Textile Asia 2025, Lahore

Dates: November 22nd to 24th 2025. Venue: Lahore Expo Centre. Textile Asia 2026, Karachi

Dates: December 05th to 07th 2026. Venue: Expo Centre, Karachi.

ShanghaiTex 2025

Dates: December 16th to 19th 2025. Venue: SNIEC, Shanghai, China.

Heimtextil 2026, Frankfurt

Dates: January 13th to 16th, 2026

Venue: Frankfurt am Main.

FESPA Middle East 2026

Dates: January 13th to 15th 2026. Venue: Dubai Exhibition Centre.

DOMOTEX Hannover 2026

Dates: January 19th to 22nd 2026. Venue: Hannover, Germany.

DOMOTEX Middle East 2026

Dates: April 22nd to 24th 2026. Venue: Dubai World Trade Centre.

DPS World Pakistan 2026

Dates: January 22th to 24th, 2026

Venue: Karachi Expo Centre.

Dates: February 26th to 28th, 2026. Venue: Ho Chi Minh City, Vietnam.

IGATEX Pakistan 2026, Lahore

Dates: April 08th to 11th 2026. Venue: Expo Centre, Lahore.

iCADEX Pakistan 2026, Lahore

Dates: April 08th to 11th 2026. Venue: Expo Centre, Lahorei.

DOMOTEX asiaCHINAFLOOR 2026

Dates: May 27th to 29th 2026. Venue: NECC, Shanghai, China.

FESPA 2026

Dates: May 19th to 22nd 2026. Venue: Fira de Barcelona in Spain.

Techtextil and Texprocess 2026

Dates: April 21st to 24th, 2026

Venue: Frankfurt, Germany.

Index 2026

Dates: May 19th to 22nd, 2026. Venue: Palexpo, Geneva, Switzerland.

ITM 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

HIGHTEX 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

ITMA ASIA + CITME 2026

Dates: November 20th to 24th, 2026. Venue: NECC, Shanghai, China.

2027

Dates: September 16th to 22nd, 2027. Venue: Hanover, Germany.

PAKISTAN

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief

Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager

Mazhar Ali

Layout & Design

Noor M. Jaan

Website / Social Media

Minhaj Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, United Kingdom.

Registered no. 09141989

Tel: +44 792 2228 721

Available on Gale and Factiva affiliated international databases through Asianet Pakistan

Engr. Naeem Ilyas Khanani Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

YKK Enters Into a Partnership with the Fashion Frontier Program .

Rieter Investor Update 2025 .

Mahlo GmbH + Co. KG Celebrates 80 Years of Company

.18

TrusTrace Recognized as a Representative Provider for Digital Product Passports in Gartner® Research

Archroma demonstrates sustainable performance without compromise at PERFORMANCE DAYS 2025

TEXTILCOLOR AG launches strategic collaboration with Alpex, Majocchi, and TransTextil in the field of Pyroshell™ flame protection

The Textile Institute marks 100 years with a Global Expansion Drive

The address of innovation and investment in textile technologies: ITM 2026 . .32

European Parquet federation at DOMOTEX 2026

Free registration now open for Textiles Recycling Expo USA

The First-Ever Dedicated Exhibition & Conference for Textile Recycling in North America

The future of technical textiles and nonwoven industry takes shape at HIGHTEX .37

Lutz Wolf becomes CEO of the KARL MAYER Group

Oritain appoints Gemma Lynch as Chief Customer Officer to drive global growth and customer excellence

