CAITME 2025

Dates: September 9th to 11th, 2025. Venue: Tashkent, Uzbekistan.

Apparel Sourcing Paris Autumn

Dates: September 15th to 17th 2025. Venue: Paris, France.

64th Dornbirn-Global Fiber Congress

Dates: September 10th to 12th 2025. Venue: Dornbirn Austria.

ITMA ASIA + CITME, Singapore 2025

Dates: October 28th to 31st, 2025.

Venue: Expo Centre Singapore.

ShanghaiTex 2025

Dates: November 16th to 19th 2025. Venue: SNIEC, Shanghai, China.

Textile Asia 2025, Lahore

Dates: November 22nd to 24th 2025. Venue: Lahore Expo Centre. Textile Asia 2026, Karachi

Dates: December 05th to 07th 2026. Venue: Expo Centre, Karachi.

Heimtextil 2026, Frankfurt

Dates: January 13th to 16th, 2026 Venue: Frankfurt, Germany.

FESPA Middle East 2026

Dates: January 13th to 15th 2026. Venue: Dubai Exhibition Centre.

DOMOTEX Hannover 2026

Dates: January 19th to 22nd 2026. Venue: Hannover, Germany.

IGATEX Pakistan 2026, Lahore

Dates: April 08th to 11th 2026.

Venue: Expo Centre, Lahore

iCADEX Pakistan 2026, Lahore

Dates: April 08th to 11th 2026.

Venue: Expo Centre, Lahore PAKISTAN

JOURNAL - July -August 2025

DOMOTEX asiaCHINAFLOOR 2026

Dates: May 27th to 29th 2026. Venue: NECC, Shanghai, China.

Techtextil and Texprocess 2026

Dates: April 21st to 24th, 2026

Venue: Frankfurt, Germany.

Index 2026

Dates: May 19th to 22nd, 2026. Venue: Palexpo, Geneva, Switzerland.

ITM 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

HIGHTEX 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

ITMA ASIA + CITME 2026

Dates: October 20th to 24th, 2026. Venue: NECC, Shanghai, China.

Dates: September 16th to 22nd, 2027. Venue: Hanover, Germany.

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief

Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager

Mazhar Ali

Layout & Design

Noor M. Jaan

Website / Social Media

Minhaj Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, United Kingdom.

Registered no. 09141989

Tel: +44 792 2228 721

Available on Gale and Factiva affiliated international databases through Asianet Pakistan

Engr. Naeem Ilyas Khanani Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

Tonello and Pacific Jeans celebrate a shared milestone: the 10,000th machine . . .18

Brückner: Inauguration of the branch office in Coimbatore, India

.20

YKK Corporation named CDP Supplier Engagement Leader for third consecutive year22

Archroma unveils breakthrough washing-off auxiliary for outstanding color fastness and resource efficiency in reactive dyeing

Transitions to full ownership by Zhejiang Longsheng Group, resolving longstanding dispute

First ITMA Sustainability Forum to feature European Commission Keynote Speaker .

Navigating the future of fashion: Intertextile Apparel unveils upgraded zones and fringe programme

COTTON USA™ forums strengthen U.S.–Pakistan cotton textile industry ties . . . .30

Hagen Lotzmann is the newManaging Director of KARL MAYER Technical Textiles .32

Circulose partners with Mango and H&M Group to make circularity at scale a reality34

Excellence in denim manufacturing with Rieter ring spinning system .

Uster Technologies: Challenges of making yarn from recycled fibres

Autocoro 11 – Leading innovation for spinning recycled fibres

.37

Mei Sheng in Vietnam: Longstanding partnership with Trützschler for outstanding quality

Performance of Italian textile machinery sector during FY24 .

by Nadeem Mazhar, Managing Editor, Pakistan Textile Journal.

Italy remains an important market for Pakistan with 1.2 billion dollar exports during FY24

by Nadeem Mazhar, Managing Editor, Pakistan Textile Journal.

Italian Textile Technology and Pakistan's Industrial Prowess

ACIMIT celebrates 80th anniversary

The association looks back with pride and ahead with renewed passion and responsibility.

Color Service S.r.l. (“Color Service”) signs definitive agreement with Graco . . .52

Over 30 Years at the administrative heart of Color Service: The story of Corrado Rampon .

