TECHNOLOGIES POSITION

ARCHITECTURAL DESIGN POSITION + TECHNICAL DETAIL STUDY PURPOSE

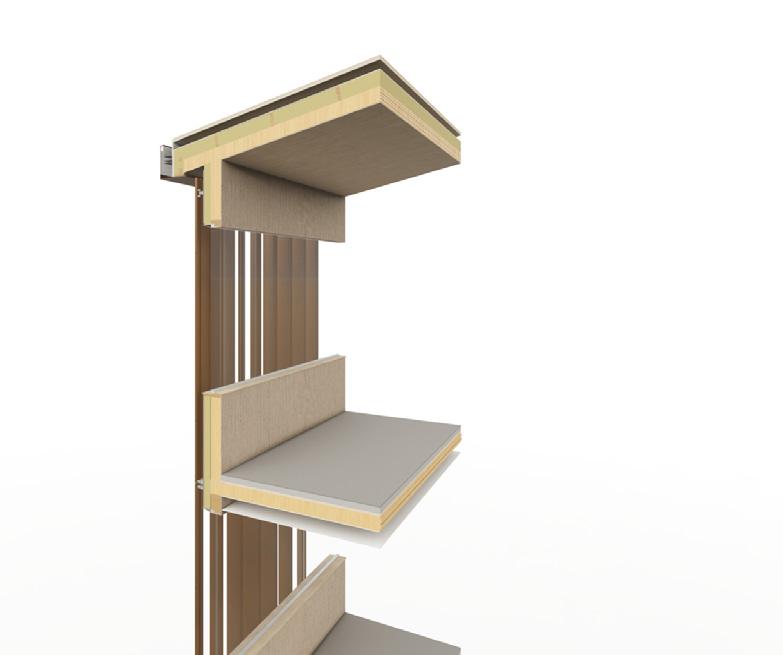

In the technical detail study an architectural bay showcasing the structure build up, facade elements and roof construction, will be analysed. In order to find the most effective design of the facade, several iterations will explore different materiality, size and properties of cladding and its impact on the environment, sustainable performance and interior quality.

Through throrough consideration of structural integrity; the processes, materials and tools required to build and maintain the building, the environmental impact of the structure can be vastly reduced. Furthermore, incorporating sustainable, low-carbon materials, sourced from the local producers can contribute to improved circular economy in the area. The technological innovations are also crucial, as they allow to develop highly effective solutions to minimise carbon footprint through application of passive energy strategies; such as sustainable envelopes which prevent from heat gains and glare, provide shading inside the structure resulting in lower energy demand for lighting and cooling and optimal conditions for users.

TECHNOLOGIES RESPONSE

CLIMATE CHANGE

The building responds to the climate change on multiple levels; through materiality, construction, lifecycle consideration and energetic self-sufficiency achieved through passive energy strategies.

1.Timber was chosen to be the main structural material, due to its minimized carbon footprint and environmental impact. Other chosen materials such as copper or steel are highly resilient and possible to recycle.

2. In order to reduce the emissions caused by sourcing and transport, CLT walls and glulam columns from local manufacturers would be used. This would ensure sustainable sourcing and positively impact local economy.

5. Overhangs and facade panels can improve interior quality; the glare may be reduced and privacy level can be defined.

different level of privacy can also improve possible reuse/ repurposing building in future.

BUILDING AND LIFE SAFETY

In the interior structural, timber elements will be covered in fire-resistant plasterboard, which prevent fire outbreak and spread to other components.

Cladding materials will be analysed in the terms of their fire-resistance properties and weathering performance. Initial idea assumed use of timber cladding, yet using copper and perforated still is likely to be more reasonable and sustainable.

TECHNOLOGIES ARTEFACTS

3. The project prioritises access to natural daylight through wide openings. This way the demand for artificial lighting is lower, thus the structure is more self sufficient.

