DUSTRIAL RINT

Z N E

MULTIPLEVERTICALS

Digital printing technologies reach many different manufacturing verticals. It is challenging to report on each and every one. However, with each issue of Industrial Print magazine, we strive to dojust that.

For example, most of the content on additive manufacturing (AM) in this edition looks at how the technology is influencing the medical field. Creating prosthetics and surgical tools or engineering biological structures like tissue are all advantages of using AM here. Medical Manufacturing as well as Hospital Use of30 goes into this in more detail.

Then we look at corrugated in packaging. Intelligent Corrugate Printing discusses the importance of adopting software solutions that enable or feature capabilities such as personalization, short-run flexibility, quick turnaround times, cost-effective prototyping, variable print quality, substrate versatility, and environmental sustainability.

Finally, Hard Hitting Print takes a look at the growth in the global wood printing market. Digitally printed wood appears in multiple end use industries, from the more obvious furniture and flooring to promotional pieces and even children's toys.

Medical, packaging, furniture, toys-there is no limit to what digital printing touches.

Cheers

Melissa Donovan, Editor

.RIAL 9PRINT

INDUSTRIALPRINTMAGAZINE.COM

Volume 12,Number2

EDITORINCHIEF

ThomasTetreault 978-921-7850

EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ASSOCIATEEDITOR

CassandraBalentine cbalentine@rockportpubs.com

ARTDIRECTOR

Sarah M.White swhite@rockportpubs.com

WEBEDITOR

Melissa Mueller

CONTRIBUTORS

Pete Basiliere, Olivia Cahoon, Kemal Carr, Maria Conrado, Mark Hanley, MelindaTetreault

ADVERTISINGSALES

PUBLISHER ThomasTetreault

300 NewburyportTurnpike, Ste.11 Rowley, Massachusetts01969 Ph978-921-7850x110 • Fx978-921-7870

edit@rockportpubs.com

SALES

Amanda Doyon Ph978-921-7850x170 • Fx978-921-7870 adoyon@rockportpubs.com

ROCKPORT CusToM PuBLISHING

CORPORATE&PUBLISHING OFFICE

300 NewburyportTurnpike, Ste.11 Rowley, Massachusetts01969

ROCKPORTCUSTOMPUBLISHING, LLC

CHAIRMAN

JeffreyJensen

PRESIDENT&CEO ThomasTetreault

CONTROLLER MissyTyler

HOSPITAL USE OF 3D

Material Options for Medical

by Melissa Donovan

Medical manufacturing encompasses a host of objects from scopes used for surgical tools to pins and needles for a prosthetic knee. Today, anything can be manufactured with the help of three-dimensional (3D) printing.

Depending on the end use, many materials are available. These of course must adhere to medical and safety requirements.

According to John Anderson, medical marketing manager, Formlabs, “medical 3D printing materials must strike a complex balance, requiring material performance—such as strength or ductility—as well as biocompatibility for the application, such as longterm skin or mucosal membrane contact.”

“When it comes to manufacturing medical products, choosing the right material is critically important. In many cases, materials need to be biocompatible, autoclave sterilizable, and offer higher flexibility than comparable materials,” shares John Kawola, CEO, Boston Micro Fabrication (BMF).

Printer Specific

teams continue to turn to 3D printing for their research and production needs,” states Kawola.

So what are some of those materials? Depending on the manufacturer, they might only be compatible with a specific printer.

BMF offers several materials for its microArch series of 3D printers that are designed for medical devices and life sciences. Its HTF is a high-temperature resistant, tough, and biocompatible resin. It is autoclave-sterilizable and ideal for applications where biocompatibility and flexibility are key. With an HDT of 152 degrees Celsius and biotech application compatibility, HTF offers versatility across demanding environments.

“I expect to see the need for flexible materials with features like biocompatibility or sterilizable only increase, as

Formlabs Nylon 11 Powder for selective laser sintering (SLS) is a biocompatible material frequently used for the production of custom orthotic insoles. Parts printed with it have demonstrated outstanding durability and resistance to heavy use. For stereolithography (SLA), Formlabs BioMed Durable offers impact resistance as well as biocompatibility.

With Lithoz’s ceramic 3D printers, resins or “slurries” are the main components. “For surgical implants, we might use bioresorbable tricalciumphosphate and

When it comes to manufacturing medical products, choosing the right materials is critically important.

— John Kawola, CEO, BMF

1. Formlabs’ BioMed Durable offers impact resistance as well as biocompatibility. 2. Surgical implants use silicon nitride; shown here is an implant made with a Lithoz printer.

hydroxyapatite. There are also implants from silicon nitride. Surgical tools are usually made from alumina, zirconia, or alumina-toughened zirconia. Orthodontic brackets are made of alumina, that can also be translucent. And in the dental field, a new development is dental restorations made from lithiumdisilicate," shares Norbert Gall, head of marketing, Lithoz.

All Encompassing

Adversely, we can speak about materials in more abstract terms, meaning they aren't designed for one specific brand of printer or type of technology.

"offering biocompatibility, lightweight properties, and the ability to mimic bone-like stiffness. Ceramic-filled polymers are ideal for dental and orthopedic applications, combining strength and precision for crowns, bridges, and mold inserts:'

While there are a variety of

JeffEnslow, head of marketing, lmpos- materials used, sible Objects, lists commonly used mate- Simon Leid, di- 2 rials as titanium, cobalt chromium, and stainless steel powders for implants; biocompatible resins for dental and surgical applications; and polymers like PEEK for lightweight, durable components.

"Titanium is widely used for implants like cranial plates and hip replacements due to its strength, lightweight nature, and biocompatibility. Its resistance to corrosion ensures long-term durability in the body," shares Rajeev Kulkarni, chief strategy and marketing officer, Axtra3D.

''As material science progresses, I anticipate a rise in high-performance composites, such as our carbon fiber material reinforced with polymers such as PEEK, which offer exceptional strengthto-weight ratios similar to aluminum, and superior thermal and chemical resistance," foresees Enslow.

