LaurysenKitchens

Growing a Dealer Network

DO YOU HAVE A RECOGNITION PROGRAM THAT TRULY REFLECTS YOUR VALUES?

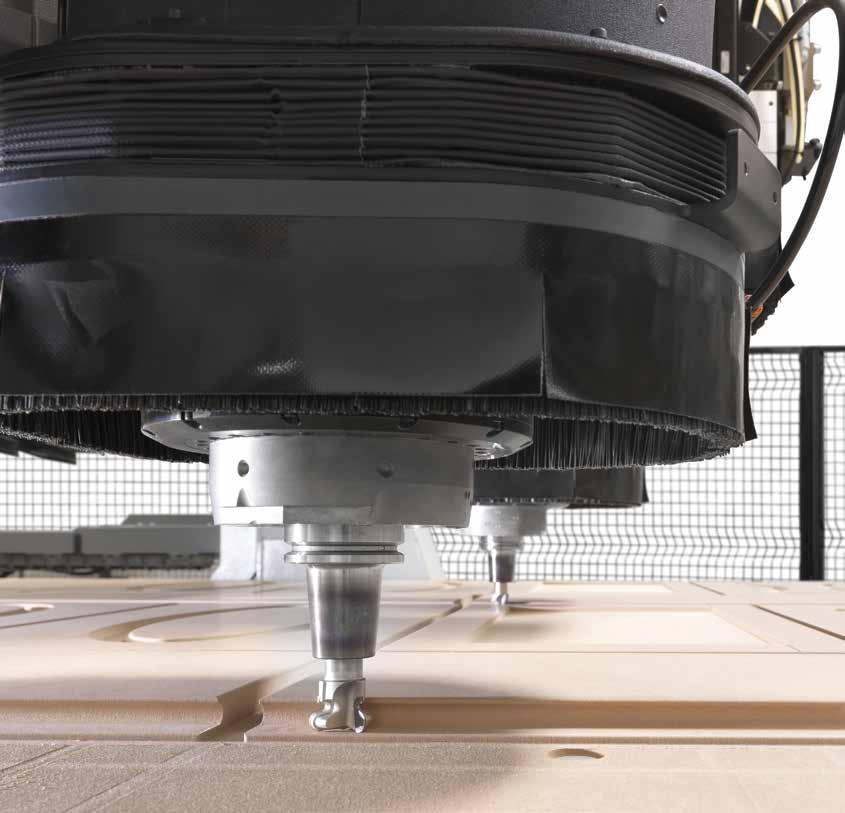

Robotics & Sorting Technology FEEDBOT D-310 & DRILLTEQ V-310

FEEDBOT D-310 & DRILLTEQ V-310

The CNC processing center with robot support forms one of the smallest possible cells of the furniture production. In this combination, the FEEDBOT D-310 increases your overall productivity. It does not have to take a break, can work around the clock on the shop floor and ensures consistently high quality. Small and medium-sized companies save a lot of time by using the robot integration FEEDBOT D-310 and reduce the workload for their staff. The resulting flexible manpower organization allows your workforce to be used more for value-added activities and production processes.

Armony robotic cell with ORRA tooling and intelligence.

Unload of a HOMAG nesting router & load/unload of a HOMAG dowel inserter.

AUTOMATECH ROBOTIK

• Fast 4-axis robot with multipick capabilities to pick up to 4 parts at the same time

• Direct interfacing with the CNC outfeed conveyor from HOMAG

• Vision system to detect part shapes following the machine’s push sequence

• Dowelling directly in the robotic cell on a DRILLTEQ

• Automated outfeed of parts to the edgebander operator

• Automatic management of off-cuts and scraps

• Automatic data feeding and processing from CAD/CAM casegood solution software Unveil your untapped manufacturing potential with Automatech Robotik solutions.

DRILLTEQ V-310

FEEDBOT D-310

AUTOMATECH ROBOTIK CELL

feature stories

28 BEYOND THE BOX

Laurysen Kitchens expands through a selective dealer network, blending traditional craftsmanship with modern CRM systems. Their balanced B2B model ensures market growth while maintaining quality and service excellence.

14

ECO-FRIENDLY, SUSTAINABLE, AND DISASTER-RESILIENT

Smart prefab homes are revolutionizing housing. Jayden Campbell highlights energy-efficient materials, solar power, and disaster-resistant designs that make modular housing a sustainable, future-proof solution.

20

SCHNEIDER’S MILLWORK AND KONSTRUX PRO

Schneider’s Millwork streamlined operations with Konstrux Pro, a project management software designed for trades. The cost-effective platform integrates estimating, job tracking, and purchasing, improving efficiency for small-to-mid-sized businesses.

38

A RECOGNITION PROGRAM THAT REFLECTS YOUR VALUES?

Sunrise Kitchens embeds employee recognition into company culture. This peer-driven program fosters engagement, workplace appreciation, and deeper team connections.

42

INSIDE THE FUTURE OF CABINET MANUFACTURING

Muskoka Cabinets integrates automation, RFID tracking, and ERP systems while preserving craftsmanship. Chris Leonard explores how they’re setting new industry benchmarks in efficiency and innovation.

IMPROVEMENT REQUIRES ANALYSIS

Hello Industry Partners, Spring is a time of renewal and change, and in this issue of Wood Industry, we explore how Canadian manufacturers and associations are embracing innovation to improve efficiency, sustainability, and engagement. From dealer networks and digital transformation to smart technology and employee recognition, this edition highlights the strategies shaping the future of wood manufacturing.

Wood Industry is also embracing change with a fresh new look. This evolution is guided by our dedicated team of design and production professionals, who work to keep us aligned with modern aesthetics and functionality. Their commitment and expertise ensures that Wood Industry reflects the same innovation and forward thinking that drives the manufacturers we feature.

Laurysen Kitchens has mastered the art of dealer networking. Leveraging software like modern CRM systems to aid in communication and organization supports their approach to creating and maintaining strong partnerships. Meanwhile, Schneider’s Millwork has been streamlining operations by developing KonstruxPro, a custom-built project management software that simplifies estimating, job tracking, and communication—helping small-to-mid-sized trades businesses modernize without breaking the bank.

Recognition in the workplace goes beyond rewards—it’s about embedding appreciation into company culture and fostering meaningful connections. In Do You Have a Recognition Program That Truly Reflects Your Values?, Amrita Bhogal, People and Culture Leader at Sunrise Kitchens, shares how organizations can shift from top-down acknowledgment to a more inclusive, peer-driven approach that strengthens engagement and aligns recognition with company values.

Manufacturers across Canada are navigating an evolving industry, and Muskoka Cabinets offers a case study in advanced manufacturing as a competitive advantage. Chris Leonard explores how its use of automation, RFID tracking, and ERP integration aligns with the CKCA Advanced Manufacturing Peer Group’s mission to help Canadian manufacturers boost efficiency, profitability, and resilience in a global market.

Jayden Campbell, Product Manager at Akhurst Machinery, takes us into the future of sustainable construction in Eco-Friendly, Sustainable, and Disaster-Resilient: The Future Role of Smart Technology in Prefabricated Homes. From energy-efficient designs to disaster-resistant materials, prefabrication is shaping the next generation of homebuilding.

In Effective Creative Strategies and Campaigns, Linda Farha, founder and president of Zenergy Communications, shares expert insights on how manufacturers can use storytelling, audience segmentation, and digital engagement to strengthen customer connections and build brand loyalty.

By embracing innovation while staying true to craftsmanship and service, manufacturers can thrive in an ever-changing market.

Thank you for reading, and as always, we welcome your feedback and insights.

ART DIRECTOR

PUBLISHER

Jake Blanchard jakeb@mediaedge.ca

EDITOR

Tyler Holt tylerh@mediaedge.ca

PRESIDENT Kevin Brown kevinb@mediaedge.ca

PRODUCTION MANAGER

Ines Louis Inesl@mediaedge.ca

Published by

Annette Carlucci annettec@mediaedge.ca

GRAPHIC DESIGNER

Thuy Huynh-Guinane roxyh@mediaedge.ca

CIRCULATION circulation@mediaedge.ca

Wood Industry is published four times annually, Spring, Summer, Fall, Winter, for the secondary wood products manufacturing and marketing industries in Canada. Subscriptions are free to qualified participants in Canada’s secondary wood processing industry. Subscribe at www.woodindustry.ca. Paid subscriptions rates: $40 to Cana dian addresses, $60 U.S. and foreign, $20 student rate. Please mail payment to Wood Industry, 251 Consumers Road, Suite 1020 Toronto, Ontario M2J 4R3. For subscription inquiries, e-mail circulation@mediaedge.ca

© 2025 by MediaEdge Communications All rights reserved. MediaEdge Communications and Wood Industry disclaim any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect to the results of any action taken or not taken in reliance upon information in this publication. The opinions of the columnists and writers are their own and are in no way influenced by or representative of the opinions of Wood Industry or MediaEdge Communications

Tyler Holt

It all adds up

When it comes to sustainability, every action counts. From renewable materials to smart adjustments along the value chain, AkzoNobel Wood Coatings helps you seize the opportunities to reduce waste, save energy, reduce your carbon footprint, and save costs.

