Apparel Sourcing Paris Autumn

Dates: September 15th to 17th 2025.

Venue: Paris

64th Dornbirn-Global Fiber Congress

Dates: September 10th to 12th 2025.

Venue: Dornbirn Austria.

ITMA ASIA + CITME, Singapore 2025

Dates: October 28th to 31st, 2025.

Venue: Expo Centre Singapore.

ShanghaiTex 2025

Dates: November 16th to 19th 2025.

Venue: SNIEC, Shanghai, China.

Textile Asia 2025, Lahore

Dates: November 22nd to 24th 2025. Venue: Lahore Expo Centre.

Textile Asia 2026, Karachi

Dates: December 05th to 07th 2026. Venue: Expo Centre, Karachi.

Heimtextil 2026, Frankfurt

Dates: January 13th to 16th, 2026

Venue: Frankfurt am Main.

FESPA Middle East 2026

Dates: January 13th to 15th 2026.

Venue: Dubai Exhibition Centre.

Dates: January 19th to 22nd 2026.

Venue: Hannover, Germany.

2025

Dates: February 26th to 28th, 2026. Venue: Ho Chi Minh City, Vietnam.

IGATEX Pakistan 2026, Lahore

Dates: April 08th to 11th 2026.

Venue: Expo Centre, Lahore

iCADEX Pakistan 2026, Lahore

Dates: April 08th to 11th 2026.

Venue: Expo Centre, Lahorei.

DOMOTEX asiaCHINAFLOOR 2026

Dates: May 27th to 29th 2026. Venue: NECC, Shanghai, China.

Techtextil and Texprocess 2026

Dates: April 21st to 24th, 2026

Venue: Frankfurt, Germany.

Index 2026

Dates: May 19th to 22nd, 2026. Venue: Palexpo, Geneva, Switzerland.

ITM 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

HIGHTEX 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

ITMA ASIA + CITME 2026

Dates: October 20th to 24th, 2026. Venue: NECC, Shanghai, China.

Dates: September 16th to 22nd, 2027. Venue: Hanover, Germany.

PAKISTAN

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief

Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager

Mazhar Ali

Layout & Design

Noor M. Jaan

Website / Social Media

Minhaj Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Engr. Naeem Ilyas Khanani

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, United Kingdom.

Registered no. 09141989 Tel: +44 792 2228 721

Available on Gale and Factiva affiliated international databases through Asianet Pakistan

Printed at: Color Plus Korangi, Karachi.

Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

Guess Jeans and Jeanologia bring the future of denim to Tokyo .

.18

Fundamentally Green Metrics launches in Latin America: A data-powered pilot to revolutionise sustainable fashion

AG acquires Schoeller Technologies AG

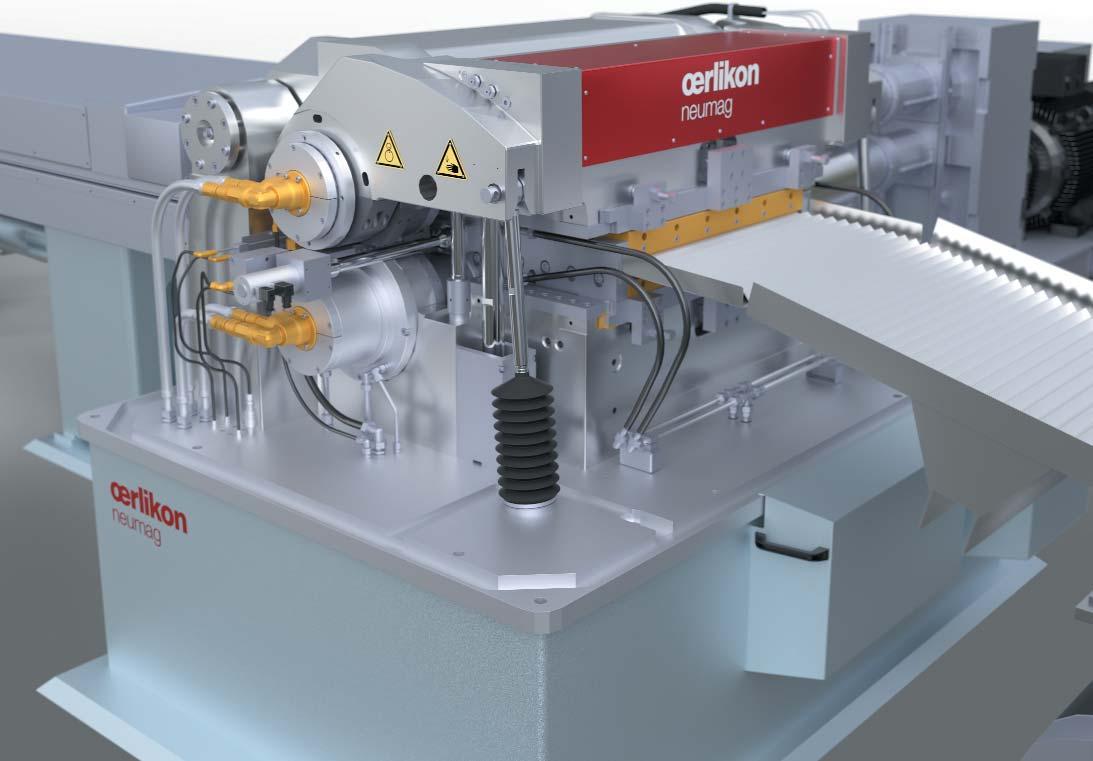

Oerlikon: Crimper repair workshop begins operations

SANITIZED and RUDOLF announce exclusive distribution partnership for Sanitized® textile

YKK: Zippers dyed with ECO-DYE® technology for the

Archroma and Veermata Jijabai Technological Institute (V.J.T.I.) forge strategic partnership

Expanding horizons through partnership: TEXTILCOLOR AG and Chemdyes Sdn. Bhd. join forces in Asia

Christian Botschek joins the management board of KARL MAYER

Crealet: 10 years with Andreas Wirz – an

AND EXHIBITIONS

Heimtextil Trends 26/27: Where AI and craftsmanship

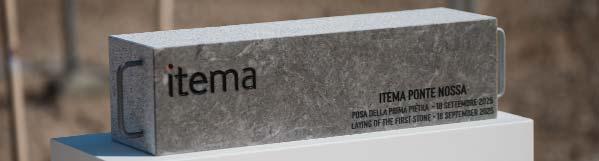

Itema lays the first stone of the new manufacturing site of Ponte Nossa . . . . . .36

