HIGH PERFORMANCE MINERAL DRAG RACING OIL

Mineral based engine oil designed to enable maximum power while providing ultimate protection under the most severe race conditions.

• Unique friction modifier system enables maximum power output

• “Stay-in-place” chemistry and 2X Zinc anti-wear system provide lasting protection

• High quality base stocks enable effective ring seal

• Advanced, proprietary additive system keeps your engine clean

• Designed to prevent separation caused by fuel dilution

• Available in 50WT, 60WT & 70WT

EDITOR-IN-CHIEF

CHRIS BIRO editor@rpmmag.com

V.P. MARKETING/CUSTOMER RELATIONS TRISH BIRO trish@rpmmag.com

EVENT MEDIA events@rpmmag.com

EVENT SUBSCRIPTIONS COORDINATOR SHERRIE WEBER sherrie@rpmmag.com

ART DIRECTOR .......................................................... JIM McHARG

Photographic Contributions: Mark - Godragracing.org, George Pich, Louis Fronkier, Blake Farnan, Jerry Garrison, Eddie Maloney, Wes Taylor, Steven Taylor and Amber Hynes

RPM Magazine is a REGISTERED TRADEMARK of Revolution Publishing & Media Inc. RPM Magazine is a worldwide motorsports publication distributed online.

To subscribe to RPM go to www.rpmmag.com or email Trish Biro at trish@rpmmag.com, or call 519752-3705.

The focus of RPM is to bring a diverse mix of high performance street and race automobiles to life within its pages including race cars, muscle cars, hot rods and street legal machines with an emphasis on the “EXTREME,” including fast doorslammer and outlaw forms of drag racing. Not familiar with these types of cars? They are considered to be the top-shelf of the industry and are on the edge with regard to design, performance, and power!

RPM Magazine does not sell its mailing list or share any of the confidential information regarding its subscribers.

Editorial Contributions:

Chuck Scott, Mark-Godragracing.org, Tim Biro, Stan Smith, George Pich, Jay Misener, Eddie Maloney, Wes Taylor, Steve Baur

Technical Writing Contribution: Chuck Scott, Shane Tecklenburg, Tim Biro and Jay Misener

For advertising information contact

TRISH BIRO ............... 519.752.3705 ................ trish@rpmmag.com

Special Events Manager: Chris Biro events@rpmmag.com

Special Events Sales: Trish Biro: 519-752-3705 trish@rpmmag.com

Subscriptions/Address Changes: Circulation circulation@rpmmag.com

General Inquiries: 519.752.3705 info@rpmmag.com

RPM Magazine has been a world leader in motorsports publishing for 26 Years and has support locations in Ontario, Canada, Alabama, Texas, and Virginia, along with contributing writers and photojournalists worldwide.

If you have a story that may fit within the focus and scope of RPM Magazine’s coverage, please email our Editor In Chief at editor@rpmmag.com. Submission of an article does not guarantee that it will be published.

Revolution Publishing & Media Inc. (RPM) / RPM Magazine IS NOT responsible for errors or omissions in ANY advertisement or article. Advertisements may be rearranged or altered at the sole discretion of RPM to allow the ad to fit in the space purchased by the advertiser.

WE RESERVE THE RIGHT TO REFUSE ANY ADVERTISING WHICH WE CONSIDER TO CONTAIN MISLEADING, OFFENSIVE OR FALSE INFORMATION. REPRODUCTION OF ANY INFORMATION HEREIN IS STRICTLY PROHIBITED WITHOUT PRIOR WRITTEN CONSENT.

As RPM readers know, it’s very important for us to recognize not only the high power and ultra-fast builds you see each month in RPM, but also the roots of fast cars, including factory built performance and race cars that have helped steer the industry since its early days on the street and strip.

Tolono, Illinois’ Tom Jenkins is an IT Project Manager with a huge soft spot for his 1972 Buick GS factory muscle car, and rightly so, he’s owned it for over 37 years.

It all started with a 13 year old boy’s trip to the Cleveland Autorama. “I just went along for the ride since it sounded like fun, and that trip led to a lifetime hobby and lifestyle” Jenkins remembered.

Tom Jenkins’ stunning 1972 Buick GS is an all steel car that he has owned for over 37 years. A cowl hood was added and the unique vinyl roof and rear spoiler along with the full compliment of stainless and chrome factory trim are icing on the cake.

And after that show he started hunting for a car right away. His mom thought he was crazy since he was only 13 and because of his BMX bikes and other sports he was into he didn’t have the time or money for a car. But by the time he was 16, and his family moved to Illinois, Jenkins

worked all summer to save for a car and purchased a 1972 Buick GS that he found in the newspaper classifieds on September 9, 1987 for $2,700. Despite a hiccup during the pur chase due to a loan on the title, his Mom helped him secure the deal and the rest is history.

He had saved $1,700 and borrowed the rest from mom, paying her back $100 per month.

At 16 Jenkins knew a bit about cars and nothing about Buicks but learned everything he could, and having some car buddies in high school helped, too. One of those friends took him to the track to watch his dad race Super Comp and that lit another fire in Jenkins… drag racing! “I started street racing and bracket racing back then and over the years.

Turn your LS into a legend in its own time with Trick Flow GenX® 280 HIP cylinder heads. These ultra-performance HIP’d (Hot Isostatic Pressed) castings are significantly stronger than regular heads, and include many other outstanding features such as:

• Industry-leading airflow

• 280cc CNC Competition Ported intake runners

• 87cc CNC Competition Ported exhaust runners

• Manley 2.165" Severe Duty intake/1.600" Inconel Extreme Duty exhaust valves

• Trick-Alloy™ powdered metal valve guides

• Trick Flow by PAC Racing dual valve springs

• Clearance for 3/8" pushrods

• .750" decks

• 6-bolt-per cylinder mounting

• LS3 rocker stands included with assembled heads

Track Max® Camshafts

Engineered for Performance! New heads are just one part of the Serious Horsepower formula. To complete it, you’ll need some more components.

