DPS World Pakistan 2025

Dates: July 25th to 27th 2025.

Venue: Lahore Expo Centre.

CAITME 2025

Dates: September 9th to 11th, 2025.

Venue: Tashkent, Uzbekistan.

Apparel Sourcing Paris Autumn

Dates: September 15th to 17th 2025.

Venue: Paris

ITMA ASIA + CITME, Singapore 2025

Dates: October 28th to 31st, 2025.

Venue: Expo Centre Singapore.

ShanghaiTex 2025

Dates: November 16th to 19th 2025.

Venue: SNIEC, Shanghai, China.

Textile Asia 2025, Lahore

Dates: November 22nd to 24th 2025.

Venue: Lahore Expo Centre. Textile Asia 2026, Karachi

Dates: December 05th to 07th 2026. Venue: Expo Centre, Karachi.

Heimtextil 2026, Frankfurt

Dates: January 13th to 16th, 2026

Venue: Frankfurt am Main.

FESPA Middle East 2026

Dates: January 13th to 15th 2026.

Venue: Dubai Exhibition Centre.

DOMOTEX Hannover 2026

Dates: January 19th to 22nd 2026.

Venue: Hannover, Germany.

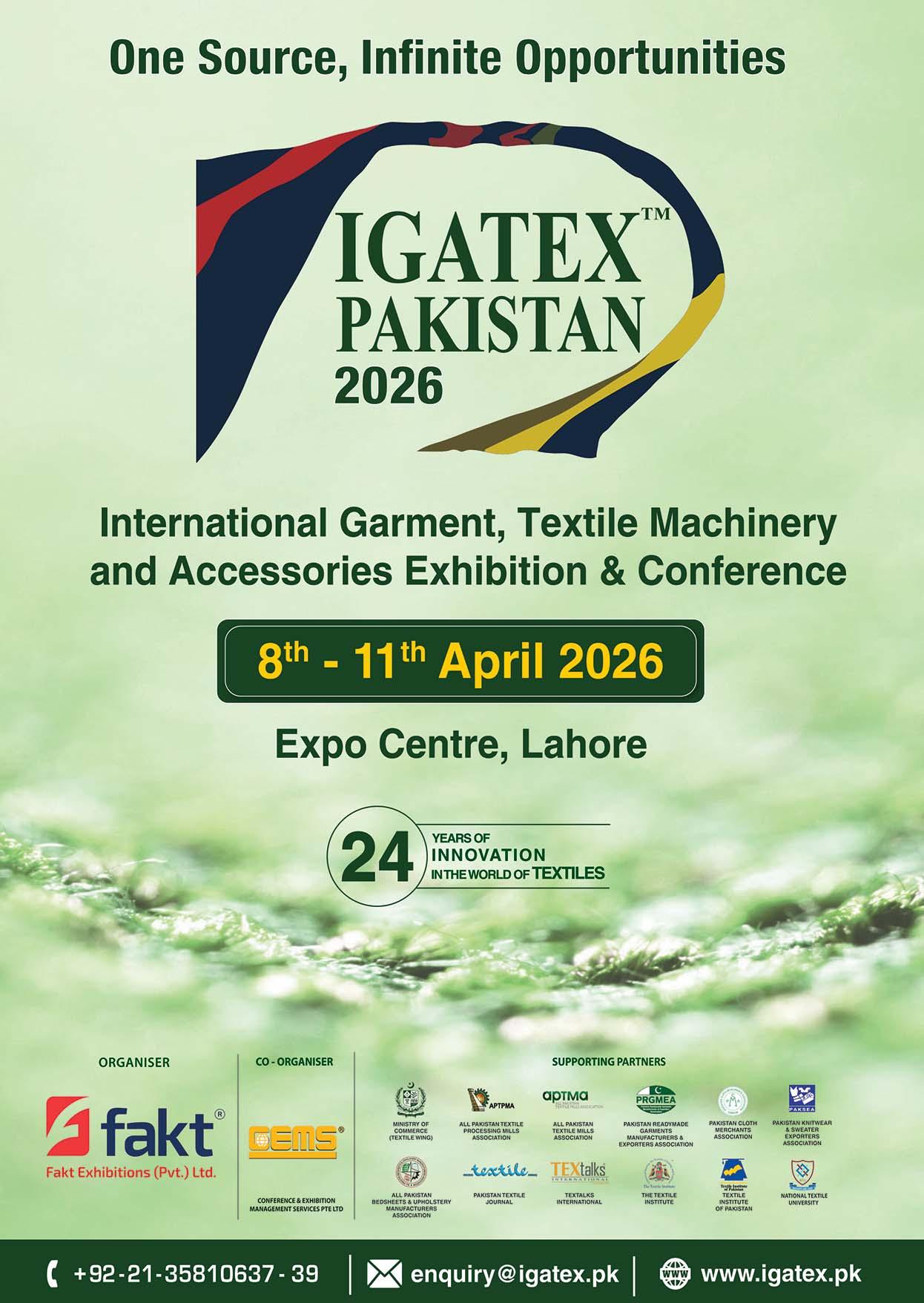

IGATEX Pakistan 2026, Lahore

Dates: April 08th to 11th 2026.

Venue: Expo Centre, Lahore

iCADEX Pakistan 2026, Lahore

Dates: April 08th to 11th 2026.

Venue: Expo Centre, Lahorei. PAKISTAN

Techtextil and Texprocess 2026

Dates: April 21st to 24th, 2026

Venue: Frankfurt, Germany.

Index 2026

Dates: May 19th to 22nd, 2026. Venue: Palexpo, Geneva, Switzerland.

ITM 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

HIGHTEX 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

ITMA ASIA + CITME 2026

Dates: October 20th to 24th, 2026. Venue: NECC, Shanghai, China.

DOMOTEX asiaCHINAFLOOR 2026

Dates: May 27th to 29th 2026.

Venue: NECC, Shanghai, China.

ITMA 2027

Dates: September 16th to 22nd, 2027. Venue: Hanover, Germany.

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager

Mazhar Ali

Layout & Design

Noor M. Jaan

Website / Social Media

Minhaj Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Engr. Naeem Ilyas Khanani

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, United Kingdom.

Registered no. 09141989

Tel: +44 792 2228 721

Available on Gale and Factiva affiliated international databases through Asianet Pakistan

Printed at: Color Plus Korangi, Karachi.

Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

Cotton Incorporated hosts global dialogue in Hong Kong to lead cotton forward . .18 Big Rock Candy Mountaineering first to market with eVent Fabrics’ high performance, PFAS-free alpineST

Register now for The Textile Institute World Conference (TIWC) 2025

.20 YKK makes the switch to 100% low-carbon aluminum for use in aluminum alloy zippers

DyStar receives top honors at 2025 P2K3 Awards for Excellence in Workplace Safety and Health

Heimtextil expands mattress area with strong German brands - ‘Sleep & Meet’ area to be launched in 2026

Rieter to acquire Barmag from OC Oerlikon to accelerate its growth strategy and become a market leader in natural and manmade fibers

Growing with a vision: BRÜCKNER opens branch office in India

Trützschler India relocates to ultra-modern manufacturing plant in Sanand . . .35

All-new Uster AFIS 6 – The indispensable process control instrument

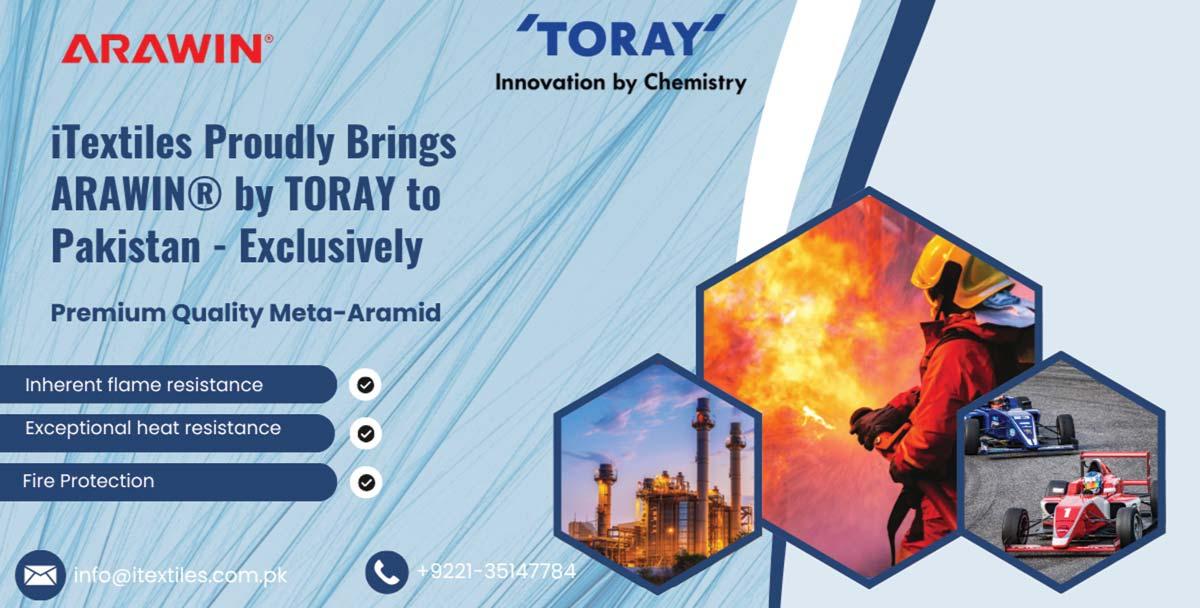

Uster Technologies introduces its new fiber process control system iTextiles® exclusively brings ARAWIN® by Toray to Pakistan

High-Performance Meta-Aramid for Advanced Protective and Industrial Textiles

Trust Protocol achieves sixth year of record growth in enrolled acres and growers, despite challenging growing conditions

Inside EFI Reggiani’s Bergamo Innovation Centre: A firsthand look at sustainable, scalable printing

By Nadeem Mazhar, Pakistan Textile Journal

Ken Hanulec, VP, WW Marketing, EFI talks about ecoTERRA and the future of digital textile printing

Vincenzo Marino, VP, General Manager, EFI discusses EFI’s leadership in sustainable digital textile printing

FESPA 2025 gathers leading visionaries from across the speciality print industry in Berlin .

