The John Deere 1050 P‑Tier Dozer delivers 354 hp (264 kW) at 1,700 rpm, offering massive pushing power through its wide 426.72 cm semi‑u blade and class‑leading track‑on‑ground footprint

Built to move more with every pass.

*Terms and conditions apply. (Available at https://www.deere.africa/en/) https://www.deere.africa/en/construction/ I cfjohndeereame@johndeere.com

For several reasons, I have always been a very big proponent of industry conferences such as the recent joint Institute of Quarrying Southern Africa (IQSA) and ASPASA October Symposium. For me, such industry gatherings not only offer valuable opportunities for networking and professional development, but more importantly for staying current with the latest trends and innovations.

This year’s event, the first Symposium since 2017, was packed with topical presentations, from legal updates to new technologies changing the face of quarrying and surface mining at large. However, something I found intriguing was not necessarily the formal presentations, but rather a conversation I had with a certain quarry manager on the sidelines of the conference.

With a growing focus on both efficiency and sustainability, my industry friend, who runs a large quarry, questioned the legacy of static plants in quarrying, which he believes is one of both economic gain and long-term environmental impact. However, due to the old nature of most existing static plants, perceived economic gains are being eroded by the inefficiency of some of the existing major components.

in long-term, large-scale operations where they offer efficiency and consistent high-volume output. However, in an environment where most quarry operations hardly go beyond the 350 tonnes per hour (tph) production mark, a move away from large, old static plants to smaller, modular type plants makes perfect sense.

For operations in the 100 to 350 tph capacity range, these plants provide a cost-effective and flexible solution. Once the throughput gets bigger than that, the equipment becomes too heavy, and the solution loses the sense of modularity and resembles a fixed plant.

Based on this school of thought, several comminution equipment suppliers have seen a growing demand for modular plants in the quarrying environment, not only in South Africa, but the SADC region at large. In a recent chat with a major supplier, he noted that the company had supplied several greenfield modular plants in southern Africa in the past two years, with the majority of sales coming from greenfield quarry and aggregate crushing projects.

One of the major benefits is that these plants often come with modern crushers that feature more advanced technology, better energy efficiency and are designed for easier maintenance and optimal performance.

MUNESU SHOKO

Publishing Editor

Email: munesu@quarryingafrica.com

Munesu Shoko

Quarrying Africa

Indeed, some of the crushers, for example, have been in operation for over 50 years. Most of these are inefficient due to worn components and outdated technology, all of which lead to reduced capacity, increased energy consumption and more downtime. As you will see in this edition of Quarrying Africa, this is exactly the reason why Danoher invested in a new plant at its flagship Kgale Quarry in Gaborone, Botswana.

Following the acquisition of the operation from PPC in 2021, Danoher took a decision to invest in a completely new plant. Why? The plant was generally old and needed replacement. For example, the crushers were old-school technology, which affected efficiencies and safety. The conveyors were also old and worn out.

While there is merit in starting to look at new options, it is important to note that large static plants still have a future in quarrying, especially

Modular plants also generally have a lower capital cost compared with their bespoke, static counterparts. From an operational cost point of view, these solutions also work out cheaper than their tracked counterparts because they do not rely on diesel power.

The modular solution is also a cost-effective option in terms of maintenance. With bespoke plants, getting replacement parts takes a bit longer, whereas in a standardised solution, parts are off-the-shelf in most instances.

The move away from static plants is also giving rise to the growing uptake of wheeled plants. In addition to mobility and ease of deployment, the wheeled plant concept offers the flexibility of a mobile plant and the productivity of a static plant. From an economic point of view, customers can enjoy the mobility of the plant without the complexity associated with additional maintenance obligations of components such as diesel engines and tracks related to mobile tracked units.

DRIVING GRADING EFFICIENCY

PUMPING AT NEW DEPTHS

RAPID UPTAKE OF INDUSTRIAL MEASURING DEVICES

RELISHING CONSTRUCTION GREEN SHOOTS

A CRITICAL STEP TO CONVEYOR SAFETY AND EFFICIENCY

SUSTAINABILITY IN FOCUS

DRIVING THE TRANSITION TO ZERO-EMISSION TRUCKING

Publishing Editor: Munesu Shoko

Sub Editor: Glynnis Koch

Admin: Linda T. Chisi

Design: Kudzo Mzire Maputire

Web Manager: Thina Bhebhe

Quarrying Africa is the information hub for the sub-Saharan African quarrying sector. It is a valued reference tool positioned as a must-read for the broader spectrum of the aggregates value chain, from quarry operators and aggregate retailers, to concrete and cement producers, mining contractors, aggregate haulage companies and the supply chain at large.

Quarrying Africa, published by DueNorth Media Africa, makes constant effort to ensure that content is accurate before publication. The views expressed in the articles reflect the source(s) opinions and are not necessarily the views of the publisher and editor.

The opinions, beliefs and viewpoints expressed by the various thought leaders and contributors do not necessarily reflect the opinions, beliefs and viewpoints of the Quarrying Africa team.

Quarrying Africa prides itself on the educational content published via www.quarryingafrica.com and in Quarrying Africa magazine in print. We believe knowledge is power, which is why we strive to cover topics that affect the quarrying value chain at large.

Printed by:

Email: munesu@quarryingafrica.com Cell: +27 (0)73 052 4335

Following Babcock’s recent launch of the Volvo New Generation articulated dump trucks (ADTs) in southern Africa, leading mining contractor JCI Mining has taken delivery of the first ten A50 units in the region, deploying them on one of its new projects in Limpopo, South Africa. Based on a lifecycle costing model, Matthew Abraham, MD of JCI Mining, is convinced that the A50 hits a ‘sweet spot’ with unmatched cost-pertonne prospects.

By Munesu Shoko

hen Babcock recently unveiled the new range of Volvo ADTs, initially the A40, A45 and the all-new A50 – which marked Volvo’s first foray in the 50-tonne hauler segment, the Middelburg facility was not randomly picked. The branch sits right at the heart of the coalfields, an important market area where an existing large fleet of Volvo ADTs is

operational and a large client base is active. One such client is JCI Mining, a prominent mining contractor with a formidable project base, primarily in coal, and in other commodities. In fact, JCI Mining is headquartered right next door to Babcock’s Middelburg Branch. If ‘written in the stars’ was anything to go by, it was therefore predestined that JCI Mining would be the first recipient of the very first ten Volvo A50 units in southern Africa. Abraham is thrilled to be the first recipient of the A50 units in southern Africa. “It is a momentous occasion to take delivery of the first Volvo A50 units in our region, but buying a completely new product comes with no local point of reference,” he says. “We relied on our relationship and trust in Babcock. For the past ten years, Babcock has become a dependable partner to our business and we have found that their projections are always accurate – be it fuel consumption or TCO at large. We therefore did not hesitate to sign on the dotted line and we have full trust in the capabilities of the A50.”

The new A50 units join an existing large fleet of Volvo ADTs within the JCI stable. The company, confirms Abraham, already owns a large number of A30, A35, A40, A45 and A60 units. JCI has recently been awarded several new projects, and this necessitated the company to expand its fleet to service these new contracts. In addition, says Abraham, the company also needed to replace a portion of its ageing fleet, which led to this large-scale investment.

While the proven track record of the Volvo ADT and the back-up service from Babcock were key considerations, Abraham says the decision was largely influenced by a cost-evaluating model that the company, together with Babcock, ran to determine the economic viability of going the A50 route, taking into account all costs associated with

JCI Mining has taken delivery of the first ten A50 units in southern Africa and has deployed them on one of its new projects in Limpopo, South Africa

JCI has recently been awarded several new projects, and this necessitated the company to expand its fleet to service these new contracts

The company also needed to replace a portion of its ageing fleet, which led to this large-scale investment

JCI Mining modelled the owning costs, projected running costs, as well as anticipated fuel consumption, and the A50 hit a ‘sweet spot’, leading to the decision to purchase the first ten units

the product throughout its lifecycle.

“We were approached by Babcock and Volvo with the specifications of the new product and we were intrigued by the information provided. We modelled the owning costs, projected running costs as well as projected fuel consumption, and the A50 hit a ‘sweet spot’, which led to the decision to purchase the first ten units,” says Abraham.