Kulkarni says PEEK is favored for a number of reasons, but used a lot in spinal implants and orthopedic devices,

rector development, freeformer, ARBURGadditive says "the decisive factor here is the corresponding requirements for the respective product. A resorbable implant is usually manufactured using an extrusion-based process, as the appropriate materials are available and may already be known from conventional processes such as injection moulding. In the Arburg Plastic Freeforming process, for example, plastic granulates certified for medical use can be used. The polyjet process is particularly suitable for anatomical models, as the surfaces and coloring are very good here."

Another example, "biocompatible resins are commonly used in SLA, hybrid photosynthesis, digital light processing printing for dental aligners, surgical guides, and hearing aids. These resins meet strict standards and provide high precision," says Kulkarni.

While all of these materials are used, Kulkarni sees in the future "growth in bioresorbable materials for implants, which could naturally absorb into the body over time. Additionally, the rise of bioprinting materials, such as hydrogels and bio inks, could open possibilities for tissue engineering and organ printing, shifting the focus to regenerative solutions. While current materials remain key drivers, advanced polymers and biocompatible composites will further expand capabilities in medical manufacturing."

"Both SLA and SLS 3D printing are used in the medical field. However, SLA materials will likely remain the most popular method for medical additive manufacturing (AM) due to their versatility. Over the next few years, it's likely that new biocompatible materials will expand 3D printing applications to cellular, tissue, and organ creation," adds Anderson.

Future At Work

The materials used tomanufacturemedical parts range from titanium to PEEK. Technological advancements mean the future is real in terms of biocompatible materials, as this will only further increase AM's use in this field, allowing for the creation of organs and tissue. 1PM

HARD HITTING PRINT

by Melissa Donovan

Digitally printed wood appears in multiple end use industries, from the more obvious furniture and flooring to promotional pieces, children’s toys, and even smaller home decorations. Based on the Digital Printing on the Global Wood Market Report: Trends, Forecast and Competitive Analysis to 2030 published by research firm Lucintel, the digital printing on the global wood market is expected to reach an estimated $5.9 billion by 2030 with a compound annual growth rate of 3.1 percent from 2024 to 2030.

Growth in this segment occurs similarly to other industrial categories. Inkjet provides many of the same advantages here as earlier adopters of the technology experienced. Of note, cost-effective personalization, shorter production runs, and environmentally friendly alternatives.

Ink for Wood

While any type of ink can print to wood, the key to success is whether the ink remains adhered to the surface and the colors appear as intended.

“If you’re looking to produce high-quality, colorfast, durable prints on wood with minimal post-print curing time, then UVcurable inks are a great choice,” recommends Tom Lang, digital applications manager, Inkcups.

Pedro J. Martínez, CEO, Afford Industrial, agrees that UV is preferred. “While there are many factors to consider when printing on wooden objects, UV inks tend to be the most robust solution across the widest range of applications. This is due to their fast curing and high durability.”

“UV inks are ideal for printing directly onto wood because they cure instantly under

UV LED light. This process eliminates the need for heat, which could warp, damage, or otherwise alter the surface of the wood. Unlike solvent or dye-sublimation inks, UV inks sit on the surface of the material rather than requiring absorption or transfer, allowing for vibrant, crisp designs with excellent adhesion,” adds Hugo Gonzalez, senior segment specialist, Industrial Printing, Mimaki USA, Inc.

Water-based inks are a consideration, as along as the proper pretreatment is performed. O&PM Europa clients print successfully to wood using water-based pigmented inks and a print receptive coating, specifically its F47X-56, which is rated food safe, according to Durson Acun, director, O&PM Europa.

The wood grain and finish can also affect adhesion and the final appearance.

The type of wood used matters. “Light colored wood appears differently in features like color after printing versus dark colored woods. The porosity of the wood, its ability to absorb fluids like sealers or inks is also a factor. Inks that require time

— Marco Zanella, global business development director - inkjet, INX Europe 1. Mimaki UV LED printers are used for DTO printing on surfaces including wood.

to dry like water-based inks will absorb into the pores of the wood versus UV inks that are ‘pinned’ quickly before they can absorb. This absorption affects the color density and printed surface appearance including gloss,” shares Martínez.

“Porous woods like pine may absorb ink unevenly without proper treatment, whereas denser, sealed, or artificial woods such as oak or MDF provide smoother surfaces for consistent prints. The wood grain and finish can also affect adhesion and the final appearance,” admits Marco Zanella, global business development director -inkjet, INX Europe.

Surface properties influence the printing process, agrees Gonzalez. “Rough or uneven grains can affect image clarity and require sanding or pretreatment for best results. Engineered

woods offer more consistent printing surfaces compared to untreated, natural woods.”

“Wood grain—fine versus textured— also appears differently after printing. Wood types commonly used for digital printing include birch, oak, cedar, and maple among others. Composite woods and laminates can also be digitally printed,” continues Martínez.

Also, whether the wood has a varnish finish influences ink adhesion. “Another consideration to bear in mind is varnish. If a wooden item already has a coating or varnish on it prior to printing, that could affect the way in which the ink bonds to the surface,” suggests Lang.

Pre and Post Considerations

Pre- or post-treatment enhances the final print.

“Depending on the wood color, color consistency across the face of the wooden object to be printed, porosity, grain, and durability requirements, it may be necessary to pre- and/or post-treat the printed surface,” says Martínez.

Pretreatment can make the type of wood chosen less of a factor, according to Gonzalez. “Pretreatments such as sanding or applying a clear coat/primer create a smoother and less absorbent surface, ensuring optimal ink adhesion, color vibrancy, and curing consistency.”

The application can also determine whether to pretreat. “For simple applications like printing a bar code on lumber to be sold at your local hardware store, no pre- or post-treatment is required. Most fast drying ink types will provide sufficient character resolution and durability,” shares Martínez.

Surface preparation is a consideration. While Lang says wood does not require any pretreatment, some work needs to be done to the surface prior to print to ensure a successful application. “Ideally, you need a smooth surface. That means it needs to be clean of any dust or dirt before printing and, if it’s rough, as may be the case with some raw wood items—you may need to consider some kind of sanding first.” Depending on the wood, preprinting with a layer of white ink is suggested. “When printing onto wood, we typically advise decorators to first print a layer of white ink, both to smooth out any depressions in the surface and to improve overall ink adhesion. However, if you’re printing to a cleanly finished wooden surface such

as a holiday ornament or toy, for example, that white layer may not be necessary if you want to retain the wood texture as part of the graphic,” explains Lang.

