Journal of the Engineering Integrity Society

ENGINEERING INTEGRITY

March 2021 | Issue No. 50

TECHNICAL PAPER:

Low Filling Ratio Acoustic Space-Filling Curve Metamaterials for Jet Engine Inlets

ALSO INSIDE:

FATIGUE 2021, DOWNING COLLEGE, CAMBRIDGE

29 – 31 MARCH 2021

INSTRUMENTATION, ANALYSIS & TESTING EXHIBITION

SILVERSTONE, 14 SEPTEMBER 2021

www.e-i-s.org.uk

FATIGUE 2021

29 - 31 March 2021

KEYNOTES

Professor Robert Akid - Manchester University

Professor Filippo Berto - Norwegian University of Science and Technology

Professor Youshi Hong - Chinese Academy of Sciences

Professor Roderick Smith - Imperial College, London

Instrumentation, Analysis & Testing Exhibition

Silverstone Wing, Silverstone Race Circuit

14 September 2021, 10am-4pm

• 60 exhibitors from aerospace, automotive, motorsport, rail, off-highway, mechanical handling, civil engineering, industrial and power generation industries. The exhibitors offer a wide variety of modern instrumentation, measuring and modelling technologies

• Free Entrance to Exhibition and Mini Seminars

• Free Car Parking

• Complimentary Refreshments

To complement the exhibition there will be a number of Mini Seminars.

To pre-register: info@e-i-s.org.uk | www.e-i-s.org.uk

If you would like to receive this journal electronically, please contact the Marketing & Events Manager:

HONORARY EDITOR

Dr Spencer Jeffs

E-mail: s.p.jeffs@swansea.ac.uk

MANAGING EDITOR

Rochelle Stanley

Tel. +44 (0)7979 270998

E-mail: managingeditor@e-i-s.org.uk

MARKETING & EVENTS MANAGER

Sara Atkin

Engineering Integrity Society

6 Brickyard Lane, Farnsfield, Notts., NG22 8JS

Tel: +44 (0)1623 884225

E-mail: info@e-i-s.org.uk

WWW: www.e-i-s.org.uk

EDITORIAL POLICY

Engineering Integrity contains various items of information of interest to, or directly generated by, the Engineering Integrity Society. The items of information can be approximately subdivided into three general categories: technical papers, topical discussion pieces and news items. The items labelled in the journal as technical papers are peer reviewed by a minimum of two reviewers in the normal manner of academic journals, following a standard protocol. The items of information labelled as topical discussions and the news items have been reviewed by the journal editorial staff and found to conform to the legal and professional standards of the Engineering Integrity Society.

COPYRIGHT

Copyright of the technical papers included in this issue is held by the Engineering Integrity Society unless otherwise stated.

Photographic contributions for the front cover are welcomed.

ISSN 1365-4101/2021

The Engineering Integrity Society (EIS) Incorporated under the Companies Act 1985.

Registered No. 1959979

Registered Office: c/o Hollis & Co., 35 Wilkinson Street, Sheffield S10 2GB

Charity No: 327121

ADVERTISING RATES & DATA

‘Engineering Integrity’ is published twice a year

Black and White

1 insert 2 Inserts

Full Page £255 £460 annual

Half Page £158 £285 annual

Quarter Page £92 £175 annual

Full Colour

1 insert 2 Inserts

Full Page £445 £800 annual

Half Page £278 £500 annual

Quarter Page £160 £290 annual

Full Page 297mm (depth) x 210mm (width) and 3mm bleed

Half Page 255mm (depth) x 86mm (width) or 125mm (depth) x 180mm (width)

Quarter Page 125mm (depth) x 86mm (width)

Space is limited so place your order soon to avoid disappointment.

A copy of the latest issue of ‘Engineering Integrity’ is published on the website and includes all advertisements.

Loose Inserts £150 per A4 sheet (up to 160 gsm)

PRINCIPAL ACTIVITY OF THE ENGINEERING INTEGRITY SOCIETY

The principal activity of the Engineering Integrity Society is the arrangement of conferences, seminars, exhibitions and workshops to advance the education of persons working in the field of engineering. This is achieved by providing a forum for the interchange of ideas and information on engineering practice. The Society is particularly committed to promoting projects which support professional development and attract young people into the profession.

‘Engineering Integrity’, the Journal of the Engineering Integrity Society is published twice a year.

‘Engineering Integrity’ is lodged with the Agency for the Legal Deposit Libraries on behalf of the Bodleian Library Oxford University, the Cambridge University Library, National Library of Scotland, National Library of Wales and Trinity College Dublin.

events in early 2021, but with local and international travel restrictions in place it is of course not safe or recommended to do so yet. As such, Fatigue 2021, the 8th conference in the series will be held online and ondemand from 29 to 31 March. I do hope many of you will join the event which will explore the latest developments in the field, with Keynotes being delivered from worldleading experts.

In November, the UK committed to ban sales of new petrol and diesel cars from 2030 under its ten-point plan for a ‘green industrial revolution’. Offshore wind, hydrogen, nuclear, electric vehicles, jet zero and greener maritime make up a significant portion of these points. Many of the points outlined are pertinent to the EIS community and will no doubt pose significant challenges and opportunities alike.

Sadly, we lead this edition with an obituary for Dr Robin Anderson who passed away in July. Our condolences go to his family and friends.

The COVID-19 global pandemic continues, and the winter months have seen a surge in both cases and deaths in the UK with highly transmissible strains being detected, health services stretched to the brink and lockdown restrictions enforced. The global picture is largely similar; at the time of writing over 100 million cases have been officially recorded along with nearing 2.5 million deaths according to John Hopkins University database – staggering and tragic numbers.

Nonetheless, some countries have largely succeeded against COVID-19, the most prominent example being New Zealand which has seen less than 30 deaths and thousands in sports stadiums since June. There is potentially light at the end of the tunnel with vaccine development occurring at record speeds, be they mRNA, viral vector, or protein-based, and a number of these now approved vaccinations being rolled out and administered across populations.

I wrote in September that we had hoped for non-virtual

Diary of Events

The technical article in this issue investigates metamaterials for jet engine inlets, a long-term goal of which is aircraft noise control. Aircraft noise can disturb sleep, cause community annoyance, increase health risks to those living in the vicinity of airports and often constrains air traffic growth. Therefore, implementing noise reduction innovations is expected to result in significant benefits to the industry.

Industry news reports the use of machine learning technology in the field of additive manufacturing, a technology that offers huge potential in areas such as process optimisation, automation, design & simulation and data management, although, any biases or limitations need to be seriously considered.

For the majority of university students, certainly those studying the in UK, the world of online learning continues, with students largely recommended not to return to campuses and rent rebates rightly being given. Missing out on the full experience of university for any time period is not a nice thought and I commend their resilience in adapting to online learning. Personally, I look forward to the day we are back in lecture theatres or practical lab classes as opposed to being faced with a majority of muted name tiles.

Stay safe.

Spencer JeffsOBITUARY

Robin Anderson

1951–2020

We are sad to report that on 24th July 2020, our friend and colleague, Dr Robin Anderson lost his fight against leukaemia. We will miss him and our thoughts are with his family.

Many will remember him for contributions to EIS events over many years and could be forgiven for assuming he was British but was in fact born in 1951 in South Africa. He first came to the UK as a teenager and flew back and forth between home and school over the African continent in what we would now consider early jet airliners, which explains his interest in 'planes and in particular reliability and performance of jet engines in hot and high conditions. Robin gained a place at the University of Cambridge in 1970, graduating in 1974 with a materials science MA; anyone referring to him as a metallurgist would be swiftly corrected with a wry smile. Soon after, he studied at the University of Sheffield for an M.Met. in Metallurgy, graduating in 1977. He then returned to South Africa to work on his PhD in "Fracture in Aluminium Alloys" at University of the Witwatersrand graduating in 1983. He still found time to travel back and forth to the UK and in 1980, at a party in London, met another PhD student (from the London school of hygiene and tropical medicine) Moira, his future wife.

From 1984 to 1986 he returned to Sheffield where he worked as a post-doc research fellow on the measurement of Fatigue Thresholds in Structural Steel used in the UK Coal-mining Industry on behalf of the UK Health and Safety executive (HSE). It was there that he also made some lifelong friendships with colleagues with whom he spent time socially and technically, and connected him to the nCode world as a customer initially. In those days, due to South African roots, he had to report to the local Sheffield police station annually to register as "an alien", a story he liked to tell as it made him smile knowing full well that his public-school accent suggested he was more British than the bobby on the front desk! Robin then left academia for industry, putting his wealth of knowledge to good use. From 1986 to 1997, he worked at the Lucas Group (later TRW) research centre with the unforgettable Dog Kennel Lane address. He worked on materials development projects and also failure investigations for the Lucas operating companies, spanning both aerospace and automotive divisions. These days composites are common place and different industries just assume a short or long fibre type and polymer matrix, which can make for initially confusing discussions.

