft, Manley rods, Icon forged pistons, 12.5:1 compression. Little John custom ground nitrous cam, LS7 lifters.

Cylinder Heads:

Dart cylinder heads, GM rockers with trunion upgrade, Pac valve springs, Trick Flow pushrods, Ferrea valves.

Induction & Fuel Delivery:

Summit sheet metal intake manifold, 102 mm throttle body, RC injectors, Holley Fuel Terminator X fuel management.

Power Adder:

Nitrous Express plate kit, Nitrous Express Maximizer 6 progressive.

Transmission:

TH 350, JW bellhousing, PTC custom built convertor, manual valve body, custom forward drum, hardened input and output shaft.

Rear Differential:

Ford 9”, 31 spline axles, Auburn posi, 4.11 gears

Tires & Wheels:

Weld Drag lites, 15x4 front, 15x8 rear with custom adaptors for dogdish caps. Tires, 165/15 front, 245/60/15 rear.

Interior:

Stock except for TCI shifter…It’s a ‘street’ car!

ET & MPH:

I race Grudge, no-time but I can say that it runs single-digit in 1/4 mile.

Most Unique Feature(s):

The fact that my dad built it. I learned so much from him before he passed and am blessed to be able to own his first Nova build.

Reason For Build:

This was the first Nova my dad built and was the first one I rode in with my dad.

Build Timeline:

Not sure how long it took my dad, but I have constantly been working on it, changing things since I got it back.

Most Memorable Experience(s):

Taking it on Drag Week in 2023 and completing it. My dad and I always talked about going, but he was diagnosed with ALS in 2020 and got too sick, too fast to be able to go.

Thanks To:

My dad and mom, for first having the car and instilling my love for speed.

My wife Halie for putting up with all the craziness. Brent Huckey, friend and cohort and co-driver. Aaron from AllOut tuning.

Nitrous Express for sponsoring me in all my nitrous needs. Dirty Dingo.

When it’s time to get rowdy, this sleeper Nova utilizes a Nitrous Express Maximizer 6 to progressively actuate the nitrous oxide plate kit.

A 347-inch LS propels the Nova and started life as an LS6 block. A forged rotating assembly is joined by a Lil Johns Motorsports Solutions custom camshaft, a pair of Dart aluminum cylinder heads, a Summit Racing fabricated aluminum intake manifold and 102mm throttle body.

The Nova’s throwback interior is ultracool, right from the 1990s custom covered front bench and full rear seat (because there’s no mini tub here) to the factory dash and trim panels. No fancy gauges etc as Andy says “after all, it is a street car”.

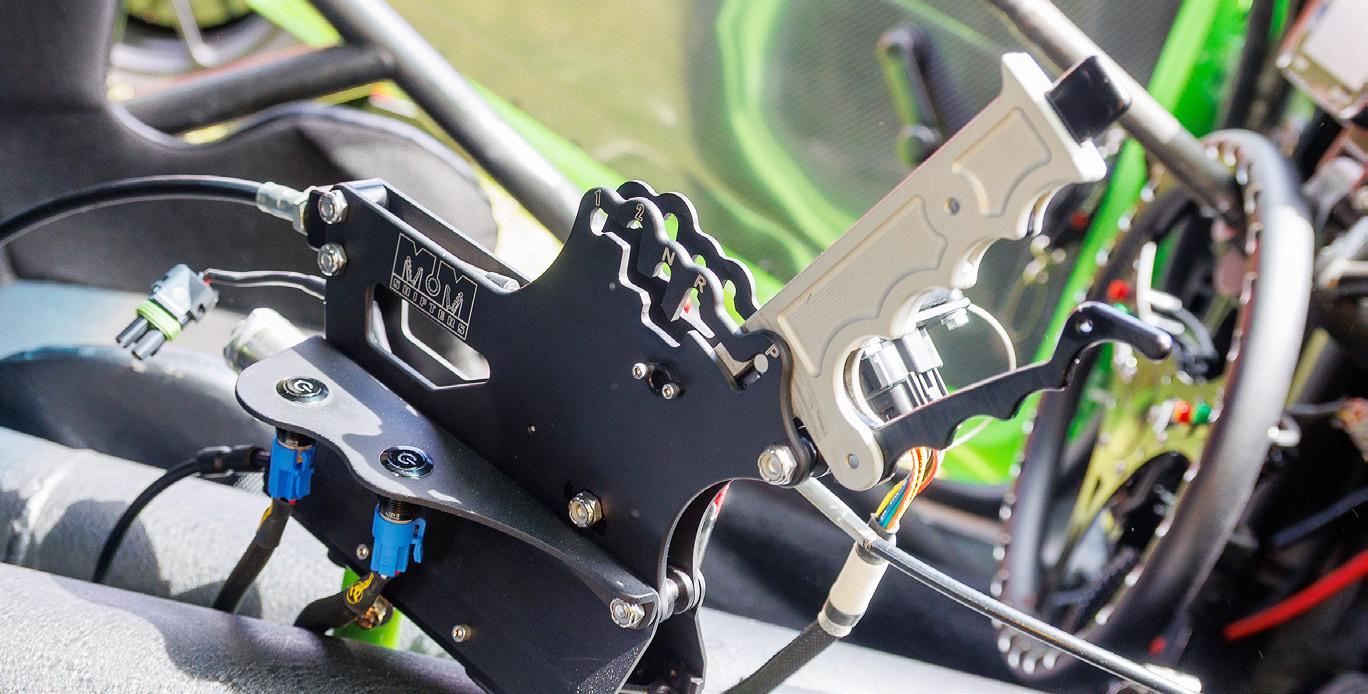

Some race-oriented equipment is required however, including the TCI billet shifter that actuates the gear changes of the hopped-up Turbo 350 with JW bellhousing, built internals, a manual valve body, and custom PTC torque converter.

Looking at the Nova you can tell that the stance has been altered a bit—not too low, but not high-inthe-sky stock, either. To achieve the desired ride height, Holleman used Landrum coil springs and QA1 double-adjustable shocks up front. At the rear, the Nova is still sprung with leaf springs, though they are Calvert Racing split mono-leaf springs with Caltrac traction bars. Another pair of QA1 shocks control the rear suspension actuation out back as well.

Rolling stock for this Chevy consists of rather sneaky looking custom, color-matched Rallye wheels with narrow pizza cutters for the front and wider versions out back. Holleman does have a set of Weld wheels for the Chevy as well that measure 15x4 up front and 15x8 inside the Nova’s narrow factory wheel wells. Behind the rims you’ll find upgraded factory brakes at all four corners.

...I learned so much from him before he passed and I am blessed to be able to own his first Nova build...

ANDY HOLLEMAN

The Brilliant Red Corvette color still looks great after all these years and there are seemingly no custom modifications to the body—it’s just as the Chevy designers intended it to be which is OK by us. On the inside, you’ll find a custom-covered and quite cozy bench seat providing the occupants comfort behind the factory steering wheel and dashboard. Basic, old-school upgrades here keep things simple and reliable for this “street” car, just as the TCI shifter performs flawless shifting.

Holleman purchased Holleman Hotrods from his parents in 2018, continuing the family business to this day. Sadly, his father was diagnosed with ALS in 2020 and passed away in 2021.

“I learned so much from him before he passed and I am blessed to be able to own his first Nova build,” Holleman said. “This was the first Nova my dad built, and I also own the last Nova my dad built called the Rivet Nova, which I also race. It has over 3,000 rivets hand placed by him. This Nova was the first one I rode in with my dad and that Rivet Nova is the last one I rode with him in.”

There’s no lack of personal attachment and sentimentality when it comes to Holleman’s Nova, and in 2023, he took on Hot Rod Magazine’s Drag Week and finished it, which was something he and his dad had always talked about doing.

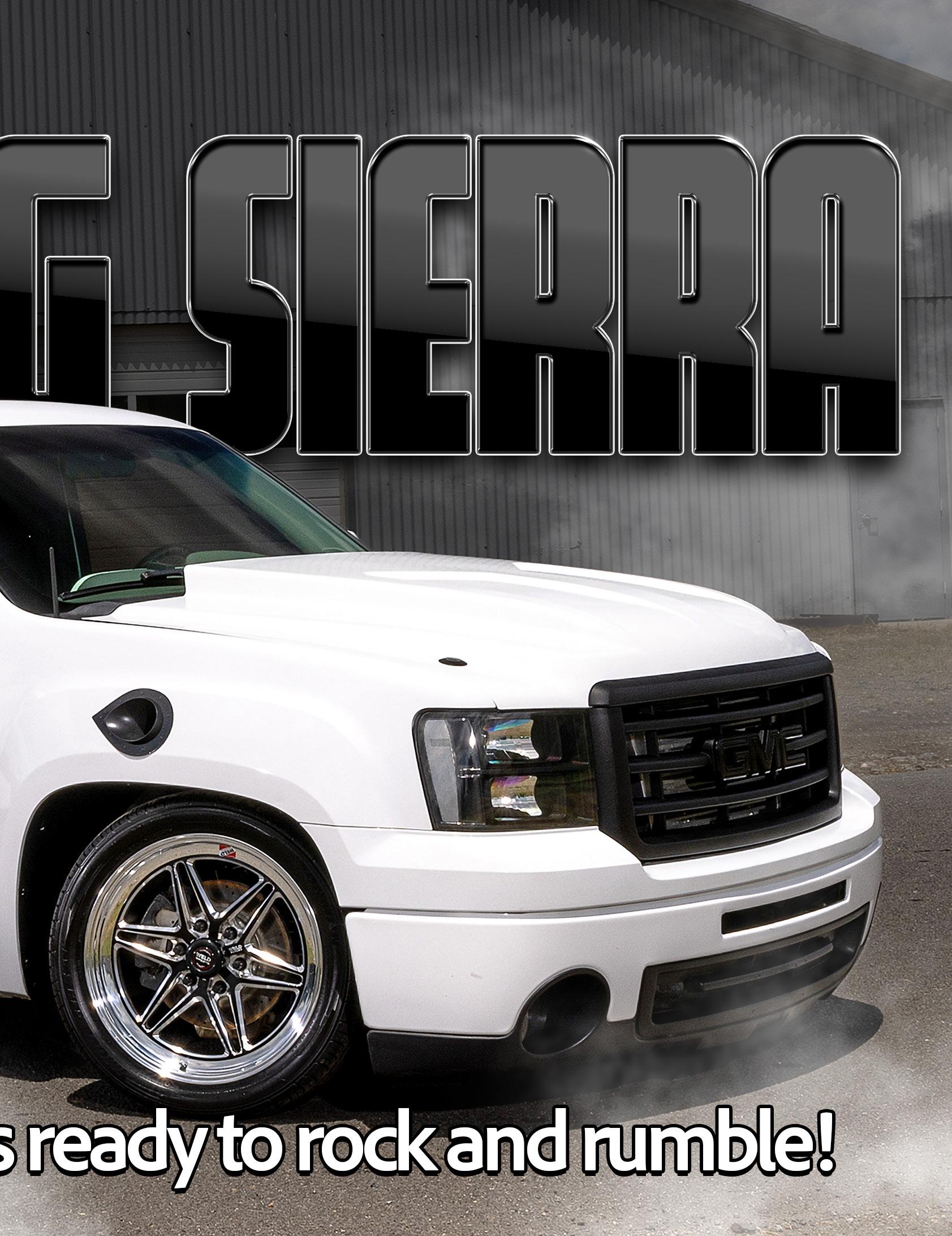

While square-body Chevy and GMC trucks from the 60s and 70s have become quite popular in recent years, their late-model brethren have as well, with the short-bed pickups of the 80s and 90s growing in interest to the point where companies like The Roadster Shop have forecast them to be the next hot trend and are fabricating entire chassis systems for them.