FESPA 2025 participation report – Spotlight on leading exhibitors

FESPA Foundation: Empowering communities through print

VDMA Joint Industry Meeting 2025: From Fibre to Fashion

Pakistan continues to shine in the global denim market

by Nadeem Mazhar, Managing Editor, Pakistan Textile Journal.

Picanol Group opens new headquarters in Ieper - Prime Minister Bart De Wever in attendance

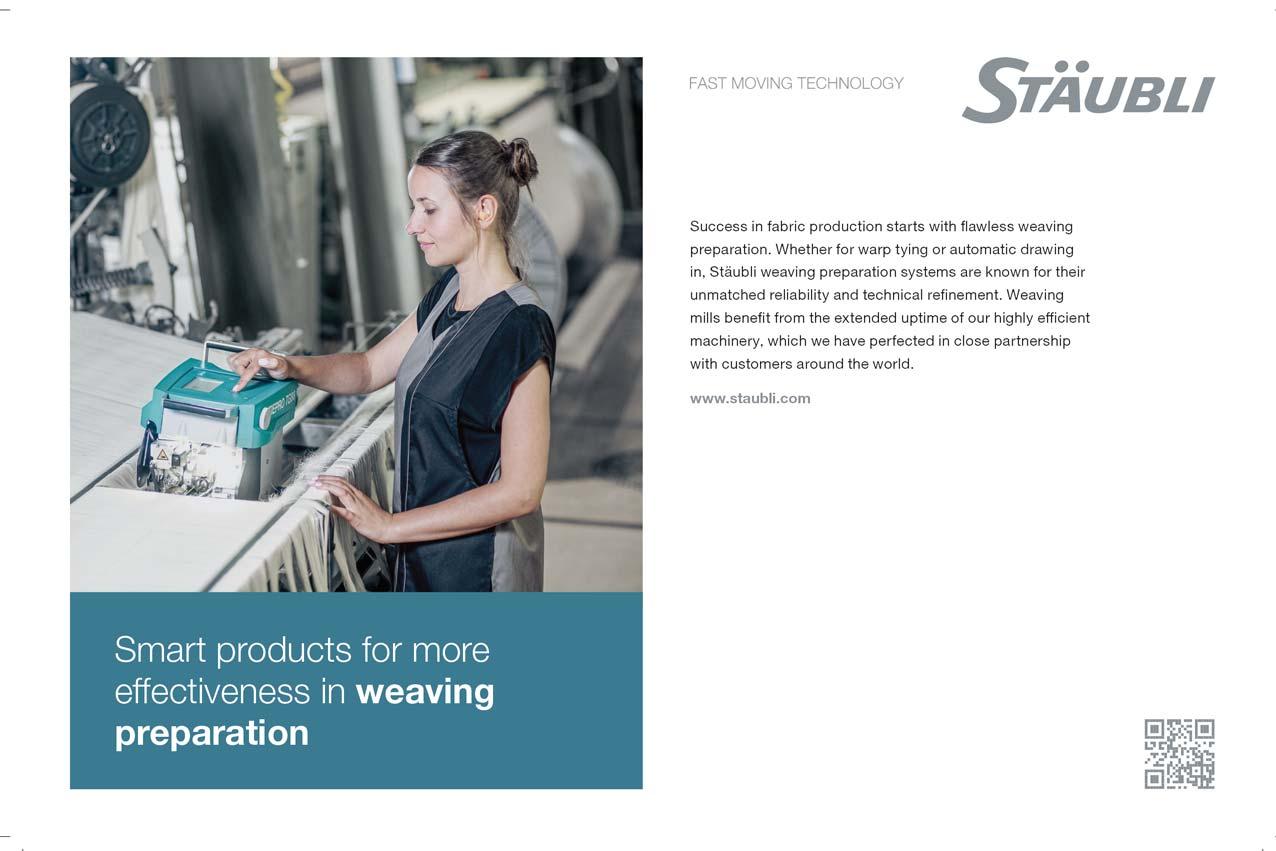

Stäubli weaving solutions for innovative home textiles and garment fabrics

Saurer:

Jeanologia: The global

Picanol:

EDITOR’S PAGE

The June 2025 issue of Pakistan Textile Journal arrives at a time when Pakistan’s textile sector is regaining its footing while contending with global volatility, shifting policy frameworks, and intense regional competition. Encouragingly, April's export earnings of $1.44 billion marked an 11% increase year-on-year, a sign of underlying resilience and strategic repositioning by key players.

This month’s Cover Story takes readers inside EFI Reggiani’s groundbreaking Innovation Centre in Bergamo, Italy. With advanced solutions like the high-speed BOLT XS and the sustainable ecoTERRA pigment platform, EFI is reshaping the future of textile printing. Their approach—combining waterless processing, workflow integration, and high scalability—offers a blueprint for Pakistani manufacturers striving to modernize responsibly and compete globally. Our exclusive interviews with EFI leadership offer deep insight into why speed, sustainability, and digitization are now essential pillars of textile success.

This theme is further amplified through our coverage of FESPA Global Print Expo 2025, held in Berlin. From breakthroughs in pigment and DTF printing to smart automation and personalized production, FESPA made clear that the industry is accelerating toward low-waste, data-driven solutions. For Pakistan, the message is clear: future competitiveness will depend not just on pricing, but on capability, compliance, and climate readiness.

On the home front, IGATEX Pakistan 2025 drew strong participation across the value chain—from machinery suppliers and automation leaders to dyeing and finishing specialists. The exhibition confirmed a renewed appetite for investment in technology, even amid broader fiscal constraints. Of particular note was the strong Italian presence, with renowned brands in weaving, finishing, printing, and technical textiles showcasing their latest advancements. This growing partnership underscores the increasing synergy between Italian innovation and Pakistan’s evolving manufacturing base.

To celebrate this momentum, our July 2025 issue will feature a special Italian Review, highlighting the contributions of Italian machinery makers to Pakistan’s valueadded growth.

However, as stakeholders across the sector continue to emphasize, innovation alone will not be enough. Calls for urgent policy reform—from reinstating the Final Tax Regime to simplifying the Export Facilitation Scheme and ensuring competitive energy pricing— remain central to export-led recovery. Without structural support, many SMEs will find it increasingly difficult to compete in global markets.

Also in this issue, we explore Pakistan’s rising strength in denim exports, cover developments in fiber processing and smart manufacturing, and report on investment trends in Bangladesh, Egypt, and Vietnam—all of whom are making strategic policy choices to boost their global footprint.

Pakistan’s textile industry has shown its ability to adapt, compete, and lead. But this moment demands bold action, shared vision, and sustained commitment from both the private and public sectors. Only then can we convert promise into performance—locally, regionally, and globally.

1Pakistan’s textile industry continued its upward trajectory in April 2025, reporting export earnings of $1.44 billion, an 11.1% increase over the $1.3 billion recorded in the same month last year, as per the latest figures from the State Bank of Pakistan (SBP). The sector also edged slightly higher on a monthly basis, posting a marginal gain of 0.042% over March’s $1.443 billion.For the July–April period of the current fiscal year (10MFY25), cumulative textile shipments amounted to $14.48 billion, representing a 6.8% rise compared to the $13.56 billion logged during the same period last year.

2

Earlier this month, the federal government informed the National Assembly that the United States has introduced a 30% reciprocal tariff on imports from Pakistan, though the measure is currently under a 90-day suspension. The announcement has drawn a mixed response from the business community.

3

Pakistan’s textile sector has the potential to add an immediate $3–4 billionto annual export revenues,provided the government creates a more supportive policy environment, accordingto the Pakistan Textile Council (PTC).

1Australia’s cotton industry has reported a robust upswing in production for the 2024–25 fiscal year, with output of cotton lint projected to hit 1.2 million tonnes—an increase of 12% over the previous year. This growth is underpinned by an expansion in planted area and exceptional crop yields, according to the latest quarterly Australian Crop Report published in June 2025 by the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES).

2

Bangladesh has allocated TK 4.8 billion (approximately $56 million) for the Ministry of Jute and Textile in the

4

Kamran Arshad, Chairperson of the All-Pakistan Textile Mills Association (APTMA), has welcomed the government's recent move to impose an 18% sales tax on imported cotton yarn, calling it a much-needed correction in the country’s textile taxation regime. The measure, he noted, addresses a long-standing imbalance in the market and marks an important step in aligning the Export Facilitation Scheme (EFS) with equitable trade principles.