Robin, being a material scientist, would never miss the opportunity to ask if this composite

was wood or metal. At Lucas he'd worked on developing metal matrix composites for automotive use. Having used nCode's software in his Lucas days, he was drawn to joining the nCode team. In 1997, Robin left the big PLC for a small Sheffield company, nCode International (later to become HBM nCode, part of Spectris PLC), working on materials and fatigue related projects for customers and internal research work. One such example, spanning many years, was Thermo Mechanical Fatigue to help meet the ever rising temperatures of turbocharged engines. His broad knowledge of materials was widely recognised and appreciated as was also his "joie de vivre" which in Robin's case also reflected into his "joie de la technologie"! He could often be found bending over cars, including his beloved Jag S type and in earlier years, his Alfasud, and other engineering systems both old and new discussing them in detail and getting his hands dirty literally! Robin loved talking with people and his relaxed and friendly manner made him a very popular presenter and mentor to young engineers. He had a gift for explaining complicated phenomena in a simple and structured way. His wide experience of materials science always provided a rich source for witty and instructive anecdotes.

Robin is most fondly remembered by his nCode friends for his warmth and enthusiasm, especially when discussing new material testing methods over a panini and cappuccino, which he's always order with "an extra shot please". We frequently joked that no problem would be insurmountable when Robin was sufficiently fuelled with coffee and Coca-Cola. Many EIS members are involved in measuring the operating conditions of products and reproducing these in the lab. Others strive to simulate and predict the performance before testing. One vital input is materials performance, which Robin was always pleased to help with, offering both quantitative and qualitative advice, whilst reminding us of the need to test the material in question. Robin retired in 2016, looking forward to life beyond work with his family of which he was obviously very proud: Moira and their sons Hamish and Duncan. Even in his retirement he could not put down the materials pen, working as a freelance engineering consultant with past colleagues!

For sure, he will be missed by all of us who knew him and enjoyed his company both professionally and socially. One of his retirement projects was to restore the family Jaguar 420 to working order and hand the keys Hamish to drive away.

One of the key challenges we faced during 2020 was how to support our Young Engineers during a global pandemic, which has necessitated a change in approach to learning. The group had discussed the value of running webinars alongside our face-to-face seminars for some time and the current crisis has proved to be the right time to introduce this additional offering.

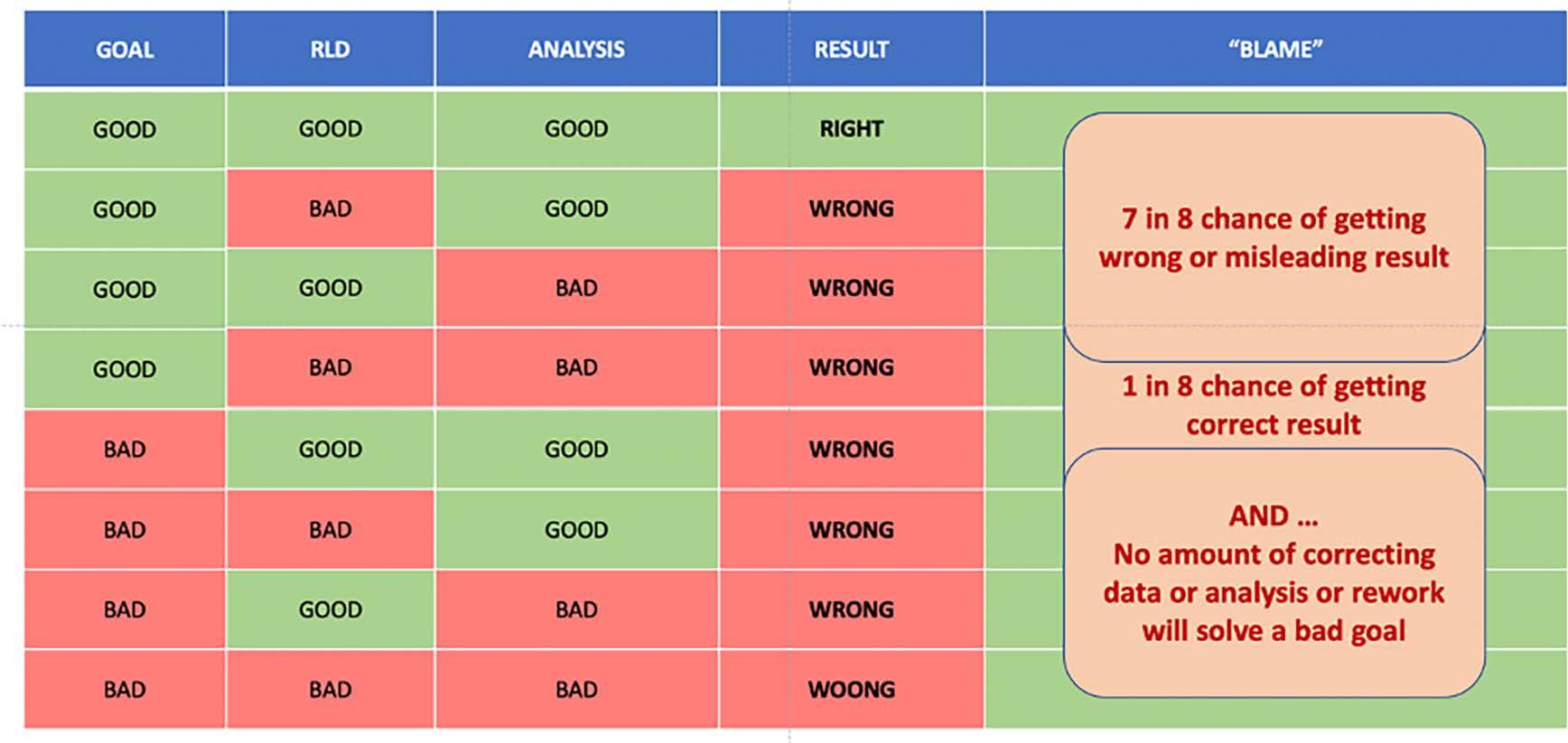

Our first webinar was delivered back in July when David Ensor (formally of HORIBA MIRA) kindly agreed to be our inaugural presenter with ‘Road Load Data Collection & Analysis - are you forgetting the basics?’ As this was our first foray into delivering virtually, we were relieved to only have a couple of minor technical hitches, but these did not detract from David’s informative and interesting talk. There was a steady stream of questions from the delegates which generated some excellent points for discussion. This resulted in the webinar continuing well over the allotted hour but almost all attendees remained on the call to the end. This is of course testament to David’s skills as a presenter and endorses our aim of sharing the knowledge and skills of experienced engineers with the next generation.

Our second webinar looked at the ‘Myth of Accuracy’ and we were grateful that Damian Harty, who had just returned to the UK from America, was willing to present during his enforced isolation period. The Myth of Accuracy was originally the focus of a paper in this journal (vol 9) back in 2001 and was subsequently presented at the very first Young Engineers meeting we held at the University of Birmingham in 2012. During his presentation Damian looked at the commonly held view that usefulness of a predictive model is directly related to its accuracy as measured in the real world. His argument was that there is a time when sufficient accuracy is optimum and he suggested an approach which encourages discernment of optimum accuracy by all involved in the process.

In a move away from our traditional technical seminars, our third and fourth webinars in the run up to Christmas focused on soft skills training. This is an area not always accessible to young engineers despite its value and importance in career and personal development and we regularly receive requests to address this gap. We were fortunate to collaborate with experienced and award-winning coach Dyfrig Jenkins of YOU.Development to bring ‘Feedback that Works’ and ‘Improving Performance through Effective Coaching’ to our audience. Dyfrig was keen to make these sessions interactive, encouraging delegates to present their own views and experiences, which encouraged greater participation. This enabled those attending to apply the presented concepts to their

own personal situations, and Dyfrig left plenty of time for questions and discussion to further the audience’s understanding and development.

We started 2021 with a webinar on a topic which is very much at the forefront of current research. ‘Destination Zero: Sustainability of the electrified vehicle whole life cycle’ looked at two important areas. Our first presenter, Dyrr Ardash of Williams Advanced Engineering, identified a number of factors along the journey from production to end-of life and highlighted the industrial development and implementation of technologies and processes towards more sustainable mobility solutions. Also discussed was the approach and requirement issues that car manufacturers should consider during the process of vehicle design and development. Our second presenter, Jonathan Saul of Millbrook, then focused on the safety concerns that the automotive industry is having to overcome to certify their new electrified vehicles. Both presentations prompted numerous questions from the audience and the webinar saw our largest audience to date with over 80 attendees.

As it is still unclear when physical events will be allowed to resume we plan to continue our series of webinars during the coming months. We are fortunate to have wide support from industry and access to presenters who cover a range of topics and technical areas. As ever, we welcome your input and if there are subjects you feel it would be beneficial to include please let us know. Whilst the webinars are primarily aimed at those at the start of their engineering careers they are equally applicable to all levels and we welcome attendance from anyone who would benefit.