Regarding post treatment, certain processes enhance the printed graphic. “Varnishes provide more durability to the print or application. While some inks are highly scratch resistant, they too will be damaged if the wood surface is scratched. Wood is a very rigid material, but some types of wood if left untreated, have a lower scratch resistance than ink. Post treatment also offers an opportunity to affect the final look of the application by providing matte or gloss overlays,” says Gonzalez.

“Post treatments such as a protective coating enhance durability, offer

scratch resistance, and lengthen longevity—especially for applications exposed to wear and tear,” notes Zanella.

Market Verticals

Those using inkjet printing to decorate wood-type items yield final product placed in many different verticals and applications. Toys, furniture, and décor manufacturers are some of the current active participants. Afford’s inks are used in a range of wood decorating applications. Martínez provides examples in the promotional products segment like plaques and wall art. It also participates in the industrial printing segment with inks for wood product marking and coding. Afford inks are used to decorate wood for home décor and signage.

Based on Inkcups’ experience, Lang has seen customers using UV inkjet printers to print directly on small home décor items such as photo frames, signs, coasters, and holiday ornaments, as well as toys such as puzzles and building blocks.

“INX ink sets are used in markets like furniture, toys, flooring, and decorative panels. Applications include custom furniture designs, branding for wooden toys, detailed flooring patterns, and creative wall panels. These markets leverage digital printing for personalization, shorter production runs, and environmentally friendly alternatives to traditional methods,” says Zanella.

2. Inkcups recommends its S1 UV-curable ink for printing directly onto wooden items because it bonds strongly to substrates. 3. O&PM Europa clients print to wood using water-based pigmented inks and a print receptive coating, specifically its F47X-56.

Mimaki customers create "applications including custom nameplates, holiday ornaments, message plaquessuch as baby announcements, beer taps, toys, fine art, etc.," adds Gonzalez.

Depending on the vertical, there are certain guidelines. In the U.S. printed toys are subject to the Consumer Product Safety Improvement Act (CPSIA), which is a U.S. law that establishes safety standards for children's products. The U.S.Consumer Product SafetyCommission website provides information on how to obtain CPSIA certification.

Mutoh America, Inc. recently announced that three of its ink lines-US-11, UH-21, and MP-31-are now compliant with U.S. toy safety regulations, including theCPSIA andCalifornia Proposition 65.

"Thesespecificinks representourcommitment to safety, innovation, and market

recognize the advantages of digital printing, including flexibility, reduced waste, and customization. However, smaller players may perceive high initial investments as a barrier. As technology becomes more cost effective and case studies showcase return on investment, we expect broader adoption in these verticals, especially with sustainability becoming a stronger market driver," shares Zanella.

Accelerating direct printing to wood, in Lang's mind, is the continued interest in sustainability. "Many brands look to promotional items made from sustainable plywood or bamboo to help boost their eco-credentials, but the growing demand for customizability, short runs, and print on demand in this market means that those who are already geared up to directly decorate these adaptability;' said Brian Phipps, president, items on demand will be best placed to Mutoh. "By ensuring our inks meet these standards, we're opening up new possibilities for clients serving industries where safety andcompliance are paramount;'

Understanding Advantages

Verticals like toy, furniture, and even flooring are at the beginning of understanding the true advantages of printing directly to wood using inkjet.

"Currently, awareness varies by sector. Larger manufacturers often

capitalize on the opportunity."

Many already recognize the benefits of digital decoration, like "shorter production runs of custom prints, personalization, DTO printing, and instant order fulfillment," says Martinez. The same advantages have led to "significant digital conversion in other business segments such as garment printing. These same dynamics will continue to influence the adoption of digital decoration of wood."

"Digital printing directly to wood offers the same benefits as printing to other surfaces, including lower or non-existent start-up/makeready costs, improved productivity, easy ability to customize, and mass DTO printing capability using jigs," says Gonzalez.

''Awareness of the possibilities of DTO printing is certainly on the rise, but as in so many market verticals, the print industry needs to drive this awareness by experimenting with the technology to both discover and show off how much more it can do than just enabling short runs and speeding up production times," admits Lang.

Acun believes "companies are trying these new techniques, but not really understanding the benefits like customizing per piece, flexibility, easy access to the technology, and enhanced color."

Enhance the Product

Printing directly to wood is becoming easier as technology changes and UV ink compositions advance. Depending on the type of wood as well as its surface characteristics, UV LED is a preferred process to decorate this porous material. To further enhance the finished product, pre- and post-treatment options might be required. When done correctly, may verticals like toy and gift industries benefit from inkjet printing. /PM

SIGNIFICANTIMPACT

Differentiatingwith AM

by IndustrialPrint Magazine Staff

Companiesoperatinginthemedicalmanufacturing space relyon three dimensional (3D) printing technologies to create very specific products. Additive manufacturing (AM) allows for this with agility and accuracy.

Familiarwith 3D

Based in Switzerland, SAMAPLAST AG produces high-quality plastic injection molded parts used for medical components and implants worldwide.

The company is familiar with 3D printing technologies, but once it discovered a biocompatible material ideal for some of the products it manufactures, it began looking for a 3D printer capable of processing plastic granules. Its research led it to ARBURGadditive. With particular interest in its freeformer printers and ARBURG Plastic Freeforming (APF) technology.

Working Out

The freeformer is an open 3D printing system, it allows up to threedifferentmaterialstobecombinedusingtheAPF process. A support material that iswashed away afterwards can be used as the third component to help create complexgeometries.

"We are driven technology leaders. We have a long history of success in medical device manufacturing and were looking for an opportunity to differentiate ourselves in the market," explains Thomas Moesli, plastics engineer, SAMAPLAST AG.

With experience in the space, SAMAPLAST needed to figure out whether APF was suited to process medically approved implant materials such as the Evonik RESOMER portfolio of bioresorbable polymers or DSM Biomedical's Bionate PCU family. After the investigative phase concluded, the SAMAPLAST team determined that the freeformer would fit its needs.

"The freeformer is ideal for additively processing absorbable and implantable materials in granule form that are typically used for injection molding. The ability to iterate with these materials even before serial production provides a significant advantage," shares Moesli.

