So Many Parts. So Many Materials. All Award Winning.

LV Swiss offers Precision CNC Machining, Milling, Turning, and Swiss Screw Machining. 2023 Recipient Of The Prestigious ‘Rural Utah Business Of The Year’ Award.

Vol. 30, No. 2, March / Apr 2024

NV.

NM.)

Southwest Edition (AZ,

and

Steel Titanium Bronze

Copper

Beryllium Copper

PEEK Plastics

Aluminum

Stainless Steel

LV SWISS

Brass

YOUR MACHINE TOOL BANK BANTERRA.BANK | MEMBER FDIC Contact Us Today For Your Machine Tool Financing Needs Why Shops Choose Banterra Bank Loan products designed speci cally for machine shops World-class deposit products including Treasury Management Industry-leading service with local decisions Bank commitment to Made In USA and Made In Arizona values ARIZONA DIVISION 950 W. Elliot Rd., Suite 114 | Tempe, AZ 15100 N. 78TH Way | Scottsdale, AZ 480-645-9005 Banterramachinetool.com Product Offerings BUILDING LOANS EQUIPMENT LOANS SBA LOANS DEBT CONSOLIDATION LINES OF CREDIT BUSINESS CHECKING AND CASH MANAGEMENT

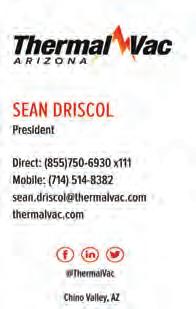

Bridge CMMs Absolute Arms Klontech Measurement Solutions Expert Analysis, Solutions, and Support www.klontech.com 480-626-8131 sales@klontech.com Optimize and automate your manufacturing quality process

Two clients I interviewed recently told me about their success bringing in ‘Fractional Executives, one a fractional CEO and another a fractional CSO (Chief Sales Officer). Also, I regularly receive job opportunities from LinkedIn on openings they say fits my experience and lately, they ‘ve included ‘fractional executive’ positions.

So, I got curious about these ‘fractional’ job openings. In short, the definition of a fractional executive is an experienced C-suite executive — CEO, CFO, CIO, COO, CSO, CTO, or CMO — who works less than full-time. They might be on the job a few hours each day or a few days each week.

Fractional executive work “has become its own career calling,” InterimExecs CEO Robert Jordan said. “They are not ‘between jobs.’ They love doing fractional work.” He adds, “Executives who excel at this have a strong repeat track record of success, and they are driven to take on new challenges, drive for results, and focus on building, growing, and transforming businesses. They may be at a place in their career where they no longer seek full time employment, and they can be invaluable and cost effective on a project basis.”

One customer I interviewed was the CEO of his company. Though he has a small sales team, he hired a fractional CSO. Mike (CEO) says, “Our team often thinks our CSO is a ‘pain in the ***, but we all know he is helping our business. Mike says that after evaluating the company’s quote to win ratio, he helped the company to see that they were quoting far too many jobs and not winning enough. The CSO helped the team to put in place procedures to no-bid; helping them to spend time on the bids they were most likely to secure. Further, the company was winning average orders of $20,000 and the CSO felt that their efficiency and margins would improve if they could get the average order size up. Mike says that months later, the company’s average order size is closer to $40,000, and profitability is improving. There are many times when hiring a fractional executive is a sound decision:

• Reduced cost; for startup companies and small companies that can’t afford a highly experienced and successful executive, you can gain invaluable insights and processes from someone who has successfully implemented changes at previous companies. In essence, you can benefit by having an experienced business leader with a proven track record that you could not normally afford.

• A company in transition, either with a planned sale, new ownership or one growing into new markets; Having an outsider lend expertise can help make the transition smoother. In this case, often the business doesn’t require a full time executive; they need it for a specific period of time.

A fractional sales leader (CSO) is a shortcut you can take to grow sales until your business has the revenue and requirement for a full-time head of sales.

Navigating strategic transitions. Entering new markets. Developing new products. Fending off market interrupters. Launching an IPO. Seeking investors. Those are all critical times for companies during which specific expertise can reap enormous rewards.

Until next issue, I encourage you to check out this concept for your business. It is low risk — you aren’t hiring an employee — and the learning he or she brings to your business as an outsider can be an outstanding boost for your business. As always, God bless our troops.

Linda Daly,Publisher

LV Swiss offers Precision CNC Machining, Milling, Turning, and Swiss Screw Machining. 2023 Recipient Of The Prestigious ‘Rural Utah Business Of The Year’ Award.

Published bi-monthly to keep precision manufacturers abreast of news and to supply a viable vendor source for the industry. Circulation: The A2Z MANUFACTURING has compiled and maintains a master list of approximately 8500 people actively engaged in the precision manufacturing Industry. It has an estimated pass on readership of more than 19,300 people. Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to A2ZMANUFACTURING. com.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher. The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

CONTRIBUTORS Kim Carpenter Takashi Sato Gene Wirth Announcements. 6-19 Feature Articles 1,34-35, 48-49,52-53,67 Buyers Guide Equipment...............77-85 Buyers Guide Processes 86-97 Card Gallery 77-97 Index of Advertisers 98 Cover Published by: A2Z Manufacturing PUBLISHER/EDITOR Linda

(602)

Daly linda@a2zMFG.com Address: 1538 E La Vieve Lane Tempe, AZ 85284 Telephone:

412-7696 www.a2zMFG.com

A2Z MANUFACTURING SW • 4 • March / Apr 2024

Corner

Editors

A2Z MANUFACTURING SW • 5 • March / Apr 2024 Designed and built for use with Haas ST and DS series CNC turning centers, the Haas Bar Feeder connects directly to the Haas control. YOUR ONE SOURCE FOR THE BEST SELECTION IN AUTOMATION SYSTEMS HAAS FACTORY OUTLET A Division of Ellison Machinery Co. LLC 1610 S. Priest Dr., Ste. 101, Tempe, AZ 85281 | HaasCNC.com | 480.968.5877 Sales & Service Scan for our complete line of integrated automation products. Haas Integrated Automation Systems. Making your job as a machinist easier. Optional Automation • 4th- and 5th-Axis Rotaries • Sub-Spindles • Parts Catcher System • Auto Door for Mills and Lathes • Automatic Coolant Refill Haas Bar Feeder All-inclusive design, with plug-and-play capabilities to Haas lathes Pallet Pool Systems • 3-Station for VF-2YT/SS, VM-2 • 6-Station for EC-400 • 6-Station for VC-400/SS • 6-Station for UMC-1250/SS • 10-Station for UMC-750/1000/SS • 10- or- 20-Station for UMC-500/SS Automatic Parts Loaders • Turning Center APL • VMC APL • Small UMC APL Robot Systems • HRP-1 System – 7 kg capacity • HRP-2 System – 25 kg capacity • HRP-3 System – 50 kg capacity

Haas Factory Outlet-Phoenix Invites Machinists to CNC Mill & Lathe G&M Code Programing Courses

Mill and lathe classes are scheduled every other month. Each course consists of 3 days of hands-on instruction led by a Haas Certified Instructor. Students will learn the basics of the Haas control, operation of machines, and Haas programming using G & M codes. Classes are free to all Haas CNC machine owners and operators. Classes are held Monday through Wednesday from 2:00 P.M. to 5:30 P.M.

Please join us for an upcoming session of the Haas CNC training. We recommend registering as early as possible as class sizes are limited.

Training is held at Haas Factory Outlet- Phoenix, a Division of Ellison Machinery facility located at 1610 S Priest Drive, #101 Tempe, AZ 85281. To register and for additional information visit www.EllisonAZ.com or call 480-968-5877.

MIDACO Unveils M264VFL Industrial Dry Vacuum: Power, Precision, and Unmatched Versatility

MIDACO CORPORATION, a leading name in industrial solutions, proudly introduces the M264VFL Industrial Dry Vacuum, setting a new standard for efficiency and reliability in managing shop dust, metal and wood shavings, and challenging materials.

Designed for versatility, the M264VFL comes equipped with multiple attachments and hoses extending several meters, catering to a diverse range of applications. The Tefloncoated pocket filter ensures peak performance with damp materials, complemented by PTFE nanotechnology for tackling the most stubborn dust particles.

Effortless maintenance is at the

A2Z MANUFACTURING SW • 6 • March / Apr 2024 Announcements Con’t Next Page

A2Z MANUFACTURING SW • 7 • March / Apr 2024 A2Z MANUFACTURING SW • 9 • March / April 2022 Okuma. Welcome to open possibilities. Okuma’s MULTUS U3000 Multitasking Machine offers an ideal combination of power, speed, and process flexibility. A broad scope of machining functions and the ability to complete tasks in a single setup make this machine simple and efficient for producing a variety of parts. Combining powerful turning and milling capabilities, made possible with Okuma’s OSP-P300 control, equals one thing – increased production capacity. Explore all of the powerful features of the MULTUS U3000, including: • Full 5-axis contouring (available as an option)

New compact B-axis spindle

240-degree B-axis range • 30 hp milling motor spindle • 12,000 RPM H1 milling spindle

Wide range of ATC configurations available (40 to 180 tools) CALLING ALL MULTITASKERS MORE IS POSSIBLE Backed by Okuma’s Industry-Leading Warranty Program To learn more, visit: okuma.com/products/multus-u3000 To inquire, visit: okuma.com/distributors Arizona CNC Equipment, LLC 1205 S Park Lane, Suite 2 Tempe, AZ 85281 www.arizonacnc.com 480-615-6353

•

•

•

Announcements & Releases Continued

forefront with the manual filter cleaning system, conveniently operated by a side-mounted “shaker” lever to expel debris from the filter and into the receptacle container. The detachable wheeled container, boasting a generous 100L capacity and reinforced outer support, prioritizes safety when handling substantial loads.

Experience the power, convenience, and reliability of the MIDACO M264VFL Industrial Dry Vacuum — your ultimate solution for tackling the toughest industrial cleaning challenges.

About MIDACO: In addition to Industrial Vacuums, MIDACO is known for Automatic and Manual Pallet Changers and Multiple Pallet Pool Systems for small and mid-size VMCs up to large Bridge Mill Machines with a 190”x72” XY travel and 32,000lb capacity. Accessories for Pallet Changers include Robot/Cobot machine tending solutions, Trunnion Systems for 4th axis machining on a VMC without needing cable management, selfcharging cableless Hydraulic Docking Systems for automated fixtures and vises, Chip Shields, Chip Fans and Blower Nozzles. For automated machine access MIDACO manufactures AutoDoor Openers for single and double door CNCs and Robot Access Door Systems for enclosed milling and turning centers - ideal for robot/cobot applications. Additionally, MIDACO offers the Grinder-GuardTM LED illuminated safety shield for bench and pedestal grinders/buffers and the Grit-GrabberTM

vacuum pedestal cabinet to capture grinder dust and debris.