It’s how we support you on the road toward a more sustainable future, every step of the way.

100 Years of Innovation in Industrial Finishing In 2025, Sames celebrates its 100th anniversary, highlighting a century of innovation in paint, adhesive, and sealant application technologies. Founded in 1925 as Kremlin, the company has integrated expertise from Rexson, Sames, and Intec to become a global leader in industrial finishing solutions. Serving industries from automotive and electronics to furniture and agriculture, Sames delivers precision-engineered pumps and applicators that enhance productivity and sustainability. “Reaching 100 years is an incredible milestone,” said CEO Cédric Perres. “This celebration reinforces our commitment to innovation, performance, and environmental responsibility.” With a global presence and a focus on advanced solutions, Sames continues to push industry boundaries, ensuring highquality, efficient, and durable finishing systems for its customers worldwide.

40 Years of Woodworking Machinery Excellence

Cantek America marks 40 years as a leading supplier of solid wood and panel processing machinery for North America. Since 1985, the company has been committed to delivering high-quality, affordable equipment designed to meet the demands of industrial woodworking shops. With a vast parts inventory, in-house financing, and a knowledgeable sales team, Cantek offers tailored solutions that enhance productivity and efficiency. Representatives provide expert guidance on equipment selection, installation, and after-sales support. A nationwide service network ensures fast technical assistance, with remote troubleshooting and on-site repairs available. Cantek’s dedication to quality, value, and innovation has driven its success, earning the loyalty of customers who rely on its reliable machinery and responsive support.

Certification for Sustainable Panels

Uniboard Canada has earned USDA Certified Biobased Product status for its MDF, TFL, and Particleboard, becoming the first North American decorative surfaces manufacturer to achieve this certification. This certification confirms Uniboard’s adherence to USDA’s renewable content standards, highlighting its commitment to sustainability without compromising performance. “Sustainability and innovation go hand in hand,” said Don Raymond, VP of Sales and Marketing. “This milestone reinforces our dedication to high-performance, eco-friendly materials.” The USDA BioPreferred® label positions Uniboard as a leader in responsible manufacturing, offering environmentally conscious engineered wood solutions.

Leadership Promotions to Drive Growth Metrie has announced several leadership promotions across marketing, sales, finance, and strategy to strengthen its long-term growth. Christian MacDonald has been promoted to Chief Marketing Officer after 25 years at Metrie, with Nicole Rocheleau stepping in as VP, Marketing. Kevin Bartel is now VP & GM, US, overseeing operations including EL & EL and Anderco. Jon Dickinson has been named VP, Sales, focusing on sales strategy. Elise Osier will now lead Financial Planning & Analysis as VP, Strategy & Planning, while Kate Vondette has been promoted to VP, Corporate Controller. “These promotions reflect our commitment to leadership development,” said CEO Kent Bowie. “Investing in top talent is key to our long-term success.”

Weinig Holz-Her Canada has named Miguel Abello as its new Account Manager in Ontario, reinforcing its commitment to growth and customer service. With 16 years in industrial machinery and woodworking production, Abello brings expertise in CNC machinery, project management, and technical sales. His background includes field service and a deep understanding of construction materials and equipment. “We are thrilled to have Miguel on board,” said Ken Ellston, Director of Sales and Service. “His knowledge will strengthen our Ontario presence.” Abello will cover the mid-GTA and northern Ontario, supporting customers with expert guidance. His hiring aligns with Weinig Holz-Her’s direct sales model and the company’s expanding showroom featuring 14 operational machines.

AWMAC Names Carolynne Yeomans as National Executive Director The Architectural Woodwork Manufacturers Association of Canada (AWMAC) has appointed Carolynne Yeomans as National Executive Director, effective February 3, 2025. Yeomans brings extensive experience in nonprofit leadership, strategic growth, and industry partnerships, making her well-suited to guide AWMAC’s future direction. She aims to build on AWMAC’s 55-year legacy by advancing the use of its Standards for architectural woodwork, strengthening industry relationships, and promoting quality and sustainability. With a strong background in member-based organizations, she is well-positioned to support AWMAC’s members, chapters, and the broader woodwork manufacturing sector. AWMAC encourages members and industry partners to welcome Yeomans as she leads the organization into its next chapter.

Our K 945S panel saw offers modern design, innovative

The precisely milled, cast iron machine table with a 700 x 840 mm (27 x 33 in) extension on three sides offers more support for large dimensioned workpieces. With the easy to mount circle cutting and sanding units, the new Felder bandsaw is a versatile investment for perfection in woodworking.

The AD 941 planer thicknesser inspires and amazes woodworkers all over the world. Perfectly planed surfaces, maximum reliability and userfriendliness that is in a class of its own and top operating safety.

Our new changeable gluepots increase flexibility giving you the productivity of larger edgebanders. The quick and easy change to other adhesive colours and the use of PUR glue guarantee productive procedures and excellent edges for all areas of application.

Audra Denny Appointed President of the Wood Manufacturing Council The Wood Manufacturing Council (WMC) has named Audra Denny as its new president. WMC, a national human resources organization, supports Canada’s advanced wood processing sector by working with industry leaders, educators, and government bodies. WMC focuses on workforce development, addressing skills gaps, labor shortages, and evolving market demands. It provides HR solutions, training programs, and industry initiatives to ensure long-term growth and sustainability. Denny’s leadership comes at a critical time as the industry adapts to technological advancements and workforce challenges. Her appointment reinforces WMC’s commitment to strengthening HR strategies, developing talent, and enhancing competitiveness within Canada’s wood manufacturing sector.

Dorel Appoints Troy Franks as CEO, Restructures Home Segment

Dorel Industries has named Troy Franks as CEO of Dorel Home amid a major restructuring. Franks, a 16-year company veteran, returns after a year away, replacing retiring CEO Norman Braunstein. The restructuring includes closing Dorel’s Montreal manufacturing plant by Q1 2025 and consolidating production at its Cornwall, Ontario facility following the Tiffin, Ohio plant closure. The company has also downsized its non-manufacturing workforce by 30%, incurring US$4 million in severance costs. Dorel is reducing SKU offerings and shrinking its U.S. warehousing footprint by 1.2 million square feet. These measures aim to boost earnings by up to US$40 million by 2026. Under Franks, Dorel Home will strengthen retail partnerships, enhance manufacturing efficiency, and focus on high-margin imported products.

Norwood Sawmills Opens Interactive Showroom in Barrie, Ontario Norwood Sawmills has launched a new interactive showroom at 35 Reid Drive in Barrie, Ontario, showcasing the latest advancements in portable sawmill technology. The showroom features Norwood’s full range of sawmills, forestry tools, and patented Sawyer Assist technologies. Visitors can explore highcapacity hydraulic sawmills for industrial use, entry-level models for hobbyists, and industryleading sawmill blades like the Sabretooth series, StelliCut, and Apex Carbide. Forestry tools, log harvesting equipment, and heavy-duty chippers are also on display. As Norwood’s global headquarters, the Barrie location reinforces the company’s 30-year legacy of innovation in sawmilling. Woodworkers, sawyers, and industry professionals are invited to visit and experience Norwood’s commitment to quality and ingenuity firsthand.

ADENTRA Announces Leadership Changes, Names New COO and Board

Members ADENTRA Inc. has announced key leadership changes, including the retirement of founding director Graham Wilson, two new board appointments, and the promotion of Drew Dickinson to Chief Operating Officer (COO). Wilson, a board member since ADENTRA’s IPO 20 years ago, retired on January 8, 2025. Rob Taylor, a director since 2019, is now Chair of the Board. New board members Marie Robinson and Richard Roy bring expertise in supply chain management, finance, and mergers and acquisitions, supporting ADENTRA’s Destination 2028 growth plan. Dickinson, formerly President of Rugby Architectural Building Products and ADENTRA’s U.S. Industrial business, will oversee operations across 86 facilities in North America. His leadership will drive operational excellence and growth initiatives as the company advances toward its US$3.5 billion revenue goal.