5The Pakistan Readymade Garments Manufacturers and Exporters Association (PRGMEA) has called on the federal government to introduce targeted policy

reforms in the upcoming national budget to address urgent issues hampering the country’s value-added textile export sector. Representing a $4.9 billion export segment, PRGMEA has submitted detailed proposals to Prime Minister Shehbaz Sharif and Haroon Akhtar Khan, Special Assistant to the Prime Minister on Industries and Production. PRGMEA also recommended the reinstatement of the Final Tax Regime (FTR) to simplify tax filing, eliminate redundant audits, and create a more business-friendly environment—particularly for small and mid-sized exporters.

upcoming fiscal year 2025–26, as revealed by Finance Adviser Salehuddin Ahmed during the national budget announcement earlier this month. Of the total sum, TK 2.32 billion is set aside for operating costs, while TK 2.48 billion will fund development initiatives.

3

Cambodia's garment industry posted robust growth in the first four months of 2025, with clothing exports soaring to $3.14 billion—up 21 per cent compared to the same period last year. This segment alone contributed more than a third (34.4 per cent) of the country’s overall export revenue, which climbed to $9.14 billion, according to figures

released by the General Department of Customs and Excise (GDCE).

4

A delegation representing 25 Chinese textile and apparel companies recently concluded a visit to Egypt as part of efforts to identify strategic investment and collaboration opportunities within the country’s burgeoning textile industry. The group held talks with Minister of Public Business Sector Mohamed Shimy, who outlined Egypt’s robust industrial infrastructure and its appeal as an investment destination.

5

Egypt’s textile and apparel sector is undergoing a dynamic transformation, fuelled by

strategic funding, operational cost advantages, and a government-backed push to enhance industrial infrastructure. Industry experts point to shifting global economic conditions and a sharp rise in foreign direct investment as key catalysts for the sector’s rapid development.

6

Vietnam’s textile and garment industry has maintained impressive momentum in the face of global economic headwinds, achieving over $17.58 billion in export revenue during the first five months of 2025—a 9% increase compared to the same period last year.

Pakistan’s textile industry continued its upward trajectory in April 2025, reporting export earnings of $1.44 billion, an 11.1% increase over the $1.3 billion recorded in the same month last year, as per the latest figures from the State Bank of Pakistan (SBP). The sector also edged slightly higher on a monthly basis, posting a marginal gain of 0.042% over March’s $1.443 billion.

This strong performance comes at a time when other export sectors are grappling with stagnation, further reinforcing the textile sector’s role as the cornerstone of the country’s export economy. In April alone, textile products accounted for more than half—55.3%— of Pakistan’s total exports.

For the July–April period of the current fiscal year (10MFY25), cumulative textile shipments amounted to $14.48 billion, representing a 6.8% rise compared to the $13.56 billion logged during the same period last year.

April’s breakdown by category presents a varied picture. Knitwear maintained its lead in terms of value, generating $360 million, but saw a 5.3% year-on-year decline—suggesting waning demand or intensified price competition in core markets like the EU and the United States.

In contrast, exports of readymade garments climbed to $350 million, a 5.6% increase from the previous year. Industry insiders attribute the growth to the launch of new collections and

stronger buyer interest, particularly from European retailers.

Home textiles also registered significant growth. Bed linen exports surged by 13.4% year-on-year to $270 million, a trend likely driven by seasonal inventory restocking in Western markets. While detailed figures were not disclosed for towels, cotton fabrics, and other highvalue segments, these too were reported to have made positive contributions.

Multiple factors are supporting the textile sector’s rebound. Macroeconomic conditions have shown signs of stabilization, the rupee has firmed up, and international freight rates have dropped. At the same time, falling cotton prices globally have eased input cost pressures for manufacturers.

Textile exporters have welcomed consistent power supplies and faster sales tax refunds, both of which have historically posed major operational hurdles. Despite these gains, industry

leaders continue to call for competitive energy pricing to maintain momentum, particularly against rivals in South and Southeast Asia.

Looking toward the end of the fiscal year, exporters remain cautiously optimistic. With just two months remaining, the sector is aiming to push total exports closer to—or beyond—the $17 billion mark. Anticipated pre-holiday orders from Western buyers and ongoing government policy support could help realize that target.

Nevertheless, the path forward is not without challenges. Exporters remain wary of a potential slowdown in global demand, intensifying competition from countries like Bangladesh and Vietnam, and the possibility of reduced domestic subsidies due to fiscal tightening.

Earlier this month, the federal government informed the National Assembly that the United States has introduced a 30% reciprocal tariff on imports from Pakistan, though the measure is currently under a 90-day suspension. The announcement has drawn a mixed response from the business community.

While many Pakistani exporters view the tariff as a hurdle to market access, others see a potential silver lining. Some believe that higher duties on competing countries may open up space for Pakistan to strengthen its export position in the US market.

Commerce Minister Jam Kamal, in a written statement responding to a query from lawmaker Mirza Ikhtiar Baig, confirmed the temporary suspension of the US tariff and acknowledged industry concerns. To address the situation, the prime minister has established a Steering Committee and a dedicated working group to evaluate the economic impact and formulate a strategic policy response. The Ministry of Commerce is actively consulting with stakeholders across government departments and the export sector to frame a coordinated approach for dialogue with Washington.

Data presented in the Assembly highlighted that Pakistan enjoyed a trade surplus with the US in the last fiscal year.

In FY 2023–24, Pakistan exported $5.3 billion worth of goods to the US, while imports stood at $2.2 billion, resulting in a $3.1 billion surplus. From July 2024 through March 2025, exports totalled $4.4 billion against imports of $1.9 billion. Key exports included garments, medical instruments, and PET-grade plastics, whereas major imports from the US consisted of cotton, steel scrap, petroleum products, computers, soybeans, and almonds.

Separately, during the session, Parliamentary Secretary for Commerce Zulfiqar Ali Khan responded to a question from Sharmila Faroqui by announcing that a new textile policy is on the horizon. Expected to be revealed within the next few months, the policy may propose an exemption from the current 11% sales tax on domestically produced cotton—a move aimed at stimulating local production and supporting the textile value chain.

Khan further noted that exports of value-added textile products have climbed by 35% over the past five years, reflecting growth in the country’s textile manufacturing and export capabilities.

Pakistan’s textile sector has the potential to add an immediate $3–4 billion to annual export revenues, provided the government creates a more supportive policy environment, according to the Pakistan Textile Council (PTC).

The statement was made by PTC Chairman Fawad Anwar during a recent meeting with Federal Minister for Commerce Jam Kamal Khan. Anwar was accompanied by Asif Tata, Chairman of the Naveena Group, and PTC CEO Muhammad H. Shafqaat. The discussion centered on key enablers for the growth of textiles and apparel exports, including tax and tariff adjustments, energy pricing reforms, and incentives for green investments.

Commerce Minister Jam Kamal reaffirmed the government’s commitment to bolstering export-oriented industries in the upcoming federal budget. He noted that efforts were underway to achieve tariff parity with regional competitors.

“A framework for long-term tariff rationalisation is already in motion, with a dedicated committee led by Finance Minister Muhammad Aurangzeb,” he said.

He further acknowledged the need for gradual adjustments, adding, “While reductions will take time, our goal is clear—supporting industrial growth remains a top priority.”

Key issues raised during the meeting included the need for regionally competitive energy rates, the effective deployment of the Export Development Fund, and the swift disbursement of outstanding claims under various government incentive schemes.

The PTC also advocated for the introduction of Green Credit Schemes, aimed at helping textile manufacturers meet evolving global sustainability benchmarks and accelerate progress on industrial decarbonization. The delegation highlighted the sector’s ongoing transition to renewable energy sources such as solar, biomass, and wind, stressing that continued government backing is essential to sustaining this shift.

Minister Kamal reiterated the administration’s intention to tailor economic policies to meet the needs of the export sector. “We must empower the formal industry to grow, invest, and drive industrial expansion—that’s the key to sustainable economic progress,” he remarked.

Kamran Arshad, Chairperson of the All-Pakistan Textile Mills Association (APTMA), has welcomed the government's recent move to impose an 18% sales tax on imported cotton yarn, calling it a much-needed correction in the country’s textile taxation regime. The measure, he noted, addresses a longstanding imbalance in the market and marks an important step in aligning the Export Facilitation Scheme (EFS) with

equitable trade principles.

“This is a positive signal that the government is serious about fostering a fairer domestic supply chain,” Arshad said, emphasizing the association’s support for the initiative. However, he cautioned that while the adjustment is a step in the right direction, it falls short of addressing deeper structural issues threatening the sustainability of the textile value chain. Arshad highlighted that the spinning sector has already endured significant setbacks due to past policy misalignments, and now the ripple effects are threatening to destabilize downstream sectors such as weaving.

Under the current EFS framework, imported raw materials for export are zero-rated, while domestically produced inputs continue to carry an 18% sales tax — a disparity that disadvantages local producers. APTMA has called on the government to close this gap by applying the 18% sales tax uniformly across all yarns and fabrics — whether cotton or polyester — imported under the EFS.

The association has also proposed that these imports be added to the EFS Negative List, thereby subjecting them to a 5% customs duty on yarn and an 11% duty on fabric. Such a step, it argues, would restore competitive neutrality and stimulate domestic production capacity rather than discouraging it.