Technical Paper:

Low Filling Ratio Acoustic Space-Filling Curve Metamaterials for Jet Engine Inlets

JN Glover | PhD Student, Department of Aeronautical and Automotive Engineering, Loughborough University, UK DJ O’Boy | Senior Lecturer in Structural Dynamics, Department of Aeronautical and Automotive Engineering, Loughborough University, UK Corresponding Author: J.Glover2@lboro.ac.uk1. Introduction

As pressure grows for aircraft noise control, from organisations like the Advisory Council for Aircraft Research and Innovation in Europe (ACARE) there is an increased need for innovation in Aeroacoustic attenuation. The nature of noise means that a targeted approach to attenuation is far more effective in achieving overall observable noise reductions. Therefore, this project focuses on the dominant noise source, the engine, which accounts for approximately 68% at approach and at take-off approximately 98% of the total aircraft noise [1] (percentage of total logarithmic dB output). Any solution needs to cope with extreme operating conditions and low frequency noise not commonly controlled by traditional methods, due to the long wavelengths involved. This paper introduces innovative metamaterial acoustic liners as solutions for the jet engine inlet and builds on the work by Glover and O’Boy 2020 [2].

Metamaterials demonstrate a huge resource for acoustic control, whether passively in coiling-up, Helmholtz resonator-like or membrane structured, as reviewed in the paper by Assouar et al [3], or actively with piezoelectric, mechanical or electric and magnetic biasing as discussed in “A Review of Tunable Acoustic Metamaterials” [4]. For this project, the metamaterials studied are space-filling curves (SFCs) defined by their sub-wavelength structural, curled cross sections. They are classed as a passive absorber acoustic liner. The SFC provides an elongated coiled propagation path able to attenuate much lower frequencies then an undivided cavity of the same dimensions. They are not governed by traditional bulk modulus and density characteristics. SFCs offer subwavelength low-frequency attenuation with the potential to provide a lightweight, thin, highperformance acoustic liner [3].

The present paper contains a comparison of some of the most promising low filling ratio metamaterial designs which utilise space-filling curves. It evaluates the liners in terms of the fundamental theory of the design and a discussion of the reflection and absorption characteristics. The design of the original inspiration for this method are provided, then the paper discusses computer simulation and experimental testing to compare the different designs based on impedance tube measurements. Conclusions are also made as to the future application for aeroacoustics with particular focus on the engine inlet.

2. Acoustic Liners

Typical acoustic liners for a commercial jet engine use the principle of a Helmholtz resonator (HR) where a mass of air oscillates on a spring of air trapped in a volume. HR implementations are cheap passive devices, are relatively lightweight and effective for one dominant frequency and most importantly, need a large depth to attenuate low frequencies. The issue of low frequency attenuation is due to the mass law. The effect is, essentially, the lower the desired attenuation frequency, the larger the liner depth needs to be [5] (and for the purposes of this paper the frequency range of interest is 200–2000Hz). By targeting one dominant frequency, any other frequencies are not substantially affected, and the same weight penalty remains. Hence, the choice of critical frequency and the potential for multiple frequency targeting is paramount.

The liners are proposed to control the dominant frequencies of jet engines, typically below 1000Hz, with the lowest at approximately 630Hz by Khardi [6]. Moreover, the industrial trend towards ultra-high bypass engines means there is a potential increase in bypass ratio from 8 to 15 [7]. Since ultra-high bypass fans result in an increase in weight and potential drag, it is predicted that there will be a subsequent reduction in the thickness of the outer casing, meaning that any soundproofing contained within needs to become thinner [7].

Therefore, in this paper the depth of the liners is tightly controlled below 50mm, the lower end of typical current liner depth. A successful metamaterial acoustic liner would show a reduced weight and thickness compared to a traditional HR liner, i.e., a low filling ratio design (the filling ratio is the proportion of wall volume to open air volume). By utilising the sub-wavelength attenuation and high reflective nature of the SFC, a significant sound reduction can be achieved with a relatively low weight liner. In addition, a 2020 paper by Glover and O’Boy concludes that low filling ratio SFCs generate a higher mean absorption coefficient when tested in head on flow conditions [2].

2.1 The Helmholtz Resonator

Traditional Helmholtz resonators (HR) are used to control steady, simple, harmonic sound at a narrow frequency range. The main advantages of this resonator is its simplicity, although careful tuning is required

for effective noise attenuation [8]. The HR works as an acoustic stopband filter with the action of the volume of air in the cavity emulating a mass spring system [8]. However, this causes an undesirable back pressure, which has a detrimental effect on the efficiency and performance of the engine. The limited narrow band can be improved with a range of tuned HRs, but this has a proportional increase in back pressure [5]. If frequency bands could be filtered out through an alternative method, such as multi-resonant scattering, there would be a far smaller effect on engine efficiency which could be a designed in characteristics of metamaterial liners.

For the purposes of comparison in this paper, a baseline acoustic liner was designed using a hexagonal 610Hz

with a sub-wavelength curled wave path creating a maze-like pattern (Figure 2-3). SFCs were developed from a purely mathematical problem where a line passes through every cell element of a grid, so that every cell is visited exactly once. They have been proposed in acoustics for a decade or so due to their potential ultrathin, low frequency, broadband attenuation overcoming the drawbacks of traditional HRs.

In this paper, three designs are investigated, termed horn, meander and spider. For the purposes of this project, the investigated SFC designs are divided into two categories: curl-up (horn and meander), where there is a single path through a unit; and maze-like (spider), where there are multiple propagation directions within the unit. To understand the advantages of metamaterials as a noise control method there needs to be an appreciation of the physical attenuation mechanisms.

The primary physical mechanism of noise reduction in both types is an extended path length compared to unit depth, which enables subwavelength attenuation. Different designs can offer multiple propagation paths, directions and scattering. For curl-up SFCs (Figure 2-6), Wang et al [9] have proposed an equivalent model which applies HR, and quarter wavelength (QWR) tube theory, to a ranging transfer matrix that defines the SFC peak frequency. The transfer matrix establishes a relationship between the acoustic pressure and volume velocities in two defined regions.

Equation 2-1 shows the two regions. The first is a straight region, which is the straightened coiling path (denoted I) equated to a resonator neck and the second is a cavity region, which would be the designated voids (denoted II). When region 1 tends to zero the HR theory alone applies and when region 2 tends to zero, the quarter

tuned HR (Figure 2-1 and Figure 2-2), see formula in [7]. This design was also used in the 2020 paper [2]. This was chosen to compromise between industry-standard design, the working frequency range of the experimental impedance tube and available 3D printing capabilities allowing rapid prototyping and experimental verification of the trends. The hexagonal HR liner was a benchmark of success criteria for the SFC liners. Thus, a good liner would show a better absorption coefficient at a wider frequency range and ideally at a lower weight.

The additional characteristics of a typical sandwich configuration was also applied to the SFCs for the following three reasons: 1) The two-microphone impedance setup does not allow for the grazing configuration and the tube was designed to record head-on resonance for sandwich liners. 2) A sandwich configuration is the current standard for soundproofing thus can be considered commercial. 3) The additional resonant conditions are predicted to improve absorption coefficients for the SFC samples.

2.2 Space-Filling Curves

Space-filling curve (SFC) metamaterials are designed

Equation 2-1: Relationship between the acoustic pressure and volume velocities at the neck of the tube and the end of the cavity [9].

wavelength theory alone applies. The curl-up SFCs studied in this project (horn, meander and zigzag from a previously published paper) all build on classical theory. The resonant frequency for the same volume of HR unit can be reduced by making use of curling channels to reduce the space required: QWR uses Equation 2-2, HR uses Equation 2-3 and Fabry–Pérot resonance (FP) using Equation 2-4. The use of voids, framing, right-angle bends and many other flow path features causes the SFC resonance to deviate from the basic theory, which is why models such as the equivalent model transfer matrix are used [9]. Although this approximation works well for curled-up designs, it is less accurate for the maze-like SFCs such as the spider.

The maze-like designs are better understood using Mie resonant theory as they offer multiple propagation directions and a high reflective index. Mie resonance is commonly defined in light rather than sound, but it still applies when the size of the scattering sphere is comparable to the wavelength. Mie-resonance particles have a high refractive index relative to the background medium. They are initiated in this case

Equation 2-2: QWR resonant frequency.

Equation 2-3: HR resonant frequency.

Equation 2-4: FP resonant frequency.

due to the ultraslow relative propagation through the flow path compared to the in-space dimensions (Figure 2-4) [10]. These liners often benefit from multiple resonances instigated at low frequency due to the high contrast of sound speed with the isotropic resonant

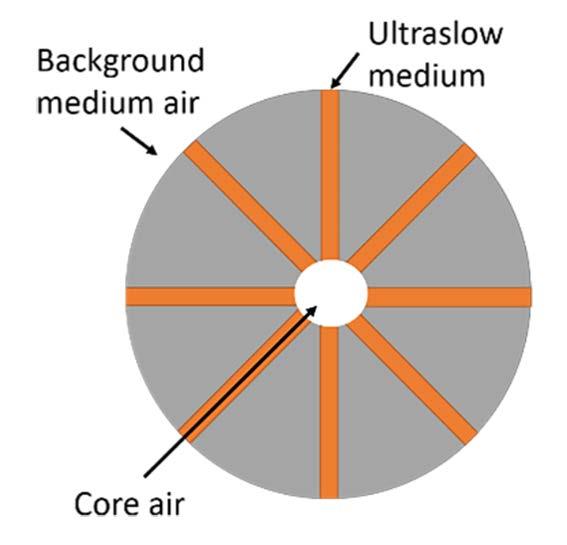

frequency shown in Equation 2-5. The proposed spider maze-like metamaterial is described as being an ultraslow medium demonstrating the high contrast in wave speed needed to observe Mie resonance [11].