In such a competitive business environment, Abraham stresses that a lifecycle cost analysis is one of the most important considerations in any purchasing decision. Based on the numbers the company ran on paper, the A50 offers the best cost-per-tonne and overall lifecycle costing.

In fact, Volvo Construction Equipment confirms that the A50 has hit a ‘sweet spot’, already showing excellent cost-per-tonne results in global trials. With a 45-t payload, the A50 delivers 10% more productivity and 8% greater fuel efficiency than the previous generation’s A45G FS. Service costs are reduced by up to 6% over 12 000 hours of operation due to simplified servicing, longer change intervals and easy component access.

“Our machines have worked just over 750 hours to date, on average, and the fuel consumption figures and projected efficiencies are very much in line with our expectations, which is pleasing,” confirms Abraham.

When Volvo CE first unveiled the machine to the global market, one of the key selling points of the machine was always going to be the full hydraulic suspension concept. This was definitely one of the key features that

With a 45-t payload, the A50 delivers 10% more productivity and 8% greater fuel efficiency than the previous generation’s A45G FS

JCI’s machines have worked just over 750 hours to date, on average, and the fuel consumption figures and projected efficiencies are very much in line with expectations

JCI has recently been awarded several new projects, and this necessitated the company to expand its fleet to service these new contracts.

JCI’s machines have worked just over 750 hours to date, on average, and the fuel consumption figures and projected efficiencies are very much in line with expectations.

attracted the attention of Abraham and his team at JCI.

Pioneered by Volvo CE in 2007, the full suspension has proved to be a reliable system for the toughest of driving conditions. The A50 takes the concept to new heights as the only full suspension machine of its size class on the market. As a result, it offers a significant improvement in cycle times, an increase in hauler production per operator-hour and lower costs when compared to its standard suspension counterparts.

Volvo CE’s full suspension reduces vibration, noise and shocks, which can help prevent repetitive strain injuries to operators. A smoother ride on the hauler and road can reduce unnecessary maintenance costs.

“In general, the A50 is a first-class product with a host of cuttingedge features designed with the operator in mind, especially the accessibility into the machine and the ergonomics in the cab – one can

easily recognise that a lot of thought has gone into the design,” explains Abraham. “Operator comfort for us is a big pull factor. A comfortable operator ensures increased productivity and efficiency through reduced fatigue and better focus.”

Investments in capital equipment are big-ticket purchases by their very nature, and Abraham reiterates the importance of dependable aftermarket support from the supplier to keep these machines running. For JCI Mining, the support for its mission-critical equipment has never been more important as it seeks to maximise availability and ultimately efficiency and productivity.

Abraham commends Babcock for placing value on aftermarket support, saying that the Volvo CE dealer in southern Africa goes beyond equipment sales. “They go the extra mile to meet our operational needs, which is very important for us because in our line of business, downtime is the enemy – and service is everything,” says Abraham. “Generally, we have built a good relationship with Babcock, based on trust, and testimony to that was the decision to buy a completely new product with no reference in the local market.”

To ensure asset longevity, uptime and peace of mind, JCI makes use of Babcock’s service level agreements. “From a maintenance perspective, we have service level agreements in place for all our Volvo haulers purchased from Babcock. We have been using this model for the past eight years and we have found it to be very effective, which is why we did not hesitate to include it in our A50 deal,” says Abraham.

David Vaughan, Executive Chairman of Babcock’s Equipment division, says aftermarket has always been a cornerstone of the company’s business model. This is driven by the understanding that customers not only invest in products, but more importantly in uptime, performance and peace of mind.

“In our market, customers want to focus on their core business of mining –rather than on equipment maintenance. Testimony to this is the ever-growing number of service contracts that we sign with customers, tailored to the level of aftermarket attention their operation needs for maximum uptime,” concludes Vaughan. a

The investment in the new plant has ushered in a new era in productivity, efficient operation, flexibility, and safety.

Following the acquisition of PPC’s Botswana-based commercial quarry assets back in October 2021, Danoher committed a large capital investment into a new processing plant for its Gaborone-based Kgale Quarry. With the new plant, CEO Scott Danoher tells Quarrying Africa, Danoher has increased capacity significantly, optimised operational efficiencies, maximised safety, and enhanced flexibility to process the variable resource. By Munesu Shoko.

Some four years ago, Danoher concluded the deal to purchase three commercial quarry assets from cement giant, PPC, in Botswana. The deal included three quarries – Kgale, Mokolodi and Francistown. Following the conclusion of the deal, all three operations required a bit of attention, especially the static processing plants at Kgale and Francistown. From the onset, says Danoher, the

company put more attention on Kgale Quarry which, by virtue of its location in the Botswanan capital of Gaborone, constituted the bulk of Danoher’s commercial quarrying business in the country. At the time of the acquisition, the Kgale plant had reached the end of its economic life, with limited scope for extension as the previous owners were preparing for a planned closure of the quarry.

“The plant was generally old and needed replacement. For example, the crushers

R80-million

The total capital investment in the new plant was about R80million

80 000 tpm

The new plant has the capacity to produce 80 000 tpm working a single shift

Some four years ago, Danoher concluded the deal to purchase three commercial quarry assets – Kgale, Mokolodi and Francistown – from cement giant, PPC, in Botswana

At the time of the acquisition, the Kgale plant had reached the end of its economic life, with limited scope for extension as the previous owners were preparing for a planned closure of the quarry

Consequently, a decision was taken to invest in a completely new plant. The 24-month upgrade period demanded a fine balance between maintaining production and completing the upgrade successfully

The investment in the new plant has ushered in a new era in productivity, efficient operation, flexibility and safety

were old-school technology, which affected efficiencies and safety. The conveyors were also old and worn out. Consequently, a decision was taken to invest in a completely new plant. This upgrade period required a careful balance between maintaining reliable, highquality production output and progressing steadily with the upgrade project. It took us about six months to decommission the existing plant. During that time, we were running a 100% mobile crushing and screening operation and at one point we had three trains on site to meet the required production capacity,” explains Danoher.

“The plant was generally old and needed replacement. For example, the crushers were old-school technology, which affected efficiencies and safety. The conveyors were also old and worn out. Consequently, a decision was taken to invest in a completely new plant. The upgrade period required a careful balance between maintaining reliable, high-quality production output and progressing steadily with the upgrade project.

Scott Danoher, CEO of Danoher

The installation of the new plant commenced soon after the decommissioning of the old static plant. While Danoher managed to sell off some of the components, the majority of the old plant was scrapped.

The new plant installation was executed in four stages. First up was the tertiary section, which was initially fed by a mobile train upon its completion.

The tertiary setup comprises a tunnel that goes into a Techroq 7’ x 20’ screen, which works in close circuit with a Metso HP400 cone crusher.

After the completion of the tertiary section, the secondary setup was up next, which is basically a Metso HP300 cone crusher with its own surge pile.

The third leg of the project saw the installation of the primary section – a Metso C125 jaw crusher and a 90-m stacking conveyor that feeds a dedicated intermediary stockpile (ISP). The last section, completed at the end of 2024, was the vertical shaft impact (VSI) crushing circuit. This section comprises a Twister VS350 VSI crusher from Pilot Crushtec International in close circuit with a 6’ x 16’ MVT screen.

Given that the four stages were not implemented immediately after one another, and the fact that Danoher maintained 60 000-70 000 tonnes per month (tpm) production during the plant upgrading phase, total completion of the whole project took some 24 months in total.

“While several components, such as the Twister VS350 VSI crusher, as well as the screens and conveyors were sourced new, some of the equipment such as crushers

were second-hand units that we sourced from Africa and Europe and refurbished in-house at our workshop. The total capital investment in the new plant was about R80-million,” explains Danoher.

The investment in the new plant has ushered in a new era in productivity, efficient operation, flexibility and safety. In terms of productivity, the new plant can produce 80 000 tpm working a single shift, up from about 30 000 tpm capacity on the previous plant. The new capacity allows Danoher to meet monthly demand, which is averaging around 75 000 tpm at the moment, without having to supplement with mobile trains.