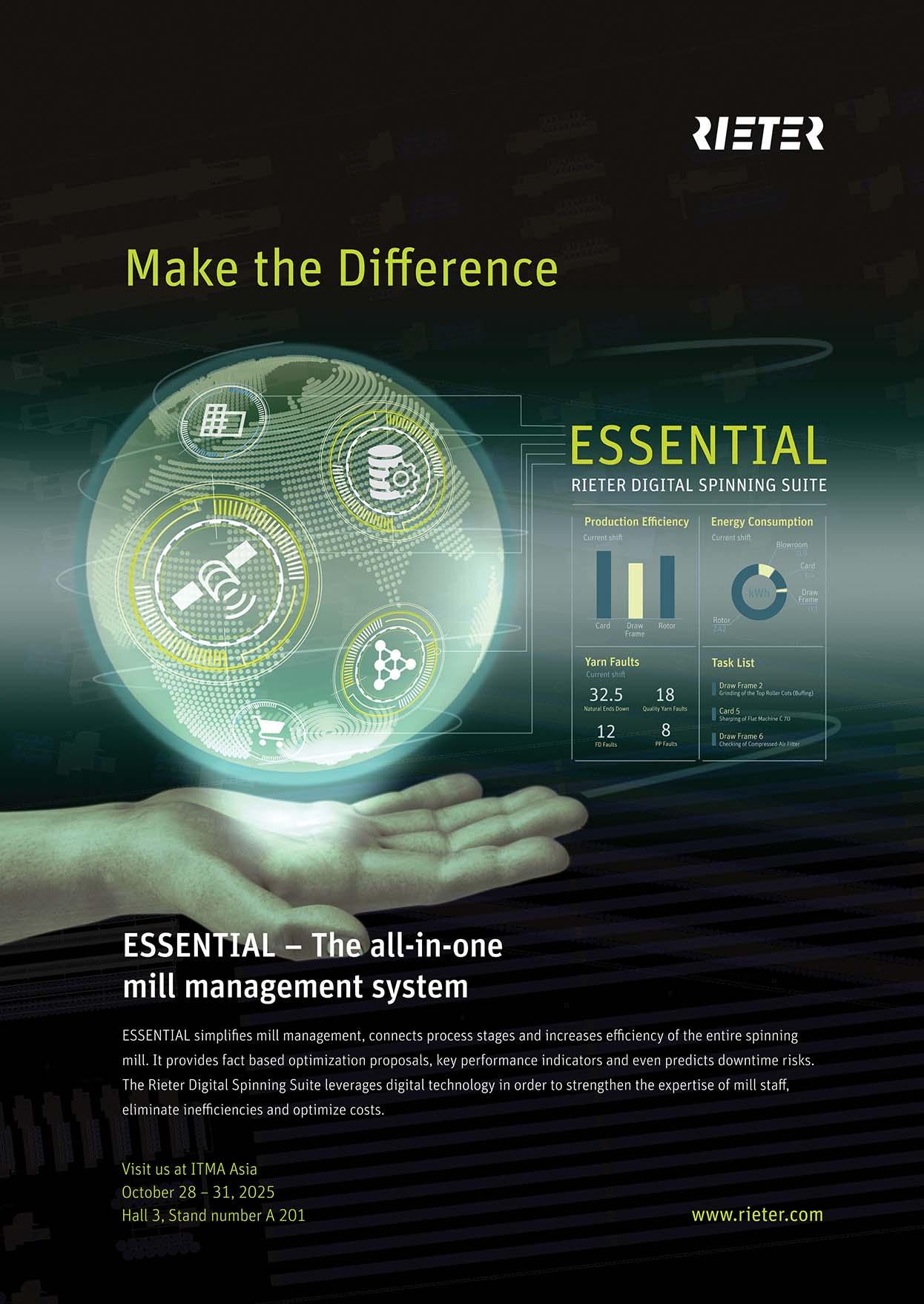

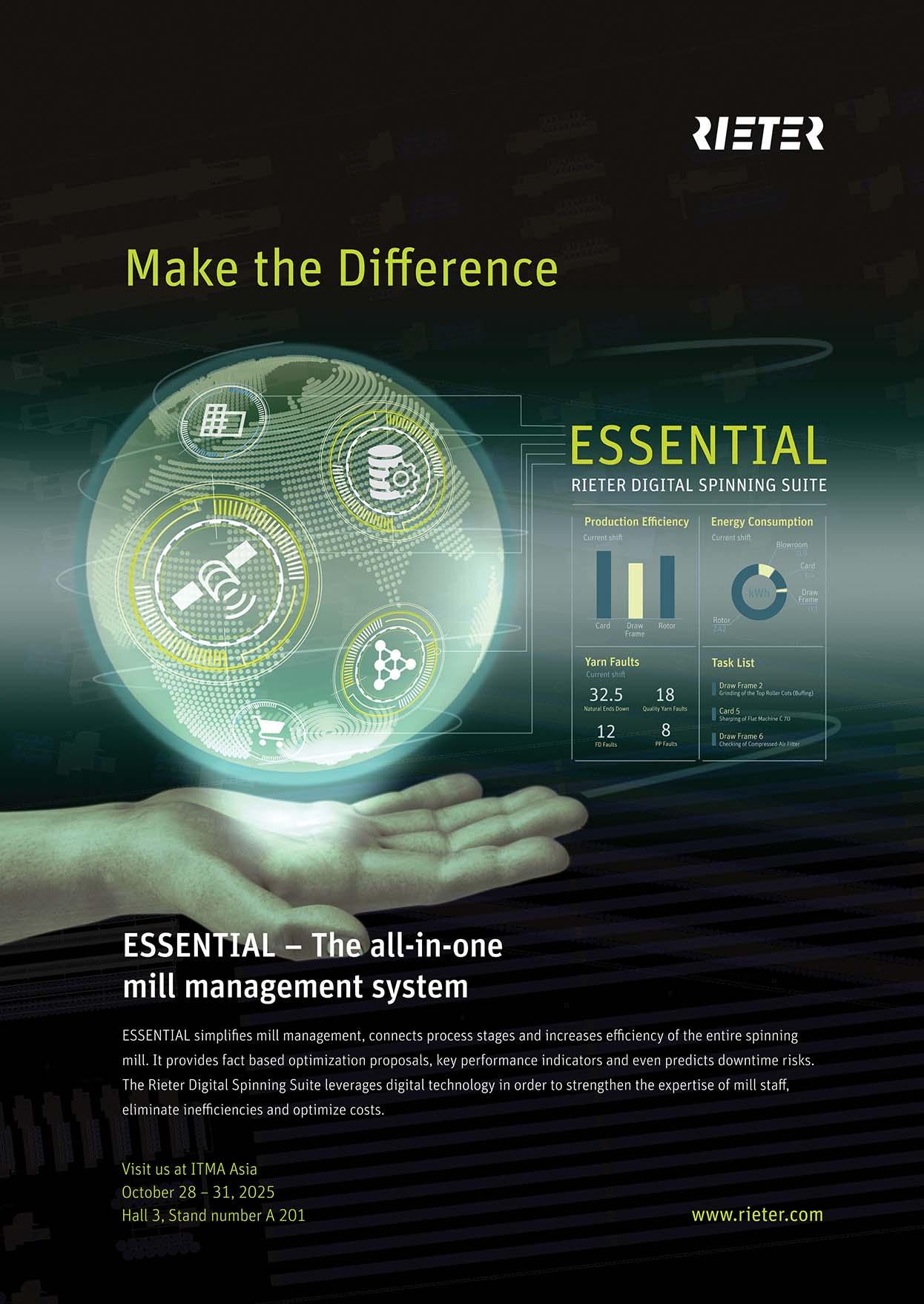

Rieter’s Mill Management Summit 2025: Advancing excellence in textile operations .38

Uster Technologies marks 150 years of empowering quality excellence .

Biancalani takes another step towards the digital factory: PLM system implementation

ecoTERRA by EFI Reggiani: a one-step revolution in pigment printing

.40

.43

Circulose launches CIRCULOSE® Forward to accelerate adoption in fashion supply chains

U.S. Cotton makes powerful impression at Intertextile Shanghai Apparel Fabrics . .45

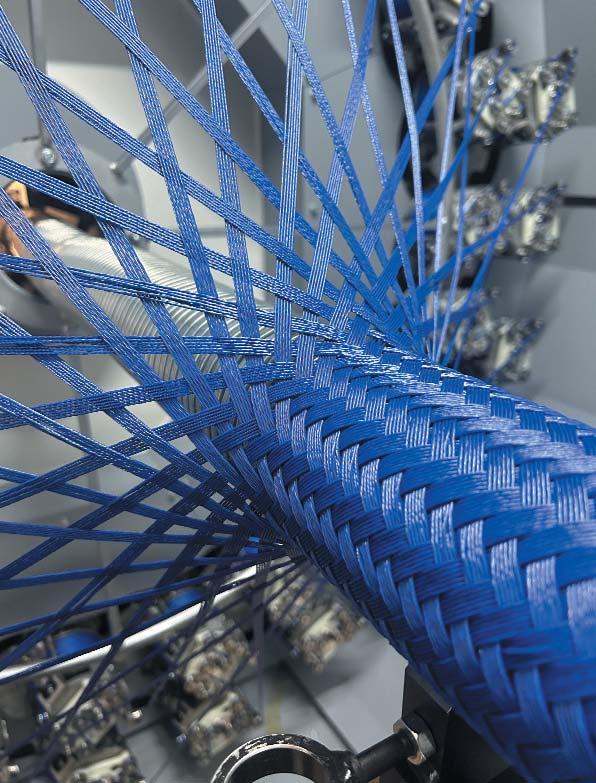

Mayer & Cie expands its braiding portfolio again

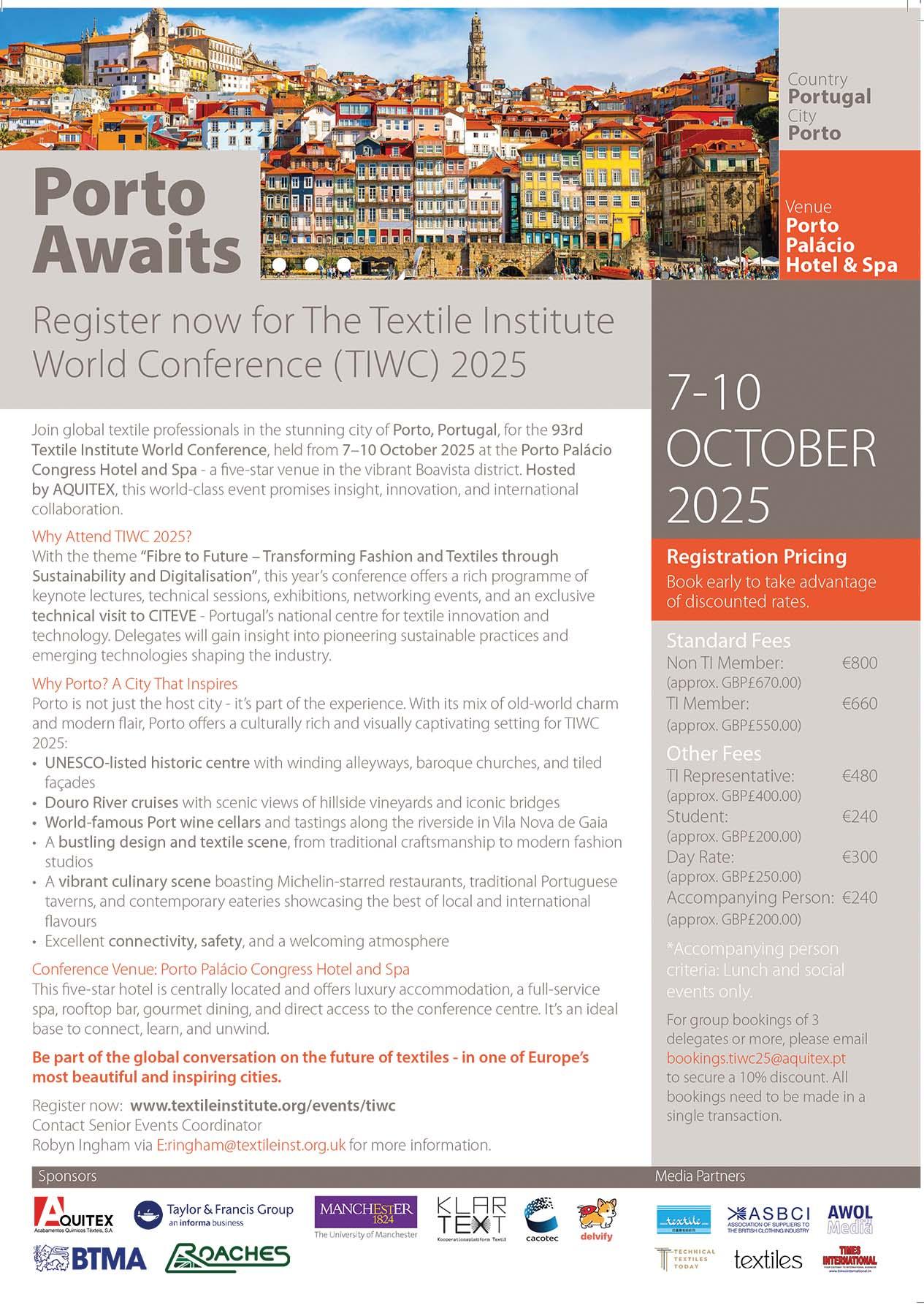

Global textile themes converge in Porto

Pakistan & China: from strategic allies to economic partners

by Nadeem Mazhar, Managing Editor, Pakistan Textile Journal

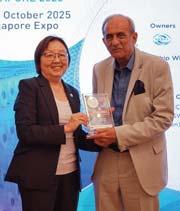

Roadshows in Karachi and Lahore build momentum for ITMA ASIA + CITME 2025 . .52

ITMA ASIA + CITME, Singapore 2025 garners strong support from industry partners .56