MATERIALS

CLT PANELS

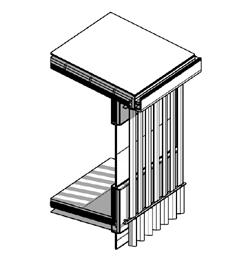

The loadbearing components would consist of hybrid structure - CLT walls combined with glulam columns.

CLT is considered to be one of the most sustainable materials due to its low carbon footprint and high strengh and loadbearing capacities.

Another benefit of mass timber structure is the psychological impact of material on users. Timber adds to the feeling of calmness and comfort.

COPPER ROOF STRUCTURE

Copper was chosen as a roof cladding due to its high weathering resistance, sustainability (long lifespan and possibility of recycling) and visual consistency with the facade.

Other materials include fiberglass insulation, steel plates and connectors, breathable and damproof mebranes, painted aluminium (external weather protection layer) and interior finishplasterboard + acoustic boards.

The main design issue of presented system is the exposed timber structure, which may contribute to the spread of fire in case of fire. For this reason, several strategies were considered to ensure the safety of users and compliance wih fire regulations.

CONSTRUCTABILITY

Timber structure was chosen due to ist sustainability and fast assembly.

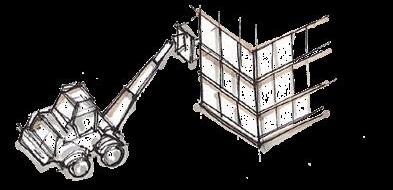

Prefabricated CLT panels can be quickly transported from local manufacturers and assembled on site.

Despite organic layout of project, structural elements are designated by modular grid, which enables faster construction.

To provide thermal comfort in predominarly glazed rooms, translucent cladding would be installed. Roof overhangs were also extended to prevent users’s from glare and structure from heat gains in summer.

Alternatively, fire-retardant coating can be used directly on the timber structure, to reduce the flammability and increase fire resistance.

Fire resistant plasterboard finish Triple glazing reduces

prefabricated walls and columns = faster, more sustainable construction.

the noise from the exterior (adjacent

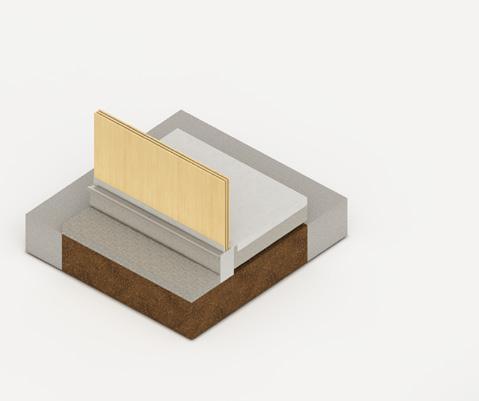

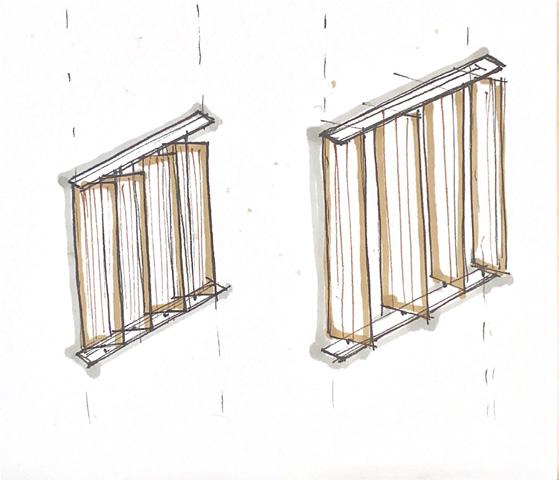

Suspended facade would consist of ankled panels, indicating the privacy of programme and providing shading for the interior. The material and specific details will be analysed on following page.

TOOLS

The components will require engineered wood products and steel joinery produced specificaly for timber structure and concrete foundation.

users.

PROCESSES

One of the benefits of timber structure is the fast construction. As timber components cannot be exposed to the weather factors for the longer period of time (which is also a drawback of the material) the construction time is much faster.

CONSTRUTION PROCESS

(on site)

1) Sustainable sourcing.

