Southwest Edition (AZ, NV, and NM)

Productivity Quality Inc. (PQI) Opens New Facility In Albuquerque, NM

Productivity Quality Inc. (PQI) Opens New Facility In Albuquerque, NM

Banterra’s team, with more than a hundred years of experience, understands the challenges of running small to mid-size businesses. The things you do, day in and day out, is truly the backbone of America and as your lender, we are right there with you to support your capital needs and doing what it takes so you can compete with the world in your industry.

Industry-leading service with local decisions

Bank commitment to Made In USA and Made In Arizona values

World-class deposit products including Treasury Management

Loan products designed speci cally for machine shops and small businesses

BUSINESS CHECKING AND CASH MANAGEMENT

Metalworking fluids formulated to meet aerospace demands.

• Improve process stability on heat-resistant Super Alloys

• Easier robotic handling with cleaner parts

• Reduce costly maintenance interruptions

• Approved for Alloys of Aluminum, Titanium, Nickel, Chrome, and Steel

• Maximize gains from high pressure systems

• Enhance filtration system performance

Artificial intelligence is accelerating at a pace that is fundamentally reshaping the labor market. For decades, the conventional wisdom has been that a college degree is the surest path to upward mobility and job security. Yet AI is steadily eroding that assumption. Roles in fields like finance, marketing, legal research, and even software development are now being automated or streamlined by tools that deliver faster results at a fraction of the cost.

This disruption poses a serious challenge for the white-collar workforce. Companies are reevaluating which jobs require human capital and which can be handled by algorithms. For many degree-based professions, the ground is shifting underfoot, and the promise of a college diploma as a long-term safeguard looks increasingly uncertain.

But this same trend represents a remarkable opportunity for the trades—particularly precision manufacturing. Far from being displaced by AI, modern manufacturing depends on skilled people who can work with advanced equipment, integrate robotics, and solve complex engineering problems on the shop floor. AI can enhance these roles, but it cannot replace the expertise required to turn raw material into critical components for aerospace, defense, energy, and medical industries.

The reality is that manufacturing is already facing a talent shortage. Thousands of high-paying, technology-driven jobs are open and unfilled across the country. Meanwhile, many young workers are being funneled into college programs that may leave them underemployed or burdened with debt in fields where AI is compressing wages. The imbalance is stark—and it’s also an inflection point for American competitiveness.

For business leaders and policymakers, the message is clear: the future depends on elevating the trades. Precision manufacturing roles are not “fallback” careers; they are essential, future-proof professions that combine technical skill, critical thinking, and hands-on innovation. Investing in apprenticeship programs, trade schools, and stronger partnerships between manufacturers and educators is not just workforce development—it’s economic strategy.

AI may be redefining what work looks like in many office settings, but on the shop floor, it is becoming an amplifier of human skill rather than a replacement for it. As AI makes many traditional degree-based jobs less valuable, it is simultaneously magnifying the worth of those who can bridge technology and craft. Precision manufacturing is thriving in this environment, and the companies that recognize and act on this shift will secure both their workforce and their competitive advantage.

The AI revolution doesn’t eliminate opportunity—it reallocates it. And right now, the greatest opportunity lies in building up the skilled manufacturing talent America needs..

Until next issue, I wish you continued success in 2025—and as always, God bless our troops.

Address: 3324 E Ray Road #459 Higley, AZ 85236

Telephone: (602) 412-7696

www.a2zMFG.com

Linda Daly,Publisher

Published bi-monthly to keep precision manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z MANUFACTURING has compiled and maintains a master list of approximately 8500 people actively engaged in the precision manufacturing Industry. It has an estimated pass on readership of more than 19,300 people. Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to A2ZMANUFACTURING.com.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher. The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

Designed and built for use with Haas ST and DS series CNC turning centers, the Haas Bar Feeder connects directly to the Haas control.

Robot Systems

• HRP-1 System – 7 kg capacity • HRP-2 System – 25 kg capacity

• HRP-3 System – 50 kg capacity

Pallet Pool Systems

• 3-Station for VF-2YT/SS, VM-2

• 6-Station for EC-400

• 6-Station for VC-400/SS

• 6-Station for UMC-1250/SS

• 10-Station for UMC-750/1000/SS

• 10- or- 20-Station for UMC-500/SS Automatic Parts Loaders

• Turning Center APL

• VMC APL

• Small UMC APL

Haas Bar Feeder

All-inclusive design, with plug-and-play capabilities to Haas lathes

• 4th- and 5th-Axis Rotaries

• Sub-Spindles

• Parts Catcher System

• Auto Door for Mills and Lathes

• Automatic Coolant Refill

KLK Inc. Expands In-House Capabilities with Addition of Two Sodick EDM Machines

KLK Inc., an AS9100-certified entity, is proud to announce the expansion of its manufacturing capabilities with the addition of two advanced Sodick EDM (Electrical Discharge Machining) systems: the VL400Q Wire EDM and the 8035L Sinker EDM. This investment marks a strategic enhancement to KLK’s precision machining services, reinforcing the company’s commitment to delivering complex components with uncompromising quality and efficiency. With this addition, KLK’s total facility footprint now spans an impressive 83,000 square feet, reflecting the company’s ongoing growth and dedication to serving high-tech industries.

The decision to bring EDM in-house was driven by a high-value customer project that required both wire and sinker EDM operations. After conducting a full audit of the part—KLK recognized an opportunity to improve lead time, control costs, and elevate quality by taking control of the process. The one part alone made a compelling case for investing in this specialized capability. KLK’s familiarity with EDM processes, paired with its drive for continuous improvement, made the transition a natural next step. Today, many current customers who were sourcing their EDM through other providers, are bringing their EDM work to KLK.

The Sodick VL400Q Wire EDM delivers high-speed, high-precision performance with linear motor drives and an advanced motion control system—ideal for

intricate cuts and fine tolerances. Complementing it is the 8035L Sinker EDM, a Japaneseengineered powerhouse designed for larger, complex cavity work with superior surface finishes.

With this latest expansion, KLK continues its legacy of innovation and customer-driven growth.

From its humble beginnings in a garage in 1967 to becoming a trusted manufacturing partner across aerospace, medical, defense, and semiconductor sectors, KLK, a family-owned and operated business, is a fullservice manufacturer, specializing in Precision CNC Machining, Sheet Metal Fabrication, Welding, and Electro-Mechanical Assembly.

For more information on how they can support your precision manufacturing needs, call (602) 267-1331 or visit: klkinc.com

Okuma’s MULTUS U3000 Multitasking Machine offers an ideal combination of power, speed, and process flexibility. A broad scope of machining functions and the ability to complete tasks in a single setup make this machine simple and efficient for producing a variety of parts. Combining powerful turning and milling capabilities, made possible with Okuma’s OSP-P300 control, equals one thing – increased production capacity.

Explore all of the powerful features of the MULTUS U3000, including:

• Full 5-axis contouring (available as an option)

• New compact B-axis spindle

• 240-degree B-axis range

• 30 hp milling motor spindle

• 12,000 RPM H1 milling spindle

• Wide range of ATC configurations available (40 to 180 tools)

As manufacturers seek new opportunities to enhance productivity and drive the industry forward, FABTECH 2025 is set to showcase the tangible solutions and technology leading the way. North America’s largest metal forming, fabricating, welding and finishing event returns to McCormick Place in Chicago from Sept. 8–11, bringing the entire industry under one roof.

The event comes at a pivotal time, offering a firsthand look at the automation, high-precision machinery and smart fabrication technology needed to address key industry challenges, including the ongoing skilled labor shortage. More than 45,000 manufacturing professionals from around the world are expected to attend to explore solutions across 850,000+ square feet of exhibits, where over 1,500 world-class suppliers—including Platinum Sponsors AMADA America, BLM Group, MC Machinery Systems, and TRUMPF Inc.— will display the latest innovations shaping the future of manufacturing.

“Manufacturers today are tasked with meeting higher production demands amid a shifting labor landscape,” said Tracy Garcia, CEM, FABTECH group director at SME. “FABTECH is where real-world answers are found. This is the place to see the technology that can immediately boost efficiency, hear what’s coming next from industry

leaders, and leave with concrete solutions that can be implemented as soon as you return to your shop.”

FABTECH 2025 will reflect the industry’s most pressing needs by showcasing the technology and equipment designed to solve them. Attendees can explore these key trends across the show floor:

Automation & Smart Manufacturing: As automation adoption accelerates, attendees will see live demonstrations of advanced robotics, cobots and AI-powered systems that detect part defects in real time, reshaping the approach to quality and speed. These solutions can be found throughout all three halls, with leaders like FANUC, KUKA, Fronius, CLOOS North America, Lincoln Electric, and Beckhoff Automation showcasing robotics and automated welding solutions in the North Building.

The Connected Smart Shop: The latest in smart factory solutions will be on display, showcasing how AR/VR, Internet of Things (IoT) and nextgen software are powering flexible, on-demand manufacturing with fewer risks and faster results.

