dpsmagazine.com

Volume 27, Number 3 • ISSN: 1529-2320

dpsmagazine.com

Volume 27, Number 3 • ISSN: 1529-2320

Many sheet-fed/cutsheet production printers output approximately 100,000 to one million impressions per month. Both toner- and inkjet-based equipment fill demands in this space. Commercial printing applications from direct mail and transactional printing to books and magazines benefit from more efficient shorter runs and variable data capabilities.

Many of the categories covered in this issue are considered embellishment. This is timely as we also preview the Amplify Print show coming this June.

New products in sheet-fed inkjet continue to enter the market. We investigate ink formulations driving popular solutions in Broadening Material Range. Find a complementary Target Chart on this topic following the article.

We dive into the latest in toner-based production in Triumphing with Toner. Known for quality and precision, these solutions advance with expanded color gamuts and specialty toners. Tune into a webinar on the topic at dpsmagazine.com/webinars.

Finishing also helps set printed output apart from the competition. This issue also covers the benefits of UV spot coating in On the Spot. The technique is used to enhance and protect digitally printed output.

Many of the categories covered in this issue are considered embellishment. This is timely as we also preview the Amplify Print show coming this June.

We also highlight technologies displayed at Dscoop Edge 2025.

Check out dpsmagazine.com for expanded show guides and additional web-exclusive articles, including a look at modern laminators targeting digital print environments.

Cheers,

Cassandra Balentine, editor cbalentine@rockportpubs.com

EDITOR IN CHIEF

Thomas Tetreault

978-921-7850

EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

WEB EDITOR

Melissa Mueller

CONTRIBUTORS

Kemal Carr, Olivia Cahoon, Gina Ferrara, Mark Hanley

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

300 Newburyport Turnpike, Ste. 11 Rowley, MA 01969

Ph 978-921-7850 x110 • Fx 978-921-7870

edit@rockportpubs.com

SALES

Amanda Doyon Ph 978-921-7850 x170 • Fx 978-921-7870 adoyon@rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE 300 Newburyport Turnpike, Ste. 11 Rowley, MA 01969

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER

Missy Tyler

By DPS Magazine Staff

The Amplify Print event takes place from June 10 to 12, 2025 in Rosemont, IL. The trade show and conference brings print finishing and embellishments to the forefront, showcasing the brands, products, and processes raising the standard for foil and coatings, die cutting, folding and gluing, binding, and direct mail.

The event attracts brand owners, commercial printers, folding carton and label producers, as well as mailing industry professionals.

Attendees are invited to experience live equipment demonstrations in the Technology Zone, connect with leading brands in the exhibit hall, and learn from industry experts during educational seminars.

Among the many exhibitors, here’s a snapshot of what to expect on the show floor. Find more online at dpsmagazine.com

Breit Technologies, booth 5143, showcases its Cast and Cure holographic micro-embossing technology that creates luxurious visual and tactile effects for packaging, collectibles and trading cards, gift wrap, and labels. Cast and

Cure’s affordable, sustainable decorative coating process delivers ultra-high gloss, matte, or holographic patterns on a range of surfaces. INFO# 230

Duplo USA, booth 4351, showcases its latest advancements in digital embellishment and die cutting. On display is the DuSense DDC-8000 B2 Raised Spot UV Coater, delivering eye-catching dimensional effects, and the DSM-1000 B2 Platen Die Cutter, built for precision packaging and die cutting applications. Stop by to see how Duplo is pushing the boundaries of print finishing. INFO# 231 GBC, booth 4825, unveils a game changer at Amplify Print 2025. The GBC CL-401 is the first inline finisher offering fully automated, two-sided lamination directly after printing—up to 100 letter sheets per minute. With no warm up time needed CL-401 delivers consistent,

ship-ready printed work in one step. Be among the first to see it live. INFO# 232 Konica Minolta, booth 4517, shows attendees how to recoup margins and capture new profit streams with digital embellishment. Experience stunning output from Konica Minolta’s cuttingedge digital embellishment solutions using JETvarnish 3D technology and learn about their comprehensive business driver program. With new seamless white-glove installations, comprehensive training, on-site consultations, embedded marketing programs, and unrivaled

1. Duplo USA, booth 4351, showcases its latest advancements in digital embellishment and die cutting.

2. Xeikon, booth 4725 invites attendees to discover effects achieved through KURZ DIGITAL METAL integration with the Xeikon TX500 press. 3. GBC, booth 4825, unveils the GBC CL-401, an inline finisher offering fully automated, two-sided lamination directly after printing.

ongoing support, it delivers a recipe to ensure customer success. INFO# 233

Neenah, booth 4912, demonstrates how the right paper can elevate print from ordinary to extraordinary. With a broad portfolio of richly colored and uniquely textured papers, Neenah offers the perfect canvas for high-impact techniques like foil, embossing, and digital foil. Printed promotions are available, providing inspiration and practical ideas to share with clients. New products, including the new CLASSIC Embellishment Papers, and uncoated paper specifically engineered for digital embellishment are on display as well. INFO# 234

FUJIFILM North America Corporation, booth 4739, demonstrates the inline embellishment capabilities of the Revoria Press SC285S. The Revoria press handles a variety of media from small cards to long banners, including specialty, metallic, and synthetic substrates. Today, people look for print that is super-special, meaning the addition of customized CMYK+ embellishments and hyper-targeted personalization— without slowing the process or adding undue costs. FUJIFILM’s print servers and integration-ready workflow automation software is discussed and the company showcases how it simplifies processes, reduces errors, and enhances productivity. The Revoria Press SC285S also includes sustainability features with its energy-efficient components and waste-reducing workflows. INFO# 235

Rollem, booth 4731, highlights the Insignia6HPLUS rotary die cutter featuring ease of operation and fast changeovers. Learn more about flexo-magnetic, rotary die cutting, and the variety of high-value products this production powerhouse produces. Rollem’s sheetfed B2 size Jetstream converting system shows automated bi-directional cutting of embellished nine-up postcards. Visitors see live demonstrations on these unique finishing systems. INFO# 236