Timber sourced from local woodlands in an ethical and responsible manner.

2. Transport CLT and glulam from local manufacturers reduces the carbon emissions caused by the transportation of material.

Extended overhangs and suspen ded loures should provi de provision from glare, heat gains and weather conditions. Plan context Location of chosen detail study CLT Acoustic wall design sketch Assembly of structure is simplified thanks to the simplified joinery system between walls and floors panels. Engineered wood product Steel screws Steel ankled plate Steel anchor bolt Steel plateexternal fixture Suspended facade joinery prefabricated steel components Drilling machines would be required for structural assembly - montage of CLT panels to concrete foundation with steel joinery. Drills would also be needed for assembly of suspended facade. Temporary scaffolding would be required as well. Excavators and backhoes Trucks and dump trucks Loaders Concrete machines Telehandlers and cranes Excavation of soil. Preparation of concrete and pouring the concrete onto foundation. Transporting building materials and moving components around the site REQUIRED EQUIPMENT Moving heavy elements around the site. Excavators and backhoes used for excavation of soil. Dumptracks are used to transport building material. Foundation is cast using concrete machines. Prefabricated elements are transported and unloaded on site. Telehandlers and cranes are used thorough the entire constrution process: to move heavier CLT panels, glazed panels and facade components on upper floors.

1. Excavation of soil.

2. Concrete foundation cast.

1. Excavation of soil.

2. Concrete foundation cast.

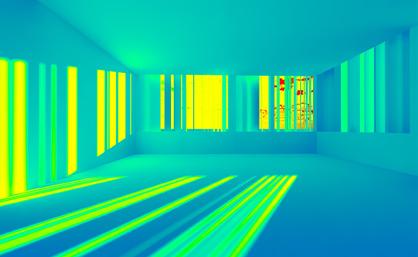

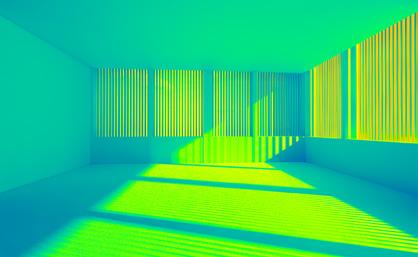

ITERATION CONCEPT 3D MODELLING TESTS ON FACADE PERFORMANCE -INTERIOR QUALITY

CONTEXT - OCCUPATION

The interior impacted by iterations on southern facade is designated for classrooms, study areas and multipurposal rooms (for workshops, meeting etc). Thus the quality of light, temperature and privacy are crucial factors for user’s comfort and wellbeing.

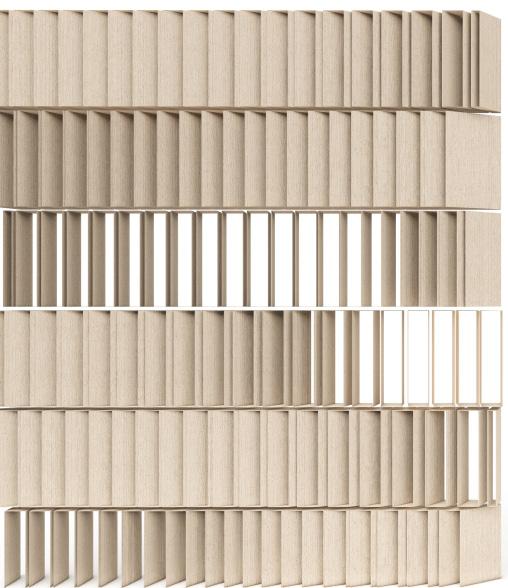

In the initial idea the timber cladding is spread evenly over the elevation with the same distance between each batten. The panels would be connceted through a steel joinery to the horizontal tracks placed on the top and bottom of each level.

Purpose + expected results

Parametric louvres would rotate providing different level of shading and privacy where needed, thus adding more flexibility to design.

Second iteration explores the parametric design in which vertical louvres rotate creating gradual transitions between For the design a grasshopper script was developed to find the most efficient way of adjusting the panels to the sunlight and programme of the project.