We deliver customized finishing solutions.

Dr. Thomas Troeger Appointed CEO of REHAU Interior Solutions Thomas Troeger, former CEO of REHAU Americas, has been named CEO of REHAU Interior Solutions, succeeding Juergen Werner, who stepped down after 30 years. Werner will remain involved as Chairman of the Interior Solutions Supervisory Board. With 18 years at REHAU, Troeger aims to drive international growth, enhance customer focus, and solidify the company’s leadership in edge banding and furniture components. “I am excited to lead REHAU Interior Solutions into a promising future,” he said. REHAU Interior Solutions operates in 60 countries with 3,200 employees and nine manufacturing facilities. Under Troeger’s leadership, the company plans to expand its decorative surface offerings and reinforce its reputation for quality and innovation in the furniture industry.

Tafisa Canada Names Gino Lévesque as New CEO Tafisa Canada has appointed Gino Lévesque as its new Chief Executive Officer, effective March 1, 2025. He succeeds Louis Brassard, who served as CEO for over 22 years and will continue as a Special Advisor and Board Member. Lévesque, joining Tafisa on January 20 for a transition period, brings over 35 years of leadership experience in manufacturing industries, including pulp and paper, steel, aluminum, and mining. He previously served as Senior VP of Containerboard and Packaging at Kruger Packaging Group. “We are confident that Mr. Lévesque’s expertise and vision will guide Tafisa Canada into its next phase of growth,” said Miguel Gil Mata, CEO of Sonae Capital Industrials. His appointment reinforces Tafisa’s commitment to innovation and industry leadership.

Eric Marshall Joins NKBA Global Connect as Advisor The National Kitchen & Bath Association (NKBA) has appointed Eric Marshall as a Global Connect Advisor, bringing his expertise in storage and organization to the international business development program. NKBA’s Global Connect initiative helps manufacturers navigate the North American kitchen and bath market. With over 55,000 members, it provides insights, distribution guidance, and strategic connections. “Eric’s deep knowledge of storage systems will offer valuable insights to our members,” said Geraldine Morrison, NKBA’s Chief Partnerships Officer. Marshall, co-founder of the Closet Training Institute, has decades of experience in custom cabinetry and closet organization. A former ACSP president, he has trained industry professionals worldwide. His appointment reinforces NKBA’s commitment to fostering innovation and supporting brands entering the North American market.

Gary LeBlanc of Richelieu Named KCMA’s 2024 Person of the Year

The Kitchen Cabinet Manufacturers Association (KCMA) has honored Gary LeBlanc of Richelieu as its 2024 Person of the Year, recognizing his significant contributions to the cabinet industry. The award was announced at KCMA’s Fall Conference in Harrisburg. LeBlanc’s career spans decades, with leadership roles at Grass America and Richelieu. His expertise in product development, operational efficiency, and client relationships has strengthened both his organizations and the broader cabinet manufacturing sector. This recognition highlights LeBlanc’s lasting impact on the industry and his role in driving innovation and growth. His strategic leadership continues to shape the future of cabinet manufacturing.

Lightbeans

CEO Philippe Hébert Named to Forbes 30 Under 30 Philippe Hébert, CEO and cofounder of Lightbeans, has been named to Forbes’ 2025 30 Under 30 list in the Manufacturing & Industry category. The honor recognizes his leadership in transforming architectural material selection with digital technology. At 28, Hébert has led Lightbeans to become North America’s largest manufacturer-specific 3D texture library, reducing reliance on physical samples and lowering the construction industry’s carbon footprint. Since its founding in 2018, the Quebec City-based company has grown to support 9,000 architects and designers, with plans to exceed 10,000 users by the end of 2024. “Forbes’ recognition is a testament to our team’s hard work and commitment to sustainability,” Hébert said. Lightbeans has also secured $1.6 million in government grants, underscoring its industry impact and growth potential.

Kasia Robinson Appointed National GIS Program Manager at AWMAC The Architectural Woodwork Manufacturers Association of Canada (AWMAC) has named Kasia Robinson as National GIS Program Manager, overseeing the Guarantee and Inspection Service (GIS) Program. This initiative ensures high-quality architectural woodwork across Canada. Robinson will coordinate GIS projects, mentor certified inspectors, manage program performance, and lead improvements. She will also oversee escalated project issues, event promotions, and reporting to AWMAC leadership. With decades of experience in architectural woodworking, Robinson previously served as AWMAC Saskatchewan’s Chapter Manager and co-owned LINN Millwork Company. Her expertise in North American Architectural Woodwork Standards (NAAWS) and business operations makes her well-suited for this role.AWMAC welcomes Robinson’s leadership as she strengthens the GIS Program and upholds the association’s commitment to excellence.

ECO-FRIENDLY, SUSTAINABLE, AND DISASTER-RESILIENT

The Future Role of Smart Technology in Prefabricated Homes

:: By Jayden Campbell, Product Manager, Akhurst Machinery

As North America faces a housing crisis, trailblazing companies are rising to meet growing housing demands while promoting environmental and economic sustainability. Confronted with the challenges of unpredictable natural disasters and rapid population growth, the housing sector is increasingly adopting sustainable, energy-efficient, and innovative practices. Prefabricated (prefab) homes—built in factories and assembled on-site—offer a practical solution, providing affordable, eco-friendly housing tailored to the needs of expanding urban populations. With a blend of sustainable materials, smart energy systems, and disaster-resistant designs, prefab homes are shaping a more economic and sustainable future.

SUSTAINABILITY IN PREFABRICATED CONSTRUCTION

Prefab construction has rapidly gained attention as a sustainable alternative to traditional building methods. Sustainability is not just a trend; it’s a necessity in construction. Traditional methods often produce significant waste due to on-site material excess and inefficient processes. Prefabri-

cated homes, however, are built with precision and consistency in controlled factory environments, significantly reducing construction waste and contributing to an eco-friendly building model.

Reduced Waste: Prefabrication uses exact material quantities based on digital models, minimizing leftover scraps.

In conventional construction, waste from materials like wood, steel, and concrete can account for up to 30% of the resources used. In contrast, prefab construction’s efficient approach can lower waste by up to 90%, as excess material can be reused in other projects or recycled more effectively.

Sustainable Materials: One of the primary materials gaining popularity in sustainable prefab construction is Cross-Laminated Timber (CLT). CLT is a robust, renewable wood product with a low carbon footprint sourced from responsibly managed forests. Not only does CLT sequester carbon (acting as a carbon sink), but it also provides structural durability comparable to steel and

“With smart energy systems, disaster-resistant materials, and modular designs, prefab homes are emerging as a lasting trend— providing reduced waste, lower energy consumption, and adaptability to evolving environmental standards.”

concrete, enabling its use in multi-story buildings.

Energy Efficiency and Prefab Construction: Factory-controlled environments allow for precise construction and integration of energy-efficient materials and designs. High-quality insulation, airtight seals, and advanced materials can be incorporated into prefab designs with minimal variation, ensuring high energy efficiency in every build. This combination reduces the home’s heating and cooling needs, reducing energy consumption and emissions over time.

ENERGY EFFICIENCY AND SMART PREFAB HOMES

Energy-efficient homes have become essential as energy demands and costs continue to rise. Smart prefab homes integrate the latest technologies to optimize energy usage, creating more comfortable living spaces while minimizing environmental impact. These buildings offer intelligent, automated systems that adapt to homeowners’ needs, and most come equipped with renewable energy features.

Solar Panels and Energy Storage: Many prefab homes are designed to incorporate solar panels that harness clean energy from the sun, reducing dependence on fossil fuels. Paired with energy storage systems like lithium-ion batteries, these homes can store excess energy produced during peak sun hours for later use. This allows prefab homes to function as microgrids, reducing reliance on traditional energy sources and contributing to a more decentralized, flexible energy grid.

Save time with PEANUT® 3, our single-component invisible connector for large-scale manufacturers. 100% hidden, it assembles cabinets in seconds without clamping or glue, boosting efficiency and reducing costs.

Water Conservation: Smart prefab homes can also incorporate water-saving technologies, such as low-flow fixtures, greywater recycling, and rainwater harvesting systems. These systems enable sustainable water use, reducing the home’s overall environmental impact, especially in water-scarce regions. As water availability becomes increasingly uncertain, such technologies become crucial components of sustainable housing.