Sakurai, booth 5145, demonstrates ScreenFoil, specialty effects, and embellishment printing at Amplify Print. Featured in the Amplify Technology Zone is Sakurai’s servo-driven MS-80DDS cylinder screen press equipped with a Natgraph Smart UV dryer, stacker, and ScreenFoil LQM 105 Hot Foil Stamper. The fully automated MS-80DDS utilizes Modern Servo-Driven Motion to insure precise deposits of ink and laydown. INFO# 237

Sharp Imaging and Information Company of America (SIICA), a division of Sharp Electronics Corporation, booth 4511, showcases its cutting-edge Digital Production Press and Pro Series Printers. A division of Japan’s Sharp Corporation, SIICA provides innovative document solutions, commercial displays, projectors, laptops, and fully managed services to help businesses achieve Simply Smarter work. The Digital Production Press Series is designed to deliver exceptional speed, precision, and efficiency for high-volume print environments. Built on proven technology, these presses achieve speeds of up to 120 pages per minute (ppm) in color and 136 ppm in B&W with real-time image quality adjustments, precise paper handling, and advanced job management capabilities. INFO# 238

Taktiful Software Solutions, booth 4627, showcases Taktify, its AI-powered estimating and pricing platform designed specifically for the digital print embellishment market. Taktify leverages advanced AI and your sales data to suggest market-appropriate selling

prices based on geographic locations, specific verticals, and application type, helping you sell more digitally embellished print. INFO# 239

Xeikon, booth 4725 invites attendees to discover digital embellishment reimagined. In its booth, visitors can explore samples and demonstration videos showcasing what’s possible with digital embellishment these days. Such as inline, foodsafe metallic effects achieved through KURZ DIGITAL METAL integration with the Xeikon TX500 press. INFO# 240

Xerox, booth 4525, shows how its technology is powering growth and elevating quality for clients. The company showcases its end-to-end Production Ecosystem including the versatile Xerox Versant 280 Production Press with the EX 280 Print Server powered by Fiery. Explore the power of Predictive AI for Production Print, an intelligent assistant that boosts reliability and efficiency, and XMPie’s omni-channel marketing platform that helps clients deliver personalized, relevant communications across print and digital media to drive deeper engagement. Plus, see what’s possible with beyond CMYK embellishments and the Xerox Genesis Initiative business development program built to help clients scale. INFO# 241

Amplify Print is designed to showcase emerging trends, technologies, and resources from concept to final product, connecting all contributors in the finishing cycle. dps

Bringinganalogprintingandfinishingequipmenttodigital lifewith KODAKPROSPER ImprintingSystems

By Kodak ,__ _

In today's printing industry, digital production presses have become an integral part of production processes. The range of digital pressesavailable onthemarketismorevariedthan everbefore, andastheindustrycontinuesto evolve, moreandmore forward-thinkingprinting companiesare investing in digital printing-mainly inkjet.

Aside from installing a stand-alone digital press, there is another option for printers who want to benefit from highly productive digital printing: the integration of digital imprinting systems that can match quality and printing speeds onto conventional equipment. Adding digital capabilities to existing printing or finishing equipment can help printers take advantage of new business opportunities, streamline processes, and increase the profit potentialoftheir production facilities without huge financial investment.

With over five decades of experience in the development and manufacture of inkjet printheads, Kodak today has the KODAK PROSPER Plus and KODAK PROSPER S-Series Imprinting Systems in its portfolio. PROSPER Printheads deliver the high speeds and print quality necessary for integration with offset (sheetfed and webfed), flexo, and gravure presses as

well as postpress and packaging converting machines. Kodak's state-of-the-art continuous inkjet imprinting solutions offer printers the easy transition to inkjet technology and the abilityto capitalize on opportunities in variable print by this hybrid approach.

Thanks to their flexible integration and diverse configuration options, KODAK PROSPER Imprinting Systems are suitable for a variety of uses where they can demonstrate their versatility. These areas of application include:

Direct mail-personalized text and images/graphics, targeted promotional offers/messaging, and coupons

Packaging-bar codes, 2D codes, mass versioning, security/anticounterfeiting features, and variable codes for connected, smart packaging applications

• Gaming-raffle tickets, sweepstakes, and contest marketing

• Personal care products and napkinsproduct decoration, versioning of designs, and adding instructions for use or marketing messages By producing applications efficiently and cost-effectively with PROSPER Imprinting Systems with short lead times, print shops can better meet their customers' needs and help them achieve their business goals faster.

Kodak's PROSPER Imprinting System portfolio features high image quality and high-speed solutions. The printheads use KODAK Stream Inkjet Technology, which enables ultra-high speed and high ink coverage on a wide range of substrates including glossy substrates thanks to precise, round drop placement.

PROSPER Imprinting Systems offer speeds of up to 900 meters per minute (3,000 feed per minute) and produce

By Cassandra Balentine 0--

The Dscoop community is about 20,000 members strong. The organization is made up of HP Industrial Print and Large Format customers and partners. The organization's annual networking event, Dscoop Edge, takes place this year in Long Beach, CA from May 14 to 17, 2025.

From networking to education and of course, entertainment, this year's event hosts six tracks of learning sessionsAccelerate, Optimize, Innovate, Sell, Inspire, and Make it Real.

Keynote speakers include Taylor St. Germain, economist and senior consulting speaker; Dror Globerman, tech expert, public speaker, and content creator; Tony Hawk, skateboarding legend and entrepreneur; Daymond John, founder/ CEO, Fubu and star of Shark Tank, Erin Meyer, company culture expert and bestselling author; and John Koller, head of print marketing, HP.