Our employees are efficiently skilled, pay attention to detail and take pride in high quality work.They set us apart from the competition by specializing in the ability to hold tight tolerances to .0001.

CNC Universal Grinding up to 5 X 24”, We have 4 Swiss Turning Centers Machining up to 32mm. Long Bar Grinding for Screw Machines. Contact Us Today: 801-487-9700, wendief@superiorgrinding.com

Swiss Screw Machining up to 1.5” OD, CNC ID/OD, ID, OD, Angled, Surface, Blanchard & Centerless Grinding, Circular Blade Grinding up to 20” Diameter, and all Types of Industrial Blades. Full Service Machine and Manufacturing with Lathe & Mill AS9100 rev D & ISO 9001:2015 Certified, WOSB, WBE and Government certified

Attendees can explore these innovations from exhibitors like Bystronic, Prima Power, Mazak Optonics, and Muratec in the South Building.

High-Precision Technology: Live demonstrations of the newest high-speed fiber lasers, press brakes, and cutting-edge fabrication machinery will offer a look at unmatched precision for cutting and welding applications. This technology, critical for industries like automotive, heavy equipment, and aerospace & defense, will be a key feature in the South Building (forming & fabricating), North Building (welding) and Lakeside Center (stamping and press automation).

Sustainable Manufacturing: Attendees can explore a range of sustainable solutions, from eco-friendly coating systems to energy-efficient machinery. This trend will be prominent in the Lakeside Center, with finishing exhibitors like Gema USA, IFS Coatings, Therma-Tron-X, Nordson, and Global Finishing Solutions.

Technology-Focused Pavilions Streamline the Attendee Experience

To help attendees navigate the vast show floor, the event is organized into seven specialized technology pavilions: Automation, Forming and Fabricating, Tube and Pipe, Stamping and Press Automation, Welding, Finishing, and the new Job Shop Pavilion.

“The show floor is a preview of where the industry is heading next,” said Mark Hoper, senior vice president of expositions and media at FMA. “The combination of established industry leaders and hundreds of new exhibiting companies creates an unmatched environment for discovery. Attendees will leave with a clear vision of the innovations that will boost their productivity and competitiveness long after the show ends.”

Learning Beyond the Action on the Show Floor

Complementing the live demonstrations and solutions attendees can experience on the show floor, FABTECH’s comprehensive education program offers more than 200 sessions and workshops across 13 tracks. The program is designed to expand on key themes attendees encounter in exhibitor booths, providing deeper insight into new processes, materials, and performance strategies. Top industry experts and thought leaders will lead collaborative sessions sharing best practices and industry trends and focusing on the latest technological advancements attendees see in real time across the exhibit halls.

For more information, visit fabtechexpo.com and connect on Facebook.

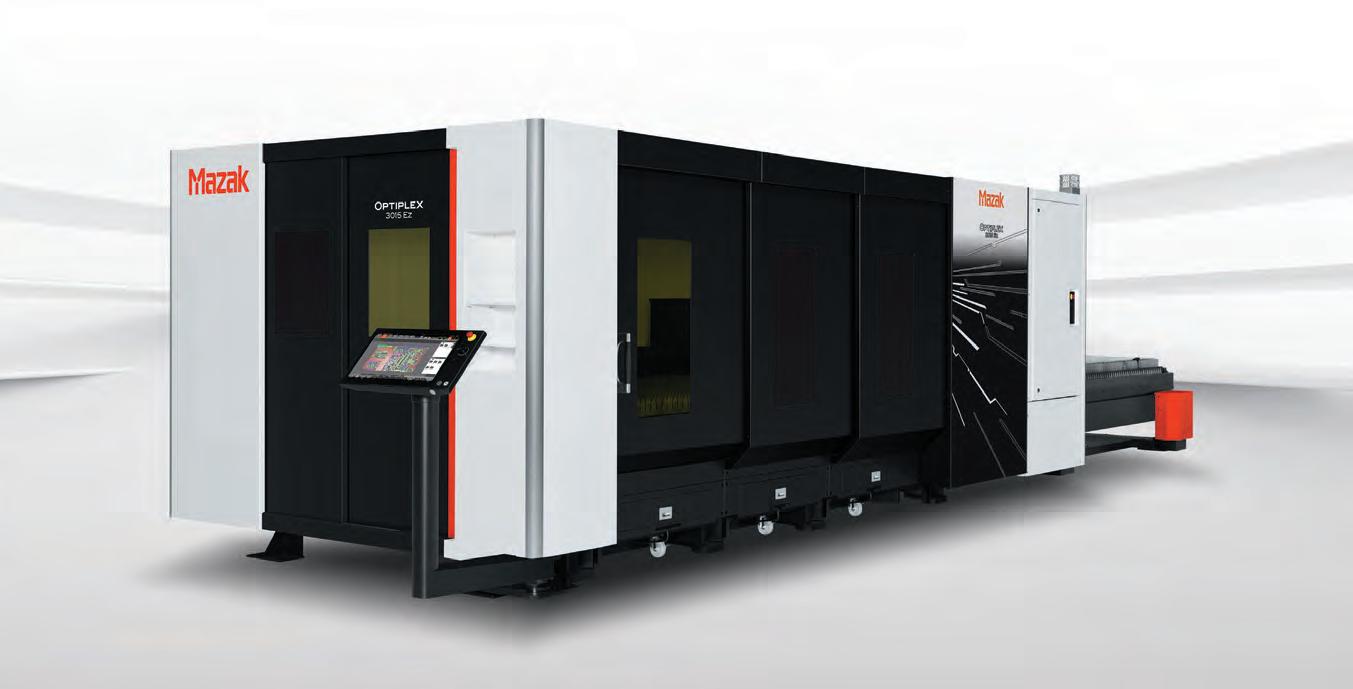

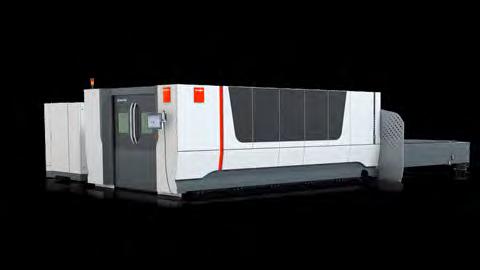

Mazak’s OPTIPLEX Ez integrates OPTIPLEX NEO’s superior design into an affordable, entry-level laser processing solution that provides the maximum value without compromising world-class customer support. Ez is available in 8kW, 6kW and 4kW power levels and 3015 or 4220 format. The machine provides high-quality cutting performance, easy accessibility with front and side doors, and cost-effective operations that make it a powerhouse of productivity. Discover the power of the OPTIPLEX Ez.

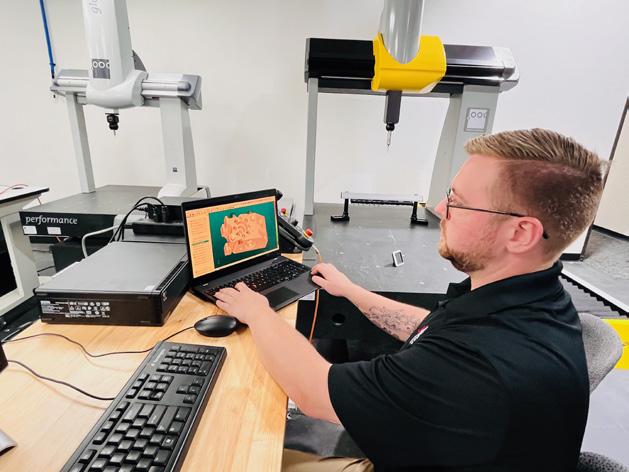

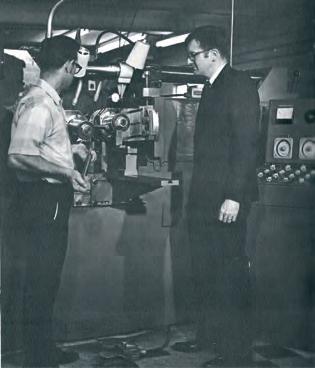

Sam Westendorf with General Manager Tim Shepherd

Usher Precision Manufacturing Arizona, under the leadership of President and Co-Owner Sam Westendorf, is proud to spotlight its advanced Swiss screw machining capabilities at its state-of-the-art facility in Phoenix, Arizona. The company specializes in high-precision turned components for demanding industries such as medical devices, aerospace, semiconductor, and defense—where micro-level tolerances and consistent quality are essential.

Usher Precision’s legacy dates back more than 50 years. Originally founded in 1972 in Forest Grove, Oregon, by Darryl and Karl Usher, the company began as a modest operation. Karl Usher, who started his machining career cutting sheet metal with tin snips, eventually took over the family business from his father and renamed it Usher Precision Manufacturing. In a strategic transition three years ago, the Usher/Westendorf Family opened their Arizona Operation, and moved on from its Oregon facility in early 2025. Usher Precision Arizona is marking a new chapter of innovation in its storied history of machining, and

with its young crew, is ‘ushering’ in a new era of manufacturing.