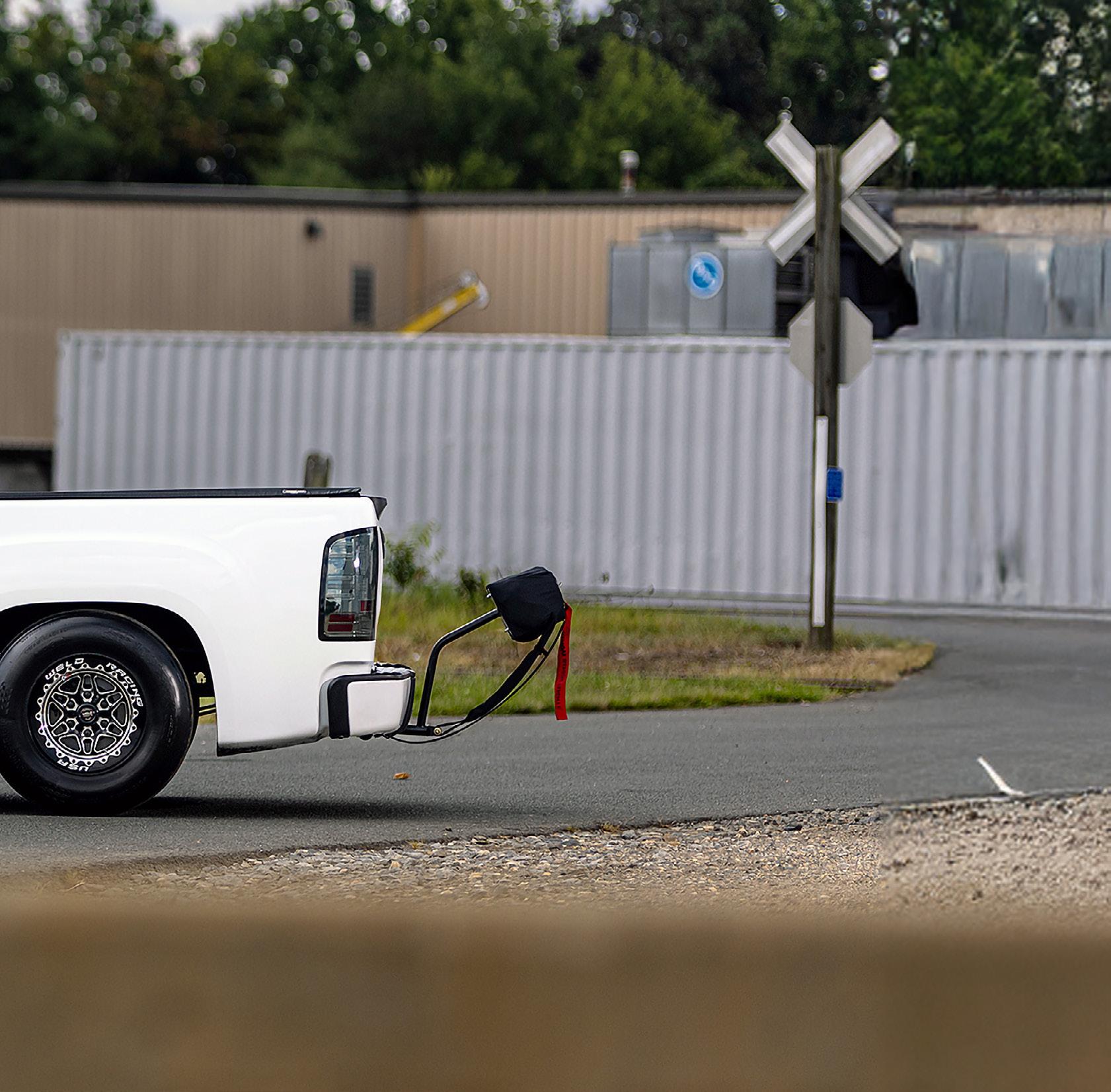

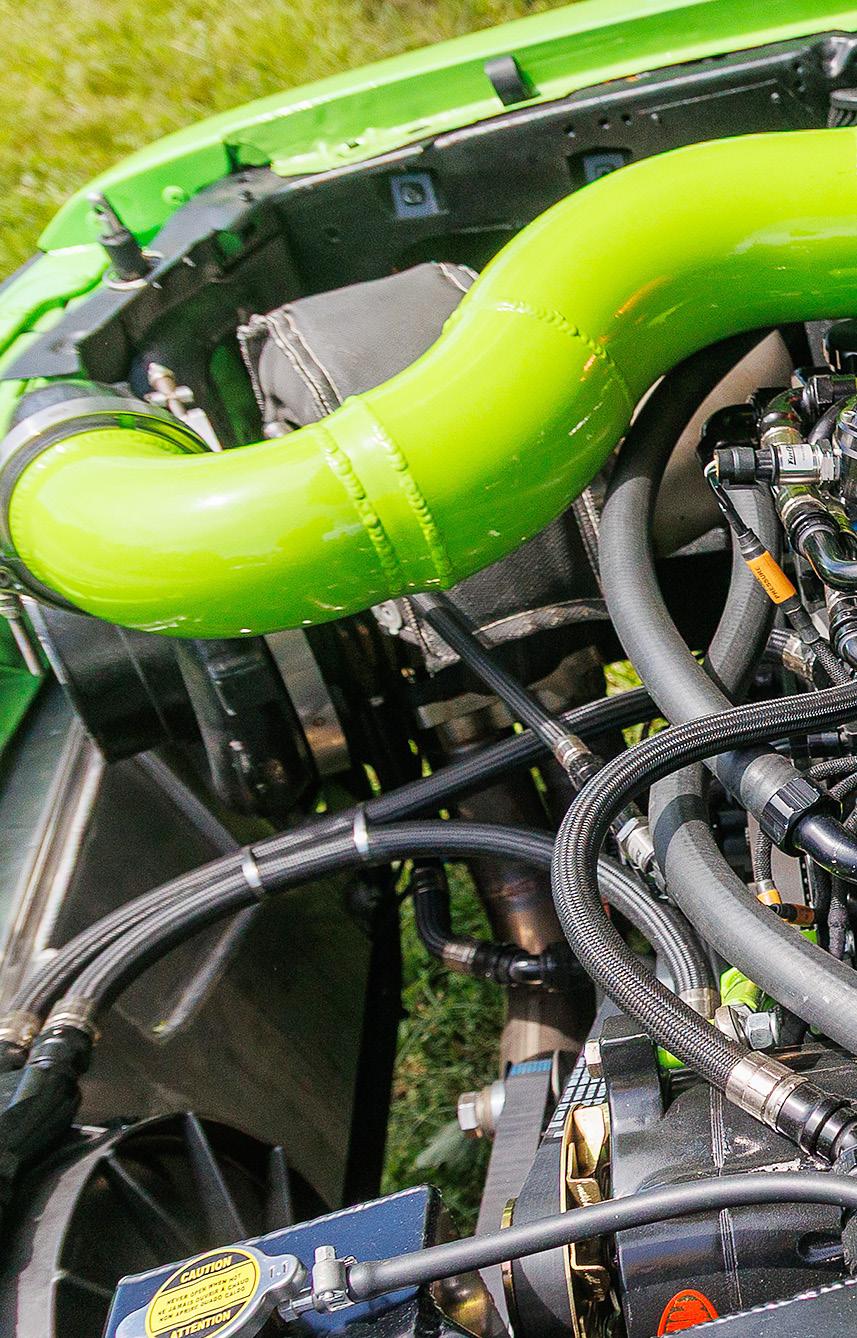

One perhaps overlooked, but certainly highly exciting, group of vehicles to keep an eye on are the LS-powered GMT800 and 900 series trucks from Chevy/GMC. Bobby Harris’ 2013 GMC Sierra you see here is a prime example of how enthusiasts are taking advantage of the LS-based powertrains of these trucks, and modifying them with the same enthusiasm and level of detail that you find in older variants.

Influenced by his father and his uncle, Harris found a hobby in hot rods and his first car was a ponycar, a 1985 Chevy Camaro. Later, after tinkering around with the ever-popular Fox-body and SN95 Mustangs for a while, he decided he wanted to do something different.

“I found the truck five years ago online,” Harris told us of the clean, stock truck that wasn’t for sale, but that caught his eye. “I messaged the guy and made him an offer he couldn’t refuse. After agreeing on a price, my wife and I loaded up the trailer and made a 9-hour road trip to pick it up.”

Bobby Harris wanted something different and even though his 2013 standard cab Sierra wasn’t for sale, he made the owner an offer he couldn’t refuse and drove 9 hours to pick it up!

Only an aftermarket hood was added to the original body of the standard cab, shortbed pickup. The required parachute hanging off the back and exhaust poking through the right fender clearly indicate that this is more than just your average hauler.

Harris noted that his latest project has undergone numerous changes throughout his ownership, starting with an all-motor, naturally aspirated engine build. From there it was easy to add a hit of nitrous and he ran

it in that configuration for a while until eventually finding his way to boost. Adding a turbocharger not only kept him from having to refill the nitrous bottle, but they make all sorts of cool noises, too.