Smart Home Systems and Energy Monitoring: Smart technology in prefab homes extends beyond traditional energy-efficient upgrades to include smart

energy systems. Homeowners can monitor and control their energy usage using devices and apps in real time. Smart lighting, automated shading, and energy-efficient appliances are all managed through integrated systems that respond to occupants’ needs, helping to cut down on unnecessary energy expenditure.

Advanced Insulation and HVAC Systems: Insulation is crucial for regulating indoor temperatures and reducing the need for heating and cooling. Smart prefab homes often utilize advanced insulation materials and techniques, such as rigid foam or spray insulation, which provide superior thermal resistance. Additionally, integrated with smart ther-

mostats, high-efficiency HVAC systems enable homes to adjust heating and cooling based on occupancy patterns and outdoor temperatures, further reducing energy consumption.

DISASTER-RESILIENT PREFABRICATED HOMES

The increasing frequency of natural disasters in different parts of North America has emphasized the need for disaster-resilient housing. With their controlled, precise manufacturing process, prefabricated homes offer significant advantages in this area. Built to strict standards, these homes can incorporate materials and designs that help them withstand extreme weather conditions, making them suitable for regions prone to hurricanes, earthquakes, floods, and other climate risks.

Hurricane-Resistant Design: Prefab homes are increasingly designed to withstand high wind speeds and heavy rain in hurricane-prone areas. These homes are fortified against intense storms by using materials such as steel-reinforced concrete and impact-resistant windows. Additionally, the modular design of prefab homes allows for the customization of structural elements, like reinforced roofs and walls, which enhances the home’s ability to endure hurricane-force winds.

Earthquake Resilience: Prefabricated homes are well-suited to earthquake-prone regions, as their modular components can be designed to flex slightly and absorb seismic forces. With its strong yet flexible structure, the use of CLT is particularly advantageous in such regions. Also, prefab homes often feature bolted connections and flexible joints, enabling the structure to move

“In conventional construction, waste from materials like wood, steel, and concrete can account for up to 30% of resources used.”

TOP: MBA X-Fill – Equipped with X-Floc Insulation blowing system using cellulose, an eco-friendly insulation BOTTOM: MBA X-Storage – Vertical storage line with finished wall panels using fireresistant materials

with seismic waves rather than breaking under stress.

Flood-Resistant Features: Floods are one of the most common and damaging natural disasters, especially in coastal areas, so flood-resistant prefab homes are gaining attention. Prefabricated homes can be elevated on stilts or raised foundations to avoid water intrusion during floods. Waterproof materials, specialized drainage systems, and raised electrical systems further equip these homes to withstand flood damage, protecting both the home and its occupants from water-related hazards.

Fire-Resistant Materials: In regions susceptible to wildfires, prefab homes can incorporate fire-resistant materials, such as non-combustible siding and metal roofing, which prevent flames from spreading. These homes can also include defensible space designs and

materials like fire-resistant insulation and glass to reduce the likelihood of ignition. Some prefab designs even feature automated fire suppression systems, providing an additional layer of safety.

THE FUTURE OF PREFAB HOMES

The next generation of prefabricated homes merges sustainability and energy efficiency, offering a forward-looking solution for eco-friendly housing. By using sustainable materials, smart energy systems, and disaster-resistant designs, factory-produced homes are emerging as a lasting trend, providing reduced waste, lower energy consumption, and adaptability to evolving environmental standards. As the industry innovates, prefab homes are on track to become

a cornerstone of sustainable housing, meeting environmental responsibility and climate adaptation needs. Partnerships, like those between Akhurst Machinery and Modular Building Automation (MBA), are advancing this transformation, promising a more efficient, cost-effective, and sustainable construction landscape. By adopting these practices, companies nationwide can help cities meet housing demands while promoting long-term environmental and economic sustainability, shaping a more resilient future.

Stay tuned for our next article – Revolutionizing Construction: Prefabrication in Healthcare, Education, and Urban Development.

Jayden Campbell is a dedicated Product Manager at Akhurst Machinery, where he leverages his industry expertise to drive product innovation and streamline operations. With a passion for machinery and technology, he is committed to delivery solutions that empower clients and support Akhurst Machinery’s growth in the industry.

HOLZ-HER TECTRA 6120

High Performance Panel Saw

TECTRA 6120 KEY FEATURES

• Saw Blade Protrusion: 95 mm max

• Sawing Unit: 15 kW max

• Cutting Lengths: 4,400 mm max

• Cutting Widths: 4,300 mm max

WEINIG HOLZ-HER CANADA

4317 Autoroute des Laurentides E, Laval QC H7L 5W5 210 Brunel Road (Unit 4), Mississauga ON L4Z 1X2

Phone:

FELDER GROUP CANADA

Machines + Tools for woodworking

FORMAT 4 EDGEBANDER

FELDER INDUSTRIAL MACHINE RANGE

Faster, greater precision, more powerful and higher yields! Your one-stop shop for productivity solutions, woodworking machinery and software - we leave nothing to chance.

PUR-edge banding without glue pot

Edgebanding needs to be as quick, easy and efficient as possible. To achieve this, the Format4 tempora models combine the core competences of speed, productivity, flexibility and ease of use in a convincing overall package. The final finishing results when processing both coiled and strip material convince with incredibly high standards.

The glueBox makes PUR glue processing easier and more convenient than ever before. Heat and water resistance, a very small glue joint as well as reduced glue consumption - all advantages of the PUR-glue can be used uncompromisingly with the glueBox.

MAYER KAPPA AUTOMATIC 100

Powerful, precise & efficient cutting

Mayer beam saws are well-thoughtout machines with numerous detailed solutions putting every requirement exactly in a nutshell. Each machine type stands for absolute excellence. The more diverse the requirements of the materials to be cut, the more it is the small details that determine the success of the entire process.

With its solid, heavy-duty saws, Mayer focuses on durable quality and first-class machine construction. It is also the full concept that convinces: The heavy-duty construction with steel pressure beam and material pusher, the simple operation even when working alone and maximum process reliability with the modularly structured cutting optimisation program as well as a new software package all guarantee maximum performance and precision in rational panel cutting.

Schneider’s Millwork and Konstrux Pro

Streamlining Operations in the Trades

:: By Joy Doonan, Wood Industry Writer

For Curtis Trann, co-owner of Schneider’s Millwork & Contracting Inc., keeping a millwork business running smoothly means more than just producing high-quality cabinetry—it requires a constant focus on efficiency, organization, and adaptability. When he joined Schneider’s in 2018, the company had a strong reputation, skilled tradespeople, and quality equipment, but like many millwork shops, it relied on outdated processes for tracking projects, managing orders, and coordinating teams. Curtis and his team sought a software solution that would streamline operations without the steep costs of existing options.

What started as an internal fix became Konstrux Pro Software Inc., a project management platform designed not just for Schneider’s, but for any trade that needs an affordable, integrated way to handle estimating, job tracking, and purchasing. Today, Curtis, along with his business partner Ian Osmaston, balance leading Schneider’s Millwork with growing Konstrux Pro, ensuring both businesses continue to evolve with the industry.

HOW IT STARTED

After working as a construction manager in the early 2000s, then as a sales rep and manager at Richelieu Hardware for 14 years, Curtis bought into Schneider’s Millwork & Contracting Inc. in 2018, where he has overseen sales and HR ever since. In 2024, Curtis hired programmer and engineer Ed Gatzke to create project renderings using CabinetVision software. When offered, Ed was initially unwilling to take over the purchasing side of operations because

of the lack of assistive software for that aspect of the business. “Everything was on paper: handwritten point-of-sales, handwritten work orders for the shop, and so on” Curtis explains.

When he started looking for software options, however, he found that they were prohibitively expensive, both in terms of start-up and monthly costs. “I really didn’t see the return on investment to help our company to make that money back,” he says. As a work-around, Ed, who codes as a hobby, decided to write a custom software for Schneider’s Millwork to use in-house.

Curtis recalls, “we got the software to the point where we’re using it and it’s completely integrated into Schneider’s Millwork, connecting our installers back with the office, and we could do receiving of goods in the back on a touchscreen computer that Ed wrote a program for, and we said, you know what, let’s look into turning this into a company.” That was the beginning of Konstrux Pro Software Inc.

KONSTRUX PRO AT SCHNEIDER’S MILLWORK

The shop floor at Schneider’s is 10,000 square feet, featuring a nested-base Hol zer CNC machine, a Holzer edge bander, and two Felder table saws. Curtis adds, “we’ve got a couple of custom benches where the CNC doesn’t really help us. So we’ve got some really skilled guys in the back who can just build anything you want. You give them a drawing and then we’ll put it together.”