SAMAPLAST wished to develop a replacement meniscus component. With APF, it manufactured a multi-material meniscus from different types ofpolyurethane in just a few days. The customer was able to begin testing the product immediately. Without the freeformer, the part would have been manufactured using injection molding, which could take months due to waiting for the appropriate mold.

Another medical-related product SAMAPLAST regularly produces are plastic spinalrods, whichare long-term implants developed for orthopedic surgery that can remain in the body for longer than 180 days. Using the freeformer, parts of these implants are produced in advance, in several different variations, both quickly and cost effectively.

Satisfied with Results

Moesli and his team are impressed with the ARBURGadditive freeformer. "I see this impacting several industries-patient-

ir I Seepage17formoreinformation. specific parts in healthcare, veterinary applications, pet orthopedics, and low-volume production in aerospace. The opportunities are endless," he concludes. 1PM

1. SAMAPLAST uses an ARBURGadditive freeformer to meet its AMneedsinthemedical field.

IDTI 6

Efficient Software Solutions

by Cassandra Balentine

lrheincreasedadoptionofdigitalprinttechnologiesforcorrugatedapplicationsleads to more reliance on sophisticated software solutions to improve efficiency and profitability. These solutions come in the form of manufacturing execution system (MES) andenterpriseresourceplanning(ERP)

''Adopting digital print has prompted corrugated manufacturers to re-evaluate and enhance their use of ERP and MES software to accommodate the short-run requirements and opportunities presented by digital printing technology. This includes tighter integration with digital printing equipment, dynamic job scheduling, enhanced data analytics and reporting, streamlined workflow integration, and

increased agility and flexibility in production operations," suggests Aleks Zlatic, VP product portfolio and market development, eProductivity Software (ePS).

Digital print goals often differ from analog print goals due to the distinct advantages and capabilities offered by digital printing technology. ''As customers transition to digital printing theytypicallyneedto watchmarginsmuchcloser due to the smaller/segmented quantities. As a resultthey need distinctfeatures and capabilities in MES and ERP software," shares Zlatic.

Capabilities such as personalization, shortrunflexibility, quickturnaroundtimes, cost-effective prototyping, variable print quality, substrate versatility, and environmental sustainability are

essential requirements. Zlatic feels that these demands reflect digital printing technology’s unique advantages and opportunities in today’s competitive and dynamic market landscape.

Software Breakdown

Two types of software solutions stand out for corrugated printing, MES and ERP. “The heartbeat of any box or sheet plant is its manufacturing efficiency,” comments Zlatic.

MES solutions are designed to enhance plant management by automating manufacturing processes and optimizing schedules, providing total machine and labor visibility to manage the plant floor and customer expectations effectively. “These specialized modules save time and resources and significantly reduce errors from manual data input throughout the production process. The real-time visibility these intelligent solutions provide translates into increased

1. ePS Escada Automatic Corrugator Warp Control addresses the challenge of board warp. 2. ePS CorrSuite includes Escada, a closed loop corrugator control system that offers highly sophisticated functionality for efficient wet- and dry-end machine control.

productivity and reduced wasted time and resources.”

When it comes to ERP, Zlatic points out that finding the right business system to manage an entire box plant enterprise can be daunting. An ERP that empowers customers with tools for precise cost modeling helps to enable accurate estimating and confident decision making regarding product margins and profitability. “This level of granularity is vital in an industry where precision and efficiency are paramount,” adds Zlatic.

In Demand Features

Users look for features that address the unique challenges and requirements of corrugated board manufacturers and box converters.

Zlatic says these features include things like precise cost tracking, efficient inventory management, scheduling optimization, automation features, and flexibility in solutions that allow for seamless integration into existing systems and workflows.

Product Round Up

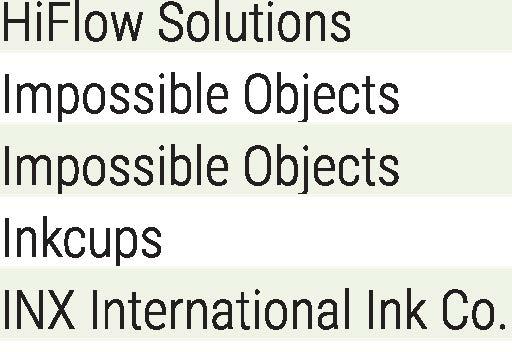

Here we share information on valuable resources for corrugated board manufacturers and box converters.

Arden Software

Web-based platform WEBcnx integrates with Arden Software’s packaging CAD/CAM software Impact, as well as other workflow systems, acting as a virtual project manager. According to the company, it’s the ultimate

workflow solution for the packaging sector, enabling users to automate the project management of their packaging production from wherever they are in the world, streamlining workflow in the packaging supply chain.

Advantive

Advantive offers both packaging ERP and MES. These tools are designed to automate and simplify complex manufacturing processes with Advantive’s corrugated and packaging ERP software; make smart decisions based on real-time data visibility and insights across global supply chains; and reduce material handling costs by managing raw material and roll stock more effectively. All of which are important features for corrugated manufacturing.

AI FOR ERP AND MES

Artificial intelligence (AI) enhances manufacturing execution system (MES) and enterprise resource planning (ERP) solutions for corrugated printing.

For example, Aleks Zlatic, VP product portfolio and market development, eProductivity Software (ePS), points out that ePS has utilized intelligent algorithms in its scheduling tools for decades. “These powerful tools suggest the best routes or purchasing requirements based on production needs and data.”

As AI technologies advance, they will increasingly be used in additional areas the software touches in order to provide actionable insights to various users within a plant, optimizing efficiency, agility, and competitiveness.

“AI can revolutionize ERP and MES systems by enabling predictive analytics, optimized production planning and scheduling, intelligent resource allocation, quality control, predictive maintenance, supply chain optimization, and continuous improvement,” says Zlatic.

For example, AI-powered predictive analytics can anticipate future trends, demand patterns, and production issues by analyzing historical data from ERP and MES systems. This enables proactive decision making, such as optimizing inventory levels, predicting equipment failures, and mitigating production bottlenecks before they occur.

AI algorithms also optimize production planning and scheduling in MES systems by considering various factors such as order priorities, machine capabilities, material availability, and workforce constraints. AI-driven scheduling algorithms can dynamically adjust

Amtech Software

Amtech Software’s completely integrated family of software, solutions, and technology ensures its customers achieve operational and bottom-line excellence throughout their entire business. For corrugated, its flagship software solutions suite is EnCore.

ePS Packaging

production schedules in real time to maximize efficiency, minimize setup times, and meet delivery deadlines.