As a veteran owned business since 1969, MIDACO is a renowned provider of innovative industrial solutions, committed to delivering high-performance products that enhance productivity and safety in challenging work environments. With a focus on quality and reliability, MIDACO continues to be a trusted partner for industries worldwide. For more information, visit www.midaco-corp.com or contact sales@midaco-corp.com, ph: (855) 5935668. See MIDACO at IMTS 2024, September 9-14, McCormick Place, Chicago, South Hall, Booth #3339347.

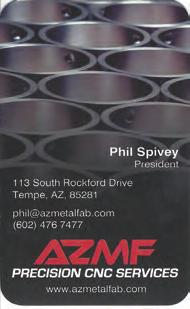

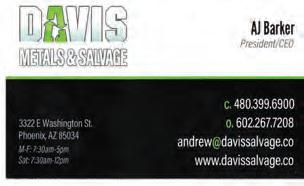

The NTMA/ Arizona Chapter Is Pleased To Announce 2 New Industry Partners!

Expense Reduction Analysts is a global leader specializing in assisting organizations in enhancing cash flow and margins through

A2Z MANUFACTURING SW • 8 • March / Apr 2024

Announcements Continued Page 10

A2Z MANUFACTURING SW • 9 • March / Apr 2024 WWW.UNITEDASSETSALES.COM PUBLIC ONLINE AUCTION INSPECT ONSITE AND BID ONLINE LATE MODEL CNC MACHINING, TURNING & METAL FABRICATION FACILITY SURPLUS TO ONGOING NEEDS: MULLER TECHNOLOGY COMPANY, INC. ONLINE AUCTION CLOSES: WEDNESDAY, APRIL 10 STARTING AT 10:00 AM MDT 2-DAY INSPECTION: MONDAY, APRIL 8 & TUESDAY, APRIL 9 FROM 9:00 AM TO 3:00 PM MDT LOCATION: 3939 AUTOMATION WAY, FORT COLLINS, CO 80525

HAAS VF-4 & HAAS MINI MILL CNC VERTICAL MACHINING CENTERS, 2021 HAAS ST-35Y CNC TURNING CENTER, BRIDGEPORT KNEE MILLS, AMADA RG-125 PRESS BRAKE, HTC 375-12A SHEAR, HEM V-100LM VERTICAL & HEM H90A HORIZONTAL BAND SAWS, STRIPPIT SINGLE END PUNCH, ABRASIVE SANDERS, DUST COLLECTORS, ACORN WELDING TABLE, CLARK FORKLIFT, CONDOR SCISSOR LIFT, JIB BOOMS, ALUMINUM & STEEL METAL MATERIALS, GIROLIFT VEHICLE LIFT, PAINT BOOTH, MACHINE SHOP TOOLING & SUPPLIES, RACKING, BENCHES, TOOL BOXES AND RELATED ITEMS 2021 2017 2021 23945 Calabasas Road, Suite 209 Calabasas, CA 91302 Office 818.264.4232 Email roy@unitedassetsales.com PAYMENT TERMS: NO DEBIT OR CREDIT CARDS! CASHIER’S CHECK, BUSINESS CHECK WITH BANK LETTER OF GUARANTEE, BANK WIRE TRANSFER. FULL PAYMENT MUST BE MADE NO LATER THAN 24 HOURS OF WINNING BID. REMOVAL: ALL ITEMS MUST BE REMOVED NO LATER THAN FRIDAY, APRIL 26. PREPPING, REMOVAL, LOADING & TRUCKING IS THE RESPONSIBILITY OF THE BUYER. BUYER’S PREMIUM: 18% FOR ALL PURCHASES. ONLINE BIDDING PROVIDED BY

2021 HAAS VF-12/40, 2017 HAAS VF-9/40, 2004 HAAS VF-11B/40,

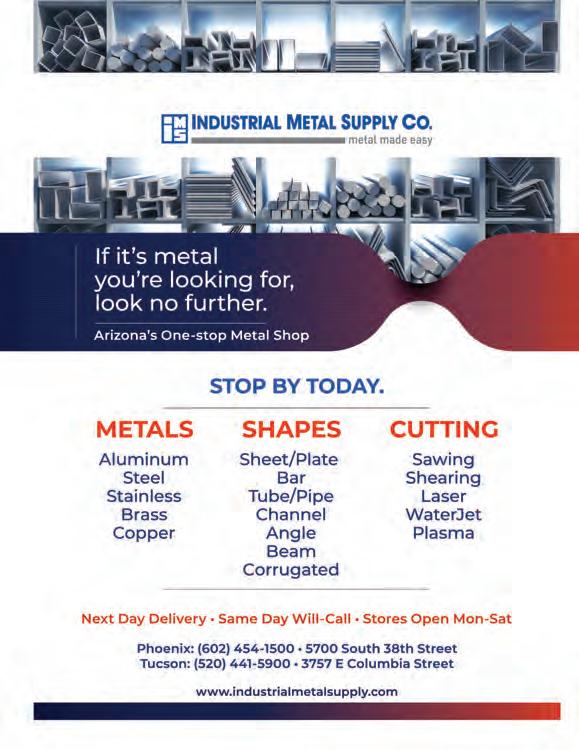

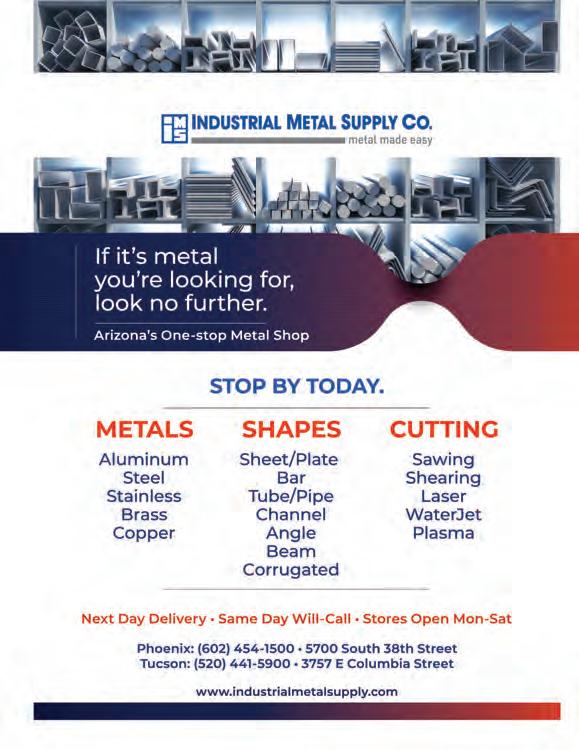

personal use, and business accounts. With the addition of Arizona Iron Supply, we can accommodate even larger industrial accounts and offer even more equipment and metal inventory to choose from.

Announcements & Releases Continued

We feel privileged to continue to serve Phoenix and surrounding areas. We can’t wait to show you how this development will improve your metal purchasing, metal recycling, and Rolloff Service experience.

Visit one of our two locations to see how this exciting change will benefit you! Davis

Metals: (602) 267-7208 / 3322 E. Washington Street, Phoenix, AZ 85034

Arizona Iron Supply: (602) 244-9649 / 130 S 23rd St, Phoenix, AZ 85034

improved efficiencies and cost management. We collaborate closely with organizations to understand their business, assessing areas where companies may not be fully optimizing their current cost strategies. Our objective is to optimize business costs and identify innovative solutions that align with the company’s needs while maintaining corporate quality without requiring additional corporate resources. Drawing upon our extensive expertise across over 50 expense categories, our professional analysts are well positioned to generate substantial savings for your organization.

Landmark Hosts Open House At Metzfab Industries

The majority of our work occurs outside your office environment. Our processes, resources, and systems are meticulously designed to minimize any impact on your internal resources. We ensure that all savings are not only realized but also sustained and improved over time by closely monitoring supplier performance in strict adherence to the supply contract. Operating on a success-based proposition, we eliminate all risk from the process. Throughout our engagement, we prioritize collaboration with the organization on a fully transparent basis, allowing you to maintain control over all key aspects of the process.

SpendVue, a cutting-edge data visualization tool meticulously developed by Expense Reduction

Analysts, represents a paradigm shift in understanding organizational spending. Our consultants leverage Spendue to bring a fresh perspective to your financial landscape, unveiling actionable insights that may be concealed within the intricacies of your financial data. This sophisticated tool is specifically engineered to pinpoint clear opportunities for cash flow improvement, offering you a comprehensive and visually intuitive understanding of your expenditure; us.expensereduction.com

L andmark Solutions held an Open House event at Metzfab Industries in Phoenix earlier this month.

Metzfab’s facility was chosen due to their company growth, and the addition of several new state of the art pieces of equipment. Metzfab is always pushing technology and equipment limits in an effort to build and deliver the best parts to their customers.

Metzfab recently installed a new OMAX 80x 5 axis waterjet, a Bystronic Tube Laser system, a Bystronic ByStar Fiber Laser with full automation, multiple large high performance press brakes, and a fully automated robotic press brake. Installing soon is a new material finishing machine also coming from the Landmark Team.

North South Machinery , founded in 1985 by CEO Jim Swartzbaugh, quickly gained notoriety by becoming the West Coast distributor of Mitsubishi EDM products, and building a prestigious reputation in the nontraditional machining industry in the process. Over the course of the next several decades, North South expanded its offerings and expertise to include a wide variety of conventional, non-traditional, and fabrication technologies. While quality product lines and an expert sales team have long been cornerstones of the North South business model, it’s the un-ending desire to create raving fans of each one of its partners that has fueled its longevity.

NSM prides itself on not as a run of the mill machinery

The Landmark Solutions open house event was a success, and we are all excited to continue our long term partnership with Metzfab. Everyone attending the event were impressed with the new equipment and technology, and how this has helped Metzfab grow and diversify their business.