Removing the need for mobiles, says Danoher, reduces operating costs significantly. While mobile units offer flexibility for short-term projects, the static plant, powered by the electrical grid, is more efficient and cost-effective than the diesel engines used in mobile units, both in terms of operation and maintenance.

“The flexibility of this plant, especially given the variability in our material, is another major operational gain for us,” explains Danoher. “In our pit, we mine both granite and dolerite and these have to be processed separately to meet different customers’ needs. Generally, our brick and block customers, as well as their concrete products manufacturer counterparts, prefer granite because of its ‘pinkish’ colour. Conversely, the roads and asphalt clients prefer

dolerite because of its high strength.”

From the onset, the plant was designed to allow for switching between materials with ease. To achieve this, each section – primary, secondary and tertiary – comes with its own surge pile. The flexibility allows Danoher to adapt to market changes by quickly switching between products, thereby minimising downtime, reducing waste, improving resource utilisation and increasing responsiveness to customer demands.

The installation of newgeneration crushers ensures better safety on site. HP cone crushers from Metso, for example, ensure safety through features such as hydraulic unblocking systems for sudden stoppages and automatic feed rate control to maintain optimal material levels and prevent blockages.

Commenting on the state of affairs in Botswana, Danoher says the “market is relatively stable”, despite a constrained economy due to the global slowdown in the diamond market, a major source of revenue for Botswana. Consequently, some of the proposed construction projects have been postponed or cancelled due to lack of funding.

In addition, says Danoher, there have been some significant fuel and electricity price increases in Botswana, which have generally put a lot of pressure on businesses. “We continue to place major emphasis on our efficiencies to ensure that we can absorb some of these cost shocks. The new plant allows us to do exactly that without having to pass all the costs to our customers because it is not sustainable. Businesses are already suffering from inflationary pressures and we are in a position to shield our customers from that by means of being better at what we do,” says Danoher.

However, like any other commercial operation, Danoher’s Kgale Quarry remains pretty much buoyant, largely sustained by a combination of month-to-month customers and projects. The quarry currently averages around 75 000 tpm, confirms Danoher, with manufactured sand being the biggest seller to date.

“The sand market is largely driven by month-tomonth customers – brick and block makers, paving brick makers and concrete product manufacturers in general – whose market is in turn driven by town council upgrades and the seemingly thriving residential property market in Gaborone,” concludes Danoher. a

Having taken over the assembly and distributorship of Powerstar trucks in 2010, Ever Star Industries (ESI) has put the brand on a continuous growth trajectory. One of the latest achievements is the recent milestone of the 10 000th Powerstar truck to roll off the company’s Pietermaritzburg, South Africa assembly plant. Munesu Shoko attended the event and filed this report for Quarrying Africa.

The assembly of the 10 000 th truck heralds the continued success of the Powerstar truck in South Africa

30

Over the years, ESI has continuously reinforced its support footprint, which to date boasts some 30 dealers in South Africa and SADC at large

ESI expects a record 1 000 truck sales in 2025, with a projection to grow the volumes even further to between 1 300 and 1 500 units in 2026

One of the first Chinese heavy commercial vehicle brands to enter the South African market, Powerstar, under the stewardship of ESI, has over the years recorded major success in southern Africa. Having celebrated its 5 000 th truck milestone back in May 2019, the company marked yet another major landmark in August 2025 – the 10 000 th truck rolling off the local Pietermaritzburg production line.

The first Powerstar trucks arrived in South Africa in 2006 under the distributorship of Super Group. In the early days, the brand did not enjoy the best of successes, primarily due to a flawed strategy by the initial distributor, which was based on pushing volumes of a cheaper Chinese product without proper support structures. The early market failures stemmed from a combination of inadequate products for the South African market and operational challenges in establishing robust aftersales support.

By 2010, the distressed Super Group Industrial Products division was acquired

by a consortium of four shareholders, which included Beiben, the original equipment manufacturer (OEM) of Powerstar, and Norinco Vehicle, the major shareholder. The deal culminated in the formation of ESI in August 2010, and the company moved its status from a dealership under the Super Group banner, to an OEM of the Powerstar brand in South Africa.

At the time of the acquisition, confirms Alan Parry, General Manager at ESI, only a couple of hundred Powerstar units had been assembled and sold locally. Armed with a clear strategy, underpinned by a rugged and simple product that comes at a cost-effective price point, complemented by a strong aftermarket regime, ESI would quickly turn the fortunes of the Powerstar brand, establishing it as a major force in the competitive South African commercial vehicle market.

Some nine years into the venture, ESI celebrated a significant milestone in its journey – the 5 000 th truck rolled off its Pietermaritzburg assembly line on May 28, 2019. Some six years later, ESI

has doubled the figure, with the 10 000 th Powerstar truck rolling off the production line, marking a major landmark in the history of the company.

“The achievement of 10 000 trucks in South Africa is not only a proud moment for ESI, but an exhibition of resilience and effort, especially in such a cutthroat market environment,” says Danny Li, CEO of ESI. “Over the years, we have had to navigate several hurdles to local production, such as electricity constraints, skills shortage and regulatory uncertainty, amongst others, to put the business on a growth trajectory. New challenges lie ahead, but we are geared to face and overcome them.”

Rodney Selesnick, Senior Head of Sales at ESI, says the assembly of the 10 000 th truck heralds the continued success of the Powerstar truck in South Africa. “The achievement confirms Powerstar’s pioneering position in the value market. When the brand first arrived on the scene, there were only two Chinese truck brands that local customers were willing to look at, and Powerstar was one of them. The product has been well accepted in the market and this milestone is a reminder of the strong recognition,” says Selesnick.

The 10 000 th truck milestone, says Parry, coincides with record-breaking sales volumes of Powerstar trucks in the local market. To provide context, ESI expects

In August 2025, Ever Star Industries celebrated a major landmark – the 10 000 th truck to roll off the local Pietermaritzburg production line

The achievement of 10 000 trucks in South Africa is not only a proud moment for ESI, but an exhibition of resilience and effort, especially in such a cutthroat market environment

While South Africa remains the major market for Powerstar, the company is encouraged by the continued sales growth in the SADC region

As part of its strategy to further grow outside South Africa, Ever Star Industries has just appointed a dealer in Mauritius

a record 1 000 truck sales in 2025, with a projection to grow the volumes even further to between 1 300 and 1 500 units in 2026.

The assembly facility, which currently has the capacity to produce 1 000 trucks a year, will also be upscaled to accommodate the growing sales volumes. Available market figures also show that Powerstar is the market leader in construction vehicle sales, with a 30-35% share of the market segment in South Africa.

Central to this success are a number of factors. “One of

While South Africa remains the major market for Powerstar, the company is encouraged by the continued sales growth in the SADC region. Selesnick tells Quarrying Africa that cross-border sales of Powerstar trucks have grown about 20% in the past two years, with Zimbabwe one of the leading markets to date. This is despite the challenges related to the influx of used truck imports and the lack of access to finance. Namibia, adds Selesnick, has traditionally been one of the strong crossborder markets for Powerstar sales, but has gone flat in recent times.

the major growth pillars of the brand has always been the rugged nature of the product, giving customers a good three to four cycles, even in challenging applications such as construction and mining,” says Selesnick, adding that this is complemented by a competitive price point and the inherent lower total cost of ownership of the truck.

However, every good product, stresses Parry, is only as good as the support behind it. “Besides the quality of the product and its favourable price point, one of the major success factors is our aftermarket support. Over the years, we have continuously reinforced our support footprint, which to date boasts some 30 dealers in South Africa and SADC at large. At any given time, our parts stockholding, housed in three big warehouses, is greater than R120-million, ensuring greater uptime for our customers in the region,” says Parry.

Just like in South Africa, the cross-border growth has been largely fuelled by a strong dealer network. Ever Star Industries has partnered with capable dealer partners in all the major markets, including Zimbabwe, Zambia, the Democratic Republic of Congo, Botswana, Namibia and Mozambique.

“In recent years we have seen some of our existing South African customers branching out into SADC markets such as Botswana, Namibia and even Mozambique, to explore new opportunities, and this has been another contributing factor to our growth in the region,” says Selesnick. “In Mozambique alone, we have put in some 30 new trucks this year, which is a big deal for us, given that it is from a zero base.”