Today, Usher Precision operates a fleet of six advanced Star Swiss screw machines, capable of handling bar stock from 1/8” to 1.5” in diameter. These machines enable the production of intricate components in a single setup, dramatically reducing cycle times and ensuring repeatability. Under Westendorf’s leadership, the Swiss department has seen rapid expansion, driven by a commitment to continuous investment in cuttingedge manufacturing technologies.

Quality remains the cornerstone of the company’s success. Usher Precision’s climate-controlled inspection lab ensures all parts meet stringent specifications for form, finish, and dimensional accuracy. This in-house metrology capability supports the company’s broader promise of precision and reliability in every component delivered.

In addition to Swiss machining, Usher Precision offers CNC milling, turning, centerless grinding, and full project management. With a highly skilled team, a culture of continuous improvement, and a sharp focus on customer service, Usher Precision is uniquely positioned to meet growing demand for complex, highprecision components throughout the Southwest.

For more information:

Sam Westendorf; Usher Precision (623)587-8444

sam.westendorf@usherprecisionaz.com www.usherprecisionaz.com

Skill Up AZ is a registered apprenticeship program with the state of Arizona. Our model allows individuals to earn a nationally recognized certificate in their chosen field while working and earning a salary.

The Arizona MEP, the Arizona Department of Education, CTE, and Arizona State University (Polytechnic and West Campuses ) have partnered again this year to host Arizona's MFG Month Celebration in a whole new trade show format.

October 24th: ASU West Campus and October 31st: ASU Polytechnic Campus

Manufacturing companies have the opportunity to set up (FOR FREE!) at both locations and talk to high school students about manufacturing careers and demonstrate what they manufacture. TABLES ARE STILL AVAILABLE!!

For full details and to sign up to participate visit the AZ MEP Website at: https://www.azcommerce.com/programs/arizona-mep/events/ REGISTRATION DEADLINE IS OCTOBER 1ST!

All individuals have successfully passed the NTMAU Mechanical Aptitude Test (MAT) and are ready to begin work through our registered apprenticeship program.

If you’re interested in sponsoring an apprentice and would like to review candidates’ resumes and test scores, visit https://www.skillupaz.org/ contact/, and we’ll get their information to you.

On June 26, NTMA Member Foresight Technologies hosted a lunch and tour of their expanded facility for our members and industry partners.

Special thanks to Jeff Hull and his amazing team for their hospitality!

The NTMA/ Arizona Chapter was proud to honor 11 Skill Up Arizona apprentice graduates at our dinner celebration and welcome them to the manufacturing community on July 17. With over 100 members, guests and apprentice family members, it was a very special evening. Also featured that evening was Jenny Stupica, Director of NTMA Workforce Development, demonstrating the updated portal for

NTMA-U which will launch later in the year. For more information on Skill Up Arizona , contact Maribeth All at executivedirector@skillupaz.org or visit their website at www.skillupaz.org.

ATMA upcoming events include:

September 25 – ATMA Fall Golf at Grand Canyon University. Foursomes are sold out, but sponsorships are still available.

October 9 – Walbar Tour followed by a happy hour Social. October 22 – Fall dinner meeting. November 5 – Empire Precision Manufacturing shop tour.

Interested in learning more about NTMA Membership and Benefits? Contact Barbe Bennett at exectutivedirector@arizonatooling. org.

Precision. Speed. Simplicity.

We combine global machining expertise with hands-on local service—delivering turnkey solutions, training, aftermarket support, and personalized service wherever you are

The future of aviation starts with the right partner, smart technology, and a strong milling process.

Announcements & Releases Continued

We are excited to welcome Bryce Keeler to the Turul Engineering team as our new Vice President of Sales and Marketing. Bryce brings nearly three decades of experience in software, manufacturing, and problem-solving to his new role. A native of Arizona, he earned his business degree from Brigham Young University (BYU) and his MBA from Thunderbird School of Global Management. His career began during the dot-com era, and in 2002 he joined Siemens, where he thrived in a variety of sales roles—inside, overlay, and outside—covering Arizona, New Mexico, and eventually aerospace and defense customers nationwide.

Over the years, Bryce built trusted, long-term relationships with customers ranging from mid-market companies such as MD Helicopters and Eclipse Aerospace to major industry leaders such as Williams International and Raytheon.

Bryce sees robotics not as a futuristic luxury, but as a here-and-

now opportunity for shops of all sizes. Traditionally, the cost, complexity, and programming time required to deploy robots—sometimes taking MONTHS!—kept many smaller manufacturers from adopting the technology. Leveraging Siemens NX software, Turul Engineering can now reduce robot programming time from weeks to just 20 minutes, making robotics more accessible and affordable [for large and small shops alike]. Bryce is passionate about breaking down these barriers so small and mid-sized shops can enjoy the same productivity, safety, and throughput advantages that larger companies have long embraced.

Zoltan says, “With his deep expertise in manufacturing software, his belief in doing business with integrity, and his enthusiasm for democratizing robotics, Bryce is a perfect fit for Turul Engineering’s mission. Please join us in welcoming him to the team—we are confident that his leadership will help more manufacturers embrace innovative technologies that drive efficiency, safety, and long-term success.”

You can reach Bryce at bryce@turulengineering. com

√ AS9100 Revision D

√ Family Run For 35 Years √ Competitive Pricing

√ 3 Companies - 1 Ownership

Frontier Group announces the acquisition of Qualitas Finishing/ Precision Finishing (“PFI”)

As Tucson’s oldest and most established anodizing and finishing company, PFI is uniquely suited to service the Tucson areas industrial and advanced manufacturing community. This acquisition brings PFI into one of the largest and leading metal finishing operators in Arizona, offering more services, quality accreditations, and a specific focus on special processing.

The recent sled test, conducted with a 103-pound mannequin, is the latest sign that the JPO can make good on its promise to finish the three design fixes by November, allowing the military services to lift restrictions on lightweight pilots flying the F-35 Last year, Defense News first repor ted that pilots under 136 pounds were barred from flying the fifth-generation aircraft after testers discovered an increased r isk of neck damage to lightweight pilots ejecting from the plane. The US Air Force has also acknowledged an “elevated level of r isk” for pilots between 136 and 165 pounds.

With 2 locations, and over 90 employees, Frontier Group is Arizona’s only independent special processing service provider that is Nadcap accredited to offer chemical processing, non-destructive testing (NDT), and welding services.

The first test of a new, lightweight F-35 helmet was successful, according to the prog ram office, a promising sign that the Pentagon can to the jet’s escape system by

Recently, at H ce Base, New Mexico, Lockheed Ma ining all three solutions d ry to F-35 pilots during ej llaVedova. Once the full gamut of ly by the end of the summer, the two modifications to the ejection seat and issuing the new Generation III “light” helmet to the fleet, he said

The prototype helmet tested weighs about 4.63 pounds, approximately 6 ounces lighter than the orig inal Gen III helmet, and is designed to ease some strain on smaller pilots’ nec ks during ejection

For more information, visit: www.frontiergroupco.com or call (602) 437-2426.

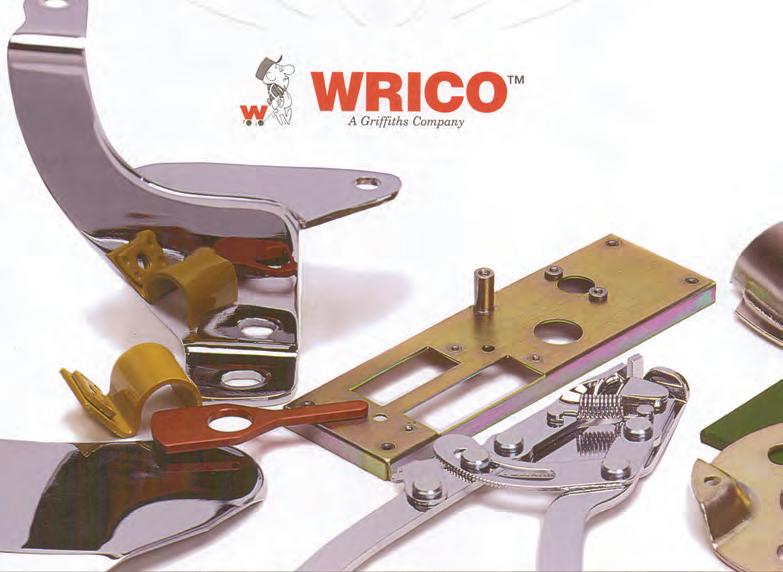

high-quality tool and die design and manufacturing craftsmanship. Founded in the mid-1970s, the company grew under the leadership of owner Ann Stirling (Thompson) and key employee Tim Bitting, who joined in 1979 and has been instrumental in its success ever since. Known for its expertise in deep draw stamping and precision tooling, Thompson Machine the Tool & Die Group Inc. has thrived by staying committed to its values, investing in equipment, and fostering long-term relationships with both employees and customers.