AI also helps with resource allocation. The technology can intelligently allocate resources, including machines, materials, and labor, based on real-time demand and production conditions. “By analyzing ERP and MES data, AI algorithms can optimize resource utilization, reduce waste, and improve production efficiency,” shares Zlatic.

When it comes to quality control and predictive maintenance, Zlatic says AI-powered image recognition and machine learning algorithms can enhance quality control processes by automatically detecting defects and anomalies in manufactured products. AI can enable predictive maintenance in MES by analyzing equipment sensor data to forecast potential failures and schedule maintenance activities proactively, minimizing downtime and optimizing equipment lifespan.

AI is also able to optimize supply chain operations by analyzing vast amounts of data from ERP systems, MES, and external sources such as weather forecasts, market trends, and geopolitical events, comments Zlatic. AI algorithms can optimize inventory levels, streamline logistics, and identify cost savings and risk mitigation opportunities across the supply chain.

All in all, adaptive learning by AI-powered ERP and MES can facilitate continuous improvement initiatives by analyzing production data, identifying inefficiencies, and recommending process optimizations. “Over time, these systems can adapt and learn from past performance to continuously refine production processes and drive operational excellence,” concludes Zlatic.

To address the demands of corrugated customers, ePS Packaging delivers on modern corrugated software requirements through its Corrugated Suite (CorrSuite) solutions, particularly through tailored solutions, cost modeling and estimating, efficient inventory

management, automation and realtime visibility, and flexibility and integration capabilities.

The CorrSuite includes specialized modules such as CorrPlan, CorrTrim, and CorrTrac, which are tailored to address the unique challenges of the industry. Corrugated Business System (CBS) can be added to have a system to manage the entire business.

ePS’ CBS within CorrSuite is an ERP that empowers customers with precise cost modeling and estimating tools. CBS enables accurate decision making regarding product margins and profitability, addressing the need for granularity in cost analysis.

The CorrTrac module within CorrSuite addresses the demand for efficient inventory management by tracking every facet of paper inventory management, from ordering to consumption. This ensures optimal inventory levels, minimizes waste, and reduces the over ordering of stock, streamlining production processes and reducing costs.

The MES modules within CorrSuite automate manufacturing processes and provide real-time visibility into plant floor and customer data. These solutions help customers save time and resources, reduce errors from manual data input, and increase productivity, meeting the demand for automation and real-time visibility.

ePS Packaging's solutions, including CorrSuite, are flexible and seamlessly integrate into existing ERP systems and workflows.

HiFlowSolutions

HiFlow Solutions offers a management information system tuned to the needs of corrugated converters with end-to-end production and management systems designed to improve productivity and profitability.

Intelligent Automation

Modern corrugated printers benefit from intelligent solutions to drive efficient and profitable digital printing. Both of today's ERP and MES solutions are able to help plants determine when, where, and how to run jobs as they enter the workflow.

''Automation coupled with data and meaningful insights gives manufacturers plant-wide visibility to adapt and respond," says Zlatic. ''As corrugated businesses navigate the challenges of today and prepare for tomorrow, investing in technology and personnel development ensures our solutions meet current demands and anticipate and address future challenges." /PM

TECHNOLOGYSE EXPANSIVE

)ET-3D PRINTERS

CompanyName/Website PnnterName

141Craftbo continued,c

craftbotcom

142Creative30TechnolooiesInc.Duo

creative3dtechnolooies,com

143Deskto□MetalInc. StudioSvstem2

desktonmetal.com

144EDS

eos.info

BinderJettinn

ShonSvstem4L BinderJettinn

ShonSvstemBL BinderJettinn

ShonSvstem12L BinderJettinn

ShooSvstem16L BinderJettino

Fiber IUAFPandFFF

essentium.com Hi□hSaeedExtrusion280i

etec,desktonmetal.com

exone.com

148FarnoAdditiveManufacturinnLulzBotTAZ6 MaterialExtrusion

S2500 lulzbotcom LulzBotMini2 MaterialExtrusion 6,3x6Jx7,09 0,05 Sl495

149FELIXnrinters

Felixnro13.0 FFF 11.Bxl5.74xl5.74 0.05 S9742 felixnrinters,com Felixnroxi3,0 FFF 23fa15.74x23,6 0,05 �15750