• Dyno proven to significantly increase power

• Made from premium billet steel blanks

• Available in several hydraulic roller designs up to 230°/238° duration and .625"/.625" of lift

R-Series Intake Manifolds for GM LS3

• Bring carbureted-style aspiration to LS3-style engines

• 3,500-7,500-plus RPM range

• Available in carbureted and carb-style EFI versions

Variable Valve Timing Delete Kits

• Removes VVT so your engine makes big power with aftermarket parts

• Available with 1- and 3-bolt cam gears

• Includes cam/crank timing gears; timing chain and damper; LS2/LS3 timing cover with bolts, seal, and gasket; cam sensor, harness, and bracket; water pump gaskets; and cam, cam sensor, and balancer bolts

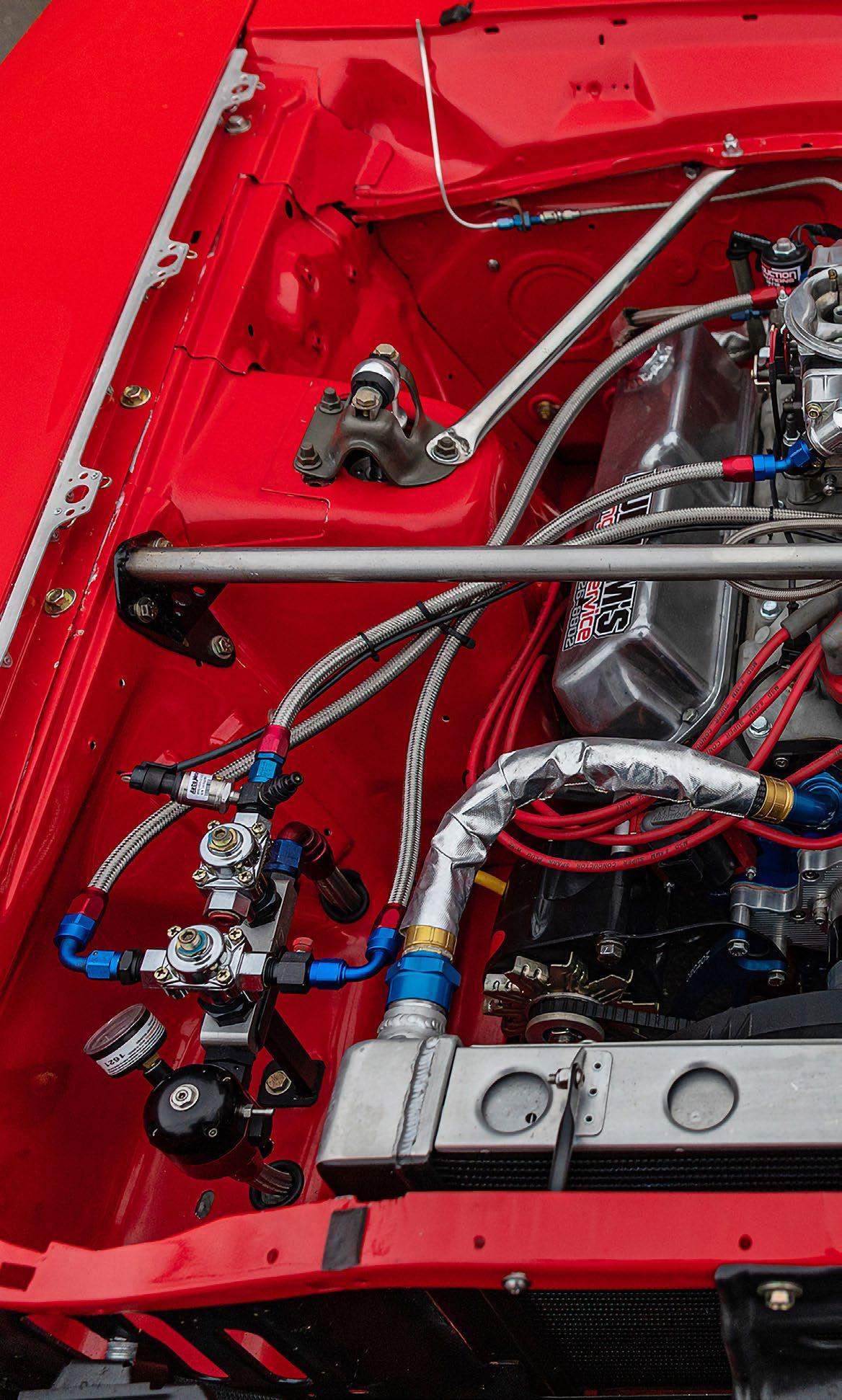

The naturally aspirated Buick mill measures out to a roomy 464 cubic inches. Precision Engine and Machine’s Richard Sliwinski originally built the bullet in 2008 and Jenkins has made upgrades ever since. Most recently, he had Precision do up a set of aluminum TA Performance Stage 2 Track Eliminator heads with all the fixins. Over the 2024/25 winter he freshened the motor and added more camshaft to the combination.

I have raced on the street, in bracket, index, and heads up classes with the same car.” Along with racing, Jenkins has attended more cruises and shows than he can count and amassed a number of awards at them.

The GS was all original and in good shape with a faded interior but a strong running 350. The most important part was that nothing was missing from the car so it made for a great foundation to build on, and that’s exactly what he did.

“My dad passed away when I was 13 and left me some money for school which I received monthly for 4 years. After paying tuition, fees, and some living expenses I would buy a few car parts here and there for the Buick, so I feel my dad played a part in this car.”

“I installed my first 455 in the car in the spring of 1991. It was mild but ran 12.30s in the quarter.

Body & Paint:

Original steel body with Glasstek hood and 5” cowl installed by LK Customs in Peoria Illinois in the mid 90’s. Shawn Brown in Champaign Illinois did the body work and Burnished Copper (original color) paint in 2004.

Chassis & Suspension:

Installed a 6 point bar in the mid 90’s using an S&W kit.

QA1 tubular control arms.

Viking double adjustable coilovers in front.

Viking double adjustable shocks in rear.

HR Parts N Stuff adjustable upper control arms, lower arms, and anti-roll bar –Atwater, OH.

Engine:

1970 Buick 455 Block bored 0.038 over for 464 cubic inches.

Bore: 4.35 Stroke: 3.90.

Bill Miller Forged Pistons - Compression Ratio: 12.69.

Total Seal Rings.

TA Performance 600+ lift 308 solid cam.

TA Performance/Johnson Lifters.

TA Performance Track Eliminator Stage 2 heads ported and assembled by Precision Engine and Machine.

Heads flow 332 at 0.600 Intake and 254 at 0.600 Exhaust 28”.

Intake Valves: 2.125 x 11/32”

Exhaust Valves: 1.75 x 11/32”

Cometic 0.040 head gaskets.

PAC valve springs and spring seats.

Comp Cams retainers and locks.

T&D 1.65 shaft roller rockers.

TA Performance 2 1/8” primary headers – Coated by LO-KO Performance Coatings Oak Lawn, IL.

Induction:

Intake - TA Performance SP-2 Intake ported by Precision Engine and Machine. Sleepy Hollow, IL.

Carb – Holley 1080 CFM Dominator Big Gun carburetor by DaVinci Performance Carburetors – Houston, TX.

Power Adder:

No power adder. Naturally aspirated.