Textile Solutions Group appoints Anton Hofmeier as Group CEO

Circulose partners with Marks & Spencer to accelerate circular fashion

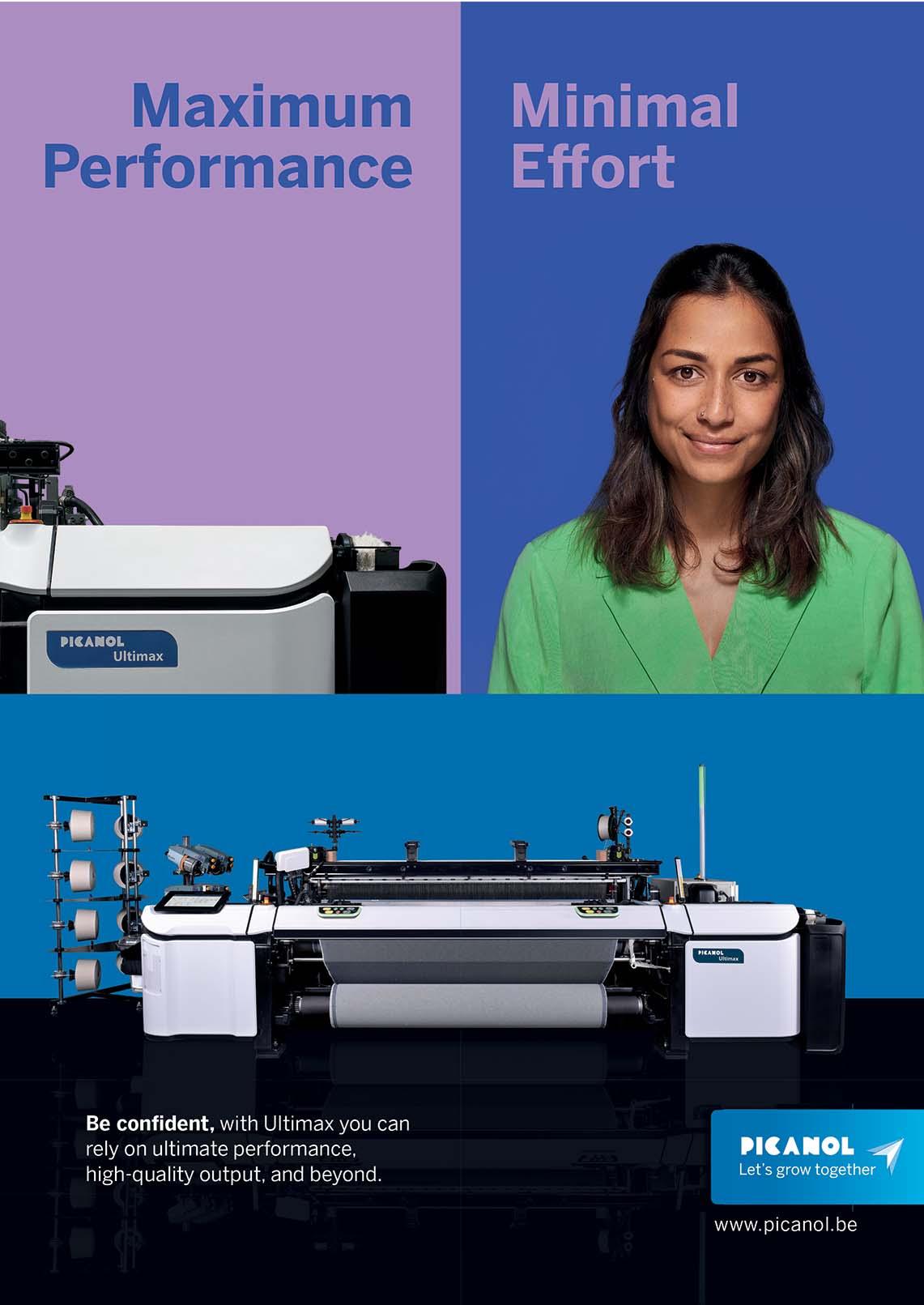

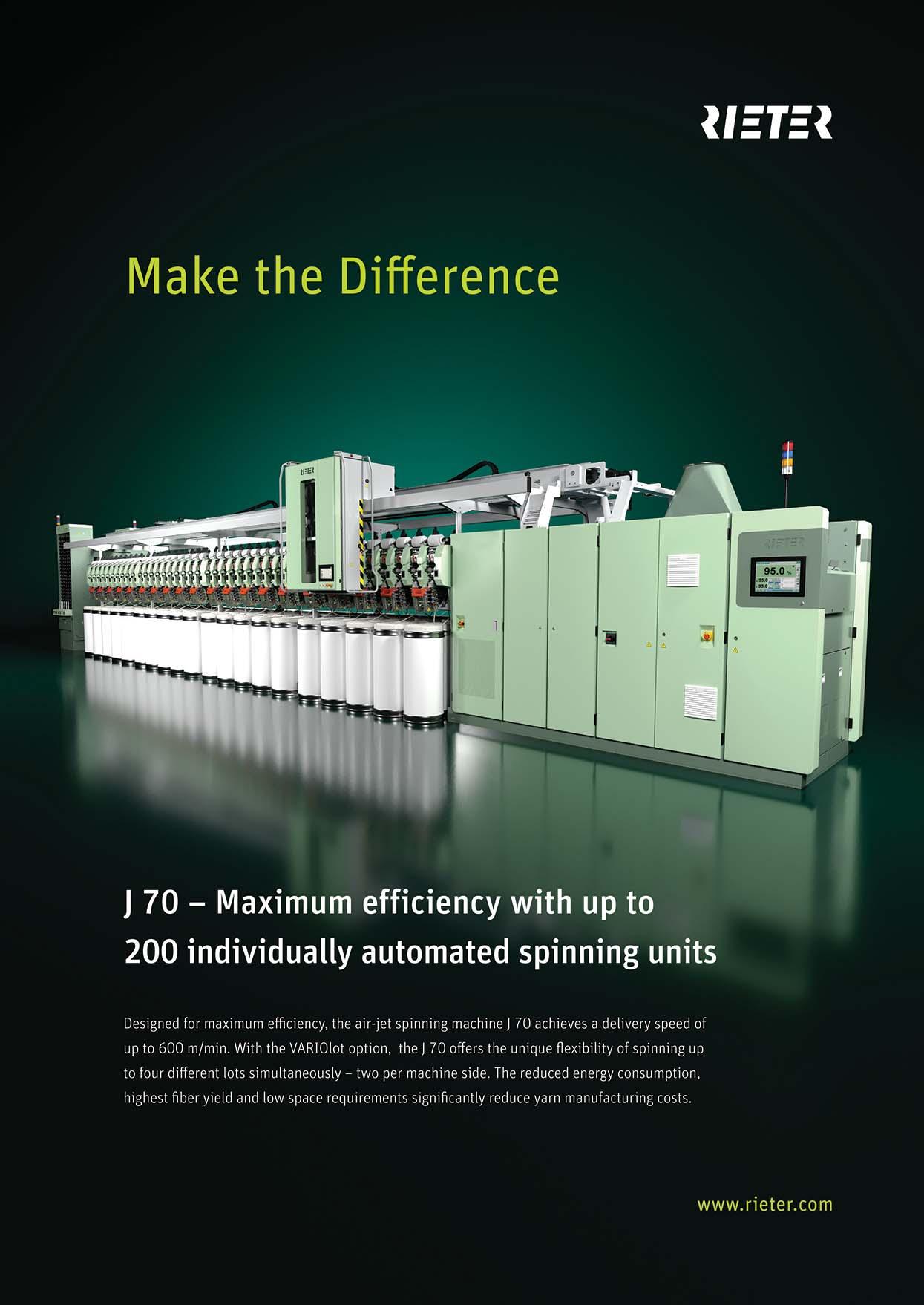

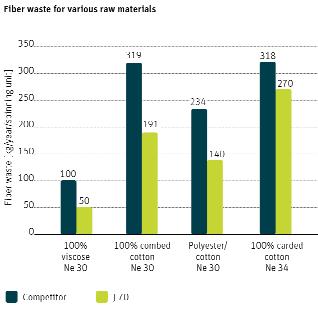

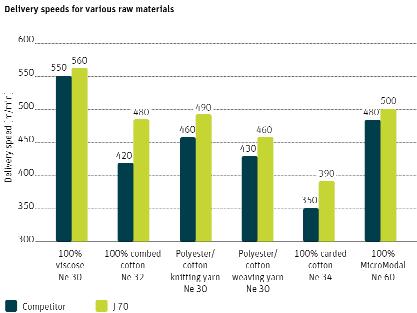

Processing carded cotton with the Rieter J 70

UHMWPE fibres: FET’s game changer for the biomedical market

COTTON USA™ Sourcing Fair in Bangkok Drives U.S. Cotton Supply Chain Partnerships43 Monforts: Third Thermex for Turkey’s Altoteks

Stäubli expands in Southeast Asia with new legal presence in Malaysia

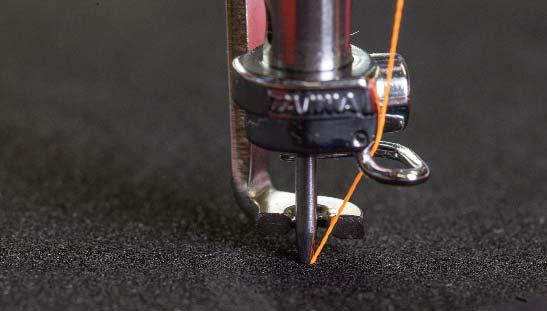

Groz-Beckert embroidery machine needles optimize industrial embroidery processes

When sparks fly, Arosa responds: Inside Zaman Textile’s fire safety transformation .48

Singapore edition of ITMA ASIA + CITME 2025 makes successful presentation . . .50

The Italian Textile Machinery industry on display at ITMA ASIA + CITME 2025 . . .52

VDMA members highly satisfied with ITMA ASIA + CITME 2025 in Singapore .

Reshaping Asian manufacturing: Taiwan’s smart & sustainable textile solutions unveiled at ITMA ASIA + CITME 2025

.54

Swiss Textile Machinery demonstrates innovation, global strength and industry optimism at ITMA ASIA + CITME Singapore 2025

ITMA ASIA + CITME Singapore 2025 - Glimpses

As this issue goes to press, the global textile industry is still absorbing the insights and technological shifts highlighted at ITMA Asia + CITME 2025. The event reinforced a clear theme: the future of textiles will be shaped not only by digitalisation and sustainability, but also by a more diversified and resilient approach to raw materials. For Pakistan, traditionally anchored in cotton, this marks a critical moment to reassess the balance of fibres driving our value chain.

Pakistan’s cotton economy continues to face deep structural pressures. Climate-driven heatwaves, irregular rainfall, pest infestations, and outdated seed varieties have kept production well below the industry’s needs. As a result, mills remain dependent on imported cotton, leaving the entire supply chain exposed to volatile global markets, freight variability, and currency fluctuations. This vulnerability limits growth at a time when international buyers are demanding greater flexibility, innovation, and value addition.

At ITMA Asia, global manufacturers demonstrated how dramatically the fibre landscape has changed. More than 70% of world apparel is now based on man-made fibres (MMF), and the fastest-growing categories include performancewear, athleisure, home textiles, hygiene products, medical textiles, filtration fabrics, and nonwovens. Exhibitors showcased advanced technologies for polyester, viscose, modal, lyocell, spandex, and high-performance synthetics—supported by automation, precise colour management, and reduced resource consumption.

In comparison, Pakistan’s export mix remains heavily cotton-centric. While cotton will always be an essential raw material for our spinning and weaving sectors, relying on it alone restricts product diversification, compresses margins, and hampers our ability to compete in high-growth technical segments. A fibre-balanced future—where cotton is complemented by a strong MMF and synthetic fibre base—is now imperative.

To move forward, Pakistan must encourage investment in MMF-based spinning, weaving, knitting, and processing; modernise existing facilities; support blended yarn and fabric development; and strengthen climate-resilient cotton farming practices. A broader fibre ecosystem will not only stabilise raw-material sourcing but also open pathways to innovation, higher value addition, and a more competitive export profile.

The direction ahead is clear: countries that embrace fibre diversity and technological flexibility will lead the next era of textile growth. For Pakistan, aligning its fibre mix with global demand is essential to ensuring long-term strength, resilience, and relevance in the international market.

1

Pakistan’s textile exports surged to a three-year high of $1.6 billion in September 2025, marking a strong rebound in the country’s largest export sector, according to provisional figures released by the State Bank of Pakistan (SBP). Analysts said the latest performance signals gradual stabilization after several challenging quarters marked by currency volatility, weak demand, and rising input costs. However, they also warned that structural constraints — including high energy tariffs, elevated financing rates, and disruptions in domestic cotton supply — continue to weigh on long-term growth.

2

Pakistan’s textile and fashion community is turning to the BRICS+ Fashion Summit 2025 in Moscow as a springboard for diversifying its export footprint and cultivating new cultural and commercial alliances beyond traditional Western markets, industry figures said to media.

3

Pakistan is moving to recalibrate its textile economy with a dual policy approach designed to strengthen the country’s raw material base, modernize production, and position its exports in line with global demand for synthetic and technical fabrics.

1

A high-level delegation from the Bangladesh Garment

Manufacturers and Exporters Association (BGMEA) is currently visiting the Netherlands to explore advanced solutions for textile waste recycling and strengthen cooperation with European partners in building a circular apparel economy.

2

Cambodia’s export performance in the garment, textile, footwear, and travel goods sectors surged during the first three quarters of 2025, with total shipments valued at US$12.2 billion, marking a 16.7% year-on-year increase, according to the latest report

4

The Pakistan Textile Council (PTC) has urged the government to implement regionally competitive energy tariffs, rationalized taxation, and a legally protected five-year industrial and export policy to secure long-term stability for the country’s leading export sector.

5

Pakistan’s cotton market witnessed a sharp revival in September 2025, with both domestic arrivals and imports recording strong growth despite prolonged monsoon rains and flooding in key producing regions. The surge signals renewed momentum in the country’s textile supply chain after months of volatility.

6

The Pakistan Business Forum (PBF) has welcomed the federal government’s approval of Rs12 billion in financial support for the textile, apparel, and other export-oriented sectors under the Duty Drawback of Local Taxes and Levies (DLTL) and Long-Term Loan for Development (LTLD) schemes.

7

The Trade Development Authority of Pakistan (TDAP) successfully organized a seminar titled “Technical Textiles & Application of Industry 4.0”, bringing together industry leaders, academics, and technology experts to explore Pakistan’s opportunities in high-value textile manufacturing and digital transformation.

from the Ministry of Commerce.

3

China’s textile and apparel sector showed a mixed export performance during the first nine months of 2025, as resilient textile shipments helped offset weaker apparel demand in key overseas markets, according to the General Administration of Customs.

4

The Egyptian Commercial Service (ECS) office in Istanbul has ramped up its efforts to attract Turkish investment in Egypt’s ready-made garments, textile, and auxiliary manufacturing sectors, as part of a broader push to

strengthen bilateral industrial ties and expand export capacity.