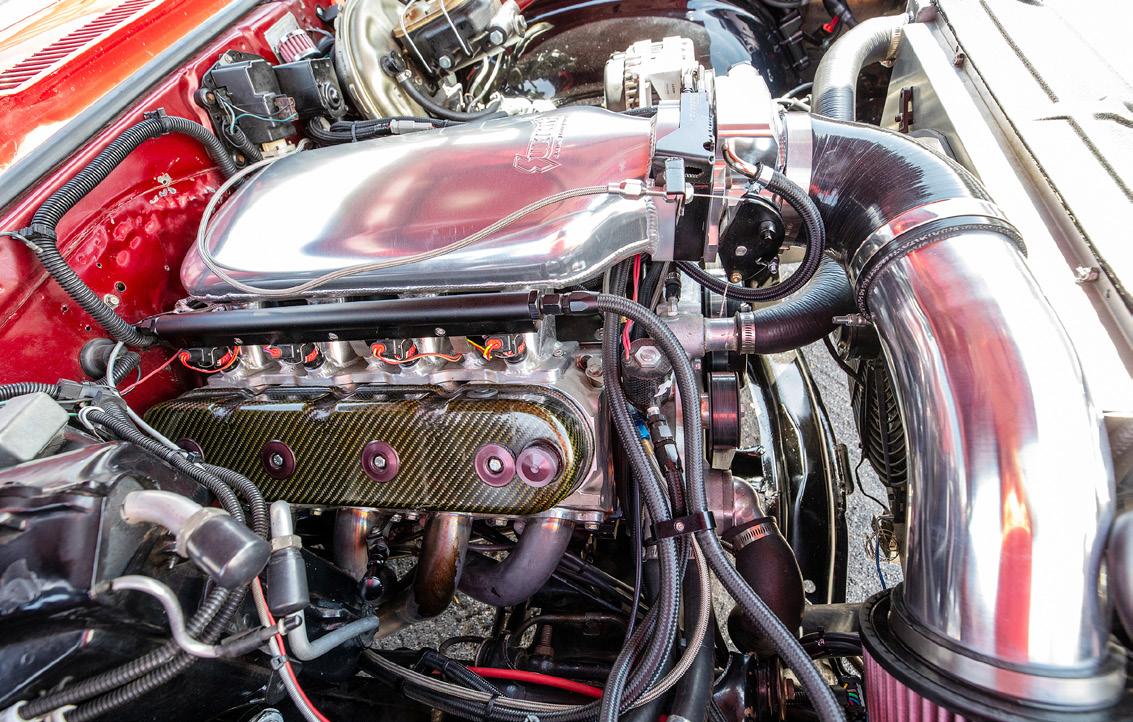

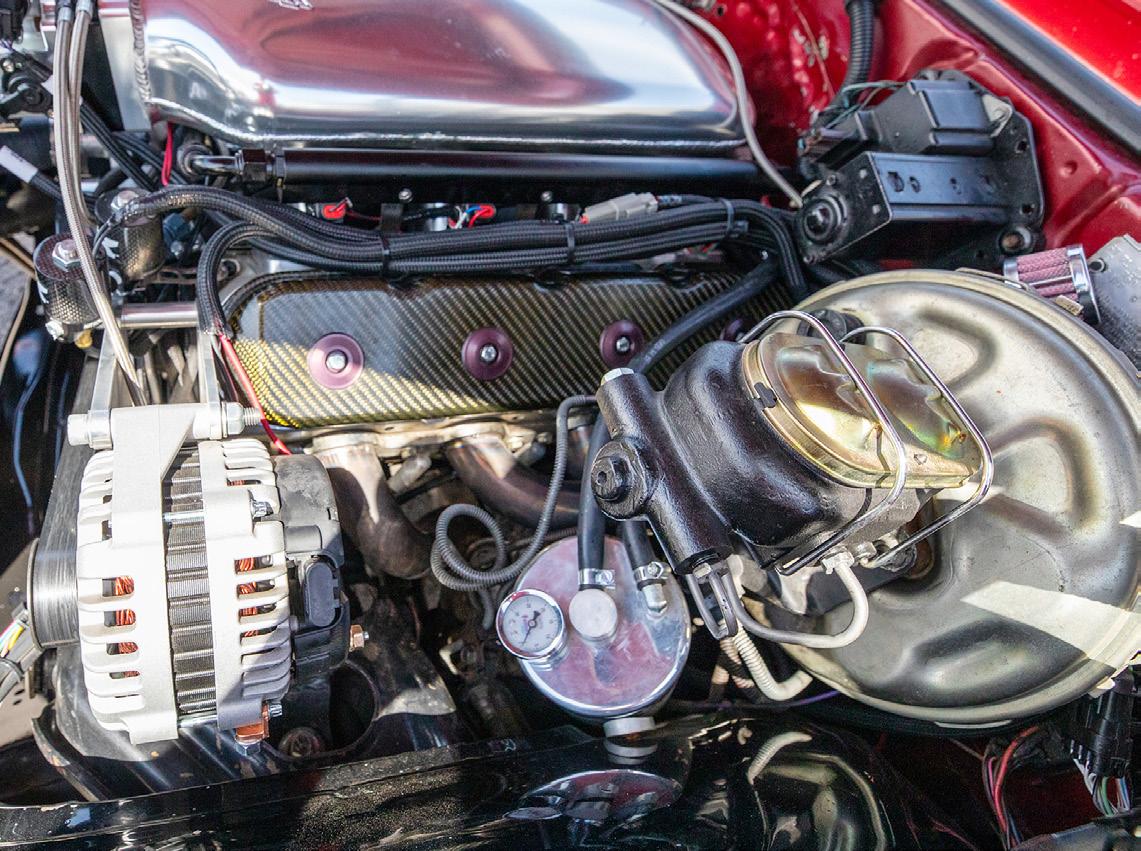

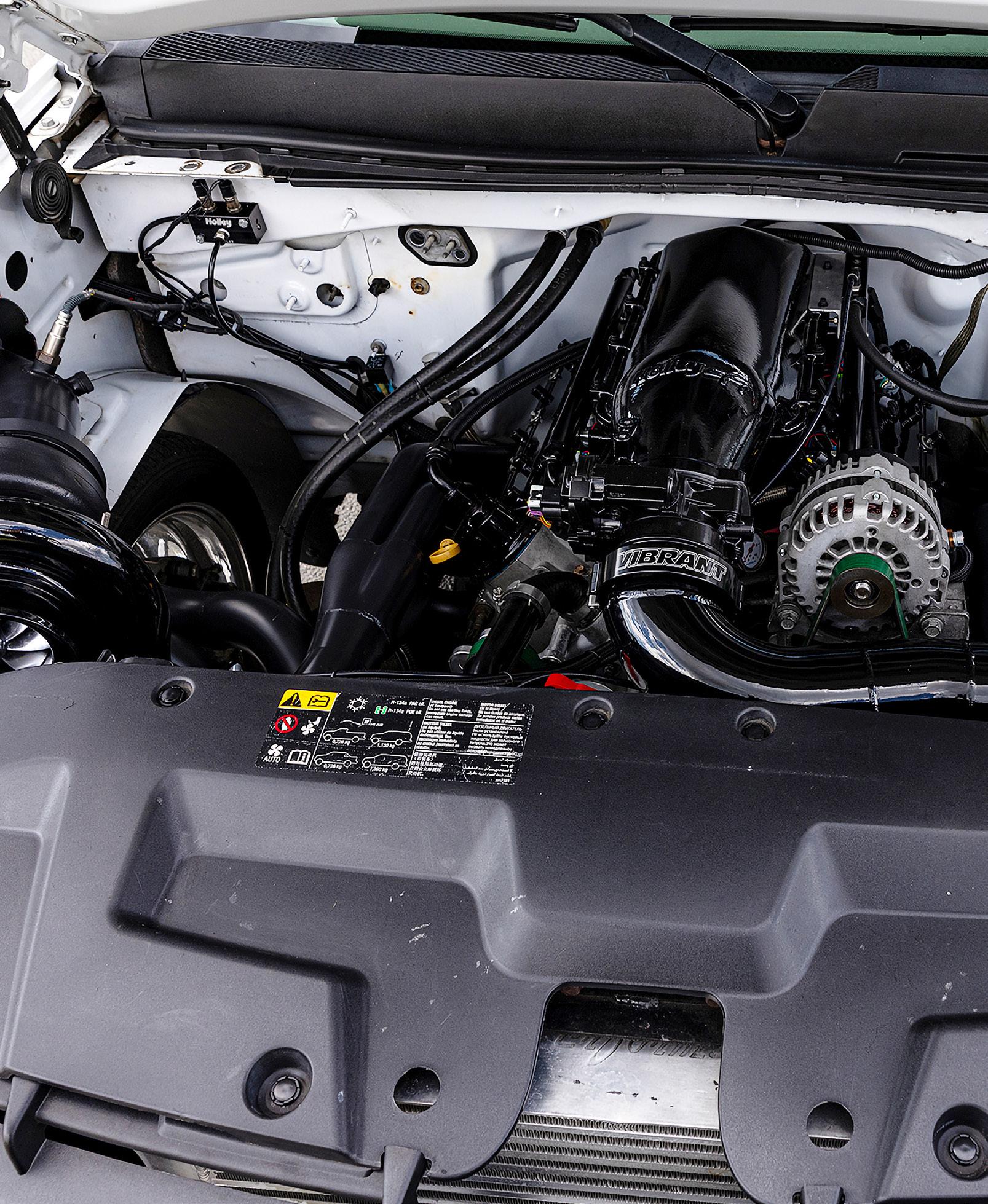

Currently, the GMC sports a Thompson Motorsports-built 400 cubic-inch engine based on a factory iron block. General Motors LSA aluminum cylinder heads and a Holley Hi-Ram intake manifold with a 90mm throttlebody top the LS powerplant that is fed compressed atmosphere thanks to a Forced Inductions 91mm turbocharger.

Harris wisely swapped out and added parts to aid in providing traction for the new power, including Viking Performance shocks at all four corners, an Atomic rear shock relocation kit and an anti-roll bar setup. A 10-bolt rearend was beefed up with a Detroit Truetrac differential, 3.73 gears and Yukon axles.

The bed of the truck holds the charge cooler, a sizeable fuel cell and battery, all mounted to the rear to add some weight over the axle to help with traction.

The 400-inch mill is based on a factory iron block. LSA aluminum cylinder heads were installed and a Holley Hi-Ram intake manifold with a 90mm throttlebody top the LS powerplant. The black coated engine parts not only contrast the white paint, but also give the appearance of a neat and tidy “factory” install.

Ensuring the air-to-air intercooled intake charge is complemented with the appropriate amount of fuel is a MagnaFuel pump pressurizing Bosch 210 lb/hr fuel injectors mounted to billet fuel rails as directed by the Holley EFI engine management. The entire underhood arrangement has been coated in a shiny black hue that perfectly complements the bright white exterior paint.

Body & Paint:

Single cab short box factory body with aftermarket hood. Factory white paint.

Chassis & Suspension:

Factory frame. Viking shocks front and rear, Atomic Fab rear shock relocation kit, with a Tin Soldiers anti-roll bar.