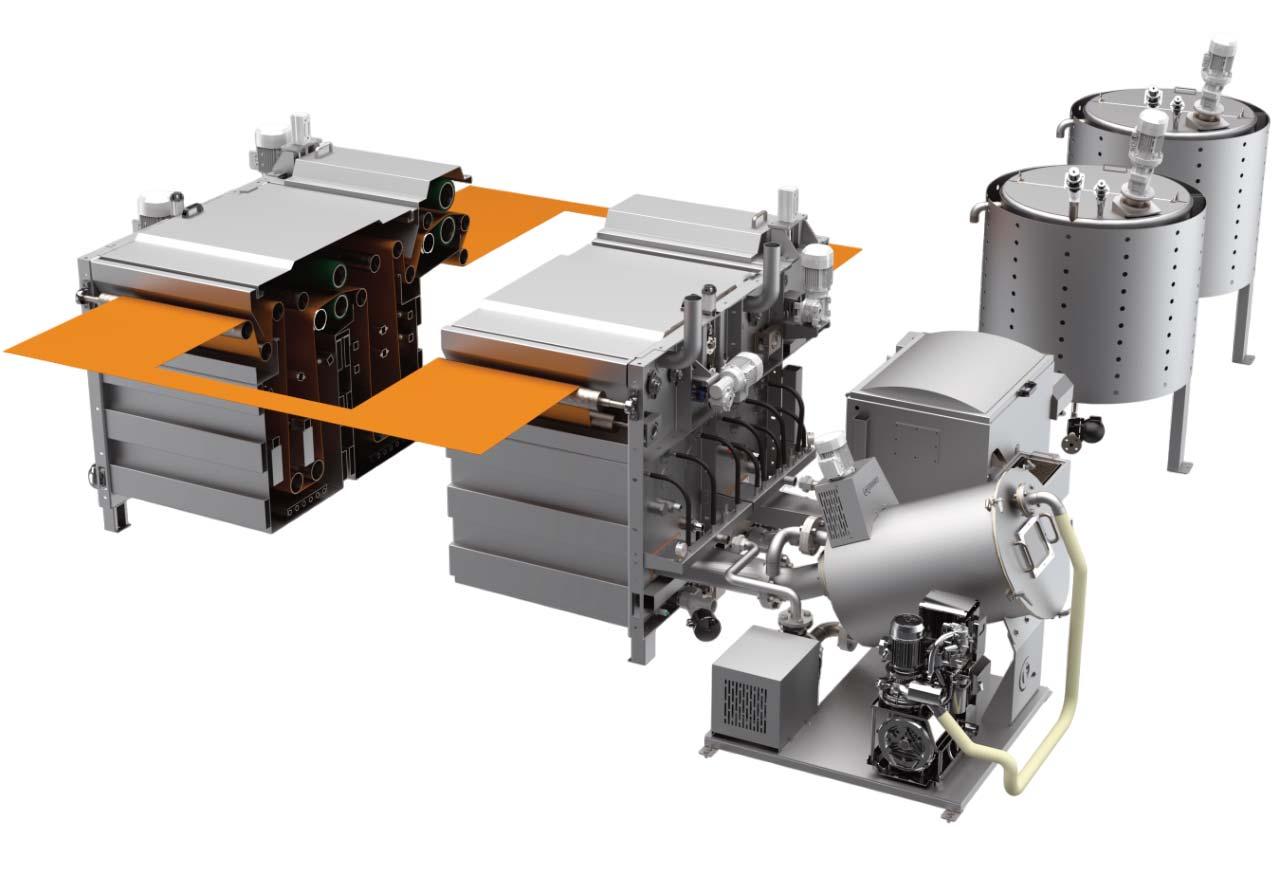

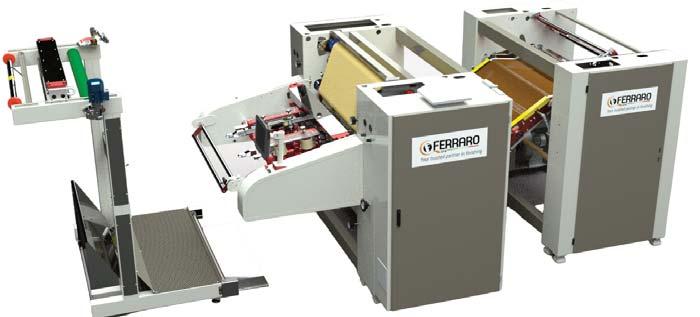

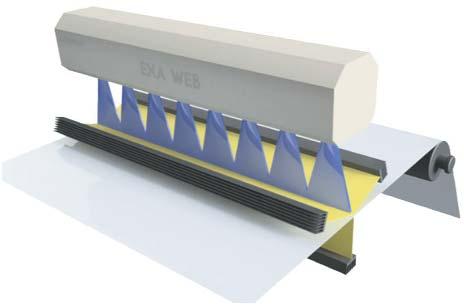

Ferraro: Excellence in sanforising technology

Loptex: Pioneering Contamination Elimination for a cleaner textile future

Durst strengthens textile printing portfolio

Through strategic acquisition of aleph — Now Durst Como

Eurojersey and Durst – A flagship customer collaboration

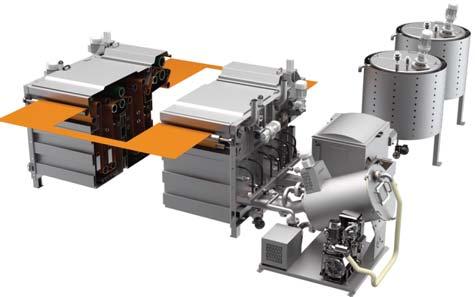

CORINO MACCHINE: Italian innovation at the heart of textile finishing

Mesdan cotton fibre testing equipment

.54

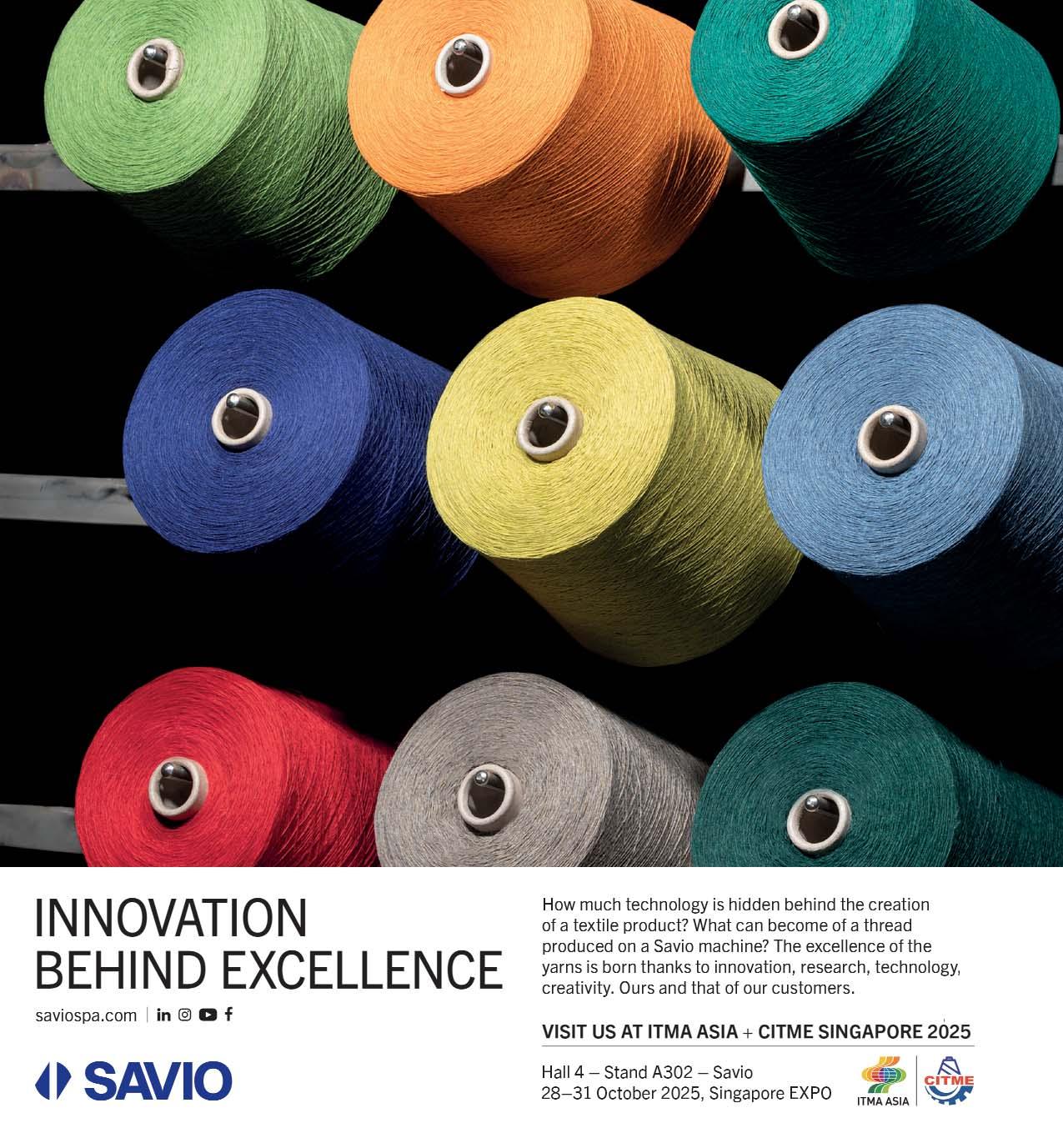

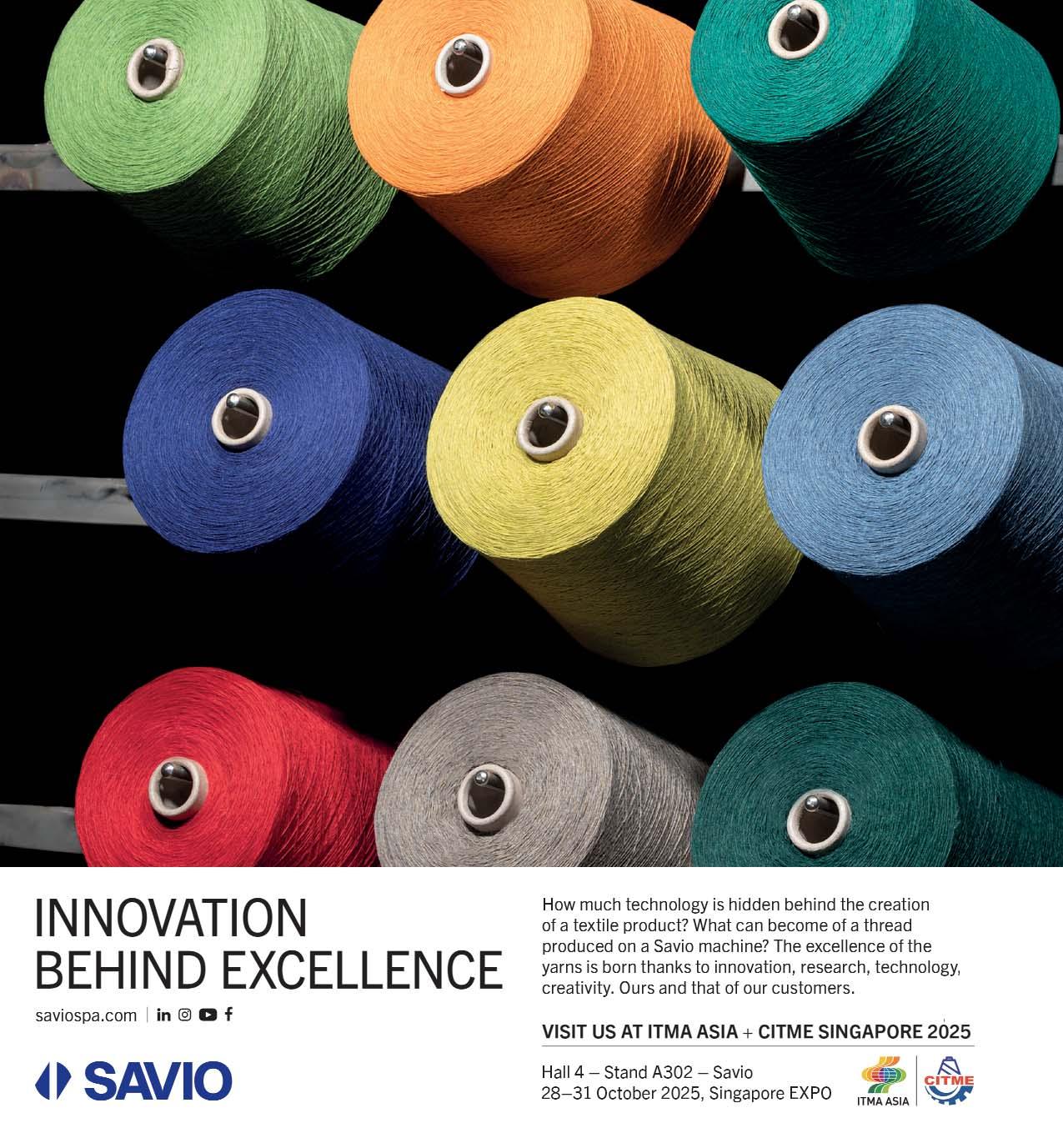

Savio redefines yarn finishing with Proxima Smartconer® and Lybra Smartspinner® .61

Santex Rimar Group’s strategic blend of Italian precision and global responsiveness 62

EDITOR’S PAGE

This year marks the 80th anniversary of ACIMIT (Association of Italian Textile Machinery Manufacturers), a milestone celebrating Italy’s leadership in textile machinery. At a commemorative General Assembly held at the Ferrari Museum in Maranello, ACIMIT reaffirmed its commitment to innovation, internationalisation, and sustainability as the cornerstones of the industry's future.

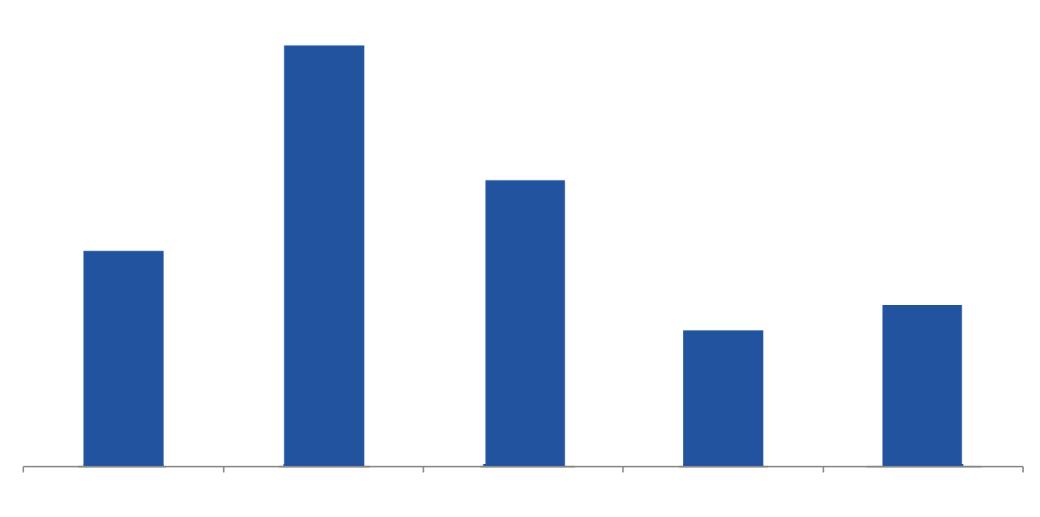

In his address, ACIMIT President Marco Salvadè acknowledged current global challenges, including an 8% drop in production and a 9% decline in exports for Italian textile machinery in 2024. However, he emphasized that "Made in Italy" must continue to represent quality, creativity, and technical excellence, especially in a volatile global economy marked by protectionism.

Despite the downturn, Italian textile machinery remains a global benchmark, thanks to the strength of ACIMIT’s 300 member companies, primarily SMEs. These firms export 86% of their output to over 130 countries, offering high-performance, sustainable, and customized solutions for both traditional and advanced textile manufacturing.