It was predicted that the low filling ratio (<20%) characteristic of these three designs could result in an overall reduction in weight whilst maintaining or improving noise attenuation in a broadband low frequency range.

This design termed horn was chosen as it was capable of phase-amplitude modulation beyond conventional space-coiling structures, with a potential for sound focusing and acoustic beam splitting. The sample seen in Figure 2-6 and unit sizing (Figure 2-7) was inspired by Ghaffarivardavagh et al. [13]. A custom 1kHz design with 1% transmission coefficient.

The test liner was tessellated (Figure 2-6) to cover the whole 95mm diameter space available in the test rig (See Figure 3-1). The filling ratio of horn was 9.4%, therefore is considered very low and the sample was the lightest of the 3 SFCs. It is the only liner lighter than the HR baseline (Table 4 1). The Ghaffarivardavagh et al. [13] data was presented only as transmission coefficient whereas the two-microphone impedance method only establishes reflection and absorption coefficient. For comparison, the peak transmission 1000Hz was taken as the peak absorption frequency although, as discussed in section 2.2.3, this may not be an accurate representation.

2.2.2. Meander

2.2.1. Horn

The first acoustic liner design investigated was proposed by Ghaffarivardavagh et al. [13] named ‘’Hornlike space-coiling’’. This design was an advancement of the zig-zag configuration based on Liang and Li [14] adding a gradual change in channel width allowing for impedance matching. The sample presented by Ghaffarivardavagh et al. was tested computationally with the Transfer Matrix Method based on computer modelling, using the finite element analysis software COMSOL. Then it was experimentally validated as a large rectangular sample with a 40cm measurement region much larger than the sample in Figure 2-6 which is 95mm in diameter.

The “Coiling-Up Space Metasurfaces” was developed by Chen et al. and is the second design under investigation in this paper [15]. This design is an acoustic metasurface with a perforated top plate and co-planer spiral tubes in coiling channels. It was tested using simulation in COMSOL and validated with an impedance tube method. Unlike the horn or spider liners or any of the phase 1 samples (see Glover and O’Boy [2]) this was the only SFC design optimised with a perforated plate. This was a key factor in its inclusion in the study as a perforated plate is the standard for traditional liner constructions. Additionally, in high flow speed and long run time regions such as a jet engine inlet, foreign object debris is a substantial concern, thus the use of perforated plates

has been the established prevention method.

The design shown in Figure 2 8 was developed based on the work by Chen et al. [15]. The channels act as nesting dampeners producing dual band resonance (in this case 256Hz and 350Hz). The thickness of the metasurface is smaller than 1/50 of the resonant frequency wavelength and set in the reproduced model as 20mm. This design is chosen as it has the lowest predicted resonant frequency and a low filling ratio of 14%. The performance of the design is particularly interesting because the predicted values are so close to the lower limit of the working frequency range, therefore open to experimental error.

2.2.3. Spider

The “Spider Web-Structured Labyrinthine Acoustic Metamaterials” was developed by Krushynska et al. and is the final design under investigation [11]. This design configuration consists of a square external frame and a circular maze-like path divided into eight independent circular-shaped channels connected at the centre. As a result of the need for consistency between the designs,

the sample is circular and unframed (Figure 2-9). However, the advantages of framing will be studied in future work.

Krushynska et al. tested the design using simulation in COMSOL only and demonstrated consistent low transmission for a frequency range 0–2000Hz. Unlike the horn or meander designs, the spider is classified as a maze-like SFC meaning there are multiple propagation routes rather than a singular flow direction. This design is also very difficult to predict through a numerical theory due to the presence of Mie scattering, which is why the origin paper’s use of simulation is vital in predicting the acoustic performance.

The design shown in Figure 2-9 was inspired by the garden spider Araneus diadematus. It was chosen due to its low filling ratio of 10%, which is much smaller than that of the maze-like SFC studied in phase 1: 17% for hexagonal and 35% for labyrinthine [2]. In addition, Krushynska et al. concluded the spider SFC is highly tuneable with activation or elimination of subwavelength band gaps and negative group-velocity modes can be refined by increasing/decreasing the edge cavity dimensions. Like the horn work, this design is presented via transmission rather than absorption thus the peak values may not consistently align. Absorption coefficient has two different formulas based on whether transmission is possible within the experimental setup (Equation 2-6 and Equation 2-7).

Generally, absorption and reflection coefficients are mirror plots, but the transmission may not follow the same trend. As a result, the accuracy of this design recreation, particularly in terms of full-range low transmission, will not be known fully until the fourmicrophone impedance test stage, which is not part of this paper.

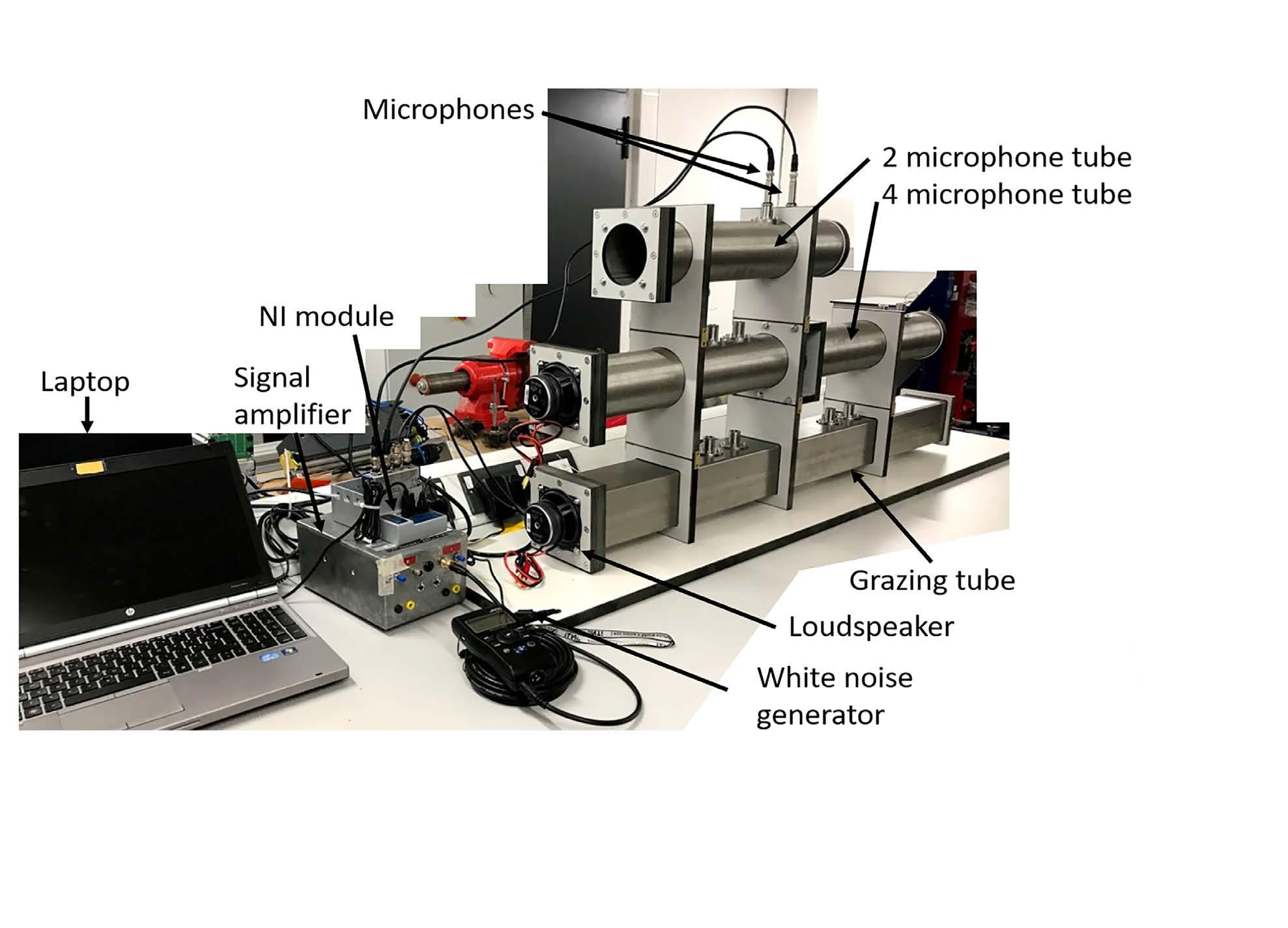

3. Impedance Tube Rig

3.1. Impedance tube theory

A two-microphone impedance tube (Figure 3-1) was designed and built to accurately measure sound reflection and absorption coefficients according to ISO10534-2 [16]. The basic principle of the tube is that a plane wave is generated by a sound source and measurements of acoustic pressure are taken at fixed locations depending on the number of microphones. The reflection or absorption through the sample generates a standing wave that can be measured by the microphones.