Electronics:

All MSD. MSD Billet Distributor. MSD 6AL Ignition Box. MSD Blaster 3 Coil. MSD Spark Plug Wires. NGK Spark Plugs. I will be installing an Innovate dual channel Wide Band this winter.

Transmission & Converter:

Turbo 400 built by Bob Alexander @ Performance Transmissions Clinton, IL. Coan 9.5” Converter.

Rear Differential:

GM 12-Bolt rearend from a 1971 Chevelle. Moser Ford 9” big bearing housing ends. Moser axles. Richmond 4.10 gear, Eaton posi with 800 LB spring. TA Performance rear end girdle.

Brakes:

Master: 7/8” bore tandem master cylinder

Front: Forged Dynalite Pro Series front disc

Rear: 1985 Buick Riviera pads and rotors. Brackets by A&A Manufacturing

Tires & Wheels:

Front: Billet Specialties Street Lite 15x4” wheels / Mickey Thompson Sportsman 26x7.5-15.

Rear: Billet Specialties Street Lite 15 x 8.5” / Mickey Thompson Drag Radial Pro 275/60 R15.

Interior:

All factory replacement interior from Legendary. Seats done by Patton’s Upholstery Champaign, IL

All gauges are Sport Comp with Playback tach.

Factory shifter converted to a rachet shifter.

I wanted to keep the interior as factory appearing as possible.

Miscellaneous:

Flowmaster Top 10 Shootout 3.5” mufflers.

Best ET & MPH:

10.70@125.70 mph at 3917 Lbs No power adder

Most Unique Feature(s):

It’s my first car I purchased in 1987, and have owned it over 37 years. There were 7,767 1972 Buick GS cars produced. The car is the original color – Burnished Copper.

Reason(s) For Build:

This was my first car. I turned 16 in May of 1987 and worked the entire summer to purchase my first car. I bought this car on September 9, 1987. I paid $2,700 for it. I had $1,700 saved and borrowed $1000 from my Mom. I paid her $100/month until paid off.

I spent my teen years around car guys of all ages. I kept hearing stories of people regretting selling cars. I didn’t want to fall in that category. I feel owning a Buick GS was something unique. I had a car not many people had and never had the desire to sell it.

My dad passed away when I was 13. He left me some money for school. I received money monthly for 4 years. After paying tuition, fees, and some living expenses I would buy a few car parts here and there. So I feel my dad played a part in this car.

National Awards:

• Street Machine Nationals Lima Ohio Editors Choice 2003

• Winning the BPG (Buick Performance Group) Buick Nationals in Salem Ohio in 2004

• Numerous show awards at Rt 66 Mother Road festival – Springfield, IL

• Street Machine Nationals Duquo in IL Judges Choice 2015

• Street Machine Nationals Duquoin IL Judges Choice 2024

• Buick GS Nationals Semi Finals GSR class – 2024

• Buick GS Nationals Top 25 Car Show – 2024

• Buick GS Nationals Best Racecar 2024

Thanks To:

My Mom for letting me buy the car when I was 16. My wife for all her help at races and other car events and help at the track. Scott Spies of Houma, LA for help tuning, crew, and advice. Chris Gosch of Bunker Hill Illinois. The Illinois Street Racers car club for many years of fun!

Clean and tidy is the order of business under the hood of the Buick and since this is a street and strip car Jenkins insured that cooling and braking parts were up to snuff.

Those were fun times driving to towns around Illinois attending cruise nights and a little racing afterwards.”

By late 1994 Jenkins stepped up to a stronger 455 based 464inch mill and ran mid 11s. He also freshened the interior and paint, installed a 6 point bar, and did suspension work. “I began racing the car a lot more and attended numerous cruise nights and shows. Almost

every weekend through the rest of the 90s included a show, race, or cruise night,” he told us.

In 2004 Jenkins had a talented friend, Shawn Brown, paint the car and engine compartment in a stunning Burnished Copper color (the original color) and that paint still looks like the day it was laid down over 20 years later. While the engine was out he freshened it as well.

The factory Buick frame and suspension are joined by tubular control arms with double adjustable coilovers up front and adjustable upper control arms, lower arms, and anti-roll bar with double adjustable shocks out back.

Billet Specialties Street Lite wheels are wrapped in Mickey T’s, with their Drag Radial Pro 275/60 R15s taking care of business out back.

Buick’s catch phrase back in the seventies for its factory performance offerings was “Fast With Class” and that’s something that’s evident both outside and inside the GS.

By 2008, he wanted to step up the program with a stronger engine and had Precision Engine and Machine’s Richard Sliwinski build the new motor that still, albeit with various addons over the years, occupies the engine bay today. “We went with iron heads back in ’04 and the car ran low 11s at 3900 lbs.”

In 2013 Jenkins had Precision do up a set of aluminum TA Performance Stage 2 Track Eliminator heads. With the head swap, along with all new suspension products from HR Parts N Stuff, Viking, and QA1, the heavyweight luxury muscle car immediately ran deep in

the 10-second zone in the quarter.

Over this past winter, Jenkins freshened up the engine and swapped out the cam. He also changed the converter and added a few other odds and ends to the car that should see improvements in ET and consistency.

We love a factory muscle car interior and Jenkins went to great lengths to preserve the inside of the GS, adding only the necessary roll cage for safety and gauges to monitor vitals.

Backing the capable Buick mill is a Bob Alexander-built Turbo 400 with Coan 9.5inch converter. A GM 12-bolt rear end from a 1971 Chevelle has been fortified with Moser axles and big bearing ends, an Eaton severe-duty posi, 4.10 gears and a TA girdle.

Helping hook the heavy -

weight Buick and keep it on the straight and narrow are QA1 tubular control arms with Viking double adjustable coilovers up front and HR Parts N Stuff adjustable upper control arms, lower arms, and anti-roll bar with Viking double adjustable shocks out back.

Jenkins had a friend, Shawn Brown, paint the car and engine compartment in the original Burnished Copper color back in 2004 and that paint still looks like the day it was laid down.

Speed Sauce Plus water-ethanol mix comes premixed and ready to use straight from the bottle. Its 20/80 water/ethanol blend delivers more power per gallon. This ethanol-based fluid is not only less corrosive to fuel systems than methanol-based fluids but also safer to handle due to its lower toxicity.

• Provides 4% more power compared to methanol-based injection fluids

• Produces up to 15% more horsepower/torque than stock, with proper tuning

• Delivers added octane when needed thanks to the ethanol’s >115 octane rating

• Less corrosive than methanol version

it yet!

Each month we host some of our past issues of RPM Magazine in this section. If you haven’t read them yet, they are new to you! If you have, maybe there’s a favourite car/story you want to read again….here they are!