Announcements Continued Page 12 A2Z MANUFACTURING SW • 10 • March / Apr 2024

A2Z MANUFACTURING SW • 16 • July / Aug 2022 Announcements Continued Page 18

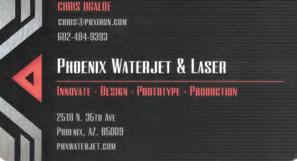

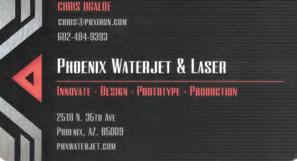

• DESIGN • PROTOTYPE • PRODUCTION BYSTRONIC XPERT 80 PRESS BRAKE FLOW IBF 4020 WATERJET BYSTRONIC 3015 BYSMART LASER Industries Served: Aerospace Military Defense Construction Automotive Marine Oil/Gas Mining Waste Water Metal Fab Hobbyist Heavy Equipment

Quick Turnaround (5-7 Days Typical)

Family-Owned & Operated Since 1981

3-D Scanning (Faro Arm Scan & Probe)

Cutting Capability Up” to 6’x12’ The Ugalde Family PHOENIX WATERJET & LASER 602-484-9393 WWW.PHXWATERJET.COM 2518 North 35th Ave, Phoenix, AZ 85009 I N N O V A T E D E S I G N P R OTOTY P E • P R O DUCTI O N P H O E N i X E S T 2 0 0 7

INNOVATION

•

•

•

•

SPINDLE MACHINE

www.magnumprecisionmachines.com

OPEN HOUSE MACHINE TOOL SHOW

ALMCO Spindle Machines are known for high-speed precision deburring. Custom fixtures attach one or multiple parts to a spindle. The rotating spindle is lowered into a rapidly moving tub of abrasive media to achieve a consistent finish on a part.

ALMCO Sutton Machines are specialized heavy-duty machines designed for high production environments. They are similar to a Spindle but are primarily designed to finish large parts that would be otherwise difficult to finish by hand such as turbine blades, disks, blisks, and impellers.

ALMCO Vibratory Round Bowls are ideal for a wide variety of part geometries and offer consistent finishing from part to part. They are available in various sizes and may be custom configured with options for your specific application.

SBB-8 Shown

U-Bend Washers: Operate in a “U” shape and discharge parts at the same side at which they are fed into the machine. Designed for single operator use or in an automated system where the direction of workflow needs to be changed. U-BEND

FORTY YEARS www.magnumprecisionmachines.com 1984 - 2024 OPEN HOUSE • MACHINE TOOL SHOW WEDNESDAY MARCH 20TH THURSDAY MARCH 21ST 10:30AM - 3:00PM MAGNUM PHOENIX SHOWROOM 4848 S. 35TH STREET PHOENIX, AZ. 85040

Come

and see

the Magnum Pecision Open House

out

ALMCO at

SUTTON MACHINE

WASHER

Scan

dealer, but as an investment company, investing in the success of each one of our partners across a wide range of industries.

With a company-wide passion for all things motorsport, North South Machinery knows that there is no podium celebration without an allstar team of people and the right equipment propelling you to the checkered flag.www.northsouthmachinery.com

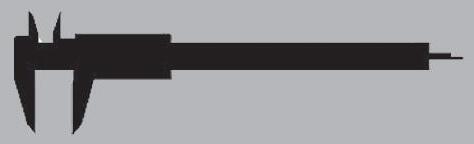

Phoenix Swissturn Is Pleased To Announce That They Have Certified To ISO 9001: 2015

Phoenix Swissturn Solutions has been in business for the last five years. Owner/Operator Tim Radziwill, has decades of experience manufacturing precision, swiss machined parts, and exclusively with the prestigious Tsugami Swiss machines.

Tim was moved from Minnesota to Phoenix back in 2012 to get a Tempe Arizona plant for Monogram Aerospace Fasteners up and running, and to get ten different part families qualified by Boeing. Under his direction, the company achieved that and grew from 1 Tsugami machine to 21 machines, operating 24 hours a day, 7 days a week. “It was always my dream to own my own shop, so

when the opportunity arrived, I made the jump”, he says.

Today, the company has several Tsugami machines and is run lean, with family members Kirstin Radziwill (Tim’s wife) managing all office operations, as well as handling the quality side of the business, and son Joshua, supporting the shop machining parts.

Tim says, “At Phoenix Swissturn, we have the ability as well as the expertise to machine various types of material, even difficult materials such as Titanium, all types and various plastics. We also machine stainless steels, brass, beryllium Copper (BeCu), as well as other various materials.”

Over the course of Tim’s career, he says he has always worked for shops that are certified. “You know it when you walk into an ISO/AS9100 certified shop”, he says, adding, “We knew that to take our business to the next

A2Z MANUFACTURING SW • 12 • March / Apr 2024 Announcements & Releases Continued Announcements Continued Page 14 602.845.1256 • info@azmep.com • www.azmep.org SUPPLY CHAIN CHALLENGES?

Arizona MEP can help improve your supply chain performance, improve cashflow, and drive savings to the bottom line. If you have any of the following contact us for help: C o n t a c t u s t o d a y t o k I c k s t a r t y o u r i m p r o v e m e n t i n i t i a t i v e s Excess inventory Missed or late deliveries Escalating shipping costs Poor cashflow Increasing material costs Trouble finding exceptional supply chain talent

The

the QR code and fill out the contact us form. Our expert t eam will respond with the assistance you need!

A2Z MANUFACTURING SW • 13 • March / Apr 2024 requirements of a vast range of industries. PRECISION MACHINING HAND-SCRAPED WAYS HEAVY FULL-LENGTH BASE VERSATILITY DOVETAIL SLIDES HIGH ACCURACY MICRO VIBRATION TECHNOLOGY (MVT) LARGE BALL SCREWS RELIABILITY EXCEEDING EXPECTATIONS OUR MACHINES EXCEL IN THE AEROSPACE INDUSTRY: COMPLEX PARTS,TOUGH MATERIALS, FINE FINISHES, AND TOOL LIFE. FOR A HIGHER STANDARD Looking for a way to improve your aerospace manufacturing operations? We are here to help! Contact your local distributor for more information! Randall Flores | Sales, Service, Applications, Training dandrmachinery.com/ 480-775-6462

526

www.az-metals.net

level, certification was critical.” The company utilized My ISO Consultants to help them to successfully certify.

To learn more about how Phoenix Swissturn can support your swiss machining needs, contact them at 602-6000-8436 or email Tim at tim@phoenixswissturn.com

Eliminating Bottlenecks With Material Handling

By Frank Arteaga, Regional Director Marketing – Americas

Bystronic Inc.; Voice.bystronic@bystronic.com

part

pallet.

Automating the supply of raw materials to the laser cutter

Automation enters the scene as a game-changer, particularly in material supply. Consider the scenario when cutting programs are released to the laser cutting machine for processing. In traditional setups, human intervention is required to retrieve raw materials from a storage area, often utilizing a forklift. The time accumulated in performing this action for each material changeover can be substantial, especially in high-mix environments with frequent daily changeovers. This manual intervention becomes a critical bottleneck.

However, with an automated material storage system in place, this bottleneck is effectively eliminated. Multiple material types and thicknesses can be supplied seamlessly across various machines. The beauty of automation lies in its ability to seamlessly communicate with the laser cutting machine. As programs are released, communication with the material storage system is

A2Z MANUFACTURING SW • 14 • March / Apr 2024 Announcements Continued Page 16

E. Juanita Ave #4 Ph: 480-353-2950 Mesa, AZ 85204 Fax: 480-353-2954

• info@az-metals.com Steel Aluminum Stainless Copper Brass Bronze Tool Steel Alloy Steel Spring Steel Shim Stock

Exotic Alloys

& Safety Grating Specialty Products

ALL METALS/ ALL SHAPES

NO MINIMUMS

STOP SHOPPING

or PICK UP

ALL MAJOR CREDIT CARDS, CASH, CHECK , TERMS AVAILABLE

thank you for your business! Owners Doug & Jill Cone Added Value Services: Shearing, Saw Cutting, Welding MIG, TIG & ARC, Hole Punching, Notching, Bending, Metal Fabrication, and Plasma Cutting

In the realm of laser cutting systems, the quest for efficiency is often hampered by bottlenecks in material handling processes. These bottlenecks, characterized by interruptions and delays, can severely impact production timelines and overall operational effectiveness. Recognizing this challenge, incorporating material handling automation has emerged as a pivotal solution, transforming the way laser cutting systems function and optimizing the entire fabricating value chain. A Continued

removal system sorts cut blanks to the appropriate

Stacking can be planned in the right sequence and orientation. At the heart of this issue

Threaded Rod

Bar

•

•

•ONE

•DELIVERY

•

We

Announcements & Releases

lies the loading and unloading process with laser cutting systems. Machines lacking material handling automation exhibit significant variability in production time, especially during these crucial stages. The waiting or idle times, meticulously recorded from the laser cutting machine’s data, clearly indicate the presence of these bottlenecks. These waiting times stem from two primary factors: the absence of raw materials supplied to the machine or the failure to unload cut parts before the machine completes processing the previous sheet. Addressing these bottlenecks at this pivotal juncture in the fabricating process is paramount, as it directly influences downstream operations and the overall process times.

Challenged with meeting customer deliveries and adapting to their ever-changing requirements?

Optimize your manufacturing workflow with modular end-to-end solutions from Bystronic. Combine best-in-class machines, automated production cells, and software for a highly agile and efficient production process that can expand as your business grows. Bystronic will guide you through your transformation journey step-by-step.

Agile Production. Scalable Solutions.

Your best choice for sheet metal processing. Modular end-to-end solutions from Bystronic. bystronic.com

3020 South Park Drive ,Tempe, AZ

sales@stp-az.com

• Tel: 602-426-9340

STP-AZ.COM

We Manufacturing Complex Intricate Parts Requiring Extreme Precision And Quality

We Are Built For High Production Parts And Can Handle Extremely Tight Tolerances

High Precision Swiss Lathe Machining 24x7

New State-of-the-art 12,500 square foot facility

ISO 9001: 2015 & AS9100D Certified

Our CNC Swiss screw machines can run lights out 24 x 7 Subsidiary of Whitley Machine

Announcements & Releases Continued

Industrial Production Returns to Growth After February’s Storms Subside

automatic, and the subsequent material order can be delivered while the machine is still processing the last sheet of the previous order. This synchronized movement of raw materials ensures a continuous supply, eliminating waiting times and optimizing production efficiency.

Automating the laser cutting machine material loading process

The Federal Reserve reported that industrial production in March rose 1.4%, returning to growth after an unseasonably stormy February knocked it down 2.6%. The report shows total industrial production rose 2.5% at an annualized rate during the first quarter of 2021 despite the losses endured in February by manufacturing, mining, and utilities companies.

unloading, a bottleneck is created, impeding the entire workflow. Addressing this challenge necessitates a thoughtful approach. Two methods of practice: unloading the entire cut sheet with parts using an unload fork system or having the parts unloaded and stacked using an automated sorting system for the parts and a fork system to remove the material skeleton when completed.