Although the test was the fir st test of the new helmet, the JPO, Loc kheed Mar tin and seat-maker Mar tin Baker have conducted at least seven other tests with the latest version of the seat, which is equipped with two modifications designed to reduce r isk to pilots.The fixes to the ejection seat itself include a switch for lightweight pilots that will delay deployment of the main parachute, and a “head support panel,” a fabric panel sewn between the parachute r isers that will protect the pilot’s head from moving backward dur ing the parachute opening.

For half a century, Thompson Machine the Tool & Die Group Inc. in Albuquerque has been a trusted partner for customers who rely on

The prog ram office has about another 10 tests planned, which will use a mix of low-, middle- and high-weight mannequins.

One of the keys to Thompson Machine’s staying power has been its willingness to evolve with the industry. Early on, the company added a mechanical shear—allowing better control over thin materials—and more recently, it invested in a Haas VF-3 mold-making machine to The company consistently invests in upgrading their equipment and new technology to expand capabilities. The shop floor is equipped with modern tool

“This initial test had promising results and the F-35 enterpr ise is on a path to qualify the helmet . by the end of this summer,” DellaVedova told Defense News. “The lighter helmet expected to be fielded by the end of the year is in line with the seat timeframe as well.”

3020 South Park Drive ,Tempe, AZ

sales@stp-az.com • Tel: 602-426-9340

We Manufacturing Complex Intricate Parts Requiring Extreme Precision And Quality

We Are Built For High Production Parts And Can Handle Extremely Tight Tolerances

and die manufacturing equipment and servo technology stamping presses, the most recent a 170-ton press and servo technology to support complex jobs. These advancements enable the team to deliver consistent, highprecision results across a wide range of industries.

team that truly feels like family.

The Federal Reserve reported that industrial production in March rose 1.4%, returning to growth after an unseasonably stormy February knocked it down 2.6%. The report shows total industrial production rose 2.5% at an annualized rate during the first quarter of 2021 despite the losses endured in February by manufacturing, mining, and utilities companies.

Behind the machines is a dedicated workforce, many of whom have been with the company for 25 years or more. Thompson Machine is proud of its long-tenured toolmakers and the mentorship opportunities it provides, including hiring talent from apprenticeship programs like the one at Los Alamos. Today, the company operates as a certified ISO facility, with a culture grounded in trust, skill, and responsibility. Ann Thompson continues to serve as President, with her daughter Leticia “Lettie” Stirling stepping in as COO and succession plan—ensuring Thompson Machine remains a woman-owned business for the future.

Contact Thompson Machine, the Tool & Die Group Inc. :

Motor vehicles and parts production, which fell 10% in February, rose 2.8% in March but remained depressed by a persistent shortage of semiconductors. Most durable goods indexes rose between 2% to 3%.

Thompson Machine, the Tool & Die Group, Inc. 8400 Washington Place NE Albuquerque, NM 87113

Phone: (505) 345-5658 823-1453

Website: www.thompsonmachineinc.com

The industrial production gauge includes productivity in three sectors: manufacturing, mining, and utilities. Manufacturing production (which excludes mining and utilities output) rose 2.7% in March after falling 3.7% the month before. Mining production improved 2.7%, while utility output fell 11.4% thanks to unseasonably warm March temperatures. Manufacturing output rose 1.9% at an annualized rate.

In nondurable manufacturing, the index for the chemicals industry rose 4.1%, and petroleum and coal products rose 5.7%, although neither sector has fully recovered from severe weather damage—the Federal Reserve noted that some chemicals factories remain offline thanks to damage sustained from February’s winter storms. Most nondurable goods indexes rose between 0.9% and 3.0%.

New orders of metalworking machinery, measured by the U.S. Manufacturing Technology Orders Report published by AMT – The Association For Manufacturing Technology, totaled $429.2 million in June 2025. This was a 9.1% increase from May 2025 and a 7.7% increase from June 2024. Machinery orders placed through June 2025 totaled $2.52 billion, a 13.7% increase over the first half of 2024.

Capacity utilization in manufacturing rose by 1.9 points, also reversing February losses.

Almost all market groups saw improvements in March, despite lingering challenges. The Federal Reserve’s index for other manufacturing, which includes publishing and logging, remained the same, but durable goods and nondurable goods indexes rose 3.0% and 2.6%, respectively.

Looking ahead, Thompson Machine the Tool & Die Group Inc. plans to continue growing its workforce while preserving the values that have defined it for 50 years. With steady leadership, new equipment, and a commitment to quality, the company is well-positioned for the next chapter. As Lettie puts it, Thompson Machine remains a small business with big capabilities—one that has built its reputation on precision, integrity, and the dedication of a

The value of orders in the first half of 2025 is 21.2% higher than for the average year, whereas units ordered in the first half of 2025 are 17.2% lower. This trend underscores the increasing importance that automated machinery

If February was notable for its storminess, March was notable for its heat. The unseasonably warm month coincided with a roughly 10% drop in consumer energy products, and the 11.4% drop in utilitie s utilization was the largest recorded in the history of the index’s 48-year history.

has played in the market for manufacturing technology in recent months, with added options and features increasing order values. Such automated solutions allow companies to gain additional productivity at current workforce levels, bridging the gap caused by the shallow, upward trend of industrial output and the continued decline in employment.

• Contract machine shops, the largest consumer of manufacturing technology, have shown signs of recovery after lagging behind the overall market for much of 2024. Both the value and unit count in new orders are up 12% compared to the first half of 2025. Looking forward, this customer segment could weaken in the remainder of the year, as a higher percentage of shops report an unwillingness to invest in additional machinery over the next 12 months.

• After surpassing $300 million in total investment in the second half of 2024, the aerospace sector continues to invest at a rapid clip, increasing the value of orders by 6% in the first half of 2025 to the highest level recorded. Although news of a strike among some of Boeing’s defense workers could be interpreted as a negative sign, the last strikes at the end of 2024 propelled substantial investment in manufacturing technology.

• Increased demands for electricity and the equipment needed for its generation and distribution have been dominant trends for several months. Demand for machinery from electrical equipment manufacturers has fallen by 19% compared to the first half of

2024, but the value of orders is still 24% above average. By contrast, manufacturers of engines, turbines, and other power transmission equipment increased orders by 19% compared to the first half of 2024, as many data centers supplement what is provided by municipal power grids with on-site generators.

• Primary metal manufacturers have increased orders of manufacturing technology by nearly 50% from the first half of 2024 to the highest level since the second half of 2022. This increased investment comes as North America increases crude steel production, one of the few regions to do so, and executives report higher quotation activity and growing backlogs.

Uncertainty has been the primary economic driver through the first half of 2025, and the first few weeks of the second half show few signs of that instability abating. In AMT’s Summer Economic Update Webinar on Aug. 7, Oxford Economics revised its forecast upward to show modest single-digit growth in machinery orders in 2025. While this is an improvement over their

BOOST YOUR OUTPUT WITH ROBODRILL AUTOMATION, LET’S BUILD YOUR DREAM NIGHT CREW TODAY!

LEAVE THE BUSY WORK TO THEM, YOU HAVE BETTER THINGS TO DO

Announcements & Releases Continued previous estimates, it implies a significant decline in order activity to erode the 13.7% growth gained through the first half of 2025. At the same time, ITR Economics forecasts a strong second half of 2025 for cutting tool consumption, lifting orders for the year. While these forecasts seem at odds at first glance, cutting tool consumption tends to peak about two quarters after a peak in machinery orders. As the rest of 2025 unfolds, the health and trends of U.S. consumers and businesses will reveal if the momentum thus far will continue – or if cyclical peaks are on the horizon.

The United States Manufacturing Technology Orders (USMTO) Report is based on the totals of actual data reported by companies participating in the USMTO program. This report, compiled by AMT – The Association For Manufacturing Technology, provides regional and national U.S. orders data of domestic and imported machine tools and related equipment. Analysis of manufacturing technology orders provides a reliable leading economic indicator as manufacturing industries invest in capital metalworking equipment to increase capacity and improve productivity. USMTO.com.

AMT – The Association For Manufacturing Technology represents U.S.-based providers of manufacturing technology – the advanced machinery, devices, and digital equipment that U.S. manufacturing relies on to be productive, innovative, and competitive. Located in McLean, Virginia, near the nation’s capital, AMT acts as the industry’s voice to accelerate the pace of innovation, increase global competitiveness, and develop manufacturing’s advanced workforce of tomorrow. With extensive expertise in industry data and market intelligence, as well as a full complement of international business operations, AMT offers its members an unparalleled level of support. AMT

also produces IMTS – The International Manufacturing Technology Show, the premier manufacturing technology event in North America. Learn more at AMTonline.org.