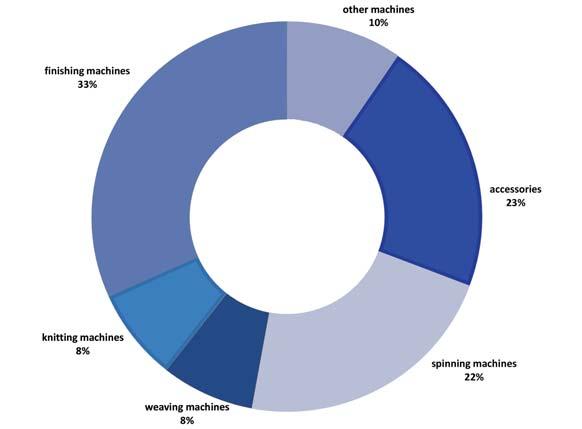

In 2024, Italy maintained its status as an industrial powerhouse, with total exports reaching euro 675 billion, an increase over the previous year. Asia accounts for 41% of Italian textile machinery exports, followed by the EU, North America, and Africa. China remains the top market, with Turkey, India, and the U.S. close behind.

Italian manufacturers continue to lead in Industry 4.0 solutions—developing machinery that integrates automation, predictive maintenance, data acquisition, and augmented reality. These innovations enable cost reductions and faster adaptation to market demands, aligning with global priorities like just-in-time production and sustainable sourcing.

Among Italy’s global trade partners, Pakistan has emerged as a key player. In 2024, bilateral trade surpassed euro 1.5 billion, with Pakistan enjoying a euro 500 million trade surplus, driven by exports of cotton fabrics, garments, leather, home textiles, and sports goods.

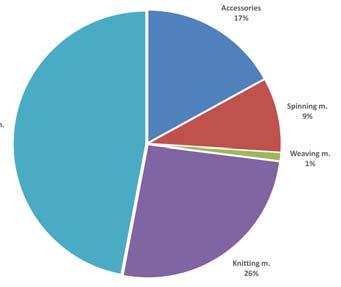

At the same time, Pakistan's imports of Italian textile machinery grew by 9% to euro 53 million, with finishing machines making up nearly half. This rise reflects growing trust in Italian technology as Pakistani manufacturers invest in high-precision, energy-efficient equipment to modernize their operations.

Italy’s contribution extends beyond machinery. Italian expertise is active in pharmaceuticals, automotive, energy, and renewables in Pakistan, reflecting a multi-sectoral partnership.

A highlight of this collaboration was Italy’s enhanced participation in IGATEX 2025, Pakistan’s leading textile machinery exhibition. Under Mr. Salvatore Parano, Trade Commissioner of the Italian Trade Agency (ITA), and supported by Mr. A.R. Daudpota, a veteran in Pakistan’s textile machinery landscape, Italian firms showcased cutting-edge solutions in spinning, weaving, finishing, and automation—strengthening Italy’s role as a preferred technology partner.

The story of Italian textile machinery is one of resilience and vision. Emerging from the 1970s energy crisis, it has evolved into a globally recognized sector that supports over 100,000 jobs and enhances Italy’s fashion and textile competitiveness.

For Pakistan, this partnership offers more than machinery. It is an avenue for the development of skills, the transfer of knowledge, and a driver of sustainable industrial growth, essential for boosting productivity and entering higher-value global supply chains.

July-August 2025

1

Pakistan’s textile industry continued its upward trajectory in April 2025, reporting export earnings of $1.44 billion, an 11.1% increase over the $1.3 billion recorded in the same month last year, as per the latest figures from the State Bank of Pakistan (SBP). The sector also edged slightly higher on a monthly basis, posting a marginal gain of 0.042% over March’s $1.443 billion.

2

Earlier this month, the federal government informed the National Assembly that the United States has introduced a 30% reciprocal tariff on imports from Pakistan, though the measure is currently under a 90-day suspension. The announcement has drawn a mixed response from the business community.

3

Pakistan’s textile sector has the potential to add an immediate $3–4 billion to annual export revenues, provided the government creates a more supportive policy environment, according to the Pakistan Textile Council (PTC).

4

Kamran Arshad, Chairperson of the AllPakistan Textile Mills Association (APTMA), has welcomed the government's recent move to impose an 18% sales tax on imported cotton yarn, calling it a much-needed correction in the country’s textile taxation regime. The measure, he noted, addresses a longstanding imbalance in the market and marks an important step in aligning the Export Facilitation Scheme

1Australia’s cotton industry has reported a robust upswing in production for the 2024–25 fiscal year, with output of cotton lint projected to hit 1.2 million tonnes—an increase of 12% over the previous year. This growth is underpinned by an expansion in planted area and exceptional crop yields, according to the latest quarterly Australian Crop Report published in June 2025 by the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES).

2

Bangladesh has allocated TK 4.8 billion (approximately $56 million) for the Ministry of

(EFS) with equitable trade principles.

5

Kristin K. Hawkins, the United States Consul General in Lahore, held a high-level meeting with the leadership of the All-Pakistan Textile Mills Association (APTMA) to discuss ways to strengthen trade and economic cooperation between the two countries, with a particular focus on the cotton and textile industries.

6

7

The Pakistan Readymade Garments Manufacturers and Exporters Association (PRGMEA) has called on the federal government to introduce targeted policy reforms in the upcoming national budget to address urgent issues hampering the country’s value-added textile export sector. Representing a $4.9 billion export segment, PRGMEA has submitted detailed proposals to Prime Minister Shehbaz Sharif and Haroon Akhtar Khan, Special Assistant to the Prime Minister on Industries and Production.

In a move aimed at strengthening regional cooperation in the apparel industry, the Pakistan Readymade Garment Manufacturers and Exporters Association (PRGMEA) and the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) have formalized a Memorandum of Understanding (MoU) to advance bilateral collaboration in garment manufacturing and export.

Jute and Textile in the upcoming fiscal year 2025–26, as revealed by Finance Adviser Salehuddin Ahmed during the national budget announcement earlier this month. Of the total sum, TK 2.32 billion is set aside for operating costs, while TK 2.48 billion will fund development initiatives.

3Cambodia's garment industry posted robust growth in the first four months of 2025, with clothing exports soaring to $3.14 billion—up 21 per cent compared to the same period last year. This segment alone contributed more than a third (34.4 per cent) of the country’s overall export revenue,

which climbed to $9.14 billion, according to figures released by the General Department of Customs and Excise (GDCE).

4

A delegation representing 25 Chinese textile and apparel companies recently concluded a visit to Egypt as part of efforts to identify strategic investment and collaboration opportunities within the country’s burgeoning textile industry. The group held talks with Minister of Public Business Sector Mohamed Shimy, who outlined Egypt’s robust industrial infrastructure and its appeal as an investment destination.

5

Egypt’s textile and apparel sector is undergoing a dynamic transformation, fuelled by strategic funding, operational cost advantages, and a government-backed push to enhance industrial infrastructure. Industry experts point to shifting global economic conditions and a sharp rise in foreign direct investment as key catalysts for the sector’s rapid development.

6

The cotton yarn sector across North India is facing continued stagnation, with sluggish demand and financial constraints hampering trade momentum despite a surge in raw cotton prices.

Pakistan's textile exports have experienced a notable year-on-year growth of 33.7%, reaching $1.69 billion in July of the current fiscal year, compared to $1.27 billion during the same month in the previous fiscal year. This marks a significant rebound after nearly three years of continuous decline in July exports, according to official sources speaking to The Nation.

In the previous years, Pakistan's textile exports in July were as follows: $1.48 billion in July 2022-23, $1.31 billion in July 2023-24, and $1.27 billion in July 2024-25. However, the industry showed signs of improvement this year.

On a month-on-month basis, exports rose by 10.45%, increasing from $1.53 billion in June 2025 to $1.69 billion in July 2025. This represents a significant jump from the $1.27 billion recorded in July 2024-25.

Looking back at historical performance, Pakistan's textile exports briefly crossed the $1.74 billion mark in April and November of FY 2021-22. However, in the subsequent fiscal years (2022-23, 2023-24, and 2024-25), the country never reached this level again. While textile exports occasionally touched$1.68 billion, most months saw exports fall below that threshold, with some months seeing figures as low as $1.18 billion.

For the fiscal year 2021-22, total textile exports stood at $19.3 billion, a decline to $16.51 billion in FY 2022-23, followed by a modest recovery to $16.68 billion in FY 2023-24. In the recently

concluded FY 2024-25, exports rose slightly to $17.88 billion.

In a joint appeal, the Pakistan Hosiery Manufacturers & Exporters Association (PHMA) and the Pakistan Readymade Garments Manufacturers & Exporters Association (PRGMEA) have urged the government to consider and implement key proposals aimed at improving the textile industry’s performance. The request was made during a post-budget meeting held earlier this month, where representatives from both associations gathered to discuss the sector’s concerns with the FBR’s Budget Anomaly Committee.

Among the attendees were PHMA chairman Abdul Hameed, former PHMA

chairmen Naseer Butt and Shehzad Azam Khan, PRGMEA Chairman Dr. Ayyazuddin, and former PRGMEA chairmen Ijaz Khokhar and Sohail Afzal Sheikh.

The associations have submitted a series of recommendations, which they believe can help boost the struggling textile export sector. The group has called on the government not only to carefully examine these proposals but also to implement the suggestions outlined in the final report from the Anomaly Committee once it is compiled.

Abdul Hameed, Chairman of PHMA, highlighted the vital role that Pakistan’s value-added textile sectors—such as apparel, bed linens, home textiles, and towels—play in the national economy. These sectors generate over $11 billion annually in exports and support millions of jobs. However, he expressed deep concern over the shift from the simplified Final Tax Regime (FTR) to the more complex Normal Tax Regime (NTR), which has introduced both a 1% minimum tax and a 1% advance tax on export proceeds. These taxes apply regardless of whether the exporter makes a profit or not, creating additional financial strain.

Naseer Butt, a former PHMA Chairman, criticized the introduction of dual taxation, calling it counterproductive and harmful to the already struggling export sector. He noted that small and medium-sized enterprises (SMEs), many of which operate on very narrow profit margins, could face closure if this policy is not reconsidered.

Former PHMA Chairman Shehzad Azam Khan also raised concerns about the growing challenges faced by exporters, such as persistent delays in refunds, rising production costs, and inflation. He emphasized that many exporters are already paying more in taxes than they are making in profits and urged the government to address these financial burdens urgently by facilitating quicker refunds and ensuring stable energy pricing.

