HIGH PERFORMANCE MINERAL DRAG RACING OIL

Mineral based engine oil designed to enable maximum power while providing ultimate protection under the most severe race conditions.

• Unique friction modifier system enables maximum power output

• “Stay-in-place” chemistry and 2X Zinc anti-wear system provide lasting protection

• High quality base stocks enable effective ring seal

• Advanced, proprietary additive system keeps your engine clean

• Designed to prevent separation caused by fuel dilution

• Available in 50WT, 60WT & 70WT

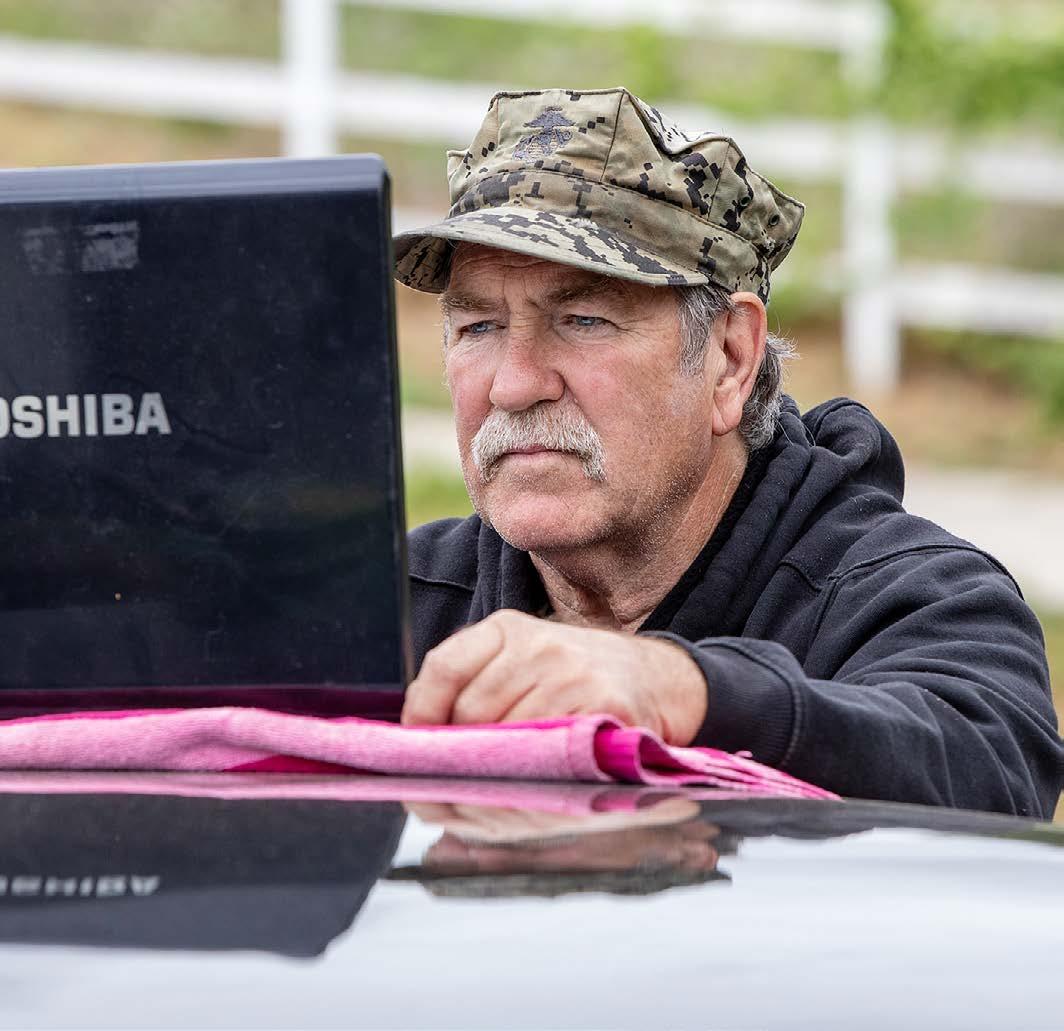

EDITOR-IN-CHIEF

CHRIS BIRO editor@rpmmag.com

V.P. MARKETING/CUSTOMER RELATIONS TRISH BIRO trish@rpmmag.com

EVENT MEDIA events@rpmmag.com

EVENT SUBSCRIPTIONS COORDINATOR SHERRIE WEBER sherrie@rpmmag.com

ART DIRECTOR .......................................................... JIM McHARG

Photographic Contributions: Mark - Godragracing.org, George Pich, Louis Fronkier, Blake Farnan, Jerry Garrison, Eddie Maloney, Wes Taylor, Steven Taylor and Amber Hynes

RPM Magazine is a REGISTERED TRADEMARK of Revolution Publishing & Media Inc. RPM Magazine is a worldwide motorsports publication distributed online.

To subscribe to RPM go to www.rpmmag.com or email Trish Biro at trish@rpmmag.com, or call 519752-3705.

The focus of RPM is to bring a diverse mix of high performance street and race automobiles to life within its pages including race cars, muscle cars, hot rods and street legal machines with an emphasis on the “EXTREME,” including fast doorslammer and outlaw forms of drag racing. Not familiar with these types of cars? They are considered to be the top-shelf of the industry and are on the edge with regard to design, performance, and power!

RPM Magazine does not sell its mailing list or share any of the confidential information regarding its subscribers.

Editorial Contributions:

Chuck Scott, Mark-Godragracing.org, Tim Biro, Stan Smith, George Pich, Jay Misener, Eddie Maloney, Wes Taylor, Steve Baur

Technical Writing Contribution: Chuck Scott, Shane Tecklenburg, Tim Biro and Jay Misener

For advertising information contact

TRISH BIRO ............... 519.752.3705 ................ trish@rpmmag.com

Special Events Manager: Chris Biro events@rpmmag.com

Special Events Sales: Trish Biro: 519-752-3705 trish@rpmmag.com

Subscriptions/Address Changes: Circulation circulation@rpmmag.com

General Inquiries: 519.752.3705 info@rpmmag.com

RPM Magazine has been a world leader in motorsports publishing for 26 Years and has support locations in Ontario, Canada, Alabama, Texas, and Virginia, along with contributing writers and photojournalists worldwide.

If you have a story that may fit within the focus and scope of RPM Magazine’s coverage, please email our Editor In Chief at editor@rpmmag.com. Submission of an article does not guarantee that it will be published.

Revolution Publishing & Media Inc. (RPM) / RPM Magazine IS NOT responsible for errors or omissions in ANY advertisement or article. Advertisements may be rearranged or altered at the sole discretion of RPM to allow the ad to fit in the space purchased by the advertiser.

WE RESERVE THE RIGHT TO REFUSE ANY ADVERTISING WHICH WE CONSIDER TO CONTAIN MISLEADING, OFFENSIVE OR FALSE INFORMATION. REPRODUCTION OF ANY INFORMATION HEREIN IS STRICTLY PROHIBITED WITHOUT PRIOR WRITTEN CONSENT.

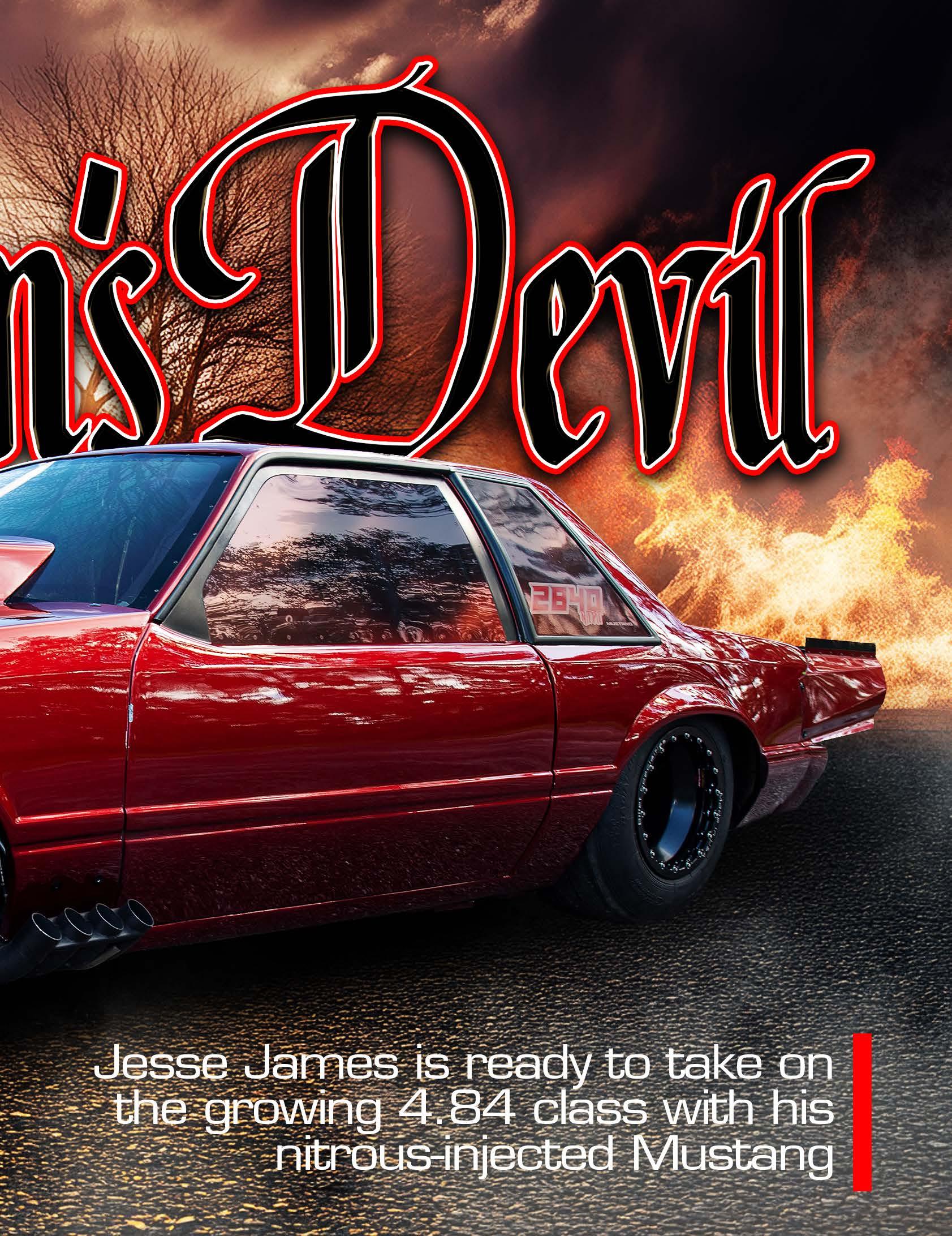

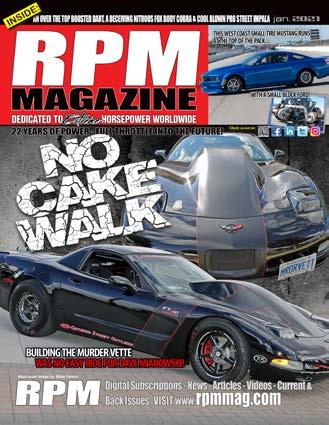

There is no shortage of racers or race cars to fill the ranks of the classes, and that means the competition is plentiful and tough as nails. With this new build, Jesse James is ready to once again throw his hat in the small-tire ring.

Like many Floridians in their early 20s, James got behind the wheel of his first Mustang in 1996. He started hitting the local test-and-tune nights at Orlando Speed World Dragway and once the speed bug bit, he began modifying his Mustang to make it quicker and faster.