Skill Up AZ is a registered apprenticeship program with the state of Arizona. We help manufacturers build the workforce they need in two ways:

Train Current Employees – Do you already have team members with potential? We provide structured training to turn them into skilled CNC machinists. With Skill Up AZ, you save on recruitment costs and build long-term retention.

Hire New Apprentices – We connect you with motivated candidates who’ve passed the NTMA Mechanical Aptitude Test and are ready to learn in your shop.

We provide structured training to turn them into skilled CNC machinists. With Skill Up AZ, you save on recruitment costs and build long-term retention.

Hire New Apprentices – We connect you with motivated candidates who’ve passed the NTMA Mechanical Aptitude Test and are ready to learn in your shop.

If you’re interested in sponsoring an apprentice and would like to review candidates’ resumes and test scores, visit https://www.skillupaz.org/contact/, and we’ll get their information to you.

We look forward to helping you find the right fit for your team!

Regards!Maribeth All M.Ed. - Executive Director

Admiral Metalworking Fluids Is Pleased To Announce They Are The NEWEST Distributor For FUCHS Lubricants

Admiral Metalworking Fluids has just announced they are Newest Distributor for FUCHS in WA, AZ, UT, NV, OR, and ID. Though they

are new to the Metalworking Fluids industry as a company, their team members are not. Dave Smith and Raúl Esparza bring years of experience and knowledge to the Metalworking Fluids Industry as well as the Manufacturing and Machining Industries.

FUCHS is the world’s largest independent Manufacturer and Supplier of Lubricants and related Specialty Products. They also produce a vast range of products for a multitude of industries and applications. The company offers over 10,000 products that serve a wide array of applications. These products include cutting fluids, quenching fluids, and corrosion preventatives among various other products for the Manufacturing Industry.

For More information, contact:

David Smith: DS@admmiralfluids; 206-600-8077

Raúl Esparza: RE@admiralfluids.com; 206-600-8501

be manufactured within a month. The first two weeks will be used to manufacture 1 kilowatt of solar cells and modules, and the second two weeks will be used to assemble and integrate the solar array.

It also helps solidify the Tempe company as an emerging player in Arizona’s booming defense contracting and aerospace sector, giving it a role in bringing more efficiency and agility to American military capabilities.

“This is a meaningful award for us that will result in critical research and development benefiting the U.S. Space Force,” Solestial CEO Margo de Naray said in a statement. “Long manufacturing lead times have plagued the incumbent solar technology for space. Through our use of affordable, accessible silicon and automated manufacturing of solar cells and solar power modules, Solestial is uniquely positioned to solve this critical bottleneck and support mission readiness.”

The deal is the latest development in what has been an eventful year for Solestial, which in May closed a $17 million series A funding round and around the same time named de Naray as its new CEO. The company was also a finalist in AZ Inno’s Fire Awards this year.

Under the deal, Solestial said it will optimize its low-mass, radiationhardened silicon solar cells and solar power modules as it develops, builds and tests a new multiorbital solar array wing for small satellites as well as develop new module electrical interconnectors.

The work will be done with fast integration and assembly in mind, with the project finishing up with a demonstration that a complete solar array wing can

Solestial was selected for the contract by Los Angeles-based SpaceWERX, the innovation arm of the Space Force. SpaceWERX collaborates with innovators in private industry, academia and the government to integrate new technologies into the space agency’s capabilities.

Solestial said that to date it has been awarded more than $7 million in Small Business Innovation Research (SBIR) contracts from the Space Force, the U.S. Air Force, the Air Force Research Laboratory, NASA and the National Science Foundation. By Jeff Gifford – Phoenix Business Journal

German vacuum pump giant expands US footprint with Arizona facility

Maulburg, Germany-based Busch Vacuum Solutions announced it leased a nearly 60,000-square-foot industrial building for its Tempe service center, slated to open in October and create “many skilled jobs,” according to the company. The lease is less than a mile from where technology services provider Zelis plans to set up a 4,436-square-foot printing production facility.

“This investment represents our long-term commitment to Arizona and the broader region,” Jake Young, spokesman for Busch Vacuum Solutions, said. “We are dedicating significant resources to equip the facility with cuttingedge technology, expand our capabilities, and build a highly skilled, diverse workforce.”

Busch Vacuum Solutions’ Tempe facility will serve as a “key regional hub” that specializes in repair, service and overhaul of vacuum pumps, systems and overpressure equipment.The facility will provide faster turnaround times, expert support and efficient service delivery to the company’s U.S. customers in the semiconductor, industrial, medical and environmental sectors.

“This investment represents more than just added square footage. It’s about proximity, partnership, and performance,” Turgay Ozan, president and CEO of Busch Group USA, said in a statement. “With the launch of our Tempe location, we’re better positioned to deliver unmatched value to customers who rely on advanced vacuum technologies in high-performance environments.”

While Busch Vacuum Solutions’ Tempe facility will support a wide range

of industries, Arizona’s “dynamic and expanding semiconductor sector” was a key factor in the company’s decision to expand to the state, Young said.

In addition to semiconductor and industrial markets, Busch’s vacuum technology supports automotive, food and beverage, packaging, metallurgy, pharmaceuticals, plastics, and largescale distribution.

Busch Vacuum Solutions is a business division of the Busch Group, a privatelyheld family business. The Busch Group, which manufactures vacuum pumps, compressors and gas abatement systems, has 8,000 employees and operates 23 production plants worldwide.

Busch Vacuum Solutions has a significant presence in the U.S., operating its national headquarters and a 200,000-square-foot manufacturing facility in Virginia Beach, Virginia. It has service centers in eight states, according to the company’s website. By Amy Edelen – Phoenix Business Journal

A retired executive with over 25 years of experience in the food and consumer product industry says revitalizing U.S. manufacturing shouldn’t be romanticized but can offer rewarding careers.By Don Brock

Manufacturing in the United States isn’t romantic. Despite what glossy ads, political speeches and tech expos suggest — gleaming robots, spotless factories and the promise of bringing jobs back home — the reality is more brutal.

I’ve learned it’s steel-toed boots, long hours and being measured by your last shift, your last run, your last screw-up. And for those who stay it’s also about pride, grit and mastery. But none of it comes easily.

As the country talks about reviving American industry, the real question is whether our workforce — and our expectations — are ready for what that truly demands. These are some of my lessons from decades on the job. The entry point is hard, fast and underpaid

Most people don’t “choose” manufacturing; they land in it. Sometimes from a technical school. Often from circumstance. You get your foot in the door — running a filler, packing pallets, loading raw materials — and you realize quickly that no one’s waiting to hand you anything.

The work is physical. The pay at the beginning is barely enough. Maybe $18 an hour, if you’re lucky. Maybe rotating 12-hour shifts with no childcare. The benefits vary widely — union shops can be solid; non-union ones often tread the fine line between acceptable and exploitative.

And the unspoken reality is you may experience injuries, repetitive stress, line fatigue and night shifts that screw up your sleep for years.

The climb has no map, few guides

Moving up in manufacturing requires more than hustle. It takes visibility, timing and often politics.

The best operators don’t always become supervisors. The best supervisors don’t always get promoted. And there’s usually no clear pathway — just a mix of luck, attrition and whoever happens to be watching.

Middle management? That’s where careers either advance or stall. You’re stuck between the C-suite’s cost obsession and the frontline’s daily chaos. You make decisions no one thanks you for and get blamed for outcomes you didn’t control.

Leadership in manufacturing is not about glossy strategy decks. It’s about walking the floor when you’re

exhausted, defusing conflicts with HR breathing down your neck, keeping lines running when half the crew calls out and still hitting a margin target that was set by someone who’s never touched a valve or heard a piston seize.

The culture varies. Some plants are toxic: blame-heavy, turfdriven, unsafe. Others are tight-knit, even familial, where veterans look out for rookies and you solve problems with duct tape and a handshake.

But make no mistake: ego, burnout and generational divides are everywhere. The old guard resents the new hires. The latest hires roll their eyes at “the way we’ve always done it.” HR often spends more time rolling out diversity initiatives than addressing the real, unresolved safety issues on the third shift, where the newest, least experienced workers face the highest risks.

And most outsiders — executives, consultants and media — don’t understand what it takes to build something, fix something, or keep it running continuously 24/7 without failure.

The rewards are real, but earned

If you survive the grind — and learn to lead — manufacturing offers something no desk job can. You can point to something and say, “We made that.”

You learn systems. You learn people. You learn what it means to stand up under pressure and keep going

when everything’s breaking. And for some, you learn how to transform not just product, but culture — how to lead turnarounds, build teams and leave plants better than you found them.

Yes, the money gets better. Six figures is attainable if you transition into operations leadership, technical direction, or supply chain management. But you’ll earn every penny in sleepless nights, holiday calls and constant stress.

And still, you might get laid off after a merger and reorganized when a private equity group cuts costs or pushed out when you’re “too expensive” after building the whole damn system.

It’s either a calling, or it breaks you

Manufacturing, although not easy, has been a productive career for me. However, are we willing to invest in what it takes to make that the case for everyone?