As part of its strategy to further grow outside South Africa, Ever Star Industries has just appointed a dealer in Mauritius, a market deemed to offer strong growth prospects for the Powerstar brand. “As we seek to grow our business in cross-border markets, we will continue investing in our dealer partners to ensure a strong foothold on the ground and reliable aftermarket support to our customers,” concludes Selesnick. a

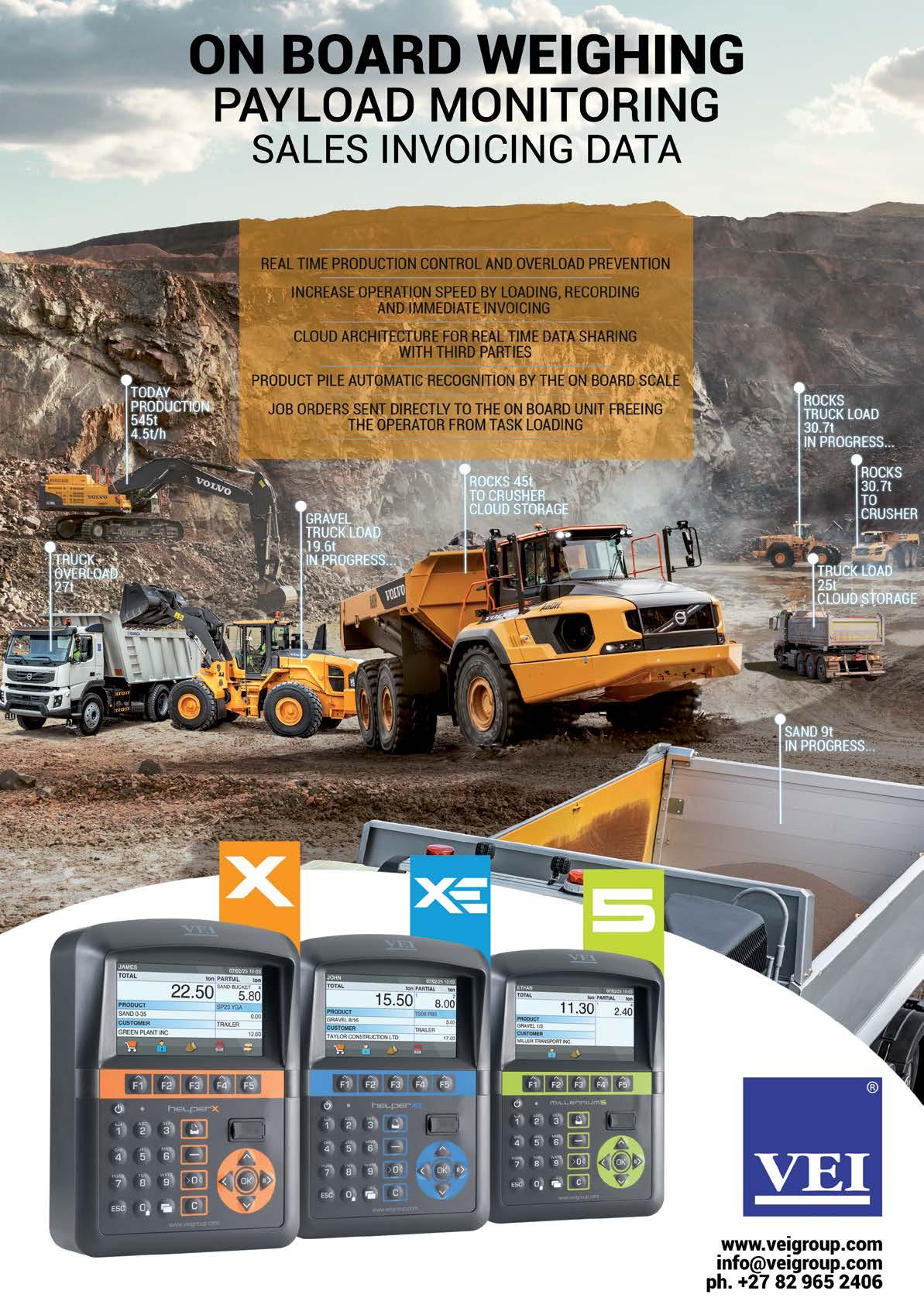

The L5000 units fit universally on any OEM loader brand, irrespective of the size or model, making it easy for any customer who wants to have a quality and accurate weighing system.

Nearly two years after its local introduction, the Loadrite L5000 advanced weighing system has gained significant traction in South Africa, with positive prospects in cross-border markets. Speaking to Quarrying Africa, Loutjie van der Merwe, Loadrite divisional manager at Loadtech Load Cells, the Loadrite distributor in southern Africa, says key markets to date include chrome and coal mining, followed closely by sand and agriculture.

BBy Munesu Shoko

arely 24 months since its local debut, the Loadrite L5000 SmartWeigh system has seen a huge uptake, with over 150 installations to date across commodities, confirms Van der Merwe. The L5000 – a rugged tablet-type smart scale interface with built-in modem – replaces the highly popular L3180 model, which is now reaching the end of its production lifetime.

“Given that the units are very similar in setup and operation, it only takes a few easy steps to upgrade any current L3180 system to the technically advanced L5000 wheel loader scale. This means that customers with an existing Loadrite system can upgrade at a fraction of the cost of installing a new system, and with very little downtime,” explains Van der Merwe.

The North West and Northen Cape provinces of South Africa, he adds, are by far the most popular areas for loading systems, hence the high adoption of the L5000 smart scale in these two mining destinations. However, Loadtech has also seen a slight increase in uptake in the Western Cape and KwaZulu-Natal in the past few months. Commenting on leading customers in terms of commodity areas, Van der Merwe says chrome and coal mining remain the top markets, with sand and agriculture following closely.

Overall, customer feedback on the Loadrite L5000 smart scale has been overwhelmingly positive. “Users appreciate accuracy, efficiency and ease of use it brings to their operations. The system not only enhances productivity but also contributes to significant cost savings and compliance, making it a valuable tool for front-end loader operations,” says Van der Merwe.

Syncing multiple devices via the cloud across various plants makes it easy for operators and managers to update data fields and customer information without manual input. This information is then backed up and stored in real time. The system can store up to 90 days of

transaction history on the device itself.

The L5000 units also fit universally on any OEM loader brand, irrespective of the size or model, making it easy for any customer who wants to have a quality and accurate weighing system that can be fitted with a printer and/ or modem to track loading reports in real time.

“The Loadrite L5000 advanced weighing system stands as a transformative solution for front-end loader operations, addressing key challenges in accuracy,

150

Barely 24 months since its local debut, the Loadrite L5000 SmartWeigh system has seen a huge uptake, with over 150 installations to date across commodities

40%

The L5000 has a 7-inch high-resolution display that is 40% bigger than the L3180

Nearly two years after its local introduction, the Loadrite L5000 advanced weighing system has gained significant traction in South Africa, with positive prospects in crossborder markets

The North West and Northen Cape provinces of South Africa are by far the most popular areas for loading systems, hence the high adoption of the L5000 smart scale in these two mining destinations

In terms of commodity areas, chrome and coal mining remain the top markets, with sand and agriculture following closely

efficiency and compliance. Its innovative features –such as real-time weight measurement, user-friendly interface and comprehensive data analytics – empower operators to optimise their workflows and enhance productivity,” he adds.

Commenting on some key features and benefits of this technology, Van der Merwe makes special mention of

The growth in uptake of the L5000 is in line with the increasing demand for advanced technology integration such as cloud connectivity to enable real-time data monitoring and analysis

the Loadrite L5000’s combination of real-time accuracy, user-friendliness and data-driven insights as the key factors behind its early success in the market.

Key features include a loadout management system which can connect to the weighbridge software, extensive

onboard metrics and loadout history. Customers can easily review and reprint their past load tickets. Easy connection to Loadrite InsightHQ with integrated 4G modem and WiFi substantially reduces the cost of connecting data to the office.