Felixnro3 FFF 9.5x9.6x9.25 0.05 ,�3090

Felixtee4,1 FFF 10x8x8,6 0,05 Sl042

Felixtee4,1Dual FFF 70x8x8,6 0,05 Sl146

Felixtee4L FFF lOxBxl5.74 0.05 Sl276

Felixtee4LDual FFF lOxBxl5.74 0,05 Sl440

Felixbio FFF 5.11x8.26x5.11 0.01 s20B4o

Felixfoodsinnlebasic FFF 8,66x7.67x6,69 0.25 S3884

Felixfoodswitchbasic FFF 4,92x7,67x6,69 0.25 i:6830

Felixfoodtwinbasic FFF

Felixfoodsinnlenremium FFF

Felixfoodswitchnremium FFF 4.92x7.67x6.69

Felixfoodtwinoremium FFF

Felixoharma FFF

Felixinsole FFF

%470

,�4700

,�7772

S7412

KEY

3SP = ScanSpinandSelectivelyPhotocure

APF=ArburgPlasticFreeforming

cDLM=ContinousOLP

CM = ContactManufacturer

CSAM = ColdSprayAdditiveManufacturing

DE□=DirectedEnergyDeposition

DLP = DigitalLightProcessing

DLS = DigitalLightSynthesis

DMP=DirectMetalPrinting

E-PBF = ElectronBeamPowderBedFusion

FDM = FusedDepositionModeling

FFF=FusedFilamentFabrication

FGF = FusedGranularFabrication

HPS = HybridPhotosynthesis

LAM=LiquidAdditiveManufacturing

LCD = LiquidCrystalDisplay

LFS = LowForceStereolithography

LIS=Laser-InducedSlipcasting

mm = millimeter

NPJ = NanoParticleJetting

PBF=PowderBedFusion

SLA = Stereolithography

SLM = SelectiveLaserMelting

SLS=SelectiveLaserSintering

WMM = WireArcAdditiveManufacturing

µAFP = MicroAutomatedFiberPlacement

TECHNOLOGYSET-3l

·eol.com

3D PRINTERS EXPANSIVE OPTIONS

ARGO500

ARGO1000

EBAM53

EBAM110

EBAM150

EBAM200

EBAM300

EBAM360

172 Sharebortsrl sharebot.it

173 SLMSolutions slm-solutions.com

174 SPEE3D s ee3d.com

175 StackerLLC stacker3d.com 176 Stratas s stratas s.com

Sharebot

Sharebot XXL SnowWhite2 metalONE

SLM125

SLM280 SLM280PS SLM500 SLM800

NXGXll600 XSPEE3D SPEE30

S4Industrial3DPrinter

S2IndustrialGrade3DPrinter

S4-XLIndustrialGrade3DPrinter F-SeriesModel1

ContinuousBuild3DPrinter F120 F170 F270 F370 F3300

Fortus380CarbonFiberEdition Fortus450MC F900 V650Flex

Connex1Ob'et260

Connex1ob·et500

Connex3Ob'et350

Connex3ob·et500

J700Dental

MaterialExtrusion

MaterialExtrusion DED DED DED OED DED DED FFF

MaterialExtrusion

MaterialExtrusion

27.5x27.5x19.7

13.98x20.67

15.35x12.4x20.66 24x24x24

11.2x11.2x11.2

4.7x4.7x4.7

10x10x10

12x10x12 14x10x14 CM 14x12x12 16x14x16 36x24x36 20x20x23

KEY

3SP = ScanSpinandSelectivelyPhotocure

APF=ArburgPlastk;Freeforming

cDLM = ContinousOLP

CM = ContactManufacturer

CSAM=ColdSprayAdditiveManufacturing

DED = DirectedEnergyDeposition

DLP = DigitalLightProcessing

DLS=DigitalLightSynthesis

DMP = DirectMetalPrinting

E-PBF = ElectronBeamPowderBedFusion

FOM=FusedDepositionModeling

FFF = FusedFilamentFabrication

FGF = FusedGranularFabrication

HPS= HybridPhotoSynthesis

LAM = LiquidAdditiveManufacturing

LCD = LiquidCrystalDisplay

LFS=LowForceStereolithography

LIS = Laser-InducedSlipcasting

mm = millimeter

NPJ=NancParticleJetting

PBF = PowderBedFusion

SLA = Stereolithography

SLM=SelectiveLaserMelting

SLS = SelectiveLaserSintering

WMM = WireArcAdditiveManufacturing

µAFP=MicroAutomatedFiberPlacement

177 Tethon3D tethon3d.com

178 Thermwood Cor oration thermwood.com

179 TRUMPF trum I.com

180 Ultimaker ultimaker.com

181 VEL03D velo3d.com

182 XactMetal xactmetal.com

J720Dental Bison1000

LSAM

LSAMMT

TruPrint1ODOBasic Edition

TruPrint1ODO

TruPrint2000

TruPrint3000

TruPrint5000200'C re-heatin

TruPrint5000500'C re-heatin

UltimakerS5

UltimakerS3

Ultimaker2+Connect

UltimakerS5ProBundle Sa hireMetalAMPrinter

XM200C

XM200C-E PerformanceModel

XM200C-ER ReactiveModel

XM200S

XM300C

XM200G

Carmel1400C

Carmel1400M

PartPro350xBC PartPro200xTCC

CastProl00xP

PartProl20xP

19.3x15.4x7.9

19.3x15.4x7.9 13.4x13.4x7.9

19.3x15.4x7.9

19.3x15.35

19.3x15.35x7.9

19.3x15.35x7.9

19.3x15.35x7.9

39.3x31.4x19.6

11.81x7.87x3.94

11.57x7.55x5.85

11.57x7.55x5.85 110x60x138

10x20x10

70x70x5

3.9x3.9 3.9x3.9 7.9x7.9 11.8x15.7 11.8x15.7

11.4x15.7

330x240x300

19Dx230x200

223x220x205

330x240x300 12.4x15.75

5x5x5

5.9x5.9x5.9 19.68x11.02x7.87 19.68x11.02x7.87

RM the Field

by Melissa Donovan

additive manufacturing (AM) has long maintained an important position in prototyping, but it continues to work on scaling up to meet full manufacturing needs. This is seen across all the verticals it touches. Medical manufacturers are doing their part to fuel advancement, relying on three dimensional (3D) printing technologies for a number of reasons.

''AM or 3D printing has empowered medical manufacturers to innovate faster, reduce costs, and deliver superior, patient-centered solutions. Customization, rapid development cycles, cost efficiency, and advancements in

materials make AM highly effective," says Rajeev Kulkarni, chief strategy and marketing officer, Axtra3D.

Creating prosthetics and surgical tools or engineering biological structures like tissue, powder bed fusion (PBF) technologies including selective laser sintering (SLS) and selective laser melting (SLM) in addition to vat polymerization methods such as stereolithography (SLA) are commonly used.

Above: BMF's micro 3D printers areinvolvedintheproductionofsingle-use scopesforendoscopicproceduresacrossclinicaldomainsfromcardiology, urology,peripheralvascular,andlaparoscopy.

Key Reasons for Usage

3D printing is particularly advantageous for manufacturers of medical products thanks to the technology's ability to costeffectively produce items in runs as low as one. In the medical field, customization is highly favored.

Simon Leid, director development, Freeformer at ARBURGadditive, believes 3D printing is an established process in medical technology, and its importance grows every year. "Examples include customized protheses and implants, as well as anatomical models with comparable properties for surgical preparation and training to help reduce risk. 3D printing also improves the time to market for the development of new products."

''AMpropelsinnovationacrossthemedical field, especially as the trend of miniaturization drives the industry to seek new ways of developing smaller products. The technology has helped product designers and engineers overcome longstanding pain points during prototyping. As a highly regulated industry, high precision and accuracy are required, which makes micro 3D printing an ideal manufacturing method;' says John Kawola, CEO,Boston Micro Fabrication (BMF).