Manufacturing will harden you, humble you, and — if you let it — shape you into something fierce and capable. But it’s not for the faint of heart or the glory-seeker.

It’s for those who believe in execution over excuses, in teams over titles and in building things that matter — even when no one’s looking. So, what’s it like to build a career in U.S. manufacturing? It’s brutal. It’s beautiful. And it’s real work.

As the country rallies around the idea of bringing

manufacturing back home, we need to ask: Is this truly what we want? And if so, are we prepared to invest in the education, training and cultural readiness it demands?

Tesla is nearing completion of its lithium iron phosphate (LFP) battery plant in Nevada, a move that strengthens U.S. energy storage capacity and chips away at the country’s reliance on foreign-made battery cells. The site is set to manufacture LFP batteries — a chemistry gaining ground due to its lower cost, safety advantages, and key material independence.

Unlike traditional lithium-ion chemistries that rely on scarce and expensive metals like cobalt and nickel, LFP batteries use more abundant materials, simplifying the supply chain. That’s a strategic advantage as global battery demand outpaces mining and refining capacity for critical minerals. Tesla’s choice to scale this chemistry domestically positions it to better control both battery costs and production timelines.

The Nevada facility will support two of Tesla’s major business lines: electric vehicles and stationary storage. The company has already started placing its second-generation LFP cells in GM’s Silverado EVs, helping trim battery costs by up to $6,000 per vehicle. Bringing volume production in-house is expected to improve margins and secure supply at a time when automakers face volatile prices and trade risks.

Tesla has filed patents aimed at boosting LFP energy density by 33%, a key step toward closing the performance gap with nickelbased batteries while keeping manufacturing costs low. The added safety benefits — LFP chemistry significantly lowers fire risks — make it well-suited for grid storage installations and entry-level EVs, where durability and price matter more than high range.

This project fits into a broader push by the federal government to onshore battery production and reduce strategic dependencies. By localizing LFP manufacturing, Tesla supports U.S. goals to decarbonize transport and power infrastructure without deepening exposure to foreign critical mineral markets.

The Nevada ramp-up signals a shift in battery tech priorities. As cost and scalability begin to outweigh outright performance in many markets, LFP is no longer a niche alternative. High-volume production from a major player like Tesla suggests it’s moving to the center of the U.S. electrification strategy.

TSMC to invest $100 billion in new Arizona fabs

Semiconductor Manufacturing Co. will invest as much as $100 billion to build three more computer chip factories, two advanced packaging centers and a research and development center that will create thousands of jobs in Arizona, the White House announced.

President Donald Trump and TSMC CEO C.C. Wei unveiled the company’s investment to spur domestic production of AI chips, building upon the company’s previously announced $65 billion investment in its north Phoenix fab site.

TSMC’s expanded investment is expected to support 40,000 construction jobs over the next four years and create tens of thousands of high-paying, permanent hightech jobs in advanced chip manufacturing and R&D.

G E T T O K N O W U S

Servicing our industry and trade customers in intelligence heat treating for over 60 years

Established in 1963

Real Time Live Job

Tracking

10+ Processes Performed

50+ Furnaces

AOG and Line Down

Services

Over 10+ Prime Approvals

24/7 Processing

“This will create hundreds of billions of dollars in economic activity and boost America’s dominance in artificial intelligence and beyond,” Trump said. “Semiconductors are the backbone of the 21st century economy, and really, without the semiconductors, there is no economy powering everything from AI to automobiles to advanced manufacturing. And we must be able to build the chips and semiconductors that we need right here in American factories with American skill and American labor. And that’s exactly what we’re doing.”

602-258-7751

cs@phxht com

www phoenix-heat-treating com

TSMC, the world’s biggest semiconductor manufacturer, produces chips for companies including Apple, Intel and Nvidia. The company began mass production of 4- nanometer chips for Apple — its largest customer — in January. Last September, the Business Journal reported that TSMC’s Arizona factory, or fab, reached a trial production yield rate similar to the company’s yield rate at its Fab 18 in Tainan, Taiwan, which had put the fab ahead of schedule.

“In Phoenix, Arizona with 3,000 employees, we are producing the most advanced chips made on U.S. soil,” Wei said during the press conference. “With the success of our first fab, we are now very happy to announce we are going to invest additional $100 billion U.S. dollars in addition to our current $65 billion U.S. dollar investment in Arizona … we are going to produce many chips to support AI progress and support smartphone progress.”

As the Business Journal reported in December, TSMC is on track to begin mass production at its Arizona fab site in Q1 of this year. Operations are expected to begin at TSMC’s second Phoenix factory in 2028. The company’s second fab will produce 2- and 3-nanometer process technologies for AMD, Apple, Nvidia and Qualcomm.

Last November, the White House finalized its award of a $6.6 billion CHIPS Act grant to TSMC with plans to disburse $1 billion to the chipmaker by the end of 2024 to support its Arizona fab.

1704 West 10Th St • Tempe, AZ 85281

Ph: 480-967-2038 • F: 480-829-0838 • www.PrecisionDie.com

and dedication to customer service are number one priorities. This type of expertise and dedication has fostered a reputation of excellence in the tooling and stamping industry.

Located in Tempe, Arizona, our 100,000 Sq. Ft. Facility contains state of the art equipment , with production capabilities ranging from simple geometries to complex forms with intricate details. Precision enjoys a world-class reputation supplying a variety of OEMs, managing their inventory levels, and making certain product quality and timely delivery are NEVER compromised.

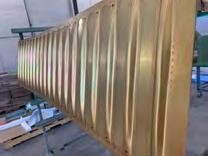

Next Level Decking opens Goodyear facility with cutting-edge technology

Next Level Decking, a steel products manufacturing company that supplies the building industry, opened a facility equipped with a topof-the-line automatic machine in Goodyear.

The company is owned by CEO and founder Brandon Bell, a Yuma-born, secondgeneration steel fabricator who owns other steel companies in Arizona. This is his latest venture in the Valley, adding to his other Goodyear companies: Next Level Steel, which also has a location in Mesa, and Roll Former Solutions.

Next Level Steel was recognized on Inc.’s 2024 5000 List and produces eco-friendly, super-spanning castellated steel beams, which Bell brought to the Phoenix area market. His specialty firm, Roll Former Solutions, manufactures support systems for metal roofing and steel structures.

Bell has been in the steel industry for around two decades and has seen first-hand the difficulty of purchasing steel deck — the construction material made from steel sheets used in both roof and floor construction — from major, out-of-state producers. “It’s known, in the industry, as kind of a pain in the butt to deal with these big companies,

these billion-dollar companies that sell deck,” Bell said. “It’s just been a hassle, and it’s a market that I can do well in, as far as providing a better product with better service.”

Next Level Decking’s Goodyear location is at 15836 W. Eddie Albert Way, a 50,000-squarefoot facility which it shares with Next Level Steel. The plant is the only one of its kind west of the Mississippi equipped with a fully automated Gasparini roll former machine, according to the company’s announcement.

“I found the team, and I needed a machine. I wanted to have the best machine out there, the most automation,” Bell said. “Because a lot of the machines, if you look in the industry, are made of 1950s technology. Nothing’s changed.”

A key component of the business and new facility is its Gasparini

machine, which he said took 14 months to ship from Italy. That machine can handle different-sized materials and loads its own coils, rather than requiring a manual process with a forklift, which is safer and faster, Bell said.

Next Level Decking’s Goodyear facility is equipped with a Gasparini roll forming machine.

“With the most advanced machinery in the industry, an all-American supply line, and a deeply experienced team, we’re built for today’s market and tomorrow’s growth,” Bell said.

Bell hopes to create a one-stop shop for structural contractors who need steel deck products, as recordsetting industrial development engulfs the Southwest. A study by Colliers found that the Phoenix area had its highest level of industrial construction deliveries in 2024 — adding 34.8 million square feet of new space and demonstrating 7.8% inventory growth.

The Business Journal reported in April that Phoenix ranked second in the country with 15.1 million square feet of industrial space under construction, trailing only Dallas.

To staff his company, Bell assembled a nine-person team of experienced professionals who were retiring from the industry. Kelsey Lavicka, senior engineer, has 12 years of steel deck and construction experience, and sales manager Thomas Edwards has over 15 years. Project manager Frankie Almonte also brings 15 years of experience, 13 years of those in the deck industry, while estimating manager Adam Snay has 20 years.

With its signature machine up and running, Next Level Decking is now catching up on orders. Next Level Decking is Bell’s mission to “revolutionize” commercial steel decking in the Southwest. It offers supply chain dependability for commercial and industrial contractors in Arizona, and other states like California, Nevada, Utah, Colorado, New Mexico, Texas and Idaho.