Schneider’s employs 14 people, and Konstrux Pro is fully integrated across all aspects of the company’s operations. Estimating & Purchasing: The software tracks material requirements, automat ically generating purchase orders and connecting them to project budgets.

OPPOSITE PAGE: Millwork installed at Conexus Credit Union in Calgary. ABOVE: Photo Credit: Schneider’s Millwork

Time Management & Payroll Integration: Employees log in and out digitally, ensuring accurate labor tracking while eliminating the need for manual payroll management.

On-Site Communication & Documentation: Installers in the field upload real-time progress photos to keep the office connected to the work happening on-site.

Curtis elaborates, “we have spaces within the creative project in the

software where the installers out on site can upload photos of every room they’re finished in.” Communications like these used to have to take place over group text messages, which didn’t always work very smoothly, especially when some crew members had iPhones and others, Androids.

He remembers that when he first joined Schneider’s, the company didn’t even have a website. “So we kind of brought it into the 2010 era,” he says. “Now we’re taking it to the next level.”

VISION FOR KONSTRUX PRO

OUTSIDE THE WOOD INDUSTRY

Although built for Schneider’s Millwork, Konstrux Pro isn’t just a woodworking tool. “It’s built for any trade to use,” Curtis explains. “You can buy anything on the program, and it creates the purchase order. It attaches all the products to the jobs so you get accurate costing. The installers log in to whatever job they’re working on, so it tracks their time and gives us accurate costs.”

The affordability of Konstrux Pro is another advantage. Curtis knew firsthand that small businesses couldn’t afford to pay tens of thousands upfront, let alone high monthly fees. “The $30,000–$40,000 U.S. upfront for a piece of software like this, plus the astronomical fees every month, just didn’t make sense to me,” he says.

“We’re not going to try and market this product to a company with 1,000 employees,” Curtis elaborates. “We’re looking to hit up the Mom and Pop shops, where maybe the children are taking over the business and they’re like, ‘Mom, Dad, why don’t you have any sort of software that’s keeping everything connected?’”

SCHNEIDER’S MILLWORK & AWMAC: COMMITMENT TO QUALITY

While technology has improved efficiency at Schneider’s Millwork, quality craftsmanship and adherence to indus-

try standards remain the company’s foundation. As a long-standing member of the Architectural Woodwork Manufacturers Association of Canada (AWMAC), Schneider’s is committed to meeting the highest standards in commercial millwork.

“We’re proud to be a member,” Curtis says. “It just shows to the consultants and architects in the world that we have a standard, and we will meet the standard with the quality of products we produce.”

Beyond his role at Schneider’s, Curtis Trann also serves as the President of AWMAC Saskatchewan, where he works to advocate for higher industry standards and promote quality assurance in millwork. One of the key challenges he faces is the inconsistent adoption of AWMAC’s Guaranteed Inspection Service (GIS) certification. While many architects reference AWMAC standards in project specifications, some omit GIS inspections, which reduces accountability in millwork projects. Without GIS, manufacturers can only provide a one-year warranty, whereas GIS-certified projects receive a twoyear warranty and undergo rigorous inspections to ensure compliance with AWMAC standards.

To address this challenge and educate industry professionals on the long-term benefits of GIS certification, AWMAC Saskatchewan will be hosting the 2025 AWMAC National Convention in Saskatoon from June 5–7, 2025. The event, themed “Build Networks. Build Knowledge” will bring together manufacturers, architects, and industry leaders to discuss best practices, emerging trends, and the importance of independent inspections in maintaining quality and consistency in millwork.

EMBRACING SMART SOLUTIONS

The combination of traditional craftsmanship and digital efficiency is transforming woodworking. With Schneider’s Millwork leveraging Konstrux Pro

to streamline operations, and AWMAC pushing for higher industry standards, the future is bright for businesses that embrace smart technology solutions.

For small-to-medium-sized businesses in the trades, the lesson is clear: mod-

ernization isn’t just for big corporations. With affordable, accessible software like Konstrux Pro, even family-run shops can take their operations to the next level—without sacrificing quality, transparency, or profitability.

Joy Doonan is a writer from Ottawa. She has a degree in Sociology and a certificate in Technical Writing, and she takes a special interest in small business sustainability.

SELEXX SERIES CNC ROUTERS

High-performance nesting CNC router for maximum output.

The Anderson Selexx Series CNC Router has been developed specifically with higher production CNC router requirements demanding the utmost precision and accuracy, all within a cost-effective investment. The Selexx is the ideal CNC router for nesting applications as it is packed with standard and optional features to maximize output.

Building Trust. Creating Together.

HOUSING STARTS IN CANADA

Q4 2024 and 2025 Outlook

:: By Tyler Holt, Editor of Wood Industry Magazine

Housing starts track the initiation of new residential construction, making them a key economic indicator of the construction sector and the broader economic health of the nation. This report analyses Q4 2024 housing starts in urban centers, compared to Q3 2024 and Q4 2023. The data are broken down into Single-Detached units and All Others (primarily apartments, row housing, and semidetached units) on a seasonally adjusted annualized basis.

In Q4 2024, total housing starts reached 228,403, slightly above the 225,500 reported in Q3 2024 and 226,694 in Q4 2023. Single-Detached starts saw a moderate increase, while “All Others” remained the dominant category despite a small decline compared to Q3 2024. Regionally, Ontario and the Prairies each posted over 60,000 starts, while Québec reached almost 47,000. Atlantic Canada contributes a smaller share but sees consistent development in Nova Scotia and New Brunswick.

Q3 2024 VS. Q4 2024

• Q3 2024: 225,500 total average

• Q4 2024: 228,403 total average

The 2,900-unit increase is modest— about a 1% rise. Single-detached housing grew more than 3,700 units, offsetting a slight decrease in multiunit projects. Possible influences include some construction inputs (e.g., lumber) have moderating since their peaks costs, helping builders manage budgets and new Suburban and edge- of- city land availability spurring rounds of new single - detached projects. The uptick in single- detached construction shows that demand for traditional homes persists, particularly where land is more affordable (e.g., Prairies, smaller Atlantic cities).

“All Others” dipped slightly from 181,155 to 180,348, still representing the majority of total starts. Large multi-unit developments can fluctuate quarter to quarter based on approvals, financing availability, and broader market sentiment.

Q4 2023 VS. Q4 2024

• Q4 2023: 226,694 total (44,938 single-detached; 181,756 all others)

• Q4 2024: 228,403 total (48,055 single-detached; 180,348 all others)

Q3 AND Q4 2024 HOUSING STARTS

HOUSING START JULY-DEC 2023

START JULY-DEC 2024

Figure 1

Figure 2

Figure 3. (All data taken from Statcan)

YEAR-OVER-YEAR, STARTS EDGED UP BY ABOUT

1,700

UNITS—LESS THAN 1% GROWTH

During Q3 (July–September) 2024, total housing starts trailed Q3 2023 by several percentage points, largely due to a sharp August dip in multi-unit construction. By Q4 (October–December) 2024, monthly data reveal notable volatility. October’s total was down from the previous year, as multi-unit projects dropped and single-detached ticked up only slightly. In November, however, starts surged far above November 2023 levels, reflecting a wave of new multi-unit projects that compensated for earlier delays. Finally, December dipped below its 2023 counterpart, with single-detached showing a mild gain but “All Others” retreating after November’s spike.

Taken together, Q4 2024 ends with a marginal increase over Q4 2023 when averaged across October, November, and December. Single-detached homes generally maintain a steadier upward trend, while multi-unit construction (apartments, condos, and other high-density builds) sees large month-to-month swings. Factors such as the exact timing of project launches, interest-rate stability, and regional market conditions all appear to shape this uneven pattern. Although total housing starts in Q3 2024 fell short of Q3 2023, Q4’s partial rebound suggests that builders and developers regained some momentum, closing out 2024 on a near-equivalent footing to the same quarter of the prior year.

REGIONAL HOUSING MARKET ANALYSIS: TRENDS AND OUTLOOK FOR 2025

While some provinces are experiencing strong growth, others are facing a decline in new builds, largely due to shifting buyer demand, financing conditions, and broader economic uncertainty. These trends highlight how affordability, migration patterns, and market conditions are shaping the trajectory of housing markets across the country.

ATLANTIC CANADA: STABILITY IN NEW HOUSING STARTS

Housing construction in Atlantic Canada has remained relatively stable despite a deceptive year-over-year decline. Q4 2023 saw an uncharacteristically high increase in housing starts for the Atlantic area. Comparing Q4 2024 to the same quarter over the past 5 years reveals a steady increase. The region continues to benefit from steady interprovincial migration and retiree demand, which has helped maintain market activity. Despite higher borrowing costs, Atlantic Canada’s affordability advantage over larger provinces has kept demand relatively strong. Looking ahead, modest growth is expected, with single-detached homes continuing to be the preferred housing option.