5

India’s textile sector faced mixed export trends during the first half of FY26, as textile shipments declined while apparel exports recorded moderate growth, according to the Confederation of Indian Textile Industry (CITI).

6

Türkiye’s fabric exports continued to face headwinds in the first half of 2025, extending a downward trend that has persisted for three consecutive years. According to industry data, exports declined by 2.55% year-onyear to US $2.10 billion

during the January–June period, reflecting sustained challenges in global competitiveness and weakening demand in key markets.

7

Vietnam’s textile and garment sector is ramping up productivity and embracing smart manufacturing as it pursues greater value addition and competitiveness in global markets. The industry’s export performance remained resilient, reaching USD 34.8 billion in the first nine months of 2025 — a 7.7% increase compared to the same period last year — despite persistent challenges in global trade.

Pakistan’s textile exports surged to a three-year high of $1.6 billion in September 2025, marking a strong rebound in the country’s largest export sector, according to provisional figures released by the State Bank of Pakistan (SBP).

The increase reflects a revival in international demand for Pakistan’s value-added textile products, supported by a more stable exchange rate and improved order flows from major Western markets. The sector accounted for roughly 60% of total goods exports during the month, reaffirming its pivotal role in Pakistan’s external trade.

Data compiled by Topline Securities showed that knitted apparel exports reached an all-time high of $485 million, underscoring the sector’s growing competitiveness in higher-value categories such as knitwear, sportswear, and fashion apparel.

Analysts said the latest performance signals gradual stabilization after several challenging quarters marked by currency volatility, weak demand, and rising input costs. However, they also warned that structural constraints — including high energy tariffs, elevated financing rates, and disruptions in domestic cotton supply — continue to weigh on long-term growth.

Industry experts noted that Pakistan’s export performance has been bolstered by recovering global retail demand and competitive pricing, particularly as US tariffs on certain regional peers have

made Pakistani products more attractive in international markets.

A textile analyst at a Karachi-based brokerage said the sector’s rebound was supported by improved cost management and a steady supply of local cotton during the last quarter. “The consistent rupee-dollar parity and stronger global orders have provided breathing room for exporters, but cost pressures remain significant,” the analyst added.

Despite the renewed momentum, manufacturers remain cautious about the coming months amid rising energy prices and yarn shortages following weatherrelated damage to cotton crops. Some exporters have begun importing raw materials to meet order commitments, which adds pressure due to payments in foreign currency.

Market observers said sustaining the upward trajectory will depend on policy continuity, competitive utility tariffs, and availability of raw materials. If current

trends persist, they added, Pakistan could see textile exports crossing $18 billion by the end of FY2026, bringing the industry closer to pre-pandemic performance levels.

Pakistan’s textile and fashion community is turning to the BRICS+ Fashion Summit 2025 in Moscow as a springboard for diversifying its export footprint and cultivating new cultural and commercial alliances beyond traditional Western markets, industry figures said to media.

The event — endorsed by more than 50 leading international fashion weeks — offered Pakistan a global stage to present its rich textile heritage and design innovation to emerging consumer hubs across Russia and Central Asia.

The Pakistan Readymade Garments Manufacturers and Exporters Association (PRGMEA) hailed the outcome of the summit, describing it as a timely opportunity to reposition Pakistan as a sourcing destination for non-traditional buyers. “Such international platforms are crucial for Pakistan to strengthen its foothold in non-traditional markets,” the association stated, emphasizing that greater participation in global trade forums could redefine the country’s textile narrative.

Industry stakeholders observed that the BRICS+ framework provides more than a trade mechanism — it represents

an evolving bridge for economic cooperation and cultural dialogue across Eurasia. By expanding its engagement within this network, they said, Pakistan could lessen its dependence on Western demand and move toward a more resilient and sustainable export model.

Among the major outcomes of the Moscow gathering was the launch of the BRICS International Fashion Federation (BRICS-IFF), a cross-border alliance created to drive innovation, sustainability, and technological advancement in the fashion sector through collaborative design and research.

According to data from the Pakistan Bureau of Statistics, the country’s textile exports stood at $17.88 billion during FY2024–25, with nearly two-thirds destined for the United States and the European Union. Industry experts said that penetrating newer markets could help shield Pakistan’s export performance from global economic headwinds and currency fluctuations.

Analysts also pointed to Pakistan’s geostrategic position as a potential advantage, allowing it to act as a trade corridor linking South Asia with Central Asia and Europe. They recommended practical measures such as creating a Pak–Russia Business Council under the BRICS+ umbrella, developing streamlined banking channels for exporters, and easing visa regimes to foster smoother trade connectivity.

Participants at the summit underscored the growing influence of Fashion Tech — from 3D digital design and smart fabrics to virtual fitting platforms — as key to enhancing productivity, reducing costs, and meeting global sustainability benchmarks.

Experts concluded that Pakistan’s textile sector stands at a pivotal moment: by embracing new technologies and diversifying its market outreach, it could move significantly closer to achieving its long-standing ambition of $25 billion in annual textile exports.

Pakistan is moving to recalibrate its textile economy with a dual policy approach designed to strengthen the

country’s raw material base, modernize production, and position its exports in line with global demand for synthetic and technical fabrics.

Officials confirmed that the Ministry of National Food Security and Research is finalizing the National Cotton Plan 2025, a comprehensive framework to revive cotton cultivation through higher-yield seeds, improved fibre quality, and sustainable farming practices aimed at lowering costs.

The plan complements the Textiles and Apparel Policy 2025–30, which is being developed by the Ministry of Commerce to promote value addition, attract investment in synthetic fibres, and accelerate the transition toward modern textile manufacturing.

According to internal documents reviewed by Wealth Pakistan, the coordinated strategy focuses on import substitution and export diversification, ensuring cotton development and industrial policy move in tandem. The National Assembly’s Standing Committee on Commerce has already endorsed recommendations aligned with these objectives.

The forthcoming Textiles and Apparel Policy sets an ambitious target: achieving $30 billion in textile exports by 2030, as approved by the National Export Development Board. The policy outlines priority sub-sectors and target markets to drive growth, emphasizing greater reliance on locally produced inputs and a stronger foothold in non-traditional export destinations.

During Fiscal Year 2025, value-added textile exports — primarily apparel and home textiles — generated $14.29

billion, representing 80 percent of total textile earnings. Exports of raw materials and intermediates, meanwhile, totalled $3.65 billion.

Despite the strong performance of finished goods, Pakistan’s textile structure remains overwhelmingly dependent on cotton, even as global production trends shift toward man-made fibres (MMF). MMFs now account for 74 percent of world fibre consumption, with polyester leading at 57 percent, followed by polyamide (6.7 percent), other synthetics (6.1 percent), and viscose (6.3 percent).

To bridge this gap, the recently approved National Tariff Policy 2025 has instructed the Tariff Policy Board to review and rationalize customs duties on non-cotton yarns and fabrics, paving the way for a new generation of MMF-based products, including sportswear, women’s fashion, and children’s clothing.

Government officials said Pakistan is also seeking foreign and domestic investment in the manufacturing of synthetic and artificial fibres such as polyamide, polyolefin, polyethylene, and polyurethane to reduce import dependence and establish a robust backward supply chain for the textile sector.

At the policy level, Islamabad is working to integrate into the $300 billion global technical textile market, which is expected to expand rapidly by 2030. The Ministry of Commerce has set up a National Technical Textile Council to steer the transition from traditional cottonbased production toward high-value technical textiles used in agriculture, construction, medicine, packaging, automotive, and protective applications.

In addition, Sectoral Councils have been activated to strengthen dialogue between public institutions and private manufacturers. These forums aim to identify regulatory bottlenecks, streamline export processes, and ensure policy implementation remains aligned with industry realities.

The Pakistan Textile Council (PTC) has urged the government to implement regionally competitive energy tariffs, rationalized taxation, and a legally protected five-year industrial and export policy to secure long-term stability for the country’s leading export sector.

In its Pakistan Textile & Apparel Exports Q1FY26 Report, the Council revealed that textile and apparel exports climbed 5.7% year-on-year to reach $4.79 billion during the first quarter of the current fiscal year. However, it warned that the sector’s recovery remains fragile amid volatile energy prices, policy inconsistency, and liquidity constraints that continue to hinder competitiveness.

The report emphasized that energy pricing reform is central to sustaining export momentum. It proposed a transparent and regionally linked tariff mechanism, suggesting that industrial electricity and gas rates should be benchmarked against key competitors, including Bangladesh and Vietnam, to restore cost parity and investor confidence.

Uncompetitive energy costs, the PTC noted, have become a major obstacle to export-led growth, while delayed tax

refunds and complex documentation have trapped working capital and limited new investment. The Council recommended a 72-hour automated refund system under a risk-based postaudit model and advocated zero-rating of export-related inputs under the Export Facilitation Scheme to improve liquidity.

On labour competitiveness, the PTC called for alignment of wage and overtime laws with regional standards, highlighting that higher payroll costs in Pakistan continue to erode exporters’ margins in major destinations such as the European Union and the United States.

To strengthen financial resilience, the Council proposed expanding the Export Finance Scheme (EFS) and Long-Term Financing Facility (LTFF), while empowering the EXIM Bank with a broader mandate and enhanced lending capacity to finance modernization, renewable energy projects, and technology upgrades.