Particularly alarming, Arshad pointed out, is the case of polycotton and polyester yarns, which already cost around 35% more to produce locally.

Granting tax-free status to their imported counterparts, while continuing to tax domestic production, undermines investment confidence and derails the goal of industrial self-reliance.

APTMA further urged the government to eliminate the 18% sales tax currently levied on cottonseed and cottonseed cake — essential byproducts used predominantly in livestock feed. These items are exempt from sales tax in virtually all major cotton-producing nations. The present tax structure, the association warned, is financially unsustainable for farmers and risks prompting a shift toward water-intensive crops, aggravating both environmental and economic vulnerabilities.

While APTMA acknowledged and appreciated the government’s broader economic stabilization efforts — including reductions in energy tariffs to around 11 cents per kWh, a significant drop in interest rates from 22% to 11%, and notable progress in taming inflation — the association stressed that more comprehensive policy alignment is urgently required.

The Pakistan Readymade Garments Manufacturers and Exporters Association (PRGMEA) has called on the federal government to introduce targeted policy reforms in the upcoming national budget to address urgent issues hampering the country’s value-added textile export sector. Representing a $4.9 billion export segment, PRGMEA has submitted detailed proposals to Prime Minister Shehbaz Sharif and Haroon Akhtar Khan, Special Assistant to the Prime Minister on Industries and Production.

In a letter shared on behalf of the association, former PRGMEA Chairman Ijaz A. Khokhar outlined six priority areas requiring immediate attention: the reinstatement of the Export Facilitation Scheme (EFS) and Final Tax Regime (FTR), engagement with U.S. trade authorities over high tariffs, resolution of refund backlogs, preparation for the upcoming GSP+ review, and the initiation of a nationwide “Made in Pakistan” branding campaign.

Khokhar stressed that Pakistan’s value-added textile sector is facing critical headwinds just as global buyers are actively diversifying supply chains beyond traditional sourcing destinations. He warned that without swift, focused action, the country risks missing a window of opportunity to expand its global market share. Policy continuity, SMEcentric incentives, and reduced business costs are vital to achieving Prime Minister Shehbaz Sharif’s vision of reaching $100 billion in exports, he added.

A key concern raised by PRGMEA is the dilution of the original EFS framework, which exporters say has become overly restrictive, especially for SMEs operating on Just-inTime (JIT) and Never-Out-of-Stock (NOS) models. Khokhar argued that recent changes have hindered flexibility and increased compliance burdens. He urged the government to restore the EFS in its original form to ensure it remains a facilitative tool rather than a barrier.

He also cautioned against imposing any form of sales tax within the EFS mechanism, noting that it could lead to duplicate taxation and financial strain for exporters already navigating thin margins and high operating costs.

Addressing recent demands from certain textile subsectors to remove fabric and yarn from EFS coverage, Khokhar pointed out that such materials are often not manufactured domestically to international specifications. Many exporters are required by international buyers to source specific technical fabrics and yarns from approved suppliers abroad. Any restrictions on these inputs would severely limit Pakistan’s ability to meet global quality benchmarks, he said.

PRGMEA also recommended the reinstatement of the Final Tax Regime (FTR) to simplify tax filing, eliminate redundant audits, and create a more business-friendly environment—particularly for small and mid-sized exporters.

The association further called for the implementation of a fully automated and time-bound refund mechanism. Khokhar noted that chronic delays in the disbursement of sales tax refunds and customs rebates continue to disrupt cash flows and operations, especially for SMEs.

To support long-term growth and improve global visibility, PRGMEA proposed a robust “Made in Pakistan” marketing initiative under the Ministry of Commerce. The campaign would include participation in international trade shows, B2B matchmaking, and digital promotion through Pakistani embassies abroad.

Australia’s cotton industry has reported a remarkable upswing in production for the 2024–25 fiscal year, with output of cotton lint projected to hit 1.2 million tonnes—an increase of 12% over the previous year. This growth is underpinned by an expansion in planted area and exceptional crop yields, according to the latest quarterly Australian Crop Report published in June 2025 by the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES).

The total area dedicated to cotton cultivation has expanded by an estimated 10%, reaching 519,000 hectares. This marks a 30% increase compared to the decade-long average up to 2023–24, with Queensland driving much of this rise. A combination of abundant water resources and higher-than-usual rainfall across eastern Australia has led to yield levels well above historical averages— bringing overall production figures to 54% above the 10-year benchmark.

In Queensland, summer cotton yields are expected to be among the highest ever recorded, despite some setbacks caused by intense rainfall in certain regions. These weather patterns supported a notable rise in planted area, which jumped 33% to approximately

162,000 hectares. As a result, Queensland’s lint production is forecast to climb by 40% year-on-year to reach 410,000 tonnes.

Meanwhile, cotton output in New South Wales has remained relatively stable at an estimated 782,000 tonnes, maintaining a strong position at 51% above the 10-year average. The area under cultivation in the state stands at 336,000 hectares—largely unchanged from the previous year, yet still significantly higher than historical trends.

The state's production benefitted from favourable growing conditions, with irrigated cotton supported by ample water supplies and dryland cotton receiving timely spring rainfall and good soil moisture levels. These optimal

environmental factors have helped both Queensland and New South Wales consolidate their roles as Australia’s primary cotton-producing regions during the fiscal year.

Bangladesh has allocated TK 4.8 billion (approximately $56 million) for the Ministry of Jute and Textile in the upcoming fiscal year 2025–26, as revealed by Finance Adviser Salehuddin Ahmed during the national budget announcement earlier this month. Of the total sum, TK 2.32 billion is set aside for operating costs, while TK 2.48 billion will fund development initiatives.

In comparison, the revised budget for the current fiscal year (FY25) had earmarked TK 4.98 billion for the ministry.

The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) welcomed key elements of the new budget, particularly the government’s move to maintain the current export source tax and industry corporate tax rates. The association highlighted this as a timely support measure amid mounting pressures on the country’s readymade garment (RMG) industry.

Challenges such as the imposition of retaliatory tariffs by the US, halted transhipments from India, elevated bank lending rates, rising labour costs, and frequent hikes in utility prices have all strained the sector. The BGMEA noted that the decision to maintain existing tax levels will offer some relief.

The proposed budget also outlines a 10 per cent reduction in the cost of electricity generation, aiming to lower government subsidies in the power sector over time. Importantly, the authorities have opted against increasing electricity prices in the near term to help curb inflation—a move the BGMEA considers highly favourable for industrial sustainability.

Cambodia's garment industry posted robust growth in the first four months of 2025, with clothing exports soaring to $3.14 billion—up 21 per cent compared to the same period last year. This segment alone contributed more than a third (34.4 per cent) of the country’s overall export revenue, which climbed to $9.14 billion, according to figures released by the General Department of Customs and Excise (GDCE).

From January to April 2025, the shipment of knitted garments and related accessories generated $1.95 billion in revenue, reflecting a growth of nearly 20 per cent. At the same time, exports of woven garments and accessories surged by 22.9 per cent to reach $1.19 billion.

April 2025 figures reinforce the upward trend. Knitted apparel exports grew by 31.3 per cent to $486 million, compared to $370 million in April 2024. Woven garments also saw a notable rise, increasing by 27 per cent to $223 million during the month.

On the import side, Cambodia brought in $1.08 billion worth of knitted or crocheted fabric between January and April 2025, marking a 20.9 per cent increase from the same period last year. Purchases of man-made fibres stood at $486 million, up 12.4 per cent, while imports of cotton and cotton yarn reached $259 million— an 11.2 per cent rise.

For context, Cambodia’s apparel exports totalled nearly $9.8 billion in 2024—an impressive 24.4 per cent jump from the previous year. That total included $6.64 billion from knitted garments and $3.15 billion from woven ones. Meanwhile, imports that year amounted to $3.08 billion for knitted fabric, $1.35 billion for synthetic fibres, and $766 million for cotton and yarn.

In contrast, 2023 had seen a downturn in garment exports, which dipped by 12.9 per cent to $7.87 billion, following a strong 12.7 per cent growth in 2022 when the industry reached $9.04 billion in total export earnings.

A delegation representing 25 Chinese textile and apparel companies recently concluded a visit to Egypt as part of efforts to identify strategic investment and collaboration opportunities within the country’s burgeoning textile industry. The group held talks with Minister of Public Business Sector Mohamed Shimy, who outlined Egypt’s robust industrial infrastructure and its appeal as an investment destination.

During the visit, the delegation was introduced to a wide range of premium textile products manufactured by Egypt’s Cotton, Spinning, Weaving, and Garments Holding Company. These included yarns, fabrics, ready-made garments, home textiles, and specialized medical textiles. The discussions reflected a shared interest in strengthening ties between Chinese manufacturers and Egyptian state-owned enterprises.

The engagement is part of Egypt’s broader push to rejuvenate its textile sector through infrastructure upgrades and strategic partnerships. A key component of this strategy involves the development of two comprehensive textile hubs in Minya and Fayyoum. These industrial cities are being designed to house the full value chain—from raw material processing to finished garments—under one roof.

Among the most ambitious projects is a $9 billion textile and apparel manufacturing complex being established by Chinese firm Ningxia Mankai. Spanning more than 3 million square meters, the mega-site is expected to accommodate around 600 factories, significantly enhancing Egypt’s manufacturing capacity and creating thousands of jobs.