Dr. Ayyazuddin, Chairman of PRGMEA, raised alarms over recent changes to the Export Facilitation Scheme (EFS), particularly the removal of the zero-rating on local purchases and the imposition of sales tax on imported cotton yarn. He argued that these changes directly contradict the objectives of the EFS, which was intended to ease liquidity pressures and simplify export processes.

Ijaz Khokhar, former PRGMEA Chairman, pointed out that Pakistan’s regional competitors, such as Bangladesh and Vietnam, offer tax-free access to raw materials, giving their exporters a significant edge. He called for a return to

the original framework of the EFS, which included zero-rated local inputs and sales tax exemptions on key imported materials.

Sohail Afzal Sheikh, another former PRGMEA Chairman, called for the immediate restoration of Regionally Competitive Energy Tariffs (RCET), which had been suspended. He argued that the lack of RCET has led to significantly higher manufacturing costs, forcing many SMEs to reduce or halt production. Additionally, he urged the government to revive the Duty Drawback on Local Taxes and Levies (DLTL) as part of the Textile & Apparel Policy for 2025-30 and to release pending claims for DLTL and Technology Upgradation Fund (TUF).

The participants at the meeting unanimously agreed that continued tax complexities, slow refunds, and increasing production costs will only erode Pakistan's textile export base and drive businesses into the informal sector. They reiterated that the textile industry remains a cornerstone of the national economy and requires urgent and decisive policy support to stay competitive.

Concluding the meeting, PHMA Chairman Abdul Hameed called on Prime Minister Shehbaz Sharif, Finance Minister Muhammad Aurangzeb, and Commerce Minister Jam Kamal to personally intervene and ensure that the textile industry’s proposals are adequately addressed. He warned that failure to act could result in long-term losses to exports, employment, and Pakistan’s position in the global textile market.

Pakistan’s textile sector has shown impressive growth during the fiscal year 2024-25, with notable increases in the export of various textile commodities. According to data from the Pakistan Bureau of Statistics, towel exports grew by 2.61% year-on-year, with over 226,335 metric tons valued at $1.082 billion exported. This was up from 222,720 metric tons worth $1.055 billion in the previous fiscal year.

The growth in towel exports is part of a broader trend within the textile industry. Ready-made garment exports

surged by 15.85% in the same period, with Pakistan exporting more than 80,147 thousand dozen of garments worth $4.128 billion. This compares to 75,754 thousand dozen valued at $3.563 billion during the previous year.

Exports of art, silk, and synthetic textiles also saw a healthy rise of 8.80%, reaching 83,918 metric tons valued at $399.515 million, compared to 82,876 metric tons worth $367.199 million in FY 2023-24.

Overall, Pakistan’s textile exports in FY 2024-25 grew by 7.39%, with total exports reaching $17.89 billion, up from $16.66 billion the previous year. This growth is attributed to several key commodities that performed well in global markets, particularly knitwear, bedwear, and towels.

Knitwear exports rose by 13.68%, reaching $5.01 billion compared to $4.41 billion in FY 2023-24, while bedwear exports increased by 11.07%, totalling $3.11 billion, up from $2.80 billion. Towels, too, contributed to the growth, with their export value rising by 2.61% to $1.08 billion from $1.06 billion in the previous year.

Other textile categories that saw growth included tents, canvas, and tarpaulin, which increased by 6.21%, reaching $124.87 million from $117.56 million last year.

The Asian Development Bank (ADB) and the All Pakistan Textile Mills Association (APTMA) held a productive brainstorming session in Lahore, discussing ways to enhance textile exports, address global challenges, and align the sector with international standards. The ADB delegation, led by Country Director Emma Fan, was accompanied by senior officials, including Asad Aleem (Deputy Country Director), Khayyam Abbasi (Programmes Officer), Shaheryar

Choudhry (Senior Investment Officer), and M. Ismail Khan (Unit Head of Media Communications & Public Policy).

The ADB delegation was warmly welcomed by APTMA leaders, including Kamran Arshad (Chairman), Asad Shafi (Chairman North), Haroon Ellahi Shaikh, Muhammad Ali, Ahsan Shahid, and Raza Baqir (Secretary General), along with other prominent members of the textile sector.

The meeting, which focused on the future trajectory of Pakistan’s textile exports, began with a call for immediate measures to align with international conventions, particularly those related to sustainability, labour rights, and human rights. ADB representatives stressed the importance of these issues in improving global competitiveness, especially as the world becomes increasingly focused on sustainable business practices.

Emma Fan highlighted ADB’s new Country Partnership Strategy for Pakistan, which identifies four key priority areas: stimulating the private sector, optimizing public sector efficiency, improving human capital, and fostering greater connectivity. These initiatives are designed to help Pakistan navigate its economic challenges while positioning the country for sustainable long-term growth.

The ADB-APTMA discussions also delved into Pakistan’s immense export potential, with a particular focus on the textile and apparel sectors. Both organizations emphasized the need for consistent, export-friendly policies and better diversification into higher valueadded products. ADB expressed a keen interest in further collaboration with APTMA, offering support to implement strategies aimed at boosting textile exports and helping the sector remain competitive on the global stage.

Kamran Arshad, Chairman of APTMA, presented an ambitious vision to elevate Pakistan’s textile export earnings to $50 billion over the next five years. This goal would be supported by the establishment of 1,000 garment manufacturing plants equipped with plug-and-play infrastructure in specialized Apparel Parks.

Arshad also urged ADB to assist in the development of these Apparel Parks, which he described as vital to driving export growth while creating employment opportunities for millions of workers. These parks are expected to play a significant role in poverty alleviation and help bolster Pakistan’s foreign exchange reserves.

Asad Shafi, Chairman North of APTMA, shared insights on how Pakistan's textile sector has made significant strides in compliance with international standards, especially following the EU’s GSP Plus status. He outlined how this preferential treatment has helped Pakistan expand its value-

added textile exports. Shafi also discussed the launch of a National Compliance Centre, designed to support businesses in meeting international compliance standards, as well as APTMA’s role in establishing a textile laboratory focused on DNA testing to authenticate cotton sources. The ultimate goal is to implement a unified, traceable system across the entire textile value chain, ensuring adherence to EU regulations.

The Pakistan Central Cotton Committee (PCCC), the Ministry of National Food Security and Research (MNFSR), and the All Pakistan Textile Mills Association (APTMA) have entered into a landmark agreement to resolve the long-standing cotton cess collection issue. The partnership is seen as a crucial step toward addressing the ongoing challenges faced by Pakistan's cotton industry and ensuring its future growth.

The agreement was formalized in a signing ceremony held at the MNFSR headquarters in Islamabad, with prominent figures in attendance, including Federal Minister for National Food Security and Research, Rana Tanveer Hussain, Secretary MNFSR Waseem Ajmal Chaudhary, APTMA Chairman Kamran Arshad, Chairman APTMA North Asad Shafi, Secretary General APTMA Shahid Sattar, APTMA Cotton Advisor Dr. Javed Hassan, Cotton Commissioner & CEO PCCC Dr. Khadim Hussain, and PCCC Secretary Dr. Peer Adrees.

government’s full backing, including plans for a visit to APTMA House in Lahore to explore further collaboration opportunities.

Kamran Arshad, Chairman of APTMA, thanked the Minister for his proactive approach in facilitating key policy measures, such as easing cotton seed imports. He also highlighted the severe cotton shortages in recent years, which have forced Pakistan to import large quantities of cotton from countries like the US, Brazil, and Australia, placing a significant strain on the textile value chain. Arshad called this agreement a historic achievement, marking the resolution of the long-standing cotton cess deadlock and reaffirming APTMA’s commitment to addressing the cotton sector’s challenges.

domestic inputs, as well as fostering the development of local brands and globally competitive products.

Kamran Arshad called for the swift implementation of PCCC restructuring, urging the transformation of the committee into a modern, efficient research institution. He emphasized that this would drive innovation and increase productivity in cotton cultivation, ensuring that Pakistan’s cotton industry becomes globally competitive once again. Additionally, he proposed the idea of holding an all-stakeholders conference, which would bring together farmers, ginners, and industry leaders to collaboratively chart a sustainable future for the cotton sector.

Federal Minister Rana Tanveer Hussain praised APTMA for its constructive involvement in resolving this critical issue, acknowledging that cotton is vital to Pakistan’s textile industry. He reiterated APTMA’s role as a key stakeholder and expressed strong support for its vision, particularly in leading the reform and revival of the PCCC. The Minister also assured the association of the

Dr. Peer Adrees, Secretary of PCCC, acknowledged the positive impact of APTMA’s ongoing support, which has helped the PCCC cover salaries and pensions for its staff, ensuring smooth operations in recent months.

Asad Shafi, Chairman of APTMA North, emphasized the critical role cotton plays in Pakistan’s textile industry. He reiterated APTMA's commitment to enhancing value addition by promoting the use of locally grown cotton and

APTMA remains steadfast in its commitment to supporting the revival of Pakistan’s cotton industry. The restoration of the cotton sector is not only critical for safeguarding millions of jobs across the textile value chain but also for strengthening the country’s textile exports. By expanding domestic value addition and increasing cotton production, Pakistan can regain its position as a leading global cotton producer—fostering economic growth, enhancing competitiveness in international markets, and ensuring the long-term success of its textile industry.

Despite economic turbulence worldwide, Bangladesh's Ready-Made Garment (RMG) sector posted a solid performance in the fiscal year 2024–25 (FY25), registering an export growth of 8.84 percent and generating $39.35 billion in revenue, according to newly published data by the Export Promotion Bureau (EPB).

The European Union retained its position as the dominant destination for Bangladeshi garments, absorbing 50.10 percent of total RMG shipments— equivalent to $19.71 billion—during the period. The United States followed with imports totalling $7.54 billion (19.18 percent), while exports to the United Kingdom reached $4.35 billion (11.05 percent). Canada also remained a notable partner, importing $1.30 billion worth of garments, accounting for 3.31 percent of the total.

Year-on-year export increases were reported across major Western markets: shipments to the EU climbed 9.10 percent, the U.S. saw a rise of 13.79 percent, and Canada recorded a 12.07 percent jump. Meanwhile, growth in exports to the UK was more modest at 3.68 percent.