The L5000 has a 7-inch high-resolution display that is 40% bigger than the L3180. This means operators can see more information and details on the screen and enjoy a clearer and sharper view of their loading tasks. The display is sunlight-readable and can switch to a night mode to suit different lighting conditions. Ground slope compensation and digital sensing technology provide superior weighing accuracy.

Based

The growth in uptake of the L5000, says Van der Merwe, is in line with the increasing demand for advanced technology integration such as cloud connectivity

to enable real-time data monitoring and analysis. In addition, he says, there is also a growing emphasis on accuracy and precision in load weighing systems to ensure compliance with industry standards and regulations. Additionally, there is a trend towards the development of more user-friendly interfaces and mobile applications for easier operation and data management. Overall, the market is moving towards more efficient, reliable and technologically advanced load weighing systems to meet the changing needs of industries.

“Based on current market trends and possible upgrade cycles for customers running the L3180 system, the L5000 should reach an additional 150 to 200 installed units in the next 12 months. We are also positive of additional uptake from neighbouring countries such as Botswana and Mozambique,” concludes Van der Merwe. a

Sandvik Rock Processing has this year seen a surge in demand for its mobile crushing and screening equipment across Africa – a remarkable achievement in an increasingly competitive landscape. Central to the growing demand are a number of initiatives, including the reinforcement of its regional footprint to increase speed to market, identifying the right products for the right markets, keeping sufficient inventory levels and matching that with an aggressive aftermarket strategy. By Munesu Shoko

Arenewed focus on its mobile crushing and screening business in Africa is resulting in a surge in demand for Sandvik Rock Processing equipment. What makes this growing demand particularly significant, says PC Kruger, Business Line Manager Crushing at Sandvik Rock Processing, is the breadth of application, with the growing fleet now equally supporting mining and quarrying/aggregates sectors, together with their contracting counterparts.

Speaking to Quarrying Africa, Kruger says three regions – Central Africa, West Africa and southern Africa – have particularly enjoyed an increased opportunity capture rate in 2025. In Central Africa – predominantly anchored by Zambia, Tanzania and the Democratic Republic of Congo (DRC) – large mining units such as the heavy duty UJ440 and the UJ640 mobile jaw crushers are driving the market.

“In southern Africa, we have seen a major uptake of our small to medium sized mobile crushing and screening models, particularly driven by the quarrying/

market. In West Africa, we have seen a growing interest in wheeled units,

11

With 11 legal entities across Africa, Sandvik has local, in-country support structures to ensure speed of service

With its semi-static wheeled plant range, Sandvik Rock Processing has the right solution for 100-150 tph capacity requirements

In southern Africa, we have seen a major uptake of our small to medium sized mobile crushing and screening models, particularly driven by the quarrying/ aggregates market. In West Africa, we have seen a growing interest in wheeled units, especially in applications requiring easy, rapid relocation and cost-effectiveness of these electrically-driven models.

In addition to our own Sandvik entities, we have an established distributor network which extends our footprint significantly, allowing us to get even closer to the customer. We have in recent times placed a major focus on finding the right partners to get us closer to customers across Africa.

A renewed focus on its mobile crushing and screening business is paying dividends for Sandvik Rock Processing in Africa, with a surge in demand in 2025

Three regions – Central Africa, West Africa and southern Africa – have particularly enjoyed an increased win rate during 2025

One of the major growth drivers has been the strategy to select the right product for the right market and match that with a strong aftermarket regime

In addition to its own Sandvik entities, the company has an established distributor network which extends its footprint significantly across Africa

especially in applications requiring easy, rapid relocation and cost-effectiveness of these electrically-driven models,” says Kruger.

Commenting on what the impressive growth in demand could be attributed to, Kruger says a combination of factors has been at the centre of Sandvik’s resurgence in the African mobile crushing and screening market. Firstly, he says, the major competitive edge is the company’s comprehensive range of primary jaw crushers, open and closed-circuit cone crushers and impact crushers, complemented by a large selection of finishing and scalping screens that suit most process needs across applications, from construction and quarrying to large mining projects. However, says Kruger, “selecting the right product for the right market” has been one of the major growth

drivers. Sandvik Rock Processing has conducted thorough market research to identify customer needs, pain points and gaps in existing offerings in each of the regions and then matched these insights with products that offer a compelling value proposition and competitive advantage for the selected market.

“The strategy is to bring specific units that align with market needs in certain regions. For example, in southern Africa, we have identified the 225-tph QJ241 and the 400-tph QJ331 as the ideal jaw crusher models, especially given that this market is currently driven by the quarrying/ aggregates market. On the cone crusher front, it is largely the QS332 and the UH440, which will soon be joined by the newly launched QH443E, a fully electric unit,” says Kruger.

Given the accelerated nature of projects and ultimately the fast-tracked procurement decisions in this specific market segment, Kruger says Sandvik places value on keeping stock on the ground. Holding stock ensures immediate product availability, enabling Sandvik to meet customer demand promptly, reduce stockouts and associated lost sales. The constant stock replenishment programme, he says, is supported by the factory to ensure success.

As cost pressures continue to bite, crushing and screening equipment owners are placing greater emphasis on reliable aftermarket support. With 11 legal entities across Africa, Sandvik has local, in-country support structures to ensure speed of service, says Lomave Sukati, Aftermarket Manager – Crushing at Sandvik Rock Processing.

“In addition to our own Sandvik entities, we have an established distributor network which extends our footprint significantly, allowing us to get even closer to the customer. We have in recent times placed a major focus on finding the right partners to get us closer to customers

across Africa,” says Sukati.

A case in point is S&R Enterprises, Sandvik’s dedicated distributor for the construction and aggregates industry in southern Africa, which has a specific focus on small to medium-sized static and mobile crushing and screening equipment in the 100-200 tph segment. The appointment of S&R Enterprises in 2024, says Kruger, has provided “extra feet on the ground”.

While Sandvik Rock Processing retains its focus on larger mining customers, S&R Enterprises provides committed support to construction and quarrying customers, as well as mining contracting companies, allowing for rapid response to the market’s needs.

“Having S&R Enterprises on board has freed up our original equipment manufacturer (OEM) resources to allow us to look after the mining and EPCM (Engineering, Procurement, and Construction Management) customers better, while S&R deals with often urgent needs of quarrying and construction customers. These are two different set of customers with different needs, hence the need for two distinct approaches,” says Kruger.

Stephen Smith, MD of S&R Enterprises, says the success in southern Africa has been a collaborative effort between his company and the principal, Sandvik Rock Processing. From the onset of the distributorship agreement, both entities cast a special focus on getting the aftermarket support structure right, and some ten months into the venture, Smith says this has been achieved and has been one of the key pillars of the quick growth.

“From the start, at the core of our strategy was to get the aftermarket regime right, particularly getting the pricing for parts in line with market expectations. We have also tripled our critical parts stock, matching the installed base within our region. Initially, we had a 24-month target to achieve this, but ten months into the distributorship venture, we are way ahead of our targets. This has been one of the biggest contributors to our early success,” says Smith.

Sandvik Rock Processing reports strong demand for its QJ241 and QJ341 models, both of which are well suited to quarrying, aggregates and contracting applications across Africa.

In addition, there has been a massive investment in skills development, with OEM training provided not only to Sandvik and distributor technicians, but also to customers in all regions. For example, at the time of writing, Sandvik Rock Processing was busy providing certified cone crusher training to clients.

Jaco Benade, Project Manager – Crushing and Screening at Sandvik, says continuous investment in training, especially in a skills-scarce environment such as Africa, ensures safe and effective use of Sandvik products, reduces customer downtime, improves competitiveness and closes a growing skills gap exacerbated by technological change and an ageing workforce.

and screens. In line with this approach, Sandvik Rock Processing has brought into South Africa its first ever dual-powered machine, a Sandvik QA452e tracked Doublescreen. At the time of writing, the machine was due for delivery to S&R’s customer operating at a flagship dam construction project in Lesotho.

S&R Enterprises, Sandvik’s dedicated distributor for the construction and aggregates industry in southern Africa, has a specific focus on small to medium-sized static and mobile crushing and screening equipment in the 100-200 tph segment

Another success driver, says Smith, has been a strong emphasis on technology. One of the principal areas of focus has been the adoption of Sandvik My Fleet, which enables data-driven crushing and screening operations. My Fleet provides access to real time data from Sandvik mobile crushers and screens equipment via a portal.