VDMA member companies on display at ITMA ASIA + CITME

From Medical Sutures to Aerospace: BTMA Showcases Advanced Fibre Innovations

TMAS: Advanced automation from Swedish machinery in Singapore . . . . . . .60

Swissmem: Swiss innovation poised to take centre stage at ITMA ASIA + CITME 2025 .62

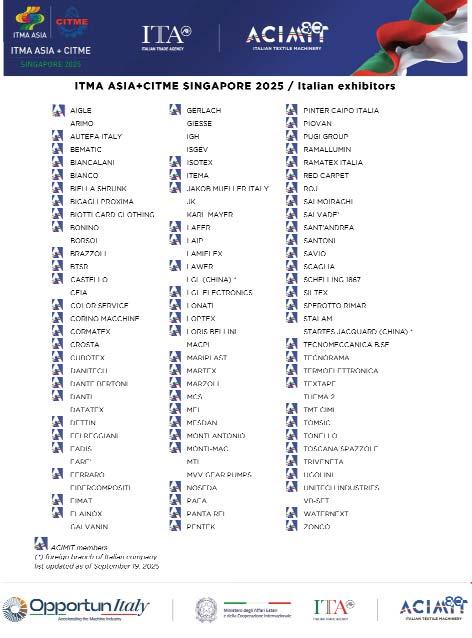

ACIMIT to showcase Italian innovation and sustainability at ITMA ASIA + CITME 2025 .63

The friendly ties between Pakistan and China have long been described as an “allweather friendship”. It is a longstanding relationship built on mutual trust, respect, and cooperation. Since the establishment of diplomatic relations in 1951, the two nations have maintained a steady course, navigating shifts in regional and global dynamics while expanding their strategic and economic partnership. From political support on key international issues to multi-dimensional cooperation in infrastructure, energy, and industrial development, Pakistan and China continue to demonstrate a model of strong bilateral relations.

China remains Pakistan’s largest trading partner and a key source of investment, particularly in the energy and infrastructure sectors. Bilateral trade between the two countries reached US$ 16 billion in 2023–24, showcasing the steady expansion of commercial ties. However, the trade balance continues to tilt in China’s favour.

On the export side, Pakistan has increased its shipments to China from US$ 2 billion in 2022–23 to US$ 2.7 billion in 2023–24, with cotton yarn, fabrics, rice, leather, frozen fish, and surgical instruments among the leading products. China also ranks among the top importers of Pakistani cotton, a vital link for the country’s textile sector. Conversely, China remains Pakistan’s leading import partner, providing more than 29% of total imports, including textile machinery, electrical equipment, high-tech components, iron and steel, organic chemicals, and man-made filaments. More than half of Pakistan’s machinery and electronics imports are sourced from China, underlining China’s critical role in Pakistan’s industrial development.

The China-Pakistan Economic Corridor (CPEC) has further elevated the bilateral partnership, bringing in US$ 25.4 billion in foreign direct investment and creating 75,000 jobs. With nine special economic zones planned, CPEC offers vast potential for industrialization and value addition, areas particularly relevant to Pakistan’s textile and apparel industry.

Against this backdrop of deepening economic ties, the upcoming ITMA ASIA + CITME exhibition in Singapore holds great significance for Pakistan’s textile sector. Traditionally held in China, this leading textile machinery exhibition provides a unique platform for global innovation, knowledge-sharing, and business networking.

For Pakistan, whose textile industry is both the backbone of the economy and the largest export earner, the exhibition presents a timely opportunity. With Chinese suppliers dominating Pakistan’s imports of textile machinery, the event will offer Pakistani entrepreneurs and manufacturers a chance to explore the latest technologies, strengthen partnerships with Chinese and global suppliers, and identify solutions to enhance competitiveness in global markets.

Participation in ITMA ASIA + CITME will also enable Pakistan’s textile sector to align with global trends in automation, sustainability, and digitalization, all critical to meeting the demands of international buyers. As Pakistan seeks to diversify its export portfolio and expand its global market share, leveraging such platforms will be essential to drive innovation and efficiency.

1

Pakistan’s textile export sector faced a challenging period in August 2025, with a notable decline in key categories. According to the latest figures from the Pakistan Textile Council (PTC), the total export value for the July–August 2025 period reached $5.1 billion, reflecting a modest increase of just 0.65% compared to the same period last year. However, the situation took a sharp downturn in August, as exports fell by 12.5% yearon-year and 10% month-onmonth, highlighting persistent volatility in the country’s trade performance.

2

Prime Minister Shehbaz Sharif recently inaugurated a special economic zone (SEZ) in Islamabad, a move expected

to significantly enhance Pakistan's export potential. The SEZ, being developed by Chinese textile giant Challenge Fashion Private Limited, is projected to generate exports worth $400 million for the country, the Associated Press of Pakistan (APP) reported.

3

Acting U.S. Ambassador to Pakistan, Natalie A. Baker, recently held a constructive discussion with the All Pakistan Textile Mills Association (APTMA) to explore avenues for enhancing bilateral trade and economic relations between the United States and Pakistan. The meeting, attended by key APTMA figures including Chairman Kamran Arshad and several senior members,

1

The European Parliament has passed a landmark law aimed at reshaping the fast fashion industry. Central to the new regulation is the concept of Extended Producer Responsibility (EPR), which will hold textile producers accountable for the end-oflife disposal of their products, including both garments and accessories sold online within the EU or exported globally.

2

In a major escalation of trade tensions, U.S. President Donald Trump has implemented a significant hike in tariffs on Indian exports, now set at a 50% levy, effective from August 27, 2025. This marks a sharp increase from the previous 25% tariff, which

aimed to strengthen the textile sector and foster mutual growth in the wake of evolving trade dynamics.

4

Pakistan is preparing to roll out a pivotal fiveyear plan to revitalize its textile and industrial sectors, with the government focusing on creating a more competitive landscape for exports and addressing critical issues like energy costs and outdated infrastructure. Commerce Minister Jam Kamal Khan confirmed that a new Textiles and Apparel Policy, alongside a broader National Industrial Policy, is set to be finalized soon, both designed to boost Pakistan’s export potential and remove trade barriers that have hindered growth.

5

Pakistan’s textile sector is bracing for a dramatic rise in cotton imports, with the country’s import bill expected to hit up to $3 billion this year— double last year’s total—following severe flooding that has ravaged key cottongrowing regions, particularly in Punjab, and is now threatening Sindh, industry officials and analysts warned.

6

The Chinese Consulate General and the All Pakistan Textile Mills Association (APTMA) have committed to boosting bilateral trade between Pakistan and China. The two parties also discussed ways to fully capitalize on the benefits of the Free Trade Agreement (FTA) and increase textile industry collaboration.

had already put considerable strain on trade relations. The new measures impact a broad array of products, including textiles, apparel, gems, footwear, furniture, and chemicals.

3

New Zealand's apparel import sector has displayed a steady recovery in the first seven months of 2025, with figures showing a 4.7% increase, reaching approximately USD 711 million compared to the same period in 2024. This growth signals a modest rebound after earlier downturns, with demand slowly picking up across key apparel categories.

4

Sri Lanka’s export sector has shown impressive resilience in the first half of 2025, with

total export earnings reaching US$ 8.34 billion, marking a solid 6.70% growth compared to the same period in 2024. This growth underscores the effectiveness of the country's export strategies and its growing competitiveness on the global stage.

5

Tajikistan has set an ambitious goal to increase its textile export value from US$ 300 million to US$ 3 billion by 2040, with a strategic focus on expanding domestic cotton processing and creating a comprehensive, fullcycle textile production ecosystem. This vision was outlined by Sherali Kabir, Minister of Industry and New Technologies, during the First International Textile Forum.

6

Şirikçioğlu Grubu Textile, a leading Turkish denim manufacturer, has signed a significant agreement with Egypt’s Suez Canal Economic Zone to establish a new denim production facility in Egypt. The deal, valued at $20 million, is expected to create around 500 direct jobs and contribute significantly to the region’s export growth.

7

Vietnam’s textile and garment sector is surging toward its 2025 export target of US$47–48 billion, propelled by strong order volumes and a broadening global presence. As the year enters its final months, the industry remains confident in its ability to meet this ambitious goal.

Pakistan’s textile export sector faced a challenging period in August 2025, with a notable decline in key categories.

According to the latest figures from the Pakistan Textile Council (PTC), the total export value for the July–August 2025 period reached $5.1 billion, reflecting a modest increase of just 0.65% compared to the same period last year. However, the situation took a sharp downturn in August, as exports fell by 12.5% yearon-year and 10% month-on-month, highlighting persistent volatility in the country’s trade performance.

The textile and apparel sector, which comprises around 63% of Pakistan’s overall export value, generated $3.21 billion during the July–August period, marking a 10% year-on-year increase. Despite this growth, August saw textile exports plunge to $1.53 billion, a 7% drop compared to August 2024 and a 9% decrease from July 2025.

The long-term decline in traditional textile segments (HS codes 50–60) has continued to affect the sector, with exports expected to drop from $685 million in FY22 to $523 million in FY26. Among these categories, cotton exports fell by 3.5%, while knitted fabrics recorded a steep 32.7% decrease. The value-added segment (HS codes 61–63), typically more resilient, also faced a 13% decline in August, with key products like knitwear, non-knit apparel, and madeups showing signs of weakness.

Meanwhile, export markets have also shown shifting trends. The European Union remains Pakistan’s largest export destination, with $1.3 billion in textile sales, but exports to the United States have stagnated, holding steady at $878 million for the fifth consecutive year. This stagnation is attributed to the diminishing competitiveness of Pakistani products in global markets.