Motor vehicles and parts production, which fell 10% in February, rose 2.8% in March but remained depressed by a persistent shortage of semiconductors. Most durable goods indexes rose between 2% to 3%.

Automation plays a pivotal role in the material loading process. Once the laser cutting machine is presented with the raw material stack, automating the loading process becomes imperative. In an automated setup, loading the material is an integral part of the automatic sequencing tied to the machine’s material request. No longer does one need to wait from sheet to sheet or from order to order. Sheets are efficiently loaded onto secondary shuttle tables while the laser cutter is seamlessly cutting on the primary table. However, a crucial sequence must occur between loading and unloading: the timely unloading of cut materials. Failure to unload the cut material promptly results in accumulating waiting times, disrupting the flow of operations.

The industrial production gauge includes productivity in three sectors: manufacturing, mining, and utilities. Manufacturing production (which excludes mining and utilities output) rose 2.7% in March after falling 3.7% the month before. Mining production improved 2.7%, while utility output fell 11.4% thanks to unseasonably warm March temperatures. Manufacturing output rose 1.9% at an annualized rate.

In nondurable manufacturing, the index for the chemicals industry rose 4.1%, and petroleum and coal products rose 5.7%, although neither sector has fully recovered from severe weather damage—the Federal Reserve noted that some chemicals factories remain offline thanks to damage sustained from February’s winter storms. Most nondurable goods indexes rose between 0.9% and 3.0%.

The system involving automated sorting proves to be efficient and transformative. The automated system separates cut parts from the sheet material based on the order they belong to. Similar parts are organized into neat stacks for subsequent fabricating processes. By reducing manual intervention and minimizing errors in stacking similar part revisions, the automated sorting system significantly reduces process times, enhancing efficiency and throughput.

Capacity utilization in manufacturing rose by 1.9 points, also reversing February losses.

Automating the laser cutting machine material unloading and parts sorting process

Here enters the significance of automating the material unloading and parts sorting process. Automating the material unloading process is not just desirable but crucial. It is the linchpin upon which the loading and cutting processes hinge. Without timely

Tangible benefits to the sheet metal fabrication business

Almost all market groups saw improvements in March, despite lingering challenges. The Federal Reserve’s index for other manufacturing, which includes publishing and logging, remained the same, but durable goods and nondurable goods indexes rose 3.0% and 2.6%, respectively.

By identifying, addressing, and eliminating material handling bottlenecks, sheet metal fabricators can pave the way for unparalleled efficiency, heightened profitability, and sustained

If February was notable for its storminess, March was notable for its heat. The unseasonably warm month coincided with a roughly 10% drop in consumer energy products, and the 11.4% drop in utilitie s utilization was the largest recorded in the history of the index’s 48-year history.

A2Z MANUFACTURING SW • 16 • March / Apr 2024

Announcements Continued Page 18

A2Z MANUFACTURING SW • 38 • May / June 2021

SPECIALTY TURN PRODUCTS

Tornos 6 axis Sigma

Tornos MultiSwiss 6x14

11 CNC Swiss Screw Machines

First Light F-35 Helmet Test A Success

Announcements & Releases

business growth. By mitigating these bottlenecks, fabricators can deliver on their promises with greater precision, ensuring that customer delivery dates are met consistently. This newfound precision not only enhances operational efficiency but also bolsters profitability. Inaccurate job quotes, a common consequence of overlooking these material handling bottlenecks, can erode profits significantly. By addressing these variabilities and accurately reflecting them in job quotes, businesses can maintain healthy profit margins, contributing to long-term sustainability and growth.

NTMA/ Arizona Chapter Hosts 2024 Kick-Off Dinner Meeting

The first test of a new, lightweight F-35 helmet was successful, a sign that the Pentagon c the jet’s escape system by

The NTMA/ Arizona Chapter held their annual kick off dinner meeting January 25 at the Phoenix Hilton Airport. Keynote speaker was Omar Nashashibi of Franklin Partners with public policy developments in Washington, DC, related to taxes,

Recently, at H ce Base, New Mexico, Lockheed Ma ining all three solutions d ry to F-35 pilots during ejection, according to spokesman Joe DellaVedova. Once the full gamut of testing is completed, hopefully by the end of the summer, the JPO can beg in implementing the two modifications to the ejection seat and issuing the new Generation III “light” helmet to the fleet, he said

Continued regulations, workforce and trade and the political outlook for Arizona.

The 2024 ATMA Boad of Directors were introduced along with the 2024 Premier and Industry Partners and NTMA Service Awards were presented.

The recent sled test, conducted with a 103-pound mannequin, is the latest sign that the JPO can make good on its promise to finish the three design fixes by November, allowing the military services to lift restrictions on lightweight pilots flying the F-35 Last year, Defense News first repor ted that pilots under 136 pounds were barred from flying the fifth-generation aircraft after testers discovered an increased r isk of neck damage to lightweight pilots ejecting from the plane. The US Air Force has also acknowledged an “elevated level of r isk” for pilots between 136 and 165 pounds.

Upcoming events include ATMA Industry Partner Star Metal Fluids tour on March 5, ATMA Eat, Drink, Mingle event on March 21, NTMA member Foresight Technologies tour on April 29 and the 9th Annual Ocotillo Golf tournament May 16. For membership and event information visit: arizonatooling.org

The prototype helmet tested weighs about 4.63 pounds, approximately 6 ounces lighter than the orig inal Gen III helmet, and is designed to ease some strain on smaller pilots’ nec ks during ejection

Although the test was the fir st test of the new helmet, the JPO, Loc kheed Mar tin and seat-maker Mar tin Baker have conducted at least seven other tests with the latest version of the seat, which is equipped with two modifications designed to reduce r isk to pilots.The fixes to the ejection seat itself include a switch for lightweight pilots that will delay deployment of the main parachute, and a “head support panel,” a fabric panel sewn between the parachute r isers that will protect the pilot’s head from moving backward dur ing the parachute opening.

The prog ram office has about another 10 tests planned, which will use a mix of low-, middle- and high-weight mannequins.

The apprenticeship arm of ATMA, Skill Up Arizona Apprenticeship and Award Foundation has named Jim Mayer, TCO Strategies (and ATMA Industry Partner) as their new President. Skill Up AZ anticipates that Gateway Community College will begin the first Uniquely Abled Academy Cohort in March. The UAA is designed to prepare candidates on the Autism Spectrum for precision manufacturing apprenticeships leading to career growth in our industry. Skill Up AZ is proud to have brought the Uniquely Abled Project and GCC together to build this incredible opportunity. For apprenticeship information please visit skillupaz.org

“This initial test had promising results and the F-35 enterpr ise is on a path to qualify the helmet . by the end of this summer,” DellaVedova told Defense News. “The lighter helmet expected to be fielded by the end of the year is in line with the seat timeframe as well.”

A2Z MANUFACTURING SW • 18 • March / Apr 2024 Announcements Continued Page 20 A 2 Z MANUFACTURING SW 41

Wir e/ Sinker Sma ll Hol e 14 Machines WATERJET CUTTING UP T O 6 ’ X 12’ 2 Mach ine s LASER NTC 2500 Watt DIE REPAIR & METAL STAMPING SCREW MACHINING Up To 32 M M whitleym achine.com www.s tp-az.com 4801 S 35 St, Phoenix Ar izona 8 5040 Tel 602-323-5550 Fax 602-323-9950 Em ail C liff@whitleym achine.com √ √ √ 3 Companies Under 1 Roof ISO 9001: 2015 Certified √ Family-Run For 34 Years Competitive Pricing

EDM

SPECIALTY TURN PRODUCTS

ISO 9001: 2015 Certified √ AS9100 Revision D Certfied √ Family Run For 35 Years √ Competitive Pricing √ 3 Companies - 1 Ownership

√

IS YOUR 2024 PREVENTATIVE MAINTENANCE SCHEDULED? NORTH SOUTH MACHINERY OFFERS FABRICATION, CNC TURNING AND MILLING EQUIPMENT SERVICE. PH: (562) 690-7616 • INFO@NORTHSOUTHMACHINERY.COM WWW.NORTHSOUTHMACHINERY.COM | MAXIMIZE YOUR MACHINE’S POTENTIAL WITH PROFESSIONAL SERVICE SOLUTIONS. BOOK TODAY! REGULAR MACHINE SERVICING IS A CRITICAL ASPECT OF MAINTENANCE THAT CAN HELP EXTEND ITS LIFESPAN, IMPROVE PERFORMANCE, REDUCE DOWNTIME, AND ULTIMATELY SAVE MONEY FOR THE BUSINESS.