AB Graphics (ABG), booth 645, displays a selection of high-speed, advanced finishing solutions, including two machines tailored for the growing shrink sleeve segment-an area of increasing interest for label and flexpack manufacturers. Among the featured systems is the Digicon Series 3 with patented Fast Track Die, ABG's flagship digital finishing solution. The Fast Track Die is a semirotary die-cutting module capable of running at speeds of up to 180 meters per minute (mpm), making it ideal for highvolume applications. Also displayed is the SR610 Seaming Rewinder, which is part ofABG's sleeving technology suite. Complementing this is the TSR750 Turreted The show floor highlights a variety of Seaming Rewinder, which also features partner technologies in software, work- Smart Wheel technology and offers unflow, and finishing. Here is a snapshot of interrupted operation thanks to its turret partner experiences. design. INFO# 250

CERM, booth 841, showcases how integration with industry-leading partners improves productivity and how its MIS software connects your entire workflow, helping you process more orders-faster and better. INFO# 251

Duplo USA, booth 331, exhibits its latestB2-formatfinishingsolutionsforHPIndigo users. Featured equipment includes the DuSense DDC-8000 B2 Raised Spot UV Coater, delivering dimensional effects; the DSM-1000 B2 Platen Die Cutter for precision packaging applications; the DC746 B2 Slitter/Cutter/Creaser for efficient multi-function finishing; and the CF375 Creaser Folder for high-speed creasing and folding. INFO# 252

1.AmongthefeaturedsystemsinABG'sboothisthe DigiconSeries3withpatented FastTrack Die,ABG's fiagship digital finishing solution. 2. Standard showcasestheBQ-300 PerfectBinderinbooth639.

Enfocus, booth 840, highlights its solutions including the latest versions of PitStop, Switch, Griffin, Review, and Phoenix, all of which were updated at the end of 2024 with a host of new features, functionality, and integrations to boost productivity and profitability across the print workflow. INFO# 253

Esko, booth 741, illustrates how integrated solutions work together to deliver the quality, productivity, and efficiency demanded of today’s converters. INFO# 254

HP showcases proven innovations shaping the future of print across commercial, labels, and packaging segments as well as advancements in data-driven automation, simplifying operations, and seamlessly integrating with brands to fuel digital growth. On the show floor HP has a complete production ecosystem driven by the HP Indigo 120K and HP Indigo 18K Digital Presses—designed to showcase their unmatched versatility and productivity across a range of applications. It also demonstrates the power of the HP Indigo 200K Digital Press, highlighting flexible packaging production, a seamless end-toend label workflow with an integrated slitter and ABG Fast Track. INFO# 255

Harris & Bruno, booth 522, showcases samples from both its ZRX for Digital Embellishment, as well as its ZRW for High-Speed Web coating. Both machines demonstrate advanced ZRX and ZRW technologies through a range of high-impact print samples. The ZRW enables high-speed coating in sync with HP PageWide Web Presses, while the ZRX delivers digital embellishment on uncoated media. INFO# 256

Hybrid Software, booth 849, presents its open architecture, industry leading prepress solutions, featuring new Packzimizer algorithms to optimize graphics onto various substrates and printing processes from label/roll manufacturing to large format output. Packzimizer intelligently analyzes order data to optimize the layout and repetition on a roll based on quantity, offering

maximum substrate usage and press uptime. INFO# 257

locr GEOservices and MAPS, booth 528, provides personalized maps and geomarketing solutions for creative, costeffective campaigns. It works worldwide with companies across all industries to enhance print and cross-media communications. INFO# 258

Mediaclip, booth 739, encourages visitors to explore its leading white-label personalization software. Whether it’s mixing in a dash of artificial intelligence or delivering serious personalization power, they’ve got fresh new features you won’t want to miss—come see how they’re taking product personalization to the next level. INFO# 259

Michelman, booth 339, helps converters succeed with shrink sleeve production and expand into new digital print opportunities. Its educational session, Shrink Sleeves: Not as Tough as They Seam, offers practical solutions for improving seamability, lowering press maintenance, and improving water resistance. Attendees can also explore Michelman’s portfolio of primers for HP Indigo and HP PageWide platforms. INFO# 260

Monadnock Paper Mills, Inc., booth 638, highlights Stello—its newest threestar HP Indigo-optimized paper. Stello’s Perfect White in both smooth and eggshell finish is engineered for premium applications like wedding invitations, photo books, and fine stationery. It showcases a full line of sustainable, FSC-certified digital papers designed for flawless performance and stunning print results. INFO# 261

Müller Martini, booth 238, is the world’s largest producer of print finishing solutions for commercial and book printers, trade binderies, newspapers, and digital book manufacturers. Through its innovative Smart Factory solutions, they are “Driving the Digital Transformation” with systems, software, and machines that optimize workflow and accommodate offset, digital, and hybrid printed products. With

U.S. headquarters in Hauppauge, NY, Müller Martini provides responsive service and support to printers and binderies nationwide through their extensive sales and support team. INFO# 262

Nobelus, booth 545, features live demonstrations of silver halide replacement digital photofinishing on the Komfi Amiga 52 Emboss. Also, learn more about EcoElement PE Thermal Sealants and StrataFlex Thermal Pre-Lams, exciting new flexible packing structures specially designed to make thermal flexible packaging more efficient. INFO# 263

Rollem International, booth 533, displays the Insignia6H PLUS Die-Cutter. The Insignia Series are loaded with features including die-cutting, kiss-cutting, creasing, perforating, embossing, hole punching, automated waste removal, and a choice of delivery options. See the PLUS model featuring a touch screen control, ideal for digital print users who change jobs frequently. INFO# 264

In partnership with Horizon International, Standard, booth 639, showcases the BQ-300 Perfect Binder, the HT300 Three-side Trimmer, the CRF-362 Creaser/Folder, and the APC-610 Paper Cutter. INFO# 265

Tecnau, booth 419, shows off its Stack 1212 cut/stack finishing system. Users convert multi-up output from Indigo B2 digital presses into smaller, stacked finished pages without guillotine cutting. Tecnau’s Stack 1212 reduces manual print handling and consolidates laborintensive finishing operations in a singlepass automated process. INFO# 266

The annual Dscoop user conference connects people and ideas to help businesses sell more, find talent, expand into new markets, improve sustainability, and transform. The community benefits from a collaborate environment with tools, training, and networking opportunities. Visit us online at dpsmagazine.com for more Dscoop news. dps

By OPS Magazine Staff

Once a means to an end, finishing technologies advance to become a profit source for modern print service providers (PSPs). As the term print embellishment/enhancement gains mainstream attention, UV spot coating is front and center of the discussion.