In light of these concerning trends, the PTC has called for urgent structural reforms to revitalize the textile export sector. Key recommendations include boosting support for traditional industries like cotton and spinning, enhancing cotton quality, and reducing production costs. The Council also stresses the need

for enhanced financing options, particularly through a stronger EXIM Bank and improved access to the Export Finance Scheme (EFS) and Long-Term Financing Facilities (LTFF). Additionally, the PTC is advocating for the introduction of a legally backed, five-year textile export strategy, with clear performance indicators to track progress.

“The decline in textile exports, especially in August, is a critical concern,” the PTC report stated. “Immediate reforms are essential to reverse the trend and ensure Pakistan’s continued competitiveness in the global textile market. The government must take swift action to safeguard jobs, market share, and foreign exchange inflows.”

through initiatives like the China-Pakistan Economic Corridor (CPEC). With Phase II of CPEC now underway, the focus is shifting towards industrialization, the creation of more special economic zones, clean energy projects, and initiatives aimed at improving agriculture and livelihoods.

Speaking at the inauguration, PM Shehbaz emphasized that the establishment of the SEZ would be a crucial step towards fostering technology transfer, skill development, and sustainable industrial growth. "This initiative will not only drive industrial growth but also contribute to the development of our workforce," he stated.

Prime Minister Shehbaz Sharif recently inaugurated a special economic zone (SEZ) in Islamabad, a move expected to significantly enhance Pakistan's export potential. The SEZ, being developed by Chinese textile giant Challenge Fashion Private Limited, is projected to generate exports worth $400 million for the country, the Associated Press of Pakistan (APP) reported.

Pakistan's longstanding partnership with China has been a cornerstone of its economic development, particularly

The Chinese textile group behind the SEZ, Challenge Fashion Private Limited, plans to invest $100 million over the next five years, signaling a strong commitment to Pakistan’s textile sector. The company aims to create a state-of-the-art textile industry in the country, enhancing its competitiveness in global markets.

During a meeting with the delegation led by Challenge Fashion’s chairman, Huwang Weiguo, Prime Minister Shehbaz reiterated Pakistan's eagerness to strengthen bilateral ties with China. “We are committed to taking our partnership to new heights,” he said, further assuring the delegation of full government support for the SEZ as part of CPEC’s industrialization component.

A number of federal ministers were also in attendance, including Ahsan Iqbal, Jam Kamal, Attaullah Tarar, Ali Pervez Malik, Sardar Awais Ahmad Leghari, and Special Assistant to the Prime Minister Tariq Fatemi.

The Prime Minister praised the Chinese investors for their trust in Pakistan's market, reiterating that more such initiatives would be welcomed in the country. "We are looking to establish more such units and learn from China’s expertise in textiles," PM Shehbaz noted. He also announced plans for a forthcoming China-Pakistan Business-to-Business Conference, which will be held in China, offering an excellent platform for private sector collaboration between the two nations.

Chairman Huwang expressed gratitude for the Prime Minister’s support and highlighted the company’s vision of building a modern and competitive textile industry in Pakistan. "We are looking forward to contributing to Pakistan’s industrial landscape," he stated.

In July, during a high-level meeting, Planning Minister Ahsan Iqbal reassured a Chinese delegation that the development of special economic zones would remain a top priority for the federal government. Earlier this year, the Sindh government also signed an agreement with Chinese and local investors to establish the Dhabeji SEZ under the second phase of CPEC.

Natalie A. Baker, Chargé D'affaires - U.S. Embassy & Consulates

Acting U.S. Ambassador to Pakistan, Natalie A. Baker, recently held a constructive discussion with the All Pakistan Textile Mills Association (APTMA) to explore avenues for enhancing bilateral trade and economic relations between the United States and Pakistan. The meeting, attended by key APTMA figures including Chairman Kamran Arshad and several senior members, aimed to strengthen the textile sector and foster mutual growth in the wake of evolving trade dynamics.

Joining Ambassador Baker were U.S. Consul General at Lahore Stetson Sanders, William Campbell, Political and Economic Chief, and Amna Anis, Economic Specialist. The group discussed the vast potential for collaboration between both nations, with a particular focus on expanding trade in cotton and textiles, addressing the trade deficit, and diversifying the range of commodities exchanged, especially in light of recent U.S. tariff policies.

The discussions underscored the opportunities for Pakistan’s textile sector to increase exports and gain a larger share in global markets, especially in the context of U.S.Pakistan relations.

In his address, APTMA Chairman Kamran Arshad presented an in-depth overview of Pakistan’s textile industry, highlighting the challenges posed by declining domestic cotton production. Arshad pointed out that the country would face significant cotton shortages this year, necessitating substantial imports to meet industry demand.

"The United States remains Pakistan’s largest cotton supplier, and we are the biggest importer of U.S. cotton in the world," he stated, emphasizing the importance of continued cooperation to secure cotton supplies for Pakistan's textile sector.

With textiles accounting for approximately 63% of Pakistan’s total exports, Arshad stressed the critical role that cotton availability plays in the country's economic stability. He also raised concerns about the withdrawal of the Regionally Competitive Energy Tariff (RCET) for electricity and gas, which he noted had led to the closure of over 100 spinning mills due to skyrocketing energy costs and rising tax burdens. Additionally, he pointed out the increased importation of yarn from other countries as a result of these challenges.

Arshad also advocated for a closer alignment between the textile sectors of the U.S. and Pakistan, proposing a new mechanism to import U.S. cotton under the GSM-102 program in exchange for textile exports to the U.S. He suggested that Pakistan’s textile export proceeds be used as collateral through an escrow account to manage this arrangement efficiently.

Asad Shafi, Chairman of APTMA North, further elaborated on the growing importance of U.S.-Pakistan trade relations, noting that the U.S. remains Pakistan's largest trading partner. "In 2024, bilateral trade between our two countries surpassed $7 billion, with textile and apparel making up 77% of Pakistan’s exports to the U.S.," he said. He also highlighted the need for a stronger focus on U.S.-Pakistan cotton linkages and the promotion of textile toll manufacturing in Pakistan by U.S. textile companies.

Shafi called for the introduction of high-yielding cotton seed technology and greater collaboration with U.S. cotton research institutes to improve quality. He

further emphasized the need for technological advancement in Pakistan’s agricultural sector, particularly through capacity building and technology transfer for cotton traceability. "Pakistan’s cotton sector could greatly benefit from the facilitation of international seed companies and the introduction of genetically modified seeds," he added.

The meeting concluded with a call for greater joint ventures and partnerships between U.S. and Pakistani investors, with a focus on strengthening the cotton supply chain and increasing the competitiveness of Pakistan’s textile industry on the global stage.

Pakistan is preparing to roll out a pivotal five-year plan to revitalize its textile and industrial sectors, with the government focusing on creating a more competitive landscape for exports and addressing critical issues like energy costs and outdated infrastructure.

Commerce

Minister Jam Kamal Khan confirmed that a new Textiles and Apparel Policy, alongside a broader National Industrial Policy, is set to be finalized soon, both designed to boost Pakistan’s export potential and remove trade barriers that have hindered growth.

The textile industry, a cornerstone of Pakistan’s economy, accounts for more

han half of the country’s total exports. It contributes approximately 8.5% to GDP and employs nearly 40% of the industrial labor force. However, the sector has faced mounting challenges, from rising energy prices to inefficiencies in policy execution, leaving Pakistan lagging behind regional competitors such as Bangladesh.

"We are fully committed to driving export growth," Minister Khan said after a meeting with representatives from the textile sector, including the All Pakistan Textile Mills Association (APTMA). “This new policy represents a shift towards a collaborative effort between the government and industry stakeholders to revive the textile sector.”

The Commerce Minister emphasized that this policy would mark a significant change from the past. "For the first time, both the government and the textile industry are aligned in their goals to ramp up export growth, and we aim to establish long-term, consistent policies," he stated. The government also plans to analyze the strategies of regional competitors, with Khan noting his recent observations in Dhaka, where Bangladesh’s ready-made garment sector has reached impressive export figures, contributing to its $50 billion annual export revenue.

Pakistan’s textile sector has long struggled to match the scale and success of Bangladesh’s garment industry, which now accounts for roughly 80% of the country's exports. However, with the right policies in place, Pakistan aims to narrow this gap.

To complement the textile policy, Prime Minister’s Special Assistant on Industries and Production, Haroon Akhtar

Khan, shared details about the broader National Industrial Policy. He outlined that the new policy would not be limited to the textile sector but would also address key industrial concerns, including energy costs, tax structure, and financing options. The policy will also include incentives for Greenfield projects and introduce landlease models through public-private partnerships, aiming to foster industrial growth across a wide range of sectors.

“The industrial policy will provide a comprehensive framework to boost industrial development, which will align with Prime Minister Shehbaz Sharif’s vision for a more robust and competitive economy,” Khan added.

Despite these promising developments, industry leaders are calling for swift action to address the sector's ongoing challenges. Representatives from APTMA have urged the government to eliminate

the structural inefficiencies that continue to hamper the textile industry’s global competitiveness.

In a related matter, the Pakistan Textile Council (PTC) voiced concerns over recent amendments to the Export Facilitation Scheme. These amendments removed key raw materials such as cotton, cotton yarn, and grey cloth from the scheme without providing clear tariff codes, creating confusion and delays in the implementation process.

warned that this uncertainty could have serious consequences for the country’s textile supply chains. "The lack of clarity is already leading to delays, inconsistent application, and disruptions in the supply chain, which could severely impact Pakistan’s textile exports," Anwar cautioned.

In a pivotal step to address the growing concern of textile waste, the European Parliament has passed a landmark law aimed at reshaping the fast fashion industry. Central to the new regulation is the concept of Extended Producer Responsibility (EPR), which will hold textile producers accountable for the end-of-life disposal of their products, including both garments and accessories sold online within the EU or exported globally.

The law requires manufacturers, including online fashion retailers, to cover the cost of collection, sorting, and recycling of textiles, with the goal of minimizing waste and encouraging sustainable practices across the sector. The deadline for compliance is set at 30 months for most companies, while microenterprises will be granted an additional year to meet the requirements.