A white noise source is used with no external flow applied. Calculations are carried out using a complex transfer function to determine the normal incidence absorption and impedance ratios of the acoustic material (Equation 3-1, Equation 3-2). The usable frequency range depends

on the width of the tube and the spacing between the microphones (Figure 3-2) [16]. In this case, the diameter of 100mm and length 500mm give a working range of 200–2000Hz. The origin papers are not all tested in the same standardised method or flow conditions therefore this paper experimental work can be uniquely compared.

4. Experimental Analysis of Liners

4.1. Methodology

The experimental analysis determined the reflection and absorption coefficients of each liner by frequency and as a mean value. The data was then compared between the liners and the simulation results in the comparison papers. The liner samples were designed such that each core liner has a diameter of 95mm and a rigid backplate of 2.5mm. The core height is 15 mm for the horn SFC is based on the core height for the 610 Hz resonant HR baseline. As the meander and spider design stated their core height it was maintained in this case at 17 mm and 20mm. An additional variable of three designed top plates of thickness 2.5 mm and no top plate options were investigated.

Each liner was tested with no top plate, the HRTP (Figure 4-1) and a many-hole top plate. The meander used MTP

(Figure 4-3) rather than MHTP (Figure 4 2) to match the perforated plate used in the origin paper’s experimental work. All components were printed using a Connex 260 and utilised a ‘’Vero White’’ plastic. The experimental analysis of all four liners followed the ISO10534-2 [16] protocol for a two-microphone impedance tube. The weights can be found in Table 4-1.

4.2. Results

The absorption coefficient relationship to frequency is presented in Figure 4-4. There are common trends between all liners: the use of a top-plate has a significant increase on the overall absorption coefficient; the non-top-plate configuration absorption values are consistent for all liners and there is no strong indication of the effect of the designed flow path without a top plate. An interesting deviation from the expected is the horn with MHTP which, unlike the other two SFCs and liner theory, does not show an increase in peak frequency when more perforations are introduced. The theoretical peak increase as predicted by the work of Bies and Handen [17].

Conversely with MHTP the horn has a dual peak at 790 and 1590Hz compared to the HRTP 1430Hz. This change is assigned to an increase in the peak frequency associated with the resonant HR mechanism of the liner and the 790Hz peak aligns with an analytical study of the Fabry–Pérot resonance peak (Equation 2-4). For all designs, Figure 4-4 does not show peak frequencies that align closely with the origin paper. This is because there is a distinct difference between the subwavelength attenuation, transmission properties and resonance attenuation. This difference will be captured by the progression work of the project summarising head-on, grazing and transmissive characteristics of SFCs for acoustic liners.

The peak frequencies are much broader than predicted and with additional multiple peaks. The baseline HR has a peak resonance of 580Hz, which is within the printing tolerance resonance range 570 to 650 Hz (this also shows some of the issues with generating exact tolerances for resonators using rapid prototyping manufacturing methods). There is an additional peak at 1600Hz, which is anticipated to be due to structural resonances caused by the outer edges of the test liner. As shown in Figure 2-1, smaller units are tessellated to fill the 95mm diameter or cropped (Figure 2-8). The structural resonances can be reduced by framing, but design factors such as this are removed from this experimental phase to create consistency. The free walls are excited by the flow through the top plate and around the edge of the tube causing additional dominant peaks. This theory was tested in later project work when additional design factors were implemented. Furthermore, the core and top plate are only temporally fixed rather than bonded due to limited printing resources, which can lead to flow creep and coupling between units. The result of these factors is a non-ideal resonant plot, but they are more consistent with working conditions where samples are cut to fit or degrade over time, thus an understanding of the impact is valuable.

4.2.1. Mean reflection and absorption coefficients

values for all sample configurations. For all SFCs and the HR, the introduction of a top plate increases the absorption coefficient significantly. It is also generally true that increasing the number of holes in the top plate increases the overall absorption but shifts the resonant frequency to higher values. This relationship is not linear; MTP has 2 holes compared to the 19 of HRTP which results in a 0.11 mean absorption increase, whereas HRTP to MHTP with 69 holes results in an average of a 0.047 coefficient increase, and this observation aligns with the perforated plate work of Bies and Handen [17].

The aim of this research is to propose an SFC acoustic liner that is comparable or better than the baseline HR. The success criteria are an increase in absorption coefficient at targeted low frequencies, at a reduced depth and weight. No SFC designs outperformed the traditional HR in absorption coefficient in these flow conditions. The best performing SFC configuration is the horn at a 3g reduction in weight. The SFCs are developed in grazing flow simulation to better represent operating conditions, but the two-microphone impedance tube was developed around the traditional HR liner, thus it may not be a surprise that the HR performs best. Nonetheless the broadband attenuation offered by the SFC at a range of frequencies in the 200–2000Hz window shows the promise they have for broader low frequency noise applications. In addition, with continued research and tuning they could be well matched to the noise profile described by Khardi [6].

4.2.2. Resonant peak

Figure 4-6 illustrates the comparisons of experimental and simulation (determined from origin journals) resonant peaks. The experimental data points are sized according to absorption coefficient to capture the weight for acoustic significance. The simulation data points are all set to 1. This is due to the range of data presentation in the origin papers not enabling this weighting. Generally, the peak frequencies in the paper do not align with the experimental resonant peaks, indicating the grazing flow peak does not determine head-on peak value.

The meander had the closest test method in the origin paper to this body of work but as seen in Figure 4-6, the peak alignment was poor, even with the Chen et al.-defined MTP. The mitigations for this difference are the cropping of the design to fit the experimental tube and the lack of a framing around the core.

However, with an experimental peak of triple the expected, other parameters need to be considered. There may be experimental differences and there was little detail presented by Chen et al. other than that a two-microphone impedance tube was used. While input source amplitude and flow may differ, the material characteristic instead of flow path may dominate or the bespoke rig (Figure 3-1) may be insensitive so

close to the lower working frequency band. Factors such as this, and more, are why consistent controlled experimental comparison was needed for all liners.

A simple numerical study using QWR, HR and FP theory described in section 2.2 and Equation 2-2 to Equation 2-4 did show good agreement. Figure 4 6 shows the meander HRTP 11mm channel FP is 1240Hz, with QWR predicted as 621Hz. For meander HRTP, the 10mm channel FP is 1465Hz and QWR 730Hz. The MTP configuration does not align well with any of the classical theories. The HR is the closest, 1298Hz for the 11 mm channel, and 1123Hz for 10 mm.

It could be argued that the open channel paths as seen in Figure 4-3 would allow for an extended volume reducing the resonant frequency to near 905Hz or this value lies in between the FB, QWR and HR theory as indicated in the equivalent model transfer matrix (Equation 2-1), but regardless, the performance was at a much higher frequency range than expected.

The spider design was defined in its origin paper as having low transmission for the full 0–2000Hz range and although transmission is not inspected here, it was predicted that this trend for the whole working frequency range would be present. Therefore, the simulation data point for the spider are set at the extremes of the range.

Conversely, the spider did not show this characteristic, rather a promising multiple low-frequency peak with HRTP and a monopole for the MHTP configuration. The spider did not show the broadest attenuation, or the largest mean absorption coefficient as might have been expected. Yet, if the pattern is as tuneable as indicated by Krushynska et al. it could be optimised to the characteristic noise of an aircraft, thus this lowfilling ratio maze-like SFC will be refined in future work.

5. Conclusion

The frequency agreement between the simulation data presented in the papers and this comparison was generally poor, demonstrating the large variation in attenuation. Although the models could not be perfectly recreated, peaks were consistently at a higher frequency than predicted. The SFCs were chosen for their broadband and multiple resonant lowfrequency resonance, but this experimental work did not reliably show the multiple resonant characteristics being highly influenced by top plate configuration. This demonstrates it was essential to test liners in consistent conditions to capture a comparable acoustic performance.

The origin paper deviated in experimentation and simulation methods and this standard test itself is not reflective of industrial environments. The results also indicate the difficulty of primarily reaching low frequency attenuation as many off design parameters result in higher frequency attenuation. The absorption

performance of horn and spider liners showed the promise of SFCs, whether at a reduced weight and comparable mean absorption to HR or multiple lower frequency absorption, respectively.

6. Future Work

The vital progression for this work is multiple environment industry-standard impedance tube tests. By using two, four-microphone and grazing impedance tubes, the full acoustic profile of absorption, reflection, transmission coefficients and sound transmission loss is captured in head-on, transmissive, and grazing flow. This full profile solution is a unique approach in capturing the potential of SFC design in a comparable experimental basis.

The result is an ability to propose a prototype metamaterial liner adapting existing space-filling curves with flow path tuned to a low-frequency range specific to jet engine inlets as prescribed by work by Khardi [6].

References

[1] N. Pignier, “The impact of traffic noise on economy and environment: a short literature study,” Stockholm, 2015.

[2] J. N. Glover and D. J. O’Boy, “A review of acoustic space filling curve metamaterials for jet engine inlets.,” in Acoustics 2020, Institute of Acoustics, 2020.

[3] B. Assouar, B. Liang, Y. Wu, Y. Li, J. C. Cheng, and Y. Jing, “Acoustic metasurfaces,” Nat. Rev. Mater., vol. 3, no. 12, pp. 460–472, 2018.