Within the European bloc, Germany stood out as Bangladesh’s top RMG buyer, importing $4.95 billion worth of goods. Other significant EU markets included Spain ($3.40 billion), France ($2.16 billion), the Netherlands ($2.09 billion), Poland ($1.70 billion), Italy ($1.54 billion), and Denmark ($1.04 billion). Some countries showed remarkable growth, including the Netherlands with a 21.21 percent increase, Sweden with 16.41 percent, Poland with 9.77 percent, and Germany with 9.47 percent.

Exports to non-traditional destinations also showed upward momentum, expanding by 5.61 percent and totalling $6.44 billion. These newer markets now account for 16.36 percent of Bangladesh’s RMG exports, underscoring a shift in the global trade landscape. Among these, Japan, India, and Australia

emerged as top contributors.

Significant growth rates were observed in several non-traditional markets: Turkey saw a 25.62 percent increase, India rose by 17.39 percent, and Japan experienced a 9.13 percent uptick in imports of Bangladeshi apparel. However, exports to countries like Russia, South Korea, the UAE, and Malaysia declined during the same period.

Within the industry itself, the knitwear segment led the charge with an impressive 9.73 percent growth, while woven garments followed closely with a 7.82 percent rise, reflecting strong demand across both categories.

Industry insiders noted that the global apparel sector continues to evolve unpredictably in the wake of the COVID19 pandemic, posing persistent challenges for exporters. Yet, Bangladesh has managed to maintain a resilient foothold in traditional markets, which continue to represent a commanding 84 percent share of its total garment exports.

The picture is different in nontraditional markets, where Bangladesh currently holds a 16 percent share. However, this segment represents a significant opportunity for growth. The International Trade Centre (ITC) estimates that the global apparel market reached $500 billion in 2024, with non-traditional destinations accounting for around $150 billion of that total.

Currently, Bangladesh holds a 6 percent share of this non-traditional market, highlighting untapped potential. For instance, Bangladeshi garments made

up 5.50 percent of Japan’s total apparel imports and 11.53 percent of Australia’s in 2024, signalling strong prospects for future expansion in those regions.

Egypt has attracted close to $70 million in new investments from Chinese enterprises focused on garment and textile manufacturing—industries that lie at the heart of Cairo’s economic reform program backed by the International Monetary Fund (IMF).

During high-level meetings with Chinese investors in Shanghai, Egypt’s Minister of Investment and Foreign Trade, Hassan El-Khatib, confirmed that two Chinese companies have finalized plans to establish production facilities within Egypt’s free trade zones.

One of the investors, Zhejiang Holding, expressed its intent to commit an initial $20 million to Egypt’s textile and apparel sector, with a long-term goal of scaling that investment up to $50 million over the next five years, as reported by local media outlets.

Another firm, Jiangsu Haite Fashion Company, disclosed its plans to invest approximately $20 million in the development of a new garment manufacturing plant in Egypt. According

to Arabic-language newspaper Al-Ahram, the facility will be strategically positioned to serve export markets in Europe and the United States, leveraging Egypt’s existing free trade agreements with multiple global partners.

This surge in interest follows a government-hosted visit in May, during which a large Chinese delegation representing textile firms toured potential investment sites in Egypt. The initiative was part of a broader effort by Cairo to draw foreign capital into its textile and fabric industries—a key component of the country's industrial and export strategy.

Egyptian officials regard the textile sector as both a cornerstone of the national economy and a vital source of foreign exchange. During discussions with representatives from over 30 Chinese industrial firms, authorities emphasized the rollout of a national initiative aimed at strengthening local production, increasing global competitiveness, and reducing import dependency.

In a related statement, Hani Salam, chairman of the Apparel Export Council of Egypt, noted that textile and garment exports reached $1.2 billion in 2023 and are projected to climb to $1.4 billion by 2025, reflecting sustained momentum in the sector.

Chinese companies are already heavily involved in Egypt’s industrial landscape, particularly in the Suez Canal Economic Zone (SCZONE). The zone’s chairman, Walid Gamal El-Din, revealed earlier this year that a promotional tour

across China resulted in securing over $1 billion in new investment deals, reinforcing Egypt’s growing status as a regional hub for manufacturing and trade.

North India’s cotton yarn sector is currently treading carefully, caught between stable pricing and a downturn in both local and international demand. Market hubs such as Ludhiana, Delhi, and Panipat are seeing minimal trading

momentum, as uncertainty over global tariffs and raw material costs continues to cast a shadow over business decisions.

In Ludhiana, pricing has remained consistent, yet mills are struggling to push higher volumes. Stakeholders report that buyers—both at home and abroad—are hesitant, leading manufacturers to hold prices steady without room for increases. Current rates show 30-count combed yarn trading at $3.11–3.23/kg, while 20and 25-count combed yarns are priced at $2.99–3.17/kg. Carded yarn of 30-count is available in the range of $2.87–2.93/kg.

Delhi’s textile trade is following a similar trajectory. While prices haven’t slipped, market participants note a distinct drop-in activity. Rising cotton yarn costs and lack of clarity on U.S. tariff policies are pushing garment producers toward alternatives like polyester and viscose, which mimic cotton in feel but are more economically viable. In the capital, 30-count combed yarn for knitting is priced at $3.13–3.14/kg, with 40-count yarn fetching $3.43–3.45/kg (excluding GST).

Panipat, a centre for recycled yarn production, is also witnessing muted demand, particularly for coarse-count yarns. Some exporters are pinning hopes on a festival-season lift, but challenges such as slow payment cycles and labour shortages are limiting market revival. Recycled polyester yarn (10s grey) is being quoted at $0.90–0.94/kg, while cotton comber is trading at $1.27–1.30/kg.

Raw cotton prices have slightly declined, dropping about $0.12 per maund, as global benchmarks—including ICE futures—trend downward. North Indian arrivals remain sparse, with around 750 new bales reported. In Punjab, cotton is trading between $68.67 and $68.80 per maund, while Haryana’s prices range from $66.63 to $67.23 per maund.

Overall, the region’s cotton yarn industry is caught in a cautious pause— stabilized by pricing but restrained by weak consumption and external policy headwinds. Until trade conditions become clearer and seasonal demand kicks in, the market is expected to remain in a wait-and-watch mode.

Japan’s Clothing Imports Hit $12.1 Billion, Marking 6.8%

Growth in H1 2025

Japan’s appetite for foreign apparel continued its upward trajectory in the first half of 2025, with clothing imports rising by 6.8% year-over-year to reach an estimated $12.1 billion. The surge reflects growing consumer demand, a rebound in retail activity, and an expanding preference for diverse and high-quality fashion.

According to the latest figures from the Ministry of Finance, import values for June 2025 alone stood at $1.9 billion—a robust 8.2% increase compared to the same month last year. The rise has been largely credited to the post-pandemic normalization of shopping habits, as well as the lifting of restrictions that had earlier dampened consumer spending.

China remained the dominant supplier during the period, delivering over 60% of Japan’s total apparel imports. Other key contributors included Vietnam and Bangladesh, both of which also played vital roles in supporting Japan’s demand for clothing during the first six months of the year.

The growing inflow of garments aligns with shifting consumer tastes in Japan, where shoppers are increasingly drawn to international styles and premium apparel. Industry analysts note that Japanese consumers are not only

seeking variety but are also becoming more receptive to global fashion influences, particularly with international travel now back on the rise.

The outlook for the remainder of 2025 remains optimistic. Market observers expect the upward trend in apparel imports to continue, buoyed by the revival of brick-and-mortar retail, the strength of e-commerce platforms, and consumers’ sustained interest in trenddriven, globally sourced products.

Nigeria’s reliance on imported textiles has escalated sharply over the past five years, with total textile imports skyrocketing by 297.8 percent—from N182.53 billion in 2020 to N726.18 billion in 2024, according to data from the Nigeria’s National Bureau of Statistics.

The statistics reflect a consistent annual increase: N278.8 billion in 2021, N365.5 billion in 2022, and N377.1 billion in 2023, before reaching its current peak. This trend highlights a growing gap between domestic production capacity and consumer demand in the country’s apparel and textile sector.

Industry analyst and investment strategist, Gagan Gupta, believes this trajectory can be reversed. As the founder and CEO of Arise Integrated Industrial Platform (ARISE IIP)—a pan-African developer of industrial zones—Gupta

recently addressed the issue during a forum themed “The Journey to Making Africa a Global Manufacturing Hub.”

He emphasized that Nigeria has the foundational resources to become a global contender in textile production. "Nigeria produces cotton locally and has the potential to develop an internationally competitive textile value chain," Gupta said, noting the nation’s opportunity to tap into the $10.3 billion global apparel export market.

Despite this potential, Gupta warned that Nigeria risks squandering one of its most strategic industrial opportunities without immediate reforms and targeted infrastructure investments. He pointed out systemic issues like poor access to capital, limited financing options for local manufacturers, and the burdensome cost of foreign exchange—factors that continue to hamper procurement of both raw materials and machinery.

“Even with abundant natural resources, a sizable workforce, and a growing domestic market, Nigeria’s advantages are undermined by inadequate industrial policy, logistical challenges, and underdeveloped support systems,” Gupta remarked.

He advocated for comprehensive reforms, including modernization of textile facilities, reliable energy supply, improved transport infrastructure, and better financing channels for industrial players.

Gupta concluded that revitalizing Nigeria’s textile industry will require strategic alignment between government policies and private sector initiatives. He underscored the need to shift from

exporting raw materials to producing value-added goods locally, calling for a unified effort to embed the textile industry within both regional and global supply chains.

The United States witnessed a 6.59% increase in textile and apparel import volumes during the first five months of 2025, signalling a rebound in the sector following recent economic disruptions. This upward movement, fuelled by renewed consumer spending and inventory restocking, reflects growing momentum in both retail and ecommerce channels.

According to newly released trade figures, the total value of these imports from January through May reached approximately $31.67 billion. The steady growth illustrates the resilience of the U.S. fashion supply chain and the industry's agility in adapting to evolving shopper behaviour and logistical challenges.

Apparel imports were a key driver behind the increase, with a notable rise in garment shipments as retailers moved to replenish depleted stock levels. The appetite for diverse clothing styles, seasonal collections, and fast-moving fashion trends—amplified by the strength of online retail—has continued to push import volumes upward.

China maintained its position as the largest exporter of textile and apparel goods to the U.S., contributing a substantial portion of the overall import share. Other major exporters, including Vietnam, Bangladesh, and India, also recorded higher shipment volumes to the American market during the same period, indicating a competitive landscape among key sourcing nations.