As technology advances it's becoming more accessible, affordable, and reliable, which in tum extends it past prototyping, shares John Anderson, medical marketing manager, Formlabs. "These technologies now address critical challenges including enabling personalized healthcare solutions, reducing overhead and operating costs, and allowing medical device companies to adopt more agile development approaches!'

"AM has really made a mark in the medical industry over the past few years. Opening up doors that allow for the creation of custom parts like implants, prosthetics, orthotics, and surgical tools

1. Printerslike FormlabsForm 4B are recognized for producing detailed anatomical models, medical device prototypes with tight tolerances, molds, tooling, patterns, andfunctionalend-useparts.

with incredible precision. The ability to quickly and cost-effectively produce items tailored to specific patient needs is a huge benefit and probably the most impactful factor to AM's growth in the medical industry," explains Jeff Enslow, head of marketing, Impossible Objects.

A key use of AM in medical is customization for patient-specific care, agrees Kulkarni. "Manufacturers like Open Bionics produce lightweight prosthetics tailored to individual anatomies, while Align Technology fabricates millions of Invisalign aligners based on unique dental scans. Surgical guides use AM for precise anatomical fit to assist in complex procedures like orthopedic and cranial surgeries, improving patient outcomes and addressing niche market needs."

A subsidiary of medical is dental, which AM also touches. "Dentists use printers to create models of teeth and jaw lines, which help them design treatment plans or surgeries. Or 3D printers can also be used to make custom retainers or aligners, which are things patients would get into direct contact with. AM is very useful when you have to make low quantities of different products, which is exactly what's happening with retainers and aligners. 3D printing can make dental technicians' jobs easier and the result more precise as well," notes a representative from Craftbot.

Cost also makes AM advantageous. "By minimizing material waste and eliminating tooling, AM reduces costs. Stryker uses it to create titanium implants with intricate internal structures that are otherwise cost prohibitive. Biocompatible materials like PEEK and nylon are utilized efficiently, making low-volume, high-complexity devices feasible,'' admits Kulkarni. All in all, "many labs and point-of-care facilities embrace 3D printing, enabling the creation of personalized, complex, and patient-specific devices, implants, and anatomical models,'' states Matthew Stark, 3D segment manager, Mimaki USA, Inc.

Methods of 3D Printing

PBF and vat polymerization technologies are used to manufacture medical parts and tools. The method used depends on the goals of the intended final product and whether plastic, metal, ceramic, or some other material is necessary.

PBF technologies include SLS, multijet fusion (MJF), direct metal printing (DMP), and SLM. "SLS technologieslike the Formlabs Fuse 1+ 30W-offer cost-effective batch production of functional plastic devices such as surgical cutting guides, orthotics, prosthetics, and surgical tools. While MJF allows for multi-color and multi-material parts, its higher costs and reduced durability can limit its use in certain medical device markets. Metal

technologies like DMP and SLM are critical for producing precision metal components such as titanium and cobaltchrome implants,” says Anderson.

According to Enslow, SLS, SLM, and direct metal laser sintering (DMLS) are popular because they can produce detailed, lightweight, high-strength parts using materials suitable for medical applications. These methods work well for creating complex shapes and maintaining precision.

“SLS is valued for its strength and durability, commonly used in orthotics, prosthetics, and surgical tools. It allows for production of complex, lightweight structures without the need for support materials. SLM is crucial for producing metal implants, such as titanium cranial plates and hip implants. The process ensures precision, biocompatibility, and the ability to create intricate geometries,” adds Kulkarni.

There are limitations to SLS, SLM, and DMLS, specifically in speed and cost, which makes room for disruption from other technologies, continues Enslow. For instance, composite-based AM (CBAM) printing methods offer faster production

2. Lithoz’s ceramic printers rely on lithography-based ceramics manufacturing technology. 3. Hybrid systems combine multiple methods, such as Axtra3D’s Hi-Speed SLA with TrueLayer technology, and optimize speed, precision, and material compatibility to create parts like this artery stent.

speeds and cost-effective strong, lightweight materials, which could appeal to manufacturers looking to scale up and innovate. Impossible Objects offers the CBAM 25 printer.

Vat polymerization technologies including SLA, digital light processing (DLP), and liquid crystal display (LCD) are also a consideration. “These enable the production of high-resolution, precise parts from a range of biocompatible and sterilizable materials,” says Anderson. SLA printers like Formlabs’ Form 4B and Form 4BL are recognized for producing detailed anatomical models, medical device prototypes with tight tolerances, molds, tooling, patterns, and functional end-use parts.

BMF’s projection micro stereolithography (PµSL) technology falls under the DLP category. “The PμSL technology leverages light, customizable optics, a high-quality movement platform, and controlled processing technology to produce ultra-high resolution, micron-scale parts. The technology is able to reach tolerances and precision levels that other 3D printing, including SLS, is not able to achieve. Many medical devices, particularly those used in laparoscopic procedures, are intentionally designed with miniaturized features. Our technology is a great fit in these scenarios,” shares Kawola.

“SLA is known for its high precision and smooth surface finish, it is popular for creating dental models, surgical guides, and anatomical models. Its ability to work with biocompatible resins makes it ideal for dental, audiology, and other medical applications,” says Kulkarni. Hybrid systems combining multiple methods, such as Axtra3D’s HiSpeed SLA with TrueLayer technology, are poised to optimize speed, precision, and material compatibility.

Ceramic 3D printing, which uses processes like DLP and SLA, is a new to the medical industry, according to Norbert Gall, head of marketing, Lithoz. However, it’s been proven that “DLP merges the best possible scalability and the highest possible precision with production efficiency. Up to 100 such printers can be synchronized to produce millions of parts at industrial scale.”

“The ultra-precise resolution of ceramic printing combined with highly efficient material use have paved the way for an entirely new generation of durable medical devices with the excellent material properties of ceramics,” adds Gall.

Similar to injection molding, but without the need for a mold, Arburg Plastic Freeforming (APF) is another method used in medical environments. “Extrusion-based processes such as APF are used for implants, orthoses, and surgical instruments. We continuously develop APF, which can be used to process original plastic granules, with a focus on build rate and surface quality,” says Leitl.

Top Manufactured Items

Currently, surgical tooling and prosthetics make up a large percentage of what is manufactured via 3D printing in the medical field.