Bob Waddington, product line leader for curing and drying, BW Converting, sees two primaryfactorsbehindthe increasing popularity of UV spot coating. First, it is a cost-effective alternative to flood coating an entire print area. "By applying coating onlytoselectportions oftheprintedpiece, printerscan achievethesamehigh-quality finish while reducing material consumption and associated costs;'

Second, UV spot coating enhances visual ap-

gloss and matte or satin spot coatings adds depth and dimension, giving the final piece a premium feel. This level of aesthetic differentiation is a major driver forbrandslooking to make an impact," offers Waddington.

Josh Romberg, EVP sales and marketing, MBO America, agrees, adding that enhancing print with spot coating not only elevates visual appeal but also

texture, spot coatings transform ordinary print intopremium, attention-grabbingpiecesthat drive engagement andgethigher conversion rates.

- Josh Romberg, EVP, sales and marketing, MBO America

By addingtactile depth, dimensionality, and that stand out." draws the viewer's attention. The combination of

The technology continues to advance. "One of

1. Harris & Bruno's ZRX UVcoating solutionsaredesignedforprecision, versatility, and long-term reliability.

unlocks new revenue opportunities-especially in the high-impact direct mail sector. "By adding tactile depth, dimensionality, and texture, spot coatings transform ordinary print into premium, attention-grabbing pieces that drive engagement and get higher conversion rates. With the ability to create striking contrast and sensory appeal, this advanced finishing technique allows printers the ability to deliver high-value applications peal, making printed applications more eye catching. "The ability to highlight specific design elementssuch as logos, images, or text-creates a striking contrast that immediately

2. MBO America's newest module introduction is the SSC23, a singlesidedcoaterthatis23incheswide.

For printers looking to adopt or expand their use of UV spot coatings, Waddington says it's advisable to consult with ink and coating suppliers to explore the range of available options. Many suppliers offer coatings specifically formulated to work with hybrid digital and flexographic press configurations, further broadening the application possibilities for spot coating.

Plash describes UV spot finishing as both niche and mainstream. "Niche markets have been created for offline digital UV coaters and flat screen coaters. Mainstream could develop further as we discover new ways to economically apply heavy coat weights inline with highspeed printing.

What's exciting about UV spot coating is the tremendous room for growth.

"The momentum is definitely growing, as more printers strive to stand out and make their customers stand out," says Bruno.

Waddington also sees UV spot coating growing, particularly within the digital print sector. "The primary driver of this

3. MBO America's FC23 isahighlyefficient anilox based coating technology equipped with cantilevered cylinders for quick and easysleevechanges.Withasmallfootprint, modular design, and integrated pumping system, thisunit iseasy toflt innearlyany pressorfinishingline. 4. lnlineorofflinethe Harris&BrunoZRWeasilypairswithavari· etyofdigitalpresses.

growth is the evolving capabilities of next-generation digital printing presses. Newer digital machines can now produce coatings that closely resemble those applied via flexographic methods, something that was not possible just a few years ago. As digital technology continues to advance, UV spot coating will likely become even more prevalent, offering printers expanded creative and functional possibilities."

Romberg sees huge potential for the usage of spot coating in the continuous inkjet space.

As digital embellishment technology evolves, Bruno says new effects and applications keep expanding and pushing the boundaries of the market. More print providers recognize the value of UV coating and invest in the capability to differentiate themselves. "With continued innovation in coatings, automation, and special effects like Harris & Bruno's patent pending xMatte effect, the industry is far from reaching its peak. The demand for highimpact, sustainable, and premium print solutions is only getting stronger."

As brands and print buyers look for ways to elevate their materials, UV spot coating technology delivers a premium look and feel.

"From high-end packaging to direct mail, these embellishments create an emotional connection with the audience, leading to higher engagement and response rates. In today's attention-driven economy, UV spot coating is driving engagement in a way that unembellished print never could. Physical engagement with products on a shelf has shown time after time to boost shelf velocity considerably," states Bruno.

Plash agrees, noting that spot coating grabs attention and brings focus to a specific area of a printed piece, like a logo, image, or important text. "Studies have proven that an extra second or two is all it takes to close a deal." dps

by Melissa Donovan

nhancementsinspeed,quality, and cost efficiencyareapparentinthenewestcutsheet inkjet technologies. Driving these updates is theconstantadvancementofinksets-water-, oil-,andUV-based-foundinthedevices.

Each ink type is influential inyielding wider color gamuts,consistencyacrossmultiplerunsofasingleprint, and most importantly expanding the range ofmaterials compatiblewitheachtechnology.

Relevant Advancements

Newinkformulationsaswellasenhancementstocurrent configurationsfuelcutsheetinkjet'sgrowth.

Michael Poulin, senior product manager - inkjet presssolutions,FUJIFILMNorthAmericaCorporation, GraphicCommunicationsDivision,listsenhancedprint quality,durability,andenvironmentalimpactasfocuses forrecentadvancementsincutsheetinkjettechnology.