As the U.S. economy continues to stabilize, analysts forecast sustained growth in import activity, driven by increasing consumer confidence and ongoing diversification of product offerings. This competitive environment may also translate into broader choices and improved pricing for end consumers.

The January–May data not only reflects the sector’s capacity to rebound but also points to future expansion opportunities. Industry stakeholders are already looking toward integrating innovation, sustainability, and trendaligned collections to meet the demands of a post-pandemic marketplace.

Vietnam’s textile and garment industry posted a strong rebound in the first six months of 2025, achieving an estimated 11% increase in export value year-on-year, thanks to large-volume orders, timely production, and a strategic focus on delivery execution. The sector's profitability surged by 30–40%, signalling improved efficiency and pricing power across the board, according to the Vietnam National Textile and Garment Group (VINATEX).

Speaking at a media briefing, VINATEX Chairman Le Tien Truong said that over the January–June period, VINATEX recorded consolidated revenue of 9.035 trillion VND (approximately $345 million USD), representing 49% of its full-year target and a 108% increase over the same period in 2024. Pre-tax profit reached nearly 556 billion VND (~$21.5 million USD)—61% of the annual goal and a 197% jump compared to the first half of 2024.

Truong noted that profitability outpaced revenue growth, a positive sign that firms secured better pricing due to

earlier-than-usual order placements. He attributed this to improved global demand and leaner inventories early in the year, which prompted buyers to make more consistent and sizeable orders—unlike the fragmented buying patterns seen in 2024 that had raised production costs.

The spike in order activity also followed the U.S. government's April 9 decision to delay reciprocal tariffs by 90 days, prompting a wave of urgent orders and flexible delivery terms. According to Truong, this allowed Vietnamese producers to negotiate delivery windows and share logistical costs more effectively.

In total, Vietnam's textile and garment exports in H1 2025 reached nearly $22 billion, representing a 10% increase from the same time last year, as reported by state media outlet Nhan Dan. Industry officials anticipate that, if current trends continue, full-year exports could hit between $46–47 billion USD, cementing the industry’s position as one of Vietnam’s top export earners.

Despite the upbeat figures, Truong cautioned that the second half of 2025 remains uncertain. Some manufacturers already have orders secured through August or September, but key year-end negotiations are still underway. "In this business, there's no such thing as zero risk," he stated, adding that manufacturers must accept exposure in order to preserve client relationships and global competitiveness.

For the full year, VINATEX is aiming for 18.3 trillion VND (approx. $700 million USD) in consolidated revenue— roughly on par with 2024—and a pre-tax profit of 910 billion VND (~$35 million USD), representing a 9% annual increase.

A meaningful chapter in the long-standing relationship between Tonello and Pacific Jeans is being written with the delivery of Tonello’s 10,000th machine: a moment marked not by numbers alone, but by the journey behind them.

The partnership began in the early 1990s, when Pacific Jeans’ visionary founder, Mr. M. Nasir Uddin, recognized the potential of innovation to transform garment production in Bangladesh. At a time when the denim industry in Asia was still emerging, Pacific Jeans became the first company in the region to adopt Tonello technologies, starting with a G1 360 machine. That early collaboration, between Mr. M. Nasir Uddin and Mr. Flavio Tonello, opened a new path, setting a standard for excellence and forward-thinking that would inspire an entire market.

Today, the relationship continues through the next generation. Mr. Syed M. Tanvir and Mr. Syed M. Tahmir, sons of Mr. Nasir, have carried the family’s vision forward, working alongside Ms. Alice Tonello and the Tonello team to strengthen and expand a partnership built on shared values: a spirit of exploration, innovation, and responsibility. Over the

decades, the collaboration has grown not only at a professional level but also through a bond of mutual trust and respect between two families.

“This 10,000th machine symbolizes more than a production milestone,” said Ms. Alice Tonello, R&D and Marketing Director. “It reflects decades of collaboration, during which we've grown and learned together, always driven by a common curiosity to anticipate trends and embrace new challenges.”

The new machine, heading to Pacific Jeans’ facilities, integrates Tonello’s latest responsible and digital innovations. Yet, while technologies have evolved, the heart of the relationship remains unchanged: a shared commitment to shaping the future of responsible garment production.

On this occasion, Mr. Syed M. Tanvir, Managing Director of Pacific Jeans, shared his reflections:

"My father, Mr. M. Nasir Uddin, was a visionary entrepreneur who pioneered premium jeans manufacturing in Bangladesh. In the early 90s, he recognized the value of Tonello’s G1 360 and introduced advanced laundry technology when few could imagine it.

Our partnership with Tonello grew over time, rooted in shared values of innovation, excellence, and quality. Both companies are driven by the pursuit of smarter, more sustainable laundry solutions for the apparel industry.

Tonello’s commitment to advancing washing technology is inspiring. Together, they combine our strengths to offer cutting-edge solutions that reduce environmental impact and promote responsibility toward people and the planet.

When market demands shift, Tonello responds quickly with innovative solutions, aligning with their strategy to adopt eco-friendly, efficient technologies that shape the future of the industry.

Receiving Tonello’s 10,000th machine is a proud milestone—symbolizing our growth, shared vision, and the incredible journey we've had together."

This milestone is not just a celebration of history, but a quiet tribute to the visionaries who saw beyond their time, and to the generations who continue to build on that foundation with care, resilience, and imagination.

With the establishment of Brückner Textile India Pvt. Ltd., the Brückner Group, based in Leonberg, Germany, marks another important milestone in its long and successful company history. The new subsidiary in Coimbatore, India, brings Brückner significantly closer to its Indian customers – both geographically and strategically. “Having a presence on the ground enables us to respond more quickly, precisely, and flexibly to the needs of the Indian market,” says the manage-

ment. “Brückner stands for German technology and precision – in India, we combine this with local speed and agility.”

The new subsidiary offers the full range of Brückner’s products and services: new machines, modifications, spare parts, technical consulting, machine upgrades, and after-sales service. All machines are still manufactured in Tittmoning, Bavaria, Germany, while sales, installation and service are handled by the newly formed local team in India.

The leadership of Brückner Textile India Pvt. Ltd. reflects deep industry experience and regional expertise: Mr. Thomas Wiget, who brings over 31 years of professional experience in India, has been appointed as Director of the subsidiary. Mr. A. Venkatesh Babu is responsible for sales across India, with a particular focus on the Eastern and Southern regions, while Mr. Vinod Kumar V. manages sales in the Northern and Western parts of the country. Together, this experienced team ensures close customer proximity, professional consultation and reliable support throughout India. With the foundation of Brückner Textile India Pvt. Ltd., the familyrun company underlines its longterm commitment to the Indian market and continues to strengthen its global sales and service network.

YKK Corporation Headquarters: Chiyoda-ku, Tokyo; President: Koichi Matsushima; hereinafter “YKK”) has been selected for top honors by the international environmental non-profit organization CDP1 as a Supplier Engagement Leader in their FY2024 Supplier Engagement Assessment2 for the third consecutive year.

This recognition shows that YKK has been evaluated as a global leader for its initiatives, ranging from governance and targets to reduce GHG emissions throughout the entire supply chain to efforts to reduce GHG emissions in collaboration with suppliers.

In February 2025, YKK was recognized with the top “A” rating in the 2024 Climate Change Survey, which was also conducted by CDP, for the second consecutive year.

YKK will continue to work on climate change action and transparent information disclosure based on the netzero target outlined by the Science Based Targets (SBT) initiative.

Comment from Takayuki Aoki, Vice President of Procurement & Logistics, YKK Corporation

Since the YKK Sustainability Vision 2050 was formulated in October 2020, the organisation has undertaken various initiatives to meet their sustainability targets. We are guided by the YKK Philosophy of the CYCLE OF GOODNESS®, which states that “No one prospers without rendering benefit to others.” In addition to their own activities to reduce GHG emissions, YKK also collaborates with suppliers to promote initiatives to contribute to reducing GHG emissions globally through engagement initiatives. To give specific examples, they work with strategic partner suppliers who agree with YKK’s vision to develop lowcarbon materials and use them in their fastening products. YKK will also contribute to bringing about a sustainable society by reducing emissions throughout

their supply chain through the establishment of a closed-loop recycling model, among other measures.

YKK Corporation’s sustainability goal is to achieve climate neutrality by 2050. YKK is working on five themes: Climate Change, Material Resources, Water Resources, Chemical Management, Respect People, along with ten SDG goals related to each of these, and each year reports on its state of progress in the YKK Integrated Report, “This is YKK.”

YKK is constantly pursuing the creation and realization of a sustainable society through our business. At the core of all their corporate activities is the philosophy of YKK founder Tadao Yoshida, the CYCLE OF GOODNESS® The idea that “no one prospers without rendering benefit to others” clearly expresses the YKK Group’s corporate spirit of continuing to prosper together with society, customers, related industries, and employees, and is highly compatible with sustainability.

Tadao Yoshida repeatedly shared the essence of this corporate spirit with employees in a variety of ways. His words “business is like building a bridge,” which are connected to the CYCLE OF GOODNESS®, can be understood in terms of the SDGs, as he believed that unless we benefit society as a whole, we will not be able to prosper ourselves. The words “manufacturing like clear spring

water” and “trash can be a great resource if it is utilized with ingenuity” are linked to environmental consideration, and the words “the strength of a forest is better than a big tree” are linked to respect for human rights and individuality. Today’s circumstances and context differ significantly from the time when our founding president spoke these words, but a philosophy that is highly compatible with sustainability has nevertheless been at the core of YKK’s management since those early days. It continues to be inherited at the company even today, more than 80 years later.

1CDP: An international non-profit organization with a global system to disclose environmental information by companies and local governments. Since its inception in 2000, the CDP has led efforts to encourage companies to disclose their environmental impact, reduce GHG emissions, and protect water resources and forests by leveraging capital markets and corporate purchasing power. The organization sends surveys to companies about their environmental activities, then analyzes and evaluates their responses. The number of companies disclosing their data through CDP is on the rise, with over 24,800 companies worldwide that disclosed their environmental data in 2024.

2Supplier Engagement Assessment: Companies that respond to the CDP Climate Change Questionnaire and receive the highest rating in their efforts to reduce CO2 emissions in collaboration with their suppliers, in addition to their climate change score, are selected as “Supplier Engagement Leaders.”