QUÉBEC: STRONG GROWTH IN HOUSING STARTS

Québec has seen a significant surge in housing starts, increasing from 33,377 to 46,695 units—an impressive 40% year-overyear jump. This growth is driven by robust activity in both

single-detached and multi-unit construction, particularly in Montreal and Quebec City. Unlike some other provinces, Québec’s strong housing supply growth has helped maintain market balance, making it less susceptible to rapid price increases. The market remains resilient despite broader economic concerns, and while momentum is expected to continue into early 2025, there may be some tapering in activity by 2026.

ONTARIO: DECLINING CONSTRUCTION AMID HIGH COSTS

Ontario’s housing starts have dropped from 76,751 to 62,905 units—an 18% decline—as multi-unit housing construction slows, particularly in Toronto. High construction costs, rising interest rates, and affordability challenges have deterred both developers and homebuyers, leading to a shift in demand to-

Q4 2023 HOUSING STARTS BY REGION

Q4 2024 HOUSING STARTS BY REGION

Figure 4

Figure 5

“Housing starts will slow down from 2025 to 2027 mainly due to fewer condominium apartments being built, but total starts will remain above their 10-year average.”

–

CMHC

ward resale homes. With fewer new units being built, Ontario’s housing supply could tighten further, keeping pressure on prices. However, while home prices are expected to rise at a moderate pace, they are unlikely to return to the rapid growth levels seen in previous years. In 2025, new construction will likely remain subdued, with buyers increasingly turning to the resale market (which impacts the renovations market).

THE PRAIRIES: SURGING CONSTRUCTION AND MARKET GROWTH

The Prairie provinces—Alberta, Saskatchewan, and Manitoba—are experiencing a housing boom, with housing starts rising from ~51,000 to ~63,000 units, a 24% increase. This growth is largely driven by strong interprovincial migration, particularly from Ontario and British Columbia, as buyers seek affordable housing and better job opportunities. Calgary and Edmonton have emerged as key growth centers, benefiting from a strong resale market that complements new construction demand. Given this momentum, the Prairies are expected to lead Canada’s housing market recovery in 2025, with moderate price increases projected as sustained demand continues.

BRITISH COLUMBIA: DECLINING CONSTRUCTION AMID MARKET ADJUSTMENTS

British Columbia has seen a decline in housing starts, falling from nearly 50,000 to around 43,000 units, a 14% drop. This downturn is largely attributed to weaker condo pre-sales in Vancouver, leading to a slowdown in new multi-unit developments. Additionally, many investors are offloading rental units, as rising costs and lower profitability make property ownership less attractive. Higher mortgage rates have also contributed to a cooling effect on demand in key urban centers. Despite these challenges, gradual market stabilization is expected in 2025, with a stronger recovery anticipated in 20262027 (CMHC, 2025 Housing Outook). In particular, detached homes and townhouses are likely to outperform high-rise condos, as buyer preferences shift toward larger living spaces outside of dense urban cores.

THE ROAD AHEAD FOR CANADA’S HOUSING MARKET

As regional housing trends continue to diverge, the construction outlook for 2025 and beyond highlights both opportuni-

ties and challenges in Canada’s housing sector. While some provinces, like Quebec and the Prairies, are experiencing an increase in new housing starts, others, such as Ontario and British Columbia, are seeing a slowdown as financing conditions and investor sentiment weaken.

With 228,403 new housing starts recorded in Q4 2024, Canada’s overall construction activity remains stable, though the rate of new developments will be regionally dependent. Multi-unit projects continue to be the dominant form of new construction, but single-detached homes have seen a resurgence in key areas, particularly in affordable regions where buyers have greater purchasing power.

However, several constraints are likely to impact the pace of new development in 2025. Skilled labor shortages are delaying project completions, while higher financing costs and construction expenses are making it more difficult for developers to break ground on large-scale projects. In cities like Toronto and Vancouver, weaker pre-construction condo sales have led to fewer high-rise projects launching, shifting new development activity toward mid-density and single-detached housing in suburban and secondary markets.

Looking ahead, zoning reforms and government-backed affordability initiatives may help support housing supply expansion, particularly in areas where densification policies encourage new multi-unit developments. Municipal policies aimed at allowing more mid-density housing in traditionally single-family neighborhoods are expected to help offset the slowdown in condo construction, ensuring that housing supply continues to evolve to meet shifting buyer demand.

While housing starts are projected to slightly decline over the next three years, they will remain above the 10year average, with affordability-driven markets leading new development. Quebec and the Prairies will likely continue their momentum, while Ontario and British Columbia will experience slower growth as developers navigate economic challenges. Despite these headwinds, Canada’s construction sector is adapting to changing market dynamics, ensuring that housing supply continues to respond to demographic shifts and evolving affordability concerns.

BEYOND THE BOX

How Laurysen Kitchens Grows Its Dealer Network with Innovation & Service

:: By Tyler Holt, Editor of Wood Industry Magazine

Photo

WHY DEALER NETWORKS MATTER IN CABINETRY

The cabinetry industry is evolving, and manufacturers must adapt to new market dynamics to remain competitive. One of the most effective ways to scale a cabinetry business while maintaining quality and service is through a strong dealer network. Rather than relying solely on direct-to-consumer (DTC) sales, more manufacturers are shifting toward business-to-business (B2B) partnerships, leveraging the expertise and reach of independent dealers. This model allows companies to expand into new regions, streamline production, and enhance customer service—all without the high overhead costs associated with multiple company-owned showrooms.

Laurysen Kitchens, a third-generation, family-owned cabinetry manufacturer based in Ottawa, Canada, is a prime example of how to execute this strategy successfully. By prioritizing strategic dealer selection, advanced technology integration, and superior service, Laurysen has built one of the most robust dealer networks in the industry. The company balances B2B dealer relationships with its own direct-to-consumer sales, allowing it to serve a diverse market while maintaining operational efficiency.

Bill Laurysen- COO, Michael LaurysenVP OPS, Corey Laurysen - VP Sales and services, Caroline Castrucci – CEO

“Balancing tradition with modernization has been key to our success.” Photo Credit: Laurysen Kitchens

At the forefront of Laurysen’s dealer strategy is Corey Laurysen, Vice President of Sales and Service. He has played a pivotal role in refining the company’s approach to dealer partnerships, ensuring that Laurysen’s network remains both exclusive and high-performing.

“Each area has its own dynamics. Some places are relatively stable due to their unique characteristics, while others are experiencing a lot of activity, and that momentum seems likely to continue. However, in certain smaller or less urbanized communities, we’ve noticed a bit of a slowdown. That said, I believe things are starting to pick up again, and we’re seeing projects move forward.” says Corey Laurysen.

With a market that is constantly shifting, Laurysen Kitchens continues to adapt, innovate, and refine its dealer model, ensuring sustainable growth and long-term success in the cabinetry industry.

A LEGACY OF QUALITY & GROWTH

For over 55 years, Laurysen Kitchens has been a leader in Canadian cabinetry manufacturing, blending craftsmanship, innovation, and business expertise to scale its operations from a local workshop to a nationally recognized brand. Founded in 1970, the company has remained family-owned and oper-

ated, now under its third generation of leadership.

The heart of Laurysen’s success is its ability to balance tradition with modernization. Corey Laurysen and his brother have taken the company into a new era by leveraging their complementary skill sets. “My brother studied wood products processing at UBC, while I earned my master’s in business,” explains Corey Laurysen. “He focused on engineering and production, while I took on sales and dealer management. That balance has been instrumental in shaping our company’s success.”

Laurysen’s Ottawa-based manufacturing facility has grown into a stateof-the-art operation equipped with multiple CNC machines, edge banders, robotic automation, and an advanced CRM system to enhance efficiency and precision. However, as demand continues to grow, so too has the need for additional capacity.

The company is currently investing in a new factory in Carleton Place, which will significantly expand its production capabilities. This facility is designed with a focus on engineering, automation, and lean manufacturing principles, ensuring that Laurysen remains at the forefront of modern cabinetry production.

“By combining a strong dealer network with direct sales, Laurysen Kitchens has developed a balanced, scalable business model that meets the needs of both dealers and end customers, ensuring long-term growth in the cabinetry industry.”