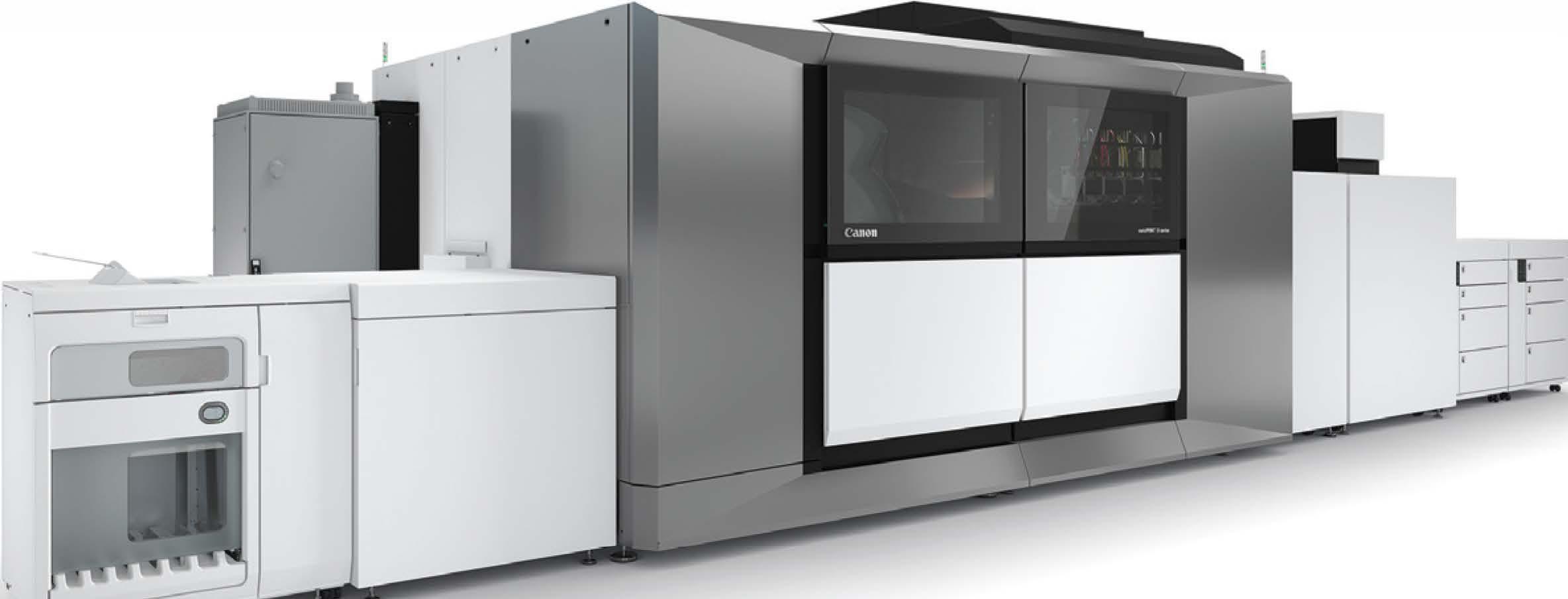

Theintroductionof1,200dpiprintheadscontributes tolesswhiteareabehindinkdots,commentsJaneNerf, varioPRINTiX2100/3200andvarioPRESSiV7product manager,productstrategymarketing,CanonU.S.A.,Inc. For Canon, this is further enforced bythe post fixation InkFusion step that creates an ink film and increases

Above: Landa Nanographic Printingachievesan arrayof colors and sharp details, ideal for a variety of cutsheet applications.

1

dot gain for improved print quality and reducedinkusage.

"The introduction of nano-pigment technology, such as in water-based nano inks,allowsforsmallerpigmentparticles, which result in higher color density and more vibrant prints. Advances in polymericresinsininkformulationsimprove adhesionandresistancetosmudgingand scratching. Eco-friendly developments focus on reducing volatile organic compound (VOC) emissions and enhancing biodegradability,"continuesPoulin.

Amir Shalev, market development director, Landa Digital Printing, believes thatnanotechnologyisapivotaladvancement in the space, specifically Landa's Nanoink."Thistechnologywasdeveloped toanswerthegrowingneedforhighlyefficientprintingprocessesthatmaintainthe environmental benefits of water-based inks,whileallowingforcost-effectivedigitalproductionatlongerrunlengths."

Bret Riecke, VP industrial print solutions, Konica Minolta, notes that ink sets' color and substrate gamuts are evolving all of the time. "Quality and consistency are becoming the

benchmarks ofinkjet systems. Cost and productivityalsomakeinkjetmoreprofitableforcustomers;'

Colorgamutboostsarecommonplace atRISO."Inmy11yearsatthiscompany, theyhavereformulatedtoboostthecolor gamutontheircyan,magenta,andyellow inks;createdatruer,richerblackink;and introduced a fifth gray ink for improved shading, halftones, and more accurate skin tones. We take color reproduction very seriously;' statesJesse Heindl, marketingmanager,RISO,Inc.

The introduction of direct-to-substrate ink sets make expanding into non-porous substrates possible, according to Dustin Graupman, senior director inkjet division, Kyocera Document SolutionsAmerica,Inc. "Thesenewformulationseliminatetheneedforpre-or post-treatmentprocesses."

"Currently, these advancements are primarily aimed at improving performanceonglossandmattecoatedpapers, making high-quality inkjet printing more versatile and efficient. However,

thetechnologyisrapidlyevolvingtotarget synthetic substrates, whicharecommonly used in packaging applications. This expansion broadens the range ofmaterialsthatcanbeprintedwhilemaintaining high-quality output and production efficiency,"sharesGraupman.

Sheet-fed inkjet devices benefit not only from enhancementsinink setsbut from the variety of compatible options. Depending on the manufacturer and device,aprintprovidermayhavetheoptiontousewater,oil,orUVink.

There are number of advantages to using water-basedinksforcutsheetinkjet. Nerfpointstoenvironmental friendliness,lowodor,andgoodprintqualityas someadvantagesofCanon'sproprietary polymerpigmentwater-basediXinks. Graupmanobservesthatwater-based ink has received the most investment from OEMs, making it the dominant technologyinproductioninkjetprinting. "It combines excellent resolution versatility,allowingforbothlow-andhigh-resolutionprinting, withalowenvironmentalimpact, whichiswhysomanyOEMs leverageitintheirdevices."

According to Poulin, water-based inks tend to be the least expensive and more environmentally friendly compared to oil- or UV-based ink. They produce less VOCs, which is great for reducing harmful emissions. Additionally, water-based inks provide excellent colorvibrancyandsharpness.Theyalso generallyhavebetteradhesiontoawide variety ofsubstrates, offering versatility fordifferenttypesofmedia."

Rieckesayswater-basedinksaregenerallyeasiertojet,makingthemsuitable

1. The Canon varioPRINT iX color digital press combines quality and a wide media range with high productivity and cost-effective inkjet printing. 2. The Komori J-throne 29 utilizes LED UV ink and prints at 6,000 sph on a B2+ sheet size.

3

becomes durable when cured, lending itselfasveryappealingforproductslike direct mail that undergo machine processes and material handling; no postpresscoatingisrequired,"addsMartin.

Other benefits ofUV ink are that it "produceshighlydurableprintsthatare resistant to fading and wear, and offer a broader range of colors, enhancing print quality. UV inks are also recyclable,"saysRiecke.