Engine:

370 LS Iron block, LS3 heads.

Induction & Fuel Delivery:

Bosch injectors, Magnafuel pumps.

Electronics: Holley EFI.

Power Adder:

Single turbo.

Transmission:

TH400, FTI converter.

Rearend:

10 bolt with a Trutrac 3.73 gears Yukon axles.

Brakes: Powerstop.

Tires & Wheels: WELDS 20X7 front, 15x10.5 Rear.

Interior:

Holley dash, Motion Raceworks shifter and parachute.

ET & MPH: It’s a no-prep and grudge truck.

Thanks To:

I would like to thank KML Performance for everything. And also big thanks to my friend Chris Lopez for all his hard work. I couldn’t have done it without them.

A 91mm turbocharger was plumbed in place to the right front of the engine bay and fuel is supplied courtesy of a MagnaFuel pump pressurizing 210 lb/hr fuel injectors mounted to billet fuel rails.

As good and reliable as GM overdrive transmission have become at the hands of aftermarket builders, Harris chose a Turbo 400 three-speed automatic transmission and coupled it with an FTI Performance torque converter.

Turbo 400s are as dura-

ble as transmissions come and will no doubt provide plenty of reliable and consistent shifts. Under the bed of the pickup you’ll find a 10-bolt rearend that has been fortified with a Detroit Truetrac differential and a 3.73:1 ring and pinion gearset along with Yukon axles.

While some often skimp on the suspension mods, Harris made choices that all but ensure his Sierra will plant the power to the pavement. Viking Performance shocks reside at all four corners, and Harris

uses an Atomic rear shock relocation kit for improved performance. With more beneficial damping, the Tin Soldiers Race Cars anti-roll bar makes sure that the truck leaves straight as an arrow.

The interior of the Sierra is mostly stock aside from the fully programmable digital display mounted in a custom face behind the steering wheel, a Motion Raceworks shifter, aftermarket transmission temperature gauge and controls and a Pioneer head unit for tunes. Harris tells us a legal roll bar has been added since our photo shoot.

Setting the stance and enhancing the pickup’s exterior aesthetic is a cowl induction-style hood and a wicked set of anodized, milled, and polished S81 HD wheels that measure 20x7 inches up front and 15x10.5 out back for the bead-

lock equipped versions. The hoops are the perfect match to the lowered ride height, and the turbo’s aggressive exhaust blatantly exits out the top of the passenger’s side front fender for that modern, street-performance look.

Harris upgraded the factory brake rotors and pads to Powerstop pieces for a little more grip when on the binders at the top end of the racing surface.

Inside the standard cab, short-bed Sierra you’ll find some customization that likely started with the aftermarket stereo head unit and trickled into the more racy components such as the interactive dash display, Motion Raceworks shifter, and aftermarket transmission temperature gauge and controls. More recently, and not pictured are a 10-point roll bar that envelops aluminum racing seats.

The shiny and crisp white paint was carried over to other parts of the Sierra thanks to

some friendly help and taking one look at the rig, it seems it’s ready for any no-prep or grudge event, which is what Harris plans to use it for.

The Woodbridge, Virginia, resident spent less than a year building this machine and wanted to thank KML Performance as well as his friend Chris Lopez for all his hard work.

While he may have wanted to do something different by choosing his Sierra, modifying this era of trucks is now trending thanks to Harris and others like him who dare to choose the path less travelled.

Let’s

Despite a last name that might insinuate he’s riding a tractor and managing crops, Matt Farmer is a residential and commercial remodeler and entrepreneur based in Barnhart, Missouri.

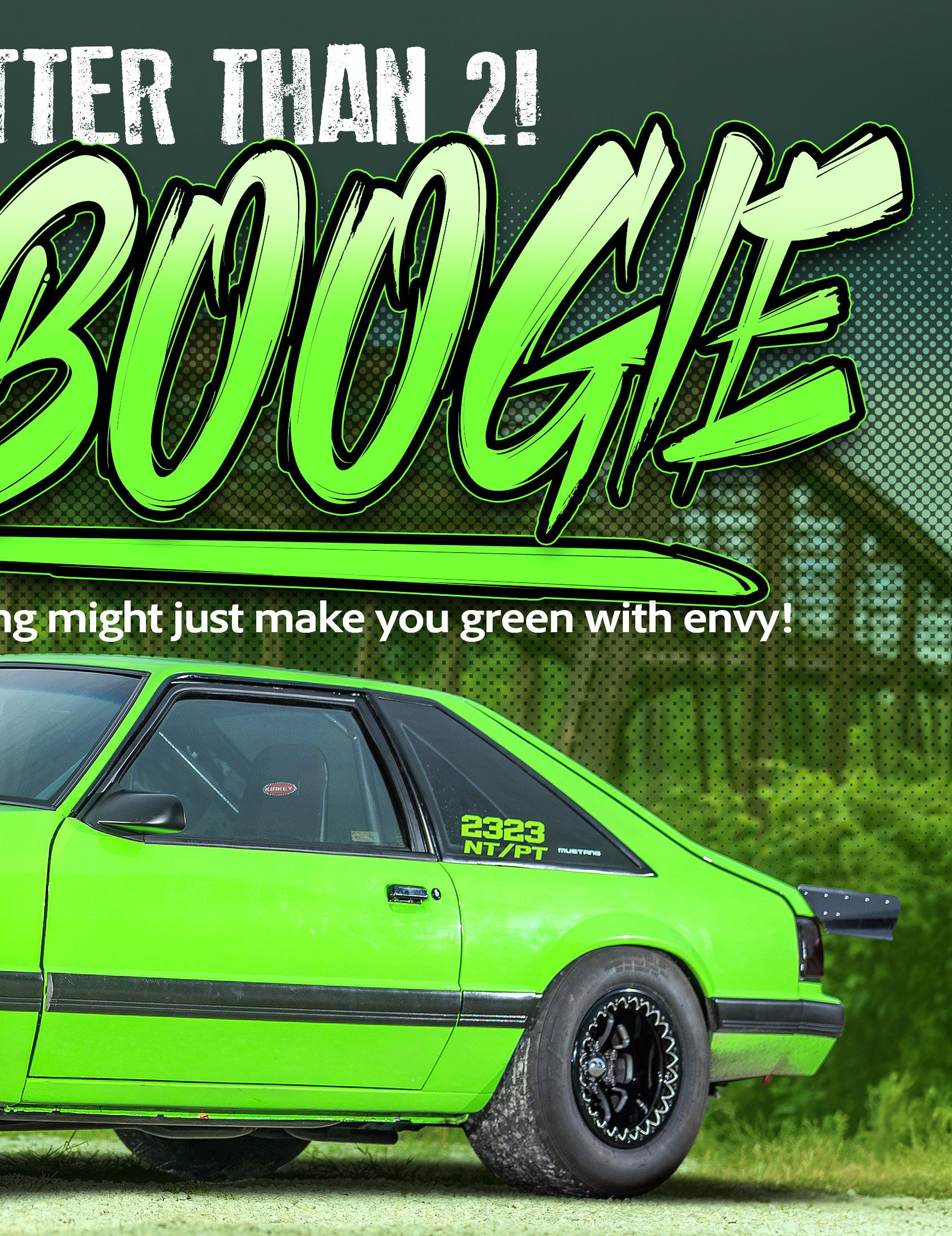

He’s also a remodeler of Mustangs having had numerous in various configurations to date. This 1986 hatchback here is his latest fixer-upper and in addition to its eye-catching appearance, it packs a serious, turbocharged punch.

The owner of Famous Construction LLC grew up with a father who worked on cars as a side hustle. In his early years, Farmer had a growing interest in both mini and mighty trucks. Things changed, though, when he bought his first Mustang in 2001. The racing bug bit, and numerous Mustangs and engine combinations later, Farmer’s latest is a turbocharged beast.

“I bought this car from a friend, Andy Wilhoit, 13 years ago” Farmer explained. “When I bought it, the car hadn’t run in a few years and was a 393 Windsor with a fogger and a C4. I got it running and sprayed it a few times and that was enough for me to want to change the combo.”

Farmer’s friend, Joey Mays, helped him re-wire the Mustang and also fabricated the turbo system that was based around a Borg Warner S480 turbocharger blowing through a C&S carburetor.

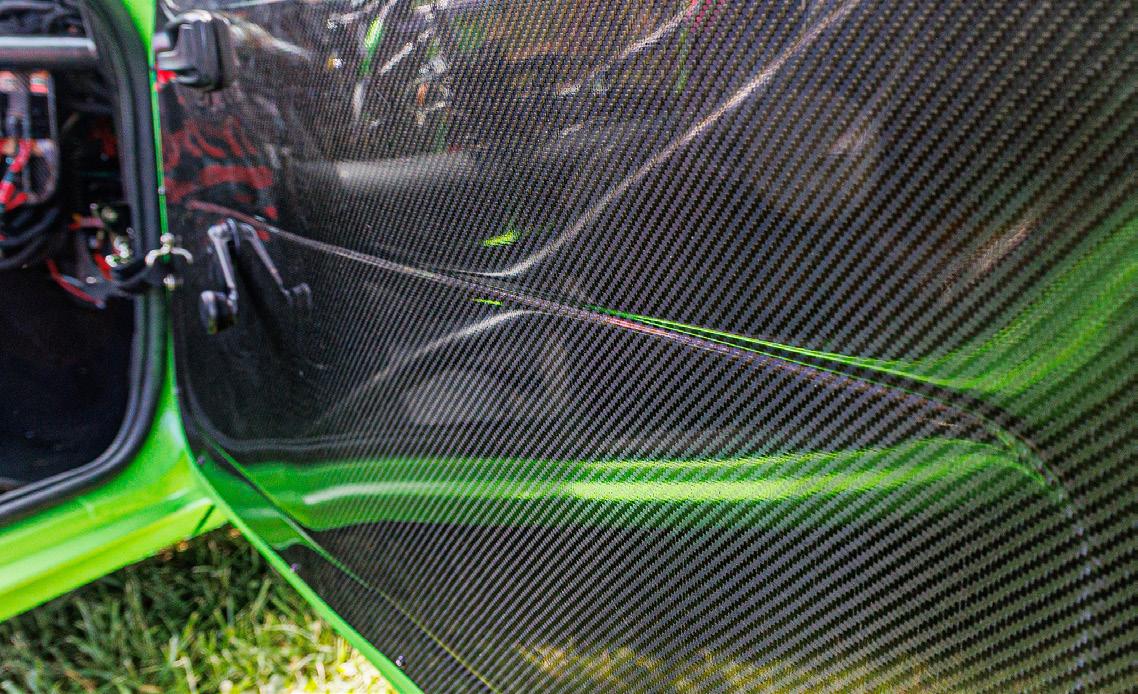

Oogie Boogie is a true 4-Eye 1986 Mustang and retains its original steel body tub. An HO Fibertrend 4-inch hood and fiberglass doors were installed along with a Team Z rear wing and a Scott Rod wiper-less cowl panel.