Egypt’s ongoing efforts to modernize its production ecosystem, improve logistics, and maintain cost-effective labour have positioned the country as a competitive alternative for global textile production. The deepening engagement with Chinese stakeholders is poised to accelerate technological advancement, expand export output, and reaffirm Egypt’s role as a textile powerhouse in the Middle East and Africa.

Egypt’s textile and apparel sector is undergoing a dynamic transformation, fuelled by strategic funding, operational cost advantages, and a governmentbacked push to enhance industrial infrastructure. Industry experts point to shifting global economic conditions and a sharp rise in foreign direct investment as key catalysts for the sector’s rapid development.

Affordable utility costs are playing a significant role in attracting international textile firms. Electricity rates stand at an average of $0.07 per kilowatt-hour, while water prices range from $0.30 to $0.50 per cubic meter. Construction expenses remain highly competitive, further strengthening Egypt’s appeal as a manufacturing destination.

Major global brands are capitalizing on these benefits, either launching new operations or scaling up existing production in the country.

Government support has been instrumental in this industrial upswing. The launch of ten dedicated textile zones, covering more than six million square meters, is expected to host around 1,250 factories and generate employment for an estimated 1.5 million workers. Foreign investment in the sector has surged,

reaching $5 billion—a strong indicator of international confidence in Egypt’s manufacturing capabilities.

In terms of trade ambitions, Egypt is targeting a rise in textile and garment exports to $1.4 billion by 2025, up from $1.2 billion in 2023. This vision was on full display at the Destination Africa 2024 exhibition in Cairo, where 30 Egyptian manufacturers engaged with more than 250 overseas buyers, underscoring the country’s expanding role on the global textile stage.

Vietnam’s Textile Sector Defies Global Headwinds, Notches $17.58 Billion in Export Revenues

Vietnam’s textile and garment industry has maintained impressive momentum in the face of global economic headwinds, achieving over $17.58 billion in export revenue during the first five months of 2025—a 9% increase compared to the same period last year. Despite persistent market

uncertainties and a slow rebound in global demand, the sector posted a healthy trade surplus of $6.95 billion, with imports totalling $10.63 billion, according to data from the Vietnam Textile and Apparel Association (VITAS).

Trương Văn Căm, vice chairman and general secretary of VITAS, emphasized the industry's ongoing resilience, noting that many companies have adapted to challenges such as geopolitical tensions and fluctuating consumer demand by refining their operations, boosting productivity, and targeting specialized market segments to generate new revenue streams.

Căm also highlighted the evolving U.S. tariff landscape as a double-edged sword, posing risks but also presenting openings for Vietnamese exporters. To hedge against these shifts, he urged local firms to broaden their export horizons and focus on emerging markets with untapped potential.

Drawing on a recent comparative analysis of textile sectors in regional economies—including Bangladesh, Cambodia, Laos, Nepal, China, and Vietnam—Căm pointed out that Vietnamese textile products

outperformed in most categories, trailing behind China only in select areas. He interpreted this as evidence of Vietnam’s increasing influence in the mid- to highend segments of the global textile and apparel value chain.

Still, structural issues persist. Chief among them is the industry’s reliance on imported raw materials, which not only complicates supply chain traceability—a critical factor for qualifying for preferential trade agreements—but also hampers product development and innovation. This dependency, Căm warned, may undermine Vietnam’s competitive edge over time.

Meanwhile, Vietnamese Ambassador to Russia, Đặng Minh Khôi, spotlighted the country’s growing export potential in the Russian market. Describing Russia as the fourth-largest economy in terms of purchasing power parity and a receptive market for Vietnamese garments, Khôi encouraged domestic producers to intensify their presence and engagement in the region.

More than 250 industry leaders convene for insight, collaboration, and business ideas.

In a powerful display of global collaboration, more than 255 industry leaders from 124 companies including over 41 top global brands and sourcing organizations gathered in Hong Kong on May 15 for Cotton ConneXions: Where Innovation Meets Opportunity, a oneday summit hosted by Cotton Incorporated.

The event united the global cotton supply chain to discover innovations, recognize industry contributions, generate business orders, network, and address the challenges and opportunities shaping the fiber’s future amid regulatory shifts and evolving market dynamics.

“Through the Cotton ConneXions event, Cotton Incorporated serves as a convenor of global decision-makers, especially within the dynamic Asian region. We recognize that meaningful progress in the supply chain happens through collaboration. Events like this allow us to bridge innovation and opportunity, while reinforcing our commitment to advancing cotton’s role in a more sustainable, transparent, and

high-performing textile future,” notes William Kimbrell, president & CEO of Cotton Incorporated.

The agenda included forward-looking insights, beginning with opening remarks from President and CEO William Kimbrell, and Chairman of the Board, Marvin Arthur Beyer, Jr. A global market outlook from Mark Messura, senior vice president of Global Supply Chain Marketing at Cotton Incorporated, highlighted the economic and trade shifts impacting cotton’s role in the supply chain. An insightful presentation by Heidi van den Hul, founder of fabriCreation, focused on global compliance impacts. Presentations included a look at Fall/Winter 2026/2027 cotton trends, highlighting preferences among consumers for durable, longlasting fashion.

Next generation dyeing and finishing technologies, strategies for reducing the environmental impact of textile production, and cotton’s role in lowcarbon, plastic-free future were addressed by conference speakers. The event showcased the newly updated Cottonworks.com website, the most

extensive resource for cotton available to the industry.

“Cotton ConneXions is where ideas become action. Whether those ideas come from Cotton Incorporated or our many industry partners, we are proud to serve as a source of inspiration and practical ideas for helping manufacturers, brands, and retailers improve and expand their cotton business,” stated Mark Messura, senior vice president of Global Supply Chain Marketing.

Cotton Incorporated is the research and promotion company for Upland cotton. Funded by U.S. cotton growers and importers of Upland cottoncontaining products, the not-for-profit organization’s mission is to increase the demand for and profitability of cotton. As a resource for the cotton industry, Cotton Incorporated conducts or oversees more than 450 research and educational projects in an average year. Research areas range from the development of agricultural and textile innovations to analyses of commodity and market data.

Made with 100% recycled fabric, a PFAS-free membrane, and C0 DWR, eVent’s alpineST delivers high tech and

eVent® Fabrics, a global leader in breathable waterproof, weatherproof, and windproof fabric laminates, is proud to announce partner brand Big Rock Candy Mountaineering (BRCM) is first-to-market with their high performance, low impact alpineST laminate.

Blending modern materials with inspiration from the early American alpinists, mountaineers, and gear innovators who defined the outdoor style of the 1950s, 60s, and 70s, BRCM’s Dawn Wall Jacket sets the standard for style and performance. Critical to the jacket’s stormproofing, eVent’s alpineST laminate is made with durable recycled materials, a PFAS-free membrane, and C0 DWR finish, proving that brands can embrace cleaner technologies while enhancing performance.

"Our partnership with Big Rock Candy Mountaineering highlights several key trends shaping the future of outdoor apparel,” said Chad Kelly, President of eVent Fabrics. “First, we’re seeing a strong shift toward more sustainable solutions, like our high-performance, lower-impact laminates. Second, there’s a growing movement toward outdoor apparel that draws inspiration from heritage aesthetics and a time when quality, utility, and craftsmanship were paramount. It’s innovative boutique brands like BRCM that are looking both forward and backward to redefine what the next generation of outdoor gear can be.”

The team at BRCM chose alpineST for the Dawn Wall Jacket as this fabric is the first three-layer fabric delivering superior durable waterproof protection with high moisture vapor transfer rate (MVTR) that lasts season after season.

“Our overall brand mission is to take the timeless styles of the golden age of climbing and update them to fit well and last a lifetime. Part of accomplishing this comes with using the latest technical, planet-positive materials where we can, to create performance pieces that look as good as they perform,” said Samuel Hardeman, Founder of Big Rock Candy Mountaineering. “eVent is a natural fit, as they have succeeded where others have failed by blending cleaner tech with first-rate performance. As a result, together we have created a jacket that is perfectly vintage in style and futuristic in fabrication.”

In addition to the expedition-grade, PFAS-free alpineST laminate, the Dawn Wall Jacket features 100% recycled nylon face fabric for added abrasion resistance and a 100% recycled polyester baker fabric for comfort, and increased breathability, two top and side entry pockets, two chest pockets, waterproof zipper, and drawstring hem and hood.

eVent® Fabrics, founded in 1999, revolutionized the industry with the first air-permeable 100% waterproof membrane and continues to innovate high-performance textiles with sustainability in mind. The company is globally recognized for its breathable waterproof solutions and commitment to reliable, high-performance laminates that help users defy the elements™. Trusted by leading brands, eVent® Fabrics sets the standard for performance and striving for sustainability in outerwear, footwear, and accessories.

About Big Rock Candy Mountaineering

Big Rock Candy Mountaineering designs outdoor clothing based on early American alpinists, mountaineers, and gear innovators who defined the outdoor style of the 1950s, 60s, and 70s.

Join global textile professionals in the stunning city of Porto, Portugal, for the 93rd Textile Institute World Conference, held from 7–10 October 2025 at the Porto Palácio Congress Hotel and Spa –a five-star venue in the vibrant Boavista district. Hosted by AQUITEX, this worldclass event promises insight, innovation, and international collaboration.