Beyond short-term interventions, the PTC advocated for a five-year industrial and export policy backed by legal protection and measurable Key Performance Indicators (KPIs). The proposed KPIs would track export growth, diversification, sustainability, and

compliance, ensuring transparency and accountability through monthly reporting.

The Council also stressed the need to align future policies with global sustainability and ESG standards, particularly in energy efficiency, wastewater management, and traceability of raw materials. It urged the government to provide concessional financing and technical support to help exporters meet rising environmental and compliance requirements set by international buyers.

Pakistan’s cotton market witnessed a sharp revival in September 2025, with both domestic arrivals and imports recording strong growth despite prolonged monsoon rains and flooding in key producing regions. The surge signals renewed momentum in the country’s textile supply chain after months of volatility.

According to data compiled by Arif Habib Limited, total cotton arrivals reached 2.06 million bales in September, representing a 118% year-on-year increase and nearly double the volume recorded a month earlier.

For the first quarter of FY26, cumulative arrivals stood at 4.06 million bales, up 55% compared to the same period a year earlier, underscoring the sector’s resilience amid weather-related disruptions.

Imports also climbed sharply, driven by renewed demand from textile exporters fulfilling international orders. In September alone, Pakistan imported 351,000 bales, marking a 168% annual rise, while the import bill expanded 137% to $137 million.

During the quarter, total cotton imports hit 1.01 million bales valued at $1.7 billion, reflecting a 63% jump in value over 1QFY25.

Industry observers attribute the increase to robust export activity in the textile sector, which saw shipment volumes grow 4% and export earnings rise 7.3% in the same period. The uptick highlights improving global demand and a more synchronized domestic supply chain.

Despite the improvement in local arrivals, analysts noted that Pakistan continues to rely heavily on imported cotton to bridge the shortfall between growing textile demand and limited domestic output. Import values reached a peak of $575 million in May 2025 before moderating slightly in recent months.

The Pakistan Business Forum (PBF) has welcomed the federal government’s approval of Rs12 billion in financial support for the textile, apparel, and other export-oriented sectors under the Duty Drawback of Local Taxes and Levies (DLTL) and Long-Term Loan for Development (LTLD) schemes.

In a statement issued by PBF President, Khawaja Mehboob ur Rehman commended the Ministry of Commerce for what he described as a timely and practical intervention aimed at easing liquidity pressures on exporters.

“This decision by the Ministry of Commerce is a welcome move and will go a long way in resolving the liquidity issues of our exporters,” he said. “Timely release of funds under the DLTL and LTLD schemes will not only ease the working capital constraints of exportoriented businesses but also help restore confidence within the sector, ultimately contributing to increased exports and economic growth.”

Rehman emphasized that the textile and apparel industries continue to serve as the cornerstone of Pakistan’s export economy, providing substantial employment and foreign exchange earnings. He added that consistent policy support and fiscal facilitation are essential to sustaining competitiveness in international markets.

The PBF president reaffirmed the forum’s commitment to working with the government and industry stakeholders to advance policies that enhance productivity, improve export performance, and support long-term economic growth.

The organization also praised the Ministry of Commerce for its proactive approach in ensuring that exporters receive financial assistance to navigate current challenges, such as rising input costs and sluggish global demand. Rehman expressed confidence that with continued government backing, Pakistan’s exporters would be better positioned to expand their international presence and contribute to national economic recovery.

The Trade Development Authority of Pakistan (TDAP) successfully organized a seminar titled “Technical Textiles & Application of Industry 4.0”, bringing together industry leaders, academics, and technology experts to explore Pakistan’s opportunities in high-value textile manufacturing and digital transformation.

Opening the session, Basit Rauf, Director General (Textile Division), TDAP, said that technical textiles are among the fastest-growing segments of the global textile market. He underscored the need for Industry 4.0 adoption—including automation, smart production, and datadriven management—to enhance productivity and global competitiveness. “TDAP remains committed to supporting

innovation-driven growth in Pakistan’s textile exports,” he added.

Prof. Dr. Dawood Husain, from the Department of Textile Engineering, NED University, presented on “Potential of Technical Textiles and Pakistan’s Role in the Global Market,” emphasizing the value of academic-industry collaboration and product diversification to move up the value chain.

Saqib Sohail, Head of Engagement at The Microfibre Consortium (UK), discussed “Automation and Traceability,” sharing insights on sustainability, data transparency, and digitization in textile supply chains.

Meanwhile, Dr. Jawairia Khan, Lecturer at the University of Technology Sydney and NTU alumna, delivered a session on “Smart Textiles for Personalized Healthcare,” highlighting breakthroughs in wearable and intelligent textile technologies.

Arbaz Adil, Manager Product Compliance at Utopia, addressed ESG frameworks, carbon management, and compliance with international sustainability standards—urging exporters to align operations with global best practices.

Participants from the textile industry, universities, and trade associations expressed strong interest in a continued series of specialized seminars focused on smart materials, automation, and sustainability-driven innovation.

The seminar concluded with TDAP announcing plans to hold follow-up workshops and training programs in partnership with universities and international experts to strengthen capacity building, technological advancement, and market readiness among Pakistan’s textile exporters.

A high-level delegation from the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) is currently visiting the Netherlands to explore advanced solutions for textile waste recycling and strengthen cooperation with European partners in building a circular apparel economy.

The visit, arranged jointly by the Netherlands Enterprise Agency (RVO) and the Dutch Embassy in Dhaka, is designed to help Bangladesh’s apparel sector—currently the second-largest in the world—gain practical exposure to innovative recycling technologies and sustainable production systems.

According to BGMEA, Bangladesh’s garment industry generates between 500,000 and 700,000 tons of textile waste annually. A large portion of this “jhut,” particularly cotton-based fabric waste, remains underutilized despite its recycling potential. In the absence of a structured recycling framework, much of it is exported or ends up in landfills and waterways, contributing to environmental degradation and fuelling an informal, unregulated waste economy.

BGMEA officials described the visit as a strategic step to bridge technological and policy gaps, noting that the initiative aligns with the organization’s Sustainability Vision 2030, which

emphasizes circularity, decarbonization, and resource efficiency.

The European Union’s upcoming sustainability regulations, which will require greater use of recycled materials by 2030, are also a major driver behind Bangladesh’s renewed focus on textile circularity. By engaging with Dutch recycling innovators, BGMEA hopes to develop scalable solutions, reduce dependency on raw cotton imports, and enhance the global competitiveness of Bangladesh’s garment exports.

Industry observers noted that a formalized recycling ecosystem could unlock new revenue streams, improve labour conditions, and promote transparency across the value chain— transforming textile waste from an environmental burden into an economic opportunity.

Cambodia’s export performance in the garment, textile, footwear, and travel goods sectors surged during the first three quarters of 2025, with total shipments valued at US$12.2 billion, marking a 16.7% year-on-year increase, according to the latest report from the Ministry of Commerce.

Garments remained the country’s dominant export, reaching US$8.63 billion between January and September — a 16.8% rise from the same period last year. Exports of textiles also posted impressive gains, growing 34.7% to US$505 million. Meanwhile, footwear exports climbed 26.7% to US$1.54 billion, and travel goods and bags recorded a 3.2% uptick, totalling US$1.53 billion.

As Cambodia’s largest foreign exchange contributor, the garment, textile, footwear, and travel goods industry continues to serve as a cornerstone of the national economy. The Ministry of Labour and Vocational Training estimates that the sector encompasses over 1,500 factories and branches, employing more than 900,000 workers, the majority of whom are women.

Thong Mengdavid, a lecturer at the Institute for International Studies and Public Policy at the Royal University of

Phnom Penh, described the sector’s robust export growth as evidence of “a strong post-pandemic rebound and effective market diversification beyond traditional trading partners.”

However, Mengdavid noted that sustaining such high growth rates will require “greater innovation, digital transformation in production, and a shift toward higher value-added manufacturing.”

China’s textile and apparel sector showed a mixed export performance during the first nine months of 2025, as resilient textile shipments helped offset weaker apparel demand in key overseas markets, according to the General Administration of Customs.

From January to September, China’s total textile and garment exports reached US$221.69 billion, a marginal decline of 0.3% year-on-year. Textile exports performed comparatively well, rising 2.1% to US$106.48 billion, while apparel exports fell 2.5% to US$115.21 billion, underscoring growing divergence between the two categories amid a challenging global trade climate.

Measured in yuan, the combined value of textile and apparel exports stood at 1.6 trillion yuan, up 0.6% over the same period last year. Textile exports totalled 764.15 billion yuan, marking a 3% increase, while apparel shipments slipped 1.6% to 826.85 billion yuan.

Industry analysts noted that despite persistent headwinds—including softer consumer demand in the United States and global economic uncertainty— Chinese textile firms have been actively diversifying their export destinations.

During the January–August period, the sector achieved positive export growth in nearly 70% of partner countries, including the European Union, United Kingdom, Japan, Cambodia, and Nigeria. This broader geographic spread has helped mitigate the impact of declining U.S. orders and contributed to the industry’s overall stability.

In September 2025, China’s textile and apparel exports were valued at US$24.42 billion, down 1.4% year-onyear. The data revealed contrasting trends: textile exports surged 6.4% to US$11.97 billion, supported by strong supply chain integration and steady demand for intermediate goods, while apparel exports dropped 8% to US$12.45 billion due to weak consumption in select markets and the lingering effects of U.S. tariff measures.