“There are a lot of people out in the industry that are fed up with the big company mentality and are excited to use somebody new,” Bell said. By Griffin Uribe Brown – ACBJ/ Dow Jones Intern, Phoenix Business Journal

Nevada Supplier expects to benefit from $16.5B Tesla, Samsung AI chip deal

Graphjet Technology says growth in U.S. semiconductor manufacturing is timely for its planned expansion in Nevada.

Tesla’s $16.5 billion AI chip deal with Samsung, announced by CEO Elon Musk on his social media platform X, is set to provide a major boost to U.S. semiconductor manufacturing

Continued Next Page

as well as benefit an emerging field of domestic suppliers including Graphjet Technology.

Graphjet, a producer of graphene and graphite, said Tesla’s announcement was timely with its plan to build a production plant in Nevada.

“As a producer of graphite and graphene, Graphjet stands to benefit from the expansion of the AI chip production as graphite and graphene plays a crucial role in semiconductor manufacturing, particularly in processes requiring high temperature and precise control,” CEO Chris Lai said in a statement.

Graphjet’s planned facility in Nevada will convert 30,000 metric tons of agricultural waste into 10,000 metric tons of graphite annually, enough material to power more than 100,000 electric vehicles.

Tesla’s eight-year agreement with Samsung ensures a pipeline of next-generation A16 chips, which will be produced at the technology firm’s new fabrication plant in Taylor, Texas. The new chips have assorted applications including use in autonomous vehicles, humanoid robots and AI data centers.

Despite slowing demand for electric vehicles, the need for high-tech components including semiconductors, batteries and critical minerals, continue to rise. Many massive manufacturing building projects are

already underway to develop a domestic supply chain.

In December, the Department of Commerce finalized Samsung’s $4.75 billion award funded through the CHIPS and Science Act to boost domestic manufacturing. It followed the previously signed preliminary memorandum of terms announced on April 15, 2024.

Taiwan Semiconductor Manufacturing Co. announced plans in March announced to invest an additional $100 billion in the U.S. on top of the $65 billion it already was spending on three chip plants it was constructing in Arizona. Nvidia in April said it would invest $500 billion to manufacture AI chips in Arizona and Texas.

These domestic semiconductor projects will mean potential business for Graphjet. Lai said his company has already started generating revenue and has experienced increasing interest in its products.

“The growth in the semiconductor industry will accelerate the growth of our company,” Lai said.

Graphjet was founded in 2019 in Malaysia. The company aims to begin production by 2026. By: Larry Avila, Manufacturing Dive

Sandia Labs, Kirtland AFB reveal record-breaking economic impacts for New Mexico

Leadership from Sandia National Laboratories and Kirtland Air Force Base, two powerhouses driving the economy in Albuquerque and across the state, discussed each entity’s economic impact Aug. 12 at the Kirtland Partnership Committee’s biannual economic impact meeting.

Sandia National Laboratories

Director Laura McGill announced that in 2024, the labs had an all-time high $5.2 billion in total expenditures. Kirtland Air Force Base Wing and Installation

Commander Col. Justin Secrest said the base had a $7.5 billion economic impact in 2024.

Here’s a recap of the economic impact numbers from McGill and Col. Secrest’s speeches.

Sandia National Laboratories

Sandia National Laboratories’ $5.2 billion total expenditures was a $424 million increase from 2023 to 2024 and a 66% increase from 2017, McGill said.

“These numbers reflect the trust our sponsors place in Sandia and the growing complexity of the challenges we are asked to solve every day,” she added.

Sandia National Laboratories spent over $3.2 billion on labor and other non-subcontract payments in 2024, McGill said. Of that $3.2 billion, $1.8 billion went to payroll in New Mexico, McGill added.

“That payroll supports thousands of families and helps spur growth across our community,” McGill said.

The lab also spent $1.7 billion on goods and services, McGill said. And nearly $615 million of that figure went to New Mexico businesses, with $505 million of $615 million supporting New

The lab also paid $133 million in gross receipts tax, McGill said. “The kind of impact we have doesn’t happen by accident,” McGill said. “It’s the result of thousands of daily decisions we make, choosing to buy local where we can, partnering with small businesses and investing in our people.”

Air Force Base

Kirtland Air Force Base’s $7.5 billion economic impact in 2024 is 12% of the entire Albuquerque area economy, Secrest said.

The base also employs 5% of the Albuquerque area’s workforce, and its payroll reached $2.6 billion in 2024, Secrest said.

The base is also responsible for $2.1 billion in job creation value, supporting over 56,000 jobs in the local economy, Secrest said.By Cooper Metts – , Albuquerque Business First

Arizona MEP offers workshops designed to meet the business needs of manufacturers.

AZ MEP Overview of Lean with Simulation - September 10th

AZ MEP Leadership Development Program - Cohort 10 - September 15th

AZ MEP CMMC Compliance: Building a Roadmap - September 17th

AZ MEP Lean Green Belt Certification Course - Cohort 7 - September 22nd

MFG Month Celebrations: October 24th & October 31st Visit our website for complete details on all of our workshops.

Register today!

NASA launches solar research mission from White Sands Missile Range

NASA launched its “groundbreaking” Solar Eruption Integral Field Spectrograph mission, or SNIFS, from New Mexicobased White Sands Missile Range on July 18.

The SNIFS payload was delivered to space via a Black Brant IX sounding rocket to an altitude of 215 miles. It then descended for recovery at White Sands. The payload will help researchers explore the “energy and dynamics of the chromosphere, one of the most complex regions of the sun’s atmosphere,” according to the release.

Reports show the launch successfully retrieved “good data.”

The chromosphere is an area located between the sun’s 602.845.1256 • info@azmep.com

visible surface and its outer layer. While other layers of the sun’s atmosphere have been studied, the chromosphere is one place where questions remain.

The chromosphere lies just below the outer layer, or “corona,” home to a variety of solar eruptions, which drive what is known as space weather, close enough to Earth that they threaten satellites and the safety of astronauts.

This mission aims to learn more about how energy moves and is converted ultimately powering explosions in the sun’s chromosphere.

“To make sure the Earth is safe from space weather, we really would like to be able to model things,” Vicki Herde, a doctoral graduate of the University of Colorado Boulder who worked with Chamberlin to develop SNIFS, said in a statement.

The entire mission was expected to last 15 minutes according to the release, and the relatively small (albeit 70-foot tall) sounding rocket carrying the payload, was expected to drift around 70 to 80 miles from the launchpad before returning, making an open desert like New Mexico’s White Sands an ideal place for the rocket to land.

Ray Watson, a U.S. Navy test officer and program manager for Launch Complex 36 at White Sands Missile Range, talked to Albuquerque Business First about the unclassified missions like this one which WSMR often supports.

Many missions study the sun, but also deep space which could include looking at remnants of supernovas or wavelengths of energy, for examples.

These include a variety of university-driven missions from places like MIT, Pennsylvania State University, Northwestern College, Embry-Riddle Aeronautical University and in this case, the University of Colorado Boulder collected data and will carry out subsequent research.

They typically conduct six to eight missions per year with NASA, who sends grants to universities to fund their selected studies and help coordinate a sounding rocket launch.

WSMR provides range scheduling and resource management for missions. NASA sends out a mission manager, and they spearhead integration of all the folks coming out, equipment including experiment materials, the payload and the rocket motors.

WSMR staff helps with the integration of the rocket motors, which are basically delivered in boxes and have to be assembled. 25-0141 Terrier Black Brant Dr. Charmberlin 36.372

The relatively small (albeit 70-foot tall) sounding rocket carrying the payload, was expected to drift around 70 to 80 miles from the launchpad before returning, making an open desert like New Mexico’s White Sands an ideal place for the rocket to land. Dylan Totilo, WSMR

“If you ever played with model rockets when you were a kid, this is just a really, really, really big model rocket,” Watson said.

He also mentioned upcoming plans for a solar campaign

involving simultaneous launches, just seconds apart, to capture data during sunspot activity.

WSMR has ramped up its recent collaborations with NASA, including streaming launches on NASA’s website, Facebook and YouTube.

The site often partners with schools and universities to conduct tours and carry out recruiting efforts and works to increase visibility with the local community.

Watson said launches can draw staff from participating organizations for weeks, impacting the local economy through hotels and restaurants primarily in Las Cruces.

“The (economic) impact on the community for just like, one little mission here is pretty small, I’d say. But if you look at it as a whole, on the amount of work that goes on at WSMR, the impact on community is huge,” he said.By Molly Callaghan – Albuquerque Business First

Schedule your no-obligation appointment and review today! Mitch Balasu 480-822-7500

O W U S

Mitch@growprotected.com www.growprotected.com

Servicing our industry and trade customers in intelligence heat treating for over 60 years.

Are You Losing Sleep With The Stock Market Ups and Downs?

Are You Planning To Retire In The Next 10 Years?

Established in 1963

Real Time Live Job Tracking

10+ Processes Performed

Did You know that On average, it takes the stock market 4.5 years to recover from a bear market, according to historical data?

50+ Furnaces

successful selection of a site and finalization of state incentives.