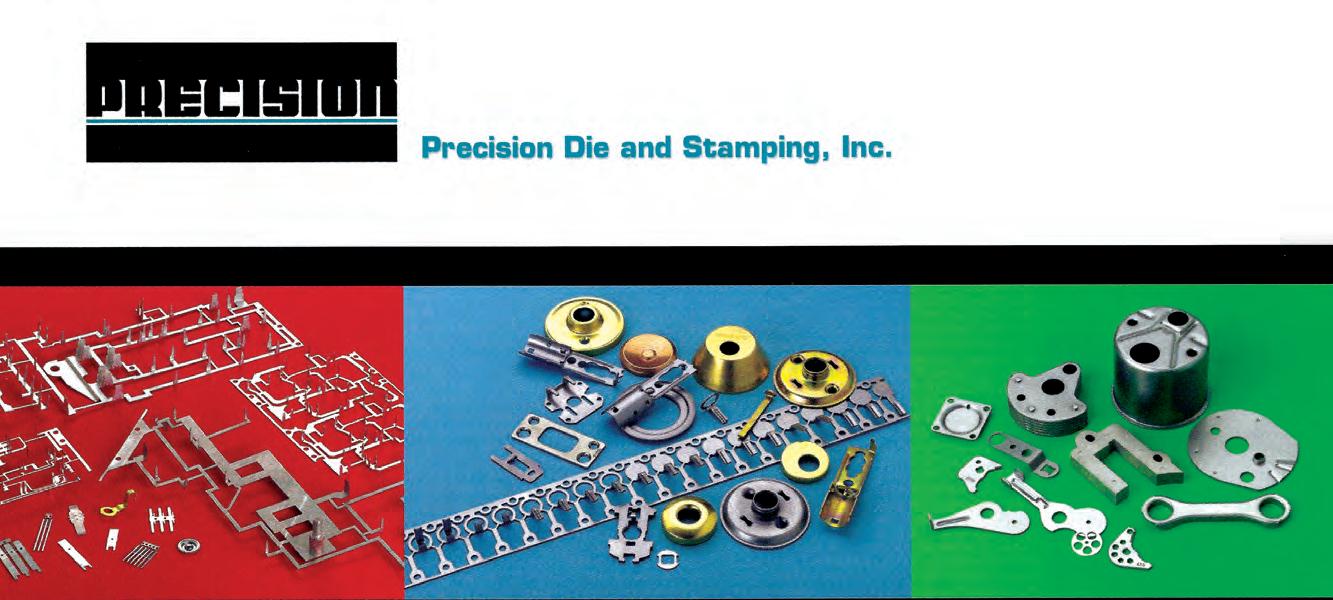

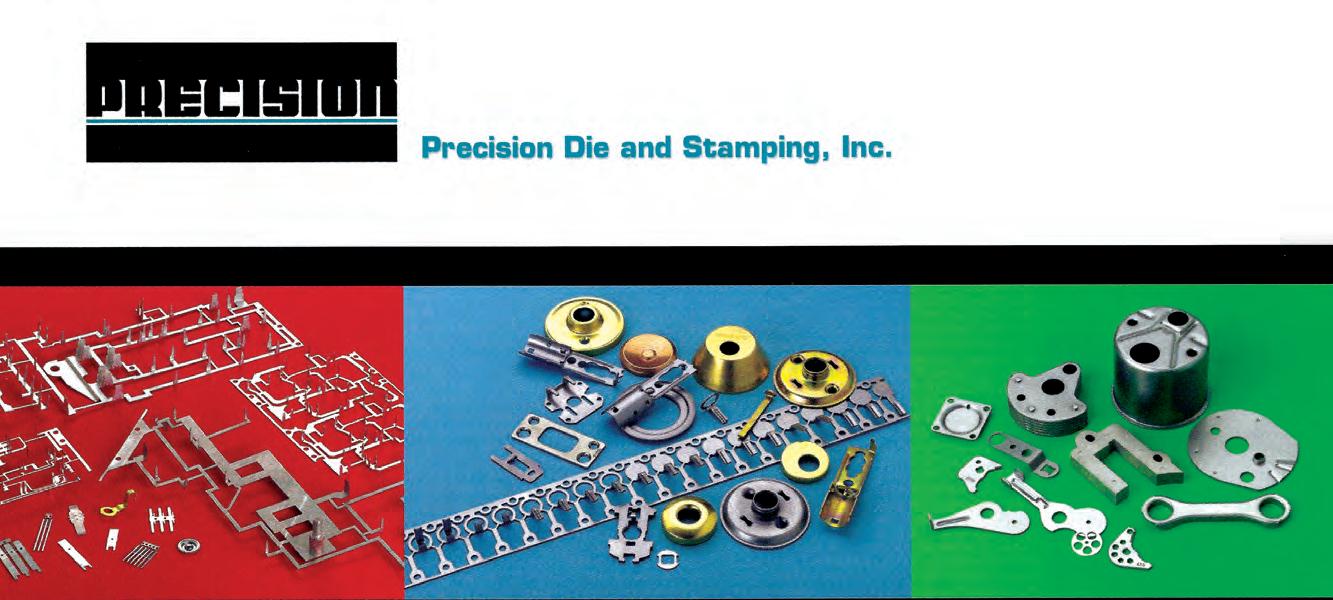

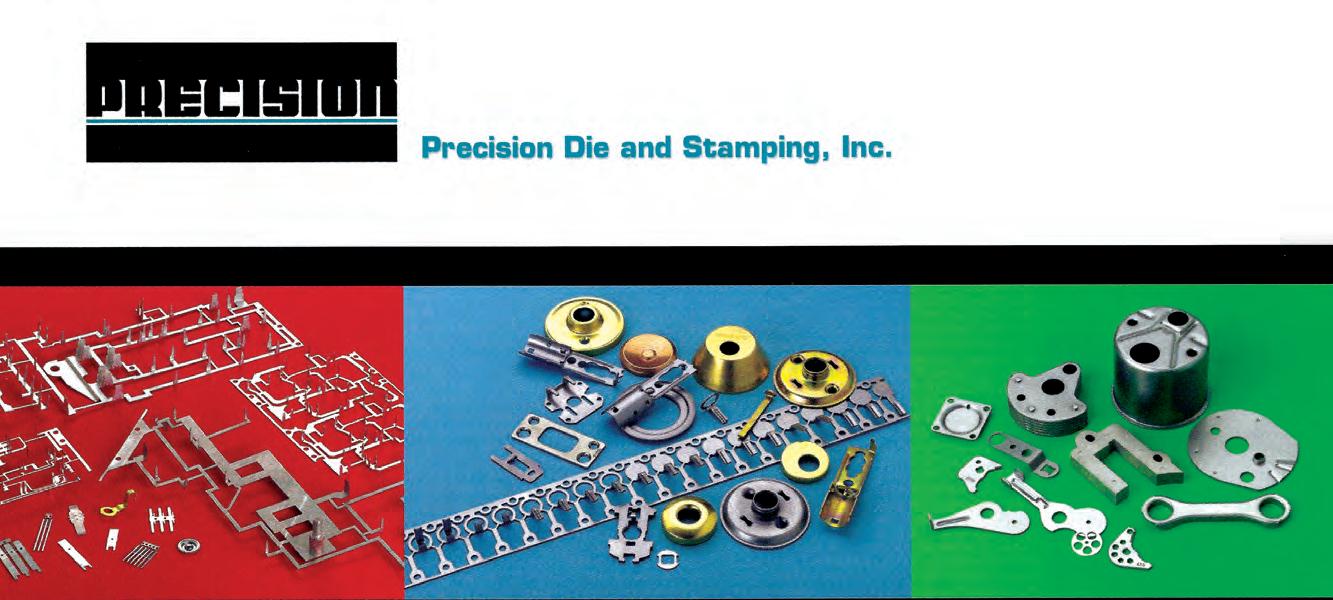

and dedication to customer service are number one priorities. This type of expertise and dedication has fostered a reputation of excellence in the tooling and stamping industry.

Located in Tempe, Arizona, our 100,000 Sq. Ft. Facility contains state of the art equipment , with production capabilities ranging from simple geometries to complex forms with intricate details. Precision enjoys a world-class reputation supplying a variety of OEMs, managing their inventory levels, and making certain product quality and timely delivery are NEVER compromised.

Announcements & Releases Continued Senate GOP Wants Changes to Housepassed Bipartisan Tax Deal; Urge Senate to Act NOW

Following an overwhelmingly bipartisan 357-70 vote in the U.S. House of Representatives, the Tax Relief for American Families and Workers Act of 2024 is now pending before the Senate where some Republican Senators indicated they would like changes. Any alterations to the tax bill would require another vote in the U.S. House and further delay the tax relief sought by manufacturers.

The One-Voice-endorsed bill will:

Reinstate R&D expensing retroactive to January 1, 2022 and through 2025, eliminating the requirement to amortize and capitalize R&D activities

Restore 100% Full Expensing (Bonus Depreciation) retroactive to January 1, 2023 (fell to 60% on January 1, 2024)

Return to full EBITDA standard for 163(j) business interest loan deductions retroactive to January 1, 2023

Increase Section 179 small business expensing limit from $1.16 million to $1.29 million Halt Employee Retention Tax Credit applications effective

January 31, 2024

Your Senators need to hear from you about the negative consequences of not acting to reverse the changes made to these tax provisions. Contact your Senators TODAY and call on them to support and immediately act on the Tax Relief for American Families and Workers Act of 2024.

New Renishaw TEMPUS™

Technology Achieves Up To 50 Percent Reduction In Additive Manufacturing Build Times

Patented technology enhances the class-leading productivity of the RenAM500 series metal additive manufacturing systems with reduced build times, detailed build insights and advanced process monitoring. New technology to be exhibited at the upcoming AAOS and RAPID shows.

Renishaw’s new TEMPUS™ technology enables users of RenAM 500 series metal additive manufacturing (AM) systems to reduce build times by up to 50

A2Z MANUFACTURING SW • 20 • March / Apr 2024

Announcements Cont Next Page

Precision Die & Stamping, Inc.

West 10Th St • Tempe, AZ 85281 Ph: 480-967-2038 • F: 480-829-0838 • www.PrecisionDie.com Automotive • Semiconductor • Lockset Hardware • Power Tools • Lawn & Garden Equipment • Aerospace

1704

Specializing in STAR CNC Swiss-type Machines

(847) 776-0073 • qualitymts.com

We are proud to announce QualityMTS has expanded sales and service to Arizona and New Mexico. For 20 years, QualityMTS has supported customers in the Midwest.

Quality Machine Tool Services provides high-quality sales and service on Swiss-type CNC machines. Our customers need reliable high-precision machines which is why we exclusively distribute Star CNC Machine Tool Corp products.

Marc Stevens, Sales Manager 773-744-3830

mstevens@qualitymts.com

Dave Polito, President 847-302-2810

dave@qualitymts.com

percent. The technology uses advanced scanning algorithms that sequence the layer data in a way that maximizes productivity while

At Quality Machine Tool Services, our goal is to provide the highest quality equipment and service available. We know Swiss machines, and you know your business. Together, we can determine what machine or part will fit your current needs and help propel you into the future.

Specializing in STAR CNC Swiss-type Machines

Services,

Quality Machine Tool

Inc.

ANNOUNCING!

Announcements & Releases Continued

maintaining part quality. The optimization suits some part geometries more than others, but all geometries can see some productivity benefits. Parts with thin, vertical features, for example, are likely to experience proportionally higher productivity savings. This new technology will be on display in February at the American Association of Orthopaedic Surgeons trade show (February 12-16 in San Francisco) and in April at the RAPID show (April 23-25 in Anaheim, CA).

TEMPUS technology is standard with the new RenAM 500 Ultra system, as well as advanced process monitoring software. The combination of significantly reduced build times and detailed build insights means that the RenAM 500 Ultra delivers cost-effective, reliable additive manufacturing for metal component production. Existing RenAM 500 series customers can access TEMPUS technology as a paid-for upgrade, helping them to make the most of their machine investment.

TEMPUS technology: jumping forward in AM

productivity

For uses in consumer electronics and computing, Renishaw has entered into an exclusive partnership agreement with metal component expert Alloyed, which has been using TEMPUS technology since 2021. “Reducing cost per part is critical to the wider adoption of AM technology,” explained Louise Callanan, Director of Additive Manufacturing at Renishaw. “The dominant contributing factor to part cost for most components today is the time spent building the part on the machine itself. Reducing the amount of machine time per part therefore results in more cost-effective production. For further information on Renishaw additive manufacturing, visit www.renishaw.com/am.