With the theme “Fibre to Future –Transforming Fashion and Textiles through Sustainability and Digitalisation”, this year’s conference offers a rich programme of keynote lectures, technical sessions, exhibitions, networking events, and an exclusive technical visit to CITEVE – Portugal’s national centre for textile innovation and technology. Delegates will gain insight into pioneering sustainable practices and emerging technologies shaping the industry.

Porto is not just the host city – it’s part of the experience. With its mix of old-world charm and modern flair, Porto

offers a culturally rich and visually captivating setting for TIWC 2025: UNESCO-listed historic centre with winding alleyways, baroque churches, and tiled façades

Douro River cruises with scenic views of hillside vineyards and iconic bridges

World-famous Port wine cellars and tastings along the riverside in Vila Nova de Gaia

A bustling design and textile scene, from traditional craftsmanship to modern fashion studios

A vibrant culinary scene boasting Michelin-starred restaurants, traditional Portuguese taverns, and contemporary eateries showcasing the best of local and international flavours

Excellent connectivity, safety, and a welcoming atmosphere

Conference Venue: Porto Palácio

Congress Hotel and Spa

This five-star hotel is centrally located and offers luxury accommodation, a fullservice spa, rooftop bar, gourmet dining, and direct access to the conference centre. It’s an ideal base to connect, learn, and unwind.

Be part of the global conversation on the future of textiles – in one of Europe’s most beautiful and inspiring cities.

The Textile Institute is the professional body for people and organisations working in the textile, clothing and footwear associated industries worldwide. For more than 110 years, the Institute has been bringing together professionals from all over the world for the exchange of ideas, and a social community promoting friendship among members. It is an international organisation governed by a Council representing members globally.

The Textile Institute is run democratically by and for its members all over the world by the Trustees of the Institute, and representatives from Sections, Special Interest Groups and internal committees.

As a registered Charity with a Royal Charter the role of the Institute is to advance the general interests of the textile industry worldwide, more particularly in relation to the acquisition and application of knowledge for the benefit of mankind.

YKK Corporation (Headquarters: Chiyoda-ku, Tokyo; President: Koichi Matsushima; hereafter, YKK) will begin using only low-carbon aluminum (*1) as the source for all aluminum alloy wire procured for zippers, as part of its initiative to convert all aluminum alloy zipper items to sustainable products.

YKK, together with aluminum material manufacturers Sumitomo Electric Industries, Ltd. (Headquarters: Chuo-ku, Osaka; President: Osamu Inoue), and Sumitomo Electric Toyama Co., Ltd. (Headquarters: Imizu City, Toyama; President Representative Director: Yasuo Yamamoto) agreed to a contract pertaining to the use of low-carbon aluminum. Beginning in FY2024, YKK began purchasing low-carbon aluminum alloy wires for use as materials in aluminum alloy zippers and gradually expanded their application.

YKK has adopted the YKK Sustainability Vision 2050, which sets the sustainability goals for realizing climate neutrality by 2050. The company has

established targets in connection to five themes— climate change, material resources, water resources, chemical management, and respect people—and is working on initiatives to achieve 10 SDGs related to each of these themes. In the key area of climate change, YKK is promoting initiatives to slash its greenhouse gas (GHG) emissions within the company and throughout its supply chain—by 90% for Scope 1 and 2 emissions and by 90% for Scope 3 emissions, compared to FY2018 levels—by 2050, based on the net-zero target outlined by the Science Based Targets (SBT) initiative (*2). Adopting low-carbon aluminum as material for zippers is one of YKK’s initiatives to achieve the reduction target for Scope 3 emissions.

YKK will continue to work with its customers and suppliers to accelerate efforts to reduce GHG emissions by developing and expanding sales of sustainable products and technologies, thereby contributing to the realization of a sustainable society.

Comment from Terry Tsukumo, Vice President, Product Strategy Division, Global Sales Headquarters, YKK Corporation

“YKK has been promoting efforts to use recycled materials and plant-based materials in textile materials for zippers and to increase the ratio of such materials. In addition to these efforts, we will promote the use of low-carbon aluminum made from renewable energy sources,

such as hydropower. Through these efforts, we aim to reduce greenhouse gas emissions and contribute to climate change mitigation by revamping our product lineup, while taking advantage of aluminum's features—its light weight and silver color that is nickel-free and platingfree—and focus on developing products which can be widely used in apparel and luggage applications.”

*1: The aluminum smelting process requires a large quantity of electricity and emits different amounts of carbon dioxide depending on the power source used. The emissions of the low-carbon aluminum to be used for this initiative will be less than 4 metric tons of CO2 per ton of aluminum ingots produced, as it uses renewable energy as the power source. This significantly reduces CO2 emissions compared to using electricity generated from fossil fuels such as thermal power.

*2: The remaining 10% of emissions in the net-zero target must be reduced to zero through carbon absorption and removal, etc.

Dye and processing innovations to be showcased at two of the world’s most influential denim fairs: Denim Première Vision Milan and Denimsandjeans Vietnam

Archroma, a global leader in specialty chemicals, is set to showcase key innovations in denim color and processing to the global denim community at Denim Première Vision Milan on May 21 and 22 and Denimsandjeans Vietnam on June 25 and 26.

Denim has remained a staple in both mainstream and high-end fashion, but traditional manufacturing methods are under increasing scrutiny for their intensive use of water, energy and chemicals.

“With a broad portfolio of textile dyes and chemicals backed by decades of advanced research, Archroma is rewriting the rules for those who love denim. From timeless indigo to trend-driven finishes, we are evolving denim with processing solutions that preserve the fabric’s iconic appeal while minimizing its impact,” Dhirendra Gautam, VP Global Marketing and Strategy, Archroma, said.

Archroma will demonstrate an array of denim innovations at Denim Première Vision Milan and Denimsandjeans Vietnam, headed by DENIM HALO – a unique pretreatment and dyeing process developed to empower mills to produce highly sought-after distressed denim looks with a significantly reduced environmental footprint.

DENIM HALO combines DIRSOL® RD p, a new product for a special/specific yarn pretreatment, with Archroma’s indigo, sulfur or biosynthetic dyes to produce laser-friendly denim with outstanding contrast on intense black and indigo shades – without modifying standard dye recipes or set up. Additionally, the solution reduces yarn shrinkage and improves garment tensile strength, while also saving water and energy, avoiding the use of potassium permanganate, and reducing the need for caustic soda in sulfur dyeing.

Archroma will also be showcasing a brand-new capsule collection at the shows. The collection will present Black

that utilizes Archroma’s DENIM HALO and DIRESUL® EVOLUTION

BLACK and made with premium fabric from Kipas Denim and finished using Jeanologia’s innovative washing technology. The result is a refined, modern take on black denim—combining elevated design with responsible production practices. With DENIM HALO, trade show visitors will explore breakthrough dyestuffs such as DIRESUL® EVOLUTION BLACK, DENISOL® PURE INDIGO 30 and EarthColors®

DIRESUL® EVOLUTION BLACK is Archroma’s cleanest sulfur black dyestuff. Manufactured using fewer resources, it has an overall impact reduction of 57% during dye synthesis compared to standard Sulfur Black 1 liquid.*

DENISOL® PURE INDIGO 30 LIQ is an aniline-free** pre-reduced indigo that creates authentic denim colors with the same performance and efficiency as conventional indigo dye, but in a way that can reduce the risk of pollution. Furthermore, it is produced in an aniline-free** process to help enable cleaner denim production. EarthColors® is a patented Archroma technology that creates high-performance biowaste-based dyes from

non-edible food and agricultural waste, leaving the edible part available for consumption. EarthColors® dyes help reduce the industry’s overall impact on the water footprint. Since they upcycle waste from other industries, they also help contribute to a circular economy.

Meet Archroma denim experts at Denim Première Vision Milan 2025

Held twice a year, Denim Première Vision is a celebration of denim trends, markets and culture. The May 2025 event will present the latest innovations and Autumn-Winter 2026-2027 collections from leading manufacturers and suppliers.

Meet Archroma denim experts at Denimsandjeans Vietnam 2025

Now in its seventh year, Denimsandjeans Vietnam attracts large denim producers from Vietnam and other leading textile manufacturing hubs. The show is organized by Denimsandjeans.com, a website dedicated to the global denim industry since 2007.

* Ecotarrae lifecycle analysis

** Below limits of detection according to industry standard test methods

DyStar, a leading specialty chemical company with a heritage of more than a century in product development and innovation, has been honored with three prestigious awards at the 2025 Provincial Occupational Safety and Health (P2K3) Awards, recognizing its exceptional performance in workplace safety and employee well-being.

The awards were presented by the Banten Provincial Government to PT. DyStar Colours Indonesia – Gabus Plant, the company’s largest manufacturing plant in Indonesia. DyStar received the following accolades:

Platinum Award for Zero Accidents (2018–2024)

Gold Award from the Committee of Occupational Safety & Health Development (P2K3)

Silver Award for HIV & AIDS Prevention Program

Mr. Clement Yang, Vice President of DyStar Global Manufacturing, said, “DyStar is honored to be recognized for our collective commitment to health and safety. This achievement is a testament to

the unwavering dedication of our employees in upholding the highest safety standards as we pursue manufacturing excellence in a safe and responsible environment. Safety is a core value embedded in our global culture— one we consistently uphold across all our operations.”