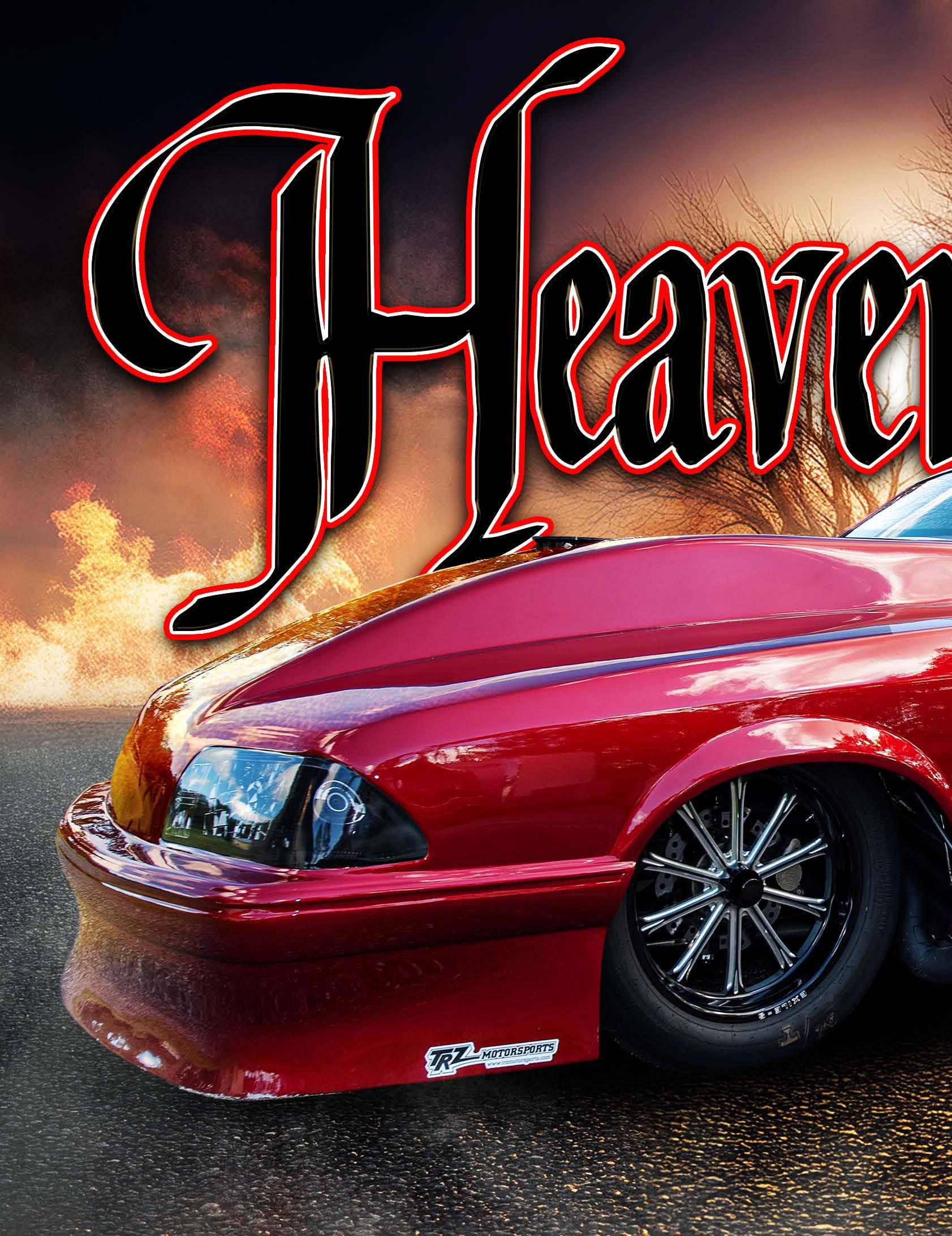

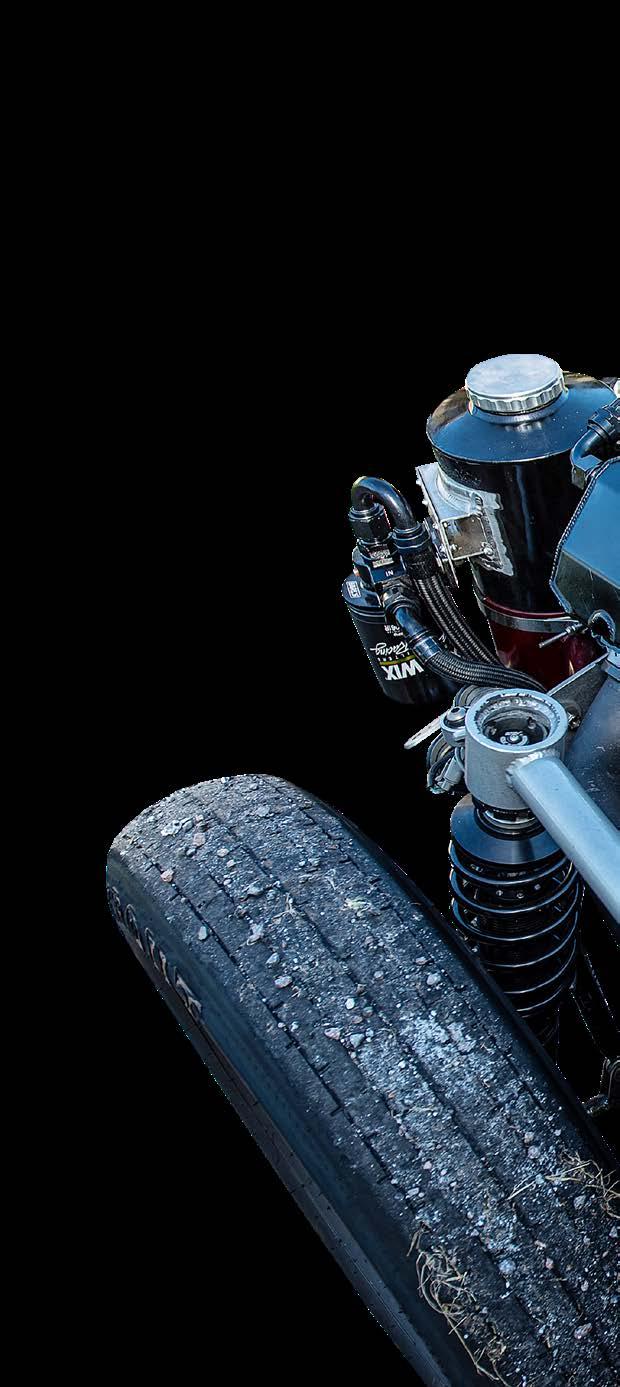

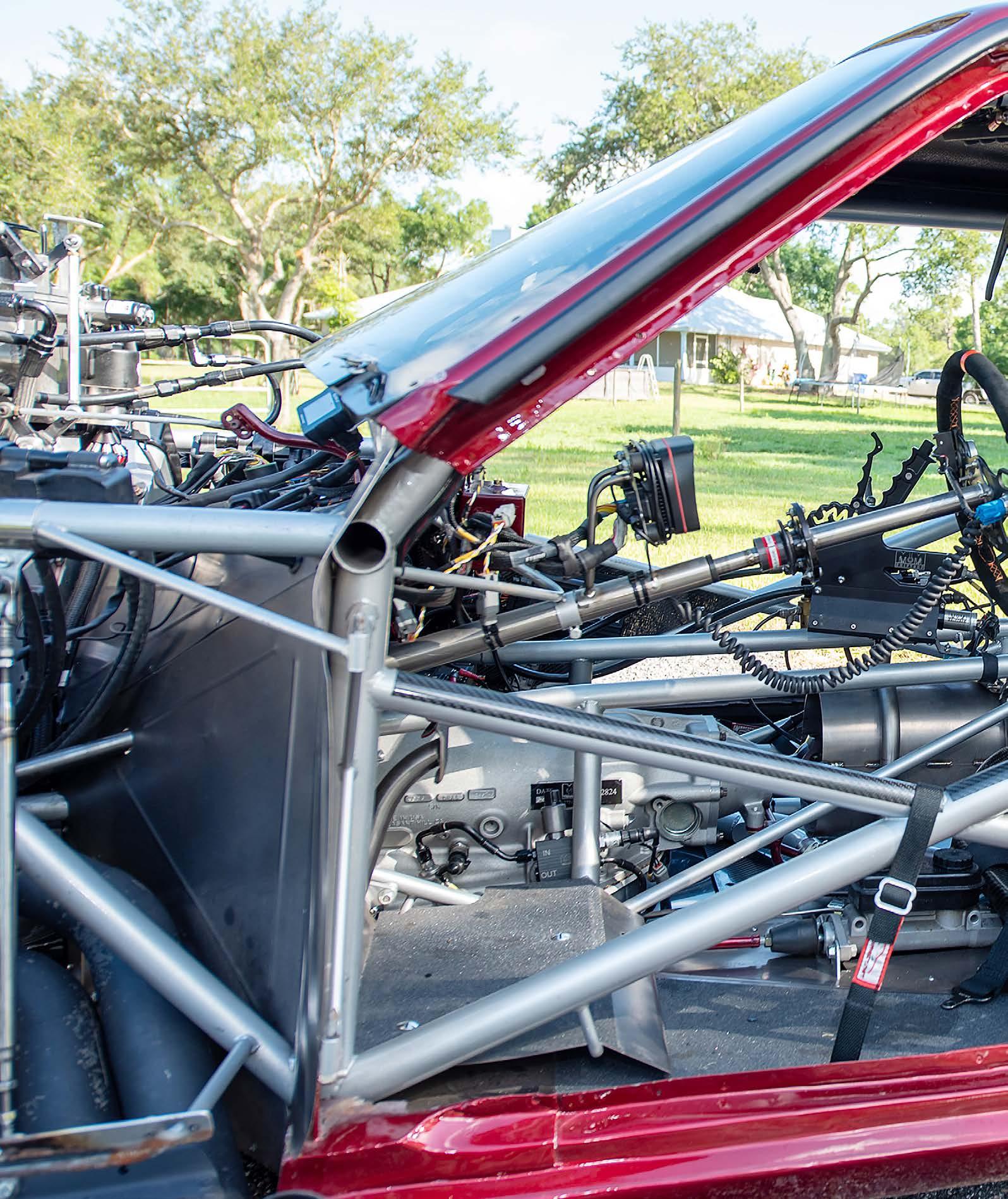

While it started out as a typical hot-rodded Fox Body, Jesse James’ Mustang Coupe now sits low and mean thanks to a full chassis and custom suspension by Ricky Chassis Shop in Melbourne, Florida, as well as Corey Blackmon.

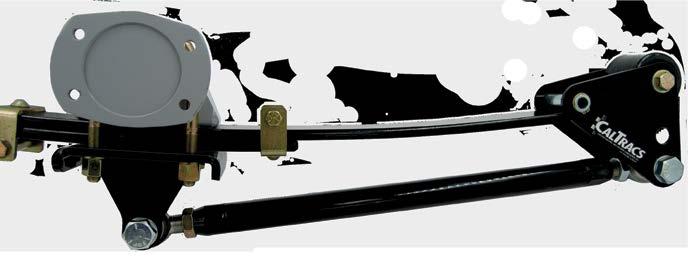

The Original Patented CalTracs Traction System

Complete bolt on system: no mods, cutting, welding, most applications

Keeps axle from rotating, maintains pinion angle

Eliminates spring wrap up

Pre-load adjustability

Durable powder coated finish

Detailed Illustrated Installation Guide

Custom sets available,

Turn your LS into a legend in its own time with Trick Flow GenX® 280 HIP cylinder heads. These ultra-performance HIP’d (Hot Isostatic Pressed) castings are significantly stronger than regular heads and include many other outstanding features such as:

• Industry-leading airflow

• 280cc CNC Competition Ported intake runners

• 87cc CNC Competition Ported exhaust runners

• Manley 2.165" Severe Duty intake/1.600" Inconel Extreme Duty exhaust valves

• Trick-Alloy™ powdered metal valve guides

• Trick Flow by PAC Racing dual valve springs

• Clearance for 3/8" pushrods

• .750" decks

• 6-bolt-per cylinder mounting

• LS3 rocker stands included with assembled heads

Engineered for Performance!

New heads are just one part of the Serious Horsepower formula. To complete it, you’ll need some more components.

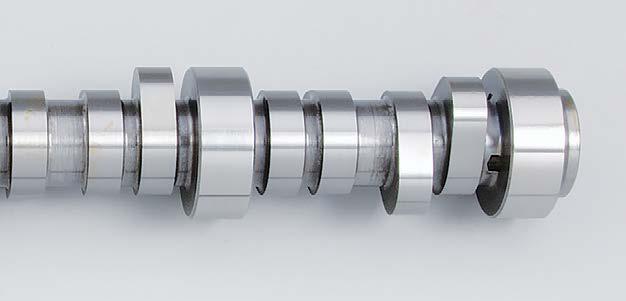

Track Max® Camshafts

• Dyno proven to significantly increase power

• Made from premium billet steel blanks

• Available in several hydraulic roller designs up to 230°/238° duration and .625"/.625" of lift

R-Series Intake Manifolds for GM LS3

• Bring carbureted-style aspiration to LS3-style engines

• 3,500-7,500-plus RPM range

• Available in carbureted and carb-style EFI versions

Variable Valve Timing Delete Kits

• Removes VVT so your engine makes big power with aftermarket parts

• Available with 1- and 3-bolt cam gears

• Includes cam/crank timing gears; timing chain and damper; LS2/LS3 timing cover with bolts, seal, and gasket; cam sensor, harness, and bracket; water pump gaskets; and cam, cam sensor, and balancer bolts

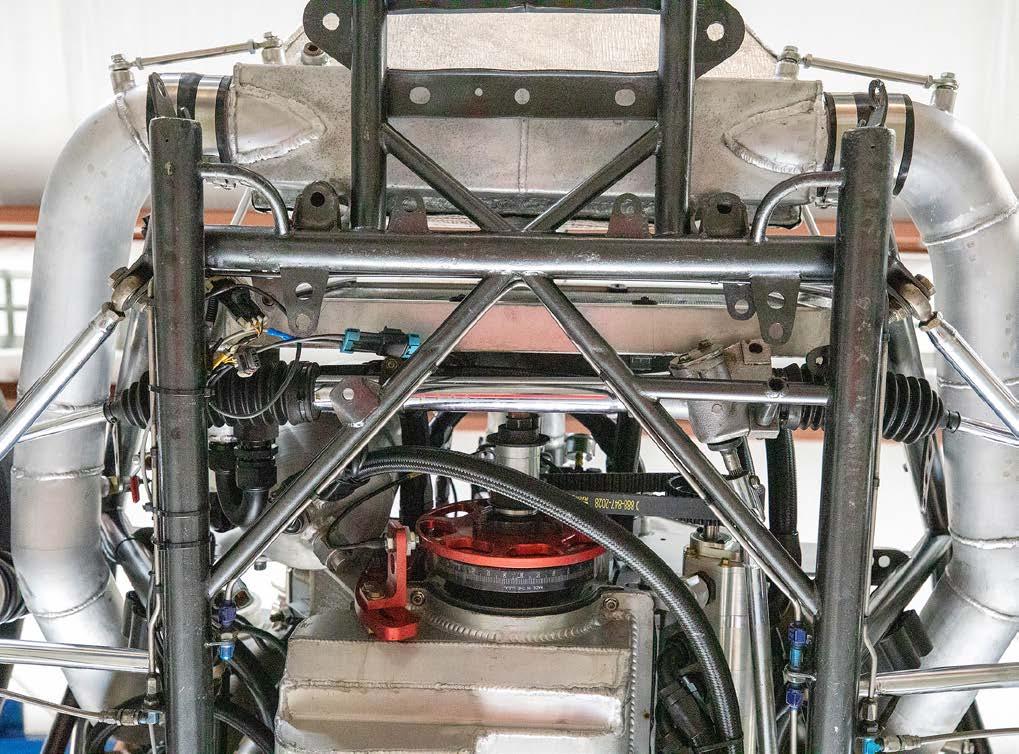

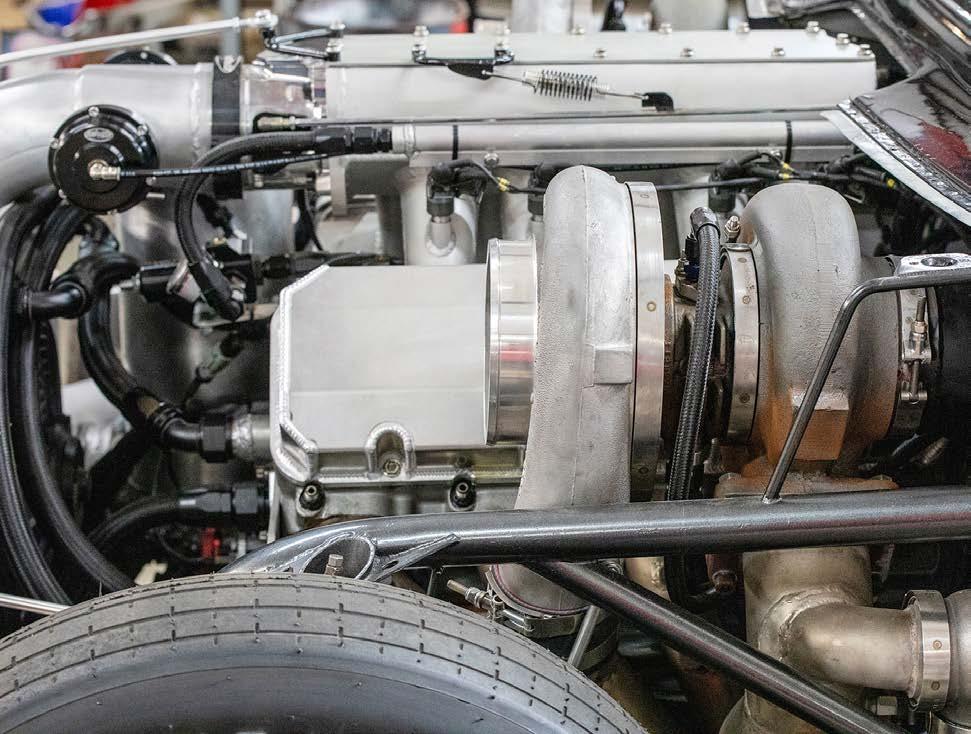

The monster located between the rails of the Mustang measures out to a whopping 765 cubic inches of displacement, but make no mistake it follows the rules of its class by utilizing a maximum bore spacing of 4.84

Once the excavation and land clearing pro was ready, James decided to get back in a car of his own and purchased the 1991 FoxBody Ford Mustang you see here. Granted, it looked nothing like this as the small-block Ford-powered machine wasn’t nearly as capable with its stock suspension and an 8.8 rearend.

Upgrade Your Ride to the Pinnacle of Elegance with Our Engine Turned Material.

With the trend of naming racecars returning to prominence particularly with the no-time drag racing crowd, James’ dubbed his new project car “Heavens Devil Mustang.” We can’t confirm if the title stems from the Starcraft video game, or if it was just decided that it sounds pretty cool, but James spent the next two

years building it into what you see here.

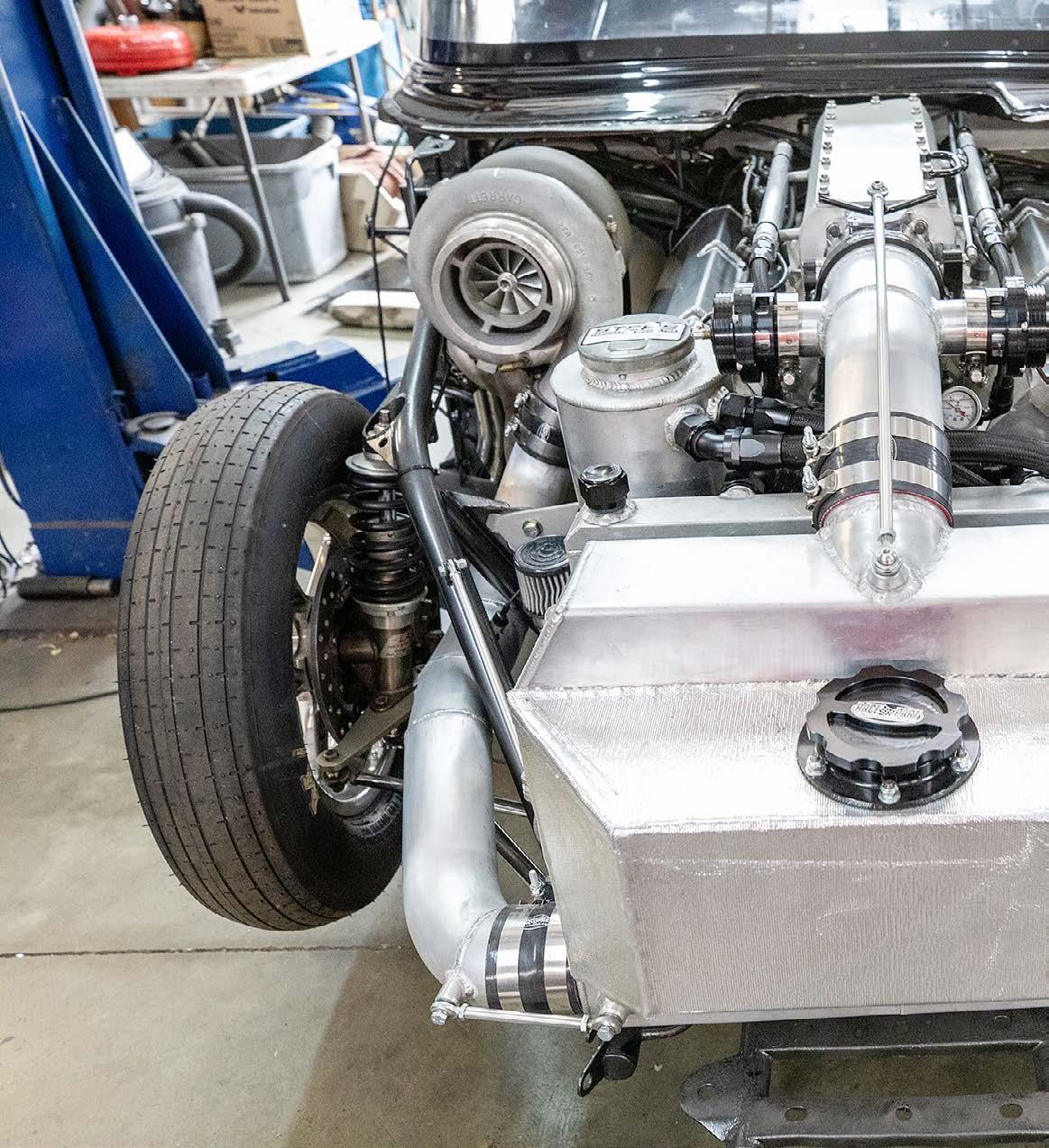

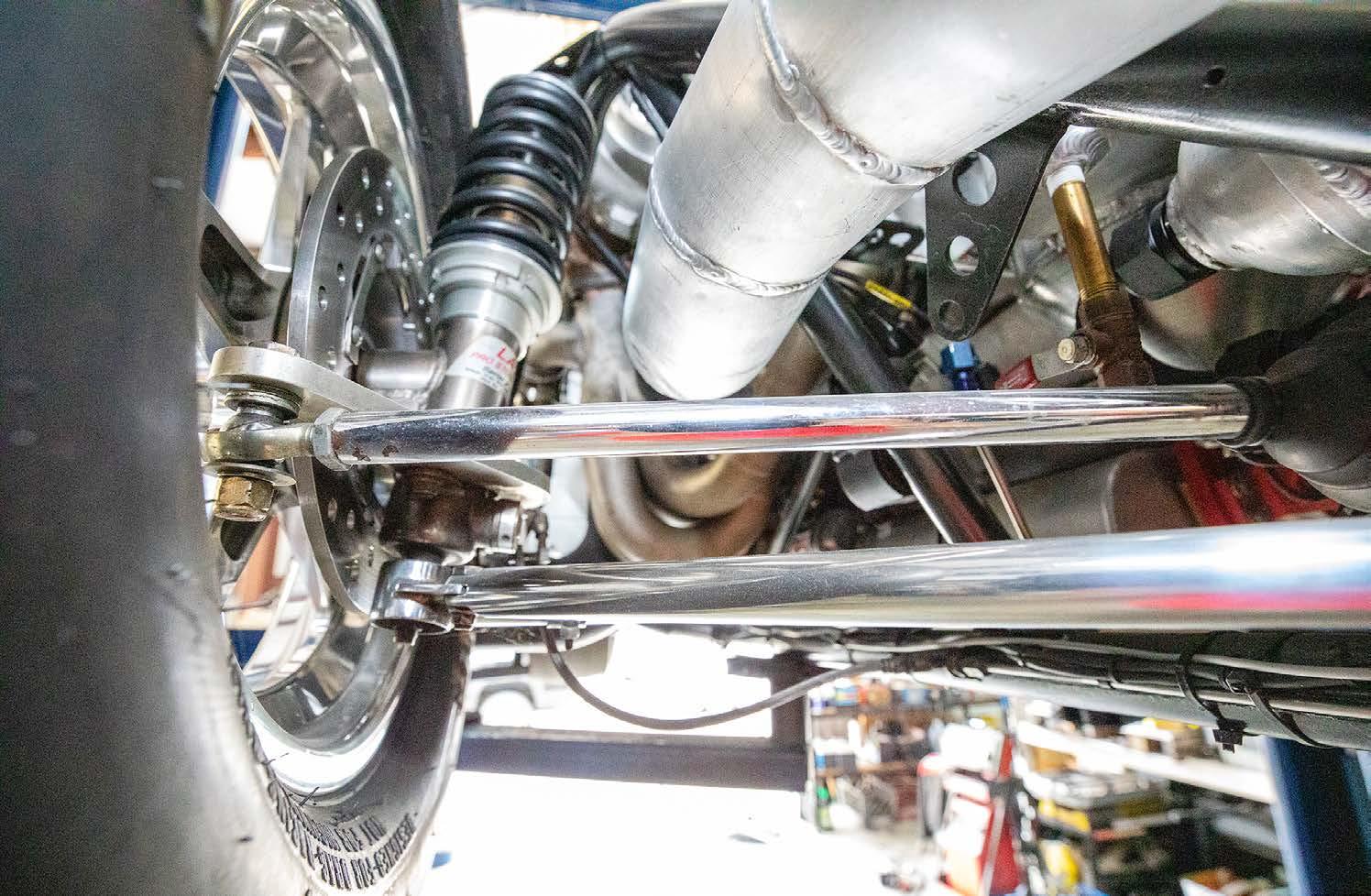

The Fellsmere, Florida, resident enlisted the help of Ricky Chassis Shop in Melbourne, Florida, as well as Corey Blackmon to fabricate the 25.1 chassis that is suspended by a set of Menscer Motorsports front spindle-mount struts and coilover shocks out back.