A key feature of this legislation is the tiered fee system that ties EPR fees to the environmental impact of fashion products. Specifically, brands that contribute to the disposable nature of fast fashion—characterized by ultra-low-cost, high-turnover clothing—will face higher fees to reflect the environmental burden of their business models.

The scope of the law extends beyond clothing, covering a wide range of textile products such as footwear, bedding,

curtains, and even mattresses. The overarching goal is to promote circular economy principles by ensuring that producers take responsibility for their products throughout their lifecycle, including their disposal or recycling.

The impact of this law is expected to extend far beyond the EU’s borders. As global supply chains are increasingly interconnected, countries that export textiles to the EU, such as Bangladesh, Vietnam, China, and India, will likely be required to meet new compliance standards. This will drive a shift in manufacturing processes, with a stronger emphasis on sustainable design, traceability, and waste reduction.

For the fast fashion industry, the law represents both a challenge and a potential opportunity. While the financial burden of compliance may be high, it also paves the way for brands to innovate in sustainable fashion, offering them a chance to capture the growing demand for eco-friendly products.

By holding brands accountable for textile waste and promoting a shift toward more sustainable production

practices, the EU’s new regulation sets a clear precedent for the rest of the world in tackling the growing issue of textile waste and fast fashion.

In a major escalation of trade tensions, U.S. President Donald Trump has implemented a significant hike in tariffs on Indian exports, now set at a 50% levy, effective from August 27, 2025. This marks a sharp increase from the previous 25% tariff, which had already put considerable strain on trade relations. The new measures impact a broad array of products, including textiles, apparel, gems, footwear, furniture, and chemicals.

The tariff increase is being framed as a punitive response to India’s ongoing purchases of Russian oil, a move that has drawn sharp criticism from both governments and industry players.

The Indian Ministry of External Affairs swiftly condemned the decision, describing it as “unfair,” “unjustified,” and “unreasonable.” The impact on India’s economy is expected to be severe, with analysts projecting a substantial reduction in trade volumes—potentially leading to billions of dollars in losses. Sectors heavily reliant on U.S. exports, such as textiles, gems, seafood, and chemicals, are poised to bear the brunt of the tariffs.

The textile and apparel sector is expected to suffer particularly high losses, with projections suggesting a 40–50%

decline in export volumes to the U.S., amounting to losses ranging from $2.5 to $3 billion. Key textile hubs like Surat and Ahmedabad in Gujarat fear that the new tariffs may render U.S. trade “impossible” for local exporters, with some warning of long-term damage to the industry’s competitiveness.

In light of the tariff hike, the Confederation of Indian Textile Industry (CITI) has called for urgent intervention from the government. Industry bodies are pushing for support schemes, incentives, and policy reforms aimed at shielding exporters from the brunt of these tariffs. They are also calling for stronger measures to maintain India’s competitive position in global markets.

The Indian government is reportedly working on a multi-pronged approach to mitigate the damage. This includes offering financial assistance to exporters, diversifying markets to regions like Africa, Latin America, and the EU, and pursuing diplomatic avenues to negotiate for exemptions or reductions in the tariff rates. Despite the blow to exports, some economists remain optimistic that India’s broader economy will continue to thrive, bolstered by domestic consumption and emerging opportunities in premium markets.

The new tariff measures are not only an economic challenge for India, but they also risk straining the diplomatic relationship between the U.S. and India. Observers suggest that the move could have far-reaching implications, potentially affecting broader areas of cooperation, including defense deals and multilateral partnerships like the Quad.

New Zealand's apparel import sector has displayed a steady recovery in the first seven months of 2025, with figures showing a 4.7% increase, reaching approximately USD 711 million compared to the same period in 2024. This growth signals a modest rebound after earlier downturns, with demand slowly picking up across key apparel categories.

During the first five months of the year, the value of apparel imports stood at USD 504.9 million, representing a slight year-on-year decline of 0.98%. Despite the dip, China maintained its dominant position as the top supplier, accounting for just over 60% of New Zealand's total apparel imports. However, shifts in sourcing patterns were apparent, as Bangladesh saw a minor decline in shipments, while Vietnam registered impressive double-digit growth. Additionally, countries like India and Indonesia also experienced gains, reflecting an increasingly diversified sourcing base.

By the mid-year point, the import figures showed signs of improvement, with imports rising by 5.1% to around USD 622 million in the first half of 2025. This increase was largely driven by a stronger demand for knitted clothing, with imports seeing a nearly 9% rise in June compared to the same month in 2024.

The cumulative total for January to July 2025 reached USD 711 million, illustrating a steady rebound in the sector. While China continues to dominate the market, the growing contributions from countries in Southeast Asia and South Asia have begun to reshape New Zealand's apparel import landscape. This shift indicates that New Zealand's supply chains are becoming more diverse, lessening reliance on a single source country and offering a more balanced outlook for the long-term stability of the market.

Although the growth rate remains modest, it underscores the resilience of consumer demand and the ongoing adjustments within global supply chains. With the growth of competitors like Vietnam, India, and Indonesia, New Zealand's apparel imports appear to be gaining momentum, signaling a more stable and sustainable future for the market.

Sri Lanka’s export sector has shown impressive resilience in the first half of 2025, with total export earnings reaching US$ 8.34 billion, marking a solid 6.70% growth compared to the same period in 2024. This growth underscores the effectiveness of the country's export strategies and its growing competitiveness on the global stage.

The apparel and textile sector, a cornerstone of Sri Lanka’s export economy, recorded steady growth with a 3.71% year-on-year increase in June 2025, bringing in US$ 463.12 million compared to June 2024. For the first six months of 2025, earnings from this sector reached US$ 2.60 billion, marking an 8.19% increase compared to the same period last year.

Exports to key markets showed positive momentum. Exports to the

United States rose by 4.35%, reaching US$ 919.92 million, while exports to the United Kingdom grew by 6.77%, amounting to US$ 371.54 million. These results highlight Sri Lanka's growing market share in its key apparel and textile destinations.

In addition to apparel and textiles, services exports have emerged as a major contributor to Sri Lanka’s export growth. In June 2025 alone, Sri Lanka earned US$ 309.61 million from services exports, reflecting a 9.78% increase over the first half of 2024. The total services export revenue for January to June 2025 stood at US$ 1.83 billion.

Sri Lanka's service sector continues to diversify, with key areas such as ICT/BPM, Construction, Financial Services, and Transport & Logistics playing pivotal roles in driving export performance. The rise of Sri Lanka’s knowledge-based economy has enhanced the country’s ability to offer high-value services, creating new employment opportunities across the island and expanding the nation’s export portfolio.

Overall, total merchandise and services exports in June 2025 reached US$ 1.46 billion, reflecting a strong 8.73% growth over June 2024. This continued upward trajectory points to the effectiveness of Sri Lanka’s long-term strategies aimed at broadening market access and enhancing its export competitiveness.

Tajikistan has set an ambitious goal to increase its textile export value from US$ 300 million to US$ 3 billion by 2040, with a strategic focus on expanding domestic cotton processing and creating a comprehensive, full-cycle textile production ecosystem. This vision was outlined by Sherali Kabir, Minister of

Industry and New Technologies, during the First International Textile Forum.

Currently, only 30% of Tajikistan’s cotton is processed locally, with the remainder exported as raw material. Kabir emphasized that the country’s target to reach US$ 3 billion in textile exports is feasible with strategic investments, infrastructure development, and a focus on adding value through the production of finished goods.

This initiative is in line with Tajikistan's Fourth National Strategy, which aims to significantly accelerate industrialization, including a goal to double industrial output within five years. A core component of this strategy is the Textile Industry Development Strategy, launched two years ago, which focuses on developing integrated clusters that cover every step of cotton production, from cultivation to finished textile products.

The government plans to fully process all cotton produced domestically, creating over 600,000 jobs in the process. Kabir noted that the government is keen to foster strong public-private collaborations and welcomed increasing interest from foreign investors, technology providers, and financial institutions.

At the forum, Kabir highlighted that Tajikistan’s long-term vision for its textile sector aligns with both the National Development Strategy 2030 and the Social Protection Strategy 2040, positioning the country to become a future hub for industrial innovation. With a solid focus on sustainable practices,

Tajikistan aims to develop a modernized, tech-driven textile sector that can compete on a global scale.

In pursuit of this goal, the government has committed to the development of several full-cycle cottonprocessing complexes. The initiative includes the construction of closed-loop production chains, combining cotton farming with manufacturing to produce finished goods like yarn, fabrics, and garments.

Şirikçioğlu Grubu Textile, a leading Turkish denim manufacturer, has signed a significant agreement with Egypt’s Suez Canal Economic Zone to establish a new denim production facility in Egypt. The deal, valued at $20 million, is expected to create around 500 direct jobs and contribute significantly to the region’s export growth.

The new factory, covering 16,700 m², will focus on producing high-quality denim yarns, threads, and fabrics—critical materials for manufacturing various types of jeans textiles. With an annual production capacity of 18 million tonnes of denim fabric, 50% of the output will be allocated for export markets, while the remaining half will supply local factories

in Egypt, reinforcing the country’s domestic textile sector.

The agreement was officially signed by Walid Gamal El-Din, Chairman of the Suez Canal Economic Zone, and Atef Şirikçi, Chairman of Şirikçioğlu Grubu. The move is part of Egypt’s ongoing strategy to boost local manufacturing and increase its export capacity in the textile industry.

El-Din emphasized the importance of attracting foreign investments to the region, stating that the Suez Canal Economic Zone is intensifying its efforts to localize key industries. He highlighted the strategic objective to deepen local manufacturing capabilities and expand exports, noting the commitment to enhancing regional infrastructure to meet rising global demand.

This new factory represents the 25th project in the Qantara West Industrial Zone, bringing the total investments in the area to $681.5 million and generating approximately 34,955 direct jobs. El-Din further underscored that the expansion of the denim production facility aligns with the government’s broader vision to strengthen Egypt's textile industry, particularly in the spinning and weaving sectors, from raw material production to finished goods.

Şirikçioğlu Grubu, established in 1997, is a well-established name in the textile industry in Turkey. The company already produces denim fabrics and yarns and has a workforce of over 5,000 employees. Its products are exported to global brands, further cementing its position as a leading player in the international denim market.