CLICK A COVER OR SCAN A QR CODE TO GO BACK IN TIME!

...I’ve built the GS from the ground up since I’ve owned it...

Tom Jenkins

Billet Specialties

Street Lite wheels are wrapped in Mickey Thompson Sportsman 26x7.5-15 front tires and Mickey Thompson Drag Radial Pro 275/60 R15 rears.

The interior of the GS has been completely restored with Jenkins being very careful to preserve the factory vibe and add only equipment necessary for racing. Aside from the S&W rollbar, a trio of gauges and a tach to monitor

the engine are about the only visible addons.

“I’ve built the GS from the ground up since I’ve owned it and pretty much touched every nut and bolt on the car. You always hear stories of people regretting selling cars and I didn’t want to fall in that category. I feel owning a Buick GS was something unique and I never had the desire to sell it.”

If we told you that Rick Kiel is a retired blueberry farmer, you might not think someone who spends their time in the fields growing small, delicious fruit could come up with something as wild as the Potent Rodent...

However, Kiel has also been cultivating his wild side when he wasn’t sowing his crops, and the Pro Street Vega you see here is the yield. Michigan resident Rick Kiel enjoyed street racing in the 1960s, but rather than making a move to on-track drag racing, he kept to the dirt and went mud racing in 1985 running cut tire and scooper tire classes nationally.

“In 1990, we built Destroyer III, a blown alky big-block Chevy ‘23 T altered, in 40 days and set 4 national records on 160ft and 200ft pits in NMRO with 3 drivers: me, Doug Dams, and Mike Fair,” Kiel recalled. “It was named 1990 car of the year. I set another record with NMRA in 1990 on their 150ft pit. The cars were named Destroyer and owned by Potent Rodent Inc., hence the name of Vega.”

After a crash in 1991, Kiel wanted to spend more time with his family and found other sports that provided that.

“My son Adam and I started drag racing alcohol Banshee and Honda 250 R quads. In 2001, we became Arizona snowbirds and started rock crawling, which I still enjoy,” Kiel explained.

Having experienced all of those various ways to build and sample horsepower, Kiel decided what he really needed was a wicked Pro Street machine that he could take to car shows and cruise-ins.

One might think that the Potent Rodent is an old drag car that some thoughtful enthusiast brought back to life, but nothing could be further from the truth. This wild freshly constructed street car is the brainchild of Rick Kiel.

The project began after taking possession of this 1971 Chevy Vega in 2014 from his friend Ray Watjer, after his untimely passing.

“It was mini-tubbed and powered by a naturally aspirated small-block Chevy,” Kiel told us. “My vision was a transformation into a bad street cruiser that would have terrorized the streets in the 70’s.”

Kiel had worked with Hot Rods by Gene on previous projects and turned to the shop once again for this build. The transformation

began from the ground up with 2x3-inch boxed frame rails being welded into the fac tory floor pan and a 12-point roll cage con structed inside the diminutive economy car.

At the rear, the team installed a 4-link sus pension set up with coilover shocks to keep the narrowed Ford 9-inch rearend properly damped. The 9-inch was fitted with an alu minum third member with 3.90 gears and aftermarket axle shafts by Jay Porsche Jeni son at Ultimate Driveline.

Rick Kiel

A custom 4-link coilover setup suspends a beefed up 9-inch rear end while the front of the Vega was retooled to accept an early funny car-style, dropped straight axle, 4-bar setup with coilover shocks and rack and pinion steering. The car rides on American Rebel Starburst 15x4-inch front wheels and 15x14 Centerline rears.

To achieve Kiel’s goals and make his design ideas a reality, the front end of the Vega received an extensive amount of work. This included scrapping the original front suspension and swapping in an early funny car-style, dropped straight axle, 4-bar setup with coilover shocks. A Pinto rack and pinion steering system provides the necessary turning capabilities.

One other major area of fabrication to the chassis was the firewall, which was custom-fabricated to allow the engine and transmission to sit 6 inches rearward. Motor plates were fabricated as well to locate the drivetrain between the frame rails. Moving on to the body and paint, John Kouw and his sons at Cruisin’ Customs were tasked with bending and cutting the sheet metal.

A Randy Hildebrandbuilt, 548 cubic-inch big block Chevy motor fills the space between the rails of the Vega. JE pistons, a Competition Cams solid roller camshaft and Dart 360 aluminum cylinder heads were used inside the build and the motor was finished on the exterior with extensive polish work and chrome accessories to make it look as good as it works.

The blown Rat runs on alcohol fed through a pair of APD carburetors. Boost is provided by an old school BDS 8-71 supercharger and the package is backed by a Turbo 400 built by Denny Koster.

Though some may not notice, the front wheel wells were shifted forward 6 inches and raised up 3 inches to match the new front wheel location that the new suspension provided, which was all part of the overall look that Kiel had envisioned.

The front fenders were also notched out for the zoomie-style headers that let everyone know the Potent Rodent is coming, and the Vega received a split-bumper front end with deleted side marker lights.

The rear wheel wells were also manipulated and opened up to fit the 32/17.50-15 rear Mickey Thompson ET Street, bias-ply tires and there is also a custom fuel door. Kiel installed the fiberglass hood and hatch and Cruisin’ Customs gapped the body panels before Mark Dunn at Precision Collision took over to complete the remaining bodywork.

Back in the day! Kiel kept the theme going inside the Vega with diamond-tufted, black with silver metalflake vinyl courtesy of Joe at Buck Skinz, and there is a matching billet aluminum steering wheel that perfectly blends in.

There, Kiel laid down the candy red base, after which Dunn and crew took over with the graphics, flames, and lettering that harken back to the 60s, 70s, and 80s. After that, Dunn sprayed on the clearcoat and buffed it to a smooth, show-quality finish.

While Kiel could have stayed with the small-block engine with it being considered a “mouse motor” and all, he opted for something more aggressive and went with a Randy Hildebrand-built, 548 cubic-inch “rat” motor.

Filled with JE pistons, a Competition Cams solid roller camshaft and topped with Dart 360 aluminum cylinder heads, the big-block Chevy is boosted by a BDS 8-71 supercharger that draws from a pair of APD boost-referenced carburetors. For that extra romp, romp, romp in the parking lots, Kiel runs the engine on alcohol, and he chose an MSD Grid ignition system and an

Accel distributor to keep the fires lit.

With such a potent powerplant residing up front, the Vega was equipped with a stout Turbo 400, three-speed transmission built by Denny Koster. It features an ATC case, a Coan torque converter, a trans brake, and an upgraded input shaft and planetary unit. Shifting comes by way of an old school B&M Quick Click shifter.