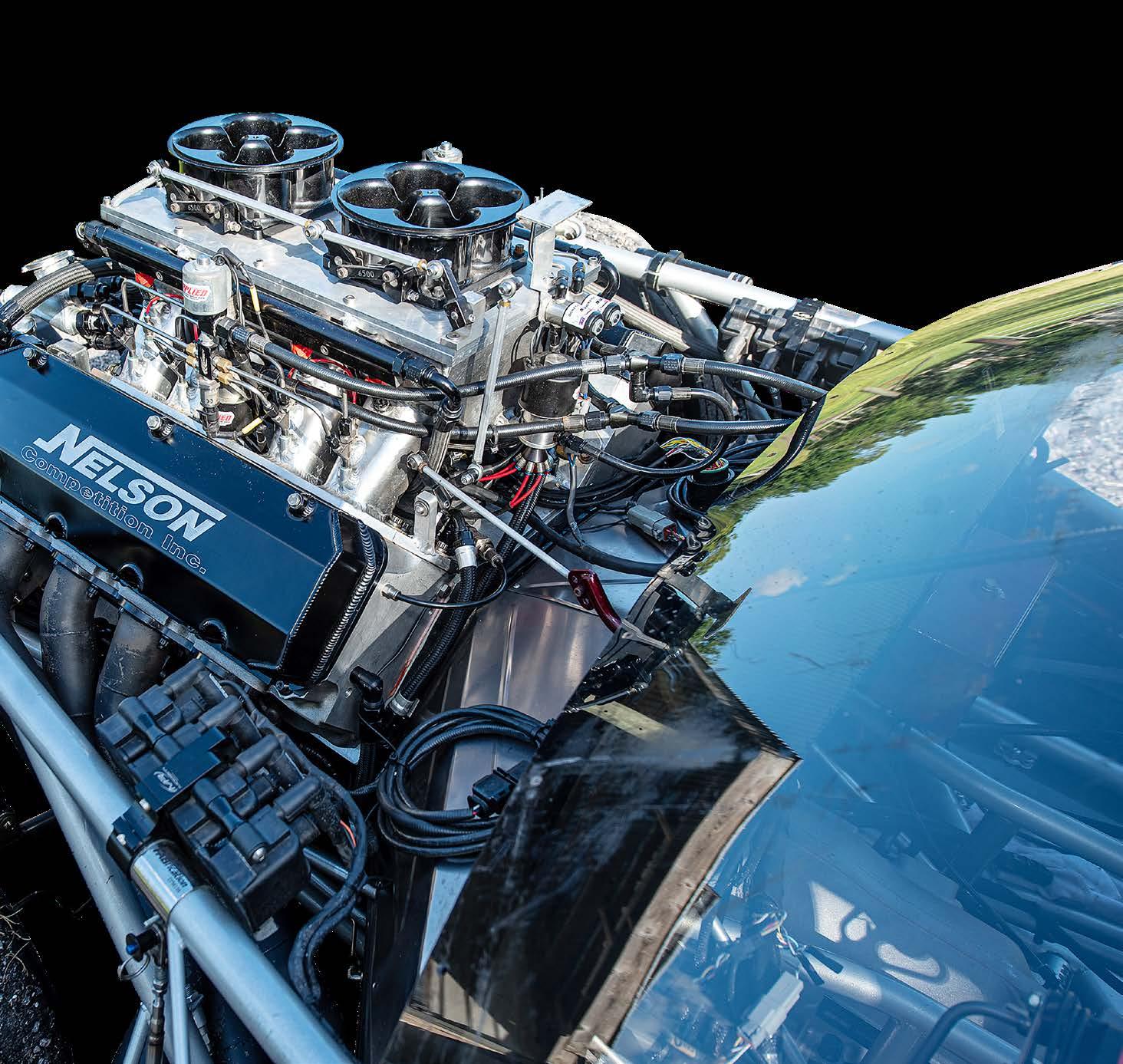

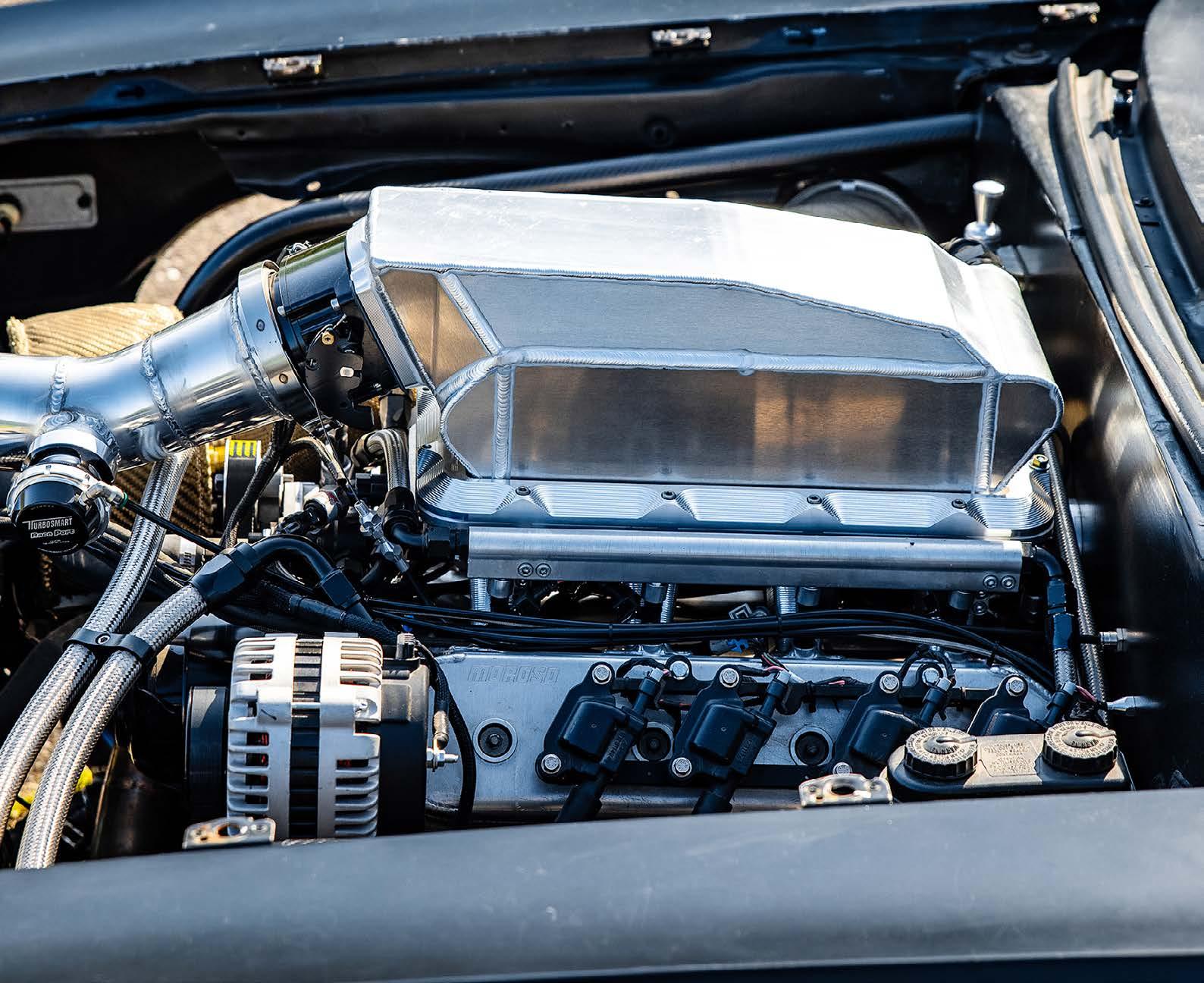

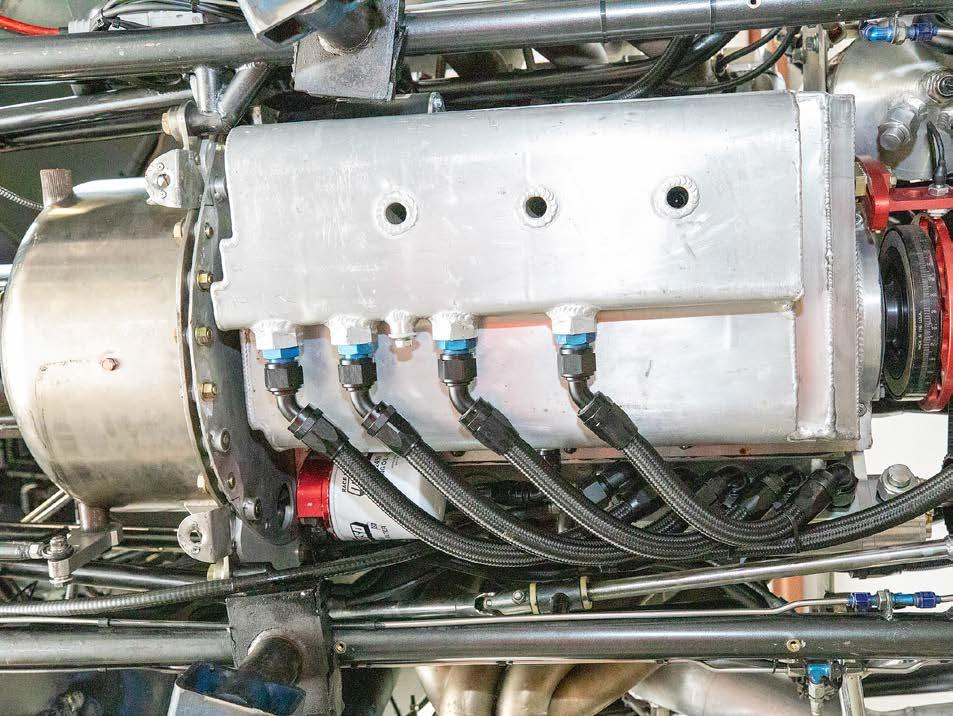

The engine is the creation of Nelson Competition and started with a billet aluminum Dart Machinery NextGen block with an 11.7-inch deck height. A billet Bryant crank swings GRP rods and Diamond pistons. Brodix 14.5-degree cast aluminum cylinder heads were studded in place.

A fabricated aluminum tunnel ram intake manifold with twin 6500-series four-barrel throttle bodies that flow 2,656 CFM top off the beast.

Carbon fiber and Titanium were used extensively throughout the build to keep the diminutive Fox-Body Mustang additionally svelte.

For the engine program, James turned to Kris Nelson of Nelson Competition in Pinellas Park, Florida. As the Mustang was des-

tined to compete in the 4.84 smalltire class, a maximum bore spacing of 4.84 inches was required for the powerplant.

Nelson Competition started with a billet aluminum Dart Machinery NextGen block with an 11.7inch deck height and the requisite 4.84-inch cylinder bore spacing.

“Jesse James” 1991 Nitrous Big Block Ford Mustang

Body & Paint:

All body work and deep Burgundy Metallic paint completed by Terry Paschal.

Chassis Modifications:

Full 25.1 chassis.

Suspension:

Menscer front spindle mount struts.

4-link coilover rear with anti-roll bar.

Engine:

Kris Nelson of Nelson Competition built Dart billet

11.7 deck 4.84 bore space 765ci

Rotating Assembly: Billet Bryant crank, GRP aluminum rods, Diamond pistons.

Cylinder Heads:

Brodix 14.5 degree Sonnys castings.

Induction & Fuel Delivery: FuelTech EFI.

Power Adder:

Nitrous; 3 systems.

Transmission:

M&M transmission, 3 speed lock up, Coan converter.

Rearend:

3.50 rear gear with a Carmack billet center section.

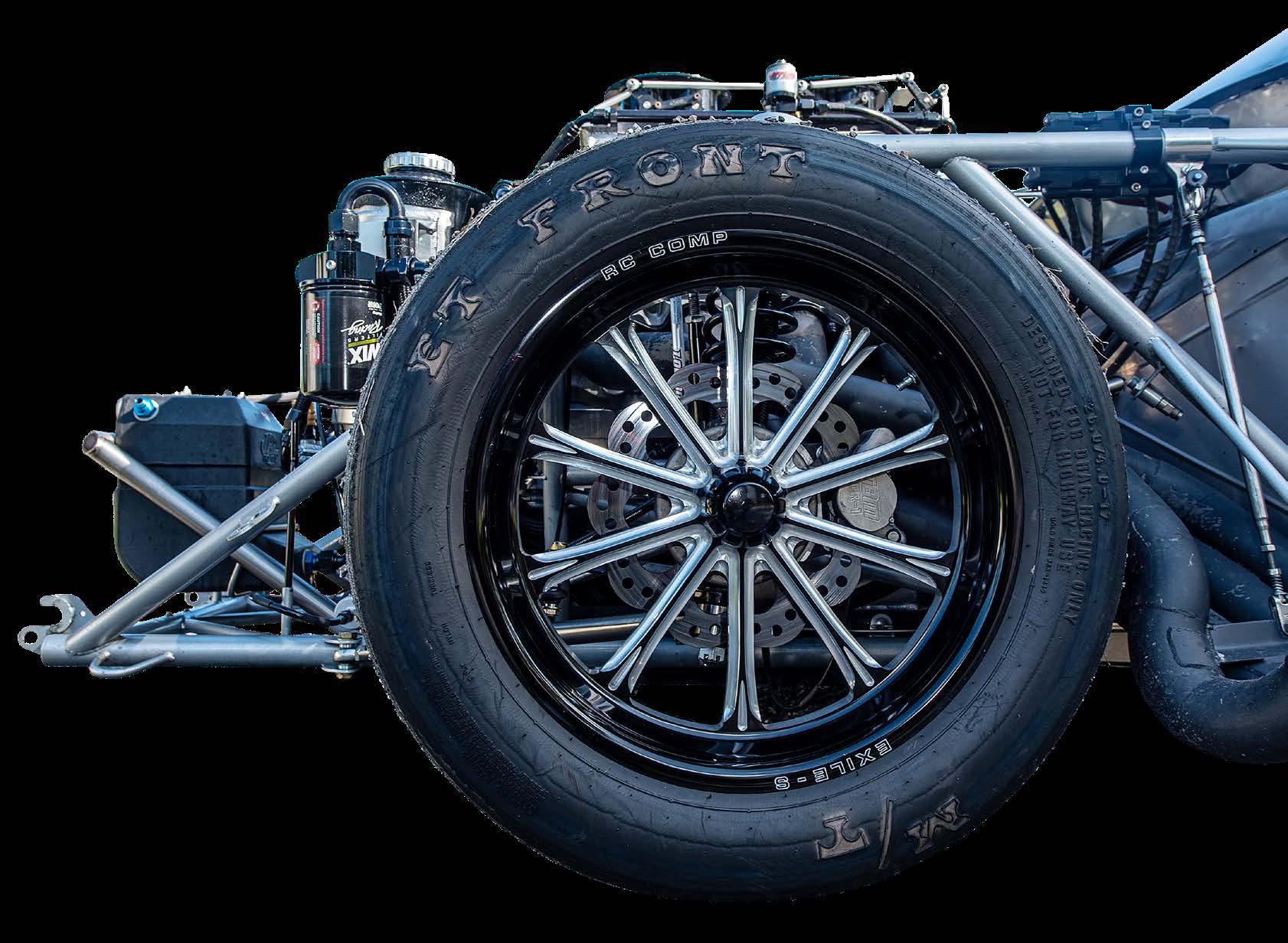

Tires & Wheels:

M/T 275 Pro radials , RC Components wheels.

Interior:

FuelTech Mini 8 switch panel and FT 600 ECU /dash. ET & MPH:

No Time car.

Most Unique Feature(s):

A lot of Carbon fiber and a lot of Titanium.

Reason For Build:

To compete in Mike Hills 4.84 No Time category. Build Timeline: 2 years.

Most Memorable Experience(s): Winning two shootouts in Bradenton FL on back to back nights.