Mr. Sunarto Djuardi, Regional Vice President for DyStar Southeast Asia, said, “Health and safety have been our highest priority since we commenced production at Gabus in 1997. These awards underscore DyStar’s ongoing commitment to fostering a proactive safety culture, adopting innovative risk management strategies, and maintaining consistent compliance with the highest occupational health and safety standards.”

The Platinum Award was granted in recognition of DyStar’s outstanding achievement of 3.1 million work hours assessed between 2018 and 2024 without a single accident. This remarkable record reflects the company’s disciplined safety culture and its dedication to protecting both employees and contractors.

The Gold Award, presented by the Committee of Occupational Safety & Health Development (P2K3), acknowledges DyStar’s success in maintaining an effective internal safety and health committee at the Gabus Plant, in compliance with national OHS regulations.

DyStar also received the Silver Award for its extraordinary efforts in promoting HIV/AIDS prevention programs in the workplace, reinforcing its commitment to creating not only a safe and pleasant working environment but also one that is inclusive and free from health-related discrimination.

As a company at the forefront of sustainability initiatives, these awards further highlight DyStar’s ongoing investment in employee well-being and strengthen its leadership in the global chemical manufacturing sector.

For further information on DyStar’s global health and safety efforts, please refer to DyStar’s Annual Sustainability Reports.

On the evening of May 31st, 2025, the Beach Luxury Hotel in Karachi transformed into a vibrant arena of creative exploration as MiTE-TMUC hosted its flagship annual fashion and arts event, Vogue Night 2025 – Regalia Reclaimed. This immersive experience celebrated emerging talent at the intersection of fashion, identity, technology, and global consciousness.

MiTE’s transnational education partner, The Millennium Universal Colleges (TMUC), curated the evening in collaboration with leading international academic institutions including the University for the Creative Arts (UCA). The event marked a significant milestone in TMUC’s ongoing commitment to fostering industry-relevant, globally competitive creative education in Pakistan.

This year’s theme, Regalia Reclaimed, invited students to reinterpret symbols of identity, memory, and cultural legacy through creative storytelling. The show combined fashion, performance, film, and digital art to present a layered, multisensory narrative underscoring the evolving role of fashion as a medium of purpose and activism.

The show unfolded across six distinct segments, showcasing over 65 garments designed by graduating students from the 2024–2025 cohorts. Styling and makeup were executed by TRIO, part of the renowned Nabila’s team, ensuring a polished runway presentation. Event

management was led by OHStar, the same agency that successfully managed the 2023 edition.

A total of 21 models walked the runway, including six MiTE students from the Fashion and other departments, reflecting a strong culture of crossdisciplinary collaboration. The remaining 15 professional models were provided by TRIO, including three prominent faces from Pakistan’s fashion industry, adding star power and visibility to the event.

The event opened with a capsule showcase by current students of the Pearson Higher National Diploma (HND) in Art & Design. Their collections addressed pressing global themes,

sustainable design, textile innovation, and cultural reinterpretation demonstrating a mature, research-led design process. Each presentation reflected a commitment to ethical practices and material consciousness, signalling a shift in how the next generation of designers perceive their role in the ecosystem.

The graduating cohort from the University for the Creative Arts (UCA) then took center stage with their final major collections. These works were introspective, emotionally resonant, and technically advanced. From garments inspired by childhood memories and trauma healing to those influenced by botanical ecosystems and celestial phenomena, each collection served as a visual narrative evoking empathy, curiosity, and critical reflection.

The event seamlessly transitioned into the realm of visual storytelling with the screening of “JADU,” a short film by UCA Film & Digital Art student Laiba

Shakeel. Deeply poetic and symbolically rich, the film bridged digital aesthetics with thematic undercurrents of mysticism, displacement, and feminine agency. It offered a contemplative pause, allowing the audience to engage with fashion as an extension of the self—both seen and unseen.

One of the evening’s most moving segments was a tribute performance by student artist Rafeh Sheikh, who seamlessly wove together fashion, performance, sound, and multimedia to honor the enduring resilience of the Palestinian people. The presentation featured garments exclusively designed and printed with motifs inspired by Palestinian architecture and cultural symbolism, transforming the runway into a powerful space of artistic resistance. Met with emotional applause, the performance underscored fashion’s profound capacity to serve as a medium for activism, empathy, and global solidarity.

Amjad – Performed by Kulsoom Aftab

Adding a literary dimension, Ms. Kulsoom Aftab delivered a powerful theatrical tribute to the late Amjad Islam Amjad. Her performance, layered with poetry and dramatic intensity, brought to life the emotional and intellectual legacy of one of Pakistan’s most revered literary icons. It was a moment of cultural introspection and reverence woven seamlessly into the evening’s theme of reclamation.

The final segment featured the University for the Creative Arts Class of 2025, presenting collections under the theme “Designing the Future: Consciousness, Change & Creativity.” Over 27 original looks were unveiled, showcasing avant-garde silhouettes, responsive textiles, and provocative social commentary. The designs ranged from experimental to couture, each contributing to a dialogue on where fashion is headed in a digitized, postpandemic, and environmentally fragile world.

The event was graced by the presence of Madam Sultana Siddiqui, President of HUM TV Network, as Chief Guest. A pioneering figure in Pakistan’s media and entertainment landscape, she praised the students’ work, stating, “The collections we saw tonight speak volumes about the future of fashion in Pakistan, one rooted in culture, yet boldly global in vision.”

Other notable attendees included:

Nadra Panjwani, Chairperson, Karachi Council on Foreign Relations (KCFR) Panutat Yodkaew, Deputy Consul General, Thailand

Nasreen Jalil, Former Senator Madam Shahnaz Wazir Ali, President, SZABIST

Mr. Farooq Sattar, Senior Political Leader

Mr. Amir Chottani, CEO, Chottani Industries & Chairman PRGMEA

Mr. Nadeem Chishti, Head External Affairs & CSR, PARCO Designers and creative icons such as Yousuf Bashir Qureshi (YBQ), Adnan Pardesi, and Zohra Alam Tech and education leaders including Jehan Ara, Dr. Maqsood Ahmed (DIG, Security), Tehmina Khalid (Take II PR)

The event was also attended by senior members of Gul Ahmed and other fashion

brands, the TMUC team, and a host of celebrated individuals from across Pakistan’s creative and industrial ecosystem.

In her closing remarks, Dr. Huma Baqai, Rector of MiTE, highlighted the institution’s strategic vision to merge academic excellence with industry engagement. “Regalia Reclaimed is not just an event it’s a statement of purpose. We believe in empowering students to lead with creativity, consciousness, and courage.”

The event was exclusively covered by HUM News, with additional media presence from Suno TV and 365 News. MiTE and TMUC extended sincere gratitude to all partners and supporters whose presence helped amplify the platform’s mission.

Vogue Night 2025 was not just a fashion showcase, it was a celebration of vision, voice, and values. A space where creativity meets conscience, and where the next generation reclaims regalia not just in style but in substance.

Picture a textile mill where machines work smarter, not harder—saving time, energy, and costs while producing topquality yarn. This vision came to life on April 25, 2025, at the Pearl Continental Hotel in Karachi, where Murata Machinery, Ltd. hosted over 300 industry professionals for a gamechanging seminar.

Setting the Stage

Mr. Syed Abdullah, CEO of Spintex, kicked off the event with heartfelt thanks after a Quran recitation. He celebrated the crowd’s enthusiasm and Murata’s steadfast support for Pakistan’s textile sector, shining a light on how innovation can overcome tough times.

The Stars of the Show

Murata unveiled technologies that promise to transform textile production:

AIcone: The Future of Winding

The AIcone auto winder isn’t just a machine—it’s a partner. With its simple

controls, easy upkeep, and eco-friendly design, it winds yarn at high speeds without breaking a sweat. Paired with Murata’s data system, it keeps mills running smoothly and profitably.

MVS 870EX: Yarn Made Simple

The MVS 870EX vortex spinner turns complexity into opportunity. It cuts production steps, delivering smooth, durable yarns that stand out in the market. Its flexibility and small footprint mean big savings for manufacturers.

MSS: The Power of Insight

The Murata Smart Support system acts like a mill’s brain, offering live data to spot problems, plan maintenance, and save energy. It’s the tool every manager needs to stay ahead.

Mr. Nomura, Murata’s Chief Operation Officer, wrapped up the day with gratitude and optimism. He saluted Pakistan’s textile leaders for their grit and

pledged Murata’s ongoing support through Spintex’s expertise.

The night ended with flair—gifts of MVS yarn shirts, a lively lucky draw, and a delicious dinner that brought everyone together.

Conclusion

More than just a seminar, this was a peek into the future of textiles. With presentations in Urdu and warm hospitality, Murata proved it’s not only about machines—it’s about building a stronger, smarter industry for Pakistan.

Strong new partnerships and optimized participation formats resonate with the industry

Preparations for DOMOTEX 2026 are in full swing, and the positive response to the new concept confirms the relevance of the world’s leading trade fair for carpets, flooring and interior finishing. The newly introduced participation formats, in particular, have been well received by the market. In addition, strong partners such as DECOR-UNION and MEGA have reaffirmed their cooperation with DOMOTEX.

Retailers Park: Successful concept to be expanded

The proven Retailers Park format, which already served as a central meeting point for retailers and craftsmen last year, will be further developed in 2026. With DECOR-UNION and MEGA once again on board, two strong partners will offer a unique platform for networking and industry exchange. A new, craftsmanoriented area called “The Work Shop” will showcase products, techniques, and innovations from Retailers Park exhibitors on a daily basis.