The Fox Body platform Mustang is obviously a wise choice for drag racing, just take a look in the pits at any given event, however the 1979 to 1986 version, now known as “4-Eyes” because of their headlight configuration, have become insanely popular for street and strip builds over the past 5 years or so.

Oogie Boogie rolls on 15x4 Champion

Stripster wheels with Mickey Thompson ET Street rubber upper front and 15x12 double-bead-locked rear wheels with 28x10.5 Pro bracket radials. Custom disc brakes sit behind the hoops at all four corners.

Later, Farmer converted the carbureted air/fuel management system to an MS3 Pro EFI that he used to control a 347ci powerplant with a GT55 turbocharger. When the head gaskets refused to contain the cylinder pressure, Farmer sidelined the project for about a year before

he formulated a new plan.

“My friend Brandon Carter had bought a motor from Dave Zimmerman from Team Z that was sitting on a stand,” Farmer recalled. “We worked out a deal and I started working towards a game plan to get the car back together.”

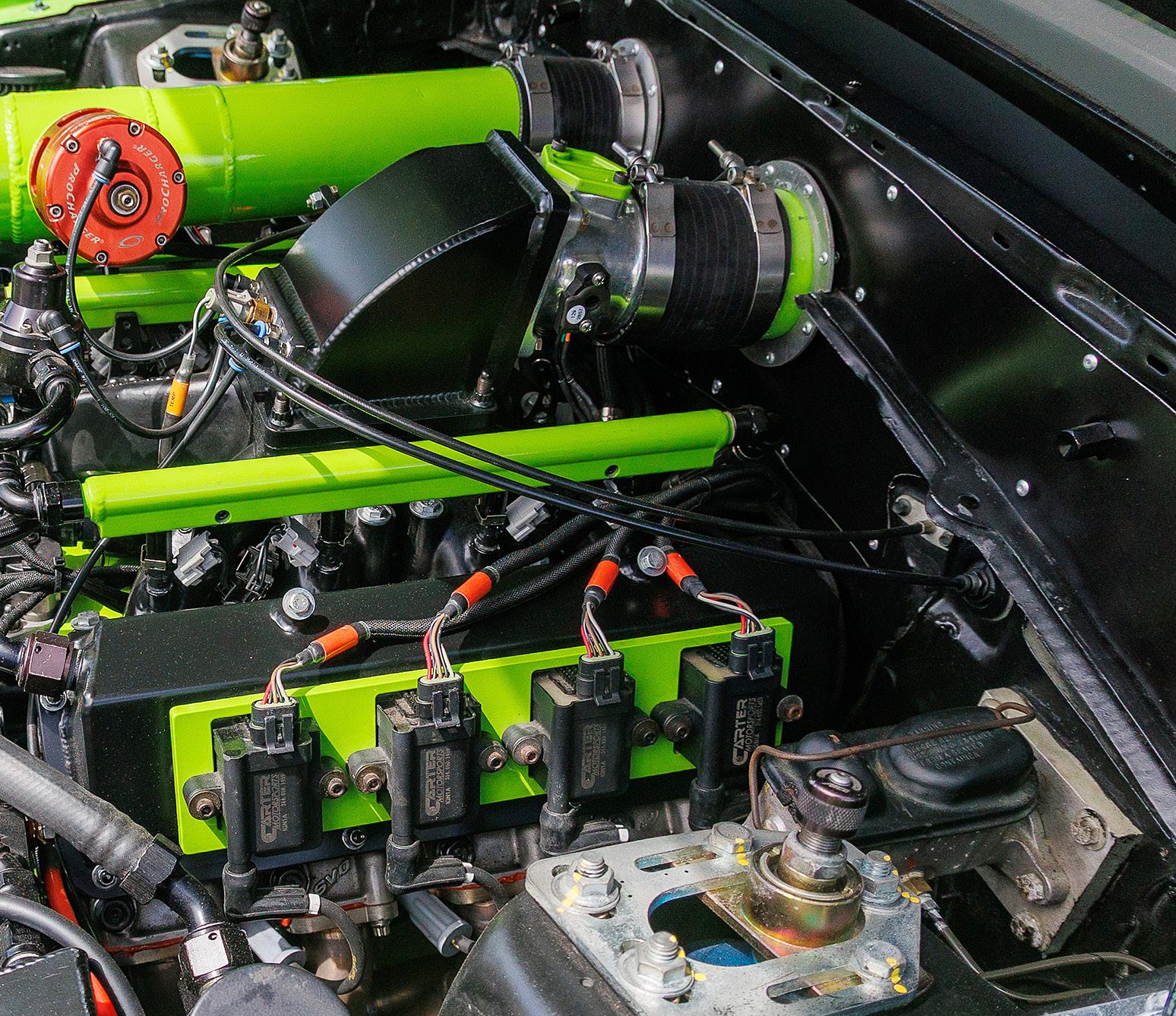

The new engine program was based on a Ford Racing Boss 8.2-inch deck height block. It was stuffed

a Bryant Racing crankshaft, Oliver billet connecting rods and Diamond Racing pistons and is lubricated

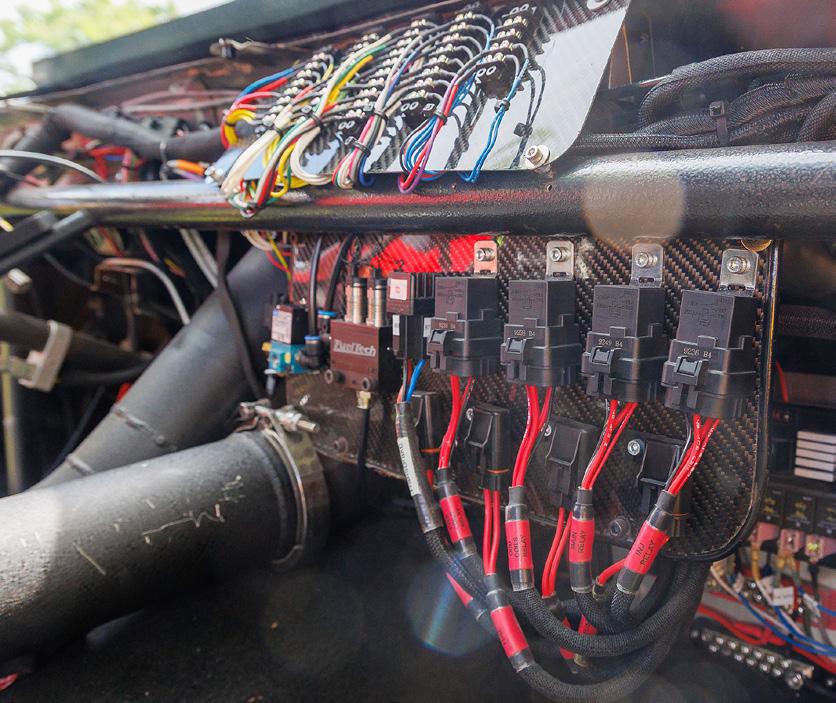

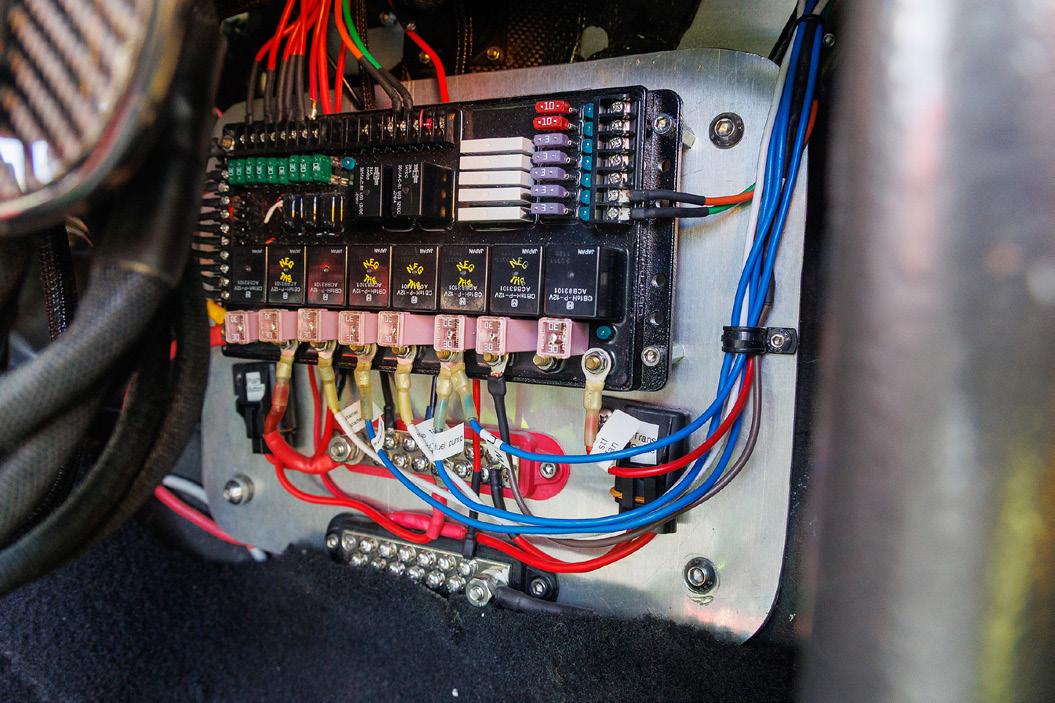

That game plan took about 4 years to execute and the Mustang underwent some major changes during that time. Farmer sourced numerous components from Carter, who owns Carter Motorsports, and he contracted Evans Wiring Solutions to clean the copper threads up and wire in a FuelTech FT600 ECU.

oil pump.

A Garrett In Motion GT55 98mm turbocharger is paired with a Precision PT2000 intercooler and Jim Hallowell with Xtreme Muscle Cars did the custom headers, front radiator mount, cold side and motor plates.

Body & Paint:

Custom Picked color green, painted by Luke at Sixtos Autobody.

HO Fibertrend 4in hood and fiberglass doors with roll up windows.

Team Z wing.

Scott Rod wiper cowl.

Hyper Performance carbon door panels.

Custom Lime Green color.

Suspension:

Outlaw K member from Team Z.

Team Z 1 inch shorter A arms.

Stiletto rack.

Mencer dbl adjustable AFCO struts.

AFCO big gun shocks.