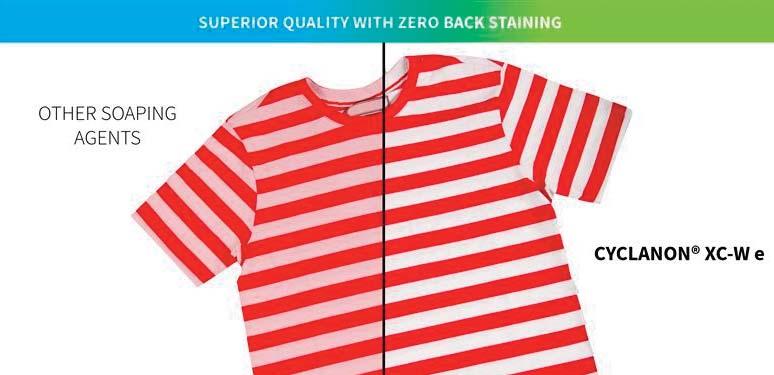

Archroma, a global leader in specialty chemicals, launched CYCLANON® XCW e, an innovative washing-off auxiliary that improves productivity and reduces resource consumption in cellulosic dyeing while delivering outstanding color fastness, even in difficult high-electrolyte or hard water conditions.

“With CYCLANON® XC-W e, we are building on our proven trio-polymer platform to give mills a way to meet rising brand expectations for durable, high-quality casual wear with a lower environmental footprint – all at a cost profile comparable to conventional washing-off agents,” said Dhirendra Gautam, VP Global Marketing and Strategy, Archroma.

Conventional polyacrylate or copolymer washing-off agents often struggle to fully remove unfixed dye from fabric, especially when a high concentration of salt remains on it from the dye bath or under hard water conditions. This can lead to excessive rinsing and multiple washing baths. Ineffective washing-off may result in quality rejections due to backstaining or uneven shade development.

Archroma’s trio-polymer CYCLANON® XC-W e was designed to overcome these challenges, delivering

high performance, improved productivity and water and energy savings, with minimal added cost compared to conventional polymer-based products.

Exceptional wet-fastness with measurable water, energy and time savings

CYCLANON® XC-W e delivers outstanding wet-fastness by minimizing the substantivity (or ‘attraction’) of unfixed dye for the fiber. This allows more effective dye removal, reducing backstaining and improving color fastness, even with the deepest shades.

With easier unfixed dye removal, mills can reduce pre-rinsing and the number of washing baths to achieve shorter washing-off cycles and save time, water, energy and chemical inputs compared to conventional polyacrylate or copolymer washing-off agents:

Up to 15% shorter process time

Up to 20% less water used in the washing-off stage

Up to 20% lower CO2 emissions through reduced energy consumption

Up to 20% reduction in chemical use

Significant productivity gains for competitive advantage

These efficiency gains also translate into higher productivity. By shortening washing-off cycles and reducing rework,

CYCLANON® XC-W e helps mills process more fabric with existing equipment.

Up to 15% increase in throughput with the same machine set up

For example, a knit production plant producing 10 metric tons (MT) of dyed fabric per day could increase daily output by 1 MT, without expanding capacity, by using CYCLANON® XC-W e to eliminate two washing baths and reduce quality rejections.

CYCLANON® XC-W e is part of Archroma’s SUPER SYSTEMS+ portfolio and can be combined with the Blue Magic all-in-one pretreatment and NOVACRON® EC/S reactive dyes to create an end-to-end solution for highquality dyeing of 100% cotton fabrics.

The system is categorized as an IMPACT+ solution within Archroma’s SUPER SYSTEMS+ Impact Matrix. This means it delivers the highest level of resource savings, high wash durability and beyond-compliance chemicals – as compared to standard FOUNDATION processes with ZDHC Gateway MRSL Level 3 compliance.

CYCLANON® XC-W e complies with the latest regulatory and brand requirements, including stringent MRSL and RSL standards. Registration for bluesign®, ZDHC Level 3, and GOTS 7.0 are underway.

DyStar, a leading specialty chemical company with a heritage of more than a century in product development and innovation has announced that its major shareholder, Zhejiang Longsheng Group Co., Ltd has entered into a Share Purchase Agreement to acquire 37.57% of issued shares in DyStar Global Holdings (Singapore) Pte. Ltd., previously held by Kiri Industries Limited.

The acquisition follows a ruling by the Singapore International Commercial Court (SICC) mandating the sale of 100% of DyStar’s equity. As controlling shareholder with 62.43% of DyStar, Zhejiang Longsheng Group’s strategic acquisition of the outstanding shares will

result in DyStar becoming a wholly owned subsidiary. This transaction resolves the long-standing litigation with Kiri Industries, thereby avoiding a full sale of DyStar.

The total consideration is valued at USD 696.5478 million, subject to adjustments on or after the closing date. Completion is contingent upon regulatory approvals and other customary conditions with an anticipated closing date no later than November 3, 2025.

Mr. Xu Yalin, Managing Director, and President of DyStar Group said, “We are delighted with the conclusive resolution of the dispute, which enables DyStar Group to move forward with certainty, confidence, and renewed strategic focus.

This marks a significant milestone in our 30-year journey as it reinforces our longterm stability and commitment to our global stakeholders.”

This development positions DyStar to further its leadership in specialty chemicals and its value chain. The Group remains firmly committed to driving innovation, advancing sustainable practices, and pursuing strategic growth initiatives to enhance its global competitiveness.

DyStar will continue to prioritize its role as a trusted partner and responsible industry leader, delivering continued sustainable progress across the global specialty chemical sector.

In response to mounting global regulations and the push for a circular economy, CEMATEX (the European Committee of Textile Machinery Manufacturers) is launching ITMA Sustainability Forum: Accelerating the Green Transition on 30 October at Singapore Expo.

The half-day forum is designed to help textile and garment manufacturers, particularly from South and Southeast Asia and the Middle East, navigate the European Union’s evolving sustainability regulations, and access to green financing opportunities to support their transition.

Held alongside ITMA ASIA + CITME, Singapore 2025, the forum brings together EU policymakers, financial institutions, and industry leaders to facilitate cross-border dialogue and knowledge exchange.

Mr. Alex Zucchi, President, CEMATEX, said “Sustainability has become a global priority. The textile industry must act swiftly to modernise production in line with regulatory demands and growing consumer expectations. This forum provides a much needed platform for manufacturers to better understand the EU’s legislative landscape and the financing tools available for sustainable growth.”

A key highlight of the forum will be the keynote presentation by Ms Kristin Schreiber, Director, European Commission DG GROW. She will provide a comprehensive overview of the EU’s sustainability roadmap and upcoming regulations driving the shift towards circular textile production.

Ms Schreiber said: “South and Southeast Asia are vital players in the global textile value chain. Many producers in these regions export to the European market, and their ability to align with upcoming requirements will be critical to a successful and inclusive transition. I look forward to exchanging perspectives at this forum on how we can collaborate globally to build a more sustainable and resilient textile industry.”

Under the EU Strategy for Sustainable and Circular Textiles, by 2030, all textiles placed on the EU market must be durable, recyclable, largely made from recycled fibres and free from hazardous substances. Manufacturers worldwide must act now to meet these requirements and remain competitive.

Programme highlights

Shaping Sustainability: Responding to EU Policy Changes

Moderator: Ms Nicole van der Elst Desai, Founder, VDE Consultancy

Speaker: Mr Robert van de Kerkhof, CEO, ReHubs

Profit Meets Purpose: Financing Sustainability

Moderator: Mr Brandon Courban, Senior Advisor (Climate), Openspace Ventures

Speakers:

Dr Rene Van Berkel, Senior Circular Economy Expert, Switch Asia, EU Policy Support

Component

Ms Iris Ng, Head, Emerging Business & Global Commercial Banking, OCBC Bank

Mr Michael Rattinger, Senior Climate Change Specialist, Asian Development Bank

Singapore Fashion Council, the official association for the textile and fashion industry in Singapore, is the programme partner of the forum organised by ITMA Services.

In today’s rapidly evolving textile and business landscape, staying ahead of competitors often requires access to the latest trends, innovative technologies, and strategic insights. In that regard, from 2 – 4 September 2025, Intertextile Shanghai Apparel Fabrics – Autumn Edition will once again serve as one of the industry’s premier trade platforms. This year, the fair will feature upgraded zones and expanded display areas designed to create a more seamless, more immersive sourcing and networking experience. Fairgoers can look forward to a dynamic fringe programme, including expert-led forums, seminars, and other insightful events, which should prove essential listening for industry players shaping the future of fashion.

A key highlight of the fair is the Functional Lab, which responds to the growing demand for athletic-inspired apparel. Located in Hall 4.1, this area showcases a comprehensive selection of innovative activewear fabrics, including smart textiles, outdoor materials, and sports textiles. Within the zone, leading exhibitors such as Burlington, Kbtex Warp Knitting Technology, and Unifi Textiles (Suzhou) will present their latest offerings. To further highlight the potential of functional fabrics, Functional Lab’s display area The CUBE will feature an array of advanced fabrics and accessories that merge innovation with

functionality, suitable for sportswear, athleisure, and protective apparel. Meanwhile, esteemed European exhibitors to showcase in Premium Wool Zone include Abraham Moon & Sons, Scop Clarenson, Thomas Mason, and Yunsa. They will showcase their latest collections, catering to the needs of modern designers and discerning consumers. Located within the zone, the former Functional Suiting Display Area will return as Bespoke Performance, further emphasising the synergy of style, functionality, and luxury. This area is set to highlight high-end textiles for suiting, shirting, and bespoke fabrics that blend performance with sophistication, offering an extensive collection of fabric samples

and garments consisting of wool, worsted, woollen, cashmere, tweed, and silk.

In addition, the Innovation & Digital Solutions Zone (previously known as Digital Solutions Zone) will spotlight advanced digital solutions, textile technologies, and materials. This specialised area will be enhanced with a series of Technology & Solutions fringe events, offering insights into how digital innovations are transforming design, manufacturing, and customer experience. Notably, The Hong Kong Research Institute of Textiles and Apparel (HKRITA) will present their Green Machine, a groundbreaking recycling system for mixed materials, demonstrating eco-

conscious advancements in textile sustainability. Additionally, Shima Seiki will showcase their latest digital fabric simulation software, while AiDLab will feature their AI-based fashion design and textile inspection technology.