Experts believe the fourth quarter will likely see continued fluctuations as external conditions remain uncertain. They recommend that Chinese exporters enhance risk management and market forecasting, strengthen supply chain resilience, and capitalize on domestic consumption upgrades to sustain growth.

Strategic measures such as product innovation, diversification of export markets—particularly in Asia, Europe, and the Global South—and greater coordination between domestic and international sales channels are seen as essential for building long-term competitiveness and sustainable expansion in an evolving global environment.

The Egyptian Commercial Service (ECS) office in Istanbul has ramped up its efforts to attract Turkish investment in

Egypt’s ready-made garments, textile, and auxiliary manufacturing sectors, as part of a broader push to strengthen bilateral industrial ties and expand export capacity.

In a recent meeting, Egypt’s Consul General in Istanbul, Ali Basha, and Deputy Consul for Commercial Affairs, Hoda Dorra, met with the Chairperson and Board Members of the Turkish Association of Clothing Accessories Manufacturers, alongside several leading Turkish companies. The discussions focused on enhancing collaboration across apparel-related industries and encouraging Turkish firms to explore Egypt’s emerging role as a competitive manufacturing base.

The Egyptian side outlined the country’s strategic plans to double garment exports in the coming years, backed by investment incentives such as tax exemptions, fast-track licensing, and priority access to industrial zones and global markets.

Both sides agreed to organize an official Turkish business delegation visit to Egypt in the final quarter of 2025. The visit aims to facilitate direct engagement between investors and local industry representatives and to assess opportunities for establishing clothing accessories and component factories that could serve both Egypt’s domestic market and export destinations across Africa, the Middle East, and Europe.

Abdel Aziz El-Sherif, Head of the Egyptian Commercial Service, underscored Türkiye’s importance in this collaboration, noting “Türkiye ranks second globally after China in the

production of clothing accessories, with nearly 1,000 companies active in the sector.”

He added that Turkish investment already plays a crucial role in Egypt’s ready-made garments industry, contributing to a total investment portfolio of around $4 billion.

El-Sherif emphasized that both nations share a strategic vision for deeper industrial integration, aiming to build on their complementary strengths and geographic advantages to promote sustainable, export-oriented growth and mutual trade expansion.

India’s textile sector faced mixed export trends during the first half of FY26, as textile shipments declined while apparel exports recorded moderate growth, according to the Confederation of Indian Textile Industry (CITI).

From April to September 2025, textile exports totalled US$9.97 billion, down 1.85% from US$10.16 billion in the same period last year. In contrast, apparel exports rose 3.42% to US$7.76 billion, compared with US$7.51 billion a year earlier.

Overall, combined textile and apparel exports reached US$17.74 billion in the six-month period, reflecting a marginal year-on-year growth of 0.39% over US$17.67 billion recorded in April–September 2024.

However, performance weakened in September 2025, with both segments witnessing notable declines. Textile exports fell 10.45% to US$1.62 billion, compared to US$1.81 billion in September 2024, while apparel exports slipped 10.14% to US$997.5 million from US$1.11 billion in the same month last year.

As a result, combined textile and apparel exports in September 2025 dropped 10.34% year-on-year to US$2.62 billion, down from US$2.92 billion a year earlier.

CITI’s analysis highlighted that despite steady apparel demand, global economic headwinds and slower textile orders weighed on India’s overall export performance. The industry remains cautiously optimistic for recovery in the second half of FY26, supported by festive season demand and improving global inventory cycles.

Türkiye’s fabric exports continued to face headwinds in the first half of 2025, extending a downward trend that has persisted for three consecutive years. According to industry data, exports declined by 2.55% year-on-year to US $2.10 billion during the January–June period, reflecting sustained challenges in global competitiveness and weakening demand in key markets.

In contrast, fabric imports registered a slight recovery after two years of contraction, increasing by 1.9% in the same period. The rebound was driven largely by stronger shipments from China, Egypt, and Italy, highlighting renewed domestic consumption and Türkiye’s ongoing reliance on foreign suppliers for certain specialized fabric categories.

On the export front, Italy maintained its position as Türkiye’s top destination for fabrics, while Belarus, Morocco, Spain, and Egypt were among the other major markets. Despite this stable network of

trade partners, the overall decline suggests that Turkish exporters are losing market share in competitive global segments, particularly against Asian suppliers benefiting from lower production costs.

The mixed trade performance underscores a critical juncture for Türkiye’s textile sector. While the modest rise in imports signals improving local demand, the contraction in exports highlights structural issues such as high input costs, limited innovation, and slower adaptation to sustainable production standards.

Industry observers emphasize that enhancing product innovation, quality differentiation, and market diversification will be essential for restoring export momentum. Strengthening collaboration across the value chain and investing in high-tech and eco-friendly fabrics could also help Türkiye reinforce its position as a key player in the global textile supply chain.

Vietnam’s textile and garment sector is ramping up productivity and embracing smart manufacturing as it pursues greater value addition and competitiveness in global markets. The industry’s export performance remained resilient, reaching

USD 34.8 billion in the first nine months of 2025 — a 7.7% increase compared to the same period last year — despite persistent challenges in global trade.

The strong performance has positioned the sector to meet its annual export target of USD 48 billion, with many manufacturers already securing orders through November and negotiating shipments for the final quarter.

Nguyen Ngoc Binh, CEO of Hoa Tho Textile Corporation, said that market volatility has required tighter cost control and operational stability. “We’ve implemented measures to stabilise production and sustain export volumes,” he noted. The company recorded VND 4.2 trillion (USD 160 million) in revenue during the ninemonth period — about 83% of its yearly goal — and achieved a pre-tax profit of VND 329 billion, equivalent to 91% of its target.

To meet year-end objectives, Hoa Tho plans to enhance equipment utilisation, improve labour productivity, and strengthen product quality while aligning production with shifting global demand. The firm is also developing model smart factories as part of its long-term automation strategy.

Binh added that global market dynamics continue to pressure exporters: “Demand in the US is likely to slow due to inflation, while buyers in the EU and Japan are increasingly requiring eco-friendly, certified products.” He also noted that Vietnam’s upcoming minimum wage hike in 2026 will further challenge cost structures, prompting companies to invest in workforce training, automation, and welfare initiatives.

Than Duc Viet, CEO of May 10 Corporation, reported that his company achieved 104% of its revenue plan after nine months, largely driven by exports. However, he acknowledged “pressures from falling order volumes, declining unit prices, and ongoing geopolitical uncertainties.”

Vinatex CEO Cao Huu Hieu highlighted that US retaliatory tariffs have reduced export orders by 20–30%, adding risk for Vietnamese producers, as the US remains the destination for over 40% of the country’s apparel exports.

Despite these headwinds, Vinatex posted VND 14.5 trillion in revenue, reaching 79% of its annual plan, and earned a pre-tax profit of VND 1.04 trillion, exceeding the target by 14% and doubling profits compared to last year. The company attributed its performance to adaptive strategies and agile market monitoring.

Of the total USD 34.8 billion in exports, garments contributed USD 27.8 billion, while fabrics, yarn, and technical textiles accounted for the remainder. The sector’s extensive reach—spanning nearly 140 export markets— has underpinned steady growth, particularly during seasonal peaks.

However, the industry remains highly dependent on imported raw materials, particularly from China, with cotton entirely imported and fibre largely sourced abroad. Most firms focus on processing and have yet to develop higher value-added stages such as design, branding, and distribution.

YKK Corporation (Headquarters: Chiyoda-ku, Tokyo; President: Koichi Matsushima; hereafter, YKK) has entered into a partnership with the Fashion Frontier Program supported by the Ministry of the Environment of Japan, which discovers and educates future fashion designers, to provide educational opportunities for thinking about sustainable design through fastening products such as zippers, snaps, and buttons.

YKK is celebrating the 25th anniversary of the YKK Fastening Awards, Japan's largest fashion design contest for students, and is working to discover and support fashion designers around the world.

The Fashion Frontier Program is an educational program and awards program for fashion designers who combine and embody social responsibility and creativity. YKK deeply resonates with the vision of this program as a space where learning and evaluation are integrated, providing opportunities for growth and reflection, along with a supportive framework that empowers future initiatives. With this shared understanding, YKK has entered into the partnership.

At the first incubation session, which will serve as a venue for learning, YKK will hold a lecture on the topic of “Little Parts. Big Difference.” in circular fashion. The aim is to create more in-depth understanding of fastening products, and apply this knowledge to sustainable design practices in the fashion industry. The lecture is scheduled to introduce products being developed by YKK towards achieving a circular economy, and there will be a discussion with the 16 program semifinalists. Products will also be offered.

Next fiscal year, YKK plans to participate in an incubation program for winners of the YKK Fastening Awards in order to create synergy between designers.

of the Fashion Frontier Program

Objective: Discovering and developing future fashion designers who combine social responsibility and creativity

Program schedule (excerpted):

First incubation session: From August 2025 Award ceremony: Mid-December 2025

Organizer: YUIMA NAKAZATO LABORATORY CO., LTD.