UVinks do present their own set of challenges.Forexample,Rieckeadmits thattheytendtobemoreexpensiveper liter and not all printheads can jet UV inks. Further, oncoatedstocksUVinks cancreatearaisedtexturethatmaynot bedesirableforallapplications.

"UV inks may also not be suitable for sensitive applications such as food packagingorthosewherechildrenmay

CanonU.S.A., Inc.

FUJIFlLM North AmericaCorporation

KomoriAmerica

Konica Minolta

Kyocera Document Solutions

Landa Digital Printing

RISO, Inc.

SCREENAmericas

interactwiththeprintedmaterial-such astoypackageprinting,"addsShalev.

Oil-based ink eliminates heat from the printingprocesssincethereisnoneedto removeexcesswaterfrom the substrate likewater-basedink.

The trickle down effect ofthis translatestoahostofadvantages,"thismeans thatRISOdevicescanbemorecompact, as there are no dryers or de-curlers involved,leadingtoasmallerfootprintand lessenergyconsumption. Italsoenhances the longevity ofour devices, as heatlessimagingpreservespartsandcomponentsthatwouldotherwisebreakdownin theheat,"sharesHeindl.

Awell-knownbenefitofoil-basedinks isthatthey adhereeasilytoawiderange of substrates, including curated stocks,

without the need for a pretreatment. "They also reduce paper distortion due to lower water content,"saysShalev.

Graupman adds that oilbased inks are also known for low power consumption and durabilitywhenprintingoncertainapplications.

However, Shalev points out that drawbacks of oil-based inks include the tendency to dryslowerthan water-basedalternativesand"maynotachieve the same high-end color reproduction needed for premium printapplications."

Oil-based ink may include higher costs and lower resolution, and when printingitisdifficulttomatchwithother printtechnologies,notesGraupman.

As more substrates are introduced to the digital print space, additional media is successfully optimized for inkjet printing. Inthecutsheetspace, vendors work to improve media compatibility withwater-, UV-, andoil-basedinksets.

Graupman says improvements are made by focusing on key technological advancements in printheads, ink formulation, and drying technology. "Printhead developments have led to higher resolution capabilities and improved recirculation within the printhead, enhancing overall print quality and consistency. Second, ongoing ink formulation development has allowed for better adhesion and compatibility withawiderrangeofsubstrates. Finally, advancements in drying technology have played a crucial role in optimizing ink performance, ensuring faster drying times and improved durability on various media types. By leveraging theseinnovations,weexpandtherange ofcompatiblesubstratesbetweeninks."

3. Konica Minolta'sAccurioJet UV Inkjet platform isa 23x29-inch press.

Water-based ink sets include standard water-based technology— and also nano-based technology from vendors such as FUJIFILM North America Corporation and Landa Digital Printing.

Water-based nano inks offer “greater detail and smoother gradients due to the smaller particle size. Nano inks also often require lower ink volumes to achieve the same color density, contributing to cost efficiency and reduced environmental impact,” shares Michael Poulin, senior product manager - inkjet press solutions, FUJIFILM North America Corporation, Graphic Communications Division.

Nanotechnology involves ultra-fine pigment particles, which are much smaller than what is found in standard water-based inks. The smaller size of the nano particulates allow them to penetrate deeper into the substrate, which leads to the greater detail and smoother gradients, according to Poulin.

Landa offers its NanoInk, part of the Nanographic Printing process, which operates similarly. “Unlike traditional water-based inks, which rely on absorption into the substrate, NanoInk contains ultra-small pigment particles measured in tens of nanometers. These tiny pigments allow for extremely thin ink layers while maintaining high optical density. This means that Nanographic Printing achieves a very wide array of colors and sharp details with far less ink usage

Nerf shares key strategies Canon implements to improve media company that include optimized ink technology with its water-based pigment inks and ColorGrip technology; advanced media handling systems including automated paper path adjustment, media detection, and profile optimization; and development of new media trough collaborations with paper manufacturers and certification programs.

Fujifilm continues to develop and refine its ink sets to work well with media manufacturers’ newest paper types and finishes. “Innovations in our ink formulations help improve adhesion and dry times, which allows for better compatibility with coated and uncoated stocks, recycled papers, and other specialty papers,” explains Poulin.

The research involved with ink development may also include priming technology. Fujifilm’s water-based VIVIDIA ink technology includes Rapid Coagulation Primer (RCP). “RCP involves applying a

than other digital or conventional printing methods. Because the pigments are so small, they provide an exceptionally wide color gamut and excellent light-scattering properties, ensuring high color vibrancy and consistency across prints,” explains Amir Shalev, market development director, Landa.

Distinct to Nanographic Printing is the unique ink transfer process, which eliminates the issues associated with drying and absorption seen in traditional water-based inkjet printing.

“Instead of applying ink directly onto the paper—where water absorption can lead to paper swelling, slower drying times, and potential substrate limitations—NanoInk is first jetted onto a heated blanket. The water content evaporates before the ink is transferred to the final substrate in a dry, ultra-thin layer,” shares Shalev.

The result is a range of substrates can be printed to, including coated and uncoated papers, plastics, and folding cartons—without the need for pretreatment or special coatings.

Since NanoInk does not soak into the substrate but rather forms a smooth, bonded layer on top; it maintains the original texture and finish of the material, preserving the premium look and feel required in many packaging and commercial print applications, adds Shalev.

primer coating to the media before the actual printing process begins. The primer helps to rapidly set the ink upon contact, ensuring better adhesion and reducing ink bleed. This not only improves print quality on a wider range of substrates but also enhances the durability and vibrancy of the printed images,” says Poulin.

Landa’s proprietary Nanograhic Printing process, based on Landa NanoInk, has developed overtime to not only allow excellent media compatibility on a wide array of paper/paperboard media—but without needing any sort of pretreatment.

Also, eliminating the use of primers and pre-coatings, “by formulating SCREEN Truepress SC inks, SCREEN is setting the stage for printers to avoid having to apply primer or digital additives to standard coated offset stocks,” shares Schlimme.