The project will potentially bring about 200 highwage jobs to New Mexico including an interdisciplinary mix of physicists, engineers, technicians and operations staff, according to Economic Development Department Secretary Rob Black and one of Pacific Fusion’s five cofounders, Chief Operating Officer Carrie Von Muench.

The company currently employs over 100 people, according to a company spokesperson.

AOG and Line Down Services

There Is Good Reason Why Americans Have Invested Over 3 Trillion Dollars Into Annuities

Over 10+ Prime Approvals

24/7 Processing

• Protection Against Stock Market Risk

• Guaranteed income for life

• Reasonable Returns

• Tax Deferred Growth

602-258-7751

• Long Term Care Benefit Potential

• Leave a Legacy

cs@phxht com

• No Fee Annuities Available

www phoenix-heat-treating com

• Bonus Potential

The race between New Mexico and California for Pacific Fusion's groundbreaking facility is heating up, with a decision expected soon.

The New Mexico Economic Development Department recently announced a memorandum of understanding between the state and Pacific Fusion, for the identification of a site for the company’s planned research and development facility, to be located in Albuquerque.The overall economic impact of the potential investment is $1.2 billion, calculated by NMEDD.

Pacific Fusion is on track to make a final decision in September 2025, currently choosing between locations in California or New Mexico, contingent upon the

“From our perspective, they couldn't pick a better place than New Mexico. … Sandia National Labs is the place where fusion started globally, and we have such an amazing workforce, whether you're talking about the scientists or the folks who will need to do the plumbing, the pipe fitting, the welding — we have very high-skilled technicians that will be important for these types of jobs,” Black told Albuquerque Business First.

The path to an MOU has involved extensive site visits and collaboration with various state and city entities according to Black including state agencies, staff at the city of Albuquerque and others.

A key stakeholder has been the Albuquerque Regional Economic Alliance, which has been helping the company identify a location and helped connect the company with regional partners throughout the process.

New Mexico offers

competitive incentives such as the Local Economic Development Act, the Job Training Incentive Program and the High-Wage Jobs Tax Credit, according to Black.

The company is exploring multiple sites in the state, including one at Mesa Del Sol, Black confirmed.

“(Fusion technology) started at Sandia National Labs with the Z Machine back in the 1960s with their Pulse Power Program, so it makes sense that they would want to be close to Sandia and some of the best minds in this space and research and be part of that research and development ecosystem here in New Mexico,” Black added.

The Fremont, California-based fusion company, which deigns and builds pulsed magnetic fusion systems, was founded in 2023 and emerged from stealth in 2024. It has already raised more than $900 million in private capital from sources, including General Catalyst and Breakthrough Energy Ventures.

The investment followed three key breakthroughs which “really changed the field” in 2022, according to Von Muench:

• Researchers at Sandia National Laboratories’ sister lab, Lawrence Livermore National Laboratory, demonstrated controlled ignition at the National Ignition Facility, definitively proving the physical conditions that are required to get more energy out of a fusion reaction than was required to drive the reaction.

• Sandia researchers demonstrated a more efficient way to reach those conditions using electric pulsers rather than lasers.

• Third, company Chief Technology Officer Keith

technology that more than doubles the efficiency and power density of traditional pulsers.

“You have a fusion company whose risk profile looks really different than that of a lot of fusion companies in the past. As a result, we had a pretty clear road map to execute against from the beginning. … It was against that very clear road map that we were able to raise the financing that we did basically from the outset,” Von Muench said.

This research facility is a key step toward the company’s access to that capital."I've just repeatedly been impressed by and grateful for the level of collaboration that many folks are willing to bring to our discussions," she said. "We're excited about New Mexico, among other reasons, because it's a state whose values are implemented in the Energy Transition Act and whose economic development priorities align really well with our project. We’ve definitely seen that reflected in our day-to-day interactions with many people in the state.” By Molly Callaghan

• Offering Next Day Delivery

• 80,000 sq. ft. Facility With Extensive Inventory

• Stocking Stainless Steel, Aluminum Stock and Specialty Metals

Raytheon's Tucson missile unit racks up another multibillion-dollar contract

RTX Corp.’s missile manufacturing operation, Tucson-based Raytheon, has been awarded a $3.5 billion contract from the U.S. Air Force for the production of missiles as part of the Advanced Medium Range Air-to-Air Missile, or AMRAAM, program.

Under the deal, Raytheon’s Tucson operation will produce AMRAAM missiles, telemetry system equipment, and initial and field spares, as well as conduct production engineering support activities.

The deal benefits foreign military sales partners including Denmark, Belgium, Japan, Netherlands, Canada, Finland, Germany, Hungary, Spain, Poland, Sweden, Taiwan, Lithuania, the United Kingdom, Australia, Switzerland, Ukraine, Israel and Kuwait, according to the U.S. military.

“As global conflicts intensify and air threats become more sophisticated, AMRAAM continues to give allied forces a decisive edge in combat,” said Sam Deneke, president of Air & Space Defense Systems at Raytheon, in a statement. “This award underscores the critical role that the fifth-generation AMRAAM plays in maintaining air superiority and will ensure service members have the advanced technology needed

to stay ahead of adversary threats.”

The contract runs through the third quarter of fiscal year 2031.

Before this latest deal, Raytheon had already racked up three contracts this year worth $1 billion or more — including one deal valued at $2.1 billion. They have helped make the company the money leader in Arizona’s booming aerospace and defense sector — which has been on a growth streak with a number of cutting-edge projects.

This latest deal also surpasses a $1.19 billion AMRAAM contract from September 2024 that had been the largest contract in the program.

The AMRAAM program is part of the U.S. military’s Form, Fit, Function Refresh program — also known as F3R — under which engineers upgrade circuit cards and other hardware in missile guidance systems and update legacy software to upgrade midrange air-to-air AIM120D3 and AIM-120C8 munitions and keep them viable for years to come as threats evolve. The first contract of its kind was awarded to Raytheon in Tucson in 2022. By Jeff Gifford –Phoenix Business Journal

BMSC LLC, A Woman Owned Business • Contact Bretta Kelly Today!

√ Are you certified and ready to simplify your ISO 9001, AS9100, AS9110 or AS9120 System?

√ Do you need Quality Management System Software? Bretta Kelly also President of CIS WWSG, is now offering $3,500 Templates FREE with purchase of CIS Software!

√ Need Help Maintaining Your Internal Audits or Management Reviews?

Visit www.businessmsc.com today and review the more than 220 company referrals!

BMSC is now offering packages to come in and conduct Internal Process Audits and Facilitate Management Reviews to ensure you are effectively maintaining your ISO 9001 and/or AS9100 System.

We Can Help! We Have Helped Over 200 Manufacturing and Service Companies. Call to Learn About our Templates - From $3500. CIS Software visit www.cissoftware.com.

TSMC’s

who flew more than 10 times in the past year wanted to hop onto an air taxi, with business travelers being chief among them (65%). And for millennials, the interest was at 65%, compared to 58% of overall respondents.

Chairman and CEO C.C. Wei provided more details of the company’s manufacturing plans in the United States. In March, TSMC announced plans to invest an additional $100 billion in the U.S., bringing its total investment to $165 billion.

Phoenix-based Honeywell Aerospace Technologies is currently a division of Honeywell International Inc. (Nasdaq: HON), but the parent company announced earlier this year that its aerospace business and its automation unit would be split off into separate publicly traded companies. That followed calls late last year from an activist investor to make the move.

The expansion includes plans for six advanced wafer manufacturing fabs in Arizona. Its fourth facility will use N2 and A16 process technology, and its fifth and sixth facilities will use “even more advanced technology,” Wei said.

“The construction and ramp schedule for those fabs will be based on our customers’ needs,” Wei said. “Our expansion plan will enable TSMC to scale up to a gigafab cluster in Arizona to support the needs of our leading-edge customers in smartphone, AI and HPC applications.”

Honeywell Aerospace — which said it will remain headquartered in Phoenix after the split, expected in the second half of 2026 — is Arizona's second-largest defense contractor, with just under 2,000 contracts in fiscal year 2024 valued at a total of $657.58 million, according to Business Journal research. With 7,124 employees in the state in 2023, Honeywell Aerospace ranked as Arizona's 23rd largest employer last year. By Jeff Gifford –Phoenix Business Journal

The investment will also be used to build two advanced packaging facilities and establish a research and development center in Arizona to complete TSMC’s AI supply chain, supporting “strong multiyear demand” from TSMC customers, Wei added.

Robotics company to establish global HQ in Phoenix

Imagine a world where a team of robots could lend a helping hand to small businesses for repetitive tasks, or clean and prep a construction job site overnight, allowing human workers to get more done during the day.

TSMC’s first Arizona fab began high-volume production in the last quarter of 2024, using N4 process technology. Construction of its second fab, which will utilize 3-nanometer

process technology, is complete. Whereas the construction of its third fabrication facility, which will use 2-nanometer and 16 process technologies, has begun.