To enhance the fair experience, Intertextile Apparel’s fringe programme provides industry peers with unique insights and a competitive edge within the fast-evolving fashion landscape. This edition’s curated lineup of expert-led seminars, discussions, and exclusive events aims to address the latest trends, sustainability initiatives, technological innovations, and market intelligence.

Key events include:

Intertextile Directions Trends

Autumn / Winter 2026-27: this seminar will discuss the Intertextile Directions Trend Forum’s theme

PUSH SENSATION, where

NeIlyRodi™ Agency will bring to life the wildest dreams of humankind: gentle > raw, classic > theatrical, childish > bizarre, and pragmatic > dreamlike, through a creative and inspiring display of on-trend fabrics and accessories. In addition to presenting the seminar, Mr Michael Bonzom, Creative Director of NeIlyRodi™ Agency, will provide deeper insights through the Trend Forum Tours.

FW26/27 Women's Fashion Trend Forecast: Ms Benedicte Peaudecerf, Style Designer and Trend Forecaster at PeclersParis, will present the latest trend publications, and provide inspiration and guidance through a comprehensive forecast for women's fashion for A/W 2026-27.

Texpertise Econogy

Building on the success of the previous edition, the Econogy Tour will once again spotlight sustainability in Hall 5.1. Guided visits to eco-focused exhibitors, led by an independent consultant, will facilitate in-depth discussions about the latest innovations in green textiles. Additional insightful Econogy Talks include:

Impact Now, Building Greener and Low-Carbon Sustainable Development Supply Chains: through optimising recycling materials, sustainable chemical management, low-carbon emission reduction designs, and improving ESG perform-

ance, SGS-CSTC Standards Technical Services will demonstrate how to create a greener, low-carbon economy and a more sustainable textile industry supply chain.

Ecodesign for Sustainable Products Regulations (ESPR): with the increasing prominence of global environmental issues, the EU is committed to promoting a green transition and a circular economy strategy. Bureau Veritas will present their services that help companies navigate and comply with the ESPR, including eco-design solutions, life cycle assessments, and environmental product declarations (EPD).

Technology & Solutions

Enhancing Fashion & Textiles through Human-AI Interaction: Professor Calvin Wong, CEO & Centre Director of AiDLab, will introduce their innovative AI-based technologies: AiDA for fashion design and WiseEye for textile inspection technology. Respectively, these solutions enhance innovation in fashion design and improve quality control for textiles.

New Era of Digital Fabric: End-toEnd DPC Solution: its design software is a key component of Shima Seiki’s end-to-end digital product creation solution. Its true-to-life fabric simulation, seamlessly integrated with physical production, is becoming the new standard for digital product creation.

Market Information & Business Strategies Opportunities in ASEAN in a Changing Trade Environment: the ASEAN Federation of Textile Industries (AFTEX) will host a forum

featuring industry representatives from across the region to share market insights and analyse emerging trends in textiles. Attendees can engage in dialogue, strengthen partnerships, and deepen their understanding of ASEAN's evolving textile landscape.

Overview of the UK Textile Industry and Opportunities for the Future: the UK Fashion and Textile Association (UKFT), one of the country's preeminent industry associations, will provide a perceptive analysis and various business insights relating to the UK‘s textile sector.

To streamline the sourcing process, buyers can more easily discover and engage with exhibitors during the fair using a range of digital tools, such as Connect PLUS. This platform enables users to refine their searches, receive AIdriven recommendations, and organise online or face-to-face meetings, via its integrated messaging feature. Additionally, it connects scheduling alerts directly to WeChat, Facebook, or SMS, enhancing the networking experience. Pre-registered visitors will automatically gain access to a Connect PLUS account. The fair is co-organised by Messe Frankfurt (HK) Ltd; the Sub-Council of Textile Industry, CCPIT; and the China Textile Information Centre. It will take place alongside Yarn Expo Autumn, CHIC and PH Value at the National Exhibition and Convention Center (Shanghai), with the venue playing host to the entire apparel textile value chain. For more details on this fair, please visit: www.intertextileapparel.com.

Cotton Council International (CCI) led a delegation of top U.S. cotton leaders to Karachi and Lahore for COTTON USA™ Leadership Forums, engaging prominent Pakistani textile leaders on key global cotton supply chain issues and the evolving trade dynamics between the U.S. and Pakistan. Pakistan is currently the second largest export market for U.S. raw cotton in the 24/25 marketing year; as of July 17, 2025, U.S. raw cotton fiber sales to Pakistan are 2.4 million bales.

Influential voices from Pakistan’s textile and spinning sectors (including the All Pakistan Textile Mills Association (APTMA)), U.S. cotton exporters and growers, and global trade experts discussed global cotton market trends, supply chain sustainability and

transparency, and innovative technologies shaping cotton’s future.

“Our COTTON USA™ Leadership Forums in Pakistan marked a significant milestone in strengthening U.S.-Pakistan cotton trade relations,” said Will Bettendorf, CCI director of South Asia and supply chain marketing. “The U.S. executive delegation reinforced mutual collaboration with its Pakistani counterparts toward advancing a sustainable cotton supply chain and

establishing a robust foundation for enduring, resilient partnerships.”

A series of expert-led panel discussions, tech-driven audience engagement tools and collaborative exercises in these executive-level forums created a high-impact platform to foster the dynamic exchange of ideas and insights between the participants.

Active involvement in the COTTON USA™ forums from Scott Urbom, U.S. Consul General in Karachi, Pakistan, and

Kristin K. Hawkins, U.S. Consul General in Lahore, underscored the importance of diplomatic support in facilitating deeper U.S. cotton industry partnerships and shared economic growth with the Pakistani textile industry.

Haroon Ellahi, a leading Pakistani mill owner from the Nagina Group, praised the COTTON USA™ workshops, leadership forums and technical guidance as a transformative force in deepening U.S.-Pakistan cotton trade.

“These initiatives provide invaluable exposure to global best practices and open direct channels with American industry leaders,“ said Ellahi. “Such engagement not only elevates Pakistan’s textile capacity but also positions Pakistan to become the largest consumer of U.S. cotton in the world.

CCI’s role is pivotal in aligning both countries’ interests through collaboration, innovation and trust, a powerful step toward a stronger and robust U.S.Pakistan relationship.“

Cotton Council International (CCI) is the export promotion arm of the National Cotton Council (NCC). CCI promotes U.S. cotton fiber, yarn and manufactured cotton products around the globe under our COTTON USA™ brand. With operations in more than 50 countries and nearly 70 years of global trade expertise, our mission is to make U.S. cotton the preferred fiber for mills, manufacturers, brands, retailers and consumers around the world. To learn more, visit: www.cottonusa.org.

KARL MAYER Technical Textiles has had a new Managing Director since July 1, 2025. Hagen Lotzmann – a manager and expert from within the company’s own ranks – has taken over the position at the head of the company and, at the same time, the role of President of the KARL MAYER Technical Textiles business unit.

Hagen Lotzmann has been contributing to the success of KARL MAYER Technical Textiles in various fields since 2008 and has learned the company’s business from the ground up. He earned his first credentials as a development engineer in application technology and later became the primary point of contact for customers as a sales engineer. In 2013, Hagen Lotzmann moved into Sales Management and went on to head the Sales, Product Management and Application Technology departments.

This gives Hagen Lotzmann a solid foundation on which to build in his role as Managing Director. His new responsibilities are demanding: the sites in Chemnitz and Selbitz will be set up as strong locations for service, sales, and development. The production and assembly of the machines will be relocated within the KARL MAYER Group.

At the KARL MAYER stand A301 in Hall 5 of the Singapore EXPO, he hopes

KARL MAYER is an innovative market leader as well as driving force in the textile machinery building. The

manufacturer offers perfect solutions for the fields of warp knitting, technical textiles, warp preparation for weaving and digitalisation.

To ensure the success of its international customers, KARL MAYER has always been eager to provide its clients with the best economical and technical products and services and to offer innovations which bring fresh impetus to the textile world.

With employees worldwide, the international organization produces in its main markets, so that KARL MAYER is always close to its customers and their needs. Today, the company has subsidiaries in China, USA, India, Italy, Hong Kong, Japan, Bangladesh and Switzerland as well as agencies all over the world.

Circulose has partnered with Mango as the first Scaling Partners since the restart – a major step toward accelerating the adoption of circular materials in the global fashion industry.

The partnership marks a milestone in Mango’s commitment to sustainable fashion, aligning with its long-term strategy to transition towards a circular model and to reduce its environmental impact. This collaboration reflects the brand’s commitment to shifting a meaningful share of their MMCF use to fibers made with CIRCULOSE®

“We’re proud to partner with the forward-thinking brand Mango and support their high ambitions in circularity. Their strong commitment brings us one step closer to restarting the factory and sets a powerful example for the industry. We hope it will inspire other brands to follow their lead.” says Jonatan Janmark, CEO of Circulose.

“We’re proud to be the first brand to partner in Circulose’s new phase and look forward to working closely together to advance our shared circularity goal” says Andrés Fernández, Sustainability and Sourcing Director at Mango. “This collaboration marks a significant step on our sustainability roadmap as we strive to exclusively use fibres with lower environmental impact by 2030 and reflects our commitment to fostering a more circular and responsible fashion ecosystem, where innovation and environmental stewardship go hand in hand.”

This partnership builds on Circulose’s strengthened commercial strategy, which focuses on forging closer brand partnerships, introducing an innovative pricing model, and offering expanded support services.

The new pricing model, developed in collaboration with Fashion for Good and Canopy as part of a joint initiative to

accelerate the shift to next-gen materials, requires brands to license CIRCULOSE® to access the fiber. It is specifically designed to reduce pricing friction and drive adoption at scale, shifting from limited capsule collections to large-scale adoption of next-gen materials.

The license also includes services that support large-scale implementation, such as transition planning, supply chain orchestration, and traceability.

Circulose has entered a multi-year partnership with H&M Group – marking another pivotal step in scaling circular materials within the fashion industry.

Since 2020, H&M Group has been a frontrunner in incorporating CIRCULOSE® into their collections. Now they are deepening their commitment by becoming one of the first official Scaling Partners for Circulose. Through the multiyear agreement, H&M is targeting to