Strong partnerships as a key success factor

One of DOMOTEX’s key success factors is its extensive partner network. By working closely with national and international multipliers, the trade fair continues to expand its global visitor outreach. Several new partnerships have recently been formed, including with the European DIY Retail Association (EDRA), the German DIY, Building and Garden Trade Association (BHB), the Federal Association of Wholesale, Home & Colour (GHF), and the Manufacturers Association for Home & Garden. These collaborations offer exhibitors greater visibility and extend the reach for showcasing innovations and new solutions.

Flexible participation options for every budget

Especially in economically challenging times, many companies need to carefully plan their trade fair participation.

DOMOTEX therefore offers costoptimized participation options for almost all special formats. Whether it's the Wall & Colour Park, Architects Space, DIY Boulevard, or Retailers Park – these formats allow exhibitors to make a strong impression even with smaller, more focused presentations.

“We understand that investments in trade fair participation must be considered carefully. That’s why we’ve developed flexible participation models that make it possible for any company to be part of DOMOTEX – regardless of budget or stand concept. DOMOTEX provides a platform for all those who want to actively shape the future of the market,” says Sonia Wedell-Castellano, Global Director DOMOTEX. She adds: “This makes it all the more important that DOMOTEX delivers compelling, relevant content – topics that matter to the

industry and offer concrete answers to today’s challenges.”

One such topic is the integration of privacy and sun protection systems, which will be a core element of the DOMOTEX 2026 concept. In addition to design aspects, the increasing importance of energy-efficient solutions is coming to the forefront. Modern systems such as blinds, shutters, and smart shading solutions play a key role in optimizing indoor climates by reducing energy consumption for heating and cooling. Given the growing demand for sustainability and energy efficiency, this segment is becoming an essential part of holistic living and working space solutions – a development that DOMOTEX 2026 actively reflects.

With such forward-looking content and a clear thematic focus, DOMOTEX continues to strengthen its role as a trendsetter and source of inspiration for the industry. Thanks to its strategically aligned concept, strong partners, and wide international reach, DOMOTEX maintains its leading market position –and promises to deliver a unique trade fair experience once again in 2026.

Heimtextil, the leading international trade fair for home and contract textiles and textile design, is strategically expanding the Smart Bedding segment. A new exhibitor area will be created for the January 2026 edition: Sleep & Meet. This newly designed format will take up around a quarter of Hall 4.0. Numerous well-known brands from the mattress sector have already registered to take part. With a clear structure and a highquality environment, Sleep & Meet offers bedding retailers, hospitality and volume buyers direct access to relevant companies and industry participants, new product range perspectives and valuable business contacts.

Numerous strong German brands from the mattress sector will be exhibiting at Heimtextil 2026. Wellknown companies such as Auping Germany, Bettwaren Stendebach, Erich Werkmeister, ergomed, Femira,

Rummel and Schwarzwald Schlafsysteme are celebrating their premiere at Heimtextil 2026 and have already registered. The EuroComfort Group with Badenia, Brinkhaus, Lück and fan frankenstolz are setting a special example: both companies are significantly expanding their space at Heimtextil 2026.

‘Heimtextil brings the bedding retailers, hospitality and volume buyers together with relevant brands and high-quality products - and offers the ideal framework for establishing new business relationships, recognising trends at an early stage and gaining fresh inspiration for the product range’, says Olaf Schmidt, Vice President Textiles & Textile Technologies at Messe Frankfurt. ‘We are delighted to be able to provide visitors with a strong and customized offer.’

Trade association Matratzen-Industrie e.V. will be present again

The trade association MatratzenIndustrie is also sending out a strong signal: the association will once again have its own stand at Heimtextil 2026. ‘Heimtextil offers the ideal platform to showcase the innovative strength and diversity of German mattress manufacturers internationally’, explains Martin Auerbach, Managing Director of the trade association MatratzenIndustrie. ‘Our presence is a clear commitment to this platform.’

With the new Sleep & Meet area, the presence of leading German brands and the participation of the trade association MatratzenIndustrie, Heimtextil is strengthening its role as the central platform for the mattress and sleep industry.

Poised to become a global showcase for the garment and ready-to-wear industry, Garment Tech Istanbul Exhibition is set to bring together leading brands that shape the sector under one roof. With its diversity of exhibitors, high-profile visitor portfolio, and substantial business potential, the exhibition promises a unique experience. It will serve as a pulse-check for the industry's ongoing transformation.

Taking place from June 25–28 at the Istanbul Expo Center (IFM), the Garment Tech Istanbul Exhibition for Garment, Embroidery Machinery, Spare Parts, and Sub-Industry will unite the key players of an industry that holds a significant share in Turkiye's exports. Organized under the motto “Innovative Touch to Fashion”, the exhibition will showcase technologies spanning the entire garment production chain—from sewing to cutting, ironing systems to packaging, embroidery to denim.

With its advanced production infrastructure, strong design capabilities, and dynamic workforce, Turkiye’s garment industry will step confidently onto the global stage through the Garment Tech Istanbul Exhibition. Bringing together all stakeholders from across the sector, the exhibition will host existing companies and attract international investors, business partners, and industry professionals.

Garment Tech Istanbul is more than just a product exhibition—it is a platform where new business collaborations will be initiated. Over the course of four days, international investors, manufacturers, suppliers, and brand representatives will engage in face-to-face meetings to establish long-term business connections.

The exhibition offers exhibiting companies the chance to achieve both short-term sales targets and make significant progress in long-term business

development strategies. Decision-makers in the business world will invest in innovations, establish new supply chain partnerships, redefine their production strategies, and explore fresh positioning opportunities in regional markets.

The Garment Tech Istanbul Exhibition will also serve as a stage for innovative machines, automation systems, and sustainable production solutions. Visitors will have the chance to explore the latest advancements in the industry and discover ways to improve operational efficiency. They’ll get hands-on with cutting-edge sewing and embroidery machines, digital automation systems, pressing technologies, cutting automation solutions, and eco-friendly sustainable machinery.

These technologies will enhance production efficiency, reduce energy consumption, and help companies meet sustainability standards more easily. Machines equipped with innovative applications such as artificial intelligence, Internet of Things (IoT), and data analytics will introduce industry professionals to not only today’s but also tomorrow’s manufacturing models. Investors, tech developers, suppliers, manufacturers, and buyers will gain fresh insights that will help steer the direction of the global textile industry.

The Garment Tech Istanbul Exhibition also stands out due to its strategic geographic location. As a bridge between Europe and Asia, Istanbul is highly accessible for global visitors. Its modern transportation infrastructure, worldwide air connections, and visa waiver agreements with many countries significantly ease international participation. Professionals from around the world are already applying online to receive their invitations and join the event to discover the latest technologies and form new business partnerships. Thousands of visitors from over 60 countries—including India, China, Pakistan, Tunisia, Iran, Sierra Leone, Ghana, Germany, Italy, the UK, and Hong Kong—have completed their online registrations. Expected to attract thousands of professional visitors, this event will once again position Istanbul as the epicenter of global garment and ready-to-wear trade.

This vibrant interaction will lead to a better understanding of regional market needs and lay the groundwork for more targeted collaborations. Moreover, participants will enjoy the rich cultural and historical heritage of Istanbul, turning their business trip into a memorable journey. From the stunning Bosphorus view and historic peninsula to world-class cuisine and much more, visitors will complement their professional experience with cultural enrichment.

Portugal

City

Hotel

Join us at the 93rd Textile Institute World Conference (TIWC) 2025, hosted by AQUITEX with industry leaders. This marks the first time a company hosts the event, emphasising collaboration between industry and academia. The theme, “Fibre to Future – Transforming Fashion and Textiles through Sustainability and Digitalisation,” explores how sustainability and digital innovation are reshaping the industry.

This year’s conference will explore cutting-edge approaches to addressing sustainability challenges, from the environmental impact of textile production to the development of circular economies. It will showcase innovative digital technologies that enhance efficiency, transparency, and sustainability across the entire supply chain—from fibre production and manufacturing to consumer use and end-of-life solutions

Invitation letters for visa applications will be provided after registration and payment are completed. Request your invitation letter as soon as you register. For more information, contact Robyn Ingham, senior events coordinator at ringham@textileinst.org.uk

Start making your plans now for TIWC 2025 to ensure you don’t miss out...

Host organisation

Sponsorship Packages

Please visit textileinstitute.org/events/tiwc for more information.

7-10

Early Bird Fees

Non TI Member: EUR €660 (approx. GBP£550.00)

TI Member: EUR €515 (approx. GBP£430.00) These rates are available until 15 June 2025.

Standard Fees

Non TI Member: EUR €800 (approx. GBP£670.00)

TI Member: EUR €660 (approx. GBP£550.00)

Other Fees

TI Representative: EUR €480 (approx. GBP£400.00)

Student: EUR €240 (approx. GBP£200.00)

Day Rate: EUR €300 (approx. GBP£250.00)

Accompanying Person: EUR €240 (approx. GBP£200.00)

*Accompanying person criteria: Lunch and social events only.

For group bookings of 3 delegates or more, please email bookings.tiwc25@aquitex.pt to secure a 10% discount

All bookings need to be made in a single transaction.