Thanks To: Ricky Chassis and Corey Blackmon for the majority of the chassis work. Kris Nelson of Nelson Competition on the engine build and many other tech questions and support. Atillio Derosa with AA Performance for opening up his shop and allowing me to a ton of fab work and finish work to the car along with his help. My friend and neighbor Terry Paschal for doing the paint and body work and also numerous repairs and paint corrections for me along the ride. Greg Powrie with tech support and problem solving random issues along the way. Ryan Grigsby for taking this thing to the limit and getting its max potential out of what I’ve given him to work with. He’s definitely a master on the keyboard. Frank Mewshaw for a multi tude of things which I’m sure I will forget some but I will try to name them all. Frank was huge in helping design and plan the car during its inception. He was involved all the way to completion and still helps in many ways still today. He and Peg Frateda also opened up their shop and allowed me to utilize Frank and the shop as if it were mine. Definitely could not have done this build without him and his input.

Between the stroke of the Bryant Racing billet crankshaft and the size of the Diamond pistons swinging on GRP aluminum connecting rods inside the bores, the engine offers 765 cubic inches of displacement.

The induction system consists of Brodix 14.5-degree cast aluminum cylinder heads from Sonny’s Racing Components, along with a fabricated aluminum tunnel ram intake

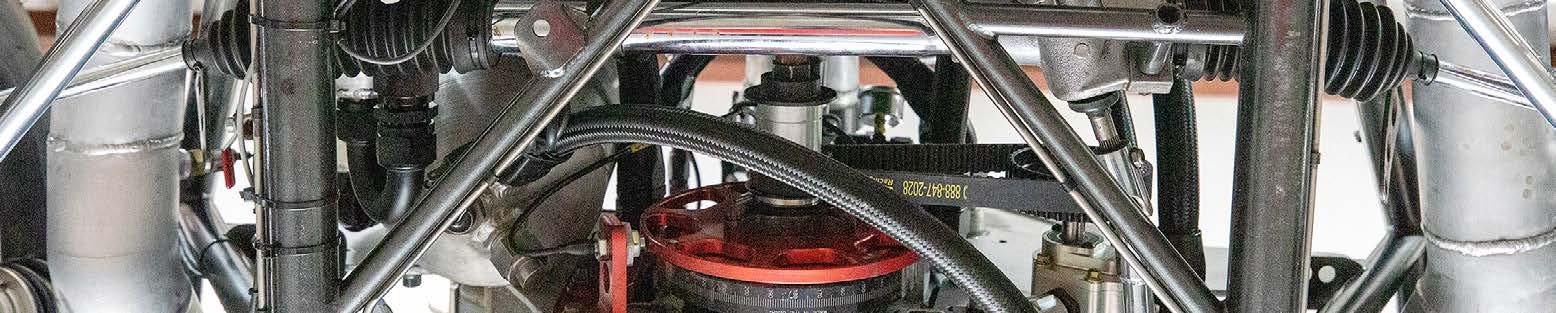

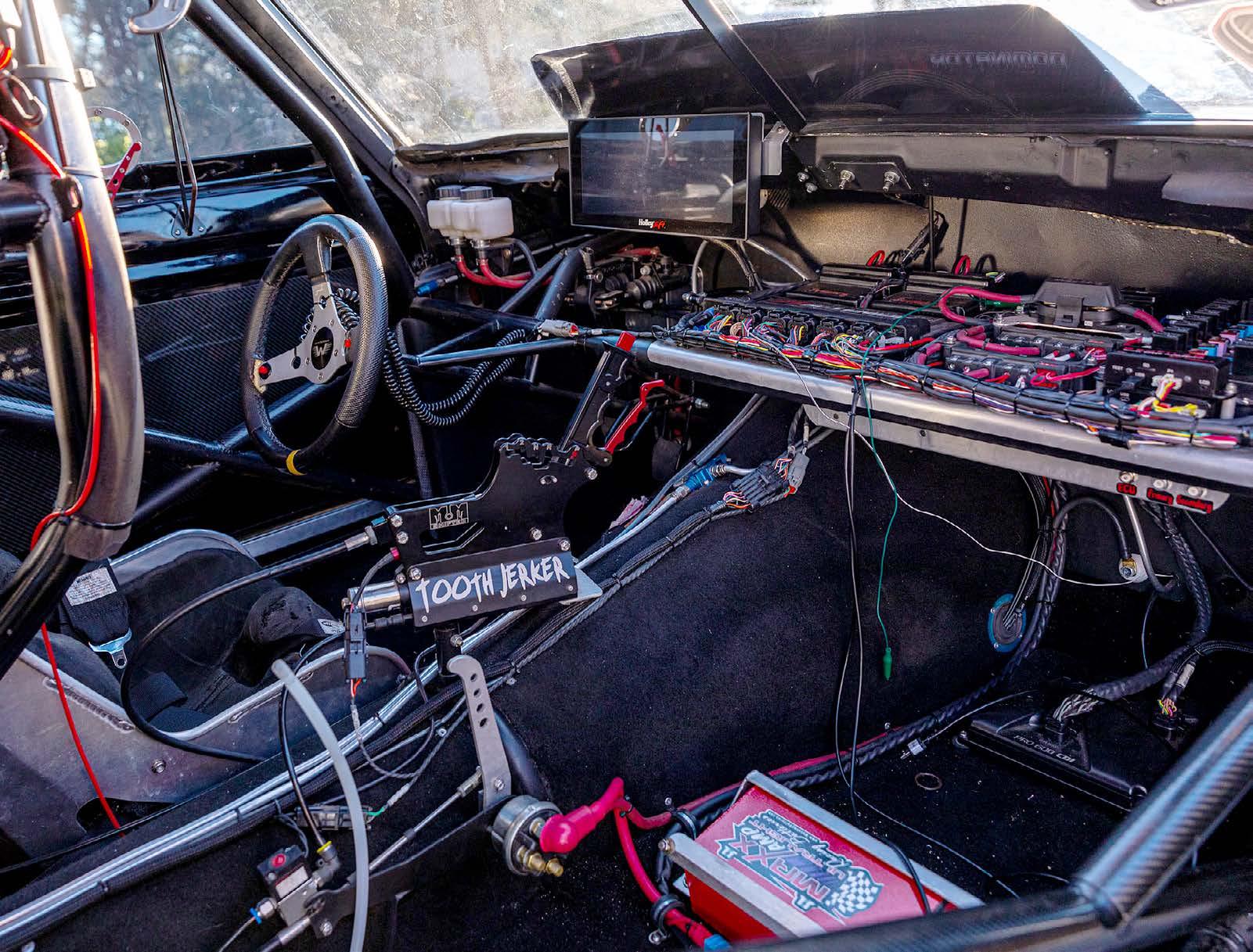

A Jungle Gym of cage bars snake their way through the interior and twin nitrous bottles ride shotgun. The Reid-cased M&M 3-speed transmission with Coan Racing lockup torque converter is also in full view.

The race interior in made up of as much billet and carbon fiber as possible in order to help get the Fox Body down to a reasonable fighting weight. Any factory equipment is long gone in favor of hardcore race parts such as the FuelTech’s ECU that also functions as the instrumentation, a single race seat and removable steering wheel.

Said throttle bodies flow 2,656 CFM at 28-inches of vacuum and the billet aluminum pieces are designed for electronic fuel injection applications. Following that, James utilizes a FuelTech FT600 engine management system and employs Ryan Grigsby for the tuning calls. Grigsby happens to specialize in tuning nitrous engine combinations and he dials in the three stages of direct-port Applied Nitrous Technology boost in a bottle.

Ensuring reliable transmission of horsepower is an M&M Transmission threespeed automatic with a Coan Racing lock-up torque converter. Further rearward is a billet Carmack Engineering third member with a 3.50 rear gear mounted in the rearend housing. Rolling stock consists of RC Components wheels wrapped in Mickey Thompson 275 Pro tires, and there are custom race disc brakes in the rear and TBM disc brakes up front to get the Ford stopped.

On the inside of James’ Mustang it’s all business with bars, billet, and carbon fiber all playing their parts—no pretending it’s a street car in here! FuelTech’s ECU also functions as the instrumentation, and James has one of the company’s SwitchPanel-8 Minis for basic functions.

The exterior of the Fox body was prepped and painted by James’ friend and neighbor, Terry Paschal, and the metallic/pearl red they chose is quite stunning. It’s hard to tell from a distance, but the “aftermarket” head lights are actually vinyl wraps by Joe and Kelly Young Nelms of Car Wraps

Along the way and since the Mustang first roared to life, James has had help from people like Atillio Derosa with AA Performance, as well as noted racers Greg Powrie and Frank Mewshaw. With the zoomie headers lit, the Heaven’s Devil Mustang has already charged to two victories, winning back-toback shootouts at Bradenton Motorsports Park in Bradenton, Florida. With proven performances like those, it’ll be interesting to see how James fares in Mike Hill’s 4.84 no-time class.

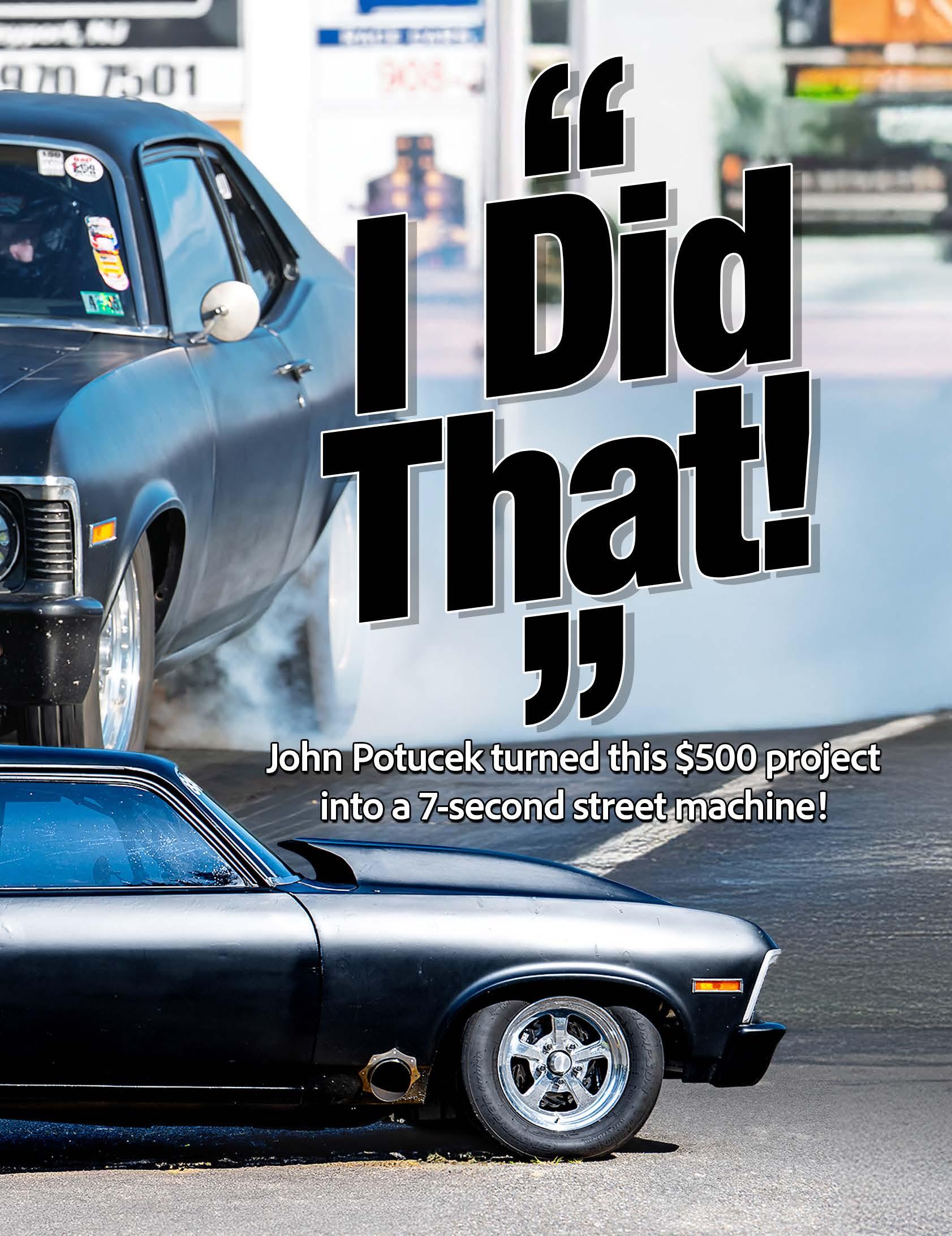

Being handson with your own project car gives you a lot of things in return, including having the end result become a reflection of your vision and hard work. There are many other benefits to doing it yourself and Wapwallopen, Pennsylvania’s John Potucek knows many of those as well after building his 1973 Chevy Nova.

Potucek grew up in the shadow of his father who built hot rods of his own and took his son to car shows and dragstrips.

“At 14 years old, I bought my first Nova and spent hundreds of hours working and learning alongside my dad,” Potucek said. When Potucek was 16, his Chevy Nova was ready for the road and not only took him to school, but also took him to his local dragstrip, Maple Grove Raceway, where he would go with his friends after school and make passes.

“During this time, I worked part time at the local speed shop,” Potucek told us. “Initially, I did small things, disassemble engines, clean parts, sand blast, help install engines, etc. By 16 years old, I was doing cylinder head work from start to finish.” Potucek continued working in the automotive industry before landing is current job with Keystone Automotive Operations. At the same time, his hands-on expertise was put to good use building another Nova to replace his original that he had parted ways with years ago.

A Ford 9-inch rearend was built by John and his dad and in the process was narrowed about 8 inches from stock then filled with a spool, 3.70 gears, aluminum center section and 40 spline axles. Rear suspension consists of Calvert springs and Caltrac bars with sliders, Viking Crusader shocks and a TRZ anti-roll bar. Residing up front are TRZ upper and lower control arms, Viking Warrior coilovers, 350-pound springs and TRZ aluminum spindles.

...I did the floors, frame connectors and got it driveable, outside in the dirt...!

J ohn P otucek

Potucek’s then-girlfriend Erica encouraged him to get another Nova and even offered to buy him one. Around 2007, his father told him about a Nova one of his coworkers had stored inside a tractor trailer. Despite the derelict Chevy being a lowly 6-cylinder-optioned car with rotted out floors, the $500 price tag was far more reasonable than the ‘68-‘72 body style Potucek sought after.

“Erica handed me the funds and we brought it home,” Potucek explained. “I didn’t even have a garage at the time. I was working in a dirt parking lot and had the engine pulled and replaced with a truck big-block in the first week of owning it. I did the floors, frame connectors and got it driveable, outside in the dirt!”