This provides a user-friendly, intuitive dashboard which gives a comprehensive overview of data with a single sign-in. It is a secure cloud-based platform which is easily accessible to all authorised users 24/7/365. The user-friendly interface can be customised to each user’s requirements.

In line with the technology drive, both Kruger and Smith note that the next area of focus is electric crushers

“We are excited about the arrival of our first hybrid machine in South Africa. As we expand our electric drive solutions, we will also be bringing in our first fully electric machine, the UJ443E cone crusher, in October this year. This forms part of our drive towards a more sustainable future and helping our customers to lower their operating costs,” says Kruger. In response to evolving market needs, Sandvik Rock Processing, in partnership with S&R Enterprises, will place a major focus on semi-static wheeled plants in southern Africa. Smith believes this solution speaks directly to the African market, excluding South Africa, where most of the new aggregate operations are generally temporary setups located close to where infrastructure development projects are taking place.

“Many of the clients in the construction/aggregates market are looking for solutions that allow them to easily relocate their plants to infrastructure development hotspots. Once they get to site, they want to mobilise quickly and start operating immediately. With our Sandvik semi-static wheeled plants, we have the right solution for 100-150 tph capacity requirements,” concludes Smith. a

Caldas brought its own range of comminution equipment to market three years ago.

Traditionally renowned a crusher wear parts specialist for the past 29 years, Caldas for Crushers Wears Spares expanded its business with the launch of its entry-level portable comminution equipment in 2022. The decision to design and manufacture simple and ready-to-operate crushing equipment was in direct response to the operational needs of an emerging pool of small contractors in the extractive sector seeking to strike a balance between equipment dependability and affordability. By Munesu Shoko.

In recent years, the mining sector – particularly in South Africa and southern Africa at large – has witnessed increased participation from small, emerging junior miners across various commodities. The growing number of small, locally-owned companies and individual entrepreneurs entering the sector is largely driven by government policies aimed at promoting emerging miners by helping them access marginal deposits and play a greater role in the industry. However, limited access to capital remains a major hurdle. These operators still need quality equipment solutions that can offer long-term value

and productivity without breaking the bank. Reliable comminution equipment is an important investment in the contracting business, but finding the balance between durability and cost remains a challenge for small-scale miners.

To help close this gap, Caldas brought its own range of comminution equipment to market three years ago, specifically in response to the growing number of small-scale miners coming to the fore.

“We recognised that many contractors needed durable crushing plants at a lower capital investment. Our focus has been on keeping the designs simple, straightforward and easy to maintain,” says Michael

11

In just three years after establishing its equipment business, Caldas for Crushers Wears Spares already offers a broad range of crushers – 11 in total

The focus is on plug-and-go, modular or skidmounted type of electric driven crushing equipment in the up to 150 tonnes per hour tph capacity range

offers plug-and-play, modular

Limited access to capital remains a major hurdle for small-scale mining contractors, yet they need quality equipment solutions that offer long-term value and productivity without breaking the bank

To help close this gap, Caldas brought its own range of comminution equipment to market three years ago, specifically in response to the growing trend of smallscale miners

Caldas plants come at a lower capital investment, offer immediate availability, are simple to transport and operate, and require low skill levels

Since the launch of the first units three years ago, the installed base has grown significantly, with chrome and aggregates currently leading the uptake

require low skill levels. Customers can also feel confident knowing they have support from a team that has amassed a lot of experience over nearly three decades.

Julius Mokuwe, Head of the Technical Department, says immediate availability is a game-changer, not only for small-scale miners, but for the industry as a whole. “Because mining projects are often fast-tracked, immediate availability matters. That is why we keep a healthy inventory of crushers that are ready to go,” says Mokuwe.

High inventory levels, adds Miles Mulder, Head of Sales at Caldas for Crushers Wears Spares, ensure product availability to meet customer demand and improve customer satisfaction. They also act as a buffer against supply chain disruptions and seasonal demand spikes as commodity prices improve. “Our inventory approach helps us deliver faster and support smooth, continuous production for our customers,” says Mulder.

One of the emerging trends in the mining market, adds Mulder, is the demand for second-hand crushers from different sources, including auctions and mothballed operations.

“With our in-house range, we aim to offer customers new equipment at a cost closer to premium secondhand options, supported by strong aftermarket service and technical support,” adds Da Camara.

In just three years since establishing its equipment business, Caldas for Crushers Wears Spares already offers a broad range of crushers – 11

in total – including seven jaw crushers, two cone crushers and two horizontal shaft impactors, highlighting the rapid pace of development in response to market needs. These units cover a broad capital cost range, from R250 000 up to R5-million, catering to various customer requirements.

The focus, explains Caldas, is on plugand-play, modular or skid-mounted electric-driven crushing equipment in the up to 150 tonnes per hour (tph) capacity range. “Because of our cost-effective capital cost and immediate availability, we are seeing growing interest in the range, even from larger customers. We will probably, in the near future, be challenged to make bigger equipment to cater for higher tonnage requirements, but at the moment the focus is on the up to 150 tph market,” says Caldas.

Since the launch of the first units three years ago, the installed base has grown significantly, with chrome and aggregates at the forefront of the uptake. The company, confirms Mulder, has also supplied a unit to a gold mine in Scotland, highlighting the growing interest in this equipment range across commodities and regions.

While the majority of units are currently operating in South Africa, Caldas notes a

growing number of enquiries from neighbouring markets such as Zimbabwe, Zambia, the Democratic Republic of Congo, Mozambique and Tanzania.

“The equipment portion now constitutes about 20% of our overall business, and based on our projections, this is still a major growth area. We forecast it to reach 30% of our business in the near future. However, it is important to note that alternative crusher wears and spares will remain the core of our business. We have been involved in this market for the past 29 years, and we have built valuable experience, which has earned us trust in several regions,” says Caldas.

To support the successful rollout of its crushing equipment range, Caldas for Crushers Wears Spares has made significant investments in facilities and people. According to Da Camara, the investment in a new warehouse next door has created more space for assembly and testing of crushers. The new facility has also allowed the company to hold more stock on the ground in terms of spares and wears.

“We have also expanded our lifting capacity significantly to cater for larger crushing units. The expanded space not only allows us to store more equipment and spares, but also provides ample room

for research and development (R&D). While this was a capital-intensive investment, it was necessary to support the growth of our equipment business,” says Da Camara.

According to Caldas, the investment in a new facility has doubled the company’s warehousing area while quadrupling the covered area. “Having bought the new warehouse some three years ago, we have only fully utilised it in the past two years following the installation of overhead cranage,” explains Caldas.

Apart from facilities, Mokuwe says there has been a major focus on people, particularly technical skills. “In the past two years, we have expanded our technical capacity to develop and support our equipment range. We will continue to grow our technical expertise as the business grows,” says Mokuwe.

“We are proud to have created opportunities for many individuals who were previously unemployed, helping them grow with us along the way,” says Caldas.

Mokuwe also notes a strong focus on R&D, with the company partnering with external laboratories to conduct crusher performance analysis and various aother tests. “We make use of several laboratories for instances such as non-conformances and predictive analysis. Working closely with these external facilities ensures product quality,” says Mokuwe.

Commenting on quality management systems, Caldas highlights that the company is ISO 9001 accredited and strives to consistently provide products and services that meet customer and regulatory requirements, enhancing customer satisfaction through continuous improvement.

Commenting on the state of affairs, Da Camara says the mining market is currently under pressure, with commodity prices presenting a mixed picture amid recent volatility: precious metals have surged, while PGM prices are falling due to reduced demand from the automotive sector caused by the shift to electric vehicles and increased supply from recycling.

Caldas also notes that the local aggregates market is seeing an uptick in certain regions of South Africa, with provinces such as KwaZulu-Natal, Eastern Cape and Western Cape experiencing strong infrastructure rollout, particularly in road projects. However, some regions, such as Gauteng, remain under pressure with limited construction projects currently underway.