Similarly, Komori continues to improve on its UV cutsheet technology in the B2+ space. The new ink set designed

to run in the J-throne 29 works with most substrates without using pre-coating.

“Konica Minolta’s UV ink set allows us to print on virtually any paper-based stock within the size and weight range of the press. We continue to test and improve our ink set for more exotic stocks such as synthetic stocks used in point of purchase and point of sale applications,” shares Riecke.

Vendors focus on improving media compatibility no matter the technology or ink set used on their devices. Many vendors’ goals surround improving their technology to print onto paper-based materials without pretreatments or coatings, while others look to push the limits and create vibrant prints directly onto synthetic stocks. Cutsheet inkjet technologies are one of the many pillars of the digital print industry where innovation leads to real possibility. dps

By Signif1cansAutomation �-

With errors cut by 90%, proofing time by 95%, throughput increased from 150 to 400 orders per day, and an estimated $250,000 yearly savings in labor, Stickerbeat is better poised for future success.

Stickerbeat, a Toronto, ON-based web-toprint business with 40 employees, was founded in 2016 by Carmine Caravaggio. In 2021 its sales reached $1.5 million (USD). In 2022, that number increased to $2.5 million, then it grew to $5.1 million in 2023, and $7.3 million in 2024. It's on track to reach $9 to $11 million in sales this year! Stickerbeat specializes in custom stickers, magnets, labels, and decals. Most importantly, the company offers a seamless online ordering process, free online proofing, and fast turnaround times. But it wasn't always that way.

In 2021, it was processing over 120 orders per day that usually resulted in over 250 individual products with their own complex production requirements. However, errors and production delays were increasing. Something had to be done. So, in 2021, the Significans Automation team, led by Sean Davis, VP of technology, partnered with Stickerbeat's production team, led by Bruce Petroff, corporate production control manager and analyst.

Significans' strategy saw the first North American deployment of its S-Launch solution, which included a dynamic, fullycustomizable 'Form Builder'. Businesses can do whatever they want with it-create a contact form, an order-submission portal, arequest-for-quote page, and more.

''At first, Stickerbeat was mostly all manual in terms of operations, and had

no automation software," Davis recalled. "Zendesk, a support ticketing system for IT, was being used as their MIS to track orders. Dropbox was used as their production server. Google Sheets were used to further track production in-house, based on the orders they were tracking in Zendesk. However; therewere ongoing issues that included constant dropping of orders, and accidental editing of Google Sheets."

In Stage 1, Significans used Enfocus Switch to build an end-to-end, 100% hands-off e-commerce platform that automatically onboards and processes new orders. "Their Canadian and U.S. sites were running offShopify;' said Davis. "The new; customized solution automatically processed new orders from Shopify, downloaded customer-supplied items within that order, pre-flighted them to make sure the files were error-free, then generated an online proof that was sent to the customer for approval."

Stage 2 involved automating Stickerbeat's incoming telephone orders. The

human touchpoints, faster; accurate shipping, and happier; more loyal clients and repeatcustomers.Allthiscollaborationhas helped to radically transform the company.

"With our current four employees in prepress, we could easily achieve $20 million dollars in yearly sales without adding more staff," said Petroff. "If we didn't have this highly customized set-up from Significans, I would likely have to spend another $250,000in laborjust to do what we were doing before. We can now generate a proofwithin 40 seconds ofan order arriving. Proofing times have been cut by Significans team set up an ultra-efficient 95% and costly human errors have been 'backdoor' ordering system, built using SLaunch. Now; when employees receive a phoneorder; theytypethe information into a customized electronic form, upload the files, then follow the same procedure used to process Stickerbeat's online orders from Shopify.

Stage 3 built an automated process to create UPS shipping labels-no manual typing of addresses. The result? Fewer

reduced about 90%. My ultimate goal is to be able to locate any job in seconds, know exactly where it is in our workflow; and access every detail about it with the click ofa mouse."

For more information on Stickerbeat, call 647-248-1676 or visit stickerbeat. com. For more information about Significans, please call 877-463-4465 or visit significans.com. dps

The configuration options available in toner-based production print lineups are also attractive to many PSPs.

Production toner presses offer support of inline finishing solutions. “These modules can help provide increased efficiency and reduce the additional labor costs and time associated with offline finishing, as well as support customers in their efforts to shorten turnaround times,” says Barbera.

For smaller PSPs and in-plants with lower print volumes and limited real estate, Vecci points out that toner-based systems are accessible and available in a range of configurations.

Food safety and sustainability considerations also come into play.

Van Gaever says that a unique advantage of Xeikon dry toner printing is its food-safe approval, making it suitable for applications that require direct or indirect food contact. “Unlike some other print technologies, dry toner formulations meet stringent regulatory standards, allowing them to be used for food packaging, labels, and even customized short-run packaging solutions for e.g. paper-based mono

2. Xerox strives to lead the way in “Beyond CMYK” innovation, most notably with its Xerox Iridesse Production Press, which supports up to six inline color stations.

layer construction food packaging. This added benefit further enhances its appeal for brands looking for safe, high-quality, and visually striking print solutions on the shelves,” he explains.

Increased automation, personalization, improved sustainability, and additional color capabilities are top toner trends.

Customers should expect to see continual advancements designed to help drive higher levels of productivity. Technologies that focus on keeping a press running include reliability, repeatability, and automation innovations that are becoming more critical as environments struggle to identify trained operators, notes Barbera.

“Increased automation is gaining momentum, both in terms of reducing manual tasks and integrating toner-based production printing with automated workflows. Additionally, artificial intelligence and machine learning to enhance quality, improve efficiency, and reduce human error, are on the rise,” shares Albano.

Demand for more personalization and variable data printing continues. “Toner-based solutions are highly effective for these types of printing applications,

making them ideal for commercial print shops and use in direct mail marketing campaigns,” offers Albano.

Print servers such as PRISMAsync help to automate many routine operator level tasks and new cloud-driven ‘press tools’ provide valuable data insight to help operations manage and track their print output. “Canon’s Smart Print Room leverages these various advancements to help customers drive increased levels of productivity and insight into their printer utilization,” says Barbera.

Albano adds that demand for sustainable solutions sparks trends towards eco-friendly toner formulations, lower energy consumption, and reduced waste in production environments.