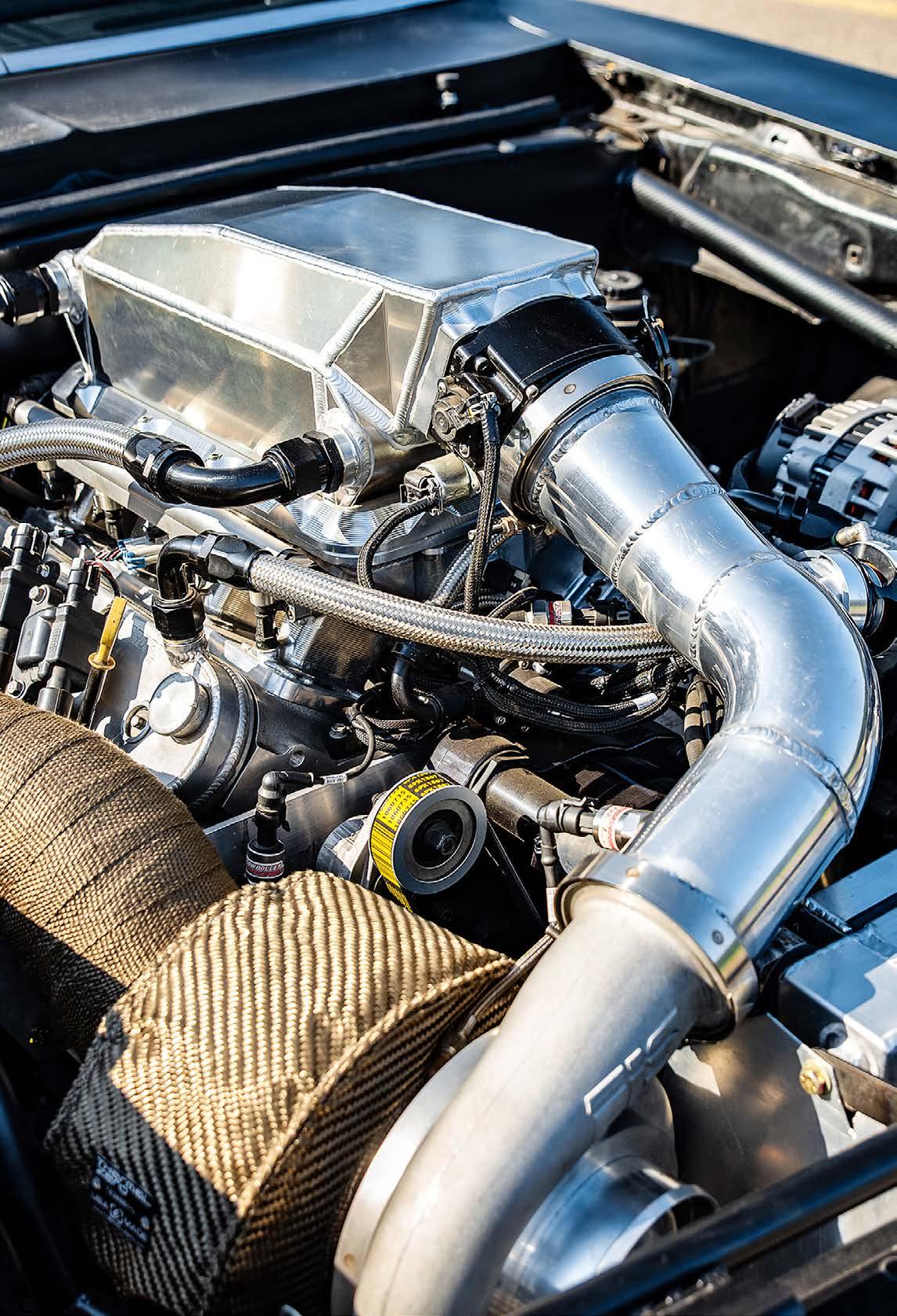

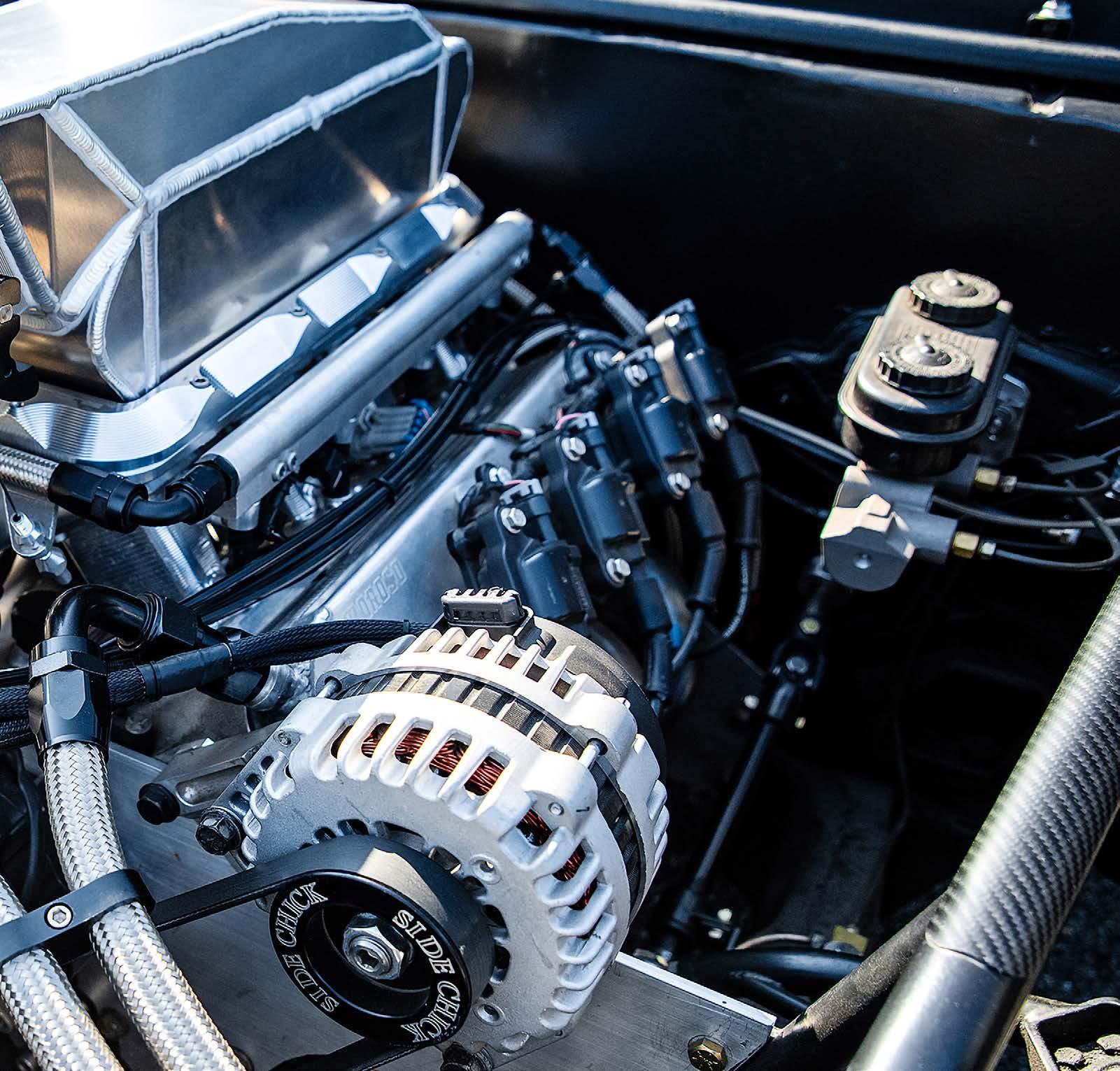

The Nova’s current mill is based on a stock aluminum 5.3 block with a 3.800 overbore and stock stroke. A K1 crankshaft, Molnar connecting rods, and Wiseco Boostline pistons swing inside the small block and as-cast Trick Flow 220 cylinder heads feature shaft rockers and Ultimate springs. A billet lower intake was mated to a Shearer Fabrications A2W upper manifold with 210 injectors squirting E85 courtesy a Fuelab 6.0 GPM pump.

As the Nova became part of the budding couple’s life, the Potuceks both agreed that the Nova needed to be used in their wedding, and the newlyweds climbed in over the roll bar and drove off into their new life together. With the Nova now having significant sentimental value, Potucek

knew he couldn’t part with it, but he still longed for that ’68’72 Nova body.

“Something I researched for years without finding a real answer or if it was ever done was cutting the quarters off, rebuilding the inner structure, and installing ‘68-‘72 quarters on a ‘73-’74,” Potucek told us.

Body & Paint:

The body is a 1973. Owner-completed full/real 68-72 conversion. Including full quarters/inner structure/ drip rail etc.

The paint is Rustoleum Satin Black paint that holds up really well. I get asked often “When are you doing a real paint job”. Probably never on this. My car has been flat black 18 years. Its known and recognized for that!

Chassis Modifications:

Owner-built through-floor frame connectors. 25.5 cage that I built with help from my dad. Still running a stock subframe in this, but I did add a Smith Racecraft rack and pinion. Front strut bars to the stock subframe that I tied the motor plate into.

Suspension:

Front suspension is TRZ upper and lower control arms, Viking Warrior coilovers and 350 pound springs, TRZ aluminum spindles. Rear suspension is Calvert springs, Caltracs, sliders and Viking Crusaders spec’d by Kelltrac. TRZ anti roll bar.

Engine:

Currently stock 5.3 L33 block. Bored to 3.800. Stock stroke. Built by Jeremy Gerz of Innovative Performance and Repair. I’m on year 4 with this setup and at the planning/early stages of a Dart block 388 build which Jeremy will also be doing for me.

Rotating Assembly:

K1 Crank, Molnar power adder rods, Wiseco boost pistons.

Cylinder Heads:

Trick Flow as-cast 220 heads from TEA. BTR shaft rocker setup and Ultimate RPM springs, BTR stage 2 turbo cam, Johnson lifters.

Induction & Fuel Delivery:

417 Motorsports billet lower intake and Shearerfab

A2W upper, Bosch 210 injectors, Fuelab 6.0 GPM pump. I run E85, no race gas here!

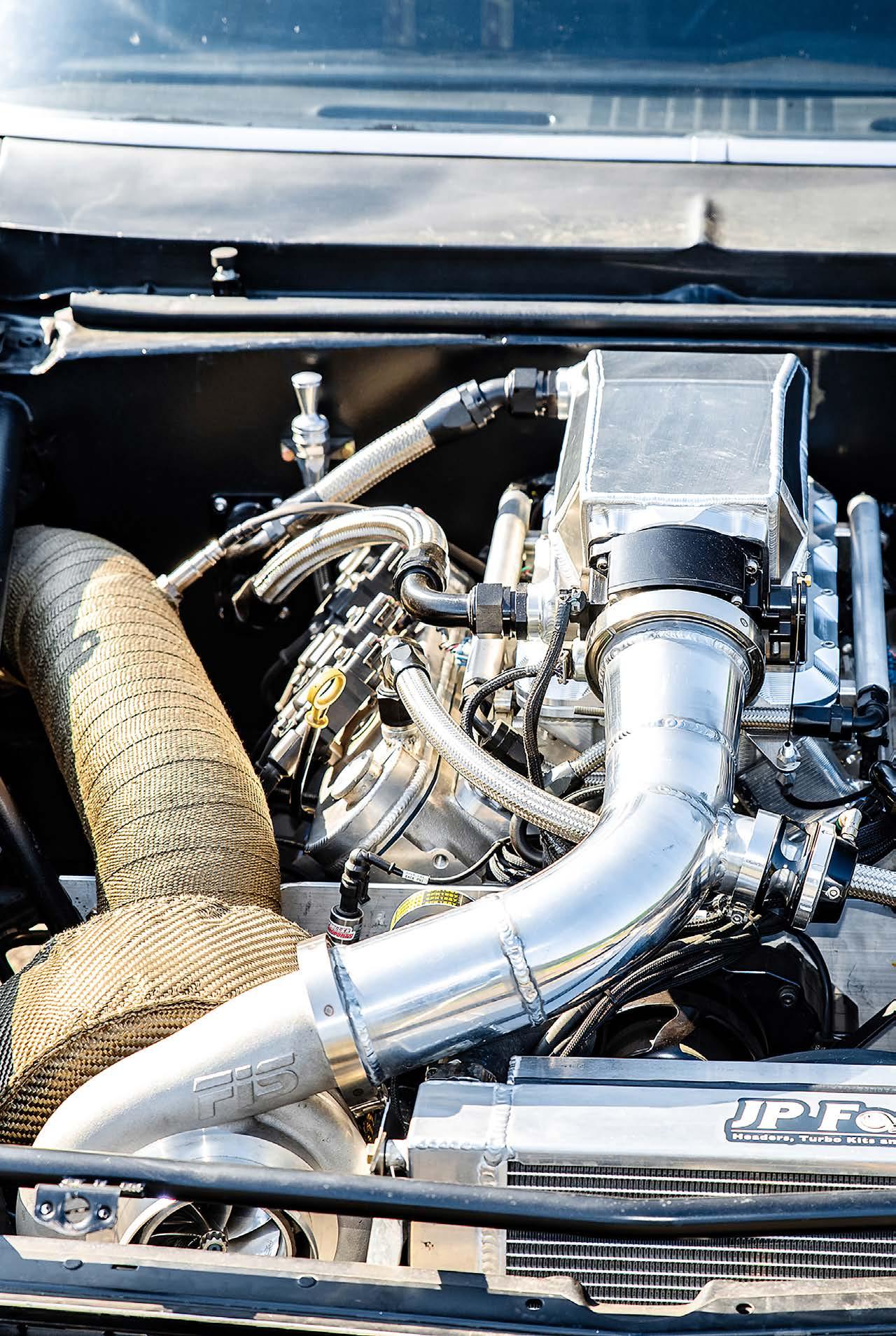

Power Adder:

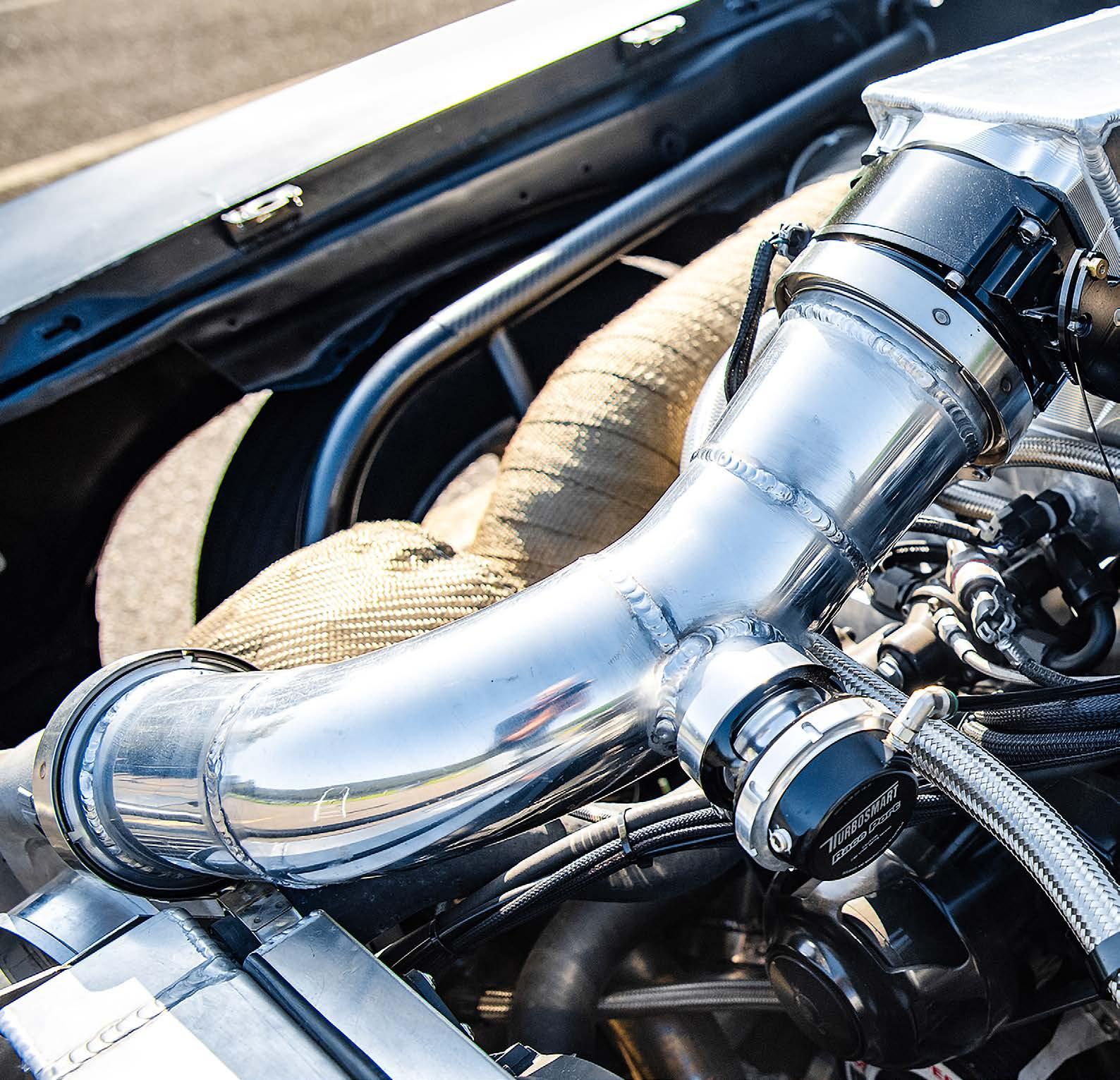

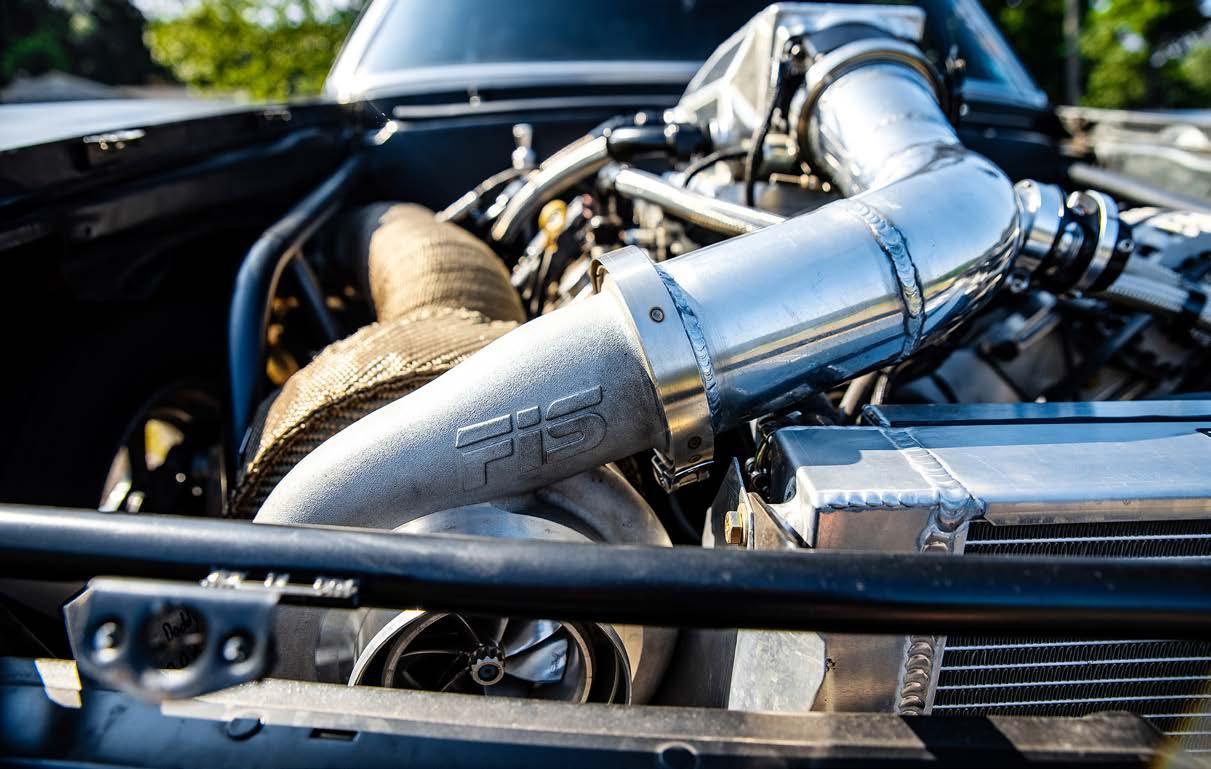

Forced Inductions 88/102, JP Fab custom 1-3/4” down and forward headers and hotside, 5” downpipe. Dual 44mm wastegates.

Transmission:

Reid-cased Powerglide, 1.80 gear, Circle D bolt together converter, Dynamic Drivelines carbon fiber driveshaft.

Rearend:

Ford 9” built by my dad and I, narrowed about 8” from stock Nova width. 3.70 rear gear, aluminum center

and 40 spline axles.

Tires & Wheels:

Billet Specialties Dominator wheels. 15x4 up front and 15x10 in the rear with double beadlocks. M/T 26X6 front tires and 275 Radial Pro tires in the rear.

Interior:

Motion Raceworks column, MPI steering wheel, M&M shifter, Kirkey seats, RCI belts, Holley digital dash, Leash street strip board.

ET & MPH:

5.12 @138 and 7.99 @170 both are with my current stock block 5.3 at 3400 pounds. We’ll see what happens next outing as I just did a stator change in the converter.