Photo Credit: Laurysen Kitchens

“With the new factory coming online, we are placing a greater emphasis on engineering and automation,” says Laurysen. “The industry is evolving, and it’s no longer just about skilled labor—robotics, lean manufacturing, and efficiency optimization are becoming just as critical.”

Laurysen Kitchens specializes in a diverse range of products, including kitchen cabinetry, vanities, closets, and custom wall units, catering to both residential and commercial clients. The company has also adapted to shifting housing trends, particularly the transition from condominiums to multi-unit rental housing developments.

By continuously investing in technology, infrastructure, and dealer partnerships, Laurysen Kitchens has positioned itself as a leader in Canadian cabinetry manufacturing, ready to meet the de-

mands of an evolving and dynamic market while maintaining the highest standards of quality and service.

WHY LAURYSEN USES A DEALER NETWORK MODEL

As the cabinetry industry grows increasingly competitive, manufacturers must find efficient ways to scale their business without sacrificing quality or service. Rather than relying solely on company-owned showrooms, Laurysen Kitchens has embraced a dealer-based distribution model, allowing the company to expand its market reach while maintaining a streamlined production process.

By working with independent dealers, Laurysen eliminates the need for costly retail locations and instead leverages the expertise of local dealers who have a deep understanding of regional market trends, customer prefer-

ences, and design aesthetics. This localized approach ensures that Laurysen’s products align with what customers want in different areas.

At the same time, this model allows for greater scalability, enabling the company to reach new markets across Canada without the logistical challenges of opening multiple showrooms.

While Laurysen maintains an inhouse design team for direct-to-consumer (B2C) sales, the dealer network remains the company’s primary driver of growth. This approach also benefits manufacturing operations, as dealer orders create a more predictable and high-volume production schedule, ensuring efficiency at Laurysen’s facilities.

ENHANCING DEALER COMMUNICATION WITH CRM SYSTEMS

Technology plays a crucial role in op-

Photo Credit: Laurysen Kitchens

timizing operations, enhancing dealer communication, and improving overall efficiency. Laurysen Kitchens has embraced cutting-edge digital tools to streamline its dealer network, ensuring that partners have real-time access to critical information throughout the entire sales and production process.

“We have integrated a CRM system, Monday.com, that we’ve customized inhouse to suit our unique needs and allows dealers to track their orders online,” explains Corey Laurysen.

This system allows dealers to track orders, monitor production status, and receive automated updates—eliminating the need for constant phone calls and manual follow-ups, creating a more transparent and responsive system that enables partners to anticipate delivery schedules and better manage customer expectations.

Beyond real-time tracking, Laurysen provides its dealers with an online portal that serves as a centralized hub for key business resources. Through this portal, dealers can:

• Access up-to-date catalogs featuring the latest cabinetry designs and materials.

• Retrieve pricing updates to streamline quoting and customer transactions.

• Review past orders and sales data, ensuring consistency in product selection and reordering.

This digital approach allows dealers to operate more independently and efficiently, reducing reliance on back-andforth communication and empowering them with the information needed to drive sales.

Laurysen continues to invest in new digital tools to further enhance the dealer experience. The company is exploring advancements such as:

• Automated processing system, allowing dealers to upload and confirm their orders directly through our CRM system via an online portal.

• Improved end-customer experience tracking, helping dealers understand customer preferences and satisfaction levels.

”Our

dealer network remains our primary driver of growth.”

Photo Credit: Laurysen Kitchens

“As cabinets move through our production chain, from order processing to engineering to assembly, dealers receive real-time updates. This level of transparency allows them to plan their projects with greater confidence,” says Laurysen.

BUILDING A STRONG DEALER NETWORK: SELECTION, ONBOARDING & GROWTH

A successful dealer network depends not just on growth but on choosing the right partners. Laurysen Kitchens takes a selective, strategic approach to dealer recruitment, ensuring that each partner can uphold the company’s standards for quality, service, and expertise.

“Most of our dealers reach out to us, either through referrals, word of mouth,

or our online presence,” says Corey Laurysen. “Our website makes it clear that we support an extensive dealer network, and many inquiries come through that channel.”

However, the company carefully evaluates inquiries to prevent market saturation and protect existing dealers.

KEY SELECTION CRITERIA

Laurysen assesses potential dealers based on:

• Showroom presence to display products professionally.

• Business model & customer base to ensure long-term viability.

• Technical expertise, including experience with design software experience.

• Commitment to quality & service, aligning with Laurysen’s brand values.

ONBOARDING NEW DEALERS FOR LONG-TERM SUCCESS

Once selected, new dealers undergo a structured onboarding process to ensure they are equipped to sell and service Laurysen’s products effectively.

1. Screening & Business Assessment

Dealers go through a detailed call to discuss their experience, infrastructure, and market position.

“That first phone call is crucial. We take the time to understand their business model and determine if they are truly prepared to be a Laurysen dealer,” explains Laurysen.

Let’s Build Something Great Together

At Planit, we don’t just sell software— we partner with you to grow your business.

With powerful tools like Cabinet Vision and Alphacam, we help you connect design and production seamlessly, saving time and boosting efficiency.

But the real difference? It’s our commitment to your success. Whether you’re optimizing workflows, automating production tasks, or tackling complex projects, we’re with you every step of the way.

Growing your business together.

Ready to see what’s possible? SCHEDULE A DEMO, SCAN HERE

As a CKCA member I’ve participated in round table discussions and national network events where we’ve toured various manufacturing facilities and made new connections in the industry.

I’ve brought all the learning back and also leaned on my connections for best practices, and software updates and sometimes just for a cup of coffee!

CKCA allows members to form lasting relationships across the country in an industry that is small but mighty. I’m thrilled our company is part of CKCA.

RISHELLE

TARR

DIRECTOR, BUSINESS OPERATIONS

LEADS. OPPORTUNITIES. CONNECTIONS.

LEARN MORE AT

CKCA.CA

2 Showroom Visit & Brand Alignment An on-site visit ensures the dealer’s showroom meets Laurysen’s standards.

3. Training in Software & Catalogs

Dealers receive training in Laurysen’s catalog and CRM system to streamline quoting and orders.

4. Guided Support on First Orders

Laurysen reviews the first few orders to ensure pricing accuracy and product selection.

“For the first few orders, I personally review what a dealer is submitting,” Laurysen says. “If they send a design and request pricing confirmation, I provide a quote to help them gain confidence in our catalog and pricing structure.”

5. Independent Operation with Ongoing Support Once dealers are comfortable, they operate independently but continue to have access to Laurysen’s support team and digital tools.

STRENGTHENING DEALER RELATIONSHIPS FOR GROWTH

Maintaining strong dealer relationships requires ongoing support, proactive communication, and efficient service resolution. Fast, effective service keeps dealers confident in Laurysen’s reliability.

“Service is critical, whether we are working with end customers or B2B partners,” says Laurysen. “Dealers need to know they can rely on us to provide timely responses and efficient solutions.”

To streamline issue resolution, Laurysen has implemented:

• A simplified service request system, often requiring just a photo submission.

• A clear escalation process for urgent cases.

• A structured warranty policy, ensuring dealers feel secure in the products they sell.

BALANCING DEALER NEEDS WITH MANUFACTURING EFFICIENCIES

Laurysen must balance dealer custom-

ization requests with streamlined production efficiency to maintain smooth operations.

• Standardized order processing allows for scalability.

• Transparent communication on lead times sets realistic dealer expectations.

• Strategic production planning ensures high-volume and custom orders are handled efficiently.

By investing in dealer relationships, technology, and training, Laurysen ensures that each dealer is set up for longterm success—strengthening the company’s reputation and market reach in the cabinetry industry.

KEY LESSONS & BEST PRACTICES IN DEALER NETWORK MANAGEMENT

Laurysen Kitchens’ success in dealer partnerships stems from strategic selection, technology adoption, and transparent communication. Rather than expanding rapidly, the company prioritizes quality over quantity, ensuring that each dealer aligns with its brand values, technical expertise, and service standards. As Corey Laurysen explains, “Not every dealer is the right fit. Some people love the idea of being a dealer but don’t have the technical expertise or infrastructure. We have to make sure they can deliver on our brand promise.”

Technology also plays a crucial role in streamlining operations. By integrating CRM systems and online dealer portals, Laurysen improves order tracking, communication, and efficiency, reducing delays and miscommunication. Additionally, transparency in pricing, timelines, and service policies fosters long-term trust and loyalty among dealers.

For manufacturers considering a dealer network, Laurysen’s approach highlights the importance of careful vetting, strong onboarding, digital integration, and proactive communication to build a scalable, high-performing dealer network.