A simple straight panel, painted to match the body covers the dash with a quintet of analogue gauges installed and a vintage Moroso cable-driven tachometer is mounted on the steering column.

Purchased as a mini-tubbed small block powered project, body and chassis modifications completed after the purchase are substantial. The front wheel wells were shifted forward 6 inches and raised up 3 inches and notched for zoomies. A split-bumper front end with deleted side marker lights was installed. The rear wheel wells were massaged for tire clearance. A fiberglass hood and hatch were installed after which the body work and Candy Red paint and graphics were completed.

The interior of the car was treated to just as many retro touches as the exterior, beginning with that vintage automatic shifter. The factory dash was removed and replaced with a simple straight panel that now houses aftermarket analogue instruments, including a vintage Moroso cable-driven tachometer. Though the Vega received modern aluminum racing seats, they are covered with retro diamond-tufted, black with silver metalflake vinyl courtesy of Joe at Buck Skinz, and there is a matching billet aluminum steering wheel that perfectly blends retro with modern aesthetics. Rounding out the interior upgrades are Simpson safety belts to keep the occupants secured and a fire-suppression system is at the ready just behind the shifter.

The last few details of this wild ride include the American Rebel Starburst

15x4-inch front wheels that are wrapped in Mickey Thompson 24.5-inch tall tires. Out back, Kiel chose Centerline 15x14-inch rims that wear the aforementioned Mickey Thompson 32/17.50-15 ET Street tires. In order to bring the rowdiness down to a stop, Kiel went with custom front and rear disc brakes, actuated by an aftermarket master cylinder.

With the project completed and the Vega accumulating mileage, you might think Kiel’s favorite part of the build would be the smile on his face as he mashes the gas pedal, or perhaps an award that the wild Vega has won. As he put it, what he has enjoyed the most is “the 3-year journey and fulfillment of a wild dream accomplished through the help of many friends, and the camaraderie enjoyed.” RPM

The body of the stunning split bumper Camaro retains its original steel and glass from the firewall back. A fiberglass front end has been installed and paint work was completed by Keith Wolk Restorations in a Mazda 46V color.

For many enthusiasts and racers, family often takes priority over fun behind the wheel, but once the kids have been raised, the house is quiet again, and the financial strain has lifted, it’s often possible to get back to your favorite pastimes. For St. Louis, Missouri’s Noel Steibel, that meant finally finishing the car he bought so long ago.

A welder by trade, Steibel has been working on cars since he was 14 years of age.

“My father, Norman Steibel, raced throughout my entire childhood,” Steibel told us. “He started street and strip racing in 1960, so I was exposed at a very early age.”

By the time he turned 18, Steibel was already stepping into a Jerry Haas-built, old-school, tube-chassis 1977 Vega that ran 9s in the quarter-mile.

“After a few years, I realized that I could live at home with Mom and Dad and keep racing or sell the car and buy property. I purchased five acres thinking I would return to it in a few years. Life happened and here we are 35 years later.”

Steibel was already wielding a welder as a teenager and one job he was tasked with at his father’s welding shop was back-halving a customer’s car. Steibel explained that the 1972 Camaro left their shop to get the bodywork and paint done and once that process was underway, the owner’s wife became pregnant and progress stopped on the build.

Original style trim is mixed seamlessly with race car goodies like the rear wing, dual ’chutes and side exhaust cutouts and, if you look closely, turbos mounted behind each of the signature Camaro parking lights. The equally as iconic front grille is complemented by a Z28 badge with matching emblems mounted on the front fenders.

“A few years later he called and offered the car to me,” Steibel recalled. “I didn’t have what he was asking—a couple years later, he took my original offer.”

This was around 199293 and though Steibel was able to make the purchase, he wasn’t able to fire up the torch and get to building it. He moved it from garage to garage until 2020, when he

met with Rob Matheis of Matheis Race Cars in High Ridge, Missouri.

“Rob assured me that he could bring all my ideas to life and we committed to the build,” Steibel said.

“Today, you see what that collaboration produced. Matheis Racecars went above and beyond through this journey to bring all my ideas to life and then some.”

The stance of this drag strip-able street machine starts with the chassis, which is crafted using 4230 chromoly tubes and features double frame rails and enough bars to meet a 25.2 SFI certification. The front is

fitted with independent suspension with coilver shocks while a four-link suspension system supports the Matheis Race Cars-built 9-inch rearend featuring an aftermarket race-quality third member and disc brakes.

While the Camaro screams “race me” it was actually built primarily for street duty with the occasional hit at the track very possible this year. Since it was a fresh build in 2024, Steibel was more concerned about shaking it down last fall on the street then beating it up at the track. And shakedown he did, logging over 250 miles in the first two weeks after he drove it home from Matheis’ shop.

The Camaro sits ultra-low thanks to a custom 25.2cert, 4130 chrome-moly double framerail chassis built by Rob Matheis Racecars. Matheis also created the four-link rear and custom tubular front suspensions. In the trunk area, aside from chassis bars, you’ll find a cooler tank and a fuel cell large enough for lengthy street and highway cruising.

With a twin turbo LSX built by AMT Performance set carefully between the rails, there’s no lack of power to motivate the Camaro. A Callies crank and connecting rods and Ross pistons rotate inside the aftermarket block and a “sizeable” Comp hydraulic roller camshaft is responsible for valvetrain manners.

Despite having a chassis that is better suited to a Pro Mod, Steibel’s 1972 Camaro is a street machine, and retains its original steel and glass from the firewall back. The front end is all fiberglass and fea -

tures a cowl-induction-style hood and split-bumper design. Keith Wolk Restorations was tasked with the body and paintwork, and that extremely vivid hue adorning the Camaro’s body is Mazda paint code 46V.

Body & Paint:

The body retains original steel and glass from the firewall back. Front end is fiberglass. Painted by Keith Wolk Restorations. Mazda 46V color code.

Chassis & Suspension:

25.2-cert, 4130 chromoly double framerail chassis built by Rob Matheis Racecars. Rob Matheis built four link suspension and custom tubular front.

Engine:

With a tube chassis like this, it can be difficult to hold onto the street vibe in the interior space. Here, you’ll find an aftermarket composite dashboard as well as high-gloss carbon fiber interior panels for the race car look. A custom 12.3-inch digital dash brings back the street a bit by offering full instrumentation, yet is easily visible through the quick release steering wheel. Kirkey racing bucket seats are about the only thing that will fit between the chassis rails and you’ll find them fitted here, along with DJ safety harnesses and a fire suppression system.

LSX aftermarket block. 4.080 inch bore and 3.622 inch stroke with a 9.88.1 compression ratio. Callies crankshaft and connecting rods, Ross pistons and a Comp hydraulic roller camshaft. The engine build was performed by AMT Performance, tuning is done by Kurt at Mid Coast Performance. Wiring was completed by Dan Campbell.