[4] S. Chen et al., “A review of tunable acoustic metamaterials,” Appl. Sci., vol. 8, no. 9, pp. 1–21, 2018.

[5] S. . Faruq, “An Experimental Investigation on Noise Reduction by Using Modified Helmholtz Resonator,” Bangladesh University of Engineering and Technology, 2014.

[6] S. Khardi, “An Experimental Analysis of Frequency Emission and Noise Diagnosis of Commercial Aircraft on Approach,” Jounal Acoust. Emiss., vol. 26, no. 2008, pp. 290–310, 2008.

[7] Y. Wang et al., “A renewable low-frequency acoustic energy harvesting noise barrier for highspeed railways using a Helmholtz resonator and a PVDF film,” Appl. Energy, vol. 230, pp. 52–61, 2018.

[8] D. Wu, N. Zhang, C. M. Mak, and C. Cai, “Noise Attenuation Performance of a Helmholtz Resonator Array Consist of Several Periodic Parts,” Sensors MDPI, vol. 5, no. 17, 2017.

[9] X. Wang, Y. Zhou, J. Sang, and W. Zhu, “A generalized model for space-coiling resonators,” Appl. Acoust., vol. 158, no. 107045, 2020.

[10] J. Li and C. T. Chan, “Double-negative acoustic metamaterial,” Phys. Rev. E - Stat. Physics, Plasmas, Fluids, Relat. Interdiscip. Top., vol. 70, no. 5, pp. 1–4, 2004.

[11] A. O. Krushynska, F. Bosia, M. Miniaci, and N. M. Pugno, “Spider web-structured labyrinthine acoustic metamaterials for low-frequency sound control,” New J. Phys., vol. 19, no. 10, 2017.

[12] Y. Jia, Y. Luo, D. Wu, Q. Wei, and X. Liu, “Enhanced Low-Frequency Monopole and Dipole Acoustic Antennas Based on a Subwavelength Bianisotropic Structure,” Adv. Mater. Technol., vol. 5, no. 4, pp. 1–6, 2020.

[13] R. Ghaffarivardavagh, J. Nikolajczyk, R. Glynn Holt, S. Anderson, and X. Zhang, “Horn-like spacecoiling metamaterials toward simultaneous phase and amplitude modulation,” Nat. Commun., vol. 9, no. 1, 2018.

[14] Z. Liang and J. Li, “Extreme acoustic metamaterial by coiling up space,” Phys. Rev. Lett., vol. 108, no. 11, p. 114301, 2012.

[15] S. Chen et al., “Engineering Coiling-Up Space Metasurfaces for Broadband Low-Frequency Acoustic Absorption,” Phys. Status Solidi - Rapid Res. Lett., vol. 13, no. 12, pp. 1–6, 2019.

[16] International originisation of standards, “ISO 10534-2 Acoustics-Determination of sound absoprtion coefficent and impedance in impedance tubes- Part 2: Transfer-function methord,” Geneve, 1998.

[17] D. A. Bies and C. H. Hansen, “Muffeling Devices,” in Engineering Noise Control: Theory and Practice, 4th ed., CRC Press, 2009.

The domestic standard is BS8887-1:2006 and the international standard is the ISO8887-1:2017. These are over-arching standards that provide design information on the manufacture, assembly, disassembly and end-oflife processing (MADE) of products. In other words, this is a holistic standard covering design information about all the stages in the life-cycle of a product from the initial raw material to end-of-life.

The first two stages, the M and the A, are the traditional ‘manufacturing’ stages of a product whereas the latter two stages, the D and the E, are the ‘un-manufacturing’ stages. The BSI committee charged with the responsibility of developing these standards is the committee with the zippy title TPR/1/7. Of interest is that the TPR stands for ‘Technical Product Realization’, the new BSI word that replaces the rather limiting term ‘manufacture’ or indeed ‘production’.

There are many standards devoted to the M and the A stages of a product design prior to a product being received by the customer. For example there are numerous standards on things like surface finish, tolerancing and 3D specification.

However, to date there are few standards published on the design stages appropriate to un-manufacturing. Committee TPR/1/7 is trying to rectify this and so far has published standards on remanufacture, reconditioning, reworking and remarketing. It would appear that of these processes, the growth area is remanufacture.

The standard focussing on remanufacture is Part 220 within the BS8887 series (BS8887-220:2010). This standard is a generic one giving the overall principles of the remanufacturing process. It has been used widely but mainly by the automotive remanufacturing sector. However, it is significant that lately, representatives from two other remanufacturing sectors (furniture and lighting), have approached the TPR/1/7 committee and asked that standards be produced specifically for their sectors, based on part 220.

To facilitate this, two sub-committees have been formed, consisting of some members of the main TPR/1/7 committee and experts appropriate to the remanufacturing fields. As of 2021, these sub-

committees will start to formulate these specific sectoral standards. The above descriptions perhaps help the reader to understand the way standards are created and developed.

If anyone "out there’"is in an industry in general or indeed a specific sector that is interested in either contributing to standards production or is interested in tailoring a standard for their industry, please feel free to contact Sarah Kelly at the BSI secretariat at Sarah.Kelly@ bsigroup.com.

Brian Griffiths Chair of

Brian Griffiths Chair of

STEM During and Hopefully After a Pandemic

Last year the world of STEM got turned upside down and whilst STEM events became curtailed due to online learning, a requirement for community outreach was never more pertinent.

In March, as the lockdown hit the UK, it became rapidly apparent that the NHS did not have adequate supplies of personal protective equipment. Across the world, the global 3D printing community came together and started producing face shield designs, which could turn a home office, a kitchen table or a garden shed into a production line. I decided that I would launch a crowdfunder, with a target of £1000. I ordered another printer, hit my target and was able to spend my days printing and making visors for the local NHS trust. I managed to personally produce 500 visors alongside 1500 ear savers, which were donated to the Nottingham Queen’s Medical Centre Neonatal unit.

Rolls-Royce provided the use of 19 3D printers owned by the company. We set up a global task force with a central hub in Derby, where the printers worked day and night to produce the visors. By the time the PPE supplies had begun to filter through into UK hospitals around June from the PPE vendors, Rolls-Royce had collectively manufactured 19,000 visors. I haven’t ever been involved in something where every door was opened, every person involved wanted to do all they could to help, until last year. The power of people pulling together to help others is amazing and, for me, provided an outlet that was similar to STEM, but with a true all-encompassing community outreach impact. In July, following my involvement I was asked to join a live Q&A session for the first virtual Big Bang. The special event was focussed on the use of 3D printing during the pandemic and I was representing the entirety of Rolls-Royce, live to anyone choosing to watch.

Even though I have happily and purposefully made a fool of myself whilst delivering an entire school or year group assembly, being on a virtual video call was more daunting. The event attracted 28, 000 virtual participants during my live broadcast, which put me under immense pressure to ensure I answered the wide-ranging questions in a concise and interesting manner. I didn’t even know what the session was going to be discussing until a few days before the event, with Rolls-Royce being asked to provide last-minute support for a guest who couldn’t attend.

Having been a STEM ambassador for 13 years, you often don’t know or get to see what long-term impact you

have had; but you hope that it is appreciated. 2020 has highlighted to me that I love causing a bit of mayhem in schools. I have honestly missed it; the extra hours spent planning, the stress leading up to a large scale event, the co-ordinating and training of new STEM ambassadors with the crescendo being the event itself. All of this is worth the feedback from the pupils who love the activities on the day itself.

I have also have spent many hours throughout last year wondering what STEM will look like beyond the pandemic. Will we have large-scale events? What can we as STEM ambassadors do to help the “lost” children of the crisis? What support will teachers, parents and carers need? With the light glimmering at the end of tunnel, the new STEM world will no doubt emerge to be a mixture of physical and digital engagement activities which I look forward to being involved in.

As ever if anyone is interested in knowing more about how they can get involved in STEM please do not hesitate to contact me or your local STEMnet contract holder.

Grant Gibson EngD BEng (Hons) Materials Technologist, Surface Engineering Rolls-Royce plc grant.gibson@rolls-royce.com 07469375700

FATIGUE 2021

FATIGUE 2021 Online and On-Demand

29 - 31 March 2021

Foreword

The Fatigue 2021 conference will bring the international fatigue and durability community together to share knowledge and understand the challenges in using sophisticated engineering simulation and modelling tools to complement sound test programmes and develop reliable and cost effective products for modern usage.

As engineering modelling and simulation tools become ever more powerful and sophisticated there still remains the challenge of correlating the virtual world with both idealised laboratory testing and the wide, and potentially unexpected, range of service conditions experienced by machines and structures. These challenges are compounded by the advent of new materials, new ways of manufacturing components, new applications and new test and measurement techniques.

Sponsored by:

We will seek to explore not only the latest developments in engineering modelling and simulation, advances in test and measurement techniques, innovations in manufacturing, and developments in materials science, but also the complex interrelations between all these topics that give rise to improvements in fatigue performance, durability and structural integrity.

The 3 day conference builds on the long established philosophy of the Engineering Integrity Society to provide a forum for practising engineers and researchers to exchange ideas and experiences in all aspects of structural integrity.