This partnership is not the only major development in the region. El-Din also recently signed a contract with Turkish company Ulusoy for an $18 million industrial project on a 35,000 m² land plot in the same industrial zone. This factory will specialize in producing various types of yarns, including fibre yarns, carpet yarns, and household crochet yarns, and is expected to generate around 855 direct job opportunities.

These strategic investments demonstrate the growing importance of the Suez Canal Economic Zone as a hub for industrial growth and export-oriented production, positioning Egypt as a key player in the regional textile industry.

Guess Airwash™, developed by Jeanologia, makes history by replacing traditional stonewashing with air

Tokyo’s iconic fashion district, will host “The Next 40 Years of Denim”, an immersive exhibition presented by Guess to celebrate the past and future of denim. This unique experience blends heritage, innovation, and sustainability to mark the beginning of a new chapter, the era of air.

Already showcased in Florence and Amsterdam, the exhibition now arrives in Tokyo, bringing its global message to one of the world’s most trendsetting cities.

At the center of this transformation is Guess Airwash™, disruptive technology developed by Jeanologia that replaces traditional stonewashing. Using air, light, and nanobubbles, it eliminates pumice stones, drastically reduces water consumption, by up to 80%, and avoids harmful chemicals and excessive energy use, while maintaining the iconic authentic denim look.

“We are proud to partner with GUESS in bringing this revolution to Japan,” says Carmen Silla, Marketing Director at Jeanologia. “Guess Airwash™ represents the perfect fusion of fashion, technology, and environmental responsibility. Its arrival in Japan is a milestone in our shared mission to transform the denim industry.”

The exhibition features a live Airwash Lab, offering behind-the-scenes insight into sustainable denim production with Jeanologia’s cutting-edge technologies, laser, e-flow, and G2 ozone. Visitors can

also enjoy a customization area, where they receive a denim tote bag to personalize with high-precision laser engraving. Local artists such as Ryota Daimon and A Love Movement add personal touches.

Additionally, the newly opened GUESS flagship store in Shibuya now features Jeanologia’s Nano laser technology, offering in-store customizations with a fast, precise, and eco-friendly process.

“The Next 40 Years of Denim” is more than an exhibition, it’s a statement. It proves that denim can be authentic, creative, and sustainable all at once. And Tokyo, with its forward-thinking spirit, is the perfect place to take the next step.

Jeanologia: 30 years of leading the transformation of the textile industry

Since its founding, Jeanologia has been on a mission to transform the textile

industry into a more ethical, sustainable, and efficient model. The company works closely with brands, retailers, and suppliers on this transformative journey, offering disruptive technologies, innovative software, and a new operational model. Their groundbreaking solutions, including laser technology, G2 ozone, Dancing Box, e-flow, H2Zero, and ColorBox, have redefined garment design and finishing standards, eliminating polluting processes and significantly reducing the use of water, energy, and chemicals. Thanks to these advancements, Jeanologia has saved millions of liters of water and eliminated harmful substances, turning its vision of a truly sustainable textile industry into reality.

In 2025, Jeanologia celebrates its 30th anniversary, marking a legacy of three decades of sustainable innovation. From the introduction of its laser technology in 1999, which revolutionized denim finishing, to its current challenge of implementing a revolutionary sustainable garment dyeing process, the Spanish company has pioneered solutions that not only benefit the environment but also optimize operational costs. Looking ahead, Jeanologia remains committed to creating an eco-efficient and ethical textile future, encouraging all industry stakeholders to join its Mission Zero initiative: dehydrate and detoxify the textile industry. No more water and toxic chemicals used in garment finishing around the world.

Fundamentally, a Mexico City-based community platform for slow fashion, and Green Story, a global leader in environmental data, have announced the launch of "Fundamentally Green Metrics – LATAM," a groundbreaking environmental data-powered pilot program designed to accelerate sustainability transformation within the Latin American fashion industry.

This initiative aims to provide small and medium-sized fashion producers in the region with access to essential sustainability metrics and tools, including digital product passports and carbon footprint analysis, powered by Green Story’s AI-enabled platform.

By participating in this pilot, selected brands can enhance their traceability and readiness to navigate rising international sustainability regulations, while exploring pathways to global competitiveness.

The fashion and textile industry is under increasing global scrutiny regarding sustainability, with emerging regulations and market expectations making traceability and impact measurement essential for brands seeking international relevance. While Latin America is home to extraordinary creativity and craftsmanship, many producers in the region face systemic barriers to accessing robust sustainability data and tools. Fundamentally Green Metrics – LATAM seeks to help close this gap by offering targeted, affordable access to advanced environmental metrics and expert guidance tailored to the region’s needs.

“Sustainability is not a nice-to-have. It’s the foundation for resilience, relevance, and growth in the fashion industry,” says Diana Hernandez, CEO and Founder of Fundamentally. "Through Fundamentally Green Metrics – LATAM, we aim to make sustainability more accessible, transparent, and inclusive for

align their values with measurable impact and gain global visibility for their creativity."

Green Story, known for its internationally recognized sustainability platform and a client base in more than 34 countries, brings deep expertise in Life Cycle Assessments (LCAs), Digital Product Passports (DPPs), and comprehensive environmental data.

Fundamentally anchors the partnership in the Latin American context by mobilizing a regional ecosystem of designers, producers, and changemakers, helping to foster conditions where sustainability becomes visible, actionable, and rooted in local realities.

"We are thrilled to partner with Fundamentally to empower Latin American fashion brands and manufacturers with the tools they need to better navigate a sustainable global market," says Akhil Sivanandan, CEO of Green Story.

“This pilot program provides meaningful access to Green Story’s sustainability tools at preferential rates

tailored to the Latin American context, thanks to a regional subsidy managed by Fundamentally. By doing so, we aim to help reduce the financial and technical barriers that have historically limited small producers in the region. This initiative strongly aligns with our mission to enable better data for better decisions, across all stakeholders worldwide.”

As part of this partnership, Fundamentally has been appointed as Green Story’s exclusive Cluster Partner for Latin America, coordinating strategic implementation across the region.

Selected participants in the pilot program for “Fundamentally Green Metrics – LATAM” will receive a suite of benefits designed to support their sustainability performance and international export readiness.

The benefits include:

One-year access to Green Story’s sustainability intelligence platform Unlimited Digital Product Passports (DPPs) Opportunity to use Green Story data

in support of Higg Index submissions (pending separate qualification)

Optional carbon offsetting via verified projects evaluated by Green Story

Training resources and sustainability communication tools

API connectivity for integrating impact metrics into e-commerce platforms

Promotional visibility through “Fundamentally Green Metrics –LATAM” campaigns

This program aims to offer significant economic and reputational benefits, including improved preparedness for emerging compliance requirements, increased alignment with EU sustainability expectations, greater visibility among responsible buyers, enhanced readiness to enter premium export markets, and the potential to build consumer trust through the communication of verified environmental impact.

The pilot cohort will be limited to 30 selected brands and manufacturers that produce fashion in Latin America and operate with small or medium-sized production capacities. Selected participants should demonstrate a strong interest in improving their sustainability practices and traceability systems, and a

commitment to preparing for international markets.

Participants will be selected jointly by Fundamentally and Green Story, based on alignment with the program’s objectives and eligibility criteria. The pilot will run for a three-month implementation period, and participating brands will retain access to Green Story’s platform and tools for one year following their onboarding date.

Based on the outcomes of the pilot, Green Story and Fundamentally aim to expand the reach of the program to support many more brands and manufacturers committed to sustainability throughout Latin America.

Brands and manufacturers interested in joining this pilot program may submit an expression of interest by emailing: greenmetrics@wefundamentally.com

TEXTILCOLOR AG, a leading provider of innovative textile chemicals, has announced the acquisition of Sevelen-based Schoeller Technologies AG from Schoeller Textil AG. With this strategically important step, TEXTILCOLOR strengthens its position in the international market, expands its technology portfolio and creates new development capacities for future-oriented textile and chemical solutions.

Schoeller Technologies AG will be integrated into the new “Brand Management” business unit of TEXTILCOLOR AG. Schoeller Technologies AG was previously responsible for the global licensing and marketing of textile technologies developed by Schoeller Textil AG. With its international experience, strong network and deep application expertise in the field of functional and protective textiles, the company has established itself as a reliable partner to numerous brands. With the integration into TEXTILCOLOR AG, the marketing of these technologies will be continued – under a new brand identity of TEXTILCOLOR AG.

“The acquisition is a consistent milestone in our long-term growth strategy,” explains Detlef Fischer, CEO of TEXTILCOLOR AG. “With Schoeller Technologies, we are not only gaining renowned technologies, but also a highly qualified

team with unique expertise. We will continue to develop and refine the products manufactured to date in this partnership in order to continue to provide our customers with future-oriented and sustainable technologies.”

Hans Kohn, former Chief Operating Officer of Schoeller Technologies AG and new Head of Brand Management, adds: “Both companies share a common vision: the development of high-performance, sustainable and innovative textile solutions for a responsible future. Existing partnerships and customer relationships of Schoeller Technologies AG will be continued in the usual high quality, the established partner network and strengthened by the expanded possibilities of TEXTILCOLOR.”

Since the beginning of the year, Oerlikon Textile Inc. has been offering a crimper repair service, making it the company's first location worldwide to do so. The workshop in Charlotte, USA specializes primarily in Fleissner and Neumag crimpers.

Crimping is one of the most important and demanding steps in the staple fiber process. A uniform and stable crimp is crucial for optimum product quality. This makes it even more important to keep the essential components in good condition and repair them promptly to prevent production downtime.

In addition to the right equipment, this precise work also requires appropriate specialist personnel. Oerlikon Textile Inc. has built up a competent team at its Charlotte site, which offers a complete overhaul including pressure roller and chamber repairs, as well as checking the pneumatic, hydraulic, and electrical systems. Each crimper is delivered pre-set and undergoes a thorough test run. These services are, of course, also covered by a warranty. “With this new

service, we can work closely with our customers and guarantee the best service with OEM standards and short response times,” says Daniel Möller-Langmaack, Team Leader Service Sales Staple Fiber at Oerlikon Neumag. “This repair center is another important step in helping our customers to be successful and profitable in their business,” adds Tilmann Seidel, Vice President and Head of Customer Services at Oerlikon Neumag.