According to Anderson, over 90 percent of the top 50 medical device companies integrate 3D printing into their workflows across nearly every area of medicine. “One advantage of 3D printing is its ability to produce devices that were previously im-

possible or prohibitively expensive to produce, through conventional manuacturing. Thanks to 3D printing, these devices are now finding a critical place in improving patient outcomes for applications like cancer treatment, joint replacement, and craniomaxillofacial surgery:'

Multi-feature surgical tools are a popular item manufactured in this space using AM. '½.part from minimal material waste in production, the magic lies in both the multifunctionality of these tools, which can be produced in just one single step, and the miniaturization made possible by the use of premium projection systems. Wall thicknesses of 90 µm have been achieved for a ceramic sleeve used in a laparoscopic tool. In serial production, 1,400 such sleeves can be fit on one build platform of a Lithoz lithography-based ceramics manufacturing printer. That opens up a completely new dimension of perfectly repeatable high-precision serial production," explains Gall.

Medical companies could use CBAM technology like that from Impossible Objects to produce components like structural prosthetics or surgical tools that can be heat sterilized. "This approach allows for both durability and the flexibility needed for medical applications;' says Enslow.

Scopes are a surgical tool created via AM. Kawola says BMF's micro 3D printers are involved in the production of "novel, single-use scopes for endoscopic procedures across clinical domains from cardiology, urology, peripheral vascular, and laparoscopy. The scopes require a high level of precision and detail, and traditional 3D printing tools could not handle the scale and accuracy required for the components."

Kulkarni cites the adoption of AM by dental and hearing aid manufacturers as widespread and impactful. "Companies like Align Technology produce millions of Invisalign aligners annually, meeting the growing demand for precise, patient-specific solutions. Other popular applications include 3D printed dentures, surgical

guides, veneers, crowns and bridges, and splints, all of which enhance accuracy and efficiency. In the hearing aid industry, nearly 90 percent of custom devices are now 3D printed, demonstrating the technology's transformative role."

Axtra3D's Hi-Speed SLA technology is advancing the industry further by enabling the production of true silicone medical devices and audiology parts, significantly reducing costs and accelerating time to market.

AM is used is what FELIXprinters refers to 3 as "bioprinting," which is "enabling the development of functional biological structures, accelerating breakthroughs in regenerative medicine, drug testing, and tissue engineering."

FELIXprinters has manufactured items under this category like 3D printed organoids, custom skin grafts, and vascularized tissue engineering. "By combining cutting-edge biomaterials with high-precision printing, bioprinting paves the way for future organ transplantation and personalized regenerative therapies;' cites a representative from FELIXprinters.

"Looking ahead, advancements in bioprinting for tissue and organ development may shift focus toward regenerative medicine. Additionally, wearable health devices and innovative drug delivery systems are emerging as high-growth areas. However, staples like prosthetics, implants, and surgical guides will remain essential due to ongoing demand for personalized, precision-driven solutions," adds Kulkarni.

An area of high interest is the orthopedic implant market. "Before selecting an implant, surgeons rely on sizing trays to determine the correct implant size. These trays represent a significant cost

burden for manufacturers. Many companies are shifting to a more cost-effective solution-3D printing single-use sizers and trials. This approach not only reduces overhead costs but also streamlines the process for surgical centers by reducing inventory and the demand for central sterilization," shares Anderson.

"There have been many advances in materials and material properties for medical device manufacturing and it is assumed that 3D printing will be a major solution for many personalized medical applications," foresees Stark.

Requirements to Consider

Users should look for AM solutions that offer precision, reliability, and material variability.

Gall says exact reproducibility and perfect precision are key requirements. And this challenges providers of printing systems to strive to reach those standards with new technology introductions.

"Precision and repeatability are nonnegotiable in the medical world. Materials need to meet high standards for biocompatibility and sterilizability. Beyond that, manufacturers are always looking

for ways to speed up production and control costs," admits Enslow.

Material versatility is important. "The ability to work with a broad range of materials is critical, as the medical industry demands a variety of customized products. Materials such as resins, ceramics, metals, and elastomers are used to meet specific needs across dental, orthopedic, and prosthetic applications," explains Kulkarni.

The materials need to offer strength and durability. "Many medical devicesparticularly implants-require materials that are strong and durable. Titanium and PEEK are commonly used

4. Accurate visual representation of pathologies are achieved withfull-color3DprintingfromMimaki.

for implants due to their lightweight, yet robust properties. The printer must support materials that mimic the mechanical properties of human bone or tissue to ensure long-term functionality," continues Kulkarni.

The trend ofminiaturization is popularizing micro 3D printing, making it more attractive to those in the medical field. "In some cases, it's the only option that's able to manufacture micro-sized parts with the ultra-high precision and accuracy required. Looking ahead, I expect that micro 3D printing, along with the introduction of new materials, will be essential to many life scientists seeking to advance medical innovation," suggests Kawola.

Small details and thin parts are commonplace in this industry. Anatomical models need to be replicated accurately to showcase the structures and pathologiesofindividualpatients. "Somephysical details are difficult to replicate with many 3D technologies, but through inkjet 3D printing, these fragile structures can be encased within clear resin or enlarged to prevent breakage," advises Stark.

Leid lists other requirements of importance such as, "the 3D printer must be suitable for use in grey respectively clean rooms, be able to process biocompatible materials, and be easy to operate and maintain. Another important requirement, especially in medical technology, is the recording and documentation of process data."

Post processing and surface finish should also be considered. "Given the stringent requirements for the surface finish in the medical industry, 3D printers must provide an excellent finish or reduce the need for extensive post processing;' recommends Kulkarni.

In conclusion, "when selecting a 3D printer, medical device manufacturers need to consider several important factors, including the intended application, build platform size, print speed, reliability, and available materials. The properties of the materials are also crucial; factors like skin or tissue exposure, flexibility, durability, andcompatibilitywithdisinfection and sterilization methods should all be evaluated," suggestsAnderson.

Scaling Up and Out

AM continues to grow beyond surgical tools and prosthetics in the medical field. Material advancements as well as the technology itself allows for monumental change in how medical products can be made, whether it's customization for patient-specific care or scaling up to create multiple iterations of a tool or tray. In addition, thefutureof3D printing and its association with bioprinting is something to watch. /PM