“The absence of mega infrastructure projects paints a bleak picture for the aggregates market. What really drives volumes are significant projects such as dams, stadia and major national highways, which have not been coming to market for a while. It is, however, encouraging to see the South African National Roads Agency (SANRAL) bringing some meaningful road projects such as the N2 and N3 to market,” concludes Caldas. a

it’s no

From large stones to the smallest grains: Bulk solids come in all types, shapes and sizes, but choosing the right measurement technology is surprisingly easy. With our level and pressure sensors, you can effortlessly keep an eye on all your important process values – and still have time to crack the really hard rocks.

Everything is possible. With VEGA.

The Tru-Trac Q-Series delivers reliable belt tracking and efficient cleaning performance, providing a cost effective solution for conveyor maintenance.

Quarrying by its nature is a price-sensitive industry because it deals with low-value bulk products, yet quarrying companies operate in complex and harsh conditions that require highquality products. Balancing the need for high-performance products with budget constraints is a constant challenge and a key factor in purchasing decisions. Against this backdrop, Tru-Trac Rollers is bringing to market its Q-Series range of belt scrapers and trackers or self-aligning idlers, specifically designed to meet the needs for quarries and related industries. By Munesu Shoko.

Seeking high-quality products at costeffective prices is a fundamental and enduring trend in the quarrying market, driven by a combination of factors, including the need for reliability in challenging environments, and the influence of market dynamics on profitability. While digital transformation and sustainability are some of the leading new trends, the core business principle of ‘value for money’ remains a constant driver for procurement decisions. This is the view of Douglas van der Westhuizen,

Technical Sales Representative at Tru-Trac Rollers, a specialist provider of conveyor components for the global mining and bulk material handling industries, who says that one of the trends shaping the industry is the requirement for high-quality products at competitive prices. This, he says, is particularly the case in the quarrying and related industries such as cement, where a combination of generally tight budgets and market dynamics are central to the need to ‘tighten the belt’. Given the arduous nature of quarrying operations, high-quality products are essential to ensure reliability,

minimise downtime and maintain safety, all of which impact the bottom line. “Traditionally, quarrying has always been deemed a light duty industry compared to mainstream mining. However, in South Africa we have noticed that the opposite is true – quarrying operations are demanding. To operate efficiently and profitably, the industry is reliant on good products, but tight budgets are a reality that operations have to contend with, mainly due to the fact that the industry processes high-volume, low-value material,” says Van der Westhuizen.

Having over the years fostered strong ties with key quarrying customers, Tru-Trac has committed itself to delivering quality products at competitive prices to the industry. This comes in the form of a newly designed range of belt scrapers and trackers that speak

Balancing the need for high-performance products with budget constraints is a constant challenge and a key factor in purchasing decisions in the quarrying sector

Against this backdrop, Tru-Trac Rollers is bringing to market its Q-Series range of belt scrapers and trackers or self-aligning idlers, specifically designed to meet the needs for quarries and related industries

One of the most common causes of unscheduled downtime on conveyor systems is belt misalignment, which causes spillage, belt edge damage, damage to the structure, increased power consumption and increased labour costs

Continuous inspection, the need to always ‘look and see’, is crucial to keeping conveyor systems operating at peak performance

directly to the needs of quarries. As with any other new product from Tru-Trac, the Q-Series range is currently undergoing a rigorous testing regime before commercial rollout, confirms Guy Fitt, National Sales Manager at Tru-Trac.

According to Fitt, the Q-Series range is ideally suited for conveyor belt widths between 300 mm and 1 200 mm – typical sizes found in most quarries and cement operations. “Having done business in the quarrying industry for a while, we saw the need for us to develop a quality product that comes at a competitive price. We put our heads together and redesigned some of our existing premium products to cut costs without sacrificing on quality and functionality,” says Fitt.

By changing some internal component designs, says Van der Westhuizen, Tru-Trac managed to cut both manufacturing and material costs. “For example, we looked at things such as the flat return tracker, the primary, and secondary scraper. While the primary scraper maintains the same quality and functionality as its premium counterpart, we changed the stainlesssteel component to the normal mild steel zinc-plated option, which reduces the price significantly. While the premium product comes with a lifetime guarantee on tensioners, the Q-Series still gives you the same performance but is not guaranteed for life,” says Van der Westhuizen.

From a physical standpoint, adds Van der Westhuizen, the flat return tracker looks exactly the same as the premium offering, but adopts slightly different brackets. The secondary belt scraper maintains the same functionality as that of the premium solution, but it

The Q-Series range is ideally suited for conveyor belt widths between 300 mm and 1 200 mm – typical sizes found in most quarries and cement operations

Designed for conveyors ranging from 300 to 1 200 mm, the Tru-Trac

uses a smaller cushion for the blades. These cushions bolt directly onto the shaft, eliminating the need for the cassette. It also has a lower profile, allowing Tru-Trac to offer it at a significantly lower price.

Quarries and mines lose thousands of productive hours each year due to conveyor system issues and, according to Fitt, some of the most common ones include belt misalignment, material carryback, and rip events – all of which directly impact throughput, operational costs, and safety.

“One of the most common causes of unscheduled downtime on conveyor systems is belt misalignment, which causes spillage, belt edge damage, damage to the structure, increased power consumption and

“Having done business in the quarrying industry for a while, we saw the need for us to develop a quality product that comes at a competitive price. We put our heads together and redesigned some of our existing premium products to cut costs without sacrificing on quality and functionality.

increased labour costs. Misaligned belts will ultimately result in lost production, increased operating costs, and safety hazards,” says Fitt.

Misaligned belts, says Van der Westhuizen, can also result in environmental issues by increasing material spillage and dust generation, which can contaminate nearby ecosystems and water sources, lead to regulatory non-compliance and negatively affect the health of both workers and nearby communities.

Carryback, adds Fitt, is another ‘common enemy’ in conveyor systems. Carryback represents loss of product, which, over time, can add up to significant financial costs, especially in systems handling large volumes.

“Carryback directly reduces conveyor productivity by creating unscheduled downtime for cleanup, degrading components such as rollers and pulleys, causing

“It is important to make sure that all the structural conveyor components such as pulleys, idlers, take-ups and the supporting structure are properly aligned at all times. In fact, these should be the principal areas of concern whenever trying to identify belt tracking problems.

Tru-Trac on-site inspections and technical support ensure that every conveyor system continues to run at peak performance.

material loss and leading to belt tracking issues that necessitate further maintenance,” says Fitt.

Drawing on decades of field experience, Fitt and Van der Westhuizen outline some of the best-practice maintenance approaches to keeping conveyors running at peak performance in demanding quarrying conditions.

According to Fitt, continuous inspection, the need to always ‘look and see’, is crucial to keeping conveyor systems operating at peak performance. With this approach, minor issues are identified early on before they escalate into major problems that lead to unexpected breakdowns. This approach minimises unplanned interruptions, ensuring that material transport is

uninterrupted and production schedules are maintained.

“Our maintenance teams are regularly on customer sites, conducting these ‘look and see’ inspections. Through these inspections, we can advise customers on potential issues before they become big setbacks. Addressing small issues when they are first noticed is significantly less expensive than emergency repairs on major failures such as belt rips,” says Fitt.

According to Van der Westhuizen, constant condition monitoring of conveyor components is one of the best practices in ensuring correct belt tracking at all times. It is essential to be fully aware of the basic characteristics of the different belt tracking components and for these to be employed correctly.

“It is important to make sure that all the structural conveyor components such as pulleys, idlers, take-ups and the supporting structure are properly aligned at all times. In fact, these should be the principal areas of concern whenever trying to identify belt tracking problems. All pulleys, snub rollers, troughing and return idlers must be square with the frame parallel to each other, and also be level,” concludes Van der Westhuizen. a

Given the criticality of conveyor systems to the success of mines and quarries, the importance of adopting a proactive maintenance strategy cannot be stressed enough.

Speaking to Quarrying Africa, Keletso Mabula, Sales Engineer: Belt Cleaners at MATO Products, stresses that conveyors are the arteries of a mining or quarrying operation, and when they stop, production stops. A proactive maintenance strategy is therefore not optional, it is essential. By Munesu Shoko.