Co-organizers: Fashion Frontier Program Executive Committee / unisteps Incorporated Association

Supported by: Ministry of the Environment

Yuima Nakazato, founder of the Fashion Frontier Program, also won the YKK Award (in 2009, in the accessories category) at Europe's largest fashion contest, the International Talent Support (ITS) design competition.

The market situation continues to be characterized by investment restraint due to trade policy uncertainty in key markets. Although Rieter registered growing interest for new machine projects, many requests did not yet lead to binding order intake as customers postponed their investment decisions until the 2026 financial year. Lower volumes in the machinery business and the associated weaker demand for installation services, along with cost-saving measures by customers, are delaying the conversion of orders into sales and are also weighing on the earnings of the After Sales and Components Divisions.

In this challenging market environment, Rieter’s order intake totaled CHF 559.3 million in the first nine months of 2025 (2024: CHF 629.8 million). Adjusted for major orders from the customer DIW (China) in the 2024 financial year, order intake increased by 11% in the first nine months. The increase was driven by a strong third quarter in 2025.

The order intake of the Machines & Systems Division fell to CHF 287.1 million, representing a decrease of 17% compared with the first nine months of the previous year. The Components Division recorded a year-on-year decline of 13% to CHF 142.6 million. At CHF 129.6 million, order intake in the After Sales Division was up by an encouraging 9%.

Converting the order backlog into sales remained challenging due to the ongoing geopolitical uncertainties. Longer book-to-bill cycles can be observed in the after-sales business in particular.

In the first nine months of 2025, Rieter generated cumulative sales of CHF 457.7 million (2024: CHF 584.3 million), representing a decrease of 22% compared with the same period last year. Sales in the third quarter of 2025 amounted to CHF 121.5 million (Q3 2024: CHF 163.3 million). The Machines & Systems Division generated sales of CHF 191.9 million in the first nine months of 2025, a decline of 27% compared with the same period last year. Sales in the Components Division amounted to CHF

154.6 million, down 16% on the previous year’s period. The After Sales Division recorded an 18% decrease in sales to CHF 111.2 million in the first nine months of 2025.

As of September 30, 2025, Rieter’s order backlog was around CHF 590 million (September 30, 2024: CHF 690 million).

The Rieter Group has made significant progress in the implementation of its strategy. This is the result of the strengthened technology leadership in automation and digitization, the consistent implementation of the performance program and the planned acquisition of the Barmag Division.

Since acquiring the winding machine business in financial year 2021, Rieter is the only systems provider that covers the complete manufacturing process from

fiber preparation through to the four end-spinning technologies. At ITMA 2027 in Hanover (Germany), Rieter will present a fully automated spinning mill that achieves maximum efficiency with minimum personnel costs. At ITMA ASIA + CITME in Singapore in October 2025, Rieter will present new automation solutions that support fully automated production.

Rieter is consistently implementing the measures of the performance program. This includes strengthening the most important sales markets, optimizing the supply chain and consistently managing overhead resources. Since the introduction of the performance program in financial year 2023, overhead costs have been reduced by more than CHF 100 million.

The planned strategic acquisition of the Barmag Division gives rise to a globally leading systems provider of natural and man-made fibers. Rieter is confident that all required regulatory approvals for the completion of the acquisition will be obtained in the fourth quarter of 2025. This step represents an important milestone in the implementation of the company strategy which was announced in October 2024.

As a number of projects have been postponed for delivery in 2026 due to macropolitical uncertainties, Rieter (without consideration of the Barmag Division) now expects sales for the full financial year 2025 of around CHF 700 million (previously: CHF 750 to 800 million).

Despite lower sales volumes, Rieter still expects an operating EBIT margin at the lower end of the range of 0% to 4%

(excluding restructuring costs and costs associated with the acquisition of Barmag).

For the full year 2025, Rieter expects:

Transaction costs with an impact on EBIT of around CHF 15 million.

Significant additional restructuring costs with an impact on EBIT. Net financial expenses, including the expenses associated with the acquisition of Barmag, of around CHF 20 million.

As a consequence, Rieter’s 2025 net result is expected to be negative and thus deviate significantly from the prior-year figure.

Rieter is the world’s leading supplier of systems for manufacturing yarn from staple fibers in spinning mills. Based in Winterthur, Switzerland, the company develops and manufactures machinery, systems and components used to convert natural and man-made fibers and their blends into yarns in the most costefficient manner.

Cutting-edge spinning technology from Rieter contributes to sustainability in the textile value chain by minimizing the use of resources. Rieter has been in business for 230 years, has 18 production locations in ten countries and employs a global workforce of around 4 400, about 15% of whom are based in Switzerland.

This year, mechanical engineering company Mahlo GmbH + Co. KG from Saal an der Donau is celebrating a very special anniversary. Since its founding in 1945, Mahlo has evolved from a small pioneering workshop into a globally sought-after specialist in measurement and control technology.

It all started with the radio. By building radio receivers, Dr. Heinz Mahlo began his entrepreneurial success story shortly after the end of World War II with the founding of the "Dr. Heinz Mahlo Electromechanical Workshops" in Saal an der Donau. The visionary engineer soon recognized the potential of the textile industry and developed the first measurement systems for fabrics. A major breakthrough came in 1958 with the patent for the first automatic weft straightener – a technological milestone that still forms the basis for modern straightening machines today.

This initial success laid the foundation for the company’s continuous development. In the decades that followed, Mahlo opened up new markets, expanded its product portfolio to applications in the nonwoven, paper, and plastics industries, and built an international sales and service network.

Step by step, subsidiaries were established in the USA, Italy, Belgium, and China, along with global service partnerships to ensure close customer support on site.

"As the global market leader in textile straightening technology, we continue to build on the ideas and entrepreneurial foresight of Dr. Heinz Mahlo – and have developed the broadest portfolio of straightening systems in various configurations on the market," summarizes CEO Rainer Mestermann. He

has been leading the company since 2011 and has helped Mahlo successfully expand beyond the textile sector. "In the late 2000s, we established a second pillar in the field of web measurement technology with our quality measurement system Qualiscan QMS – also to become less dependent on typical market fluctuations in the textile industry." The new product line was so successful that in 2018, a new production hall was built specifically for this area. And in true Mahlo fashion, the bar was set high –today the company is considered the provider with the most comprehensive portfolio of in-house developed sensors.

But even a solid flagship like Mahlo is not immune to turbulent developments in the global market. “With an export share of around 80 percent, we are naturally closely tied to the global economy,” says Mestermann. Current geopolitical crises are dampening the demand for capital goods. Ultimately, the demand for Mahlo technology is closely linked to the consumption of high-quality products –such as in the clothing or packaging industries. “And it’s precisely this quality we stand for – and our systems ensure it is reliably achieved.”

Still, the managing director remains optimistic that Mahlo will weather these rough waters as well: “Keeping a company successful in the market over eight decades is only possible with a spirit of innovation, reliability, and the dedication of many smart minds. I am proud of our team and grateful for the trust of our customers around the world.”

One of the key pillars is the motivated and skilled team at the Saal headquarters. All systems are developed and built there – in line with the company’s guiding principle that explicitly emphasizes its commitment to Germany as a development and production location. To secure the necessary skilled workforce –known to be in short supply in Germany – Mahlo strongly promotes young talent as one of the largest training companies in the Kelheim area. “That was already

very important to my grandfather,” emphasizes Ralph Greenwood-Mahlo, grandson of the company founder and, together with his wife Aura, owner of the company. Both continue to lead Mahlo in the spirit of Dr. Heinz Mahlo: “We want to preserve the company culture that has grown over time while also providing momentum for new developments. It’s important to us to allow room for fresh ideas while offering continuity.”

For the Greenwood-Mahlo family, running a family business means thinking in generations, not in quarterly numbers. This also means making sustainable decisions.

“By firmly integrating resource-saving behavior into our company practices, we can not only protect the environment but also ensure our company’s long-term success.” Mahlo’s systems also contribute to this – helping manufacturers save raw materials, make processes more efficient, and minimize waste.

According to Ralph GreenwoodMahlo, this reflects a lived responsibility towards employees, customers, the region, and future generations: “Dr. Heinz Mahlo was a pioneer who had the courage to tackle technical challenges while always striving to find the best solution for his customers. This spirit of innovation still shapes Mahlo today – and we see it as our duty to carry this legacy forward without losing touch with reality. Innovation with responsibility – that was his core idea, and it’s ours too.

Forward-looking brands piloting TrusTrace’s Digital Product Passports (DPP) solutions report early readiness, sharper insights, and operational edge.

TrusTrace, a leader in AI-powered supply chain traceability and compliance, today announced it has been named a Representative Provider in the Gartner® report Innovation Insight: Digital Product Passport — Unlocking Value Beyond Compliance (Kevin Lawrence, July 2025).

According to the research, “Instigated through sustainability regulations, digital product passports create a rich digital identity for products throughout their life cycle.” Gartner expected that, “the DPP market is anticipated to grow at a 24.43% compound annual growth rate from 2025 to 2034.” Far from a one-sizefits-all tool, DPPs will evolve across industries to enable not only compliance but also richer consumer experiences, improved supply chain transparency, and new business value.

For companies operating in the EU fashion or battery markets, compliance regulations and deadlines are approaching fast, yet many still underestimate the scope of the challenge. “DPPs are not a project, they represent a permanent operational shift,” said Shameek Ghosh, CEO at TrusTrace. “We are proud of our inclusion in Gartner’s research, as we believe it underscores our commitment to enabling DPP adoption and value creation. Brands piloting full readiness today will gain early advantage through stronger infrastructure, sharper insights, and more credible consumer engagement.”