Landmark Solutions Welcomes Applications Specialist, Jeff Dawson

In order to continue providing excellent service to its growing family of customers, Landmark Solutions recently welcomed SoCal native, Jeff Dawson, to the team as an Applications Specialist. Jeff brings with him over 20 years of customer solutions experience and enjoys working closely with businesses to develop

A2Z MANUFACTURING SW • 22 • March / Apr 2024

Announcements Cont Next Page

High performing, long lasting coolants

Hysol® MB products are the best-selling, highest volume coolants sold by Castrol® due to their all-around performance and overall value.

Product advantages

• High-quality finish across multi-metals and operations

• Excellent anti-corrosion properties

• Clean running and have a very mild odor

• Wide tolerance to water hardness

• Robust pH stability fights bacterial growth

Simplify operations and make it easier to meet the demands of your business. Contact Star Metal Fluids today to learn why Hysol® MB products are the favorite among machine operators.

A2Z MANUFACTURING SW • 23 • March / Apr 2024

24

LOCAL PICK

is NADCAP Accredited To Meet Your Heat Treat And Passivate Needs.

American Global Standards (AGS) announces its Virtual Cert™ for ISO 9001 certification For Less Than $2K Per Year

AGS Virtual Cert™ ASRP Program™ is a cost-effective and viable alternative to the “policeman” approach of other registrars. Benefits include:

• Total Fee: Just $1875 Per Year Per Site

• Multi-Site & Multi-Program Discounts Available

• Save T op Management

Valuable Time

• Remote assessment – No onsite meeting with auditor(s) required

• Satisfy Customers Who Require ISO 9001

• No travel expenses, No other fees!

Feel free to contact AGS if you have any questions: 617 838 4648; info@americanglobal.org

& Releases Continued

custom-tailored solutions for their operation’s challenges. Jeff looks forward to serving the metal fabrication industry as a member of the Landmark team.

Reiter’s Custom Welding Inc. Adds To Their Capabilities With 165-ton Bystronic Press Brake

Reiter’s Custom Welding Inc. is proud to introduce a game-changing addition to their arsenal with their new BYSTRONIC PRESS BRAKE (BYSTRONIC XPERT 150 DYNAMIC EDITION).

Landmark

Landmark Solutions was awarded the Legacy Club – Premier Level Award by saw Industry leader, Pat Mooney Saws, for the 2nd consecutive year. The Legacy Club award is given to high-performing distributors of Pat Mooney’s FMB, Nishijimax, PMI and PMI Panther lines. Landmark is proud to partner with Pat Mooney Saws and looks forward to another excellent year of providing their best-in-class sawing solutions to customers.

A2Z MANUFACTURING SW • 24 • March / Apr 2024

HOUR TURN TIMES AVAILABLE FREE

UP & DELIVERY DROP OFF ORDERS 24 HOURS

DAY

TREATING *

With an impressive 165-ton capacity and a bend length surpassing 10 feet, this state-ofthe-art machine is engineered to elevate your steel fabrication and manufacturing processes SERVICE

A

M-F HEAT

ALWAYS BETTER

ABS

TESTING & GLASS BEADING

*

Honeywell, Boeing, MD Helicopter Specifications

METALLURGICAL PROCESSORS INC.

ABSHeatTreat.com

Since 1960. Fair Prices, Superior Quality, Quick Turn Times And Exceptional Customer Service Are Guaranteed When You Work With Us. ROCKWELL

PASSIVATE

*

ABS

4313 EAST MAGNOLIA STREET, PHOENIX, AZ 602-437-3008 •

Announcements

to new heights. Don’t miss out on the next level “heights”. Don’t miss out on the next level of precision and efficiency in production! Contact: (623)-8474028 or visit AZWELDER.COM

Solutions Receives Pat Mooney Saws Legacy Club Award

Highlights of Hurco U Series

✓ Integrated trunnion table design provides more clearance in Z-axis and ability to machine heavier parts compared to 3-axis mills with trunnion table added.

✓ +30°/-110° A-axis motion delivers better undercut capability.

✓ Solid one-piece cast iron frame

✓ Best-In-Class Yaskawa Sigma V Drives.

✓ LED lighting shines brighter and saves energy.

✓ 2 or 4 passage rotary unions for hydraulics and/or air.

✓ 5-axis/5-sided software features – Tool Path Linearization, Tool Center Point Management, Transform Plane, 3D Tool Compensation, Tool Vector Input & Retract, Shortest Angular Traverse, 3D Import.

✓ Robust control specifications (standard not an option) – 4GB RAM Memory, 10,000 block lookahead, 128GB Solid State Hard Drive, 2.7GHz Dual Core Processor.

✓ Ergonomically designed control console with two* 19” LCD touch-screens.

✓ Adjustable height control arm.

✓ WinMax ® Mill Conversational and Industry Standard NC programming.

✓ Patented Motion Control System (UltiMotion ® ) is standard not an option.

*The VM10Ui has a single-screen 19” LCD touch-screen.

A2Z MANUFACTURING SW • 25 • March / Apr 2024 Hurco Companies, Inc. | One Technology Way | Indianapolis, IN 46268 | 800.634.2416 | info@hurco.com | HURCO.com | Machines shown with options. Information may change without notice. DoubleColumnBoringMillHorizontal3-AxisVertical5-AxisDoubleColumnBridgeTurningCenter IN STOCK AND READY TO SHIP! • Table Diameter: 9.8" • X/Y/Z Travel: 30" x 20" x 20.5" • X/Y/Z Rapids: 1,496, 14,496, 1,260 inches/minute • 12K RPM Spindle Watch The Video

Industry Standard NC Conversational NC/Conversational Merge A2Z-D&R-Machinery_5-Axis_VMX30Ui_July-2023.indd 1 6/29/2023 3:24:37 PM

Robots Are Looking Better to Detroit as Labor Costs Rise

Automakers are looking to an old friend to help offset rising labor costs: robots.

For decades, car companies have increased automation inside their factories. Now, auto executives are looking more closely at this approach, to address a rising labor bill and take advantage of more sophisticated technology.

Competition from relative newcomers like Tesla, which has been more aggressive in deploying this factory technology, is also nudging more traditional auto manufacturers in this direction.

While automakers have been moving to automation for some time, rising labor costs are poised to accelerate the adoption of such technologies, said Laurie Harbour, president of Michigan manufacturing consulting firm Harbour Results.“Automation is the future. More so than we’ve ever seen,” she said.

United Auto Workers members approved a labor contract in late 2023 with Ford, General Motors GM that included a record 25% wage increase over four years and marked the sharpest labor-cost increase for the companies in recent memory.

The effect from the deals in Detroit quickly rippled through the industry, with Toyota Motor, Hyundai Motor and other nonunionized automakers increasing wages to stay competitive.

Detroit executives have said the contracts were richer than they had planned for, and they are strategizing ways to blunt the increased costs. Ford said the new terms would add about $900 in cost per vehicle by the time the contract expires in early 2028. GM executives pegged the hit from richer labor contracts during that period at roughly $500 a vehicle.

A spokesman for GM said the company will continue to use technology to help its team members increase productivity, and make work environments safer. Stellantis, Ford and the UAW declined to comment.

Automakers have used robotics since at least the 1960s to make manufacturing easier and more efficient. One of the earliest examples of these machines was an automotive assembly robot called Unimate that was installed in a

Your one stop shop for 623.847.4028

NEW 10KW BYSTRONIC FIBER LASER - NEW CNC PRESS BREAK - 5-AXIS WATERJET CUTTING (table 13’10” x 6’7”) - CERTIFIED MIG, STICK, & TIG WELDING - LASER CUTTING SERVICES

DEBURRING SERVICES

PUNCH & SHEARING

STAINLESS STEEL FABRICATION - PRECISION SHEET METAL WORK - GENERAL METAL FABRICATION & DESIGN - SAW CUTTING - TUBE BENDING SERVICES - PRODUCT MANUFACTURING & ASSEMBLY - PRODUCTION & PROTOTYPING - MOBILE FABRICATION & WELDING 623.847.4028 Address : 5815 W McLellan Rd Glendale, AZ 85301 Our Phone : 623.847.4028 Email : sales@azwelder.com QUICK TURNAROUND 1-2 Day Lead TIME

-

-

-

-

GM factory in 1961 to handle die castings.

The auto industry is a top consumer of robots, according to the International Federation of Robotics. The global automotive industry installed 136,000 new industrial robotic units in 2022, the federation found, second only to the electronics industry.

Often these so-called cobots work alongside workers to access hard-toreach spots or perform tasks that are particularly physically demanding. Ford said in 2018 that it had at least 100 of these cobots across two dozen plants around the world.

Tesla has been a leader in factory robotization, putting pressure on competitors to follow suit. Last year, executives at the world’s most valuable automaker said introducing more automated equipment was a crucial tool in its goal to cut the cost of making future models by 50%.

Dozens of new battery factories and electric-vehicle plants in the works will also open the door to broader use of high-tech systems, analysts say. It is easier and less costly to install robots in a new facility versus retrofitting an existing one. Plus, it is more streamlined to have updated systems that “speak” to each other smoothly, as opposed to popping in a new machine among older ones.

Your trusted partner for kitting solutions.

The UPE Solution

UPE provides comprehensive kitting solutions to businesses—from startups to Fortune 500 companies. We specialize in assembling complex BOMs (Bill of Materials) into production-ready kits, streamlining the process and saving you valuable time and resources. Our team of experts has 50+ years of experience in kitting, ensuring that your products are assembled to the highest standards.

Save time, energy and money.

At UPE we customize every kit to meet your unique needs and requirements. Our electronic component kitting services cater to a broad spectrum of industries, including aerospace, telecommunications, military and more. We use state-of-the-art equipment and technology to ensure that your kits are assembled with precision and accuracy. Our commitment to customer satisfaction means that we work closely with you to ensure that your needs are met.

We take pride in our attention to detail and our ability to provide cost-effective kitting solutions without sacrificing quality. Your time is a valuable resource—UPE understands what it takes to keep production moving.

Choose UPE for all your kitting needs.

Our experienced team is always available to offer expert guidance and support. Contact us today to learn more about our services and how we can help you streamline production.