Purpose + expected results

Corten steel panels with mesh would rotate resulting in possibility to control the level of privacy and adding a shading in the interior depending on the time of the day.

Third iteration explores the impact on the internal light quality with the corten steel perforated panels. The panels consist of a corten frames fitted with a parametric mesh, which aims to reduce glare and provide subtle sunlight inside. The panels can would also rotate or slide to provide possibility of adjustment in each area.

FIXED PANELS

mechanised system with rotating louvres would require more complex structure to provide space for controll mechanisms.

I. DAYLIGHT QUALITY

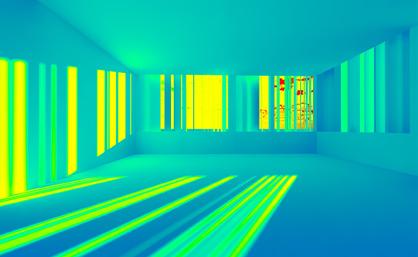

In the initial facade concept sunlight is spread evenly in the interior. The regular positioning of louvres provides sufficient daylight for effective and comfortable conditions, yet it is not very flexible (the exact same layout over the entire facade).

II. GLARE

Thanks to the suspended structure and small distances between each panel, interior is shaded and the glare effect is reduced. However, due to the southern exposure, in such facade layout blinds or additional sunscreens would be needed.

III. PRIVACY

The exact panels spread over the elevation provides some privacy, yet it does not offer manual or automatic adjustment for each space.

I. DAYLIGHT QUALITY

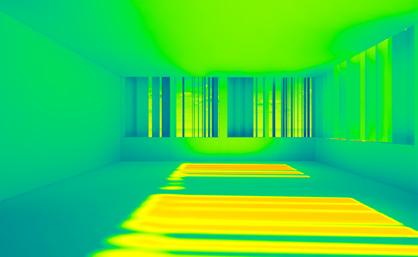

In the first iteration rotating louvres can provide sufficient sunlight and shading based on the specific users needs. The angle of rotation may follow sun trajectory and allow maximum sunlight over the day, reducing the demand for artificial lighting.

II. GLARE

Based on the light analysis, second iteration offers shading particular areas when needed, which contributes to more efficient, overal performance. Yet, it results in higher contrast when exposed to the direct sunlight, which is not comfortable to human eye.

III. PRIVACY

In the terms of privacy, kinetic louvres are the most effective, as they allow user to control the level of privacy - offering almost complete visual closure of the space.

I. DAYLIGHT QUALITY

In the third iteration corten steel panels provide diffused light into the interior thatnks to the perforated mesh and ability to partial rotation (due to the average size of such panelling design of fully rotating panel would not be efficient).

II. GLARE

The perforated mesh provide prevenyion from glare and delicate shading in the interior over the day. However, in noon hours, glare may occure in the rooms of southern exposure.

III. PRIVACY

Sufficient level of privacy is provided in the rooms, with a possibility of adjustment. Yet the scope of the flexibility is limited due to the panels size and weight (corten steel is much heavier that timber, thus automatic system with kinetic panels would result in higher energy demand).

REFLECTIONS ON BUILDING AND

Corten steel panels

Copper is a fire resistant material, which means that it can stand fire and does not contribute to fire spread. Thus it does not require any additional treatment to meet fire regulations.

Copper is also highly durable material - it can bear very hot and cold temperatures and does not require maintenance, which make it safer and more affordable in longer term.

Ventilation

Another reflection resulted from the consideration of building safety and internal comfort was the possibility of incorporation of openable windows, located at the top of glazed panels. Such solution would improve air circulation and provide natural ventilation inside the structure.

Simirarly corten steel panels are fire resistant, as it withstands heat without any damage. It is also a low maintenance material; it is anti-corosive which reduces the maintenance costs and risk of facade damage. As the material does not get affected by the corrosion it protects the structure from weather conditions and lasts for decades (estimated lifespan of +50 years).