Since 2025, the Swiss Oerlikon Group has been operating its manmade fibers business as a subsidiary under the traditional name Barmag. This includes the established product brands Oerlikon Barmag, Oerlikon Neumag and Oerlikon Nonwoven. As a future-oriented company, the research and development of Barmag is driven by energy-efficiency and sustainable technologies (e-save).

Barmag is one of the leading providers of manmade fibers filament spinning systems, texturing machines, BCF systems, staple fibers systems and solutions for the production of nonwovens. Together with its range of polycondensation and extrusion systems and their key components, Barmag caters

to the entire manufacturing process, from the monomer all the way through to the textured yarn, and supports it with customer-oriented engineering services. The product portfolio is rounded off with automation and digital solutions. In addition, Barmag offers high-precision gear metering pumps for the textile industry and other sectors, including the automotive, chemical and paint industries.

The main markets for the Barmag product portfolio are in Asia, particularly China, India, Türkiye. The USA is another significant market. Worldwide, Barmag –with round about 2,500 employees – has a presence in 120 countries with production, sales and distribution and service organizations. At the Research and Development centers in Remscheid, Neumünster (Germany), and Suzhou (China), highly qualified engineers, technologists and technicians develop innovative and technologically leading products for tomorrow’s world.

Oerlikon (SIX: OERL) is a global leader in surface technologies. Headquartered in Pfäffikon, Switzerland, the Group has a global presence with over 12 000 employees across 199 locations in 38 countries, achieving sales of CHF 2.4 billion in 2024.

SANITIZED AG, a global leader in hygiene function and material protection technologies, and Rudolf Holding SE & Co. KG, a leading global specialty chemical company, are pleased to jointly announce a new exclusive distribution partnership. Effective February 1, 2026, RUDOLF will become the exclusive distributor of Sanitized® textile additives worldwide. A transition period will begin on September 1 2025, during which both the current and new distributors will ensure continuity of supply and support to customers.

This strategic collaboration brings together two family-owned companies that share common values: a deep commitment to customer proximity, a sustainable business mindset, and the ambition to drive game-changing innovation in the global textile industry. With SANITIZED’s trusted expertise in hygiene management and odor control and RUDOLF’s world-leading capabilities in textile finishing, the partnership unites two highly competent and respected industry players in service of the global textile industry.

The shift comes at a time of increasing market complexity. Evolving customer requirements, trade barriers, and structural overcapacity are placing new demands on the industry. In response, SANITIZED and RUDOLF are joining forces to deliver even greater value through close collaboration, global availability of products and technical support, and ongoing innovation aligned with the latest technological and sustainability standards.

With more than 2,000 employees, 18 production sites, and 50 sales offices across Europe, Africa, the Americas, and Asia, RUDOLF offers market access and customer support at a global scale. Its “One-Phase to the Customer” mindset ensures that service, technical consulting, and customer needs are handled with a seamless, integrated approach.

“We are very much looking forward to working with our new distribution partner,” said Michael Lüthi, CEO of SANITIZED. “RUDOLF shares the same long-term values as SANITIZED – a deep commitment to partnership, trust, and delivering added value to the textile industry. Together, we are ready to take

the next step in serving our customers worldwide and striving to be the industry’s preferred partner.”

Marcos Furrer, CEO of RUDOLF, added: “With over a century of experience in textile chemistry, we deeply value the importance of trusted partnerships and staying close to the customer. This new exciting collaboration with SANITIZED is a strong strategic fit that allows us to combine technical excellence with a shared ambition to use our common understanding of customer’s needs. We are thrilled to embark on this journey together.”

Customers will benefit from global availability, strong local support, and broad range of trusted high-quality products. The Sanitized® Seal of Confidence further builds consumer trust and helps customers differentiate their offerings, showcasing proven effectiveness and lasting product reliability. Sanitized® technologies will be available through RUDOLF from September 1, 2025, onward. As of February 1, 2026, RUDOLF will assume full exclusive distribution rights.

Collaborating with the University of Fukui’s Fukumira Design Factory

YKK Corporation (Headquarters: Chiyoda-ku, Tokyo; President: Koichi Matsushima; hereafter, YKK) provided zippers to the University of Fukui’s Fukumira Design Factory for its booth at the “Science: Connecting You to the Future” exhibit (sponsored by the Ministry of Education, Culture, Sports, Science and Technology), which took place at the Expo 2025 Osaka, Kansai, Japan between August 14 -19.

At the Fukumira Design Factory booth, visitors experienced a simulated future envisioned by supercritical fluid technology, where the patterns on their clothing were decolorized and re-dyed into new designs using this advanced technique. As a product related to this technique, YKK provided zippers dyed with ECO-DYE® technology. ECO-DYE® dyeing technology utilizes carbon dioxide in a supercritical fluid state to reduce the amount of water consumed in the dyeing arrangements assembly to almost zero, making it possible to significantly reduce water consumption due to dyeing.

Under the YKK Philosophy of the CYCLE OF GOODNESS® – No one prospers without rendering benefit to others – YKK contributes to the

realization of a sustainable society through the development of sustainable products and technologies.

“Science: Connecting You to the Future” Overview

The Fukumira Design Factory exhibited at the EXPO Exhibition Center WASSE North located on Yumeshima for

Expo 2025 Osaka, Kansai, Japan. This event, sponsored by the Ministry of Education, Culture, Sports, Science and Technology, ran from Thursday, August 14, to Tuesday, August 19, 2025, with daily hours from 10 AM to 7:30 PM, except for the final day when it concluded at 6 PM. Fukumira Design Factory's booth was situated in the “Connect with the Earth” Zone.

Archroma, a global leader in sustainable specialty chemicals, has entered into a strategic collaboration with Veermata Jijabai Technological Institute (V.J.T.I.), Mumbai, to advance research and innovation in green chemistry and sustainable technologies. This strategic partnership brings together industry expertise and academic excellence to tackle some of today’s most pressing environmental challenges.

The collaboration focuses on pioneering research and development in green chemistry, emphasizing the design of safer chemicals and cleaner industrial processes. Key areas of innovation include renewable energy solutions such as biofuels and hydrogen technologies, and the development of sustainable materials like bioplastics, advanced composites, and nanomaterials.

Water treatment is also a major area of focus, with initiatives targeting advanced wastewater recycling and the recovery of valuable resources. In parallel, education and training programs are being developed to raise awareness about sustainable practices and to equip the next generation of engineers and scientists with the tools needed to drive lasting change.

As part of this partnership, VJTI is launching a new course, “Sustainability: Industry Perspectives for a Greener World,” developed in close collaboration with Archroma. The syllabus seamlessly integrates academic principles with realworld industry applications, offering students a comprehensive framework on sustainability. Topics include waste management, greenhouse gas emission measurement and ESG compliance. By incorporating theoretical concepts alongside industry case studies, the course is designed to equip students with

the technical and decision-making skills needed to lead sustainable transformation across sectors.

“We are proud to partner with V.J.T.I. in this bold initiative to push the boundaries of green chemistry and sustainable technologies. At Archroma, sustainability is not just a commitment— it’s at the core of how we innovate and operate,” said Anjani Prasad, VP South Asia, Archroma. “This partnership enables us to combine our global industrial expertise with academic excellence to create scalable, science-driven solutions for the environmental challenges facing our industry and planet.”

The partnership also includes a strong industry collaboration component, aimed at accelerating the adoption of sustainable manufacturing practices. This includes the development of life cycle assessment tools, carbon footprint analysis methodologies, and policy advocacy to support the creation of environmentally responsible regulations. Scientific insights generated through the partnership will guide decision-making and promote public awareness.

Community outreach forms a vital part of this initiative, with workshops,

seminars, and local collaborations designed to implement and promote ecofriendly technologies at the grassroots level.

To further strengthen the industryacademia bridge, the collaboration will focus on securing CSR funding, inviting industry leaders for guest lectures, launching student training programs, and modernizing laboratory infrastructure. These steps are expected to drive industry-funded research projects and foster real-world applications of academic research in sustainable industrial practices.

“This collaboration with Archroma strengthens our commitment to innovation in sustainable technologies and opens new avenues for research, real-world application, and student development. We are proud to join forces with a global leader and look forward to setting new benchmarks in industryacademia cooperation,” said Mr. Sachin Kore, Director of V.J.T.I.

Through these multifaceted efforts, Archroma and V.J.T.I. aim to become a model for impactful, sustainable collaboration that delivers tangible environmental and societal benefits.

TEXTILCOLOR AG is pleased to announce the beginning of a strategic and forward-looking partnership between TEXTILCOLOR AG, Switzerland, and Chemdyes Sdn. Bhd., Malaysia.

As part of this collaboration, Chemdyes Sdn. Bhd. will take on the role of official distributor, production site, and agent for TEXTILCOLOR AG in the key markets of Malaysia, Vietnam, Thailand, and Pakistan.

This alliance brings together the innovation-driven excellence of TEXTILCOLOR AG and the strong regional expertise of Chemdyes Sdn. Bhd.

The goal of this partnership is to enhance service quality, streamline product availability, and strengthen technical support for customers in these dynamic and fast-growing textile regions.

By combining Swiss precision with Southeast Asian agility, TEXTILCOLOR AG is confident this partnership will deliver exceptional value, responsiveness, and reliability to the industry.

TEXTILCOLOR AG looks forward to a long-lasting and mutually beneficial collaboration.

About

TEXTILCOLOR AG stands for the development, manufacture, and

distribution of textile auxiliaries, textile dyes, pigments, and optical brighteners. Based in Sevelen, Switzerland, TEXTILCOLOR AG supports its customers with in-depth know-how and technical consulting across all stages of textile production and finishing.

With decades of experience in application technology, product development, and product safety - and a presence in over 50 countriesTEXTILCOLOR AG is a trusted partner for sustainable and innovative solutions tailored to the needs of the global textile industry.