Induction:

Holley 16 injector lower intake with Rob Matheis custom upper intake.

Power Adder: Twin 76/75 turbos.

Electronics:

Fully programmable digital.

Transmission & Converter:

Powerglide transmission built by Transmissions To Go with a Trans Specialties converter. Custom driveshaft.

Rear differential:

In-house built rear end housing includes a custom third member.

Tires & Wheels:

V Series wheels 17” front and 15x13 double beadlock rears.

Best ET & MPH: Fresh build un-tested. 251 street miles to date.

Interior:

Strange steering wheel.

B&M Pro Bandit shifter.

Kirkey seats.

DJ safety harnesses.

Fire suppression bottles.

Holley 12.3 dash.

Vintage air.

Nu Relic power windows.

Cup holders.

USB ports.

OEM body by Fischer sill plates.

Full carbon fiber interior.

Wolf Box rear view mirror with front and rear cameras.

Most Unique Feature(s):

Basically a pro-mod chassis with late model comforts. A one of a kind “PRO STREET”.

Reason For Build:

My father had second gen Camaro’s from early 1970 until 1986 when he retired from racing. This is a tribute to my father. He passed in 2012.

Build Timeline: 4 years.

Most Memorable Experience(s):

Being the first to drive this caliber of car home from Rob Matheis Racecars and put 251 street miles on it within a few weeks.

Thanks To:

Rob Matheis Racecars, Keith Wolk Restorations, AMT Performance, Dan Campbell and Sherri Belknap for her love and support through the build.

A Holley 16 injector lower intake was matched to a Rob Matheis custom upper intake and Kurt at Mid Coast Performance is responsible for tuning the Dominator system that controls the 379 cubic inch small block mill.

With a chassis like this, you might expect to find a Noonan Hemi or perhaps some other behemoth engine with five-plus inches of bore spacing, but that sort of equipment was unnecessary for this build. Something a little more drivable was called for and in Steibel’s machine, you’ll find an LSX block as the basis for the powerplant. With a 4.080-inch bore and 3.622-inch stroke, the engine checks in at a relatively average 379 cubic inches of displacement.

The full carbon interior is equipped with a race-oriented steering wheel, shifter, seats and harnesses mixed with street friendly Vintage Air, Nu Relic power windows, cup holders, front and rear cameras and USB ports. The Fully programmable digital dash is set up to display more traditional style gauges, but with high tech performance.

AMT Performance built the combination using a Callies Performance Products crankshaft and connecting rods that swing Ross Racing pistons, while a Comp Cams hydraulic roller camshaft actuates the valves.

On the induction side of things you’ll find a fabri -

cated intake manifold that is fed air-to-water intercooled atmosphere thanks to the twin 76/75 Precision turbochargers. Mid Coast Performance performed the calibration of the EFI system that fires the 16 fuel injectors and Dan Campbell ensured everything was wired up and ready to fire.

Backing the potent powerplant is a Powerglide transmission built by Transmissions To Go and it works in concert with a Transmission Specialties torque converter to send power back via a custom driveshaft. Gear selection comes by way of a B&M Pro Bandit shifter mounted to the carbon fiber transmission tunnel.

Steibel chose highly polished V Series wheels to set off that vibrant exterior. The rear double-beadlock wheels measure 15x13 inches and the fronts are modern 17-inch units. All of them wear Mickey

Thompson rubber and frame the custom disc brakes behind them.

The entire build took about four years to complete. While there have been no track times to talk about as yet, Steibel has logged over 250 miles on the street behind the wheel of his Camaro.

“It’s basically a pro-mod chassis with late-model comforts—a one of a kind ‘Pro Street’ . My father had second-gen Camaros from early 1970 until 1986 when he retired from racing. This is a tribute to my father.”

Article first appeared in the May 2021 digital issue.

RPM MAGAZINE Reprint IN Print!

RPM MAG’s commitment to features that appeared digital-only since June 2020.

The wildly popular Mustang seems to overshadow many other performance oriented models Ford produced, but they did build others, and nearing the end of the classic muscle car era, they built the Maverick. The offering was a compact, similar in size and room to the Mustang, but different. The model ran from 1970 to 1977, and in its first year, 1970, with nearly 580,000 produced the Maverick almost tripled the sales of the 1970 Mustang! The car was offered in a number of different configurations, but none as popular as the Grabber.

James Hutchens’ 1972 model praises that era and just so happens to be a “Grabber’ variant, Ford’s performance-oriented version consisting mostly of an exterior and interior trim package including larger tires, graphics package and cool double bump hood. In the early seventies, with high gas prices and emissions coming down the pipes quick, there were no real factory performance upgrades to the car. But Hutchens’ wheelstanding Grabber is a completely different story.

James is a lifelong car fanatic, and by day is a mechanic, but enjoys welding and bodywork on the side as a hobby. Almost immediately after he got his driver’s license, he became addicted to drag racing, on and off the street, and by the time he got out of school had moved onto racing go-karts and then circle track.

Interestingly, this car was built more for cruising and shows, but then Hutchens’ need for speed took over and he just couldn’t help himself – the Maverick would have to hit the strip, too! It was a junkyard find, housing a family of raccoons, and James traded painting his buddies Harley for the shell. Over the course of six years, James and his good friend Zach Clontz

completed the build all on their own.

The Maverick needed a lot of bodywork and Hutchens straightened everything himself, rolled and enlarged the wheel wells, installed a Feather Carbon fiberglass hood and found some fiberglass bumpers at a local swap meet. The rest of the factory metal James beat and shaped back to perfection.

The side graphics, blacked out front and rear panels were all part of the Grabber package in 1972. This car is super straight and clean thanks to owner James Hutchens who is a Mechanic by day but

He welded in some sub-frame connectors and a 10-point roll cage himself as well, in fact, the only thing he didn’t do was repaint it, only because he doesn’t have a booth. A local body shop laid the paint, and they chose to stay with the factory red Grabber theme, black side stripping, and yellow lettering.

The engine’s foundation starts with a Ford Racing Boss block that Durham’s Engine Service machined in preparation for a stroker setup. The rotating assembly boasts a forged Scat stroker crank, Molnar stroker rods and a set of Mahle nitrous pistons.

Finishing off the 347cube mill bottom end is a custom spec Ed Curtis profile cam, also suited for nitrous applications. AFR 205 heads are equipped with T&D rockers activated by Comp Cam pushrods and, for now, James has decided to keep things old school, staying carbureted, but not just any carb; a 780 nitrous carb from Pro Systems mounted on an Edelbrock Victor Jr. intake handles the inhaled fuel and air. Exhaust fumes exit through JET Hot coated Hooker Super Comp 1-3/4 long tube headers then routed through Magnaflow mufflers and dumped just shy of the rear axle.