Racecraft lower control arms.

Mega Bite Jr upper control arms.

Tin Soldiers anti roll bar.

Aftermarket caster camber plates.

Engine:

Ford Boss block 8.2 deck.

Yates C3 heads ported by HRD Al Dixon.

Jesel shaft mount rockers.

Titanium valves.

Diamond pistons.

Oliver rods.

Bryant crank.

Custom Ford Racing intake.

Manton 3/8 pushrods.

Jesel timing belt.

Custom cam from Disomma Racing Engines.

Carter Motorsports 210lb fuel injectors.

Custom 10an fuel rails from Linear Fabrication.

Carter Motorsports ignition coils.

Firecore spark plug wires.

Aeromotive 12gal belt drive fuel pump.

Moroso single stage oil pump.

Power Adder:

Garrett gt55 98mm turbo.

Precision pt2000 intercooler.

Fueltech FT600.

Fueltech Nano Pro controls all the switches to run the car.

Transmission:

JW-cased Powerglide with 1.80 straight cut gears

rebuilt by Greg at Transmissions To Go in Arnold MO.

Hughes dump valve.

PTC converter.

M&M shifter.

Rearend:

8.8 braced and narrowed.

3.55 gears.

Moser axles and spool.

Wheels:

Champion Stripster.

15x12 double beadlock 28x10.5 M/T Pro Bracket Radial.

15x4 front wheel M/T ET Street Radial.

Interior:

Racequip harnesses.

Race seats.

Firebottle 5lb fire suppression .

Larry Jeffers steering wheel with quick release.

Motion Raceworks mono cord adapter.

Simpson parachute with Motion Raceworks handle.

Mags Fab Worx fire handle mount.

HFR Fabrication Nano Pro mount and 2 button switch mount.

ET & MPH:

Best to date is 5.70@ 124 on 11.5lbs in the 1/8 and coasted to 8.90@144 letting off at 8 seconds in the run on only the 3rd outing on the car.

Unique Features:

The most unique feature is the color.

Build Timeline:

Took roughly 5 years in this current form to build this time.

Most Memorable Moment(s):

Was my wife riding with me 6 months pregnant with our daughter while holding the laptop as we were trying to get the drivability right.

Thanks to:

So Many people to thank. First and foremost my wife and kids for the late nights working on the car and sitting at the car shows and track long hours with me. I listed most but Jon Huber (tuning the MS3 Pro), Scott Lowery (tuning the Fueltech), Ben Stum (installed anti roll bar and made custom oil drain) and helped do different things on the car over the years. Garrett Shelton, Gene Crain, Danny Brouk and Mike Kotraba for all the help at track outings. Also Big thank you to Jeremy Mifflin for always pushing me to keep making changes and getting the car to where it is now.

Ooogie Boogie is all Ford under the hood with a Ford Racing Boss 8.2-inch deck height block stuffed with a Bryant crankshaft, Oliver billet connecting rods and Diamond Racing pistons and lubricated by a Moroso single-stage oil pump. A pair of ported Yates C3 cylinder heads with Titanium valves, Jesel shaft-mount rocker arms, and Manton pushrods were studded in place. A custom-spec cam calls the valvetrain shots and a tricked out Ford Racing intake manifold was matched with a custom elbow and sizeable throttle body.

Post-race videos on

Bolted to the deck surfaces are Yates C3 cylinder heads that have been ported by HRD Al Dixon. They’ve been fitted with Titanium valves, Jesel shaft-mount rocker arms, and Manton pushrods. A Jesel timing

belt timed by a DiSomma Racing Engines custom camshaft actuates the valvetrain so the incoming air charged from the customized Ford Racing intake manifold gets to the combustion chambers efficiently.

Wiring a modern fuel injected car with a power adder can be a daunting task, so Matt tapped Evans Wiring Solutions to clean the copper threads up and wire in a new ECU. He also chose to opt out of any type of dash cover and instead keep everything fully accessible.

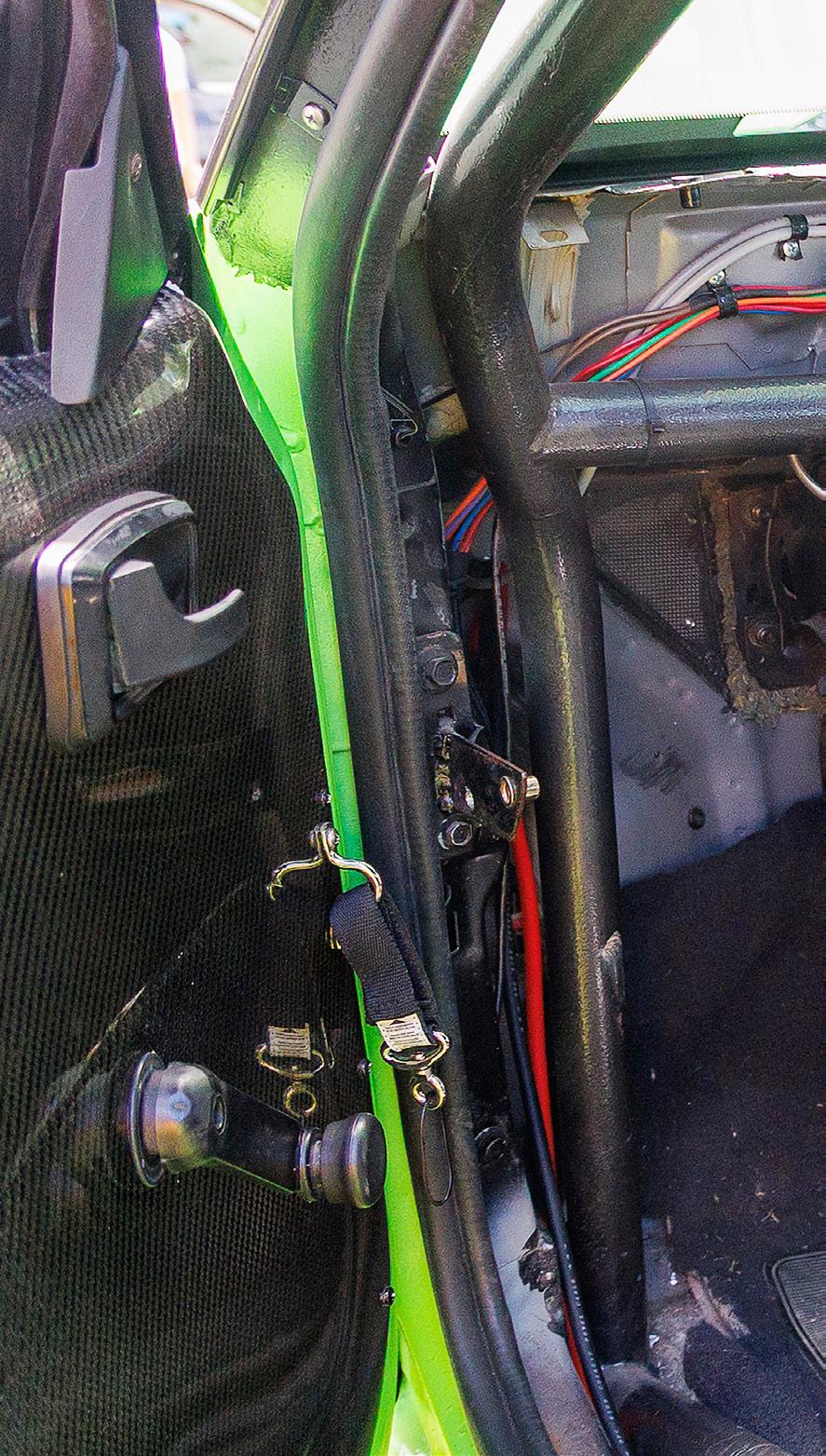

There’s little to nothing left of the factory interior inside the Mustang. Instead, held within the confines of the cage you’ll find a custom dash panel integrated with the cage crossbar providing easy access to all wiring, a pair of racing seats, a Motion Raceworks shifter controlling the shifts of the built JW-cased Powerglide, Hyper Performance carbon fiber door panels, and a quick release Larry Jeffers Race Cars steering wheel.

After the fuel flows from the belt-drive pump and into the Linear Fabrication fuel rails, Carter Motorsports 210lb/ hr fuel injectors dispense the gasoline and the air/ fuel mixture that is lit off by an

octet of Carter Motorsports IGN1A ignition coils and Firecore spark plug wires. Farmer kept the Garrett In Motion GT55 98mm turbocharger and paired it with a Precision PT2000 intercooler.

“Jim Hallowell with Xtreme Muscle Cars did the custom headers, front radiator mount, cold side and motor plates,” Farmer told us. “Sutton Mcgee with Linear Fabrication got all the accessories mounted to the motor plates.

He also had to cut the intake in half and fabbed up a new flange to mount the custom-sized elbow and valley tray. Sutton also has helped set up the suspension on the car as well as other custom pieces that were needed.”

Mini tub work was completed by Jeremy Mifflin who also worked on the rear coil overs and mounting the factory fuel tank back in the car and allow the hatch space for a cooler tank and battery.

Keeping the Mustang planted to the pavement is a Team Z Outlaw K-member and A-Arms, aftermarket caster/camber plates, and Menscer Motorsports double-adjustable AFCO struts. Out back, the stock-suspension-styled setup consists of AFCO Big Gun shocks and an 8.8 rearend packed with Moser Engineering spool, axles, and Ford Racing 3.55 gears. Managing the rear axle is a pair of HP Megabite Jr. upper control arms, Racecraft lower control arms, and a Tin Soldiers Race Cars anti-roll bar. Stiffening the unibody chassis and providing the necessary safety struc -

ture for on-track use is an Albert Ruck-built 8.50-certified roll cage. A Fire suppression system was installed and Racequip harnesses and a Simpson Racing parachute all play their part in providing adequate safety measures.

On the inside of the Fox Body you’ll find a pair of aluminum bucket racing seats, a Motion Raceworks shifter controlling the Transmissions To Go-built, JW-cased Powerglide transmission with PTC torque converter, Hyper Performance carbon fiber door panels, and a quick release Larry Jeffers Race Cars steering wheel.

“Jeremy Mifflin helped do the mini tub, rear coil overs and mounting the factory fuel tank back in,” Farmer said. “Brad Kruckeberg with Wagon Wheel Performance helped with all the Redhorse fuel lines and fittings. Sean Eckman and Travis Ludwig did all the power coating at King coatings.”

If there is one thing you can’t miss on Farmer’s Mustang, it’s the wickedly vivid, custom green paint that his wife picked out. Sixtos Auto Body laid down the sweet hue, and while the Mustang had always been a shade of blue, the new green hue inspired Farmer’s wife to name the car “Oogie Boogie.”