Much of the current industry conversation around DPPs focuses on consumer-facing pilots. But true readiness goes far deeper. DPPs will be required at the individual product level, with accurate, auditable data on origin, production, and impact. Managing this at

scale demands robust backend systems for data integration, governance, and interoperability. Without that foundation, consumer-facing efforts fall flat.

Forward-looking brands are already piloting with TrusTrace to gain early insights and an operational edge. One such pilot is a two-year project with The Swedish School of Textiles.

Three of the participating brands elaborated on the benefits:

“Our collaboration with TrusTrace in the System Demonstrator project has been an important step in preparing for the upcoming Digital Product Passport (DPP) implementation,” said Lina Ödeen, Head of Sustainability at ETON. “Testing their solution has given us valuable insights and practical experience that will not only help us meet future requirements but also strengthen our ability to reduce our climate impact while driving even greater transparency and traceability throughout our value chain.”

“Many of the new legal requirements under the EU Strategy for Sustainable and Circular Textiles have been quite theoretical and vague,” explained Sandra Roos, VP Sustainability at Kappahl. “Creating a DPP ‘for real’, so we could attach a unique QR code to each garment, scan with a mobile phone, and

access the interface created by TrusTrace – and see what all the collected data looked like in this context – gave us a tangible example and increased the organization’s understanding of what the DPP will be.”

“TrusTrace’s DPP solution allows us to test relevant processes and visualize potential outcomes, supporting our preparation for upcoming compliance requirements and driving future product transparency,” said Julia Persson, Sustainability Coordinator at Gina Tricot.

Last year, TrusTrace launched Unlocking DPP, a playbook with everything brands need to prepare for DPPs and capture value beyond compliance, including a proposed data protocol for expected requirements in the delegated acts.

TrusTrace’s AI-enabled platform delivers an end-to-end solution for DPP readiness, streamlining traceability, automating compliance workflows, and consolidating product-level data across regulations. By connecting brands, suppliers, solution partners, and industry stakeholders, TrusTrace ensures companies are ready for compliance and equipped to leverage DPPs to improve operations, impact, and consumer engagement.

Archroma, a global leader in specialty chemicals towards sustainable solutions, will showcase innovations that deliver sustainable performance for functional fabrics without compromise at PERFORMANCE DAYS 2025 in Munich this month.

The company's team of specialists will present breakthrough dyes and finishes that prove brands don’t need to choose between high-performance textiles and environmental responsibility, featuring solutions for sportswear, athleisure and workwear applications where durability, comfort and sustainability are equally critical.

"It is no longer true that you need to sacrifice high performance for sustainability," said Dhirendra Gautam, Vice President, Commercial, Archroma.

"Whether it's colors that stay vibrant wash after wash, or softness that lasts without sacrificing absorbency, we're showing that brands can deliver the performance consumers demand while advancing their environmental commitments. This is especially critical for functional fabrics where performance is non-negotiable."

At Performance Days, Archroma will feature its HIGH IQ® LASTINGCOLOR PRO series, including LASTINGCOLOR PRO and LASTINGBLACK PRO , reinforcing the company's commitment to colors that perform without compromise.

The HIGH IQ® performance assurance program ensures that fabrics deliver

sustainable performance for garments that stay looking new, wash after wash, with bright shades that retain their intensity and dark shades that stay dark. Powered by specially selected AVITERA® SE reactive dyes, the program helps mills and brands achieve superior color retention while reducing their environmental footprint by using up to 50% less water and energy in processing. For functional fabric applications where color durability is essential, from highvisibility workwear to activewear that must maintain its aesthetic appeal, the HIGH IQ® LASTINGCOLOR PRO retains their colors up to 50 repeated washes, and delivers performance, protection and comfort while meeting the textile industry's strict environmental regulations.

SILIGEN® D2W LIQ C: Solving the Softness-Absorbency

Performance Days will also give industry professionals a first chance to experience SILIGEN® D2W LIQ C, the industry's first truly durable silicone softener for cellulosic and cotton-lycra blended knits that maintains both luxurious softness and natural absorbency over extended use.

Historically, manufacturers had to choose between a durable softener that compromised the fiber's natural absorbency or a softener that preserved moisture-holding properties but quickly washed away. SILIGEN® D2W LIQ C eliminates this trade-off through Archroma's patent-pending micro-x chemistry, which creates a cross-linkable microemulsion that forms a stable silicone network within cellulosic fibers. This breakthrough ensures uniform softener distribution and locks in softness over time while maintaining wash resistance— ideal for functional textile applications where both comfort and moisture management are critical.

The innovation also represents a first in objective handfeel measurement, enabling mills and brands to quantify and communicate softness durability with unprecedented transparency.

Drawing on Archroma’s extensive portfolio, the team will also highlight

PHOBOTEX® NTR-

50 liq, a bio-based durable water repellent that is non-PFAS (per- and polyfluoroalkyl substances) and non-formaldehyde, as well as 50% renewable carbon content (based on ASTM D6866).

bringing economical sustainability to dark shades, including black, navy and red.

PHOBOTEX® NTR-50 provides excellent water repellence on all kinds of fibers and also achieves a soft handle that makes fabrics more comfortable to wear. This makes it ideal for sports apparel and outdoor wear.

Rounding out the Archroma’s Performance Days showcase, the company will present EarthColors® technology, which creates colors from agricultural waste such as nutshells and cotton plant residues; and AVITERA® GENERATION NEXT, the latest extension to the revolutionary AVITERA® platform,

Meet the Archroma Team at PERFORMANCE DAYS 2025

A leading trade fair with a tight focus on functional fabrics and sustainable textile innovations, PERFORMANCE DAYS is held twice a year to support seasonal sourcing. More than 3,000 specialist visitors, including designers, product managers and purchasing professionals, are expected to attend the October 2025 edition in Munich, alongside online attendees from around the world.

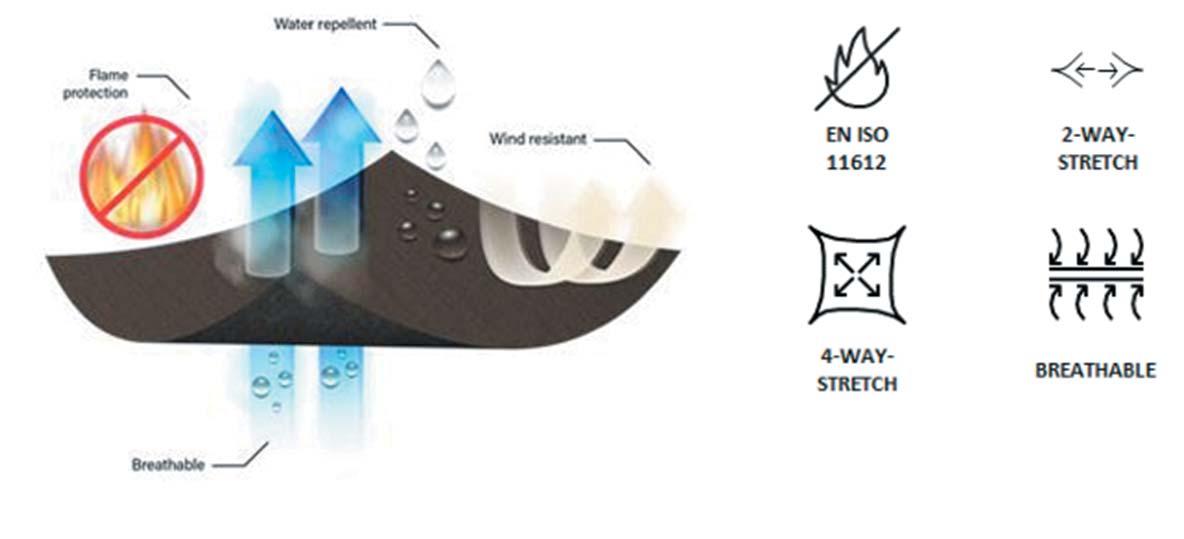

TEXTILCOLOR AG, a leading provider of innovative solutions in textile chemistry, today announces the start of a strategic collaboration with Alpex Protection, Majocchi, and Trans-Textil. Starting November 1, 2025, the partners will jointly advance the flame-retardant finishing of textiles using the patented Pyroshell™ technology at production sites in Germany, France, and Italy.

Pyroshell™ technology is a patented, permanent flame protection for polyamide and polyester fabrics and represents a milestone in the field of

protective equipment for synthetic textiles. Pyroshell™ is revolutionising flame protection by significantly reducing the risk of burns. When a fabric equipped with Pyroshell™ is exposed to a flame, its textile structure expands substantially in volume. This effect keeps heat and firepromoting gases largely away from the fabric. Therefore the time between the first sensation of pain from heat exposure and the onset of second-degree burns doubles. As a result, wearers gain valuable additional reaction time compared to conventional flame protection solutions.

The partnership with Alpex, Majocchi, and Trans-Textil enables the Pyroshell™ technology to be implemented even more efficiently within production processes and made accessible to a broader customer base. Alpex Protection (France) specializes in technical textiles and functional fabrics, Majocchi (Italy) manufactures high-quality textiles for the military, PPE, and luxury/fashion sectors, and Trans-Textil (Germany) produces innovative materials for safety and operational applications. The goal is to provide high-quality, safe, and comfortable functional and protective textiles throughout Europe.