The Mickey Thompson Street Radial Pro 215/60s just fit inside the wheelwells, after a bit of massaging by Hutchens, of course.

Induction Solutions handles additional power with their Real Street nitrous plate system.

Initially, a Jerico stick-shifted transmission found its way into the tunnel, but James wanted calmer launches and street cruising manners, so he swapped out to the automatic. Radial tire racing has become all the craze at many events so Hutchens went with a beefed-up ATI Powerglide, com-

plete with a Wicked Quick trans brake and an Ultimate Converter Concepts 3500 stalled torque converter. Precision Performance Products handles the shifting and power transfers back to a braced Strange Engineering Ford 9-inch rear end with an aluminum heavy-duty Pro case.

Internally, a Strange spool, 3.91 gears, and their 35 spline axles solidify the stout assembly.

The Original Patented CalTracs Traction System

Complete bolt on system: no mods, cutting, welding, most applications

Keeps axle from rotating, maintains pinion angle

Eliminates spring wrap up

Pre-load adjustability

Durable powder coated finish

Detailed Illustrated Installation Guide

Custom sets available, call for info

This is true stock suspension, no coilover conversions here folks! A factory style leaf spring setup assisted by a host of Calvert Racing offerings out back hangs a complete Strange 9-inch. Up front, 6 cylinder springs are matched with double adjustable shocks.

Body & Paint:

All body mods and straightening done by owner. Local body shop Isom’s Collision sprayed the car.

Chassis & Suspension:

Owner installed frame connectors and 10point roll cage. Opentracker roller bearing spring perch along with modified control arms for smooth non-binding action. Rear is Calvert suspension with their split mono leaf springs, Caltrac bars and single adjustable shocks. Up front are 6cyl coil springs with Viking double adjustable shocks.

Engine:

347ci small block Ford. Ford Racing block with Scat 3.4 stroke forged crank, Molnar power adder 5.4 rods and Mahle pistons.

Cylinder Heads:

Ed Curtis was tapped for the engine top end and spec’d the cam profile along with the AFR 205 heads with T&D rockers and Comp Cams push rods.

Induction & fuel delivery:

Edelbrock Victor Jr. intake and Pro Systems 780 nitrous carb.

Power Adder:

Induction Solutions Real Street plate nitrous system.

Transmission:

ATI Powerglide with the Wicked Quick trans brake along with an Ultimate Converter Concepts 3500 rpm converter.

Rear:

All Strange brand parts, 35 spline axles, spool, housing with back brace and aluminum bolt-thru Pro case with 3.91 gears.

Brakes:

Aerospace Components four piston calipers with drilled and slotted rotors front and rear.

Tires & Wheels:

Mickey Thompson wheels with ET Street Pro tires.

Interior:

Aluminum race seats and upholstery, rear seat delete, full carpeting and headliner installed by owner and Zach Clontz. Grant steering wheel with Mark Williams quick release. Racepak UDX display. Precision Performance Products shifter with internal transbrake and neutral safety switch. Auto Rod Controls switch panel with relay board beside the shifter. Induction solutions nitrous pressure gauge and shut off valve to protect the solenoids from sitting under pressure for prolonged periods. Leash nitrous controller and MSD Power Grid system ET & MPH:

Personal best set to date was 5.51 at 126 mph in the 1/8th in fall of 2020. Not near fast enough to be a contender but we are still learning the suspension tune which has been plagued by bumper dragging wheelies as evidenced by three oil pans, front end alignments and one trip to the frame shop!

Most Memorable Experience(s):

I decided to go to the 2019 Street Car Takeover at Bristol Dragway and had a great time. After getting put out first round, we decided to go to Charlotte Zmax Dragway for their Street Car event and I was lucky enough to runner-up in their Extreme Street Race.

Thanks To:

First of all, my wife Lisa for putting up with the insanity, Zach Clontz for helping get it finished and crewing along with my little brother Chris Hutchens.

Many classic cars have one thing in common; they run leaf-sprung rear suspension setups. James stuck with the Maverick’s stock design, but made it better. He completed some updates using an Opentracker roller bearing spring perch to go along with split mono springs from Calvert Racing, Caltracs bars, and Caltrac adjustable shocks to keep the rear end planted. And plant it does, in fact, James has to

find a way to keep the front end down now, as he’s finding himself looking to the sky far too often.

The Maverick has some good looks all on its own – the signature “fastback” sloping roofline that ties into trunk gives a killer style, but add in Mickey Thompson drag wheels wrapped in sticky Mickey radial rubber and a raised cowl hood and now you have some serious intimidation factor.

Much of the factory interior remains. Hutchens added the Racepak dash, cage, racing buckets, quick release wheel and other necessary electronics.

Street or strip, this Maverick has it covered!

James Hutchens with his Maverick. There’s nothing better than that “I did this” feeling after completing a 6 year build at this level.

Aerospace Components discs with four-piston calipers are found on all corners to slow the Mav down after a 130mph 1/8-mile pass.

Much of the factory interior remains; after all, the car is a piece of history, so keeping as much of the cool factory interior possible seemed like the right thing to do. Racing seats and a Grant quickrelease steering wheel were added.

A Racepak UDX LCD dash displays the engine vitals, while an Auto

Rod Controls switch/relay board sits beside the shifter. Placed on the board are all the Induction Solutions controls along with the fail-safes to keep the system in check. Above it, the Leash nitrous controller is also within reach. An MSD Power Grid along with the complete electrical system hidden behind the dash for easy access.

What started as a weekend cruiser made it to a wheelie happy street/ strip car and James just can’t seem to

get enough of it. For 2021, he plans to continue to enjoy the streetcarstyle races and, through tuning and keeping the front end in check, work on improving his best 1/8thmile time to date of 5.51 at 126 mph.

Hutchens completed all of the work on the Maverick with his righthand man Zach Clontz’s help and couldn’t be happier with how far the car has come in the past six years. There’s just nothing like looking at your car and saying, “I did this”.

Article first appeared in the March 2022 digital issue.

RPM MAGAZINE Reprint IN Print!

RPM MAG’s commitment to features that appeared digital-only since June 2020.

Barracuda: “A large, predatory, ray-finned fish known for its fearsome appearance and ferocious behavior.”

Story By George Pich

Glenn Hamilton’s wild Ultra Street 1967 Plymouth Barracuda certainly checks off all of the aforementioned boxes, except the fish part, of course.