The Mustang’s exterior appearance deviates from the factory thanks to an HO Fibertrend 4-inch hood and fiberglass doors, a Team Z rear wing, and a Scott Rod wiperless cowl panel.

An Outlaw K-member and A-Arms, aftermarket caster/camber plates, and double-adjustable AFCO struts were installed up front. Out back, the stock-suspension-styled setup consists of AFCO Big Gun shocks and an 8.8 rearend packed with Moser Engineering spool, axles, and 3.55 gears. Managing the rear axle is a pair of HP Megabite Jr. upper control arms, Racecraft lower control arms, and a Tin Soldiers Race Cars anti-roll bar.

knock, knock, knockin’ on seven’s door...!

The wicked stance of the Mustang is due to numerous suspension mods to aid in keeping the car planted during soon-to-be 7-second hits in the quarter (Matt’s best as of a few months back was 8.008 at

Rolling stock for the pony consists of Champion Stripster wheels measuring 15x4 up front with Mickey Thompson ET Street rubber and 15x12 double-bead-locked rear wheels with Mickey’s 28x10.5 Pro bracket radials. Custom disc brakes sit behind the hoops at all four corners. Farmer’s best run to date in Oogie Boogie is a 5.142 at 137.58 mph at the 1/8, and 8.008 at 170.19 at the quarter-mile clocks. So he’s definitely knock, knock, knockin’ on seven’s door!

“It hasn’t been an easy road to get here, with lots of headaches from the car being in body shop jail for a year to hurting parts all while trying to get out testing and make passes,” Farmer said. But his most memorable moment in the car so far occurred off-track when his wife was helping him work on the car while being six months pregnant and holding the laptop while they nailed down the drivability and tune-up.

RPM

Article first appeared in the February 2021 digital issue.

RPM MAGAZINE Reprint IN Print!

RPM MAG’s commitment to features that appeared digital-only since June 2020.

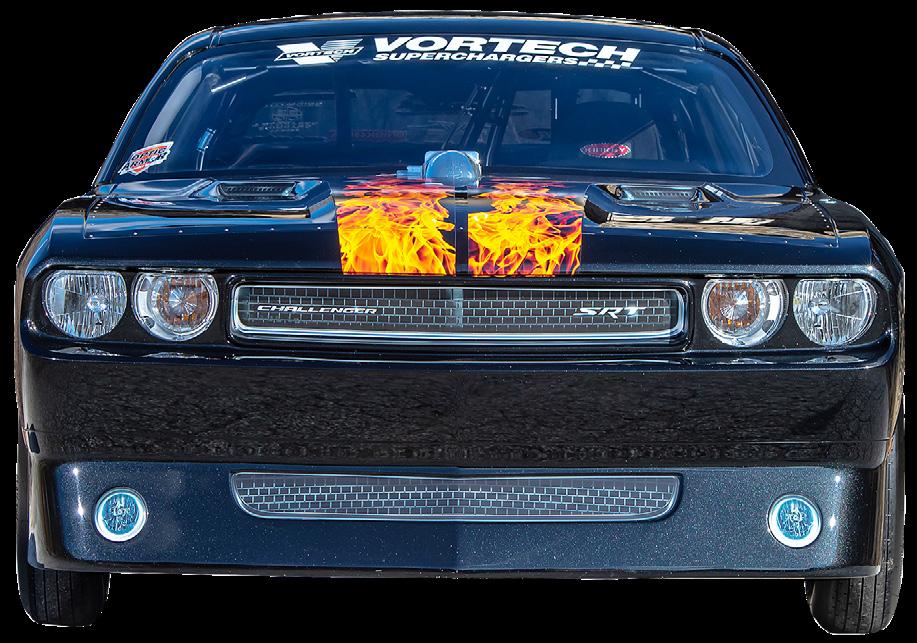

Back in 2010, Newark, Delaware’s John Reed bought a pristine 2009 Challenger with just 7500 miles on it from a local Dodge dealer. His plans were to bolt on a few goodies and street drive it, yeah, sure, how did that work out for you John?

“I was looking for a stick shift non sunroof car and the original plan was to lower it, put wheels and exhaust on it. Well, that lasted a few months, at least I think it was that long,” Reed said with a chuckle. Next up was nitrous and most anything else Reed could find to bolt on the Mopar. “Let’s just say I got the bug for racing again,” he added. Something he had lost with the passing of his dad in 2006. The pair had run a 1971 Dodge Demon over the years, so it’s safe to say that Mopar roots were well set early in life for John.

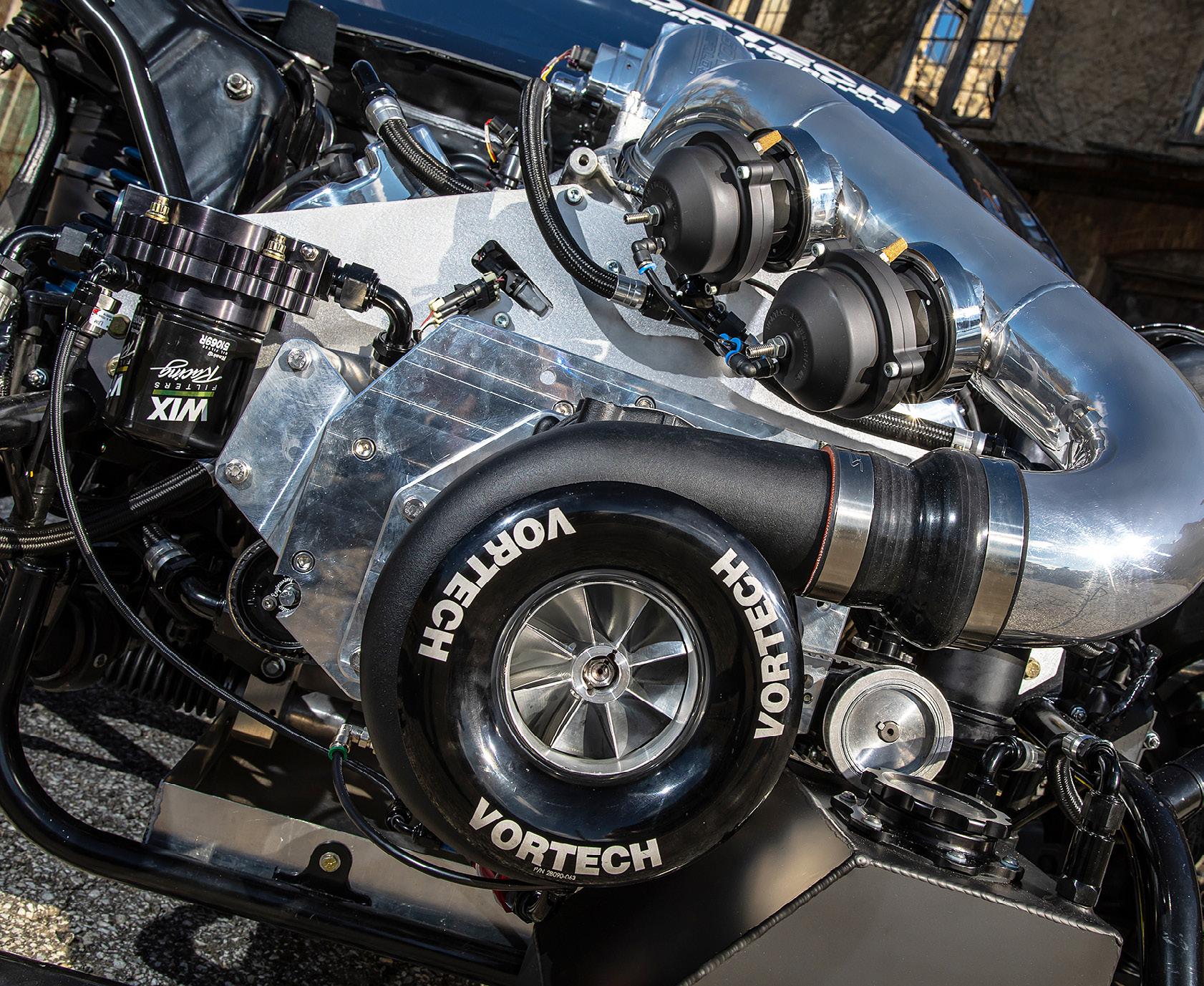

A Hyundai Master Mechanic by day and horsepower junky during off-hours, John soon had the Challenger running 11.0s, which made way for a more serious effort involving a stroked 394ci mill that Reed got his first taste of forced induction with when he in-

stalled a Vortech supercharger on it and made 1000+hp to the wheels. This work added a whole new dimension to street driving the Challenger, which eventually became the turning point from street/ strip to making it a dedicated small tire drag car.

The Challenger retains its OEM steel roof and quarters, but Reed had Rhodes Custom Auto work a fiberglass front end and doors into the mix.

Make no mistake this factory looking small tire Challenger is a serious contender, running 4.60 in the 1/8th-mile and easy mid-sevens in the 1/4.