INDUSTRIES SERVED

‣�AEROSPACE

‣�AGRICULTURE

‣�AUTOMOTIVE

‣�AVIATION

‣�COMPUTING

‣��COMMUNICATIONS/ TELECOM

Automakers are likely to introduce more robots and other forms of automation over time, replacing workers as they retire, rather than displacing swaths of their current workforce.

‣�CONSUMER PRODUCTS

‣�DEFENSE

‣�ENERGY

‣�INDUSTRIAL

‣�MARINE

SERVICES

Big Factory Capability — Small Shop Agility

‣ Kitting — Complete BOM

‣ Consigned / Turnkey Kits

‣ Purchasing Services

‣ Project Management

‣ Materials Management

‣ Assembly Services

‣ Engineering Services

‣ Bonded Inventory

‣ PCB Fabrication

‣ Component Evaluation

‣�MEDICAL ‣�MILITARY ‣�TECHNOLOGY

760.438.2370

Spaceport America Inks MOU with GloballyRecognized Economic Development Engine The Borderplex Alliance

robots, some academics say. Humans are sometimes better at completing precise tasks that require visual judgment and the ability to nimbly adjust equipment.

LAS CRUCES, N.M -The Borderplex Alliance and Spaceport America today signed a Memorandum of Understanding, formalizing a new collaboration between the two organizations. This partnership will open up thrilling opportunities to propel the Borderplex region’s economy to new heights.

The trend is making the UAW and its members nervous about the prospect of machines replacing jobs.

There are varying views on how extensive auto-industry automation will become in the next decade, and many analysts point out that other strategies—such as streamlining the production process by offering fewer vehicle options— can have larger cost savings.

“We are thrilled about teaming up with Spaceport America,” said Jon Barela, CEO of The Borderplex Alliance. “Together, we will initiate new programs that stimulate job creation and capital investment in our region. The commercial space industry is expanding rapidly, and this alliance ensures the Borderplex will be at the forefront of this 21st-century industry.”

“Partnering a big said

Spaceport our leader With the capitalize has development alliance R&D, “Together, development engineering, Through organizations business the Borderplex to that growth.

Spaceport commercial licensed

acres adjacent to the U.S. Army New Mexico, has a rocket-friendly restricted airspace, low population vertical launch complexes, and

There are other risks to automating. Adding robots to a process for the first time can introduce quality problems, said Mark Wakefield, managing director at advisory firm AlixPartners. There needs to be a clear advantage to using a machine, either from a cost standpoint or because the task hasn’t been effectively carried out by workers, he said.

Some

Spaceport America, the world’s first purpose-built commercial spaceport,

Additionally, whatever machines gain in terms of productivity can be zeroed out by the needed personnel to fix or program

It can also be too expensive to retrofit an existing factory with this new machinery, making it more attractive to remain with the status quo, analysts say. “If the way you put the last car together worked well, if you change something, you have to balance the risk with the reward of some lower cost,” Wakefield said. By Nora Eckert, WSJ

A2Z MANUFACTURING SW • 27 • March / Apr 2024

A2Z MANUFACTURING WEST COAST • 18 • FEB - MAR ’24

has The innovate space

UNITED PACIFIC ELECTRONICS

of the most respected are tenants at Spaceport America: AeroVironment, UP Aerospace, subsidiary of BAE Systems. The Borderplex Alliance is an policy advocacy organization. sector-led. The mission of The and opportunity to the Borderplex

Corte Del Nogal, Suite K, Carlsbad,

unitedpacificinc.com sales@unitedpacificinc.com 2075

CA 92011

OUR HISTORY

Sterling Fab Tech is a fabrication machinery supplier that represents the most cutting-edge manufacturing technologies in the fabrication industry. With locally based sales and service employees, we support the Southwest region from California to Louisiana.

OUR APPROACH

We pride ourselves in being the subject matter experts in fabrication processes and machine technologies. Combining this engineering approach to sales, our goal is to understand your needs and educate your team without any sales puffery.

OUR CUSTOMERS

Scan the QR code to get an inside look at customer facility tours and what our customers are saying about SFT.

A2Z MANUFACTURING SW • 28 • March / Apr 2024

TECH CENTER SALES ENGINEER APPLICATION ENGINEER SERVICE ENGINEER

Dallas,

Schedule a private demo with us at info@sterlingfabtech.com

CENTER LOCATIONS

MACHINE TOOL SOLUTIONS FOR YOUR FABRICATION CHALLENGES Costa Mesa, CA

TX

TECH

MACHINERY SOLUTIONS

MACHINERY SOLUTIONS

PRECISION MACHINE TOOLS

PRECISION MACHINE TOOLS

Coil Lines

Coil Lines

Flat Sheet & Tube Lasers

Flat Sheet & Tube Lasers

Punch and Laser/ Punch Combo

Punch and Laser/ Punch Combo

Waterjets

Waterjets

Press Brakes & Robotic Bending Cells

Press Brakes & Robotic Bending Cells

Panel Benders

Panel Benders

Plate Rolls

Plate Rolls

BRANDS

BRANDS

Tube Bending

Tube Bending

Deburring & Finishing Machines

Deburring & Finishing Machines

Robotic Mig & Laser Welding Cells

Robotic Mig & Laser Welding Cells

Quality Inspection Machines

Quality Inspection Machines

Sheet & Tube Storage Racks

Sheet & Tube Storage Racks

Nitrogen Generators

Nitrogen Generators

INDUSTRIAL MACHINE TOOLS

INDUSTRIAL MACHINE TOOLS

Plasma & Oxy-Fuel Burning Tables

Plasma & Oxy-Fuel Burning Tables

Gantry Style Machining Centers

Gantry Style Machining Centers

Pipe & Tube Cutting

Pipe & Tube Cutting

Robotic Plasma for Profile Cutting

Robotic Plasma for Profile Cutting

High Tonnage Press Brakes

High Tonnage Press Brakes

Heavy Duty Plate Rolls

Heavy Duty Plate Rolls

Angle & Pipe Bending

Angle & Pipe Bending

Automated Beam Welding

Automated Beam Welding

Power Tools for Bevelings

Power Tools for Bevelings

MACHINERY SERVICE + SUPPORT

MACHINERY SERVICE + SUPPORT

SERVICE TEAM

SERVICE TEAM

APPLICATIONS TEAM

APPLICATIONS TEAM

SFT’s Applications team supports you during machine selection, installation/commissioning throughout the life of the machine. We offer services to improve efficiency and productivity, while reducing the common headaches of implementing new technologies or dealing with labor shortages.

SFT’s Applications team supports you during machine selection, installation/commissioning throughout the life of the machine. We offer services to improve efficiency and productivity, while reducing the common headaches of implementing new technologies or dealing with labor shortages.

SFT’s Service team are factory trained technicians dedicated to getting your machine installed correctly, preventing unexpected downtime through preventative maintenance, assisting with machine relocations, and promptly completing machine repairs. They are also trained to handle TRUMPF and Bystronic lasers.

SFT’s Service team are factory trained technicians dedicated to getting your machine installed correctly, preventing unexpected downtime through preventative maintenance, assisting with machine relocations, and promptly completing machine repairs. They are also trained to handle TRUMPF and Bystronic lasers.

A2Z MANUFACTURING SW • 29 • March / Apr 2024

ANDY WHITE Applications Engineer

JOSE BOTELLO Applications Engineer

JEREMY GARLAND Senior Applications Engineer

TODD WASKOW Service Engineer

FERMIN HERNANDEZ Service Engineer

LUCAS HERBERT Service Engineer

JAMES DONOVAN Applications & Service Engineer

EDGAR MONCADA Service Engineer

EDDIE ANZALDUA JR Service Engineer

info@sterlingfabtech.com • sterlingfabtech.com • 855-222-7084

ANDY WHITE Applications Engineer

JOSE BOTELLO Applications Engineer

JEREMY GARLAND Senior Applications Engineer

TODD WASKOW Service Engineer

FERMIN HERNANDEZ Service Engineer

LUCAS HERBERT Service Engineer

JAMES DONOVAN Applications & Service Engineer

EDGAR MONCADA Service Engineer

EDDIE ANZALDUA JR Service Engineer

info@sterlingfabtech.com • sterlingfabtech.com • 855-222-7084

A2Z MANUFACTURING SW • 30 • March / Apr 2024

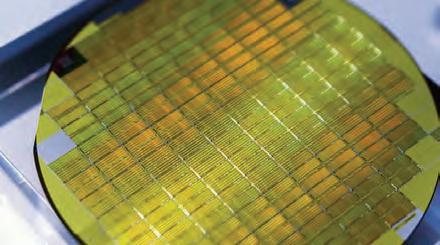

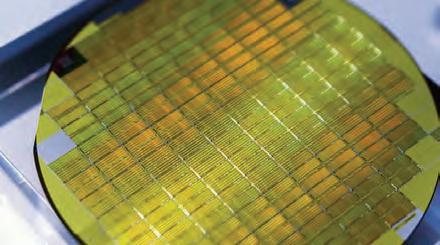

German Microelectronics Company Expands Into University of Arizona Tech Park Facility

An international maker of microelectronics and infrared sensors has set up shop at the University of Arizona Tech Park. The company, Micro-Hybrid Electronic GmbH, which is based in Germany, set up a United States application center at the UA Tech Park in the Tucson metro, where it had already been doing some manufacturing work since 2015 through subsidiary Micro-Hybrid Electronics Inc.

The move was facilitated by the University of Arizona Center for Innovation’s Soft Landings Global Advantage program, which is managed by Tech Parks Arizona to foster international business opportunities.

Micro-Hybrid has been in operation since 1992 and builds high precision sensors and components for a range of industries. Manufacturing at the Tucson location will focus on infrared emitters to enable components for spectroscopic sensors used for infrared gas analysis, the company’s website said.

The company has six employees in Tucson, with two of them hired last year, and it anticipates further expanding the workforce in the coming years, Micro-Hybrid Electronics Inc. Chief Operating Officer Jenny Tauber told the Business Journal.

The company hailed the location’s state-of-the-art facilities as well as its talent pool, resources and collaborative opportunities

in an ecosystem with several optical and electronic technology companies.

“Our parent company, Micro-Hybrid Electronic GmbH – Germany, chose to expand operations in Tucson, AZ by opening the Application Center knowing the potential that the region offers due to its geographical position, the proximity to key industries and to the University of Arizona,” Tauber wrote in a statement to the Business Journal. “From Tucson we can offer better service and support to our existent customers and tap into new customer segments within existent markets in the USA.”

Micro-Hybrid said the expansion into North America was a vital part of its growth strategy. It already has several locations worldwide.