DO YOU HAVE A RECOGNITION PROGRAM THAT TRULY REFLECTS YOUR VALUES?

:: By Amrita Bhogal, People and Culture Leader, Sunrise Kitchens

Formalizing a recognition program is a key strategy for employee engagement and retention. While many organizations acknowledge great work informally, structuring a program around core values ensures consistency, fairness, and meaningful impact. Over the past year, Sunrise Kitchens has taken significant steps to formalize our recognition efforts—building a culture where appreciation is not just encouraged but embedded in the way we work.

WHERE DID WE START?

To create a meaningful recognition program, we structured our approach into three tiers:

• Individual

• Team

• Organizational

While we had existing structures for Team and Organizational recognition, which were largely management-driven, we noticed a significant gap in peer-to-peer recognition at the Individual level. This presented a valuable opportunity: empowering employees to recognize and celebrate one another directly.

Peer-to-peer recognition shifts the culture from top-down appreciation to a more organic, inclusive model where recognition flows in all directions. Traditional programs often place the responsibility on leadership to highlight achievements, but by giving employees the power to nominate their peers, we created a program that fostered deeper connections and a sense of shared purpose.

BRINGING OUR VALUES TO LIFE

One of our biggest goals was to ensure our values weren’t just words on a wall but principles lived out every day. While our values were well known, we wanted to elevate them beyond communication—we wanted them to shape our workplace culture in a tangible way. This led to the creation of Living Our Values, a peer-to-peer recognition program designed to celebrate employees who truly embody what we stand for.

By embedding our values into the recognition process, we provided a clear framework for acknowledging behaviours that reflect our culture. Employees weren’t just recognizing hard work; they were recognizing the very actions that make our workplace stronger. Appreciation became an everyday practice, reinforcing respect, collaboration, and shared accountability.

In addition to peer-driven recognition, leadership played an active role by championing the program, creating awareness, and making nominations across departments—especially recognizing individuals they might not typically interact with in their day-to-day work. This broader engagement helped foster a more connected and appreciative workplace.

HOW DID WE MAKE THIS HAPPEN?

To turn Living Our Values into reality, the HR team took a strategic and structured approach. We started by reviewing our

core values and defining five key actions for each—clear, concrete examples of how employees could demonstrate these values in the workplace. By providing this clarity, we made it easier for employees to recognize their peers with specific, meaningful nominations.

To ensure a diverse perspective, we formed a volunteer-based recognition committee with members from different departments and leadership levels. This team played a crucial role in refining the key actions and ensuring the program was both inclusive and relevant.

To maintain transparency and encourage participation, we launched a weeklong email campaign, spotlighting one value per day to reinforce its meaning and practical application. Alongside this, we developed a detailed FAQ document and held leadership meetings to ensure managers and team leads understood the program and could confidently address any employee questions.

The Clean Air Company

We made the nomination process simple and accessible by using MS Forms, allowing employees to submit nominations over a two-week period. To ensure fairness, HR anonymized the nominations before sharing them with the recognition committee for review. One Value Champion (winner) per value was selected based on the committee’s evaluation.

Recognition doesn’t stop at nominations—we wanted to celebrate our employees in a way that made them feel seen and valued. We designed a custom Living Our Values logo, featured on personalized shirts for the Value Champions to wear proudly. As part of our commitment to supporting local businesses, we also sourced locally manufactured products from small businesses to create a gift basket for the winners, reinforcing our dedication to community partnerships while celebrating our people.

MEASURING THE IMPACT ON CULTURE

The response to Living Our Values was overwhelmingly positive, with 81% of employees participating in the nomination process. This high engagement signaled that employees not only understood our values but felt personally invested in recognizing and celebrating them. By shifting recognition into the hands of employees, we saw increased engagement, stronger team connections, and a deepened sense of belonging. The nomination process also provided valuable insights into how our values show up across the organization, offering a real-time view of our workplace culture.

BREAKDOWN OF NOMINATIONS BY VALUE:

Dedication – 33% of total nominations

(6 individuals received multiple nominations) Diversity & Inclusion – 11% of total nominations

(3 individuals received multiple nominations) Growth – 27% of total nominations

(5 individuals received multiple nominations) Respect – 26% of total nominations

(5 individuals received multiple nominations)

This data provided valuable insight into how our values are perceived and practiced. While Dedication, Growth, and Respect saw strong engagement, the lower percentage of nominations for Diversity & Inclusion highlighted an opportunity to strengthen awareness and education around this value. This insight creates a pathway for future learning initiatives, ensuring inclusivity remains a focus in our workplace.

KEY TAKEAWAYS

Through this initiative, we saw several key benefits:

• Employees gained a deeper understanding of our values and how they connect to daily work.

• Our recognition committee became champions for culture, actively driving awareness and engagement.

• Employees were given a platform to share meaningful stories of their colleagues’ impact.

• The program fostered a stronger sense of appreciation and connection across teams.

By analyzing nomination trends, HR gained insights into areas where additional education and reinforcement are needed. The lower engagement in Diversity & Inclusion nominations signaled an opportunity to enhance learning initiatives, ensuring that all employees feel equipped and encouraged to recognize inclusivity in action.

LOOKING AHEAD

The success of Living Our Values reinforced that recognition isn’t just a program—it’s a catalyst for cultural alignment and deeper engagement. By weaving recognition into daily actions, we’ve created a framework where our values aren’t just acknowledged but actively practiced. Moving forward, we will continue refining and expanding the program to ensure every value is consistently demonstrated, recognized, and celebrated across all levels of our organization.

FINAL THOUGHTS

Creating a values-driven recognition program isn’t just about celebrating great work—it’s about fostering a workplace where appreciation is a shared responsibility, culture is actively shaped by employees, and values are more than just words. At Sunrise Kitchens, we’re proud to see how Living Our Values has brought our culture to life, and we look forward to continuing this journey of appreciation, connection, and growth.

How does your organization recognize its people?

Amrita Bhogal is the 3rd generation at Sunrise Kitchens. With a focus on People and Culture. She is leading change through lean principles and continues to strengthen culture through values and behaviours.

Inside the Future of Cabinet Manufacturing

My Visit to Muskoka Cabinets

:: By Chris Leonard, Director at Kaizen Learning Partners and Chair of the CKCA Advanced Manufacturing Peer Group

Walking into Muskoka Cabinets, I wasn’t sure what to expect. Having spent over 30 years visiting factories across industries—from food processing to custom cabinet shops—I’ve seen everything from old-school craftsmanship to cutting-edge automation. But as I stepped onto the production floor, I quickly realized that this wasn’t just another cabinet shop. This was a glimpse into the future of advanced manufacturing.

A FACTORY LIKE NO OTHER

Muskoka Cabinets has undergone a remarkable transformation, integrating advanced automation while maintaining the craftsmanship that defines high-quality kitchen cabinetry. The first thing that caught my eye was the seamless coordination between human workers and robotic systems, something rarely seen in traditional woodworking shops. From CNC machines precisely

cutting components to RFID-tagged parts moving through the process with ease, every detail seemed meticulously planned.

One of the most impressive features was their ERP system, which not only plans production but also provides real-time visual management for every employee on the floor. This digital backbone keeps track of work-in-progress, inventory, and finished goods, ensuring that every step of the process is synchronized. It also plays a key role in their monthly bonus system, where employees are incentivized for exceeding department targets—a smart approach to driving efficiency and engagement.

THE AUTOMATION JOURNEY

Automation at Muskoka Cabinets isn’t just about implementing technology for the sake of it. It’s about making the production process more efficient, reducing errors, and ultimately improving profitability.

The robotic arm feeding the CNC machines ensures parts are cut with extreme precision. Each piece is labeled with RFID tags, allowing for seamless tracking throughout the plant. The same robotic technology feeds the doweling machine, creating an almost fully auto-

mated parts production cell. However, one area still required human intervention: the edgebanding process.

Luke Elias, the driving force behind Muskoka Cabinets’ transformation, walked me through his vision. His next big step is introducing a vision system on the edgebander to fully automate this last manual touchpoint. Once complete,

the parts production cell will run continuously with minimal human involvement—just as he envisions.

THE CKCA ADVANCED

MANUFACTURING PEER GROUP: A BLUEPRINT FOR SUCCESS

Muskoka Cabinets’ journey aligns perfectly with the mission of the CKCA

Muskoka Cabinets isn’t just another cabinet shop—this is a glimpse into the future of advanced manufacturing. Photo Credit: Muskoka Cabinet Co.