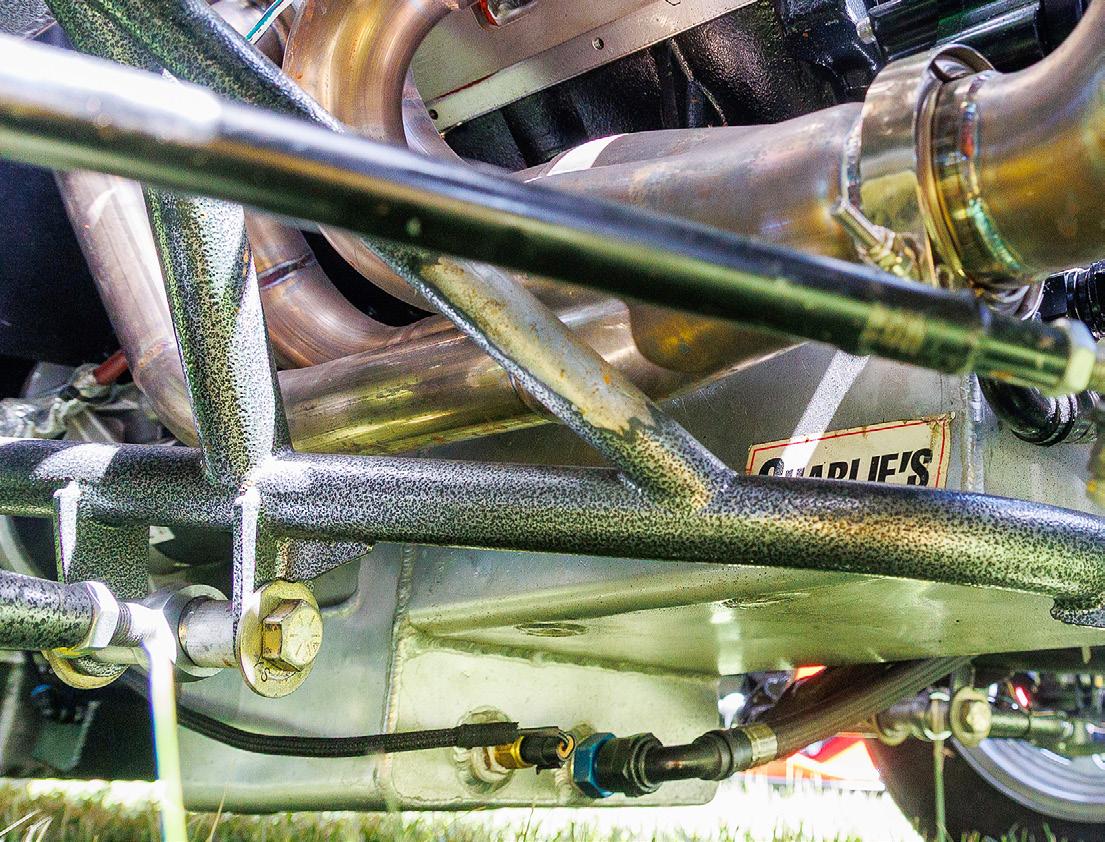

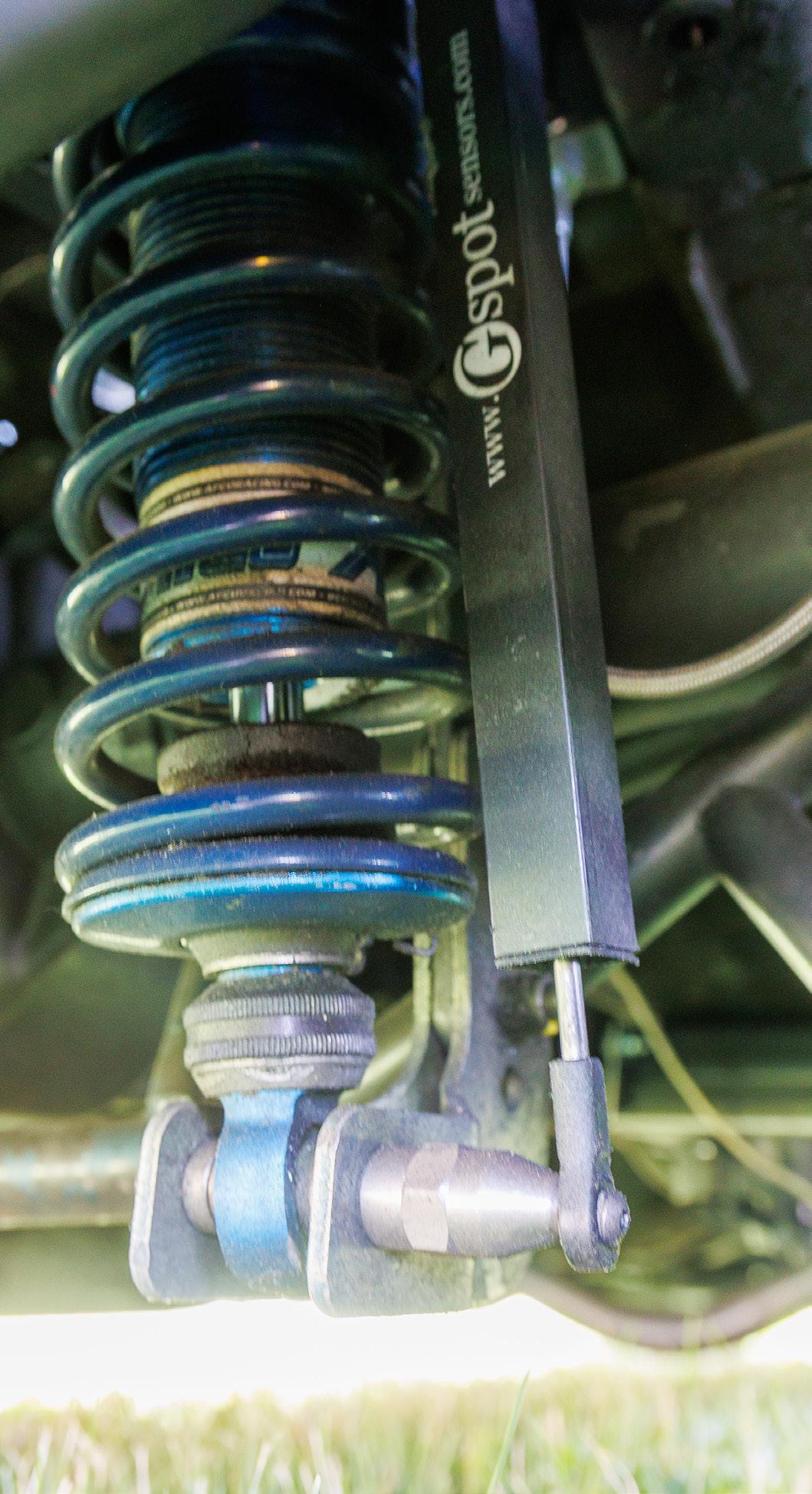

Along the way, John created Reed Motorsports where he sells Menscer suspension parts and sets up cars, something that has helped motivate him towards his goals with his own car. First up, Reed had RPM Transmissions build a TH400 and his buddy Frank at The Driveshaft Shop set him up with an IRS 9” kit with cv axles and a carbon driveshaft that would take the power when the car hooked hard at the strip.

Reed now had an 8-second car and became the first IRS Gen3 Hemi in the 8s, and to top that off won that same event he set the record at.

By 2017, a new goal of being the first in the 7s with this platform was set and some

big changes were part of the formula to get there. “I like thinking outside the box,” said Reed. “Especially when people say something can’t be done.”

Rhodes Custom Auto created the 25.3 cert chassis along with the

fiberglass front end, doors, dash and the stunning paint work on the car. Suspension was upgraded as well, but most of all the power combination was completely retooled by Billy Briggs Racing Engines.

“The first time back out, actually while doing my licensing passes, I went an 8.23 at 160mph to reclaim the record. Then, at the end of 2018 on the second pass out at an ATCO event, we went 7.82 at 178... we did it!” Reed added with a smile.

2019 saw Reed try running the car in a new Ultra Street Series at Cecil County Dragway, and it was the best decision he had ever made.

Old Is New if you haven’t read it yet!

Each month we host some of our past issues of RPM Magazine in this section. If you haven’t read them yet, they are new to you! If you have, maybe there’s a favourite car/story you want to read again….here they are!

NOVEMBER 2017 NOVEMBER 2016

CLICK A COVER OR SCAN A QR CODE TO GO BACK IN TIME!

NOVEMBER 2022 NOVEMBER 2019

Reed is a diehard Vortech fan and this monster gear driven version helps push the power to 1600-plus at the rear wheels!

He qualified at every event and ended up 6th in points with a best 1/8th mile ET of 4.87. “Man that was the most fun I had racing in years!” he exclaimed. “After that, it was time to upgrade!” During 2020, considering racing would be reduced, Reed reworked his combination with what he describes as “a beefier version of the last one with a little more thinking outside the box”. The most recent mill is a stock-block Billy Briggs built 426ci Gen3 Hemi with Winberg crank, GRP aluminum rods and Gibtec pistons.

Chassis Type & Mods:

Stock floors and frame rails with 25.3 certified cage.

Suspension:

Stock style front and stock style rear IRS suspension with Menscer Motorsports coilovers, BMR suspension arms and bushings.

Body & Paint:

OEM steel roof and quarters with fiberglass doors and front end that look stock with lights. Has true fire flames in factory style stripes on hood.

Engine:

426ci Gen3 hemi (stock block), Thitek cylinder heads and only running 8 plugs. Built by Billy Briggs Racing Engines.

Rotating Assembly:

Gibtec pistons, GRP aluminum rods and Winberg crank.

Induction:

Modified Mopar Drag Pack intake with a Wilson elbow and DBW throttle-body.

Power Adder:

Vortech supercharger v30/94 gear drive.

Electronics:

Holley EFI

Transmission & Converter:

2 speed th400 from RPM Transmissions, Coan converter.

Rear Differential:

9” IRS differential with CV axles from the Driveshaft Shop

Other Important Vehicle Information:

It was the first IRS Gen3 hemi in the 7 second zone with a 7.82. Holds the Gen3 IRS records in 60ft, 1/8 and ¼-mile.

Best ET & MPH:

1/8-mile 4.69 at 153mph and ¼-mile to date is 7.59 at 145 coasting from the 1/8. Makes 1600+hp to wheels.

Division/Class Run: Ultra Street

Thanks To:

I would like to thank all the people that helped me: My uncle Joe Truszcienski and Scott Chalfant who always has my back and works on the car with me. George Weicker who makes sure I’m always lined up in the groove. Darcy Kyle for always supporting everything I do. Craig Thibeau for being my go to guy with my ideas and cylinder heads. My buddy Dan Leazier for welding when needed. Brian Ellis with Vortech Supercharger, Jack French of Billet Atomizers, Frank Rehak from the Driveshaft Shop, Frank Steadman at BMR Suspension, Mark Menscer of Menscer Motorsports, Trevor Manton at Manton Pushrods, Rodney Massengale at RPM Transmissions, Dale Heiler and Dennis Moore for helping me learn how to tune a car. Also, thanks to Joe at Deters Custom Finishing for all the polish work under the hood.

Thitek cylinder heads (8 plugs) are mated to a modified Mopar Drag Pack intake with a Wilson elbow and drive by wire throttle body.

That out of the box attitude also included a switch from the belt drive Vortech YSI to the Vortech V30/94 gear drive, switching from gas to methanol and having a 2 speed TH400 with Coan converter built to back it up.

The current combination is good for just north of 1600hp to the rear wheels! Getting parts was definitely an issue last year, so it was late in 2020 when John got back behind the wheel, but the wait was worth it.

You’re looking at the first IRS Gen3 Hemi in the 8s, and then smashing that when it hit the seven second zone late in 2020.

On just the 3rd hit the Challenger went 4.69 at 153mph with a 1.18 60ft; “I was just creeping up on the power to get data, so there’s a lot of potential there to go really fast,” Reed said of the latest results.

As this new year unfolds, there’s no doubt that the tracks of the world will resume a more usual pace and new builds will hit the asphalt throwing down record after record in the wake of an usual 2020.

For Reed, though, he turned those Challenging times into better times for his supercharged small tire Challenger, and did so before a year most would rather forget even ended!