Most Unique Feature(s):

Unique; the fact that it’s a 73 I did the full conversion on! It gets so many people wound up or confused until I SHOW them that I changed the quarters. Second would be just how much of the work I do myself. All the kits and designs I’ve built and tested on my car is what lead to me starting JP Fab. It’s the platform that got me going.

Reason For Build:

I missed my first car. I had a supportive spouse and that’s like a free pass to build.

Build Timeline:

Forever! Are they ever really done? I’ve owned it 18 years and upgraded or changed something every year, as money or time would allow. So, it took 18 years to get to where it is now. While it’s not done, it is very close. There is hardly anything I wish to change (at this time).

Most Memorable Experience(s):

A bunch of them…that why I can never get rid of it! Using it in my wedding is number 1. It was also my first car to make 1000whp+, first 9, 8, 7 second passes! They’re all killer memories.

Thanks To:

Thanks to my supportive wife, Erica! My kids, Johnny and Eleanor. My good friend John Borick, who is always ready to help, especially on the wiring! Jeremy Gerz on the engine work and Jace Nester with the tuning.

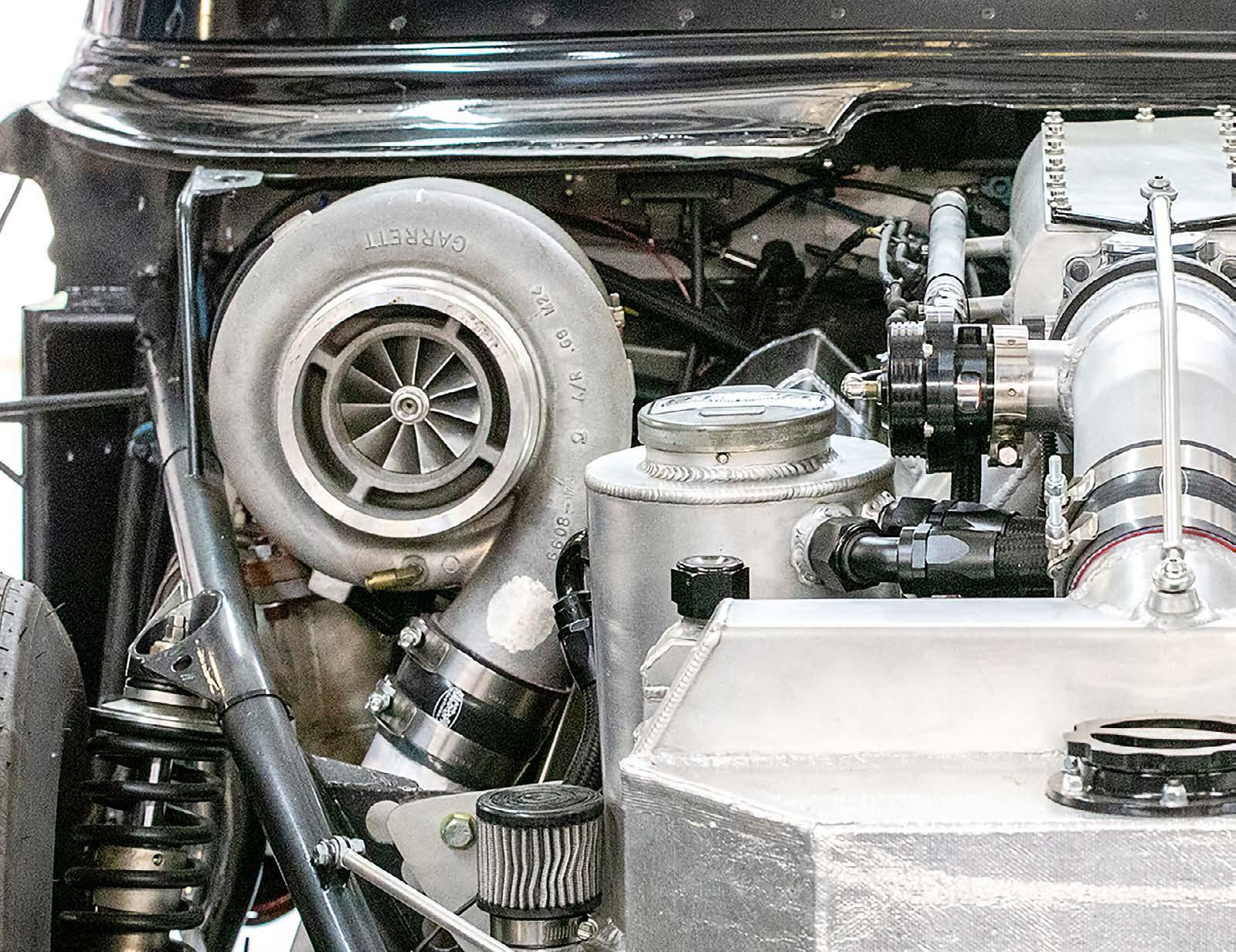

An 88/102 turbo adds extra punch and the 1-3/4inch headers and hotside were created by Potucek’s own JP Fab. His work on the Nova has led him to develop turbo kits and other items for them, having now built over 50 kits.

“Too many people with ‘73-‘74 [body] will change the front and back lights and say it’s done.” Some 60 hours of metal fabrication later, Potucek had the ’68-’72 Nova look he had always wanted, but there’s always more to do.

Next, he focused his attention on the drivetrain and built a blow-throughcarbureted turbo

system for the bigblock engine that he ran for about a year before switching to LS small-block power. Potucek turbocharged this new engine combination, too, first with another blowthrough carbureted induction system. He then converted it to EFI with a stock computer before working with Brandon Doller on a Holley HP system.

The 25.5 roll cage was completed by John with help from his dad. While the stock dash remains, it houses an aftermarket digital dash. Door panels are custom fabricated aluminum with factory handles and since he was not worried about weight, the factory glass was kept.

Even with a junkyard L33 5.3-liter LS with original 330k miles, the Nova was making 830whp on pump gas. It fulfilled three years of service until Potucek decided it was time to build something better. To accomplish that, he worked with Jeremy Gerz of Innovative Performance and Repair and built the Nova’s current engine using the stock aluminum 5.3 block. With a 3.800 overbore and stock stroke, the small-block features a stock-stroke K1 crankshaft, Molnar connecting rods, and Wiseco Boostline pistons. Moving air in and out of the powerplant are Total Engine Airflow-modified Trick Flow as-cast 220 cylinder heads that feature Brian Tooley Racing shaft rockers and Ultimate springs. A Stage 2 turbo camshaft and Johnson lifters round out the valvetrain. Above all of that you’ll find a 417 Motorsports billet lower intake and Shearer Fabrications A2W upper manifold with 210 injectors squirting E85 thanks to a Fuelab 6.0 GPM pump.

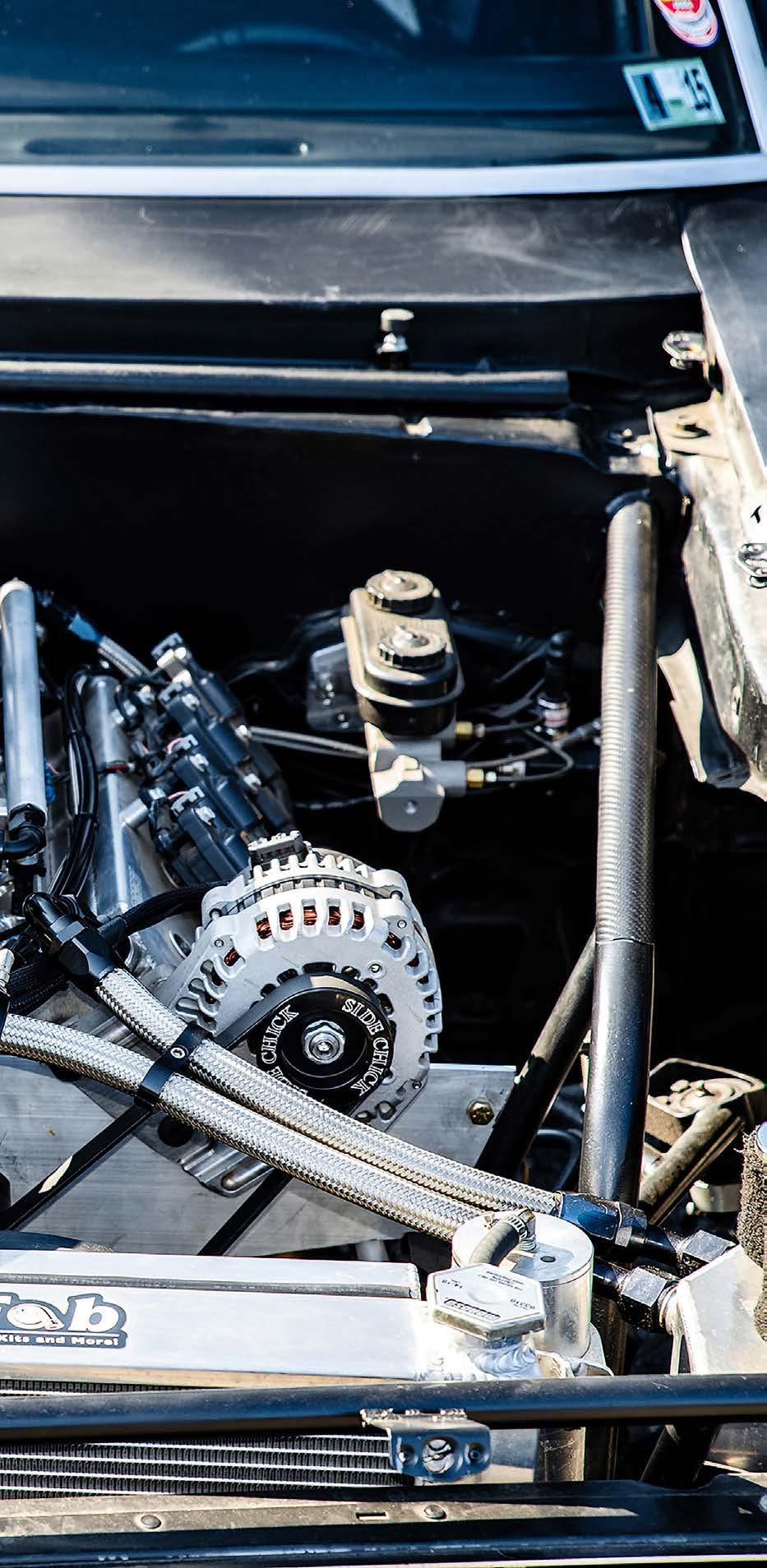

A race column and quick release steering wheel were installed and twin aluminum race seats keep occupants in place as do RCI safety harnesses. John shifts the Reid-cased Powerglide through a billet shifter. The backseat was eliminated to make room for a battery box and the trunk space is now used for the fuel and cooler tanks.

The fuel is complemented with pressurized atmosphere courtesy of an 88/102 turbo. Potucek’s own JP Fab custom 1-3/4-inch headers and hotside are matched with a 5-inch downpipe, and dual 44mm wastegates manage the pressure.

Having fabricated several turbo systems at this point, Potucek eventually bought fixtures to be able to reproduce Nova turbo kits for his side hustle, JP Fab LLC. “I’m thrilled to say I’ve built turbo kits for about 50 people now.”

John Potucek had always wanted the ’68-’72 Nova look and just couldn’t part with his car that was now a big part of his life, so some 60 hours of metal fabrication later, he had the look he had always wanted.

John and his wife climbed over the cage bars of the Nova to make it part of their wedding.

Backing the built engine is a Powerglide transmission with a Reid case and a 1.80 gear, as well as a Circle D bolt-together torque converter and Dynamic Drivelines carbon fiber driveshaft. Putting the power to the pavement is a narrowed Ford 9-inch rearend with a 3.70:1 ring and pinion, aluminum center and 40-spline axles.

Bathed in durable Rustoleum black paint, the Nova’s satin exterior is offset by Billet Specialties Dominator wheels measuring 15x4 up front and

15x10 in the rear. Double beadlocks hold the Mickey Thompson 275 Radial Pro tires out back. Between the bright rims and the blacked-out body you’ll find TRZ spindles and upper and lower control arms with Viking Warrior coilovers, as well as a Smith Racecraft rack and pinion supporting and steering the front of the Nova. In the rear, Potucek relies on Calvert Racing leaf springs, Caltrac bars, Viking Crusaders spec’d by Kelltrac and a TRZ anti-roll bar.

John wouldn’t trade his times with the Nova for anything, and he’d never part with it. His whole family enjoys being part of the car, including his daughter, Eleanor, who wants to be involved in every single project that happens on the Nova.

From the driver’s seat, you’re surrounded by a 25.5 roll cage and grip an MPI steering wheel that is attached to a Motion Raceworks column. Kirkey seats keep occupants in place as do RCI safety harnesses. Holley’s digital dash provides the engine data, and a Leash Street/Strip board provides a capable foundation for the car’s electronics.

Presently, Potucek’s Nova has run a best elapsed time of 5.12 at 138 mph in the 1/8-mile and 7.99 at 170 in the 1/4...

Presently, Potucek’s Nova has run a best elapsed time of 5.12 at 138 mph in the 1/8-mile and 7.99 at 170 in the 1/4. This is with the stock-block build and a curb weight of 3400 lbs.

The Potucek’s children, Johnny (14) and Eleanor (11), have grown up with the Nova. “My daughter, Eleanor, wants to be involved in every single project that happens on the car,” Potucek told us. Having my kids involved, a supportive wife, and a dad who loves going to the track with me recording and cheering me on are priceless. The car that means so much and has been in my life so long is now exactly what I wanted from the beginning, and I can proudly say, ‘I did that.’”

The Pro Street movement saw race cars that had been turned into street cars go racing once again...

Eventually, it became a sanctioned racing class and cars were purpose-built just for it, with fulltube-chassis machines becoming the norm. After winning two Fastest Street Car championships, Bob Rieger had this ’57 Chevy built and he proceeded to collect a third championship. The

car was then sold, raced, won more championships, and later became a parts donator until Mike Hayden rescued it and returned it to the strip.

Growing up in Michigan in the heyday of automotive manufacturing meant you had a front row seat to the muscle car wars that ruled the streets.

Low, sleek and ready to rock! The 57 was known to be ahead of its time in design and function and was also known for winning races if it got down the track – it had some tire shake issues until Hayden had Tommy Mauney welded in double frame rails to firm up the chassis and eliminate the twist.

Having then moved to California after that and being submersed in the home of hotrodding culture would solidify any automotive enthusiast’s path in life, and that’s exactly what happened to Mike Hayden.

“I remember going for my first ride in a car during a street race when I was 14. There was nothing more thrilling than that for me,” Hayden recalled.

Hayden’s family moved to Whittier, California, when he was 15. He procured his driver’s license at 15 and by 16, he had built a high-compression 327 small-block with dual 4-barrel carburetors.

You might notice that the ‘57 is not an overly stretched, chopped composite body that somewhat resembles a 57 Chevy. Instead, this classic fits the part with original trim and emblems used throughout and the classic headlights, taillights and detailed fiberglass front and rear bumpers and simple cowl hood rock the nostalgic Pro Street style.

Thanks to the efforts of the Hotrods by Havliks staff and Mike Hayden, Bob Rieger’s trend-setting ’57 Chevy once again hit the track, with Hayden behind its steering wheel for the first time since 2008. Hayden is looking forward to getting some full-power runs down and making even more memories with this legendary machine.

Yes, there are three pedals! Back in the day, most winning combinations included a clutched standard transmission and in true nostalgic pro street fashion, the transmission is a Lenco CS1 3-speed with an AFT triple-disc clutch to send the thousands of horsepower back to a Mark Williams 9.5-inch rearend with 40-spline axles.

Hayden’s engine assembly prowess earned him a fulltime job as a mechanic while he was still in high school, and later went into business for himself in 1989. His interest in cars and drag racing went beyond working on customer projects, though, as he purchased and raced a 1969 Camaro in the Pacific Street Car Association.

“I had a customer, Hal, who was having me build a Corvette for him and he really admired our Camaro racing program,” Hayden said.

Hal Lashley suggested Hayden switch to turbochargers, but the change in performance would push his Camaro past its chassis certification.

Hayden explained he couldn’t afford another car to which Lashley replied with, “Well, I can.”

“The next day, my manager brought in National Dragster that had Bob Rieger’s 1957 Chevy in it for sale,” Hayden said. As the story goes, Rieger stormed into the Pro Street ranks in a big way with a Fourth-Gen Pontiac Firebird and claimed two championships with it. Pro Street legend and ’57 Chevy pilot Tony

Christian pinned its performance on the car’s modern aerodynamics. Subsequently, Rieger had the ’57 built to show that he could be quick and fast with anything.

He campaigned the car in the 2001, but a crash early in the season meant he missed out on valuable points. He was planning on selling the car at the end of the season to move up to Pro Mod, but was determined to collect that third trophy.