“We are very excited about collaborating with our experienced partners in Germany, France, and Italy,” says Detlef Fischer, CEO of TEXTILCOLOR AG. “Together, we can leverage Pyroshell™ optimally within the production processes. The technology provides not only maximum protection but also exceptional comfort for users in demanding operational environments.”

Fresh from its highly successful 63rd conference held in Porto, Portugal, from October 7-10, The Textile Institute (TI) will celebrate a major milestone at the ITMA Asia+CITME textile machinery exhibition in Singapore later this month.

One hundred years ago, in 1925, TI was granted its Royal Charter by King George V, transforming it from a professional association into a globally recognised chartered body, and in Singapore from October 28-31, is seeking to strengthen its international partnerships while welcoming new Corporate Members to its expanding global network.

At Stand B105 in Hall 8, TI will exhibit as a reciprocal member of the British Textile Machinery Association (BTMA), showcasing the power of collaboration and shared growth. The long-standing partnership between the two organisations has been further strengthened by the appointment of BTMA CEO Jason Kent as TI’s new Commercial Vice President, bringing fresh industry insight and influence to the role.

“Our joint presence in Singapore underlines how enduring partnerships strengthen the entire industry,” Kent says. “Corporate Membership of The Textile Institute gives organisations access to an international network of professionals, cutting-edge research and strategic benefits valued at over British Pound10,000 a year.”

Membership unlocks a host of advantages, including global promotion and visibility, invitations to high-level networking events and training, collaboration on industry-led research, professional recognition through chartered qualifications and access to TI’s publications, data and R&D resources.

“As the only global professional body in this sector with a Royal Charter, we are driving the industry forward through high-quality events and training courses that equip professionals for the future,” says TI CEO Stephanie Dick. “Together with our Corporate Members, we’re tackling skills gaps, developing practical training solutions and reaching international audiences.”

“This is an exciting time for the industry, especially with the major opportunities being opened up in new technical textiles for rising industries such as energy and data storage, future mobility and advanced infrastructure,” adds TI President Charles Wood. “Whether you’re a multinational manufacturer or a fast-growing SME, TI offers a neutral, not-for-profit platform where your voice is heard and your ambitions are supported. As we expand our influence across Asia and beyond, we’re inviting new Corporate Members to join us, benefit from our resources and help shape the Institute with their expertise.”

The Textile Institute is ideally positioned to help organisations stay competitive, connected and compliant. From its first foundation in Manchester in 1910, its approach has always been to be “not of Manchester, but international”, and with

sections and special interest groups active across the globe, it now serves members in over 60 countries, empowering professionals across every link in the textile supply chain.

Sales for ITM 2026, one of the world’s most comprehensive and prestigious exhibitions in textile technologies, are continuing at full steam. The record number of exhibitors and visitors achieved at ITM 2024 once again proved the industry’s confidence and the commercial success of the exhibition; meanwhile, the strong interest shown in ITM 2026, to be held on 9-13 June 2026, has far exceeded expectations.

The world's leading textile machinery manufacturers and technology giants are expanding their stands at ITM 2026 to establish new business connections and gain a stronger foothold in global markets. Rising demand and strong applications are transforming the

exhibition into an even more attractive and profitable investment platform for exhibitors.

The ITM 2026 International Textile Machinery Exhibition will host industry professionals at the Tüyap Fair and Congress Center from June 9-13, 2026.

Standing out as one of the world's leading textile technology gatherings, the exhibition will transform Istanbul into a global textile technology hub over five days. Throughout the exhibition, investors and professional visitors will have the opportunity to closely examine the latest machines and innovative solutions. With its showcase of advanced technology products, new business connections, and investment decisions, ITM 2026 will make a significant contribution to the growth of the textile machinery sector and to strengthening its competitiveness in the international arena.

The ITM Exhibition held in 2024 set new records in terms of both the number of exhibitors and visitors, as well as machine sales. A total of 1,385 companies and company representatives from 71 countries participated in ITM 2024, which was visited by 66,200 people from 99 countries — 45% from abroad and 55% from Türkiye. The exhibition boosted the textile industry with machine sales and a business volume worth billions of euros over its five-day duration. This strong outcome achieved at ITM 2024 laid a solid foundation for ITM 2026. Hosting the leaders of textile technologies in Istanbul, ITM 2026 aims to carry this legacy forward and set new records.

ITM 2026 will not only be an exhibition, but also the most accurate address for new investments, collaborations, and technological transformations in the sector. The B2B meetings to be organized within the scope of the exhibition will provide companies with the opportunity to establish long-term business connections and increase sales potential. Visitors will be able to closely examine the latest technologies and have the chance to receive first-hand information from industry experts. Delegations from countries with intensive textile production such as Pakistan, Bangladesh, Uzbekistan, India, and Egypt, as well as global investors, will prefer ITM 2026. The machinery sales and business partnerships of manufacturers coming from all around the world will give significant momentum to both the Turkish and global textile machinery industries. ITM 2026 will be a prestigious meeting point where the heart of investments, collaborations, and innovations in the sector will beat.

ITM 2026, to be held in Istanbul, one of the crossroads of global trade, stands out with its geographically strategic location. Easily accessible from Europe, Asia, the Middle East, and Turkic Republics, Istanbul offers great advantages for exhibition participants. In addition, the visa agreements between Turkey and many countries such as India,

Pakistan, Bangladesh, Indonesia, Vietnam, Egypt, Algeria, Tunisia, Morocco, Iran, Uzbekistan, and Turkmenistan further enhance the significance of ITM 2026. Textile manufacturers from countries that face visa challenges when traveling to Europe will not encounter such difficulties when coming to Istanbul, which will play an important role in increasing the number of participants and visitors at ITM 2026.

Istanbul’s Advantages in Transportation, Accommodation, and Gastronomy will Elevate ITM 2026 to the Top

Istanbul offers great convenience to ITM 2026 participants and visitors not

only with its strategic location but also with its wide range of accommodation and dining options. The availability of hotels to suit every budget in areas close to the exhibition venue ensures that participants enjoy a comfortable and pleasant stay throughout the event. In addition to the rich flavors of Turkish cuisine, Istanbul also offers countless alternatives from world cuisines. With its restaurants, cafés, and easily accessible dining spots, the city fully meets the needs of exhibition visitors. These advantages make ITM 2026 not only a hub for business but also a center for cultural and gastronomy discovery.

DOMOTEX 2026 brings together the international flooring and interior finishing industry, with numerous top companies already confirmed. A particular focus will be on the members of the European Parquet Federation (FEP), including Kährs, Weitzer Parkett, and ter Hürne, who will showcase high-quality, sustainable parquet solutions in the FEP Lounge, fostering professional exchange and networking within the industry.

Under the motto “Creating Rooms. Transforming Spaces.”, DOMOTEX 2026 will open its doors from 19 to 22 January as the Home of Flooring & Interior Finishing, bringing together the international flooring and interior design community. Numerous leading parquet manufacturers have already confirmed their participation and will present highquality, innovative, and sustainable solutions at the show.

A special spotlight will be on the FEP member companies. Across the fair, companies such as Kährs, Weitzer Parkett, ter Hürne, Stile, PPS Galekovic, Pan Parket, Baltic Wood, Befag, and

Decospan will demonstrate the diversity, innovation, and sustainability of the European parquet industry. Many of them follow the Reel Wood Initiative, launched by the FEP to highlight the unique advantages of real wood flooring – from longevity and refurbishability to reusability and its positive contribution to climate protection.

In this context, the FEP Lounge will serve as an exclusive meeting space at DOMOTEX 2026, offering networking opportunities, expert dialogue, and inspiration for the parquet community.

“FEP, with its members, is delighted to join DOMOTEX,” says Isabelle Brose, Managing Director of the FEP. “This is a unique occasion to show to a large and diversified audience how our industry is united to propose its sustainable and durable flooring solution:

Parquet, which is made of genuine wood, can be used, reused, renovated, and used again. We look forward to introducing you to parquet!”

The exhibiting companies share this enthusiasm. Josef Stoppacher, CEO of the

Weitzer Group / Weitzer Parkett, emphasizes:“Participating in DOMOTEX allows us to showcase our commitment to innovation and sustainability in the flooring industry. It’s a unique opportunity to connect with international partners and present our latest developments to a global audience.”

With the FEP Lounge, DOMOTEX 2026 not only offers a dedicated forum for the parquet industry but also embodies the spirit of its guiding theme: creating inspiring spaces and shaping sustainable living environments. At the same time, it perfectly complements the show’s diverse special displays, seamlessly integrating into the overall DOMOTEX experience.

While formats such as the Retailers Park, Architects Space, Innovationparcours, and Green Collection present different facets of the industry, the FEP Lounge invites visitors to connect, exchange ideas, and experience the innovation and sustainability that define the European parquet sector.

The First-Ever Dedicated Exhibition & Conference for Textile Recycling in North America

Registration is now officially open for the Textiles Recycling Expo USA, the first dedicated exhibition and conference for textile recycling in North America. The landmark event will take place April 29–30, 2026, at the Charlotte Convention Center in North Carolina, and attendance is completely free.