The adoption of fifth or sixth color stations is growing, enabling PSPs to offer customers more possibilities. “Specialty colors add impact and appeal to print, create premium effects, and accentuate designs,” offers Vecci.

Van Gaever points out that when it comes to dry toner production printing, the future is shaped by technological advancements with hundreds of patents and increasing sustainability considerations. “Key trends we see are higher speeds and productivity complemented with intelligent automation; implementation of dry toner printing in hybrid workflows and complementary deployment in offset and inkjet environments; continued expansion of substrates for a wider range of end-use applications; further development of sustainability initiatives driving legislation for reduced environmental impact; and continued development of extended color capabilities and special effects.”

Print providers are always looking for ways to expand their application range and offer high-value print services. “We are finding near-line embellishment solutions provide customers with a higher level of flexibility and options to help

them enhance and expand their range of print applications,” says Barbera.

Kent J. Villarreal, senior product manager, Production Print, Sharp Electronics Corporation, feels that as the production toner market continues to evolve, one of the most significant trends on the horizon is the expansion of inline and near-line embellishments. “The four-color printing market has become increasingly commoditized, making differentiation more critical than ever. To stay competitive, print providers are seeking ways to add value beyond standard CMYK printing.”

The addition of specialty colors and fifth and sixth print stations are a game changer, allowing printers to differentiate their offerings. “Printers are leveraging these enhancements to offer unique, premium-quality prints that command higher margins,” says Raab.

“This introduces new toners such as pink, white, clear, as well as metallics like gold and silver—allowing for more versatile and creative applications, with the ability to add highlights, create textures, or print on dark-colored or transparent materials,” agrees Albano.

This expanded capability opens up new markets for packaging, label printing, and more advanced, luxurious looking marketing collateral, and is “boosting adoption among print shops that want to differentiate themselves with unique products,” comments Albano.

“These solutions enhance the value of toner presses, allowing PSPs to offer more higher value applications, create more differentiation in the market, and increase their profitability,” agrees Vecci.

The integration of specialty colors and additional channels is driving new

growth opportunities, enabling PSPs to produce striking, high-margin applications. “These advancements not only enhance the visual appeal of printed materials but also help businesses stand out in a crowded marketplace,” adds Villarreal.

Vecci points out that additional color stations also open up more substrate possibilities. “With white toner as an underlay, it becomes possible to print vibrant images and text on dark and colored papers or to create dramatic effects with high-end appeal. “Embellishments become easy with metallic toners such as gold and silver, and one can even create different shades of metallic such as rose gold and silver blue. And clear toner allows spot varnish effects, adding further value to prints.”

Even though dry toner is a mature technology, Van Gaever says that with

While color production printing receives deserved attention, Andrew Vecci, director, portfolio and product management, Ricoh USA, Inc., says there is still a strong need for monochrome toner systems in the market, particularly in transactional, educational, and legal industries. “Ricoh continues to develop monochrome production engines to serve these customers where productivity and text and image clarity are paramount.”

The biggest advances in B&W toner-based devices have been in speed and efficiency. “These systems deliver crisp, sharp text and graphics at a higher volume and lower operational cost and are now equipped with advanced feeding and finishing options, such as booklet making or inline folding, to streamline workflows and reduce the need for post-production processes,” shares Paul Albano, senior manager, product marketing, Toner Press Solutions, Fujifilm.

Canon also continues to invest in the development of its monochrome production presses including the high-speed varioPRINT 6000 series TITAN and varioPRINT 140 series QUARTZ. Last year Canon introduced the varioPRINT 6000TPxp TITAN model. “This is designed to provide increased print durability, which is especially important for transactional and direct mail print providers,” shares Robert Barbera, director, Production Printing Solutions Strategy, Canon U.S.A., Inc.

Canon’s Speed Pass Program provides flexible speed licensing to help customers manage peak production and the cost of their investment. “Customers can purchase a lower speed model that supports the majority of their business and then purchase a temporary speed upgrade to help with peak production periods.

expanded color capabilities and unique embellishment options, dry toner printing continues to bridge the gap between traditional and digital printing. “It provides high-value, short-to-medium-run print solutions that stand out. We believe dry toner offers a wide range of end-use

They can also upgrade permanently in the future as production demands grow or change providing customers with added flexibility in matching their existing equipment to their business needs,” explains Barbera.

The Konica Minolta AccurioPrint 2100 B&W digital printing press features speeds of up to 100 pages per minute (ppm) of B&W output, high paper and toner capacity, and a standard built-in print controller. Its compact footprint makes it suitable for production environments as well as an office with high-volume printing needs.

Sharp’s BP-1360M monochrome production printer is designed for high-speed, high-quality output. With printing speeds of up to of 136 ppm and 2,400x2,400 dpi resolution, it is designed to deliver sharp solids and smooth halftones. Features include airfed vacuum technology for precise media handling and a modern control panel for effortless operation.

Further, Sharp’s BP-1360M is driven by a Fiery controller that enhances workflows, enabling advanced job management, and provides seamless integration with color devices like Sharp’s Color Pro series.

B&W production remains a cornerstone of transactional, book, and direct mail printing. The Xerox PrimeLink series continues to set the standard with high resolution, superior halftone rendering, and high-speed production capabilities. Innovations in automated finishing and workflow integration have also streamlined largescale monochrome print runs, improving productivity for high-volume print environments.

applications covering the needs of brand owners and PSPs. Thanks to extra colors like green, blue, and red the already wide gamut can be expanded, but also white and fluorescent offer unlimited creativity and technical combinations. And finally specialty toners like clear, metallic, and

See page 27 for more information.

security in combination with variable printing of digital provide access to applications that are out of scope for traditional technologies.”

Toner-based production is a mature technology that continues to expand its appeal with options for white, metallic, fluorescent, and clear toners that enable premium, high-value print products.

“As the industry continues to push boundaries, we anticipate further innovation in toner-based embellishments, offering printers greater flexibility and profitability,” notes Villarreal.

Find a webinar on the topic of production toner advancements online at dpsmagazine.com/webinars. dps COMPANIES