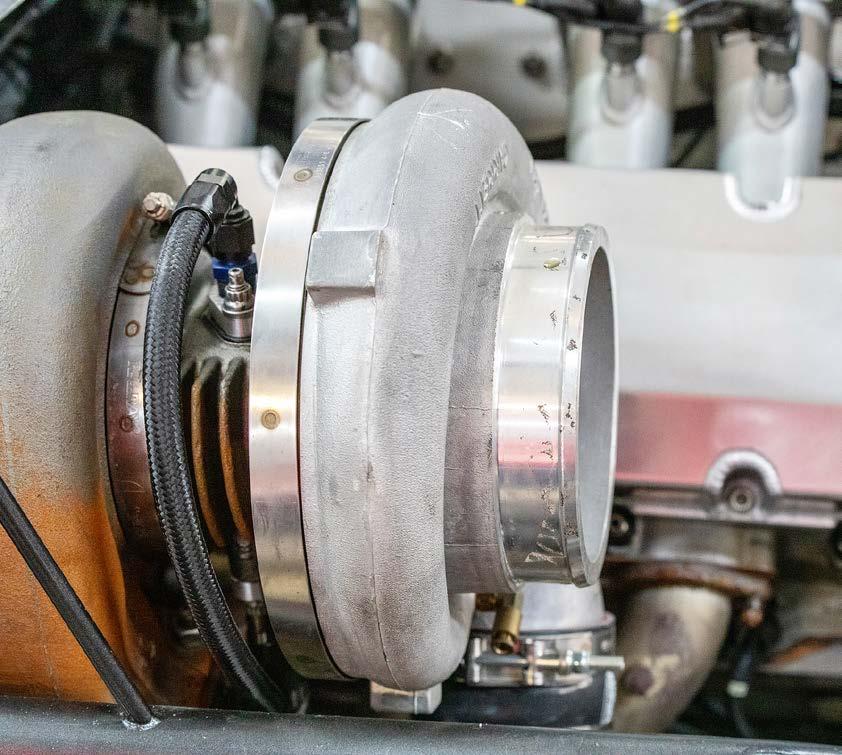

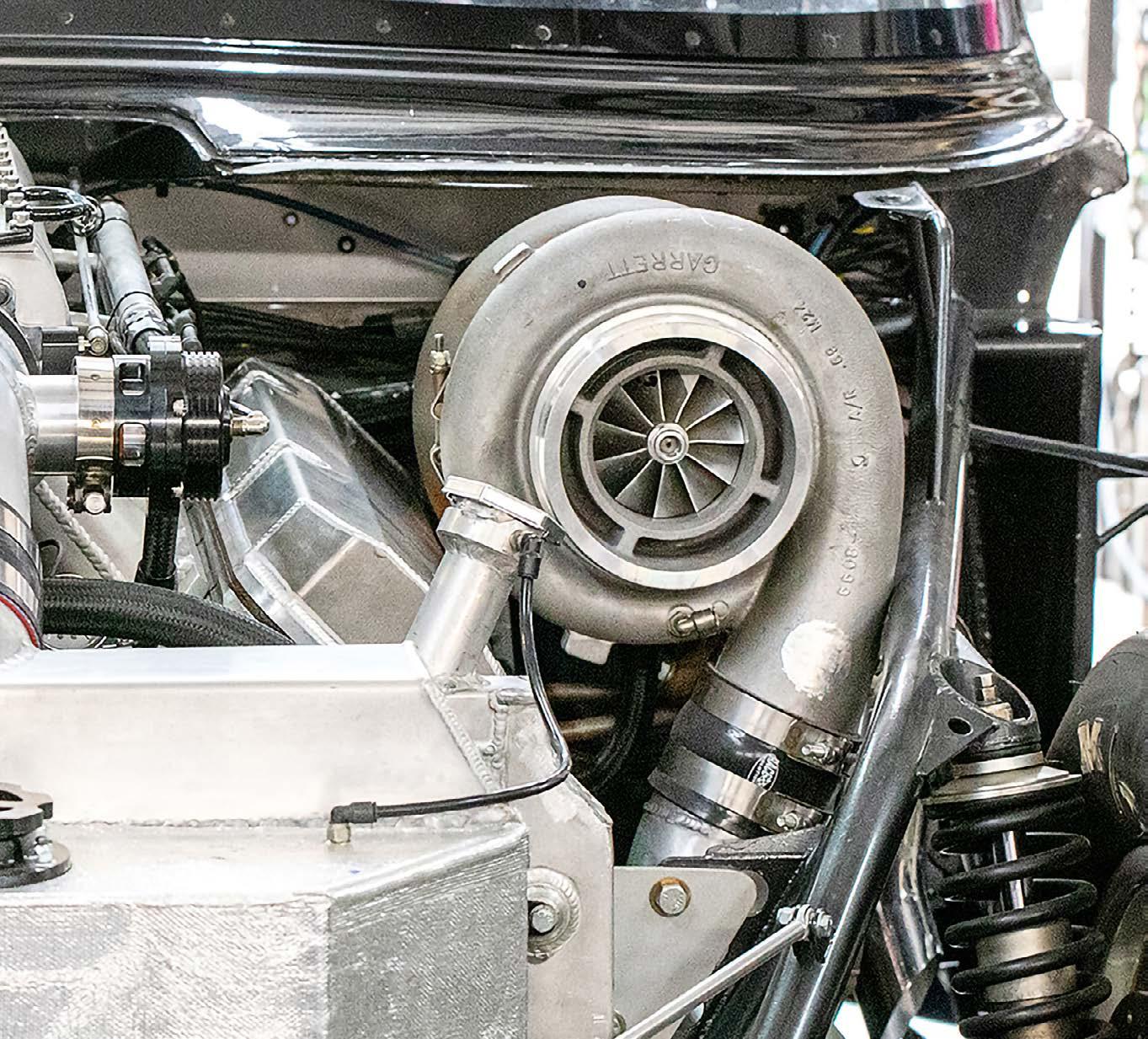

Twin Garrett 88mm turbochargers pressurize the Hogan’s sheet-metal intake manifold, and the MoTeC engine management system is still in place to operate the 160 lb/hr fuel injectors. The high and wide turbocharger placement was also cutting edge for the time and took outside-thebox fabrication and tuning skills to take full advantage of its performance potential.

Post-race videos on

After Lashley sent a deposit for the Chevy, Hayden and his crew picked it up in Florida and took it to Commerce, Georgia, where Rieger needed to wheel it one more time to try and secure the Fastest Street Car Shootout Pro Street championship for the year.

“Bob set the record, qualified number 1, and won the event and became the Fastest Street Car champ that year,” Hayden told us.

“He taught me how to do everything in that car. It was a true stick shift car. In my head I taught myself how to do this over a thousand times before I got in the car and when I got in the car, I did it and Bob was so impressed.”

Mike Hayden’s Twin Turbo Pro Street 1957 Chevy AKA “The Rieger‘57 Chevy”

Body & Paint:

Jerry Bickel Race Cars

Chassis Modifications:

Full tube chassis by Bickel

Suspension:

Lamb Strut front, 4-link coilover rear

Engine:

Donavan aluminum block, 447 CID. Crower billet crank, Oliver rods, JE 10.5:1 compression pistons.

Cylinder Heads:

Oldsmobile 14 degree Pro Stock oval port heads with T&D rockers, Manley springs and Manton pushrods.

Induction & Fuel Delivery:

Hogan’s sheet metal intake, 160lb injectors, Motec engine management system.

Power Adder:

Twin 88mm turbochargers.

Transmission:

Lenco CS1 3 speed with AFT 3 disc clutch. Rearend:

Mark Williams 9.5” with 40 spline axles. Brakes:

Mark Williams carbon rears with Lamb steel fronts.

Tires & Wheels:

Mickey Thompson 15X35.5x16 with Little Bubba drag slicks on the rear. Mickeys out front on Weld wheels.

Interior:

Motec complete system, Motec dash/interface, Lenco lever shifters, quick release wheel and 3 PEDALS! Custom aluminum interior panels and sound system!

ET & MPH:

Back in 2002 my best was 6.71@212.39. Ed Thornton got it to go 6.40 @ 229 (or so). Since the restoration there have been no full throttle passes to date.

Most Unique Feature(s):

This car set the standard when it was built. It was the most advanced and EXPENSIVE Pro Street car built up to that time.

Build Timeline:

One year.

Most Memorable Experience(s):

A couple come to mind. First one was in March of 2002 at Pomona, the second race with the 57. After pedaling the car due to tire shake, it went down pretty good it seemed. At the end of the track I stopped to pull in the chutes and in front of me were all the other Pro Street guys doing the same. I looked at these guys who I respected so much, and got a little emotional as I realized I was now a part of this group. Randy Walker came walking over as I got out and said “Pretty good run Hayden, you just set the MPH record.” He hugged me. Pretty cool! Second, that race at Pomona got rained out and we had to finish it at Vegas. We finished Pomona during qualifying, where I had Joe Delamajorie in the final and won. Then in the regular race the next day we had Joe again in the final and beat him again! That was awesome!

Thanks To:

Hal for getting me involved. Annette and Vern Summer for help with a clutch and a Motec they donated to the project and lots of support along the way. Brian and Jess Havlik for the massive amount of work they put in to get the car to put it back together for their Havliks Fastest Street Car Reunion in August of 2024.John MacIntire for helping me get ready for the long drive to Cedar Rapids, Iowa and crewing on the car for the whole 2002 season. And the rest of the 2002 crewBrian Hayes, clutch, Chuck Roberts, my sons Matt and Adam Hayden, and my lovely wife Diane, for putting up with all this!

The ’57 Chevy’s chassis was originally built by Jerry Bickel Race Cars and still sports the Lamb front struts and 4-link rear suspension setups. The vintage powerplant is based on a 447 cubic-inch Donovan aluminum block with a Crower billet

crankshaft, Oliver connecting rods and JE pistons. Equally vintage are the Oldsmobile 14-degree Pro Stock oval-port cylinder heads that have been fitted with Manley Performance valve springs, Manton pushrods, and T&D rocker arms.

Based on a 447 cubic-inch Donovan aluminum block with a Crower billet crankshaft, the powerplant is now considered vintage, but numbers don’t lie and the ‘57 was running the numbers over 20 years ago so why mess with success. Oliver connecting rods and JE pistons rotate inside the block but it’s the Oldsmobile 14-degree Pro Stock oval-port cylinder heads that garner the most attention. They have been fitted with Manley Performance valve springs, Manton pushrods, and T&D rocker arms.

Due to years of racing and then sitting, most of the car had to be rebuilt and the work was done as close as possible to original spec.

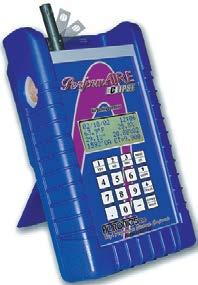

Motec runs the show in the 57 and the extensive electronics to do so have been mounted on the passenger side firewall. Speaking of Motec, right around 2002 wellknown tuner Shane Tecklenburg refit the 57 with a MoTeC EFI system and Ed Thornton – with Shane’s tuning and crew abilities – drove to PSCA championships in 2004, 2005, 2007, and 2008. The pair got the car to go 6.34 and 229 mph!

The induction system consists of twin Garrett 88mm turbochargers that pressurize the Hogan’s sheet-metal intake manifold, and the MoTeC engine management system is still in place to operate the 160 lb/hr fuel injectors.

In true nostalgic pro street fashion, the transmission is a Lenco CS1 3-speed with an AFT triple-disc clutch to send the thousands of horsepower back

to a Mark Williams 9.5-inch rearend with 40-spline axles.

Rolling stock consists of Weld Racing Aluma Star wheels wrapped in Mickey Thompson 15X35.5x16 Little Bubbas on the rear.

Hayden brought the ’57 Chevy home to California just after Christmas of 2001 and campaigned it throughout 2002 in the Pacific Street Car Association.

While the Pro Street race movement initially saw some minor “street” equipment required in certain classes, eventually these cars became full on drag cars. The interior of the 57 is a perfect example, sporting an extensive cage, custom tinwork throughout, carbon tubs and a simple aluminum dash.

“During that time, we set all the records,” Hayden recalled. “We qualified number 1 at every event. The car was basically unstoppable, if it went down the track. It was known for tire shake problems.” To rectify that issue, Hayden had Tommy Mauney welded in double frame rails to firm up the chassis and eliminate the twist.

At the end of the 2002 racing year, Hayden and Lashley parted ways so Hayden could focus on his business. Pro Street legend Annette Summer and her husband Vern took over stewardship of the Chevy and both Hayden’s crewmember Chuck Roberts as well as Todd Tutterow wheeled the Chevy in 2003. At the end of the season, it received a MoTeC EFI system and with tuning by Shane T, and Ed Thornton drove to PSCA championships in 2004, 2005, 2007, and 2008.

“We debuted it in 2004 and immediately ran 6.56 at 220 mph,

which was a massive speed at the time,” Shane Tecklenburg told us. “The best we ever got it to go was 6.34 and 229 mph.” Thornton took over driving duties in another car after that, and the Chevy was parked and its parts were plundered.

Hayden always wanted to buy the car, though, and Lashley eventually offered to sell it to Hayden in 2022.

“I bought the car and it looked really good until we started really looking at it and realized there was not much left and had to start from scratch and build the whole car,” Hayden explained.

Tunes are required and the vintage setup remains in the ‘57.

This legendary Pro Street 1957 Chevy, known by many as “The Rieger ‘57 Chevy”, has been completely rebuilt as a tribute to not only its original wheelman but other notables like Ed Thornton, Annette Summer and Chuck Roberts. Of course, its current owner and caretaker Mike Hayden also drove this trend setting machine to the finish line several times.

drove the shoebox, Hayden began putting it back in working order. After Annette Summer mentioned the 2024 Havlicks FSC Shootout event and suggested he take it to the nostalgic pro street event, Hayden put his efforts in high gear, but eventually determined he wasn’t going to make it in time.

“I was offered help from the Hot Rods by Havlik team,” Hayden said. “They told me if I got it to them in Cedar Rapids, Iowa, they would put it together so that I could get it to their race.”

staff and Mike Hayden, Bob Rieger’s trend-setting ’57 Chevy once again hit the track, with Hayden behind its steering wheel for the first time since 2008. After displaying the Chevy in the Hotrods by Havliks booth at the 2024 PRI Show, Hayden brought the car back to California. He still has a long way to go with getting some full-power runs down, but the car and driver are there to produce some serious numbers and now he has a second chance to make even more memories with this legendary machine.

RPM

RPM MAGAZINE Reprint IN Print! RPM MAG’s commitment to features that appeared digitalonly since June 2020. Article first appeared in the January 2021 digital issue.

With all the technology poured into today’s drag racing world, why would anyone even think about using technology dating back many decades, if not back to the horse and buggy?

Jason Digby, founder of Leafspring Nations, that’s who! When it comes to clocking up wins, Jason just enjoys gettin’ things done old school!

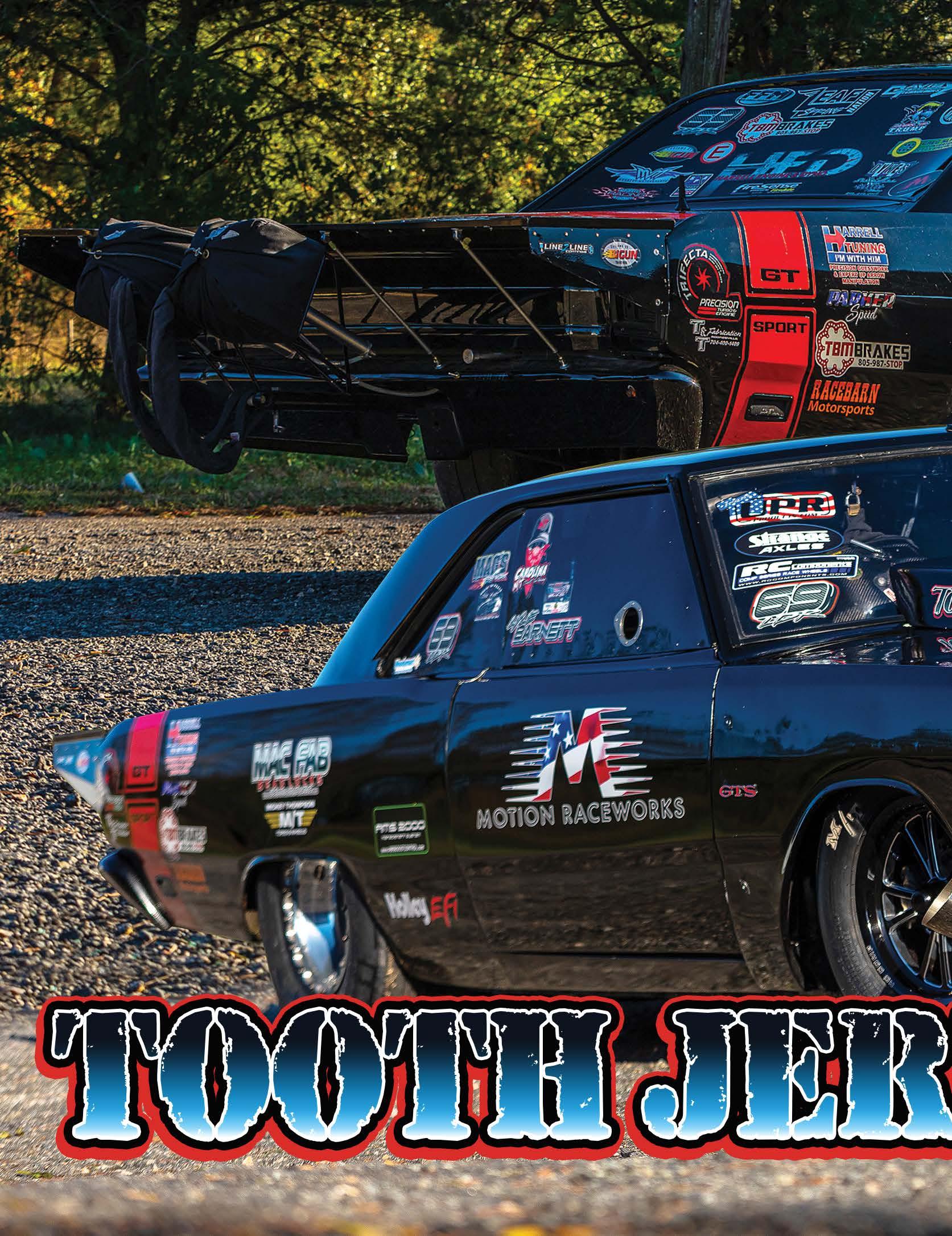

Owned by Digby and driven by Lyle Barnett, the “Tooth Jerker” 1969 Dodge

Dart mixes high tech turbocharged power with some solid leaf spring technology. Jason also runs a prominent company in the industry, Mag’s Fab Worx, which performed a larger portion of the Dart’s build.

118mm of Precision turbo goodness peers its way from the center of the carbon front end.

The reputation of Dodge’s big block wedge motor speaks for itself...

With the front end off, the symmetrical tube work gives the Dart an almost humanlike look, as if it has a moustache.

Many RPM readers along with drag racers worldwide have heard the name Lyle Barnett. He’s known as a competitive drag racer who has run in several top tier classes. Most will also know the riveting story of how Lyle almost lost his life in a very severe crash that resulted in a fire that burned most of his body. Barnett didn’t give up, though, and when he wanted to get back out on the dragstrip, Jason had to have him onboard with the Tooth Jerker Dart.