One of the most significant threats to a mining or quarrying operation is the failure of a belt conveyor and the resultant downtime and ultimately lost production. Given that the consequences can vary from expensive to disastrous, it is logical for operations to take every

possible measure to prevent such events from happening. A proactive maintenance strategy is therefore crucial for efficient conveyor performance and serves as the best defence against catastrophic failures.

According to Mabula, conveyors are the lifeblood of mining or quarrying operations, and their stoppage means lost production.

The MATO MCP3 Primary Cleaner is designed to effectively remove carryback from conveyor belts at the head pulley, reducing spillage and preventing material buildup.

“Proactive maintenance helps optimise operating costs by reducing emergency repairs, minimising spillage and improving energy efficiency through properly aligned and tensioned belts. Ultimately, it shifts maintenance from being a cost centre to a value-adding function that safeguards production continuity.

Conveyors are the arteries of a mining or quarrying operation, and when they stop, production stops

By anticipating wear and addressing issues before they become failures, operations can significantly reduce unplanned downtime, extend the lifespan of belts and components, as well as improve safety

Proper splice maintenance reduces the risk of belt failure, material loss and damage to other components, while also lowering long-term costs associated with repairs and replacements

Mines and quarries that empower their teams with the right tools, training and mindset to care for their conveyors consistently outperform those that wait for breakdowns to occur

A proactive maintenance strategy is therefore nonnegotiable. By anticipating wear and addressing issues before they become failures, explains Mabula, operations can significantly reduce unplanned downtime, extend the lifespan of belts and components, as well as improve safety.

“Proactive maintenance also helps optimise operating costs by reducing emergency repairs, minimising spillage and improving energy efficiency through properly aligned and tensioned belts. Ultimately, it shifts maintenance from being a cost centre to a value-adding function that safeguards production continuity,” says Mabula.

As someone who is always on the ground to help operations optimise their conveyor systems, Mabula highlights some of the proven best practices, and one of the principal ones is regular belt inspections

checking for signs of wear, mistracking and joint failures. Early detection of these issues allows for proactive, preventative maintenance before problems escalate into expensive, production-halting failures.

It is also important to maintain splices regularly, adds Mabula, ensuring clips are properly installed and replaced on time. Proper splice maintenance reduces the risk of belt failure, material loss and damage to other components, while also lowering long-term costs associated with repairs and replacements.

Regular belt cleaner maintenance – replacing blades and maintaining correct tension to minimise carryback and spillage – is critical. Maintaining proper belt cleaner operation extends belt life, reduces energy consumption, enhances worker safety, ensures product quality, and ultimately lowers maintenance costs and increases operational productivity.

Lubrication – keeping idlers, pulleys, and bearings in peak condition – is another key component of a proactive conveyor maintenance regime. By minimising friction and wear between components such as pins and bushings in chains, lubrication significantly extends the life of the conveyor system.

“Regular training and operator involvement also ensures teams are equipped to spot early warning signs and perform routine checks. When these practices are embedded into daily routines, plants experience fewer breakdowns and better overall belt performance,” says Mabula.

Designed for easy installation and long-lasting performance, Mato belt clips minimise belt slippage and downtime.

The advent of technologies such as real-time monitoring systems has over the years changed the face of conveyor maintenance. Real-time monitoring systems transform conveyor maintenance by shifting from reactive to predictive maintenance, enabling continuous data collection and analysis to detect anomalies early.

“Real-time monitoring systems are transforming conveyor maintenance. Technologies such as belt misalignment detectors, load sensors and vibration monitoring, provide continuous data on conveyor performance. This enables predictive maintenance, where teams can act on early warnings, such as a bearing overheating or a splice beginning to fail, before the issue escalates. Beyond reliability, monitoring also improves safety by reducing the need for constant manual inspections in hazardous areas,” says Mabula.

Apart from real-time monitoring, Mabula notes that several other technologies have come to market to help with conveyor system maintenance. These include automated belt cleaners that adjust themselves to maintain optimal pressure; advanced splicing tools and fasteners designed to improve joint strength and reduce installation time; wear sensors embedded into liners and scrapers that trigger alerts when replacement is due; and drone and AI-based inspections to survey long overland conveyors or inaccessible sections of plant conveyors.

In conclusion, Mabula stresses that a proactive conveyor maintenance strategy is not just about technology or best practice, it is about culture. Mines and quarries that empower their teams with the right tools, training and mindset to care for their conveyors consistently outperform those that wait for breakdowns to occur.

“In today’s competitive environment, proactive maintenance is a competitive advantage, not just a technical necessity. Overall, investing in proactive strategies and smart tools enhances reliability, safety and productivity,” concludes Mabula. a

The introduction of the Leica iCON grade iGG3 Dual GNSS Grader solution provided high-a precision, durable and user-friendly system to enhance the overall efficiency and accuracy of the grading work.

Haw & Inglis Engineering (H&I Engineering), founded in 1984 and based in Cape Town, South Africa, is a construction company specialising in road construction and rehabilitation. While the company’s core focus is major national and provincial arterial roads and urban highways, its expertise extends to urban infrastructure and select industrial, commercial, residential and sporting building projects.

The group has strong vertical integration with in-house crushing and concrete work operations to support its roadwork activities. H&I Engineering is established as one of the leading independent contractors operating throughout South Africa and has recently expanded market focus to include certain Southern African Development Community (SADC) countries.

In recent years, the R61 Corridor has experienced a substantial increase in traffic volume, which has significantly impeded access to Mthatha Airport in the Eastern Cape. The upgrade of the R61 Corridor will assist in improving traffic flow and access to the airport. Numerous intersections have already been upgraded to improve traffic flow and ease turning into and out of the R61. Some access road

In recent years, the R61 Corridor has experienced a substantial increase in traffic volume, which has significantly impeded access to Mthatha Airport in the Eastern Cape

During the road upgrade project of the R61 in the Eastern Cape, H&I Engineering encountered several challenges that could have impacted the efficiency and effectiveness of the grading work

One of the primary issues was the excessive banks on the road (hyper elevations), especially where curved sections met straight stretches. This made it extremely difficult to maintain a consistent level while operating the grader

The introduction of the Leica iCON grade iGG3 Dual GNSS Grader solution addressed these specific issues, providing a high-precision, durable and userfriendly system to enhance the overall efficiency and accuracy of the grading work

Since the success of the R61 Corridor project, H&I Engineering has invested in three more Leica iCON iGG3 solutions. Additionally, the company has acquired more Leica survey equipment, including total stations and GPS systems

intersections have also been re-gravelled or surfaced. The R61 Corridor plays a key role in helping move people and freight around the region and beyond. An investment of R18,9-million from the project helped create

An investment of R18,9-million from the project helped create about 160-200 job opportunities for local skilled and semi-skilled workers during the construction phase

about 160-200 job opportunities for local skilled and semi-skilled workers during the construction phase. Skills development and other training opportunities have been offered to those working on site.

The R61 will now be a vital link and catalyst for the development of the Wild Coast Special Economic Zone – which aims to create new jobs and stimulate industrial development in the Eastern Cape.

During the road upgrade project, several challenges emerged that could have impacted the efficiency and effectiveness of the grading work. One of the primary issues was the excessive banks on the road (hyper elevations), especially where curved sections met straight stretches. This made it extremely difficult to maintain a consistent level while operating the grader.

The previous system struggled to cut to design level and had a wave effect, forcing operators to use the grader machine in first gear. This significantly reduced operational speed, leading to several inefficiencies.

Furthermore, critical parts, such as the hydraulic system, experienced accelerated wear and frequent leakages, which increased maintenance costs.

H&I Engineering was looking for a more advanced and reliable solution to ensure consistent grading levels, reduce operational inefficiencies and minimise equipment wear. The introduction of the Leica iCON grade iGG3 Dual GNSS Grader solution addressed these specific issues, providing a high-precision, durable and user-friendly system to enhance the overall efficiency and accuracy of the grading work.

The system underwent a trial period for three months on one of H&I Engineering’s graders, rigorously tested during a contract for the Western Cape Government. Initially, the contractor used another solution, but the Leica Geosystems team proposed a trial for a solution supported by dedicated technical specialists.