Chemdyes Sdn. Bhd. has established itself as one of the leading companies for textile auxiliaries in Malaysia. The company specializes in high-performance textile chemicals for weaving, pretreatment, dyeing, printing, finishing, optical brighteners, injection printing, and textile coating.

Thanks to its commitment to quality, innovation, and customer service, Chemdyes has built a strong reputation in the regional textile industry. Their local expertise and modern infrastructure make them an ideal partner for expanding the reach of TEXTILCOLOR AG’s premium product range and technical support across Southeast Asia and beyond.

The mechanical engineer has been part of the KARL MAYER team since 2005 and has since made significant contributions to the company’s success in various positions. His varied activities have focused on the areas of logistics and assembly.

Christian Botschek has continuously taken on more responsibility improving the worldwide profitability situation through optimisation and increased customer benefits. He managed the overall assembly and logistics centre at the headquarters in Obertshausen for three years and then, as Chief of Technology, played a key role in the development and expansion of the company’s Chinese site in Changzhou for several years.

In 2023, he became Deputy Managing Director of KARL MAYER China. At the same time, he was also Managing Director of KARL MAYER Technische Textilien GmbH.

In his new position as part of the Management Board of KARL MAYER STOLL

Textilmaschinenfabrik, Christian Botschek is also responsible for assembly, production, and prototype construction, among other things. His primary goal is to achieve a sustainable increase in profitability.

“I want to help make processes more efficient, reduce waste, and sustainably strengthen our performance in production. Our ambition is to work economically successfully – with consistently high customer satisfaction,” says Christian Botschek.

On October 1, 2015 Andreas Wirz joined Crealet AG as a technical specialist. Starting in this initial role, he quickly took on responsibility in the areas of technology, with projects in control engineering and documentation creation, as well as in sales, where he played a key role in quotations, calculations, and customer service.

From the outset, it was clear that he would gradually grow into a potential successor to the company.

With commitment, expertise, and entrepreneurial flair, he quickly progressed: in 2018, he took on the role of sales manager, and later joined the management team. Since 2022, he has held overall responsibility for Crealet AG as CEO and shareholder.

Under his leadership, Crealet has not only been given a new look, but has also successfully advanced the development of its control systems and warp-feeding devices.

In addition, he has strengthened the company’s international market position and placed greater emphasis on personal customer relationships.

Today, Andreas Wirz stands for a clear vision: innovations in electronics and embedded systems that help textile companies worldwide to reliably manufacture the most sophisticated fabrics.

Crealet AG would like to thank Andreas for 10 years of dedication, leadership, and passion, and looks forward to many more years full of ideas, progress, and shared success.

Artificial intelligence has long been part of design: precise, efficient, omnipresent. At the same time, there is a growing desire for the handmade, for intuition and irregularity. It is exactly within this field of tension that the Heimtextil Trends 26/27 unfold: under the central theme of ‘Craft is a verb’, they show how high-tech, and craftsmanship are not contradictory, but open up new creative perspectives together.

Together with the founders of Alcova, Heimtextil presents a trend landscape in which craftsmanship and digital design methods merge. Tangible textures meet generative patterns, natural structures meet algorithmic precision. This does not create a contrast, but rather an interplay: where traditional craft techniques reach their limits, artificial intelligence opens up new possibilities. This gives rise to a new type of player: the techno-craftsman. He does not see digital tools as competition, but as an extension of his toolkit. Heimtextil Trends 26/27 thus address the current challenges of the creative industry: AI streamlines processes but raises questions about control and creative identity. The trends therefore

focus on the lasting importance of craftsmanship – and how AI can meaningfully complement and support it.

‘The Heimtextil Trends 26/27 illustrate how artificial intelligence will change the textile industry and, in combination with craftsmanship, opens up new perspectives. They provide the industry with impulses for sustainable production methods, innovative cooperation models and the development of future-proof business strategies,’ says Olaf Schmidt, Vice President Textiles & Textile Technologies at Messe Frankfurt.

Alcova is not just about material and aesthetic trends. Rather, the curators focus on an attitude towards the mindful use of AI in design, as a complement to human creativity and as a means of relief and inspiration. This perspective also shapes their work: ‘At Alcova, we are drawn to objects and processes that are unexpected, experimental, even a little unruly – yet somehow find their way into our homes,’ explains Valentina Ciuffi from Alcova. ‘What surrounds us each day should provoke, raise questions, and invite conversation. That's why our focus

is on projects that anticipate trends rather than chase them,’ adds Joseph Grima from Alcova.

Six key trends at a glance

Six key trends illustrate how this fusion of craftsmanship and technology is manifesting itself in concrete terms. They open up different perspectives on how AI and manual design will interact in the future.

1. Re: media

Textiles that emerge from the interplay of digital design and handcraft: drawings are first transferred into digital renderings, then converted back into jacquards or hand-embroidered patterns. This results in works that reveal the tension between different media. Motifs inspired by glitches – broken aesthetics, pixelated colour gradients and digitally reworked hand drawings can be expected.

2. Visible co-work

AI provides the designs, humans complete them: in these works, the boundaries between craftsmanship and code become blurred. The design is created using artificial intelligence and is completed through skilled craftsmanship. Examples include digitally embroidered linen, 3D knitted patchwork pieces and generative patterns on classic fabrics.

3. Sensing nature

Nature is the original source of inspiration here. Its forms, rhythms and structures reveal a diversity that is waiting to be decoded. Digital tools take on the role of translators: the rough surface of the ocean is transformed into a textile

grid, while the lichen patterns growing over rocks are turned into decorative motifs through algorithmic processing.

4. A playful touch

At a time when design is characterised by functionality and optimisation, small decorative details are

coming back into focus – not for practical reasons, but for pleasure. A ruffle on an otherwise minimalist curtain, a neon element on a naturalcoloured linen blanket or an unexpectedly placed tassel: such gestures act as deliberate interruptions. They remind us that joy remains an essential part of design – and that textiles can also have humour.

5. Crafted irregularity

Fabrics with knots, irregular dyeing, visible seams and asymmetrical finishes take centre stage. These materials do not hide the craftsmanship but emphasise it – as a conscious counterpoint to the flawless perfection of AI-assisted design.

6. The uncanny valley

Technical elements such as wires, connections and coils are no longer hidden but deliberately displayed and showcased. They appear as visible details and draw the eye to the inner workings of the machine, rather than its flawless surface. This results in designs that reveal what is hidden – and, with their playful expression, unfold something strange, almost alien.

The colour palette of Heimtextil Trends 26/27

The colour palette ranges from downto-earth tones to digital irritation: shades such as sand, clay, soot, olive and tree bark convey stability, materiality and connection. However, this natural calm is deliberately disrupted by sharp, synthetic accents such as acidic green, digital lilac and bright screen blue. These ‘glitches’ create tension and turn the colour scheme into a vibrant statement.

Stand space application is now open for ITMA 2027. The 7-day exhibition will be held at Messegelaende Hannover, Germany from 16 to 22 September 2027. Featuring the theme ‘Co-creating the Future of Textiles’, the exhibition is expected to bring together global leaders and innovators to shape the industry’s future.

Following the success of ITMA 2023 in Milan, leading textile and garment machinery manufacturers are invited to secure their presence early at the industry’s most influential platform to launch their technologies, forge partnerships and grow their businesses worldwide.

Alex Zucchi, President of CEMATEX, owner of ITMA, said: “In 2027, ITMA returns to Hanover after 36 years. More than a platform for the promotion of innovative technologies, it is a turning point in the textile industry. As we evolve from Industry 4.0 to 5.0, we’re not just automating, we’re humanising technology. Together, we’ll accelerate the shift towards a circular economy – one that is built on collaboration, innovation and regeneration.”

Dr. Janpeter Horn, Chairperson of VDMA Textile Machinery Association, said: “We expect to have a strong

presence of VDMA companies as our members are excited that ITMA will be staged in Germany after a long break. Supported by Hanover’s best-in-class exhibition infrastructure, ITMA 2027 will be an excellent platform for them to launch their latest innovations, focusing on efficiency, automation, digitalisation and sustainability.”

The exhibition is expected to gross 200,000 square metres and draw over 1,500 exhibitors. Well known as the Olympics of textile machinery exhibitions, the upcoming edition prepares the industry to meet new challenges and opportunities amidst tighter sustainability regulations and rapidly evolving technological developments. To apply for space, visit www.itma.com.

ITMA 2027 will feature 20 product sectors, encompassing the entire textile and garment manufacturing value chain. One of the sectors is Research and Innovation. Research and educational institutions applying to exhibit in this sector will be able to leverage a CEMATEX grant to defray 50% of their participation costs.

CEMATEX will also be providing a grant to fully subsidise the participation

of up to 20 young companies with innovative products and services for the textile industry. Launched in 2023, 15 companies were selected to participate in the Start-Up Valley.

One of the exhibitors, TreeToTextilea Swedish-based cellulose fibre producer - was delighted with the outcome of their participation. Ida Alnemo, Head of Application & Sustainability, enthused: “ITMA has been a great platform for future collaboration needed to scale breakthrough innovations like ours, to make a positive change in the textile industry in offering better fibres to all.”

Information on the two grants can be found on the exhibition website

More information on ITMA 2027 is also available at the upcoming ITMA ASIA + CITME, Singapore 2025 exhibition which will be held at Singapore Expo from 28 to 31 October 2025. Visit stand H5-D304 to learn more about the exhibition, venue, accommodation options and Hanover city from the ITMA Services team and partners.

The last ITMA exhibition was held in Milan in 2023. It featured the participation of 1,709 exhibitors from 47 countries, and visitorship of over 111,000 from 143 countries.

Texworld Apparel Sourcing Paris returns for its 57th edition at the Paris–Le Bourget Exhibition Centre from 15 to 17 September 2025, offering for the first time a perfect balance between textile manufacturers (Texworld) and clothing manufacturers (Apparel Sourcing). With nearly 1,300 exhibitors from over 35 countries, the Parisian trade shows will present an unmissable sourcing offer, the largest and most diverse in Europe.