FATIGUE 2021

Online & On-Demand

29 - 31 March 2021

Delegates

Delegates attending the live online event can:

• Stream live presentations via the conference portal

• Ask questions & participate in online chat during the live sessions

• Network with speakers and other delegates during the live event

• Visit the live exhibitor ‘booths’ and chat with exhibitors

• Access the recorded presentations for 6 months after the conference (1 day after the live event)

• Access exhibitor ‘booths’ for 6 months after the conference (1 day after the live event)

• View abstracts of all presentations for 6 months after the conference

• Access the conference proceedings for 6 months after the conference

Exhibition

There will be an accompanying exhibition of material testing systems, durability software tools and engineering services where delegates will have the opportunity to discuss the latest developments in the field of fatigue and durability.

Keynote Lectures

Very-high-cycle fatigue of additive manufactured materialsProfessor Youshi Hong, Chinese Academy of Sciences

Integrating Cellular Automata and Extended Finite Element Methods to Model Pitting Corrosion and Fatigue Behaviour

- Professor Robert Akid, Manchester University

50 years of Fatigue Research: Progress and Perspectives –Professor Roderick Smith, Imperial College

3D printed mechanical interlocking and fatigue design

- Filippo Berto, Norwegian University of Science & Technology

Conference Topics:

Delegates registering after the deadline for live attendance have on-demand access for 6 months after the conference to:

• Watch recorded sessions

• Message authors and other attendees

• Access exhibitor profiles and materials

• View abstracts of all presentations

• Access the conference proceedings

• Additive Manufacturing

• Composites

• Continuum Scale Modelling

• Crack Propagation

• Design & Assessment

• Experimental Methods

• Environmental Fatigue

• Manufacturing

• Microstructure Scale Modelling

• Thermomechanical Fatigue

• Variable & Random Loading

• Welds

www.fatigue2021.com

Programme

Monday 29 March 2021

Keynote: Professor Youshi Hong - Chinese Academy of Sciences

Session 1: Additive Manufacturing I

Session 3: Environmental Fatigue

Session 5: Variable & Random Loading

Session 7: Welds (hosted by TWI)

Session 2: Continuum Scale Modelling

Session 4: Crack Propagation I

Session 6: Experimental Methods I

Session 8: Multi-axial Fatigue

Tuesday 30 March 2021

Keynote: Professor Robert Akid - Manchester University

Session 9: Design & Assessment I

Session 11: Additive Manufacturing III

Provisional Programme

With over 65 presenters from across the globe the conference will offer a full programme over the three days. The full provisional programme including list of speakers is available at: www.fatigue2021.com.

Registration

The booking form available at www.fatigue2021.com should be completed and emailed to the conference secretariat, Sara Atkin: info@e-i-s.org.uk The deadline for registration for live attendance is 25 March 2021.

Registration Fees

Presenting Author £170+VAT

Delegate - EIS Member £170+VAT

Delegate - Non Member £200+VAT

Delegate - Student £110+VAT

Session 10: Additive Manufacturing II

Session 12: Microstructure Scale Modelling

Keynote: Professor Roderick Smith - Imperial College

Session 13: Experimental Methods II

Session 14: Thermomechanical Fatigue

Wednesday 31 March 2021

Keynote: Professor Filippo Berto - Norwegian University of Science & Technology

Session 15: Additive Manufacturing IV

Session 17: Design & Assessment II

Session 19: Composites

Session 16: Crack Propagation II

Session 18: Welds II

Please find all the latest information relating to the conference and details of how to book your place on the Fatigue 2021 website.

www.fatigue2021.com

INTERNATIONAL SCIENTIFIC COMMITTEE

André Galtier (France)

Andrea Carpinteri (Italy)

Martin Bache (UK)

Christophe Pinna (UK)

Filippo Berto (Norway)

Francesco Iacoviello (Italy)

Hossein Farrahi (Iran)

Youshi Hong (China)

Jie Tong (UK)

Johan Moverare (Sweden)

Luca Susmel (UK)

Liviu Marsavina – (Romania)

Marc Geers (The Netherlands)

Matteo Luca Facchinetti (France)

Muhsin J Jweeg (Iraq)

Alfredo Navarro (Spain)

Phil Irving (UK)

Robert Akid (UK)

Michael Sangid (USA)

Shahrum Abdullah (Malaysia)

Thierry Palin-Luc (France)

Yee Han Tai (UK)

CONFERENCE SECRETARIAT

Sara Atkin

Engineering Integrity Society

6 Brickyard Lane, Farnsfield

Nottinghamshire, NG22 8JS, UK

Tel. +44 (0)1623 884225

Email: info@e-i-s.org.uk

Website: www.fatigue2021.com

LOCAL TECHNICAL COMMITTEE

Dr Hayder Ahmad

Andrew Blows

Dr Peter Bailey

Prof Mohamed Bennebach

Dr Filippo Berto

Robert Cawte

Dr Amir Chahardehi

Hollie Cockings

Sandra Craig

Oscar De Souza

Prof Francisco Diaz

Dr Farnoosh Farhad

Prof Yi Gao

Dr Hassan Ghadbeigi

Prof Philip Irving

Dr Spencer Jeffs

Dr Pablo Lopez Crespo

Chris Magazzeni

Paul Roberts

Yee Han Tai

Vicki Wilkes

Prof Mark Whittaker

Dr John Yates

News from the Tipper Group

How Do We Accommodate Non-Binary Engineers When Seeking Gender Equality Between Men and Women?

Our society has made significant steps in passing legislation to ensure that female engineers do not face prejudice in the workplace.

Setting targets for proportionate female representation on executive boards is a powerful way to articulate a corporate commitment to diversity and inclusion, and accountability about measures in place to achieve those targets. In addition, we are getting used to reviewing the annual gender pay statistics each April to review how companies perform in relation to the gender pay gap between men and women at all levels.

But what about people who do not fit easily into the categorisation of either ‘male’ or ‘female’? Non-binary is not currently a recognised alternative gender identity in UK law; but it is becoming more common for people to identify with a gender other than either male or female. An employment tribunal case of an engineer at Jaguar Land Rover reported that ruled last September that nonbinary and gender fluid people are protected under the

of engineers overall, but it remains an important consideration in diversity and inclusion policy.

So what should we do? Companies could easily make provision of toilet and changing rooms for people other than only male and female, especially where the disabled facilities are not available for the use of ablebodied employees. Another issue is the use of a person’s pronouns, and having clear policy on how people might express or change their preferred pronouns, for instance from he/him or she/her to they/them. This might be comfortably accepted by the generation that grew up with celebrities such as Sam Smith, Eliot Page and Harry Styles who have famously championed and express their gender-queer identities. But for many engineers who began their careers before the 1990s, the relatively recent ability to change one’s pronouns can seem perplexing and challenging. A corporate culture of tolerance, kindness and understanding goes a long way to smooth the inevitable mistakes that will get made!

So let’s not ignore the fact that there are those who can feel alienated by the campaign for “women’s” equality, despite suffering as much, or more so, from the same discrimination and prejudices. However, the ultimate aim of setting diversity and equality targets is to change the systems and processes for employment and career progression to become independent of a person’s background, race, gender or sexual orientation. Once that happens, the playing field will become level to everyone, however they identify their gender – we all win!

UK’s Equality Act. This ruling was a milestone moment in recognising the rights of non-binary and gender fluid people to be protected from discrimination under the Equality Act, as previously it had not been clear whether non-binary people were actually protected by antidiscrimination legislation.

For transgender individuals, it is possible legally to change gender, but the process can take a number of years, and requires that an individual lives as their preferred gender for at least two of them. During this transition period, the categorisation of their gender can therefore be unclear. The current systems comparing men and women in diversity metrics often leaves nonbinary, gender non-conforming, transgender, genderfluid and intersex people without clear representation in either group. True, this might only be a small percentage

Dr Philippa Moore

Contact Us:

The Tipper Group, TWI Ltd, Granta Park, Great Abington, Cambridge CB21 6AL

Email: tippergroupevents@twi.co.uk

Twitter: @TheTipperGroup

Other useful links:

https://www.bbc.co.uk/news/uk-40709420

https://www.theguardian.com/world/2020/ sep/17/gender-fluid-engineer-wins-landmark-ukdiscrimination-case

https://www.insider.com/9-celebrities-who-identify-asgender-non-binary-2019-6

Engineering in a Post-Pandemic World

The onset of the COVID-19 pandemic has wreaked havoc across the globe and acutely affected all our lives. There have been enormous challenges to overcome, especially within the health sector. With the threat of hospitals being overwhelmed, our normal way of life has been radically altered and the impact on society as a whole has far-reaching consequences.

Changes in Working Practices

Figures from the Engineering & Technology Board show that at the height of the first UK lockdown, 24% of businesses had paused or temporarily stopped trading¹. Many workers and employers in the engineering industry have been negatively affected with staff furloughed, made redundant or offered reduced hours. Homeworking has become the new normal and in April 2020, the Office for National Statistics reported that 46.6% of people in employment carried out at least some work at home².

Ben Bryson, Chief Operating Officer for HBK, explains “In the manufacturing supply chain we have worked hard to keep factories open as we serve critical environments including medical, farming and key industrial sites (food processing for example). We have found a way to be successful in spite of the challenges faced and this success is largely due to working closely with our supply chain and implementing safe working protocols for our teams.”