Hamilton has been racing for over 25 years in various cars and along the way he was subconsciously developing the design of what he calls his “dream car”. It would have to be something out of the ordinary, definitely attention getting and be seriously quick. A little over 10 years ago, Glenn decided it was time to finally take all those ideas from years of cars and racing and put them to work in a new build.

Gary Naughton Race Cars did a ton of work to fit the factory grills and headlights into the VFN front clip and still maintain that factory appearance, flat hood and all! The killer cool Lime Green paint is accented by factory style black stripes.

The first step was to find just the right car, and for Glenn that would have to be a Mopar, specifically, a Barracuda. The thing about most Mopar muscle car offerings is that they look mean and fast, so there’s not much they need in the way of appearance work, but make no mistake, Hamilton would hit every single area of this car with as much high-end parts and detail as possible, and the result is nothing short of stunning!

The ’67 would soon find itself stripped to the bones where Gary Naughton Race Cars would take over and integrate an Ultra Street class legal 25.3 chromoly back-half chassis and cage with the factory frame rails and floor.

To keep things serviceable with easy to source parts, the front suspension was built by Maryland Performance Specialties as a oneoff factory bolt-in Mustang strut front end with Racecraft lower control arms, drop spindles and Afco double adjustable struts with Sti-

letto 20° billet rack. A custom ladder bar with x-brace track locator, Afco double adjustable shocks and anti-roll bar resides out back suspending a Moser fabricated 9-inch rear with Moser aluminum center section, 35 spline axles, 3.89 gears and spool.

Removing the front-end provides more than enough access to the meat and potatoes of the build.

The floors and frame, along with all the suspension work were then powder coated by Powder Coat Express.

The front clip started off as a VFN glass unit that was modded by Gary Naughton Race Cars to fit the factory grills and headlights along with building the one of kind low air dam, turbo inlet and bracing, all while keeping the factory style functional hood. That low profile hood is also a VFN piece as are the rear bumper and trunk lid. Phil Connor took over from there and finished the body to perfection after which the Lime Green paint was laid down and highlighted with factory style black stripes.

Maryland Performance Specialties took care of fabricating the custom rear wing that partially shrouds the twin ’chute setup.

While the chassis and body were being completed, Glenn turned his attention to power and enlisted the help of Hartsock Race Engines to build a tough-as-nails small block Mopar mill.

Chassis Type & Mods:

25.3 chromoly chassis/cage built by Gary Naughton Race Cars to meet Ultra Street class rules. Mini tubed, factory frame rails & floors. The chassis floors and all suspension were powder coated by Powder Coat Express. Car weighs 3380 with driver.

Suspension:

The front suspension was built by Maryland Performance Specialties as a one-off factory bolt-in Mustang strut front end with Racecraft lower control arms, drop spindles & Afco/Menser double adjustable struts. Also has a 20° billet Stiletto rack and pinion

The rear suspension is a ladder bar with x-brace track locator with Afco/Menser double adjustable coilover shocks, with antiroll bar.

Body & Paint:

The front clip started off as a VFN glass front clip. Gary Naughton Race Cars did substatial work to fit the factory grills and headlights and also building the one of a kind low air dam, turbo inlet, bracing etc. to keep a factory style functional hood. VFN glass hood, rear bumper and trunk lid. Custom wing from Maryland Performance Specialties and all body work and paint was done by Phil Connor.

Engine:

358 cubic inch R5P7 Mopar engine built by Hartsock Race Engines. Sonny Bryant crank, Manley rods and pistons, 11.5 to 1 compression. Custom ground cam. Mopar aluminum heads with Jesel rockers.

Induction & Fuel Delivery:

Cast intake with Wilson Manifolds throttle body. 2250 Injector Dynamics injectors, Weldon 2345 fuel pump, Weldon fuel regulator

Power Adder:

Forced Induction billet 76 turbo, Chiseled Performance intercooler, ProCharger blow off valve. Stainless headers, Y pipe & intercooler plumbing built by Aaron Hamilton.

Electronics:

The car is controlled By Fueltech FT600 with Fueltech boost controller, smart coils and shock sensors. Tuned by Brendan Mills and Jon Balinsky at OAB Racing.

Transmission & Converter:

Reid case Pro Mod Powerglide with a Sonnax 158 gear set and Pro Torque GenX Torque converter. Precision air shifter and Chiseled tans cooler. Transmission is maintained by Keith at Performance Transmission.

Rear Differential:

Moser Fab 9 with Moser 35 spline axles, aluminum 3rd member, 3.89 gears and spool. Best ET & MPH: 1/8 mile - 4.70’s/150mph

The race oriented FT600 display and Precision shifter are mixed with a generous amount of factory trim and two race seats, just in case a passenger needs to experience what a boosted small block Mopar can do.

A true Mopar fanatic will rarely mix and match their car with another brand engine – it’s a sure way to be completely ostracized from most every brand-dedicated enthusiast club or forum in the world – and Glenn Hamilton is no different, choosing to keep his Plymouth full blooded.

A 358-inch R5P7 Mopar engine was built using a Bryant crank, Manley rods and pistons and the final compression ratio is 11.5 to 1. A custom ground cam was spec’d and aluminum heads were massaged and treated to a set of Jesel rockers. A port-matched cast intake works in conjunction with a Wilson Manifolds throttle body and 2250 Injector Dynamics injectors are fed by a Weldon 2345 fuel pump with Weldon regulator.

The battery and coolers are installed in a well detailed trunk along with an ample sized fuel cell to fulfill the needs of any type of driving Glenn might want to do.

A Forced Induction billet 76 turbo forces copious amounts of extra atmosphere into the mix and is paired with a Chiseled Performance intercooler and ProCharger blow off valve. Stainless headers, Y pipe and intercooler plumbing were all fabricated by Glenn’s brother, Aaron Hamilton.

A Reid-cased Pro Mod Powerglide transmission with Sonnax

158 gear set and Pro Torque GenX torque converter back up the small block powerhouse and the entire package is controlled by a Fueltech FT600 system with Fueltech boost controller, smart coils and shock sensors. Tuning duties fall on Brendan Mills and Jon Balinsky at OAB Racing.

“This was a 10 year project, and wouldn’t be possible without all of

Glenn Hamilton with his admitted “dream car”. It took 10 years to build but is worth every hour and dollar spent. With the car being completed in 2021 and just a handful of passes on it, Glenn has wheeled it to 4.70s in the 1/8th mile at over 150MPH in Ultra Street trim!

the countless hours from my family & close friends,” said Hamilton. And as far as being a ferocious predator goes, at the end of 2021 with just 4 months in the car under his belt, Glenn was able to bust out 4.70s in the 1/8th, and you can bet there’s more to come. So yeah, we’d say this Barracuda definitely has some serious bite!