Digby originally bought the Dart as a streetcar and he kept it relatively mild, but the time came when he wanted more, and the Dart was a more than willing candidate.

The reputation of Dodge’s big block wedge motor speaks for itself, however, in more recent years builders and tuners have found that not only do they make power and hold together when built with the right parts, but they love boost!

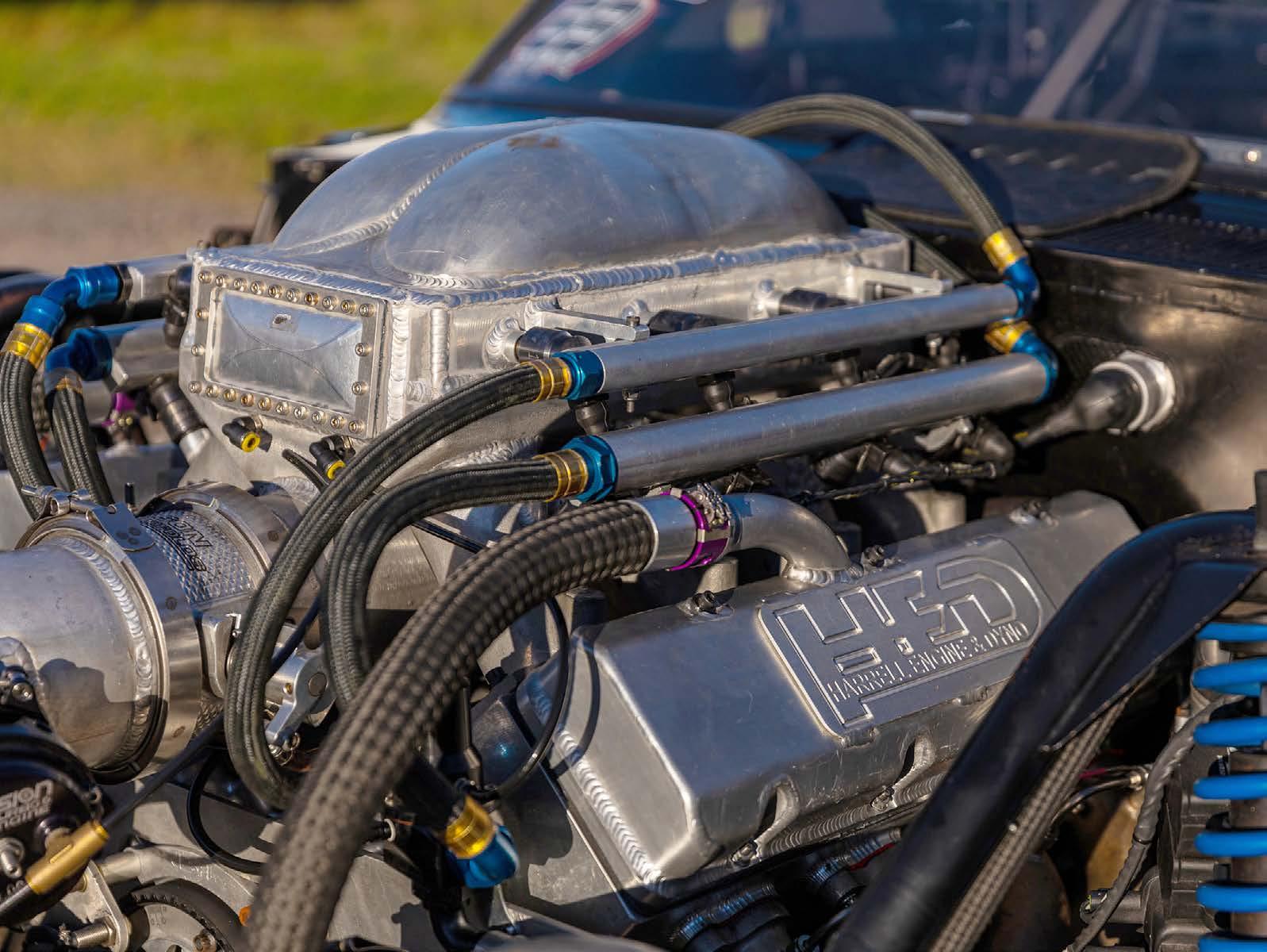

The 440 block that came in the car remains, but pretty much everything else has been replaced. All machine work was done at Harrell Engine and Dyno

(HED) and the rotating assembly consists of a HED machined forged crank, R&R rods, and custom Ross pistons pushing the cubic inches to 547ci. Pete Harrell has many tricks up his sleeve when it comes to engine building and, due to the competitive nature of racing, much of that knowledge is closely guarded, including the exact compression ratio and cam specs for this mill.

“G

Spot” sensors paired with Rife sensors help keep the nose of the Dart planted.

Harrell ported a set of RMC billet cylinder heads, fitted them with Victory valves and studded them in place.

A set of 1.8 ratio T&D steel roller rockers were also used and the intake manifold is a custom one-off design made in-house, as well.

The owner of Customs by Bigun, Eric Yost, built the entire turbo system, including the massive 2 ¾ inch headers, hot and cold side, plumbing for the wastegate and the downpipe. The design is based on a 118mm Precision Turbo and Engine turbocharger paired with a JGS wastegate.

Eric “Bigun” Yost has his signature work in all areas of the car; all of the turbo system fabrication work is from Customs by Bigun.

Bigun also worked with Digby’s shop, Mags Fab Worx, to build the custom certified cage. Two sets of Billet Atomizer injectors, the first set being 850’s, while the second set is 225lb/min, and Aeromotive pumps supply them. A Holley EFI system con-

trols everything with precision thanks to tuning by, you guessed it, Pete Harrell.

Backing the wicked wedge is a tried and true Turbo 400 transmission built by Proformance Racing Transmissions and a Greg Slack converter pairs the two together.

Moser’s M9 rear end provides a near indestructible link between the horsepower and the tires

TBM Brakes sport their signature lightweight rotor design on all four corners.

Old Is New if you haven’t read it yet!

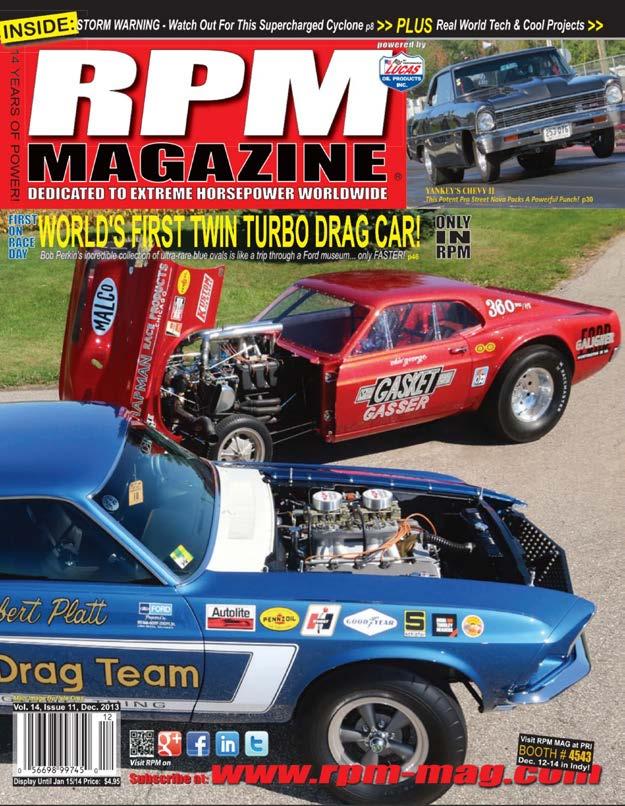

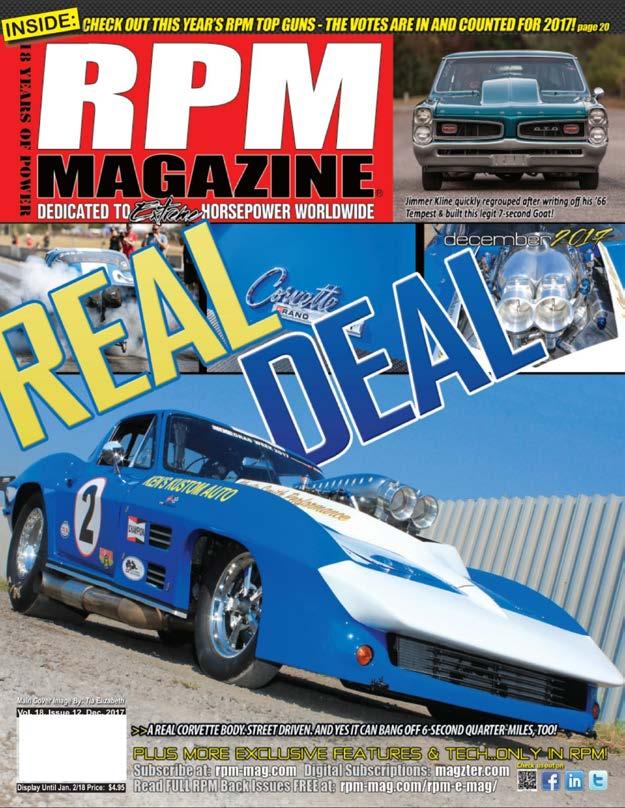

Each month we host some of our past issues of RPM Magazine in this section. If you haven’t read them yet, they are new to you! If you have, maybe there’s a favourite car/story you want to read again….here they are!

DECEMBER 2013

CLICK A COVER OR SCAN A QR CODE TO GO BACK IN TIME!

DECEMBER 2022 DECEMBER 2016

Engine:

Chrysler Wedge 440, now 547 inches.

Bore/Stroke: 4.500/4.125

Crankshaft: HED custom grind

Pistons: Ross custom

Connecting rods: R&R

Compression ratio: top secret

Engine built by: Pete Harrell. Harrell Engine & Dyno

(HED) Mooresville, NC

Camshaft make: HED custom grind solid.

Duration @ .050 in/ex: top secret

Lift @ .050 in/ex: top secret

LSA: top secret

Cylinder heads make/type: Custom RMC billet heads,

Machine work: finish machining done in house at HED

Intake valves make/size: Victory, top secret

Exhaust valves make/size: Victory, top secret

Rocker arms: T&D, steel 1.8 ratio.

Air & Fuel:

VCM: Holley EFI

Engine tuner: Pete Harrell

Injector size: Billet Atomizer 850’s and 225’s

Pump(s): Aeromotive

Intake manifold: Custom

Throttle body make/size: Wilson, big

Mass air meter/Map Sensor: Holley

Ignition box: Holley

Power Adder:

Turbocharger System: Customs by Bigun

Turbocharger Model: PTE 118mm

Blow Off Valve: PTE

Wastegate: JGS

Boost: All of it

Intercooler: none

Hot side piping size: 5”

Cold side piping size: 4”

Downpipe: 2.75

Transmission:

Type: Turbo 400

Converter: Greg Slack, Converter Design Specialities

Shifter: M&M

Driveshaft: Carbon Fiber

Trans built by: Proformance Racing Transmissions

Chassis:

Back half rear, tube chassis front.

Front upper/lower control arms: Custom tubular

Front shocks/struts: Santhuff

Rear: Leaf Springs Smith Racecraft Assassin Bars, Menscer shocks.

Performance:

Best 1/8 mile ET: 4.10

MPH: 186

60ft. time: 1.09

Horsepower: 3000ish

Miscellaneous:

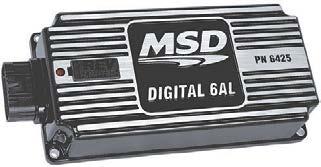

Coil: MSD

Distributor: none

Wires: Scott Wires

Plugs: NGK

Headers: Customs by Bigun, 2.75”

Roll bar/cage: MAG’s Fab Worx/ Customs by Bigun

Gauges: Holley EFI Dash

Carbon fiber front end and doors

TBM Brakes

RC Components wheels, Mickey Thompson tires.

Thanks to all of our friends, partners, and sponsors who’ve spent countless hours helping us achieve what we have thus far. With Lyle driving, we plan to break into the 3s in 2021 while doin’ it old school, on leafspings!

The Dart has decals all over it, but the trunk showcases everyone who is involved with the car.

A custom carbon fiber driveshaft connects power to a complete fabricated Moser rear end stuffed with Strange Engineering axles. Suspending the rear diff is, of course, leaf springs! Sure, we know the setup is based on tech from 1969, but why mess with success. With the help of race quality springs, Smith Racecraft Assassin traction bars, a pair of Menscer Motorsports shocks along with chassis and suspension tuning guru Eric Yost, they have no reason to change it, mostly because they continue to run at the front of the pack. Up front, tubular control arms with Santhuff struts and rack and pinion steering keep things low and straight.

As you might expect, the Digby Dart looks much more menacing than it’s fairly mild mannered off-the-showroom-floor look.

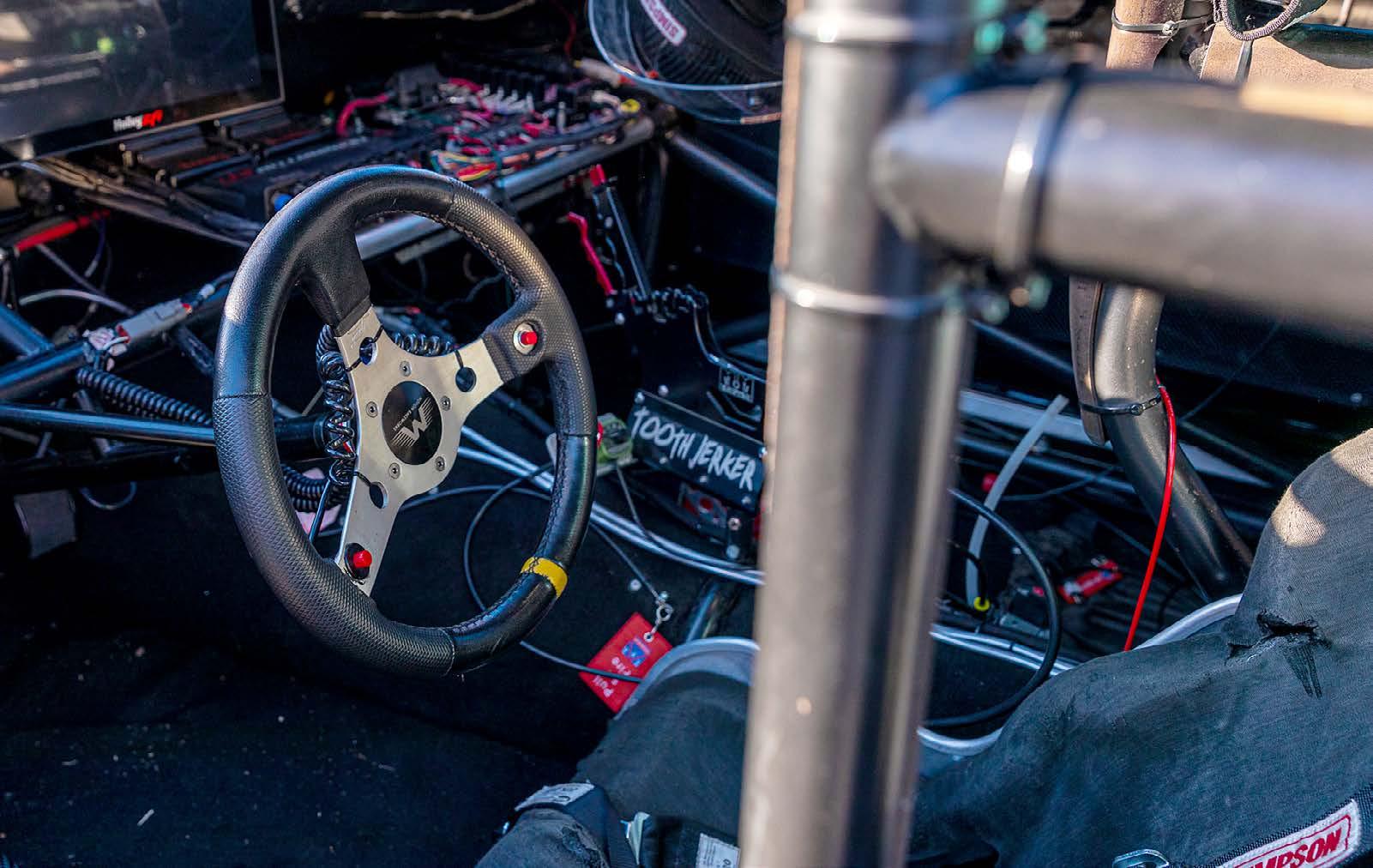

All of the electronics are neatly placed on a fabricated panel to the right of the driver.

Originally it was Canary yellow, but after installing a carbon fiber front end and doors, the color was swapped out for the much more intimidating black. The Dart sticks to its original roots, though, with a “GT Sport” rally stripe on the rear and GTS badges on the front fenders.

Polishing off its low stance, the Tooth Jerker sits on 15 inch RC Components wheels, sporting Mickey Thompson 26 inch front runners and Mickey 275 radials to meet class rules outback.

TBM brakes stare back at you through the wheels with their signature lightweight rotor design while a Stroud parachute hangs off the rear, making sure things get slowed up in a hurry after a pass.

Inside the cockpit, through the maze of cage bars, Spartan best describes what you see. All the essentials are there and not much more. A Holley dash sits in front of a Motion Raceworks steering wheel.

pad used to be, Eric fabbed up an entire electronics panel to ensure they could quickly get to things for maintenance and parts swaps between rounds. Jason is adamant about safety gear; a Firerade suppression system was installed along with the SFI approved harnesses and seat. Rife Sensors help control tunable actions the Dart experiences while on a pass,

power to the ground is approximately 3000whp on “all the boost”. At class weight, the Dart punished the 8th mile cutting a 1.09 sixty-foot while coming out the back door at 186mph in 4.10 seconds, and watch for them to break into the 3-second range this season. That’s insane, don’t ya think? Especially for a car riding on horse and buggy technology!