With the application center, Micro-Hybrid will be able to more easily offer technical consulting in the United States to customize its products to the industrial, medical, safety, transportation, agricultural and other sectors.

By Jeff Gifford - Phx Business Journal

A2Z MANUFACTURING SW • 31 • March / Apr 2024

Your source for Precision Machine Parts

Phoenix Swissturn Solutions is a screw machine shop opened in Tempe, Arizona to provide swiss screw machining capabilities to the RF/microwave, Medical, Aerospace and other specialized markets.

Expertise, Precision machining, dedication, Timely & quality service. We can machine difficult materials:

Titanium, Stainless Steel, Brass, Beryllium Copper (BeCu), Various types of plastic

Phoenix Swissturn Solutions LLC

www.phoenixswissturn.com

607 S. 48th Street, Ste. 104 Tempe AZ, USA 85281

602.600.8436

Info@phoenixswissturn.com

Arizona’s EV Boom Brings Big Benefits To Rural Communities

When it comes to manufacturing growth in recent years, Arizona beats out nearly every state in the country, with a significant portion of these jobs coming in the battery and electrical vehicle (EV) industry. Even more noteworthy is the fact that a majority of these expansions have taken place in rural communities.

In 2016, Lucid Motors made history when it announced Casa Grande as the site of its new, 1-million-square-foot EV manufacturing facility.

“We started with over 60 potential factory sites in 13 states scattered across the United States,” said Brian Barron, then director of global manufacturing at Lucid Motors. “We chose Arizona because you showed genuine interest in our company from the outset, because you negotiated in fairness and understanding, and because you continue working together with us from a partnership perspective and not just a business perspective.”

Lucid’s AMP-1 factory began construction in December 2019 and was operational within 12 months. A few years later, Motor Trend Magazine named Lucid Air its 2022 Car of the Year.

Lucid’s success has sparked a growing network of electric vehicle manufacturers, parts makers, and battery innovators. Five EV manufacturers have established operations in Arizona since 2016. In just the past two years, the state has attracted nearly a dozen battery expansions, including manufacturers, recyclers, and mineral processing facilities. Roughly half of these expansions have occurred in rural Arizona.

In 2021, Midwestern-based auto parts maker UACJ Whitehall selected Flagstaff for its $60 million factory, citing Northern Arizona’s proximity to university talent and nearby manufacturing partners. The announcement from the Lucid supplier represented the largest economic development win in Flagstaff in nearly half a century.

“UACJ Whitehall’s expansion into Flagstaff is a gamechanger for our local economy,” said Julie Pastrick, president and CEO of the Greater Flagstaff Chamber of Commerce. “The company’s investment here locally will eventually grow into hundreds of high-wage jobs and further establishes Arizona as a leader in EV innovation.”

It seems every corner of Arizona has attracted jobs in the EV/battery industry.For EVelution Energy, a small town outside Yuma, Arizona, represented the ideal location for its solar-powered, cobalt-processing facility for electric

A2Z MANUFACTURING SW • 32 • March / Apr 2024

Certifying United States & International Manufacturers, Services Organizations, and Government Entities

Contact: Steve Keneally at 617-838-4648; info@americanglobal.org; www.americanglobal.org

vehicle batteries. Once operational, the facility will be the only cobalt processing facility in North America.

Gil Michel-Garcia, EVelution’s co-founder, cited Yuma’s “lower cost of living” and “lower regulatory jurisdiction” as well as its proximity to California’s EV market in choosing southwestern Arizona.

Additional battery innovators have set up in Casa Grande, Eloy, Coolidge, Queen Creek, and Buckeye, in addition to larger cities including Tucson and Gilbert.

Last year, LG Energy Solution’s decision to build a state-of-theart battery manufacturing complex in Queen Creek represented one of the largest foreign direct investments in the country. Once complete, the complex, which will support thousands of new jobs, will represent the largest single investment for a stand-alone battery manufacturing facility in North America.

A key enabling factor for rural Arizona’s manufacturing attractiveness lies in strategic training partnerships. A new initiative led by the Arizona Commerce Authority, in partnership with local community colleges, has brought unique training facilities to places such as Coolidge, Yuma, and Kingman.

The network, known as Future48 Workforce Accelerators, offers customized training pathways, designed in collaboration with

industry partners and hosted at local community colleges. The program builds off the model of Drive48, a partnership between the ACA, Central Arizona College, the city of Casa Grande, Pinal County, and Lucid.

“Casa Grande has seen nothing like this. Pinal County has seen nothing like this,” said Vicente Procela, one of the more than 2,400 students to graduate from the Drive48 program since 2021.

Since 2011, the ACA has worked with local partners to land more than 166 expansion projects in rural communities, representing over 25,000 jobs and more than $13 billion in capital investment.

Flagstaff business advocate Julie Pastrick credited wins like Lucid with helping rural communities diversify and be “a larger part of the new statewide economy.”

“The Arizona Commerce Authority and other economic partners have worked hard to keep that economic momentum going for cities and towns of all sizes,” she said. Find out more about the advantages of Arizona’s rural communities at www. azcommerce.com/programs/rural-destinations/.

A2Z MANUFACTURING SW • 33 • March / Apr 2024

Virtual Cert® ISO-9001 certification with American Global Standards can lower operational costs, improve your bottom line and offer your business a competitive advantage.

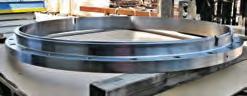

Do You Get 24-48 Hour Turnaround When Your Machine Goes Down, Even When Its A 5 Axis Machine?

You Do With Adams Machinery

Experiencing a machine breakdown can be a nightmare scenario for any business. When you reach out to your machine tool dealer for assistance, the typical wait time of 24 to 48 hours may seem like wishful thinking. In reality, it often stretches into weeks. The stress of lost productivity and the daunting task of informing customers about potential delays can keep you up at night. Does this sound all too familiar?

But fear not, for if you’ve procured your precision machine tools from Adams Machinery, you’re in good hands. Eugene Hendrix, now serving as Vice President/General Manager, came to Adams Machinery with a wealth of industry experience, spanning sales and machine shop operations. He understands the critical importance of providing exceptional aftermarket support to customers. “We lead the pack in selling and installing more 5-axis machines than nearly anyone else in the Valley,” Eugene asserts. He underscores the necessity for a top-tier service and applications team to handle installations swiftly and seamlessly, a standard Adams Machinery consistently meets.

Eugene recounts a recent triumph where Adams Machinery intervened to support the installation of a DN Solutions 5-axis machine, stepping in when another dealer faltered. “They expected the install to take 2 weeks, and we had it done in 4 days!” he proudly states. This prowess in 5-axis machining owes much to Eugene’s background as a former 5-axis programmer. “I intuitively knew that transitioning our customers to 5-axis machining would give them a competitive edge,” Eugene adds.

Just over a year ago, Eugene enlisted Jeff Altimus to lead Adams Machinery’s Applications and Service team as Director of Support Services. Jeff brings decades of industry experience, earning a reputation as a skilled service professional and CNC machine expert in Arizona. Eugene lauds Jeff’s return to Adams Machinery, recognizing his instrumental role in enhancing the Applications and Service team.

Under Jeff’s leadership, the ‘A Team’ has thrived, comprising seasoned veterans and tech-savvy Gen Zers. Leveraging digital tools like Discord for seamless collaboration, the team shares insights and troubleshoots issues effectively. Jeff emphasizes the importance of teamwork and mutual respect, fostering an environment where employees thrive and customers benefit.

Acknowledging the value of ongoing training, Eugene highlights the

team’s participation in factory training programs both domestically and abroad. Mentoring initiatives and online platforms like Titans of CNC supplement this training, ensuring the team remains adept at handling complex machinery.

Jeff advocates for cross-training, eschewing specialization to promote versatility within the team. Responding to customer issues promptly, the team aims for a two-tiered approach: resolving problems remotely whenever possible and dispatching technicians onsite within 24-48 hours when required.

Identifying gaps in machine tool service provision, Jeff and Eugene are committed to addressing specific needs, including timely support in Southern Arizona and comprehensive preventative maintenance services.

Adams Machinery carefully selects the machine tools it represents, prioritizing builders who share their commitment to customer support. Eugene commends DN Solutions for their responsiveness to customer feedback, citing instances where suggested improvements were

A2Z MANUFACTURING SW • 34 • March / Apr 2024

Jeff Altimus, Director of Support Services

swiftly implemented. The company also values its longstanding partnership with Marubeni CitizenCincom, Inc., noting their exceptional support.

In an era marked by a shortage of qualified workers and high turnover, Jeff emphasizes the importance of local, highly trained service. Adams Machinery aims to exceed customer expectations with prompt, reliable support, ensuring satisfaction beyond the initial sale.

With a focus on quality and customer satisfaction, Adams Machinery stands ready to impress with its comprehensive support services, including machine repairs, preventative maintenance, and spindle repairs.

To learn more about how they can support your needs, contact them at: 480-968-3711 or visit adamsmachineryaz.com. Prepare to be wowed by the service you receive from Adams Machinery.

Hear From A Few Of Adams Machinery’s Customers

“We bought 2 DNM 4000 machines from Adams Machinery a couple of years ago. Their service has been outstanding; when we have an issue, they are here same day or at the latest the next day. Their service team is knowledgeable, and they communicate very well with us. Parts are in stock or shipped overnight. We crashed a machine, they came out that day, the parts overnighted, and we were up and running in 3 days. Adams Machinery is amongst the best in the Valley for service.” Kevin, GM Precision Machine Shop

“We have operations in CA and AZ, and so we bought our DN Solutions machines from Adams Machinery. For one machine, it was to be placed in our CA location. Adams Machinery had more experience installing this machine than their CA counterparts, so all agreed that Adams would do the install and the dealer in CA would come to learn. The Adams Machinery technician had the machine up and running in days, not weeks! They are so knowledgeable and professional and I am already looking at some new purchases through Adams; they are that good!” Mike,

CEO Precision Machine Shop

“We are almost all Adams Machinery – have 8 DN Solutions Machines; The service is outstanding; they are very knowledge about the products; in all our years with them we have had very few machine issues; pretty much they are user initiated When we’ve had a spindle crash, they are out here right away and we are up and running in days.

We’ve used other machine dealers in the past, and we value the service we get from Adams Machinery; friendly, knowledgeable just very good to work with.“ Brandon –CNC Specialist/Programmer

“I’ve been buying my machines from Adams Machinery over the past decade. Not only do we really like their machines, but we also have an excellent relationship with their team. Their service is really good - if we have an issue, they come when they say they will, and if it’s a critical need, they are out right away.