Resilience

In spite of the many hardships, tragic loss of life and the negative social and mental impacts of the past year, there is much to applaud, especially within the engineering community. Resilience is key to building a brighter future for the UK and engineers will play an important role in the revitalisation of the economy once we emerge from the current crisis. Lockdown has necessitated a move towards digitalisation and the rapid adoption of home working has forced us to adapt our working practices. This in itself has been a challenge for many but has also brought about new opportunities allowing us to develop alternative ways of working.

“The pandemic has compelled us to learn to connect with our customers in a virtual world with real-time connections such as video calling” agrees Ben. “This has resulted in increased speed of development and a stronger connection with our customers.” Ben is quick to recognise that the engagement of people has been key to solving problems. “The team quickly grasped the challenges of keeping safe along with finding ways to continue to produce and put customers first,” he explains. “The mental health impacts of the pandemic have been an important consideration and we have tried to think of ways to help people stay connected through strong communication both at an individual level and through company-wide communication.”

In the early days of the pandemic, high-tech engineering companies worked together to solve critical problems including the shortage of ventilators, hand sanitiser and PPE. In recent years engineers have often felt unable to share information outside of their company despite the mutual need to solve problems in their day-to-day work. This inevitably hinders progress and perhaps one positive legacy of this crisis will be increased openness to collaborative working, leading to greater innovation. Speed has been an important factor in solving the immediate problems created by the virus and engineers have streamlined processes and found new ways of working to bring development times down and facilitating rapid scale up.

Ben is optimistic about the future. “It is important to look forward in 2021 and to focus on how to succeed in a COVID and post-COVID world. At HBK we will focus more on simulation activity. Beyond simulation, physical testing will become smarter in the future and we will expand our testing platform to become more efficient. All the solutions implemented have to be future COVID-proof and we have learnt to become leaner and create the best solutions to secure success for our customers,” he concludes.

There is no question that the next year is full of challenges but the key to success will be continued focus on the customer, strong communication and commitment to new ways of working. In addition, the ability to be agile and respond quickly will surely be a necessity in a post-

¹https://www.theengineer.co.uk/comment-covid-19-engineering-industry/ ²https://www.ons.gov.uk/employmentandlabourmarket/peopleinwork/ employmentandemployeetypes/bulletins/coronavirusandhomeworkingintheuk/april2020

“It is important to look forward in 2021 and to focus on how to succeed in a COVID and post-COVID world.”

Ben Bryceson, Chief Operating Officer, HBK

Machine learning making light work of AM aerospace alloys

Machine learning technology will be used to make the additive manufacturing (AM) process of metallic alloys for aerospace cheaper and faster, encouraging production of lightweight, energy-efficient aircraft to support net zero targets for aviation.

Machine Learning for Additive Manufacturing

Experimental Design is led by Intellegens, a University of Cambridge spin-out specialising in artificial intelligence, the University of Sheffield AMRC North West, and global aerospace giant Boeing. It aims to accelerate the product development lifecycle of aerospace components by using a machine learning model to optimise additive manufacturing (AM) processing parameters for new metal alloys at a lower cost and faster rate.

AM is a group of technologies that create 3D objects from computer aided design (CAD) data. AM techniques reduce material waste and energy usage; allow easy prototyping, optimising and improvement of components; and enable the manufacture of components with superior engineering performance over their lifecycle. The global AM market is worth £12bn and that is expected to triple in size over the next five years. Project MEDAL’s research will concentrate on metal laser powder bed fusion – the most widely used AM approach in industry – focusing on key parameter variables required to manufacture highdensity, high-strength parts.

The project is part of the National Aerospace Technology Exploitation Programme (NATEP), a £10 million initiative for UK SMEs to develop innovative aerospace technologies funded by the Department for Business, Energy and Industrial Strategy and delivered in partnership with the Aerospace Technology Institute (ATI) and Innovate UK. Intellegens was a start-up in the first group of companies to complete the ATI Boeing Accelerator last year.

www.amrc.co.uk

Pay as you sense

Equipment rentals are increasingly helping companies overcome the hurdle of finding investment capital to fund development and verification projects. The current phase of the economic cycle, recovery from a slowdown, is always difficult and frustrating, as Mark Ingham of Sensor Technology identifies:

"Having survived more than one downturn and recovery, Sensor Technology already has a rental option in place for its TorqSense range of torque sensors. Potential users can choose to rent the equipment, rather than purchase it, thus circumventing the bottleneck of raising capital

purchase approval. And to help companies along, if they decide that they want to hold onto their TorqSense for longer than they had anticipated, Sensor Technology are happy to convert the rental to a sale, with a percentage of the hire fee already paid offset against the purchase price."

Interestingly, Mark says that rentals are a popular option at all times: “Many of our customers have a project where they need to measure torque, but know that when the project is concluded they will have no further need for a TorqSense. For them, renting is very attractive.”

www.sensors.co.uk

Nissan, E.ON Drive and Imperial College highlight the carbon saving and economic benefits of Vehicle-to-Grid technology

A White Paper published today – the result of a major collaboration involving carmaker Nissan, E.ON Drive and Imperial College London – explores how the bidirectional charging capability of electric vehicles (EVs) could contribute to lower emissions and help achieve long-term goals in relation to climate change.

The White Paper offers supporting recommendations and calls for the introduction of incentives to accelerate widespread adoption of vehicle-to-grid (V2G) charging systems, enabling potential benefits to be unlocked.

V2G technology allows electricity to flow in both directions to and from electric vehicle batteries, allowing energy stored in the battery to be sold back to the grid when demand for power is high. Vehicles can then charge when demand is lower or renewable generation is high, reducing reliance on fossil-fuelled generation and giving V2G a role in carbon reduction efforts. It can also release capacity on the electricity networks which distribute power around the country.

www.uk.nissannews.com

British engine production falls -27.0% in 2020 as pandemic hits output

• UK engine manufacturing down -27.0% in 2020 to just over 1.8 million units.

• Production for domestic and overseas markets falls -23.4% and -29.1% respectively.

• December saw production fall -7.9% to round off bleak year for sector.

Mike Hawes, SMMT Chief Executive, said, “2020 was a tough year for UK engine manufacturers with the coronavirus pandemic chiefly responsible for the fall in output. That said, factories still turned out more than 1.8 million internal combustion engines, with the

majority of these exported globally. This reinforces how important it is that, in the increasingly rapid transition to electrification, the UK’s skilled engine manufacturing workforce is not left behind, as they should be a critical component in positioning the country as a competitive place to produce ultra-low and zero emission vehicles.”

www.newspressuk.com

Firstmark Controls sign distributor agreement with Strainsense

January 2021 – Firstmark Controls, a USA manufacturer of high precision and compact displacement sensors have appointed Strainsense Limited as the exclusive distributor for the UK & Ireland.

Firstmark Controls bought the former Spaceage Controls brand of draw wire sensors (known as string pots, cable displacement transducers) in 2014 and have since further developed the product line to enable the use in a wide variety of applications such as Crash, Flight Test, Structural and covering solutions for Military & Aerospace, Medical, Automotive and Control system feedback.

Manufactured to ISO 9001 and AS9100D certified, custom designs can be offered beyond the extensive and flexible standard offering. Unique features include high tension spring options for fast acceleration/deceleration, high frequency response versions, unique mounting bases to accommodate severe fleet angles without the need for re-orientation or use with two rotational axis for ultimate alignment. Output options include voltage divider, analogue, current 4-20 mA or digital and infinite resolution options. Design temperatures to -65 Deg C to 125 Deg C and miniature versions for 0-35mm stroke length and versions to 100 million cycles.

All products are available with Installation kits, cables, mountings & bases and repair service. This product addition greatly adds to our existing position capability portfolio which includes LVDTs, Linear & Rotary Potentiometers, Inclinometers and Industrial string pots. More information can be found www.strainsense.co.uk/ sensors/position.

Techni Measure turns 50!

January 2021 – Techni Measure, distributor of sensors and instrumentation, is proud to be celebrating our 50th anniversary. Founded in 1971 by Frank & Betty Ramage, the company has remained a private business to this date, currently now owned and operated by the third generation of the family.

Initially supplying strain gauges from Japanese manufacturer TML into the UK market and operating out of the family home in Chalfont St Giles, the company steadily grew and moved to a dedicated office in Studley in the 1980s under the management of brothers Ian & Peter Ramage, later joined by sister Patricia Newton.

In 2016 the company moved to new premises located at the Doncaster Sheffield Airport site, as well as opening an additional office in Bristol and we are currently supporting our customer base in the UK & Ireland from these two sites with Andrew Ramage and Steve Brown forming the leadership team.

Over the years the company has continually increased its product range and, whilst still providing strain gauges from TML, we now supply sensors from many different leading manufacturers around the globe to cover the majority of industrial metrology parameters including strain, vibration/acceleration, displacement, force/load, torque, pressure, temperature, profile, inertial & navigation. We also supply structural test & excitation systems and calibration systems for vibration, shock, acoustic, dynamic angular and pressure sensors, as well as operating our own calibration lab for accelerometers in accordance with ISO 17025.